System Identification Toolbox™ 7

Getting Started Guide

Lennart Ljung

How to Contact The MathWorks

www.mathworks.

comp.soft-sys.matlab Newsgroup

www.mathworks.com/contact_TS.html Technical Support

suggest@mathworks.com Product enhancement suggestions

bugs@mathwo

doc@mathworks.com Documentation error reports

service@mathworks.com Order status, license renewals, passcodes

info@mathwo

com

rks.com

rks.com

Web

Bug reports

Sales, prici

ng, and general information

508-647-7000 (Phone)

508-647-7001 (Fax)

The MathWorks, Inc.

3 Apple Hill Drive

Natick, MA 01760-2098

For contact information about worldwide offices, see the MathWorks Web site.

System Identification Toolbox™ Getting Started Guide

© COPYRIGHT 1988–2010 by The MathWorks, Inc.

The software described in this document is furnished under a license agreement. The software may be used

or copied only under the terms of the license agreement. No part of this manual may be photocopied or

reproduced in any form without prior written consent from The MathW orks, Inc.

FEDERAL ACQUISITION: This provision applies to all acquisitions of the Program and Documentation

by, for, or through the federal government of the United States. By accepting delivery of the Program

or Documentation, the government hereby agrees that this software or d ocumentation qualifies as

commercial computer software or commercial computer software documentation as such terms are used

or defined in FAR 12.212, DFARS Part 227.72, and DFARS 252.227-7014. Accordingly, the terms and

conditions of this Agreement and only those rights specified in this Agreement, shall pertain to and govern

theuse,modification,reproduction,release,performance,display,anddisclosureoftheProgramand

Documentation by the federal government (or other entity acquiring for or through the federal government)

and shall supersede any conflicting contractual terms or conditions. If this License fails to meet the

government’s needs or is inconsistent in any respect with federal procurement law, the government agrees

to return the Program and Docu mentation, unused, to The MathW orks, Inc.

Trademarks

MATLAB and Simulink are registered trademarks of The MathWorks, Inc. See

www.mathworks.com/trademarks for a list of additional trademarks. Other product or brand

names may be trademarks or registered trademarks of their respective holders.

Patents

The MathWorks products are protected by one or more U.S. patents. Please see

www.mathworks.com/patents for more information.

Revision History

March 2007 First printing New for Version 7.0 (Release 2007a)

September 2007 Second printing Revised for Version 7.1 (Release 2007b)

March 2008 Third printing Revised for Version 7.2 (Release 2008a)

October 2008 Online only Revised for Version 7.2.1 (Release 2008b)

March 2009 Online only Revised for Version 7.3 (Release 2009a)

September 2009 Online only Revised for Version 7.3.1 (Release 2009b)

March 2010 Online only Revised for Version 7.4 (Release 2010a)

About the Developers

System Identification Toolbox™ so ftw are is developed in association with the

following leading researchers in the system identification field:

Lennart Ljung. Professor Lennart Ljung is with the Department of

Electrical Engineering at Linköping University in Sweden. He is a recognized

leader in system identification and has published numerous papers and books

in this area.

Qinghua Zhang. Dr. Qinghua Zhang is a researcher at Institut National

de Recherche en Informatique et en Automatique (INRIA) and at Institut de

Recherche en Informatique et Systèmes Aléatoires (IRISA), both in Rennes,

France. He conducts research in the areas of nonlinear system identification,

fault diagn osis, and signal processing with applications in the fields of energy,

automotive, and biomedical systems.

Peter Lindskog. Dr. Peter Lindskog is employed by NIRA Dynam ics

AB, Sweden. He conducts research in the areas of system identification,

signal processing, and automatic control with a focus on vehicle industry

applications.

About the Developers

Anatoli Juditsky. Professor Anatoli Juditsky is with the Laboratoire Jean

Kuntzmann at the Université Joseph Fourier, Grenoble, France. He conducts

research in the areas of nonparametric statistics, system id entification, and

stochastic optimization.

About the Developers

1

Contents

Product Overview

Why Use This Too

Related Produ

Documentati

cts

on

lbox?

....................................

.............................

..................................

About Syst

em Identification

2

What Is System Identification? ...................... 2-2

About Dynamic Systems and Mo dels

What Is a Dynamic Model?

Continuous-Time Dynamic Model Example

Discrete-Time Dynamic Model Example

System Identification Requir es Measured Data

Why Does System Identification Require Data?

Time Domain Data

Frequency D omain Data

Data Quality Requirements

Data Represe n tatio n in This Toolbox

................................ 2-7

.......................... 2-3

............................ 2-8

......................... 2-8

................ 2-3

............ 2-4

............... 2-5

...... 2-7

......... 2-7

................. 2-9

1-2

1-3

1-5

Building M odels from Data

System Ide ntification Requires a Model Structure

How the Toolbox Computes Model Parameters

Configuring the Parameter Estimation Algorithm

Black-Box Modeling

................................ 2-13

......................... 2-10

....... 2-10

.......... 2-11

....... 2-11

vii

Selecting Black-Box Model Structure and Order ........ 2-13

When to Use Nonlinear Model Structures?

Black-Box Estimation Example

...................... 2-15

............. 2-15

Grey-Box Modeling

Evaluating Model Quality

HowtoEvaluateandImproveModelQuality

Comparing Model Response to Measured Response

Analyzing Residuals

Analyzing Model Uncertainty

Learn More

....................................... 2-24

................................ 2-18

.......................... 2-20

........... 2-20

...... 2-20

............................... 2-22

........................ 2-22

Using This Product

3

When to Use the GUI Versus the Command Line ...... 3-2

Starting This Toolbox

Steps for Using This Toolbox

.............................. 3-3

....................... 3-4

viii Contents

Commands for Model Estimation

Tutorials to Help You Get Started

.................... 3-6

................... 3-7

Tutorial – Identifying Linear Models Using the

4

About This Tutorial ................................ 4-2

Objectives

........................................ 4-2

GUI

Data Description .................................. 4-2

Preparing Data for System Identification

Loading Data into the MATLAB Workspace

Opening the System Identification Tool GUI

Importing Data Arrays into the System Identification

Tool

.......................................... 4-5

Plotting and Processing Data

Saving the GUI Session

Estimating Linear Models Using Quick Start

How to Estimate Linear M odels Using Quick Start

Types of Quick Start Linear Models

Validating the Quick Start Models

Estimating Accurate Linear Models

Strategy for Estimating Accurate Models

Estimating Possible Model Orders

Identifying State-Space Models

Identifying ARMAX Input-Output Polynomial Models

Choosing the Best Model

Viewing Model Parameters

Viewing Model Parameter Values

Viewing Parameter Uncertainties

........................ 4-10

............................ 4-20

.................. 4-24

................... 4-25

.................... 4-30

...................... 4-35

........................... 4-39

......................... 4-43

.................... 4-43

.................... 4-46

............ 4-4

............ 4-4

........... 4-4

................. 4-30

.............. 4-30

......... 4-23

...... 4-23

... 4-36

Exporting the Model to the MATLAB Workspace

Exporting the Model to the LTI Viewer

.............. 4-49

Tutorial – Identifying Low-Order Transfer

Functions (Process Models) Using the GUI

5

About This Tutorial ................................ 5-2

Objectives

........................................ 5-2

..... 4-47

ix

Data Description .................................. 5-3

What Is a Continuous-Time Process Model?

Preparing Data for System Identification

Loading Data into the MATLAB Workspace

Opening the System Identification Tool GUI

Importing Data Objects into the System Identification

Tool

.......................................... 5-6

Plotting and Processing Data

Estimating a Second-Order Transfer Function (Process

Model) with Complex Poles

Estimating a Second-Order Transfer Function Using

Default Setting s

Tips for Specifying Known Parameters

Validating the Model

Estimating a Transfer F unction with a Noise Model

Estimating a Second-OrderTransferFunctionwith

Complex Poles and Noise

Validating the Models

Viewing Model Parameters

Viewing Model Parameter Values

Viewing Parameter Uncertainties

................................ 5-13

............................... 5-18

.............................. 5-24

........................ 5-9

....................... 5-13

................ 5-18

......................... 5-22

......................... 5-30

.................... 5-30

.................... 5-31

.......... 5-4

............ 5-5

............ 5-5

........... 5-5

.. 5-22

x Contents

Exporting the Model to the MATLAB Workspace

Simulating a System Identification Toolbox Model in

Simulink Software

Prerequisites for This Tutorial

Preparing Input Data

Building the Simulink Model

Configuring Blocks and Simulation Parameters

Running the Simulation

............................... 5-34

....................... 5-34

.............................. 5-34

........................ 5-35

............................ 5-40

..... 5-33

......... 5-36

Tutorial – Identifying Linear Models Using the

Command Line

6

About This Tutorial ................................ 6-2

Objectives

Data Description

........................................ 6-2

.................................. 6-2

Preparing Data

Loading Data into the MATLAB Workspace

Plotting the Input/Output Data

Removing Equilibrium Values from the Data

Using Objects to Represent Data for System

Identification

Creating iddata Objects

Plotting the Data in a Data Object

Selecting a Subset of the Data

Estimating Step- and Frequency-Response Models

Why Estimate Step- and Frequency-Response Models?

Estimating the Frequency Response

Estimating the Step Response

Estimating Delays in the Multiple-Input System

Why Estimate Delays?

Estimating Delays Using the ARX Model Structure

Estimating Delays Using Alternative Methods

Estimating Model O rders Using an ARX Model

Structure

Why Estimate Model Order?

Commands for Estimating the Model Order

Model Order for the First Input-Output Combination

Model Order for the Second Input-Output Combination

.................................... 6-4

............ 6-4

...................... 6-5

........... 6-6

................................... 6-7

............................ 6-8

.................... 6-9

....................... 6-13

.................. 6-15

....................... 6-18

............................. 6-20

.......... 6-21

....................................... 6-23

........................ 6-23

............ 6-23

... 6-15

... 6-15

...... 6-20

...... 6-20

.... 6-25

.. 6-28

Estimating Continuous-Time Transfer Functions

(Process Models)

Specifying the Structure of the Process M odel

Viewing the Model Structure and Parameter Values

Specifying Initial Guesses for Time Delays

Estimating Model Parameters Using pem

................................ 6-31

.......... 6-31

............. 6-34

.............. 6-34

..... 6-32

xi

Validating the Process Model ........................ 6-36

Estimating a Transfer Function with a Noise Model

..... 6-39

Estimating Black-Box Polynomial Models

Model Orders for Estimating Polynomial Models

Estimating a Linear ARX Model

Estimating a State-Space Model

Estimating a Box-Jenkins Model

Comparing Model Output to Measured Output

Simulating and Predicting Model Output

Simulating the Model Output

Predicting the Future Output

..................... 6-43

..................... 6-46

..................... 6-49

....................... 6-54

....................... 6-55

............ 6-42

........ 6-42

......... 6-51

............ 6-54

Tutorial – Identifying Nonlinear Black-Box

Models Using the GUI

7

About This Tutorial ................................ 7-2

Objectives

Data Description

What Are Nonlinear Black-Box Models?

Types of Nonlinear Black-Box Models

What Is a Nonlinear ARX Model?

What Is a Hammerstein-Wiener M odel?

........................................ 7-2

.................................. 7-2

.............. 7-4

................. 7-4

.................... 7-4

............... 7-6

xii Contents

Preparing Data

Loading Data into the MATLAB Workspace

Creating iddata Objects

Starting the System Identification Tool

Importing Data Objects into the System Identification

Tool

.......................................... 7-12

Estimating Non linear ARX M odels

Estimating a Nonlinear ARX Model with Default

Settings

.................................... 7-9

............ 7-9

............................ 7-9

................ 7-11

.................. 7-15

....................................... 7-15

Plotting Nonlinearity Cross-Sections for Nonlinear ARX

Models

Changing the Nonlinear ARX Model Structure

Selecting a Subset of Regressors in the Nonlinear Block

Efficiently Modifying Model Structure for Estimating

Nonlinear ARX Models

Selecting the Best Model

........................................ 7-19

......... 7-22

........................... 7-25

........................... 7-26

.. 7-24

Estimating Hamm erstein-Wiener Models

Estimating Hammerstein-Wiener Models with Default

Settings

Plotting the Nonlinearities and Linear Transfer

Function

Changing the Hammerstein-Wiener M odel Structure

Changing the Nonlinearity E sti mator in a

Hammerstein-Wiener M odel

Selecting the Best Model

....................................... 7-28

....................................... 7-31

...................... 7-36

........................... 7-37

............ 7-28

.... 7-35

Index

xiii

xiv Contents

Product O verview

• “Why Use This Toolbox?” on page 1-2

• “Related Products” on page 1-3

• “Documentation” on page 1-5

1

1 Product Overview

Why Use This Toolbox?

System Ide n tification Toolbox software lets you estimate linear and nonlinear

mathematical models of dynamic systems from measured data. Use the

resulting models for analyzing system dynamics, simulating the output of

a system for a given input, predicting future outputs b as ed on previous

observations of inputs and outputs, or for control design.

System identification is especially helpful for modeling systems that you

cannot easily model from first principles or specifications, such as engine

subsystems, thermofluid processes, and electromechanical systems. Such

black-box models can simplify detailed first-principle models, such as

finite-element models of structures and flight dynamics models, by fitting

simpler models to their simulated responses.

You can also use System Identification Toolbox functions to compute the

coefficients of ordinary differential and difference equations for systems

modeled from first principles. Such models are called grey-box models.

1-2

For real-time applications in adaptive control, adaptive filtering, or adaptive

prediction, you can use this product to perform recursive parameter

estimation.

Related Products

The following table summarizes MathWorks™ products that extend and

complement the System Identification Toolbox software. For current

information about these and other MathWorks products, point your Web

browser to:

www.mathworks.com

Related Products

Product

Control System Toolbox™

Model Predictive Control Toolbox™

Neural Network Toolbox™

ization Toolbox™

Optim

Robust Control Toolbox™

Description

Provides extensive tools to analyze

plant models created in the System

Identification Toolbox software and

to tune control systems based on

these plant models.

Uses the l

created i

Toolbox

behavio

model-p

Provid

struct

model

Ident

When this toolbox is installed,

you have the option of using

the

algorithm for linear and nonlinear

identification.

Provides tools to design

multiple-input and multiple-output

(MIMO) control systems based on

plant models created in the System

Identification Toolbox software.

Helps you assess robustness based

on confidence bounds for the

identified plant model.

inear plant models

n the System Identification

software for predicting plant

rthatisoptimizedbythe

redictive controller.

es flexible neural-network

ures for estimating nonlinear

s using the System

ification Toolbox software.

lsqnonlin optimization

1-3

1 Product Overview

Product

Signal Processing Toolbox™ Provides additio nal options fo r:

Simulink

®

Description

• Filtering

(The System Identification

Toolbox software provides only

the fifth-order Butterworth filter.)

• Spectral analysis

After using the advanced data

processing capabilities of the Signal

Processing Toolbox software, you

can import the data into the System

Identification Toolbox software for

modeling.

Provides System Identification

blocks for simulating the models

you identified using the System

Identification Toolbox software. Also

provides blocks for model estimation.

1-4

Documentation

System Identification Toolbox documentation includes:

• Getting Started Guide — Summarizes the capabilities of the System

Identification Toolbox software and provides an o vervie w of system

identification. Step-by-step tutorials walk you through the most common

System Identification Too lbox tasks.

• User’s Guide — Describes the variou s tasks of using the System

Identification Toolbox software.

• Reference — Describes System Identification Toolbox commands.

• Release Notes — Describes important changes in the current product

version and compatibility considerations.

Documentation

View the documentation online from the Help menu on the MATLAB

desktop.

®

1-5

1 Product Overview

1-6

2

About System Identification

• “What Is System Identification?” on page 2-2

• “About Dynamic Systems and Models” on page 2-3

• “System Identification Requires Measured Data” on page 2-7

• “Building Models from Data” on page 2-10

• “Black-Box Modeling” on page 2-13

• “Grey-Box Modeling” on page 2-18

• “Evaluating Model Quality” on page 2-20

• “Learn More” on page 2-24

2 About System Identification

What Is System Identification?

System identification is a methodology for building mathematical models

of dynamic systems using measurements of the system’s input and output

signals.

The process of system identification requires that you:

• Measure the input and output signals from your system in time or

frequency domain.

• Select a model structure.

• Apply an estimation method to estimate value for the adjustable

parameters in the candidate model structure.

• Evaluate the estimated model to see if the model is adequate for your

application needs.

2-2

About Dynamic Systems and Models

In this section...

“What Is a Dynamic Model?” on page 2-3

“Continuous-Time Dynamic Model Example” on page 2-4

“Discrete-Time D ynamic Model Example” on page 2-5

What Is a Dynam ic Model?

In a dynamic system, the values of the output signals depend on both the

instantaneous values of its input signals and also on the past behavior of the

system. For example, a car seat is a dynamic system—the seat shape (settling

position) depends on both the current weight of the passenger (instantaneous

value) and how long this passenger has been riding in the car (past behavior).

A model is a mathematical relationship between a system’s input and output

variables. Models of dynamic systems are typically described by differential

or difference equations, transfer functions, state-space equations, and

pole-zero-gain models.

About Dynamic Systems and Models

You can represent dynamic models both in continuous-time and discrete-tim e

form.

An often-used example of a dynamic model is the equation of motion of a

spring-mass-damper system. As show n in the next figure, the mass moves in

response to the force F(t)appliedonthebasetowhichthemassisattached.

The input and output of this system are the force F(t)anddisplacementy(t)

respectively.

2-3

2 About System Identification

F(t)

y(t)

k

C

Mass-Spring-Damper System Excited by Force F(t)

m

Continuous-Time Dynamic Model Example

You can represent the same physical system as several equivalent models.

For example, you can represent the mass-spring-damper system in continuous

time as a second order differential equation:

2

dy

m

dt

where m is the mass, k the spring’s stiffness constant, and c the damping

coefficient. The solution to this differential equation lets you determine the

displacement of the mass, y(t), as a function of external force F(t)atanytimet

for known values of constant m, c and k.

If you treat displacement y(t)andvelocity

express the previous equation of motion as a state-space model of the system:

dy

ky t F t

c

++ =() ()

2

dt

vt

()()=

dy t

as state variables, you can

dt

2-4

dY

AY t BF t

=+

dt

yt CYt

() ()

() ()

=

where Y(t)=[y(t);v(t)] is a vector of model states. The matrices A, B,andC

are related to the constants m, c and k as follows:

A=[01;–k/m –c/m]

About Dynamic Systems and Models

B=[0;1/m]

C=[10]

You can also obtain a transfer function model of the spring-mass-damper

system by taking the Laplace transform of the differential equation:

Gs

()

==

Fs

()

()

1

2

ms cs k

()

++

Ys

where s is the Laplace variable.

Discrete-Time Dynamic Model Example

Suppose you can only observe the in pu t and output variables F(t)andy(t)

of the mass-spring-damper system at discrete time instants t = nT

T

is a fixed time interval and n =0,1,2,.... Thevariablesaresaidtobe

s

sampled wi th sampling interval T

. Then, you can represent the relationship

s

between the sampled input-output variables as a second order difference

equation, such as:

,where

s

yt aytT ayt T bFtT

() () ( )()+−+−=−

12

sss

2

Often, for simplicity, Tsis taken as one time unit, and the equation can be

written as:

yt a yt a yt bFt() () () ()+−+−=−

121

12

where a1and a2arethemodelparameters.Themodelparametersarerelated

to the system constants m, c,andk,andthesamplingintervalT

.

s

This difference equation shows the dynamic nature of the model. The

displacement value at the time instant t depends not only on the value of

force F at a previous time instant, but also on the displacement values at the

previous two time instants y(t–1) and y(t–2).

You can use this equation to compute the displacement at a specific time.

The displacement is represented as a weighted sum of the past input and

output values:

2-5

2 About System Identification

yt bFt a yt a yt() () () ()=−− −− −11 2

This equation shows an iterative way of generating values of output y(t)

starting from initial conditions (y(0)andy(1)) and measurements of input F(t).

This computation is called simulation.

Alternatively, the output value at a given time t can be computed using the

measured values of output at previous two time instants and the input value

at a previous time instant. This computation is called prediction.Formore

information on simulation and prediction using a model, see “Simulating and

Predicting M odel Output” in the User’s Guide.

You can also represent a discrete-time equation of motion in state-space and

transfer-function forms by performing the transformations similar to those

described in “Continuous-Time Dynamic Model Example” on page 2-4.

12

2-6

System Identification Requires Measured Data

System Identification Requires Measured Data

In this section...

“Why Does System Identification Require Data?” on page 2-7

“Time Domain Data” on page 2-7

“Frequency Domain Data” on page 2-8

“Data Quality Requirements” on page 2-8

“Data Representation in This Toolbox” on page 2-9

Why Does System Identification Require Data?

System identification uses the input and output signals you measure from

asystemtoestimatethevaluesofadjustable parameters in a given model

structure.

Using this toolbox, you build models using time-domain input-output signals,

frequency response data, time series signals, and time-series spectra.

Obtaining a good model of your system depends on how well your measured

data reflects the behavior of the system. See “Data Quality Requirements”

on page 2-8.

Time Domain Data

Time-domain data consists of the input and output variables of the system

that you record a t a uniform sampling interval over a period of time.

For example, if you measure the input force F(t) and mass displaceme nt x(t)of

the spring-mass-damper system at a uniform sampling frequency of 10 Hz,

you obtain the following v ectors of measured values:

u FTFTFT FNT

==[ ( ), ( ), ( ),..., ( )]

meas sss s

yxTxT

where Ts= 0.1 seconds and NTsis time of the last measurement.

[( ),( ),

meas s s

23

2 xxT xNT

( ),..., ( )]3

ss

2-7

2 About System Identification

If you want to build a discrete-time model from this data, the data vectors

u

creating such a model.

If you want to build a continuous-time model, you should also know the

intersample behavior of the input signals during the experiment. For

example, the input may be piecewise constant (zero-order hold) or piecewise

linear (first-order hold) between samples.

Frequency Domain Data

Frequency domain data represents measurements of the system input and

output variables that you record or store in the frequency domain. The

frequency domain signals are Fourier transforms of the corres ponding time

domain signals.

Frequency domain data can also represent the frequency response of the

system, represented by the set of complex response values over a given

frequency range. The frequency response describes the outputs to sinusoidal

inputs. If the input is a sine wave with frequency ω, then the output is also

a sine wave of the same frequency, whose amplitude is A(ω)timestheinput

signal amplitude and a phase shift of Φ(ω) with respect to the input signal.

The frequency response is A(ω)e

meas

and y

and the sampling interval Tsprovide sufficient information for

meas

(iΦ(ω))

.

2-8

In case of mass-spring-damper system, you can obtain the frequency response

data by using a sinusoidal input force and measuring the corresponding

amplitude gain and phase shift of the response, over a range of input

frequencies.

You can use frequency-dom ain data to build both discrete-time and

continuous-time models of your system.

Data Quality Requirements

System identification requires that your data capture the important dynamics

of your system. Good experimental design ensures that you measure the right

variables with sufficient accuracy and duration to capture the dynamics you

want to model. In general, your experiment must:

System Identification Requires Measured Data

• Use inputs that excite the system dynamics adequately. For example, a

single step is seldom enough excitation.

• Measure data long enough to capture the important time constants.

• Set up data acquisition system to have good signal-to-noise ratio.

• Measure data at appropriate sampling intervals or frequency resolution.

You can analyze the data quality before building the model using techniques

available in the Signal P rocess ing Toolbox software. For example, analyze

the input spectra to determine if the input signals have sufficient power over

the bandwidth of the system.

You can also analyze your data to determine peak frequencies, input

delays, important time constants, and indication of nonlinearities using

non-parametric analysis tools in this toolbox. You can use this information for

configuring model structures for building models from data. See the following

User’s Guide topics:

• “Identifying Impulse-Response Models”

• “Identifying Frequency-Response Models”

Data Representation in This Toolbox

If you build models using the System Identification Tool GUI, you must

import your data into the GUI.

If you use the command-line interface, specify your data using

and idfrd objects. These objects conveniently store data values and other

information about the data, such as its sampling interval and intersample

behavior.

For more information, see “Data Import and Processing” in the User’s Guide.

iddata

2-9

2 About System Identification

Building Models from Data

In this section...

“System Identification Requ ires a Model Structure” on page 2-10

“How the Toolbox Computes Model Parameters” on page 2-11

“Configuring the Parameter Estimation Algorithm” on page 2-11

System Identification Requires a Model Structure

A model structure is a mathematical relationship between input and output

variables that contains unknown parameters. Examples of model structures

are transfer functions with adjustable poles and zeros, state space equations

with unknown system matrices, and nonlinear parameterized functions.

The f ollow ing difference equation represents a simple m o del structure:

yk ayk buk() ( ) ()+−=1

2-10

where a and b areadjustableparameters.

The s ystem identification process requires that you choose a model structure

and apply the estimation methods to determine the num erical values of the

model parameters.

You can use one of the following approaches to choose the model structure:

• You want a model that is able to reproduce your measured data and is as

simple as possible. You can try various mathematical structures available

in the toolbox. This modeling approach is called black-box modeling.

• You want a specific structure for your model, which you may have derived

from first principles, but do not know numerical values of its parameters.

You can then represent the model structure as a set of equations or

state-space system in MA TLAB and estimate the values of its parameters

fromdata. Thisapproachisknownasgrey-box modeling.

Building Models from Data

How the Toolbox C

The System Ident

minimizing the e

The output y

y

(t)=Gu

model

where G is the t

To determine

output y

mode

is a weighte

v(t)=y

y

model

(t)–y

meas

is one of the following:

(t)

• Simulate

• Predicte

d response of the mo de l for a given input u(t)andpast

measurem

Accordi

estimat

the nor

ngly, the error v(t)iscalledsimulation error or prediction error.The

ion algorithms adjust parameters in the model structure G such that

mofthiserrorisassmallaspossible.

ification Toolbox software estimates m odel parameters by

rror betw een the model output and the measured response.

of the linear model is given by:

el

mod

(t)

ransfer function.

G, the toolbox minimizes the difference between the model

(t)andthemeasuredoutputy

l

d norm of the error v(t), where:

(t)=y

model

meas

d response of the mo de l for a given input u(t).

ents of output (y

omputes Model Parameters

(t). The minimization criterion

meas

(t)–Gu(t).

meas

(t-1), y

meas

(t-2),...).

Config

You ca

• Confi

freq

deem

the c

as si

• Spe

The

con

th

uring the Parameter Estimation Algorithm

n configure the estimation algorithm by:

guring the minimization criterion to focus the estimation in a desired

uency range, such as put more emphasis at lower frequencies and

phasize higher frequency noise contributions. You can also configure

riterion to target the intended application needs for the model such

mulation or prediction.

cifying optimization optio ns for iterative estimation algorithms.

majority of estimation algorithms in this toolbox are iterative. You can

figure an iterative estimation algorithm by specifying options, such as

e o ptimization method and the maximum number of iterations.

2-11

2 About System Identification

For more information about configuring the estimation algorithm, see the

topics for estimating specific model structures in the System Identification

Toolbox User’s Guide.

2-12

Black-Box Modeling

In this section...

“Selecting Black-Box Model Structure and Order” on page 2-13

“When to Use Nonlinear Model Structures?” on page 2-15

“Black-Box Estimation Example” on page 2-15

Selecting Black-Box Model Structure and Order

Black-box modeling is useful when your primary interest is in fitting the data

regardless of a particular mathematical structure of the model. The toolbox

provides several linear and nonlinear black-box model structures, which have

traditionally been useful for representing dynamic systems. These models

structures vary in complexity depending on the flexibility you nee d to account

for the dynamics and noise in your system. You can choose one of these

structures and compute its parameters to fit the measured response data.

Black-Box Modeling

Black-box modeling is usually a trial-and-error process, where you estimate

the parameters of various structures and compare the results. Typically, you

start with the simple linear model structure and progress to more complex

structures. You might also choose a model structure because you are more

familiar with this structure or because you have specific application needs.

The simplest linear black-box structures require the fewest options to

configure:

• Linear ARX model, which is th e simplest input-output polynom ia l model.

• State-space model, which you can estimate by specifying the number of

model states

Estimation of these structures also uses noniterative estimation algorithms,

which further reduces complexity.

You can configure a model structure using the model order. The definition of

model order varies depending on the type of model you select. For example, if

you choose a transfer function representation, the model order is related to the

number of poles and zeros. For state-space representation, the model order

2-13

2 About System Identification

corresponds to the number of states. In some cases, such as for linear A RX and

state-space model structures, you can estimate the model order from the data.

If the simple model structures do not produce good models, you can select

more complex model structures by:

• Specifying a higher model order for the same linear model structure.

• Explicitly modeling the noise:

Higher model order increases the model flexibility for capturing complex

phenomena. H owev er, unnecessarily high orders can make the model less

reliable.

y(t)=Gu(t)+He(t)

where H models the additive disturban ce by treating the disturbance as

the output of a linear system driven by a white noise source e(t).

Using a model structure that explicitly models the additive disturbance can

help to improve the accuracy of the measured component G.Furthermore,

such a model structure is useful when your main interest is using the model

for predicting future response values.

2-14

• Using a different linear model structure.

See “Linear Model Structures” in the User’s Guide.

• Using a nonlinear model structure.

Nonlinear models have more flexibility in capturing complex phenomena

than linear models of similar orders. See “Nonlinear Model Structures”

in User’s Guide.

Ultimately, you choose the sim plest model structure that provides the best

fit to your m easured data. For m ore information, see Chapter 4, “Tutorial –

Identifying Linear Models Using the GUI”.

Regardless of the structure you choos e for estimation, you can simplify the

model for your application needs. For example, you can separate out the

measured dynamics (G) from the noise dynamics (H) to obtain a simpler model

that represents just the relationship between y and u. You can also convert

an estimated model into an linear time-invariant (LTI) object and linearize a

nonlinear model about an operating point.

Black-Box Modeling

When to Use Nonli

A linear model is

and, in most case

output does not

to use a nonline

You can assess

response of th

depending on

example, if t

to a step down

Before buil

try transfo

between th

that has cu

temperatu

inputs vi

and volta

one-outp

of curre

relatio

If you ca

relati

struct

alisto

“Nonl

ding a nonlinear model of a system that you know is nonlinear,

rming the input and output variables such that the relationship

e transformed variables is linear.Forexample,considerasystem

re of the heated liquid as an output. The output depends on the

a the power of the heater, which is equal to the product of current

ge. Instead of building a nonlinear model for this two-input and

ut system, you can create a new input variable by taking the product

nt and voltage and then build a linear model that describes the

nship between powe r and temperature.

nnot determine variable transformations that yield a linear

onship between input and output variables, you can use nonlinear

ures such as Nonlinear ARX or Hammerstein-Wiener models. For

f supported nonlinear model structures and when to use them, see

inear Model Structures” in User’s Guide.

often sufficient to accurately describe the system dynamics

s, you should first try to f it linear models. If t he linear model

adequately reproduce the measured output, you might need

ar model.

theneedtouseanonlinearmodel structure by plotting the

e system to an input. If you notice that the responses differ

the input level or input sign, try using a nonlinear model. For

he output response to an input step up is faster than the response

, you might need a nonlinear model.

rrent and voltage as inputs to an immersion heater, and the

near Model Structures?

Black

You c

vari

the m

Con

Sys

of t

Fo

sp

-Box Estimation Example

an use the GUI or commands to estimate linear and nonlinear models of

ous structures. In most cases, you choose a model structure and estimate

odel parameters using a single command.

sider the mass-spring-damper system, described in “About Dynamic

tems and Models” on page 2-3. If you do not know the equation of motion

his system, you can use a black-box modeling approach to build a model.

rexample,youcanestimatetransferfunctionsorstate-spacemodelsby

ecifying the orders of these model structures.

2-15

2 About System Identification

A transfer function is a ratio of polynomials:

2

...

2

...

Gs

()

()

bbsbs

++ +

01 2

=

()

fs f s

++ +

1

12

In discrete-time, the transfer function of the mass-spring-damper system

can be:

−

1

−

1

()

Gz

=

()

bz

−−

1

fz fz

++

1

1

2

2

where the model orders correspond to the number of coefficients of the

numerator and the denominator (

delay equals the lowest order exponent of z

nb =1andnf = 2) and the input-output

–1

in the numerator (nk =1).

You can build a linear black-box model of a mass-spring-damper sy stem using

an Output Error structure using the following command:

m = oe(data, [1 2 1])

where data is your measured input-output data, represented as an iddata

object and the model order is [nb nf nk]=[121]. U sua lly, you d o not know

the model orders in advance. You should try several model order values until

you find the orders that produce an acceptable model.

2-16

Alternatively, you can choose a state-space structure to repres ent the

mass-spring-damper system and estimate the model parameters using the

n4sid command:

m = n4sid(data, 2)

where order = 2 represents the number of states in the model.

In black-box modeling, you do not need the system’s equation of motion—only

a guess of the model orders.

Black-Box Modeling

For more information abo ut building models, see “Steps for Using the System

Identification Tool GUI” and “Commands for Model Estimation” in the User’s

Guide.

2-17

2 About System Identification

Grey-Box Modeling

In some situations, you can deduce the model structure from physical

principles. For example, the mathematical relationship between the input

force and the resulting mass displacement in the mass-spring-damper system

is well known. In state-space form, the model is given by:

where Y ( t)=[y(t);v(t)] is the state vector. The coefficients A, B,andC are

functions of the model parameters:

A=[01;–k/m –c/m]

B=[0;1/m]

C=[10]

dY

AY t BF t

=+

dt

yt CYt

() ()

() ()

=

2-18

Here, you fully know the model structure but do not know the values of its

parameters—m, c and k.

Inthegrey-boxapproach,youusethedatatoestimatethevaluesofthe

unknown parameters of your model structure. You specify the model structure

by a set of differential or difference equations in MATLAB and provide some

initial guess for the unknown parameters specified.

In general, you build grey-box models by:

1 Creating a template model structure.

2 Configuring the model parameters with initial values and constraints (if

any).

lying a n estimation method to the model structure and computing the

3 App

el parameter values.

mod

Grey-Box Modeling

The following table summarizes the ways you can specify a grey -box model

structure.

Grey-Box Structure

Representation

Represent the state-space model

structure as a structured

idss model

object and estimate the state-space

matrices A, B and C.

You can compute the parameter

values, such as m, c,andk,from

the state space matrices A and B.

For example, m =1/B(2) and k =

–A(2,1)m.

Represent the state-space model

structure as an

idgrey model object.

You can directly estimate the values

of parameters

m, c and k.

LearnMoreintheUser’sGuide

• “How to Estimate State-Space

Models with Canonical

Parameterization”

• “How to Estimate State-Space

Models with Structured

Parameterization”

“ODE Parameter Estimation

(Grey-Box Modeling)”

2-19

2 About System Identification

Evaluating Model Quality

In this section...

“How to Evaluate and Improve Model Quality” on page 2-20

“Comparing M odel Response to Measured Response” on page 2-20

“Analyzing Residuals” on page 2-22

“Analyzing Model Uncertainty” on page 2-22

How to Evaluate and Improve Model Quality

After y ou estimate the model, y ou can evaluate the model quality by:

• “Comparing Model Respons e to Measured Response” on page 2-20

• “Analyzing Residuals” on page 2-22

• “Analyzing Model Uncertainty” on page 2-22

2-20

Ultimately, you must assess the quality of your model based on whether the

model adequately addresses the needs of your application. For information

about other available model analysis techniques, see Model Analysis in the

User’s Guide.

If you do not get a satisfactory model, you can iteratively improve your results

by trying a different model structure, changing the estimation algorithm

settings, or performing additional data processing. For more information

about estimating each type of model structure, see the User’s Guide. If

these changes do not improve your results, you might need to revisit your

experimental design and data gathering procedures.

Comparing Model Response to Measured Response

Typically, you evaluate the quality of a model by comparing the model

response to the measured outputforthesameinputsignal.

Suppose you use a black-box modeling approach to create dynamic models

of the spring-mass damper system. You try various model structures and

orders, such as:

Evaluating Model Quality

model1 = arx(data, [2 1 1]);

model2 = n4sid(data, 3)

You can simulate these models with a particular input and compare their

responses against the measured values of the displacement for the same input

applied to the real system . The following figure compares the simulated and

measured responses for a step input.

Thepreviousfigureindicatesthatmodel2 is better than model1 because

model2 better fits the data (65% vs. 83%).

The%fitindicatestheagreementbetween the model response and the

measured output: 100 means a perfect fit, and 0 indicates a poor fit (that is,

the model output has the same fit to the measured output as the mean of

the measured output).

2-21

2 About System Identification

For more information, see “Simulating and Predicting Model Output” in the

User’s Guide.

Analyzing Residuals

The System Identification Toolbox software lets you perform residual analysis

to assess the model quality. Residuals represent the portion of the output

data not explained by the estimated model. A good model has residuals

uncorrelated with past inputs.

For more information, see “Residual Analysis” in the User’s Guide.

Analyzing Model Uncertainty

When you estimate the model parameters from data, you obtain their nominal

valuesthatareaccuratewithinaconfidenceregion. Thesizeofthisregionis

determined by the values o f the parameter uncertainties computed during

estimation. The magnitude of the uncertainties provide a measure of the

reliability of the model. Large uncertainties in parameters can result from

unnecessarily high model orders, inadequate excitation levels in the input

data, and poor signal-to-noise ratio in measured data.

2-22

You can compute and visualize the effect of parameter uncertainties on

the model response in time and frequency domains using pole-zero maps,

Bode response, and step response plots. For example, in the fo llow ing Bode

plot of an estimated model, the shaded regions represent the uncertainty

in amplitude and phase of model’s frequency response, computed using the

uncertainty in the parameters. The plot show s that the uncertainty is low

only in the 5 to 50 rad/s frequency range, which indicates that the model is

reliable only in this frequency range.

Evaluating Model Quality

For more information, see “Computing Model Uncertainty” in the User’s

Guide.

2-23

2 About System Identification

Learn More

The System Identification Toolbox documentation pro vides you with the

necessary information to use this product. Additional resources are available

to help you learn more about specific aspects of system identification theory

and applications.

The following book describes methods for system identification and physical

modeling:

Ljung, L., an

Upper Saddle

These books

and algorit

• Ljung, L. S

Prentice H

• Söderstr

Internat

For info

book:

For informatio n on nonlinear identification, see the following refe r ences:

• Sjöberg,J.,Q.Zhang,L.Ljung,A.Benveniste,B.Deylon,P.Glorennec,H.

• Juditsky, A., H. Hjalmarsson, A. Benveniste, B. Delyon, L. Ljung,

rmation about working with frequency-domain data, see the following

Pintelon, R., and J. Schoukens. System Identification. A Frequency Domain

Approach. Wiley-IEEE Press, New York, 2001.

Hjalmarsson, and A. Juditsky, “Nonlinear Black-Box Modeling in System

Identification: a Unified Overview.” Automatica. Vol. 31, Issue 12, 1995,

pp. 1691–1724.

J. Sjöberg, and Q. Zhang, “Nonlinear Black-Box Models in System

Identification: Mathematical Foundations.” Automatica. Vol. 31, Issue 12,

1995, pp. 1725–1750.

dT.Glad. Modeling of Dynamic Systems.PTRPrenticeHall,

River, NJ, 1994.

provide detailed information about system identification theory

hms:

ystem Identification: Theory for the User. Second edition. PTR

all, Upper Saddle River, NJ, 1999.

öm, T., and P. Stoica. System Identification.PrenticeHall

ional, London, 1989.

2-24

• Zhang, Q., and A. Benveniste, “Wavelet networks.” IEEE Transactions on

Neural Networks. Vol. 3, Issue 6, 1992, pp. 889–898.

Learn More

• Zhang, Q., “Using Wavelet Network in Nonparametric Estimation.” IEEE

Transactions on Neural Networks. Vol. 8, Issue 2, 1997, pp. 227–236.

For mo re information about systems and signals, see the following book:

Oppenheim, J., and Willsky, A.S. Signals and Systems. PTR Prentice Hall,

Upper Saddle River, NJ, 1985.

The following textbook describes numerical techniques for parameter

estimation using criterion minimization:

Dennis, J.E., Jr., and R.B. Schnabel. Numerical Methods for Unconstrained

Optimization and Nonlinear E quations. PTR Prentice Hall, Upper Saddle

River, NJ, 1983.

2-25

2 About System Identification

2-26

UsingThisProduct

• “WhentoUsetheGUIVersustheCommandLine”onpage3-2

• “Starting This Toolbox” on page 3-3

• “Steps for Using This Toolbox” on page 3-4

• “Comman ds for Model Estimation” on page 3-6

• “Tutorials to Help You Get Started” on page 3-7

3

3 Using This Product

When to Use the GUI Versus the Command Line

New users should start by using the System Identification Tool GUI to become

familiar with the product.

You can work either in the GUI or at the command line to preprocess data,

and estimate, validate, and compare models.

The following operations are available only at the command line:

• Generating input and output data (see

• Estimating coefficients of linear and nonlinear ordinary differential or

difference equations (grey-box models).

• Using recursive online estimation methods. See topics about estimating

linear models recursively in the System Identification Toolbox User’s Guide.

• Converting between continuous-time and discrete-time models (see

and d2c reference pages).

• Converting models to Control System Toolbox LTI objects (see the

and

zpk reference pages).

Note Conversions to LTI objects require the Control System Toolbox

software.

Tip To learn more about estimating and validating models at the command

line, see Chapter 6, “Tutorial – Identifying Linear Models Using the

Command Line”.

idinput).

c2d

ss, tf,

3-2

Starting This Toolbox

After installing the System Identification Toolbox product, you can start the

System Identification Tool GUI or work at the command line.

For information about whether to use the GUI or the command line, see

“WhentoUsetheGUIVersustheCommandLine”onpage3-2.

To open th e System Identification Tool GUI:

• Select Start > Toolboxes > System Identification > System

Identification Tool from the MATLAB desktop.

Alternatively, you can open the System Identification Tool GUI by typing the

following command in the MATLAB Command W indow:

ident

To work at the command line, type the commands directly in the MATLAB

Command Window. For more information about supported commands, see

the reference pages.

Starting This Toolbox

3-3

3 Using This Product

Steps for Using This Toolbox

System identification is an iterative process, where you identify models with

different structures from data and compare model performance. Ultimately,

you choose the simplest model that best describes the dynamics of your

system.

Because this toolbox lets you estimate different model structures quickly, you

should try as many different structures as possible to see which one produces

the best results.

A system identification workflow might include the following tasks:

1 Process data f or system identification by:

• Importing data into the MATLAB workspace.

• Representing data in the System Identification Tool G UI or as an

or idfrd object in the MATLAB workspace.

• Plotting data to examine both time- and frequency-domain behavior.

To analyze the data for the presence of constant offsets and trends,

delay, feedback, and signal excitation levels, you can also use the

command.

• Preprocessing data by removing offsets and linear trends, interpolating

missing values, filtering to emphasize a specific frequency range, or

resampling (interpolating or decimating) using a different time interval.

2 Identify linear or nonlinear models:

• Frequency-response models

• Impulse-response models

• Low-order transfer functions (process models)

• Input-output polynomial models

• State-space models

• Nonlinear black-box models

• Ordinary difference or differential equations (grey-box models)

iddata

advice

3-4

StepsforUsingThisToolbox

3 Validate models.

When you do not achieve a satisfactory model, try a different model

structure and order or try another identification algorithm. In some cases,

you can impr ove results by including a noise model.

You might need to preproce ss your data before doing further estimation.

For example, if there is too much high-frequency noise in your data, you

might need to filter or decimate (resa mple) the data before modeling.

4 Simulate or predict model output.

5 Design a controller for the estimated plant using other MathWorks

products.

You can import an estimated linear model into the Control System Toolbox,

Model Predictive Control Toolbox, Robust Control Toolbox, or Simulink

products for control design. For more information about linearizing a

nonlinear plant, see the

linapp and linearize reference pages.

3-5

3 Using This Product

Commands for Model Estimation

The following table summarizes System Identification Toolbox estimation

commands. For detailed information about using each command, see the

corresponding reference page.

Commands for Constructing and Estimating Models

Model Type Estimation Commands

Continuous-time low-order

transfer functions (process

models)

pem

Linear input-output

polynomial models

State-space models

Linear time-series models

Nonlinear ARX models

Hammerstein-Wiener

models

armax (ARM AX only)

arx (ARX only)

bj (BJ only)

iv4 (ARX only)

oe (OE only)

pem (for all models)

n4sid

pem

ar

(for mu l t ip le outputs)

arx

ivar

nlarx

nlhw

3-6

Tutorials to Help You Get Started

You can use the following tutorials to help you quickly get started with the

System Identification Toolbox software.

Tutorials to Help You Get Started

Tutorial

Chapter 4, “Tutorial – Identifying

Linear Models Using the GUI”

Chapter 5, “Tutorial – Identifying

Low-Order Transfer Functions

(Process Models) Using the GUI”

Chapter 6, “Tutorial – Identifying

Linear Models Using the Command

Line”

Chapter 7, “Tutorial – Identifying

Nonlinear Black-Box Models Using

the GUI”

Description

You learn how to identify and

compare different linear black-box

models from data using the System

Identification Tool GUI.

You learn how to estimate

the parameters of low-order,

continuous-time transfer functions

from data using the System

Identification Tool GUI.

You learn how to identify different

linear models from data using

System Identification Toolbox

commands.

You learn how to identify nonlinear

black-box models from data using

the Sys tem Identification Tool GUI.

3-7

3 Using This Product

3-8

Tutorial – Identifying Linear Models Using the GUI

• “About This Tutorial” on page 4-2

• “Preparing Data for System Identification” on page 4-4

• “Saving the GUI Session” on page 4-20

4

• “Estimating Linear Models Using Quick Start” on page 4-23

• “Estimating Accurate Linear Models” on page 4-30

• “Viewing Model Parameters” on page 4-43

• “Exporting the Model to the MATLAB Workspace” on page 4-47

• “Exporting the M odel to the LTI Viewer” on page 4-49

4 Tutorial – Identifying Linear Models Using the GUI

About This Tutorial

In this section...

“Objectives” on page 4-2

“Data Description” on page 4-2

Objectives

Estimate and validate linear models from sin gl e-input/single-output (SISO)

data to find the one that best describes the system dynamics.

After completing this tutorial, you will be able to accomplish the following

tasks using the System Identification Tool GUI:

• Import data arrays from the MATLAB workspace into the GUI.

• Plot the data.

• Process data by removing offsets from the input and output s ig nals.

4-2

• Estimate, validate, and compare linear models.

• Export models to the MATLAB workspace.

Note The tutorial uses time-domain data to demonstrate how you

can estimate linear models. The same workflow applies to fitting

frequency-domain data.

This tutorial is based on the example in section 17.3 of System Identification:

Theory for the User, Second Edition, by Lennart Ljung, Prentice Hall PTR,

1999.

Data Description

This tutorial uses the data file dryer2.mat, which contains

single-input/single-output (SISO) time-domain data from Feedback Process

Trainer PT326. The input and output signals each contain 1000 data samples.

About This Tutorial

This system heats the air at the inlet using a mesh of resistor wire, similar to

a hair dryer. The input is the power supplied to the resistor wires, and the

output is the air temperature at the outlet.

4-3

4 Tutorial – Identifying Linear Models Using the GUI

Preparing Data for System Identification

In this section...

“Loading D ata into the MATLAB Workspace” on page 4-4

“Opening the System Identification Tool GUI” on page 4-4

“Importing Data Arrays into the System Identification Tool” on page 4-5

“Plotting and Processing Data” on page 4-10

Loading Data into the MATLAB Workspace

Load the data in dryer2.mat by typing the following command in the

MATLAB Command Window:

load dryer2

This command loads the data into the MATLAB workspace as two column

vectors,

the output data.

u2 and y2, respectively. The variable u2 is the input data and y2 is

4-4

Opening the System Identification Tool GUI

To open the System Identification Tool GUI, type the following command

in the MATLAB Command Window:

ident

Preparing Data for System Identification

The default session name, Untitled, appears in the title bar.

Importin

g Data Arrays into the System Identification

Tool

You can i

file

You mus

in “Loa

the Sy

Ident

mport the single-input/single-output (SISO) data from a sample data

er2.mat

dry

t h ave already loaded the sample data into MATLAB, as described

ding Data into the MATLAB Workspace” on page 5-5, and opened

stem Identification Tool GUI, as described in “Opening the System

ification Tool GUI” on page 4-4.

into the GUI from the MATLAB workspace.

4-5

4 Tutorial – Identifying Linear Models Using the GUI

To import data arrays into the System Identification Tool GUI:

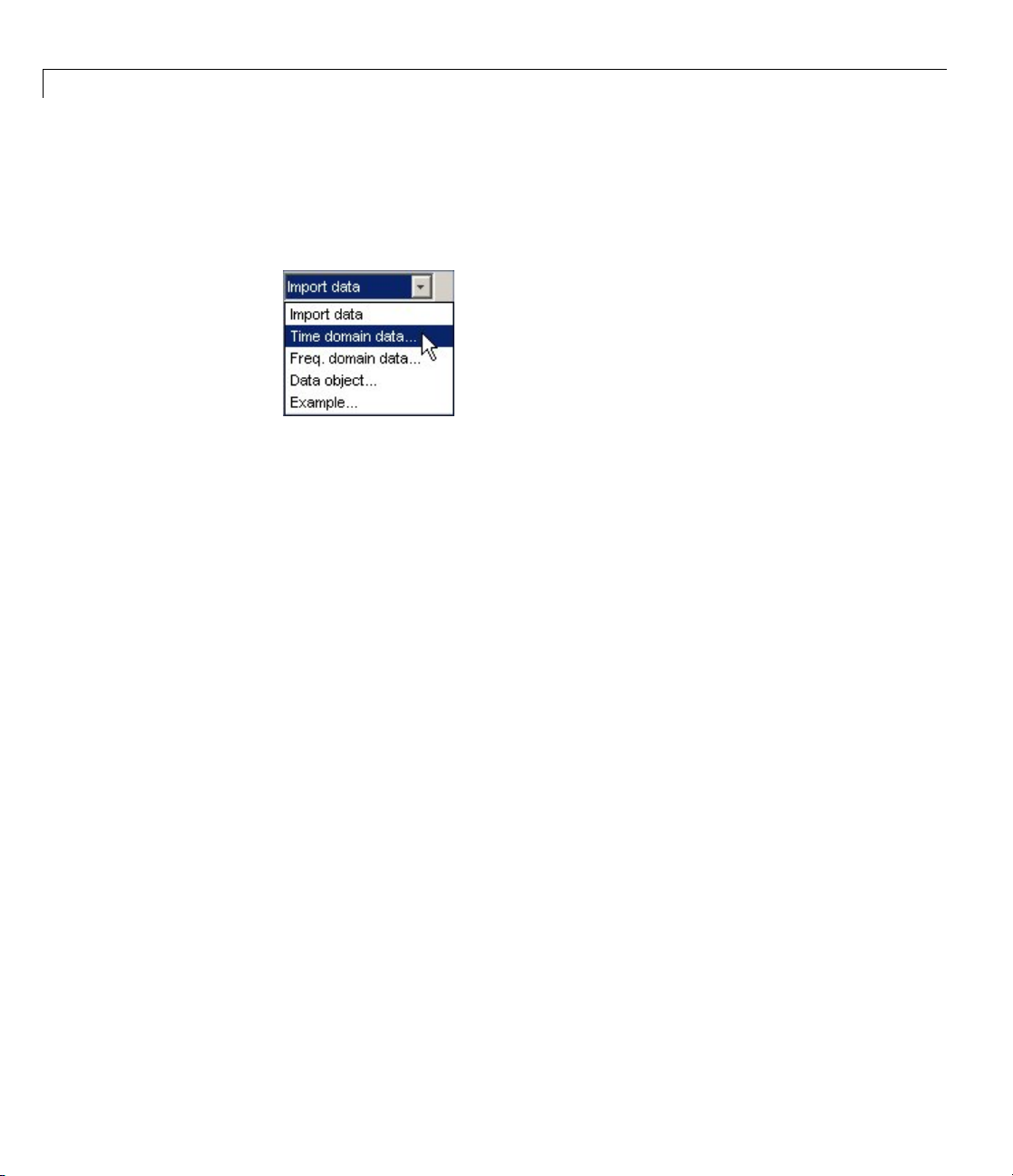

1 In the System Identification Tool GUI, select Import data > Time

domain data. This action opens the Import Data dialog box.

2 Specify the following options:

• Input —Enter

• Output —Enter

• Data name — Change the default name to

u2 as the name of the input variable.

y2 as the name of the output variable.

data. Thisnamelabelsthe

data in the System Identification Tool GUI after the impo rt operation is

completed.

• Starting time —Enter

0 as the starting time. This value designates

thestartingvalueofthetimeaxisontimeplots.

• Sampling interval —Enter

0.08 asthetimebetweensuccessive

samples in seconds. This value is the actual sampling interval in the

experiment.

4-6

Preparing Data for System Identification

The Import Data dialog box now resembles the following figure.

4-7

4 Tutorial – Identifying Linear Models Using the GUI

3 In the Data Information area, click More to expand the dialog box. Enter

the settings shown in the following figure.

4-8

Input Properties

Preparing Data for System Identification

• InterSample — Accept the default

zoh (zero-order hold) to indicate

that the input signal was piecewise-constant between samples during

data acquisition. This setting specifies the behavior of the input signals

between samples whe n you transform the resulting models between

discrete-time and continuous-time representations.

• Period — Accept the default

inf to specify a nonperiodic input.

Note For a pe riodic input, enter the whole number of periods of the

input signal in your experiment.

Channel Names

• Input —Enter

power.

Tip Naming channels helps you to identify data in plots. For

multivariable input and output signals, you can specify the names of

individual Input and Output channels, separated by commas.

• Output —Entertemperature.

Physical Units of V ariables

• Input —Enter

W for pow er units.

Tip When you have multiple inputs and outputs, enter a

comma-separated list of Input and Output units corresponding to each

channel.

• Output —Enter^oC for temperature units.

Notes — Enter comments about the experiment or the data. For

example, you might enter the experiment name, date, and a description

4-9

4 Tutorial – Identifying Linear Models Using the GUI

of experimental co nditions. When you estimate models from this data,

these models inhe rit your data notes.

4 Click Import to add the icon named data to the System Identification

Tool GUI.

4-10

5 Click Close to close the Import Data dialog box.

Plotting and Processing Data

In this portion of the tutorial, you evaluate the data and process it for system

identification. Y ou learn how to:

• Plot the data.

• Subtract the mean values of the input and the output to remove offsets.

• Split the data into two parts. You use one part of the data for model

estimation, and the other part of the data for model validation.

The reason you subtract the mean values from each signal is because,

typically, you build linear models that describe the responses for deviations

from a physical equilibrium. With steady-state data, it is reasonable to

assume that the mean levels of the signals correspond to such an equilibrium.

Thus, you can seek models around zero without modeling the absolute

equilibrium levels in physical units.

Preparing Data for System Identification

You must have already imported data into the System Identification Tool, as

described in “Importing Data Arrays into the System Identification Tool”

on page 4-5.

To plot and process the data:

1 In the System Identification Tool GUI, select the Time plot check box to

open the Time Plot. If the plot window is empty, click the data icon in

the System Identification Tool GUI.

op axes show the output d ata (temperature), and the bottom axes

The t

the input data (power). Both the input and the output data have

show

ero mean values.

nonz

4-11

4 Tutorial – Identifying Linear Models Using the GUI

2 In the System Identification Tool GUI, select <--Preprocess > Remove

means to subtract the mean input value from the input data and the mean

output value from the output data.

4-12

Preparing Data for System Identification

This action adds a new data set to the System Identification Tool GUI with

the default name

datad (the suffix d means detrend), and updates the

Time Plot window to display both the original and the detrended data. The

detrended data has a zero mean value.

4-13

4 Tutorial – Identifying Linear Models Using the GUI

3 In the System Identification Tool GUI, drag the datad data set to the

Working Data rectangle. This action specifies the detrended data to be

used for estimating models.

4-14

4 Select <--Preprocess > Select range to open the Select Range window.

In this window, you can split the data into two parts and specify the first

part for model estimation, and the second part for model validation, as

described in the following steps.

Preparing Data for System Identification

5 In the Select Range window, change the Samples field to select the first

500 samples, as follows:

1 500

Tip You can also select data samples using the mouse by clicking and

dragging a rectangular region on the plot. If you select samples on the

input-channel axes, the corresponding region is also selected on the

output-channel axes.

4-15

4 Tutorial – Identifying Linear Models Using the GUI

6 In the Data name field, type the name estima te,andclickInsert.This

action adds a new data set to the System Identification Tool GUI to be

used for model estimation.

7 In the Select Range window, change the Samples field to select the last

500 samples, as follows:

501 1000

4-16

Preparing Data for System Identification

8 In the Data name field, type the name valida te,andclickInsert.This

action adds a new data set to the System Identification Tool GUI to be

used for model validatio n.

9 Drag and drop estimate to the Working Data rectangle, and drag and

drop

validate to the Validation Data rectangle so that the System

Identification Tool GUI resembles the following figure.

4-17

4 Tutorial – Identifying Linear Models Using the GUI

10 To get information about a data set, right-click its icon. For example,

right-click the

estimate data set to open the Data/model Info dialog box.

4-18

Preparing Data for System Identification

IntheData/modelInfodialogbox,youcan perform the following actions:

• Change the name of the data set in the Data name field.

• Change the color of the data icon by changing the RGB values (relative

amounts of red, green, and blue). Each value is between

example,

[1,0,0] indicates that only red is present, and no green and

0 and 1.For

blue are mixed into the o verall color.

• In the noneditable area, view the total number of samples, the sampling

interval, and the output and input channel names and units.

• In the editable Diary And Notes area, view or edit the actions you

performed on this data set. The actions are translated into commands

equivalent to your GUI operations. For example, as shown in the

Data/model Info: estimate window, the

estimate data set is a result of

importing the data, detrending the mean values, and selecting the first

500 samples o f the data:

% Import data

datad = detrend(data,0)

estimate = datad([1:500])

For m ore information about these and other toolbox commands, see the

reference page corresponding to each command.

Tip As an alternative shortcut, you can select Preprocess > Quick start

from the System Identification Tool GUI to perform all of the data processing

stepsinthistutorial.

Learn More

For information about supported data processing operations, such as

resampling and filtering the data, see the System Identification Toolbox

User’s Guide.

4-19

4 Tutorial – Identifying Linear Models Using the GUI

Saving the GUI Session

After you process the data, as describedin“PlottingandProcessingData”

on page 4-10, you can delete any data sets in the window that you do not

need for estimation and validation, and save your session. You can open this

session later and use it as a starting point for model estimation and validation

without repeating these preparatory steps.

You must have already processed the data into the System Identification Tool,

as described in “Plotting and Processing Data” on page 4-10.

To delete specific data sets from a session and save the session:

1 In the Sy s tem Identification Tool GUI, drag and drop the data data set

into the Trash.

2 Drag and drop the datad data set into the Trash.

4-20

Note Moving items to the Trash does not delete them. To permanently

delete items, select Options > Empty trash in the System Identification

Tool GUI.

Saving the GUI Session

The following figure shows the System Identification Tool GUI after moving

the items to the Trash.

3 Drag and drop the estimate and validate data sets to fill the empty

rectangles, as shown in the following figure.

4 Select File > Save session as to open the Save Session dialog box, and

browse to the folder where you want to save the session file.

5 In the File name field, type the name of the session dryer2_prep_data,

and click Save. The resulting file has a

.sid extension.

4-21

4 Tutorial – Identifying Linear Models Using the GUI

Tip You can open a saved se ssion when starting the System Identification

Tool. For example, you can type the following command in the MATLAB

Command Window:

ident('dryer2_prep_data')

For more information about managing sessions, see the topics on working

with the System Identification Tool GUI in the System Identification Toolbox

User’s Guide.

4-22

Estimating Linear Models Using Quick Start

Estimating Linear Models Using Quick Start

In this section...

“How to Estimate Linear Models Using Quick Start” on page 4-23

“Types of Quick Start Linear Models” o n page 4-24

“Validating the Quick Start Models” on page 4-25

How to Estimate Linear Models Using Quick Start

You can use the Quick Start feature in the System Identification Toolbox to

estimate linear models. Quick Start might produce the final linear models

you decide to use, or provide you with information required to configure the

estimation of accurate parametric models, such as time constants, input

delays, and resonant frequencies.

You must have already processed the data for estimation, as described in

“Plotting and Processing Data” on page 4-10.

To identify linear models:

• In the System Identification Tool GUI, select E stimate > Quick start.

This action generates plots of step response, frequency-response, and the

output of state-space and polynomial models. For more information about

these plots, see “Validating the Quick Start Models” on page 4-25.

4-23

4 Tutorial – Identifying Linear Models Using the GUI

Types of Quick Start Linear Models

Quick Start estimates the following four types of models and adds the

following to the System Identification Tool GUI w ith default names:

4-24

•

imp — Step response over a period of time using the impulse algorithm.

spad — Frequency response over a range of frequencies using the spa

•

algorithm. The frequency response is the Fourier transform of the impulse

response of a linear system.

By default, the model is evaluated at 128 frequency values, ranging from

0 to the Nyquist frequency.

Estimating Linear Models Using Quick Start

• arxqs — Fourth-order autoregressive (ARX) model using the arx algorithm.

This model is parametric and has the following structure:

yt a yt a yt n

() ( ) ( )

+−++ −=

1 …

1

ut n b ut n

() (

−++ −−

1

knbk

na a

… b

nnet

++1) ( )

b

y(t) representstheoutputattimet, u(t) represents the input at time t,

n

is the number of poles, nbis the number of b parameters (equal to the

a

number of zeros plus 1), n

is the number of samp le s before the input affects

k

output of the system (called the delay or dead time of the model), and e(t) is

the white-noise disturbance. The System Identification Toolbox product

estimates the parameters

…

n1

and

bb

…

n1

using the input and output

aa