Page 1

Simulink

®

PLC Code

User’s Guide

r™ 1

Page 2

How to Contact The MathWorks

www.mathworks.

comp.soft-sys.matlab Newsgroup

www.mathworks.com/contact_TS.html Technical Support

suggest@mathworks.com Product enhancement suggestions

bugs@mathwo

doc@mathworks.com Documentation error reports

service@mathworks.com Order status, license renewals, passcodes

info@mathwo

com

rks.com

rks.com

Web

Bug reports

Sales, prici

ng, and general information

508-647-7000 (Phone)

508-647-7001 (Fax)

The MathWorks, Inc.

3 Apple Hill Drive

Natick, MA 01760-2098

For contact information about worldwide offices, see the MathWorks Web site.

®

Simulink

© COPYR IG HT 2010 by The MathWorks, Inc.

The software described in this document is furnished under a license agreement. The software may be used

or copied only under the terms of the license agreement. No part of this manual may be photocopied or

reproduced in any form without prior written consent from The MathW orks, Inc.

FEDERAL ACQUISITION: This provision applies to all acquisitions of the Program and Documentation

by, for, or through the federal government of the United States. By accepting delivery of the Program

or Documentation, the government hereby agrees that this software or documen tation qualifies as

commercial computer software or commercial computer software documentation as such terms are used

or defined in FAR 12.212, DFARS Part 227.72, and DFARS 252.227-7014. Accordingly, the terms and

conditions of this Agreement and only those rights specified in this Agreement, shall pertain to and govern

theuse,modification,reproduction,release,performance,display,anddisclosureoftheProgramand

Documentation by the federal government (or other entity acquiring for or through the federal government)

and shall supersede any conflicting contractual terms or conditions. If this License fails to meet the

government’s needs or is inconsistent in any respect with federal procurement law, the government agrees

to return the Program and Docu mentation, unused, to The Mat hWorks, Inc.

Trademarks

MATLAB and Simulink are registered trademarks of The MathWorks, Inc. See

www.mathworks.com/trademarks for a list of additional trademarks. Other product or brand

names may be trademarks or registered trademarks of their respective holders.

Patents

The MathWorks products are protected by one or more U.S. patents. Please see

www.mathworks.com/patents for more information.

Revision History

March 2010 Online only New for Version 1.0 (Release 2010a)

PLC Coder™ User’s Guide

Page 3

Getting Started

1

Product Overview ................................. 1-2

Introduction

PLC C ode Generation in the Dev elo pment Process

Expected Users

Glossary

Expected Background

Accessing Demos

...................................... 1-2

...... 1-3

................................... 1-4

......................................... 1-4

.............................. 1-4

.................................. 1-5

Contents

Related Products

Requirements for the Simulink

Supported Simulink and Stateflow Blocks

System Require ments

Supported IDE Platforms

Basic Workflow

Preparing Your Model to Generate Structured Text

Code

Configuring Simulink Models for Structured Text Code

Ensuring System Compatibility for Structured Text Code

Generating an d Examining Structured Text Code

Generating Structured Text Code from the Model

Generating Structured Text Code with the MATLAB

........................................... 1-11

Generation

Generation

Window

Interface

.................................. 1-6

®

PLC Code r Product ..... 1-6

............. 1-6

.............................. 1-7

........................... 1-7

.................................... 1-10

..................................... 1-11

..................................... 1-16

....................................... 1-20

...................................... 1-25

.... 1-20

iii

Page 4

Mapping Simulink Semantics to Structured

2

How Simple Subsystem Code Maps to Function

Blocks

How Reusable Subsystem Code Maps to Function

Blocks

How Stateflow Subsystem Code Maps to Function

Blocks

How Embedded MATLAB Subsystem Code Maps to

Function Blocks

.......................................... 2-2

.......................................... 2-4

.......................................... 2-6

................................. 2-8

Text

How A lias Data Types Map in Generated Code

....... 2-10

Generating Test Bench Code

3

Working with Generated Structured Text ............ 3-2

How Test Bench Verification Works

Generating and Importing Structured Text

Generated Files

................................... 3-4

.................. 3-2

............ 3-2

Working with Tunable Parameters in the

Simulink

®

PLC Coder Environment

4

Configuring Tunable Parameters for Your Model ..... 4-2

About Tunable Parameters in the Simulink

Environment

Workflow O v erview

................................... 4-2

................................ 4-2

®

PLC Coder

iv Contents

Page 5

Identifying Tunable Parameters ..................... 4-3

Defining Tunable Parameters in the MATLAB

Workspace

Configuring Parameters to Be Tunable

Tunable Parameters Considerations

..................................... 4-5

................ 4-8

.................. 4-12

Controlling Generated Code Partitions

5

Function Block Partitions .......................... 5-2

About Function Block Partitions

Example: One Function Block for Atomic Subsystems

Example: One Function Block for Virtual Subsystems

Example: Multiple Function Blocks for Nonvirtual

Subsystems

Controlling Generated Code Using Subsystem Block

Parameters

.................................... 5-4

.................................... 5-5

..................... 5-2

.... 5-2

... 5-3

IDE-Specific Considerations

6

Introduction ...................................... 6-2

Considerations forAllTargetIDEs

Rockwell Automation RSLogix Considerations

................... 6-2

.......... 6-2

Limitations

7

Coder Limitations ................................. 7-2

Current Limitations

Permanent Limitations

Block Restrictions

............................... 7-2

............................. 7-2

................................. 7-4

v

Page 6

Simulink Block Support Exceptions ................... 7-4

Stateflow Chart Exceptions

......................... 7-4

Functions — Alphabetical List

8

Configuration Parameters for Simulink®PLC

Coder Models

9

PLC Coder: General ............................... 9-2

PLC Overview

Target IDE

Output directory

Generate testbench for subsystem

.................................... 9-3

....................................... 9-4

.................................. 9-6

.................... 9-7

vi Contents

PLC Coder: Comments

Comments Overview

Include comments

Simulink block / Stateflow object comments

Show eliminated blocks

PLC Coder: Symbols

Symbols Overview

Maximum identifier length

Use the same reserved names as Simulation Target

Reserved names

................................... 9-16

............................. 9-8

............................... 9-9

................................. 9-9

............................ 9-11

............................... 9-12

................................. 9-13

.......................... 9-14

........... 9-10

..... 9-15

Index

Page 7

Getting Started

• “Product Overview” on page 1-2

• “Related Products” on page 1-6

• “Basic Workflow” on page 1-10

• “Preparing Your Model to Generate Structured Text Code” on page 1-11

• “Generating and Examining Structured Text Code” on page 1-20

1

Page 8

1 Getting Started

Product Overview

Introduction

Simulink®PLC Coder™ generates hardware-independent IEC 61131

structured text from Simulink

MATLAB

file formats supported by widely used integrated develo pment environments

(IDEs). As a result, you can compile and deploy your application to numerous

programmable logic controller (PLC) and programmable automation

controller (PAC) devices.

In this section...

“Introduction” on page 1-2

“PLC C ode Generation in the Development Process” on page 1-3

“Expected Users” on page 1-4

“Glossary” on page 1-4

“Expected Background” on page 1-4

“Accessing Demos” on page 1-5

®

®

functions. The structured text is generated in PLCopen and other

models, Stateflow®charts, and Embedded

1-2

Simulink PLC Coder generates test benches that help you verify the

structured text using PLC and PAC IDEs and simulation tools.

Key features:

• Automatic generation of IEC 61131-3 structured text

• Simulink support, including reusable subsystems, PID controller blocks,

and lookup tables

• Stateflow support, including graphical functions, truth tables, and state

machines

• Embedded MATLAB support, including if-else statements, loop constructs,

and math operations

Page 9

Product Overview

• Support for multiple data types, including Boolean, integer, enumerated,

and floating-point, as well as vectors, matrices, buses, and tunable

parameters

• IDE support, including B&R Automation Studio

Automation

®

RSLogix™ 5000, and Smart Software Solutions CoDeSys

®

, PLCopen, Rockwell

• Test-bench creation

PLC Code Generation in the Development Process

Simulink PLC Coder software lets you generate IEC-61131 compliant

structured text code from Simulink models. Thissoftwarebringsthe

Model-Based Design approach into the domain of PLC and PAC development.

Using the coder, system architects and designers can spend more time

fine-tuning algorithms and models through rapid prototyping and

experimentation, and less time on coding PLCs.

Typically, you use a Simulink model to simulate a design for realization

in a PLC. Once satisfied that the model meets design requirements, run

the Simulink P L C Coder compatibility checker utility. This utility verifies

compliance of model semantics and blocks for PLC target IDE code generation

compatibility. Next, invoke the Simulink PLC Coder tool, using either the

command line or the graphical user interface. The coder generates structured

text code that implements the design embodied in the model.

Usually, you also generate a corresponding test bench. You can use the test

bench with PLC emulator tools to drive the generated structured text code

and evaluate its behavior.

The test bench feature increases confidence in the correctness of the generated

code and saves time spent on test bench implementation. The design and

test process are fully iterative. At any point, you can return to the original

model, modify it, and regenerate code.

At completion of the design and test phase of the project, you can easily export

the generated Structure Text code to your PLC development environment.

You can then deploy the code.

1-3

Page 10

1 Getting Started

Expected Users

The Simulink PLC

and test enginee

Coder product is a tool for control and algorithm design

rs in the following applications:

• PLC manufactur

• Machine manuf

• Systems integ

ing

acturing

ration

Glossary

Term

PAC

PLC

IEC 61131-3 IEC standard that d efines PLC coder languages, including the structured

PLCOpen

tured text

struc

function block Structured text language programming concept that allows the

Definition

Programmable automation controller.

Programmable logic controller.

text language that the Simulink PLC Coder software generates.

Vendor- and product-independent organization that works with the

IEC 61131-3 standard. The Simulink PLC Coder product can generate

structured text using the PLCOpen XML standard format. See

http://www.plcopen.org/pages/tc6_xml/xml_intro/index.htm for

details.

High-level textual language defined by IEC-61131-3 standard for the

programming of PLCs.

encapsulation and reuse of algorithmic functionality.

1-4

ected Background

Exp

should be familiar with:

You

®

TLAB

• MA

Cs

• PL

ructured text language

• St

and Simulink software and concepts

Page 11

Product Overview

If you want to download generated code to a PLC IDE, you should also be

familiar with your chosen PLC IDE platform. See “Supported IDE Platforms”

onpage1-7foralistoftheseplatforms.

Accessing Demos

The Simulink PLC Coder software provides demos in:

matlabroot\toolbox\plccoder\plccoderdemos

To see a list of available demos, in the MATLAB Command Window, type:

plccoderdemos

This command displays the Simulink PLC Coder demos page in the MATLAB

Help browser. The MATLAB Help browser allows you to access the

documentation and demo models for all the MathWorks products that you

have installed. To access any of these demos, select the name on the demo

page. Some of the demos included with the product are:

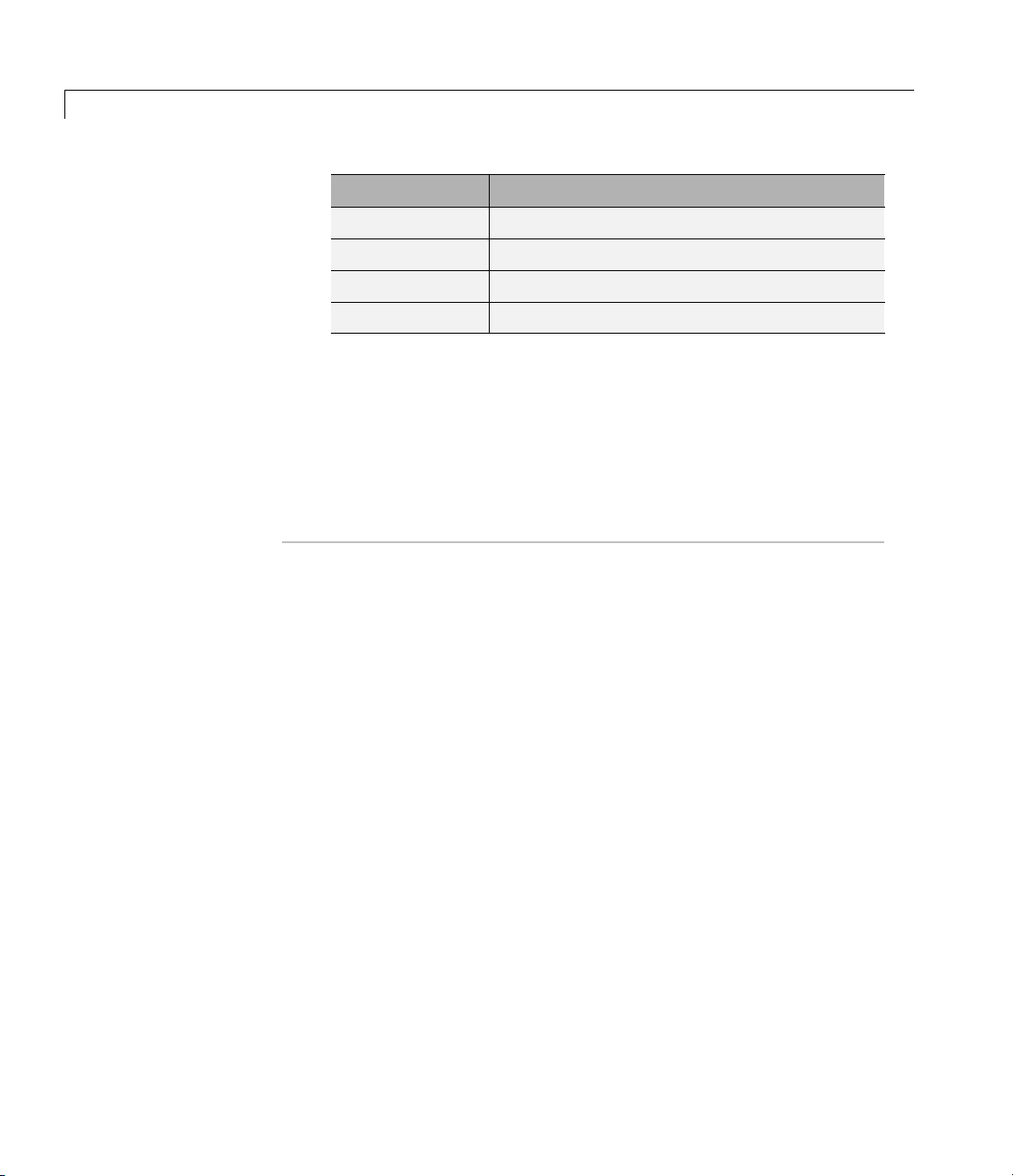

Demo

Generating Structured

Text for a Simple

Simulink Subsystem

Generating Structured

Text for a Hierarchical

Simulink Subsystem

Generating Structured

Text for a Reusable

Simulink Subsystem

Generating Structured

Text for a Stateflow Chart

Generating Structured

Text for an Embedded

MATLAB Block

Description

Demonstrates the code generated for a simple

subsystem co nsisting of basic Simulink blocks.

Demonstrates the code generated for a

hierarchical subsystem consisting of other

Simulink subsystems.

Demonstrates the code generated for a reusable

subsystem co nsisting of basic Simulink blocks.

Demonstrates the code generated for a

Stateflow Chart block.

Demonstrates the code generated for

an Embedded MATLAB Function block

implementing tank valve control logic.

1-5

Page 12

1 Getting Started

Related Products

In this section...

“Requirements for the Simulink®PLC Co de r Product” on page 1-6

“Supported Simulink and Stateflow Blocks” on p age 1-6

“System Requirements” on page 1-7

“Supported IDE Platforms” on page 1-7

Requirements for the Simulink PLC Coder Product

The Simulink PLC Coder product requires current versions of these products:

• MATLAB

• Simulink

The Stateflow product is recommended.

1-6

See the MathWorks Web site at Related Products for a list of related products.

Supported Simulink and Stateflow Blocks

To access a Simulink library of blocks that the Simulink PLC Coder software

supports, type

generate structured text code for subsystems that contain these blocks. The

library window is displayed.

plclib in the MATLAB Command Window. The coder can

Page 13

Related Products

This library contains two sublibraries, Simulink and Stateflow. Each

sublibrary contains the blocks that you can include in a Simulink PLC Coder

model.

See “Block Restrictions” on page 7-4 for restrictions on using these blocks.

System Requirements

Requirement Description

32-bit operating

system

Windows

®

platform supported by The MathWorks

Supported IDE Platforms

The Simulink PLC Coder produ ct supports the following IDE platforms :

• 3S-Smart Software Solutions CoDeSys Version 2.3 or 3.3

1-7

Page 14

1 Getting Started

• Rockwell Automation RSLogix 5000 Series Version 17

• B&R Automation Studio 3.0

• PLCOpen XML

®

• Beckhoff

TwinCAT®2.11

• Generic

3S-Smart Software Solutions CoDeSys Software

To get CoDeSy s Version 2.3 or 3.3, see:

http://www.3s-software.com/index.shtml?en_download

This download page requires you to be a registered user.

1 If you are not yet a registered user, create an account. It might take a few

days to receive a password for the account.

2 When you receive a passwo rd, use it to access the download page.

1-8

3 On the download page, select the CoDeSys software to download.

You do not need to download the CoDeSys SP RTE demo.

4 Follow CoDeSys download and installation instructions to install the

software.

Rockwell Automation RSLogix 5000 Software

To get the Rockwell Automation RSLogix 5000 product, see:

http://www.rockwellautomation.com/rockwellsoftware/design/rslogix5000/

B&R Automation Studio 3.0 Software

To get the B&R Automation Studio product, see:

http://www.br-automation.com/cps/rde/xchg/br-productcatalogue/hs.xsl/cookies_allowed.htm?caller=products_5309_ENG_HTML.htm/

Page 15

Beckhoff TwinCAT 2.11

To get the Beckhoff TwinCAT 2.11 product, see:

http://www.beckhoff.com/english.asp?twincat/default.htm

Related Products

1-9

Page 16

1 Getting Started

Basic Workflow

The basic workflow of Simulink PLC Coder users includes:

1 Define and design a Simulink model from which you want to generate code.

2 Identify the m odel components for which you want to generate code for

downloading to a PLC.

3 Place the compon ents in a Subsystem block.

4 Identify your target PLC IDE.

5 Configure the Subsystem block to be atomic.

6 Check that the model is compatible with the Simulink PLC Coder software.

7 Simulate your model.

8 Configure model parameters to generate code for your PLC IDE.

1-10

9 Examine the generated code.

10 Import code to your PLC IDE.

Page 17

Preparing Your Model to Generate Structured Text Code

Preparing Your M odel to Generate Structured Text Code

In this section...

“Configuring Simulink Models for Structured Text Code Generation” on

page 1-11

“Ensuring System Compatibility for Structured Text Code Generation”

on page 1-16

Configuring Simulink Models for Structured Text

Code Generation

This topic assumes that you have a model for which you want to generate and

import code to a PLC. Before you use this model, perform the following.

1 In the MATLAB Command Window, open your model. For example:

2 Save this model as plcdemo_simple_subsystem1.mdl.

3 Place the components for which you want to generate structured text code

in a subsystem. For example:

1-11

Page 18

1 Getting Started

1-12

Optionally, rename In1 and Out1 to U and Y respectively. This operation

results in a subsystem like the following:

Page 19

Preparing Your Model to Generate Structured Text Code

4 Save the subsystem.

5 In the top-level model, right-click the Subsystem block and select

Subsystem Parameters.

1-13

Page 20

1 Getting Started

1-14

6 In the re

sulting block dialog box, select Treat as atomic unit.

Page 21

Preparing Your Model to Generate Structured Text Code

7 Click OK.

8 Simulate your model.

9 Save

You a

“Ge

your model. In later procedures, you can use either this model, or the

emo_simple_subsystem.mdl

plcd

model that comes with your software.

re now ready to generate structured text code for your IDE. See

nerating and Examining Structured Text Code” on page 1-20.

1-15

Page 22

1 Getting Started

Ensuring System Compatibility for Structured Text

Code Generation

This topic assumes that you have a model that you have prepared to work

with the Simulink PLC Coder software.

1 In your model, navigate to the subsystem for which you want to generate

code.

2 Right-click that Subsystem block and select PLC Coder > Check

Subsystem Compatibility.

1-16

The coder verifies that your model satisfies the Simulink PLC Coder

criteria and displays an information window when done.

Page 23

Preparing Your Model to Generate Structured Text Code

If the subsystem is not atomic, right-clicking the Subsystem block and

selecting PLC Coder prompts you to sele ct Enable “Treat as atomic

unit” to generate code.

1-17

Page 24

1 Getting Started

1-18

This command opens the block parameter dialog box so that you can select

the Treat as atomic unit check box.

Page 25

Preparing Your Model to Generate Structured Text Code

You ar

“Gene

e now ready to generate structured text code for your IDE. See

rating and Examining Structured Text Code” on page 1-20.

1-19

Page 26

1 Getting Started

Generating and Examining Structured Text Code

In this section...

“Generating Structured Text Code from the Model Window” on page 1-20

“Generating Structured Text Code with the MATLAB Interface” on page

1-25

Generating Structured Text Code from the Model

Window

This topic assumes that you have set up your environment and Simulink

modeltousetheSimulinkPLCCodersoftwaretogeneratestructuredtext

code. If you have not yet done so, see “Preparing Your Model to Generate

Structured Text Code” on page 1-11.

1 If you do not have the plcdemo_simpl e_subsystem model open, open it now.

2 Right-click the Subsystem block and select PLC Coder > Options.

1-20

Page 27

Generating and Examining Structured Text Code

The Conf

iguration Parameters dialog box is displayed.

1-21

Page 28

1 Getting Started

3 In PLC Coder > General options > Target IDE, select a target IDE.

For example, select

CoDeSys 2.3.

1-22

4 Click Apply.

5 Click the Generate code button.

This button:

• Generates structured text code (same as the PLC Coder > Generate

Code for Subsystem option)

• Stores generated code in

plcdemo_simple_subsystem.exp)

model_name.exp (for ex ample,

When code generation is complete, an information window is displayed.

Page 29

Generating and Examining Structured Text Code

This window has links that you can click to open the associated files.

The Simulink PLC Coder software generates structured text code and stores

it depending on the target IDE platform.

Platform

Generated Files

CoDeSys IDE current_folder\plcsrc\model_name.exp — Structured text file

appropriate for downloading to the target IDE.

Rockwell Automation

RSLogix 5000 IDE

current_folder\plcsrc\plcdemo_simple_subsystem.L5X

(model_name.L5X). — Structured text file appropriate for downloading

to the target IDE. This file is in XML format and contains the

generated structured text code for your model.

1-23

Page 30

1 Getting Started

Platform

B&R Automation

Studio IDE

Generated Files

Five or six files in folder

current_folder\plcsrc\model_name\subsystem — Files appropriate

for downloading to the target IDE. Note that the

subsystem folder

name might be truncated.

•

IEC.lby

Main project definition file in XML format.

subsystem_block_name.fun

•

Text file. Function block interface definitions file. The coder

generates one file per project.

•

subsystem_block_name.st

Text file. Structured text f unction body files. The coder generates

one file per function block in the generated code.

•

subsystem_block_name.typ

Text file. Structure and enumerated type definitions file. The coder

generates one file per project.

•

subsystem_block_name.var

Text file. Global constant definitions file. The coder generates one

file per project.

PLCOpen XML

Beckhoff TwinCAT

2.11

Generic

1-24

•

TestBench.st (If test bench is generated.)

Text file. structured text file for generated test bench code.

current_folder\plcsrc\plcdemo_simple_subsystem.xml

(model_name.xml) — Structured text file formatted using the

PLCOpen XML standard.

current_folder\plcsrc\plcdemo_simple_subsystem.exp

(model_name.exp). — Structured text file appropriate for downloading

to the target IDE.

current_folder\plcsrc\plcdemo_simple_subsystem.st

(model_name.st) — Pure structured text file. If your target ID E is not

available for the Simulink PLC Coder product, consider generating

and downloading a generic structured text file.

Page 31

Generating and Examining Structured Text Code

The example in this topic illustrates generated code for the C oD eSys

Version 2.3 PLC IDE. Generated code for other platforms, such as Rockwell

Automation RSLogix 5000, i s in XML form at and looks different.

After generating structured text code, examine it to ensure that it is what you

expect. See Chapter 2, “Mapping Simulink Semantics to Structured Text” for

a d escription of h ow the generated code for the Simulink components map to

structured text components.

Generating Structured Text Code with the MATLAB

Interface

You can generate structured text code for a subsystem from the MATLAB

Command Window with the

assumes that you have configured the parameters for the model, or that you

plcgeneratecode function. The function

1-25

Page 32

1 Getting Started

want to use the default settings. For example, to open the Configuration

Parameters dialog box for the subsystem, type:

plcopenconfigset('plcdemo_simple_subsystem/Simple_Subsystem')

Configure the subsystem as described in “Generating Structured Text Code

from the Model Window” on page 1-20.

To generate the code for the subsystem, type:

generatedfiles = plcgeneratecode('plcdem o_simple_subsystem/Simple_Subsystem')

1-26

Page 33

Mapping Simulink

Semantics to Structured

Text

When you examine generated code, you evaluate how well the Simulink PLC

Coder software has generated code from your model. The following topics

describe how the coder maps Simulink subsystem semantics to function block

semantics in structured text. As examples, the topics describe the m apping

in the context of the different subsystem types that Simulink supports. The

examples assume that you have already generated code (see “Generating

Structured Tex t Code from the Model Window” on page 1-20). All demos are

located in the

matlabroot\toolbox\plccoder\plccoderdemos folder.

2

These topics use code generated with CoDeSys Version 2.3.

• “How Simple Subsystem Code Maps to Function Blocks” on page 2-2

• “How Reusable Subs ystem Code Maps to Function Blocks” on page 2-4

• “How Stateflow Subsystem Code Maps to Function Blocks” on page 2-6

• “How Embedded MATLAB Subsystem Code Maps to Function Blocks”

on page 2-8

• “How Alias Data Types Map in Generated Code” on page 2-10

Page 34

2 Mapping Simulink

®

Semantics to Structured Text

How Simple Subsystem Code Maps to Function Blocks

This topic assumes that you have generated structured text code from a

Simulink model. If you have not yet done so, see “Generating Structured Text

Code from the Model Window” on page 1-20.

The example in this topic shows generated code for the CoDeSys Version 2.3

PLC IDE. Generated code for other IDE platforms looks different.

1 If you do not have the plcdemo_simple_subsystem.exp file open, open it

now in the MATLAB editor. Type the following in the folder that contains

the file:

edit plcdemo_simple_subsystem.exp

A file like the following is displayed.

This figure illustrates the mapping of the generated code for a simple

Simulink subsystem to structured text components. The Simulink

subsystem corresponds to the structured text function block,

Subsystem.

2-2

Page 35

How Simple Subsystem Code Maps to Function Blocks

Input parameter for

subsystem method

type

Subsystem

inputs and

outputs

Subsystem

State (DWork)

variables

Initialize, output,

and update

methods

Atomic subsystem name

Inlined

parameters

Subsystem

2 Inspect this code as you ordinarily do for PLC code. Ensure that the

generatedcodeisasyouexpect.

2-3

Page 36

2 Mapping Simulink

®

Semantics to Structured Text

How Reusable Subsystem Code Maps to Function Blocks

This topic assumes that you have generated structured text code from a

Simulink model. If you have not yet done so, see “Generating Structured Text

Code from the Model Window” on page 1-20.

The example in this topic shows generated code for the CoDeSys Version 2.3

PLC IDE. Generated code for other IDE platforms looks different.

1 Open the plcdemo_reusable_subsystem model.

2 Right-click the Subsystem block and select PLC Coder > Generate Code

for Subsystem.

The Simulin

places it i

3 If you do not have the plcdemo_reusable_subsystem .ex p file open, open it

k PLC C oder software generates structured tex t code and

n

current_folder/plcsrc/plcdemo_reusable_subsystem.exp.

now in the MATLAB editor.

This figure illustrates the mapping of the generated code for a reusable

Simulink subsystem to structured text components. This graphic contains

a copy of the hierarchical subsystem, ReusableSubsystem. This subsystem

contains two identical subsystems, S1 and S2. This configuration enables

code reuse between the two instances (look for the

ReusableSubysstem

string in the code).

2-4

Page 37

How Reusable Subsystem Code Maps to Function Blocks

Instance variables

Instance invocations (call sites)

Reused code in

FUNCTION_BLOCK

4 Examine the generated structured text code. The code define s

FUNCTION_BLOCK S0_S1 once.

5 Look for two instance variables that correspond to the two instances

declared inside the parent

S0_S1

instances separately by passing in different inputs. The code invokes the

outputs p er the Simulink execution semantics.

FUNCTION_BLOCK S0 (_instance_S0_S1_1:

and _instance_S0_S1_0: S0_S1). The code invokes these two

2-5

Page 38

2 Mapping Simulink

®

Semantics to Structured Text

How Stateflow Subsystem Code Maps to Function Blocks

This topic assumes that you have generated structured text code from a

Simulink model. If you have not yet done so, see “Generating Structured Text

Code from the Model Window” on page 1-20.

The example in this topic shows generated code for the CoDeSys Version 2.3

PLC IDE. Generated code for other IDE platforms looks different.

1 Open the plcdemo_stateflow_controller model.

2 Right-click the ControlModule chart and select PLC Coder > Generate

Code for Subsystem.

The Simulink PLC Coder software generates structured text code and p laces

it in

current_folder/plcsrc/plcdemo_stateflow_controller.exp.

3 If you do not have the plcdemo_stateflow_controller.exp file open,

open it now in the MATLAB editor.

2-6

This figure illustrates the mapping of the generated code for a Simulink

Subsystem block that contains a Stateflow chart to structured text

components.

Page 39

How Stateflow®Subsystem Code Maps to Function Blocks

Inlined code for Stateflow chart

4 Examine the gene rate d structured text code.

The Simulink PLC Coder software aggressively inlines the generated code

for the Stateflow chart. The coder performs this inlining because different

functions from S tateflow charts share some global state data. However,

function blocks in structured text code do not share state data. As a result,

the coder software cannot map these functions onto separate function blocks.

Instead, it must inline these functions.

2-7

Page 40

2 Mapping Simulink

®

Semantics to Structured Text

How Embedded M ATLAB Subsystem Code Maps to

Function Blocks

This topic assu

Simulink model

Code from the M

The example in

PLC IDE. Gene

1 Open the plcd

2 Right-click the TankControl block and select PLC Coder > Generate

Code for Subsystem.

The Simulink P LC Coder software generates structured text code and

places it in

3 If you do n

now in the

This figure illustrates the mapping of the generated code for a Simulink

Subsystem block that contains an Embedded MATLAB Function block to

structured text components. The coder tries to perform inline optim iza t ion

on the generated code for Embedded MATLAB subfunctions. If the coder

determines that it is more efficient to leave the subfunction as is, it

places the generated code in a structured text construct called

Themaindifferencebetweena

FUNCTION cannot have states and cannot access global variables.

mes that you have generated structured text code from a

. If you have not yet done so, see “Generating Structured Text

odel Window” on page 1-20.

this topic shows generated code for the CoDeSys Version 2.3

rated code for other IDE platforms looks different.

emo_eml_tankcontrol

current_folder/plcsrc/plcdemo_eml_tankcontrol.exp.

ot have the

MATLAB editor.

plcdemo_eml_tankcontrol.exp file open, open it

model.

FUNCTION.

FUNCTION_BLOCK and FUNCTION is that a

2-8

Page 41

Embedded MATLAB code

How Embedded MATLAB®Subsystem Code Maps to Function Blocks

Generated

Embedded MATLAB

function code

4 Examine the gene rate d structured text code.

2-9

Page 42

2 Mapping Simulink

®

Semantics to Structured Text

How Alias Data Types Map in Generated Code

The coder maps alias data types to the base data type in the generated code.

2-10

Page 43

Generating Test Bench

Code

3

Page 44

3 Generating Test Bench Code

Working with Generated Structured Text

In this section...

“How Test Bench Verification Works” on page 3-2

“Generating a nd Importing Structured Text” on page 3-2

“Generated Files” on page 3-4

How Test Bench Verification Works

The Sim ulink PLC Coder software simulates your model and automatically

captures the input and output signals for the subsystem that contains your

algorithm. This set of input and output signal data is the test bench data.

The coder also automatically generates a test bench (test harness) using

the text bench data. The test bench verifies that the generated code is

functionally and numerically equivalent to the Simulink model. To perform

this verification, import the generated structured text and the test bench data

into your target IDE.

3-2

Generating and Importing Structured Text

This topic describes the basic procedure for how to generate test bench code.

It uses the CoDeSys environment as an example target IDE.

This topic assumes that you have an appropriately configured model from

which to generate structured text. If you have not yet done this procedure,

see “Preparing Your Model to Generate Structured Text Code” on page 1-11.

All dem os are located in the

folder.

1 If you do not have the plcdemo_simpl e_subsystem model open, open it now.

2 Ensure that you have connected the inputs and outputs of the subsystem

for which you want to generate the test bench. You can import this test

bench with the generated code to the target IDE to verify simulation results

with Simulink output. For example:

matlabroot\toolbox\plccoder\plccoderdemos

Page 45

Working with Generated Structured Text

3 Right-click the Subsystem block and select PLC Coder > Options.

The Con

4 In PLC Coder > General options > Target ID E, select your target IDE,

for example,

5 Select the Generate testbench for subsystem check box.

6 Click

7 Click the Generate code button.

figuration Parameters dialog box is displayed.

CoDeSys 2.3.

Apply.

This button:

• Generates structured text code (same as the PLC Coder > Generate

Code for Subsystem option)

• Generates test bench for code through Simulink simulation

3-3

Page 46

3 Generating Test Bench Code

• Combines generated code and test bench into m odel_name.exp (for

example,

When the code generation is complete, an information window is displayed.

plcdemo_simple_subsystem.exp).

3-4

8 Click OK.

The Simulink P LC Coder software generates structured text code and

writes it to

Depending on the target IDE, the coder might generate additional

supporting files.

9 See the user manual for your target IDE for information on how to import

generated code into the target IDE.

current_folder/plcsrc/plcdemo_simple_subsystem.

Generated Files

Depending on the target IDE platform, the Simulink PLC Coder software

generates code into one or more files. See “Generating Structured Text Code

Page 47

Working with Generated Structured Text

from the Model Window” on page 1-20 for list of the target IDE platforms and

the possible generated files.

3-5

Page 48

3 Generating Test Bench Code

3-6

Page 49

4

Working with Tunable

Parameters in the Simulink

PLC Coder Environment

Page 50

4 Working with Tunable Parameters in the Simulink

®

PLC Coder™ Environment

Configuring Tunable Parameters for Your Model

In this section...

“About Tunable Parameters in the Simulink®PLC Coder Environment”

on page 4-2

“Workflow Overview” on page 4-2

“Identifying Tunable Parameters” on page 4-3

“Defining Tunable Parameters in the MATLAB Workspace” on page 4-5

“Configuring Parameters to Be Tuna ble” on page 4-8

“Tunable Parameters Considerations” on page 4-12

About Tunable Parameters in the Simulink PLC Coder

Environment

Dialog parameters can be either tunable or nontunable. A tunable parameter

is a parameter that you can change while the simulation is running. The

Simulink PLC Coder software allows you to tune parameters:

4-2

• From the MATLAB workspace, while the model simulation is running

• In the ID E, while the generated code is running

Workflow Overview

This topic describes how to configure your model to enable tunable parameters.

By default, Simulink PLC Coder parameters are inlined and not tunable.

The general workflow for configuring a model to enable tunable parameters is:

1 Identify the model parameters yo u want to be tunable.

2 Define these parameters in the MATLAB workspace.

3 Configure tunable parameters in the Configuration

Parameters > O ptimization > Model Parame ter Config ur atio n

dialog box.

Page 51

Configuring Tunable Parameters for Your Model

Identifying Tunable Parameters

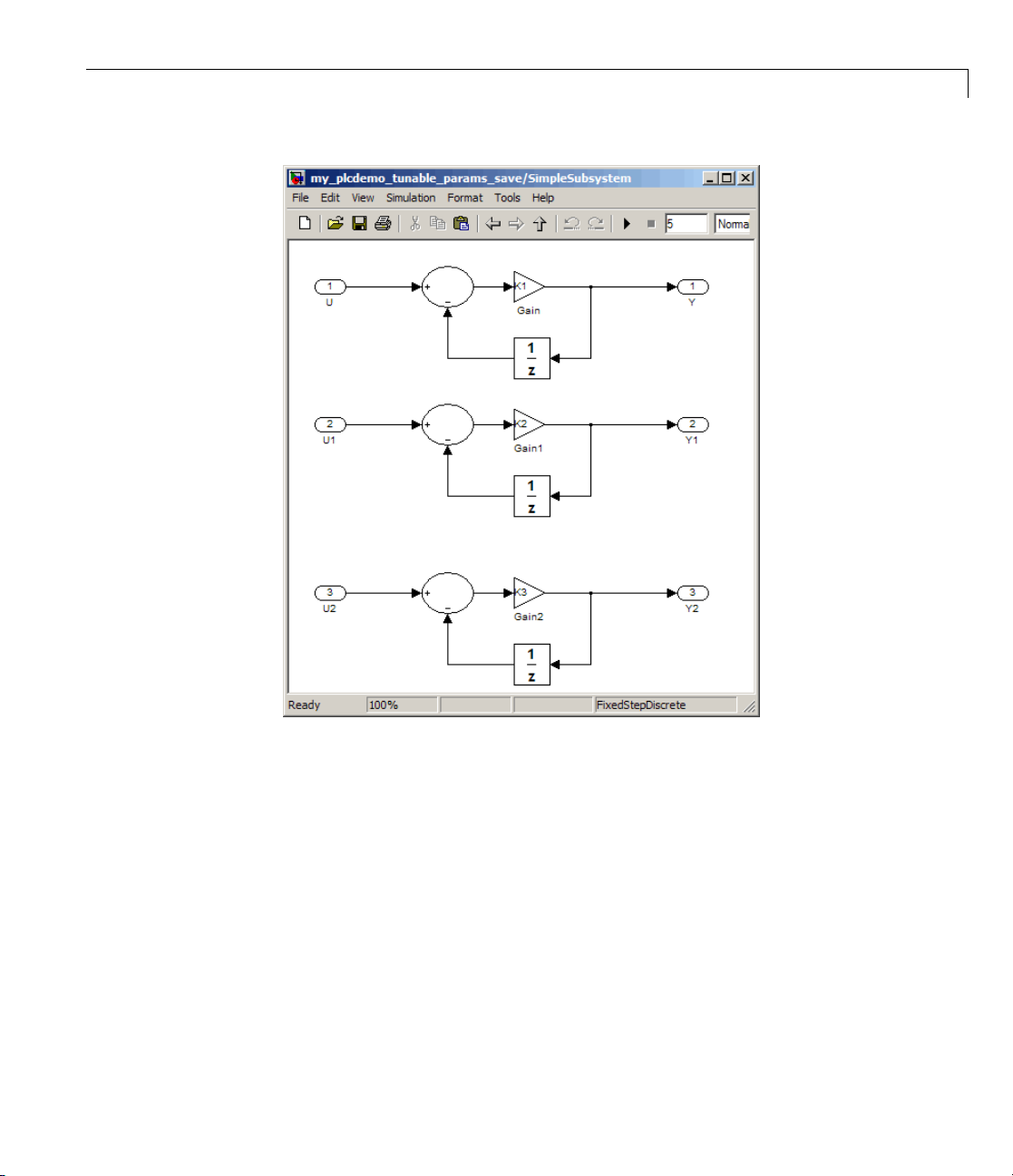

This topic creates the model my_plcdemo_tunable _par ams to show

how to configure tunable parameters. This model is the same as the

plcdemo_tunable_params model. Thedifferenceisthatthedemomodel

already has the tunable parameters configured, while this topic guides you in

configuring the tunable parameters.

1 IntheMATLABCommandWindow,createamodeltolooklikethe

following:

ct the Sum, Gain, and Unit Delay blocks and create an atomic

2 Sele

ystem with inputs U, U1, and U2 and outputs Y, Y1, and Y2. Rename

subs

ubsystem block as SimpleSubystem. When you are finished, the top

the S

l and atomic subsystem model should look like the following:

mode

4-3

Page 52

4 Working with Tunable Parameters in the Simulink

®

PLC Coder™ Environment

4-4

3 Save this subsystem as my_plcdemo_tunable_params.mdl.

4 Double-click SimpleSubsystem.

Page 53

Configuring Tunable Parameters for Your Model

5 Note the three Gain blocks that have the constants that you want to make

tunable: K1, K2,andK3.

Next, define these parameters in the MATLAB workspace. See “Defining

Tunable Parameters in the MATLAB Workspace” on page 4-5.

Defining Tunable Parameters in the MATLAB

Workspace

This topic describes h ow to define tunable parameters in the MATLAB

workspace using the Simulink Model Properties dialog box. Defining tunable

parameters in this way ensures that the model automatically defines the

parameters each time you open the model.

4-5

Page 54

4 Working with Tunable Parameters in the Simulink

It assumes that you created the my_plcdemo_tunable_params model or

opened

youhavenotyetdoneso,see“IdentifyingTunableParameters”onpage4-3.

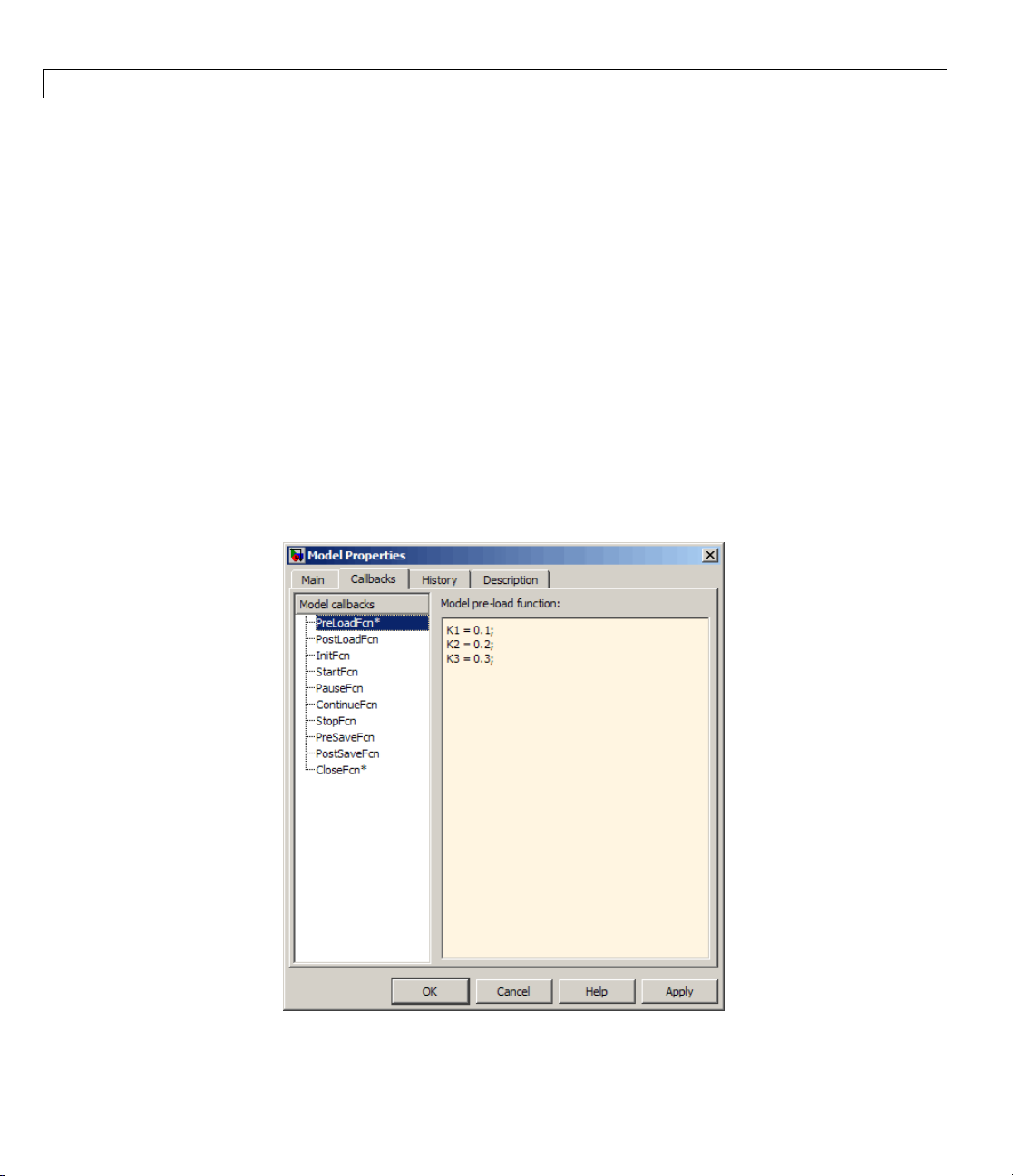

1 In the my_plcdemo_tunable_params model, select File > Model

2 In the Callbacks pane, select PreLoadFcn.

3 In the Model pre-load function pane, enter the three constants K1, K2,

plcdemo_tunable_params and identified the parameters for tuning. If

Properties.

The Model Properties dialog box is displayed.

and K3. Assign initial values to them. For example:

K1 = 0.1;

K2 = 0.2;

K3 = 0.3;

®

PLC Coder™ Environment

4-6

Page 55

Configuring Tunable Parameters for Your Model

4 Click Apply.

5 In the Callbacks pane, select CloseFcn.

6 In the Model close function pane, enter the clear command to clear

these constants. For example:

clear K1 K2 K3;

This command ensures that you clear the se constants from the MATLAB

workspace when you close the model.

7 Click Apply,thenOK.

Your next task is to configure these parameters to be tunable. See

“Configuring Parameters to Be Tunable” on page 4-8.

4-7

Page 56

4 Working with Tunable Parameters in the Simulink

Configuring Param eters to Be Tunable

This topic describes how to configure parameters to be tunable using the

Simulink Configuration Parameters dialog box.

®

PLC Coder™ Environment

It assumes that you created the

opened

plcdemo_tunable_params and defined the parameters for tuning. If

my_plcdemo_tunable_params model or

you have not yet done so, see “Defining Tunable Parameters in the MATLAB

Workspace” on page 4-5.

This topic uses code generated with CoDeSys Version 2.3.

1 In the model, right-click SimpleSubsystem and select PLC

Coder > Options.

2 Navigate to the Optimization node.

3 In the Simulation and code generation section of the Optimization

pane, ensure that the Inline parameters check box is selecte d. (This

check box is selected by default.)

4 In this section, click Configure.

4-8

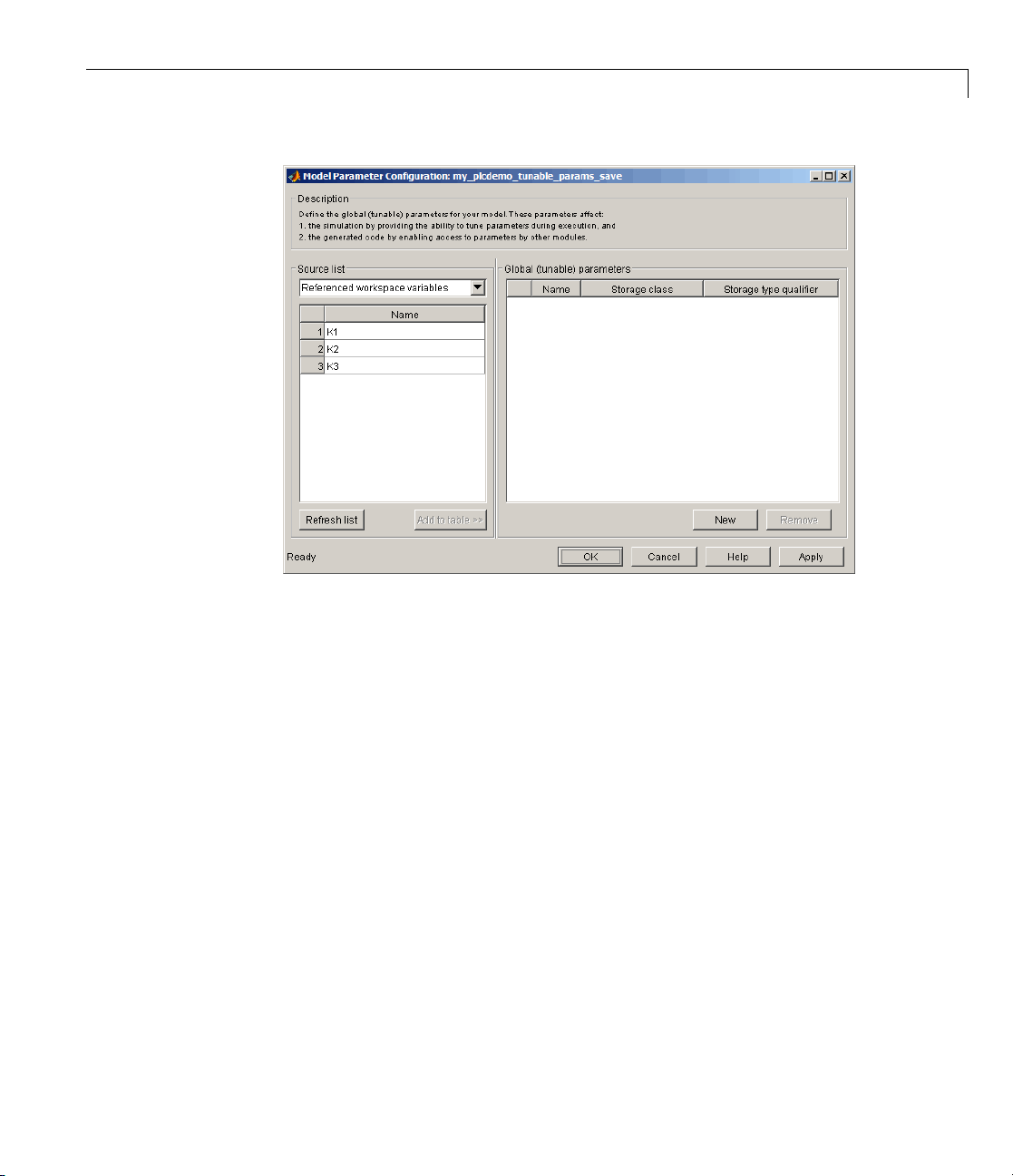

The Model Parameter Configuration dialog box is displayed.

Page 57

Configuring Tunable Parameters for Your Model

5 From Source list, select Referenced workspace variables.

6 Use the Ctrl key to select all the parameters and click Add to table >> to

add them to the Global (tunable) parameters table.

4-9

Page 58

4 Working with Tunable Parameters in the Simulink

®

PLC Coder™ Environment

4-10

By default, this dialog box sets all parameters to the SimulinkGlobal

(Auto)

storage class. This setting generates code with the tunable

parameters set at the local level. In this case, these parameters appear at

the function block level in each function block that uses the parameter.

You can also optionally set the storage type qualifier for a parameter to

const.

7 Click Apply and OK.

8 In the Configuration Parameters dialog box, navigate to PLC

Coder > General options.

9 Ensure that Target IDE and Output Directory settings are appropriate,

then click Generate Code.

10 Observe that the VAR section of Function Block SimpleSubsystem defines

K1, K2,andK3.

Page 59

Configuring Tunable Parameters for Your Model

11 Toconfigureaparametertobeaglobalvariableinthegeneratedcode,set

the parameter storage class of K2 to

ExportedGlobal. Leave the storage

type qualifier unset.

Some ta

suppor

softw

rget IDEs, such as the Rockwell Automation RSLogix IDE, do not

t the access of global variables. In this case, the Simulink PLC Coder

are uses

SimulinkGlobal as the automatic storage class.

Toconfigureaparametertobeaglobalconstant in the generated code, set

the parameter storage class of K3 to

qualifier to

12 Click Apply and OK, then rebuild the code.

13 Obs

erve that K2 is now in the

_GLOBAL_CONSTANT

VAR

const.

section.

ExportedGlobal. Set storage type

VAR_GLOBAL section. K3 is in the

4-11

Page 60

4 Working with Tunable Parameters in the Simulink

14 To configure a parameter so that you or somebody else can provide it

through external structured text, set the parameter storage class of K1 to

ImportedExtern. The coder does not generate a variable declaration for

theparameterinthecode. Leavethestoragetypequalifierunset.

15 Click Apply and OK, then rebuild the code.

16 Observe that K1 no longer appears in the VAR section of the generated code.

®

PLC Coder™ Environment

4-12

Note The Simulink PLC Coder software does not support the setting of

the parameter storage class to

parameter to this value, the software treats it the same as

ImportedExternPointer.Ifyousetthe

ImportedExtern.

Tunable Parameters Considerations

When tuning parameters, the coder does not support:

• Specifying parameters using

tunable parameters instead.

• Tuning parameters of bus data type.

Simulink.Parameter object. Use global

Page 61

5

Controlling Generated Code

Partitions

Page 62

5 Controlling Generated Code Partitions

Function Block Partitions

In this section...

“About Function Block Partitions” on page 5-2

“Example: One Function Block for Atomic Subsystems” on page 5-2

“Example: One Function Block for Virtual Subsystems” on page 5-3

“Example: Multiple Function Blocks for Nonvirtual Subsystems” on page

5-4

“Controlling Generated Code Using Subsystem Block Parameters” on page

5-5

About Function Block Partitions

The Simulink PLC Coder software converts subsystems to function block

units, one subsystem per function block. You control generated code

partitioning by the number and types of Subsystem blocks that you have in

your model. The coder generates structured text function blocks as follows:

5-2

• Generates one function block for an atomic subsystem that contains no

other subsystems.

• Generates one function block for an atomic subsystem that contains only

virtual subsystems. For virtual subsystems, the Simulink PLC Coder

software generates code that is indistinguishable from the rest of the

contents of the atomic subsystem. It generates code that is flattened.

• Generates a function block for each nonvirtual subsystem contained in

an atomic subsystem . Nonvirtual subsystems can be atomic, fcn-call,

or enabled. You can customize this partitioning with the Real-Time

Workshop system code parameter of the Subsystem block.

These topic use code generated with CoDeSys Version 2.3.

Example: One Function Block for Atomic Subsystems

Thecodefortheplcdemo_simple_subsystem demo is an example of

generating code with one function block. The atomic subsystem for which you

generate code does not contain any other subsystems.

Page 63

Function Block Partitions

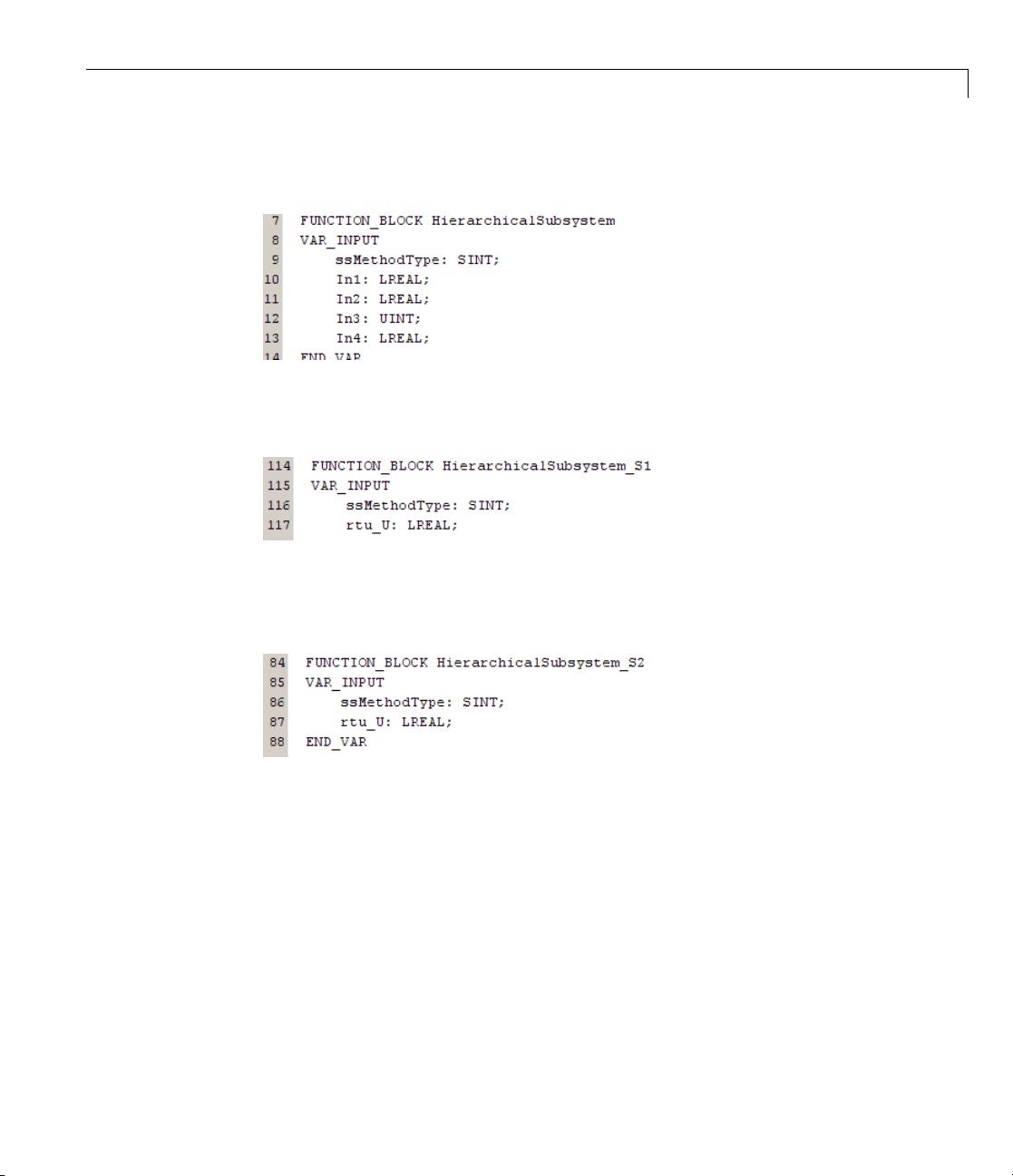

Example: One Function Block for Virtual Subsystems

The plcdem o_hi erarchical_virtual_subsystem demo contains an atomic

subsystem that has two virtual subsystems, S1 and S2, inlined. A virtual

subsystem does not have the Treat as atomic unit parameter selected.

Whenyougeneratecodeforthehierarchicalsubsystem,thecodecontains

only the

additional function blocks for the S1 and S2 subsystems.

FUNCTION_BLOCK HierarchicalSubsystem component. There are no

5-3

Page 64

5 Controlling Generated Code Partitions

5-4

Example: Multiple Function Blocks for Nonvirtual

Subsystems

The plcdemo_hierarchical_subsystem demo contains an atomic subsystem

that has two nonvirtual subsystems, S1 and S2. Virtual subsystems have

the Treat as atomic unit parameter selected. When you generate code

for the hierarchical subsystem, that code contains the

HierarchicalSubsystem

and

FUNCTION_BLOCK HierarchicalSubsystem_S2 components.

, FUNCTION_BLOCK HierarchicalSubsystem_S1,

FUNCTION_BLOCK

Page 65

Function Block for Hierarchical Subsystem

Function Block for Hierarchical S1

Function Block Partitions

Function Block for Hierarchical S2

Controlling Generated Code Using Subsystem Block

Parameters

You can partition generated code us ing the following Subsystem block

parameters:

• Real-Time Workshop system code

• Real-Time Workshop function name options

Leave the Real-Time Workshop file name options set to the default,

Auto.

5-5

Page 66

5 Controlling Generated Code Partitions

Generating Separate Partitions and Inlining Subsystem Code

Use the Real-Time Workshop system code parameter to specify the code

format to generate for an atomic (nonvirtual) subsystem. The Simulink PLC

Coder software interprets this parameter:

If Real-Time Workshop system

code is

Auto,

Reusable function, Function

Inline

For example, in the plcdemo_hierarchical_virtual_subsystem,youcan:

• Inline the S1 subsystem code by setting Real-Time Workshop system

code to

the S1 subsystem inlined.

• Create a function block for the S2 subsystem by setting Real-Time

Workshop system code to

setting creates two function blocks, one for the parent, one for S2.

Inline. This setting creates one function block for the parent w ith

Reusable function, Auto,orFunction.This

Coder Interpretation

Chooses the optimal format based

on the type and number of instances

of the subsystem that exist in the

model.

Generates a function with arguments

that allows the subsystem code to be

shared by other instances of it in the

model.

Inlines the subsystem

unconditionally.

5-6

Page 67

Function Block Partitions

Changing the Name of a Subsystem

You can use the Real-Time Workshop function n am e options parameter

to change the name of a subsystem from the one on the block label. When

the Simulink PLC Coder software generates software, it uses the string

you specify for this parameter as the subsystem name. For example, in the

plcdemo_hierarchical_virtual_subsystem demo:

1 Open the S1 subsystem block parameter dialog box.

2 Set Real-Time Workshop system code to Function.

3 Set Real-Time Workshop function name options to User specified.

4 In the Real-Time Workshop function name field, specify a custom

name. For example, type

my_own_subsystem.

5-7

Page 68

5 Controlling Generated Code Partitions

5-8

5 Save the new settings.

6 Generate code for the parent subsystem.

7 Observe the renamed function block.

Page 69

6

IDE-Specific Considerations

Page 70

6 ID E-Specific Considerations

Introduction

This chapter describes IDE-specific considerations you should be aware of

when generating and downloading code.

Considerations for All Target IDEs

The coder converts matrix data types to single-dimensional vectors

(column-major) in the generated structured text.

Rockwell Automation RSLogix Considerations

This topic d escribes the considerations to remember for this target IDE

platform.

In this section...

“Considerations for All Target IDEs” on page 6-2

“Rockwell Automation RSLogix Considerations” on page 6-2

6-2

Add-On Instruction and Function Blocks

The structured text concept of function block exists for Rockwell Automation

RSLogix target IDEs as an Add-On instruction (AOI). The Simulink PLC

Coder software generates AOIs for this target, not FUNCTION_BLOCK.

Double-Precision Data Types

The Rockwell Automation RSLogix target IDE d oe s not support

double-precision data types. At code generation, the Simulink PLC Coder

converts this data type to single-precision data types in generated code.

Note Design your model to use single-precision data type (single) as much

as possible instead of double-precision data type (double). If you must use

doubles in your model, note that the numerical results produced by the

generated structured text might differ from Simulink results. This difference

isduetodouble-singleconversion during code generation.

Page 71

Introduction

Unsigned Integer Data Types

The Rockwell Automation RSLogix target IDE does not support unsigned

integer data types. At code generation, the Simulink PLC Coder converts this

data type to signed integer data types in generated code.

Note Design your model to use signed integer data types (int8, int16, int32)

as much as possible instead of unsigned integer data types (uint8, uint16,

uint32). D oing so avoids overflow issues that unsigned-to-signed integer

conversions can cause at code generatio n.

Enumerated Data Types

The Rockwell Automation RSLogix target IDE does not support enumerated

data types. At code generation, the Simulink PLC Coder converts this data

type to 32–bit signed integer data types in generated code.

6-3

Page 72

6 ID E-Specific Considerations

6-4

Page 73

Limitations

• “Coder Limitations” on page 7-2

• “Block Restrictions” on page 7-4

7

Page 74

7 Limita tions

Coder Limitations

In this section...

“Current Limitations” on page 7-2

“Permanent Limitations” on page 7-2

Current Limitations

The Simulink PLC Coder softw are does not support the following Simulink

semantics:

• Fixed-point data types

• Complex data types

• Model reference

• Global data store memory (DSM)

• Absolute time temporal logic in Stateflow charts

7-2

• Stateflow machine-parented data and events

• Exported graphical functions in Stateflow charts

• Limited support for math functions. The coder does not support the

following functions:

• Triggered subsystems

• Merge block

• Multi-rate mode ls

• Signal and state storage classes

tanh, cosh, sinh, atan2, rand.

Permanent Limitations

The structured text language has inherent restrictions. As a result, the

Simulink PLC Coder software has the following restrictions:

• The Simulink PLC Coder software supports generating code only for

atomic subsystems.

• The solver type for the Simulink model must be fixed-step and discrete.

Page 75

Coder Limitations

• No blocks that require continuous time semantics. This restriction includes

continuous integrators, zero-crossing blocks, physical modeling blocks,

and so on.

• No pointer data types.

• No recursion (including recursive events).

7-3

Page 76

7 Limita tions

Block Restrictions

In this section...

“Simulink Block Support Exceptions” on page 7-4

“Stateflow Chart Exceptions” on page 7-4

Simulink Block Support Exceptions

The Simulink PLC Coder software supports the plclib blocks with the

following exceptions. Also, see Chapter 7, “Limitations” for a list of limitations

of the software.

If you get unsupported fixed-point type error messages during code

generation, update the block parameter. Open the block param eter dialog

box. Navigate to the Signal Attributes and Parameter Attributes tabs.

Ensure that the Output data type and Parameter data type parameters

are not

either

type, such as

Inherit: Inherit via internal rule. Set these parameters to

Inherit: Same as input or an appropriate non-fixed-point data

double or int8.

7-4

Stateflow Chart Exceptions

If you receive an error like t he following during code generation and the model

contains a Stateflow chart that contains one or more Simulink functions, use

thefollowingproceduretoaddresstheissue:

The 'State when enabling' parameter of the Trigger Port

block inside the Function-Call subsystem

'msimpleslFcn/Subsystem/Chart/slFcn' is set to 'inherit'.

Simulink cannot ensure con sistency between the origi nal

subsystem 'msimpleslFcn/Subsystem' and the S-function

generated from subsystem b uild. The 'Stat e when enabling'

parameter must be set to 'reset' or 'held'.

1 Open the model and double-click the Stateflow chart that is causing the

issue.

The chart Statef low Editor dialog box is displayed.

Page 77

Block Restrictions

2 Right-click in this dialog box.

3 In the context-sensitive menu, select Properties.

The Chart dialog box is displayed.

4 In the C hart dialog box, navigate to the States When Enabling parameter

and select

5 Click Apply and OK and save the model.

Held.

7-5

Page 78

7 Limita tions

7-6

Page 79

Functions — Alphabetical

List

8

Page 80

plccoderdemos

Purpose Product demos

Syntax plccoderdemos

Description plccoderdemos displays the Simulink PLC Co der demos in the

MATLAB Help browser.

Example Display demos in the MATLAB Help browser.

plccoderdemos

See Also plcopenconfigset

8-2

Page 81

plccoderpref

Purpose Set target IDE

Syntax plccoderpref

plccoderpref('plctargetide')

plccoderpref('plctargetide', IDEcodename)

plccoderpref('plctargetide', 'default')

Description plccoderpref displays the current set of user preferences, including

the default target IDE.

plccoderpref('plctargetide') returns the current default target

IDE. This default can be the target IDE set previoiusly, or the factory

default. The factory default is

plccoderpref('plctargetide', IDEcodename) sets the default target

IDEtotheonethatyouspecifyin

that IDEcodename persists as the default target IDE for all future

MATLAB sessions.

plccoderpref('plctargetide', 'default') sets the default target

IDE to the factory default target IDE (

'codesys23'.

IDEcodename. This command ensures

'codesys23').

Input

Arguments

'plctargetide'

String directive that specifies the default target IDE.

'IDEcodename'

String that specifies the default target IDE. String must be one of:

Name

codesys23

codesys33

rslogix5000

Description

3S-Smart Software Solutions CoDeSys

Version 2.3 (default) target IDE

3S-Smart Software Solutions CoDeSys

Version 3.3 target IDE

Rockwell Automation RSLogix 5000 Series

target IDE

8-3

Page 82

plccoderpref

Name

brautomation30

plcopen

twincat211

generic

'default'

Description

B&R Automation Studio 3.0 target IDE

PLCOpen XML target IDE

Beckhoff TwinCA T 2.11 target IDE

Generic target IDE

String directive that sets 'plctargetide' to factory default

(

'codesys23').

Example Return the current default target IDE.

plccoderpref('plctargetide')

Set rslogix5000 as the new default target IDE.

plccoderpref('plctargetide', 'rslogix5000')

8-4

Page 83

plcgeneratecode

Purpose Generate structured text for subsystem

Syntax generatedfiles = plcgeneratecode(subsystem)

Description generatedfiles = plcgeneratecode(subsystem) generates

structured text for the specified atomic subsystem in a model.

subsystem is the fully qualified path name of the atomic subsystem.

generatedfiles is a cell array of the generated file names.

Example Generate code for the subsystem,

plcdemo_simple_subsystem/Simple_Subsystem.

generatedfiles = plcgeneratecode('plcdemo_simple_subsystem/Simple_Subsystem')

See Also plcopenconfigset

8-5

Page 84

plcopenconfigset

Purpose Open Configuration Parameters dialog box for subsystem

Syntax plcopenconfigset(subsystem)

Description plcopenconfigset(subsystem) opens the Configuration Parameters

dialog box for the specified atomic subsystem in the model. subsystem is

the fully qualified path name of the atomic subsystem.

Example Open the Configuration Paramete rs dialog box for the subsystem,

plcdemo_simple_subsystem/Simple_Subsystem.

plcopenconfigset('plcdemo_simple_subsystem/Simple_Subsystem')

See Also plcgeneratecode

8-6

Page 85

Configuration Parameters

for Simulink PLC Coder

Models

• “PLC Coder: General” on page 9-2

• “PLC Coder: Comments” on page 9-8

• “PLC Coder: Symbols” on page 9-12

9

Page 86

9 Configuration Parameters for Simulink

PLC Coder: General

In this section...

®

PLC Coder™ Models

9-2

“PLC Overview” on page 9-3

“TargetIDE”onpage9-4

“Output directory ” on page 9-6

“Generate testbench for subsystem” on page 9-7

Page 87

PLC Coder: General

PLC Overview

Set up general information about generating structured text code to download

to target PLC IDEs.

Configuration

This pane appears only if your model contains an atomic Subsystem block.

To enable the Simulink PLC Coder options pane, you must:

1 Create a model.

2 Add either an Atomic Subsystem block, or a Subsystem block for which you

have selected the Treat as atomic unit check box.

3 Right-cli

Tip

In additi

can also u

code for t

on to configuring parameters for the Simulink PLC Coder model, you

See Also

“Gener

ating Structured Text Code from the Model Window” on page 1-20

ck the subsystem block and select PLC Coder > Options.

se this dialog box to generate structured text code and test bench

he Subsystem block.

9-3

Page 88

9 Configuration Parameters for Simulink

Target IDE

Select the target language in which to generate code.

Settings

Default: Structured Text (CoDeSys)

CoDeSys 2.3

Generates structured text (IEC 61131) code for 3S-Smart Software

Solutions CoDeSys software Version 2.3.

CoDeSys 3.3

Generates structured text (IEC 61131) code for 3S-Smart Software

Solutions CoDeSys software Version 3.3.

RSLogix 5000

Generates structured text code for Rockwell Automation RSLogix 5000

software.

B&R Automation Studio 3 .0

Generates structured text code for B&R Automation S tudio 3.0 software.

®

PLC Coder™ Models

9-4

PLCOpen XML

Generates structured text code formatted using PLCOpen XML

standard.

Beckhoff TwinCAT 2.11

Generates structured text code fir Beckhoff TwinCAT 2.11 software.

Generic

Generates a pure structured text file. If your desired target IDE is not

available for the Simulink PLC Coder product, consider generating and

downloading a generic structured text file.

Tip

• Start each reserved name with a letter or an underscore to prevent error

messages.

• Each reserved name must contain only letters, numbers, or underscores.

• Separate the reserved names using commas or spaces.

Page 89

PLC Coder: General

Command-Line Information

Parameter: PL C_TargetIDE

Type: string

Value:

'brautomation30' | 'plcopen' | 'twincat211' | 'generic'

Default: 'codesys23'

'codesys23' | 'c odesys33' | 'rslogix5000' |

See Also

“Generating S tructured Text Code from the Model Window” on page 1-20

9-5

Page 90

9 Configuration Parameters for Simulink

®

PLC Coder™ Models

Output director

Enter a path to th

y

e target folder into which code is generated.

Settings

rc

Default: plcs

subfolder in your working folder

Command-Line Information

Parameter: P

Type: string

Value:

Default: '.

'./plcsrc'

LC_OutputDir

/plcsrc'

See Also

“Generati

ng Structured Text Co de from the Model Window ” on pag e 1-20

9-6

Page 91

Generate testbench for subsystem

Specify the generation of test bench code for the subsystem.

Settings

Default: off

On

Enables generation of test bench code for subsystem.

Disables generation of test bench code for subsystems.

Command-Line Information

Parameter: PLC_Generate Testbench

Type: string

Value:

Default: 'off'

'on' | 'off'

PLC Coder: General

See Also

“Generating S tructured Text Code from the Model Window” on page 1-20

9-7

Page 92

9 Configuration Parameters for Simulink

PLC Coder: Comments

In this section...

“Comments Overview” on page 9-9

“Include comments” on page 9-9

“Simulink block / Stateflow object comments ” on page 9-10

“Show eliminated blocks” on page 9-11

®

PLC Coder™ Models

9-8

Page 93

PLC Coder: Comments

Comments Overview

Control the comments that the Simulink PLC Coder software a utomatically

creates and inserts into the generated code.

See Also

“Generating S tructured Text Code from the Model Window” on page 1-20

Include comments

Specify which comments are in generated files.

Settings

Default: on

On

Places comments in the generated files based on the selections in the

Auto generated comments pane.

Off

Omits comments from the generated files.

Command-Line Information

Parameter: PLC_RTWGenerat eComments

Type: string

'on' | 'off'

Value

Default: 'on'

:

See Also

“Generating S tructured Text Code from the Model Window” on page 1-20

9-9

Page 94

9 Configuration Parameters for Simulink

Simulink block / Stateflow object comments

Specify whether to insert Simulink block and Stateflow object com ments.

Settings

Default: on

On

Inserts automatically generated comments that describe block code and

objects. The comments precede that code in the generated file.

Off

Suppresses comments.

Command-Line Information

Parameter: PLC_RTWSimulinkBlockC omments

Type: string

Value:

Default: 'on'

®

PLC Coder™ Models

'on' | 'off'

9-10

See Also

“Generating S tructured Text Code from the Model Window” on page 1-20

Page 95

PLC Coder: Comments

Show eliminated

Specify whether

to insert eliminated block comments.

blocks

Settings

Default: off

On

Inserts stat

result of opt

Off

Suppresses

ements in the g enerated code from blocks eliminated as the

imizations (such as parameter inlining).

statements.

Command-Line Information

r:

Paramete

Type: string

Value:

Default

PLC_RTWShowEliminatedStatement

'on' | 'off'

:

'off'

See Also

“Gener

ating Structured Text Code from the Model Window” on page 1-20

9-11

Page 96

9 Configuration Parameters for Simulink

PLC Coder: Symbols

®

PLC Coder™ Models

9-12

In this section...

“Symbols Overview” o n page 9-13

“Maximum identifier length” on page 9-14

“Use the same reserved names as Simulation Target” on page 9-15

“Reserved names” on page 9-16

Page 97

PLC Coder: Symbols

Symbols Overvie

Select the autom

See Also

“Generating S

atically generated identifier nam ing rules.

tructured Text Code from the Model Window” on page 1-20

w

9-13

Page 98

9 Configuration Parameters for Simulink

Maximum identifier length

Specify the maximum number of characters in generated function, type

definition, and variable names.

Settings

Default: 31

Minimum: 31

Maximum: 256

You can use this parameter to limit the number of characters in function,

type definition, and variable names.

Command-Line Information

Parameter: PLC_RTWM axIdLength

Type: int

Value:

Default: 31

®

PLC Coder™ Models

31 to 256

9-14

See Also

“Generating S tructured Text Code from the Model Window” on page 1-20

Page 99

PLC Coder: Symbols

Use the same rese

Specify whether

Simulation Targ

to use the same reserved names as those specified in the

et > Symbols pane.

rvednamesasSimulationTarget

Settings

Default: off

On

Enables usin

Simulation T

Off

Disables u

Simulatio

g the same reserved names as those specified in the

arget > Symbols pane pane.

sing the same reserved names as those specified in the

n Target > Symbols pane pane.

Command-Line Information

r:

Paramete

Type: string

Value:

Default

PLC_RTWUseSimReservedNames

'on' | 'off'

:

'off'

See Also

“Gener

ating Structured Text Code from the Model Window” on page 1-20

9-15

Page 100

9 Configuration Parameters for Simulink

Reserved names

Enter the names o

donotwantmodif

Settings

Default: ()

®

PLC Coder™ Models

f variables or functions in the generated code that y ou

ied.

This action c

code to avoid

must be short

hanges the names of variables or functions in the generated

name conflicts with identifiers in custom code. Reserved names

er than 256 characters.

Tips

• Start each reserved name with a letter or an underscore to prevent error

messages.

• Each reserved name must contain only letters, numbers, or underscores.

• Separate the reserved names using commas or spaces.

Command-Line Information

Parameter: PLC_RTWRese rvedNames

Type: string

Value:

Default: ''

string

See Also

“Generating S tructured Text Code from the Model Window” on page 1-20

9-16

Loading...

Loading...