Page 1

Simulink®Design Verifier™ 1

User’s Guide

Page 2

How to Contact The MathWorks

www.mathworks.

comp.soft-sys.matlab Newsgroup

www.mathworks.com/contact_TS.html Technical Support

suggest@mathworks.com Product enhancement suggestions

bugs@mathwo

doc@mathworks.com Documentation error reports

service@mathworks.com Order status, license renewals, passcodes

info@mathwo

com

rks.com

rks.com

Web

Bug reports

Sales, prici

ng, and general information

508-647-7000 (Phone)

508-647-7001 (Fax)

The MathWorks, Inc.

3 Apple Hill Drive

Natick, MA 01760-2098

For contact information about worldwide offices, see the MathWorks Web site.

®

Simulink

© COPYRIGHT 2007–20 10 by The MathWorks, Inc.

The software described in this document is furnished under a license agreement. The software may be used

or copied only under the terms of the license agreement. No part of this manual may be photocopied or

reproduced in any form without prior written consent from The MathW orks, Inc.

FEDERAL ACQUISITION: This provision applies to all acquisitions of the Program and Documentation

by, for, or through the federal government of the United States. By accepting delivery of the Program

or Documentation, the government hereby agrees that this software or documentation qualifies as

commercial computer software or commercial computer software documentation as such terms are used

or defined in FAR 12.212, DFARS Part 227.72, and DFARS 252.227-7014. Accordingly, the terms and

conditions of this Agreement and only those rights specified in this Agreement, shall pertain to and govern

theuse,modification,reproduction,release,performance,display,anddisclosureoftheProgramand

Documentation by the federal government (or other entity acquiring for or through the federal government)

and shall supersede any conflicting contractual terms or conditions. If this License fails to meet the

government’s needs or is inconsistent in any respect with federal procurement law, the government agrees

to return the Program and Docu mentation, unused, to The MathWorks, Inc.

Trademarks

MATLAB and Simulink are registered trademarks of The MathWorks, Inc. See

www.mathworks.com/trademarks for a list of additional trademarks. Other product or brand

names may be trademarks or registered trademarks of their respective holders.

Patents

The MathWorks products are protected by one or more U.S. patents. Please see

www.mathworks.com/patents for more information.

Design Verifier™ User’s Guide

Page 3

Revision History

May 2007 Online only New for Version 1.0 (Release 2007a+)

September 2007 Online only Revised for Version 1.1 (Release 2007b)

March 2008 Online only Revised for Version 1.2 (Release 2008a)

October 2008 Online only Revised for Version 1.3 (Release 2008b)

March 2009 Online only Revised for Version 1.4 (Release 2009a)

September 2009 Online only Revised for Version 1.5 (Release 2009b)

March 2010 Online only Revised for Version 1.6 (Release 2010a)

Page 4

Acknowledgment

Acknowledgment

The Simulink®Design Verifier™ software uses Prover Plug-In®products from

Prover

®

Technology to generate test cases and prove model properties.

®

Page 5

Acknowledgment

Getting Started

1

Product Overview ................................. 1-2

Contents

Before You Begin

What You Need to Know

Required Products

Starting th e Simulink

Analyzing a Model

About This Demo

Opening the Model

Generating Test Cases

Combining Test Cases

Analyzing a Subsystem

Basic Workflow for Using the Simulink

Software

Learning M ore

Next Step

Product Help

The MathWorks Online

........................................ 1-30

........................................ 1-31

.................................. 1-3

............................ 1-3

................................. 1-3

®

Design Verifier Software ..... 1-4

................................. 1-6

.................................. 1-6

................................ 1-6

............................. 1-7

.............................. 1-23

............................. 1-26

.................................... 1-31

..................................... 1-31

............................ 1-32

®

Design Verifier

v

Page 6

How the Simulink®Design Verifier Software

2

Analyzing a Model with Simulink®Design Verifier

Software

........................................ 2-2

Works

Analyzing a Simple Model

Short-Circuiting Logic Blocks

Analyzing Large Models

Handling Incompatibilities with Automatic

Stubbing

What Is Automatic Stubbing?

Analyzing a Model Using Automatic Stubbing

Approximations

Approximations During Model Analysis

Types of Approximations

Converting Floating-Point Arithmetic to Rational-Number

Arithmetic

Linearizing 2-D Loo kup Tables

Unrolling While Loops

Ensuring the Validity of the Analysis

........................................ 2-7

................................... 2-15

.................................... 2-15

.......................... 2-3

...................... 2-5

............................ 2-6

....................... 2-7

.......... 2-7

............... 2-15

........................... 2-15

...................... 2-16

............................. 2-17

................. 2-17

vi Contents

Ensuring Compatibility with the Simulink

Design Verifier Software

3

Checking Mo del Compatibility ...................... 3-2

Model Is Compatible

Model Is Incompatible

Some Model Objects Are Incompatible

............................... 3-4

.............................. 3-4

................ 3-6

®

Page 7

Unsupported Sim ulink Software Features ........... 3-9

Simulink Software Features Not Supported

Simulink Block Support Limitations

Limitations of Support for Model Reference

.................. 3-11

............ 3-9

............ 3-11

Unsupported Stateflow Software Features

Support Limitations for the Embedded MATLAB

Subset

Unsupported Embedded MATLAB Subset Features

Limitations of Embedded MATLAB Library Function

Fixed-Point Support Limitations

.......................................... 3-15

Support

....................................... 3-16

.................... 3-18

........... 3-13

Working with Block Replacements

4

About Block Replacements ......................... 4-2

Built-In Block Replacements

Template for Block Replacement Rules

....................... 4-4

.............. 4-7

..... 3-15

Defining Custom Block Replacements

Basic Workflow for Defining C ustom Block

Replacements

Specifying Replacement Blocks

Writing Block Replacement Rules

Example: Replacing Multiport Switch Blocks

Executing Block Replacements

Configuring Block Replacements

Replacing Blocks in a Model

.................................. 4-8

...................... 4-8

.................... 4-9

..................... 4-17

..................... 4-17

......................... 4-18

............... 4-8

........... 4-9

vii

Page 8

Specifying Parameter Configurations

5

About Parameter Configurations ................... 5-2

Template for Parameter Configurations

Defining Parameter Configurations

Parameter Configuration Example

About This Example

Constructing the Example Model

Parameterizing the Constant Block

Specifying a Parameter Configuration

Analyzing the Example Model

Simulating the Test Cases

............................... 5-7

..................... 5-8

................... 5-10

....................... 5-13

.......................... 5-15

............. 5-3

................. 5-4

.................. 5-7

................. 5-11

Configuring Simulink®Design Verifier Options

6

Viewing Simulink®Design Verifier Options .......... 6-2

Configuring Sim ulink

Design Verifier Pane

Block Replacements Pane

Parameters Pane

Test Generation Pane

Property Proving Pane

Results Pane

Report Pane

..................................... 6-16

...................................... 6-19

®

Design Verifier Options ...... 6-5

............................... 6-5

........................... 6-7

.................................. 6-9

.............................. 6-10

............................. 6-14

viii Contents

Saving Simulink

®

Design Verifier Options ........... 6-21

Page 9

Generating Test Cases

7

About Test Case Generation ........................ 7-2

Test Case Blocks

Test Case Functions

.................................. 7-2

............................... 7-2

Workflow for Generating Test Cases

Generating Test Cases for a Model

About This Example

Constructing the Example Model

Checking Compatibility of the Example Model

Configuring Test Generation Options

Analyzing the Example Model

Customizing Tes t Generation

Reanalyzing the Example Model

Analyzing Contradictory Models

Generating Test Cases for a Subsystem

............................... 7-5

....................... 7-14

........................ 7-22

................. 7-4

.................. 7-5

..................... 7-6

.......... 7-7

................. 7-11

..................... 7-26

..................... 7-30

.............. 7-31

Extending Existing Test Cases

8

When to Extend Existing Test Cases ................. 8-2

Common Workflow for Extending Existing Test

Cases

Example: Extending Existing Test Cases for a Model

that Uses Temporal Logic

Creating a Starting Test Case

Logging the Starting Test Case

Extending the Existing Test Cases

Verifying the Analysis Results

........................................... 8-3

........................ 8-4

....................... 8-4

...................... 8-7

................... 8-8

....................... 8-9

ix

Page 10

Example: Extending Existing Test Cases for a

Closed-Loop System

Logging a Starting Test Case

Extending the Existing Test Cases

Example: Extending Existing Test Cases for a Modified

Model

Creating Starting Test Cases

Extending the Existing Test Cases

.......................................... 8-14

............................. 8-11

........................ 8-11

................... 8-12

........................ 8-14

................... 8-15

Achieving Test Cases for Missing Model

Coverage

9

Generating Test Cases for Missing Coverage Data .... 9-2

Example: Achieving Missing Coverage in a Referenced

Model

Recording Cove rag e Data for the Model

Finding Test Cases for the Missing Coverage

Achieving the Missing Cov erage

Verifying 100% Model Coverage

.......................................... 9-3

............... 9-3

........... 9-5

..................... 9-6

...................... 9-6

x Contents

10

Achieving M issing Coverage for Subsystems and Model

Blocks

Example: Achieving Missing Coverage in a Closed-Loop

Simulation Model

Recording Cove rag e Data for the Model

Finding Test Cases for Missing Coverage

.......................................... 9-8

................................ 9-9

............... 9-9

.............. 9-11

Proving Properties of a Model

About Property Proving ............................ 10-2

Page 11

Proof Blocks ...................................... 10-2

Proof Functions

................................... 10-2

Workflow for Proving Model Properties

Proving Properties in a Model

About This Example

Constructing the Example Model

Checking Compatibility of the Example Model

Instrumenting the Example Model

Configuring Property-Proving Options

Analyzing the Example Model

Customizing the Example Proof

Reanalyzing the Example Model

Analyzing Contradictory Models

Proving Properties in a Subsystem

Proving Complex Properties

Property-Proving Examples

............................... 10-5

...................... 10-5

..................... 10-6

................... 10-11

....................... 10-16

...................... 10-22

..................... 10-25

..................... 10-26

.................. 10-28

........................ 10-29

......................... 10-29

Reviewing the Results

............. 10-4

.......... 10-7

................ 10-14

11

Examining S imulink®Design Verifier Data Files ..... 11-2

About Simulink

Overview of the sldvData Structure

Model Information Fields in sldvData

Simulating Models with Simulink

Files

.......................................... 11-7

Exploring Test Harness Models

About Test Harness Models

Anatomy of a Test Harness

Configuration of the Test Harness

Simulating the Test Harness

Creating a SystemTest TEST-File

®

Design Verifier Data Files ............ 11-2

................... 11-2

................. 11-3

®

Design Verifier Data

..................... 11-8

......................... 11-8

......................... 11-8

.................... 11-13

........................ 11-13

................... 11-15

xi

Page 12

12

Understanding Simulink®Design Verifier Reports .... 11-18

About Simulink

Front Matter

Summary Chapter

Analysis Information Chapter

Test / Proof Objectives Status Chapter

Model Items Chapter

Test Cases / Properties Chapter

®

Design Verifier Reports .............. 11-18

..................................... 11-18

................................. 11-19

....................... 11-20

................ 11-25

.............................. 11-29

...................... 11-30

Analyzing Large Models and Improving

Performance

Sources of Model Complexity ....................... 12-2

Analyzing a Large Model

Types of Large Model Problems

Using the Default Parameter Values

Modifying the Analysis Parameters

Using the Large Model Optimization

Stopping the Analysis Before Completion

Generating Reports for Large Models

Managing M odel Data to Simplify the Analysis

Simplifying Data Type s

Constraining Data

Partitioning Model Inputs and Generating Tests

Incrementally

Analyzing the Model Using a Bottom-Up Approach

Analyzing Logical Operations

Handling Models with Large State Spaces

................................. 12-9

................................... 12-13

........................... 12-3

...................... 12-3

.................. 12-4

................... 12-5

.................. 12-6

.............. 12-6

............... 12-8

....... 12-9

............................ 12-9

....................... 12-16

........... 12-17

... 12-15

xii Contents

Page 13

Handling Problems with Counters and Timers ....... 12-18

13

14

15

Techniques for Proving Properties of Large Models

.. 12-20

Function Reference

Block Reference

Configuration Parameters

Design Verifier Pane ............................... 15-2

Design Verifier Pane Overview

Mode

Maximum analysis time

Display unsatisfiable test objectives

Automatic stubbing of unsupported blocks and functions

Output directory

Make output file names unique by adding a suffix

............................................ 15-3

............................ 15-5

.................................. 15-8

...................... 15-3

.................. 15-6

.. 15-7

....... 15-9

Design Verifier Pane: Block Replacements

Block Replacements Pane Overview

Apply block replacements

List of block replacement rules

File path of the output model

Design Verifier Pane: Parameters

Parameters Pane Overview

Apply parameters

Parameter configuration file

................................. 15-16

........................... 15-12

........................ 15-14

......................... 15-16

........................ 15-16

.................. 15-11

...................... 15-13

................... 15-15

........... 15-10

xiii

Page 14

Design Verifier Pane: Test Generation .............. 15-18

Test Generation Pane Overview

Model cov erage objectives

Test conditions

Test objectives

Maximum test case steps

Test suite optimization

Extend existing test cases

Data file

Ignore objectives satisfied by existing test cases

Ignore objectives satisfied in existing coverage data

Coverage data file

......................................... 15-27

................................... 15-22

.................................... 15-23

............................. 15-25

................................. 15-29

...................... 15-20

........................... 15-21

........................... 15-24

........................... 15-26

......... 15-27

..... 15-28

Design Verifier Pane: Property Proving

Property Proving Pane Ove rview

Assertion blocks

Proof assumptions

Strategy

Maximum violation steps

Design Verifier Pane: Results

Results Pane Overview

Save test data to file

Data file name

Include expected output values

Randomize data that does not affect outcome

Savetestharnessasmodel

Harness model file name

Reference input model in generated harness

Save test harness as SystemTest TEST-file (will reference

saved data file)

SystemTest file name

Design Verifier Pane: Report

Report Pane Overview

Generate report of the results

Report file name

Include screen shots of properties

Display report

......................................... 15-34

................................... 15-32

................................. 15-33

........................... 15-35

............................. 15-38

............................... 15-39

.................................... 15-40

........................... 15-46

................................. 15-48

.............................. 15-49

............................. 15-51

.................................. 15-53

.................................... 15-55

..................... 15-31

....................... 15-36

...................... 15-41

.......................... 15-45

....................... 15-50

....................... 15-52

.................... 15-54

............. 15-30

........... 15-43

........... 15-47

xiv Contents

Parameter Command-Line Information Summary

.... 15-56

Page 15

16

Simulink Block Support

Overview of Simulink Block Support ................ 16-2

Additional Math and Discrete Library

Commonly Used Blocks Library

Continuous Library

Discontinuities Library

Discrete Library

Logic and Bit Operations Libra ry

Lookup Tables Library

Math Operations Library

Model V erification Library

Model-Wide Utilities Library

................................ 16-5

............................ 16-6

................................... 16-7

............................. 16-9

........................... 16-10

..................... 16-4

................... 16-8

......................... 16-12

....................... 16-13

............... 16-3

Ports & Subsystems Library

Signal Attributes Library

Signal Routing Library

Sinks Library

Sources Library

..................................... 16-17

................................... 16-18

........................... 16-15

............................. 16-16

........................ 16-14

xv

Page 16

17

A

User-Defined Functions Library .................... 16-19

Embedded MATLAB Subset Support

Glossary

Examples

Generating Test Cases ............................. A-2

xvi Contents

Automatic S tubbin g

Working with Block Replacements

Specifying Parameter Configurations

Proving Properties of a Model

................................ A-2

...................... A-3

.................. A-2

............... A-2

Index

Page 17

Getting Started

• “Product Overview” on page 1-2

• “Before You Begin” on page 1-3

®

• “Starting the Simulink

• “Analyzing a Model” on page 1-6

• “Analyzing a Subsystem” on page 1-26

• “Basic Workflow for Using the Simulink

page 1-30

Design Verifier Software” on page 1-4

®

Design Verifier Software” on

1

• “Learning More” on page 1-31

Page 18

1 Getting Started

Product Overview

The Simulink Design Verifier sof tware extends the Simulin k®product by

performing exhaustive formal analyses of your models to confirm that they

behave correctly.

The Simulink Design Verifier software allows you to perform the fo ll owing

tasks:

• Generate test cases that achieve model coverage and custom objectives

• Prove properties that you specify in a model, and identify examples of any

• Detect unreachable design elements in a model, such as inaccessible

• Produce detailed reports regarding test case generation and property

you specify in a model.

property violations.

subsystems, illegal switch conditions, and unachievable states.

proofs.

1-2

Page 19

Before You Begin

In this section...

“What You Need to Know” on page 1-3

“Required Products” on page 1-3

What You Need to Know

Getting started with the Simulink Design Verifier software requires that

you have experience using model coverage, as well as building and running

Simulink models.

To learn more about these topics, see the following:

Before You Begin

• “Using Model Coverage” in the Simulink

User’s Guide

• Simulink Getting Started Guide and Simulink User’s Guide

®

Verification and Validation™

Required Products

You must have the following products installed to use the Simulink Design

Verifier software:

• MATLAB

• Simulink

• Simulink Verification and Validation

If you wan t to use the Simulink Design Verifier software with Stateflow

charts, you must have the following software product:

• Stateflow

®

®

1-3

Page 20

1 Getting Started

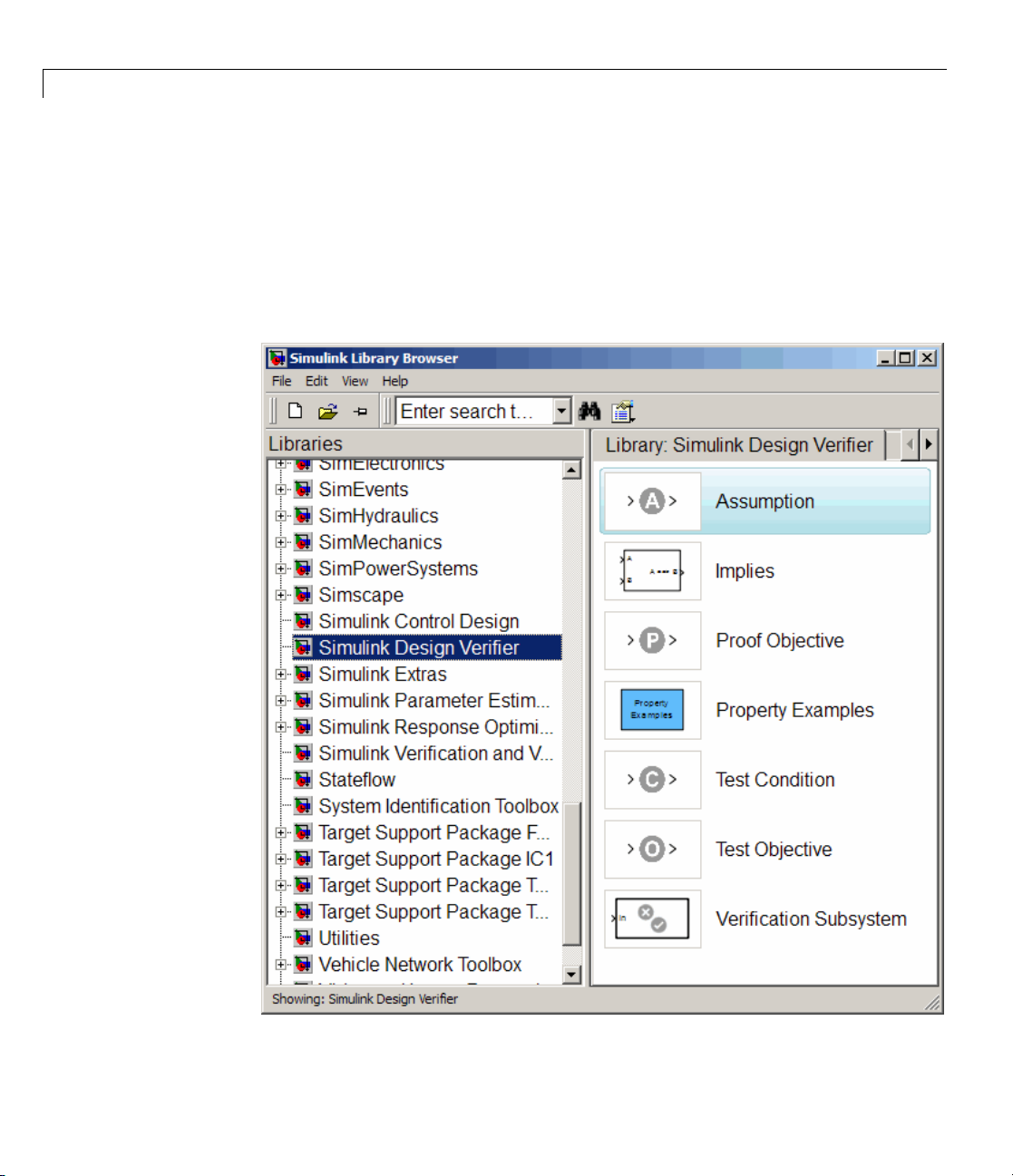

Starting the Simulink Design Verifier Software

The Simulink Design Verifier software is part of your MATLAB installation.

To open the Simulin k Design Verifier block library, type

MATLAB prompt to display the Simulink Library Browser, and then select

the S imulink Design Verifier entry in the contents tree.

simulink at the

1-4

Page 21

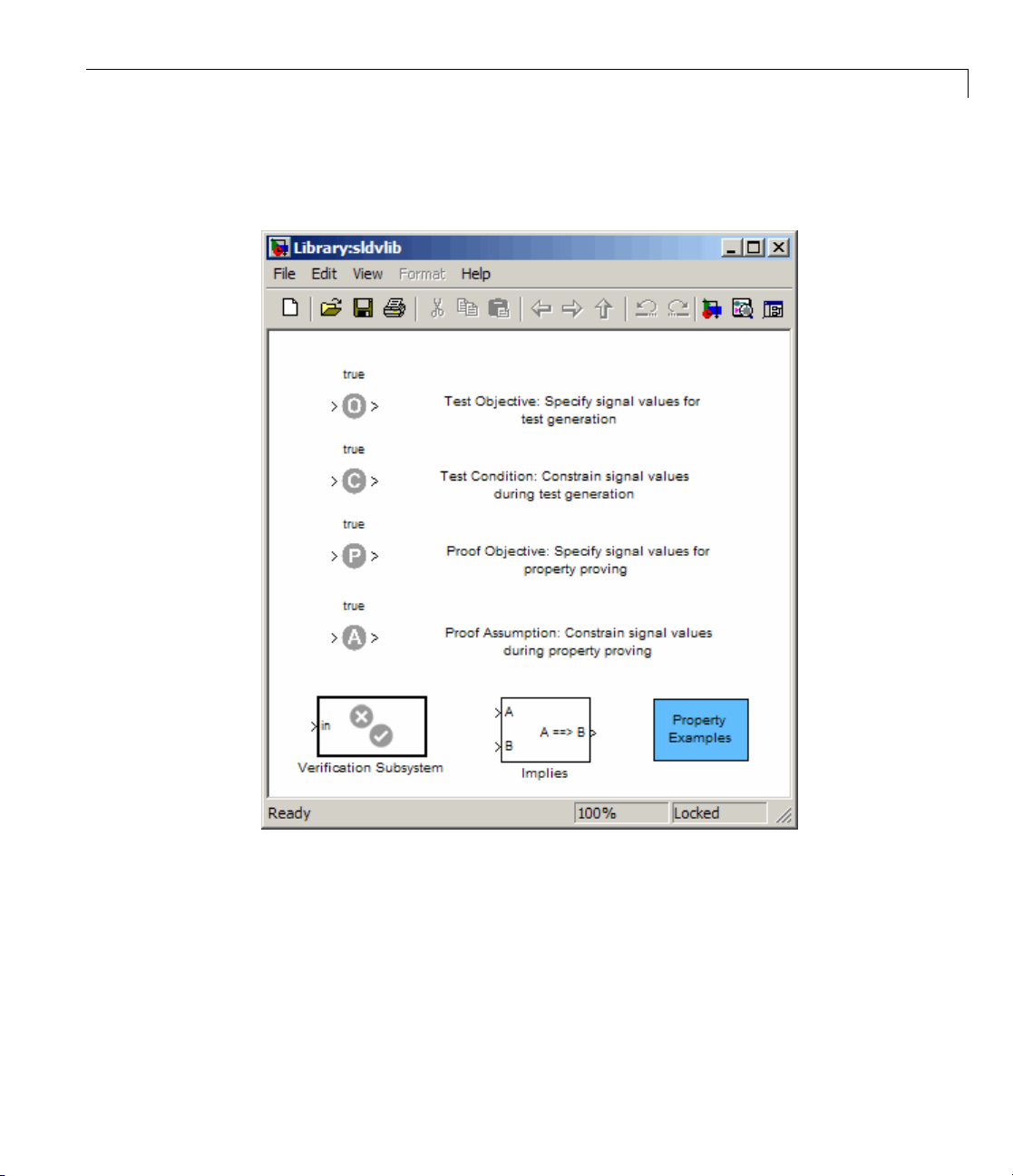

Starting the Simulink®Design Verifier™ Software

Alternatively, type sldvlib attheMATLABprompttodisplaytheSimulink

Design Verifier library.

1-5

Page 22

1 Getting Started

Analyzing a Model

In this section...

“About This Demo” on page 1-6

“Opening the M odel” on page 1-6

“Generating Test Cases” on page 1-7

“Combining Test Cases” on page 1-23

About This Demo

The following sections describe a demo model, Cruise Control Test Ge neration.

This demo illustrates how to use the Simulink Design Verifier software to

generate test cas es that achieve complete model coverage. Through this

demo, you learn how to analyze models with the Simulink Design Verifier

software and interpret the results.

1-6

Opening the Model

To open the Cruise Control Test Generation model, enter

sldvdemo_cruise_control at the MATLAB prompt.

The Cruise Control Test Generation model opens.

Page 23

Analyzing a Model

Generating Test Cases

• “Running the Analysis” on page 1-8

1-7

Page 24

1 Getting Started

• “Exploring the Test Harness” on page 1-10

®

• “Interpreting the Simulink

Design Verifier HTML Report” on page 1-15

Running the Analysis

To generate test cases for the C ruise Control Test Generation model, open the

model window and double-click the block labeled Run.

The Simulink Design Verifier softwar e begins analyzing the m odel to generate

test cases. During its analysis, thesoftwaredisplaysalogwindow.

1-8

Page 25

Analyzing a Model

The log window updates you on the progress of the Simulink Design Verifier

software as it analyzes the model.

1-9

Page 26

1 Getting Started

Note If you need to terminate an analysis while it is running, click Stop.

The software asks you if you want to produce results. If you click Yes,the

software creates the data file and report based on the results achieved so far.

The names of those files appear in the log window.

When the Simulink Design Verifier so ftware completes its analysis, it opens:

• Test harness model:

• Signal Builder dialog box containing the test-case signals

• HTML report containing the analysis results:

sldvdemo_cruise_control_report.html

The sections that follow describe the test harness, the Signal Builder data,

and the HTML report in detail.

sldvdemo_cruise_control_harness.mdl

Exploring the Test Harness

The Simulink Design Verifier software creates a test harness model w hen

it completes its analysis. The test harness for the Cruise Control Test

Generation model appears as shown in the following figure.

1-10

Page 27

Analyzing a Model

1 The block labeled Test Case Explanation is a DocBlock block that

documents the generated test cases. Double-click the Test Case

Explanationblocktoviewadescriptionofeachtestcaseintermsofthe

objectives that the test case satisfies.

1-11

Page 28

1 Getting Started

1-12

2 The block labeled Test Unit is a Subsystem blo ck that contains a copy of

the original model the software analyzed. Double-click the Test Unit block

to view its contents and confirm that it is a copy of the Cruise Control

Test Generation model.

Page 29

Analyzing a Model

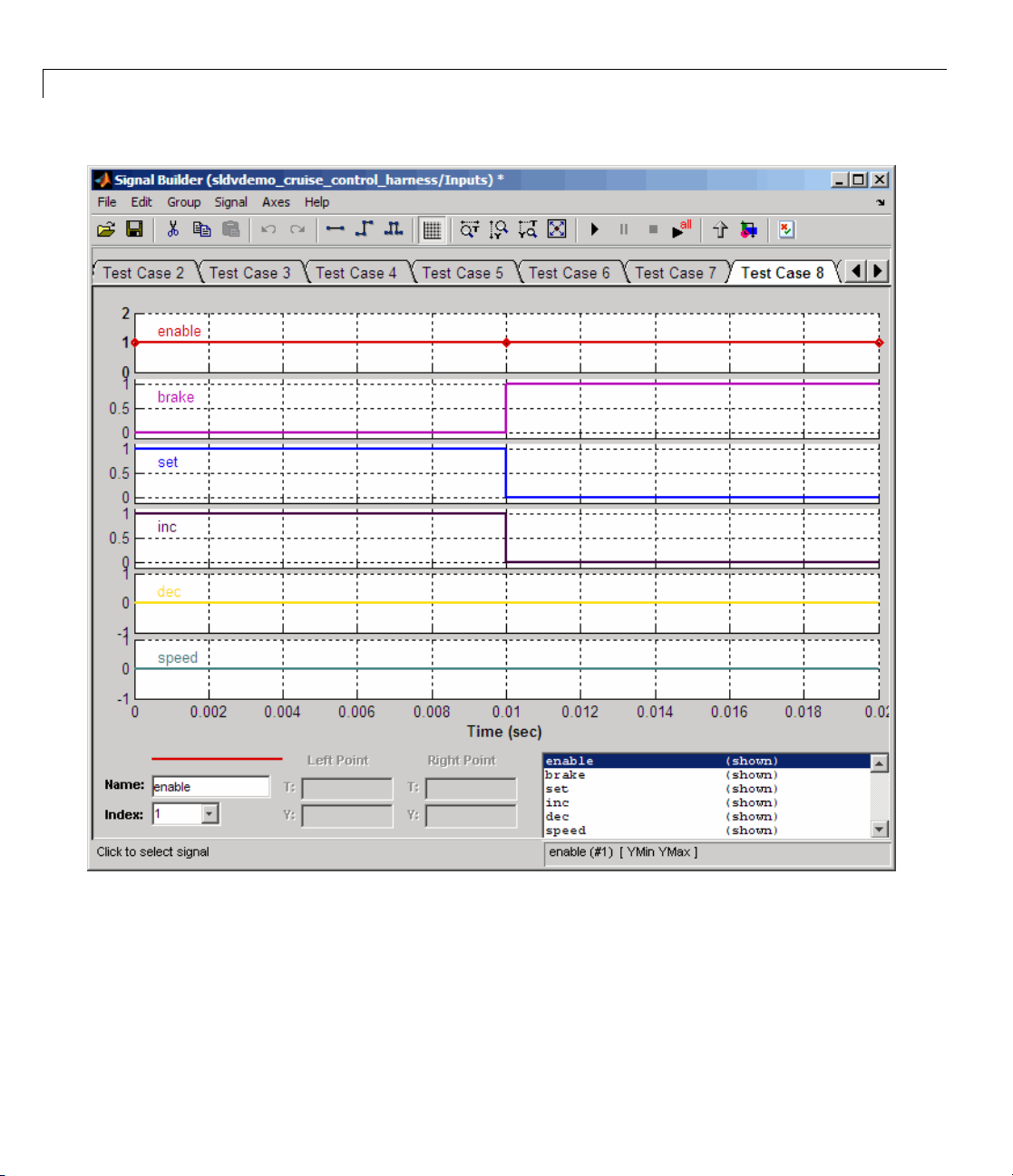

3 The block labeled Inputs is a Signal Builder block that contains the

generated test case signals. Double-click the Inputs block to open the

Signal Builder dialog box and view the 10 test case signals.

4 In the Signal Builder dialog box, click the right-facing arrow next to the

test case tabs

to find the Test Case 8 tab.

5 Click the Test

Case 8 tab to display the signal values for Test Case 8.

1-13

Page 30

1 Getting Started

1-14

In Test Case 8 at 0.1 seconds:

• The enable signal remains 1.

• The brake signal transitions from 0 to 1.

• The inc and set signals transition from 1 to 0.

Page 31

Analyzing a Model

• The dec and s pee d signals remain 0.

This group of signals achieves the test objectives described in the Test

Case Explanation block.

6 To confirm that the Simulink Design Verifier softw are achieved complete

model coverage, simulate the test harness using all the test cases. In the

Signal Builder dialog box, click the Run all and produce coverage

button

.

The Simulink softw are simulates the test harn e ss using all the test cases,

while the Simulink Verification and Validation software collects model

coverage information and displays a coverage report with the following

summary.

The coverage report indicates the Simulink Design Verifier software

generated tes t cases that achieve complete coverage for the Cruise Control

Test Generation model.

Interpreting the Simulink Design Verifier HTML Repor t

The Simulink Design Verifier software creates an HTML report that

summarizes its analysis results.

If the report is not open in a Web Browser window, open it now. The path

name is:

1-15

Page 32

1 Getting Started

matlabroot/sldv_output/sldvdemo_cruise_control/sldvdemo_cruise_control_report.html

Note The log window contains the exact path name for the HTML report.

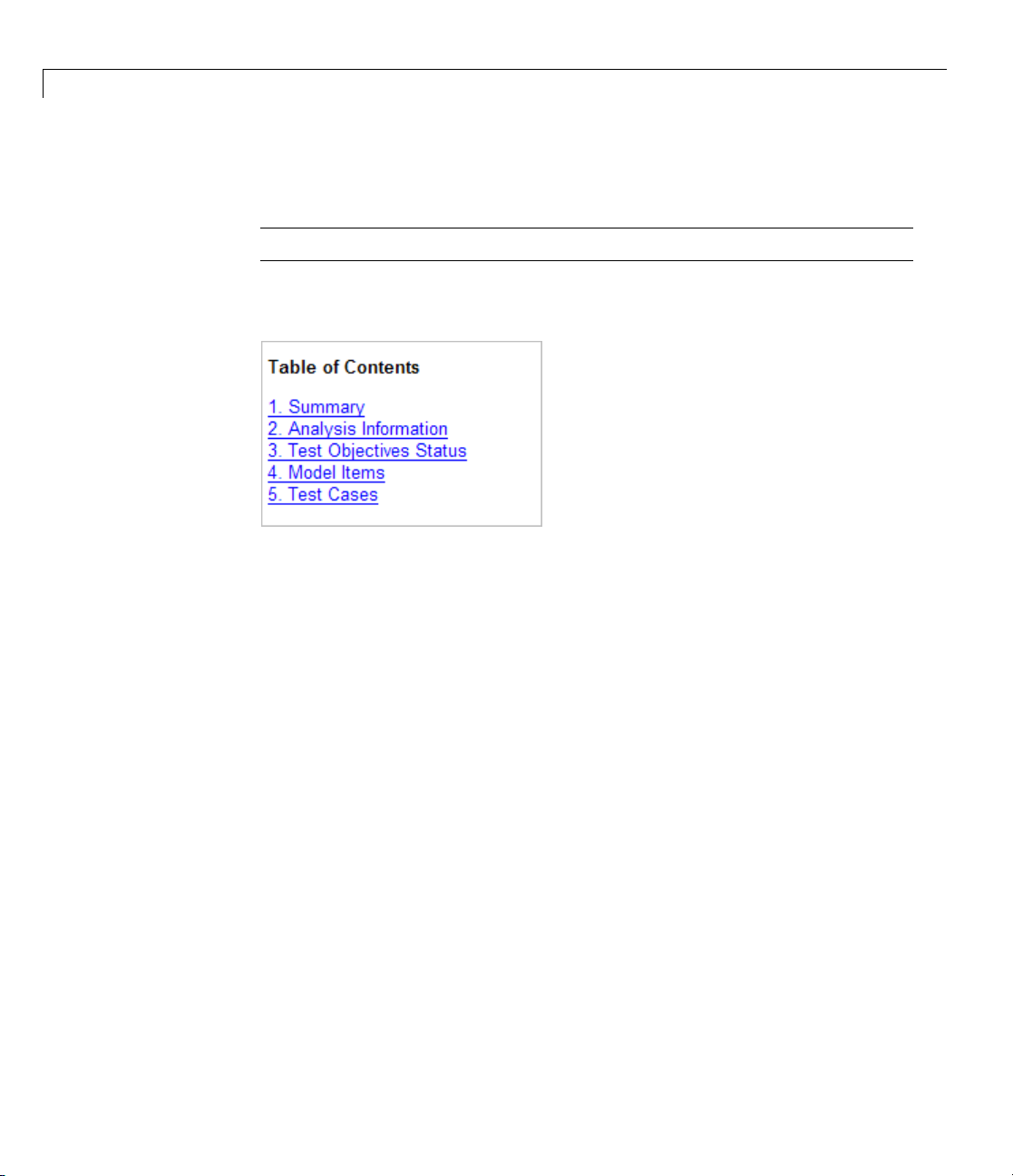

The HTML report includes the following chapters.

Each the following sections for a description of each report chapter:

1-16

• “Summary” on page 1-16

• “Analysis Information” on page 1-17

• “Test Objectives Status” on page 1-19

• “Model Items” on page 1-21

• “Test Cases” on page 1-22

Summary. In the Table of Contents,clickSummary to display the

Summary chapter, which includes the following information:

• Name of the model

• Mode of the analysis (test generation or property proving)

• Status of the analysis

• Number of objectives satisfied

Page 33

Analyzing a Model

Analysis Information. In the Table of Contents,clickAnalysis

Information to display information about the analyzed model and the

analysis options.

1-17

Page 34

1 Getting Started

1-18

Page 35

Analyzing a Model

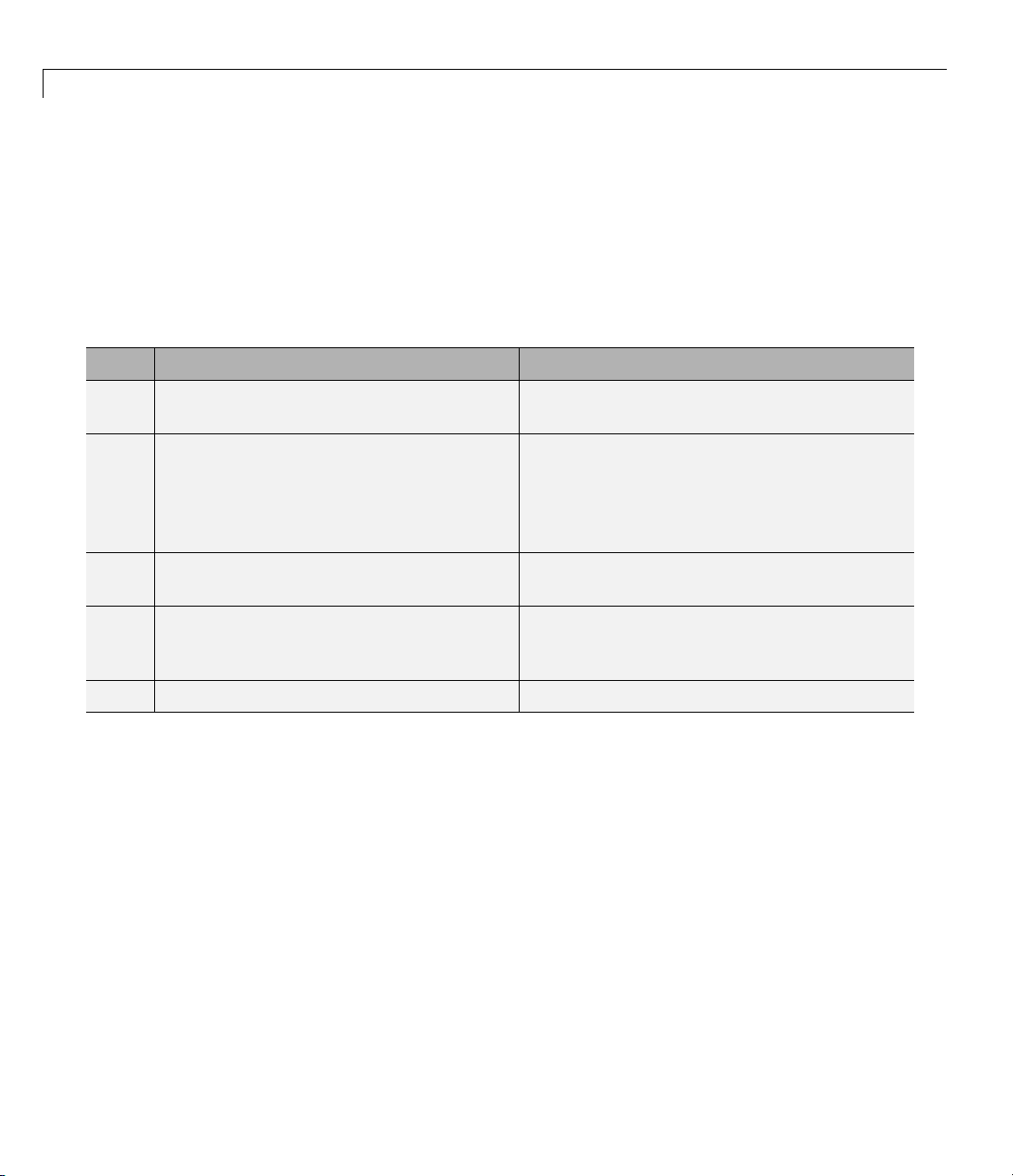

Test Objective s Status. In the Table of Contents,clickTest Objectives

Status to display a table of satisfied objectives. The following figure shows a

partial list of the objectives satisfied in the Cruise Control Test Generation

model.

The Obje c tive s Satisfied table lists the following information for the model:

• # — Objective number.

• Type — Objective type.

• Model Item — Element in the model for which the objective was tested.

Click this link to display the model with this element highlighted.

• Description — Description of the objective.

• Test case — Test case that achieves the objective. Click this link to get

more information about that test case.

1-19

Page 36

1 Getting Started

In the row for objective 17, click the test case number (8)todisplaymore

information about test case 8 in the report’s Test Cases chapter.

1-20

In this example, T est Case 8 satisfies 2 m odel coverage objectives. The

following signal values achieve the objectives listed in the Objectives column

of the table:

• Theenablesignalremains1.

• The brake signal transitions from 0 to 1 at 0.1 seconds.

Page 37

Analyzing a Model

• The inc and set signals transition from 1 to 0 at 0.1 seconds.

• The dec and speed signals remain 0.

This information matches what you see in the test harness model. Specifically,

the Inputs block in the test harness depicts identical signal values for Test

Case 8, and the Test Case Explanation block lists 2 objectives that Test Case

8 achieves (see “Exploring the Test Harness” on page 1-10).

Model Items. In the Table of Contents,clickModel Items to see detailed

information about each item in the model that defines coverage objectives.

This table includes the status of the objective at the end of the analysis. Click

the links in the table to get detailed information about the satisfied objectives.

1-21

Page 38

1 Getting Started

1-22

Test Cases. In the Table of Contents,clickTest Cases to display detailed

information about each generated test case, including:

• Length of time to execute the test case

• Number of objectives satisfied

Page 39

Analyzing a Model

• Detailed information about the satisfied objectives

• Input data

See the section fo r Test Case 8 in “Test Ob jectives Status” on page 1-19

Combining Test Cases

Ifyouprefertoreviewresultsthatarecombined into a smaller number of test

cases, set the Test suite optimization parameter to

When you use the

Long test cases optimization, the analysis generates

fewer, but longer, test cases that each satisfy multiple test objectives. This

optimization creates a more efficient analysis and easier-to-review results.

Long test cases.

Open the

Long test cases optimization:

1 Select Tools > Design Verifier > Options.

2 In the Select tree on the left side of th e Configuration Parameters dialog

sldvdemo_cruise_control model and rerun the analysis with the

box, in the Design Verifier category, select Test Generation.

3 Set the Test suite optimization parameter to Long test cases.

4 Click Apply and OK to close the Configuration Parameters dialog box.

5 In the sldvdemo_cruise_control model, double-click the blo ck labeled

Run.

The Signal Builder dialog box now contains one test case instead of ten test

cases.

1-23

Page 40

1 Getting Started

1-24

This HTM L report contains one section describing Test Case 1.

Page 41

Analyzing a Model

1-25

Page 42

1 Getting Started

Analyzing a Subsystem

In addition to analyzing a model, you can analyze a subsystem within a

model. This techn ique is good for large models, where you want to review the

analysis in smaller, manageable reports.

This example analyzes the Controller subsystem in the

sldvdemo_cruise_control model from “Analyzing a Model” on

page 1-6.

1 Open the demo model:

sldvdemo_cruise_control

2 Right-click the Controller subsystem, and select Design Verifier > Enable

“Treat as atomic unit” to analyze.

The Function Block Parameters dialog box for the Controller subsystem

opens.

1-26

3 Select Tr

An atomic subsystem executes as a unit relative to the parent model;

subsystem b lock execution does not interleave with parent block executio n .

This makes it possible to extract subsystems for use as standalone models.

You must set the Treat as atomic unit parameter to analyze a subsystem

with the Simulink Design Verifier software.

eat as atomic unit.

Page 43

Analyzing a Subsystem

After you set the parameter, other opt ions become available, but you can

ignore them.

4 Click Apply and OK to close the dialog box.

ct File > Save As and save the Cruise Control Test Generation model

5 Sele

ranewname.

unde

6 To start the subsystem analysis and generate test cases, right-click the

Controller subsystem, and select Design Verifier > Generate Tests for

Subsystem.

1-27

Page 44

1 Getting Started

1-28

7 The Simulink Design Verifier software creates and opens the following

output. Except for the new model, all of these correspond to the model

analysis output:

• A new model containing just the Controller subsystem:

• Test harness model: Controller_harness.mdl

• Signal Builder dialog box containing the test-case signals

• HTML report containing the analysis results:

8 Revi

ew the results of the subsystem analysis (harness model and HTML

rt) and compare them to the results of the full-model analysis described

repo

Analyzing a Model” on page 1-6.

in “

• The

subsystem analysis analyzes the Controller as a standalone model.

Controller_report.htm

Controller.mdl

Page 45

Analyzing a Subsystem

• The Controller subsystem contains all the test objectives in the Cruise

Control Test G eneration model, so both a nalyses generate the same

test cases.

1-29

Page 46

1 Getting Started

Basic Workflow for Using the Simulink Design Verifier

Software

The Simulink Design Verifier User’s Guide is organized on the basis of

workflow that you follow when generating tests for your model or proving

its properties. This workflow is described in the following steps, which cite

locations in the documentation that you can refer to for more information:

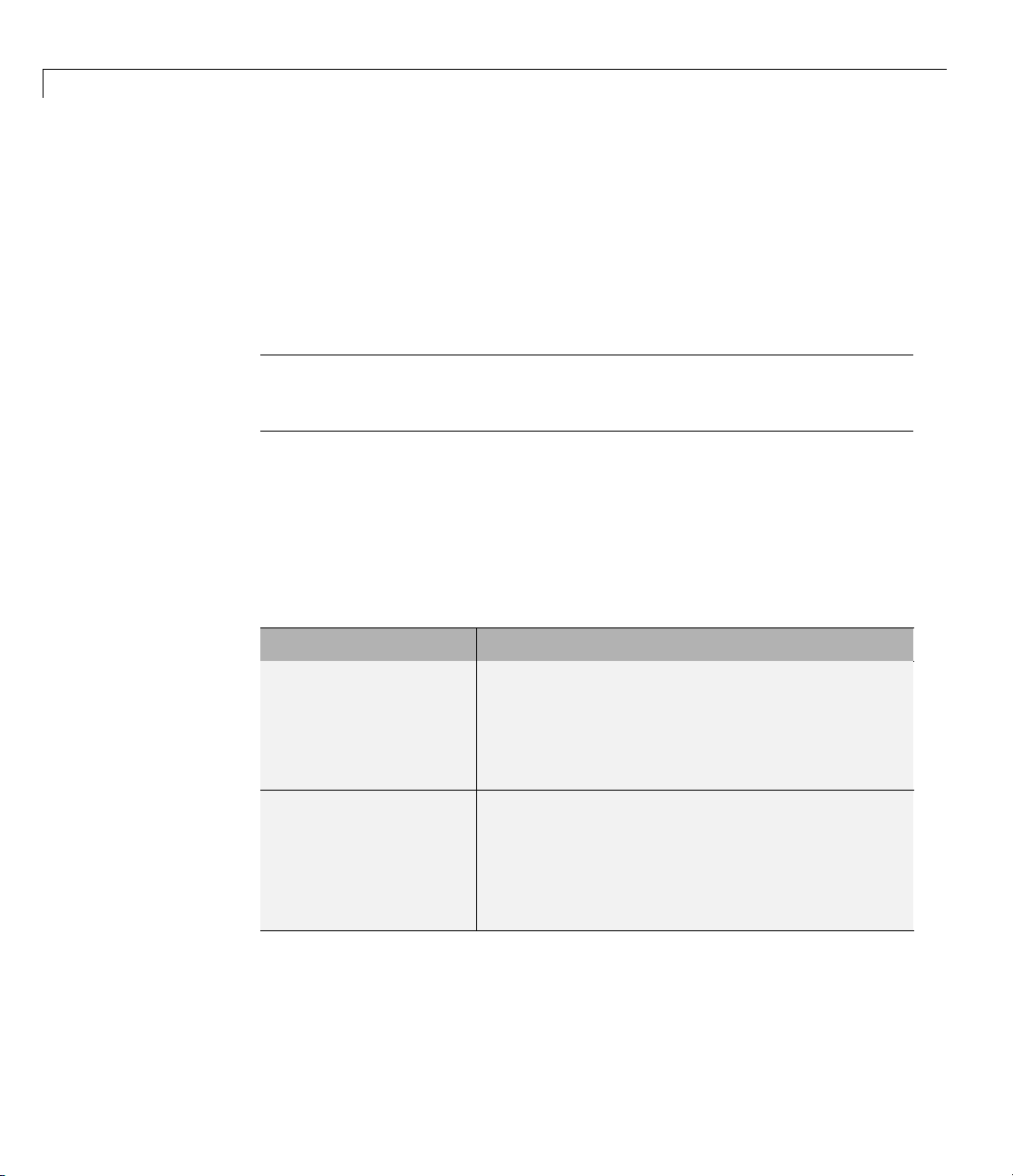

Step

1

2

3

4

5

Action

Check the compatibility of your model. Chapter 3, “Ensuring Compatibility with the

Optionally, prepare your model for

analysis.

Set Simulink Design Verifier options. Chapter 6, “Configuring Simulink

Generate test cases for your model or

prove its properties.

Interpret the results.

See...

Simulink

Chapter 4, “Working with Block

Replacements”

Chapter 5, “Specifying Parameter

Configurations”

Verifier Options”

Chapter 7, “Generating Test Cases”

Chapter 10, “Proving Properties of a Model”

Chapter 11, “Reviewing the Results”

®

Design Verifier Software”

®

Design

1-30

Page 47

Learning More

In this section...

“Next Step” on page 1-31

“Product Help” on page 1-31

“The MathWorks Online” on page 1-32

Next Step

To begin learning how to use the Simulink Design Verifier software, s ee

Chapter 3, “Ensuring Compatibility with the Simulink

Software”. Also see the following topics to continue your exploration of the

software:

®

Design Verifier

Learning More

For...

Exercise that walks you through the

process of generating test cases for

a model

se that walks you through the

Exerci

s of proving a model property

proces

Produ

More i

desktop, click

For...

Lis

Tutorials Examples in Documentation

More product demonstrations

What’s new in this product

ct Help

nformation is available with your product installation. In the MATLAB

for help, and click the product name in the Contents pane.

tofblocks

See...

“Generating Test Cases for a Model”

on page 7-5

“Proving Properties in a Model” on

page 10-5

..

See.

cks — Alphabetical List

Blo

Simulink Design Verifier Demos

Release Notes

1-31

Page 48

1 Getting Started

The MathWorks On

Point your brows

and support at

http://www.mathworks.com/products/sldesignverifier/

er to the MathWorks Web site for additional information

line

1-32

Page 49

How the Simulink Design

Verifier Software Works

• “Analyzing a Model with Simulink®Design Verifier Software” on page 2-2

• “Analyzing a Simple Model” on page 2-3

• “Short-Circuiting Logic Blocks” on page 2-5

• “Analyzing Large Models” on page 2-6

• “Handling Incompatibilities with Automatic Stubbing” on page 2-7

2

• “Approximations” on page 2-15

Page 50

2 How the Simulink

®

Design Verifier™ Software Works

Analyzing a Model with Simulink Design Verifier Software

Simulink Design Verifier software is an efficient analysis tool that explores

the simulation behavior of a Simulink model. It searches the possible values

of model inputs and block parameters to find a simulation that satisfies test

objectives. The software also proves model properties and generates examples

of violations.

Such analysis always begins with the initial configuration of the model

and can span an arbitrary number of time steps. Generally, there is an

infinite number of paths through the model because the values of inputs are

independent from one time step to th e next, and there is no fixed limit to the

number of time steps.

Ifthesoftwarefindsnowaytoreduce the search space, it would continue

its analysis indef in i t ely. Thus, the software limits the analysis by tracking

the persistent information in the model such as discrete states, data-store

memories, and persistent variables.

2-2

After an analysis explores all possible inputs and parameters from all possible

configurations, the results equal those of a complete search of every possible

infinite sequence of inputs parameters.

Page 51

Analyzing a Simple Model

This simple Simulink model includes two Logical Operator blocks and a

Memory block.

The persistent information in this model is limited to the Boolean value of

the Memory block. The input to the model is a single Boolean value. The

following table describes the complete behavior of the model, including the

behavior that would result from an arbitrarily long sequence of inputs.

Analyzing a Simple Model

#

Input Memory

Value

1

false false false false

true

2

3

false

4 true true

Suppose you want to generate test cases that result in a true output; this goal

is your test objective. If you run the Simulink D esign Verifier software to

generate test cases that result in a true output, the software searches this

table to see if such a scenario is possible.

After the Simulink Design Verifier software discovers a configuration that

satisfies the test objective (in this case, when both the input and the Memory

block output are true), it needs to find a path to reach this configuration from

false

true true

Output of XOR

Block = Next

Memory Value

true

false

Output of AND

Block

false

false

true

2-3

Page 52

2 How the Simulink

®

Design Verifier™ Software Works

the initial conditions. If the initial memory value is true, the test case only

needs to be a single time step (row 4) where the input was true.

If the initial m emory value is false (the default), the test case must force the

memoryvaluetobetrue.Inthisexample,thepathrequirestwosteps:

1 The input value is true and the memory value is false (row 2). Thus, the

output of the XOR block is true, making the memory value true.

2 Now that the input value and memory value are both true (row 4), the

output is true, so the analysis achieves the specified test objective.

An infinite number o f test cases can cause the output to be true, and

regardless of the state value, the output can be held false for an arbitrary time

before making it true. When the Simulink Design Verifier software searches,

it returns the first test case it encounters that satisfies the objective. This

case is invariably the simulation with the fewest tim e steps. Sometimes you

may find this result undesirable because it is unrealistic or does not satisfy

some other test requirement.

2-4

Thesamebasicprinciplesfromthisexample apply to property proving and

test case generation. During test case generation, option parameters explicitly

specify the search criteria. For e xample, you can specify that Simulink Design

Verifier software find paths for all outputs or find only those paths that make

where the output is true.

During property proving, you specify a functional requirement, or p roperty,

that you want the Simulink Design Verifier software to prove, for example,

that the output is always true. If the search completes without finding

a path that violates the property, the proof of that property completes

successfully. If the software finds a path where the output is false, it creates a

counterexample that causestheoutputtobefalse.

Page 53

Short-Circuiting Logic Blocks

When the Simulink Design Verifier software p erforms an analysis, if possible,

the software short-circuits logic blocks. When the previous inputs alone

determine the block output, the analysis ignores any remaining block inputs.

For e xample, if the first input to a Logical Operator block whose Operator

parameter specifies

inputs.

Consider the following example model, with the Model coverage objectives

parameter set to

AND is false, the analysis ignores the v alues of the other

Condition Decision.

Short-Circuiting Logic Blocks

When the Simulink Design Verifier software analyzes this model for Condition

Decision coverage, the analysis can only satisfy five of six objectives for the

Logical Operator block inputs. The software cannot generate a test case for

when the third input to the Logical Operator block is false. If the second input

isfalse,thethirdinputisfalse,butthesoftwareignoresthethirdinputdueto

the short-circuiting. If the second input is true, the third input is never false.

2-5

Page 54

2 How the Simulink

®

Design Verifier™ Software Works

Analyzing Large Models

In larger, more complicated models, the Simulink Design Verifier software

uses m athematical techniques to simplify the analysis:

• It identifies portions of the model that do not affect the desired objectives.

• It discovers relations hips within the model that reduce the complexity of

the search.

• It reuses intermediate results from one objective to another.

In this way, the problem is reduced to a search though the logical values that

describe your model.

For detailed information about analyzing large models, see Chapter 12,

“Analyzing Large Models and Improving Performance”.

2-6

Page 55

Handling Incompatibilities with Automatic Stubb ing

Handling Incompatibilities with Automatic Stubbing

In this section...

“What Is Automatic Stubbing?” on page 2-7

“Analyzing a Model Using Automatic Stubbing” on page 2-7

What Is Automatic Stubbing?

Automatic stubbing allows you to run a test case generation or

property-proving analysis on a model that contains elements that the

Simulink Design Verifier software does not support.

When you enable automatic stubbing option, the software considers only

the interface of the unsupported elements, not their actual behavior. This

technique allows the software to complete the analysis. However, the analysis

may achieve only partial results if any of the unsupported model elements

affect the simulation outcome.

Analyzing a Model Using Automatic Stubbing

This section describes a workflow for using automatic stubbing, using a

simple Simulink model (

• “Checking Model Compatibility” on page 2-8

• “Turning On Automatic Stubbing” on page 2-11

• “Reviewing the Results” on page 2-13

• “Achieving Complete Results” on page 2-14

The

t1 model contains a Trigonometric Function block, which is not

compatible with the Simulink Design Verifier software.

t1)asanexample.

2-7

Page 56

2 How the Simulink

®

Design Verifier™ Software Works

2-8

Checking Model Compatibility

From the Model Editor, there are two ways to check whether a model is

compatible with the Simulink Design Verifier software:

• Run the Simulink De sig n Ve rif ier compatibility check by selecting

Tools > Design Verifier > Check Model C ompatibility.

Page 57

Handling Incompatibilities with Automatic Stubb ing

• Select the analysis that you want:

- Tools > Design Verifier > Generate Tests

- Tools > Design Verifier > Prove Properties

Thesoftwarefirstchecksthecompatibility of the model. If the model itself

is incompatible, for example, if it uses a variable-step solver, the analysis

cannot continue.

If it finds incompatible elements in the model, the software stops and asks

if you want to turn on automatic stubbing.

2-9

Page 58

2 How the Simulink

®

Design Verifier™ Software Works

2-10

an:

You c

- Save

- Con

- Ter

the log file.

tinue the analysis.

minate the analysis.

Page 59

Handling Incompatibilities with Automatic Stubb ing

The Simulatio n Diagnostics Viewer is also displayed, listing the

incompatibilities. (For more information about this dialog box, see

“Simulation Diagnostics Viewer” in the Simulink User’s Guide.)

Turning On Automatic Stubbing

There are two ways to turn on automatic stubbing:

• If you have not turned on automatic stubbing and the analysis finds at

least one incompatibility, the analysis stops and asks if you want to turn on

automatic stubbing. Click Continue to proceed with the analysis.

2-11

Page 60

2 How the Simulink

®

Design Verifier™ Software Works

• Before starting the analysis, in the Configuration Parameters dialog

box, on the main Design Verifier pane, select Automatic stubbing of

unsupportedblockandfunctions. Whenyouruntheanalysis,youare

notified that stubbing is turned on and the analysis continues.

2-12

Page 61

Handling Incompatibilities with Automatic Stubb ing

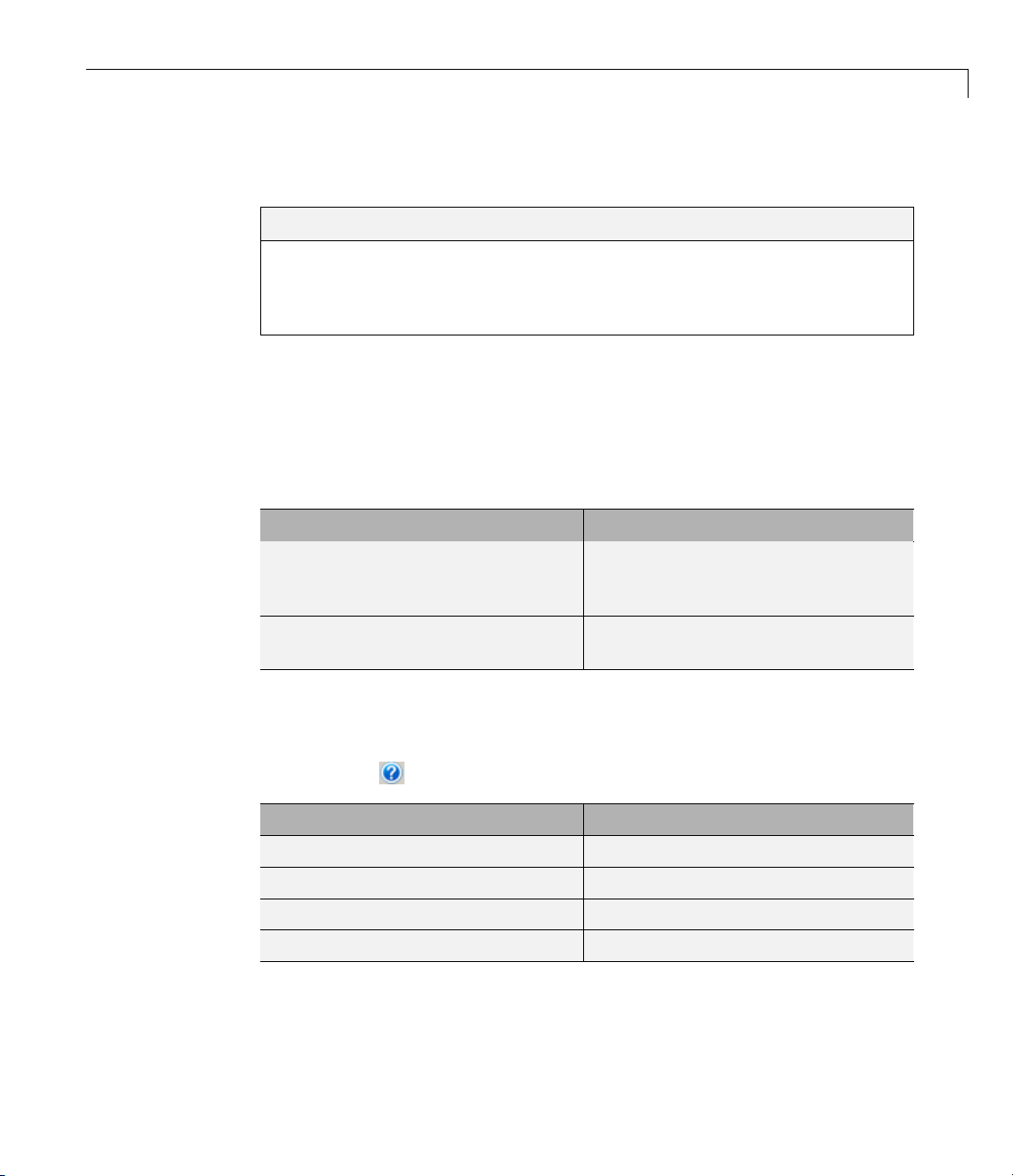

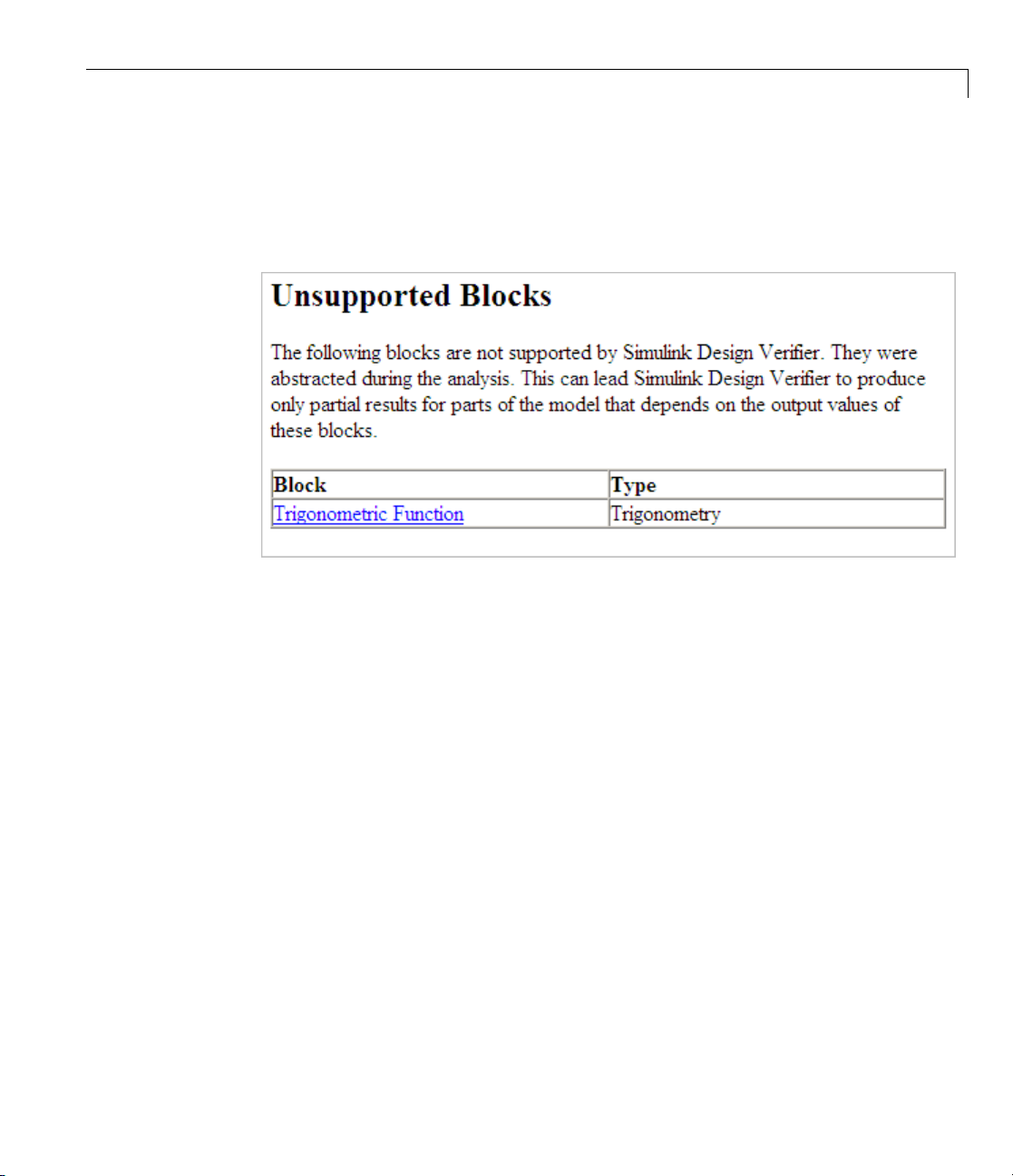

Reviewing the Results

If you ran the analysis with automatic stubbing enabled, make sure to review

the results. In this report, you see a table of unsupported blocks that the

software encountered.

The Summary report for the t1 example model shows that one objective was

satisfied without generating a test case. The software cannot generate the

test case because it does not understand the operation of the Trigonometric

Function block.

2-13

Page 62

2 How the Simulink

®

Design Verifier™ Software Works

Achieving Complete Results

If your analysis does not achieve complete results because of the stubbing,

you can define custom block replacements to give a more precise definition

of the unsupported blocks. For more information:

• “Defining Custom Block Replacements” on p age 4-8.

• Enter

echodemo sldvdemo_blockreplacement_unsupportedblocks

to step through the “Block Replacements for Unsupported Models” demo.

2-14

Page 63

Approximations

In this section...

“Approximations During Model Analysis” on page 2-15

“Types of Approximations” on page 2-15

“Converting Floating-Point Arithmetic to Rational-Number Arithmetic ”

on page 2-15

“Linearizing 2-D Lookup Tables” on page 2-16

“Unrolling While Loops” on page 2-17

“Ensuring the Validity of the Analysis” on page 2-17

Approximations During Model Analysis

The Simulink Design Verifier software attempts to generate inputs and

parameters to achieve test and proof objectives. However, there could be an

infinitenumberofvaluesforthesoftwaretosearch. Tocreatereasonable

limits on the analysis, the software perform s approximations to simplify

the analysis. The software records any approximations it performed in the

Analysis Information chapter of the Simulink Design Verifier HTML report.

Approximations

Types of Approximations

Simulink Design Verifier software performs three types of approximations

when it analyzes a model:

• “Converting Floating-Point Arithmetic to Ra tional-Number Arithmetic ”

on page 2-15

• “Linearizing 2-D Lookup Tables” on page 2-16

• “Unrolling While Loops” on page 2-17

Converting Floating-Point Arithmetic to

Rational-Number Arithmetic

The Simulink Design Verifier software simplifies the linear arithmetic

of floating-point numbers by approximating them with infinite-precision

rational numbers. The software discovers how the logical relationships

2-15

Page 64

2 How the Simulink

®

Design Verifier™ Software Works

between these values affects the proof and test objectives. This analysis

enables the software to support supervisory logic that is commonly found in

embedded controls designs.

If your model contains floating-point values in the signals, input values, or

block parameters, the Simulink Design Verifier software converts those

values to rational numbers before performing its analysis.

Note As a result of these approximations, Simulink Design Verifier software

does no t consider the effect of round-off error, or the upper and lower bounds

of floating-point numbers.

Linearizing 2-D Lookup Tables

The S imulink Design Verifier software does not support n on li near ar ithmetic.

If your model contains any Lookup Table (2-D) blocks, or Lookup Table (n-D)

blocks where n = 2, with all of the following characteristics, the software

approximates nonlinear 2-D interpolation with linear interpolation by fitting

planes to each interpolation interval.

2-16

Block Characteristics

Lookup Table (2-D)

block

• Lookup method parameter is

Interpolation-Extrapolation or

Interpolation-Use End Values

• The input and output signals both have the

floating-point data type

Lookup Table (n-D)

block, n =2:

• Interpolation method parameter is

• Extrapolation method parameter is None -

or Linear

Clip

• The input and output signals both have the

floating-point data type

Linear

Page 65

Approximations

Unrolling While

If your model or a

Simulink Design

loop to exit. To

times. If the so

it sets the num

you are perfor

Ensuring the

The Simulink

performed i

descriptio

on page 11-20.

Review the

Evaluate y

software

In rare ca

test obj

example

achieve

might pr

n of the contents of this chapter, see “Analysis Information Chapter”

our model to identify which blocks or subsystems caused the

to perform th e approximations.

ses, an approximation can result in test cases that fail to achieve

ectives, or counterexamples that fail to falsify proof objectives. For

, suppose the software generates a test case signal that should

an objectiv e by excee ding a thre shold; a floating-point round-off error

event that signal from attaining the threshold value.

ny Stateflow chart in your model contains a

Verifier software tries to find a bound that allows the

find a bound, it unrolls the

ftware does not find a bound for a test case generation analysis,

ber of loop iterations to three for the purpose of the analysis. If

ming a property-proving analysis, the analysis terminates.

Validity of the Analysis

Design Verifier software records all approximations it

n the Analysis Information chapter of the HTML report. (For a

)

analysis results carefully when thesoftwareusesapproximations.

Loops

while loop, the

while

while loop and executes it three

2-17

Page 66

2 How the Simulink

®

Design Verifier™ Software Works

2-18

Page 67

Ensuring Compatibility

with the Simulink Design

Verifier Software

• “Checking Model Compatibility” on page 3-2

• “Unsupported Simulink Software Features” on page 3-9

• “Unsupported Stateflow Software Features” on page 3-13

3

• “Support Limitations for the Embedded MATLAB Subset” on page 3-15

• “Fixed-Point Support Limitations” on page 3-18

Page 68

3 Ensuring Compatibility with the Simulink

®

Design Verifier™ Software

Checking Model Compatibility

The Simulink Design Verifier software supports a broad range of Simulink

and Stateflow software features. However, there are features that the product

does not support. Therefore, avoid using particular features in models that

you plan to analyze with the Simulink Design Verifier software.

The Simulink Design Verifier software automatically checks the compatibility

of your model before it begins a test-generation or property-pro ving analysis.

In addition, you can run the same check before you start the analysis. To run

this check, in the model window, select Tools > Design Verifier > Check

Model Compatibility.

3-2

Page 69

Checking Model Compatibility

natively, you can use the

Alter

ker programmatically at the command line or in a MA TLAB program.

chec

ore information, see the

For m

e are three outcomes of a compatibility check:

Ther

del Is Compatible” on page 3-4

• “Mo

del Is Incompatible” on page 3-4

• “Mo

sldvcompat function to run the compatibility

sldvcompat reference page.

3-3

Page 70

3 Ensuring Compatibility with the Simulink

• “Some Model O bjects Are Incompatible” on page 3-6

Model Is Compatible

In the log window, you see if your model is compatible with the Simulink

Design Verifier software.

®

Design Verifier™ Software

3-4

Model Is Incompatible

If the model itself is incompatible with the software, for example, if it uses

a variable-step solver, you see two dialog boxes:

• Simulink Design Verifier log

Page 71

Checking Model Compatibility

• Simulation Diagnostics Viewer. Use the informa t ion in this dialog box to

identify and correct theincompatibility.

3-5

Page 72

3 Ensuring Compatibility with the Simulink

®

Design Verifier™ Software

3-6

Note For more information about this dialog box, see “Simulation

Diagnostics Viewer” i n the Simulink User’s Guide.

Some Model Objects Are Incompatible

If at least one object in the model is incompatible, a message appears in

the Simulink Design Verifier log window. If you have turned on automatic

stubbing, the analysis proceeds.

Page 73

Checking Model Compatibility

If you have not turned on automatic stubbing, the analysis stops. You see a

query asking if you want to turn it on so that the analysis can proceed.

3-7

Page 74

3 Ensuring Compatibility with the Simulink

®

Design Verifier™ Software

3-8

Note

Inc

For instructions on how to use automatic stubbing, see “Handling

ompatibilities with Automatic Stubbing” on page 2-7.

Page 75

Unsupported Simulink Software Features

In this section...

“Simulink Software Features Not Supported” on page 3-9

“Simulink Block Support Limitat ions” on page 3-11

“Limitations of Support for Model Reference” on page 3-11

Simulink Software Features Not Suppor ted

The Simulink Design Verifier software does not support the following

Simulink software features. Avoid using these unsupported features in

models that you analyze w ith the Simulink Design Verifier software.

Unsupported Simulink®Software Features

Not Supported

Variable-step solvers

Callback functions The Simulink Design Verifier software does not

Complex signals The Simulink Design Verifier software supports only

Description

The Simulink Design Verifier software supports

only f ix e d -ste p solvers. (See “C hoosing a Fixed-Step

Solver” in the Simulink User’s Guide.)

execute model callback functions during the

analysis. As a result, if a callback function changes

any m odel parameters or workspace variables, the

analysis does not reflect those changes.

Callbacks called prior to analysis, such as the

PreLoadFcn or Po stL oadFcn model callbacks, are

fully supported.

real signals. (For contrast, see “Complex Signals” in

Simulink User’s Guide.)

3-9

Page 76

3 Ensuring Compatibility with the Simulink

®

Design Verifier™ Software

Not Supported

Variable-size signals

Multiword

fixed-point data

types

Signals with nonzero

sample tim e offset

Nonzero start times

Description

The Simulink Design Verifier software does not

support variable-size signals. A variable-size signal

is a signal whose size (number of elements in a

dimension), in addition to its values, can change

during model execution.

For more information, see “Working with

Variable-Size Signals” in Simulink User’s Guide.

The Simulink Design Verifier software does not

support multiword fixed-point data types.

The Simulink Design Verifier software does not

support models with signals that have nonz ero

sample time offsets.

Although Simulink allows you to specify a nonzero

simulation start time, the Simulink Desig n Verifier

software generates signal data that begins only at

zero. If your model specifies a nonzero start time:

• If you do not select the Reference input model

in generated harness parameter (the default),

the harness model is a subsystem. The software

sets the start time of the harness model to 1 and

continues the analysis.

3-10

Models with no

output ports

• If you select the Reference input model in

generated harness parameter, a Model block

references the harness model. The Simulink

Design Verifier software cannot change the start

time of the harness model, so the analysis stops

and you see a recommendation to set the Start

time parameter to 0.

The Simulink Design Verifier software only s upports

models that have one or more output ports.

Page 77

Unsupported Simulink®Software Features

Simulink Block S

The Simulink D es

Simulink blocks

blocks. It does

If your model c

stubbing, whi

not their beha

simulation o

about automa

Stubbing” on

To guarante

you analyze

Similarly

software r

“Simulin

Limitati

The Simu

the foll

one or mo

, specify only the block parameters that the Simulink Design Verifier

ecognizes for blocks that it partially supports. See Chapter 16,

k Block Support”.

onsofSupportforModelReference

link Design Verifier software supports the Model block, but with

owing limitations. The software cannot analyze a model that contains

re Model blocks if:

ign Verifier software provides various levels of support for

. The software either fully or partially supports pa rticular

not support other blocks.

ontains unsupported blocks, you can turn on automatic

ch considers the interface of the unsupported blocks, but

vior. However, if any of the unsupported blocks affect the

utcome, the analysis may achieve only partial results. For details

tic stubbing, see “Handling Incompatibilities with Automatic

page 2-7.

e 100% coverage, avoid using unsupported blocks in models that

with the Simulink Design Verifier software.

upport Limitations

• Simuli

models

This f

being

more i

User’

• The p

ne of the following model parameters to

set o

- Diag

- Dia

sig

nk Design Verifier software doe s not support protected referenced

. Protected referenced models are encoded to obscure their contents.

eature allows third parties to use the referenced model without

able to view the intellectual property that makes up the model. For

nformation, see “Protecting Referenced Models” in the Simulink

s Guide.

arent model or any of the referenced models gives an error when you

Error:

nostics > Connectivity > Element name mismatch

gnostics > Connectivity > Mux blocks used to create bus

nals

3-11

Page 78

3 Ensuring Compatibility with the Simulink

You can use the Element name mismatch diagnostic along with bus

objects to ensure that your model meets bus element naming requirements

imposed by some blocks.

If your model contains Mux blocks that create bus signals, refer to “Tips” in

“Mux blocks used to create bus signals” to resolve this problem.

• A referenced model references a variable in its workspace that is either

defined in its ow n workspace or in the base MATLA B workspace. It is also

defined with the same name in the parent model’s workspace. Rename

the variable used by the referenced model to a unique name so that you

can analyze the model.

Exception: If the parent model and a referenced model both define an

instance of a

same name, the software can analyze the model.

• Any of the models in the model reference hierarchy have algebraic loops

that algebraic loop minimization cannot eliminate. If you encounter

this limitation, set the Minimize algebraic loop parameter on the

Diagnostics pane of the Configuration Parameters dialog box to Error.

Then, update the model to identify the location of algebraic loop in the

model.

®

Design Verifier™ Software

Simulink.Signal object used as local data storage with the

3-12

To eliminate this problem so that the software can analyze the model,

break any algebraic loops with Unit Delay blocks to ensure that the

execution order is predictable.

For more information, see “Algebraic Loops” in the Simulink User’s Guide.

Page 79

Unsupported Stateflow®Software Features

Unsupported Stateflow Software Features

The Simulink Design Verifier software does not support the following

Stateflow software features. Avoid using these unsupported features in

models that you analyze w ith the Simulink Design Verifier software.

Not Supported

ml namespace operator,

ml function, ml

expressions

Description

The Simulink Design Verifier software does

not support calls to MATLAB functions or

access to MATLAB workspace variables, which

the Stateflow software allows. (See “Using

MATLAB Functions and Data in Actions” in the

Stateflow and Stateflow

®

Coder™ User’s Guide.)

C math functions The Simulink Design Verifier software supports

calls to the following C math functions:

ceil, fabs, floor, fmod, labs, ldexp,andpow

abs,

(only for an integer exponent).

The software does not support calls to other

C math functions that the Stateflow software

allows. Turning on auto matic stubbing causes

the software to eliminate these functions during

the analysis. For details about automatic

stubbing, see “Handling Incompatibilities with

Automatic Stubbing” on page 2-7.

For information about C math functions in

Stateflow, see “Calling C Functions in Actions”

in the Stateflow and Stateflow Coder User’s

Guide.

3-13

Page 80

3 Ensuring Compatibility with the Simulink

®

Design Verifier™ Software

Not Supported

Recursion

Description

The Simulink Design Verifier software does

not support recursive functions, which the

Stateflow software allows you to implement

using graphical functions. (See “Using

Graphical Functions to Extend Actions” in the

Stateflow and Stateflow Coder User’s Guide.)

Also, the Simulink Design Verifier software

does not support recursion that the Stateflow

software allows you to implement using a

combination of event broadcasts and function

calls.

Custom C or C++ code The Simulink Design Verifier software does

not support custom C or C++ code, which the

Stateflow software allows. (See “Building

Targets” in the Stateflow and Stateflow Coder

User’s Guide.)

Machine-parented data

The Simulink Design Verifier software does not

support machine-parented data (i.e., defined at

the level of the Stateflow machine), which the

Stateflow software allows. (See “Defining Data”

in the Stateflow and Stateflow Coder User’s

Guide.)

3-14

Textual functions with

literal string arguments

The Simulink Design Verifier software does

not support literal string arguments to textual

functions in a Stateflow chart.

Page 81

Support Limitations for the Embedded MATLAB®Subset

Support Limitations for the Embedded MATLAB Subset

In this section...

“Unsupported Embedded MATLAB Subset Features” on page 3-15

“Limitations of Embedded MATLAB Library Function Support” on page

3-16

Unsupported Embedded MATLAB Subset Features

The Simulink Design Verifier software does not support the following features

of the Embedded MATLAB

Embedded MATLAB functions in the Stateflow software. Avoid using these

unsupported features in models that you analyze with the Simulink Design

Verifier software.

®

Function block in the Simulink software and

Not Supported

Complex numbers The Simulink Design Verifier software supports

Characters The Simulink Design Verifier software does

Description

only real numbers. The Embedded MATLAB

subset also supports complex numbers.

For more information, see “Working with

Complex N umbers” in the Embedded MATLAB

User’s Guide.

not support characters, which the Embedded

MATLAB subset allows.

For more information, see “Working with

Characters” in the Embedded MATLAB User’s

Guide.

3-15

Page 82

3 Ensuring Compatibility with the Simulink

®

Design Verifier™ Software

Not Supported

C functions The Simulink Design Verifier software does not

Extrinsic functions The Simulink Design Verifier software supports

Description

support calls to external C functions, which the

Embedded MATLAB subset allows.

For more information about the Embedded

MATLAB subset, see“Calling C/C++ Functions

from the Embedded MATLAB Subset” in the

Embedded MATLAB User’s Guide.

extrinsic functions only when they do not affect

the output of an Embedded MATLAB function.

For more information about calling extrinsic

functions, see “Calling MATLAB Functions” in

the Embedded MATLAB User’s Guide.

Limitations of Embedded MATLAB Library Function

Support

The Simulink Desig n Verifier software provides various levels of support for

Embedded MATLAB library functions. The software either fully or partially

supports particular functions. It does not support other functions.

3-16

If your model contains unsupported functions, you can turn on automatic

stubbing, which considers the interface of the unsupported functions, but

not their behavior. However, if any of the unsupported functions affect the

simulation outcome, the analysis may achieve only partial results. For details

about automatic stubbing, see “Handling Incompatibilities with Automatic

Stubbing” on page 2-7.

To guarantee 100% coverage, avoid using unsupported Embedded MATLAB

library functions in models that you analyze with the Simulink Design

Verifier software.

Avoid using unsupported Embedded MATLAB library functions in models

that you analyze with the Simulink Design Verifier software. See Chapter 17,

“Embedded MATLAB Subset Support” for a list of the Embedded MATLAB

Page 83

Support Limitations for the Embedded MATLAB®Subset

library functions for which the Simulink Design Verifier software provides

limited or no support.

3-17

Page 84

3 Ensuring Compatibility with the Simulink

®

Design Verifier™ Software

Fixed-Point Support Limitations

The Simulink Design Verifier software supports fixed-point data types in

models that it analyzes , with one exception. Parameter configurations do

not support fixed-point data types. For more information about configuring

Simulink D esign Verifier parameters, see Chapter 5, “Specifying Parameter

Configurations”.

For detailed information about these limitations, see “Tunable Expression

Limitations” in the Real-Time Workshop

®

User’s Guide.

3-18

Page 85

Working with Block

Replacements

• “About Block Replacements” on page 4-2

• “Built-In Block Replacements” on page 4-4

• “Template for Block Replacement Rules” on page 4-7

• “Defining Custom Block Replacements” on page 4-8

• “Executing Block Replacements” on page 4-17

4

Page 86

4 Working with Block Replacements

About Block Replacements

Using the Simulink D esign Verifier software, you can define rules to replace

blocks automatically in your model. For example, you can work around a

block that is incompatible with the software by creating a rule that replaces

an unsupported Simulink block in your model with a supported block that is

functionally equivalent. Or, you can customize blocks for analysis by creating

a rule that adds constraints or objectives to particular blocks in your model.

When performing block replacements, the software makes a copy of your

model a nd replaces blocks in the copy, without altering your original model.

In this way, you can easily customize a model for analysis.

The Simulink Design Verifier software replaces blocks automatically in a

model using:

• Libraries of replacement blocks

• Rules that define which blocks to replace and under what conditions

4-2

You replace any block with any built-in block, library block, or subsystem.

Block replacements are extensible, allowing you to define your own libraries

of replacement blocks and custom block replacement rules. Use this capability

if you need to:

• Work around an incompatibility, such as the presence of unsupported

blocks in your model.

• Customize a block for analysis, such as:

- Adding constraints to its input signals

- Adding objectives to its output signals

- Eliminating the contents of a subsystem or Model block to simplify your

analysis

Page 87

About Block Replacements

Note You can use automatic stubbing as an alternative to block replacements

in order to resolve incompatibilities. Automatic stubbing replaces unsupported

blocks with elements that have the same interface. For more information, see

“Handling Incom patibilities with Automatic Stubbing” on page 2-7.

4-3

Page 88

4 Working with Block Replacements

Built-In Block Replacements

The Simulink Design Verifier software provides a set of block replacement

rules and a corresponding library of replacement blocks. Use these built-in

block replacements when analyzing models. They serve as examples that you

can exam ine to learn how to create your own block replacements.

The following table lists the factory default block replacement rules, available

in the

implementations of each factory-default block replacement rule. Rules whose

file names end with

whose file names end with

Subsystem blocks.

matlabroot\toolbox\sldv\sldv\private folder. There are two

_normal.m replace blocks with Subsystem blocks. Rules

_configss.m replace blocks with Configurable

File Name

blkrep_rule_lookup_normal.m

blkrep_rule_lookup_configss.m

blkrep_rule_lookup2D_normal.m

blkrep_rule_lookup2D_configss.m

blkrep_rule_mpswitch2_normal.m

blkrep_rule_mpswitch2_configss.m

Descriptio

A rule that replaces Lookup Table blocks with

an implementation that includes test objectives

for each breakpoint and interval specified by the

Vector of input values parameter.

A rule that adds Test Condition/Proof Assumption

blocks to the input ports of Lookup Table (2-D)

blocks. Each Test Condition/Proof Assumption

block constrains signal values to the interval

specified by the corresponding breakpoint vector.

A rule that adds a Test Condition/Proof

Assumption block to the control input port of

Multiport Switch blocks whose Number of

inputs parameter is

Assumption block constrains signal values to the