Page 1

Simulink®Control

Getting Started Guide

Design™ 3

Page 2

How to Contact The MathWorks

www.mathworks.

comp.soft-sys.matlab Newsgroup

www.mathworks.com/contact_TS.html Technical Support

suggest@mathworks.com Product enhancement suggestions

bugs@mathwo

doc@mathworks.com Documentation error reports

service@mathworks.com Order status, license renewals, passcodes

info@mathwo

com

rks.com

rks.com

Web

Bug reports

Sales, prici

ng, and general information

508-647-7000 (Phone)

508-647-7001 (Fax)

The MathWorks, Inc.

3 Apple Hill Drive

Natick, MA 01760-2098

For contact information about worldwide offices, see the MathWorks Web site.

®

Simulink

© COPYRIGHT 2004–20 10 by The MathWorks, Inc.

The software described in this document is furnished under a license agreement. The software may be used

or copied only under the terms of the license agreement. No part of this manual may be photocopied or

reproduced in any form without prior written consent from The MathW orks, Inc.

FEDERAL ACQUISITION: This provision applies to all acquisitions of the Program and Documentation

by, for, or through the federal government of the United States. By accepting delivery of the Program

or Documentation, the government hereby agrees that this software or documentation qualifies as

commercial computer software or commercial computer software documentation as such terms are used

or defined in FAR 12.212, DFARS Part 227.72, and DFARS 252.227-7014. Accordingly, the terms and

conditions of this Agreement and only those rights specified in this Agreement, shall pertain to and govern

theuse,modification,reproduction,release,performance,display,anddisclosureoftheProgramand

Documentation by the federal government (or other entity acquiring for or through the federal government)

and shall supersede any conflicting contractual terms or conditions. If this License fails to meet the

government’s needs or is inconsistent in any respect with federal procurement law, the government agrees

to return the Program and Docu mentation, unused, to The MathWorks, Inc.

Trademarks

MATLAB and Simulink are registered trademarks of The MathWorks, Inc. See

www.mathworks.com/trademarks for a list of additional trademarks. Other product or brand

names may be trademarks or registered trademarks of their respective holders.

Patents

The MathWorks products are protected by one or more U.S. patents. Please see

www.mathworks.com/patents for more information.

Control Design™ Getting Started Guide

Page 3

Revision History

June 2004 Online only New for V ersion 1.0 (Release 14)

October 2004 Online only Revised for Version 1.1 (Release 14SP1)

March 2005 Online only Revised for Version 1.2 (Release 14SP2)

September 2005 Online only Revised for Version 1.3 (Release 14SP3)

March 2006 First printing Revised for Version 2.0 (Release 2006a)

September 2006 Online only Revised for Version 2.0.1 (Release 2006b)

March 2007 Online only Revised for Version 2.1 (Release 2007a)

September 2007 Online only Revised for Version 2.2 (Release 2007b)

March 2008 Second printing Revised for Version 2.3 (Release 2008a)

October 2008 Online only Revised for Version 2.4 (Release 2008b)

March 2009 Online only Revised for Version 2.5 (Release 2009a)

September 2009 Third printing Revised for Version 3.0 (Release 2009b)

March 2010 Online only Revised for Version 3.1 (Release 2010a)

Page 4

Page 5

Product Overview

1

Introduction ...................................... 1-2

Contents

Purpose of Lin

Role of Linea

Using the GU

Using the D

Expected B

How to Use T

Online Do

Using Exa

Related P

Tutori

al — Computing a Steady-State Operating

Point f

earization

rization in Compensator Design

I Versus Command-Line Functions

ocumentation

ackground

his Guide

cumentation

mples and Demos

roducts

..................................

or a Simulink Model Using t he GUI

...........................

........

..........................

..............................

.............................

.............................

.........................

2

About This Tutorial ................................ 2-2

Objectives

About the Model

........................................ 2-2

.................................. 2-2

.....

1-3

1-4

1-5

1-6

1-6

1-6

1-7

1-7

1-7

Computing a Steady-State Operating Point

Why Compute a Steady-State Operating Point?

How to Compute a Steady-State Operating Point

Simulating the Model at the Steady-State Operating

Point

........................................... 2-13

.......... 2-6

......... 2-6

........ 2-6

v

Page 6

Steps for Simulating the Model ...................... 2-13

Initializing the Simulink Model with the Steady-State

Operating Point

Simulating the Initialized Model

................................. 2-13

..................... 2-15

Tutorial — Computing a Steady-State Operating

Point for a Simulink Model Using the Command

3

About This Tutorial ................................ 3-2

Objectives

About the Model

........................................ 3-2

.................................. 3-2

Line

Computing a Steady-State Operating Point

Why Compute a Steady-State Operating Point?

How to Compute a Steady-State Operating Point

Simulating the Model at the Steady-State Operating

Point

Steps for Simulating the Model

Initializing the Simulink Model with the Steady-State

Simulating the Initialized Model

........................................... 3-10

...................... 3-10

Operating Point

................................. 3-10

..................... 3-11

.......... 3-6

......... 3-6

........ 3-6

Tutorial — Linearizing a Plant in a Single-Loop

Control System Using the GUI

4

About This Tutorial ................................ 4-2

Objectives

About the Model

Linearizing the Magnetic Ball Plant

Why Linearize a Nonlinear Plant?

........................................ 4-2

.................................. 4-2

................. 4-6

.................... 4-6

vi Contents

Page 7

Overview o f the Linearization Process ................. 4-6

How to Linearize the Magnetic Ball Plant

............. 4-7

Tutorial — Linearizing a Plant in a Single-Loop

Control System Using the Command Line

5

About This Tutorial ................................ 5-2

Objectives

About the Model

........................................ 5-2

.................................. 5-2

Linearizing the Magnetic Ball Plant

Why Linearize a Nonlinear Plant?

Overview o f the Linearization Process

How to Linearize the Magnetic Ball Plant

................. 5-6

.................... 5-6

................. 5-6

............. 5-7

Tutorial — Designing a Compensator Using

Classical PID Techniques

6

About This Tutorial ................................ 6-2

Objectives

About the Model

Requirements for the Compensator Design

Overview of the Com pensator Design Proc ess

Designing a PID Compensator Using the Robust

Response Time Tuning Algorithm

Tuning the PID Compensator Using Bode Graphical

Tuning

........................................ 6-2

.................................. 6-2

............. 6-6

.......... 6-6

................. 6-8

......................................... 6-17

Simulating the Closed-Loop Simulink Model

......... 6-22

vii

Page 8

Examples

A

Getting Started .................................... A-2

Index

viii Contents

Page 9

Product O verview

• “Introduction” on page 1-2

• “Purpose of Linearization” on page 1-3

• “Role of Line arization in Compensator Design” on page 1-4

• “Using the GUI Versus Command-Line Functions” on page 1-5

• “Using the Documentation” on page 1-6

1

Page 10

1 Product Overview

Introduction

The Simulink®Control D esign™ software prov ides tools for linearization and

compensator design for control systems and models. Linearized models often

simplify compensator design and systemanalysis. Thisisusefulinmany

industries and applications, including

• Aerospace: flight control, guidance, navigation

• Automotive: cruise control, emissions control, transmission

• Equipment manufacturing: motors, disk drives, servos

The Simulink Control Design software works with the Sim u li nk

engine and the Control System Toolbox™ SISO Design Tool. Use it to

• Compute operating points of models using specifications or simulation.

• Extract linear models from models.

• Tune compensator blocks in models with either single or multi-loop

configurations.

The Simulink Control Design software provides a graphical user interface

(GUI) for performing linearization and compensator design for Simulink

models.

®

linearization

1-2

Page 11

Purpose of Linearization

Many common control system analysis and design methodologies require

linear, time-invariant models. However, control systems and physical models

created with Simulink are often nonlinear and time-varying. Linearization

is the approximation of a nonlinear system as a linear system, based on

the assumption that the system is almost linear within a certain range of

operation. With a linearized model you can

• Use the Control System Toolbox LTI Viewer to display and analyze the

dynamic behaviors of a model.

• Use the compensator design tools in the Control System Toolbox software,

the Robust Control Toolbox™ software , and the Model Predictive Control

Toolbox™ software to tune control systems.

• Express a model as a transfer function, state space model, or zero-pole-gain

model.

• Determine the response of a model to arbitrary input signals.

Purpose of Linearization

A linearized model can provide a good approximation to a nonlinear system

when created and used carefully. Factors affecting the accuracy of the

approximation are

• Choice of operating points. See “Why Are O p erating Points Important?”.

• Understanding the equations for the linearized model. See “What Is

Linearization?”.

• Controlling the effect of feedback loops. See “What Is Open-Loop Analysis?”.

1-3

Page 12

1 Product Overview

Role of Linearization in Com pensator Design

Linearized mo de ls are especially important for designing compensators. Most

compensator design methodologies, such as Bode plots, require a linear plant

model. Since most real-world plant models are nonlinear, you must typically

linearize the system before you design the compensators for it. As a result,

the d esign of good compensators relies on a good linearization.

The m odel is automatically linearized for you during compensator design , but

it is still important to understand the fundamentals of creating an accurate

linear model. Additionally, you should always check that the compensator

you designed for the linearized system also works for the nonlinear system.

Typically, the compensator works well for the nonlinear system as long as the

system does not vary widely from the operating point.

1-4

Page 13

Using the GUI Versus Command-Line Functions

Using the GUI Versus Command-Line Functions

The Simulink Control Design GUI provides a graphical environment for

control system linearization and design. With the graphical environment, you

can easily inspect and analyze operating points and results of linearization.

In addition, you can save and restore settings as well as export results to the

MATLAB

You can also linearize models using the command-line functions. With the

functions, you can automate many of your linearization tasks and perform

batch linearization, such as linearization of a system at several different

values of a parameter. There are no Simulink Control Design functions

specifically intended for designing compensators.

®

workspace.

1-5

Page 14

1 Product Overview

Using the Documentation

In this section...

“Expected Background” on page 1-6

“How to Use This Guide” on page 1-6

“Online Documentation” on page 1-7

“Using Examples and Demos” on page 1-7

“Related Products” on page 1-7

Expected Background

Users should be familiar with control systems design and analysis, and have

experience creating Simulink models. Familiarity with the Control System

Toolbox software is also desirable.

How to Use This Guide

To quickly get started linearizing models,seeChapter4,“Tutorial—

Linearizing a Plant in a Single-Loop Control System Using the GUI”.

1-6

To quickly get started d es ig ning compensators, see Chapter 6, “Tutorial

— Designing a Compensator Using Classical PID Techniques”.

If you are new to linearization, read “What Are Operating Points?” and

“What Is Linearization?”. These sections introduce linearization concepts that

are important for accurate creation and use of linearized models.

All users should read “Exact Linearization U sing the GUI” and “Designing

Compensators”, which d escribe features and use of the Simulink Control

Design GUI.

To automate the linearization process, or perform batch linearization,

continue with “Exact Linearization Using the Command Line” in the Simulink

Control Design User’s Guide.

Page 15

Using the Documentation

Online Document

Further documen

the function and

Reference”.

Using Example

The Simulink C

can access th

demo

at the MATLA

the Simulin

Related Pr

The MathW

the kinds

For more i

http://w

of tasks you can perform with Simulink Control Design software.

nformation about these products, visit the MathWorks Web site at

ww.mathworks.com/products/simcontrol/

tation is available online or in the Help browser, including

block references: “Functions — Alphabetical List” and “Block

sandDemos

ontrol Design documentation uses several examples. You

ese examples by typing

B prompt and selecting Simulink Control Design under

k node.

oducts

orks™ provides several products that are especially relevant to

ation

.

1-7

Page 16

1 Product Overview

1-8

Page 17

2

Tutorial — Computing a

Steady-State Operating

Point for a Simulink Model

Using the GUI

• “About This Tutorial” on page 2-2

• “Computing a Steady-State Operating Point” on page 2-6

• “Simulating the Model at the Steady-State Operating Point” on page 2-13

Page 18

2 Tutorial — Computing a Steady-State Operating Point for a Simulink

About This Tutorial

In this section...

“Objectives” on page 2-2

“About the Model” on page 2-2

Objectives

In this tutorial, you learn how to use the Simulink Control Design GUI to

accomplish the following tasks:

• Compute a steady-state operating point of a Simulink Model.

• Simulate the model at the steady-state operating point.

About the Model

• “The watertank S imulink Model” on page 2-2

®

Model Using the GUI

2-2

• “Water-Tank Subsystem” on page 2-3

The watertank Simulink Model

The watertank model shown in the following figure contains the Water-Tank

System plant and a PI controller configured in the PID Controller block, in a

single-loop feedback system.

Page 19

About This Tutorial

To view the Water-Tank System, double-click the corres ponding subsystem in

the

watertank model. For descriptions of these subsystems, see “Water-Tank

Subsystem” on page 2-3.

For information about creating Simulink m od el s, see “Creating a Simulink

Model”.

Water-Tank Subsystem

The Water-Tank subsystem of the watertank model appears in the following

figure.

This model represents the water-tank system depicted in the following figure.

2-3

Page 20

2 Tutorial — Computing a Steady-State Operating Point for a Simulink

®

Model Using the GUI

2-4

Water enters the tank from the top at a rate proportional to the voltage, V,

applied to the pump. The water leaves through an opening in the tank base

at a rate that is proportional to the square root of the water height, H,in

the tank. The presence of the square root in the water flow rate results in a

nonlinear plant.

The following table describes the variables, parameters, differential

equations, states, inputs, and outputs of the water-tank system.

Variables

Parameters

H is the

Vol is

tank.

V is th

A is t

tank

b is

rat

height of water in the tank.

the volume of water in the

evoltageappliedtothepump.

he cross-sectional area of the

.

a constant related to the flow

eintothetank.

Page 21

Differential equation

About This Tutorial

a is a constant related to the flow

rate out of the tank.

d

Vol A

dt

dH

dt

bV a H==−

States

Inputs V

Outputs

H

H

2-5

Page 22

2 Tutorial — Computing a Steady-State Operating Point for a Simulink

®

Model Using the GUI

Computing a Steady-State Operating Point

In this section...

“Why Compute a Steady-State Operating Point?” on page 2-6

“How to Compute a Steady-State Operating Point” on page 2-6

Why Compute a Steady-State Operating Point?

An operating point is a set of inputs, outputs, and states that describe

the operating conditions of a system. A steady-state operating point is

an operating point in which all states remain constant over time. M any

real-world systems are designed to operate at steady-state o perating points.

Computing a steady-state operating point is required for:

• Analyzing system d yna mics at steady state using simulation

• Linearizing a model at a steady-state operating point

• Designing a compensator for use at a steady-state operating point

For more information about steady-state operating points, see “Equilibrium

Operating Points”.

How to Compute a Steady-State Operating Point

To compute a steady-state operating point:

1 Open the watertank model by typing the following in the MATLAB

command window:

watertank

The model opens in Simulink, as shown in the following figure.

2-6

Page 23

Computing a Steady-State Operating Point

2 In the watertank model window, select Tools > Control Design > Linear

Analysis.

This action opens the Control and Estimation Tools Manager, and creates

the following project nodes:

• Operating Points (used in this tutorial)

• Linearization Task (not used in this tutorial)

2-7

Page 24

2 Tutorial — Computing a Steady-State Operating Point for a Simulink

®

Model Using the GUI

2-8

3 Select the Operating Points node. Then, select the Compute Operating

Points tab.

By default, the Steady State check boxes are selected for both states in

the model, Integrator and H. T his selection indicate that a steady-state

operating point will be computed.

Page 25

Computing a Steady-State Operating Point

4 Click Compute Operating Poin ts.

This action computes the operating point, and adds an Operating Point

node under the Operating Points node. The results of the computation

appear in the Computation Results tab.

2-9

Page 26

2 Tutorial — Computing a Steady-State Operating Point for a Simulink

®

Model Using the GUI

2-10

To view the new operating point, select the new Operating Point node.

Page 27

Computing a Steady-State Operating Point

The new Operating Point node displays the following information for

each state:

• Actual Value: Values of the states in the operating point.

The values are 1.2649 for the state Integrator and 10 for the state H.

• Actual dx: The time derivative of the state. For a steady-state operating

point, the time derivatives of all states are very close to or equal to zero.

Thetimederivativesare0forthestateIntegrator and -3.4634e-10 for the

state H. These values show that the operating point is at steady state.

Tip To automatically generate MATLAB code that computes operating

nts as specified in the Control and Estimation Tools Manager, click

poi

elect File > Generate MATLAB Code.

or s

ve the project, which now includes a steady-state operating point.

5 Sa

2-11

Page 28

2 Tutorial — Computing a Steady-State Operating Point for a Simulink

a In the Control and Estimation Tools Manager, select File > Save.

This action opens the Save Projects dialog box.

b In the Save Projects dialog box, click OK.

This action opens the Save Projects window.

®

Model Using the GUI

2-12

c In the Save Projects window, enter a project name, and click Save.

The proj

Tip You

linear

asaved

ect is sav ed as a MAT-file.

can open this project, and use the operating points for future

ization and compensator design. For more information about opening

project, see “Opening Previously Saved Projects”.

Page 29

Simulating the Mod el at the Steady-State Operating Point

Simulating the Model at the Steady-State Operating Point

In this section...

“Steps for Sim ulating the Model” on page 2-13

“Initializing the Simulink M odel with the Steady-State Operating Point”

on page 2-13

“Simulating the Initialized Model” on page 2-15

Steps for Simulating the Model

In this portion of the tutorial, y ou simulate the model a steady-state operating

point. You must have already computed this operating point, as described in

“Computing a Steady-State Operating Point” on page 2-6.

To simulate the model at the steady-state operating point you computed:

1 Initialize the Simulink model with the steady-state operating point. See

“Initializing the Simulink Model with the Steady-State Operating Point ”

on page 2-13.

2 Simulate the initialized model. See “Simulating the Initialized Model”

on page 2-15.

Initializing the Simulink Model with the Steady-State

Operating Point

To initialize the model with the ste ady-state operating point:

1 Right-click the Operating Point node, which contains the steady-state

operating point you created, and select Export to Workspace.

2-13

Page 30

2 Tutorial — Computing a Steady-State Operating Point for a Simulink

®

Model Using the GUI

2-14

This action opens the Export to Workspace dialog box.

2 IntheExporttoWorkspacedialogbox,makethefollowingselections:

• For Select destination workspace,selecttheModel Workspace

option.

• Select the Use the operating point to initialize the model check box.

Page 31

Simulating the Mod el at the Steady-State Operating Point

3 Click OK.

This action loads the operating point into the Simulink model workspace.

Tip You can view the operating point in the model workspace by selecting

View > Model Explorer in the S imulink model window, and then

selecting the Model Workspace node under the watertank node.

Simulating the Initialized Model

To simulate the initialized model:

1 In the Water-Tank System subsystem, right-click the output signal of

the integrator, which is the state H,andselectCreate and Connect

Viewer > Simulink > Scope. This action opens a Scope for viewing the

state H.

2 Add a

a In th

Scope for viewing the state Integrator:

e

watertank model, right-click the PID Controller block a nd s elect

Under Mask.

Look

This action opens the PID Controller block mask.

2-15

Page 32

2 Tutorial — Computing a Steady-State Operating Point for a Simulink

b In the block mask, right-click the output signal of the Integrator,

which is the state Integrator,andselectCreate and Connect

Viewer > Simulink > Scope. This action opens a Scope for viewing

the state Integrator.

3 Simulate each model by clicking the play arrow in the Simulink model

windows.

®

Model Using the GUI

2-16

This action displays the states H and Integrator in their respective Scope

windows. The Scope outputs shows these results:

• The state H remains constant ove r time at the expected value of 10.

• The state Integrator remains constant over time at the expected value of

1.2649.

Both state values match the values found during the steady-state operating

point computation.

Page 33

Simulating the Mod el at the Steady-State Operating Point

Scope Outpu

Scope Output for State In tegrator

tforStateH

The simulations show that both of the states in the model remain constant

over time.

2-17

Page 34

2 Tutorial — Computing a Steady-State Operating Point for a Simulink

®

Model Using the GUI

2-18

Page 35

3

Tutorial — Computing a

Steady-State Operating

Point for a Simulink Model

Using the Command Line

• “About This Tutorial” on page 3-2

• “Computing a Steady-State Operating Point” on page 3-6

• “Simulating the Model at the Steady-State Operating Point” on page 3-10

Page 36

3 Tutorial — Computing a Stead y-State Operating Point for a Simulink

About This Tutorial

In this section...

“Objectives” on page 3-2

“About the Model” on page 3-2

Objectives

In this tutorial, you learn how to use Simulink Control Design functions at

the command line to accomplish the following tasks:

• Compute a steady-state operating point of a Simulink Model.

• Simulating the model at the steady-state operating point.

About the Model

• “The watertank S imulink Model” on page 3-2

®

Model Using the Command Line

3-2

• “Water-Tank Subsystem” on page 3-3

The watertank Simulink Model

The watertank model shown in the following figure contains the Water-Tank

System plant and a PI controller configured in the PID Controller block, in a

single-loop feedback system.

Page 37

About This Tutorial

To view the Water-Tank System, double-click the corres ponding subsystem in

the

watertank model. For descriptions of these subsystems, see “Water-Tank

Subsystem” on page 3-3.

For information about creating Simulink m od el s, see “Creating a Simulink

Model”.

Water-Tank Subsystem

The Water-Tank subsystem of the watertank model appears in the following

figure.

This model represents the water-tank system depicted in the following figure.

3-3

Page 38

3 Tutorial — Computing a Stead y-State Operating Point for a Simulink

®

Model Using the Command Line

3-4

Water enters the tank from the top at a rate proportional to the voltage, V,

applied to the pump. The water leaves through an opening in the tank base

at a rate that is proportional to the square root of the water height in the

tank. The presence of the square root in the water flow rate results in a

nonlinear plant.

The following table describes the variables, parameters, differential

equations, states, inputs, and outputs of the water-tank system.

Variables

Parameters

H is the

Vol is

tank.

V is th

A is t

tank

b is

rat

height of water in the tank.

the volume of water in the

evoltageappliedtothepump.

he cross-sectional area of the

.

a constant related to the flow

eintothetank.

Page 39

Differential equation

About This Tutorial

a is a constant related to the flow

rate out of the tank.

d

Vol A

dt

dH

dt

bV a H==−

States

Inputs V

Outputs

H

H

3-5

Page 40

3 Tutorial — Computing a Stead y-State Operating Point for a Simulink

®

Model Using the Command Line

Computing a Steady-State Operating Point

In this section...

“Why Compute a Steady-State Operating Point?” on page 3-6

“How to Compute a Steady-State Operating Point” on page 3-6

Why Compute a Steady-State Operating Point?

An operating point is a set of inputs, outputs, and states that describe

the operating conditions of a system. A steady-state operating point is

an operating point in which all states remain constant over time. M any

real-world systems are designed to operate at steady-state o perating points.

Computing a steady-state operating point is required for:

• Analyzing system dynamics at steady state

• Linearizing a model at a steady-state operating point

• Designing a compensator for use at a steady-state operating point

For more information about steady-state operating points, see “Equilibrium

Operating Points”.

How to Compute a Steady-State Operating Point

To compute a steady-state operating point:

1 Open the watertank model by typing the following in the MATLAB

command window:

watertank

The model opens in Simulink, as shown in the following figure.

3-6

Page 41

Computing a Steady-State Operating Point

2 Create an operating point specification obje ct using the operspec command

by typing the following:

watertank_spec = operspec('watertank')

This command returns the following result:

Operating Specification for the Model watertank.

(Time-Varying Components Evaluated at time t=0)

States:

---------(1.) watertank/PID Controller/Integrator

spec: dx = 0, initial guess: 0

(2.) watertank/Water-Tank System/H

spec: dx = 0, initial guess: 1

Inputs: None

----------

Outputs: None

----------

The operating point specification object watertank_spec contains objects

for all the states, inputs, and outputs in the model. You can view the

operating point specification for a state using the

get command. For

example, to view the state H, type the following:

3-7

Page 42

3 Tutorial — Computing a Stead y-State Operating Point for a Simulink

get(watertank_spec.States(2))

This command returns the following result:

Block: 'watertank/Water-Tank System/H'

StateName: ''

x: 0

Nx: 1

Ts: [0 0]

SampleType: 'CSTATE'

inReferencedModel: 0

Known: 0

SteadyState: 1

Min: -Inf

Max: Inf

Description: ''

®

Model Using the Command Line

SteadyState

defaults to a value of 1 for both states, H and Integrator.This

indicates that a steady-state operating point will be computed.

3 Compute the operating point from the operating point specification object

watertank_spec using the findop command by typing the following:

[watertank_op,op_report]=findop('watertank',watertank_spec)

This command returns the following result:

Operating Point for the Model watertank.

(Time-Varying Components Evaluated at time t=0)

States:

---------(1.) watertank/PID Controller/Integrator

x: 1.26

(2.) watertank/Water-Tank System/H

x: 10

Inputs: None

----------

Operating Report for the Model watertank.

3-8

Page 43

Computing a Steady-State Operating Point

(Time-Varying Components Evaluated at time t=0)

Operating point specifications were s uccessfully met.

States:

---------(1.) watertank/PID Controller/Integrator

x: 1.26 dx: 0 (0)

(2.) watertank/Water-Tank System/H

x: 10 dx: -3.46e-010 (0)

Inputs: None

----------

Outputs: None

----------

This operating point and operating point report shows the following

information for each state:

• Values of the states,

x, in the operating point.

The values are 1.26 for the state Integrator and 10 for the state H.

• Time derivatives of the states,

dx, with the desired v alue in parentheses.

For a steady-state operating point, the time derivatives of all states

are very clos e to or equal to zero.

The time derivatives are 0 for the state Integrator and -3.46e-010 for the

state H. These values show that the operating point is at steady state.

4 Save the operating point for future reuse using the save command by

typing the following:

save watertank_op

Tip You can use the load command to reload this operating point.

3-9

Page 44

3 Tutorial — Computing a Stead y-State Operating Point for a Simulink

®

Model Using the Command Line

Simulating the Model at the Steady-State Operating Point

In this section...

“Steps for Sim ulating the Model” on page 3-10

“Initializing the Simulink M odel with the Steady-State Operating Point”

on page 3-10

“Simulating the Initialized Model” on page 3-11

Steps for Simulating the Model

In this portion of the tutorial, y ou simulate the model a steady-state operating

point.

You must have already computed this operating point, as described in

“Computing a Steady-State Operating Point” on page 3-6.

To simulate the model at the steady-state operating point you computed,

perform the following steps:

3-10

1 Initialize the Simulink model with the steady-state operating point. See

“Initializing the Simulink Model with the Steady-State Operating Point ”

on page 3-10.

2 Simulate the initialized model. See “Simulating the Initialized Model”

on page 3-11.

Initializing the Simulink Model with the Steady-State

Operating Point

To initialize the model with the ste ady-state operating point:

1 In the watertank Simulink model window, select

Simulation > Configuration Parameters.

Configuration Parameters dialog box opens.

The

2 Select the Data Import/Export node.

Page 45

Simulating the Mod el at the Steady-State Operating Point

3 In the Load from workspace portion of the Data Import/Export node,

do the following:

• For Input, select the check box, and type

getinputstruct(watertank_op).

This action sets the inputs of the model operating point to the input

values in

watertank_op.

• For Initial State, select the check box, and type

getstatestruct(watertank_op).

This action sets the initial states of the model operating point to the

initial state v a lues in

watertank_op.

4 Click OK.

Simulating the Initialized Model

To simulate the initialized model:

3-11

Page 46

3 Tutorial — Computing a Stead y-State Operating Point for a Simulink

1 In the Water-Tank System subsystem, right-click the output signal of

the integrator, which is the state H,andselectCreate and Connect

Viewer > Simulink > Scope. This action opens a Scope for viewing the

state H.

2 Add a Scope for viewing the state Integrator:

a In the watert ank model, right-click the PID Controller block and select

Look Under Mask.

®

Model Using the Command Line

3-12

This act

b In the block mask, right-click the output signal of the Integrator,

ion opens the PID Controller block mask.

which is the state Integrator,andselectCreate and Connect

Viewer > Simulink > Scope. This action opens a Scope for viewing

the state Integrator.

Page 47

Simulating the Mod el at the Steady-State Operating Point

3 Simulate each model by clicking the play arrow in the Simulink model

windows.

This action displays the states H and Integrator in their respective Scope

windows. The Scope outputs shows these results:

• The state H remains constant ove r time at the expected value of 10.

• The state Integrator remains constant over time at the expected value of

1.2649.

Both state values match the values found during the steady-state operating

point computation.

Scope O

Scope Output for State In tegrator

utput for State H

3-13

Page 48

3 Tutorial — Computing a Stead y-State Operating Point for a Simulink

The simulations show that both of the states in the model remain constant

over time.

®

Model Using the Command Line

3-14

Page 49

Tutorial — Linearizing

a Plant in a Single-Loop

Control System Using the

GUI

• “About This Tutorial” on page 4-2

• “Linearizing the Magnetic Ball P lant” on page 4-6

4

Page 50

4 Tutorial — Linearizing a Plant in a Single-Loop Control System Using the GUI

About This Tutorial

In this section...

“Objectives” on page 4-2

“About the Model” on page 4-2

Objectives

In this tutorial, you learn how to use the Simulink Control Design GUI to

linearize a nonlinear plant in a single-loop control system about the operating

point in the Simulink model.

About the Model

• “The magball Simulink Model” on page 4-2

• “Magnetic Ball Plant Subsystem” on page 4-3

4-2

The magball Simulink Model

The magball Simulink model shown in the following figure contains the

nonlinear Magnetic Ball Plant and a controller in a single-loop feedback

system.

Page 51

About This Tutorial

To view the model of the Magnetic Ball Plant subsystem, double-click the

corresponding block in the

magball model. The blocks in this model represent

the mathematical system described in “Magnetic Ball Plant Subsystem” on

page 4-3.

For information about creating Simulink m od el s, see “Creating a Simulink

Model”.

Magnetic Ball Plant Subsystem

The Magnetic Ball Plant subsystem of the magball model is shown in the

following figure.

4-3

Page 52

4 Tutorial — Linearizing a Plant in a Single-Loop Control System Using the GUI

The Magnetic Ball Plant model represents an iron ball of mass M.Thisball

moves under the influence of the gravitational force, Mg,andaninduced

4-4

2

magnetic force,

magnetic force results in a nonlinear plant.

The inductor in the electric circuit, shown in the following figure, causes the

induced magnetic force. This circuit also includes a voltage source and a

resistor.

i

. The presence of the squared term in the induced

h

Page 53

About This Tutorial

The following table describes the variables, parameters, differential

equations, states, inputs, and outputs of the Magnetic Ball Plant subsystem.

Variables

Parameters

Differential

equations

h is th e height of the ball.

i is the current.

V is the voltage in the circuit.

M is the mass of the ball.

g is the gravitational acceleration.

β is a constant related to the magnetic force.

L is the inductance of the coil.

R is the resistance of the circuit.

The height of the ball, h, is described in the following

equation:

M

2

dh

=−

2

dt

Mg

2

i

h

The current in the circuit, i, is described in the following

equation:

di

L

dt

ViR=−

States

Inputs V

Outputs

h

dh/dt

i

h

4-5

Page 54

4 Tutorial — Linearizing a Plant in a Single-Loop Control System Using the GUI

Linearizing the Magnetic Ball Plant

In this section...

“Why Linearize a Nonlinear Plant?” on page 4-6

“Overview of the Linearization Process” on page 4-6

“How to Linearize the Magnetic Ball Plant” on page 4-7

Why Linearize a Nonlinear Plant?

Linearization is a linear approximation of a nonlinear system, based on the

assumption that the system is approximately linear within a specific range of

operation. This approximation is valid in a small region around the operating

point of the system. An operating point is a set of inputs, o u t pu ts, and states

that describe the operating conditions of a system. For more information

about operating points and how they impact linearization, see “Why Are

Operating Points Important?”.

4-6

In real-world problems, models are nonlinear. Because you need a linear,

time-invariant model for most control design and analysis applications, you

must linearize a nonlinear model before you can accomplish these goals.

For mo re information about linearization, see “What Is Linearization?”.

Overview of the Linearization Process

The process for linearizing the Magnetic Ball Plant in this tutorial includes

the following tasks:

• Defining the portion of the model to linearize, also known as the

linearization path.

• Removing the effects of a feedback loop in a single-loop control system.

• Linearizing about the existing operating point in the Simulink model.

• Viewing the linearization results in a step response plot and as state-space

equations.

Page 55

Linearizing the Magnetic Ball P lant

How to Linearize

1 Open the magball

Command Window

magball

The model open

Simulink model by typing the following in the MATLAB

:

s i n Simulink as sho wn in the following figure.

the Magnetic Ball Plant

2 In the

Analy

This action opens the Control and Estimation Tools Manager and creates

the following project nodes:

• Operating Points (not used in this tutorial)

• Linearization Task (used in this tutorial)

magball model window, select Tools > Control Design > Linear

sis.

4-7

Page 56

4 Tutorial — Linearizing a Plant in a Single-Loop Control System Using the GUI

4-8

3 Define the portion of the model to linearize.

a In the magball model, right-click the input signal to the Magnetic Ball

Plant subsystem, named

V,andselectLinearization Points > Input

Point.

This action displays the

symbol on the signal line. This symbol

indicates the start of the linearization path.

b Right-click the output signal from the Magnetic Ball Plant subsystem,

named

This action displays the

h,andselectLinearization Points > Output Point.

symbol on the signal line. This symbol

indicates the end of the linearization path.

The Simulink model now resembles the following figure.

Page 57

Linearizing the Magnetic Ball P lant

The linearization input and output points in the Simulink model also

display in the Analysis I/Os tab of the Linearization Task node of the

Control and Estimation Tools Manager.

4-9

Page 58

4 Tutorial — Linearizing a Plant in a Single-Loop Control System Using the GUI

4-10

4 Remove the effects of the feedback loop for open-loop analysis by

right-clicking the output signal from the Magnetic Ball Plant subsystem,

named

This action displays an

the loop opening. Opening the loop ensures that the linearization result

includes only the plant while preserving the model operating point. For

more information on the affects of a feedback loop on linearization results,

see “Performing Open-Lo op Analysis”.

h.Then,selectLinearization Points > Open Loop.

x on the signal line, which in dicates the location of

Page 59

Linearizing the Magnetic Ball P lant

When you open the loop in the Simulink model, the Open Loop check box

is selected for

magball/Magnetic Ball Plant in the Analysis I/Os tab

of the Control and Estimation Tools Manager.

4-11

Page 60

4 Tutorial — Linearizing a Plant in a Single-Loop Control System Using the GUI

4-12

5 In the Operating Points tab of the Linearization Task node, verify

that the Linearize at the operating point currently specified in the

Simulink model option is selected. By default, this option i s selected

whenyouopentheOperating Points tab.

Page 61

Linearizing the Magnetic Ball P lant

Tip You can view the operating point currently specified in the Simulink

model by selecting the Default Operating Point node under the

Operating Points node.

6 Click Linearize Model.

This action computes the linearized model, adds a Model node under the

Linearization Task node, and opens the LTI Viewer G UI, which display s

a step response plot of the linear model.

4-13

Page 62

4 Tutorial — Linearizing a Plant in a Single-Loop Control System Using the GUI

4-14

The step response decreases exponentially after about 0.8 seconds, which

indicates that the plant model is unstable. The linear model provides an

accurate approximation of the nonlinear Magnetic Ball Plant, which is

also unstable.

Tip You can use the right-click menu of the LTI Viewer GUI to display

a different plot or add characteristics to the response plot, such as peak

response and settling time. For more information about working with

response plots, see “LTI Viewer” in the Control System Toolbox Getting

Started Guide.

Tip For information about designing a stabilizing controller for the

Magnetic Ball Pla n t, see “Designing Compensators”.

Page 63

Linearizing the Magnetic Ball P lant

Tip To automatically generate MATLAB code that linearizes your model

as specified in the Control and Estimation Tools Manager, click

or select

File > Generate MATLAB Code.

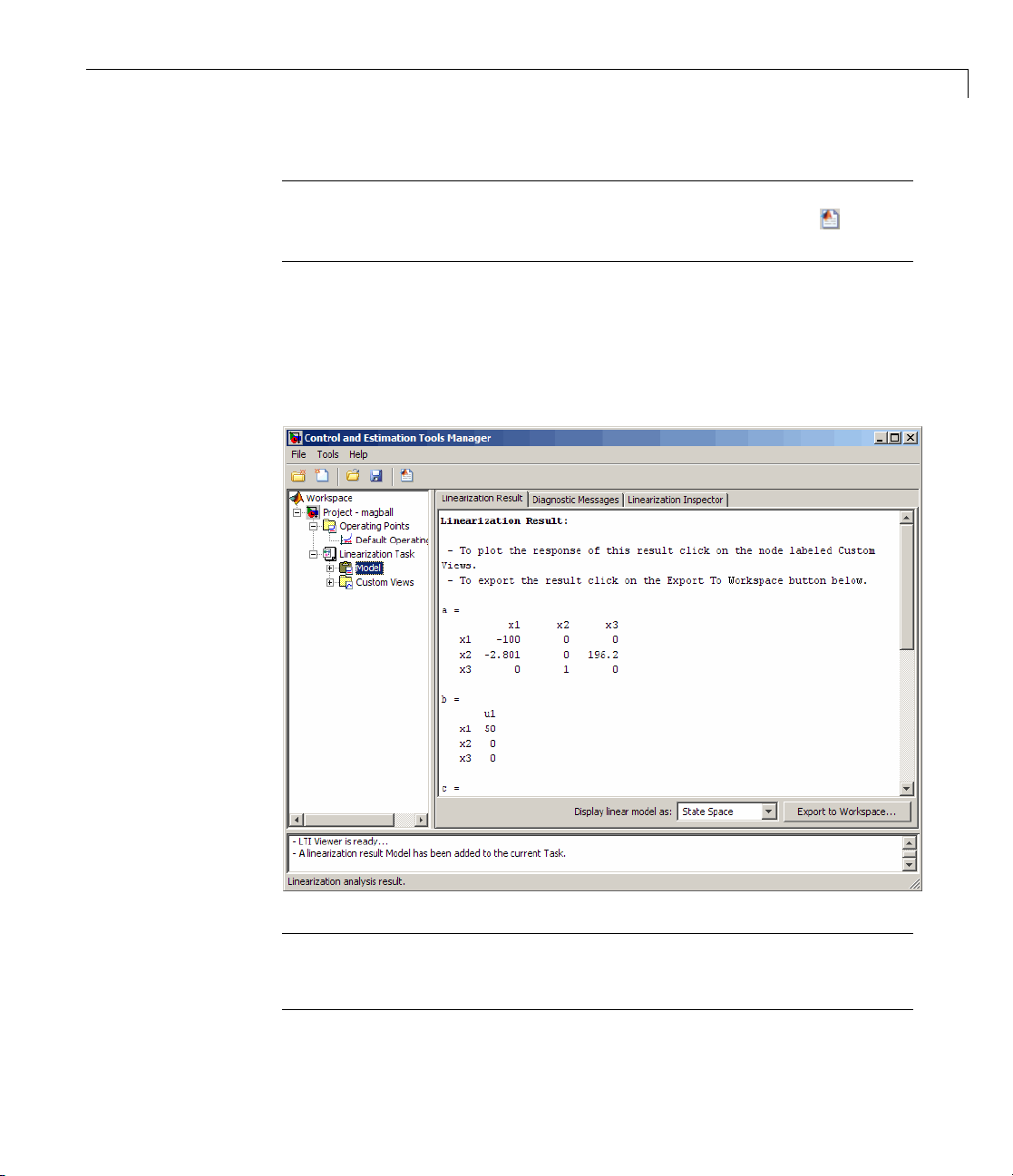

7 View the state-space matrices of the linearization result by selecting the

Model node under the Linearization Task node.

This action opens the Linearization Results tab shown in the following

figure.

Tip To display linearization results using a different mathematical form,

such as zero-pole-gain or transfer function, select the corresponding option

from the Display linear model as list.

4-15

Page 64

4 Tutorial — Linearizing a Plant in a Single-Loop Control System Using the GUI

8 Save the Control and Estimation Tools Manager project, which contains

the linearization results.

a In the Co ntrol and E s timation Tools Manger, select File > Save.

This action opens the Save Projects dialog box.

4-16

b In the S

ave Projects dialog box, click OK.

This action opens the Save Projects window.

c In the Save Projects window, enter a project name, and click Save.

This action saves the project as a MAT-file.

Tip You can load this project by selecting File > Load in the Control and

Estimation Tools Manager.

Page 65

Tutorial — Linearizing

a Plant in a Single-Loop

Control System Using the

Command Line

• “About This Tutorial” on page 5-2

• “Linearizing the Magnetic Ball P lant” on page 5-6

5

Page 66

5 Tutorial — Linearizing a Plant in a Single-Loop Control System Using the Command Line

About This Tutorial

In this section...

“Objectives” on page 5-2

“About the Model” on page 5-2

Objectives

In this tutorial, you learn how to use Simulink Control Design functions at the

command line to linearize a nonlinear plant in a single-loop control system

about the existing operating point in the Simulink model.

About the Model

• “The magball Simulink Model” on page 5-2

• “Magnetic Ball Plant Subsystem” on page 5-3

5-2

The magball Simulink Model

The magball Simulink model shown in the following figure contains the

nonlinear Magnetic Ball Plant and a controller in a single-loop feedback

system.

Page 67

About This Tutorial

To view the model of the Magnetic Ball Plant subsystem, double-click the

corresponding block in the

magball model. The blocks in this model represent

the mathematical system described in “Magnetic Ball Plant Subsystem” on

page 5-3.

For information about creating Simulink m od el s, see “Creating a Simulink

Model”.

Magnetic Ball Plant Subsystem

The Magnetic Ball Plant subsystem of the magball model is shown in the

following figure.

5-3

Page 68

5 Tutorial — Linearizing a Plant in a Single-Loop Control System Using the Command Line

The Magnetic Ball Plant model represents an iron ball of mass M.Thisball

moves under the influence of the gravitational force, Mg,andaninduced

5-4

2

magnetic force,

magnetic force results in a nonlinear plant.

The inductor in the electric circuit, shown in the following figure, causes the

induced magnetic force. This circuit also includes a voltage source and a

resistor.

i

. The presence of the squared term in the induced

h

Page 69

About This Tutorial

The following table describes the variables, parameters, differential

equations, states, inputs, and outputs of the Magnetic Ball Plant subsystem.

Variables

Parameters

Differential

equations

h is th e height of the ball.

i is the current.

V is the voltage in the circuit.

M is the mass of the ball.

g is the gravitational acceleration.

β is a constant related to the magnetic force.

L is the inductance of the coil.

R is the resistance of the circuit.

The height of the ball, h, is described in the following

equation:

M

2

dh

=−

2

dt

Mg

2

i

h

The current in the circuit, i, is described in the following

equation:

di

L

dt

ViR=−

States

Inputs V

Outputs

h

dh/dt

i

h

5-5

Page 70

5 Tutorial — Linearizing a Plant in a Single-Loop Control System Using the Command Line

Linearizing the Magnetic Ball Plant

In this section...

“Why Linearize a Nonlinear Plant?” on page 5-6

“Overview of the Linearization Process” on page 5-6

“How to Linearize the Magnetic Ball Plant” on page 5-7

Why Linearize a Nonlinear Plant?

Linearization is a linear approximation of a nonlinear system, based on the

assumption that the system is approximately linear within a specific range of

operation. This approximation is valid in a small region around the operating

point of the system. An operating point is a set of inputs, o u t pu ts, and states

that describe the operating conditions of a system. For more information

about operating points and how they impact linearization, see “Why Are

Operating Points Important?”.

5-6

In real-world problems, models are nonlinear. Because you need a linear,

time-invariant model for most control design and analysis applications, you

must linearize a nonlinear model before you can accomplish these goals.

For mo re information about linearization, see “What Is Linearization?”.

Overview of the Linearization Process

The process for linearizing the Magnetic Ball Plant in this tutorial includes

the following tasks:

• Defining the portion of the model to linearize, also known as the

linearization path.

• Removing the effects of a feedback loop in a single-loop control system.

• Linearizing about the existing operating point in the Simulink model.

• Viewing the linearization results in a step response plot and as state-space

equations.

Page 71

Linearizing the Magnetic Ball P lant

How to Linearize

1 Open the magneti

Command Window

magball

the Magnetic Ball Plant

c ball model by typing the following in the MATLAB

:

The model opens in Simulink as shown in the following figure.

2 Define the portion of the model to linearize using the linio command.

a Insert a linearization input point before the Magnetic Ball Pla n t by

typing the following command:

magball_io(1)=linio('magball/Controller',1,'in')

This command creates the magball_io linear ization I/O obj ect in the

MATLAB workspace. This object contains a linearization I/O setting

for the input point.

Linearization IOs:

--------------------------

Block magball/Controller, Port 1 is marked with the following properties:

5-7

Page 72

5 Tutorial — Linearizing a Plant in a Single-Loop Control System Using the Command Line

- No Loop Opening

- An Input Perturbatio n

- No signal name. Linearization will use the block name

b Insert a

typing t

linearization output point after the Magnetic Ball Plant by

he following command:

magball_io(2)=linio('magball/Magnetic Ball Plant',1,'out')

This command updates the magball_io object to include a second

linearization I/O setting for the output point.

Linearization IOs:

--------------------------

Block magball/Controller, Port 1 is marked with the following properties:

- No Loop Opening

- An Input Perturbatio n

- No signal name. Linearization will use the block name

Block magball/Magnetic Ball Plant, Port 1 is marked with the following properties:

- An Output Measuremen t

- No Loop Opening

- No signal name. Linearization will use the block name

3 Remove the effects of the feedback loop for open-loop analysis by typing the

following command:

magball_io(2).OpenLoop='on'

This command updates the magball_io object to include a loop opening at

the output signal of t h e Magnetic Ball Plant. Opening the loop ensures that

the linearization result includes only theplantwhilepreservingthemodel

operating point. For more information on the effects of a feedback loop on

linearization results, see “Performing Open-Loop Analysis”.

5-8

Linearization IOs:

--------------------------

Block magball/Controller, Port 1 is marked with the following properties:

- No Loop Opening

- An Input Perturbatio n

- No signal name. Linearization will use the block name

Page 73

Linearizing the Magnetic Ball P lant

Block magball/Magnetic Ball Plant, Port 1 is marked with the following properties:

- An Output Measuremen t

- A Loop Opening

- No signal name. Linearization will use the block name

4 Perform the linearization using the l inea rize command by typing the

following:

magball_lin=linearize('magball',magball_io)

This command linearizes the portion of the model defined in the m agba ll_io

object about the operating point currently specified in the model. This

command returns the following linearization result as a state-space object.

a=

magball/Magn magball/Magn magball/Magn

magball/Magn001

magball/Magn 0 -100 0

magball/Magn 196.2 -2.801 0

b=

magball/Cont

magball/Magn 0

magball/Magn 50

magball/Magn 0

c=

magball/Magn magball/Magn magball/Magn

Magnetic Bal100

d=

magball/Cont

Magnetic Bal 0

Continuous-time model.

5 View the step response of the linearized model by typing the following

command:

ltiview(magball_lin)

5-9

Page 74

5 Tutorial — Linearizing a Plant in a Single-Loop Control System Using the Command Line

This command opens the LTI Viewer GUI, which displays the step response

plot of the linear model.

5-10

The step response decreases exponentially after about 0.8 seconds, which

indicates that the plant model is unstable. The linear model provides an

accurate approximation of the nonlinear Magnetic Ball Plant, which is

also unstable.

Tip You can use the right-click menu of the LTI Viewer GUI to display

a different plot or add characteristics to the response plot, such as peak

response and settling time. For more information about working with

response plots, see “LTI Viewer” in the Control System Toolbox Getting

Started Guide.

Tip For information about designing a stabilizing controller for the

Magnetic Ball Pla n t, see “Designing Compensators”.

Page 75

Linearizing the Magnetic Ball P lant

6 Save the linearized model and I/O object of the magball model using the

save command by typing the following:

save magball_project magball_lin magball_io

This command creates a file named magball_project. mat in the current

folder.

Tip You can use the load command to reload this project.

5-11

Page 76

5 Tutorial — Linearizing a Plant in a Single-Loop Control System Using the Command Line

5-12

Page 77

Tutorial — Designing

a Compensator Using

Classical PID Techniques

• “About This Tutorial” on page 6-2

• “Designing a PID Compensator Using the Robust Response Time Tuning

Algorithm” on page 6-8

• “Tuning the PID Compensator Using Bode Graphical Tuning” on page 6-17

6

• “Simulating the Closed-Loop Simulink Model” on page 6-22

Page 78

6 Tutorial — Designing a Compensator Using Classical PID Techniques

About This Tutorial

In this section...

“Objectives” on page 6-2

“About the Model” on page 6-2

“Requirements for the Compensator Design” on page 6-6

“Overview of the Compensator Design Process” on page 6-6

Objectives

In this tutorial, you learn how to use the Simulink Control Design GUI to

design a PID compensator for a single-loop feedback system that is operating

at the operating conditions specified in the Simulink model. You accomplish

the following tasks:

• Configure the model and GUI for compensator design.

6-2

• Design a PID compensator using the robust response time tuning algorithm

and Bode graphical design.

• Simulate the closed-loop nonlinear model.

About the Model

• “The watertank_comp_design Simulink Model” on page 6-3

• “Water-Tank Subsystem” on page 6-3

• “Controller Subsystem” on page 6-6

Page 79

About This Tutorial

The watertank_comp_design Simulink Model

The watertank_comp_design model, shown in the following figure, contains

the Water-Tank System plant and a simple proportio nal-integral-de riv ative

(PID) controller, called Controller, in a single-loop feedback system.

To view the Water-Tank System and the Controller, double-click the

corresponding subsystem in the

descriptions of these subsystems, see the following topics:

• “Water-Tank Subsystem” on page 6-3

• “Controller Subsystem” on page 6-6

For information about creating Simulink m od el s, see “Creating a Simulink

Model”.

watertank_comp_design model. For

Water-Tank Subsystem

The Water-Tank subsystem of the watertank_comp_design model appears in

the following figure.

6-3

Page 80

6 Tutorial — Designing a Compensator Using Classical PID Techniques

This model represents the water-tank system depicted in the following figure.

6-4

Water enters the tank from the top at a rate proportional to the voltage, V,

applied to the pump. The water leaves through an opening in the tank base

at a rate that is proportional to the square root of the water height, H,in

the tank. The presence of the square root in the water flow rate results in a

nonlinear plant.

Page 81

The following table describes the variables, parameters, differential

equations, states, inputs, and outputs of the water-tank system.

About This Tutorial

Variables

Parameters

Differential equation

States

Inputs V

H is the height of water in the tank.

Vol is the volume of water in the

tank.

V isthevoltageappliedtothepump.

A is the cross-sectional area of the

tank.

b is a constant related to the flow

rate into the tank.

a is a constant related to the flow

rate out of the tank.

H

d

Vol A

dt

dH

dt

bV a H==−

6-5

Page 82

6 Tutorial — Designing a Compensator Using Classical PID Techniques

Outputs

H

Controller Subsystem

The Controller subsystem appears in the following figure.

This mod

water in

Requir

The com

System

el contains a PID Controller block that controls the height of the

the Water-Tank System.

ements for the Compensator Design

pensator you design in this tutorial must control the Water-Tank

response as follows:

6-6

• The ov

• The ri

Over

The p

tut

• Con

• De

al

ershoot is l ess than 5%.

se time is less than 5 seconds.

view of the Compensator Design Process

rocess for designing a compensator for the Water-Tank System in this

orial includes the following tasks:

figuring the model andGUIforthedesign.

signing a PID compensator using the robust response time tuning

gorithm.

Page 83

About This Tutorial

• Tuning the compensator using the Bode design technique.

• Simulating the closed-loop Simulink model with the compensator design to

analyze the system dynamics.

Simulink Control Design tools support linear control design. Although

the Water-Tank System is nonlinear, you do not need to linearize this

nonlinear plant model as a separate step–Simulink Control Design software

automatically linearizes the model about the model operating point when

you do not specify a different operating point. Th e linearization provides a

valid a ppro ximation of the nonlinear model in a region around the operating

point. For more information about linearization and how the operating point

impacts linearization results, see “What Is Linearization?” and “Why Are

Operating Points Important?”

6-7

Page 84

6 Tutorial — Designing a Compensator Using Classical PID Techniques

Designing a PID Compensator Using the Robust Response

Time Tuning Algo

rithm

In this portion

PID robust resp

by The MathWor

phase margin.

To design a PI

1 Open the wate

the MATLAB C

watertank_comp_design

The comman

showninth

of the tutorial, you design a compensator using the autom ate d

onse time tuning algorithm. This tuning method, developed

ks,tunes the PID gains to maximize bandwidth and optimize

D compensator:

rtank_comp_design

dopensthe

efollowingfigure.

modelbytypingthemodelnamein

ommand Window:

watertank_comp_design model in Simulink, as

6-8

e

2 In th

Des

This action opens the Control and Estimation Tools Manager with the

Simulink Compensator Design Task node selected.

watertank_comp_design model window, select Tools > Control

ign > Compensator Design.

Page 85

Designing a PID Compensator Using the Robust Response Time Tuning Algorithm

3 Select the PID Controller block as the block to tune.

a In the Tunable Blocks tab, click Select Blocks.

This ac

b In the w

c Selec

tion opens the Select Blocks to Tune window.

atertank_comp_design tree, select the Controller subsystem.

ttheTune? checkbox for PID Controller.

6-9

Page 86

6 Tutorial — Designing a Compensator Using Classical PID Techniques

d Click OK.

4 Define the closed-loop systems for which you want to analyze the response.

6-10

The input and output points of the closed-loop path are already defined in

the

watertank_comp_design model. If you needed to add or define them,

you would use the following steps:

a In the watertank_comp_design model, right-click the output of the

Desired Water Level block, and select Linearization Points > Input

Point.

This action displays the

symbol on the signal line. This symbol

indicates the input of the closed-loop path.

b Right-click the output signal from the Water-Tank System, and select

Linearization Points > Output Point.

This action displays the

symbol on the signal line. This symbol

indicates the output of the closed-loop path.

Page 87

Designing a PID Compensator Using the Robust Response Time Tuning Algorithm

The Simulink model now resembles the following figure.

5 In the Control and Estimation Tools Manager, click Tune Blocks to open

the Design Configuration Wizard. Click Next.

6 Step 1 of the Design Configuration Wizard prompts you to select the design

plotsyouwillusetotunethecontroller. Accept the d efault settings and

click Next.

7 In Step 2 of the Design Configuration Wizard, specify the type of plot for

analyzing the response.

a In the Analysis Plots area, select Step for the Plot Type corresponding

to Plot 1.

b In the Plots section of the Contents in Plots pane, select 1 fo r Closed

Loop from Step to Water-Tank System.

6-11

Page 88

6 Tutorial — Designing a Compensator Using Classical PID Techniques

8 Click Finish.

6-12

The software performs the following actions:

• Linearizes the Simulink model about the operating point specified in

the model.

• Creates a SISO Design Task node under the Simulink Compensator

Design Task node.

• Opens the following plot windows:

– LTI Viewer for SISO Design Task window, which shows the

closed-loop Step Response plot of the linearized model

– SISO Design for SISO Design Task window, which is empty

You do not use in this window in this section of the tutorial. Keep this

window open for the next section of the tutorial.

The Control and Estimation Tools mana ger resembles the following figure.

Page 89

Designing a PID Compensator Using the Robust Response Time Tuning Algorithm

The Step Response plot shows an overshoot that does not mee t the

overshoot design requirement of less than 5%.

6-13

Page 90

6 Tutorial — Designing a Compensator Using Classical PID Techniques

6-14

9 In the A utomated Tuning tab of the SISO Design Task node in the

Control and Estimation Tools Manager, select

method.

10 In the Specifications area, select the following options:

• Controller type:

• Tuning algorithm: Robust response time

PI

PID Tuning as the Design

Page 91

Designing a PID Compensator Using the Robust Response Time Tuning Algorithm

11 Click Upd

ate Compensator.

This action computes the PI values for the compensator using the robus t

response time tuning algorithm and updates the Step Response plot.

Tip You can view the PI values in the Parameter tab of the Compensator

Editor tab in the SISO Design Task node.

12 Evaluate whether the compensator design meets the design requirements

by analyzing the overshoot and the rise time, as follows:

a Right-click the Step Response plot and select the following options:

• Characteristics > Peak Response

• Characteristics > Rise Time

These actions add a plot marker to the plot for each characteristic,

shown as blue dots.

b Left-click each blue dot to open the corresponding data marker.

6-15

Page 92

6 Tutorial — Designing a Compensator Using Classical PID Techniques

The data markers show the following response characteristics:

• The overshoot is 11.6%.

• The rise time is 82.2 seconds.

6-16

This sy

allowe

rise t

You decrease the rise time by increasing the gain of the compensator, as

described in “Tuning the PID Compensator Using Bode Graphical Tuning”

on page 6-17.

stem response with the PID compensator exceeds the maximum

d overshoot of 5%. The rise time is much slower than the required

ime of 5 seconds.

Page 93

Tuning the PID Compensator Using Bode Graphical Tuning

Tuning the PID Compensator Using Bode Graphical Tuning

In this portion of the tutorial, you decrease the rise time of the Water-Tank

System response by incre as ing the gain in the compensator using Bode

graphical tuning. Bode graphical tuning lets you design a compensator by

manipulating Bode diagrams of the open-loop response. This process is also

called loop shaping.

You must have already designed an initial compensator using PID tuning,

as described in “Designing a PID Compensator Using the Robust Response

Time Tuning Algorithm” on page 6-8.

To design a compensator using Bode graphical tuning:

1 In the Control and Estimation Tools Manager, select the Graphical

Tuning tab of the SISO Design Task node.

2 In the Plot Type cell that corresponds to Plot 1, select Open-Loop Bode.

6-17

Page 94

6 Tutorial — Designing a Compensator Using Classical PID Techniques

6-18

This action creates an Open-Loop Bode plot in the S ISO Design for SISO

Design Task window. This plot shows a Bode plot of the linearized m o del

with the compensator designed using automated PID tuning.

Page 95

Tuning the PID Compensator Using Bode Graphical Tuning

3 IntheSISODesignwindow,dragtheBodeMagnitudelineupwardto

increasethegain. Asyouadjustthegain,viewtheaffectsontheclosed-loop

response in the Step Response plot.

By increasing the gain, you increase the bandwidth and speed up the

response. One possible compensato r design that meets the tutorial

requirements has the following parameters:

• P=

5.0368

• I=0.11434

• D=0

6-19

Page 96

6 Tutorial — Designing a Compensator Using Classical PID Techniques

Tip You can view the parameter values corresponding to the gain

adjustment you made in the Bode Magnitude plot in the Compensator

Editor tab of the SISO Design Task. You can also adjust the parameter

values in this tab.

4 Evaluate whether the compensator design meets t he design requirements

by analyzing the overshoot and the rise time, as follows:

a Right-click the Step Response plot and select the following options, if you

have not done so already:

• Characteristics > Peak Response

• Characteristics > Rise Time

These actions add a plot marker to the plot for each characteristic,

shown as blue dots.

b Left-click each blue dot to open the corresponding data marker.

6-20

The data markers show the following response characteristics:

• The overshoot is 0.437%.

• The rise time is 1.72 seconds.

Page 97

Tuning the PID Compensator Using Bode Graphical Tuning

This compensator design satisfies the design requirements of less than 5%

overshoot and less than 5 second rise time.

6-21

Page 98

6 Tutorial — Designing a Compensator Using Classical PID Techniques

Simulating the Closed-Loop Simulink Model

In this portion of the tutorial, you simulate th e nonlinear closed-loop Simulink

model that includes a PID com pensator to determine if the design meets

the requirements.

You must have already designed the compensator, a s described in “Tuning

the PID Compensator Using Bode Graphical Tuning” on page 6-17.

To simulate the model:

1 In the Control and Estimation Tools Manager SISO Design Task node,

click Update Simulink Block Parameters.

This action writes the compensator parameters into the PID Controller

block of the Controller subsystem in the Simulink model.

Tip You can view the PID Controller block parameters in the Function

Block Parameters Dialog box. To open this dialog box, double-click the

PID Controller block.

6-22

Page 99

Simulating the Closed-Loop Simulink®Model

2 In the Simulink model, double-click the Scope block to open the Scope block

window.

3 In the Simulink model, click to simulate the model. Then, click

to autoscale the axis.

6-23

Page 100

6 Tutorial — Designing a Compensator Using Classical PID Techniques

This action

model with t

is less tha

design mee

second ris

n 5 seconds and there is minimal overshoot. Thus, this compensator

etime.

updates the Scope window with the response of the nonlinear

he compensator design. This simulation shows that the rise time

ts the requirements of less than 5% overshoot and less than 5

6-24

Loading...

Loading...