Page 1

Simulink®Control

User’s Guide

Design™ 3

Page 2

How to Contact The MathWorks

www.mathworks.

comp.soft-sys.matlab Newsgroup

www.mathworks.com/contact_TS.html T echnical Support

suggest@mathworks.com Product enhancement suggestions

bugs@mathwo

doc@mathworks.com Documentation error reports

service@mathworks.com Order status, license renewals, passcodes

info@mathwo

com

rks.com

rks.com

Web

Bug reports

Sales, prici

ng, and general information

508-647-7000 (Phone)

508-647-7001 (Fax)

The MathWorks, Inc.

3 Apple Hill Drive

Natick, MA 01760-2098

For contact information about worldwide offices, see the MathWorks Web site.

®

Simulink

© COPYRIGHT 2004–20 10 by The MathWorks, Inc.

The software described in this document is furnished under a license agreement. The software may be used

or copied only under the terms of the license agreement. No part of this manual may be photocopied or

reproduced in any form without prior written consent from The MathW orks, Inc.

FEDERAL ACQUISITION: This provision applies to all acquisitions of the Program and Documentation

by, for, or through the federal government of the United States. By accepting delivery of the Program

or Documentation, the government hereby agrees that this software or documentation qualifies as

commercial computer software or commercial computer software documentation as such terms are used

or defined in FAR 12.212, DFARS Part 227.72, and DFARS 252.227-7014. Accordingly, the terms and

conditions of this Agreement and only those rights specified in this Agreement, shall pertain to and govern

theuse,modification,reproduction,release,performance,display,anddisclosureoftheProgramand

Documentation by the federal government (or other entity acquiring for or through the federal government)

and shall supersede any conflicting contractual terms or conditions. If this License fails to meet the

government’s needs or is inconsistent in any respect with federal procurement law, the government agrees

to return the Program and Docu mentation, unused, to The MathWorks, Inc.

Trademarks

MATLAB and Simulink are registered trademarks of The MathWorks, Inc. See

www.mathworks.com/trademarks for a list of additional trademarks. Other product or brand

names may be trademarks or registered trademarks of their respective holders.

Patents

The MathWorks products are protected by one or more U.S. patents. Please see

www.mathworks.com/patents for more information.

Control D es ign ™ User’s G uid e

Page 3

Revision History

June 2004 Online only New for V ersion 1.0 (Release 14)

October 2004 Online only Revised for Version 1.1 (Release 14SP1)

March 2005 Online only Revised for Version 1.2 (Release 14SP2)

September 2005 O nline only Revised for Version 1.3 (Release 14SP3)

March 2006 Online only Revised for Version 2.0 (Release 2006a)

September 2006 O nline only Revised for Version 2.0.1 (Release 2006b)

March 2007 Online only Revised for Version 2.1 (Release 2007a)

September 2007 O nline only Revised for Version 2.2 (Release 2007b)

March 2008 Online only Revised for Version 2.3 (Release 2008a)

October 2008 Online only Revised for Version 2.4 (Release 2008b)

March 2009 Online only Revised for Version 2.5 (Release 2009a)

September 2009 O nline only Revised for Version 3.0 (Release 2009b)

March 2010 Online only Revised for Version 3.1 (Release 2010a)

Page 4

Page 5

Working with Simulink®Control Design

1

Creating or Opening a Simulink Model .............. 1-2

Details of Possible Models

Example Model: The Magnetic Ball System

.......................... 1-2

............ 1-2

Contents

Projects

BeginningaProject

Creating a Simulink

Creating an Operating Points Task

Creating a Linearization Task

Creating a Simulink Compensator Design Task

Saving Projects

Opening Previously Saved Projects

Exporting Results

Exporting Linearization Results

Exporting Compensator Designs

Exporting Operating Points

ExportingandRestoringLinearization I/O Settings

................................ 1-7

®

Control Design Project ........... 1-7

.................................... 1-11

................................. 1-13

Operating Point Analysis Using the GUI

2

................... 1-8

....................... 1-8

......... 1-10

................. 1-12

..................... 1-13

..................... 1-14

......................... 1-15

..... 1-15

What Are Operating Points? ........................ 2-2

Definition of an Operating Point

Equilibrium Operating Points

Simulink Model Operating Points

..................... 2-2

....................... 2-2

.................... 2-3

v

Page 6

Why Are Operating Points Important? ............... 2-6

Impact of Operating Points

Choosing an Operating Point for Accurate Linearization

......................... 2-6

.. 2-7

Ways to Create Operating Points

Creating Operating Points

Simulink

Computing Operating Points from S pecifications

Specifying Operating Points from Known Values

Extracting Operating Points From Simulation

Computing Equilibrium Operating Points

Working with Operating Points

Copying Operating Points

Exporting Operating Points

Saving Operating Points

Importing Operating Points

Importing Initial Values

Constraining Outputs

Changing Optimization Settings

Recommendations for Computing Operating Points

How to Create Accurate Operating Points

Impact of Blocks on the Simulink M odel Operating

Point

Computing Operating Points for SimMechanics Models

Choosing Initial Values for Computing Operating

Points

Computing Operating Points for B l ock s with Special

Behavior

®

Control D esign De fa ult Opera t in g Point ...... 2-10

........................... 2-23

............................ 2-25

............................ 2-26

.............................. 2-27

......................................... 2-31

......................................... 2-37

...................................... 2-38

.................... 2-9

......................... 2-10

........ 2-10

........ 2-15

.......... 2-17

............. 2-22

..................... 2-23

......................... 2-24

......................... 2-25

..................... 2-27

............. 2-31

.. 2-31

.. 2-36

vi Contents

Operating Point Analysis Using the Command

Line

3

Overview ......................................... 3-2

Page 7

Example: Water-Tank System ....................... 3-3

Water-Tank System

Model Equations

............................... 3-3

.................................. 3-4

Creating or Opening a Simulink Model

Computing Operating Points from Specifications

Workflow for Computing Operating Points from

Specifications

Creating an Operating Poin t Specification Object

Configuring the Operating Point Specification Object

Computing the Complete Operating Point

Alternative Method for Specifying Initial Guesses

Adding Output Constraints to Specifications

Specifying Completely Known Operating Points

Workflow for Specifying Completely Known O pe rating

Points

Creating an Operating Point Object

Changing Operating Point Values

Extracting Values from Simulation

Using Structures and Vectors of Operating Point

Values

......................................... 3-14

.......................................... 3-17

.................................. 3-7

.................... 3-15

.............. 3-5

............. 3-10

........... 3-12

.................. 3-14

.................. 3-16

..... 3-7

....... 3-7

.... 3-8

....... 3-11

...... 3-14

Exact Linearization Using the GUI

4

What Is Linearization? ............................. 4-2

Linearization Background

Analytic Repre sentations of Linear Models

Ways to Linearize Models

Steps for Linearizing Models Using the GUI

.......................... 4-2

............. 4-3

.......................... 4-7

.......... 4-8

vii

Page 8

Choosing Linearization Settings and Algorithms ..... 4-9

HowtoChooseLinearizationSe tti ngs and Algorithms

Options for Linearization Algorithm Method

Block-by-Block Analytic Linearization

Numerical-Perturbation Linearization

Changing State Ordering in the Linearized Model

Configuring the Linearization of Specific Blocks and

Subsystems

Ways to Configure Blocks and Subsystems For

Linearization

Controlling the Analytic Linearization of Individual

Blocks

Specifying the Linearization of Blocks and Subsystems

Controlling the Block Perturbation Linearization of

Individual Blocks

Selecting Inputs and Outputs for the Linearized

Model

What are Linearization Points?

Inserting Linearization Points

Removing Linearization Points

Performing Open-Loop Analysis

Inspecting Analysis I/Os

..................................... 4-36

................................... 4-36

........................................ 4-36

............................... 4-40

.......................................... 4-45

...................... 4-45

....................... 4-46

...................... 4-48

..................... 4-49

............................ 4-52

........... 4-11

................ 4-12

................ 4-24

... 4-9

....... 4-34

... 4-37

viii Contents

Linearizing a Block

Linearizing the Model

Linearizing at an Operating Poin t

Creating Other Types of Linear Models

Linearizing Discrete-Time and Multirate M odels

Viewing Linearization Results

Using the LTI Viewer

Displaying Linearization Results

Highlighting Blocks in the Linearization

Inspecting the Linearization Results Block by Block

Comparing the Results of Multiple Linearizations

Validating Exact Linearization Results

Ways to Validate Exact Linearization Results

................................ 4-55

.............................. 4-57

.................... 4-57

............... 4-64

...................... 4-66

.............................. 4-66

..................... 4-66

.............. 4-68

.............. 4-76

........ 4-65

..... 4-69

....... 4-71

.......... 4-76

Page 9

Creating Input Signals for Validation ................. 4-76

Frequency-Domain Validation

Time-Domain Validation

....................... 4-77

........................... 4-80

Troubleshooting Exact Linearization Results

Diagnosing Blocks

Troubleshooting Your Model at the Subsystem and Block

Level

Troubleshooting L ine arization Settings

Troubleshooting Models with Events-Based Subsystems

Troubleshooting Yo ur Operating Point

......................................... 4-86

................................. 4-82

............... 4-87

................ 4-88

Exact Linearization Using the Command Line

5

Steps for Linearizing Models Using the Command

Line

Configuring the Linearization for Specific Blocks and

Subsystems

Selecting Inputs and Outputs for the Linearized

Model

Workflow for Selecting Inputs and Outputs

Choosing and Storing Linearization Points

Extracting Linearization Points from a Model

Editing an I/O Object

Open-Loop Analysis Using Functions

............................................ 5-2

..................................... 5-3

.......................................... 5-4

............. 5-4

.............................. 5-8

................. 5-10

........ 4-82

.. 4-88

............ 5-4

.......... 5-7

Linearizing the Model Using Functions

Linearizing the Model

Linearizing Discrete-Time and Multirate M odels

Computing Multiple Linearizations for Large Models

Analyzing th e Results U sing Functions

Options for Analyzing the Results

Using the LTI Viewer

Saving Your Work

.............................. 5-11

.................... 5-14

.............................. 5-14

................................. 5-16

.............. 5-11

.............. 5-14

........ 5-13

.... 5-13

ix

Page 10

Restoring Linearization I/O Settings .................. 5-16

Frequency Response Estimation of Simulink

6

About Frequency Response Estimation .............. 6-2

Using Frequency Response Models

What Is a Frequency Response Model?

Model Requirements

Estimation Requires Input and Output Signals

............................... 6-4

................... 6-2

................ 6-2

........ 6-5

Models

Creating Input Signals for Estimation

Supported Input Signals

Creating Sinestream Input Signals

Creating Chirp Input Signals

Modifying Input Signals

Estimating Frequency Response

Analyzing E stimated Frequency Response

Opening the Simulation Results Viewer

Interpreting Frequency Response Analysis Plots

Analyzing Simulated Output and FFT at Specific

Frequencies

Annotating Frequency Response Estimation Plots

Displaying Frequency Response of Multiple-Input

Multiple-Output (MIMO) Systems

Troubleshooting Frequency Response Estimation

When to Troubleshoot

Time Respo nse Not at Steady State

FFT Contains Large Harmonics at Frequencies Other than

the Inp u t Signal Frequency

Time Response Grows Without Bound

Time Respon se Is Discontinuous or Zero

Time Respo n se Is Noisy

.................................... 6-25

............................ 6-7

........................ 6-14

............................ 6-16

.............................. 6-29

....................... 6-35

............................ 6-42

............... 6-7

................... 6-7

.................... 6-18

........... 6-22

............... 6-22

........ 6-23

....... 6-27

.................. 6-28

................... 6-29

................ 6-37

............... 6-39

.... 6-29

x Contents

Page 11

Managing Estimation Speed and Memory ............ 6-51

Ways to Speed up Frequency Response Estimation

Speeding Up Estimation Using Parallel Computing

Managing Memory During Frequency Response

Estimation

..................................... 6-56

...... 6-51

Designing Compensators

7

Compensator Design Using Simulink ................ 7-2

..... 6-53

Automatic P ID Tuning

Automatic PID Tuning O v erview

Designing Controllers with the PID Tuner

Troubleshooting Automatic PID Tuning

Design and Analysis of Control Systems

Compensator Des ig n Process Overview

Beginning a Compensator Design Task

Selecting Blocks to Tune

Selecting C lo sed-Loop Responses to Des ig n

Selecting an Operating Point

Creating a SISO Design Task

Completing the Design

............................. 7-4

..................... 7-4

............. 7-6

............... 7-19

............. 7-27

................ 7-27

................ 7-27

............................ 7-29

............ 7-32

........................ 7-34

........................ 7-37

............................. 7-48

Function Reference

8

Linearization Analysis I/Os ......................... 8-1

Operating Points

.................................. 8-2

Linearization

Frequency Response Estimation

...................................... 8-3

.................... 8-3

xi

Page 12

9

10

A

Functions — Alphabetical List

Block Reference

Linearization Example Using the Graphical

Interface

........................................ A-2

Examples

Linearization Example Using Functions

Frequency Response Estimation

.................... A-2

............. A-2

Index

xii Contents

Page 13

Working with Simulink Control Design Projects

• “Creating or Opening a Simulink Model” on page 1-2

• “Beginning a Project” on page 1-7

• “Saving Projects” on page 1-11

• “Opening Previously Saved Projects” on page 1-12

• “Exporting Results” on page 1-13

1

Page 14

1 Working with Simulink

®

Control Design™ Projects

Creating or Opening a Simulink Model

In this section...

“Details of Possible Models” on page 1-2

“Example Model: The Magnetic Ball System” on page 1-2

DetailsofPossibleModels

The first step in the linearization or compensator design process is to create

or open a Simulink

inputs and outputs (including none), and any number of states. The model

can include user-defined blocks or S-functions. Your model can involve

multiple compensators in addition to the plant, multiple feedback loops, and

any number of subsystems.

Example Model: The Magnetic Ball System

This section introduces an example model, the magnetic ball system, that the

remaining sections and chapters use to illustrate the process of linearizing a

model or designing a compensator.

®

model of y our system. The model can have any number of

1-2

Magnetic Ball System

The electronic circuit in the following figure consists of a voltage source, a

resistor, and an inductor in the form of a tightly wound coil. An iron ball

beneath the inductor experiences a gravitational force as well as an induced

magnetic force (from the inductor) that opposes the gravitational force.

Page 15

Creating or Opening a Simulink®Model

Model Equations

Adiffer

where M is the mass of the ball, h is the height (position) of the ball, g is the

acceleration due to gravity, i is the current, and β is a constant related to the

magnetic force experienced by the ball. This equation describes the height, h,

of the ball due to the unbalanced forces acting upon it.

The current in the circuit also varies with time and is given by the following

differential equation

ential equation for the force balance on the ball is given by

M

L

2

dh

dt

di

dt

2

Mg

=−

ViR=−

2

i

β

h

1-3

Page 16

1 Working with Simulink

®

Control Design™ Projects

where L is the inductance of the coil, V is the voltage in the circuit, and R is

the resistance of the circuit.

The system of equations has three states:

dh

h

i,,

dt

Thesystemalsohasoneinput(V), and o ne output (h). It is a nonlinear system

duetothetermintheequationinvolvingthesquareofi and the inverse of h.

Due to its nonlinearity, you cannot analyze this system using methods

for linear-time-invariant (LTI) systems such as step response plots, bode

diagrams, and root-locus plots. However, you can linearize the model using

the Simulink

®

Control Design™ software to approximate the nonlinear system

as an LTI system. Linearization also occurs automatically when designing a

compensator. This linearized system can then use the LTI Viewer for display

and analysis and the SISO Design Tool for compensator design. Refer to for a

discussion of the uses of linearized models and “What Is Linearization?” on

page 4-2 for a discussion of the linearization process.

1-4

Opening the Model

To open the model for the magnetic ball example, type

magball

at the MATLAB®prompt. The magnetic ball system opens in the Simulink

model viewer as shown in this figure.

Page 17

Creating or Opening a Simulink®Model

The magball model consists of

• The magnetic ball system itself, within the sub system labeled Magnetic

Ball Plant.

• A Controller subsystem that controls the height of the ball by balancing

the forces acting on it.

• A reference signal that sets the desired height of the ball.

• A

Scope block that displays the height of the ball as a function of time.

Double-click a block to view its contents. The Controller block contains a

zero-pole-gain model. The Magnetic Ball Plant block is shown in this figure.

1-5

Page 18

1 Working with Simulink

®

Control Design™ Projects

1-6

The input to the Magnetic Ball Plant system, which is also the output of the

Controller subsystem, is the voltage, V. The output is the height of the ball,

h. The system contains three states within the three integrators:

dhdt,andCurrent.

Values of the parameters are given a s M=0.1 kg, g=9.81 m /s

height,

2

, R=2 Ohm,

L=0.02 H, and β=0.001.

Page 19

Beginning a Project

In this section...

“Creating a Simulink®Control Design Project” on page 1-7

“Creating an Operating Points Task” on page 1-8

“Creating a Linearization Task” on page 1-8

“Creating a Simulink Compensator Design Task” on page 1-10

Creating a Simulink Control Design Project

With Simulink Co ntrol Design software you can create operating points,

linearize, and design compensators for Simulink models. You perform all

these tasks in a graphical environment called the Control and Estimation

Tools Manager. The tasks are contained within a Control and Estimation

Tools Manager project. Each project is associated with a single Simulink

model and in addition to Simulink Control Design tasks, it can include tasks

from other products such as the Simulink

the Control System Toolbox™ product, and the Model Predictive Control

Toolbox™ product.

Beginning a Project

®

Design Optimization™ product,

To open a new Simulink Control Design project:

1 Select Start > Simulink > Simulink Control Design > Linearization

Task or select Start > Simulink > Simulink Control Design

> Simulink Compensator Design Task.

2 Enter a project name, select a model to analyze, and choose the tasks you

want to perform. Click OK to close the dialog box and open the new project.

Alternatively, you can create a new project from a Simul in k model window.

Within the model window select Tools > Control Design > Linear Analysis

to open a project containing a linearization task, or select Tools > Control

Design > Control Design to open a project containing a compensator design

task.

1-7

Page 20

1 Working with Simulink

®

Control Design™ Projects

Creating an Oper

An Operating Poi

automatically c

Compensator De

create operati

Creating a Lin

To create a li

use one of the

page 1-7 to ope

task for thi

File>New>T

open the New

that you wa

To open a ne

lineariz

Analysis

Manager o

followi

s project. To add a linearization task to an existing project, select

nt to open the task within, and then click OK.

w project within the Control and Estimation Tools Manager for

ation of the magball model, select Tools > Control Design > Linear

from the

pens and creates a new linearization task, as shown in the

ng figure.

nts node in the Control and Estimation Tools Manager is

reated when you begin a Linearization Task or a Simulink

sign Task.YoucanusetheOperating Points node to

ng points for a Simulink model.

earization Task

nearization task in the Control and Estimation Tools Manager,

methods in “Creating a Simulink

n a new project for your model, and choose a linearization

ask in the Control and Estimatio n Tools Manager window to

Task dialog box. Select Linearization Task and the project

magball window. The Control and Estimation Tools

ating Points Task

®

Control D es ign Project” on

1-8

Page 21

Beginning a Project

The left pane of the Control and E stimatio n Tools Manager shows the project

tree, w hich contains all your current projects. At this stage you should have

just one project, Project - magball. Select a node within the tree to display

its contents in the pane on the right.

1-9

Page 22

1 Working with Simulink

®

Control Design™ Projects

View the default operating point

and create new operating points.

Set up the linearization and

inspect theresults listed in

the Linearization Results pane.

Create customized plots of

the linearization results.

• For information on the Operating Points node or the Operating Points

pane w ithin the Linearization Task node, refer to “Creating Operating

Points” on page 2-10.

• For information on the Analysis I/Os pane within the Linearization

Task node, refer to “Selecting Inputs and Outputs for the Linearized

Model” on page 4-45.

1-10

• For information on the Linearization Results pane within the

Linearization Task node and inspecting linearization re sults, refer to

“Viewing Linearization Results” on page 4-66.

• For information on Custom Views, refer to “Viewing Linearization

Results” on page 4-66.

Creating a Simulink Compensator Design Task

To create a Simulink Compensator Design Task in the Control and Estimation

Tools Manager, use one of the methods in “Beginning a Project” on page 1-7 to

open a new project for your model, and choose a compensator design task for

this project. To add a compensator design task to an existing project, select

File>New>Taskin the Control and Estimation Tools Manager window to

open the New Task dialog box. Select Simulink Compensator Design Task

and the project that you want to open the task within, and then click OK.

Page 23

Saving Projects

A Control and Estimation Tools Manager project can consist of multiple tasks

such as linearization, compensator design, and operating points tasks as

well as Simulink Design Optimization tasks and Model Predictive Control

Toolbox tasks. Each task contains data, objects, and results for the analysis

of a particular model.

1 To save a project as a MAT-file, select File > Save from the Control and

Estimation Tools Manager window.

Saving Projects

2 In the Save Projects dialog box, select one or m ore projects you want to

save. Youcansavemultipleprojects in one file. Click OK,andbrowseto

the folder where you want to save the project. Enter the project name,

and click Save.

1-11

Page 24

1 Working with Simulink

®

Control Design™ Projects

Opening Previously Saved Projects

1 To open previously saved projects, select File > Load from the Control and

Estimation Tools Manager window. This opens the Load Projects dialog

box.

1-12

2 Choose a project-file by either brows ing for the folder and file, or typing

the full path and filename in the Load from field. Project files are always

MAT-files. After you specify the file, the projects contained in this file

appear in the list. Select one or more projects in the list, and then click

OK. When a file contains multiple projects, you can choose to load them

all or just a few.

Page 25

Exporting Results

In this section...

“Exporting Linearization Results” on page 1-13

“Exporting Compensator Designs” on page 1-14

“Exporting Operating Points” on page 1-15

“Exporting and Restoring Linearization I/O Settings” on page 1-15

Exporting Linearization Results

To export linearization results and the corresponding operating points,

right-click the results node, Model,undertheLinearization Task node

and select Export fromthemenu. IntheExportToWorkspacedialogbox,

choose new names for the linearized model and operating point, or accept the

defaults, and then click OK.

Exporting Results

The MATLAB workspace now contains two new objects, Model_op and

Model_sys.Toseethis,type

who

at the MATLAB prompt. This returns

Your variables are:

L Model_sys beta m

Model_op R g

Alternatively, you can export the results to the MATLAB workspace by

selecting File > Export from the LTI Viewer window or by clicking the

1-13

Page 26

1 Working with Simulink

®

Control Design™ Projects

Export to Workspace button at the bottom of the L inearization Summary

pane within the Model node.

By right-clicking the results node, Model, you can also de lete results.

Exporting Compensator Designs

To export a compensator design to the MATLAB workspace:

1 Select File > Export from the SISO Design Tool window.

2 In the SISO Tool Export dialog box, use the Select design list to choose

the design y ou want to export.

3 In the list, select the compensators to export, and then click either Export

to Workspace or Export to Disk.

1-14

Page 27

Exporting Results

Exporting Operating Points

After creating operating points, you can use the Export To Workspace dialog

box to export them for use outside of the Control and Estimation Tools

Manager. You can use the exported operating point to perform analysis at the

MATLAB command line or to initialize a model for simulation.

1 Under Select destination workspace, select either

• Base workspace to export the operating point to the MATLAB

workspace where you can use it with Simulink Control Design

command-line functions

• Model workspace to export the operating poin t to the Mo d el workspace

where you can save it with the model for future use.

2 Enter a nam e for the exported operating point.

3 Select Use

to use the o

inputs in

Data Impo

Simulink

Exporti

To expor

getlin

them in

them to

For mo

setli

ng and Restoring Linearization I/O Settings

t linearization I/O settings to the MATLAB workspace, use the

io

function. You can save these settings using the save function. Use

a later session by reloading them with the

the model diagram with the

re information, see the function reference pages for

nio

.

the operating point to initialize model when you want

perating point values as initial conditions for the states and

the model. The initial values are automatically set in the

rt/Export pane of the Configuration Parameters dialog box.

software uses these initial conditions when simulating the model.

load function. Upload

setlinio function.

getlinio and

1-15

Page 28

1 Working with Simulink

®

Control Design™ Projects

1-16

Page 29

Operating Point Analysis Using the GUI

• “What Are Operating Points?” on page 2-2

• “Why Are Operating Points Important?” on page 2-6

• “Ways to Create Operating Points” on page 2-9

• “Creating Operating Points” on page 2-10

• “Working with Operating Points” on page 2-23

2

• “Recommendations for Computing Operating Points” on page 2-31

Page 30

2 Operating Point Analysis Using the GUI

What Are Operating Points?

In this section...

“Definition of an Operating Point” on page 2-2

“Equilibrium Operating Points” on page 2-2

“Simulink Model Operating Points” on page 2-3

Definition of an Operating Point

The operating point of a dynamic system defines its overall state at a given

time. For example, in a model of a car engine, variable s such as engine

speed, throttle angle, engine temperature, and surrounding atmospheric

conditions typically describe the o perating point. It is important to specify

the operating point accurately because it affects the system’s behavior. For

example, the behavior of a car engine can vary greatly when it operates at

high or low elevations.

2-2

Equilibrium Operating Points

An equilibrium operating point remains steady and constant with time; all

states in the model are at equilibrium. It is also known as a steady state or

trimmed operating point. For example, a car operating on cruise control on

a flat road maintains a constant speed. Its operating point is steady, or at

equilibrium.

A hanging pendulum provides an example of a stable equilibrium operating

point. When the pendulum hangs straight down, its position does not change

with time because it is at an equilibrium position. When its position deviates

slightly fro m this position, it always returns to the equilibrium; small changes

in the operating point do not cause the system to leave the region of good

approximation around the equilibrium v alue.

A pendulum that points upward provides an example of an unstable

equilibrium operating point. As long as the pendulum points exactly upward,

it is steady at this equilibrium state. However, when the pendulum deviates

slightly from this state, it swings downward and the operating point leaves

the region around the equilibrium value.

Page 31

What Are Operating Points?

Simulink Model O

This section inc

• “Operating Poi

• “Example of a S

ludes the following topics:

nt Versus Simulink Full-Model Operating Point” on page 2-3

imulink Model Operating Point” on page 2-4

perating Points

Operating Point Versus Simulink Full-Model Operating Point

The Simulink

the b locks in

GUI or the MAT

you are actu

operating p

operating p

The follow

full-mode

Makeup of

Block Types

Blocks

value s

nport blocks with

level i

edatatype

doubl

full model operating point includes information from all of

a Simulink model. When you use the Simulink Control Design

LAB command line to create operating points for a model,

ally creating an operating point object (whatisreferredtoasthe

oint). The operating point is a subset of the Simulink full-model

oint.

ing table shows the different types of blocks that make up a

l operating point and which types are included in the operating point.

Simulink Full-Model Operating Point

Included in

Operating Point?

Yes

with double

tates and root

Example of Block s

Integrator, State Space,

Transfer Function,

Inport

Root level inport blocks

with nondouble or

complex d ata type

Blocks with internal

state representation

that impacts block

outputs

Source blocks with

outputs specified by

block dialog pa r ameters

Inport No

Backlash, Memory,

Stateflow

Constant, Step

No

No

2-3

Page 32

2 Operating Point Analysis Using the GUI

The operating point includes only the block information most comm only

redefined by users. This information provides you with three places to make

changes to the parameters of these common blocks in your model:

• Directly in the Simulink Control De sig n Control and Estimation Tools

Manager GUI

• At the MATLAB command line

• In the Simulink model

Note If you want to m ake changes to any block not included in the operating

point, you must m ake the changes directly in the Simulink model.

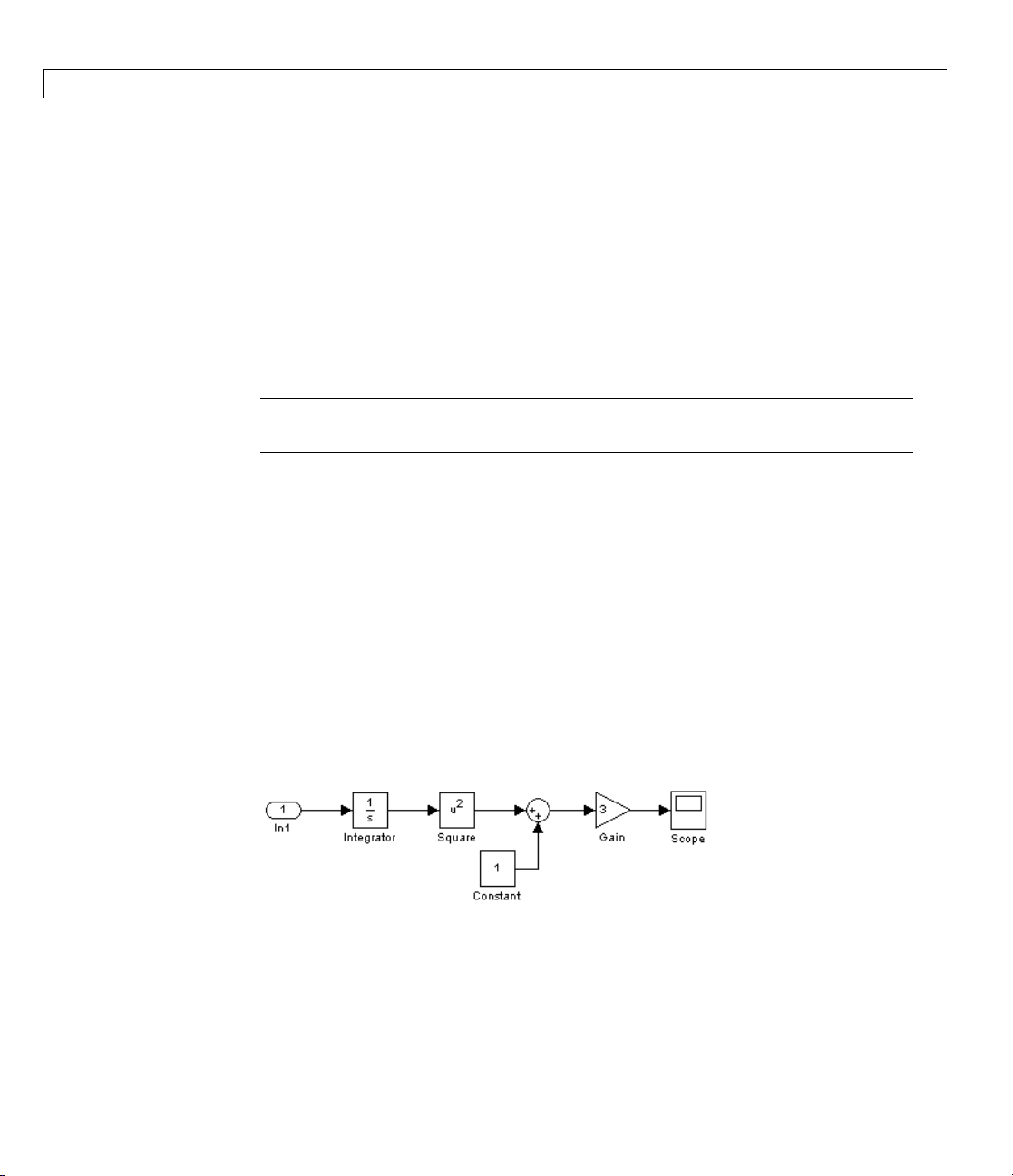

Example of a Simulink Model Operating Point

The following figure shows a simple Simulink model that has one block with

state(theintegratorblock)andthereforeonestate,

on the initial conditions set in the integrator block. The value of this state

and the input from the inport block define the operating point in the Simulink

Control Design software.

x1. This state depends

2-4

The square block output is derived from just the initial condition of the

integrator block while the gain block has its output derived from both the

initial condition of the integrator block and output of the constant block. The

derivative dx/dt of the integrator block state is defined by the output level of

therootinportblock.

tate,

The s

he model by propagating through the blocks in the model as follows.

in t

1 The

x1, defines the signal levels at the input and output of every block

integrator block initial condition of

x0 = 5 sets the state x1=5.

Page 33

What Are Operating Points?

2 The state, x1, propagates in the direction of the arrows through the blocks

in the model, defining input and output signals on each block, as described

in the following table.

Block Input Signal

Level

Square

5

Sum 25 from square,

Block

Operation

squares

sums

Output Signal

Level

25

26

1fromconstant

Gain

26

multiplies by 3

78

The following figure shows these input and output signal levels for each block.

2-5

Page 34

2 Operating Point Analysis Using the GUI

Why Are Operating Points Important?

In this section...

“Impact of Operating Points” on page 2-6

“Choosing an Operating Point for Accurate L inearization” on page 2-7

Impact of Operating Points

A linearized model is an approximation that is valid in a region around the

operating point of the syste m where the linearization took place. Near the

operating point the approximation is good, while far away it may be poor.

A linearized model of a car being operated at 3000 ft. is very accurate at

elevations close to 3000 ft. but less accurate as the car travels higher or lower.

Example of a Linear Approximation of a Nonlinear Function

The following figure shows a nonlinear function,

n,

functio

functio

approxi

is poor

The fol

linearization of

yx=−21

n about the operating point x=1, y=1. Near this operating point, the

mation is good. Away from this operating point, the approximation

. The precise boundaries of this region a re often somewhat arbitrary.

lowing figure shows a possible region of good approximation for the

. The linear function is an approximation to the nonlinear

2

.

yx=

2

yx=

,andalinear

2-6

Page 35

Why Are Operating Points Important?

Choosing an Operating Point for Accurate Linearization

Your choice of operating point is important when you:

• Linearize a Simulink model. The choice of operating point determines the

accuracy of the linear approximation.

• Designing compensators with Simulink Control Design software. A

Compensator Design Task uses linearization when analyzing a Simulink

model.

Tip Choose an operating point that is very close to the expected operating

values of the system. One option is to use an equilibrium operating point,

described in “Equilibrium Operating Points” on page 2-2.

2-7

Page 36

2 Operating Point Analysis Using the GUI

Example of Linearization Results About Two Different

Operating Points

A model can have two entirely different linearizations when the linearization

is performed about different operating points. The following model can be

linearized using the Simulink Control Design software.

The lineari

When this li nearization is performed about two different operating points,

two different linearization results occur as shown in the following table.

Operating Point

Initial Condition = 5, State x1 =5

Initial Condition = 0, State x1 =0

Note The operating point consists of values for all the states in the model,

although only those states between the linearization points are linearized.

The whole model contributes to the operating point values of the states,

inputs, and outputs of the portion of the model you are linearizing.

zation res ult for this model is shown in the following figure.

Linearization Result

30/s

0

2-8

Page 37

Ways to Create Operating Points

You can compute operating points using any technique either:

• Interactively in the GUI

• Programmatically at the command line using MATLAB code

Tip You can automatically generate MATLAB code from your GUI

configuration.

Use the following table to choose a technique for creating operating points.

Ways to Create Operating Points

When you know...

Some values and constraints for

inputs and states

Exact values for all inputs and states

Thetimeoreventinyourmodelto

extractanoperatingpointduring

simulation

Compute ope

from...

Specifications

• GUI

• Command line

Known Values

• GUI

• Command line

Simulation

• GUI

• Command line

rating points

2-9

Page 38

2 Operating Point Analysis Using the GUI

Creating Operating Points

In this section...

“Simulink®Control D esign Default Operating Point” on page 2-10

“Computing Operating Points from Specifications” on page 2-10

“Specifying O perating Points from Known Values” on page 2-15

“Extracting O perati ng Points From Simulation” on page 2-17

“Computing Equilibrium Operating Points” on page 2-22

Simulink Control Design Default Operating Point

A default operating point is automatically created and stored in a node in the

project tree every time you open the Control and Estimation Tools Manag er

unless you indicate otherwise. The default operating point consists of a

snapshot of initial condition variables in the Simulink model. Initial condi tion

variables are a special set of variables that can be set in the Simulink

model. These variable include initial c onditions for blocks with state, such

as the integrator o r state space blocks, and output values of root level inport

blocks. F or more information on setting these variables, see “Importing and

Exporting Data” in the Simulink User’s Guide.

2-10

By clicking on the Default Operating Point node, you can view these values

and modify them for use in a linearization. The output levels for blocks like a

constant block remain defined in the model.

Computing Operating Points from Specifications

You can specify target values or constraints on a subset of the model’s inputs,

outputs, and states. The software uses numerical optimization methods to

determine the full operating poin t based on this partial specification.

This section continues the magball example from “Creating a Linearization

Task” on page 1-8. At this stage in the example, a linearization task has

already been created for the model.

Page 39

Creating Operating Points

You compute the operating point from specifications when you only know

partial or implicit information. Typical operating point specifications search

for steady state or equilibrium operating points.

2-11

Page 40

2 Operating Point Analysis Using the GUI

1 Create a new operating point by either:

• Selecting the Operating Points node and then clicking the Compute

Operating Points tab

• Clicking the New Operating Point button on the Operating Points

pane of the Linearization Task node

2 From the Compute new operating points using li st, select operating

specifications

should now resemble the following figure.

Enter a known value

or an initial guess in

this column

. The Control and Estimation Tools Manager window

Select these check boxes

when a steady-state

Select these check boxes

when the operating point

is known exactly

value is desired.

Enter maximum and

minimum bounds on

operating point values

2-12

Page 41

Creating Operating Points

3 Enter operating point specifications in the table, such as any known values

or constraints on signal values. Switch between states, inputs, and outputs

using the tabs on the left.

A suitable set of specifications for the

magball model is shown in the

following figure. This model does not contain any root-level input or output

ports and, as a result, the Inputs and Outputs panes are empty. You

can still constrain the output signal of any block by adding an Output

Constraint linearizat ion point to the model . See “Constraining Outputs”

on page 2-27 for information about adding an output constraint to the

specifications for an operating point.

The height of the ball is known exactly

(same as the reference signal height).

The ball height is 0.05 (same as the reference signal

value). For a steady ball, use initial guess of 0 for dhdt.

For the remaining states, choose arbitrary initial guesses.

A steady-state operating point

is desired.

Use a minimum value of zero for

the current (by convention

current is positive when flowing

clockwise around the circuit).

2-13

Page 42

2 Operating Point Analysis Using the GUI

When y ou add states, inputs, or outputs to the model, or remove them from

the model, click the Sync with Model button to update the operating

pointtabletoreflectthesechanges.

4 Click Compute Operating Points. The Simulink Control Design software

finds an operating point that closely matches the specifications and adds

the new operating point, labeled Operating Point,totheOperating

Points node. Some specifications, even values specified as Known,may

not be met exactly. Select the operating point in the project tree to view

its contents and assess the results.

Actual dx values are

small, because a

a steady-state

value was found.

2-14

For information on options that you can set when finding operating points

from partial specifications, see “Changing Optimization Settings” on page

2-27.

Page 43

Creating Operating Points

Note Inputs and o utputs for the operating point are not the same as the

linearization input and output points, or analysis I/Os, used to define the

inputs and outputs of the linearized model. Instead, operating-point inputs

and outputs define the full operating point of a Simulink model, along with

any additional, user-defined output constraints.

Tip To automatically generate MATLAB code that computes operating points

as specified in the Control and Estimation Tools Manager, click

or select

File > Generate MATLAB Code.

Specifying Operating Points from Known Values

You can completely specify all inputs and states in the operating point.

This section continues the magball example from “Computing Operating

Points from Specifications” on page 2 -10. At this stage in the example, a

linearization task has already been created for the model, and a steady state

operating point has been computed from specifications.

When you know the values of all states and inputs at the operating p oint,

you can create a new operating point in the Control and Estim a tion Tools

Manager and manually edit the operating point values:

1 Select the Operating Points node in the left pane and then click the

Operating Points tab in the right pane.

2 Click the New button in the bottom-right corner to create a new operating

point under the Operating Points node. This new operating point is

labeled Default Operating Point (2).

2-15

Page 44

2 Operating Point Analysis Using the GUI

3 View the details of DefaultOperatingPoint(2)(shown in the following

figure) by either:

• Selecting it under the Operating Points node in the project tree

• Selecting it in the Operating Points pane of the Linearization Task

node, and then clicking View

Enter known values

of states and inputs

at the operating point.

2-16

4 Edit the operating point by entering new values in the table. Switch

between state and input values using the tabs on the left.

Change the value of State-1 of Integrator to

to

7. The model does not contain any root-level input ports, and, as a result,

-14 and the value of Current

the Inputs pane is empty.

When y ou add states, inputs, or outputs to the model, or remove them from

the model, click the Sync with Model button to update the operating

pointtabletoreflectthesechanges.

Page 45

Creating Operating Points

5 Rename the operating point by right-clicking Default Operating Point

(2) under the Operating Points node, selecting Rename, and entering a

new name in the dialog box.

For example, label this operating condition

Thepaneshouldnowresemblethefollowingfigure.

Known Operating Conditions.

o automatically generate MATLAB code that computes operating points

Tip T

as specified in the Control and Estimation Tools Manager, click

File > Generate MATLAB Code.

or select

Extracting Operating Points From Simulation

You can create an operating point from a simulation of your model a t the

following simulation points:

2-17

Page 46

2 Operating Point Analysis Using the GUI

• Specified simulation times, such as when the simulation reaches a steady

state solution (see “Creating Operating Points at Specified Simulations

Times” on page 2-18example in this section).

• Events during a specified simulation interval (see “Creating Operating

Points at Simulation Events” on page 2-21)

CreatingOperatingPointsatSpecifiedSimulationsTimes

Youcanextractanoperatingpointatspecifiedtimesduringasimulation

of the model.

This section continues the magball example from “Specifying Operating

Points from Known Values” on page 2-15. A t this stage in the example,

a linearization task has already been created for the model, a steady state

operating point has been computed from specifications, and a completely

known operating point has been specified.

To create operating points at specified simulation times:

2-18

1 Open the Compute Operating Points tab by either:

• Selecting the Operating Points node in the project tree, and then

clicking the Compute Operating Points tab

• Clicking the New Operating Point button on the Operating Points

pane of the Linearization Task node

Page 47

Creating Operating Points

2 From the Compute new operating points using list, select simulation

snapshots

. The window sho u ld now resemble the following figure.

3 Enter a vector of times in the Simulation snapshot times (sec) field.

Enter

[1,10] to compute operating points at t=1 and t=10.

4 Click Compute Operating Points. The Simulink Control Design software

simulates the model, extracts operating points, labeled Operating Point

2-19

Page 48

2 Operating Point Analysis Using the GUI

at t=1 and Operating Point at t=10, and adds them to the Operating

Points node in the project tree.

To view the contents of the operating point you created, select the operating

point in the project tree as shown in this figure.

2-20

Note W

them

oper

To automatically generate MATLAB code that computes operating points

Tip

as specified in the Control and Estimation Tools Manager, click

File > Generate MATLAB Code.

hen you add states, inputs, or outputs to the model, or remove

from the model, click the Sync with Model button to update the

ating point table to reflect these changes.

or select

Page 49

Creating Operating Points

CreatingOperatingPointsatSimulationEvents

You can create an operating point from a simulation of your model at one or

more of the following simulation events:

• Trigger-based events

• Function-call events

For more information about modeling events in Simulink models, see

“Creating Conditional Subsystems” in the Simulink User’s Guide.

The Simulink Control Design software creates operating points at all

simulation events within a specified simulation time.

Tocreateoperatingpointsatoneormoresimulationevents:

1 AddaTrigger-BasedOperatingPoint Snapshot block to your model. This

block is in the Simulink Control Design block library.

The model in the Trigger-Based O perating Point Snapshot demo shows

the use of this block.

2 Select the Compute Operating Points tab in the Operating Points

node.

3 From the Compute new operating points using list, select simulation

snapshots

4 Enter a scalar value that specifies the simulation end time in the

.

Simulation snapshot times (sec.) field, shown in the following figure.

2-21

Page 50

2 Operating Point Analysis Using the GUI

2-22

5 Click Compute Operating Points. The software simulates the model,

extracts operating points, and adds them to the Operating Points node in

the project tree. Select an o perating point to view its contents and assess

the results.

Computing Equilibrium Operating Points

You can use the software to compute equilibrium operating points. Follow

the basic instructions in “Computing Operating Points from Specifications”

on page 2-10. When you enter specifications in the States pane, select the

Steady State check box at the top of the table. Selecting this check box

causes the algorithm to look for an operating point in which all states are at

equilibrium, or steady state.

Page 51

Working with Operating Points

In this section...

“Copying Operating Points” on page 2-23

“Exporting Operating Points” on page 2-24

“Saving Operating Poin ts” on page 2-25

“Importing Operating Points” on page 2-25

“Importing Initial Values” on page 2-26

“Constraining Outputs” on page 2-27

“Changing Optimization Settings” on page 2-27

Copying Operating Points

In some situations you might want to create and edit a copy of an operating

point. To create a copy of an operating point, right-click the operating point

in the tree on the left, and select Duplicate from the right-click menu, as

shown in the following figure.

Working with Operating Points

The new operating point appears beneath the original one in the tree. Click

the new operating point to display i ts contents in the pane on the right. To

change state or input values in the duplicated operating point, edit the values

in the right pane. To change the name of the new operating point, right-click

the operating point in the tree, select Rename from the right-click menu, and

then enter a new name for the operating point.

2-23

Page 52

2 Operating Point Analysis Using the GUI

Note that you cannot copy operating points that were computed from

specifications. These operating points contain information related to the

success of the optimization which would not be meaningful when the operating

point values were changed.

Exporting Operating Points

After creating operating points using the Simulink Control Design software,

you can export them from the Control and Estimation Tools Manager to

the MATLAB workspace or the model workspace. You can use an exported

operating point to perform analysis at the MATLAB command line or to

initialize a Simulink model for simulation. To export an operating point,

right-click the operating point under Operating Points in the pane on the

left and select Export to Workspace. This opens the Export to Workspace

dialog box, as shown below:

2-24

1 Click either

• Base Workspace to export the operating point to the MATLAB

workspace where you can use it with Simulink Control Design

command-line functions

• Model Workspace to export the operating point to the Model workspace

where you can save it with the model for future use.

2 Enter a nam e for the exported operating point.

Page 53

Working with Operating Points

3 Select Use the operating point to initialize model when you want

to use the operating point values as initial conditions for the states and

inputs in the model. The initial values are automaticall y set in the Data

Import/Export pane of the Configuration Parameters dialog box and

Simulink uses these initial conditions when simulating the model.

Saving Operating Points

After you have exported the operating point to the MATLAB workspace,

you can save it in a MAT-file for later use. To save the operating point

Operating_Point in a file named magball_operating_points.mat,enter

the following command:

save magball_operating_point Operating_Point

Importing Operating Points

This section continues the example from “Example Model: The Magnetic Ball

System”onpage1-2. Atthisstageinthe example, a linearization project

has already been created for the model, and linearization points have been

inserted, and operating points have been created from specifications, known

values, and simulation.

To import operating points from the MATLAB workspace or from a MAT-file.

1 To import a new operating point, select the Operating Points node in the

project tree and then select the Operating Points tab on the right. Click

the Im port button at the bottom of the pane. This displays the Operating

Point Import dialog box.

2-25

Page 54

2 Operating Point Analysis Using the GUI

2 Click Workspace or MAT-file as the location to import the operating point

from, select an operating point from the list below, and then click Import.

For this example, two operating points are loaded into the MA TLAB

workspace when you open the magball model.

2-26

Importing Initial Values

When you want populate the Value column of the operating point

specifications by importing initial or known values from another operating

point, a Simulink states structure, o r a vector of values, click the Import

Initial Values button at the bottom of the window. The Operating Point

Import dialog box opens, as shown below.

Page 55

Working with Operating Points

Select where to import th e initial values from (a project, the workspace, or a

file), then select the operating point from the list of available operating points

below ( or in the case of MAT-files, browse for a file). Click Import to import

the initial values from the selected operating point into the Value column

of the operating point specifications.

Constraining Outputs

Operating specifications often includeconstraintsonthevaluesofspecific

signalsinthemodel. Toconstrainoutput signals when determining operating

points from specifications, add an output constraint annotation to the model

by right-clicking the signal line and choosing Output Constraint from the

menu. This adds a small T to the signal line. Then, within the Outputs pane

of the Compute Operating Points pane, select the Known check box and

enter desired values as well as minimum and maximum values for this signal.

Changing Optimization Settings

To change the settings used when determining operating points by

optimization, select Tools > Options and then click the Operating Point

Search tab. This opens the Options dialog box.

2-27

Page 56

2 Operating Point Analysis Using the GUI

2-28

To get help on each option or setting in the Options dialog box, right-click an

option’s label and select What’s This?.

Additionally, you can r efer to the Optimization Toolbox™ documentation and

the

linoptions reference page for more information about these settings. If

youdonothavetheOptimizationToolbox documentation you can find it at

http://www.mathworks.com/access/helpdesk/help/toolbox/optim/optim.shtml

The methods Gradient descent with elimination, Simplex search,and

Nonlinear least squares refer to the optim ization methods fmincon,

fminsearch,andlsqnonlin respectively. The method Gradient descent

Page 57

Working with Operating Points

refers to the optimization method graddescent, described in the linoptions

reference page. The reference page for the Optimization Toolbox function

optimset contains documentation for the following operating point search

settings (the corresponding

optimset parameter values are given in

parentheses):

Operating Point Search Option

Large Scale

Medium Scale

Maximum change

Minimum change

Function tolerance

Constraint tolerance

Maximum fun evals

Maximum iterations

Parameter tolerance

Enable analytic jacobian

Parameter in

LargeScale set to 'on'

LargeScale set to 'off'

DiffMaxChange

DiffMinChange

TolFun

TolCon

MaxFunEvals

MaxIter

TolX

Jacobian.

optimset

When this option is selected, the

Jacobian is computed at each

iteration by linearizing the model

about the current operating point.

This option does not work with

models that contain references to

other models using the Model block

or with models from products based

on the Simscape™ platform that are

in Trimming mode.

Display results

Display information contained in the

output variable of the optimization

functions, such as number of

iterations, stepsize, etc.

2-29

Page 58

2 Operating Point Analysis Using the GUI

2-30

Page 59

Recommendations for Computing Operating Points

Recommendations for Computing Operating Points

In this section...

“How to Create Accurate Operating Points” on page 2-31

“Impact of Blocks on the Simulink Model Operating Point” on page 2-31

“Computing Operating Points for SimMechanics Mo de ls” on page 2-36

“Choosing Initial Values for Computing Operating Points” on page 2-37

“Computing Operating Points for Blocks with Special Behavior” on page

2-38

How to Create Accurate Operating Points

Particular Simulink blocks and modeling situations can sometimes cause

difficulties with computing operating points (trimming). However, by

understanding what it means to trim a Simulink model and by using the

correct modeling techniques, you can create accurate operating points for

use in further analysis and design.

This section consists of examples that highlight modeling situations that can

lead to problems when computing operating points, with recommendations

for ways to avoid these situations.

Impact of Blocks on the Simulink Model Operating Point

The full operating point in a Simulink model is specified in a number of ways

by the blocks in the model:

• Integrator, State Space, and Transfer Function blocks have their outputs

defined by double-valued discrete states.

• Source blocks such as Constant or Step blocks have their output specified

by their block dialog parameters.

• Blocks such as Backlash, Memory, and Stateflow blocks have an internal

state representation that impacts block outputs.

2-31

Page 60

2 Operating Point Analysis Using the GUI

It is important to understand the impact of the blocks on the full operating

point of your Simulink model. In particular, blocks with internal state

representation can have a profound impact when you search for operating

points or linearize a Simulink model. For more information on which blocks’

states are included in an operating point versus a full model operating point,

see “Simulink Model Operating Points” on page 2-3.

Example of the Impact of Blocks w ith Internal States

The following simple Simulink model shows the impact of blocks with internal

states on the full operating point of a Simulink model. Each Backlash block

has internal states that are initialized by the Initial output block dialog

parameter.

2-32

The operating point for this model in the Simulink Control Design software

does not include the backlash block states that exist in the model. See the

following table for a comparison.

States

Full model operating

point

Operating point

In this case, the value specified for the root level input is not propagated

through the full model. However, the initial output for the Backlash1 b lock is

propagated through the model.

When you linearize this model, the linearization is performed around the

full model operating point, which includes the two states. For the input and

2

0

Inputs

1

1

Page 61

Recommendations for Computing Operating Points

output points specified in this model, the second backlash block is not in the

linearization path and thus its state does not impact the linearization result.

TypesofBlockswithInternalStates

Blocks with internal states that cannot be seen by the operating point object

include:

• Action Subsystem blocks which are not enabled

• Backlash block

• Embedded MATLAB Function block with persistent data

• Transport Delay and Variable Transport Delay blocks

• Memory block

• Rate Transition block

®

• Stateflow

• S-Function blocks with states not registered as Continuous or Double

Value Discrete

blocks

Finding Blocks with Internal States in Your Model

To determine when your model contains any of these blocks with internal

states, run the following command:

sldiagnostics('modelname','CountBlocks')

This command returns a list of all the blocks in the model and the number of

occurrences of each.

Working with Models Containing Blocks with Internal States

The following techniques provide strategies for working with models

containing blocks with internal states:

• Block specific techniques

• Removing, replacing blocks, or both

• Linearizing at steady state using linearization snapshots

2-33

Page 62

2 Operating Point Analysis Using the GUI

Block specific techniques exist for accurately computing operating points and

linearizing m odels that contain the following blocks with internal states:

• “Memory Blocks” on page 2-34

• “Transport Delay and Variable Transport Delay Blocks” on page 2-36

• “Backlash Block” on page 2-36

For other blocks with internal states, you should consider their impact on the

analysis tools in the Simulink Control Design software in the following ways:

• When searching for an operating point you should determine if the output

of the block impacts any of the state derivatives or desired output levels.

• When linearizing a model you should ascertain the effects on the model

operating point. In particular, you should determine the effect on blocks

between linearization input and output points.

If the block does have impact, consider replacing it using a configurable

subsystem when searching for an operating point and linearizing.

2-34

In many cases, performing a linearization using linearization snapshots

avoids the challenges associated with blocks with internal states. You

can linearize your model at steady state using linearization snapshots as

described in “Linearizing at Specified Simulation Times” on page 4-61 and

“Linearizing at Simulation Events” o n page 4-63.

Memory Blocks. When you have Memory blocks in your model, y ou can

configure the block to use a steady state output value when using the

Simulink Control Design software. The model

illustrates this issue.

delayex.mdl,shownbelow,

Page 63

Recommendations for Computing Operating Points

In this model the Memory block is configured in the block dialog to have an

initial output of 0 but is driven by a Constant block with an output of 1. This

causes the output signal of the block to be 0 in the operating point. However,

in the steady-state operating point for this model, the output of the Memory

block is 1. When searching for an operating point or when linearizing a model

at a steady state condition, select the Direct feedthrough of input during

linearization option in the block dialog. This will force the output of the

Memory block to be the same as the input during operating point searches

or linearization.

2-35

Page 64

2 Operating Point Analysis Using the GUI

2-36

Transport Delay and Variable Transport Delay Blocks. When you have

Transport Delay or Variable Transport Delay blocks in your model, you

can properly configure the initial outputs of these blocks so that operating

point searches or linearization uses the correct output value at steady state

condition. The discussion in “Memory Blocks” on page 2-34 applies to

configuring the initial outputs of the Transport Delay and Variable Transport

Delay blocks.

Backlash Block. The initial output and the output at the steady-state

operating point of the Backlash block do not always match. There is no way

to force the output of the Backlash block to be the same as the input during

operating point searches or linearization. Extra care should be taken when

working with a model containing Backlash blocks.

Computing Operating Points for SimMechanics Models

When computing operating points (trimming) for a SimMechanics™ model,

youfirstneedtoputitintrimmingmode. Todothis:

Page 65

Recommendations for Computing Operating Points

1 Locate and open the machine environment (Env) block for the system.

2 From the Parameters pane, set Analysis mode to Trimming.ClickOK to

close the block dialog box. This will create an output port in the model that

contains constraints related to errors in the system that must be set to zero

for a steady state operating point.

3 To set these constraints to zero within a project for the model in the Control

and Estimation Tools Manager, select Operating Points in the pane on

the left, and then select Compute Operating Points > Outputs.Within

this pane, set all constraints to

0.

At this point you can enter other design specifications on the states and inputs,

and then compute an operating point for your model. After you have finished

computing operating points for the SimMechanics model, make sure that you

reset the Analysis mode to

Forward dynamics in the Env block dialog box.

Choosing Initial Values for Computing Operating Points

When you compute an operating point from design specifications (trimming),

it is often important to begin with a set of state and input values that are

close to the actual steady state operating point values that you are trying

to compute. To do this you can simulate the model for a specified period of

time and then take a snapshot of the state and input values at that time.

You can do this using either the Control and Estimation Tools Manager

(see “Extracting Operating Points From Simulation” on page 2-17for more

information) or using the

Simulation” on page 3-16 for more information).

findop function (see “Extracting Values from

You can then use the values from the simulation snapshot as initial values for

an operating point that you compute from specifications using optimization

methods. To initialize the operating point specifications using these snapshot

values, click the Import Initial Values buttonintheCompute Operating

Points pane of the Control and Estimation Tools Manager, or use the

initopspec function. For more information, see “Importing Operating

Points” on page 2-25.

2-37

Page 66

2 Operating Point Analysis Using the GUI

Computing Operating Points for Blocks with Special Behavior

Blocks such as Memory, Transport Delay, and Variable Transport Delay

have states that cannot be optimized when com puting operating points from

specifications. In ad di tion they do not have dire ct feedthrough as the input to

the block at the current time does not determine the output of the block at the

current tim e. This can cause problems when you determine operating points

from specifications or create linearized models. To avoid these proble ms,

select the Direct feedthrough of input during linearization option in

the Block Parameters dialog box for the block in question (such as a Memory

block) when determin in g operating points from specification s or linearizing

models. Thisforcestheinputtofeed through to the o utput, as if the system

were operating at steady-state, and removes the problems associated with the

states that cannot be used to compute operating points.

2-38

Page 67

Operating Point Analysis Using the Command Line

• “Overview” on page 3-2

• “Example: Water-Tank System” on page 3-3

• “Creating or Opening a Simulink Model” on page 3-5

• “Computing Operating Points from Specifications” on page 3-7

• “Specifying Completely Know n Operating Points” on page 3-14

3

• “Extracting Values from Simulation” on page 3-16

• “Using Structures and Vectors of Operating Point Values” on page 3-17

Page 68

3 Operating Point Analysis Using the Command Line

Overview

This section describes how to specify operating points for a model using

functions in the MATLAB comm and window. Use the functions when you

want to create code files to automate the linearization process, or when

you want to use an operating point to initialize a Simulink model. For a

description of how to use the graphical interface for this task, see Chapter 2,

“Operating Point Analysis Using the GUI”.

Before linearizing the model, you must choose an operating point to linearize

the system a bout. This is often a steady-state value. Refer to “Why Are

Operating Points Important?” on page 2-6 for more information on the role

of operating points in linearization.

Use the Simulink Control Design functions for any of the following methods of

specifying the operating point:

• You do not know all the input and state values, but you can characterize

the operating point indirectly by specifying operating point values and

constraints for specific signals and variables in the model (implicit

specification).

3-2

• You know the operating point explicitly, i.e., you know the values of all

inputs and states in the model.

• Youwanttosimulatethemodelandextract the operating point at a given

time.

Note The operating point consists of values for all the states in the

model although only those states between the linearization points will be

linearized. This is because the whole model contributes to the operating

point values of the states/inputs/outputs of the portion of the model you

are linearizing.

Page 69

Example: Water-Tank System

aH

In this section...

“Water-Tank System” on page 3-3

“Model Equations” on page 3-4

Water-Tank System

This section introduces an example that continues throughout the remaining

sections of this chapter. By following this example, you will learn the process

of linearizing a model using Simulink Control Design functions.

Water enters a tank from the top and leaves through an orifice in its base.

The rate that water enters is proportional to the voltage, V, applied to the

pump. The rate that water leaves is proportional to the square root of the

height of water in the tank.