Page 1

Simulink

®

7

Graphical User Interface

Page 2

How to Contact The MathWorks

www.mathworks.

comp.soft-sys.matlab Newsgroup

www.mathworks.com/contact_TS.html T echnical Support

suggest@mathworks.com Product enhancement suggestions

bugs@mathwo

doc@mathworks.com Documentation error reports

service@mathworks.com Order status, license renewals, passcodes

info@mathwo

com

rks.com

rks.com

Web

Bug reports

Sales, prici

ng, and general information

508-647-7000 (Phone)

508-647-7001 (Fax)

The MathWorks, Inc.

3 Apple Hill Drive

Natick, MA 01760-2098

For contact information about worldwide offices, see the MathWorks Web site.

®

Simulink

© COPYRIGHT 1990–20 10 by The MathWorks, Inc.

The software described in this document is furnished under a license agreement. The software may be used

or copied only under the terms of the license agreement. No part of this manual may be photocopied or

reproduced in any form without prior written consent from The MathW orks, Inc.

FEDERAL ACQUISITION: This provision applies to all acquisitions of the Program and Documentation

by, for, or through the federal government of the United States. By accepting delivery of the Program

or Documentation, the government hereby agrees that this software or documentation qualifies as

commercial computer software or commercial computer software documentation as such terms are used

or defined in FAR 12.212, DFARS Part 227.72, and DFARS 252.227-7014. Accordingly, the terms and

conditions of this Agreement and only those rights specified in this Agreement, shall pertain to and govern

theuse,modification,reproduction,release,performance,display,anddisclosureoftheProgramand

Documentation by the federal government (or other entity acquiring for or through the federal government)

and shall supersede any conflicting contractual terms or conditions. If this License fails to meet the

government’s needs or is inconsistent in any respect with federal procurement law, the government agrees

to return the Program and Docu mentation, unused, to The MathWorks, Inc.

Trademarks

MATLAB and Simulink are registered trademarks of The MathWorks, Inc. See

www.mathworks.com/trademarks for a list of additional trademarks. Other product or brand

names may be trademarks or registered trademarks of their respective holders.

Patents

The MathWorks products are protected by one or more U.S. patents. Please see

www.mathworks.com/patents for more information.

Graphical User Interface

Page 3

Revision History

September 2007 Online only New for Simulink 7.0 (Release 2007b)

March 2008 Online only Revised for Simulink 7.1 (Release 2008a)

October 2008 Online only Revised for Simulink 7.2 (Release 2008b)

March 2009 Online only Revised for Simulink 7.3 (Release 2009a)

September 2009 Online only Revised for Simulink 7.4 (Release 2009b)

March 2010 Online only Revised for Simulink 7.5 (Release 2010a)

Page 4

Page 5

Configuration Parameters Dialog Box

• “Configuration Parameters Dialog Box Overview” on page 1-2

• “Model Configuration Pane” on page 1-5

• “Solver Pane” on page 1-8

• “Data Import/Export Pane” on page 1-77

• “Optimization Pane” on page 1-114

1

• “Diagnostics Pane: Solver” on page 1-190

• “Diagnostics Pane: Sample Time” on page 1-216

• “Diagnostics Pane: Data Validity” on page 1-232

• “Diagnostics Pane: Type Conversion” on page 1-287

• “Diagnostics Pane: Connectivity” on page 1-300

• “Diagnostics Pane: Compatibility” on page 1-329

• “Diagnostics Pane: Model Referencing” on page 1-333

• “Diagnostics Pane: Saving” on page 1-347

• “Hardware Implementation Pane” on page 1-353

• “Model Referencing Pane” on page 1-418

• “Simulation Target Pane: General” on page 1-442

• “Simulation Target Pane: Symbols” on page 1-458

• “Simulation Target Pane: Custom Code” on page 1-462

Page 6

1 Configuration Parameters Dialog Box

Configuration Parameters Dialog Box Overview

The Configuration Parameters dialog box specifies the setting s for a

model’s active configuration set. These parameters determine the type of

solver use d, import and export settings, and other values that determine how

the m odel runs. See Configuration Sets for more information.

Note YoucanalsousetheModelExplorertomodifysettingsfortheactive

configuration set or any other configuration set. See “The M odel Explorer:

Overview” for more information.

To display the dialog box, select Simulation > Configuration Parameters

in the Model Editor, or press Ctrl+E. The dialog box appears.

1-2

Page 7

Configuration Parameters Dialog Box Overview

The dialog box groups the configuration parameters into various categories.

To display the parameters for a specific category, click the category in the

Select tree on the left side of the dialog box.

In most cases, Simulink

®

software does not apply changes until you click OK

or Apply at the bottom of th e dialog box. The OK button applies your changes

and dismisses the dialog box. The Apply button applies your changes but

leaves the dialog box open.

1-3

Page 8

1 Configuration Parameters Dialog Box

Note Each of the parameters in the Configuration Parameters dialog box

canalsobesetviathe

the corresponding command line information.

sim comm and. Each parameter description includes

1-4

Page 9

Model Configuration Pane

In this section...

“Model Configuration Overview” on page 1-5

“Name” on page 1-6

“Description” on page 1-7

Model Configuration Overview

View or edit the name and description of your configuration set.

In the Model Explorer you can edit the name and description of your

configuration sets.

In the Model Explorer or Simulink Preferences window you can edit

the description of your template configuration set, Model Configuration

Preferences. Go to the Model Configuration Preferences to edit the template

Configuration Parameters to be used as defaults for new models.

Model Configuration Pane

When editing the Model Configuration preferences, you can click Restore

to Default Preferences to restore the default configuration settings for

creating new models. These underlying defaults cannot be changed.

1-5

Page 10

1 Configuration Parameters Dialog Box

Name

Specify the name of your configuration set.

Settings

Default: Configuration (for Active configuration set) or Configuration

Preferences

Edit the name of your configuration set.

In the Model Configuration Preferences, the name of the default configu r a t ion

is always Configuration Preferences, and cannot be changed.

(for default configuration set).

1-6

Page 11

Description

Specify a description of your configuration set.

Settings

No Default

Enter text to describe your configuration set.

Model Configuration Pane

1-7

Page 12

1 Configuration Parameters Dialog Box

Solver Pane

1-8

In this section...

“Solver Overview” on page 1-10

“Start time” on page 1-12

“Stop time” on page 1-14

“Type” on page 1-16

“Solver” on page 1-19

“Max Step Size” on page 1-27

“Initial Step Size” on page 1-29

“Min Step Size” on page 1-31

“Relative tolerance” on page 1-33

“Absolute tolerance” o n page 1-35

“Maximum order” on page 1-38

“Solver reset method” on page 1-40

Page 13

In this section...

“Number of consecutive min steps” on page 1-42

“Number of consecutive min steps” on page 1-43

“Solver Jacobian Method” on page 1-45

“Tasking mode for periodic sample times” on page 1-47

“Automatically handle rate transition for data transfer” on page 1-49

“Deterministic data transfer” on page 1-51

“Higher priority value indicates h igher t a sk priority” on page 1-53

“Zero-crossing control” on page 1-55

“Time tolerance” on page 1-57

“Number of consecutive zero crossings” on page 1-59

“Algorithm” on page 1-61

“Signal threshold” on page 1-63

Solver Pane

“Periodic s ample time constraint” on page 1-65

“Fixed-step size (fundamental sample time)” on page 1-68

“Sample time properties” on page 1-70

“Extrapolation order” on page 1-73

“Number Newton’s iterations” on page 1-75

1-9

Page 14

1 Configuration Parameters Dialog Box

Solver Overview

Specify the simu

the simulation.

configuration

lation start and stop time, and the solver configuration for

Use the Sol ver pane to set up a solver for a model’s active

set.

A solver compu

specified tim

tes a dynamic system’s states atsuccessivetimestepsovera

e span, using information provided by the model.

Configuration

1 Select a solver type from the Type list.

2 Select a solver from the Solver list.

3 Set the par

4 Apply the changes.

ameters displayed for the selected type and solver combination.

Tips

• Simulation time is not the same as clock time. For example, running

a simulation for 10 seconds u sually does not take 10 seconds. Total

simulation time depends on factors such as model complexity, solver step

sizes, and computer speed.

•

Fixed-step solver type is required for code generation, unless you use an

S-function or RSim target.

•

Variable-step solver type can significantly shorten the time required

to simulate models in wh ich states change rapidly or which contain

discontinuities.

1-10

See A

• Sol

• Cho

• Spe

lso

vers

osing a Solver

cifying a Simulation Start and Stop Time

Page 15

• Configuration Parameters Dialog Box

• Solver Pane

Solver Pane

1-11

Page 16

1 Configuration Parameters Dialog Box

Start time

Specify the start time for the simulation or generated code as a

double-precision value, scaled to seconds.

Settings

Default: 0.0

• A start time other than 0.0 is an offset, and must be less than or equal to

the stop time. An example of when you migh t use an offset is to set up a

delay to accommo da te some type of initialization.

• The values of block parameters with initial conditions must match the

initial condition settings at the specified start time.

• Simulation time is not the same as clock time. For example, running

a simulation for 10 seconds u sually does not take 10 seconds. Total

simulation time depends on factors such as model complexity, solver step

sizes, and computer speed.

1-12

Command-Line Information

Parameter: StartTime

Type: string

Value: a

Default:

ny valid value

'0.0'

Recommended Settings

cation

Appli

Debugging No impact

Traceability No impact

Efficiency

Safety precaution

Setting

mpact

No i

0.0

Page 17

See Also

• Specifying a Simulation Start and Stop Time

• Configuration Parameters Dialog Box

• Solver Pane

Solver Pane

1-13

Page 18

1 Configuration Parameters Dialog Box

Stop time

Specify the stop time for the simulation or generated code as a double-precision

value, scaled to seconds.

Settings

Default: 10

• Stop time must be greater than or equal to the start time.

• Specify

pause or stop it.

• If the stop time is the same as the start time, the simulation or generated

program runs for one step.

• Simulation time is not the same as clock time. For example, running

a simulation for 10 seconds u sually does not take 10 seconds. Total

simulation time depends on factors such as model complexity, solver step

sizes, and computer speed.

• If your model includes blocks that depend on absolute time and you are

creating a design that runs indefinitely, see Blocks That Depend on

Absolute Time.

inf to run a simulation or generated program until you explicitly

Command-Line Information

Parameter: StopTime

Type: string

Value: any valid value

Default:

'10.0'

Recommended Settings

Application

Setting

1-14

Debugging No impact

Traceability No impact

Efficiency

Safety precaution Any positive value

No impact

Page 19

See Also

• Blocks That Depend on Absolute Time

• Using Blocks to Stop or Pause a Simulation

• Specifying a Simulation Start and Stop Time

• Configuration Parameters Dialog Box

• Solver Pane

Solver Pane

1-15

Page 20

1 Configuration Parameters Dialog Box

Type

Selectthetypeofsolveryouwanttousetosimulateyourmodel.

Settings

Default: Variable-step

Variable-step

Step size varies from step to step, depending on model dynamics. A

variable-step solver:

• Reduces step size when model states change rapidly, to maintain

accuracy.

• Increases step size when model states change slowly, to avoid

unnecessary steps.

Variable-step is recommended for models in which states change

rapidly or that contain discontinuities. In these cases, a variable-step

solver requires fewer time steps than a fixed-step solver to achieve a

comparable level of accuracy. This can significantl y shorten simulation

time.

1-16

Fixed-step

Step size remains constant throughout the simulation.

Required for code generation, unless you use an S-function or RSim

target.

Note The solv er computes the next time as the sum of the current time and

the step size.

Dependencies

Selecting Variable-step enables the following parameters:

• Solver

• Max step size

• Min step size

Page 21

• Initial step size

• Relative tolerance

• Absolute tolerance

• Shape preservation

• Initial step size

• Number of consecutive min steps

• Zero-crossing control

• Time tolerance

• Number of consecutive zero crossings

• Algorithm

Solver Pane

Selecting

Fixed-step enables the following parameters:

• Solver

• Periodic sample time constraint

• Fixed-step size (fundamental sample time)

• Tasking mode for periodic sample times

• Higher priority value indicates higher task priority

• Automatically handle rate transitions for data transfers

Command-Line Information

Parameter: SolverType

Type: string

Value:

Default: 'Variable-step'

'Variable-step' | 'Fixed-step'

1-17

Page 22

1 Configuration Parameters Dialog Box

Recommended Settings

Application

Debugging No impact

Traceability No impact

Efficiency

Safety precaution

Setting

No impact

Fixed-step

See Also

• Solvers

• Choosing a Solver

• “Purely Discrete Systems”

• Configuration Parameters Dialog Box

• Solver Pane

1-18

Page 23

Solver

Select the solve

simulation or co

Settings

The available

solvers chang e depending on which solv er Type you selected:

Solver Pane

r you want to use to compute the model’s states during

de generation.

• “Fixed-step

• “Variable-s

Fixed-step

ode3 (Bogac

Computes t

of the curr

Bogacki-S

derivati

derivati

X(n+1) = X(n) + h * DX(n)

Discret

e (no continuous states)

Compute

to the c

Use thi

step size. Relies on the model’s blocks to update discrete states.

fixed

The ac

ize of the steps taken by the simulation: the smaller the step size,

the s

ore accurate the results but the longer the simulation takes.

the m

Solvers” on page 1-19

tep Solvers” on p age 1-21

Solvers. Default:

ki-Shampine)

ode3 (Bogacki-Shampine)

he model’s state at the next time step as an explicit function

ent value of the state and the state derivatives, using the

hampine Formula integration technique to compute the state

ves. In the following example,

ve, and

h is the step size:

X is the state, DX is the state

s the time of the n ext time step by adding a fixed step size

urrent time.

s solver for models with no states or discrete states only, using a

curacy and length of time of the resulting simulation depends on

e Thefixed-stepdiscretesolvercannotbeusedtosimulatemodels

Not

t have continuous states.

tha

1-19

Page 24

1 Configuration Parameters Dialog Box

ode5 (Dormand-Prince)

Computes the model’s state at the next time step as an explicit function

of the current value of the state and the state derivatives. Uses the

Dormand-Prince Formula integration technique to compute the state

derivatives. In the following example,

derivative, and

X(n+1) = X(n) + h * DX(n)

ode4 (Runge-Kutta)

Uses the Fourth-Order Runge-Kutta (RK4) Formula integration

technique to compute the model’s state at the next time step as

an explicit function of the current value of the state and the state

derivatives. In the following example,

derivative, and

X(n+1) = X(n) + h * DX(n)

ode2 (Heun)

Uses the Heun’s Method integration technique to compute the model’s

state at the next time step as an explicit function of the current value of

the state and the state derivatives. In the following example,

state,

X is the state, DX is the state

h is the step size:

X is the state, DX is the state

h is the step size:

X is the

DX is the state derivative, and h is the step size:

1-20

X(n+1) = X(n) + h * DX(n)

ode1 (Euler)

Uses the Euler’s Method integration technique to computes the model’s

state at the next time step as an explicit function of the current value of

the state and the state derivatives. In the following example,

state,

DX is the state derivative, and h is the step size:

X(n+1) = X(n) + h * DX(n)

ode14x (extrapolation)

Uses a combination of Newton’s method and extrapolation from the

currentvaluetocomputethemodel’sstateatthenexttimestep,asan

implicit function of the state and the state derivative at the next time

step. In the following example,

and

h is the step size:

X(n+1) - X(n) - h * DX(n+1) = 0

X is the state, DX is the state derivative,

X is the

Page 25

Solver Pane

This solver requires more computation per step than an e xplicit solver,

but is more accurate for a given step size.

Variab le-step Solvers. Default:

ode45 (Dormand-Prince)

ode45 (Dormand-Prince)

Computes the model’s state at the next time step using an explicit

Runge-Kutta (4,5) formula (the Dormand-Prince pair) for numerical

integration.

ode45 is a one-step solver, and therefore only needs the solution at the

preceding time point.

Use

ode45 as a first try for most problems.

Discrete (no continuous states)

Computes the time of the next step by adding a step size that varies

depending on the rate of change of the model’s states.

Use this solver for models with no states or discrete states only, using

a variable step size.

ode23 (Bogacki-Shampine)

Computes the model’s state at the next time step using an explicit

Runge-Kutta (2,3) formula (the Bogacki-Shampine pair) for numerical

integration.

ode23 is a one-step solver, and therefore only needs the solution at the

preceding time point.

ode23 is more efficient than ode45 at crude tolerances and in the

presence of mild stiffness.

ode113 (Adams)

Computes the model’s state at the next time step using a variable-order

Adams-Bashforth-Moulton PECE numerical integration technique.

ode113 is a multistep solver, and thus generally needs the solutions at

several preceding time points to compute the current solution.

ode113 canbemoreefficientthanode45 at stringent tolerances.

1-21

Page 26

1 Configuration Parameters Dialog Box

ode15s (stiff/NDF)

Computes the model’s state at the next time step using variable-order

numerical differentiation formulas (NDFs). These are related to, but

more efficient than the backward differentiation formulas (BDFs), also

known as Gear’s method.

ode15s is a multistep solver, and thus generally needs the solutions at

several preceding time points to compute the current solution.

ode15s is efficient for stiff problems. Try this solve r if ode45 fails or is

inefficient.

ode23s (stiff/Mod. Rosenbrock)

Computes the model’s state at the next time step using a modified

Rosenbrock formula of order 2.

ode23s is a one-step solver, and therefore only needs the solution at

the preceding time point.

ode23s is more efficient than ode15s at crude tolerances, and can solve

stiff problems for which

ode15s is ineffective.

1-22

ode23t (Mod. stiff/Trapezoidal)

Computes the m odel’s state at the next time step using an

implementation of the trapezoidal rule with a “free” interpolant.

ode23t is a one-step solver, and therefore only needs the solution at

the preceding time point.

Use

ode23t if the problem is only moderately stiff and you need a

solution with no numerical damping.

ode23tb (stiff/TR-BDF2)

Computes the model’s state at the next time step using a multistep

implementation of TR-BDF2, an implicit Runge-Kutta formula with a

trapezoidal rule first stage, and a second stage consisting of a backward

differentiation formula of order two. By construction, the same iteration

matrix is used in evaluating both stages.

ode23tb is more efficient than ode15s at crude tolerances, and can solve

stiff problems for which

ode15s is ineffective.

Page 27

Solver Pane

Tips

• Identifying the optimal solver for a model re quires experimentation, for an

in-depth discussion, see Choosing a Solver.

• The optimal solver ba la n c es a cceptable accuracy with the shortest

simulation time.

• Simulink software uses a discrete solver for any model with no states or

discrete state s only, even if you specify a continuous solver.

• A smaller step size increases accuracy, but also increases simulation time.

• The degree of computational complexity increases for

oden,asn increases.

• As computational com plexity increases, the accuracy of the results also

increases.

Dependencies

Selecting the ode1 (Euler) , ode2 (Huen), ode 3 (Bogacki-Shampine),

ode4 (Runge-Kutta), ode 5 (Dormand-Prince),orDiscrete (no

continuous states)

• Fixed-step size (fundamental sample time)

• Periodic sample time constraint

• Tasking mode for periodic sample times

• Automatically handle rate transition for data transfers

• Higher priority value indicates higher task priority

Selecting

ode14x (extrapolation) enables the following parameters:

• Fixed-step size (fundamental sample time)

• Extrapolation order

• Number Newton’s iterations

fixed-step solvers enables the following parameters:

• Periodic sample time constraint

• Tasking mode for periodic sample times

• Automatically handle rate transition for data transfers

1-23

Page 28

1 Configuration Parameters Dialog Box

• Higher priority value indicates higher task priority

Selecting the

enables the following parameters:

• Max step size

• Automatically handle rate transition for data transfers

• Higher priority value indicates higher task priority

• Zero-crossing control

• Time tolerance

• Number of consecutive zero crossings

• Algorithm

Selecting

(Adams)

parameters:

• Max step size

• Min step size

• Initial step size

• Relative tolerance

• Absolute tolerance

Discrete (no continuous states) variable-step solver

ode45 (Dormand-Prince), ode23 (Bogacki-Shampine), ode113

,orode23s (stiff/Mod. Rosenbrock) enables the following

1-24

• Shape preservation

• Number of consecutive min steps

• Automatically handle rate transition for data transfers

• Higher priority value indicates higher task priority

• Zero-crossing control

• Time tolerance

• Number of consecutive zero crossings

• Algorithm

Page 29

Selecting ode15s (stiff/NDF), ode23t (Mod. stiff/Trapezoidal),or

ode23tb (stiff/TR-BDF2) enables the following parameters:

• Max step size

• Min step size

• Initial step size

• Solver reset method

• Number of consecutive min steps

• Relative tolerance

• Absolute tolerance

• Shape preservation

• Maximum order

• Automatically handle rate transition for data transfers

• Higher priority value indicates higher task priority

Solver Pane

• Zero-crossing control

• Time tolerance

• Number of consecutive zero crossings

• Algorithm

Command-Line Information

Parameter: Solver

Type: string

Value:

'ode113' | 'ode15s' | 'ode23s' | 'ode23t' | 'ode23tb' |

'FixedStepDiscrete' | 'ode5' | 'ode4' | 'ode3' | 'ode2' |

'ode1' | 'ode14x'

Default: 'ode45'

'VariableStepDiscrete' | 'ode45' | 'ode23' |

1-25

Page 30

1 Configuration Parameters Dialog Box

Recommended Settings

Application

Debugging No impact

Traceability No impact

Efficiency

Safety precaution

Setting

No impact

Discrete (no continuous states)

See Also

• Solvers

• Choosing a Solver

• “Purely Discrete Systems”

• Configuration Parameters Dialog Box

• Solver Pane

1-26

Page 31

Max Step Size

Specify the largest time step that the solver can take.

Settings

Default: auto

• For the discrete solver, the default value (auto)isthemodel’sshortest

sample time.

Solver Pane

• For continuous solvers, the default value (

the start and stop times. If the stop time equals the start time or is

inf, Simulink software chooses 0.2 secondsasthemaximumstepsize.

Otherwise, it sets the maximum step size to

auto)isdeterminedfrom

Tips

• Generally, the default maximum step size is sufficient. If you are concerned

about the solver missing significant behavior, change the parameter to

prevent the solver from taking too large a step.

• If the time span of the simulation is very long, the default step size might

be too large for the solver to find the solution.

• Ifyourmodelcontainsperiodicornearlyperiodicbehaviorandyouknow

theperiod,setthemaximumstepsizetosomefraction(suchas1/4)of

that period.

• In general, for more output points, change the refine factor, not the

maximum step size. For more information, see Specifying Output Options.

Dependencies

This parameter is enabled only if the solver Type is set to Variable-step.

1-27

Page 32

1 Configuration Parameters Dialog Box

Command-Line Information

Parameter: MaxStep

Type: string

Value: any valid value

Default:

Recommended Settings

'auto'

Application

Debugging No impact

Traceability No impact

Efficiency

Safety precaution

Setting

No impact

No impact

See Also

• “Purely Discrete Systems”

• Specifying Output Options

• Configuration Parameters Dialog Box

• Solver Pane

1-28

Page 33

Solver Pane

Initial Step Siz

Specify the size

e

of the first time step that the solver takes.

Settings

Default: auto

By default, th

of the states

e solver selects an initial step size by e xamining the derivatives

at the start time.

Tips

• Be careful w

large, the s

• The initia

tries this

hen increasing the initial step size. If the first step size is too

olver might step over important behavior.

l step size parameter is a suggested first step size. The solver

step size but re duces it if error criteria are not satisfied.

Dependencies

This para

meter is enabled only if the solver Type is set to

Command-Line Information

er:

'auto'

t:

InitialStep

Paramet

Type: string

Value: any valid value

Defaul

Variable-step.

Recommended Settings

ng

Application

Debugging No impact

ceability

Tra

ficiency

Ef

fety precaution

Sa

Setti

mpact

No i

No impact

No impact

1-29

Page 34

1 Configuration Parameters Dialog Box

See Also

• “Purely Discrete Systems”

• Improving Simulation Performance and Accuracy

• Configuration Parameters Dialog Box

• Solver Pane

1-30

Page 35

Min Step Size

Specify the smallest time step that the solver can take.

Settings

Default: auto

• Thedefaultvalue(auto) sets an unlimited number of warnings and a

minimum step size on the order of machine precision.

• You can specify either a real number greater than zero, or a two-element

vector for which the first element is the minimum step size and the second

element is the maximum number of minimum step size warnings before

an error was issued.

Tips

• If the solver takes a smaller step to meet error tolerances, it issues a

warning indicating the current effective relative tolerance.

Solver Pane

• Setting the second element to zero results in an error the first time the

solver must take a step smaller than the specified minimum. This is

equivalent to changing the Min step size violation diagnostic to

the Diagnostics pane (see M i n step size v iolation).

• Setting the second element to -1 results in an unlimited number of

warnings. This is also the default if the input is a scalar.

Depend

This parameter is enabled only if the solver Type is set to Variable-step.

Comm

Parameter: MinStep

Type

Value: any valid value

Default:

encies

and-Line Information

: string

'auto'

error on

1-31

Page 36

1 Configuration Parameters Dialog Box

Recommended Settings

Application

Debugging No impact

Traceability No impact

Efficiency

Safety precaution

Setting

No impact

No impact

See Also

• “Purely Discrete Systems”

• Min step size violation

• Configuration Parameters Dialog Box

• Solver Pane

1-32

Page 37

Solver Pane

Relative tolera

Specify the larg

during each time

reduces the tim

nce

est acceptable solver error, relative to the size of each state

step. If the relative error exceeds this tolerance, the solver

estepsize.

Settings

Default: 1e-3

• The relative

• The default v

within 0.1%

tolerance i s a percentage of the state’s value.

alue (

1e-3) means that the computed state is accurate to

.

Tips

• The acceptable error at each time step is a function of both the Relative

tolerance and the Absolute tolerance. For more information about how

these settings work together, see Specifying Variable-Step Solver Error

Tolerances.

• During each time step, the solver computes the state v alues at the end of

the step and also determines the local error – the estimated error of these

state values. If the error is greater than the acceptable error for any state,

the solver reduces the step size and tries again.

• The default relative tolerance value is sufficient for most applications.

Decreasing the relative tolerance valuecanslowdownthesimulation.

• To check the accuracy of a simulationafteryourunit,youcanreduce

the relative tolerance to 1e-4 and run it again. If the results of the two

simulations are not significantly different, you can feel confident that the

solution has converged.

Dependencies

This parameter is enabled only if you set:

• Solver Type to

• Solver to a continuous variable-step solver.

Variable-step.

1-33

Page 38

1 Configuration Parameters Dialog Box

This parameter w orks along with Absolute tolerance to determine the

acceptable error at each time step. For more information about how these

settings w ork together, see Specifying Variable-Step Solver Error Tolerances.

Command-Line Information

Parameter: RelTol

Type: string

Value: any valid value

Default:

Recommended Settings

'1e-3'

Application

Debugging No impact

Traceability No impact

Efficiency

Safety precaution

Setting

No impact

No impact

See Also

• Specifying Variable-Step Solver Error Tolerances

• Improving Simulation Performance and Accuracy

• Configuration Parameters Dialog Box

• Solver Pane

1-34

Page 39

Solver Pane

Absolute tolera

Specify the larg

state approache

reduces the tim

est acceptable solver error, as the value of the measured

s zero . If the absolute error exceeds this tole rance , the solver

estepsize.

nce

Settings

Default: auto

alue (

• The default v

to 1e-6. As th

is reset to t

the relativ

For example

then by the

• If the comp

setting yo

he maximum value that the state has thus far assumed times

e tolerance for that state.

uted se tting is not suitable, you can determine an appropriate

urself.

, if a state goes from 0 to 1 and the Relative tolerance is 1e-3,

end of the simulation the Absolute tolerance is set to 1e-3.

auto) initially sets the absolute tolerance for each state

e simulation progresses, the absolute tolerance for each state

Tips

• The acceptable error at each time step is a function of both the Relative

tolerance and the Absolute tolerance. For more information about how

these settings work together, see Specifying Variable-Step Solver Error

Tolerances.

• The Integrator, Transfer Fcn, State-Space, and Zero-Pole blocks allow you

to specify absolute tolerance values for solving the model states that they

compute or that determine their output. Theabsolutetolerancevaluesthat

you specify in these blocks override the global setting in the Configuration

Parameters dialog box.

• You might want to override the Absolute tolerance setting using blocks if

the global setting does not provide sufficient error control for all of your

model’s states, for example if they vary widely in magnitude.

• If you set the Absolute tolerance too low, the solv er may take too many

steps around near-zero state values, slowing down the simulation.

• To check the accuracy of a simulation after you run it, you can reduce the

absolute tolerance and run it again. If the results of the two simulations

1-35

Page 40

1 Configuration Parameters Dialog Box

are not significantly different, you can feel confident that the solution

has converged.

• If your simulation results do not seem accurate, and your model has states

whose values ap pro ach zero, the Absolute tolerance may be too large.

Reduce the Absolute tolerance toforcethesimulationtotakemoresteps

around areas of near-zero state values.

Dependencies

This parameter is enabled only if you set:

• Solver Type to

• Solver to a continuous variable-step solver.

This parameter works along with Relative tolerance to determine the

acceptable error at each time step. For more information about how these

settings w ork together, see Specifying Variable-Step Solver Error Tolerances.

Variable-step.

Command-Line Information

Parameter: AbsTol

Type: string

Value: any valid value

Default:

'auto'

Recommended Settings

Application

Debugging No impact

Traceability No impact

Efficiency

Safety precaution

Setting

No impact

No impact

1-36

Page 41

See Also

• Specifying Variable-Step Solver Error Tolerances

• Improving Simulation Performance and Accuracy

• Configuration Parameters Dialog Box

• Solver Pane

Solver Pane

1-37

Page 42

1 Configuration Parameters Dialog Box

Maximum order

Select the orde

the

ode15s solv

r of the numerical differentiation formulas (NDFs) used in

er.

Settings

Default: 5

5

Specifies t

1

Specifies t

2

Specifies

3

Specifie

4

Specifi

hat the solver uses fifth order NDFs.

hat the solver uses first order NDFs.

that the solver uses second order NDFs.

s that the solver uses third order NDFs.

es that the solver u ses fourth order NDFs .

Tips

• Although the higher order formulas are more accurate, they are less stable.

• If your model is stiff and requires more stability, reduce the maximum

order to 2 (the highest order for which the NDF formula is A-stable).

1-38

• As an alternative, you can try using the

order (and A-stable) solver.

ode23s solver, which is a lower

Dependencies

This parameter is enabled only if Solver is set to ode15s.

Page 43

Command-Line Information

Parameter: MaxOrder

Type: integ er

Value:

Default: 5

1 | 2 | 3 | 4 | 5

Recommended Settings

Solver Pane

Application

Debugging No impact

Traceability No impact

Efficiency

Safety precaution

Setting

No impact

No impact

See Also

• Specifying Variable-Step Solver Error Tolerances

• Improving Simulation Performance and Accuracy

• Configuration Parameters Dialog Box

• Solver Pane

1-39

Page 44

1 Configuration Parameters Dialog Box

Solver reset met

Select how the so

crossing.

lver behaves during a reset, such as when it detects a zero

hod

Settings

Default: Fast

Fast

Specifies th

solver reset

Robust

Specifies t

the integra

at the solver will not recompute the Jacobian matrix at a

.

hat the solver will recompute the Jacobian matrix needed by

tion step at every solver reset.

Tips

• Selecting Fast speeds up the simulation. However, it can result in incorrect

solutions in some cases.

• If you suspect that the simulation is giving incorrect results, try the

setting. If there is no difference in simulation results between the fast and

robust settings, revert to the fast setting.

Robust

1-40

Dependencies

This parameter is enabled only if you select one of the following solvers:

•

ode15s (Stiff/NDF)

• ode23t (Mod. Stiff/Trapezoidal)

• ode23tb (Stiff/TR-BDF2)

Command-Line Information

Parameter: SolverResetMethod Type: string

'Fast' | 'Robust'

ue:

Val

Default: 'Fast'

Page 45

Recommended Settings

Solver Pane

Application

Debugging No impact

Traceability No impact

Efficiency

Safety precaution

Setting

No impact

No impact

See Also

• Choosing a Solver

• Configuration Parameters Dialog Box

• Solver Pane

1-41

Page 46

1 Configuration Parameters Dialog Box

Number of consecutive min steps

Specify the maximum number of consecutive minimum step size violations

allowed during simulation.

Settings

Default: 1

• A minimum step size violation occurs when a variable-step continuous

solver takes a smaller step than tha t specified by the Min step size

property (see Min step size).

• Simulink software counts the number of consecutive violations that it

detects. If the count exceeds the value of Number of consecutive min

steps, Simulink software displays either a warning or error message as

specified by the Min step size violation diagnostic (see Min step size

violation).

Dependencies

This parameter is enabled only if you set:

1-42

• Solver Type to

• Solver to a continuous variable step solver.

Variable-step.

Command-Line Information

Parameter: MaxConsecutiveMinStep

Type: string

Value: any valid value

Default:

'1'

Recommended Settings

Application

Debugging No impact

Traceability No impact

Setting

Page 47

Solver Pane

Application

Efficiency

Safety precaution

Setting

No impact

No impact

See Also

• Choosing a Solver

• Min step size violation

• Min step size

• Configuration Parameters Dialog Box

• Solver Pane

Number of consecutive min steps

Specify the maximum number of consecutive minimum step size violations

allowed during simulation.

Settings

Default: 1

• A minimum step size violation occurs when a variable-step continuous

solver takes a smaller step than tha t specified by the Min step size

property (see Min step size).

• Simulink software counts the number of consecutive violations that it

detects. If the count exceeds the value of Number of consecutive min

steps, Simulink software displays either a warning or error message as

specified by the Min step size violation diagnostic (see Min step size

violation).

Dependencies

This parameter is enabled only if you set:

• Solver Type to

• Solver to a continuous variable step solver.

Variable-step.

1-43

Page 48

1 Configuration Parameters Dialog Box

Command-Line Information

Parameter: MaxConsecutiveMinStep

Type: string

Value: any valid value

Default:

Recommended Settings

'1'

Application

Debugging No impact

Traceability No impact

Efficiency

Safety precaution

Setting

No impact

No impact

See Also

• Choosing a Solver

• Min step size violation

• Min step size

• Configuration Parameters Dialog Box

• Solver Pane

1-44

Page 49

Solver Pane

Solver Jacobian

Method

Settings

Default: Auto

auto

Sparse pertur

Full perturb

Sparse analy

Full analyt

bation

ation

tical

ical

Tips

• The default setting (Auto) usually provides good accuracy for most models.

Dependencies

This parameter is enabled only if an implicit solver is used.

Command-Line Information

Parameter: SolverJacobianMethodControl

Type: s

Value:

'SparseAnalytical' |'FullAnalytical'

Default: 'auto'

Reco

Application

Deb

Traceability No impact

Efficiency

Safety precaution

tring

'auto' | 'SparsePerturbation'|'FullPerturbation' |

mmended Settings

Setting

ugging

mpact

No i

No impact

No impact

1-45

Page 50

1 Configuration Parameters Dialog Box

See Also

• “Choosing a Solver”

• Solver Pane

1-46

Page 51

Tasking mode for periodic sample times

Select how block s with periodic sample times execute.

Settings

Default: Auto

Auto

Specifies that single-tasking execution is used if:

• Your model contains one sample time.

• Your model contains a continuous and a discrete sample time, and

the fixed-step size is equal to the discrete sample time.

Selects multitasking execution for models operating at different sample

rates.

SingleTasking

Specifies that all blocks are processed through each stage of simulation

together (for example, calculating output and updating discrete states).

Solver Pane

MultiTasking

Specifies that groups of blocks with the same executio n priority

are processed through each stage of simulation (for ex ample,

calculating output and updating discrete states) based on task

priority. M ultitasking mode helps to create valid models of real-world

multitasking systems, where sections of yo ur model represent

concurrent tasks.

Tip

The Multitask rate transition parameter on the Diagnostics > Sample

Time pane allows you to adjust error checking for sample rate transitions

between blocks that operate at different sample rates.

Dependency

This parameter is enabled by selecting Fixed-step solve r type.

1-47

Page 52

1 Configuration Parameters Dialog Box

Command-Line Information

Parameter: SolverMode

Type: string

Value:

Default: 'Auto'

Recommended Settings

'Auto' | 'SingleTasking' | 'MultiTasking'

Application

Debugging No impact

Traceability No impact

Efficiency

Safety precaution

Setting

No impact

No impact

See Also

• Rate Transition block

• Model Execution and Rate Transitions

• Single-Tasking and Multitasking Execution Modes

• Sample Rate Transitions

• Single-Tasking and Multitasking Execution of a Model: an Example

• Configuration Parameters Dialog Box

• Solver Pane

1-48

Page 53

Solver Pane

Automatically handle rate transition for data transfer

Specify whether Simulink software automatically inserts hidden Rate

Transition blocks between blocks that have different sa m ple rates to ensure:

the integrity of data transfers between tasks; and optional determinism o f

data transfers for periodic tasks.

Settings

Default: Off

On

Inserts hidden Rate Transition blocks between blocks when rate

transitions are detected. Handles rate transitions for asynchronous and

periodic tasks. Simulink software adds the hidden blocks configured

to ensure data integrity for data transfers. Selecting this option also

enables the parameter Deterministic data transfer,whichallowsyou

to control the level of data transferdeterminismforperiodictasks.

Off

Does not insert hidden Rate Transition blocks when rate transitions are

detected. If Simulink software detects invalid tra n s itions, you m ust

adjust the model such that the sample rates for the blocks in question

match or manually add a Rate Transition block.

See Rate Transition Block Options in the Real-Tim e Workshop

documentation for further details.

®

Tips

• Selecting this parameter allows you to handle rate transition issues

automatically. This saves you from having to manually insert Rate

Transition blocks to avoid invalid rate transitions, including invalid

asynchronous-to-periodic and asynchronous-to-asynchronous rate

transitions, in multirate models.

• For asynchronous tasks, Simulink software configures the inserted blocks

to ensure data integrity but not determinism during data transfers.

1-49

Page 54

1 Configuration Parameters Dialog Box

Command-Line Information

Parameter: AutoInsertRateTranBlk

Type: string

Value:

Default: 'off'

Recommended Settings

'on' | 'off'

Application

Debugging No impact

Traceability

Efficiency

Safety precaution Off

Setting

No impact (for simulation an d d uring

development)

Off (for production code generation)

No impact

See Also

• Rate Transition Block Options

• Configuration Parameters Dialog Box

• Solver Pane

1-50

Page 55

Solver Pane

Deterministic data transfer

Control whether the Rate Transition block parameter Ensure deterministic

data transfer (maximum delay) is set for auto-inserted Rate Transition

blocks

Default:

Always

Whenever possible

Specifies that the block parameter Ensure deterministic d ata

transfer (maximum delay) is always set for auto-inserted Rate

Transition blocks.

If

Always is selected and if a model needs to auto-insert a Rate

Transition block to handle a rate transition that is not between two

periodic sample times related by an integer multiple, Simulink errors

out.

Whenever possible

Specifies that the block parameter Ensure deterministic d ata

transfer (maximum delay) is set for auto-inserted Rate Transition

blocks whenever po ssible. If an auto-inserted R ate Transition block

handles data transfer between two periodic sample times that are

related by an integer m u ltip le, Ensure deterministic data transfer

(maximum delay) is set; otherwise, it is cleared.

Never (minimum delay)

Specifies that the block parameter Ensure deterministic d ata

transfer (maximum delay) isneversetforauto-insertedRate

Transition blocks.

Note Clearing the Rate Transition block parameter Ensure deterministic

data transfer (maximum delay) can provide reduced latency for

models that do not require determinism. See the description of Ensure

deterministic data transfer (maximum delay) on the Rate Transition

block reference page for more inform ation.

1-51

Page 56

1 Configuration Parameters Dialog Box

Dependencies

This parameter is enabled only if Automatically handle rate transition

for data transfer is checked.

Command-Line Information

Parameter: InsertRTBMode

Type: string

Value:

Default: 'Whenever possible'

Recommended Settings

'Always' | 'Whenever possible'| 'Never (minimum delay)'

Application

Debugging No impact

Traceability No impact

Efficiency

Safety precaution

Setting

No impact

'Whenever possible'

See Also

• Rate Transition Block Options

• Configuration Parameters Dialog Box

• Solver Pane

1-52

Page 57

Solver Pane

Higher priority

Specify whether

or lower priorit

asynchronous d

y values to higher priority tasks when implementing

ata transfers

value indicates higher task priority

the real-time system targeted by the model assigns higher

Settings

Default: Off

On

Real-time system assigns higher priority values to higher priority tasks,

for exam ple, 8 has a higher task priority than 4. Rate Transition blocks

treat asynchronous transitions between rates with lower priority values

and rates with higher priority values as low-to-high rate transitions.

Off

Real-time system assigns lower priority values to higher priority tasks,

for exam ple, 4 has a higher task priority than 8. Rate Transition blocks

treat asynchronous transitions between rates with lower priority values

and rates with higher priority values as high-to-low rate transitions.

Command-Line Information

Parameter: PositivePriorityOrder

Type: string

Value:

Default: 'off'

'on' | 'off'

Recommended Settings

ication

Appl

Debugging No impact

Traceability No impact

Efficiency

Safety precaution

Setting

impact

No

oimpact

N

1-53

Page 58

1 Configuration Parameters Dialog Box

See Also

• Rate Transitions and Asynchronous Blocks

• Configuration Parameters Dialog Box

• Solver Pane

1-54

Page 59

Solver Pane

Zero-crossing c

Enables zero-cr

For most models,

larger time ste

Settings

Default: Use l

Use local set

Specifies th

basis. For a

To specify z

block’s pa

detection

Enable all

Enables z

Disable a

Disables

Tips

ossing detectio n during variable-ste p simulation of the model.

this speeds up simulation by enabling the solver to take

ps.

ocal settings

tings

at zero-crossing detection be enabled on a block-by-block

list of applicable blocks, see “Simulating Dynamic Systems”

ero-crossing detection for one of these blocks, open the

rameter dialog b ox and select the E nable zero-crossing

option.

ero-crossing detection for all blocks in the model.

ll

zero-crossing detection for all blocks in the model.

ontrol

• For most models, enabling zero-crossing detection speeds up simulation by

allowingthesolvertotakelargertimesteps.

• If a model has extreme dynamic changes, disabling this option can speed

up the simulation but can also decrease the accuracy of simulation results.

See Zero-crossing Detection for more information.

• Selecting

detection setting for individual blocks.

Enable all or Disable all overrides the local zero-crossing

Dependencies

This parameter is enabled only if the solver Type is set to Variable-step.

Selecting either

parameters:

Use local settings or Enable all enables the following

1-55

Page 60

1 Configuration Parameters Dialog Box

• Time tolerance

• Number of consecutive zero crossings

• Algorithm

Command-Line Information

Parameter: ZeroCrossControl

Type: string

Value:

Default: 'UseLocalSettings'

Recommended Settings

'UseLocalSettings' | 'EnableAll' | 'DisableAll'

Application

Debugging No impact

Traceability No impact

Efficiency

Safety precaution

Setting

No impact

No impact

See Also

• Zero-Crossing Detection

• Number of consecutive zero crossings

• Consecutive zero-crossings violation

• Time tolerance

• Configuration Parameters Dialog Box

• Solver Pane

1-56

Page 61

Time tolerance

Specify a tolera

occurtobeconsi

Settings

Default: 10*1

nce factor that controls how closely zero-crossing events must

dered consecutive.

28*eps

Solver Pane

• Simulink sof

events is les

simulation t

ZC

and ZC2,

1

tware defines zero crossings as consecutive if the time between

s than a particular interval. The following figure d epicts a

imeline during which Simulink software detects zero crossings

bracketed a t successive time steps t

and t2.

1

Simulink software determines that the zero crossings are consecutive if

dt < Rel

TolZC * t

2

where dt is the time between zero crossings and RelTolZC is the Time

tolerance.

• Simulink software counts the number of consecutive zero crossings that it

detects. If the count exceeds the value of Number of consecutive zero

crossings allowed, Simu li nk software displays either a warni ng or error

as s p ecified by the Consecutive zero-crossings violation diagnostic (see

Consecutive zero-crossings violation).

s

Tip

• Sim

ulink software resets the counter each time it detects nonconsecutive

ro crossings (successive zero crossings that fail to meet the relative

ze

lerance setting); therefore, decreasing the relative tolerance value may

to

ford your model’s behavior more time to recov er.

af

1-57

Page 62

1 Configuration Parameters Dialog Box

• If your model experiences excessive zero crossings, you can also increase

the Number of consecutive zero crossings to increase the threshold

at which Simulink so ftw are triggers the Consecutive zero-crossings

violation diagnostic.

Dependencies

This parameter is enabled only if Zero-crossing control is set to either

Use local settings or Enable all.

Command-Line Information

Parameter: ConsecutiveZCsStepRelTol

Type: string

Value: any valid value

Default:

Recommended Settings

'10*128*eps'

1-58

Application

Debugging No impact

Traceability No impact

Efficiency

Safety precaution

Setting

No impact

No impact

See Also

• Zero-crossing Detection

• Zero-crossing Control

• Number of consecutive zero crossings

• Consecutive zero-crossings violation

• Configuration Parameters Dialog Box

• Solver Pane

Page 63

Solver Pane

Number of consecutive zero crossings

Specify the number of consecutive zero crossings that can occur before

Simulink software displays a warning or an error.

Settings

Default: 1000

• Simulink software counts the number of consecutive zero crossings that

it detects. If the count exceeds the specified value, Simulink software

displays either a warning or an error as specified by the Consecutive

zero-crossings violation diagnostic (see Consecutive zero-crossings

violation).

• Simulink software defines zero crossingsasconsecutiveifthetimebetween

events is less than a particular interval (see Time tolerance).

Tips

• If your model experiences excessive zero crossings, you can increase this

parameter to increase the threshold at which Simulink software triggers

the Consecutive zero-crossings violation diagnostic. This may afford

your model’s behavior more time to recover.

• Simulink software resets the counter each time it detects nonconsecutive

zero crossings; therefore, decreasing the relative tolerance value may also

afford your model’s behavior more time to recov er.

Dependencies

This parameter is enabled only if Zero-crossing control is set to either

Use local settings or Enable all.

Command-Line Information

Parameter: MaxConsecutiveZCs

Type: string

Value: any valid value

Default:

'1000'

1-59

Page 64

1 Configuration Parameters Dialog Box

Recommended Settings

Application

Debugging No impact

Traceability No impact

Efficiency

Safety precaution

Setting

No impact

No impact

See Also

• Zero-Crossing Detection

• Zero-Crossing Control

• Consecutive zero-crossings violation

• Time tolerance

• Configuration Parameters Dialog Box

• Solver Pane

1-60

Page 65

Algorithm

Specifies the al

is used.

Settings

Default: Nona

Adaptive

Use an improv

and deactiva

set a zero-c

learn how to

Solver Pane

gorithm to detect zero cro ssing s when a variable-step solver

daptive

ed z ero-crossing algorithm which dynamically activates

tes zero-crossing bracketing. With this algorithm you can

rossing tolerance. See “Signal threshold” on page 1-63 to

set the zero-crossing tolerance.

Nonadaptiv

e

Use the non

software p

backward c

adaptive zero-crossing algorithm present in the Simulink

rior to Vers ion 7.0 (R2008a). This option is provided for

ompatibility.

Tips

• The adaptive zero-crossing algorithm is especially useful in systems

having strong “chattering”, or Zeno behavior. In such systems, this

algorithm yields shorter simulation run times compared to the nonadaptive

algorithm. See Zero-Crossing Detection for more information.

Dependencies

• This parameter is enabled only if the solver Type is set to Variable-step.

• Selecting

Comm

Parameter: ZeroCrossAlgorithm

Typ

Value:

Default: 'Nonadaptive'

Adaptive enables the Signal threshold parameter.

and-Line Information

e: string

'Nonadaptive' | 'Adaptive'

1-61

Page 66

1 Configuration Parameters Dialog Box

Recommended Settings

Application

Debugging No impact

Traceability No impact

Efficiency

Safety precaution

Setting

No impact

No impact

See Also

• Zero-Crossing Detection

• Number of consecutive zero crossings

• Consecutive zero-crossings violation

• Time tolerance

• Configuration Parameters Dialog Box

• Solver Pane

1-62

Page 67

Solver Pane

Signal threshol

Specifies the de

Signals falling

The signal thre

adband region used during the detection of zero crossings.

within this region are defined as having crossed through zero.

shold is a real number, greater than or equal to zero.

d

Settings

Default: Aut

Auto

The signal t

algorithm.

String

Use the spe

real numbe

o

hreshold is determined automaticallybytheadaptive

cified value for the signal threshold. The value must be a

r equal to or greater than zero.

Tips

• Entering too small of a value for the Signal Threshold parameter will

result in long simul ation run times.

• Entering a large Signal Threshold valuemayimprovethesimulation

speed (especially in systems having extensive chattering). How ever,

making the value too large may reduce the simulation accuracy.

Dependency

This parameter is enabled if the zero-crossing Algorithm is set to Adaptive.

Command-Line Information

Parameter: ZCThreshold

Type: string

'auto' | any real number greater than or equal to zero

ue:

Val

Default: 'auto'

1-63

Page 68

1 Configuration Parameters Dialog Box

Recommended Settings

Application

Debugging No impact

Traceability No impact

Efficiency

Safety precaution

Setting

No impact

No impact

See Also

• Zero-Crossing Detection

• Number of consecutive zero crossings

• Consecutive zero-crossings violation

• Time tolerance

• Configuration Parameters Dialog Box

• Solver Pane

1-64

Page 69

Solver Pane

Periodic sample

Select constrai

does not satisfy

software displ

Settings

Default: Unco

Unconstrain

Specifies no

to display a

Use the Fixe

specify so

Ensure sam

Specifies

which the

intrinsi

youplano

you shou

can dete

• Model Bl

nts on the sample time s defined by this model. If the m odel

the specified constraints during simulation, Simulink

ays an error message.

nstrained

ed

constraints. Sele cti ng this option causes Simulink software

field for entering the solver step size.

d-step size (fundamental sample time) option to

lver step size.

ple time independent

that Model blocks inherit sample time from the context in

y are used. You cannot use a referenced m odel that has

c sample times in a triggered subsystem or iterator subsystem. If

n referencing this model in a triggered or iterator subsystem,

ld select

ct sam p le time problems while unit testing this model.

ock Sample Times

time constraint

Ensure sample time independent so that Simulink

Spe

• Inheri

• Functi

Simul

sampl

behav

cann

caus

Fixe

cified

Spe

ope

the

mo

ted Sample Time for Re fe renced Models

on Call Models

ink software checks to ensure that this model can inherit its

e times from a model that references it without altering its

ior. Models that specify a step size (i.e., a base sample time)

ot satisfy this constraint. For this reason, selecting this option

es Simulink software to hide the group’s step size field (see

d-step size (fundamental sample time)).

cifies that Simulink software check to ensure that this model

rates at a specified set of prioritized periodic sample times. Use

Sample time properties option to specify and assign priorities to

del sample times.

1-65

Page 70

1 Configuration Parameters Dialog Box

Executing Multitasking Models explains how to use this option for

multitasking models.

Tips

During simulation, Simulink software checks to ensure that the model

satisfies the constraints. If the model does not satisfy the specified constraint,

then Simulink software displays an error message.

Dependencies

This parameter is enabled only if the solver Type is set to Fixed-step.

Selecting

• Fixed-step size (fundamental sample time)

• Tasking mode for periodic sample times

• Higher priority value indicates higher task priority

• Automatically handle rate transitions for data transfers

Selecting

• Sample time properties

• Tasking mode for periodic sample times

• Higher priority value indicates higher task priority

• Automatically handle rate transitions for data transfers

Unconstrained enables the following parameters:

Specified enables the following parameters:

Command-Line Information

Parameter: SampleTimeConstraint

Type: string

Value:

Default: 'unconstrained'

'unconstrained' | 'STIndependent' | 'Specified'

1-66

Page 71

Recommended Settings

Solver Pane

Application

Debugging No impact

Traceability No impact

Efficiency

Safety precaution

Setting

No impact

Specified or Ensure sample time

independent

See Also

• Model Block Sample Times

• Inherited Sample Time for Referenced Models

• Function Call Models

• Fixed-step size (fundamental sample time)

• Executing Multitasking Models

• Configuration Parameters Dialog Box

• Solver Pane

1-67

Page 72

1 Configuration Parameters Dialog Box

Fixed-step size (fundamental sample time)

Specify the step size used by the selected fixed-step solver.

Settings

Default: auto

• Entering auto (the default) in this field causes Simulink software to choose

the step size.

• If the model specifies one or more periodic sample times, Simulink software

chooses a step size equal to the least common denominator of the specified

sample times. This step size, known as the fundamental sample time of

the model, ensures that the solver will take a step at every sample time

defined by the model.

• If the model does not define any periodic sample times, Simulink software

chooses a step size that divides the total simulation time into 50 equal steps.

Dependencies

This param eter is enabled only if the Periodic sample time constraint is

set to

Unconstrained.

1-68

Command-Line Information

Parameter: FixedStep

Type: string

Value: any valid value

Default:

'auto'

Recommended Settings

Application

Debugging No impact

Traceability No impact

Efficiency

Safety precaution

Setting

No impact

No impact

Page 73

See Also

• Modeling Dynamic Systems

• Configuration Parameters Dialog Box

• Solver Pane

Solver Pane

1-69

Page 74

1 Configuration Parameters Dialog Box

Sample time prop

Specify and assi

Settings

No Default

• Enter an Nx3 ma

time propert

• Faster sampl

Format.

[period, of

period

offset

priorit

y

gn priorities to the sample times that this model implements.

trix with rows that specify the model’s discrete sample

ies in order from fastest rate to slowest rate.

e times must have higher priorities.

fset, priority]

Thetimein

during the

Atimeint

is update

operatin

Executi

the samp

erties

terval (sample rate) at which updates occur

simulation.

erval indicating an update delay. The block

d later in the sample interval than other blocks

gatthesamesamplerate.

on priority of the real-time task associated with

le rate.

1-70

SeeSpecifyingSampleTimeformoredetails and options for specifying

sample time.

Example.

[[0.1, 0, 10]; [0.2, 0, 11]; [0.3, 0, 12]]

• Declares that the model s hou ld specify three sample times.

• Sets the fundamental sample time period to 0.1 second.

• Assigns priorities of 10, 11, and 12 to the sample times.

• Assumes higher priority values indicate lower priorities — the Higher

priority value indicates higher task priority optio n is not selected.

Page 75

Solver Pane

Tips

• If the model’s fundamental rate differs from the fastest rate specified by

the model, specify the fundamental rate as the first entry in the matrix

followed by the specified rates, in order from fastest to slowest. See “Purely

Discrete Systems”.

• If the model operates at one rate, enter the rate as a three-element vector

in this field — for example, [0.1, 0, 10].

• When you update a model, Simulink softw are displays an error message if

what you specify does not match the sample times defined by the model.

• If Periodic sample time constraint is set to

Unconstrained, Simulink

software assigns priority 40 to the model base sample rate. If Higher

priority value indicates higher task priority is selecte d, Simulink

software assigns priorities 39, 38, 37, and so on, to subrates of the base

rate. Otherwise, it assigns priorities 41, 42, 43, and so on, to the subrates.

• Continuous rate is assigned a higher priority than is the discrete base rate

regardless of whether Pe riodic sample time constraint is

Unconstrained.

Specified or

Dependencies

This parameter is enabled by selecting Specified from the Periodic sample

time constraint list.

1-71

Page 76

1 Configuration Parameters Dialog Box

Command-Line Information

Parameter: SampleTimeProperty

Type: structure

Value: any valid matrix

Default:

Note If you specify SampleTimeProperty at the command line, you must

enter the sample time properties as a structure with the following fields:

•

SampleTime

• Offset

• Priority

Recommended Settings

[]

1-72

Application

Debugging No impact

Traceability No impact

Efficiency

Safety precaution Period, offset, and priority of each sample

Setting

No impact

time in the model; faster sample times

must have higher priority than slower

sample times

See Also

• “Purely Discrete Systems”

• Specifying Sample Time

• Configuration Parameters Dialog Box

• Solver Pane

Page 77

Solver Pane

Extrapolation o

Select the extra

states at the nex

Settings

Default: 4

1

Specifies fi

2

Specifies s

3

Specifies

4

Specifies

Tip

Selecti

computa

ng a h igher order produces a more accurate solution, but is more

tionally intensive per step size.

Dependencies

This pa

Solver

rameter i s enabled by selecting

list.

polation order used by the

t time step from the states at the current time step.

rst order extrapolation.

econd order extrapolation.

third order extrapolation.

fourth order extrapolation.

rder

ode14x so lver to compute a model’s

ode14x (extrapolation) from the

Command-Line Information

eter:

Param

Type: integer

Value:

ult:

Defa

ExtrapolationOrder

1 | 2 | 3 | 4

4

1-73

Page 78

1 Configuration Parameters Dialog Box

Recommended Settings

Application

Debugging No impact

Traceability No impact

Efficiency

Safety precaution

Setting

No impact

No impact

See Also

• Choosing a Fixed-Step Solver

• Configuration Parameters Dialog Box

• Solver Pane

1-74

Page 79

Solver Pane

Number Newton’s

Specify the numb

to compute a mode

current time st

er of Newton’s method iterations used by the

l’s states a t the next time step from the states at the

ep.

iterations

Settings

Default: 1

Minimum: 1

Maximum: 214

More iterat

computatio

7483647

ions produce a more accurate solution, but are more

nally intensive per step size.

Dependencies

This param

Solver lis

eter is enabled by selecting

t.

Command-Line Information

er:

Paramet

Type: integer

Value: any valid number

Defaul

NumberNewtonIterations

t:

1

ode14x solver

ode14x (extrapolation) from the

Recommended Settings

ng

Application

Debugging No impact

ceability

Tra

iciency

Eff

fety precaution

Sa

Setti

mpact

No i

No impact

No impact

1-75

Page 80

1 Configuration Parameters Dialog Box

See Also

• Choosing a Fixed-Step Solver

• Configuration Parameters Dialog Box

• Solver Pane

• “Purely Discrete Systems”

1-76

Page 81

Data Import/Export Pane

Data Import/Export Pane

In this

“Data

“Inpu

“Ini

“Ti

“St

“O

“F

Save complete SimState in final state” on page 1-92

“

“Signal logging” on page 1-95

section...

Import/Export Overview” on page 1-79

t” on page 1-80

tial state” on page 1-82

me” on page 1-84

ates” on page 1-86

utput” on page 1-88

inal states” on page 1-90

1-77

Page 82

1 Configuration Parameters Dialog Box

In this section...

“Inspect signal logs when simulation is paused/stopped” on page 1-97

“Data stores” on page 1-99

“Limit data points to last” on page 1-100

“Decimation” on page 1-103

“Format” on page 1-105

“Output options” on page 1-107

“Refine factor” on page 1-109

“Output times” on page 1-111

“Return as Single Object” on page 1-112

1-78

Page 83

Data Import/Export Pane

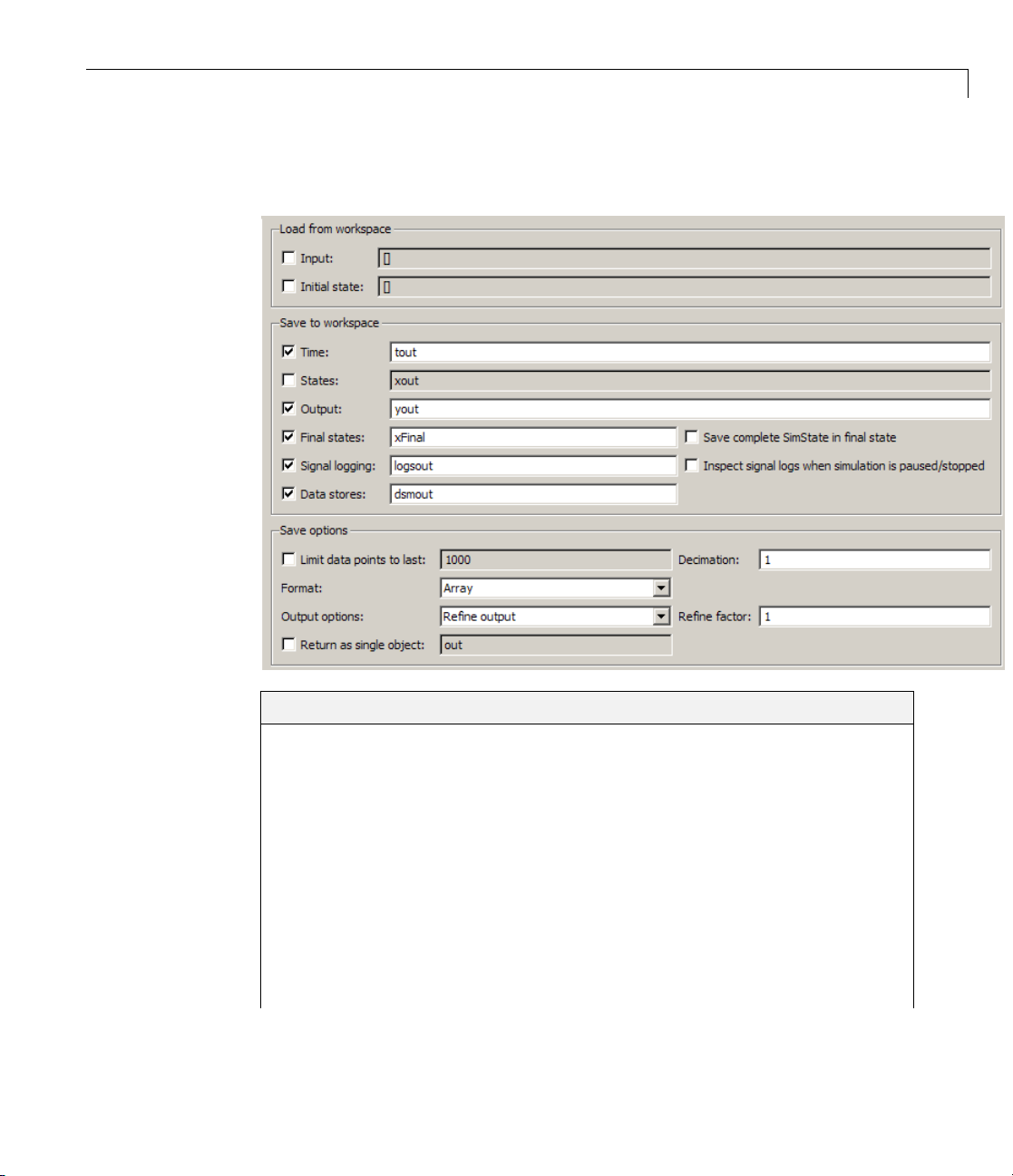

Data Import/Exp

The Data Import/

state data from a

MATLAB

standard or cus

signals and to

®

Export pane allows you to import input signal and initial

workspace and export output signal and state data to the

worksp

tom MATLAB functions to generate a simulated system’s input

graph, analyze, or otherwise postprocess the system’s outputs.

ort Overview

ace during simulation. This capability allows you to use

Configuration

1 Specify the data to load from a workspace before simulation begins.

2 Specify the data to save to the MATLAB workspace after simulation

completes.

Tips

• For more i

Simulati

• See the do

availab

nformation on using this pane, see Importing and Exporting

on Data.

cumentation of the

leonlyforprogrammaticsimulation.

sim command for some cap a bilities th at are

See Also

• Importing Data from a Workspace

• Exporting Data to the MATLAB Workspace

• Configuration Parameters Dialog Box

• Data Import/Export P ane

1-79

Page 84

1 Configuration Parameters Dialog Box

Input

Loads input data from a workspace be fore the simulation beg ins.

Settings

Default: Off, [t,u]

On

Loads data from a workspace.

Specify a MATLAB expression for the data to be imported from a

workspace. The Simulink software resolves symbols used in this

specification as de scrib ed in “Resolving Symbols”. Th e input data can

take any of the following forms:

• Time series

• Data array

• Time expression

1-80

• Data structure

See Importing Data from a Workspace for information on how to use

this field.

Off

Does not load data from a workspace.