Page 1

Simscape™ 3

Reference

Page 2

How to Contact The MathWorks

www.mathworks.

comp.soft-sys.matlab Newsgroup

www.mathworks.com/contact_TS.html T echnical Support

suggest@mathworks.com Product enhancement suggestions

bugs@mathwo

doc@mathworks.com Documentation error reports

service@mathworks.com Order status, license renewals, passcodes

info@mathwo

com

rks.com

rks.com

Web

Bug reports

Sales, prici

ng, and general information

508-647-7000 (Phone)

508-647-7001 (Fax)

The MathWorks, Inc.

3 Apple Hill Drive

Natick, MA 01760-2098

For contact information about worldwide offices, see the MathWorks Web site.

Simscape™ Reference

© COPYRIGHT 2007–20 10 by The MathWorks, Inc.

The software described in this document is furnished under a license agreement. The software may be used

or copied only under the terms of the license agreement. No part of this manual may be photocopied or

reproduced in any form without prior written consent from The MathW orks, Inc.

FEDERAL ACQUISITION: This provision applies to all acquisitions of the Program and Documentation

by, for, or through the federal government of the United States. By accepting delivery of the Program

or Documentation, the government hereby agrees that this software or documentation qualifies as

commercial computer software or commercial computer software documentation as such terms are used

or defined in FAR 12.212, DFARS Part 227.72, and DFARS 252.227-7014. Accordingly, the terms and

conditions of this Agreement and only those rights specified in this Agreement, shall pertain to and govern

theuse,modification,reproduction,release,performance,display,anddisclosureoftheProgramand

Documentation by the federal government (or other entity acquiring for or through the federal government)

and shall supersede any conflicting contractual terms or conditions. If this License fails to meet the

government’s needs or is inconsistent in any respect with federal procurement law, the government agrees

to return the Program and Docu mentation, unused, to The MathWorks, Inc.

Trademarks

MATLAB and Simulink are registered trademarks of The MathWorks, Inc. See

www.mathworks.com/trademarks for a list of additional trademarks. Other product or brand

names may be trademarks or registered trademarks of their respective holders.

Patents

The MathWorks products are protected by one or more U.S. patents. Please see

www.mathworks.com/patents for more information.

Page 3

Revision History

March 2007 Online only New for Version 1.0 (Release 2007a)

September 2007 Online only Revised for Version 2.0 (Release 2007b)

March 2008 Online only Revised for Version 2.1 (Release 2008a)

October 2008 Online only Revised for Version 3.0 (Release 2008b)

March 2009 Online only Revised for Version 3.1 (Release 2009a)

September 2009 Online only Revised for Version 3.2 (Release 2009b)

March 2010 Online only Revised for Version 3.3 (Release 2010a)

Page 4

Page 5

Block Reference

1

Foundation ....................................... 1-2

Electrical

Hydraulic

Magnetic

Mechanical

Physical Signals

Pneumatic

Thermal

........................................ 1-2

........................................ 1-5

........................................ 1-6

....................................... 1-7

.................................. 1-10

....................................... 1-12

......................................... 1-14

Contents

Utilities

........................................... 1-16

v

Page 6

Blocks — Alphabetical List

2

Function Reference

3

Language Reference

4

Simscape Foundation Domains

5

Domain Types and Directory Structure .............. 5-2

vi Contents

Electrical Domain

Hydraulic Domain

Magnetic Dom ain

Mechanical Rotational Domain

Mechanical Translational Domain

Pneumatic Domain

Thermal Domain

................................. 5-4

................................. 5-5

.................................. 5-7

................................ 5-10

.................................. 5-12

..................... 5-8

.................. 5-9

Page 7

Configuration Parameters

6

Simscape Pane: General ............................ 6-2

Simscape Pane Overview

Editing Mode

Explicit solver used in model containing Physical Networks

blocks

Input f il teri ng used in model containing Physical Networks

blocks

Log simulation data

Workspace v aria ble name

Limit data points

Data history (last N steps)

..................................... 6-5

......................................... 6-7

......................................... 6-9

.................................. 6-12

........................... 6-4

............................... 6-10

........................... 6-11

.......................... 6-13

Bibliography

A

Glossary

Index

vii

Page 8

viii Contents

Page 9

Block Reference

1

Foundation (p. 1-2 )

Utilities (p. 1-16) Essential environment blocks for

Basic hydraulic, pneumatic,

mechanical, electrical, magnetic,

thermal, and physical signal blocks

creating Physical Networks models

Page 10

1 Block Reference

Foundation

Electrical (p. 1-2)

Hydraulic (p. 1-5)

Magnetic (p.

Mechanical (p. 1-7) Mechanical elements for rotational

Physical Signals (p. 1-10) Blocks for transmitting physical

Pneumatic (p. 1-12)

Thermal (p. 1-14)

1-6)

Basic electrical diagram blocks, such

as inductors, diodes, capacitors,

sensors and source s

Basic hydraul

such as orif ic

and sources,

Basic electromagnetic diagram

blocks, such as reluctances,

electromagnetic converters, sensors

and sources

and translational motion, as well as

mechanical sensors and sources

control signals

Basic pneumatic diagram blocks,

such as orifices, chambers, sensors

and s ou rces, and pneumatic utilities

thermal blocks, such as heat

Basic

sfer blocks, thermal mass,

tran

ors and source s

sens

ic diagram blocks,

es, chambers, sensors

and hydraulic utilities

1-2

Electrical

ctrical E lements (p. 1-3)

Ele

Electrical Sensors (p. 1-4) Current and voltage sensors

Electrical Sources (p. 1-4) Current and voltage sources

Electrical building blocks, such as

inductors, diodes, and capacitors

Page 11

Electrical Elements

Capacitor Simulate linear capacitor in

electrical systems

Foundation

Diode

Electrical Reference Simulate connection to electrical

Gyrator Simulate ideal gyrator in electrical

Ideal Transformer Simulate ideal transformer in

Inductor

Mutual Inductor

Op-Amp Simulate ideal operational amplifier

Resistor

Rotational Electromechanical

Converter

Switch Simulate switch controlled by

Translational Electromechanical

Converter

Simulate piecewise linear diode in

electrical systems

ground

systems

electrical systems

Simulate linear inductor in electrical

systems

Simulate mutual inductor in

electrical systems

Simulate linear resistor in electrical

systems

Provide i nterface between electrical

and mechanical rotational domains

external physical signal

Provide i nterface between electrical

and mechanical translational

domains

Variable Resistor

Simulate linear variable resistor in

electrical systems

1-3

Page 12

1 Block Reference

Electrical Sensors

Current Sensor Simulate current sensor in electrical

systems

Voltage Sensor Simulate v oltage sensor in electrical

systems

Electrical Sources

AC Current Source Simulate ideal sinusoidal current

source

AC Voltage Source Simulate ideal constant voltage

source

Controlled Current Source Simulate ideal current source driven

by input signal

Controlled Voltage Source Simulate ideal voltage source driven

by input signal

1-4

Current-Controlled Current Source Simulate linear current-controlled

current source

Current-Controlled Voltage Source Simulate linear current-controlled

voltage source

DC Current Source Simulate ideal constant current

source

DC Voltage Source Simulate ideal constant voltage

source

Voltage-Controlled Current Source Simulate linear voltage-controlled

current source

Voltage-Controlled Voltage Source Simulate linear voltage-controlled

voltage source

Page 13

Hydraulic

Foundation

Hydraulic Elements (p. 1-5)

Hydraulic Sen

Hydraulic So

Hydraulic Ut

sors (p. 1-6)

urces (p. 1-6)

ilities (p. 1-6)

Hydraulic Elements

Constant A

Constant

Chamber

Fluid Inertia

Hydra

Hydr

rea Hydraulic Orifice

Volume Hydraulic

ulic Piston Chamber

aulic Reference

Hydraulic build

such as orifice

hydro-mechani

Hydraulic sensors

Hydraulic sources

Basic hydraulic environment blocks,

such as custom hydraulic fluid

Simulate h

constant

Simulate

constan

Simulat

tube or

fluid v

Simul

capac

Simu

pres

cross-sectional area

tvolume

e pressure differential across

channel due to change in

elocity

ate variable volume hydraulic

ity in cylind ers

late connection to atmospheric

sure

ing blocks,

s, chambers, and

cal converters

ydraulic orifice with

hydraulic capacity of

Hydraulic Resistive Tube

Linear Hydraulic Resistance

Rotational Hydro-Mechanical

Converter

Translational Hydro-Mechanical

Converter

late hydraulic pipeline which

Simu

ounts for friction losses only

acc

ulate hydraulic pipeline with

Sim

near resistance losses

li

mulate ideal hydro-mechanical

Si

ansducer as building block for

tr

otary actuators

r

imulate single chamber of hydraulic

S

cylinder as building block for various

cylinder models

1-5

Page 14

1 Block Reference

Variable Area Hydraulic O rifice Simulate hydraulic variable orifice

created by cylindrical spool and

sleeve

Variable Hydraulic Chamber Simulate hydraulic capacity of

variable volume with compressible

fluid

Hydraulic Sensors

Hydraulic Flow Rate Sensor Simulate ideal flow meter

Hydraulic Pressure Sensor Simulate ideal pressure sensing

device

Hydraulic Sources

Hydraulic Flow Rate Source Simulate ideal source of hydraulic

energy, characterized by flow rate

1-6

Hydraulic Pressure Source Simulate ideal source of hydraulic

energy, characterized by pressure

Hydraulic Utilities

Custom Hydraulic Fluid Set working fluid prop erties by

specifying parameter values

Magnetic

Magnetic Elements (p. 1-7)

Magnetic Sensors (p. 1-7) Flux and mmf sensors

Magnetic Sources (p. 1-7) Flux and mmf sources

Magnetic building blocks, such

as reluctances, electromagnetic

converters, and actuators

Page 15

Magnetic Elements

Electromagnetic Converter Simulate lossless electromagnetic

energy conversion device

Magnetic Reference Simulate reference for magnetic

ports

Foundation

Reluctance

Reluctance Force Actuator Simulate magnetomotive device

Variable R eluctance

Simulate magnetic reluctance

based on reluctance force

Simulate variable reluctance

Magnetic Sensors

Flux Sensor Simulate ideal flux s ensor

MMF Sensor Simulate ideal magnetomotive force

sensor

Magnetic Sources

Controlled Flux Source Simulate ideal flux source driven by

input signal

Controlled MMF Source Simulate ideal magnetomotive force

source driven by input signal

Flux Source Simulate ideal flux source

MMF Source Simulate ideal magnetomotive force

source

Mechanical

Mechanical Sensors (p. 1-8)

Mechanical Sources (p. 1-8)

Mechanisms (p. 1-9)

Mechanical sensors and sources

Mechanical sensors and sources

Various simple mechanisms

1-7

Page 16

1 Block Reference

Rotational E lements (p. 1-9) Mechanical elements for rotational

motion

Translational Elements (p. 1-9) Mechanical elements for

translational motion

Mechanical Sensors

Ideal Force Sensor Simulate force sensor in mechanical

translational systems

Ideal Rotational Motion Sensor Simulate motion sensor in

mechanical rotational systems

Ideal Torque Sensor Simulate torque sensor in

mechanical rotational systems

Ideal Trans lational Motion Sensor Simulate motion sensor in

mechanical translational systems

1-8

Mechanical Sources

Ideal Angular Velocity Source Simulate ideal angular velocity

source in mechanical rotational

systems

Ideal Force Source Simulate ideal source of mechanical

energy that generates force

proportional to the input signal

Ideal Torque Source Simulate ideal source of mechanical

energy that generates torque

proportional to the input signal

Ideal Translational Velocity Source Simulate ideal velocity source in

mechanical translational systems

Page 17

Mechanisms

Gear Box Simulate gear bo xe s in mechanical

systems

Foundation

Lever

Wheel and Axle Simulate wheel and axle mechanism

Simulate lever in mechanical

systems

in mechanical system s

Rotational Elements

Inertia

Mechanical Rotational Reference Simulate reference for mechanical

Rotational Damper

Rotational Friction

Rotational Hard Stop Simulate double-sided rotational

Rotational Spring Simulate ideal spring in mechanical

Simulate inertia in mechanical

rotational systems

rotational ports

Simulate viscous damper in

mechanical rotational systems

Simulate friction in contact between

rotating bodies

hard stop

rotational systems

Translational Elements

Mass

Mechanical Translational Reference Simulate reference for mechanical

Translational Damper

Simulate mass in mechanical

translational systems

translational ports

Simulate viscous damper in

mechanical translational systems

1-9

Page 18

1 Block Reference

Translational Friction

Translational Hard Stop Simulate double-sided translational

Translational Spring Simulate ideal spring in mechanical

Simulate friction in contact between

moving bodies

hard stop

translational systems

Physical Signals

Functions (p. 1-10) Perform math operations on physical

signals

Linear Operators (p. 1-11) Simulate continuous-time functions

for physical signals

Lookup Tables (p. 1-11) Perform one- and two-dimensional

table lookup to generate physical

signals

Nonlinear O perators (p. 1-11) Simulate discontinuities, such as

saturation or dead zone, for physical

signals

Sources (p. 1-12) Simulate physical signal sources

1-10

Functions

PS Add Add two physical signal inputs

PSDivide Computesimpledivisionoftwo

input physical signals

PS Gain

PS Math Function Apply mathematical function to

Multiply input physical signal by

constant

input physical signal

Page 19

Foundation

PS Product

PS Subtract Compute simple subtraction of two

Multiply two physical signal inputs

input physical signals

Linear Operators

PS Integrator

Integrate physical signal

Lookup Tables

PS Lookup Table (1D) Approximate one-dimensional

function using specified lookup

method

PS Lookup Table (2D) Approximate two-dimensional

function using specified lookup

method

Nonlinear Operators

PS Abs Output absolute value of input

physical signal

PS Ceil Output the smallest integer larger

than or equal to input physical signal

PS Dead Zone Provide region of zero output for

physical signals

PS Fix

PS Floor Output the largest integer smaller

PS Max Output maximum of two input

PS Min Output minimum of two input

Round input physical signal toward

zero

than or equal to input physical signal

physical signals

physical signals

1-11

Page 20

1 Block Reference

PS Saturation Limit range of physical signal

PS Sign Output sign of input physical signal

PS Switch Simulate single-pole double-throw

switch controlled by external

physical signal

Sources

PS Constant Generate constant physical signal

Pneumatic

Pneumatic Elements (p. 1-12)

Pneumatic Sensors (p. 1-13)

Pneumatic Sources (p. 1-13)

Pneumatic Utilities (p. 1-14)

Pneumatic building blocks,

such as orifices, chambers, and

pneumo-mechanical converters

Pneumatic sensors

Pneumatic sources

Basic pneumatic environment

blocks, s uch as gas properties

Pneumatic Elements

Adiabatic Cup Simulate thermal element with no

thermal mass and perfect insulation

Constant Area Pneumatic Orifice Simulate sharp-edged orifice in

pneumatic systems

Constant Area Pneumatic Orifice

(ISO 6358)

Constant Volume Pneumatic

Chamber

Simulate fixed-area pn eumatic

orifice complying with ISO 6358

standard

Simulate constant volume pneumatic

chamber based on ideal gas law

1-12

Page 21

Pneumatic A bso lute Reference Simulate reference to zero absolute

pressure and temperature for

pneumatic ports

Pneumatic Atmospheric Reference Simulate reference to ambient

pressure and temperature for

pneumatic ports

Pneumatic Piston Chamber Simulate translational pneumatic

piston chamber based on ideal gas

law

Foundation

Pneumatic Resistive Tube

Rotary Pneumatic Piston Chamber Simulate rotational pneumatic

Rotational Pneumatic-Mechanical

Converter

Variable Area Pneumatic Orifice Simulate variable orifice in

Simulate pressure loss and added

heatduetoflowresistancein

pneumatic pipe

piston chamber based on ideal gas

law

Provide interface between pneumatic

and mechanical rotational domains

pneumatic systems

Pneumatic Sensors

Pneumatic Mass & H eat Flow Sensor Simulate ideal mass flow and heat

flow sensor

Pneumatic Pressure & Temperature

Sensor

Simulate ideal pressure and

temperature sensor

Pneumatic Sources

Controlled Pneumatic Flow Rate

Source

Simulate ideal compressor with

signal-controlled mass flow rate

Controlled Pneumatic Pressure

Source

Simulate ideal compressor with

signal-controlled pressure difference

1-13

Page 22

1 Block Reference

Pneumatic Flow Rate Source Simulate ideal compressor with

constant mass flow rate

Pneumatic Pressure Source Simulate ideal compressor with

constant pressure difference

Pneumatic Utilities

Gas Properties Specify pneumatic domain properties

for attached circuit

Thermal

Thermal Elements (p. 1-14)

Thermal Sensors (p. 1-15) Temperature and heat flow sensors

Thermal Sources (p. 1-15) Temperature and heat flow sensors

Thermal building blocks, such as

thermal mass and various heat

transfer blocks

and sources

and sources

Thermal Elements

Conductive Heat Transfer Simulate heat transfer by conduction

Convective Heat Transfer Simulate heat transfer by convection

Radiative Heat Transfer Simulate heat transfer by radiation

Thermal Mass

Thermal Reference Simulate reference for thermal ports

Simulate mass in thermal systems

1-14

Page 23

Thermal Sensors

Ideal Heat Flow Sensor Simulate ideal heat flow meter

Ideal Temperature Sensor Simulate ideal temperature sensor

Thermal Sources

Ideal Heat Flow Source Simulate ideal source of thermal

energy, characterized by heat flow

Ideal Temperature Source Simulate ideal source of

thermal energy, characterized

by temperature

Foundation

1-15

Page 24

1 Block Reference

Utilities

Connection Port Create P hysical Modeling connector

port for subsystem

PS-Simulink Converter Convert physical signal into

Simulink

Simulink-PS Converter Convert Simulink input signal into

physical signal

Solver Configuration

Two-Way Connection Create two-way connector port for

Represent Physical Networks

environment and solver

configuration

subsystem

®

output signal

1-16

Page 25

2

Blocks — Alphabetical List

Page 26

AC Current Source

Purpose Simulate ide al sinusoidal current source

Library Electrical Sources

Description The AC Current Source block represents an ideal current source that

maintains sinusoidal current through it, independent of the voltage

across its terminals.

The output current is defined by the following equation:

II t=+

iisin( )ωϕ

0

where

Dialog

Box a nd

Parameters

I

I

0

ω

φ

t

The p ositive direction of the current flow is indicated by the arro w.

Current

Peak amplitude

Frequency

Phase shift

Time

2-2

Page 27

AC Current Source

Peak amplitude

Peak current amplitude. The default value is 10*sqrt(2), or

14.1421 A.

Phase shift

Phase shift in angular units. The default value is

Frequency

Current frequency. The default value is

60 Hz.

Ports The block has two electrical conserving ports associated with its

terminals.

See Also AC Voltage Source

0.

2-3

Page 28

AC Voltage Source

Purpose Simulate ideal constant voltage source

Library Electrical Sources

Description The AC Voltage Source block represents an ideal voltage source that

maintains sinusoidal voltage across its output terminals, independent

of the current flowing through the source.

The output voltage is defined by the following equation:

VV t=+

where

V

V

0

ω

φ

t

Connections + and – are conserving electrical ports corresponding to the

positive and negative terminals of the voltage source, respectively. The

current is positive if it flows from positive to negative, and the voltage

across the source is equal to the difference between the voltage at the

positive and the negative terminal, V(+) – V(–).

iisin( )ωϕ

0

Voltage

Peak amplitude

Frequency

Phase shift

Time

2-4

Page 29

Dialog

Box a nd

Parameters

AC Voltage Source

Peak amplit

Peak voltag

169.71 V.

Phase shif

Phase shi

Frequenc

Voltage f

ude

e amplitude. The default value is 120*sqrt(2), or

t

ft in angular units. The default value is

y

requency. The default value is

Ports The block has the following ports:

+

Electrical conserving port associated with the source positive

terminal.

Electrical conserving port associated with the source negative

terminal.

See Also AC Current Source

0.

60 Hz.

2-5

Page 30

Adiabatic Cup

Purpose Simulate thermal element with no thermal mass and perfect insulation

Library Pneumatic Elements

Description The Adiabatic Cup block models a thermal element w ith no thermal

mass and perfect insulation. Use this block as an insulation for thermal

ports to prevent heat exchange with the environment and to model

an adiabatic process.

Dialog

Box a nd

Parameters

The block has no parameters.

Ports The block has one pneumatic conserving port.

2-6

Page 31

Capacitor

Purpose Simulate linear capacitor in electrical systems

Library Electrical Elements

Description The Capacitor block models a linear capacitor, described with the

following equation:

dV

IC

=

dt

where

I

V

C

t

The Initial voltage parameter sets the initial voltage across the

capacitor.

Note This value is not used if the solver configuration is set to Start

simulation from steady state.

The Series resistance and Parallel conductance parameters

represent small parasitic effects. The parallel conductance directly

across the capacitor can be used to model dielectric losses, or

equivalently leakage current per volt. The series resistance can be used

to represent component effective series resistance (ESR) or connection

resistance. Simulation of some circuits may require the presence of

the small series resistance. For more information, see “Modeling Best

Practices” in the Simscape™ User’s Guide.

Connections + and – are conserving electrical ports corresponding to

the p ositive and negative terminals of the capacitor, respectively. The

Current

Voltage

Capacitance

Time

2-7

Page 32

Capacitor

Dialog

Box a nd

Parameters

current is positive if it flows from positive to negative, and the voltage

across the capacitor is equal to the difference betw een the voltage at the

positive and the negative terminal, V(+) – V(–).

2-8

Capacitance

Capacitance, in farads. The default value is

Initial voltage

Initial voltage across the capacitor. This parameter is not used if

the solver configuration is set to Start simulation from steady

state. The default value is

Series resistance

Represents small parasitic effects. The series resistance can be

used to represent component internal resistance. Simulation

of some circuits may require the presence of the small series

resistance. The default value is

0.

1 µΩ.

1 µF.

Page 33

Parallel conductance

Represents small parasitic effects. The parallel conductance

directly across the capacitor canbeusedtomodelleakagecurrent

per volt. The default value is

Ports The block has the following ports:

+

Electrical conserving port associated with the capacitor positive

terminal.

-

Electrical conserving port as sociated with the capacitor negative

terminal.

Capacitor

0.

2-9

Page 34

Conductive Heat Transfer

Purpose Simulate heat transfer by conduction

Library Thermal Elements

Description The Conductive Heat Transfer block represents a heat transfer by

conduction between two layers of thesamematerial. Thetransfer

is governed by the Fourier law and is described with the following

equation:

A

Qk

=−i ()

where

Q Heat flow

k Material thermal conductivity

TT

AB

D

A

D

T

A,TB

Connections A and B are thermal conserving ports associated with

material layers. The block positive direction is from port A to port B.

This means that the heat flow is positive if it flows from A to B.

Area normal to the h eat flow direction

Distance between layers

Temperatures of the layers

2-10

Page 35

Dialog

Box a nd

Parameters

Conductive Heat Transfer

Area

Area of heat transfer, normal to the heat flow direction. The

default value is

Thickness

Thickness between layers. The default value is

0.0001 m^2.

0.1 m.

Thermal conductivity

Thermal conductivity of the material. The default value is

W/m/K.

Ports The block has the following ports:

A

Thermal conserving port associated with layer A.

B

Thermal conserving port associated with layer B.

See Also Convective Heat Transfer

Radiative Heat Transfer

401

2-11

Page 36

Connection Port

Purpose Create Physical Modeling connector port for subsystem

Library Utilities

Description The Connection Port block transfers both the conserving and the

physical signal connections to the outside boundary of a subsystem

block. This transfer is similar to the Inport and Outport blocks in

Simulink models. A subsystem needs a Connection Port block for each

physical connection line that crosses its boundary. You can manually

place a Conne ction Port block inside a subsystem, or Simulink can

automatically insert a Connection P ort block when you create a

subsystemwithinanexistingnetwork.

Port Appearance on Subsystem Boundary

The ports on the subsystem boundary change their appearance

depending on the type of port to which the Connection Port block is

connected inside the subsystem.

Connection Port Block Inside a

Subsystem Connects to ...

A Conserving port

A Physical Signal inport or outport

Atwo-wayconnectorportofthe

Two-Way Connection block

A SimMechanics™ connector port,

either:

Round connector port Round connector port

Body coordinate sys tem

port

2-12

... and Appears on the Outside Boundary of

the Subsystem as ...

A square Conserving port

A triangular Physical Signal

A two-way connector port

A SimMechanics connector port, either:

Body coordinate system port

inport or outport

Page 37

Connection Port

Port Location and Orientation on Subsystem Boundary

The orientation of the parent subsystem block and your choice of port

location determine the Connection Port block port location on the p arent

subsystem boundary.

• A subsystem is in its fundamental orientation when its Simulink

signal inports occur on its left side and its Simulink signal outports

occur on its right side.

When a subsystem is oriented in this way, the actual port location

on the subsystem boundary respects your choice of port location (left

or right) for the connector port.

• A subsyste m orientation is reversed, with left and right interchanged,

when its Simulink signal inports occur on i ts right side and its

Simulink signal outports occur on its left side.

When a subsystem is oriented in this way, the actual port location on

the subsystem boundary reverses your choice of port location. If you

choose left, the port appears on the right side. If you choose right,

the port appears on the left side.

2-13

Page 38

Connection Port

Dialog

Box a nd

Parameters

Port number

Labels the subsystem connector port that this block creates. Each

connector port on the boundary of a single subsystem requires a

unique number as a label. The default v alue for the first port is

1.

Port location on parent subsystem

Choose here which side of the parent subsystem boundary the

port is located. T h e choices are

is

Left.

See “Port Location and Orientation on Subsystem Boundary” on

page 2-13.

Left or Right. The default choice

See Also In the Simulink User’s Guide, see “Working w ith Block Masks”.

2-14

Page 39

Constant Area Hydraulic Orifice

⎝

⎠

Purpose Simulate hydraulic orifice with constant cross-sectional area

Library Hydraulic Elements

Description The Constant Area Hydraulic Orifice block models a sharp- e d ged

constant-area orifice. T he model distinguishes between the laminar and

turbulent flow regimes by comparing the Reynolds number with its

critical value. The flow rate through the orifice is proportional to the

pressure differential across the orifice, and is determined according

to the follow i ng equations:

⎧

⎪

⎪

q

=

⎨

⎪

⎪

⎩

pp p

=−

Re =

C

DL

D

=

H

where

q

p

pA,p

B

C A p sign p Re Re

D

CADpReRe

2

AB

qD

i

A

⎛

=

⎜

⎜

| | for >=

ρ

H

i

DL

i

νρ

H

()

iν

2

⎞

C

D

⎟

⎟

Re

cr

A

4

for <

cr

cr

2

ii

π

Flow rate

Pressure differential

Gauge pressures at the block terminals

2-15

Page 40

Constant Area Hydraulic Orifice

Basic

Assumptions

and

Limitations

C

A

D

ρ

ν

Re

Re

D

H

Flow discharge coe fficient

Orifice passage area

Orifice hydraulic diameter

Fluid density

Fluid kinematic viscosity

Reynolds number

Critical Reynolds num ber

cr

The block positive direction is from port A to port B. This means

thattheflowrateispositiveifitflowsfromAtoB,andthepressure

differential is determined as

pp p

=−

AB

.

The model is based on the following assumptions:

• Fluid inertia is not taken into account.

• The transition between laminar and turbulent regimes is assumed to

be sharp and taking place exactly at

Re=Re

.

cr

2-16

Page 41

Dialog

Box a nd

Parameters

Constant Area Hydraulic Orifice

Orifice area

Orifice passage area. The default value is

Flow discharge coefficient

Semi-empirical parameter for orifice capacity characterization.

Its value depends on the geometrical properties of the orifice, and

usually is provided in textbooks or manufacturer data sheets.

The default value is

Critical Reynolds number

The maximum Reynolds number for laminar flow. The transition

from laminar to turbulent re gime is supposed to take place

when the Reynolds number reaches this value. The value

of the parameter depends on orifice geometrical profile, and

the recommendations on the parameter value can be found in

hydraulic textbooks. The default value is

a round orifice in thin material with sharp edges.

0.7.

1e-4 m^2.

12, which corresponds to

2-17

Page 42

Constant Area Hydraulic Orifice

Global

Parameters

Fluid density

The parameter is determined by the type of working fluid selected

for the system under design. Use the Custom Hydraulic Fluid

block, or the Hydraulic Fluid block a vailable with SimHydraulics

block libraries, to specify the fluid properties.

Fluid kinematic viscosity

The parameter is determined by the type of working fluid selected

for the system under design. Use the Custom Hydraulic Fluid

block, or the Hydraulic Flui d block available with SimHydraulics

block libraries, to specify the fluid properties.

Ports The block has the following ports:

A

Hydraulic co n serving port a sso ciated with the orifice inlet.

B

Hydraulic conserving port associated with the orifice outlet.

See Also Variable Area Hydraulic Orifice

®

2-18

Page 43

Constant Area Pneumatic Orifice

Purpose Simulate sharp-edged orifice in pneumatic systems

Library Pneumatic Elements

Description The Constant Area Pneumatic Orifice block models the flow rate of an

ideal gas through a sharp-edged orifice.

Theflowratethroughtheorificeisproportion al to the orifice area and

the pressure differential across the orifice.

+

γ

⎤

γ

⎞

⎛

p

⎜

p

⎝

⎥

o

⎟

⎥

i

⎠

⎥

⎦

GCAp

=

ii i

di

γ

211

γ

−

⎡

⎛

⎢

⎜

⎢

RTpp

i

⎝

⎢

⎣

21

γ

⎞

o

−

⎟

i

⎠

where

G Mass flow rate

C

d

Discharge coefficient, to account for effective loss of area due

to orifice shape

A

p

i,po

Orifice cross-sectional area

Absolute pressures at the orifice inlet and outlet, respectively.

The inlet and outlet change depending on flow direction. For

positive flow (G >0),p

γ

R

T

The ratio of specific heats a t constant pressure and constant

volume, c

p/cv

Specific gas constant

Absolute gas temperature

= pA,otherwisepi= pB.

i

The choked flow occurs at the critical pressure ratio defined by

γ

β

==

cr

p

⎛

o

⎜

p

⎝

i

γ

−

1

⎞

2

⎟

1

γ

+

⎠

2-19

Page 44

Constant Area Pneumatic Orifice

after which the flow rate depends on the inlet pressure only and is

computed with the expression

+

γγ1

GCAp

=

ii i

diicr

The square root relationship has infinite gradient at zero flow, which

can present numerical solver difficulties. Therefore,forverysmall

pressure differences, defined by p

replaced by a linear flow-pressure relationship

GkCAT p p

=−

ii

di io

where k is a constant such that the flow predicted for po/piis the same

as that predicted by the original flow equatio n for p

Theheatflowoutoftheorificeisassumedequaltotheheatflowinto

the orifice, based on the following considerations:

γ

β

RT

−

05.

()

> 0.999, the flow equation is

o/pi

o/pi

=0.999.

2-20

• The orifice is square-edged or sharp-edged, and as such is

characterized by an abrupt change of the downstream area. This

means that practically all the dynamic pressure is lost in the

expansion.

• The lost energy appears in the form of internal energy that rises the

output temperature and makes it very close to the inlet temperature.

Therefore, q

= qo,whereqiand qoare the input and output heat flows,

i

respectively.

The block positive direction is from port A to port B. This means that

theflowrateispositiveifitflowsfromAtoB.

Page 45

Constant Area Pneumatic Orifice

Basic

Assumptions

and

Limitations

Dialog

Box a nd

Parameters

The model is based on the following assumptions:

• The gas is ideal.

• Specific heats at constant pressure and constant volume, c

are constant.

• The process is adiabatic, that is, there is no heat transfer with the

environment.

• Gravitational effects can be neglected.

• The orifice adds no net heat to the flow.

and cv,

p

Discha

Orifi

rge coefficient, Cd

Semi-e

Its val

usual

The de

ce area

Spec

m^2.

mpirical parameter for orifice capacity characterization.

ue depends on the geometrical properties of the orifice, and

ly is provided in textbooks or manufacturer data sheets.

fault value is

ify the orifice cross-sectional area. The default value is

0.82.

Ports The block has the following ports:

1e-5

2-21

Page 46

Constant Area Pneumatic Orifice

A

Pneumatic conserving port associated with the orifice inlet for

positive flow.

B

Pneumatic conserving port associated with the orifice outlet for

positive flow.

See Also Constant Area Pneumatic Orifice (ISO 6358)

Variable Area Pneumatic Orifice

2-22

Page 47

Constant Area Pneumatic Orifice (ISO 6358)

Purpose Simulate fixed-area pneumatic orifice complying with ISO 6358

standard

Library Pneumatic Elements

Description The Constant Area Pneumatic Orifice (ISO 6358) block models the flow

rate of an ideal gas through a fixed-area sharp-edged o rifice. The model

conforms to the ISO 6358 standard and is based on the following flow

equations, originally proposed by Sanville [1]:

⎧

kp

⎪

1

⎪

⎛

⎜

i

⎝

⎞

p

o

−

1iiif (laminarβ ))

⎟

p

i

⎠

⎪

⎪

⎪

⎪

G

=

ii iρβ1

⎨

i ref

⎪

T

ref

T

i

⎪

⎪

ii

T

ref

T

i

ρ

ref

⎪

iiρ<=

⎪

i ref

⎪⎪

⎩

1

=

kC

1

1

−

β

lam

where

G Mass flow rate

β

lam

Pressure ratio at laminar flow, a value between 0.999 and

0.995

b

Critical pressure ratio, that is, the ratio between the outlet

pressure p

and inlet pressure piat which the gas velocity

o

achieves sonic speed

T

ref

T

i

−

⎛

1

−

⎜

⎝

sign p p

⎛

⎜

⎜

⎜

⎜

⎝

β

lam

1

−

()

io

p

p

1

2

⎞

o

b

−

⎟

i

⎟

b

−

⎟

⎟

⎠

2

−

b

⎞

⎟

−

b

⎠

p

o

>

lam

p

i

p

o

if (pC

if (choked)pC

>>

lam

p

o

p

i

ssubsonic)

b

p

i

b

2-23

Page 48

Constant Area Pneumatic Orifice (ISO 6358)

C Sonic conductance of the component, that is, the ratio

between the mass flow rate and the product of inlet pressure

p

and the mass density at standard conditions when the flow

1

is choked

ρ

p

T

ref

i,po

i,To

Gas de nsity at standard conditions (1.185 kg/m^3 for air)

Absolute pressures at the orifice inlet and outlet, respectively.

The inlet and outlet change depending on flow direction. For

positive flow (G >0),p

= pA,otherwisepi= pB.

i

Absolute gas temperatures at the orifice inlet and outlet,

respectively

T

ref

Gas temperature at standard conditions (T

=293.15K)

ref

The equation itself, parameters b and C, and the heuristic on how

to measure these parameters experimentally form the basis for the

standard ISO 6358 (1989). The values of the critical pressure ratio

b and the sonic conductance C depend on a particular design of a

component. Typically, they are determined experimentally and are

sometimes given on a manufacturer data sheet.

The block can also be parameterized in terms of orifice effective area

or flow coefficient, instead of sonic conductance. When doing so,

block parameters are co nv erted into an equivalent value for sonic

conductance. When specifying effective area, the following formula

proposed by Gidlund and de tailed in [2] is used:

C =0.128d

2

where

C Sonic conductance in dm^3/(s*bar)

d

Inner diameter of restriction in mm

The effective area (whether specified directly, or calculated when the

orifice is parameterized in terms of C

or Kv, as described below) is used

v

2-24

Page 49

Constant Area Pneumatic Orifice (ISO 6358)

to determine the inner diameter d in the Gidlund formula, assuming a

circular cross section.

Gidlund also gives an approximate formula for the critical pressure

ratio in terms of the pneumatic line diameter D,

b = 0.41 + 0.272 d / D

This equation is not used by the block and you must specify the critical

pressure ratio directly.

If the orifice is parameterized in terms of the C

the C

coefficient is turned into an equivalent effective o rifice area for

v

[2] coefficient, then

v

use in the Gidlund formula:

A = 1.6986e – 5 C

v

By definition, an opening or restriction has a Cvcoefficient of 1 if it

passes 1 gpm (gallon per minute) of water at pressure drop of 1 psi.

If the orifice is parameterized in ter ms of the K

the K

coefficient is turned into an equivalent effective o rifice area for

v

[2] coefficient, then

v

use in the Gidlund formula:

A = 1.1785e – 6 C

Kvis the SI counterpart of Cv. An opening or restriction has a K

v

v

coefficient of 1 if it passes 1 lpm (liter per minute) of water at pressure

drop of 1 bar.

Theheatflowoutoftheorificeisassumedequaltotheheatflowinto

the orifice, based on the following considerations:

• The orifice is square-edged or sharp-edged, and as such is

characterized by an abrupt change of the downstream area. This

means that practically all the dynamic pressure is lost in the

expansion.

2-25

Page 50

Constant Area Pneumatic Orifice (ISO 6358)

• The lost energy appears in the form of internal energy that rises the

output temperature and makes it very close to the inlet temperature.

Basic

Assumptions

and

Limitations

Therefore, q

respectively.

The block positive direction is from port A to port B. This means that

theflowrateispositiveifitflowsfromAtoB.

The model is based on the following assumptions:

• The gas is ideal.

• Specific heats at constant pressure and constant volume, c

are constant.

• The process is adiabatic, that is, there is no heat transfer with the

environment.

• Gravitational effects can be neglected.

• The orifice adds no net heat to the flow.

= qo,whereqiand qoare the input and output heat flows,

i

and cv,

p

2-26

Page 51

Dialog

Box a nd

Parameters

Constant Area Pneumatic Orifice (ISO 6358)

2-27

Page 52

Constant Area Pneumatic Orifice (ISO 6358)

2-28

Orifice is s pecified with

Select one of the following model parameterization methods:

Page 53

Constant Area Pneumatic Orifice (ISO 6358)

• Sonic conductance —Providevalueforthesonicconductance

of the orifice. The values of the sonic conductance and the

critical pressure ratio form the basis for the ISO 6358 compliant

flow equations for the orifice. This is the default m ethod.

•

Effective area — Provide value for the orifice effective

area. This value is internally converted by the block into an

equivalent value for sonic conductance.

•

Cv coefficient (USCU) —Providevaluefortheflow

coefficient specified in US units. This value is internally

converted by the block into an equivalent value for the orifice

effective area.

•

Kv coefficient (SI) — Provide value for the flow coefficient

specified in SI units. This value is internally converted by the

block into an equivalent value for the orifice effective area.

Sonic conductance

Specify the sonic conductance of the orifice, that is, the ratio

between the mass flow rate and the product of upstream pressure

and the mass density at standard conditions w hen the flow is

choked. This value depends on the geometrical properties of the

orifice, and usually is provided in textbooks or manufacturer data

sheets. The default value is

in the dialog box if Orifice is specified with parameter is set

to

Sonic conductance.

1.6 l/s/bar. This parameter appears

Effective area

Specify the orifice cross-sectional area. The default value is

m^2. This parameter appears in the dialog box if Orifice is

specified with parameter is set to

Effective area.

Cv coefficient

Specify the value for the flow coefficient in US units. The default

value is

is specified with parameter is set to

0.6. This parameter appears in the dialog box if Orifice

Cv coefficient (USCU).

1e-5

2-29

Page 54

Constant Area Pneumatic Orifice (ISO 6358)

Kv coefficient

Specify the value for the flow coefficient in SI units. The default

value is

is specified with parameter is set to

Critical pressure ratio

Specify the critical pressure ratio, that is, the ratio between the

downstream pressure and the upstream pressure at w hich the gas

velocity achieves sonic speed. The default value is

Pressure ratio at laminar flow

Specify the ratio b etween the downstream pressure and the

upstream pressure at laminar flow. This value can be in the range

between 0.995 and 0.999. The default value is

Temperature at standard conditions

Specify the gas temperature at which the sonic conductance was

measured. The default value is

Pressure at standard conditions

Specify the gas pressure at which the sonic conductance was

measured. The default value is

8.5. This parameter appears in the dialog box if Orifice

Kv coefficient (SI).

293.15 K.

101325 Pa.

0.528.

0.999.

Ports The block has the following ports:

A

Pneumatic conserving port associated with the orifice inlet for

positive flow.

B

Pneumatic conserving port associated with the orifice outlet for

positive flow.

References [1] Sanville, F. E. “A New Method of Specifying the Flow Capacity of

Pneumatic Fluid Power Valves.” Paper D3, p.37-47. BHRA. Second

International Fluid Power Symposium, Guildford, England, 1971.

[2] Beater, P. Pneumatic Drives. System Design, Modeling, and Control.

New York: Springer, 2007.

2-30

Page 55

Constant Area Pneumatic Orifice (ISO 6358)

See Also Constant Area Pneumatic Orifice

Variable Area Pneumatic Orifice

2-31

Page 56

Constant Volume Hydraulic Chamber

Purpose Simulate hydraulic capacity of constant volume

Library Hydraulic Elements

Description The Constant Volume Hydraulic Chamber block models a fixed-volume

chamber with rigid or flexible walls, to be used in hydraulic valves,

pumps, manifolds, pipes, hoses, and so on. Use this block in models

where you have to account for some form of fluid compressibility. You

can select the appropriate representation of fluid compressibility using

the block parameters.

Fluid compressibility in its simplest form is simulated according to the

following equations:

V

dt

c

p

E

f

VV

=+

fc

dV

q

=

2-32

where

q

V

f

V

c

E

p

Flow rate into the chamber

Volume of fluid in the chamber

Geometrical chamber volume

Fluid bulk modulus

Gauge pressure of fluid in the chamber

If pressure in the chamber is likely to fall to negative values and

approach cavitation limit, the above equations must be enhanced. In

this block, it is done by representing the fluid in the chamb er as a

mixture o f liquid and a small amount of entrained, nondissolved gas.

The mixture bulk modulus is determined as:

Page 57

EE

where

Constant Volume Hydraulic Chamber

1

/

⎛

+

1

=

l

1

α

+

p

α

⎜

pp

a

⎝

1

p

a

i

np p

+

()

a

n

⎞

a

⎟

+

⎠

/

n

E

l

n

+

1

n

E

l

p

α

α

V

G

V

L

n

Pure liquid bulk modulus

Atmospheric pressure

Relative gas content at atmospheric pressure, α =

Gas volume at atmospheric pressure

Volume of liquid

Gas-specific heat ratio

V

G/VL

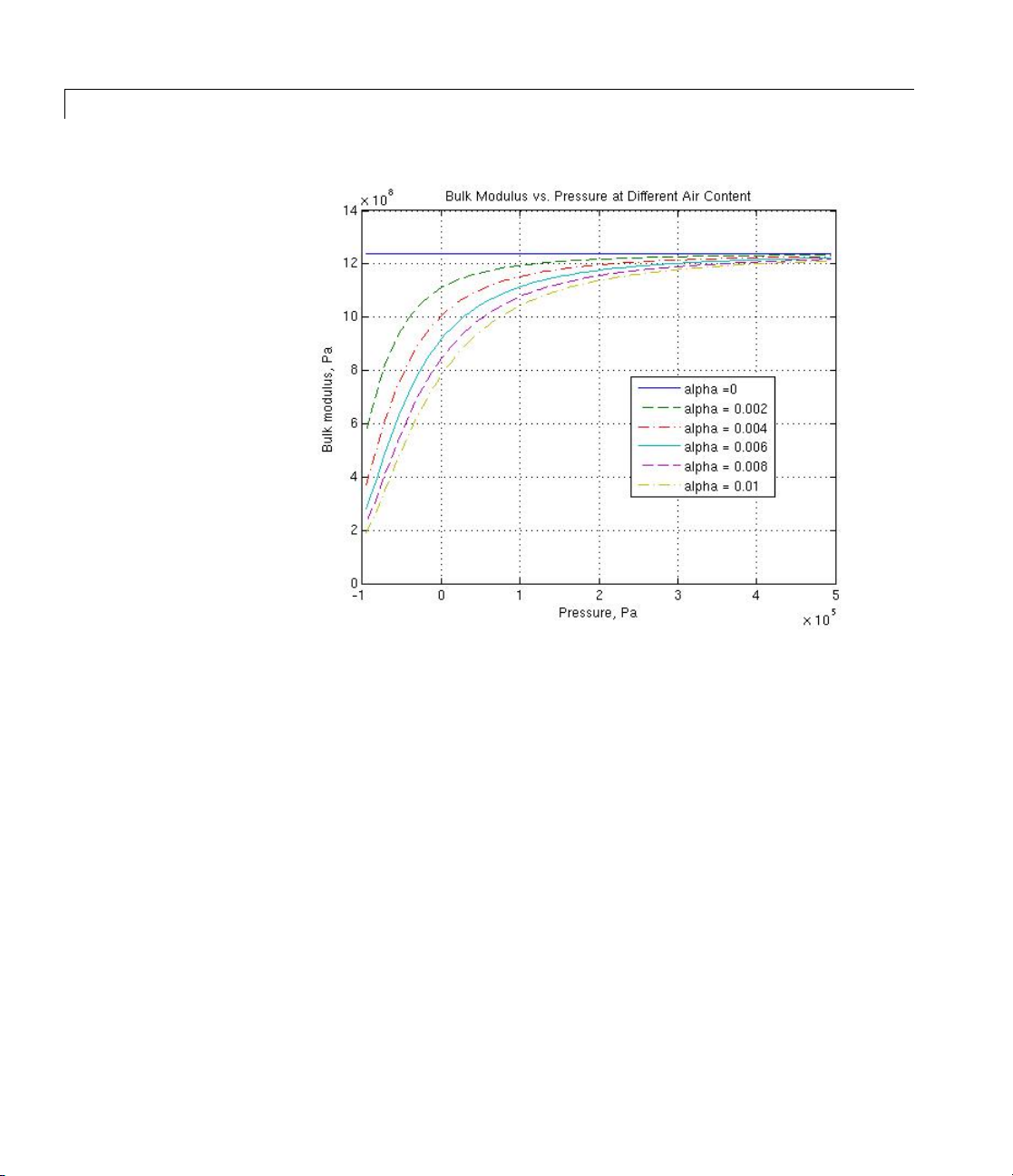

The main objective of representing fluid as a mixture of liquid and gas

is to introduce an approximate model of cavitation, which takes place

in a chamber if pressure drops below fluid vapor saturation level. As

it is seen in the graph below, the bulk modulus of a mixture decreases

at

pp

At high pressure,

, thus considerably slowing down further pressure change.

→

a

pp

>>

, a small amount of nondissolved gas has

a

practically no effect on the system behavior.

2-33

Page 58

Constant Volume Hydraulic Chamber

2-34

Cavitation is an inherently thermodynamic process, requiring

consideration of multiple-phase fluids, heat transfers, etc., and as

such cannot be accurately simulated with Simscape software. But the

simplified version implemented in the block is good enough to signal

if pressure falls below dangerous level, and to prevent computation

failure that normally occurs at negative pressures.

If it is known t hat cavitation is unlikely in the system under design, you

can set the relative gas content in the fluid properties to zero, thus

increasing the speed of computations. Use the Hydraulic Fluid or the

Custom Hydraulic Fluid block to set the fluid properties.

If chamber walls have noticeable compliance , the ab ov e equations must

be further enhanced by representing geometrical chamber volume as a

function of pressure:

Page 59

Constant Volume Hydraulic Chamber

VdL

=π24/ i

c

K

ds

where

() ()=

p

+1 τ

s

ps

d

L

K

p

τ

s

Coefficient

Internal diameter of the cylindrical chamber

Length of the cylindrical chamber

Proportionality coefficient (m/Pa)

Time constant

Laplace operator

K

establishes relationship between press ure and the

p

internal diameter at steady-state conditions. For metal tubes, the

coefficient can be computed as (see [1]):

22

⎛

K

dEDd

=

p

M

+

⎜

22

⎜

Dd

−

⎝

⎞

+

ν

⎟

⎟

⎠

where

D

E

M

Pipe external diameter

Modulus of elasticity (Young’s modulus) for the pipe material

Poisson’s ratio for the pipe material

For hoses, the coefficient can be provided by the manufacturer.

The process of expansion and contraction in pipes and especially in

hosesisacomplexcombinationofnonlinear elastic and viscoelastic

deformations. This process is approximated in the block with the

2-35

Page 60

Constant Volume Hydraulic Chamber

first-order lag, whose time constant is determined empirically (for

example, see [2]).

As a result, by selecting appropriate values, you can implement four

different models of fluid compressibility with this block:

• Chamber with rigid walls, no entrained gas in the fluid

• Cylindrical chamber with compliant walls, no entrained gas in the

fluid

• Chamber with rigid walls, fluid with entrained gas

• Cylindrical chamber with compliant walls, fluid with entrained g as

The block allows two methods of specifying the chamber size:

• By volume — Use this option for cylindrical or non-cylindrical

chambers w ith rigid walls. You only need to know the volume of the

chamber. This chamber type does not account for wall compliance.

• By length and diameter — Use this option for cylindrical chambers

with rigid or compliant walls, such as circular pipes or hoses.

Basic

Assumptions

and

Limitations

2-36

The block has one hydraulic conserving port associated with the

chamber inlet. The block positive direction is from its port to the

referencepoint. Thismeansthattheflowrateispositiveifitflows

into the chamber.

The model is based on the following assumptions:

• No inertia associated with pipe walls is taken into account.

• Chamber with compliant walls is assumed to have a cylindrical

shape. Chamber with rigid wall can ha ve any shape.

Page 61

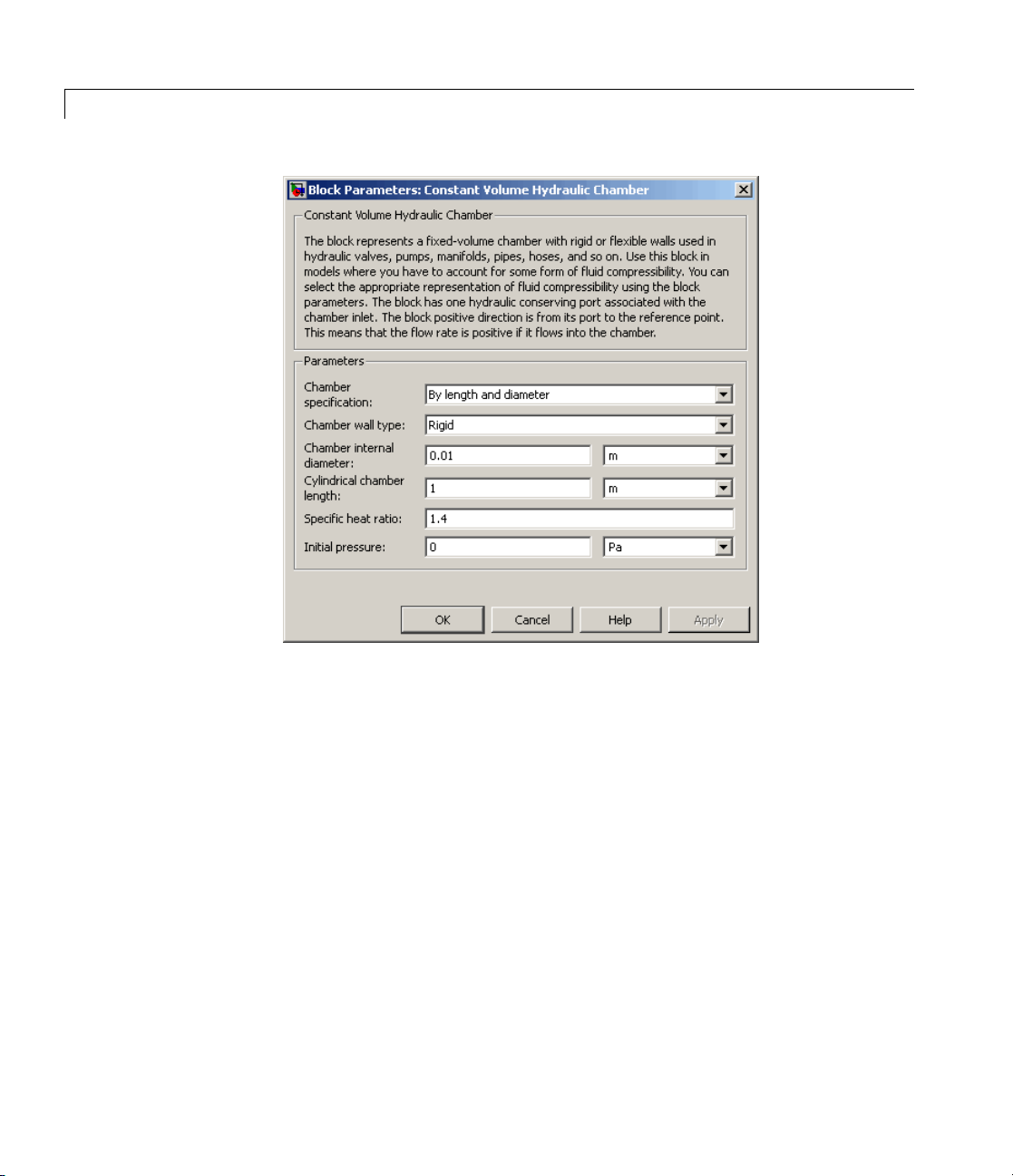

Dialog

Box a nd

Parameters

Constant Volume Hydraulic Chamber

2-37

Page 62

Constant Volume Hydraulic Chamber

2-38

Page 63

Constant Volume Hydraulic Chamber

Chamber specification

Theparametercanhaveoneoftwovalues:

length and diameter

recommended if a chamber is formed by a circular pipe. If the

parameter i s set to

account. The default value of the parameter is

Chamber wall type

Theparametercanhaveoneoftwovalues:

If the parameter is set to

account, which can improve computational efficiency. The value

Compliant is recommended for hoses and metal pipes, where

.ThevalueBy length and diameter is

By volume, wall compliance is not taken into

Rigid, wall compliance is not taken into

By volume or By

By volume.

Rigid or Compliant.

2-39

Page 64

Constant Volume Hydraulic Chamber

compliance can affect the system behavior. The default value of

the p arameter is

specification parameter is set to

Chamber volume

Volume of fluid in the chamber. The default value is

The parameter is used if the Chamber specification parameter

is set to

By volume.

Chamber internal diameter

Internal diameter of the cylindrical chamber. The default value is

0.01 m. The parameter is used if the Chamber specification

parameter is set to

Cylindrical chamber length

Length of the cylindrical chamber. The default value is

parameter is used if the Chamber specification param eter is

set to

By length and diameter.

Static pressure-diameter coefficient

Coefficient

the internal diameter at steady-state conditions. The parameter

can be determ ined analytically or experimentally. The default

value is

1.2e-12 m/Pa. The parameter is used if Chamber wall

type is set to

Rigid. The parameter is used if the Chamber

By length and diameter.

K

that establishes relationship between pressure and

p

Compliant.

By length and diameter.

1e-4 m^3.

1 m. The

2-40

Viscoelastic process time constant

Time constant in the transfer function relating pipe internal

diameter to pressure variations. With this parameter, the

simulated elastic or v iscoelastic process is approximated with the

first-order lag. The parameter is determined experimentally or

provided by the manufacturer. The default value is

parameter is used if Chamber wall type is set to

Compliant.

Specific heat ratio

Gas-specific heat ratio. The default value is

1.4.

Initial pressure

Initial pressure in the chamber. This parameter specifies the

initial condition for use in computing the block’s initial state at

0.01 s. The

Page 65

Constant Volume Hydraulic Chamber

the beginning of a simulation run. For more information, see

“Computing Initial Conditions”. The default value is

Restricted Parameters

When your model is in Restricted editing mode, you cannot modify the

following parameters:

• Chamber specification

• Chamber wall type

All other block parameters are available for modification. The actual

set of modifiable block parameters depends on the values of the Tube

cross section type and Chamber wall type parameters at the time

the model entered Restricted mode.

0.

Global

Parameters

Fluidbulkmodulus

The parameter is determined by the type of working fluid selected

for the system under design. Use the Hydraulic Fluid block or the

Custom Hydraulic Fluid block to specify the fluid properties.

Nondissolved gas ratio

Nondissolved gas relative content determined as a ratio of gas

volume to the liquid volume. The parameter is determined by the

type of working fluid se le cted for the system under design. Use

the Hydraulic Fluid block or the Custom Hydraulic Fluid block

to specify the fluid properties.

Ports The block has one hydraulic conserving port associated with the

chamber inlet.

References [1] Meritt, H.E., Hydraulic Control Systems, John Wiley & Sons, N ew

York, 1967

[2] Holcke, Jan, Frequency Response of Hydraulic Hoses, RIT, FTH,

Stockholm, 2002

2-41

Page 66

Constant Volume Hydraulic Chamber

See Also Hydraulic Piston Chamber

Variable Hydraulic Chamber

2-42

Page 67

Constant Volume Pneumatic Chamber

Purpose Simulate constant volume pneumatic chamber based on ideal gas law

Library Pneumatic Elements

Description The Constant Volume Pneumatic Chamber block models a constant

volume pneumatic chamber based on the ideal gas law and assuming

constant specific heats.

The continuity equation for the network representation of the co n stant

chamber is

VRTdpdtpTdT

G

where

G Mass flow rate at input port

⎛

=−

⎜

⎝

dt

⎞

⎟

⎠

V

p

R

T

t

The energy equation is

where

Chamber volume

Absolute pressure in the chamber

Specific gas constant

Absolute gas temperature

Time

cV

v

q

=−i

Rdpdt

q

w

2-43

Page 68

Constant Volume Pneumatic Chamber

Basic

Assumptions

and

Limitations

Dialog

Box a nd

Parameters

q

q

w

c

v

Port A is the pneumatic conserving port associated with the chamber

inlet. Port H is a thermal conserving port through which heat exchange

with the environment takes place. The gas flow a nd the heat flow are

considered positive if they flow into the chamber.

The model is based on the following assumptions:

• The gas is ideal.

• Specific heats at constant pressure and constant volume, c

are constant.

Heat flow due to ga s inflow in the chamber (through the

pneumatic port)

Heat flow through the chamber walls (through the thermal

port)

Specific heat at constant volume

and cv,

p

2-44

Page 69

Constant Volume Pneumatic Chamber

Chamber volume

Specify the volume of the chamber. The default value is

Initial pressure

Specify the initial pressure in the chamber. This parameter

specifies the initial condition for use in computing the initial state

at the beginning of a simulation run. For more information, see

“Computing Initial Conditions”. The default val ue is

Initial temperature

Specify the initial temperature of the gas in the chamber. This

parameter specifies the initial condition for use in computing

the initial state at the beginning of a simulation run. For more

information, see “Computing Initial Conditions”. The default

value is

Ports The block has the following ports:

A

Pneumatic conserving port associated with the chamber inlet.

293.15 K.

.001 m^3.

101235 Pa.

H

Thermal conserving port through which heat exchange with the

environment takes place.

See Also Pneumatic Piston Chamber

Rotary Pneumatic Piston Chamber

2-45

Page 70

Controlled Current Source

Purpose Simulate ideal current source driven by input signal

Library Electrical Sources

Description The Controlled Current Source block repres ents an ideal current source

that is powerful enough to maintain the specified current through it

regardless of the voltage across the source.

The output current is I=Is,whereIs is the numerical value presented

at the physical signal port.

The p ositive direction of the current flow is indicated by the arro w.

Dialog

Box a nd

Parameters

The block has no parameters.

Ports The block has one physical signal input port and two electrical

conserving ports associated with its electrical terminals.

See Also Controlled Voltage Source

2-46

Page 71

Controlled Flux Source

Purpose Simulate ideal flux source driven by input signal

Library Magnetic Sources

Description The Controlled Flux Source block represents an ideal flux source that is

powerful enough to maintain the specified flux through it regardless of

the mmf across the source.

The output flux is PHI = PHIs,wherePHIs is the numerical value

presented at the physical signal port.

The positive direction of the flux flow is indicated by the arrow.

Dialog

Box a nd

Parameters

The block has no parameters.

Ports The blo

conse

ck has one physical signal input port and two magnetic

rving ports associated with its magnetic terminals.

See Also Controlled MMF Source

Flux Source

MMF Source

2-47

Page 72

Controlled MMF Source

Purpose Simulate ideal magnetomotive force source driven by input signal

Library Magnetic Sources

Description The Controlled MMF Source block represents an ideal magnetomotive

force (mmf) source that is powerful enough to maintain the specified

mmf at its output regardless of the flux passing through it.

The output mmf is MMF = MMFI,whereMMFI is the numerical value

presented at the physical signal port.

Dialog

Box a nd

Parameters

The block has no parameters.

Ports The block has one physical signal input port and two magnetic

conserving ports associated with its magnetic terminals.

See Also Controlled Flux Source

Flux Source

MMF Source

2-48

Page 73

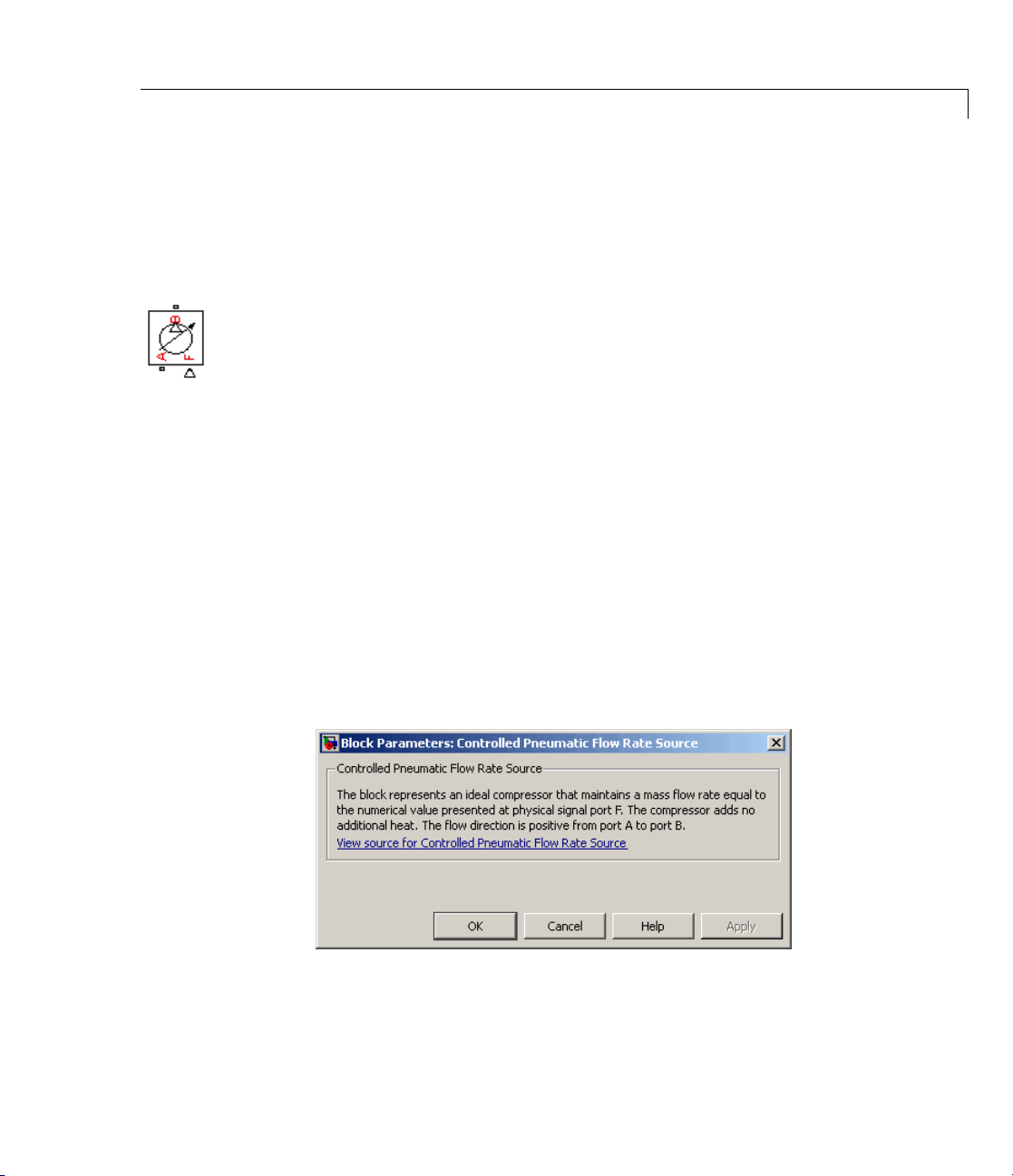

Controlled Pneumatic Flow Rate Source

Purpose Simulate ideal compressor with signal-controlled mass flow rate

Library Pneumatic Sources

Description The Controlled Pneumatic Flow Rate Source block represents an ideal

compressor that maintains a mass flow rate equal to the numerical

value presented at physical signal port F. The compressor adds no heat.

Block connections A and B correspond to the pneumatic inlet and outlet

ports, respectively, and connection F represents a control signal port.

The block positive direction is from port A to port B. This means that

theflowrateispositiveifitflowsfromAtoB.Thepressuredifferential

is determined as p=p

outlet is greater than pressure at its inlet. The power generated by the

source is negative if the source adds energy to the flow.

Warning

Be careful w hen driving an orifice directly from a flow rate

source. The choked flow condition limits the flow that is

possible through an orifice as a function of upstream pressure

and temperature. Hence the flow rate value produced by the

flow rate source must be compatible with upstream pressure

and temperature. Specifying a flow rate that is too h igh will

result in an unsolvable set of equations.

and is negative if press ure at the source

A–pB

Dialog

Box a nd

Parameters

The block has no parameters.

2-49

Page 74

Controlled Pneumatic Flow R ate Source

Ports The block has the following ports:

A

Pneumatic conserving port associated with the source inlet.

B

Pneumatic conserving port associated with the source outlet.

F

Control signal port.

See Also Pneumatic Flow Rate Source

Pneumatic Mass & Heat Flow Sensor

2-50

Page 75

Controlled Pneumatic Pressure Source

Purpose Simulate ideal compressor with signal-controlled pressure difference

Library Pneumatic Sources

Description The Controlled Pneumatic Pressure Source block represents an ideal

compressor that maintains a pressure difference equal to the numerical

value presented at physical signal port F. The compressor adds no heat.

Block connections A and B correspond to the pneumatic inlet and outlet

ports, respectively, and connection F represents a control signal port.

A positive pressure difference results in the pre ssu re at port B being

higher than the pressure at port A.

Dialog

Box a nd

Parameters

The block has no parameters.

Ports The block has the following ports:

A

Pneumatic conserving port associated with the source inlet.

B

Pneumatic conserving port associated with the source outlet.

F

Control signal port.

2-51

Page 76

Controlled Pneumatic Pressure Source

See Also Pneumatic Pressure Source

Pneumatic Pressure & Temperature Sensor

2-52

Page 77

Controlled Voltage Source

Purpose Simulate ideal voltage source driven by input signal

Library Electrical Sources

Description The Controlled Voltage Source block represents an ideal voltage source

that is powerful enough to maintain thespecifiedvoltageatitsoutput

regardless of the current flowing through the source.

The output current is V=Vs,whereVs is the numerical value presented

at the physical signal port.

Dialog

Box a nd

Parameters

The block has no parameters.

Ports The block has one physical signal input port and two electrical

conserving ports associated with its electrical terminals.

See Also Controlled Current Source

2-53

Page 78

Convective Heat Transfer

Purpose Simulate heat transfer by convection

Library Thermal Elements

Description TheConvectiveHeatTransferblock represents a heat transfer by

convection between two bodies by means of fluid motion. T he transfer

is governed by the Newton law of cooling and is described with the

following equation:

QkAT T

=−ii()

where

Q Heat flow

AB

k

A

T

A,TB

Connections A and B are thermal conserving ports associated with the

points between which the heat transfer by convection takes place. The

block positive direction is from port A to port B. This means that the

heat flow is positive if it flows from A to B.

Convection heat transfer coefficient

Surface area

Temperatures of the bodies

2-54

Page 79

Dialog

Box a nd

Parameters

Convective Heat Transfer

Area

Surface area of heat transfer. The d efault value is

Heat transfer coefficient

Convection heat transfer coefficient. Th e default value is

W/m^2/K.

0.0001 m^2.

20

Ports The block has the following ports:

A

Thermal conserving port associated with body A .

B

Thermal conserving port associated with body B .

See Al

so

Condu

Radia

ctive Heat Transfer

tive Heat Transfer

2-55

Page 80

Current-Controlled Current Source

Purpose Simulate linear current-controlled current source

Library Electrical Sources

Description The Current-Controlled Current Source block models a linear

current-controlled current source, described with the following equation:

IKI21= i

where

Dialog

Box a nd

Parameters

I2

K

I1

To use the block, connect the + and – ports on the left side of the block

(the control ports) to the control current source. The arrow between

these p orts indicates the positive direction of the control current flow.

The two ports on the right side of the block (the output ports) generate

the output current, with the arrow between them indicating the positive

direction of the output current flow.

Output current

Current gain

Current flowing from the + to the – control port

2-56

Page 81

Current-Controlled Current Source

Current gain K

Ratio of the current between the two output terminals to the

current passing between the two control terminals. The default

value is

Ports The block has four electrical conserving ports. Connections + and – on

the left side of the block are the control ports. The other two ports are

the electrical terminals that provide the output current. The arrows

between each pair of ports indicate the positive direction of the current

flow.

See Also Current-Controlled Voltage Source

Voltage-Controlled Current Source

Voltage-Controlled Voltage Source

1.

2-57

Page 82

Current-Controlled Voltage Source

Purpose Simulate linear current-controlled voltage source

Library Electrical Sources

Description The Current-Controlled Voltage Source block models a linear

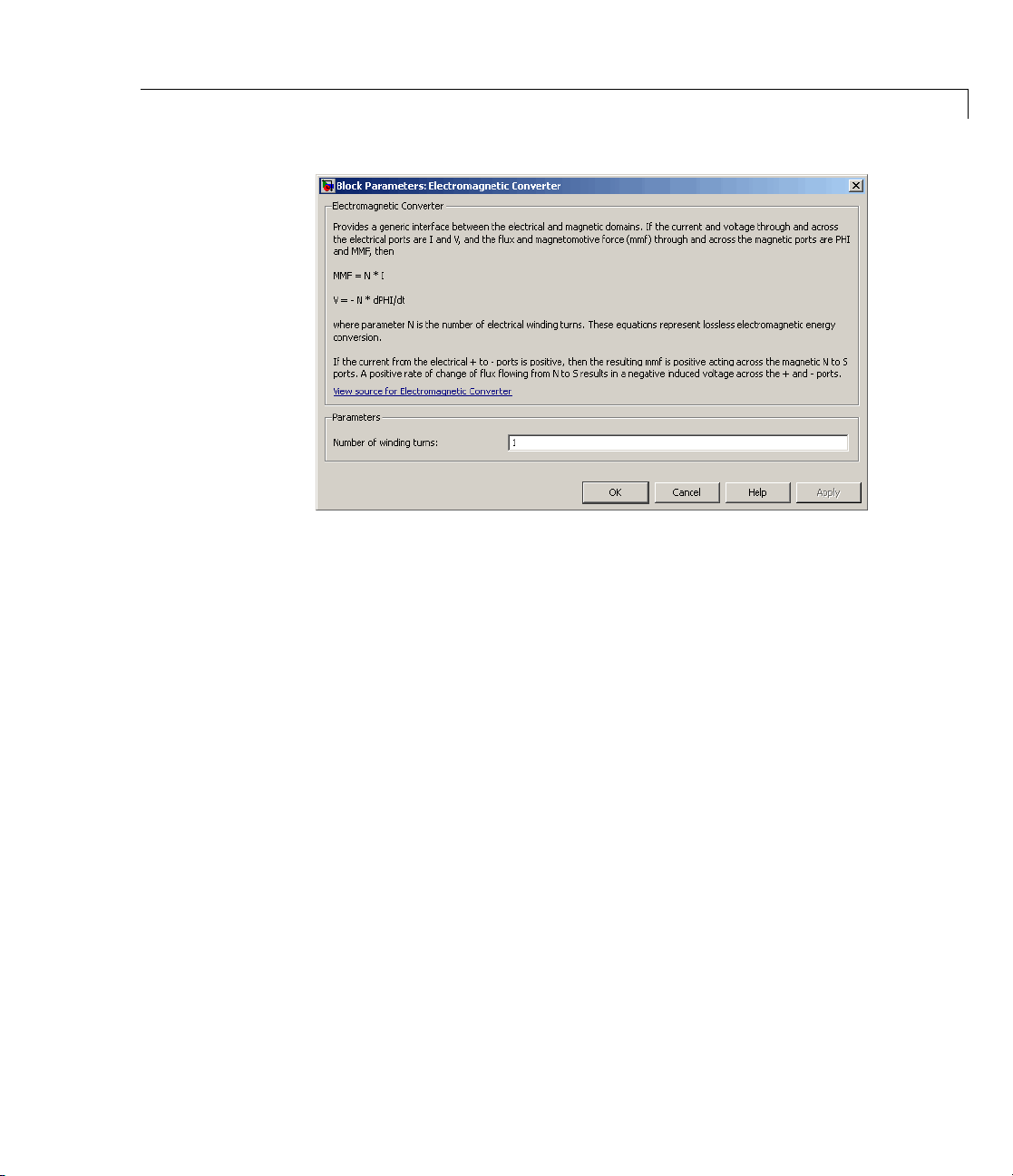

current-controlled voltage source, described with the following equation:

VKI= i 1

where

Dialog

Box a nd

Parameters

V

K

I1

To use the block, connect the + and – ports on the left side of the block

(the control ports) to the control current source. The arrow indicates the

positive direction of the current flow. The two ports on the right side

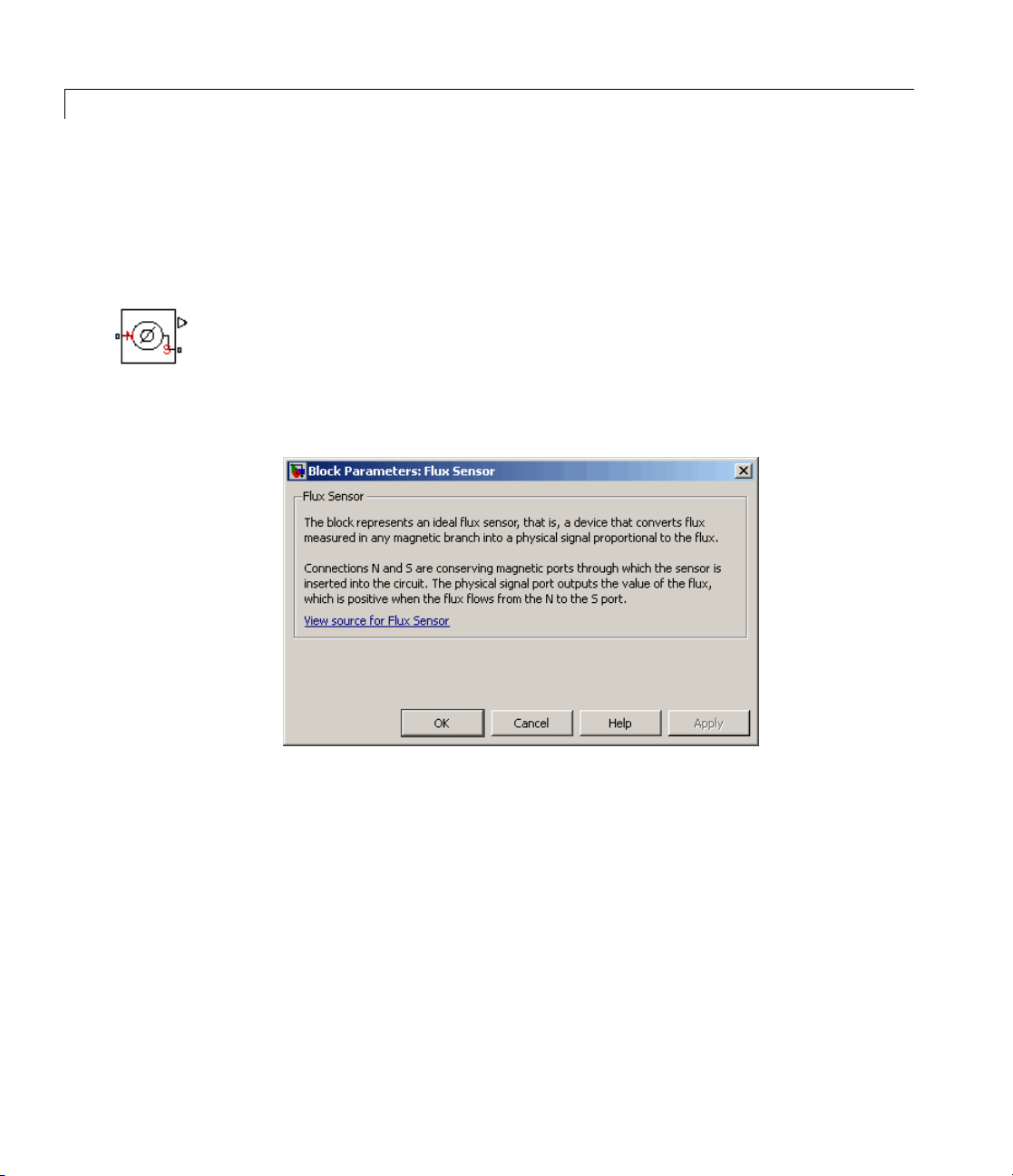

of the block (the output ports) generate the output voltage. Polarity

is indicated by the + and – signs.

Transresistance K

Voltage

Transresistance

Current flowing from the + to the – control port

Ratioofthevoltagebetweenthe two output terminals to the

current passing between the two control terminals. The default

value is

1 Ω.

2-58

Page 83

Current-Controlled Voltage Source

Ports The block has four electrical conserving ports. Connections + and –

on the left side of the block are the control ports. The arrow indicates

the positive direction of the current flow. The other two ports are

the electrical terminals that provide the output voltage. Polarity is

indicated by the + and – signs.

See Also Current-Controlled Current Source

Voltage-Controlled Current Source

Voltage-Controlled Voltage Source

2-59

Page 84

Current Sensor

Purpose Simulate current sensor in electrical systems

Library Electrical Sensors

Description The Current Sensor block represents an ideal current sensor, that is,

a device that converts current measured in any electrical branch into

a physical signal proportional to the current.

Connections + and – are electrical conserving ports through which the

sensor is inserted into the circuit. Connection I is a physical signal port

that outputs the measurement result.

Dialog

Box a nd

Parameters

Ports The blo

2-60

The block has no parameters.

ck has t he following ports:

+

rical conserving p ort associated with the sensor positive

Elect

nal.

termi

-

trical conserving port associated with the sensor negative

Elec

inal.

term

Page 85

I

Physical signal output port for current.

See Also Voltage Sensor

Current Sensor

2-61

Page 86

Custom Hydraulic Fluid

Purpose Set working fluid properties by specifying parameter values

Library Hydraulic Utilities

Description The Custom Hydraulic F luid block lets you specify the type of hydraulic

fluid used in a loo p of hydraulic blocks. It provides the hydraulic fluid

properties, such as kinematic viscosity, density, and bulk modulus, for

all the hydraulic blocks in the loop. These fluid properties are assumed

to be constant during simulation time.

The Custom Hydraulic Fluid block lets you specify the fluid properties,

such as kinematic viscosity, density, bulk modulus, and relative amount

of entrapped air, as block parameters.