Page 1

SimPowerSystems™ 5

User’s Guide

Hydro-Québec

Page 2

How to Contact The MathWorks

www.mathworks.

comp.soft-sys.matlab Newsgroup

www.mathworks.com/contact_TS.html T echnical Support

suggest@mathworks.com Product enhancement suggestions

bugs@mathwo

doc@mathworks.com Documentation error reports

service@mathworks.com Order status, license renewals, passcodes

info@mathwo

com

rks.com

rks.com

Web

Bug reports

Sales, prici

ng, and general information

508-647-7000 (Phone)

508-647-7001 (Fax)

The MathWorks, Inc.

3 Apple Hill Drive

Natick, MA 01760-2098

For contact information about worldwide offices, see the MathWorks Web site.

SimPowerSystems™ User’s Guide

© COPYRIGHT 1998–2010 by Hydro-Québec and The MathWorks, Inc.

The software desc ribed in this docu ment is furnished under a license ag reement. The software may be used

or copied only under the terms of the license agreement. No part of this manual may be photocopied or

reproduced in any form without prior written consent from The MathWorks, Inc.

FEDERAL ACQUISITION: This provision applies to all acquisitions of the Program and Documentation

by, for, or through the federal government of the United States. By accepting delivery of the Program

or Docum entation, the government hereby agrees tha t this software or documentation qualifies as

commercial computer software or commercial computer software documentation as such terms are used

or defined in FAR 12.212, DFARS Part 227.72, and DFARS 252.227-7014. Accordingly, the terms and

conditions of this Agreement and only those rights specified in this Agreement, shall pertain to and govern

theuse,modification,reproduction,release,performance,display,anddisclosureoftheProgramand

Documentation by the federal government (or other entity acquiring for or through the federal governme nt)

and shall supersede any conflicti ng contractual terms or conditions. If this License fails to meet the

government’s needs or is inconsistent in any respect with federal procurement law, the government agrees

to return the Program and Documentation, unused, to The MathWorks, Inc.

Trademarks

MATLAB and Simulink are registered trademarks of The MathWorks, Inc. See

www.mathworks.com/trademarks for a list of additional trademarks. Other product or brand

names may be trademarks or registered trademarks of their respective holders.

Patents

The MathWorks products are protected by one or more U.S. patents. Please see

www.mathworks.com/patents for more information.

Page 3

Revision History

January 1998 First printing Version 1.0 (Release 10)

September 2000 Second printing Revised for Version 2.1 (Release 12)

June 2001 Online only Revised for Version 2.2 (Release 12.1)

July 2002 Online only Revised for Version 2.3 (Release 13) (Renamed from Power

System Blockset User’s Guide)

February 2003 Third printing Revised for Version 3.0 (Release 13SP1)

June 2004 Online only Revised for Version 3.1 (Release 14)

October 2004 Fourth printing Revised for Version 4.0 (Release 14SP1)

March 2005 Online only Revised for Version 4.0.1 (Release 14SP2)

May 2005 Online only Revised for Version 4.1 (Release 14SP2+)

September 2005 Online only Revised for Version 4.1.1 (Release 14SP3)

March 2006 Online only Revised for Version 4.2 (Release 2006a)

September 2006 Online only Revised for Version 4.3 (Release 2006b)

March 2007 Online only Revised for Version 4.4 (Release 2007a)

September 2007 Online only Revised for Version 4.5 (Release 2007b)

March 2008 Online only Revised for Version 4.6 (Release 2008a)

October 2008 Online only Revised for Version 5.0 (Release 2008b)

March 2009 Online only Revised for Version 5.1 (Release 2009a)

September 2009 Online only Revised for Version 5.2 (Release 2009b)

March 2010 Online only Revised for Version 5.2.1 (Release 2010a)

Page 4

Page 5

Acknowledgments

SimPowerSystems™ software was developed by the following people and

organizations.

Gilbert Sybille

Hydro-Québec Research Institute (IREQ), Varennes, Québec. Original

author of SimPowerSystems software, technical coordinator, author

of the Ideal Switching Solution Method, autho r of phasor simulation,

discretization techniques, and documentation. Technical supervision

and design of the FACTS and Distributed Resources libraries , and

documentation.

_

Louis-A. Dessaint

École de Technologie Supérieure (ETS), Montréal, Québec. Author of

machine models. Technical supervision and design of the electric drive

library contents, and documentation.

Bruno DeKelper

École de Technologie Supérieure (ETS), Montréal, Québec. Author

of the Ideal Switching Solution Method and author of TLC functions

associated with the simulation of the state space equations.

Olivier Tremblay, Jean-Roch Cossa

École de Technologie Supérieure (ETS), M o n tré al, Q u ébec. Validations

and tests of the Ideal Sw itching Solution Method.

Patrice Brunelle

Hydro-Québec Research Institute (IREQ), Varennes, Québec. Main

software engineer. Author of graphical user interfaces, model

integration into Simulink

®

and Physical Modeling, and documentation.

v

Page 6

Acknowledgments

Roger Champagne

École de Technologie Supérieure (ETS), Montréal, Québec. Author

of machine models, of revised state space fo rmulation. Design of the

graphical user interface of the electric drive library.

Pierre Giroux, Richard Gagnon, Silvano Casoria

Hydro-Québec Research Institute (IREQ), Varennes, Québec.

Development of the FACTS and Distributed R esources libraries. Key

beta testers and developers of several SimPowerSystems blocks, demos,

and documentation.

Hoang Lehuy

Université Laval, Québec City. Validation tests and author of several

models, functions, and documentation. Validation of the electric drives

library.

Handy Fortin-Blanchette, Olivier Tremblay, Christophe Semaille

École de Technologie Supérieure (ETS), Montréal, Québec. Development

of the AC and DC drives models.

Hassan Ouquelle, Jean-Nicolas Paquin

École de Technologie Supérieure (ETS), Montréal, Québec. Development

of the Single-Phase Asynchronous Machine model and Saturation in

Asynchronous Machine model.

vi

Pierre Mercier

iOMEGAt. Project manager for the Power System Blockset™ software

versions 1 and 2 and for the Simulink electric drives library.

The authors acknowledge the contributions of the following people:

Innocent Kamwa, Raymond Roussel, Kamal Al-Haddad, Mohamed Tou,

Christian Dufour, Momcilo Gavrilovic, Christian Larose, David McCallum,

Bahram Khodabakhchian, Manuel Alvarado Sandoval, and Stéphane

Desjardins

Page 7

Acknowledgments

Getting Started

1

Product Overview ................................. 1-2

Introduction

TheRoleofSimulationinDesign

SimPowerSystems Libraries

Required and Related Products

...................................... 1-2

..................... 1-2

........................ 1-3

...................... 1-4

Contents

Using This Guide

If You Are a New User

If You Are an Experienced Blockset User

All Users

Units

Building and Simulating a Simple Circuit

Introduction

Building the Electrical Circuit with powerlib Library

Interfacing the Electrical Circuit with Other Simulink

Blocks

Measuring Voltages and Currents

Basic Principles of Connecting Capacitors and Inductors

Using the Powergui Block to Simulate SimPowerSystems

Models

Analyzing a Simple Circuit

Introduction

Electrical State Variables

State-Space Representation Using power_analyze

Steady-State Analysis

Frequency Analysis

........................................ 1-6

........................................... 1-6

........................................ 1-13

........................................ 1-16

.................................. 1-5

............................. 1-5

.............. 1-5

........... 1-7

...................................... 1-7

.................... 1-14

......................... 1-18

...................................... 1-18

........................... 1-18

.............................. 1-19

................................ 1-21

.... 1-8

.. 1-15

....... 1-19

vii

Page 8

Specifying Initial Conditions ....................... 1-27

Introduction

State Variables

Initial States

Specify Initial Electrical States with Powergui

...................................... 1-27

................................... 1-27

..................................... 1-28

.......... 1-29

Simulating Transients

Introduction

Simulating Transients with a Circuit B reaker

Continuous, Variable Time Step Integration Algorithms

Discretizing the Electrical System

Introducing the Phasor Simulation Method

Introduction

When to Use the Phasor Solution

Phasor Simulation of a Circuit Transient

...................................... 1-33

...................................... 1-40

............................. 1-33

.......... 1-33

.................... 1-37

.......... 1-40

.................... 1-40

.............. 1-41

Advanced Components and Techniques

2

Introducing Power Electronics ..................... 2-2

Introduction

Simulation of the TCR Branch

Simulation of the TSC Branch

Simulating Variable Speed Motor Control

Introduction

Building and Simulating the PWM Motor Drive

Using the Multimeter Block

Discretizing the PWM Motor Drive

Performing Harmonic Analy sis Using the FFT Tool

...................................... 2-2

....................... 2-4

....................... 2-8

........... 2-11

...................................... 2-11

......... 2-13

......................... 2-19

................... 2-21

.. 1-35

..... 2-21

viii Contents

Three-Phase Systems and Machines

Introduction

Three-Phase Network with Electrical Machines

Load Flow and Machine Initialization

Using the Phasor Solution Method for Stability Studies

...................................... 2-25

................. 2-25

................. 2-28

......... 2-25

.. 2-36

Page 9

Building and Customizing Nonlinear Models ......... 2-40

Introduction

Modeling a Nonlinear Inductance

Customizing Your Nonlinear Model

Modeling a Nonlinear Resistance

Creating Your Own Library

Connecting Your Model with Other Nonlinear Blocks

Building a Model Using Model Construction

Commands

...................................... 2-40

.................... 2-40

................... 2-45

..................... 2-48

......................... 2-53

...................................... 2-57

Improving Simulation Performance

3

How SimPowerSystems Software Works ............. 3-2

.... 2-53

Choosing an Integration Method

Introduction

Continuous Versus Discrete Solution

Phasor Solution Method

Simulating with Continuous Integration Algorithms

Choosing an Integration Algorithm

Simulating Switches and Power Electronic Devices

Using the Ideal Switching Device Method

Simulating Discretized Electrical Systems

Introduction

Limitations of Discretization with Nonlinear Models

Simulating Power Electronic Models

Introduction

Circuit Using Forced-Commutated Power Electronics

Circuit Using Naturally Commutated Power Electronics

Increasing Simulation Speed

Ways to Increase Simulation Speed

...................................... 3-4

............................ 3-5

...................................... 3-15

...................................... 3-17

.................... 3-4

................. 3-4

................... 3-6

...... 3-7

.............. 3-8

........... 3-15

..... 3-15

................ 3-17

....................... 3-19

................... 3-19

.. 3-6

.... 3-17

.. 3-17

ix

Page 10

Using Accelerator Mode and Real-Time Workshop

Software

....................................... 3-19

The Nonlinear Model Library

HowtoAccesstheNonlinear Model Library

The Continuous Library

The Discrete Library

The Phasors Library

The Switch Current Source Library

Limitations of the Nonlinear Models

Modifying the Nonlinear Models of the powerlib_ m odels

Library

Creating Your Own Library of Models

Changing Your Circuit Parameters

Introduction

Example of MATLAB Script Performing a Parametric

Study

........................................ 3-24

...................................... 3-26

......................................... 3-26

............................ 3-22

............................... 3-23

............................... 3-23

Systems with Electric Driv es

4

....................... 3-22

............ 3-22

................... 3-23

.................. 3-23

............... 3-25

.................. 3-26

x Contents

About the Electric Drives Library ................... 4-2

Getting Started with Electric Drives Library

What Is an Electric Drive?

Three Main Components of an Electric Drive

Multiquadrant Operation

Average-Value Models

User Interface

General Layout of the Library’s GUIs

Features of the New GUIs

Advanced Usage

Simulating a DC Motor Drive

Introduction

Regenerative Braking

.................................... 4-9

.................................. 4-12

...................................... 4-13

.......................... 4-4

........................... 4-7

............................. 4-8

................. 4-9

.......................... 4-10

....................... 4-13

.............................. 4-14

......... 4-4

........... 4-4

Page 11

Example: Thyristor Converter-Based DC Motor Drive ... 4-14

Simulating an AC Motor Drive

Introduction

Dynamic Braking

Modulation Techniques

Open-Loop Volts/Hertz Control

Closed-Loop Speed Control with Slip Compensation

Flux-Oriented Control

Direct Torque Control

Example: AC Motor Drive

Mechanical Models

Mechanical Shaft Block

Speed Reducer Block

Mechanical Coupling of Two Motor Drives

Introduction

System Description

Speed Regulated AC4 with Torque Regulated DC2

Torque Regulated AC4 with Speed Regulated DC2

Winding Machine

Introduction

Description of the Winder

Block Description

Simulation Results

...................................... 4-39

................................. 4-39

............................. 4-40

.............................. 4-46

.............................. 4-49

................................ 4-69

............................ 4-69

............................... 4-70

...................................... 4-71

................................ 4-72

.................................. 4-78

...................................... 4-78

................................. 4-80

................................ 4-83

...................... 4-39

...................... 4-45

.......................... 4-50

........................... 4-78

..... 4-46

........... 4-71

...... 4-74

...... 4-75

Robot Axis Control Using Brushless DC Motor Drive

Introduction

Description of the Robot Manipu la tor

Position Control Systems for Joints 1 and 2

Modeling the Robot Position Control Systems

Tracking Performance of the Motor Drives

Building Your Own Drive

Introduction

Description of the Drive

Modeling the Induction Motor Drive

Starting the Drive

Steady-State Voltage and Current Waveforms

...................................... 4-86

................. 4-86

............ 4-87

.......... 4-88

............. 4-92

.......................... 4-97

...................................... 4-97

............................ 4-98

.................. 4-100

................................. 4-104

.......... 4-105

.. 4-86

xi

Page 12

Speed Regulation Dynamic Performance ............... 4-106

Advanced Users: Retune the Drive P a ra m ete rs

Modify the Motor Parameters

Retune the Parameters of the Flux Regulator

Retune the Parameters of the Speed Regulator

Retune the Parameters of the DC Bus Voltage

Simulate and Analyze the Results

Advanced Users: Modify a Drive Block

Disable the Drive Link

Modify the Electrical Connections

Simulate the Sys tem and Observe the R esults

Multi-Level Modeling for Rapid Prototyping

Introduction

The System Architecture

The Simplified Model

The Average-Value Model

The Detailed Model

Comparison of the Multi-Level Modeling Precision

Conclusion

...................................... 4-130

....................................... 4-150

............................. 4-123

.............................. 4-132

................................ 4-142

....................... 4-108

.......... 4-109

.......... 4-119

.................... 4-122

.............. 4-123

.................... 4-124

.......... 4-128

........................... 4-131

........................... 4-135

....... 4-108

......... 4-115

......... 4-130

...... 4-145

xii Contents

Transients and Power Electronics in Power

5

Series-Compensated Transmission System ........... 5-2

Description of the Transmission System

Setting the Initial Load Flow and Obtaining Steady

State

.......................................... 5-8

Transient Performance for a Line Fault

Frequency Analysis

TransientPerformanceforaFaultatBusB2

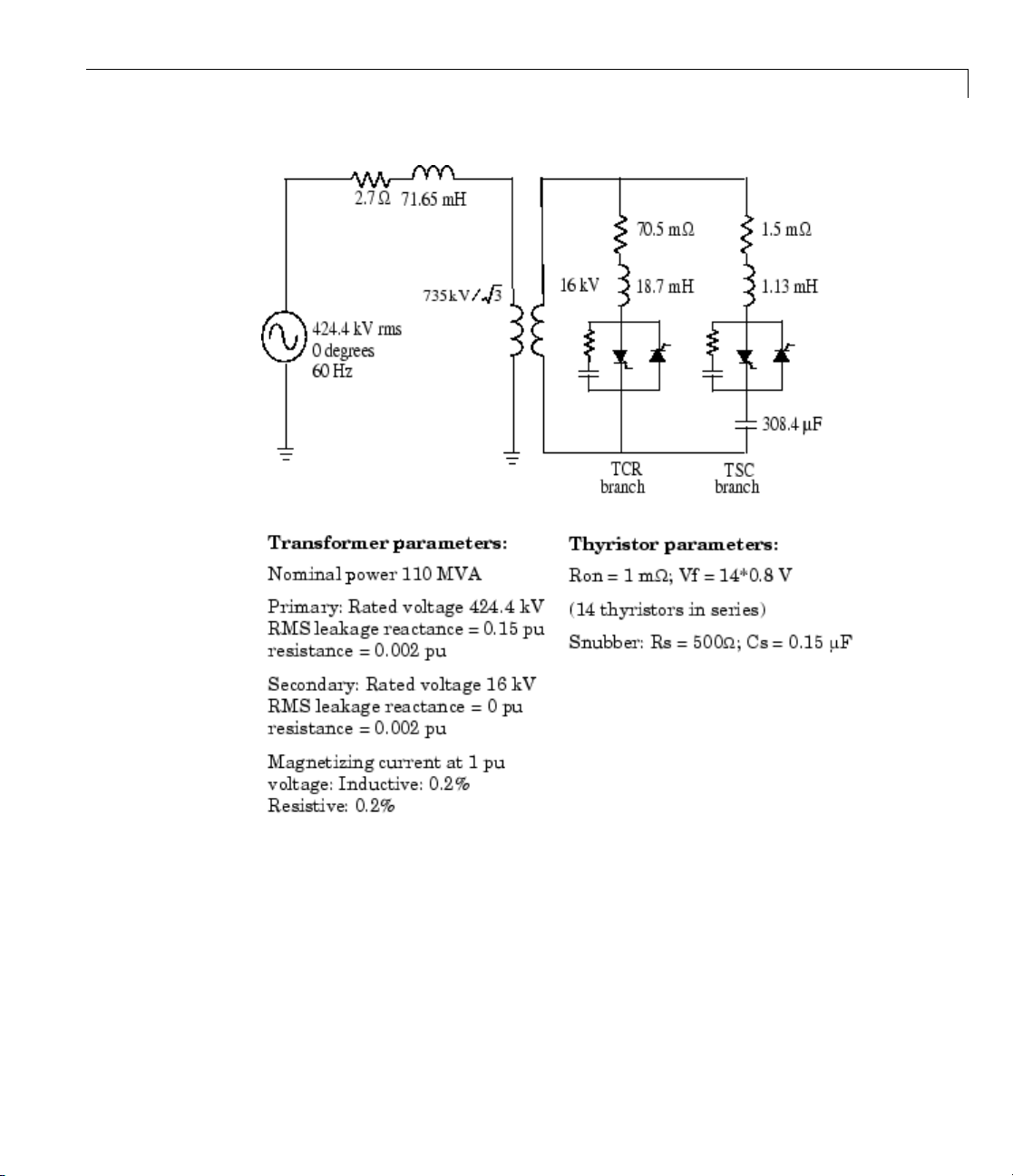

Thyristor-Based Static Var Compensator

Introduction

Description of the SVC

...................................... 5-20

................................ 5-13

............................. 5-21

............... 5-2

............... 5-9

........... 5-16

............ 5-20

Systems

Page 13

Steady-State and Dynamic Performance of the SVC ..... 5-24

Misfiring of TSC1

................................. 5-26

GTO-Based STATCOM

Introduction

Description of the STATCOM

Steady-State and Dynamic Performance of the

STATCOM

Thyristor-Based HVDC Link

Description of the HVDC Transmission System

Frequency Response of the AC and DC Systems

Description of the Control and Protection Systems

System Startup/Stop — Steady-State and Step

Response

DC Line Fault

AC Line-to-Ground Fault at the Inverter

VSC-Based HVDC Link

Introduction

Description of the HVDC Link

VSC Control System

Dynamic Performance

...................................... 5-29

..................................... 5-36

...................................... 5-48

.................................... 5-54

...................................... 5-61

............................. 5-29

........................ 5-30

........................ 5-39

.............. 5-57

............................. 5-61

....................... 5-61

............................... 5-65

.............................. 5-71

......... 5-39

........ 5-41

...... 5-43

Transient Stability of Power Systems Using

Phasor Simulation

6

Transient Stability of a Power System with SVC and

PSS

Introduction

Description of the Transmission System

Single-Phase Fault — Impact of PSS — No SVC

Three-Phase Fault — Impact of SVC — PSS in Service

Control of Power Flow Using a UPFC and a PST

Introduction

Description of the Power System

Power Flow Control with the UPFC

............................................ 6-2

...................................... 6-2

............... 6-2

...................................... 6-9

..................... 6-9

.................. 6-12

........ 6-4

... 6-6

..... 6-9

xiii

Page 14

UPFC P-Q Controllable Region ...................... 6-13

Power Flow Control Using a PST

..................... 6-14

Wind Farm Using Doubly-Fed Induction Generators

Description of the Wind Farm

TurbineResponsetoaChangeinWindSpeed

Simulation of a Voltage Sag on the 120 kV System

Simulation of a Fault on the 25 kV System

....................... 6-19

.......... 6-23

...... 6-25

............. 6-27

.. 6-19

Index

xiv Contents

Page 15

Getting Started

• “Product Overview” on page 1-2

• “Using This Guide” on page 1-5

• “Building and Simulating a Simple Circuit” on page 1- 7

• “Analyzing a Simple Circuit” on page 1-18

• “Specifying Initial Conditions” on page 1-27

• “Simulating Transients” on page 1-33

1

• “Introducing the Phasor Simulation Method” on page 1-40

Page 16

1 Getting Started

Product Overview

Introduction

SimPowerSystems software and other products of the Physical Modeling

product family work together with Simulink software to model electrical,

mechanical, and control s ystem s.

SimPowerSystems software operates in the Simulink environment. Therefore,

before starting this user’s guide, make yourself familiar with Simulink

documentation. Or, if you perform signal processing and communications

tasks (as opposed to control system design tasks), see the Signal Processing

Blockset™ documentation.

In this section...

“Introduction” on page 1-2

“The Role of Simulation in Design” on page 1-2

“SimPowerSystems Libraries” on page 1-3

“Required and Related Products” on page 1-4

1-2

TheRoleofSimulationinDesign

Electrical power systems are combinations of electrical circuits and

electromechanical devices like motors and generators. Engineers working

in this discipline are constantly improving the performance of the s ystem s.

Requirements for dra stica lly increased efficiency have forced power system

designers to use power electronic devices and sophisticated control system

concepts that tax traditional analysis tools and techniques. Further

complicating the analyst’s role is the fact that the system is often so nonlinear

that the only way to understand it is through simulation.

Land-based power generation from hydroelectric, steam, or other devices is

not the only use of power system s. A common attribute of these system s

is their use of power electronics and control systems to achieve their

performance objectives.

Page 17

Product Overview

SimPowerSystems software is a modern design tool that allows scientists

and engineers to rapidly and easily build models that simulate power

systems. It uses the Simulink environment, allowing you to build a model

using simple click and drag procedures. Not only can you draw the circuit

topology rapidly, but your analysis of the circuit can include its interactions

with mechanical, thermal, control, and other disciplines. This is possible

because all the electrical parts of the simulation interact with the extensive

Simulink modeling library. Since Simulink uses the MATLAB

®

computational

engine, designers can also use MATLAB toolboxes and Simulink blocksets.

SimPowerSystems software belongs to the Physical M odeling product family

and uses similar block and connection line interface.

SimPowerSystems Libraries

SimPowerSystems libraries contain models of typical power equipment

such as transformers, lines, machines, and power ele ctronics. These models

are proven one s coming from textbooks, and their validity is based on the

experience of the Power Systems Testing and Simulation Laboratory of

Hydro-Québec, a large North American utility located in Canada, and also on

the experience of École de Technologie Supérieure and Université Laval. The

capabilities of SimPowerSystems software for modeling a typical electrical

system are illustrated in demonstration files. And for users who w an t to

refresh their knowledge of power system theory, there are also self-learning

case studies.

The SimPowerSystems main library, powerlib, organizes its blocks into

libraries according to their behavior. The powerlib library window displa ys

the block library icons and names. Double-click a library icon to open the

library and access the blocks. The main powerlib library window also

contains the Pow erg u i block that opens a graphical user interface for the

steady-state analysis of electrical circuits.

Nonlinear Simulink Blocks for SimPowerSystems Models

The nonlinear Simulink blocks of the powerlib library a re stored in a special

block library named powerlib_models. These masked Simulink models are

used by SimPowerSystems software to build the equivalent Simulink model

of your circuit. See Chapter 3, “Improving Simulation Performance” for a

description of the powerlib_models library.

1-3

Page 18

1 Getting Started

Required and Rel

SimPowerSystem

• MATLAB

• Simulink

In addition to

family includ

and electric

systems in Si

toolboxes a

with SimPow

products, s

the “Produc

ee the MathWorks Web site at

s software requires the following products:

SimPowerSystems software, the Physical Modeling product

es other products for modeling and simulating mechanical

al systems. Use these products together to model physical

mulink environment. There are also a number of closely related

nd other products from The MathWorks™ that you can use

erSystems software. For more information about any of these

ts” section.

ated Products

http://www.mathworks.com;see

1-4

Page 19

Using This Guide

In this section...

“If You Are a New User” on page 1-5

“If You Are an Experienced Blockset User” on page 1-5

“All Users” on page 1-6

“Units” on page 1-6

If You Are a New User

Begin with this chapter and also the next chapter to learn how to

• Build and simulate electrical circui ts using the powerlib library

• Interface an electrical circuit with Simulink blocks

• Analyze the steady-state and frequency response of an electrical circuit

Using This Guide

• Discretize your model to increase simulation speed, especially for power

electronic circuits and large power systems

• Use the phasor simulation method

• Build your own nonlinear models

If You Are an Experienced Blockset User

See the Release Notes for details on the latest release.

Also, see these chapters:

• Chapter 1, “Getting Started” to learn how to simulate discretized electrical

circuits

• Chapter 2, “Advanced Components and Techniques” to learn how to apply

the phasor simulation to transient stability study of multimachine systems

• Chapter 3, “Improving Simulation Performance” to learn how to increase

simulation speed

1-5

Page 20

1 Getting Started

All Users

For reference in

use the SimPower

formation on blocks, simple demos, and G UI-based tools,

Systems Reference.

For commands, r

syntax, as wel

l as a complete explanation of options and operation.

Units

This guide us

system. See T

es the International System of Units (SI) and the per unit (pu)

echnical Conventions for details.

efer to “Function Reference” for a synopsis of the command

1-6

Page 21

Building and Simulating a Simple Circuit

In this section...

“Introduction” on page 1-7

“Building the Electrical Circuit with powerlib Library” on page 1-8

“Interfacing the Electrical Circuit with Other Simulink Blocks” on page 1-13

“Measuring Voltages and Currents” on page 1-14

“Basic Principles of Connecting Capacitors and Inductors” on page 1-15

“Using the Powergui Block to Simulate SimPowerSystems Models” on page

1-16

Introduction

SimPowerSystems software allows you to build and simulate electrical

circuits containing linear and nonlinear elem ents.

Building and Simulating a Simple Circuit

In this section you

• Explore the powerlib library

• Learn how to build a sim ple circuit from the powerlib library

• Interconnect Sim u l in k blocks with your circuit

The circuit below represe nts an equivalent power system feeding a 300 km

transmission line. The line is compensated by a shunt inductor at its receiving

end. A circuit breaker allows energizing a nd de-energizing of the line. To

simplify matters, only one of the three phases is represented. The parameters

shown in the figure are typical of a 735 kV power system.

1-7

Page 22

1 Getting Started

CircuittoBeModeled

Building the Electrical Circuit with powerlib Library

The graphical user interface makes use of the Simulink functionality to

interconnect various electrical components. The electrical components are

grouped in a library called powerlib.

1 Open the SimPowerSystems main library by entering the following

command at the MATLAB prompt.

1-8

powerlib

This command displays a Simulink window showing icons of different

block libraries.

You can open these libraries to produce the windows containing the blocks

to be copied into your circuit. Each component is represented by a special

icon having one or several inputs and outputs corresponding to the different

terminals of the component:

2 From the File menu of the powerlib window, open a new window to

contain your first circuit and save it as

3 Open the Electrical Sources library and copy the AC Voltage Source block

into the circuit1 window.

circuit1.

Page 23

Building and Simulating a Simple Circuit

4 Open the AC Voltage Source dialog box by double-clicking the icon and

enter the Amplitude, Phase, and Frequency parameters according to the

valuesshowninCircuittoBeModeledonpage1-8.

Note that the amplitude to be specified f or a sinusoidal source is its p eak

value (424.4e3*sqrt(2) volts in this case).

5 Change the name of this block from AC Voltage Source to Vs.

6 Copy the Parallel RLC Branch block, which can be found in the Elements

library of powerlib, set its parameters as shown in Circuit to Be Modeled

on page 1-8, and n ame it Z_eq.

7 The resistance Rs_eq of the circuit can be obtained from the Parallel RLC

Branch block. Duplicate the Parallel RLC Branch block, which is already

in your circuit1 window. Select R for the Branch Type parameter and set

the R parameter according to Circuit to Be M odeled on page 1-8.

Once the dialog box is closed, notice that the L and C components have

disappeared so that the icon now shows a single resistor.

Note With the Branch Type parameter set to RLC, setting L and C

respectively to

inf and zero in a parallel branch changes automatically the

Branch Type to R and produces the same result. Similarly, with the Series

RLC Branch block, setting R, L, and C respectively to zero, zero, and

inf

eliminates the corresponding element.

8 Name this block Rs_eq.

9 Resize the various components and interconnect blocks by dragging lines

from outputs to inputs of appropriate blocks.

1-9

Page 24

1 Getting Started

10 To complete the circuit of Circuit to Be Modeled on page 1 -8, you need to

add a transmission line and a shunt reactor. You add the circuit breaker

later in “Simulating Transients” on page 1-33.

The model of a line with uniformly distributed R, L, and C parameters

normally consists of a delay equal to the wave propagation time along the

line. This model cannot be simulated as a linear system because a delay

corresponds to an infinite number of states. However, a good approximation

of the line with a finite number of states can be obtained by cascading

several PI circuits, each representing a small section of the line.

1-10

A PI section consists of a series R-L branch and two shunt C branches. The

model accuracy depends on the number of PI sections used for the model.

Copy the PI Section Line block from the Elements library into the circuit1

window, set its parameters as shown in Circuit to Be Modeled on page 1-8,

andspecifyonelinesection.

11 The shunt reactor is modeled b y a resistor in serie s with an inductor. You

could use a Series RLC Branch block to model the shunt reactor, but then

you would have to manually calculate and set the R and L values from

the quality factor and reactive power specified in Circuit to Be Modeled

on page 1-8.

Therefore, you might find it more convenient to use a Series RLC Load

block that allows you to specify directly the active and re active powers

absorbed by the shunt reactor.

Copy the Series RLC Load block, w h ich can be found in the Elements

library of powerlib. Name this block 110 Mvar. Set its parameters as

follows:

Page 25

Building and Simulating a Simple Circuit

Vn

fn

P

QL

Qc

424.4e3 V

60 Hz

110e6/300 W (quality factor = 300)

110e6 vars

0

Note th at, as no reactive capacitive po w er is specified, the capacitor

disappears o n the block icon when the dialog box is closed. Interconnect the

newblocksasshown.

12 You need a Voltage Measurement block to measure the voltage at node B1.

This block is found in the Measurements library of powerlib.Copyitand

name it U1. Connect its positive input to the node B1 and its negative

input to a new Ground block.

13 To observe the voltage measured by the Voltage Measurement block

named U1, a display system is needed. This can be any device found in

the Simulink Sinks library.

OpentheSinkslibraryandcopytheScopeblockintoyourcircuit1

window. If the scope were connected directly at the output of the voltag e

measurement, it would display the voltage in volts. However, electrical

engineers in pow er systems are used to working with normalized quantities

(per unit system). The voltage is normalized by dividing the v alue in volts

by a base voltage corresponding to thepeakvalueofthesystemnominal

voltage. In this case the scaling factor K is

1-11

Page 26

1 Getting Started

K =

424 4 10 2

14 Copy a Gain block from the Simulink library and set its gain as above.

1

3

××

.

Connect its output to the Scope block and connect the output of the Voltage

Measurement block to the Gain bl ock . Duplicate this voltage measurement

system at the node B2, as shown below.

15 Add a Powergui block to your model. The purpose of this block is discussed

in “Using the Powergu i Block to Simulate SimPowerSystems Models” on

page 1-16.

1-12

16 From the Simulation menu, select Start.

17 Open the Scope blocks and o bs erve the voltages at nodes B1 and B2.

18 While the simulation is running, open the Vs block dialog box and modify

the amplitude. Observe the effect onthetwoscopes. Youcanalsomodify

the frequency and the phase. You can zoom in on the waveforms in the

scope windows by drawing a box around the region of interest with the

left mouse button.

To simulate this circuit, the default integration algorithm (

ode45)wasused.

However, for most SimPowerSystems applications, your circuits contain

switches and other nonlinear models. In such a case, you must specify a

Page 27

Building and Simulating a Simple Circuit

different integration algorithm. This is discussed in “Simulating Transients”

on page 1-33, where a circuit breaker is added to your circuit.

Interfacing the Electrical Circuit with Other Simulink Blocks

The Voltage Measurement block acts as an interface between the

SimPowerSystems blocks and the Simulink blocks. For the system shown

above, you implemented such an interface from the electrical system to the

Simulink system. The Voltage Measurement block converts the measured

voltages into Sim ulink signals.

Similarly, the Current Measurement block from the Measurements library of

powerlib can be used to convert any measured current into a Simulink signal.

You can also interface from Simulink blocks to the electrical system. For

example, you can use the Controlled Voltage Source block to inject a voltage

in an electrical circuit, as shown in the following figure.

1-13

Page 28

1 Getting Started

Electrical Terminal Ports and Connection Lines SimPowerSystems

modeling environment is similar to that of other products in the Physical

Modeling family. Its blocks often feature both normal Simulink input and

output ports

> and special electrical terminal ports :

• Lines that connect normal Simulink ports

• Lines that connect terminal ports

These lines are nondirectional and can be branched, but you cannot connect

them to Simulink ports > or to normal Simulink signal lines.

• You can connect Simulink ports

electrical terminal ports

• Converting Simulink signals to electrical connections or vice versa requires

using a SimPowerSystems block that features both Simulink ports and

electrical terminal ports.

Some SimPowerSystems blocks feature only one type of port.

only to other electrical terminal ports.

are special electrical connection lines.

> only to othe r Simulink ports and

> are directional signal lines.

Measuring Voltages and Currents

When you measure a current using a Current Measurement block, the positive

direction of current is indicated on the block icon (positive current flowing

from + terminal to – terminal). Similarly, when you measure a voltage using

a Voltage Measurement block, the measured voltage is the voltage of the +

terminal w ith respect to the – terminal. However, when voltages and currents

of blocks from the Elements library are measured using the Multimeter block,

the voltage and current polarities are not immediately obvious because blocks

might have been rotated and there are no signs indicating polarities on the

block icons.

1-14

Unlike Simulink signal lines and input and output ports, the

SimPowerSystems connection lines and terminal ports

directionality. The voltage and current polarities are determined, not by line

direction, but instead by block orientation. To find out a block orientation,

first click the block to select it. Then enter the following command.

get_param(gcb,'Orientation')

lack intrinsic

Page 29

Building and Simulating a Simple Circuit

The following table indicates the polarities of the currents and voltages

measured with the Multimeter block for single-phase and three-phase RLC

branch and loads (and of the polarity of the capacitor voltage and the inductor

current), surge arresters, and single-phaseandthree-phasebreakers.

Positive Current

Block Orientation

right

left

down

up

The natural orientation of the blocks (that is, their orientation in the Element

library) is right for horizontal blocks and down for vertical blocks.

For single-phase transformers (linear or saturable), with the winding

connectors appearing on the left and right sides, the winding voltages are the

voltages of the top connector with respect to the bottom connector, irrespective

of the block orientation (right or left). The winding currents are the currents

entering the top connector.

Direction Measured Voltage

left —> right Vleft – Vright

right —> left Vright – Vleft

top —> bottom Vtop – Vbottom

bottom —> top Vbottom – Vtop

For three-phase transformers, the voltage polarities and positive current

directions are indicated by the signal labels used in th e Multimeter block.

For example, Uan_w2 means phase A-to-ne utral voltage o f the Y connected

winding #2 , Iab_w1 me an s winding current flowing from A to B in the

delta-connected winding #1.

Basic Principles of Connecting Capacitors and Inductors

You have to pay particular attention when you connect cap a c itor elements

together with voltage sources, or inductor elements in series with current

sources. When you start the simulation, the software displays an error

message if one of the following two connection errors are present in your

diagram:

1-15

Page 30

1 Getting Started

1 You have connected a voltage source in parallel with a capacitor, or a series

of capacitor elements in series, like in the two examples below.

To fix this problem, y ou can a dd a small resistance in series between the

voltage source and the capacitors.

2 You have connected a current source in series with an inductor, or a s eries

of inductors connected in parallel, like in the example below.

1-16

To fix t

induct

Using

SimPo

The P

cont

Simu

Sim

You

his problem, you can add a large re sistance in parallel with the

or.

the Powergui Block to Simulate

werSystems Models

owergui block is necessary for simulation of any Simulink model

aining SimPowerSystems blocks. It is use d to store the equivalent

link circuit that represents the state-space equations of the

PowerSystems blocks.

must follow these rules when using this block in a m o del:

Page 31

Building and Simulating a Simple Circuit

• Place the Powergui block at the top lev el of diagram for optimal

performance. However, you can place it anywhere inside subsystems for

your convenience; its functionality will not be affected.

• You can have a maximum of one Powerg ui block per m ode l

• You must name the block

powergui

Note When you start the simulation, yo u will get an error if no Powergui

block is found in your model.

1-17

Page 32

1 Getting Started

Analyzing a Simple Circuit

In this section...

“Introduction” on page 1-18

“Electrical State Variables” on page 1-18

“State-Space Representation Using power_analyze” on page 1-19

“Steady-State Analysis” on page 1-19

“Frequency Analysis” on page 1-21

Introduction

In this section you

• Obtain the state-space representation of your model with the

power_analyze comm and

• Compute the steady-state voltages and currents using the graphical user

interface of the Powergui block

1-18

• Analyze an electrical circuit in the frequency domain

Electrical State Variables

The electrical state variables are the Simulink states of your diagram

associated to the capacitor and inductor devices of the SimPowerSystems

blocks. Inductors and capacitors elements are found in the RLC-branch type

blocks such as the Series RLC Branch block, Three-Phase Parallel RLC Load

block, in the transformer models, in the PI Section Line block, in the snubber

devices of the power e lectronic devices, etc.

The electrical state variables consist of the inductor currents and the capacitor

voltages. Variable names forSimPowerSystems electrical states contain the

name of the block where the inductor or capacitor i s found, preceded b y the

Il_ prefix for inductor currents or the Uc_ prefix for capacitor voltages.

Page 33

Analyzing a Simple Circuit

State-Space Rep

You compute the s

power_analyze c

resentation Using power_analyze

tate-space representation of the model

ommand. Enter the following command at the MATLAB

circuitl with the

prompt.

[A,B,C,D,x0,electrical_states,inputs,outputs]=power_analyze('circuit1')

lyze

The power_ana

the four matr

electrical s

inputs, and o

electrical_states =

Il_110 Mvars

Uc_input PI Section Line

Il_ sect1 PI Section Line

Uc_output PI Section Line

Il_Z_eq

Uc_Z_eq

inputs =

U_Vs

ices A, B, C, and D. x0 is the vector of initial conditions of the

tates of your circuit. The names of the electrical state variables,

utputs are returned in three string matrices.

command returns the state-space model of your circuit in

outputs =

U_U1

U_U2

hat you could have obtained the names and ordering of the electrical

Note t

es, inputs, and outputs directly from the Powergui block. See the

stat

r_analyze

powe

ady-State Analysis

Ste

acilitate the ste ad y-state analysis of your circuit, the powerlib library

To f

ludes a graphical user interface tool. If the Powergui block is not already

inc

sent in your model, copy the block from the library into your circuit1

pre

del and double-click the block icon to open it.

mo

reference page for more details on how to use this function.

1-19

Page 34

1 Getting Started

From the Analysis tools menu of the Powergui block, select Steady-State

Voltages and Currents. This opens the Steady-State Tool window where

thesteady-statephasorsvoltagesmeasuredbythetwovoltagemeasurement

blocks of your model are displayed in polar form.

1-20

Eachmeasurementoutputisidentified b y a string corresponding to the

measurement block name. The magnitudes of the phasors U1 and U2

correspond to the peak value of the sinusoidal voltages.

From the Steady-State Tool window, you can also display the steady-state

values of the source voltage or the steady-state values of the inductor currents

and capacitor voltages by selecting either the Sources or the States check

box.

Page 35

Analyzing a Simple Circuit

Note Depending on the order you added the blocks in your circuit1 diagram,

the electrical state variables might not be ordered in the same way as in

the preceding figure.

Refer to the section “Measuring Voltages and Currents” on page 1-14 for more

details on the sign conventions used for the voltages and currents of sources

and electrical state variables listed in the Steady-State Tool window.

Frequency Analysis

The Measurements library of powerlib contains an Impedance Measurement

block that measures the impedance between any two nodes of a circuit. In the

following two sections, you measure the impedance of your circuit between

node B2 and ground by using two methods:

• Calculation from the state-space m odel

• Automatic measurement using the Impedance Measurement block and the

Powergui block

1-21

Page 36

1 Getting Started

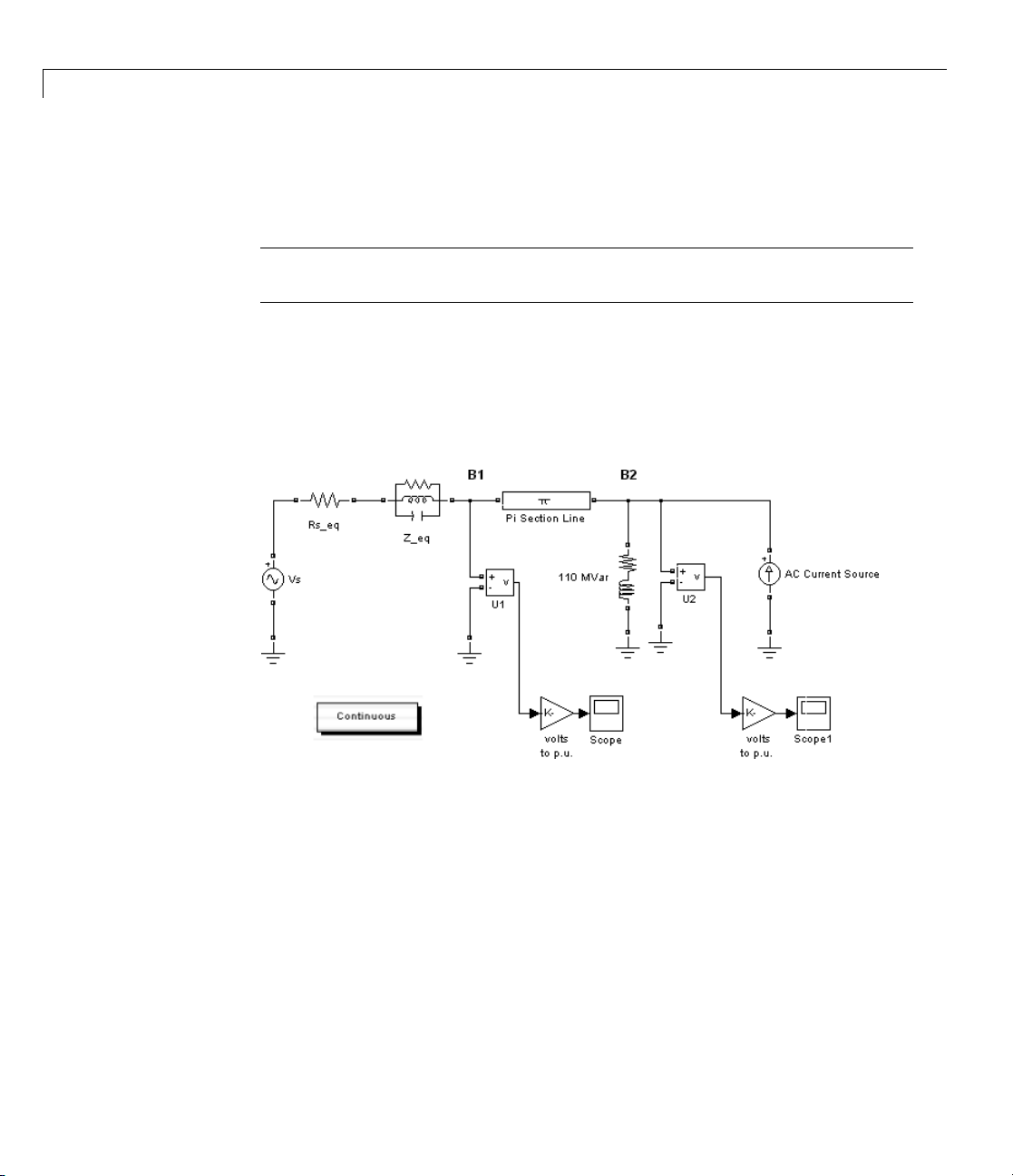

Obtaining the Impedance vs. Frequency Relation from the

State-Space Model

Note The following section assumes you have Control System Toolbox™

software installed.

To measure the impedance versus frequency at node B2, you need a current

source at node B2 providing a second input to the state-space model. Open

the Electrical Sources library and copy the AC Current Source block into

your model. Connect this source at node B2, as shown below. Set the current

source magnitude to zero and keep its frequency at

blocks as follows.

60 Hz. Rearrange the

1-22

AC Current Source at the B2 Node

Now compute the state-space representation of the model circuitl with the

power_analyze command. Enter the following command at the MATLAB

prompt.

sys1 = power_analyze('circuit1','ss')

This command returns a state-space model representing the continuous-time

state-space model of your electrical circuit.

Page 37

Analyzing a Simple Circuit

IntheLaplacedomain,theimpedanceZ2atnodeB2isdefinedasthetransfer

function between the current injected by the AC current Source block and the

voltage measured by the U2 Voltage Measurement block.

Us

2

=

Is

()

2

()

Zs

2

()

You obtain the names of the inputs and outputs of this state-space model as

follows.

sys1.InputName

ans =

'U_Vs'

'I_AC Current Source'

sys1.OutputName

ans =

'U_U2'

'U_U1'

The impedance at node B2 then corresponds to the transfer function between

output 1 and input 2 of this state-space model. For the 0 to 1500 Hz range, it

can be calculated and displayed as follows.

freq=0:1500;

w=2*pi*freq;

bode(sys1(1,2),w);

Repeat the same process to get the frequency response with a 10 section

line model. Open the PI Section Line dialog box and change the number

of sections from

1 to 10. To calculate the new frequency response and

superimpose it upon the one obtained with a single line section, enter the

following commands.

sys10 = power_analyze('circuit1','ss');

bode(sys1(1,2),sys10(1,2),w);

Open the property editor of the Bode plot and select units for Frequency in H z

using linear scale and Magnitude in absolute using log scale. The resulting

plot is shown below.

1-23

Page 38

1 Getting Started

Impedance at Node B2 as Function of Frequency

This graph indicates that the frequency rangerepresentedbythesingleline

section model is limited to approximately 150 Hz. For higher frequencies, the

10 line section model is a better approximation.

1-24

The system with a single PI section has two oscillatory modes at 89 Hz and

229 Hz. The 89 Hz m ode is due to the equivalent source, which is modeled

by a single pole equivalent. The 229 Hz mode is the first mode of the line

modeled by a single PI section.

For a distributed parameter line model the propagation speed is

v

The propagation time for 300 km is therefore T = 300/293,208 = 1.023 ms

and the frequency of the first line mode is f1 = 1/4T = 244 Hz. A distributed

parameter line would have an infinite number of modes every 244 + n*488 Hz

(n=1,2,3...). The10sectionlinemodelsimulatesthefirst10modes. The

first three line modes can be seen in Impedance at Node B2 as Function of

Frequency on page 1-24 (244 Hz, 732 Hz, and 1220 Hz).

LC

⋅

=1293 208,/

km s=

Page 39

Analyzing a Simple Circuit

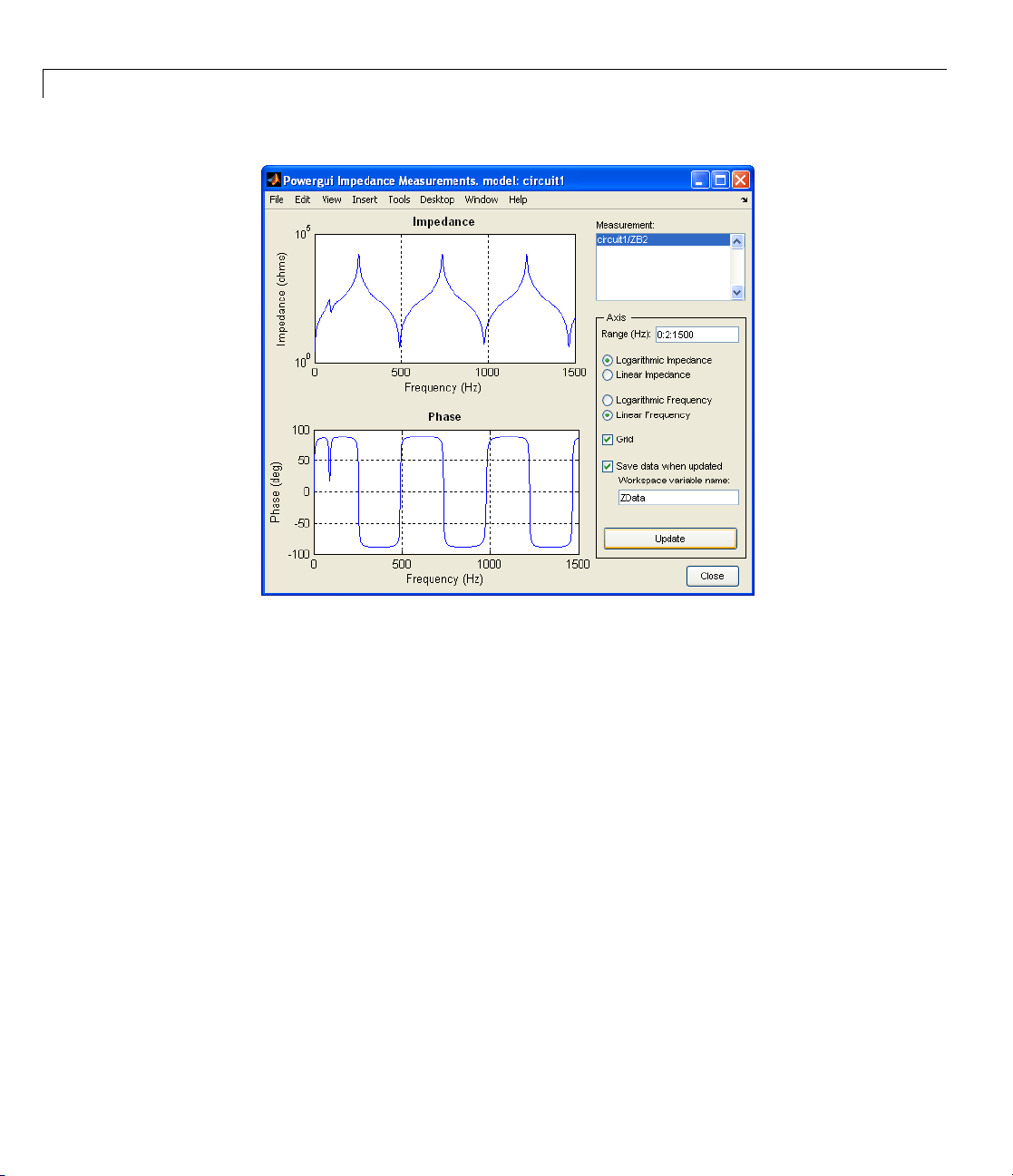

Obtaining the Impedance vs. Frequency Relation from the

Impedance Measurement and Powergui Blocks

The process described above to measure a circuit impedance has been

automated in a SimPowerSystems block. Open the Measurements library of

powerlib, copy the Impedance Measurement block into your model, and

rename it ZB2. Connect the two inputs of this block between node B2 and

ground as shown.

Measuring Impedance vs. Frequency with the Impedance Measurement

Block

Now open the Powergui dialog. In the Tools menu, select Impedance

vs Frequency Measurement. A new window opens, showing the list of

Impedance Measurement blocks available in your circuit.

In your case, only one impedance is measured, and it is identified by ZB2 (the

name of the ZB2 block) in the window. Fill in the frequency range by en ter in g

0:2:1500 (zero to 1500 Hz by steps of 2 Hz). Select the logarithmic scale to

display Z magnitude. Select the Save data when updated check box and

enter

ZData as the variable name to contain the impedance vs. frequency.

Click the Update button.

1-25

Page 40

1 Getting Started

1-26

When the

phase as

plot (fo

Freque

variab

column

r one line section) shown in Impedance at Node B2 as Function of

ncy on page 1-24. If you look in your workspace, you should have a

le named

1 and complex impedance in column 2.

calculation is finished, the window displays the ma gnitude and

functions of frequency. The m agnitude should be identical to the

ZData. It is a two-column matrix containing frequency in

Page 41

Specifying Initial Conditions

In this section...

“Introduction” on page 1-27

“State Variables” on page 1-27

“Initial States” on page 1-28

“Specify Initial Electrical States with Powergui” on page 1-29

Introduction

In this section you

• Learn what are the state variables of a Simulink diagram containing

SimPowerSystems blocks

• Specify initial conditions for the electrical state variables

Specifying Initial Conditions

State Variables

The state variables of a Simulink diagram containing SimPowerSystems

blocks consist of

• The electrical states associated to RLC branch-type SimPowerSystems

blocks. They are defined by the state-space representation of your m odel.

See “Electrical State Variables” on page 1 -18 for more details about the

electrical states.

• The Simulink states of the SimPowerSystems electrical models such as

the Synchronous Machine block, the Saturable Transformer block, or the

Three-Phase Dynam ic Load block.

• The Simulink states of the other Simulink blocks of your model (controls,

user-defined blocks, and other blocksets).

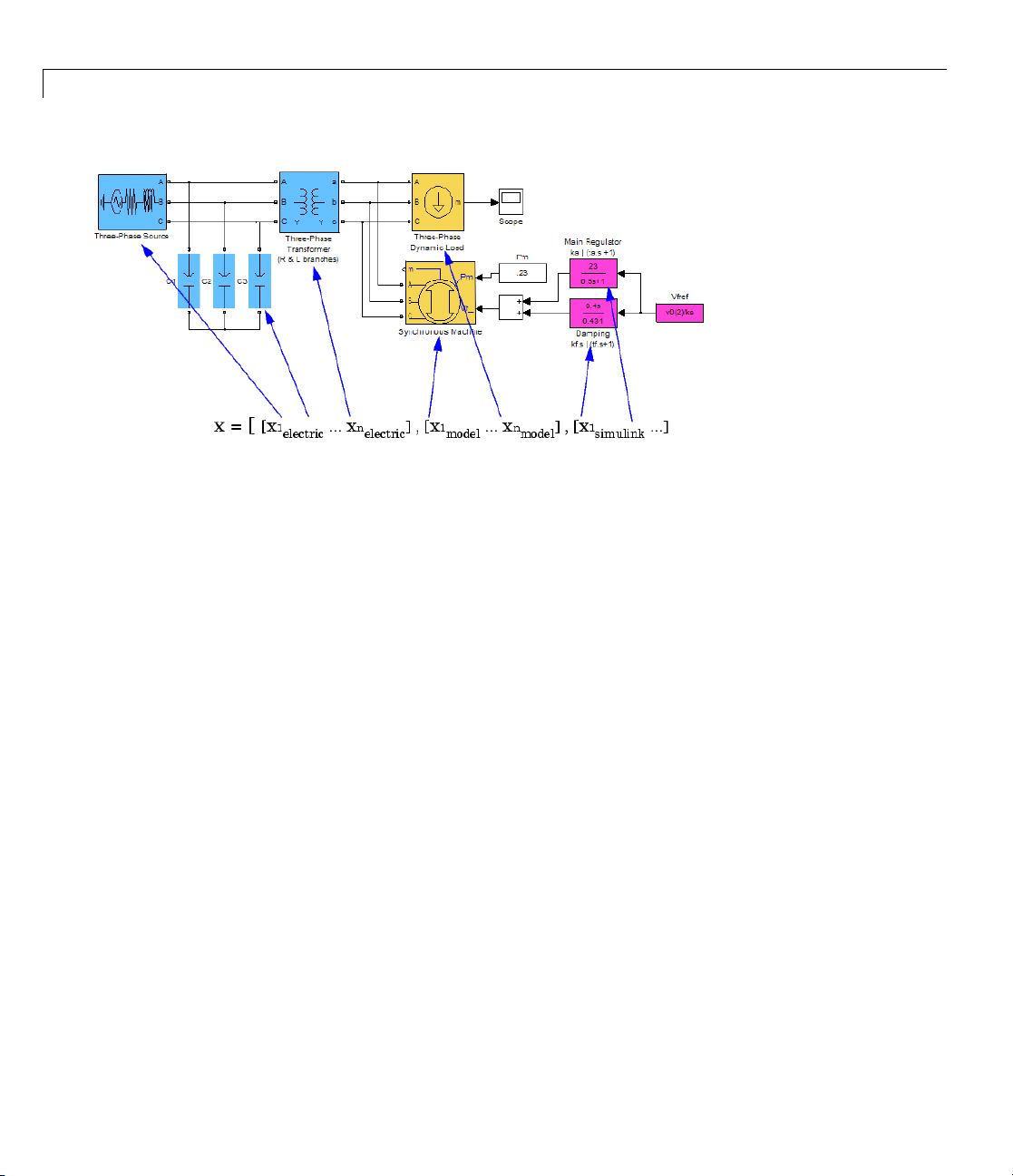

The following picture provides an example that contains the three types of

state variables:

1-27

Page 42

1 Getting Started

Initial States

Initial conditions, which are applied to the entire system at the start of the

simulation, are generally set in the blo ck s. Most of the Simulink blocks

allow you to specify initial conditions. For the case of the electrical states,

the SimPowerSystems software automaticall y sets the initial values of the

electrical states to start the simulation in steady state.

1-28

However, you can specify the initial conditions for the capacitor voltage and

inductor currents in the mask of these blocks:

• the Series and Parallel RLC Branch blocks

• the Series and Parallel RLC Load blocks

The initial values entered in the mask of these block will overwrite the default

steady-state parameters calculated by the SimPowe rSystem s software. In

the same sense, you can overwrite initial conditions of the overall blocks by

specifying them in the States area of the Configuration Parameters dialog

box.

See the

specify initial states for a Simulink diagram with SimPowerSystems blocks.

power_init function reference page for moredetailsonhowyoucan

Page 43

Specifying Initial Conditions

Specify Initial Electrical States with Powergui

1 Open the Transient Ana lys is of a Linear Circuit demo by typing

power_transient at the comm and line. Rename the RLC Branch blocks

asshowninthenextfigure.

2 From the Analysis tools menu of the Powergui block, select Initial State

Settings. The initial values of the five electrical state variables (three

inductor currents and two capacitor voltages) are displayed. These initial

values corresponds to the values that the software automatically sets to

start the simulation in steady state.

1-29

Page 44

1 Getting Started

1-30

3 Open the Scope block and start the simulation. As the electrical state

variables are automatically initialized, the system starts in steady state

and sinusoidal waveforms are observed.

4 The initial value for STATE_D state is set to 1.589e5 V. It corresponds to the

initial capacitor voltage found in the

STATE_D block. Open this block, select

the Set the initial capacitor voltage parameter, then specify a capacitor

initial voltage of -2e5 V. Click the OK button.

5 Click the From diagram button of the Powergui Initial States Tool to

refresh the display of initial states. The initial state of

STATE_D block is

now set to -2e5 V.

6 Start the simulation. In the second trace of the Scope block, z oom around

the transient at the beginning of the simulation. As expected, the model

does not start in steady state, but the initial value for the capacitor voltage

measured by the Voltage Measurement block is -2e5 V.

Page 45

Specifying Initial Conditions

7 Select the STATE_A state variable in the Initial States Tool list. In t he

Set selected electrical state field, set the initial inductor current to 50

A, and click Apply.Openthemaskofthe

STATE_A block, and note that the

Set the initial inductor current parameter is selected and the initial

inductor current is set to 50 A.

Run the simulation and observe the new transient caused by this new setting.

Forcing Initial States to Zero

Now suppose that you want to reset all the initial electrical states to zero

without loosing the settings you have done in the previous steps.

1 From the Initial State Tool window, select the To zero check box under

Force initial electrical states,thenclickApply. Restart the simulation

and observe the transient when all the initial conditions starts from zero.

2 Open the masks of the STATE_C and STATE_A blocks and note that even if

initial conditions are still specified in these blocks, the setting for the initial

states is forced to zero by the Powergui block.

A message is displayed at the command l ine to remind you every time you

start the simulation that the e lectrical initial states of your model are forced to

zero by the Powergui block, which overwrites the block settings in your model.

Forcing Initial States to Steady State

Similarly, you can set all the initial states to steady without loosing the

settings you have done in the previous steps.

1 From the Initial State Tool window , select the To steady state check box

under Force initial electrical states,thenclickApply.

2 Restart the simulation and observe that the simulation starts in steady

state.

A message is displayed at the command line to remind you every time you

start the simulation that the electrical initial states of your model are forced

to steady state by the Powergui block.

1-31

Page 46

1 Getting Started

Returning to Block Settings

To return to the block settings, clear both check boxes under Force initial

electrical states,thenclickApply.

1-32

Page 47

Simulating Transients

In this section...

“Introduction” on page 1-33

“Simulating Transients with a Circuit Breaker” on page 1-33

“Continuous, Variable Time Step Integration Algorithms” on page 1-35

“Discretizing the Electrical System” on page 1-37

Introduction

In this section you

• Learn how to create an electrical subsystem

• Simulate transients with a circuit breaker

• Compare time domain simulation results with different line models

Simulating Transients

• Learn how to discretize a circuit and compare results thus obtained with

results from a continuous, variable time step algorithm

Simulating Transients with a Circuit Breaker

One of the main uses of SimPowerSystems software is to simulate transients

in electrical circuits. This can be done with either mechanical switches (circuit

breakers) or switches using power electronic devices.

First open your

node B2. Save this new system as

breaker, you need to modify the schematic diagram of

group several components into a subsystem. This feature is useful to simplify

complex schematic diagrams.

Use this feature to transform the source impedance into a subsystem:

1 Select the two blocks identified as Rs_eq and Z_eq by surrounding them by

a box with the left mouse button and use the Edit > Create subsystem

menu item. The two blocks now form a new block called Subsystem.

circuit1 system and delete the current source connected at

circuit2. Before connecting a circuit

circuit2.Youcan

1-33

Page 48

1 Getting Started

2 Using the Edit > Mask subsystem menu item, change the icon of that

subsystem. In the Icon section of the mask editor, enter the following

drawing command:

disp('Equivalent\nCircuit')

The icon now reads Equivalent Circuit, as shown in the figure above.

1-34

3 Use the Format > Show drop shadow menu item to add a drop shado w

to the Subsystem block.

4 You can double-click the Subsystem block and look at its content.

5 Insert a circuit breaker into your circuit to sim ulate a line energization by

opening the Elements library of powerlib.CopytheBreakerblockinto

your circuit2 window.

The circuit breaker is a nonlinear element modeled by an ideal switch in

series with a resistance. Because of modeling constraints, this resistance

cannot be set to zero. However, it can be set to a very small value, say 0.001

Ω, that does not affect the performance of the circuit:

1 Open the Breaker block dialog box and set its parameters as follows:

Ron

Initial state

Rs

0.001 Ω

0 (open)

inf

Page 49

Simulating Transients

Cs

Switching times

2 Insert the circuit breaker in series with the sending end of the line, then

0

[(1/60)/4]

rearrange the circuit as shown in the previous figure.

3 Open the scope U2 and click the P ara me te rs icon and select the Data

history tab. Click the Save data to workspace button and specify a

variable name

U2 to save the simulation results; then change the Format

option for U2 to be Array.Also,clearLimit data points to last to display

the entire waveform for long simulation times.

You are now ready to simulate your system.

Continuous, Variable Time Step Integration Algorithms

Open the PI section Line dialog box and make sure the num ber of sections

is set to 1. Open the Simulation > Configuration Parameters dialog box.

As you now have a system containing switches, you need a stiff integration

algorithm to simulate the circuit. In the Solver pane, select the variable-step

stiff integration algorithm

ode23tb.

Keep the default parameters (relative tolerance set at

time to

0.02 seconds. Open the scopes and start the simulation. Look at

1e-3) and set the stop

the waveforms of the sending and receiving en d voltages on ScopeU1 and

ScopeU2.

Once the simulation is complete, copy the variable

U2 into U2_1 by entering

the following command in the MATLAB Command Window.

U2_1 = U2;

These two variables now contain the waveform obtained with a single PI

section line model.

1-35

Page 50

1 Getting Started

Open the PI section Line dialog box and change the number of sections

from

1 to 10. Start the simulation. Once the simulation is complete, copy

the variable

U2 into U2_10.

Before modifying your circuit to use a distributed parameter line m odel, save

your system as

circuit2_10pi, which you can reuse later.

Delete the PI section line model and replace it with a single-phase D istributed

Parameter Line block . S et the number of phases to

1 and use the same R, L,

C, and length parameters as for the PI section line (see Circuit to Be Modeled

on page 1-8). Save this system as

circuit2_dist.

Restart the simulation and save the

U2 voltage in the U2_d variable.

You can now compare the three waveforms obtained with the three line

models. Each variable

U2_1, U2_10,andU2_d is a t w o-column matrix where

thetimeisincolumn1andthevoltageisincolumn2. Plotthethree

waveforms on the same graph by entering the following command.

plot(U2_1(:,1), U2_1(:,2), U2_10(:,1),U2_10(:,2),

U2_d(:,1),U2_d(:,2));

These w av eforms are shown in the next f ig ure . As expected from the

frequency analysis performed during “Analyzing a Simple Circuit” on page

1-18, the single PI model does not respond to frequencies higher than 229 Hz.

The 10 PI section model gives a better accuracy, although high-frequency

oscillations are introduced by the discretization of the line. You can clearly

see in the figure the propagation time delay of 1.03 ms associated with the

distributed parameter line.

1-36

Page 51

Receiving End Voltage Obtained with Three Different Line Models

Simulating Transients

Discretizing the Electrical System

An important product feature is its ability to simulate either with continuous,

variable step integration algorithms or w ith discrete solvers. For small

systems, variable time step algorithms are usually faster than fixed step

methods, because the number of integration steps is lower. For large systems

that contain many states or many nonli near blocks such as power electronic

switches, however, it is advantageous to discretize the electrical system.

When you discretize your system, the precision of the simulation is controlled

by the time step. If you use too large a time step, the precision might not be

sufficient. The only way to know if it is accept able is to repeat the simula t ion

withdifferenttimestepsandfindacompromise for the largest acceptable

time step. Usually time steps of 20 µs to 50 µs give good results for simulation

of switching transients on 5 0 Hz or 60 Hz power systems or on systems using

line-commutated power electronic devices such as diodes and thyristors.

You must reduce the time step for systems using forced-commutated power

electronic switches. These devices, the insulated-gate bipolar transistor

(IGBT), the field-effect transistor (FET), a n d the gate-turnof f th yri stor ( GT O )

are operating at high switching frequencies.

1-37

Page 52

1 Getting Started

For example, simulating a pulse-width-modulated (PWM) inverter operating

at 8 kHz would require a time step of at most 1 µs.

Younowlearnhowtodiscretizeyoursystem and compare simulation results

obtained with continuous and discrete systems. Open the

circuit2_10pi

system that you saved from a previous simulation. This system contains

24 electrical states and one switch. Open the Powergui, click Configure

Parameters, and in the Powergui block parameters dialog box set

Simulation type to

Discrete.Setthesampletimeto25e-6 s. When you

restart the simulation, the power system is discretized using the Tustin

method (corresponding to trapezoidal integration) using a 25 µs sample time.

Open the Simulation > Configuration Parameters dialog box and on the

Solver pane set the simulation time to

0.2 s. Start the simulation.

Note Once the system is discretized, there are no more continuous states in

the electrical system. So you do not need a variable-step integration method

to simulate. In the Sim ulation > Configuration Parameters > Solver

pane, you could have selected the

states)

options and specified a fixe d step of 25 µs.

Fixed-step and Discrete (no continuous

1-38

To measure the simulation time, you can restart the simulation by e ntering

the following commands.

tic; sim(gcs); toc

When the simulation is finished the elapsed time in seconds is displayed

in the MATLA B Command Window.

To return to the continuous simulation, open the Powergui block parameters

dialog box a nd set Simulation type to

Continuous.Ifyoucomparethe

simulation times, you find that the discrete system simulates approximately

3.5 times faster than the continuous system.

To compare the precision of the two methods, perform the following three

simulations:

1 Simulate a continuous s ystem , with Ts = 0.

Page 53

Simulating Transients

2 Simulate a discrete system, with Ts = 25 µs.

3 Simulate a discrete system, with Ts = 50 µs.

For each simulation, save the voltage U2 in a different variable. Use

respectively

U2c, U2d25,andU2d50. Plot the U2 waveforms on the same graph

by entering the following command.

plot(U2c(:,1), U2c(:,2), U2d25(:,1),U2d25(:,2),

U2d50(:,1),U2d50(:,2))

Zoom in on the 4 to 12 ms region of the plot window to compare the differences

on the high-frequency transients. The 25 µs compares reasonably well

with the continuous simulation. However, increasing the time step to 50

µs produces appreciable errors. The 25 µs time step would therefore be

acceptable for this circuit, while obta ining a gain of 3.5 on simulation speed .

parison of Simulation Results for Continuous and Discrete Systems

Com

1-39

Page 54

1 Getting Started

Introducing the Phasor Simulation Method

In this section...

“Introduction” on page 1-40

“When to Use the Phasor Solution” on page 1-40

“Phasor Simulation of a Circuit Transient” on page 1-41

Introduction

In this section, you

• Apply the phasor simulation method to a simple linear circuit

• Learn advantages and limitations of this method

Up to now you have used two methods to simulate electrical circuits:

• Simulation with variable time steps using the continuous Simulink solvers

1-40

• Simulation with fixed time steps using a discretized system

This section explains how to use a third simulation method, the phasor

solution method.

When to Use the Phasor Solution

The phasor solution method is mainly used to study electromechanical

oscillations of power systems consisting o f large generators and motors.

An example of this method is the simulation of a multimachine system in

“Three-Phase Systems and Machines” on page 2-25. However, this technique

is not restricted to the study of transient stability of machines. It can be

applied to any linear system.

If, in a linear circuit, you are interested only in the changes in magnitude and

phase of all voltages and currents when switches are closed or opened, you do

not need to solve all differential equations (state-space model) resulting from

the interaction of R, L, and C elements. You can instead solve a much simpler

set of algebraic equations relating the voltage and current phasors. This is

what the phasor solution method does. As its name implies, this method

Page 55

Introducing the Phasor Simulation Method

computes voltages and currents as p hasors. Phasors are complex numbers

representing sinusoidal voltages and currents at a particular frequency. They

can be expressed either in Cartesian coord inates (real and imaginary) or in

polar coordinates (amplitude and phase). As the electrical states are ignored,

the phasor solution method does no t require a particular solver to solve the

electrical part of your system. T he simulation is therefore much faster to

execute. You must keep in mind, however, that this faster solution technique

gives the solu tion only at one particular frequency.

Phasor Simulation of a Circuit Transient

You now apply the phasor solution method to a simple linear circuit. Open

the demo named Transient Analysis of a Linear Circuit (

power_transient).

Simple Linear Circuit

This circuit is a simplified model of a 60 Hz, 230 kV three-phase power system

where only one phase is represented. The equivalent source is modeled by a

voltage source (230 kV RMS / sqrt(3) or 132.8 kV RMS, 60 Hz) in series with

its internal impedance (Rs Ls). The source feeds an RL load through a 150 km

transmission line modeled by a single PI section (RL1 branch and two shunt

capacitances, C1 and C2). A circuit breaker is used to switch the load (75 MW,

1-41

Page 56

1 Getting Started

20 Mvar) at the receiving end of the transmission line. Two measurement

blocks are used to monitor the load voltage and current.

The Powergu i block at the lower-left corner indicates that the model is

continuous. Start the simulation and observe transients in voltage and

current waveforms when the load is first switched off at t = 0.0333 s (2 cycles)

and switched on again at t = 0.1167 s (7 cycles).

Invoking the Phasor Solution in the Powergui Block

You now simulate the same circuit using the phasor simulation method. This

option is accessible through the Powergui block. Open the Powergui, click

Configure Parameters, and in the Powergui block parameters dialog box

set Simulation type to

to solve the algebraic network equations. A default value of 60 Hz should

already be entered in the Phasor frequency field. Close the Powergui and

notice that the word

that the Powergui now applies this me thod to simulate your circuit. Before

restarting the simulation, you need to specify the appropriate format for the

two signals sent to the Scope block.

Phasor. You must also specify the frequency used

Phasors now appears on the Pow ergui icon, indicating

1-42

Selecting Phasor Signal Measurement Formats

If you now double-click the Voltage Measurement block or the Current

Measurement block, you see that a menu allows you to output phasor

signals in four different formats:

Magnitude-Angle,orjustMagnitude.TheComplex format is useful when you

want to process com plex signals. Note that the oscilloscope d oes not accept

complex signals . Select

the Load Current Measurement blocks. This will allow you to observe the

magnitude of the voltage and current phasors.

Restart the simulation. The magnitudes of the 60 Hz voltage and current

are now displayed o n the scope. Waveforms obtained from the continuous

simulation and the phasor simulation are superimposed in this plot.

Magnitude format for both the Line Voltage and

Complex (default choice), Real-Imag,

Page 57

Introducing the Phasor Simulation Method

Waveform

Note tha

occurs a

whereas

becaus

s Obtained with the Continuous and Phasor Simulation Methods

t with continuous simulation, the opening of the circuit breaker

t the next zero crossing of current following the opening order;

for the phasor simulation, this opening is instantaneous. This is

e there is no concept of zero crossing in the phasor simulation.

Processing Voltage and Current Phasors

The Co

phaso

that y

P and

and c

mplex

rs without separating real and imaginary parts. Suppose, for example,

ou need to compute the power consumption of the load (active power

reactive power

urrent phasors as

SPjQ VI=+ =⋅⋅

format allows the use of complex operations and processing of

Q). The complex power S is obtained from the voltage

1

∗

2

1-43

Page 58

1 Getting Started

where I* is the conjugate of the current phasor. The 1/2 factor is required to

convert magnitudes of voltage and current from peak values to RMS values.

Power Co

Select the

the Simulink Math library, implement the power measurement as shown.

mputation Using Complex Voltage and Current

The Comp

phasor

The pow

SimPo

block

Complex format for both current and voltage and, using blocks from

lex to Magnitude-Angle blocks are now required to convert complex

s to magnitudes before sending them to the scope.