Page 1

SimMechanics™ 3

User’s Guide

Page 2

How to Contact The MathWorks

www.mathworks.

comp.soft-sys.matlab Newsgroup

www.mathworks.com/contact_TS.html Technical Support

suggest@mathworks.com Product enhancement suggestions

bugs@mathwo

doc@mathworks.com Documentation error reports

service@mathworks.com Order status, license renewals, passcodes

info@mathwo

com

rks.com

rks.com

Web

Bug reports

Sales, prici

ng, and general information

508-647-7000 (Phone)

508-647-7001 (Fax)

The MathWorks, Inc.

3 Apple Hill Drive

Natick, MA 01760-2098

For contact information about worldwide offices, see the MathWorks Web site.

SimMechanics™ User’s Guide

© COPYRIGHT 2001–20 10 by The MathWorks, Inc.

The software described in this document is furnished under a license agreement. The software may be used

or copied only under the terms of the license agreement. No part of this manual may be photocopied or

reproduced in any form without prior written consent from The MathW orks, Inc.

FEDERAL ACQUISITION: This provision applies to all acquisitions of the Program and Documentation

by, for, or through the federal government of the United States. By accepting delivery of the Program

or Documentation, the government hereby agrees that this software or documentation qualifies as

commercial computer software or commercial computer software documentation as such terms are used

or defined in FAR 12.212, DFARS Part 227.72, and DFARS 252.227-7014. Accordingly, the terms and

conditions of this Agreement and only those rights specified in this Agreement, shall pertain to and govern

theuse,modification,reproduction,release,performance,display,anddisclosureoftheProgramand

Documentation by the federal government (or other entity acquiring for or through the federal government)

and shall supersede any conflicting contractual terms or conditions. If this License fails to meet the

government’s needs or is inconsistent in any respect with federal procurement law, the government agrees

to return the Program and Docu mentation, unused, to The MathWorks, Inc.

Trademarks

MATLAB and Simulink are registered trademarks of The MathWorks, Inc. See

www.mathworks.com/trademarks for a list of additional trademarks. Other product or brand

names may be trademarks or registered trademarks of their respective holders.

Patents

The MathWorks products are protected by one or more U.S. patents. Please see

www.mathworks.com/patents for more information.

Page 3

Revision History

December 2001 Online only Version 1.0 (Release 12.1+)

July 2002 First printing Revised for Version 1.1 (Release 13)

November 2002 Online only Revised for Version 2.0 (Release 13+)

June 2004 Second printing Revised for Version 2.2 (Release 14)

October 2004 Online only Revised for Version 2.2.1 (Release 14SP1)

March 2005 Online only Revised for Version 2.2.2 (Release 14SP2)

September 2005 O nline only Revised for Version 2.3 (Release 14SP3)

March 2006 Online only Revised for Version 2.4 (Release 2006a)

September 2006 Third printing Revised for Version 2.5 (Release 2006b)

March 2007 Online only Revised for Version 2.6 (Release 2007a)

September 2007 O nline only Revised for Version 2.7 (Release 2007b)

March 2008 Online only Revised for Version 2.7.1 (Release 2008a)

October 2008 Online only Revised for Version 3.0 (Release 2008b)

March 2009 Online only Revised for Version 3.1 (Release 2009a)

September 2009 O nline only Revised for Version 3.1.1 (Release 2009b)

March 2010 Online only Revised for Version 3.2 (Release 2010a)

Page 4

Page 5

Modeling Mechanical Systems

1

Representing Machines with Models ................ 1-2

About Machines

About SimM echanics Models

Creating a SimMechanics Model

Connecting SimMechanics Blocks

Interfacing SimMechanics Blocks to Simulink Blocks

Creating SimMechanics Subsystems

Creating Custom SimMechanics Blocks with Masks

................................... 1-2

........................ 1-2

..................... 1-3

.................... 1-5

.................. 1-6

Contents

.... 1-6

..... 1-8

Modeling Grounds and Bodies

About Bodies and Grounds

Modeling Grounds

Modeling Rigid Bodies

WorkingwithBodyCoordinateSystems

Modeling Degrees of Freedom

About Joints

Modeling Joints

Creating a Joint

Modeling Massless Connectors

Modeling Disassem bled Joints

Constraining and Driving Degrees of Freedom

About Constraints

Types of Mechanical Constraints

What Constraints and Drivers Do

Directionality of Constraints and Drivers

Solving Constraints

Restrictions on Using Constraint and Driver Blocks

Constraint Example: Gear Constraint

Driver Example: Angle Driver

................................. 1-9

............................. 1-11

...................................... 1-19

................................... 1-20

................................... 1-27

................................. 1-38

................................ 1-40

...................... 1-9

.......................... 1-9

............... 1-14

...................... 1-19

....................... 1-30

....................... 1-34

..................... 1-38

.................... 1-39

.............. 1-40

................. 1-41

....................... 1-43

....... 1-38

..... 1-41

Cutting Machine Diagram Loops

Rules for Valid Machine Diagram Loops

.................... 1-46

............... 1-46

v

Page 6

Rules for Automatic Loop Cutting .................... 1-46

Specifying a Loop Joint for Cutting

Displaying the Cut Joints

For More About Disassembled and Cut Joints

For More About Constraints and Drivers

........................... 1-47

................... 1-47

.......... 1-47

.............. 1-47

Applying Motions and Forces

About Actuators

Actuating a Body

Varying a Body’s Mass and Inertia Tensor

Actuating a Joint

Actuating a Driver

Specifying Initial Positions and Velocities

Sensing Motions and Forces

About Sensors

SensingBodyMotions

Sensing Joint Motions and Forces

Sensing Constraint Reaction Forces

Adding Internal Forces

About Force Elements

Inserting a Linear Force Between Bodies

Inserting a Linear Force or Torque Through a Joint

Customizing Force Elements with Sensor-Actuator

Feedback

Combining One- and Three-Dimensional Mechanical

Elements

About Interface Elements

Working with Interface Elements

Example: Rotational Spring-Damper with Hard Stop

.................................. 1-48

.................................. 1-50

.................................. 1-56

................................ 1-62

.................................... 1-68

.............................. 1-69

.............................. 1-74

...................................... 1-78

....................................... 1-79

....................... 1-48

............. 1-53

.............. 1-62

........................ 1-68

.................... 1-70

.................. 1-71

............................ 1-74

.............. 1-74

..... 1-76

........................... 1-79

.................... 1-81

.... 1-82

vi Contents

Validating Mechanical Models

Essential Tests for Model Validity

Verifying Model Topology

Counting Model Degrees of Freedom

........................... 1-85

...................... 1-85

.................... 1-85

.................. 1-89

Page 7

Running M echanical Models

2

Configuring SimMechanics Models in Simulink ...... 2-2

SimMechanics and Simulink Options

Distinguishing Models and Machines

Machine Settings via the Machine Environment Block

Model-Wide Settings via Simulink and Simscape

Software

....................................... 2-3

................. 2-2

................. 2-2

... 2-2

Configuring Methods of Solution

About Mechanical and Mathematical Settings

Defining Gravity

Choosing Your Machine’s Dimensionality

Choosing an Analysis Mode

Hierarchy of Solvers and Tolerances

Controlling Machine Assembly

Maintaining Constraints

Configuring a Simulink Solver

Avoiding Simulation Failures

Starting Visualization and Simulation

About S im s cap e and Visualization Settings

Using the Simscape Editing Mode

Setting Up Visualization

Starting the Simulation

How Sim Mechanics Software Works

About Machine Simulation

Model Validation

Machine In itialization

Force Analys is and Motion Integration

Stiction Mode Iteration

.................................. 2-6

........................... 2-12

........................... 2-22

............................ 2-23

.......................... 2-24

.................................. 2-24

.............................. 2-24

............................. 2-25

.................... 2-6

......................... 2-8

.................. 2-11

....................... 2-12

....................... 2-16

........................ 2-17

.................... 2-20

.......... 2-6

.............. 2-7

............... 2-20

............ 2-20

................. 2-24

................ 2-25

Troubleshooting Simulation Errors

About Simulation Errors

Data Validation Errors

Ground and Body Geometry Errors

Joint Geometry Errors

Block Connection and Topology Errors

Motion Inconsistency and Singularity Errors

........................... 2-26

............................. 2-26

................... 2-27

............................. 2-27

................. 2-26

................ 2-28

........... 2-28

vii

Page 8

Analysis M ode Errors .............................. 2-31

Improving Performance

Optimizing Mechanical and Mathematical Settings

Simplifying the Degrees of Freedom

Adjusting Constraint Tolerances

Smoothing Motion Singularities

Changing the Simulink Solver and Tolerances

Adjusting the Time Step in Real-Time Simulation

Generating Code

About Code Generation from SimMechanics M odels

Using Code-Related Products and Features

How SimMechanics Code Generation Differs from

Simulink

Using Run-Time Parameters in Generated Code

Limitations

About SimMechanics and Simulink Limitations

Continuous Sample Times Required

Restricted Simulink Tools

Unsupported Simulink Tool

Simulink Tools Not Compatible with SimMechanics

Blocks

Restrictions on Two-Dimensional Simulation

Restrictions with Generated Code

........................................ 2-43

.................................. 2-38

...................................... 2-39

....................................... 2-42

............................ 2-32

.................. 2-32

..................... 2-34

..................... 2-34

............ 2-38

.................. 2-42

.......................... 2-42

......................... 2-43

.................... 2-44

...... 2-32

.......... 2-35

....... 2-36

..... 2-38

........ 2-40

........ 2-42

........... 2-44

viii Contents

Analyzing Motion

3

Dynamics of Mechanical Systems ................... 3-2

About Machine Dynamics

Forward and Inverse Dynamics

Forces, Torques, and Accelerations

Finding Forces from Motions

About Inverse Dynamics in SimMechanics Software

Inverse Dynamics Mode with a Double Pendulum

Kinematics Mode with a Four Bar Machine

........................... 3-2

...................... 3-3

................... 3-4

....................... 3-7

....... 3-8

............ 3-14

..... 3-7

Page 9

Trimming M e chanical Models ...................... 3-18

About Trimming in SimMechanics S oftware

Unconstrained Trimming of a Spring-Loaded Double

Pendulum

Constrained Trimming of a Four Bar Machine

..................................... 3-20

............ 3-18

.......... 3-26

Linearizing Mechanical Models

About Linearization and SimMechanics Software

Open-Topology Linearization: Double Pendulum

Closed-Loop Linearization: Four Bar Machine

..................... 3-32

....... 3-32

........ 3-34

.......... 3-40

Motion, Control, and Real-Time Simulation

4

Guide to This Chapter ............................. 4-3

AbouttheStewartPlatformandHowItIsModeled

About the Case Studies

Products N eeded for the Case Studies

References

About the Stewart Platform

Origin and Uses of the Stewart Platform

Characteristics of the Stewart Platform

Counting Degre es of Freedom in the Stewart Platform

Modeling the Stewart Platform

How the Stewart Platform Is Modeled

Modeling the Physical Plant

Modeling Controllers

Initializing the Stewart Platform

Identifying the Simulink and Mechanical States of the

Stewart Platform

Visualizing the Stewart Platform M otion

....................................... 4-5

............................. 4-3

................. 4-4

........................ 4-7

.............. 4-7

............... 4-7

..................... 4-13

................. 4-13

......................... 4-13

............................... 4-15

..................... 4-18

............................... 4-21

.............. 4-23

..... 4-3

... 4-8

Trimming and Linearizing Through Inverse

Dynamics

About Trimm ing and Inverse Dynamics

What Is Trimming?

Ways to Find an Operating Point

....................................... 4-24

............... 4-24

................................ 4-24

..................... 4-25

ix

Page 10

Trimming in the Kinematics Mode ................... 4-25

Linearizing the Stewart Platform at an Operating Point

Further Suggestions for Inverse Dynamics Trimming

.. 4-29

.... 4-32

About Controllers and Plants

Modeling Co ntrollers in Simulink and Plants in

SimMechanics Software

Nature of the Control Problem

Control Transfer Function Forms and Units

Controller-Plant Case Study Files

For More About Designing Controllers

Analyzing Controllers

Implementing a Simple Contro ller for the Stewart

Platform

A First Look at the Stewart Platform Control M odel

Improper and Biproper PID Controllers

Analyzing the PID Controller Response

Designing and Improving Controllers

Creating Improved Controllers for the Stewart Platform

Designing a New PID Controller

Trimming and Linearizing the Platform Motion

Improving the New PID Controller

Synthesizing a Robust, Multichannel Controller

Generating an d Simulating with Code

About the Stewart Platform Code Generation Examples

For More Information About Code Generation

Learning About the Model

Generating an S-Function Block for the Plant

Model Referencing the Plant

Generating Stand-Alone Code for the Whole Model

....................................... 4-39

.............................. 4-39

....................... 4-35

.......................... 4-35

....................... 4-36

............ 4-37

.................... 4-37

................ 4-37

............... 4-42

............... 4-46

............... 4-50

..................... 4-51

......... 4-53

................... 4-59

............... 4-71

.......... 4-71

.......................... 4-72

.......... 4-76

........................ 4-77

..... 4-39

.. 4-50

........ 4-66

.. 4-71

...... 4-80

x Contents

Simulating with Hardware in the Loop

About Dedicated Hardware Targets for Stewart Platform

Simulation

For More Information About xPC Target Software

Files Needed for This Study

Adjusting Hardware for Computational Demands

Downloading a Complete Model to the Target

Configuring for Realistic Hardware

..................................... 4-82

......................... 4-83

.............. 4-82

.......... 4-85

................... 4-90

...... 4-83

....... 4-83

Page 11

Index

xi

Page 12

xii Contents

Page 13

Modeling Mechanical Systems

1

SimMechanics™ software gives you a complete set of block libraries for

modeling machine parts and connecting them into a Simulink

• “Representing Machines with Models” on page 1-2

• “Modeling Grounds and Bodies” on page 1 -9

• “Modeling Degrees of Freedom” on page 1-19

• “Constraining and Driving Degrees of Freedom” on page 1-38

• “Cutting Machine Diagram Loops” on page 1-46

• “Applying Motions and Forces” o n page 1-48

• “Sensing Motions and Forces” on page 1-68

• “Adding Internal Forces” on page 1-74

• “Combining One- and Three-Dimensional Mechanical Elements” on page

1-79

• “Validating Mechanical Models” on page 1-85

Consult “Representing Motion” to review body kinematics. If you need more

information on rigid body mechanics, consult the physics and engineering

literature, beginning with the “Bibliography”. Classic engineering mechanics

texts include Goodman and Warner [2], [3] and Meriam [8]. The books of

Goldstein [1] and J osé and Saletan [5] are more theoretically oriented.

®

block diagram.

Page 14

1 Modeling Mechanical Systems

Representing Machines with Models

In this section...

“About Machines” on page 1-2

“About SimMechanics Models” on page 1-2

“Creating a SimMechanics Model” on page 1-3

“Connecting SimMechanics Blocks” on page 1-5

“Interfacing SimMechanics Blocks to Simulink Blocks” on page 1-6

“Creating SimMechanics Subsystems” on page 1-6

“Creating Custom SimMechanics Blocks with Masks” on page 1-8

About Machines

The SimMechanics term machine has two meanings.

1-2

• It refers to a physical system that includes at least one rigid body. The

SimMechanics block library allows you to create Simulink models of

machines.

• It also refers to a topologically distinct and separate block diagram

representing one physical m achine. A model can have one o r more

machines.

This section explains the nature of machines an d SimMechanics models.

About SimMechanics Models

ASimMechanicsmodel consists of a block diagram composed of one or more

machines, each of which is a set of connected blocks representing a single

physical machine. For example, the following model contains two mach ines.

Page 15

Representing Machines with Models

Compari

A SimMechanics model differs significantly from other Simulink models in

how it represents a machine.

• An ordinary Simulink model represents the mathematics of a machine’s

motion, i.e., the algebraic and differential equations that predict the

machine’s future state from its present state. The mathematical model

enables Simulink to simulate the machine.

• A SimMechanics model represents the physical structure of a machine,

the mass properties and geometric and kinematic relationships of its

component bodies. SimMechanics software converts this structural

representation to an internal, equivalent m athematical model. T his saves

you the time and effort of developing the mathematical model yourself.

son to Other Simulink Models

Creating a SimMechanics Model

You create a SimMechanics model in much the same way you create any

other Simulink model. First, you open a Simulink model window. Then you

1-3

Page 16

1 Modeling Mechanical Systems

drag instances of SimMechanics and other Simulink blocks from the Simulink

block libraries into the window and draw lines to interconnect the blocks (see

“Connecting SimMechanics Blocks” on page 1-5).

The SimMechanics block library provides the following blocks specifically

for modeling machines:

• Machine Environment blocks set the mechanical environment for a

machine. Exactly one Ground block in each machine m ust be connected to a

Machine Environment block. See Chapter 2, “Running Mechanical Models”.

• Body blocks represent a machine’s components and the machine’s immobile

surroundings (ground). See “Modeling Grounds and Bodies” on page 1-9.

• Joint blocks represent the degrees of freedom of one body relative to

another body or to a point on ground. See “Modeling Degrees of Freedom”

on page 1-19.

• Constraint and Driver blocks restrict motions of or impose motions on

bodies relative to one another. See “Constraining and Driving D egrees

of Freedom” on page 1-38.

1-4

• Actuator blocks specify forces, motions, variable masses and inertias, or

initial conditions applied to bodies, joints, and drivers. See “Applying

Motions and Forces” on page 1-48.

• Sensor blocks measure the forces on and motions of bodies, joints, and

drivers. See “Sensing Motions and Forces” on page 1-68.

• Force element blocks model interbody forces. See “Sensing Motions and

Forces” on page 1-68.

• Simscape™ mechanical elements model one-dimensional motion and, with

certain restrictions, can be interfaced with SimMechanics m achines. See

“Combining One- and Three-Dimensional Mechanical Elements” on page

1-79.

You can use blocks from othe r Simulink libraries in SimMechanics models.

For example, you can connect the output of SimMechanics Sensor blocks

to Scope blocks from the Simulink Sinks library to display the forces and

motions of your model’s bodies and joints. Similarly, you can connect blocks

from the Simulink Sources library to SimMechanics Driver blocks to specify

relative motions of your machine’s bodies.

Page 17

Representing Machines with Models

Connecting SimM

In general, you c

other Simulink b

exist, however

SimMechanics b

Connection Lines

The lines tha

lines, repre

represented

SimMechani

and spatial

You can dra

available

branch exi

connected

only on SimMechanics blocks (see next section) and you cannot

Connector Ports

Standar

SimMech

you to dr

connec

d Simulink blocks have input and output ports. By contrast, most

anics blocks contain only specialized connector ports that permit

aw connection lines among SimMechanics blocks. SimMechanics

tor ports are of two types: Body CS ports and general-purpose ports.

onnect SimMechanics blocks in the same w ay you connect

locks: by drawing lines between them. Significant differences

, between connecting standard Simulink blocks and connecting

locks. This section discusses these differences.

t you dra w between standard Simulink blocks, called signal

sent inputs to and outputs from the mathematical functions

by the blocks. By contrast, the lines that you draw between

cs blocks, called connection lines, represent physical connections

relationships among the bodies represented by the blocks.

w connection lines only between specialized connector ports

sting connection lines. Connection lin es appe ar as so lid black w he n

and as dashed red lines when either end is unconnected.

echanics Blocks

Body CS

on a bod

origi

General-purpose connector ports appear on Joint, Constraint, Driver, Sensor,

and Actuator blocks. They permit you to connect Joints to Bodies and connect

Sensors and Actuators to Joints, Constraints, and Drivers. General-purpose

ports appear on Body and Ground blo cks and define connection points

y or ground. Each is associated with a local coordinate system whose

nspecifiesthelocationoftheassociated connection point on the body.

1-5

Page 18

1 Modeling Mechanical Systems

connector ports appear as circles on the block icon. The circle is unfilled if the

port is unconnected and filled if the port is connected.

Interfacing

SimMechanic

1-48) contain

Simulink bl

SimMechani

and Forces

Simulink b

SimMechanics Blocks to Simulink Blocks

s Actuator blocks (see “Applying Motions and Forces” on page

standard Simulink input ports. Thus, you can connect standard

ocks to a SimMechanics model via Actuator blocks. Sim ilarly,

cs Sensor blocks contain output ports (see “Sensing Motions

” on page 1-68). Thus, you can connect a SimMechanics model to

locks via Sensor blocks.

Creating SimMechanics Subsystems

Large, complex block diagram models are often ha rd to analyze. Enclosing

functionally related groups of blocks in subsystems alleviates this difficulty

and facilitates reuse of block groups in different models.

1-6

You can create subsystems containing SimMechanics blocks that you can

connect to other SimMechanics blocks. You do this in two ways:

Page 19

Representing Machines with Models

• Automatically

• Manually

The Simulink documentation explains more about creating subsystems.

Creating a Subsystem Automatically

To create a SimMechanics subsystem automatically,

1 Create the subsystem block diagram in your model window, leaving

unconnected ports for external connections.

2 Group-se

3 Select Create subsystem from the Edit menu of the Simulink model

lect the subsystem block diagram.

window.

The last step replaces the block diagram with a Subsystem block co ntaining

the selected block diagram. It also creates and connects SimMechanics

Connection Port blocks for the ports that you left unconnected in the block

diagram. The Connection Port blocks in turn create connector port icons on

the subsystem icon, enabling you to connect external SimMechanics blocks

to the new subsystem.

1-7

Page 20

1 Modeling Mechanical Systems

Creating a S

Sometimes you need to make a subsystem configured differently from an

automatically created one. To create a SimMechanics subsystem manually,

1 Drag a Subsystem block into your model window.

2 Open the S

3 Create the subsystem block diagram in the subsystem wi ndow .

4 Drag a Connection Port block from the SimMechanics Utilities library

into the subsystem window for each port that you want to be available

externally.

5 Connec

Creat

You ca

aspr

diag

diag

to th

or w

sub

to c

ing Custom SimMechanics Blocks with Masks

n create your own SimMechanics blocks from subsystems, for example,

ing-loaded Joint block or a sphere Body block. To do this, create a block

ram that implements the functionality of your custom block, enclose the

ram as a subsystem, and add a mask (i.e., a graphical user interface)

e subsystem. To facilitate sharing your custom blocks across m odels

ith other users, create a Simulink block library and add these masked

system blocks to the library. The Simulink documentation explains how

reate custom blocks with masks.

ubsystem Manually

ubsystem block.

t the external connector ports to the Connection Port blocks.

1-8

Page 21

Modeling Grounds and Bodies

In this section...

“About Bodies and Grounds” on page 1-9

“Modeling Grounds” o n page 1-9

“Modeling Rigid Bodies” on page 1-11

“Working w ith Body Coordinate Systems” on page 1-14

About Bodies and Grounds

The basic components of any mechanism are its constitu ent rigid bodies. A

SimMechanics body refers to any point or spatially extended object that has

mass. SimMechanics bodies, unlike physical bodies, do not have degrees

of freedom. The SimMechanics Bodies library contains two blocks for

representing bodies in a Simulink model:

• Ground

Modeling Grounds and Bodies

Models a point on an ideal body of infinite mass and extent that serves as a

fixed reference point for machines (see “Modeling Grounds” on page 1-9).

• Body

Models rigid bodies of finite mass and extent, including their attached

body coordinate systems (see “Modeling Rigid Bodies” on page 1-11 and

“Working with Body Coordinate Systems” on page 1-14).

“Representing Motion” explains, with detailed examples, more about

configuring bodies and their coordinate systems in space.

Modeling Grounds

ASimMechanicsground refers to a body of infinite mass that acts both

as a reference frame at rest for a whole machine and as a fixed base for

attaching machine components, e.g., the factory floor on which a robot stands.

SimMechanics Ground blocks enable you to represent points on ground in your

machine. This in turn enables you to specify the degrees of freedom that your

system has relative to its surroundings. You do this by connecting Joint blocks

1-9

Page 22

1 Modeling Mechanical Systems

representing the degrees of freedom between the Body blocks representing

parts of your machine and the Ground blocks representing ground points.

Each Ground block has a single connector port to which you can connect a

Joint block that can in turn be connected to a single Body block. Each Ground

block therefore allows you to represent the degrees of freedom betw een a

single part of your machine and its surroundings. If you want to specify the

motion of other parts of your machine relative to the surroundings, you must

create additional Ground blocks.

Caution Each machine in a SimMechanics m odel must contain at least one

Ground block connected to a Body block via a Joint block. Each submachine

connected by a Shared Environment block must have at least one Ground.

Machine Environment Required for Each Machine

One Ground block in each machine of your model plays a second role,

connection to that machine’s Machine Environment block, which sets its

mechanical environment. See Chapter 2, “Running Mechanical Models”.

1-10

Caution Exactly one Ground block in each machine in your model must be

connected to a Machine Environment block.

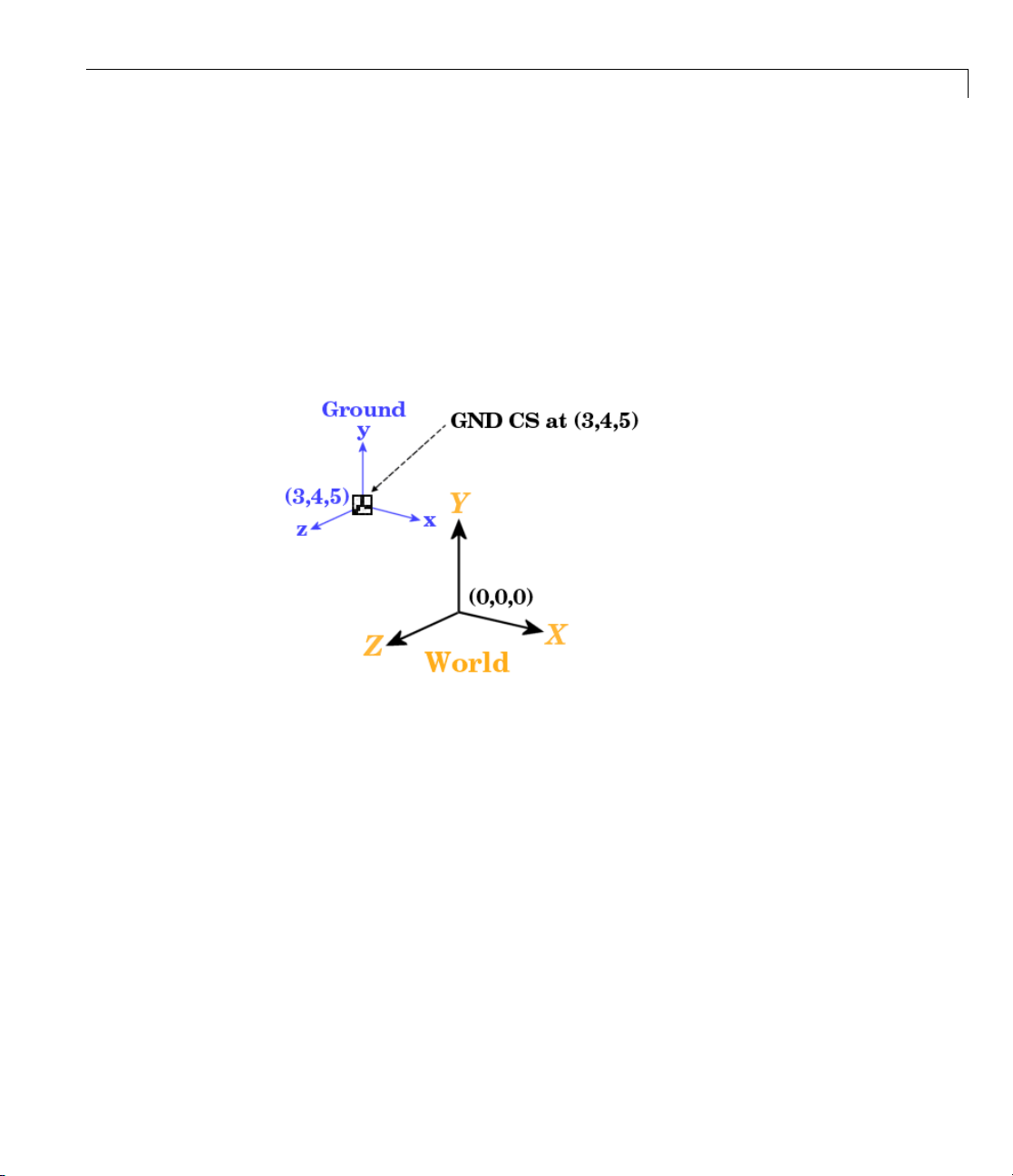

World and Grounded Coordinate Systems

The SimMechanics master coordinate system and reference frame is called

World. All grounds are at rest in World. The connector port of each Ground

block defines a grounded coordinate system called GND. The GND coordinate

system’s axes are parallel to World.

Page 23

Modeling Grounds and Bodies

By default the origin of the grounded coordinate sys tem coincides with the

origin of the World coordinate system. The Location field of a Ground block’s

dialog allows you to move the origin of GND to some other point in the World

coordinate system, as in the exampl e “Modeling and Simulating a Simple

Machine”.

The GND coordinate system allows you to specify the positions and motions of

parts of your machine relative to fixed points in the machine’s surroundings.

With a shifted origin, GND remains at rest.

Modeling Rigid Bodies

The SimMechanics Body block enables you to model rigid bodies of finite

mass and extent. A body is rigid if its internal parts cannot move relative to

one another.

About Body Blocks

A B od y block allows you to specify the following attributes of a rigid body.

Mass Properties. These include the body’s mass, which determines its

response to translational forces, and its inertia tensor, which determines its

response to rotational torques.

1-11

Page 24

1 Modeling Mechanical Systems

Body Coordinate Systems. By default a Body block defines three local

coordinate systems, one associated with a body’s center o f gravity, labeled

CG, and two others, labeled CS1 and CS2, respectively, associated w ith two

otherpointsonthebodythatyoucanspecify.YoucancreateadditionalBody

coordinate systems or delete them as necessary.

A Body block’s dialog box allows you to specify a Body CS’s origin (see “Setting

a Body CS’s Pos itio n” on pag e 1-14) and orientation (see “Setting a Body CS’s

Orientation” on page 1-16). The origin and orientation of a body’s CG CS

specify the body’s starting location and orientation. The origins o f the other

Body coordinate systems specify the initial locations of other points on the

body.

The Body b lock allows flexibility in specifying the origi ns and orientations

of Body coordinate systems. You can specify the origin and orientation of

a body CS relative to

• The World CS

• Any other CS on the same body

1-12

• The Adjoining CS, the CS on the neighboring body or ground directly

connected by a Joint, Constraint, orDrivertotheselectedBodyCSyou

are configuring

This simplifies creation and maintenance of models. The only limitation is

that you must specify the origin and location of at least one of a machine’s

Body coordinate systems relative to the World CS.

Home Configuration. Once you enter all the needed positions and

orientations into the Bodies of your model, your machine is in its home

configuration. The body velocities are zero, and any disassembled joints

remain disassembled.

Connector Ports. AnyBodyCScandisplayaBodyCSPort. ABodyCSPort

allows you to attach Joints, Actuators, and Sensors to a Body. By default, a

Body’s CS1 and CS2 coordinate systems each display a Body CS port. You

can display a port for any other Body coordinate system as well, including

aBody’sCGCS.

Page 25

Modeling Grounds and Bodies

Creating a Body Block

To create a Body block,

1 Drag a Body block icon from the SimMechanics Bodies Library and drop

it into your model window.

2 Open the Body block’s dialog box.

3 Enter the mass of the body you are modeling in the Mass field.

4 Select the units of mass from the adjacent units list.

5 Enter a 3-by-3 matrix representing the body’s inertia tensor relative to its

center of gravity coordinate system (CG CS) origin and axes in the Inertia

field (see “Determining Inertia Tensors for Common Shapes” on page 1-13).

6 Enter the initial positions of the body’s C G and coordinate systems in the

Position tab.

7 Enter the initial orientation of the body’s CG and coordinate systems in

the Orientation tab.

8 Click OK or A pply.

Determining Inertia Tensors for Common Shapes

The following table enables you to determine the inertia tensors for some

common shapes. For each shape of mass

moments of inertia, I

, I2,andI3,alongthex-, y-,andz-axes of th e shape’s

1

CG coordinate system.

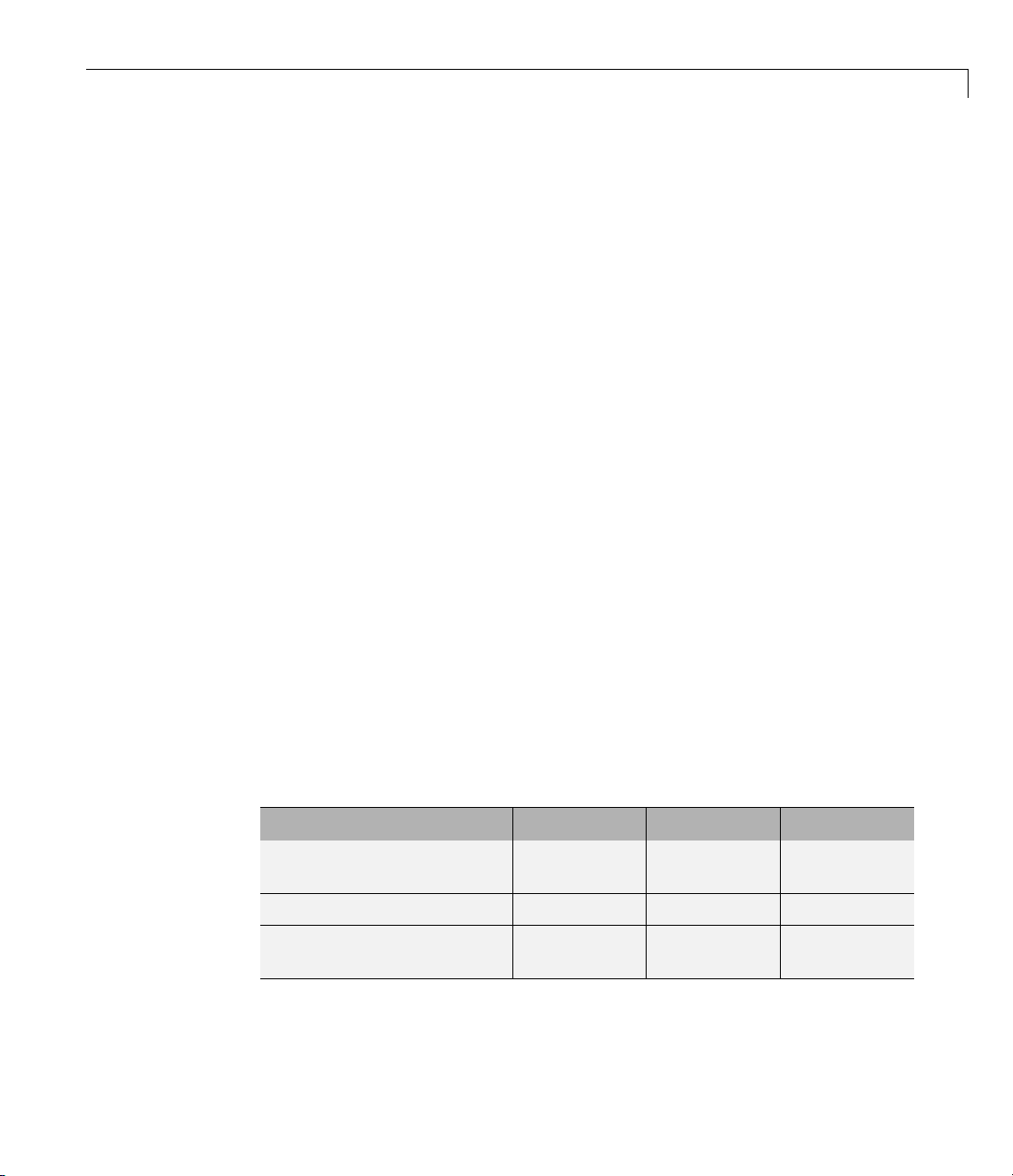

Shape I

Thin rod of length L aligned

1

mL

along z

Sphere of radius R

Cylinder of radius R and

height h aligned along z

2mR

(m/4)(R2+

2

h

/3)

m, the table lists the shape’s principal

I

2

2

/12 mL2/12

2

/5 2mR2/5 2mR2/5

(m/4)(R

2

h

2

/3)

I

3

0

mR

+

2

/2

1-13

Page 26

1 Modeling Mechanical Systems

Shape I

Rectangular parallelopiped

of sides a, b,andc aligned

1

(m/12)(b

2

c

)

2

+

I

2

(m/12)(a

2

c

)

I

3

2

+

(m/12)(a

2

b

)

2

+

along x, y, z,respectively

Cone of base radius R and

height h along z

Ellipsoid of semiaxes a, b,

(m/4)(3R2/5

2

+h

)

(m/4)(3R

+h

2

2

/5

)

(m/5)(b2+c2)(m/5)(a2+c2)(m/5)(a2+b2)

3mR

2

/10

and c aligned along x, y , z,

respectively

The c orresponding inertia tensor for the shape is the following 3-by-3 matrix:

I

00

⎛

1

⎜

I

00

⎜

⎜

00

⎝

⎞

⎟

2

⎟

⎟

I

3

⎠

Working with Body Coordinate Systems

Every SimMechanics body has Body coordinate systems (CSs) attached to it.

The location of a body CS is the origin of that CS. The CS’s rectangular x-y-z

coordinate axes are rotated at some o rie ntatio n. Y ou set up body CS origins

and orientations before running your model. But once the bodies start to

move, the origins and orientations of a body’s CSs remain fixe d in the body .

The elements of a body’s inertia tensor also remain fixed in the body. Consult

“Representing Motion” for more about orienting bodies and body CSs.

1-14

The sections “Managing Body Coordinate Systems” on page 1-17 and

“Creating B ody CS Ports” on page 1-18 explain how to create custom Body

coordinate sy stems and Body CS ports or delete existing ports.

Setting a Body CS’s Position

The Position tab of a Body block’s dialog box allows you to specify the

position of any of a body’s local coordinate systems.

The Tran slate d from Origin of and Components in Axes of lists in the

tab together specify which other of your machine’s coordinate systems you

Page 27

Modeling Grounds and Bodies

use as reference points and orientations to set up the coordinate s ystem s of

the body y ou are configuring.

To specify the position of a Body CS,

1 Open the Body block’s dialog box.

The dialog box’s Position tab lists the body’s local coordinate systems in

atable.

Each row specifies the position of the coordinate system specified in the

Name column.

2 Select the units in which you want to specify the origin of the Body CS from

the CS’s Units list.

3 Specify the reference coordinate systems for the Body CS, i.e., the

coordinate systems relative to which you want to m easure the Body CS

origin and the orientation of the Body CS’s coordinate axes. The choices are

World, the adjoining CS, and other Body CSs on the same Body.

You must directly or indirectly define all Body CSs by reference to a

Ground or to World. Indirect reference means that you specify a Body CS

relative to another CS and so on, in a chain of references that ultimately

ends in a Ground or World.

1-15

Page 28

1 Modeling Mechanical Systems

You do this by selecting the origin and orientation of the specification CS

from the Body CS’s Translated from Origin o f and Components in

Axes of lists, respectively. For example, suppose that you want to specify

the position of CS2 relative to another coordinate system , whose origin is at

the origin of CS1 but whose axes run parallel to those of the CG CS. Then

you would select CS1 from the Translated from Origin of list of CS2 an d

CG from the Components in Axes of list of CS2.

1-16

4 Enter a ve

Position

The components of the vector must be in the units that you selected a nd

relative to the coordinate system that you selected. For example, suppose

that you had selected

and World as the CSs specifying the origin and orientation for CS2. Now

suppose that you want to specify the loca tion of CS2 as one meter to the

right of CS1 along the W orld x-axis. Then you would enter

CS2’s position vector.

5 Click Apply to accept the p osition setting or OK to accept the setting and

dismiss the dialog box.

ing a Body CS’s Orientation

Sett

The Orien tation tab of a Body block’s dialog box allows you to specify the

orientation of any of a body’s local coordinate systems.

To specify the orientation of a Body CS,

ctor specifying the location of the Body CS in the Origin

Vector [x y z] field of the CS.

m as the unit for specifying CS2’s origin and CS1

[1 0 0] as

Page 29

Modeling Grounds and Bodies

1 Open the Body block’s dialog box.

2 Select the dialog box’s Orientation tab.

3 Select the units (degrees or radians) in which you want to specify the

orientation of the CS from the CS’s Units list.

4 Selectthecoordinatesystemrelativetowhichyouwanttospecifythe

orientation of the Body CS from the Body CS’s Relative CS list. The

choices are World, the adjoining CS, and other Body CSs on the same Body.

5 Select the convention y ou want to use to specify the orientation of the Body

CS from the CS’s Specified Using Convention list.

6 Enter a vector that specifies the orientation of the Body CS relative to

the CS you choose for that purpose, according to the selected specification

convention.

7 Click Ap ply to accept the orientation setting or OK to accept the setting

and dismiss the dialog box.

Managing Body Coordinate Systems

You will often need to modify the default Body coordinate systems of a Body

block. You might want to connect a Body to more than two Joints, in which

case you need not only more Body CSs, but their Body CS ports as well.

Connecting Actuators and Sensors to Bodies requires a Body CS and Body

CS port for each connection.

The Body coordinate systems tab of a Body block’s dialog box contains a row

of buttons that allow you to add, delete, and reorder a Body’s local coordinate

systems.

1-17

Page 30

1 Modeling Mechanical Systems

To use these b

• Delete to re

• Up to move th

• Down to move

Select Add

uttons, select a Body CS in the CS table and select

move the selected CS from the table

e CS’s entry one row up in the CS table

theCS’sentryonerowdownintheCStable

to add a new CS.

Creating Body CS Ports

To add or d

and sele

table. C

elete a port from a Body block’s icon, open the block’s dialog box

ct or clear the CS’s Show Port check box in the dialog box’s Body CS

lick OK or Apply to confirm the change.

1-18

Page 31

Modeling Degrees of Freedom

In this section...

“About Joints” on page 1-19

“Modeling Joints” on page 1-20

“Creating a Joint” on page 1-27

“Modeling Massless Connectors” on page 1-30

“Modeling Disassembled Joints” on page 1-34

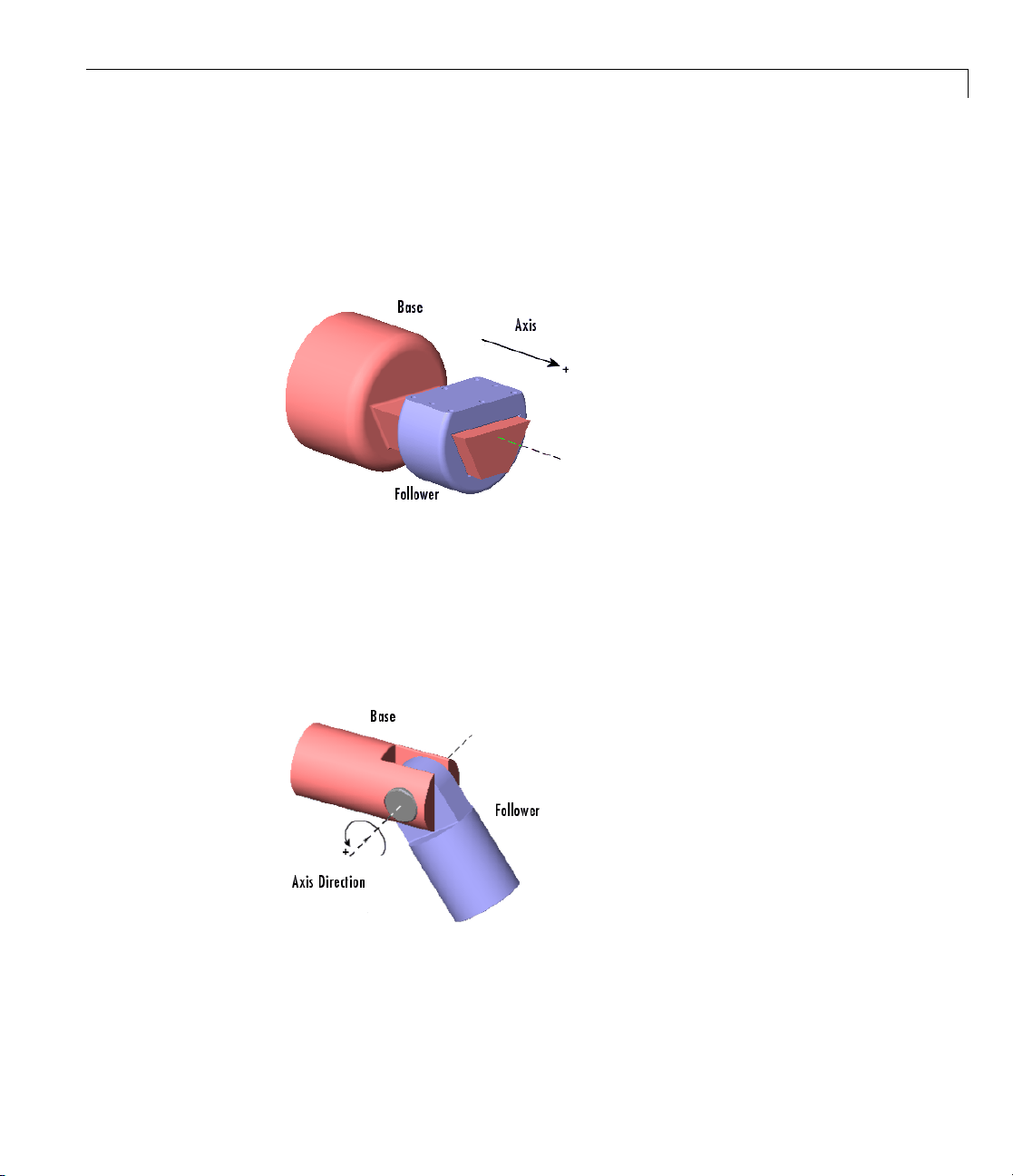

About Joints

A SimMechanics joint represents the degrees of freedom (DoF) that one body

(the follower) has relative to another body (the base). The base body can be

a movable rigid body or a ground. Unl ike a physical joint, a SimMechanics

joint has no mass, although some joints have spatial extension (see “Modeling

Massless Connectors” on page 1-30).

Modeling Degrees of Freedom

A SimMechanics joint does not necessarily imply a physical connection

between two bodies. For example, a SimMechanics Six-DoF joint allows the

follower, e.g., an airplane, unconstrained movement relative to the base, e.g.,

ground, and does not require that the followerevercomeintocontactwith

the base.

SimMechanics joints only add degrees of freedom to a machine, because the

Body blocks carry no degrees of freedom. Contrast this with physical joints,

which both add DoFs (with axes of motion) and remove DoFs (by connecting

bodies). See “Counting Model Degrees of Freedom” on page 1-89 for more

on this point.

The SimMechanics Joints Library provides an extensive selection of blocks for

modeling various types of jo ints. This section explains how to use these blocks.

1-19

Page 32

1 Modeling Mechanical Systems

Note A SimMechanics joint represents the relative degrees of freedom of

one body relative to another body. Only if a joint is connected on one side

to a ground and on the other to a body does the joint represent an absolute

DoF of the body with respect to World.

Modeling Joints

Modeling with Joint blocks requires an understanding of the following key

concepts:

• Joint primitives

• Joint types

• Joint axes

• Joint directionality

• Assembly restrictions

1-20

Joint Primitives

Each Joint block bundles together one or more joint primitives that together

specify the degrees of freedom that a follower body has relative to the base

body. The following table summarizes the joint primitives found singly or

multiply in Joint blocks.

Primitive

Type Symbol Degrees of Freedom

Prismatic

Revolute

Spherical

Weld

P

R

S

W

One degree of translational freedom along a

prismatic axis

One degree of rotational f reedom about a revolute

axis

Three degrees of rotational freedom about a pivot

point

Zero degrees of freedom

Page 33

Modeling Degrees of Freedom

Joint Types

The blocks in the SimMechanics Joint Library fall into the following

categories:

• Primitive joints

Each of these blocks contains a single joint primitive. For example, the

Revolute block contains a revolute joint primitive.

• Composit

These bl

specify

relativ

Gimbal

multiple rotational and translational degrees of freedom of one body

e to another. Some model idealized real joints, for example, the

ejoints

ocks contain combinatio ns of joint primitives, enabling you to

and Bearing joints.

1-21

Page 34

1 Modeling Mechanical Systems

Others spec

the Six-Do

the base.

The Custom

of rotati

prefabri

of their p

• Massles

These bl

primit

assembled joints

• Dis

ify a bstract combinations of degrees of freedom. For example,

F block specifies unlimited motion of the follower relative to

Joint allows you to create joints with any desired combination

onal and translational degrees of freedom, in any order. The

cated composite Joints of the Joints library have the type and order

rimitives fixed. See “Axis Order” on page 1-24.

s connectors

ocks represent extended joints with spatially separated joint

ive axes, for example, a Revo lute-Rev olute Massless Connector.

1-22

Page 35

Modeling Degrees of Freedom

These blocks represent joints not assembled until simulation starts — for

example, a Disassembled Prismatic.

See “Assembly Restrictions” on page 1-26 and “Modeling Disassembled

Joints” on page 1-34.

Joint Axes

Joint blocks define one or more axes of translation or rotation along which

or around which a fo ll ower block can move in relation to the base b lock. T he

axes of a Joint block are the axes defined by its component primitives:

• A prismatic primitive defines an axis of translation.

• A revolute primitive defines an axis of revolution.

• A spherical primitive defines a pivot point for axis-angle rotation.

For example, a Planar Joint block combines two prismatic axes and hence

defines two axes of translation.

Axis Direction. By default the axes of prismatic and revolute primitives

point in the same direction as the z-axis of the World coordinate system (CS).

A Joint block’s dialog box allows you to point its prismatic and revolute axes

in any other direction (see “Directing Joint Axes” on page 1-28).

1-23

Page 36

1 Modeling Mechanical Systems

Axis Order. Composite SimMechanics Joints execute their motion one joint

primitive at a time. A joint that defines more than one axis of motion also

defines the order in which the follower body moves along each axis or about a

pivot. The order in which the axes and/or pivot appear in the Joint block’s

dialog box is the order in which the follower body moves.

Different primitive execution orders are physically equivalent, unless the

joint includes one spherical or three revolute primitives. Pure translations

and pure two-dimensional rotations are independent of primitive ordering.

Axis Span. The span of the primitive axes is the complete space spanned by

their combination. For example, one primitive axis defines a line, a nd two

primitive axes define a plane.

Joint Directionality

Directionality is a property of a joint that determines the dependence of the

joint on the sign of forces or torques applied to it. A joint’s directionality also

determines the sign of signals output by sensors attached to the joint. Every

SimMechanics joint in your model has a directionality. You must be able to

determine the directionality of a joint in order to actuate it correctly and to

interpret the output of sensors attached to it.

1-24

A joint’s follower moves relative to the joint’s bas e. The joint’s directionality

takes into account the joint type and the direction of the joint’s axis, as follows.

Page 37

Modeling Degrees of Freedom

Directionality of a Prismatic Joint. If the joint is prismatic, a positive force

applied to the joint moves the follower in the positive direction along the axis

of translation. A sensor attached to the joint outputs a positive signal if the

follower moves in a positive direction along the joint’s axis of translation

relative to the base.

Directionality of a Revolute J oint. If the joint is revolute, a positive

torque applied to the joint rotates thefollowerbyapositiveanglearound

the joint’s axis of rotation, as determined by the right-hand rule. A sensor

attached to the revolute joint outputs a positive signal if the follower rotates

by a positive angle around the joint’s axis of revolution, as determined by

the right-hand rule.

1-25

Page 38

1 Modeling Mechanical Systems

Directionality of a Spherical Joint. Spherical joint directionality means

the positive sense of rotation of the three rotational DoFs. P ick a rotation

axis, rotating using the right-hand rule from the base Body CS axes. Then

rotate the follower Body about that axis in the right-handed sense.

Directionality and Or d er ing of Composite Joint Primitives. Each joint

primitive separately has its own directionality, based on the primitive’s

type and the direction of its axis of tran slation or rotation. In each case,

the follower body of the composite joint moves along or around the joint

primitive’s axis relativetothebasebody.

The order of primitives in the composite Joint’s dialog determines the spatial

construction of the joint.

The first listed primitive is attached to the base, the second to the first, and so

on, down to the follower, which is attached to the last primitive.

• Moving the first listed primitive moves the subsequent primitives in the

list, including the follower, relative to the base.

1-26

• Moving any primitive moves the primitives below it in the list (but not

those above it), as well as the follower.

• Moving the last listed primitive moves only the follower.

Changing the Directionality of a Joint. You can change the directionality

of a joint by either

• Reversing and reconnecting the Joint block to reverse the roles of the base

and follower bodies.

• Reversing the sign (direction) of the joint axis.

Assembly Restrictions

Many joints impose one or more restrictions, called assembly restrictions,

on the placement of the bodies that they join. The conjoined bodies must

satisfy these restrictions at the beginning of simulation and thereafter within

assembly tolerances tha t you can specify (see “Co ntrolling Mach i n e Assembly”

on page 2-12). For example, the Body CSs attached to revolute and spherical

joints must coincide within assembly tolerances; the Body CSs attached to a

Prismatic joint must lie on the prismatic axis within assembly tolerances; the

Page 39

Modeling Degrees of Freedom

Body CSs attached to a Planar joint must be coplanar with Planar primitives,

etc. Composite joints, e.g., the Six-DoF joint, impose assembly restrictions

equal to the most restrictive of its joint primitives. See the block reference for

each Joint for information on the assembly restrictions, if any, that it imposes.

Positioning bodies so that they satisfy a joint’s assembly restrictions is called

assembling the joint.

AllSimMechanicsJointsexceptblocksintheDisassembledJointssublibrary

require m anual assembly. Manual assembly entails your setting the initial

positions of conjoined bodies to valid locations (see “Assembling Joints”

on page 1-29). The simulation assembles disassembled joints during the

model initialization phase. It assumes that you have already assembled all

other joints before the start of simulation. Hence joints that require manual

assembly are called assembled joints. During model initialization and at

each time step, the simulation also checks to ensure that your model’s bodies

satisfy all assembly restrictions. If any of your model bodies fails to satisfy

assembly restrictions, the simulation stops and displays an error message.

Creating a Joint

A joint must connect exactly two bodies. Tocreateajointbetweentwobodies:

1 Select the Joint from the SimMechanics Joints library that best represents

the degrees of freedom of the follower body relative to the base body.

2 Connect the base connector port of the Joint block (labeled B) to the

Body CS origin on the base block that serves as the point of reference for

specifying the degrees of fre edom of the follower block.

3 Connect the follo we r connector port of the Joint block (labeled F) to the

Body CS origin on the follower block that serves as the point of reference

for specifying the degrees of freedom of the base block.

4 Specify the directions of the joint’s axes (see “Directing Joint Axes” on

page 1-28).

5 If you plan to attach Sensors or Actuators to the Joint, create an additional

port for each Sensor and Actuator (see “Creating Actuator and Sensor Ports

on a Joint” on page 1-28).

1-27

Page 40

1 Modeling Mechanical Systems

6 If the joint is an assembled joint, assemble the bodies joined by the joint

(see “Assembling Joints” on page 1-29).

Directing Joint Axes

By default the prism atic and revolute axes of a joint point in the same

direction as the z-axis of the World coordinate system. To change the direction

of the axis of a joint primitive:

1 Open the joint’s dialog box and select a reference coordinate system for

specifying the axis direction from thecoordinatesystemlistassociated

with the axis p rimitive.

TheoptionsaretheWorldcoordinate system or the local coordinate

systems of the base or follower attachment point. Choose the coordinate

system that is most convenient.

1-28

2 Enter in the primitive’s axis direction field a vector that points in the

desired direction of the axis in the selected coordinate system.

ting Actuator and Sensor Ports on a Joint

Crea

To create additional connector ports on a Joint for Actuators and Sensors,

open the Joint’s dialog box and set the Number of sensor/actuator ports to

the number of Actuators and Sensors you plan to attach to the Joint.

Page 41

Modeling Degrees of Freedom

Apply the setting by clicking OK or Apply.

Assembling Joints

You must manually assemble all assembled joints in your model. Assembling

a joint requires setting the initial positions of its attached base and follower

Body CSs such that they satisfy the assembly restrictions imposed by the

joint (see “Assembly Restrictions” on page 1-26). Consider, for example, the

“Modeling and Simulating a Clo sed-Loop Machine”.

This model comprises three bars connected by revolute joints to each other

and to two ground points. The model collocates the CS o rigins of the Body CS

ports connected to each Joint, thereby satisfying the assembly restrictions

imposed by the revolute joints.

Assembled Revolute Joint in the Four Bar Mechanism

1-29

Page 42

1 Modeling Mechanical Systems

Modeling Massle

Massless connec

light body to con

use a Body block

motion might be

and the simula

avoids global

model the conn

A massless co

Think of a mas

at each end.

tors simplify the modeling of machines that use a relatively

nect two relatively massive bodies. For example, you could

to model such a connector. But the resulting equations of

ill-conditioned, because that connectingbody’smassissmall,

tion can be slow or prone to failure. A massless connector also

inconsistencies that can arise if you use a Constraint block to

ector.

nnector consists of a pair of joints located a fixed distance apart.

sless connector as a massless rod with a joint primitive affixed

ss Connectors

1-30

nitial orientation and length of the massless connector are defined by

The i

tor drawn from the base attachment point to the follower attachment

avec

nt. During simulation, the orientation of the massless connecto r can

poi

nge b ut not its length. In other words, the massless connector preserves

cha

initial separation of the base and follower bodies during machine motion.

the

Page 43

Modeling Degrees of Freedom

Note You cannot actuate or sense a massless connector.

The SimMechanics Joints/Massless Connectors sublibrary contains these

Massless Connectors:

• Two revolute primitives (Revolute-Revolute)

• A revolute primitive and a spherical primitive (Revolute-Spherical)

• Two spherical primitives (Spherical-Spherical)

Creating a Massless Connector

To create a massless connector between two bodies:

1 Drag an instance of a Massless Connector block from the Massless

Connectors sublibrary into your model and connect it to the base and

follower blocks.

You can set the direction of the axes of revolute primitives. If necessary,

point the axes of the connector’s revolute joints in the direction required by

thedynamicsofthemachineyouaremodeling.

2 Assemble the connector by setting the initial positions of the base and

follower body attachment points to the initial positions required by your

machine’s structure.

During simulation, the massless connector maintains the initi al separation

between the bodies though not necessari ly the initial relative orientation.

1-31

Page 44

1 Modeling Mechanical Systems

Massless Connector Example: Triple Pendulum

Consider a triple pendulum comprising massive upper and lower bodies and a

middle body of negligible mass. The following model uses a Revolute-Revolute

massless connector to model such a pendulum.

In this model, the joint axes of the Revolute-Revolute connector have their

default orientation along the World z-axis. As a result, the lower arm (Body1)

rotates parallel to the World’s x-y plane.

1-32

Page 45

Modeling Degrees of Freedom

Massless Connector Example: Four Bar Mechanism

The following model replaces one of the bars (Bar2) in the mech_four_bar

model from the Demos library with a Revolute-Revolute massless connector.

This model changes the Body CS origins of Bar3 to the following values.

Name Origi

CG [-0.

CS1 [0.

CS2 [0 0

054 0.096 0]

npositionvector

027 -0.048 0]

0]

lated from origin of

Trans

CS1

CS2

ADJ

OINING

(Ground_2)

This creates a separation between Bar3 and Bar1 equal to the length of Bar2

in the original model.

1-33

Page 46

1 Modeling Mechanical Systems

Try simulating both the original and the modified model. Notice that the

massless connector vers ion moves differently, because you eliminated the

mass of B ar2 from the model. Notice also that the massless bar does not

appear in the animation of the massless connector version of the model.

1-34

Modeling Disassembled Joints

The SimMechanics Joints/Disassembled Joints sublibrary contains a set

of joints automatically assembled at the start of simulation; that is, the

simulation positions the joints such that they satisfy the assembly restrictions

imposed by the type of joint, e.g., prismatic or revolute. Using these joints

eliminates the need for you to assem ble the joints yourself.

Disassembled joints differ from assembled joints in significant ways. An

assembled joint primitive has only one axis of translation or rev olu ti on or on e

spherical pivot point. A disassembled prismatic or revolute primitive has two

axes of translation or rotation, one for the base and one for the follower body.

A disassembled spherical primitive similarly has two pivot points.

Page 47

Modeling Degrees of Freedom

Caution Disassembled joints can appear only in closed loops. Each closed

loop can contain at most one disassembled joint.

The dialog box for a disassembled joint allows you to specify the direction

of each axis.

During model assembly, the simulation determines a common axis of

revolution or translation that satisfies model assembly restrictions, and aligns

the base and follower axes along the common axis.

Controlling Automatic Assembly and the Assembled Configuration

If your machine contains Joint Initial Condition Actuator (JICA) blocks,

the machine is moved from its hom e to its initial configuration by applying

the initial condition information to the machine’s joints first. Then any

disassembled joints are assembled, leading to the assembled configuration.

During model assembly, the simulation might move bodies connected

by assembled joints from their in itia l positions in order to assemble the

disassembled joints. The SimMechanics solution to the assembly problem

cannot be predicted beforehand, except in simple cases. If you do not want

bodies to move during model assembly, use JICA blocks to specify the initial

positions of bodies whose positions you want to remain fixed during the

assembly process. The resulting assembly will satisfy the initial conditions

specified by the JICA blocks.

1-35

Page 48

1 Modeling Mechanical Systems

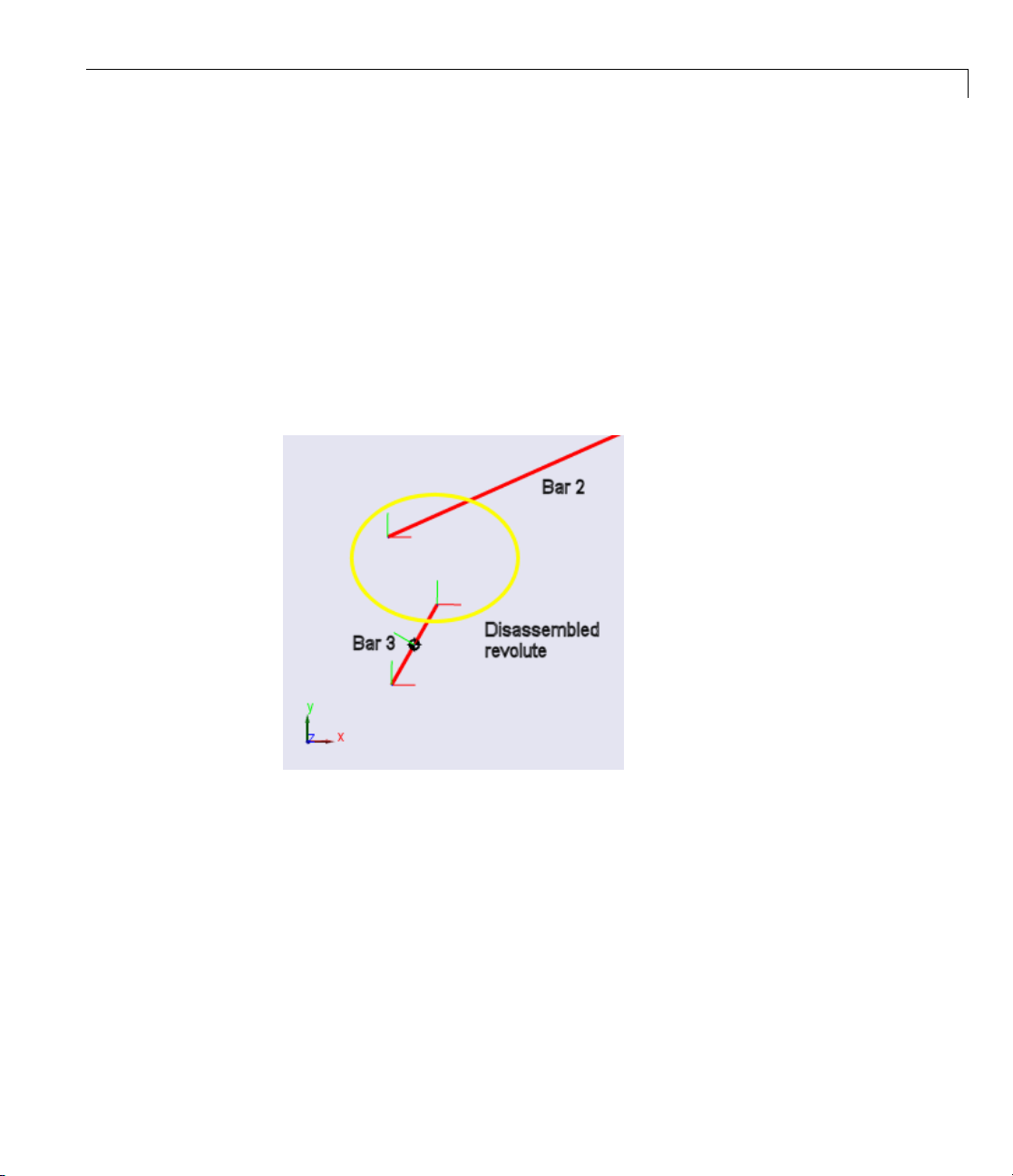

Disassembled Joint Example: Four Bar Mechanism

This example creates and runs a model of a disassembled four bar machine.

1-36

Refer to the tutorial, “Modeling and Simulating a Closed-Loop Machine”,

and the

1 Disconnect the Joint Sensor1 block from the Revolute3 block.

2 Replace Revolute3 with a Disassembled Revolute block from the

mech_four_bar demo:

Joints/Disassembled Joints sublibrary.

3 Open the Disassembled Revolute dialog box and, under Axis of Action for

both

Base and Follower axes, enter [001]. Close the dialog.

4 Open the Bar2 dialog box and dislocate the joint by displacing Bar2’s CS2

origin from Bar 3 ’s CS1 origin.

Page 49

Modeling Degrees of Freedom

Do this by entering a nonzero vector under Origin Position Vector [x

yz]for CS2, then changing the Translated from Origin of pull-down

entry to

ADJOINING. CS1 on Bar3 is the Adjoining CS of CS2 of Bar2.

Close the dialog.

5 To avoid circular CS referencing, you must check the Bar3 dialog entry for

CS1 on Bar3. Be sure that CS1 on Bar3 does not reference CS2 on Bar2.

Reference it instead to CS2 on Bar3, which adjoins Ground_2.

6 Rerun the model.

Note that the motion is different from the manually assembled case.

1-37

Page 50

1 Modeling Mechanical Systems

Constraining and Driving Degrees of Freedom

In this section...

“About Constraints” on page 1-38

“Types of Mechanical Constraints” on page 1-38

“What Constraints and Drivers D o” on page 1-39

“Directionality of Constraints and Drivers” on page 1-40

“Solving Constraints” on page 1-40

“Restrictions on Using Constraint and Driver Blocks” on page 1-41

“Constraint Example: Gear Constraint” on page 1-41

“Driver Example: Angle Driver” on page 1-43

About Constraints

The SimMechanics Constraints & Drivers Library provides a set of blocks

to model constraints on the relative motions of two bodies. You model the

constraint by connecting the appropriate Constraint or Driver block between

thetwobodies. Aswithjoints,theblockseachhaveabaseandfollower

connector port, with the body connected to the follower port viewed as moving

relative to the body connected to the base port. For example, the following

model constrains Body2 to move along a track that is parallel to the track

of Body1.

1-38

TypesofMechanicalConstraints

Constraint and Driver blocks enable you to model time-independent

constraints or time-dependent drivers.

Page 51

Constraining and Driving Degrees of Freedom

• Constraint and unactuated Driver blocks model scleronomic

(time-independent) constraints.

• Actuated Driver blocks (see “Actuating a Driver” on page 1-62) model

rheonomic (time-dependent) constraints.

Scleronomic constraints lack explicit time dependence; that is, the ir time

dependence appears only implicitly through the coordinates x.Rheonomic

constraints have explicit time de pendence as well, in addition to impli c it time

dependence through the x.

Holonomic constraint functions depend only on body p ositions, not velocities:

ft

(,;)xx = 0

BF

Constraints of the form

gt

can sometimes be integrated into a form dependent only on positions; but if

not, they are nonholonomic. For example,

• The one-dimensional rolling of a wheel of radius R along a line (the x-a xis)

imposes a holonomic constraint, x = Rθ.

• The two-dimensional rolling of a sphere of radius R on a plane (the

xy-plane) imposes a nonholonomic constraint, ds = R·dθ,withds

+dy2. This constraint is nonholo nomic because there is not enough

information to solve the constraint independently of the dynamics.

(,,,;)xxxx

BBFF

= 0

2

=dx

2

What Constraints and Drivers Do

Constrained and driven bodies are still free to respond to externally imposed

forces/torques, but only in a way consistent with the constraints.

Constraints and drivers can only remove degrees of freedom from a machine.

Constraints and unactuated Drivers prevent the machine from moving in

certain ways. Unactuated Drivers hold the constrained degrees of freedom

between the connected pair of bodies in their initial state. Actuated Drivers

externally impose a relative motion between pairs of bodies, starting with the

bodies’ initial state. See “Counting Model Degrees of Freedom” on page 1-89.

1-39

Page 52

1 Modeling Mechanical Systems

This section discusses modeling constraints and drivers in a general way.

• “Directionality of Constraints and Drivers” on page 1-40

• “Solving Constraints” on page 1-40

• “Restrictions on Using Constraint and Driver Blocks” on page 1-41

The section ends with two examples, “Constraint Example: Gear Constraint”

on page 1-41 and “Driver Example: Angle Driver” on page 1-43.

See the reference pages for information on the specific constraint that a

Constraint or D riv er block imposes.

Directionality of Constraints and Drivers

Like joints, constraints and drivers have directionality. The sequence of base

to follower body determines the directionality of the constraint or driver. The

directionality determines how the sign of Driver Actuator signals affects the

motion of the follower relative to the base and the sign of sign als output by

constraint and driver sensors.

1-40

Solving Constraints

A SimM echanics simulation uses a constraint solver to find the motion, given

the model’s Constraint and Driver blocks. You can specify both the constraint

solver type and the constraint tolerances used to find the constraint solution.

See “Maintaining Constra in ts” on page 2-12 for more in f o rm ation.

Mitigating Constraint Singularities

Some constraints, whether time-independent (Constraints) or time-dependent

(Drivers), can become singular when the constrained bodies take on certain

relative configurations; for example, if the two body axes line up when the

Bodies are connected by an Angle Driver. The simulation slows down as a

constraint becomes singular.

If you find a constrained model running slowly, consider selecting the

Use robust singularity handling option in the Constraints tab of

your machine’s Machine Environment block dialog. See “Handling Mo tion

Singularities” on page 2-18.

Page 53

Constraining and Driving Degrees of Freedom

Restrictions on

The following re

in a model:

• Constraint and

cannot contai

• AConstrainto

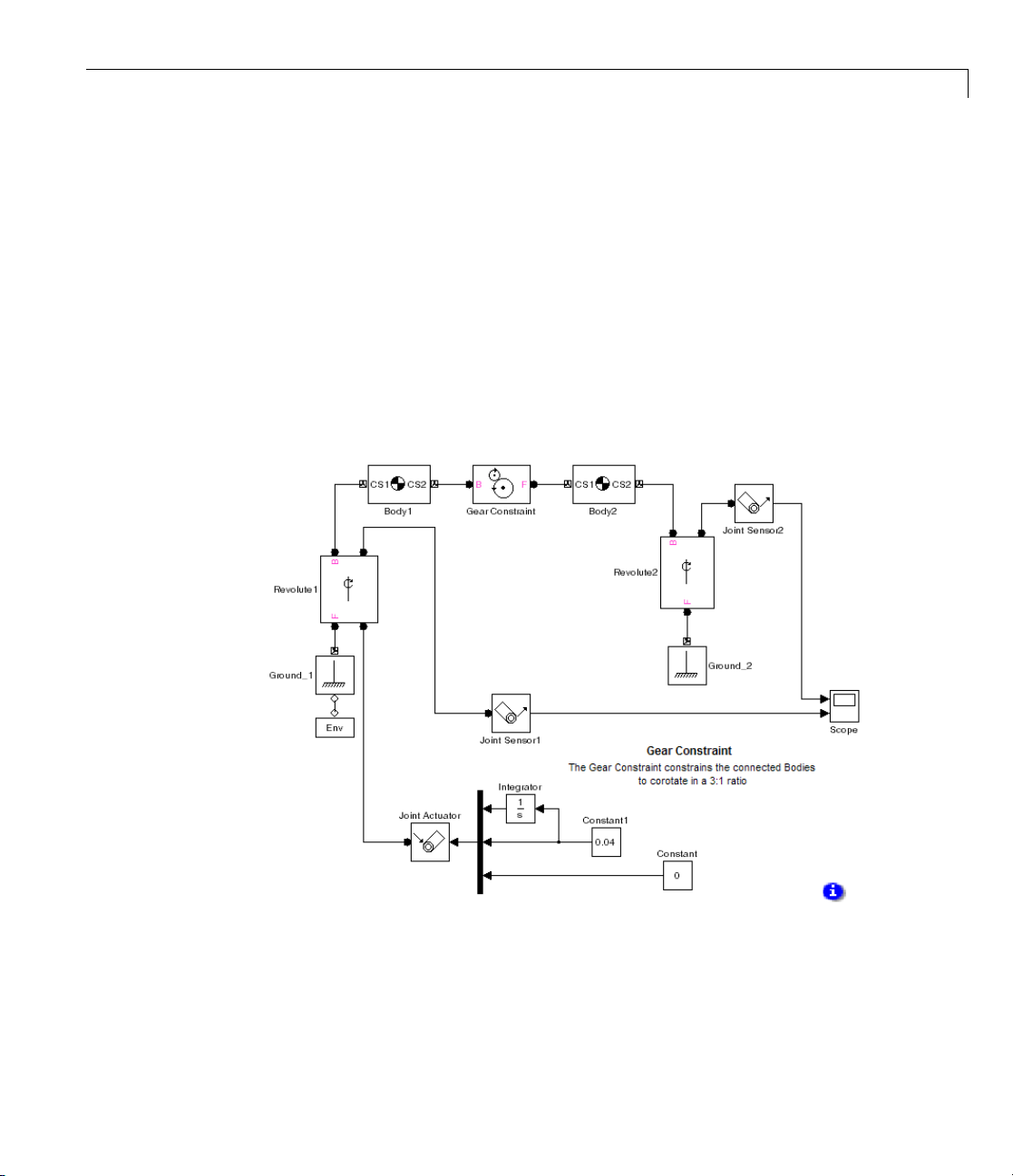

Constraint E

The mech_ge a

Gear Constr

strictions apply to the use of Constraint and Driver blocks

Driver blocks can appear only in closed loops. A closed loop

n m ore than one Constraint or Driver block.

r Driver must connect exactly two Bodies.

xample: G ear Constraint

rs

model illustrates the Gear Constraint. Open the Body and

aint blocks.

Using Constraint and Driver Blocks

y1 and Body2 have their CG positions 2 meters apart. CS1 and CS2 on

Bod

y1 are collocated with the Body1 CG, and similarly, CS1 and CS2 on

Bod

y2 are collocated with the Body2 CG.

Bod

1-41

Page 54

1 Modeling Mechanical Systems

The Gear Constraint between them has two pitch circles. One is centered

ontheCS2atthebaseBody,whichisBody1,andhasradius1.5meters.

The other is centered on CS1 at the follower Body, which is Body2, and has

radius 0.5 meters. The distance between CS2 on Body1 and CS1 on Body2 is 2

meters. The sum of the pitch circle radii equals this distance, as it must.

Visualizing the Gear Motion

The model is set up to open the visualization window automatically upon

simulation start, with convex hulls, as explained in the SimMechanics

Visualization and Import Guide. Start the simulation and watch the CG CS

axis triads sp in around. The CG triad at Body2 rotates three times faster

than the CG triad at Body1, because the pitch circle centered on Body2 is

three times smaller.

You can see the same behavior in the Scope. The upper plot shows the motion

of Revolute2, and the lower plot the motion of Revolute1. Note that angular

motion is mapped to the interval (-180

o

, +180o] degrees.

1-42

Page 55

Constraining and Driving Degrees of Freedom

The Gear Constraint is inside a closed loop formed by

Ground_1–Revolute1–Body1–Gear Constraint–Body–Revolute2–Ground_2

Although Ground_1 and Ground_2 are distinct blocks, they represent

different points on the same immobile ground at rest in World. So the blocks

form a loop.

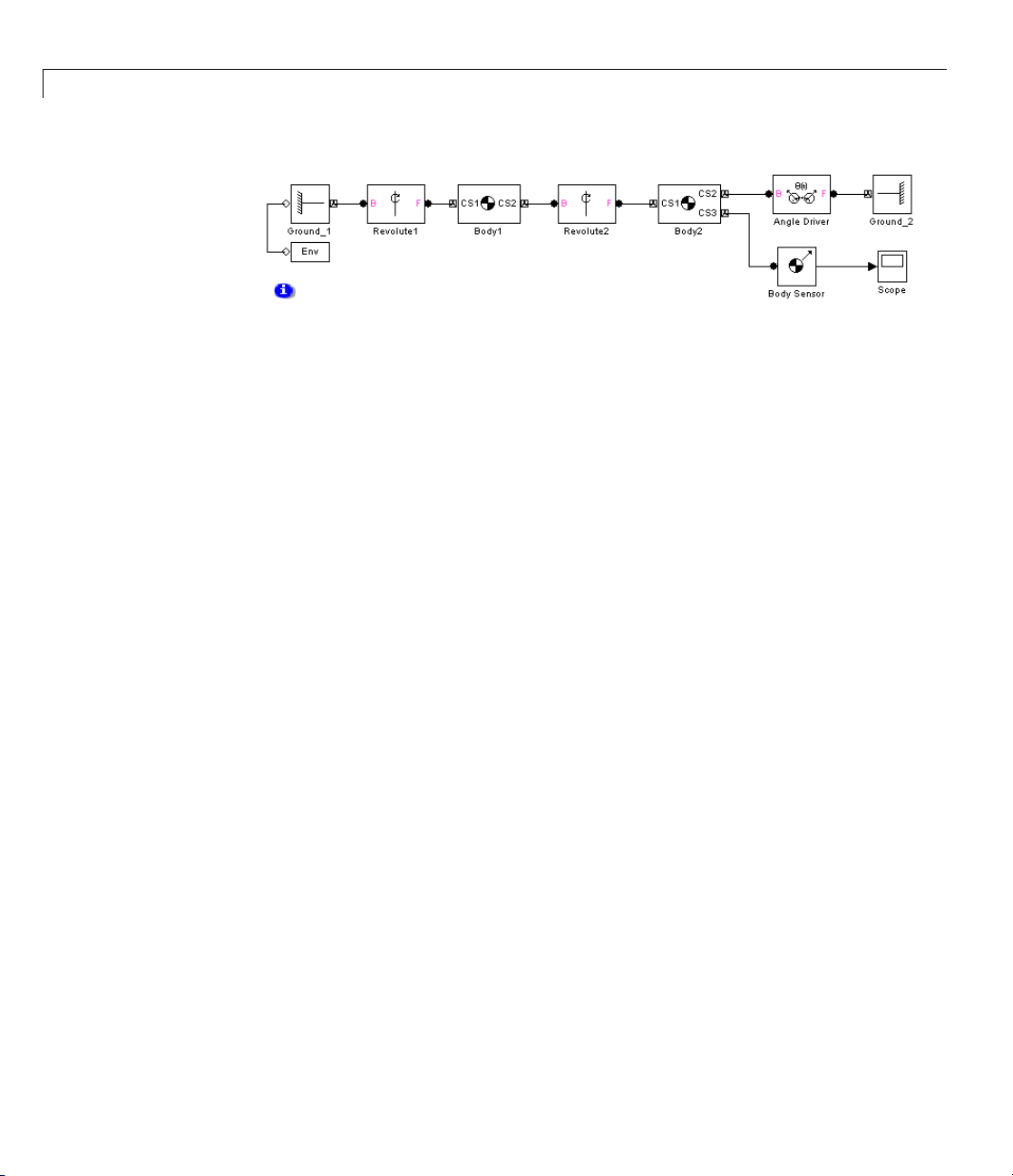

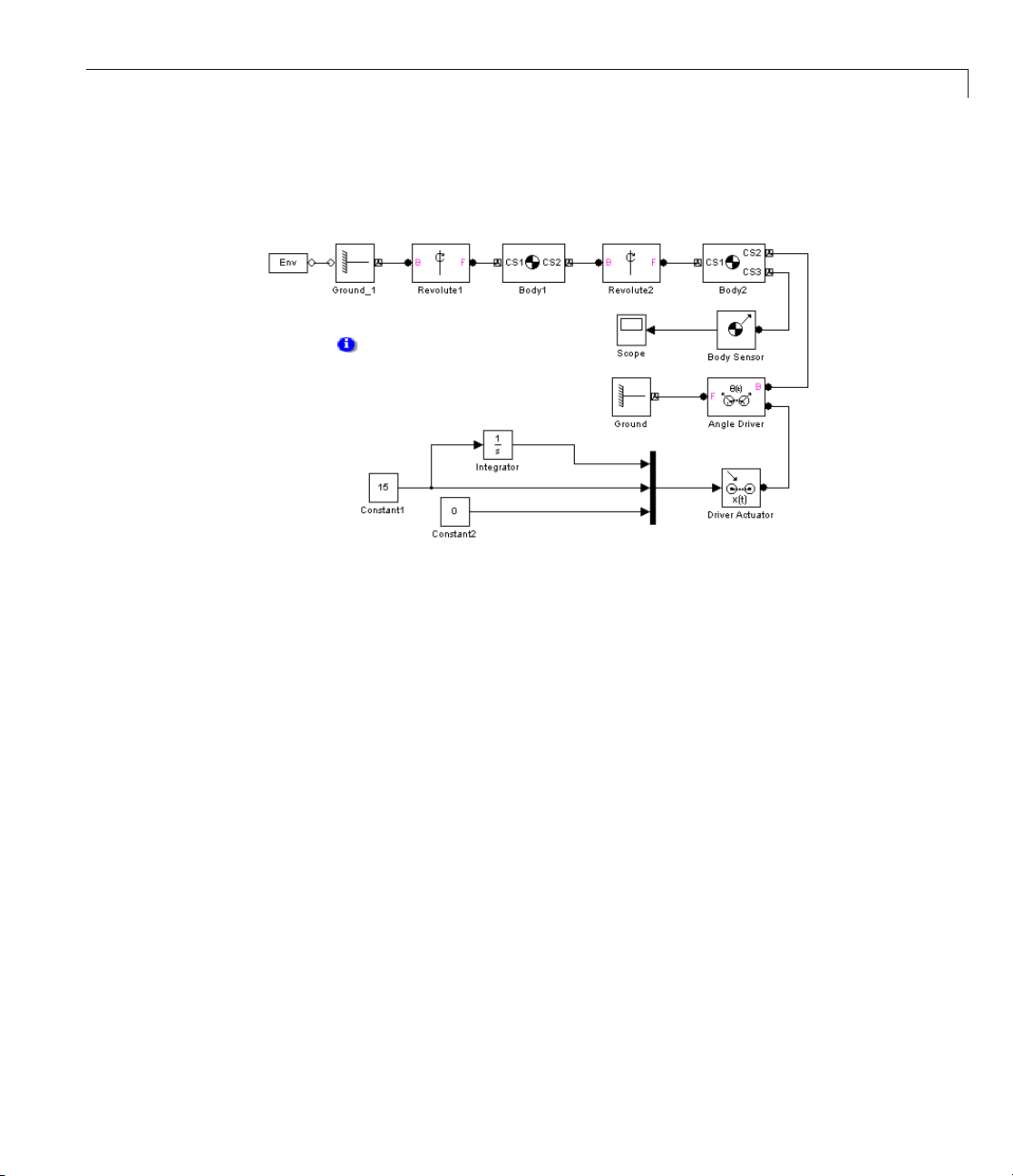

Driver Example: Angle Driver

The following two models illustrate the Angle Driver, both without and with a

Driver Actuator.

The Angle Driver Without a Driver Actuator

The first is mech_angle_unact.OpentheBody2block.

1-43

Page 56

1 Modeling Mechanical Systems

The bodies for

to Body2 at CS3

velocity vect

The Angle Dri

Angle Drive

time-indep

constant at

m a double pendulum of two rods. The Body Sensor is connected

= CS2 and measures all three components of Body2’s angular

or with respect to the ground.

ver is connected between Body2 and Ground_2. Because the

r is not actuated in this model, it acts during the simulation as a

endent constraint to hold the angle between Body2 and Ground_2

its initial value.

Visualizing the Angle Driver Motion

The model

simulati

Visualiz

Start th

body mai

ground.

and thi

is set up to open the visualization window automatically upon

on start, with convex hulls, as explained in the SimMechanics

ation and Import Guide.

e simulation. The upper body swings like a pendulum, but the lower

ntains its horizontal orientation with respect to the horizontal

The Scope measures Body2’s angular velocity with respect to ground,

s remains at zero.

1-44

Page 57

Constraining and Driving Degrees of Freedom

The Angle Driver With a Driver Actuator

The second model is mech_angle_act. Open the Driver Actuator block.

The Driver Actuator drives the Angle Driver block. Here, the Actuator accepts

a constant angu la r velocity signal from the Simulink blocks. The Actuator

also requires the angle itse lf and the angular acceleration, together with the

angular velocity, in a vector signal format. The Angle Driver’s angle signal

is added to the angle’s initial value.

The Body Sensor again measures three components of Body2’s angular

velocity with respect to the ground. Constant1 drives the angle at 15

o

/second.

While the simulation is running, this angle changes at the constant rate. At

the same time, the assembly and the constant length of the two pendulum

rods must be maintained by Simulink, while both rods are subject to gravity.

As the two axes line up, the mutual constraint between the bodies enforced

the D river becomes singular. The simulation slows down.

As in the Gear Constraint model, the two Ground blocks in these models

represent points on the same immobile ground at rest in World, so the Angle

Driver is part of a closed loop.

1-45

Page 58

1 Modeling Mechanical Systems

Cutting Machine Diagram Loops

In this section...

“Rules for Valid Machine Diagram Loops” on page 1-46

“Rules for Automatic Loop Cutting” on page 1-46

“Specifying a Loop Joint for Cutting” on page 1-47

“Displaying the Cut Joints” on page 1-47

“For More About Disassembled and Cut Joints” on page 1-47

“For More About Constraints and Drivers” on page 1-47

Rules for Valid Machine Diagram Loops

In a SimMechanics model, you form a closed loop by the closure of

SimMechanics blocks, of any type, on themselves. From a starting point, you

can trace a path around a closed loop back to the starting point with no jumps

or cuts. A closed loop is valid if it contains:

1-46

• AtleastoneJointblock

• No more than one Disassembled Joint block

• No more than one Constraint or Driver block

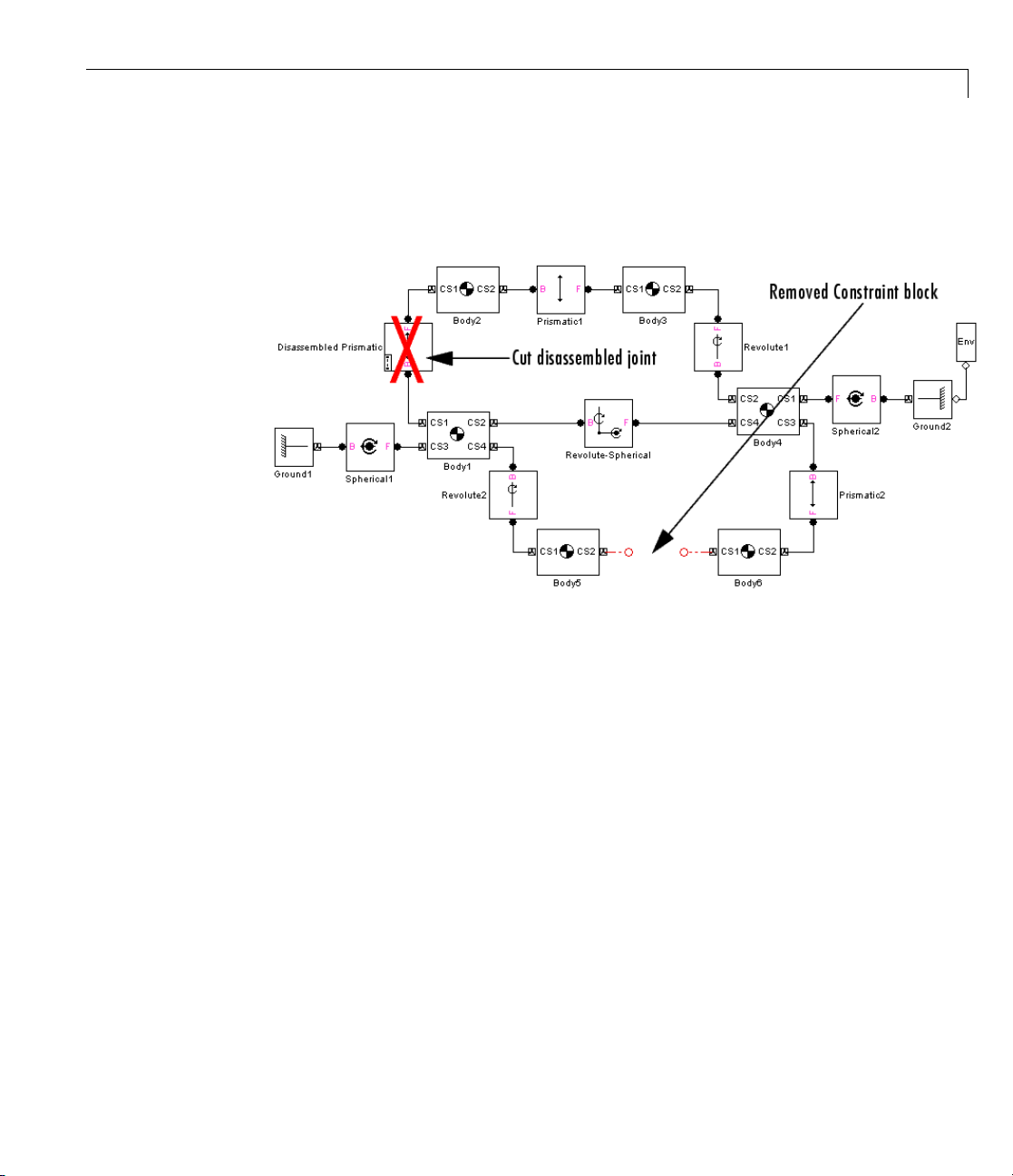

To simulate a model containing closed loops, the SimMechanics simulation

internally co nverts a closed-loop model to an op en-topology tree model. This is

accomplished by internally cutting each of the model’s closed loops once, at

a joint, constraint, or driver block, then replacing each cut by an additional

internal constraint.

Rules for Automatic Loop Cutting

A SimMechanics simulation follows these loop-cutting rules.

• If a loop contains a constraint, driver, or disassembled joint, the simulation

cuts the loop at one of those blocks. Selecting a preferred cut joint has

no effect.

Page 59

Cutting Machine Diagram Loops

• If the loop does not contain a constraint, driver, or disassembled joint, the

simulation cuts the loop at the preferred cut joint if you have specified one.

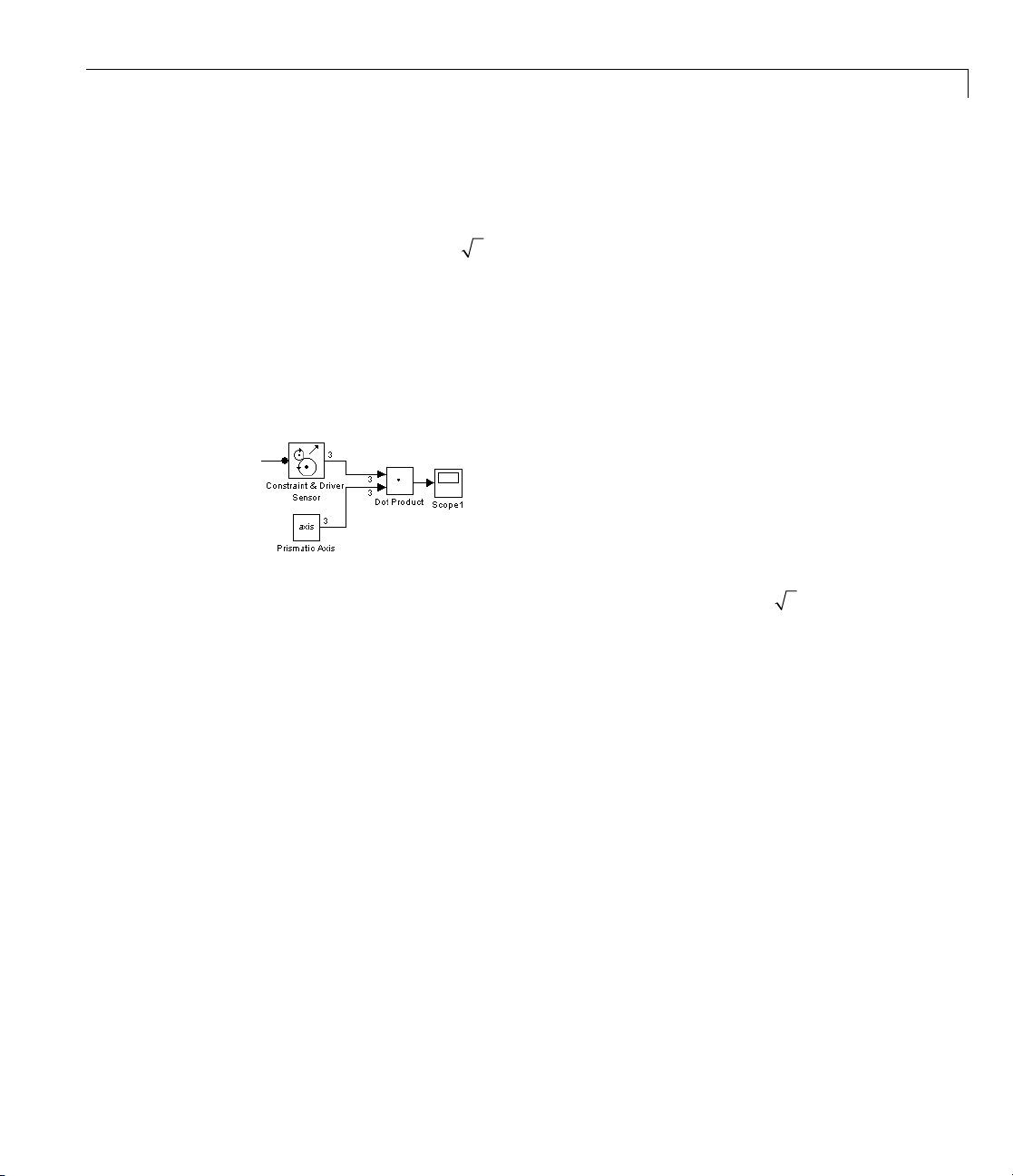

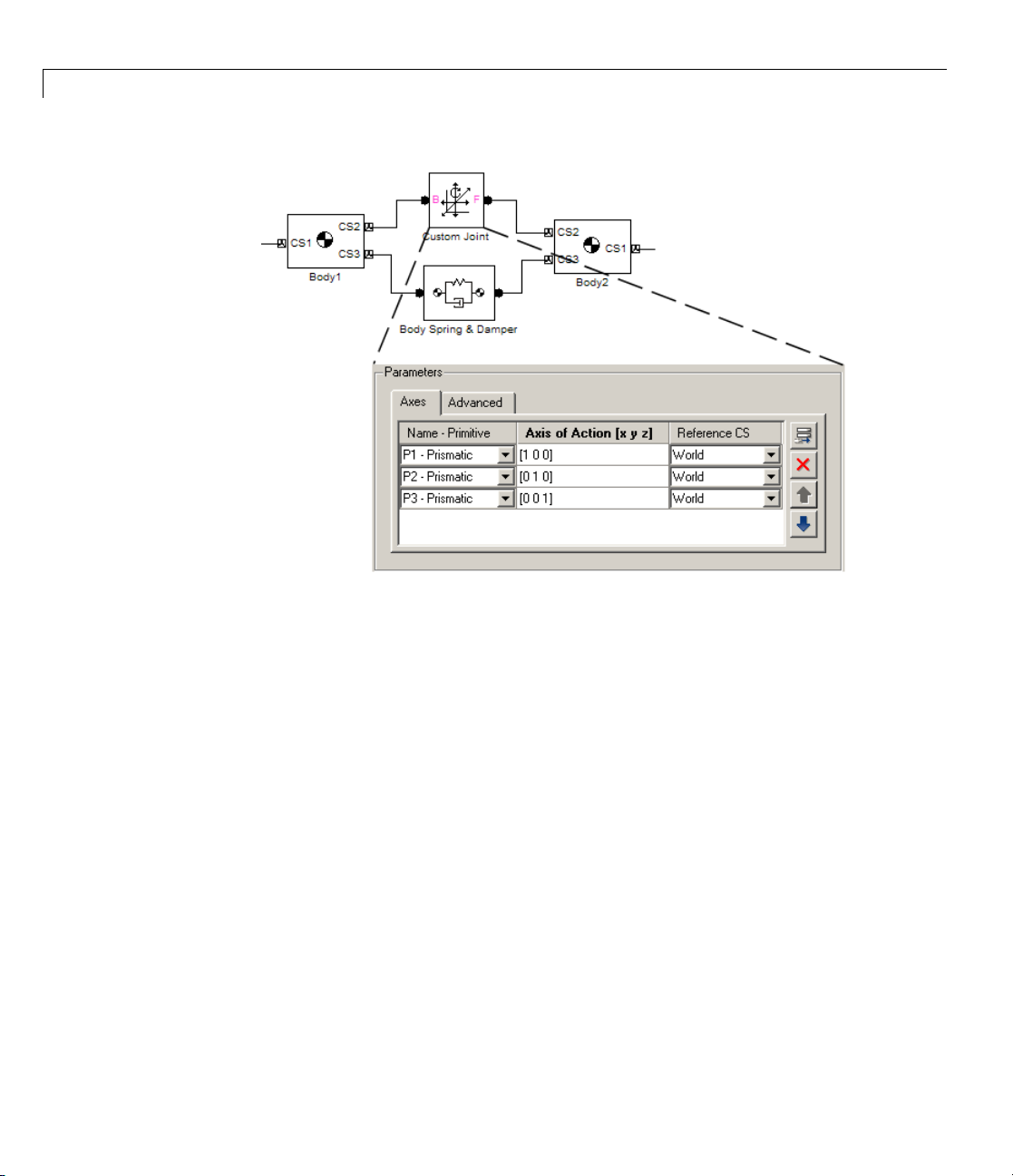

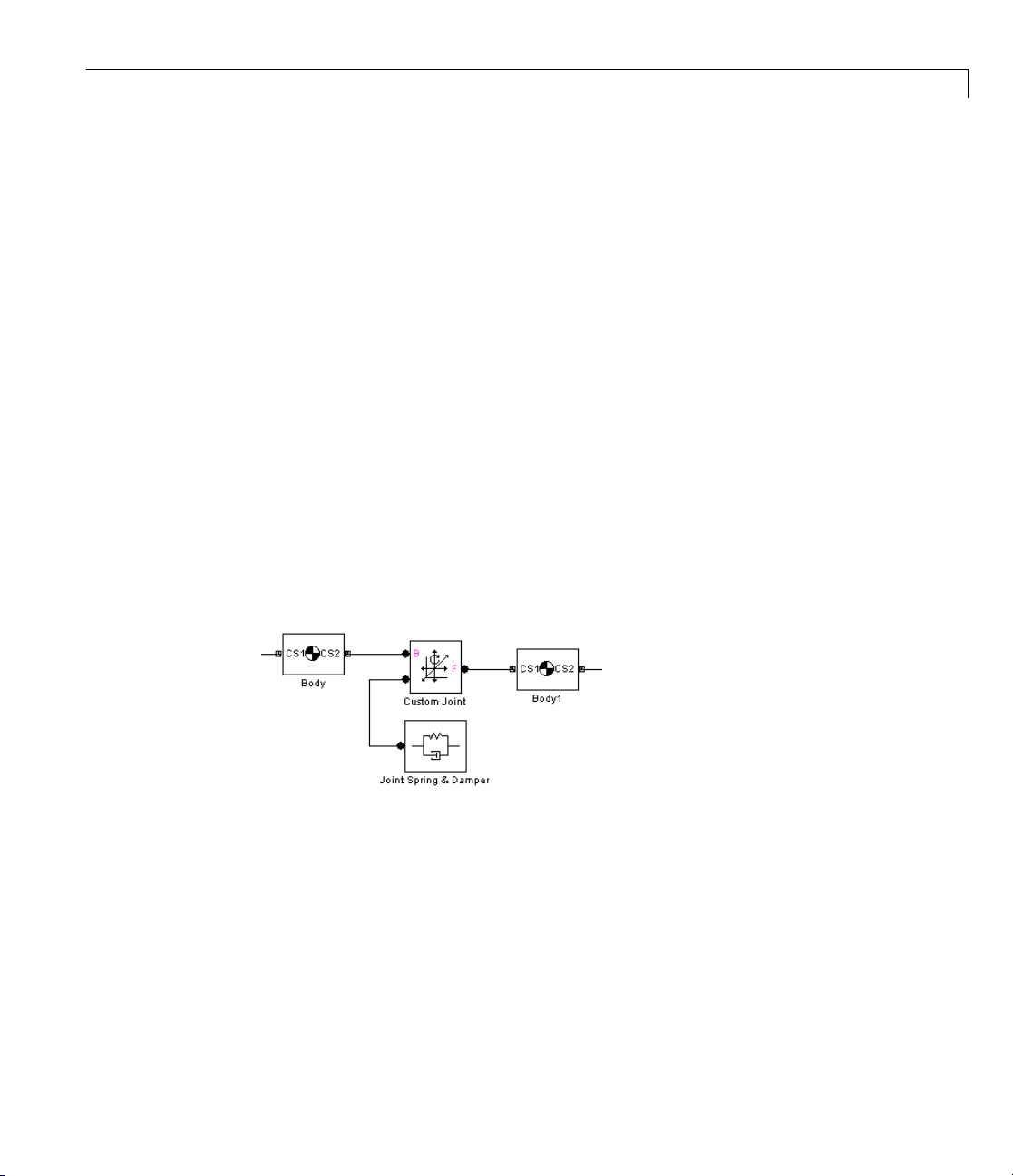

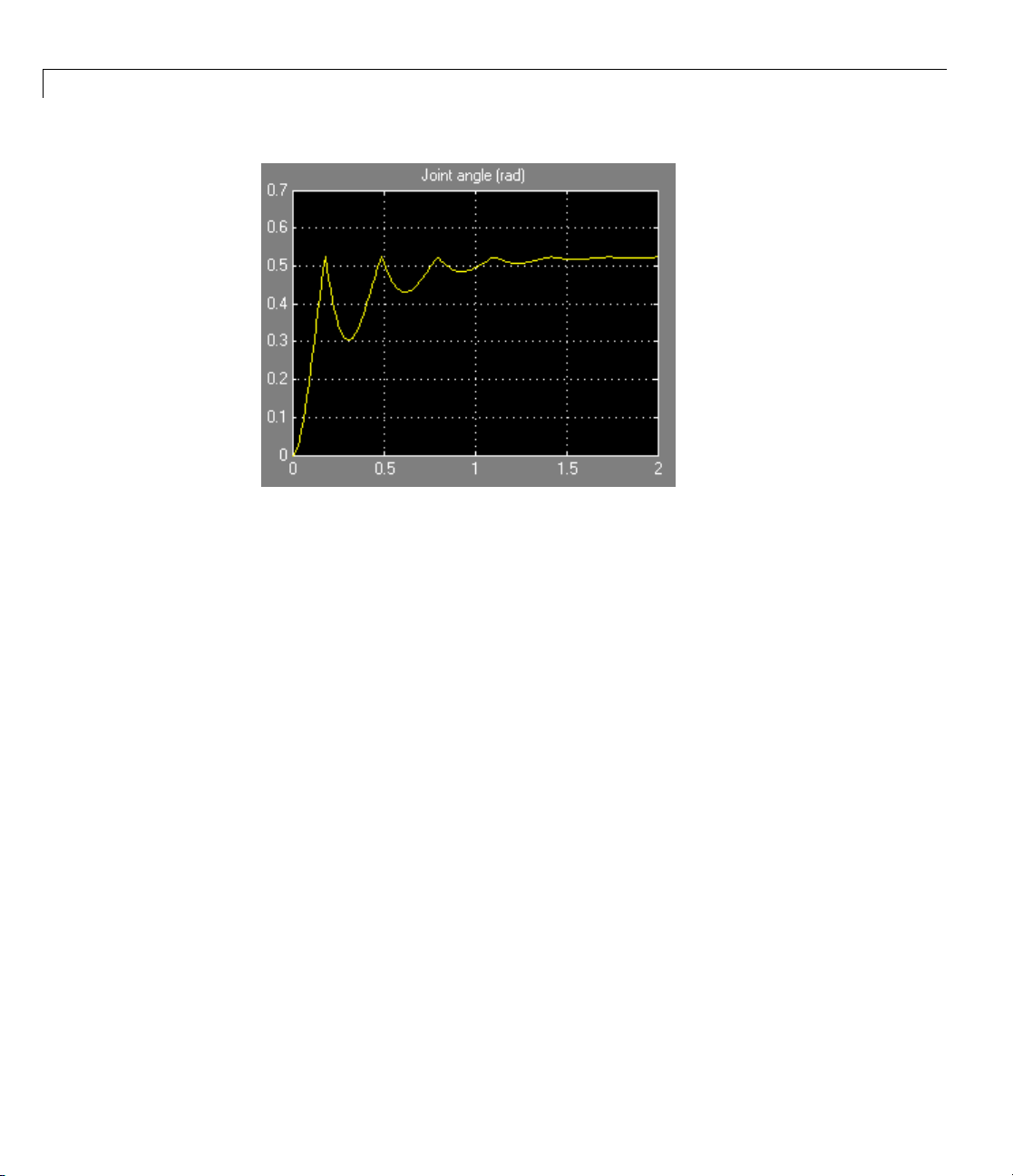

• If the loop does not contain a constraint, drive r , or disassembled joint, and