SimMechanics™ 3

Visualization and Import Guide

How to Contact The MathWorks

www.mathworks.

comp.soft-sys.matlab Newsgroup

www.mathworks.com/contact_TS.html Technical Support

suggest@mathworks.com Product enhancement suggestions

bugs@mathwo

doc@mathworks.com Documentation error reports

service@mathworks.com Order status, license renewals, passcodes

info@mathwo

com

rks.com

rks.com

Web

Bug reports

Sales, prici

ng, and general information

508-647-7000 (Phone)

508-647-7001 (Fax)

The MathWorks, Inc.

3 Apple Hill Drive

Natick, MA 01760-2098

For contact information about worldwide offices, see the MathWorks Web site.

SimMechanics™ Visualization and Import Guide

© COPYRIGHT 2001–2010 by The MathWorks, Inc.

The software described in this document is furnished under a license agreemen t. The software may be used

or copied only under the terms of the license agreement. No part of this manual may be photocopied or

reproduced in any form without prior written consent from The MathW orks, Inc.

FEDERAL ACQUISITION: This provision applies to all acquisitions of the Program and Documentation

by, for, or through the federal government of the United States. By accepting delivery of the Program

or Documentation, the government hereby agrees that this software or documentation qualifies as

commercial computer software or commercial computer software documentation as such terms are used

or defined in FAR 12.212, DFARS Part 227.72, and DFARS 252.227-7014. Accordingly, the term s and

conditions of this Agreement and only those rights specified in this Agreement, shall pertain to and govern

theuse,modification,reproduction,release,performance,display,anddisclosureoftheProgramand

Documentation by the federal government (or other entity acquiring for or through the federal government)

and shall supersede any conflicting contractual terms or conditions. If this License fails to meet the

government’s needs or is inconsistent in any respect with federal procurement law, the government agrees

to return the Program and Docu mentation, unused, to The MathWorks, Inc.

Trademarks

MATLAB and Simulink are registered trademarks of The MathWorks, Inc. See

www.mathworks.com/trademarks for a list of additional trademarks. Other product or brand

names may be trademarks or registered trademarks of their respective holders.

Patents

The MathWorks products are protected by one or more U.S. patents. Please see

www.mathworks.com/patents for more information.

Revision History

October 2008 Online only New for Version 3.0 (Release 2008b)

March 2009 Online only Revised for Version 3.1 (Release 2009a)

September 2009 Online only Revised for Version 3.1.1 (Release 2009b)

March 2010 Online only Revised for Version 3.2 (Release 2010a)

Introducing Visualization and Animation

1

About SimM echanics Visualization .................. 1-2

Starting SimMechanics Visualization

Using SimMechanics Visualization

About Body Color and Geometry: Default, Standard,

and Custom

About Body Color: Default and Custom

About Body Geometry: Default, Standard, and Custom

Standard Body Geometry: Equivalent Ellipsoids

Standard Body Geometry: Convex Hulls

Custom B ody Geometry and External Graphics Files

Hierarchy of Body, Machine, and Model Visualization

Settings

Visualized Geometries and Colors from Body Block

Settings

Body Block Settings Affecting Body Visualization

Visualization Settings in the Machine and Model

Hierarchy

..................................... 1-5

........................................ 1-11

....................................... 1-11

...................................... 1-13

................. 1-2

................... 1-3

............... 1-5

........ 1-5

............... 1-9

....... 1-12

Contents

.. 1-5

.... 1-10

Getting Started with the Visualization Window

2

Introducing the SimMechanics Visualization

Window

About the Visualization Window

Opening and Updating the Visualization Window

Visualization Toolbar and Its Controls

Controlling Body and Body Component Display

About Body and Body Component Display

......................................... 2-2

..................... 2-2

....... 2-2

................ 2-4

...... 2-6

............. 2-6

iii

Interpreting the Body Display Symbols and Shapes ..... 2-6

Changing Body Display Symbols

Changing Body Display Shapes

..................... 2-7

...................... 2-7

Adjusting the Camera View

Setting the Background Color

Interpreting the Camera Pro j ection, Field of View, and

Viewpoint

Automatically Sizing the Camera Field of View

Automatically Setting a Camera Viewpoint

Actively Controlling the Camera View point

Camera Viewpoint and Mouse Controls

Communicating with the Model from the Visualization

Window

Highlighting Bodies, B ody Components, and Body

Blocks

Updating the Model Diagram

Saving Visualization Settings to the Model

Controlling and Timing Simulation from the

Visualization Window

Starting, Pausing, and Stopping the Simulation

Timing the Simulation

Controlling Animation

About Animation

How Animation Works

Automatically Adapting the Camera View to the D isplayed

Motion

Changing How the Animation Is Updated

Speeding Up the Animation in Real Time

...................................... 2-9

......................................... 2-17

........................................ 2-17

.................................. 2-23

........................................ 2-24

......................... 2-9

....................... 2-9

......... 2-11

............ 2-12

............ 2-13

............... 2-14

........................ 2-18

............. 2-19

............................ 2-21

........ 2-21

............................. 2-21

............................. 2-23

............................. 2-23

............. 2-25

.............. 2-27

iv Contents

Recording Animation

About Recording

How Recording Works

Recording Animations

Compressing Anim ation Recordings

Controlling the Size of the Recorded Animation

Playing Recordings of Animation

.............................. 2-28

.................................. 2-28

.............................. 2-28

.............................. 2-28

.................. 2-30

..................... 2-31

......... 2-31

Visualization Menus and Their Controls ............. 2-33

About the SimMechanics Visualization Window Menus

View Menu

Simulation Menu

Model Menu

Help Menu

....................................... 2-34

.................................. 2-35

...................................... 2-38

....................................... 2-39

Customizing Visualization and Animation

3

About Custom SimMechanics Visualization .......... 3-2

Customizing Visualization Settings

Creating an External Virtual Reality Client

................... 3-2

............ 3-3

.. 2-33

Customizing Visualized Body Colors

Choosing Custom Body Colors

Switching Between Default and Custom Body Colors

Customizing Visualized Body Geometries

Choosing Custom Body Geometries

Switching Between Standard Body Geometries

About STL Body Graphics Files

Obtaining STL Body Graphics Files for Custom Body

Geometries

Switching Between Standard and Custom Body

Geometries

Visualizing with a Virtual Reality Client

About Virtual Worlds for Machines and Models

Creating Virtual Worlds for SimMechanics Models

Interfacing SimMechanics Models with Virtual Worlds

Reference

.................................... 3-9

.................................... 3-10

........................................ 3-27

....................... 3-4

...................... 3-8

................ 3-4

............ 3-7

................... 3-7

............. 3-13

.... 3-4

......... 3-7

......... 3-13

...... 3-13

... 3-18

v

Importing Mechanical Models

4

Introducing M echanical Import ..................... 4-2

About Mechanical Import and CAD Translation

Requirements for CAD Export and Mechanical Import

Essential CAD Translation Steps

Generating New Models from Physical Modeling

XML

About Generated SimMechanics Models Based on CAD

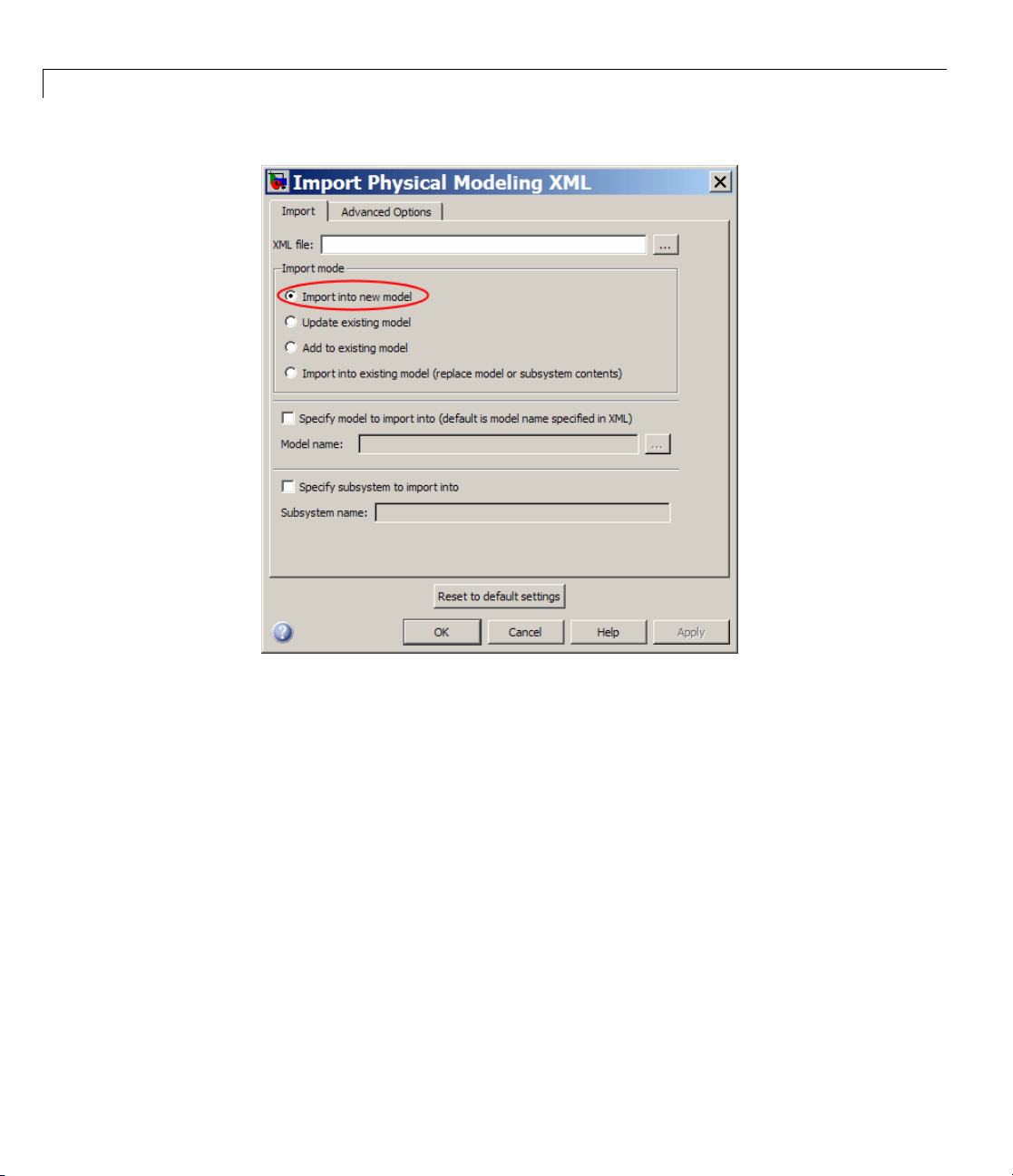

Generating a New Model from a Physical Modeling XML

Controlling New Model Import with Nondefault Options

............................................ 4-6

File

........................................... 4-7

.................... 4-4

........ 4-2

... 4-3

.. 4-6

.. 4-8

Working with Generated Models

About CAD-Based Models

Common Features of CAD-Based Models

Nondefault Features in Generated Models

Manually Modifying and Extending Generated Models

After Import

Updating Generated Models Using Physical Modeling

XML

About Model Update and Mechanical Import

Updating a Machine in a Generated Model with

Adding a New Machine to a Generated Model

Replacing Generated Model or Subsystem Contents with a

Controlling Model Update at the Block Level

About Associativity and Updating

Working with Associativity in Common Updating

Controlling How Update-Import Changes Individual Blocks

Associativity in an Updating Sequence Example

............................................ 4-22

Revisions

New Machine

Situations

and Connections

................................... 4-17

...................................... 4-25

................................... 4-29

..................................... 4-35

........................... 4-12

................................ 4-38

.................... 4-12

.............. 4-12

............. 4-15

........... 4-22

.......... 4-28

......... 4-32

.................... 4-32

........ 4-42

vi Contents

Troubleshooting Imported and Updated Models

Best Practices for Creating and Exporting Assemblies

...... 4-46

... 4-46

Inserting Reference Coordinate Systems into Assemblies

Before Export

Controlling Mechanical Import to Assist

Troubleshooting

Troubleshooting Erro rs During Model Generation

Troubleshooting Errors During Model Update

Troubleshooting M ode l Simulation Errors

Troubleshooting SimMechanics an d Simulink Problems

.................................. 4-46

................................ 4-47

....... 4-47

.......... 4-48

............. 4-48

Computer-Aided Design Translation

5

About the CAD Translation Case Studies ............ 5-2

Introducing the Case Studies

Requirements for the CAD Translation Case Studies

About Specialized CAD Terms

........................ 5-2

....................... 5-3

.. 4-49

.... 5-3

Translating a CAD Part into a Body

Locating the Single-Part Assembly Files

Viewing the CAD Assembly

Exporting the CAD Assembly

Generating the SimMechanics Model

Translating CAD Constraints into Joints

Modeling CAD and SimMechanics Degrees of Freedom

Locating the Constraint Assembly Files

Generating the Two-Part Models : Common Steps

About the Common Block Structure of the Two-Part

Models

Modeling a Six-DoF Joint

Modeling a Prismatic Joint

Modeling a Revolute Joint

Modeling an Inplane Joint

Modeling a Spherical-Spherical Massless Connector

Updating and Retranslating a CAD Pendulum

AboutAssemblyRe-ExportandModelUpdate

Locating the Assembly Files

Translating the Assembly For the First Time

........................................ 5-11

......................... 5-5

........................ 5-7

........................... 5-12

.......................... 5-13

.......................... 5-17

.......................... 5-18

......................... 5-22

................. 5-5

............... 5-5

................. 5-7

............ 5-9

............... 5-10

.......... 5-22

........... 5-23

... 5-9

....... 5-11

..... 5-19

....... 5-22

vii

Updating the Original Imported Model with Chang es to

Bodies

Adding a New Body to Create a Triple Pendulum

Updating an Existing Generated Model While Retaining

Manual Joint Replacements

SelectivelyUpdatinganExistingGeneratedModel

........................................ 5-28

....... 5-34

....................... 5-39

...... 5-40

Translating a CAD Robot Arm

Locating the Robot Arm Assembly Files

Viewing the Robot Arm Assembly

Exporting the Robot Arm Assembly

Generating and Completing the Robot Arm Model

Simulating and Observing the Robot Arm Motion

Translating a CAD Stewart Platform

Introducing the Stewart Platform

Introducing the Stewart Platform Assembly

Viewing the Stewart Platform Assembly

Exporting the Stewart Platform Assembly

Generating the Stewart Platform Model

Visualizing the Stewart Platform M otion

...................... 5-42

............... 5-42

.................... 5-43

................... 5-44

................ 5-49

.................... 5-49

............... 5-50

............... 5-51

.............. 5-54

....... 5-44

....... 5-48

............ 5-49

............. 5-51

Index

viii Contents

Introducing Visualization and Animation

You can visualize your model’s bo dies using the SimMechanics™ visualization

window. This overview explains the essentials of starting visualization and

choosing body colors and geometries.

• “About SimMechanics Visualization” on page 1-2

• “About Body Color and Geometry: Default, Standard, and Custom” on

page 1-5

1

• “Hierarchy of Body, Machine, and Model Visualization Settings” on page

1-11

1 Introducing Visualization and Animation

About SimMechanics Visualization

In this section...

“Starting SimMechanics Visualization” on page 1-2

“Using SimMechanics Visualization” on page 1-3

Starting SimMechanics Visualization

Starting SimMechanics visualization requires two choices, one for your

entire model, the second for each machine in your m odel. T hese choices

are part of configuring your model for simulation, as discussed in “Starting

Visualization and Simulation” in the SimMechanics User’s Guide. Implement

your visualization cho ices at any time by clicking Apply or OK.

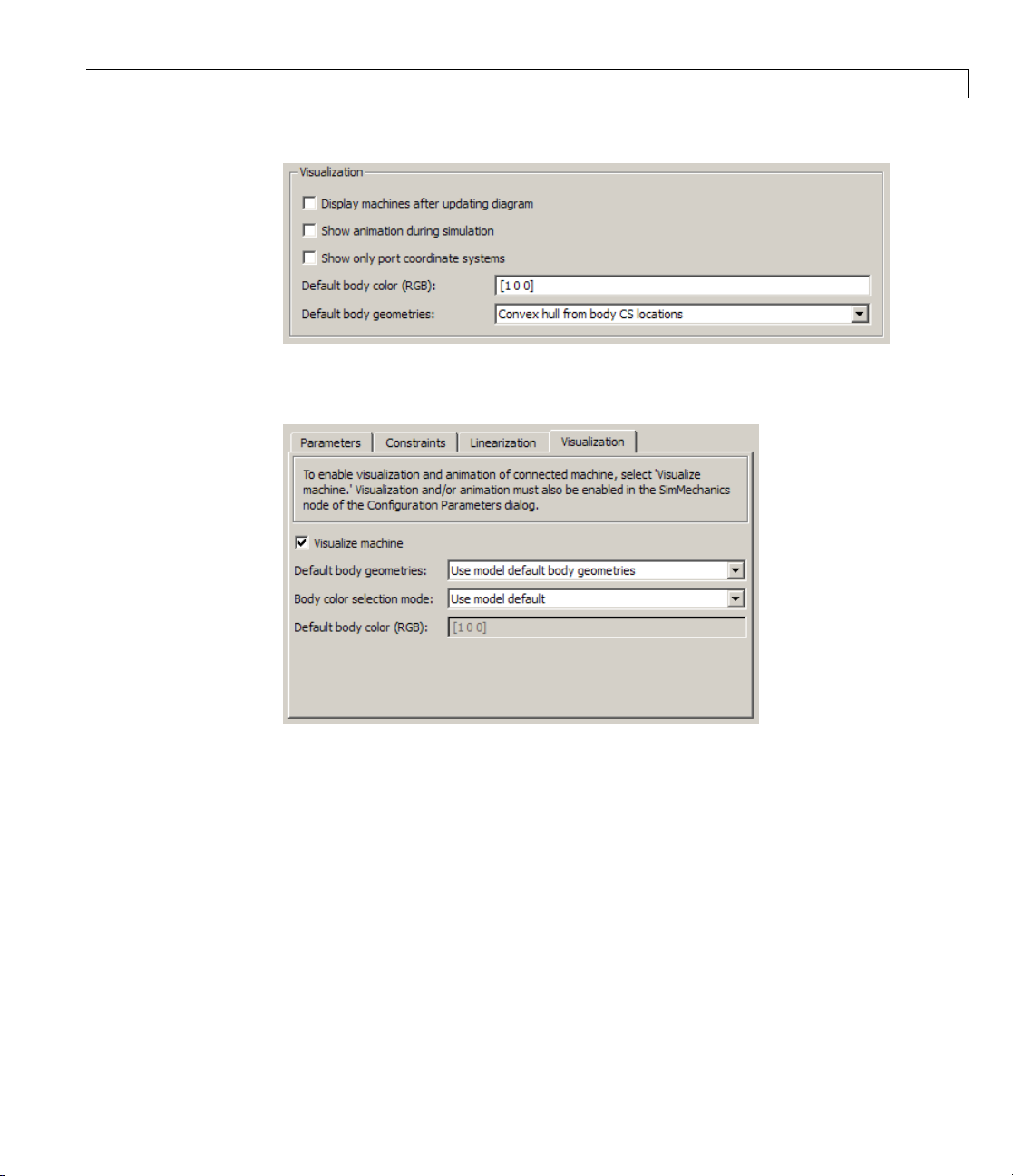

Enabling Visualization for an Entire Model

You enter the visualization settings for an entire model in the Visualization

area of the SimMechanics node of the Configuration Parameters dialog. To

open visualization, you must select at least one of these check boxes.

1-2

Model-wide visualization is turned off by default.

To start visualization, you must select at least one of the first two check boxes:

• Display machines after updating diagram forstaticvisualization

• Show animation during simulation for dynamic animation

Select the Show only port coordinate systems check box if you want to

visualize only those Body coordinate systems with visible ports on their

About SimMechanics™ Visualization

respective Body blocks in the m odel. The default is unselected, so that all

Body co ordinate systems are visualized on their respective bodies.

Visualizing All Bodies in a Machine

You can choose whether or not to visualize a specific machine in your model

through the Visualization tab of its Ma ch in e Environment block dialog. A

single window displays all selected machines in a model.

By default, each machine is selected for visualization. If you turn off machine

visualization, your choice only affects that machine, not the entire model.

Other Si mMechanics Visualization Controls

All other visualization controls are located on the SimMechanics visualization

window itself. You can access them once the window is open, as discussed in

Chapter 2, “Getting Started with the Visualization Window”.

You control custom visualization choices for individual bodies in their

respective Body dialogs.

Using SimMechanics Visualization

The visualization chapters guide you in making appropriate SimMechanics

visualization choices, includ in g why you might want to visualize y o u r model’s

bodies and animate their motion.

1-3

1 Introducing Visualization and Animation

Display Versus Animation

SimMechanics visualization serves two distinct purposes, static and dynamic.

In both cases, you can change your observer viewpoint and navigate through

the scene, as well as change the visualized body properties.

Static Display

You can display a static state of your model at different stages of modeling.

Use static display in the initial state, during construction. Either:

• Open the visualization before or while you build your model. You display

each body as you add it to your model, if you also update the block diagram.

Having the visualization window open during model building lets you keep

track of your model’s bodies and how they are connected. Yo u can see

unphysical or mistaken constructions before you finish the model.

• Open the visualization after you finish the model. All the bodies in the

model appear together.

1-4

Also use static display after a simulation ends, or after you pause or stop

it. In these cases, the visualization window shows the model at later times

or in the final state.

Dynamic Animation

You can also display an animation of body motion while the Si m M echanics

model is running. Use this feature to watch the model’s dynamics in three

dimensions and visualize motions and relationships more easily than is

possible with Scope blocks alone.

About Body Color and Geometry: Default, Standard, and Custom

About Body Color and Geometry: Default, Standard, and

Custom

In this section...

“About Body Color: Default and Custom” on page 1-5

“About Body Geometry: Default, Standard, and Custom” on page 1-5

“Standard Bo dy Geometry: Equivalent Ellipsoids” on page 1-5

“Standard Body Geometry: Convex Hulls” on page 1-9

“Custom Body Geometry and External Graphics Files” on page 1-10

About Body Color: Default and Custom

The initial default color of all visualizedbodiesisred. Youcanmodifythis

default or replace it by custom colors for individual bodies, one at a time. See

Chapter 3, “Customizing Visualization and Animation”.

About Body Geometry: Default, Standard, and Custom

You can choose how the visualization window displays the bodies in size and

shape ( ge ometry ). There are two available standard geometries:

• Equivalent ellipsoid for each body, based on its mass properties and center

of gravity (CG) position

• Convex hull for each body, based on its Body coordinate systems (CSs)

The convex hull geometry is the initial default body geometry for all visualized

bodies.

Standard Body Geometry: Equivalent Ellipsoids

The inertia tensor I of a rigid body is real and symmetric, so it has three real

eigenvalues (I

are the principal axes of the body. In the coordinate system defined by those

axes, the inertia tensor is diagonal. The trace of the inertia tensor, Tr(I)=

, I2, I3) and three orthogonal eigenvectors. These eigenvectors

1

1-5

1 Introducing Visualization and Animation

I1+ I2+ I3, i s the same in any coordinate system with its origin at the body’s

center of gravity (CG).

Every rigid body has a unique equivalent ellipsoid, a homogeneous solid

ellipsoid of the same inertia ten sor. In Cartesian coordinates, the ell ip soid

surface is given by

⎡

⎣

⎛

⎜

⎝

y

a

()

2

⎞

⎟

⎠

2

z

()

a

−

⎤

()

⎦

1

2

x

++=

()

a

xyz

where m isthebody’smass. Thethreeparameters(ax, ay, az)arethe

generalized radii of the ellipsoid. For axis i = 1,2,3,

aTrIm

=

522I

ii

Triangle Inequalities

The principal moments (I1, I2, I3) must satisfy the triangle inequalities:

II I

+≥

231

III

+≥

31 2

II I

+≥

12 3

Violation of the triangle inequality for Iileads to an unphysical imaginary

generalized radius a

Caution Visualizing the equivalent ellipsoid of a body whose principal

moments do not satisfy the triangle inequalities leads to a SimMechanics

warning indicating that one or more triangle inequalities have been violated.

The simulation continues, but the body in violation is not displayed.

.

i

1-6

Ellipsoids with Special Symmetry

In general, all three Ii, i = 1,2,3, are unequal. Such a body is an asymmetric

top. If two of the three I

symmetric top. Thethirdaxisistheaxisofsymmetry. IfallthreeI

are equal (double degeneracy), the bo dy is a

i

are equal

i

About Body Color and Geometry: Default, Standard, and Custom

(triple deg eneracy), the body is a spherical top and dynamically equivalent to

a homogeneous sphere.

Reduced-Dimension Ellipsoids

In special cases, the equivalent ellipsoid reduces to a planar, linear, or p oint

figure.

Let (i,j,k) label the three axes (1,2,3) = (x,y,z)inanyorder.

• For a true ellipsoid,withnonzerovolume,allthea

are nonzero. Th e

i

triangle inequalities are strict inequalities in this case:

II I

+>

jki

III

+>

ki j

II I

+>

ijk

• For an ellipse, with zero volume but nonzero area, one ai=0andtheother

two a

, akare nonzero. One of the triangle inequalities beco m es an equality:

j

II I

+=

jki

III

+>

ki j

II I

+>

ijk

• For a line, with zero volume and area but nonzero length, two ai, aj=0and

the third a

II I

jki

III

ki j

II I

+>

ijk

is nonzero. Two of the triangle inequalities become equalities:

k

+=

+=

Equivalently, Ii= Ijare nonzero and Ik=0.

• For a point,withnospatialsize,allthreea

inequalities become equalities:

vanish. All three triangle

i

1-7

1 Introducing Visualization and Animation

II I

+=

jki

III

+=

ki j

II I

+=

ijk

Equivalently, all three Iivanish.

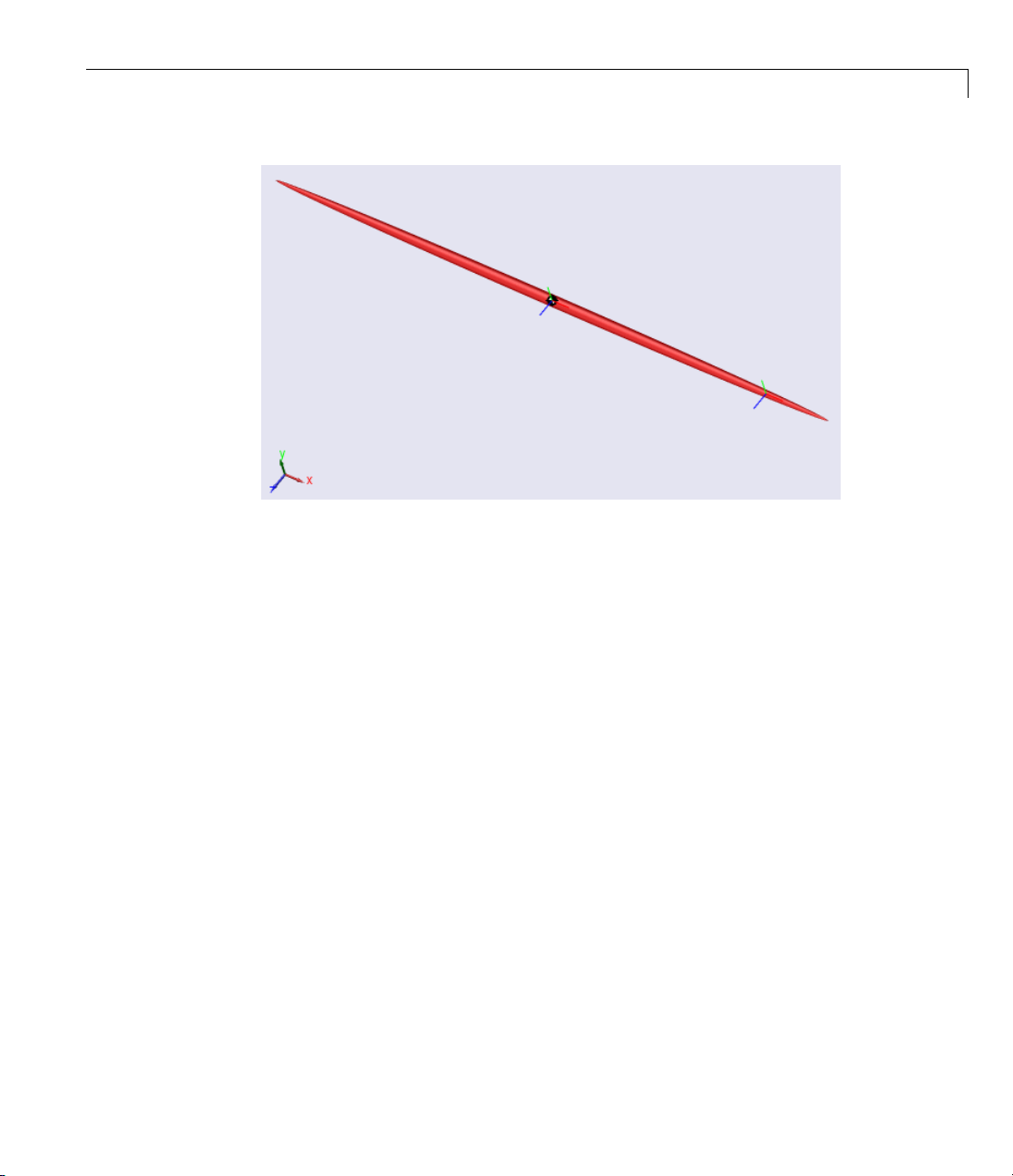

Example: Simple Pendulum Rod

Consider the simple pendulum rod in “Visualizing a Simple Machine” in the

SimMechanics Getting Started Guide.Youcanopenthemodelbyentering

mech_spen at the command line.

The rod length L =1m,anditsradiusr = 1 cm. The inertia tensor is

I

⎛

⎜

⎜

⎜

⎝

00

xx

I

00

yy

00

2

⎛

mr

⎞

⎟

=

⎟

⎟

I

zz

⎠

20 0

⎜

⎜

0120

⎜

⎜

00 12

⎝

mL

2

mL

⎞

⎟

⎟

⎟

2

⎟

⎠

1-8

Because the rod has an axis of symmetry, the x-axisinthiscase,twoofits

three p rincipal moments are equal: I

radii are equal: a

= az. The rod is a symmetric top and, since r is much smaller

y

= Izz, a nd two of its three generalized

yy

than L, its equivalent ellipsoid is almost a line of zero volume and area.

53 2L

The ge ne raliz ed radii of the equivalent ellipsoid are a

52r

and a

= az=

y

()

= 1.12 cm. This is the rod so displayed:

=

x

()

= 0.646 m

About Body Color and Geometry: Default, Standard, and Custom

Standard Body Geometr y: Convex Hulls

Every Body has at least one Body coordinate system (CS) at the CG. A

Body also has one or more extra Body CSs for the attached Joints, as well

as possible Actuators and Sensors. Each Body CS has an origin point, and

the collection of all these points, in general, defines a volume in space. The

minimum outward-bending surface enclosing such a volume is the convex hull

of the Body CSs, and this is the alternative standard body geometry. The

SimMechanics convex hull excludes the CG CS.

To enclose a nonzero volume, this set must have at least four non-coplanar

Body CSs. Three non-collinear Body CSs are displayed instead by a triangle,

and two non-coincident origins by a line. One origin is displayed just as

apoint.

Four or more coplanar origins are displayed as a triangle, three or more

collinear origins are displayed as a line, and two or more coincident origins

are displayed as a point.

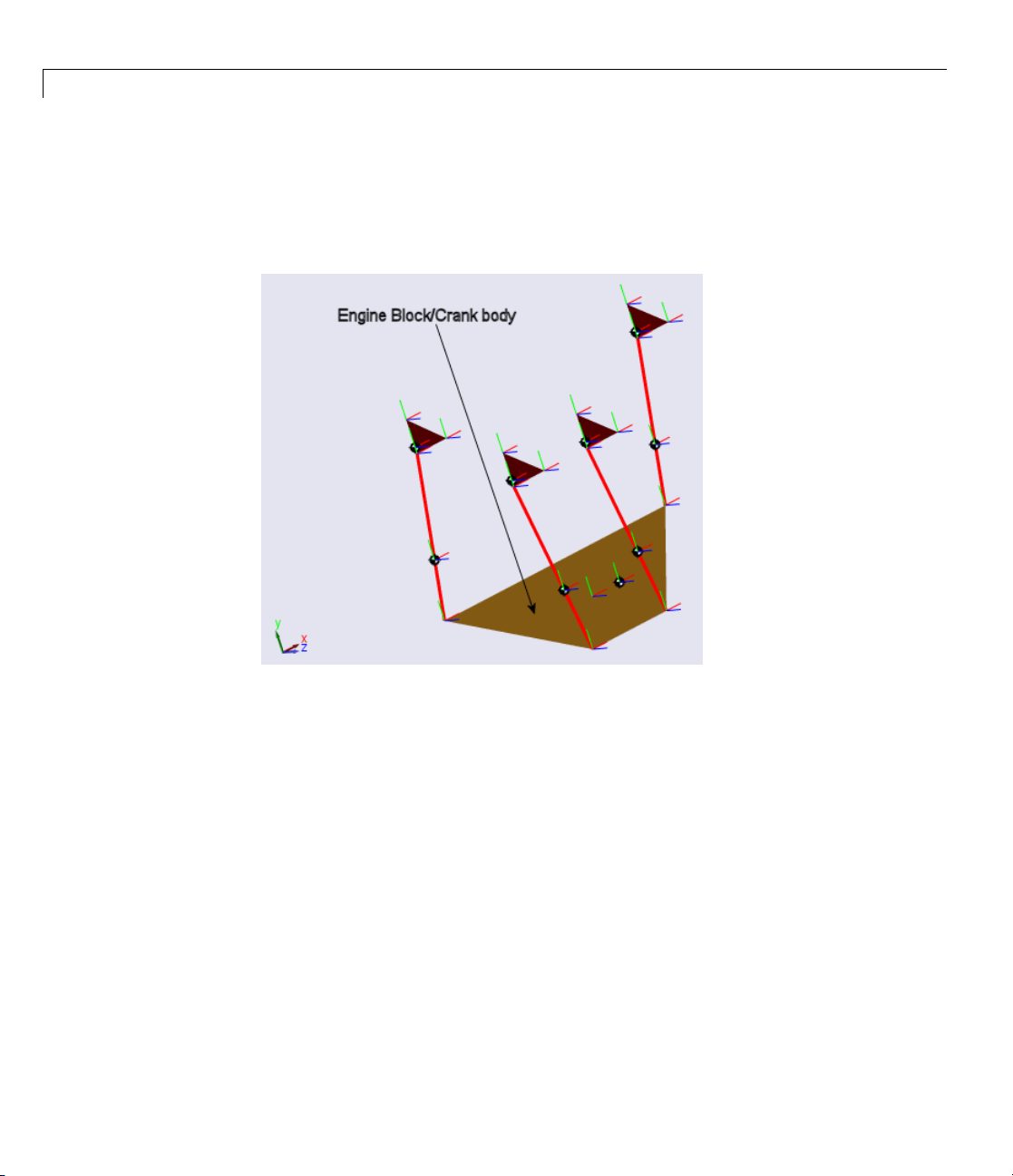

Example: Four-Cylinder Engine Crank

Open the four-cylinder engine model by entering mech_fceng at the command

line. Start visualization.

1-9

1 Introducing Visualization and Animation

Open the Engine Block subsystem and note the Crank block representing the

engine crank. This Body block has five coplanar Body CSs, not including the

CG CS. Visualize the engine as convex hul ls and click the Crank body, the

largest body. The convex hull forms a planar polygon.

1-10

Custom

In plac

geomet

s. See Chapter 3, “Customizing Visualization and Animation”.

bodie

Body Geometry and External Graphics Files

e of the standard body geometry choices, you can provide a custom

ry defined with external graphics files for one or more individual

Hierarchy of Bod y, Machine, and Model Visualization Settings

Hierarchy of Body, Machine, and Model Visualization

Settings

In this section...

“Visualized Geometries and Colors from Body Block Settings” on page 1-11

“BodyBlockSettingsAffectingBodyVisualization”onpage1-12

“Visualization Settings in the Machine and Model Hierarchy” on page 1-13

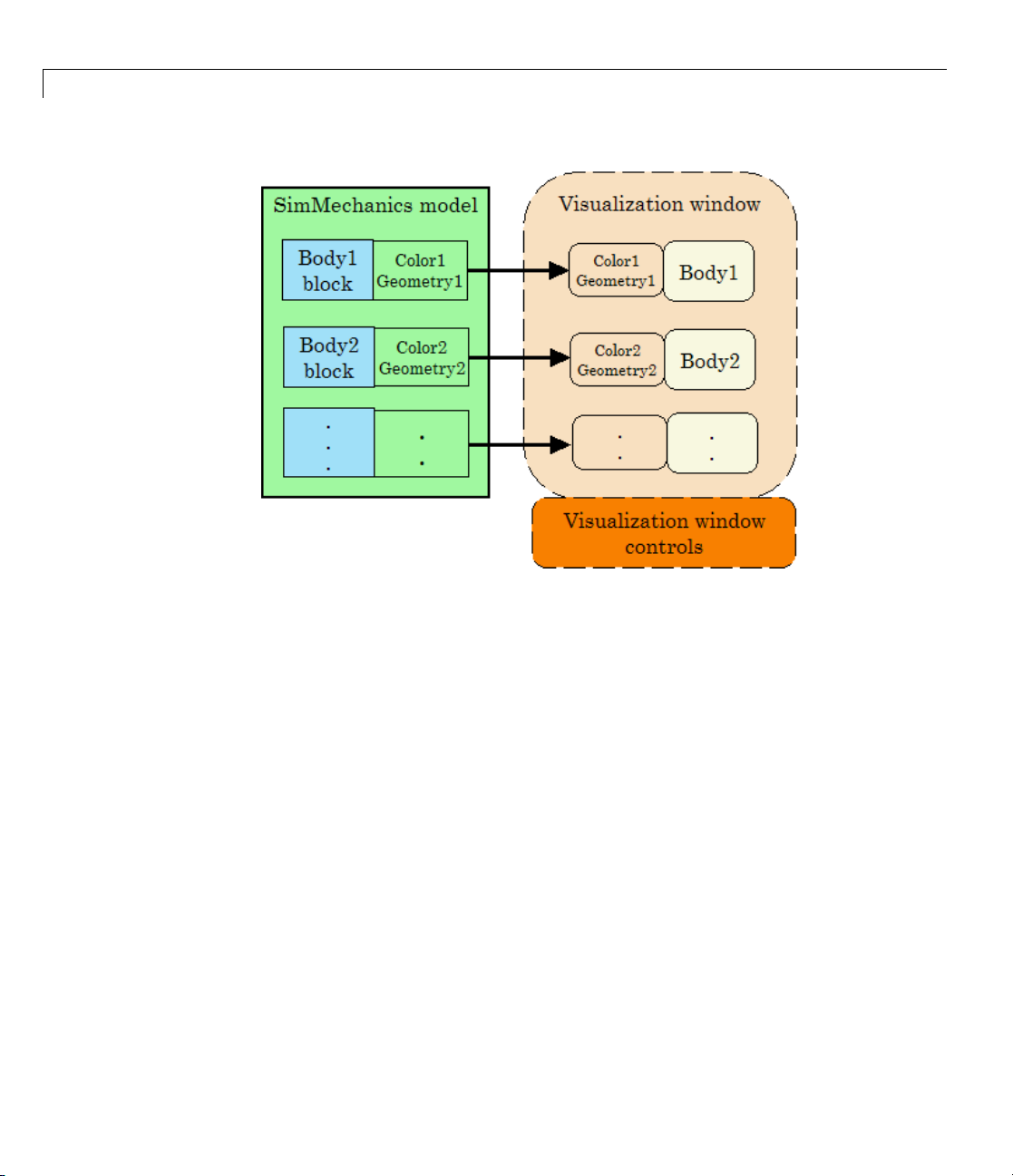

Visualized Geometries and Colors from Body Block Settings

The SimMechanics visualization window visualizes bodies repre s en ted by

Body blocks in your model. The visualization information that the window

uses from the model comes strictly from the mass, coordinate system, and

visualization properties set individually in each Body block’s dialog.

Note The window itself contains addi t ion a l visualization controls that affect

visualized body geometries and colors. See Chapter 2, “Getting Started with

the Visualization Window”.

1-11

1 Introducing Visualization and Animation

1-12

Body Block and V isu al ization Window Setti ngs Control Body Visualization

Body Block Settings Affecting Body Visualization

How settings in Body block dialogs affect visualization depends on which type

of body geometry and which color you ch oose for a particular body. The Body

dialog contains three classes of such choices.

Mass Properties

The principal inertial moments and the mass of a body determine the size

and shape of its equivalent ellipsoid.

Body Coordinate Systems: Origins and Orientation

The relative positions of the Body’s coordinate systems (CSs) determine the

size and shape of its convex hull.

Visualization

The color choice in the Body dialog’s Visualization tab determines the color

of the visualized body.

Hierarchy of Bod y, Machine, and Model Visualization Settings

You make the choice of convex hull or equivalent ellipsoid to visualize an

individual body in the Body dialog’s Visualization tab.

If you choose a custom body geometry for a Body, the external body geometry

file referenced in the Body dialog’s Visualization tab determines the

visualized body’s size and shape .

Note The choice of standard or custom body geometry has no effect on the

visualized body’s color. The choice of body color has no effect on the visualized

body’s geometry.

Visualization Settings in the Machine and Model Hierarchy

SimMechanics models start with initial default visualization settings. A

model a nd machines within the model also possess, respectively, model-wide

and machine-wide default visualization settings. Visualization settings are

inherited from the highest level (model) through machines to individual

Bodies. You can change these default and inherited settings.

Chapter 3, “Customizing Visualization and Animation” discusses the controls

you need to adjust to change these default and inherited settings at the

model, machine, and body levels.

1-13

1 Introducing Visualization and Animation

1-14

Inheritance Hierarchy of Default Visualization Settings

Initial Default Settings for a Model

The initial default visualization settings for an entire model are:

• Model-wide default body color: red (RGB value o f

• Model-wide default body geometry: convex hull

[1 0 0])

Machine Inheritance of Model-Wide Default Settings

The initial default visualization settings for a m achine are:

Hierarchy of Bod y, Machine, and Model Visualization Settings

• Machine-wide default body color: inherit model-wide default

• Machine-wide default body geometry: inherit model-wide d efault

Body Inheritance of Machine-Wide Default Settings

The initial default visualization settings for a Body are:

• Default Body color: inherit machine-wide default

• Default Body geometry: inherit machine-wide default

1-15

1 Introducing Visualization and Animation

1-16

Getting Started with the Visualization Window

The SimMechanics visualization window allows you to control how you view

yourmodel’sbodiesinbothstaticdisplay and dynamic simulation-based

animation. It also allows you to record animations.

• “Introducing the SimMechanics Visualization Window” on page 2-2

• “Controlling Body and Body Component Display” on page 2-6

2

• “Adjusting the Camera View” on page 2-9

• “Communicating with the Model from the Visualization Window” on page

2-17

• “Controlling and Timing Simulation from the Visualization Window” on

page 2-21

• “Controlling Animation” on page 2-23

• “Recording Animation” on page 2-28

• “Visualization Menus and Their Controls” on page 2-33

2 Getting Started with the Visualization Window

Introducing the SimMechanics Visualization Window

In this section...

“About the Visualization Window” on page 2-2

“Opening and Updating the Visualization Window” on page 2-2

“Visualization Toolbar and Its Controls” on page 2-4

About the Visualization Window

The visualization window is an integral part of SimMechanics software. With

it, you can visualize y our machines using a comprehensive set of display

controls, interact with your model, and watch and record animations.

The window uses a distinctive set of symbols and shapes to display bodies and

Body coordinate systems (CSs). This section is an overview of what you can

do with the SimMechanics window.

2-2

Caution The S imMechanics visualization window resembles a MATLAB

Graphics figure window. But it is not a feature of MATLAB and has no figure

handle.

®

Opening and Updating the Visualization Window

Starting visualization and choosing the default display options are discussed

in “About SimMechanics Visualization” on page 1-2.

• Once you configure your SimMechanics model for visualization, select

Update Diagram from the model’s Edit menu (or press Ctrl+D).

The window opens and displays the machines in your model that you

have chosen to visualize. O n e window displays all selected machines

simultaneously.

• To synchronize the static visualization display with you r model, reselect

Update Diagram at any time.

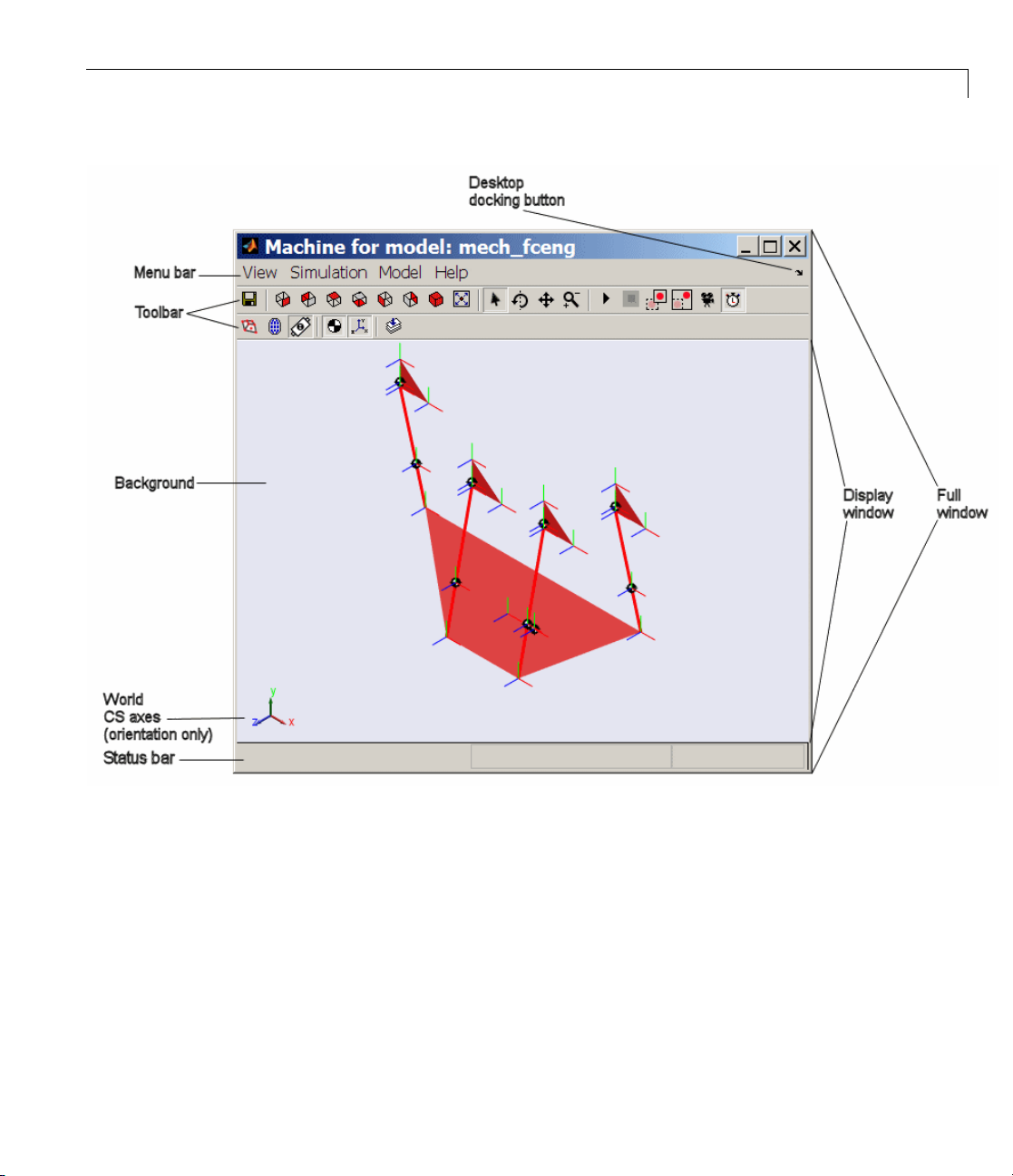

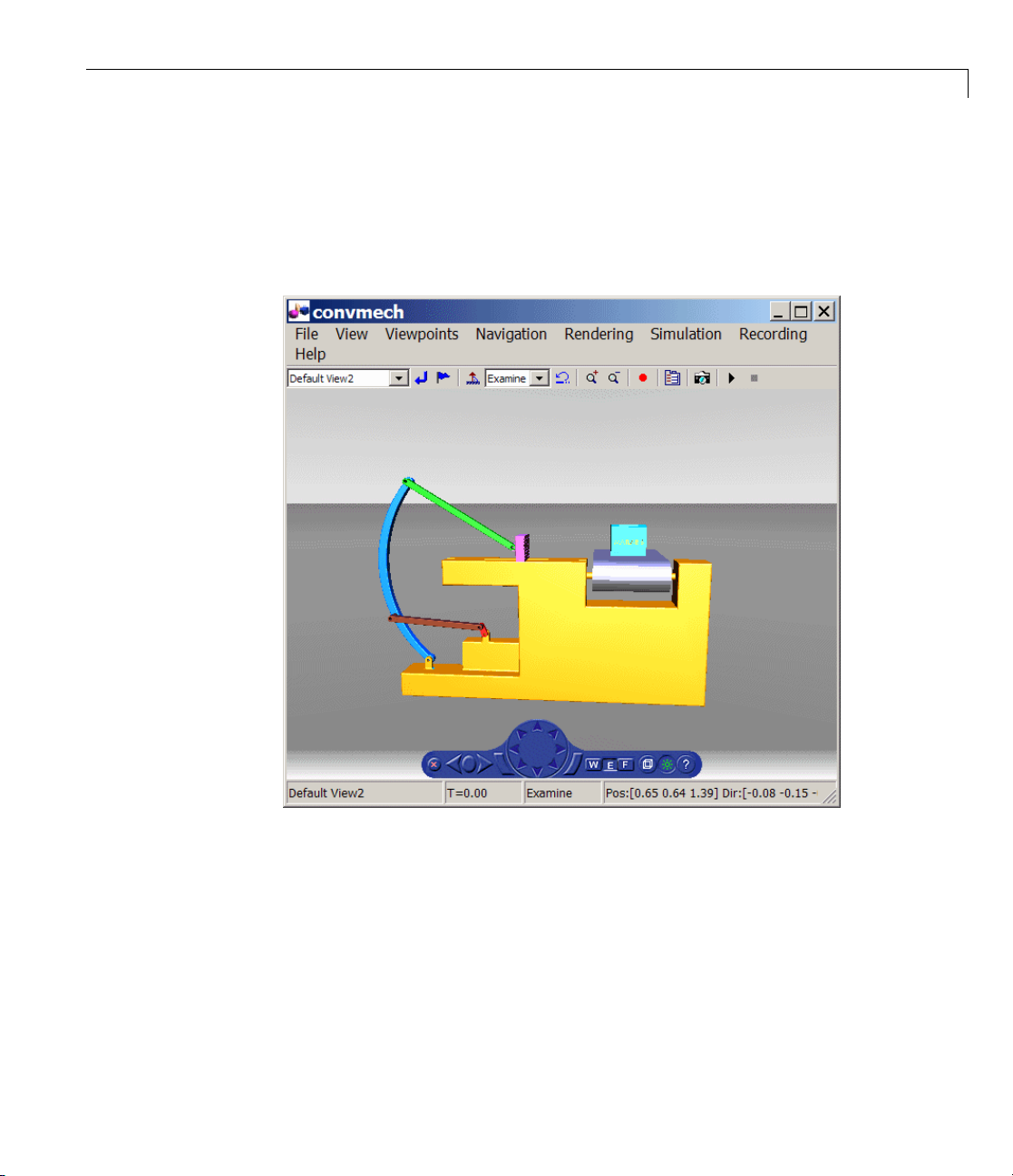

This figure shows a model with the default background color.

Introducing the SimMechanic s ™ Visualization Window

SimMechanics™ Visualization Window Displaying a Four-Cylinder Engine (Isometric V iew)

Menu Bar Versus Toolbar Controls

Onceyouopenthevisualizationwindow,youhavetwowaystocontrolthe

display and carry out these tasks:

• Use the buttons in the toolbar. Every feature on this toolbar occurs in the

menus, although the reverse is not true. See “Visualization Toolbar and

Its Controls” on page 2-4.

2-3

2 Getting Started with the Visualization Window

• Use the menus in the menu bar. The menu contains specialized items and

submenus. See “Visualization Menus and Their Controls” on page 2-33.

Note Changing the display settings using the visualization window controls

changes only your immediate view in the display window. By itself, it does

not change the visualization settings in the model.

Ifyouwanttosaveachangeinthevisualization window settings to the model,

and thus change the model’s visualization settings, see “Communicating with

the Model from the Visualization Window” on page 2-17.

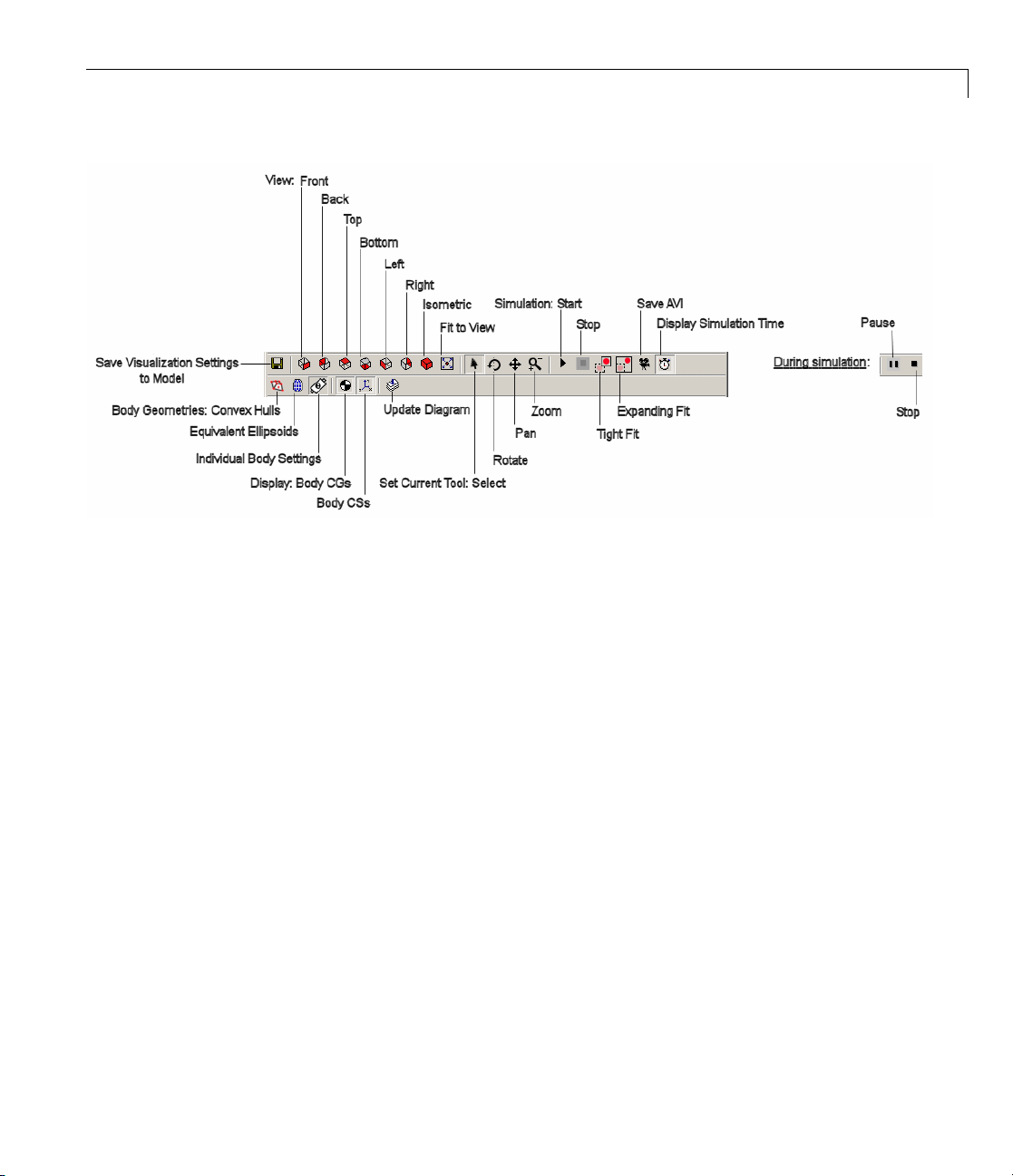

Visualization Toolbar and I ts Controls

You can activate or change most visualization features by selecting buttons on

the window toolbar, instead of selecting items from the menus. The setting

changes initiated by the toolbar are the same as the corresponding menu

actions: either you activate a feature, enable or disable a feature, or initiate

an immediate action.

2-4

Hovering your mouse cursor over a toolbar button displays the button’s tooltip

indicating its function.

SimMechanics™ Toolbar Buttons

Introducing the SimMechanic s ™ Visualization Window

Toolbar Relationship to the Menus

You can access all of the toolbar functions in the menus as an alternative. The

toolbar reproduces most of the menu functions.

See “Visualization Menus and Their Controls” on page 2-33 for a complete

overview of the visualization window controls.

2-5

2 Getting Started with the Visualization Window

Controlling Body and Body Component Display

In this section...

“About Body and Body Component Display” on page 2-6

“Interpreting the Body Display Symbols and Shapes” on page 2-6

“Changing Body Display Symbols” on page 2-7

“Changing Body Display Shapes” on page 2-7

About Body and Body Component Display

You can change how bodies look in the SimMechanics visualization window.

This section explains how to control body and body compo n ent display.

Interpreting the Body Display Symbols and Shapes

When a visualization window opens, it uses distin ctive conventions to display

the bodies of your model.

2-6

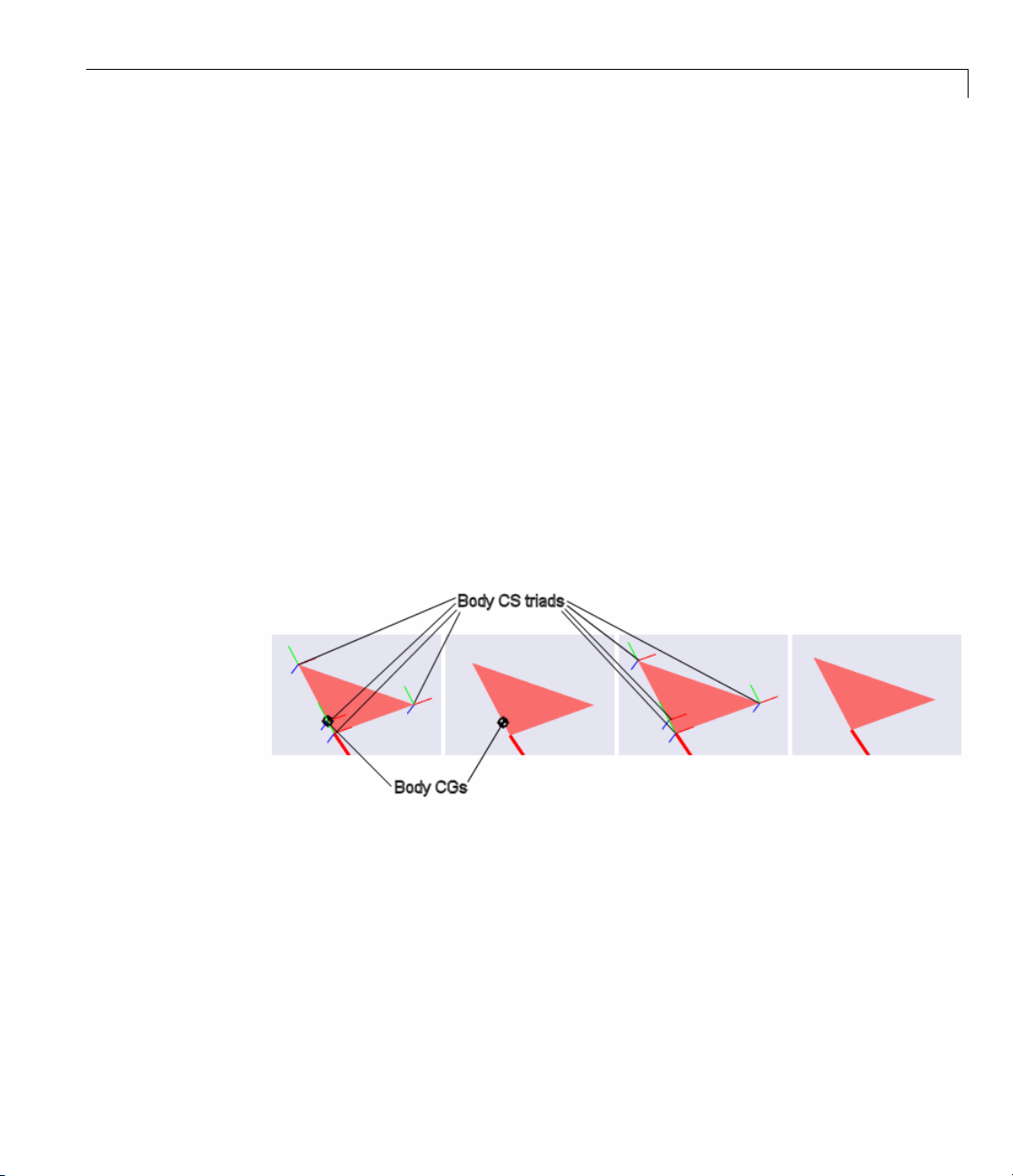

Body Component Display

Body components are d isplayed with two distinctive symbols:

• The center of gravity (CG) point of each body is marked by a half-filled

circle-plus symbol

• Each Body coordinate system (CS) is marked by coordinate axis triads. The

color coding is X-Y-Z ax es = RGB = red-green-blue.

.

Controlling Body and Body Component Display

Body Surface Display

The window displays all the bodies of every machine with visualization

enabled. Theentirebodysurfaceisshadedwiththecoloryouchooseforit.Its

shape is one of these:

• Convex hull: a line, one or more joined surface patches, or a closed surface

enclosing a volume

• Equivalent ellipsoid

• A custom shape

Changing Body Display Symbols

You can turn off the CS triads, the CG symbols, or both using the toolbar,

with the Display Centers of Gravity and Display Coordinate Systems

buttons.

You can activate or deactivate each button separately. The default for both

is active.

Four-Cylinder Engine: Cylinder Piston With and Without Body CS Triads

and CGs (Detail)

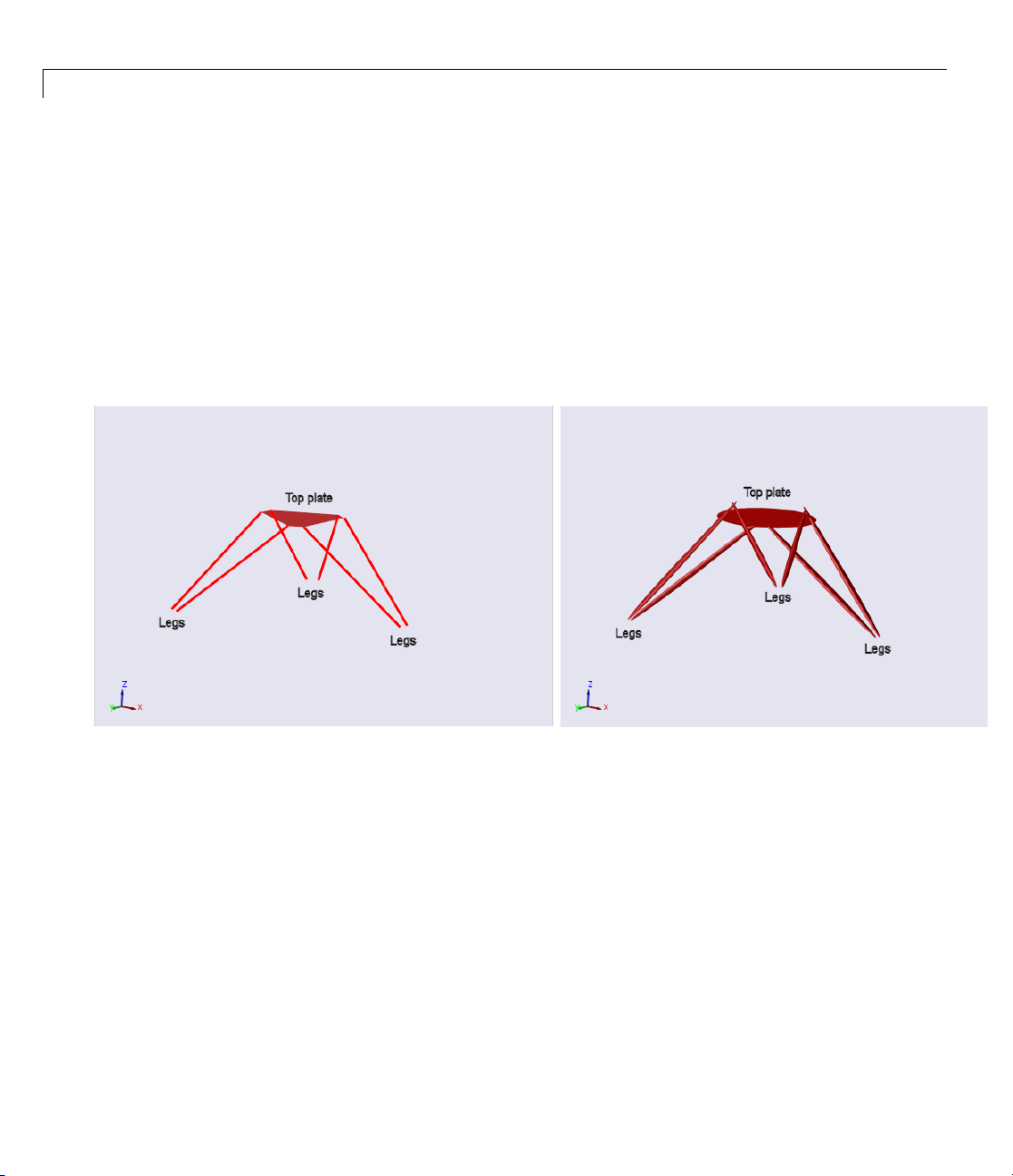

Changing Body Display Shapes

You can switch among three possible display shape options using the toolbar.

They are mutually exclusive; one is always active.

2-7

2 Getting Started with the Visualization Window

• Clicking the Set Body Geometries to Convex Hulls button displays

allbodiesasconvexhulls,regardless of the visualization settings in the

Body blocks in the model.

• Clicking the Set Body Geometries to Ellipsoids button displays all

bodies as convex hulls, regardless of the visualization settings in the Body

blocks in the model.

• Clicking the Set Body Geometries to Individual Body Settings button

displays each body according to the visualization settings in its Body block

in the model. This is the default.

2-8

rt Platform: Bodies Displayed as Convex Hulls and as Equivalent Ellipsoids

Stewa

Adjusting the Camera V iew

In this section...

“Setting the Background Color” on page 2-9

“Interpreting the Camera Projection, Field of View, and Viewpoint” on

page 2-9

“Automatically Sizing the Camera Field of View” on page 2-11

“Automatically Setting a Camera Viewpoint” on page 2-12

“Actively Controlling the Camera Viewpoint” on page 2-13

“Camera Viewpoint and Mouse Contro ls” on page 2-14

Setting the Background Color

You must use the menu bar to change the background color of the display

window within th e SimMechanics visualization window.

Adjusting the Camera View

1 Open View,thenselectChange Background Color. A color palette

opens.

2 Select a color. Click OK to implement your choice. The background color

changes immediately.

The color palette for the background is the same as the palette for custom

body color. See “Customizing Vis ua l ize d Body Colors” on page 3-4.

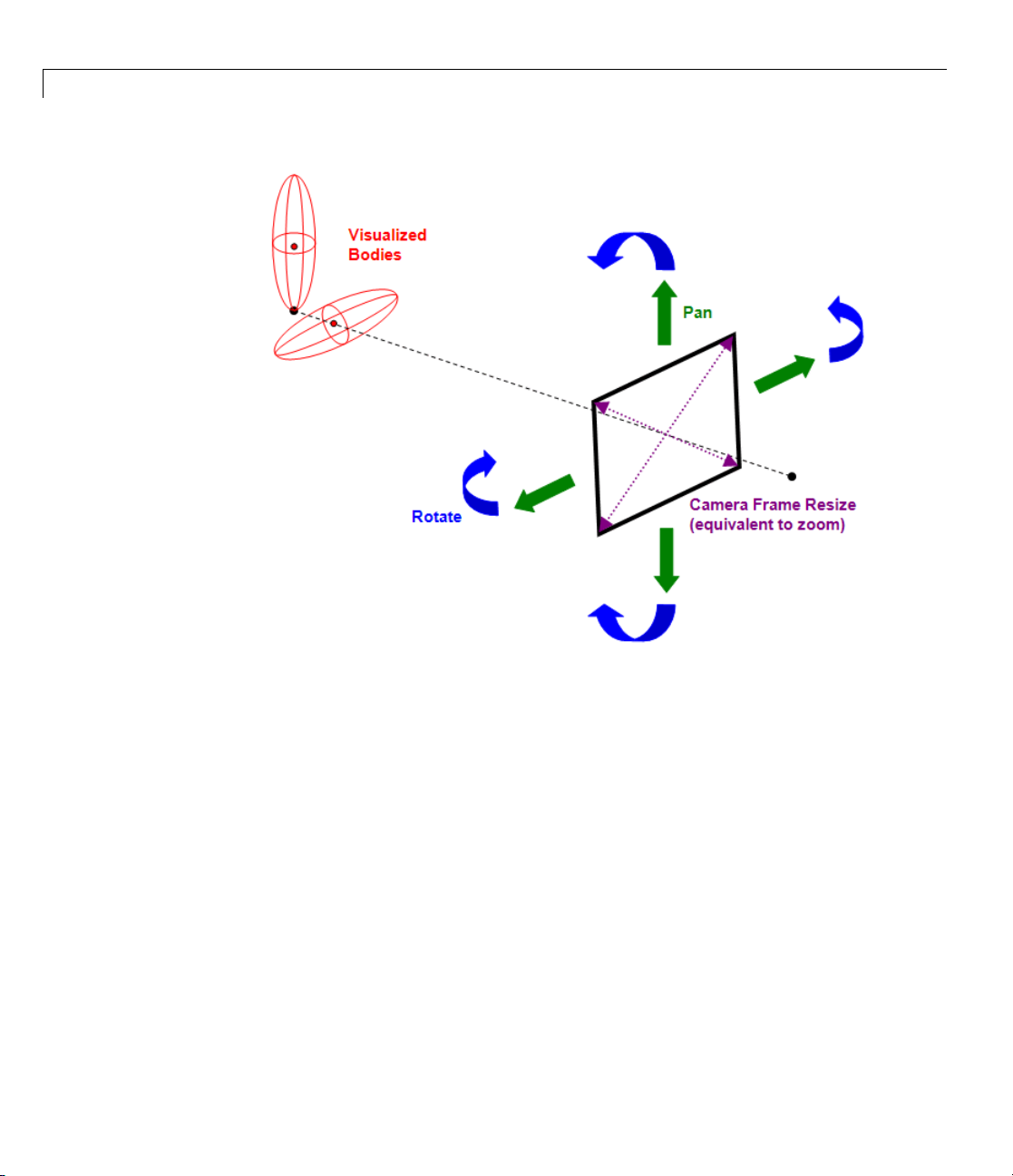

Interpreting the Camera Projection, Field o f View, and Viewpoint

To properly interpret what you see in visualization, imagine that the display

window shows the field of view of a camera. The properties of this virtual

camera determine most of what you need to know about controlling your

view of the model’s machines.

2-9

2 Getting Started with the Visualization Window

2-10

Visuali

zation Window Camera Field and Visualized Scene

Visualization and Orthographic Projection

The vis

threelines

windo

ualization window uses orthographic (parallel) projection to reduce a

dimensional scene to two dimensio ns on your screen. That is, parallel

of view representing depth converge to a point only at infinity. The

w displays the scene without finite perspective.

Camera Field of View, Viewpoint, and Frame Size

ield of view is what you see within the virtual camera frame. The virtual

The f

ra’s viewpoint is the point and direction from which it views the scene.

came

virtual camera frame has a size or aperture.

The

Adjusting the Camera View

Zooming. Changing the camera frame size or aperture, then shrinking

or expanding the overall size of the machines, is the equivalent of zooming

in or out. The camera cannot zoom directly, because there is no point of

convergence or perspective.

Panning. Panning changes the camera’s virtual location without changing its

direction of view. It means moving the camera frame horizontally or vertically

in a constant virtual plane, maintaining the orientation of the camera frame.

Rotating. Rotating means viewing the scene from a different direction, wh ile

maintaining a constant zoom (effective distance from the machines).

A rotation rotates about the center of the geometric bounding box containing

all the objects in the field of view. (This geometric center is unrelated to

body pro perties , such as Body coordinate systems or centers of gravity.) The

viewpoint is moved to another point on the virtual sphere with this same

geometric center. The view direction changes to maintain the geometric

center at the center of the display window.

World Coordinate System Axes Indicate Orientation Only

The World CS axis triad always appears at the lower-left corner of the display

window.

The directions of the axes indicate orientation only. The position of the axes

does not, in general, indicate the position of the World coordinate system

(CS) origin.

Automatically Sizing the Camera Field of View

You can automatically resize the camera’sfieldoraperturesizetofitallthe

visualized objects. This step is equivalent to an automatic zoom. It d oes not

rotate the viewpoint or pan the camera.

2-11

2 Getting Started with the Visualization Window

To fit the field of view to size, click the Fit to View button on the toolbar. The

camera field resizes itself immediately.

2-12

Automatically Setting a Camera Viewpoint

You can automatically change your viewpoint of the visualized bodies by

clicking one of the six viewpoint buttons on the toolbar. The action applies

immediately.

Clicking these buttons is equivalent to setting a plane of view defined by the

World CS axes. Except for the isometric view, these predefine d viewpoints

always have one a xis perpendicular to the plane of view (pointing into or out

of the plane of view). The isometric view is a viewpoint direction with equal

ection cosines (all

dir

default is the front view, with X pointing right, Y pointing up, and Z

The

nting out of the plane of view.

poi

13/

).

Adjusting the Camera View

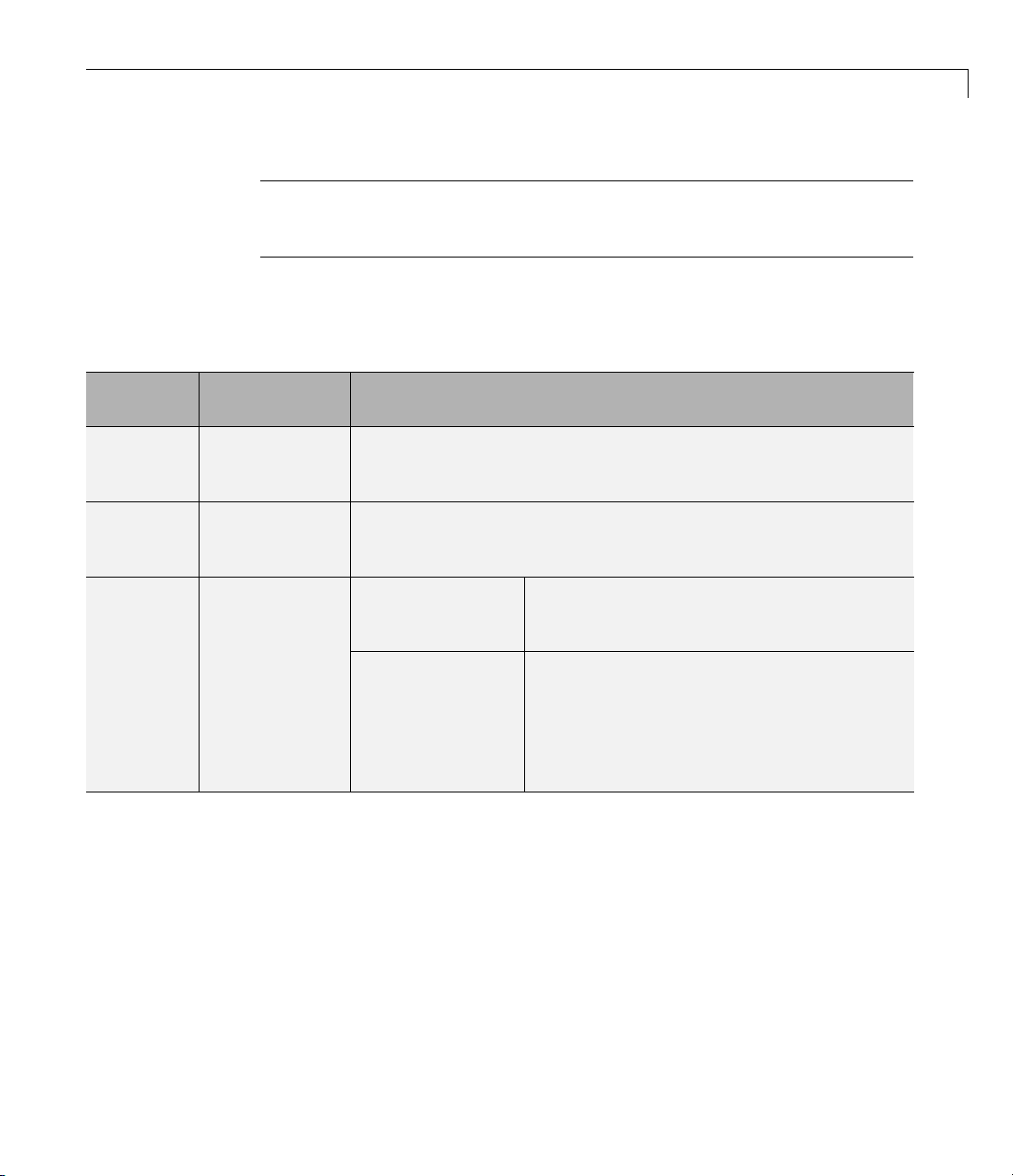

Toolbar Button

Front View

(default)

Back View

Top View

Bottom View

Left View

Right View

Isometric View

Axes and Orientation of View Plane

X points right – Y points up

X points left – Y points up

X points rig ht – Z points down

X points right – Z points up

Z points right – Y points up

Z points left – Y points up

X points down and right – Y points up – Z points

down and left

Actively Controlling the Camera Viewpoint

The four selection-viewpoint toolbar control buttons enable certain

interactions between your mouse and the display w indow through

point-and-click or point-click-hold-and-roll.

These four toolbar-menu controls are mutually exclusive; you can activate at

most one of them at a time. The default is for the Select Tool to be activ e.

• Enable a tool by clicking on its button.

• Disable all of them by clicking the currently active tool button.

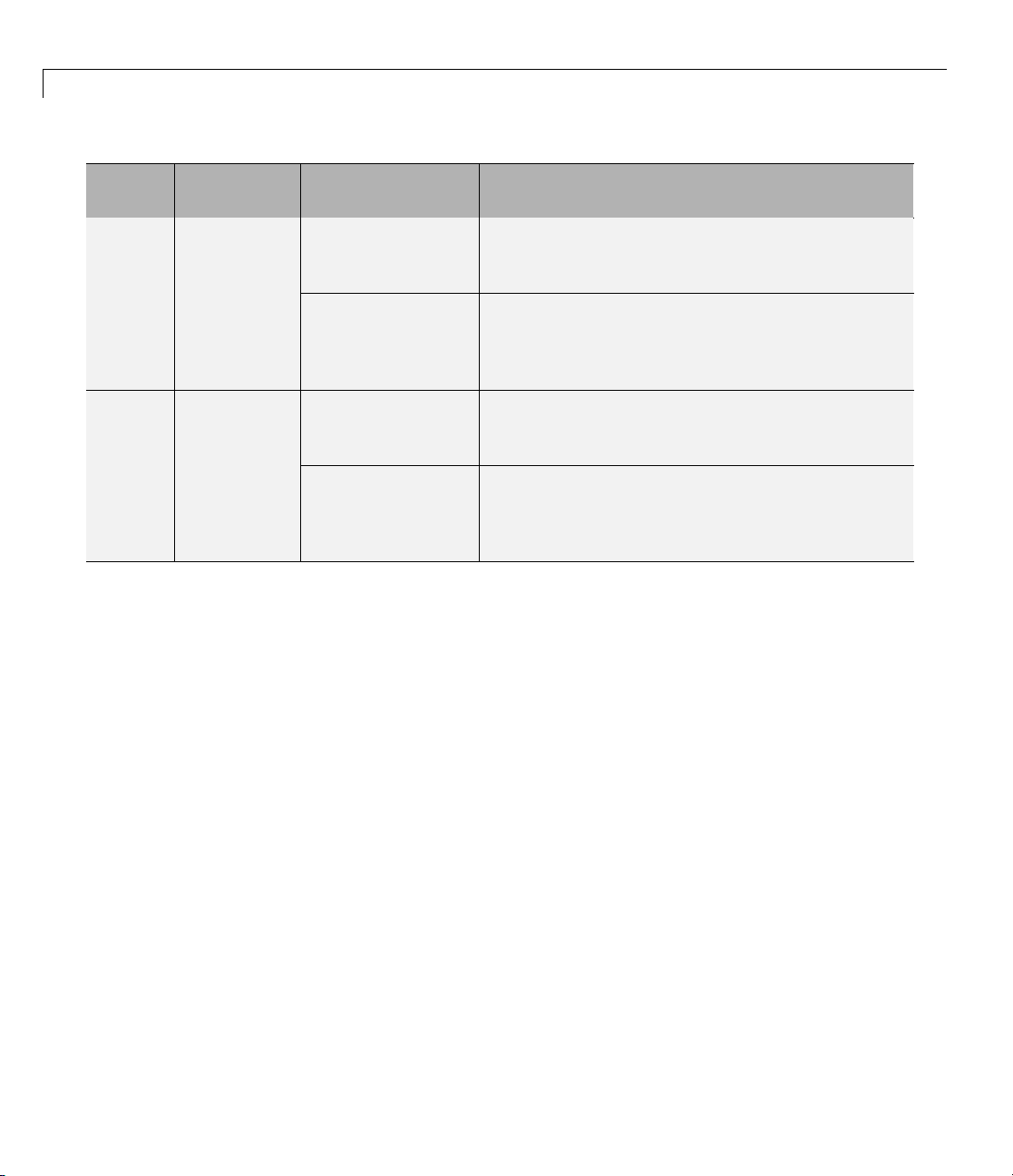

Function

Select

bodies

Viewpoint

controls

Tool

Select

(default)

Rotate

Pan

Zoom

How to Use

Point with the mouse at a visualized body, then

click on any mouse button.

Point with the mouse anywhere in display window.

Then left-click, holding the mouse button, and roll

mouse.

2-13

2 Getting Started with the Visualization Window

Results of Rolling t he Mouse with the Viewpoint Controls

With one of the three viewpoint control tools enabled, rolling the mouse

produces one of three possible results in the display window.

Rotate Tool. Rolling so that the arrow moves in the display window along

a line, rotates the view about that line. R olling in a more complex figure

rotates the view in a m ore complex way.

Pan Tool. Rolling forward, back, left, or right pans up, down, left, or right,

respectively.

Zoom Tool. Rolling forward or back zooms out or in, respectively. You

zoom toward or away from the point that you initially clicked on. Rolling left

or right does nothing.

ForMoreAbouttheSelectTool

See “Highlighting Bodies, Body Components, and Body Blocks” on page 2-17.

2-14

Camera Viewpoint and Mouse Controls

The four selection-viewpoint tool controls and the computer mouse have a

complementary relationship to each other.

Normal Versus Dynamic Mouse Control

In normal mouse control, the left mouse button’s function corresponds to the

function activated in the menus or toolbar. Depending on which function you

activate from the menu or toolbar, you can switch the left mouse button from

normal to dynamic mouse control and back. “Actively Controlling the Camera

Viewpoint” on page 2-13 explains this case.

In dynamic mouse control, the viewpoint controls are disabled from the menu

or toolbar. (Either the Select Tool is enabled, or all four selection-viewpoint

controls are disabled from the menu or toolbar.) You can still exercise

the viewpoint controls with the three mouse buttons, which are mapped

one-to-one to the viewpoint controls.

Adjusting the Camera View

Note If your mouse has fewer than three buttons, y ou cannot access the

dynamic mouse control functions associated with the missing button or

buttons.

Normal and Dynamic Mouse Control with Left Mouse Button

The left mouse button’s mapping is more complex.

Viewpoint

Control

Normal:

Pan

Normal:

Zoom

Dynamic:

Rotate

Active

If Pan Tool is

enabled from

menu or toolbar

If Zoom Tool is

enabled from

menu or toolbar

If Pan and

Zoom Tools are

disabled from

menu or toolbar

Dyna

The center and right mouse buttons’ mappings are always dynamic.

How to Use

Pan field of view by clicking and holding anywhere in display

window and rolling mouse.

Zoom field of view by clicking and holding anywhere in display

window and rolling mouse.

If Select Tool is

disabled from

menu or toolbar:

If Select Tool

is enabled from

menu or toolbar:

Rotate viewpoint by clicking and holding

anywhere in display window and rolling

mouse.

Rotate

on only

rollin

Click

selec

viewp

viewpoint by clicking and holding

background in display window and

gmouse.

ing on a visualized body in this case

ts the body and has no effect on

oint.

mic Mouse Control with Center and Right Mouse Buttons

2-15

2 Getting Started with the Visualization Window

Mouse

Button

Center

Right Dynamic:

Viewpoint

Control

Dynamic:

Pan

Zoom

Active

If Select Tool is

disabled from

menu or toolbar:

If Select Tool is

enabled from menu

or toolbar:

If Select Tool is

disabled from

menu or toolbar:

If Select Tool is

enabled from menu

or toolbar:

How to Use

Pan field of view by clicking and holding

anywhere in display window and rolling mouse.

Pan field of view by clicking and holding on only

background in display window and rolling m ouse.

Clicking on a visualized body in this case selects

the body and has no effect on field of view.

Zoom field of view by clicking and ho lding

anywhere in display window and rolling mouse.

Zoom field of view by clicking and holding on only

background in display window and rolling m ouse.

Clicking on a visualized body in this case selects

the body and has no effect on field of view.

2-16

Communicating with the Model from the Visualization Window

Communicating with the Model from the Visualization

Window

In this section...

“Highlighting Bodies, Body Components, and Body Blocks” on page 2-17

“Updating the Model Diagram” on page 2-18

“Saving Visualization Settings to the Model” on page 2-19

Highlighting Bodies, Body Components, and Body Blocks

If you have the Select Tool enabled, clicking a body, Body coordinate system

(CS),orBodycenterofgravity(CG)in the SimMechanics visualization

window causes the following:

• The displayed body or body component changes color:

- A selected body surface or CS triad becomes yellow.

- A selected CG changes from white-black to yellow-black.

• The visualization window displays the associated Body block or Body CS

name and its path at the low er left just below the display window, in the

status bar.

• The associated Body block is outlined in red in the model window.

To unhighlight, click the highlighted body again. You can select and highlight

a body both in static displ ay and during simulation.

2-17

2 Getting Started with the Visualization Window

SimMechanics™ Visualization Window with Highlighted Body and Body Block (Four-Cylinder

Engine)

Enabling and Disabling Highlighting

You can enable or disable the highlighting of model Body blocks from the

Model menu item Enable Model Highlighting. The default is enabled.

Whether model highlighting is enabled or disabled, clicking a body or

body component in the window always highlights it. If you disable model

highlighting, the associated Body block is not highlighted when you click the

displayed body or body component.

Updating the Model Diagram

You can update your Simulink model diagram from the model toolbar or Edit

menu, or by pressing Ctrl+D from the keyboard.

You can also update it by clicking the Update Simulink Diagram button

in the visualization window toolbar.

2-18

Communicating with the Model from the Visualization Window

Saving Visualiz

As you work with t

setting changes

• Changes you mak

while the wind

then upon reop

whatever mode

Machine, and

• If you want to

controls be

the Save Vis

window tool

the model it

• If you want

you must sa

model too

lbar.

he visualization settings, you might want to save the

that you make.

e to the visualization settings apply only to the display

ow is open. If you do nothing else and close the window,

ening the visualization window, the display will revert to

l requires for visualization settings. See “Hierarchy of Body,

Model V isualization Settings” on page 1-11.

save the display setting changes you made from the window

fore closing the window, you must save them to the model. Click

ualization Settings to Model buttononthevisualization

bar. A warning dialog ap pears, asking if you want to save

self.

to save these display setting changes before closing the model,

ve or resave the model itself. Click the Save button in the

ation Settings to the Model

2-19

2 Getting Started with the Visualization Window

2-20

Caution If the changes to the display settings include changing the

displayed body geometries, the saved visualization settings will make the

visualization window display whatever the setting requires (all conve x hulls,

all equivalent ellipsoids, or individual body geometries). But the saved

visualization display settings do not change the visualization settings at the

model, machine, or Body block level in the model described in Chapter 1,

“Introducing Visualization and Animation”.

Controlling and Timing Simulation from the Visualization Window

Controlling and Timing Simulation from the Visualization

Window

In this section...

“Starting, Pausing, a nd Stopping the Simulation” on page 2-21

“Timing the Simulation” on pag e 2-21

Starting, Pausing, and Stopping the Simulation

You can control a simulation from the SimMechanics visualization window

with the pair of simulation control buttons. The pair takes two different

appearances, depending on whether the simulation is running.

With Simulation Stopped

From left to right, the buttons are Start and Stop,withStop disabled:

.

With Simulation Running

From left to right, the buttons are Pause and Stop: .

• If you pause a running simulation, restarting it begins the simulation at

the simulated time when it was stopped.

• If you stop a running simulation, restarting it begins the simulation at a

simulated time of zero.

Timing the Simulation

Once you start the simulation, you can track the simulation time at the

lower right of the visualization window, in the status bar, if the simulation

time display is active.

2-21

2 Getting Started with the Visualization Window

2-22

Simulation Time Display (Robot Arm Simulation with Visualized Body CSs

and CGs Deactivated)

Activating and Deactivating the Simulation Time Display

You can activate or deactivate the simulation time display using the Display

Simulation Time button on the toolbar. The default is active.

Controlling Animation

In this section...

“About Animation” on page 2-23

“How Animation Works” on page 2-23

“Automatically Adapting the Camera View to the Displayed Motion” on

page 2-24

“Changing How the Animation Is Updated” on page 2-25

“Speeding Up the Animation in Real Time” on page 2-27

About Animation

When you start a simulation with visualization and animation enabled, the

SimMechanics visualization window displays the body motion. This section

shows how you can control the animation.

Controlling Animation

How Animation Works

The v isualization window displays the animated bodies in whatever camera

view you previously set before starting simulation. By default, the cam era

remainsatrestinWorld.

The animation that you see in the display window is the result of three

distinct processes operating in parallel.

• Simulink

• Simulink updates the model outputs at every output sample time step.

• During animation, the visualization window updates the display of the

bodies at every visualization sample time step.

Each updated, displayed simulation scene is also called a frame.

By default, the output sample times are every major time step, and the

visualization sample times are the output sample tim es. But, within limits,

you can change the relationships among these time steps.

®

updates the model simulation at every simulation time step.

2-23

2 Getting Started with the Visualization Window

Caution Because visualization needs the model outputs to update the

animation, the visualization sample time should be equal to or longer than

the m odel output sample time. If the visualization sample time is shorter, the

displayed animation is updated at the model output sample times.

Automatically Adapting the Camera View to the Displayed Motion

As the bodies move in the animation, the camera view you set for the static

case before simulation might not encompass their full range of motion. Or the

bodies might move out of the field of view altogether.

You can require the display window to adapt the field of view dynamically

to the animation with the Enable Automatic Expanding Fit and Enable

Automatic Tight Fit buttons on the toolbar. These buttons are mutually

exclusive. The default for both is disabled.

2-24

Allowing the Field of View to Expand with the Moving Bodies

If the animated bodies tend to move out of the field of view once, repeatedly, or

continually, click the Enable Automatic Expanding Fit button. The field

of view will then expand as necessary to encompass the geometric bounding

box of all the bodies, as visualized. The camera remains at rest in World.

Keeping the Field of View Limited to the Moving Bodies

If you want your field of view to encompass just the moving bodies and track

them as they move, click the Enable Automatic Tight Fit button. The

center of the field of view will remain fixed to the center of the geometric

bounding box of all the bodies, as visualized. The camera is no longer at rest

in World, but continually zooms and pans to track this geometric center.

Controlling Animation

Caution With automatic tight fit enabled, the observer’s reference frame is

no longer at rest in World and, in general, is noninertial. The motion of bodies

thatyouseeisnotthatseenbyanobserverinWorld.

This autom atic tight fit can create the illusion that the bodies as a whole are

not moving. Disable the automatic tight fit to check if this is the case.

Changing How the Animation Is Updated

You might find it convenient to change how quickly the animation in the

display window responds to changes in the simulation, especially if the

animation is going by to o fast in real (clock) time.

You can change most of these con trols by going to the Simulation menu in

themenubar,thentoControl Animation Speed. The Animation Speed

Control Parameters dialog box opens. You can apply any changes and close

the dialog by clicking OK.

Delaying the Simulation at Every Display Update

At each update of the animation display, the SimMechanics simulation is

delayed for some (simulated) time to allow you to follow the motion. You can

change this delay time in the Animation Speed Control Parameters dialog.

Enter a nonnegative time (in milliseconds) in the Delay per frame field.

The default is

3 (ms).

Changing the Visualization Sample Time

You can break the default connection between visualization and model output

sample times in the Animation Speed Control Parameters dialog as well.

Enter a specified visualization sample time (in seconds) in th e Visualization

sample time field. This time is simulated (not real) time.

The default is

time, and the visualization is effectively updated at the output sample times.

Require the visualization explicitly to inherit the model output sample time

by entering

0 (s). This is smaller than any positive model output sample

-1.

2-25

2 Getting Started with the Visualization Window

Changing the Model Output Sample Time

You can also change the effective visualization sampling rate by changing the

model output sample time in the model’s Configuration Parameters dialog

and leaving the visualization sample time to be whatever the model output

sample time is. This time is simulated (not real ) time.

1 Open the Configuration Parameters dialog from the Simulation menu of

your model window.

2 On the Data Import/Export node, in the Save options area, change the

Output options pull-down menu entry to

.

only

3 Use the Output times field on the right to specify explicitly how often

Simulink should capture the simulation output. In this field, enter a vector

ofsampletimes.Thesampletimerangemustbethesameasorliewithin

the Start time and Stop time range of the Simulation time area in th e

Solver node of Configuration Parameters.

Produce specified output

2-26

If you want a uniform output sampling, use the

linspace command to specify

thetimerangeandnumberofsamplepoints:

linspace(start-time, end-time, number-of-points)

Forexample,tosample200pointsfrom0to10seconds:

1 Open Configuration Parameters f rom the Simulation menu.

2 Locate Output options in the Data Import/Export node. Change the

pull-downmenuto

3 Enter linspace(0,10,200) in the Output times field. Click Apply or OK.

Produce specified output o nly.

Tip This approach does change two distinct model features at once. Changing

the visualization sample time by itself (preceding) has the advantage of

letting y ou specify the model output sample time separately.

See the Simulink documentation for more about model output sample time.

Controlling Animation

Speeding Up the A

As the simulatio

make the animati

n animates the bo dies’ motions, it might slow down. You can

on computationally less demanding with these measures.

nimation in Real Time

Skipping Frames

By default, th

fixed number o

From the Simu

Animation Sp

frames per u

default is

Using fewe

simulatio

e animation displays every updated frame. But you can skip a

f frames between displayed frames.

lation menu, select Control Animation Speed.Inthe

eed Control Parameters dialog, change the Number of skipped

pdate field to a positive integer to specify this number. The

.

0

r sample points leads to a more disjointed animation, but a faster

n and a smaller recorded animation file.

Turning Off Visualization Features

You can sp

• Body cen

• Body coo

eed up the animation if you turn off one or both of these symbols:

ters of gravity (CGs)

rdinate systems (CSs)

The pre

page 2-

You ca

displ

the Vi

ceding section, “Controlling Body and Body Component Display” on

6, explains how to control their display.

nalsospeeduptheanimationbyturning off the simulation time

ay. See the preceding section, “Controlling and Timing Simulation from

sualization Window” on page 2-21.

2-27

2 Getting Started with the Visualization Window

Recording Animation

In this section...

“About Recording” on page 2-28

“How Recording Works” on page 2-28

“Recording Animations” on page 2-28

“Compressing Animation Recordings” on page 2-30

“Controlling the Size of the Recorded Animation” on page 2-31

“Playing Recordings of Animation” on page 2-31

About Recording

As the SimMechanics visualization window displays the body motion, you can

capture what you see as a recording and save it. This section explains how

to record animations. See the preceding section, “Control li ng Animation” on

page 2-23, for more about animation.

2-28

How Recording Works

If you record an animation, the recording captures e ach updated, displayed

simulation scene as a frame.

Whatever you see in the animated display window, is what the recording

captures, as closely as it can within the limitations of the format.

Recording Animations

When you record an animation from the window, it is stored as a file on your

system in Audio Video Interleave (AVI) format.

Caution Recording an animation overwrites any existing file with the same

name as the AVI file in the same folder. The AVI file write fails if a file of the

same name that is locked by another application exis ts in the same folder.

Recording Animation

Activating and Controlling Animation Recording

• You can activate animation recording by clicking the Store Animation in

AVI File button on the toolbar. The default is deactivated.

If you activate, the AVI File L ocation file browser opens, as discussed next.

• You control recording settings using the Simulation menu.

Specifying the Name and folder of the Animation File

You can specify a location and name for your AVI file recording by selecting

Choose AVI File Location from the Simulation menu. If you activate

recording, an AVI File Location file browser opens and requires you to select a

location and specify an AVI name. The default AVI name for a model called

modelname.mdl is modelname.avi, bu t you can change this default name.

Click Save to complete the AVI file specification.

When you activate recording, this AVI file name appears in the bottom middle

of the full visualization window, below the display, in the status bar.

If y ou cancel the file browser, the recording is canceled as well.

2-29

2 Getting Started with the Visualization Window

2-30

How MAT

The simulation first records a MATLAB movie by capturing the display at

every visualization sample time step. Then, in the termination phase of

your simulation, it converts this movie to AVI format and stores it in the

AVI file. A small AVI Conversion window opens to indicate that conversion

and storage are complete and to display the path of the AVI file. Click OK

to close this prompt.

LAB Records the Animation

Compressing Animation Recordings

You can reduce the size of your AVI file by compressing it. Select Compress

AVI File to activate this feature. The default is active.

Recording Animation

Support Restrictions for Recording Compression

AVI compression is available only on the Windows®platform. MATLAB uses

the Indeo 5 compression algorithm. You must have the corresponding video

codec installed to

• Compress an animation while recording.

• Decompress and play back a compressed animation recording.

Check your operating system configuration for installed video codecs.

Caution YoumusthavetheIndeo5videocodecinstalledtocompressan

animation recording. If you do not have this codec installed, a nimation and

recording proceed, but with compression deactivated.

Controlling the Size of the Recorded Animation

Any technique that reduces the number of visualization samplings and

updates reduces the total stream of animated frames and the size of the

recorded file. See “Controlling Animation” on page 2-23.

Tip If MATLAB runs out of memory while recording an animation, you will

receive a warning. The simulation continues until completion, but recording

is truncated at the simulation time when memory was exhausted.

Useoneofthetechniquesdiscussedtoreducethetotalstreamofanimated

frames and attempt the recording again. The simplest technique is to skip

frames.

Playing Recordings of Animation

You need an AVI-compatible video player to view the recorded file. You can

use the internal MATLAB movie viewer or an external video player.

2-31

2 Getting Started with the Visualization Window

Caution You must have the Indeo 5 video codec installed to decompress and

play back a compressed animation recording.

Matching Playback Speed to Simulation Speed

Your computer will play back an AVI animation recording at 15 frames per

second of real (clock) time, regardless of the simulation speed or visualization

sample time during recording.

To guarantee that the animation playback show the simulation in real (clock)

time, before recording, set:

• The model output sample time to be 1/15th of a second.

• The visualization sample time to be equal to or less than the model output

sample time.

See “Changing How the Animation Is Updated” on page 2-25 for more about

sample times.

2-32

Visualization Menus and Their Controls

In this section...

“About the SimMechanics Visualization Window Menus” on page 2-33

“View Menu” on page 2-34

“Simulation M enu” on page 2-35

“Model Menu” on page 2-38

“Help Menu” on page 2-39

About the SimMechanics Visualization Window Menus

The m enus of the visualization window group similar functions and contain

all visualization functions.

Some menu items have a default setting. Others do not, as indicated by a “—”

entry for the default in the menu tables following.

Visualization Menus and Their Controls

Menu

Group Featur

View

ation

Simul

Model

Help

rsistent Settings Versus Immediate Action

Pe

In most situations, all menu items are enabled in the sense that you can

activate it. In some conditions, a menu item can be disabled, and you cannot

activate it.

Change

view;

Contr

anima

Chan

comm

Get

eorFunction

camera viewpoint or frame; manipulate camera

change background

ol simulation; change dynamic camera response to

tion; record animations

ge dis play of body components and geometries; change

on visualization-model features

visualization help

2-33

2 Getting Started with the Visualization Window

Some menu items control a persistent setting and switch between active and

not active; for example, Enable Model Highlighting. By selecting the item,

you either activate it, and a check mark appears; or you deactivate it, and

the check m ark disappears.

Othermenuitems,whenyouselectthem,insteadtriggeranimmediate

action, for example, Simulation > Start.

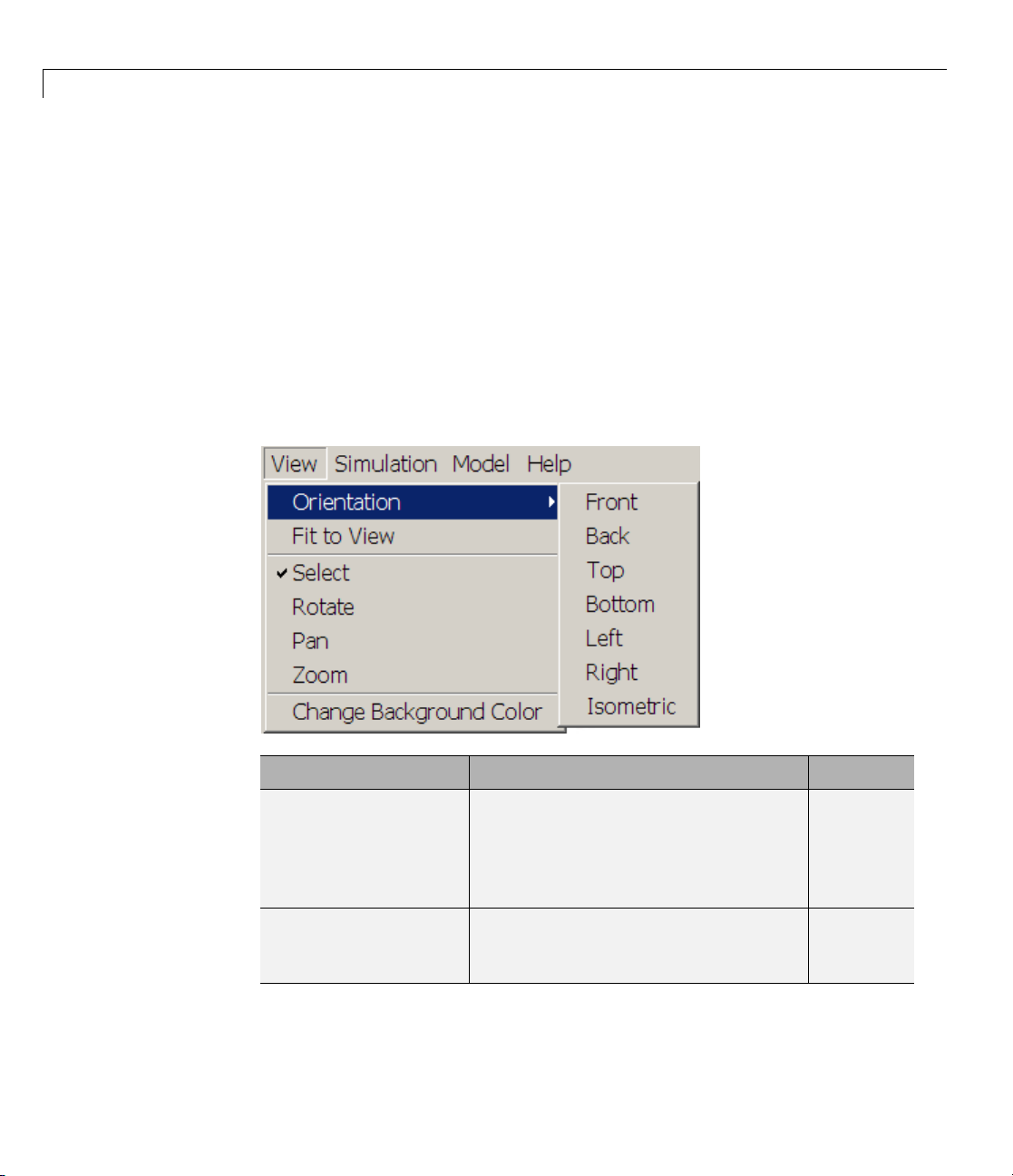

View Menu

This menu allows you to control two distinct visualization features, the

camera viewpoint and frame and the background color.

2-34

Menu Item

Orientation

submenu:

Front, Back, Top,

Bottom, Left, Right,

Isometric

Fit to View

Function

Set camera viewpoint.

Onechoiceisalwaysactive,andthe

choices are mutually exclusive.

Resize camera field to closely fit the

bodies as viewed.

Applies immediately.

Default

Front

—

Visualization Menus and Their Controls

Menu Item

Current Tool:

Select Select objects in the display window. Selected

Rotate

Pan

Zoom

Change

Background Color

Function

Enable mo us e point-and-click tool.

The choices are mutually exclusive,

and can all be unselected

(deactivated).

Rotate camera viewpoint. Unselected

Pan camera field laterally and

vertically.

Zoom in and out of camera field.

Open color palette to choose

background color.

Default

—

Unselected

Unselected

—

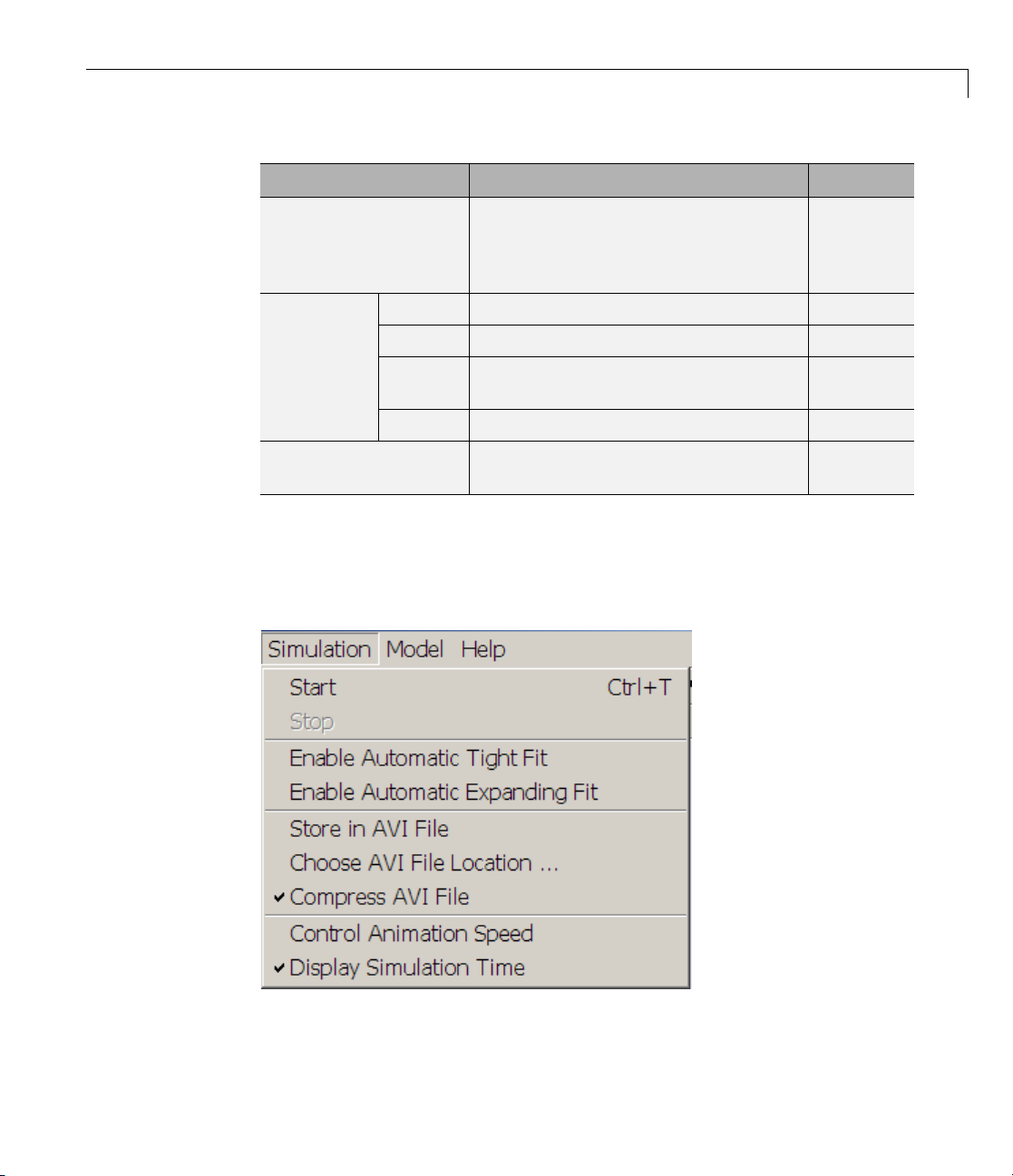

Simulation Menu

Thismenuallowsyoutocontrolthesimulation,thedynamiccamerafield,

and the recording of the animation.

2-35

2 Getting Started with the Visualization Window

Menu Item

Simulation

start,

pause,

and stop

Dynamic camera field Enable adaptive dynamic cam era field

Start Start simulation. Appears and enabled

Pause

Stop Stop simulation. Enabled only when

Enable

Automatic

Tight Fit

Enable

Automatic

Expanding

Fit

Function

only w hen simulation is stopped.

Applies immediately. Keyboard equivalent

is Ctrl+T.

Pause simulation. Appears and enabled

only w hen simulation is running.

Applies immediately.

simulation is running.

Applies immediately. Keyboard equivalent

is Ctrl+T.

during animation.

The choices are mutually exclusive, and

can all be unselected (deactivated).

Enable automatic resizing and zooming

of camera field to keep moving bodies in

fit-to-view field at all simulation times.

Virtual camera moves with overall model

motion with respect to World.

Enable automatic expansion of camera

field to keep moving bodies in field at all

simulation times.

Virtual camera remains at rest w ith

respect to W orld.

Default

—

—

—

Fixed camera field,

viewpoint, and zoom;

camera at rest in

World.

Unselected

Unselected

Store in AVI File Record and save animation in AVI file.

Choose AVI File

Location

Compress AVI File Apply compression to saved AVI recording

Choose nondefault location for AVI file. Default location

of animation.

2-36

Unselected

for saved AVI file

is current working

MATLAB folder.

Selected

Visualization Menus and Their Controls

Menu Item

Control Animation

Speed

Display Simulation Time Show simulation time in lower-right corner

Function

Opens Animation speed control parameters

dialog.

Applies immediately.

of full w indow.

Start–Pause–Stop Menu During Simulation

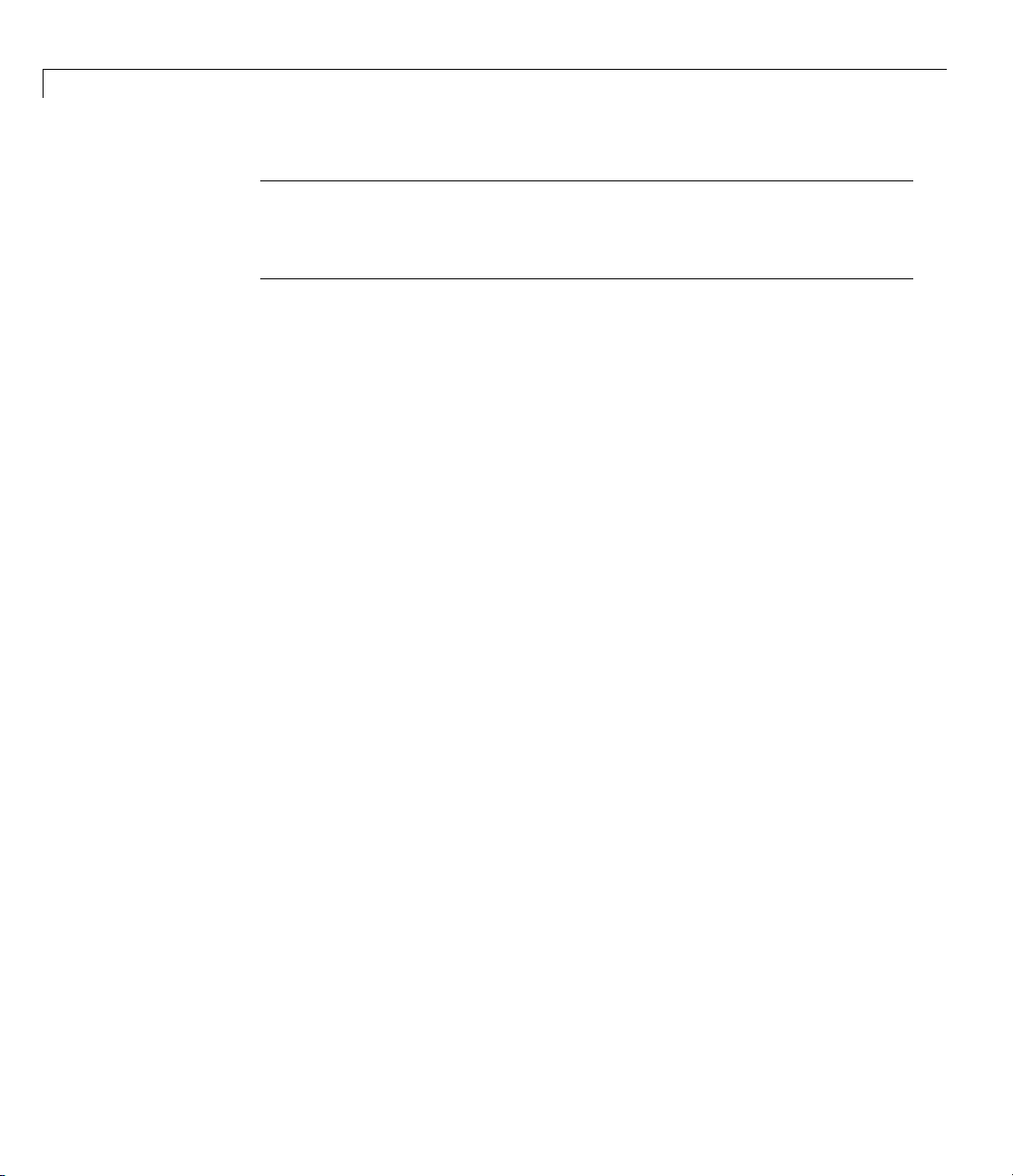

During simulation, the start–pause–stop part of the Simulation menu looks

like this:

Default

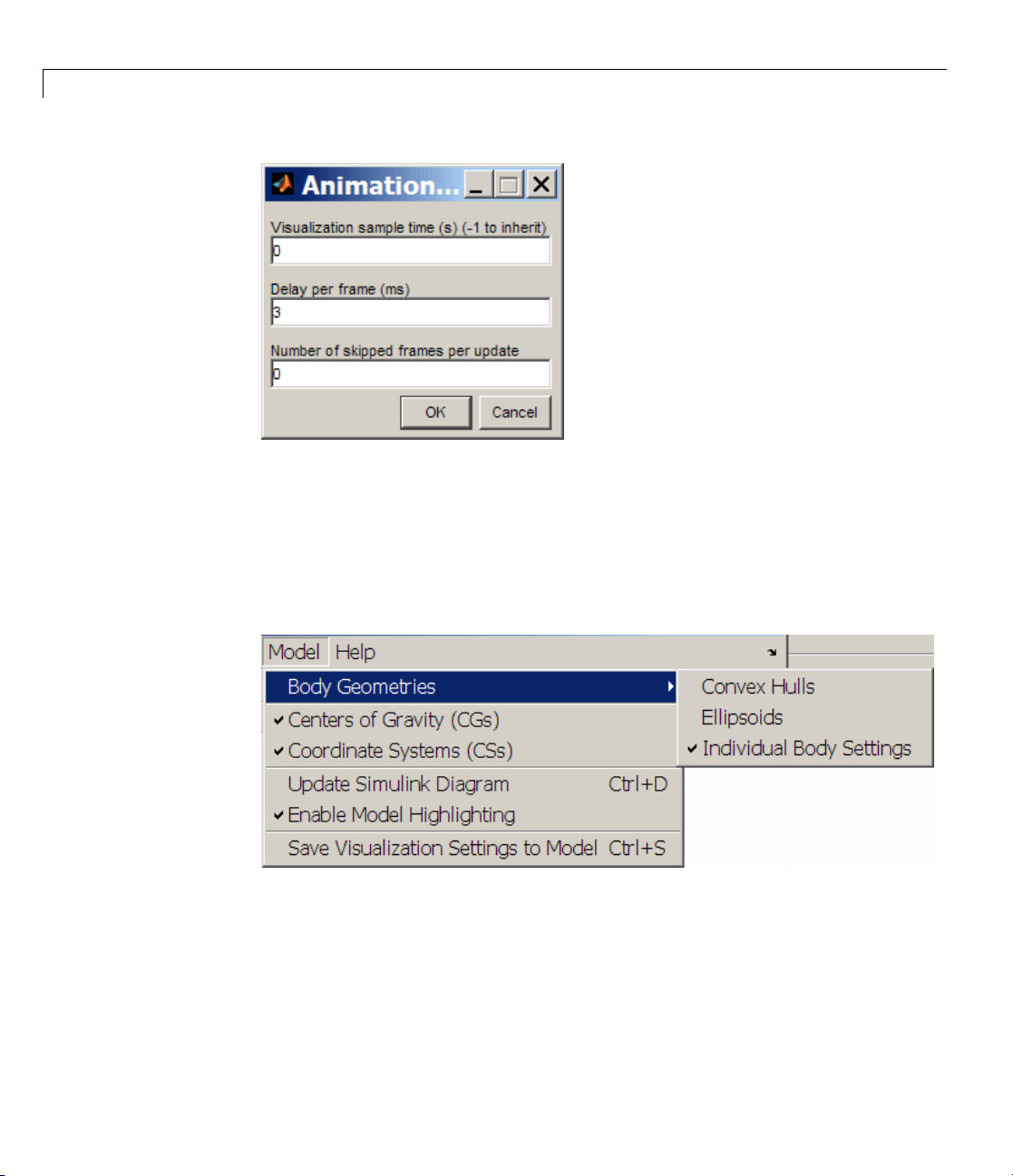

Visualization

sample time (s)

Delay per

frame (ms)

Number

of skipped

frames per

update

Selected

0

3

0

Animation Speed Control Parameters Dialog

The Control Animation Speed m enu item opens the Animation Speed

Control Parameters dialog:

2-37

2 Getting Started with the Visualization Window

See “Controlling Animation” on page 2-23.

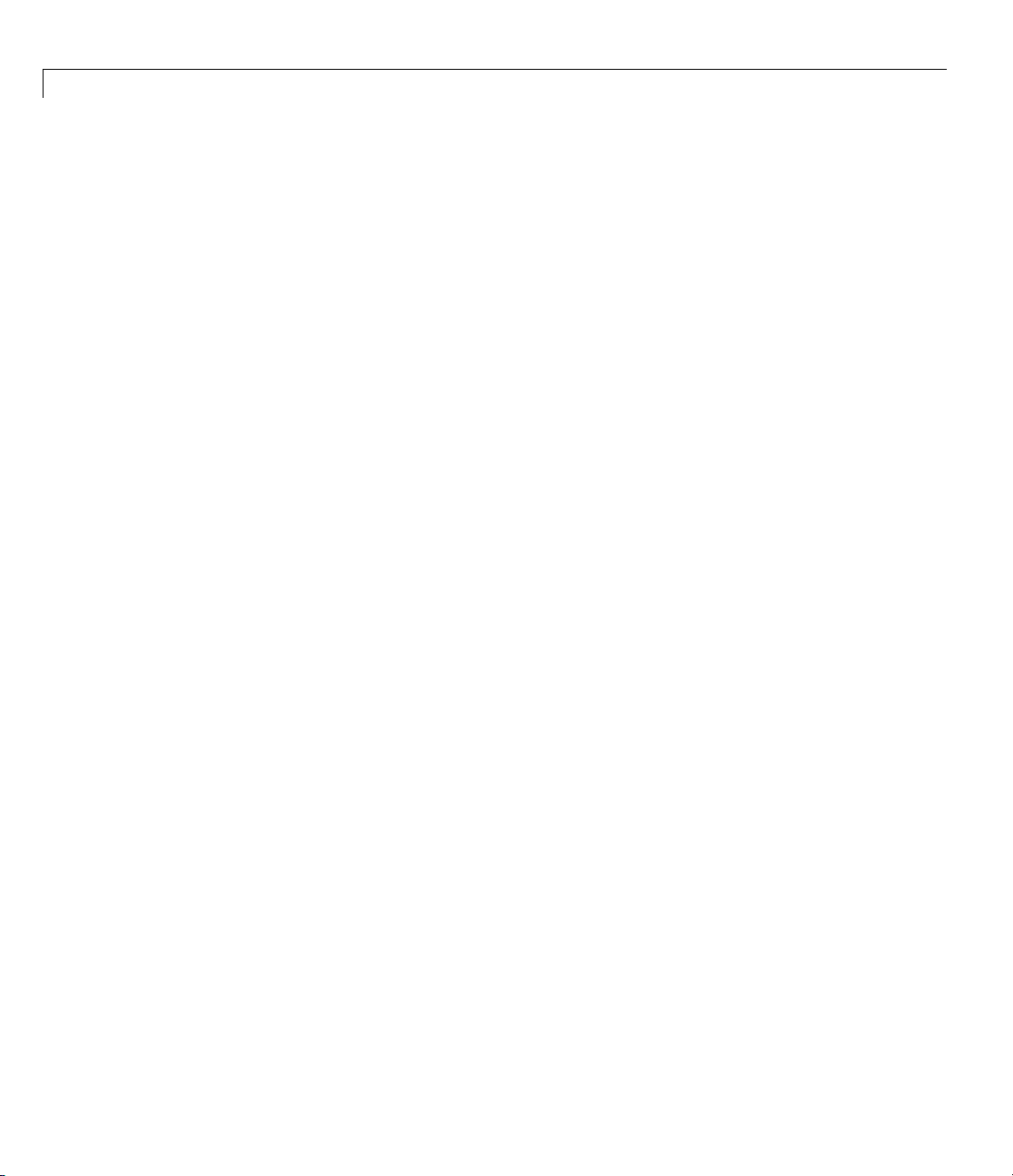

Model Menu

This menu allows you to control the display of body geometries and body

components, as well as communicate from the visualization window to the

model.

2-38

Visualization Menus and Their Controls

Menu Item

Body Geometries

submenu:

Convex Hulls

Ellipsoids Visualize all bodies in window as equivalent ellipsoids. Unselected

Individual

Body Setting

Centers of G

(CGs)

Coordinat

(CSs)

Update Si

Diagram

Enable Model

Highlighting

Save Visualization

Settings to Model

ravity

eSystems

mulink

Function

Set geo metries of visualized bodies.

One choice is always active, and the choices are

mutually exclusive.

Visualize all bodies in window as convex hulls. Unselected

Visualize al

s

respective B

Display cen

Display all Body coordinate systems attached to all

visualized bodies.

Apply Upd

immedia

Keyboar

Edit > Up

Enable automatic Body block h ig hlighting when

visualized body is selected in display window.

Save current state of visualization window controls to

model. Applies immediately.

(You need to save the m odel itself to save the settings

permanently.)

l bodies in window according to their

ody block visualization settings.

ters of gravity of all visualized bodies.

ate Diagram command to m odel. Applies

tely.

dequivalentisCtrl+D. Model equivalent is

date Diagram.

Default

—

Selected

Selected

Selected

—

Select

—

ed

Help Menu

This menu allows you to get online help for the visualization window.

Selecting Open Visualization Help immediately opens the Help browser to

the SimMechanics visualization documentation.

2-39

2 Getting Started with the Visualization Window

2-40

Customizing Visualization and Animation

You can customize the colors and geometries of visualized bodies in

the SimMechanics visualization window. Choice of colors is intrinsic to

visualization. Specifying a custom body geometry requires an external

graphics file for each custom ized body.

As an alternative to the visualization window, you can also visualize your

mechanical system with virtual reality.

3

• “About Custom SimMechanics Visualization” on page 3-2

• “Customizing Visualized Body Colors” on page 3-4

• “Customizing Visualized Body Geometrie s ” on page 3-7

• “Visualizing with a Virtual Reality Client” on page 3-13

3 Custom izing Visualization and Animation

About Custom SimMechanics Visualization

In this section...

“Customizing Visualization Settings” on page 3-2

“Creating an External Virtual Reality Client” on page 3-3

Customizing Visualization Settings

You can customize the way that SimMechanics visualization displays bodies,

in terms of their colors and geometry. The geometry is composed of the body’s

size and shape.

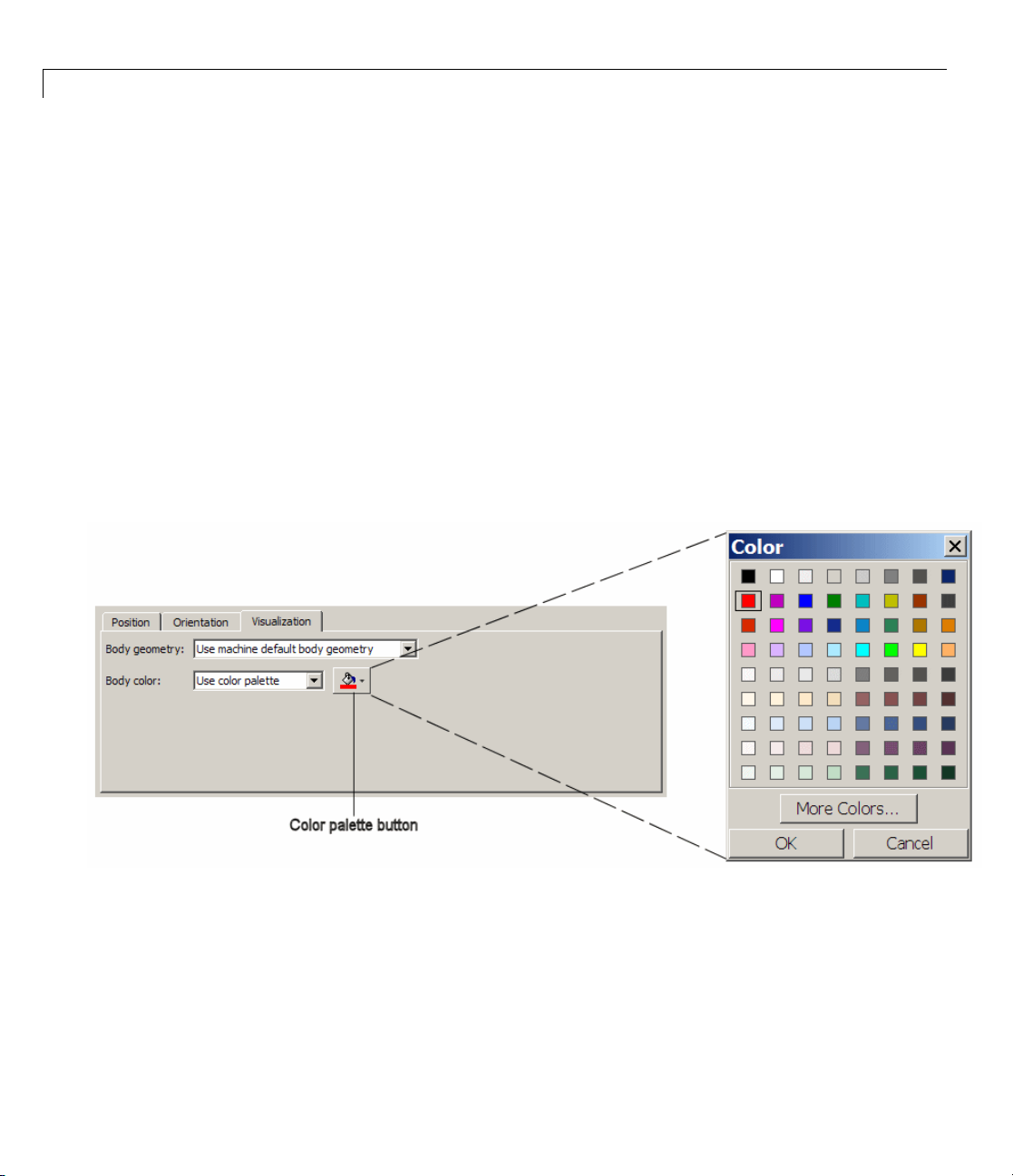

• You can adjust the body color on a model- or machine-wide basis, or on an

individual body basis.

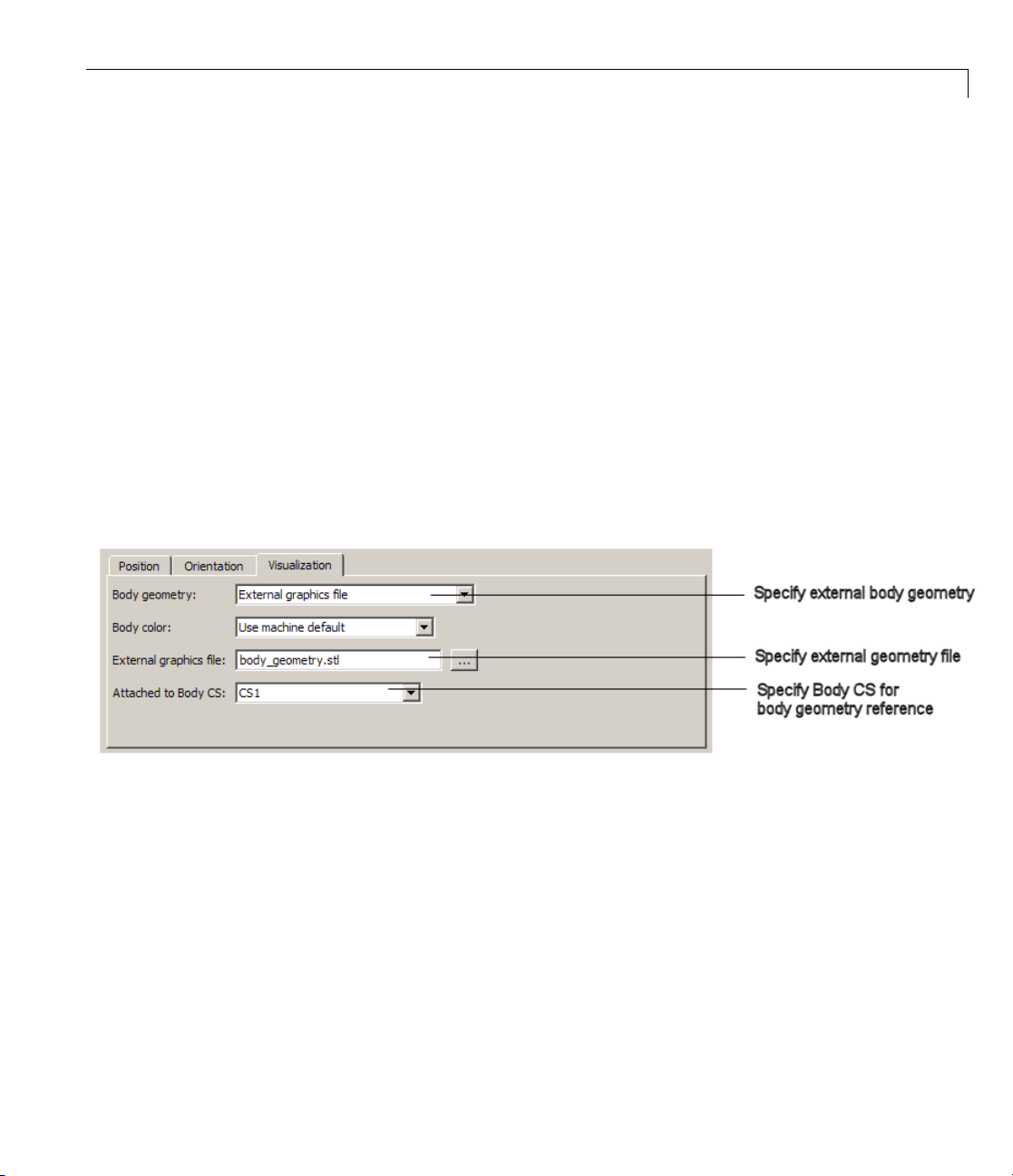

• With an external graphics file referenced by a Body block, the visualization

window can visualize the body with whatever shape the graphics file

specifies.

3-2

Starting visualization is discussed in

• Chapter 1, “Introducing Visualization and Animation”

• The SimMechanics User’s Guide

Model- and Machine-Wide Body Color and Geometry Controls

The model–machine–body hierarchy controls the model- and machine-defau lt

body colors and geometries. See “Hierarchy of Body, Machine, and Model

Visualization Settings” on page 1-11.