Page 1

SimHydraulics

®

Release Notes

Page 2

How to Contact The MathWorks

www.mathworks.

comp.soft-sys.matlab Newsgroup

www.mathworks.com/contact_TS.html Technical Support

suggest@mathworks.com Product enhancement suggestions

bugs@mathwo

doc@mathworks.com Documentation error reports

service@mathworks.com Order status, license renewals, passcodes

info@mathwo

com

rks.com

rks.com

Web

Bug reports

Sales, prici

ng, and general information

508-647-7000 (Phone)

508-647-7001 (Fax)

The MathWorks, Inc.

3 Apple Hill Drive

Natick, MA 01760-2098

For contact information about worldwide offices, see the MathWorks Web site.

®

SimHydraulics

© COPYRIGHT 2006–20 10 by The MathWorks, Inc.

The software described in this document is furnished under a license agreement. The software may be used

or copied only under the terms of the license agreement. No part of this manual may be photocopied or

reproduced in any form without prior written consent from The MathW orks, Inc.

FEDERAL ACQUISITION: This provision applies to all acquisitions of the Program and Documentation

by, for, or through the federal government of the United States. By accepting delivery of the Program

or Documentation, the government hereby agrees that this software or documentation qualifies as

commercial computer software or commercial computer software documentation as such terms are used

or defined in FAR 12.212, DFARS Part 227.72, and DFARS 252.227-7014. Accordingly, the terms and

conditions of this Agreement and only those rights specified in this Agreement, shall pertain to and govern

theuse,modification,reproduction,release,performance,display,anddisclosureoftheProgramand

Documentation by the federal government (or other entity acquiring for or through the federal government)

and shall supersede any conflicting contractual terms or conditions. If this License fails to meet the

government’s needs or is inconsistent in any respect with federal procurement law, the government agrees

to return the Program and Docu mentation, unused, to The MathWorks, Inc.

Trademarks

MATLAB and Simulink are registered trademarks of The MathWorks, Inc. See

www.mathworks.com/trademarks for a list of additional trademarks. Other product or brand

names may be trademarks or registered trademarks of their respective holders.

Patents

The MathWorks products are protected by one or more U.S. patents. Please see

www.mathworks.com/patents for more information.

Release Notes

Page 3

Summary by Version ............................... 1

Contents

Version 1.7 (R2010a) SimHydraulics Software

Version 1.6 (R2009b) SimHydraulics Software

Version 1.5 (R2009a) SimHydraulics Software

Version 1.4 (R2008b) SimHydraulics Software

Version 1.3 (R2008a) SimHydraulics Software

Version 1.2.1 (R2007b) SimHydraulics Software

Version 1.2 (R2007a) SimHydraulics Software

Version 1.1 (R2006b) SimHydraulics Software

Version 1.0 (R2006a+) SimHydraulics Software

Compatibility Summary for S imHydraulics

Software

........................................ 31

........ 4

........ 9

........ 11

........ 13

........ 16

...... 19

........ 20

........ 26

....... 29

iii

Page 4

iv Contents

Page 5

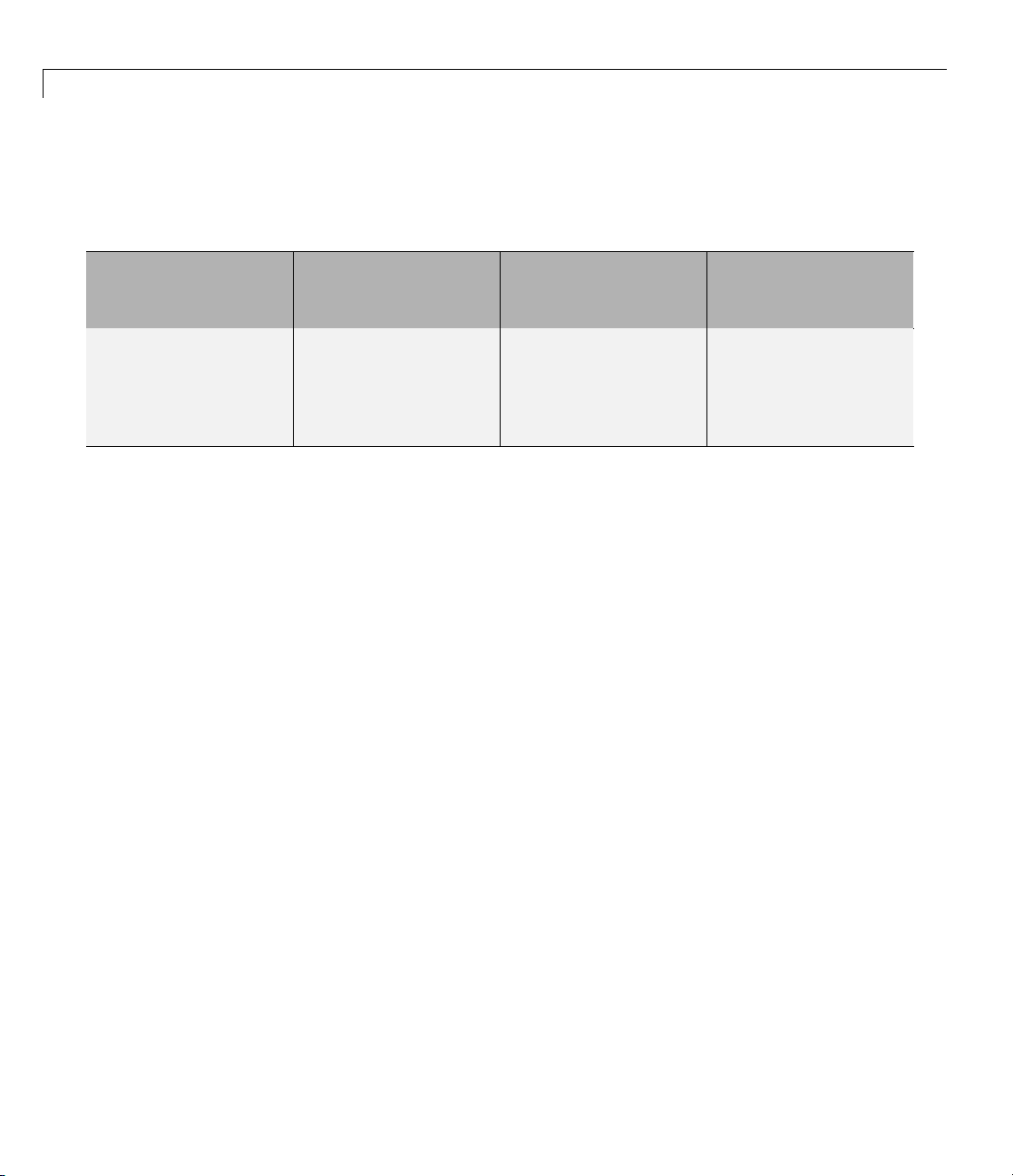

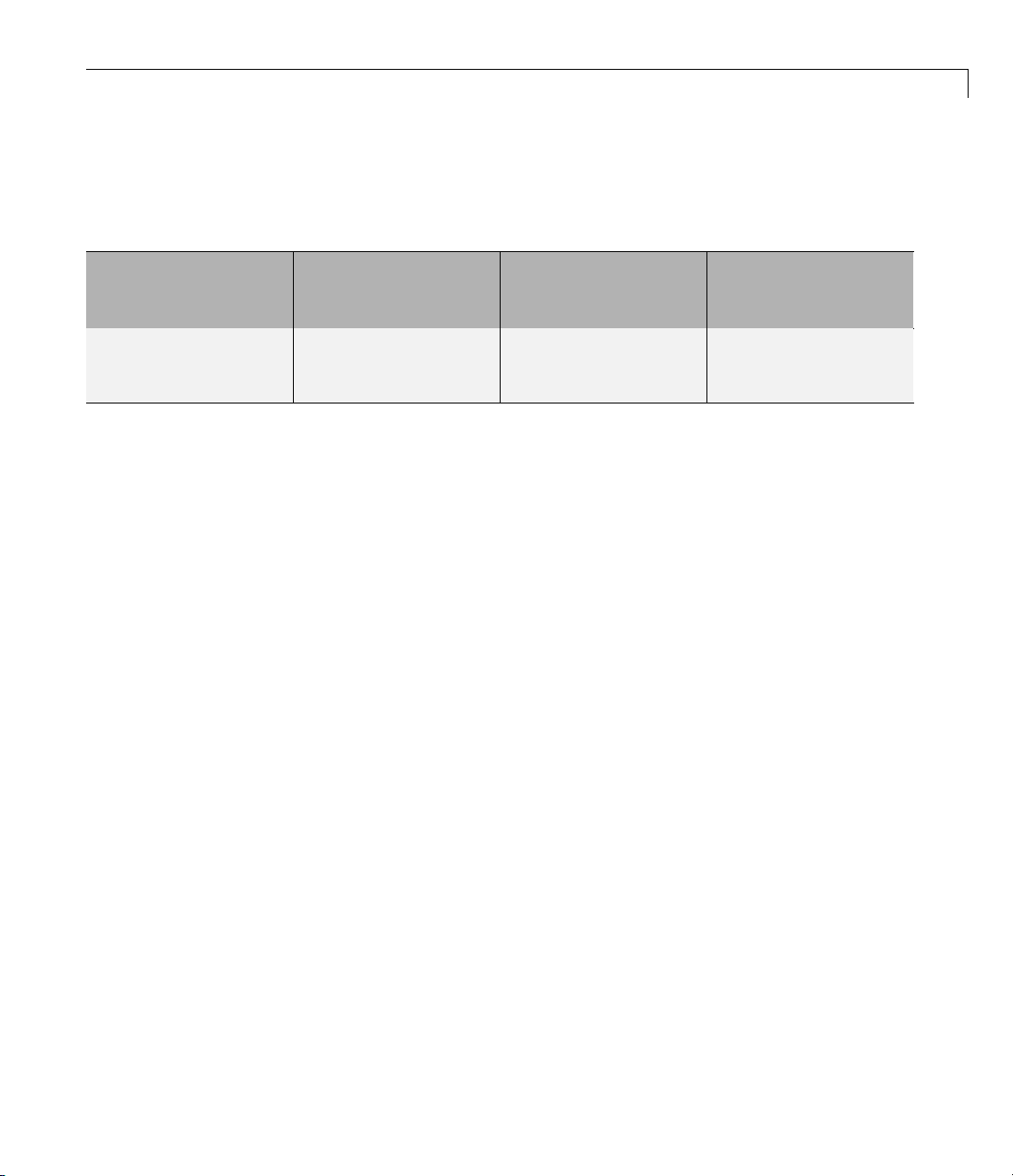

SummarybyVersion

This table provides quick access to what’s new in each version. For

clarification, see “Using Release Notes” on page 2 .

SimHydraulics®Release Notes

Version

(Release)

Latest Versi

V1.7 (R2010a

V1.6 (R2009b)

V1.5 (R2009a)

V1.4 (R2

V1.3 (R2008a)

V1.2.1 (R2007b)

on

)

008b)

New Features

and Changes

Yes

Details

Yes

Details

Yes

Details

Yes

Details

Yes

Details

Yes

ils

Deta

Version

Compatibilit

Consideratio

Yes

Summary

No Bug Reports

No Bug Repor

No Bug Reports

No Bug Reports

No Bug R

y

ns

Fixed Bugs

and Known

Problems

Bug Reports

Includes fix

Includes fixes

ts

Include

Includes fixes

Includes fixes

Incl

sfixes

eports

udes fixes

es

Related

Documentation

at Web Site

Printable R elease

Notes: PDF

Current product

documentation

No

No

No

No

No

2 (R2007a)

V1.

Yes

Details

Yes

Summary

Bug Reports

Includes fixes

No

1

Page 6

SimHydraulics®Release Notes

Version

(Release)

V1.1 (R2006b)

V1.0 (R2006a+)

New Features

and Changes

Yes

Details

Yes

Details

Version

Compatibility

Considerations

No Bug Reports

Not applicable

Fixed Bugs

and Known

Problems

Includes fixes

Bug Reports No

Related

Documentation

at Web Site

No

Using Release Notes

Use release notes when upgrading to a newer version to learn about:

• New features

• Changes

• Potential impact on your existing files and practices

Review the release notes for other MathWorks™ products required for this

product (for example, MATLAB

bugs, or compatibility considerations in other products impact you.

®

or Simulink®). Determine if enhancements,

If you are upgrading from a software version other than the m ost recent one,

review the current release notes and all interim versions. For example, when

you upg rade from V1.0 to V1.2, review the release notes for V1.1 and V1.2.

What Is in the Release Notes

New Features and Changes

• New functionality

• Changes to existing functionality

2

Page 7

SummarybyVersion

Version Compatibility Con si derations

When a new feature or change introduces a reported incompatibility between

versions, the Compatibility Considerations subsection explains the

impact.

Compatibility issues reported after the product release appear under Bug

Reports at The MathWorks™ Web site. Bug fixes can sometimes result

in incompatibilities, so review the fixed bugs in Bug Reports for any

compatibility impact.

Fixed Bugs and Known Problems

The MathWorks offers a user-searchable Bug Reports database so you can

view Bug Reports. The development team updates this database at release

time and as more information becomes available. Bug Reports include

provisions for any known workarounds or file replacem ents. Information is

available for bugs existing in or fixed in Release 14SP2 or later. Information

is not avail able for all bugs in earlier releases.

Access Bug Reports using y our MathWorks Account.

3

Page 8

SimHydraulics®Release Notes

Version 1.7 (R2010a) SimHydraulics Software

This table summarizes what’s new in Version 1.7 (R2010a):

New Features and

Changes

Yes

Details below

Version

Compatibility

Considerations

Yes—Details labeled

as Compatibility

Considerations,

below. See also

Summary.

New features and changes introduced in this version are

• “Simplified Blocks for Real-Time Simulation” on page 4

• “Low-Pressure Blocks with Variable Elevations” on page 5

• “Cartridge Valve Modeling Blocks ” on page 5

• “Lubrication System Modeling Blocks” on page 6

• “Centrifugal Pump Enhancement” on page 6

• “Initial Piston Position in the Single-Acting Hydraulic Cylinder Block”

on page 6

• “Changes to SimHydraulics Demos” on page 7

Fixed Bugs an d

Known Problems

Bug Reports

Includes fixes

Related

Documentation at

Web Site

Printable Release

Notes: PDF

Current product

documentation

Simplified Blocks for Real-Time Simulation

The following new blocks implement simplified models that reproduce only

basic functionality in exchange for better numerical efficiency:

• Single-Acting Hydraulic Cylinder (Simple) block represents a simplified

version of a single-acting hydraulic cylinder. The model assumes fluid

compressibility, friction, and leakages to be negligible. The hard stops

areassumedtobefullyinelastic,toeliminateanypossibleoscillationsat

the end of the stroke.

• Double-Acting Hydraulic Cylinder (Simple) block represents a simplified

version of a double-acting hydraulic cylinder. The model assumes fluid

4

Page 9

Version 1.7 (R2010a) SimHydraulics®Software

compressibility, friction, and leakages to be negligible. The hard stops

areassumedtobefullyinelastic,toeliminateanypossibleoscillationsat

the end of the stroke.

• 4-Way Ideal Valve block represents a 4-way critically-centered valve. Initial

openings of all orifices are set to 0, which significantly simplifies the model.

• Valve Actuator block represents a simplified version of a valve actuator,

built as a first-order lag.

Use these blocks for real-time and HIL (hardware-in-the-loop) simulation, if

such simplifications are acceptable.

Low-Pressure Blocks with Variable Elevations

Additional blocks in the Low-Pressure Blocks library incorporate elevation

information and let you specify elevations as input signals, rather than as

block parameters:

• Resistive Pipe LP with Variable Elevation block represents a hydraulic

pipeline which accounts for friction losses and port elevations.

• Hydraulic Pipe LP with Variable Elevation block represents a hydraulic

pipeline with resistive, fluid compressibility, and elevation propertie s.

Use these blocks for low-pressure system simulation in which the pipe ends

change their positions with respect to the reference plane.

Cartridge Valve Modeling Blocks

Two new blocks extend the cartridge valve modeling capabilities:

• Cartridge Valve Insert with Conical S eat block represents an insert of a

hydraulic cartridge valve consisting of a poppet intera ctin g with the conical

seat.

• Hydraulic 4-Port Cartridge Valve Actuator block represents double-acting

hydraulic valve actuator driven by four pressures. Use this block as a pilot

actuator for cartridge valves, as well as pilot-operated pressure and control

valves, in applications where all the forces, except spring and pressure

forces, and flow consumption can be neglected.

5

Page 10

SimHydraulics®Release Notes

There are also additional parameters in the Hydraulic Cartridge Valve

Actuator block that account for initial conditions and dynamic properties of

themodel. Seetheblockreferencepagefordetails.

Lubrication System Modeling Blocks

The following blocks hav e been added to facilitate modeling lubrication

systems:

• Centrifugal Force in Rotating Cylinder block simulates centrifugal forces

• Rotating Pipe block models a hydraulic pipeline represented as a short bore

exerted by fluid on a piston if the cylinder rotates about its symmetry axis.

Such cylinders are used in control mechanisms of various friction clutches,

brakes, square-jaw positive clutches, dog clutches, and so on. No inertial

effects are considered in the model. In other words, the angular velocity is

assumed to be constant or changing at very low speed.

drilled through a shaft at some angle to its axis, or as a short pipe that

connects actuator or bearings, mounted on the shaft, with the channel

inside the shaft. Such connections are typical for lubrication systems and

for hydraulically-operated clutches and mechanisms. The shaft angular

velocity is assumed to be constant or changing at very low speed.

Centrifugal Pump Enhancement

The Centrifugal Pump block now contains additional parameters that let you

simulate operation at zero angular velocity. See the block reference page for

details.

Initial Piston Position in the Single-Acting Hydraulic

Cylinder Block

The Piston initial position parameter in the block dialog box has been

renamed to Initial distance between piston and cap, and the way it is

used in the block output has been changed.

In previous versions, the Piston initial position parameter let you specify

the distance that the piston is extended at the beginning of simulation by

setting the piston initial position to any point w ithin its stroke, but this value

was not included in calculating the rod displacement. In other words, the

6

Page 11

Version 1.7 (R2010a) SimHydraulics®Software

rod displacement output at the block’s physical signal port was with respect

to the initial piston position.

In the current version, the Initial distance between piston and cap

parameter value is included in calculating the rod displacement output by

the block:

x

= x0+ x

pst

p

where

x

pst

x

0

x

p

Rod displacement output by the physical signal port

Initial distance between piston and cap

Rod displacement with respect to its initial position

For details, see the block reference page.

Compatibility Considerations

The block output changes because of the ne w way it calculates rod

displacement. It used to start out at zero but now starts out at the initial

position. If you have used this block with nonzero initial position in your

models, the block output will differ by this value:

x

= x0+ x

new

where

x

new

x

old

x

0

old

Rod displacement output by the physical signal port in the current

version

Rod displacement output by the physical signal port in the

previous version

Piston initial position value

Changes to SimHydraulics Demos

The following demos have been added in Version 1.7:

7

Page 12

SimHydraulics®Release Notes

Demo Name

Diesel Engine In-Line Injection System

(

sh_diesel_engine_in_line_injection_system)

Fuel Supply System with Variable Elevation

(

sh_fuel_supply_system_with_variable_elevations)

Hydraulic Actuation System with Cartridge Valves

(

sh_actuation_system_cartridge_valve)

Hydraulic Closed-Loop Actuator with Fixed-Step

Integration

(

sh_hydraulic_closed_loop_actuator_fixed_step )

Description

Simulates an in-line multi-element

injection system. The objective of the

simulation is to investigate the entire

system operation.

Simulates a three-tank fuel supply

systemwheresidetanksperiodically

change elevations during the simulation

cycle.

Simulates a complex actuation system

equipped w ith cartridge valves.

Represents two versions of the

same closed-loop hydraulic actuator.

In the second version, standard

SimHydraulics

®

blocks are replaced

with their simplified versions and

the model is optimized for fixed-step

integration.

8

Page 13

Version 1.6 (R2009b) SimHydraulics®Software

Version 1.6 (R2009b) SimHydraulics Software

This table summarizes what’s new in Version 1.6 (R2009b):

New Features and

Changes

Yes

Details below

Version

Compatibility

Considerations

No Bug Reports

New features and changes introduced in this version are

• “Additional 4-Way and 6-Way Directional Valve Configurations” on page 9

• “Additional Low-Pressure Blocks” on page 9

• “New Ball Valve with Conical Seat Block” on page 10

Fixed Bugs an d

Known Problems

Includes fixes

Related

Documentation at

Web Site

No

Additional 4-Way and 6-Way Directional Valve

Configurations

Nine 4-way directional valve block s and one 6-way directio na l valve block

have been added to the Directional Valves library, and the original 4-Way

Directional Valve block has been modified, to enable additional valve

configurations. For more information, see “Modeling Directional Valves” in

the SimHydraulics User’s Guide, as well as individual block reference pages.

Additional Low-Pressure Blocks

The following blocks have been added to the Low-Pressure Blocks library:

• Variable Head Two-Arm Tank block represents a tank with constant

pressurization and volume-dependent fluid level. The tank has two

hydraulic p orts and a physical signal port, which exports the volume of

fluid in the tank.

• Variable Head Three-Arm Tank block represents a tank with constant

pressurization and volume-dependent fluid level. The tank has three

9

Page 14

SimHydraulics®Release Notes

Both blocks account for the fluid level change caused by the volume variation,

as well as for pressure loss in the connecting p ipes that can be caused by

a filter, fittings, or some other local resistance. You can specify pipeline

diameter, pressure loss coefficient, and elevation information for each

hydraulic port separately.

New Ball Valve with Co nical Seat Block

The new Ball Valve with Conical Seat block in the Flow Control Valves library

models a ball valve created by a spherical ball and a conical seat. The valve is

characterized by the ball d iameter, cone angle, and o r if ice diameter.

hydraulic p orts and a physical signal port, which exports the volume of

fluid in the tank.

10

Page 15

Version 1.5 (R2009a) SimHydraulics®Software

Version 1.5 (R2009a) SimHydraulics Software

This table summarizes what’s new in Version 1.5 (R2009a):

New Features and

Changes

Yes

Details below

Version

Compatibility

Considerations

No Bug Reports

New features and changes introduced in this version are

• “New Low-Pressure Blocks Library” on page 11

• “Changes to SimHydraulics Demos” on page 12

Fixed Bugs an d

Known Problems

Includes fixes

Related

Documentation at

Web Site

No

New Low-Pressure Blocks Library

The Low-Pressure Blocks library, added in this release, contains five new

blocks that incorporate elevation information:

• Constant Head Tank block represents a tank where pressurization and

fluid level remain constant regardless of vo lume change. T h e block

accounts for the fluid level elevation with respect to the tank bottom, as

well as for pressure loss in the connecting pipe that can be caused by a

filter, fittings, or some other local resistance.

• Variable Head Tank block represents a tank with constant pressurization

and volume-dependent fluid level. The block accounts for the fluid level

change caused by the volume variation, as well as for pressure loss in

the connecting pipe that can be caused by a filter, fittings, or some other

local resistance.

• Resistive Pipe L P block represents a hydraulic pipeline which accounts for

friction losses and port elevations.

• Hydraulic Pipe LP block repre s en ts a hydraulic pipeline with resistive,

fluid compressibility, and elevation properties.

• Segmented Pipe LP block represents a hydraulic pipeline with resistive,

fluid inertia, fluid compressibi lity, and elevation properties.

11

Page 16

SimHydraulics®Release Notes

These blocks enable additional applications, such as low-pressure fluid

transportation system simulation.

Changes to SimHydraulics Demos

The following demos have been added in Version 1.5:

Demo Name

Water Supply System

sh_water_supply_system)

(

Fluid Transportation System with Three Tanks

(

sh_three_tanks)

Description

The water supply system modeled in the demo

consists of three pumping stations located at

45, 25, and 30 m with respect to the reference

plane, respectively. All three stations are

expected to pump water in a tank located at 61

m. The objective of simulation is to determine

steady-state flow rates and pressures.

The demo illustrates a classical problem of

fluid transportation: to determine flow rates,

pressures, and fluid volumes in a system built

of three constant head tanks. The tanks are

located at dif ferent elevations and connected

with pipelines combined together in a common

node. The pipelines are simulated with the

Segmented Pipeline LP block, which accounts

for hydraulic losses, fluid inertia, and the head

due to different node elevations.

12

Page 17

Version 1.4 (R2008b) SimHydraulics®Software

Version 1.4 (R2008b) SimHydraulics Software

This table summarizes what’s new in Version 1.4 (R2008b):

New Features and

Changes

Yes

Details below

Version

Compatibility

Considerations

No Bug Reports

New features and changes introduced in this version are

• “Explicit Solvers Now Available for SimHydraulics Models” on page 13

• “New Variable-Displacement Hydraulic Machine Block” on page 13

• “Improved Usability of the 4-Way Directional Valve Block” on page 14

• “Changes to SimHydraulics Demos” on page 14

Fixed Bugs an d

Known Problems

Includes fixes

Related

Documentation at

Web Site

No

Explicit Solvers Now Available for SimHydraulics

Models

Using explicit solvers has been implemented for models that include

Simscape™ and SimHydraulics blocks. For more information, see “Working

with Solvers” in the Simscape documentation.

New Variable-Displacement Hydraulic Machine Block

The Variable-Displacement Hydraulic Machine block, able to work as a

pump or a motor, enables modeling variable-efficiency machines based on

manufacturer’s data sheets. The machine displacement is controlled by the

signal provided through the physical signal port C. The machine efficiency is

simulated by im pl em enting regime-dependable leakage and friction torque

based on the experimentally established correlations between the machine

efficiencies and pressure, angular velocity, and displacement.

13

Page 18

SimHydraulics®Release Notes

Improved Usability of the 4-Way Directional Valve

Block

The 4-Way Directional Valve block dialog box has been reorganized using tabs

to improve usability. Use the Initial openings tab to set all the initial orifice

openings. The Basic param eters tab contains the model parameterization

options and the corresponding parameters. The parameters themselves have

not changed.

Changes to SimHydraulics Demos

The following demos have been added in Version 1.4:

Demo Name

Hydraulic Drill-Ream Actuator

(

sh_drill_ream_actuator)

Front-Loader Actuation System

(

sh_front_loader_actuation_system)

Pipeline System with Centrifugal Pump

(

sh_pipeline_system_centrifugal_pump)

Description

The actuator is intended to drive a machine

tool working unit performing a sequence

of three technological operations: coarse

drilling, fine drilling, and reaming. The

actuator speed is controlled by one of three

pressure-compensated flow control valves

metering out return flow from the cylinder.

The selection of an appropriate flow control

is performed by directional valves that are

activated by a control unit.

The model shows a simplified version of an

actuation system consisting of the lift and tilt

cylinders. Each of the cylinders is controlled by

an open center, 5-way, 3-position directional

valve. The valves are connected in series

through their unloading branch in such a

way that the system pump is unloaded when

both command levers are in neutral position.

If either tilt or lift command is applied, the

unloading path is closed.

The demo represents a typical pipeline system

with the centrifugal pump. The system is

built of three manifolds connected with hoses.

The combination of valves installed inside

manifoldsallowsflowratetobedirected

14

Page 19

Version 1.4 (R2008b) SimHydraulics®Software

through different branches. The manifold

models account for local resistances, elbows,

and cylindrical channels.

Also, the Variable Volume Chamber Test Rig

(

sh_variable_chamber_test_rig) demo has been renamed to Variable

Volume Piston Chamber Test Rig, and all the Variable Volume Chamber

blocks in it have been replaced with Piston Chamber b locks.

15

Page 20

SimHydraulics®Release Notes

Version 1.3 (R2008a) SimHydraulics Software

This table summarizes what’s new in Version 1.3 (R2008a):

New Features and

Changes

Yes

Details below

Version

Compatibility

Considerations

No Bug Reports

New features and changes introduced in this version are

• “Trimming Now Available for SimHydraulics Models” on page 16

• “New Cartridge Valve Insert and Hydraulic Cartridge Valve Actuator

Blocks” on page 16

• “Additional Configurations for the Centrifugal Pump Block” on page 17

• “Additional Fluids Available in the Hy draulic Fluid Block” on page 17

Fixed Bugs an d

Known Problems

Includes fixes

Related

Documentation at

Web Site

No

Trimming Now Available for SimHydraulics Models

Finding and managing operating points by trimming has been implemented

for models that include Simscape and SimHydraulics blocks. Simulink

Control Design™ product is required for using this functionality. For more

information, see Trimming Simscape Models in the Simscape d ocumentation.

®

16

New Cartridge Valve Insert and Hydraulic Cartridge

Valve Actuator Blocks

Two new blocks facilitate modeling cartridge valves:

• Cartridge Valve Insert block in the Directional Valves library represents

an insert of a hydraulic cartridge valve consisting of a poppet interacting

with the sleeve seat. The poppet position is determined by pressures at

ports A , B, and X and force of the spring. This is a structural model based

on a Variable Orifice block and a Hydraulic Cartridge Valve Actuator

block, described below.

Page 21

Version 1.3 (R2008a) SimHydraulics®Software

• Hydraulic Cartridge Valve Actuator block in the Valve Actuators library

represents a double-acting hydraulic valve actuator driven by three

pressures. Use this block as a pilot actuator for cartridge valves, as well

as pilot-operated pressure and control valves in applications where a ll

the forces, except spring and pressure forces, and flow consumption can

be neglected.

Additional Configurations for the Centrifugal Pump

Block

The Centrifugal Pump block represents a centrifugal pump of any type as a

data-sheet-based model. Depending on data listed in the manufacturer’s

catalogs or data sheets for your particular pump, you can now choose one of

the following model parameterization options:

•

By approximating polynomial — Provide va lues for the polynomi al

coefficients. These values can be determined analytically or experimentally,

depending on the data available. This is the default method, equivalent to

the implementation available in the previous release.

•

By two 1D characteristi cs: P-Q and N-Q — Provide tabulated

data of pressure differential and brake power versus pump delivery

characteristics. The pressure differential and brake power are determined

by one-dime nsional t able lookup. You have a choice of three interpolation

methods and two extrapolation methods.

•

By two 2D characteristi cs: P-Q-W and N-Q-W — Provide tabulated

data of pressure differential and brake power versus pump delivery

characteristics at d ifferent angular velocities. The pressure differential and

brake pow er are determined by two-dimensional table lookup. You have a

choice of three interpolation methods and two extrapolation methods.

Additional Fluids Available in the Hydraulic Fluid

Block

The follow i ng predefined fluids have been added to the Hydraulic Fluid block:

•

ISO VG 22 (ESSO UNIVIS N 22)

• ISO VG 46 (ESSO UNIVIS N 46)

• Brake fluid DOT3

17

Page 22

SimHydraulics®Release Notes

• Brake fluid DOT4

• Brake fluid DOT5

• Water

See the block reference page for more information. The “Examples” section

shows how you can get information on the fluids and their properties.

18

Page 23

Version 1.2.1 (R2007b) SimHydraulics®Software

Version 1.2.1 (R2007b) Si mHydraulics Software

This table summarizes what’s new in Version 1.2.1 (R2007b):

New Features and

Changes

Yes

Details below

Version

Compatibility

Considerations

No Bug Reports

New features and changes introduced in this version are described here:

Fixed Bugs an d

Known Problems

Includes fixes

Related

Documentation at

Web Site

Printable Release

Notes: PDF

Current product

documentation

Code Generation Now Available for SimHydraulics

Models

Code generation has been implemented for models that include Simscape

and SimHydraulics blocks. For more information, see “Generating Code” in

theSimscapedocumentation.

19

Page 24

SimHydraulics®Release Notes

Version 1.2 (R2007a) SimHydraulics Software

This table summarizes what’s new in Version 1.2 (R2007a):

New Features and

Changes

Yes

Details below

Version

Compatibility

Considerations

Yes—Details labeled

as Compatibility

Considerations,

below. See also

Summary.

New features and changes introduced in this version are

• “SimHydraulics Now Requires Simscape” on page 20

• “Block Libraries Moved from SimHydraulics to Simscape” on page 20

• “Sharing Models Using the Simscape Editing Modes” on page 21

• “New SimHydraulics Blocks” on page 21

• “Initial Conditions Added for Certain Blocks” on page 21

• “Block Library Links Must Be Resolved” on page 22

• “Changes to SimHydraulics Demos” on page 23

Fixed Bugs an d

Known Problems

Bug Reports

Includes fixes

Related

Documentation at

Web Site

No

SimHydraulics Now Requires Simscape

SimHydraulics now depends on and requires Simscape, the platform for

all Physical Modeling products, which includes common Physical Modeling

utilities and block libraries.

20

Block Libraries Moved from SimHydraulics to

Simscape

The Foundation and Utilities block libraries that used to be included in

SimHydraulics (V1.0 and V1.1) are now part of Simscape produc t.

Page 25

Version 1.2 (R2007a) SimHydraulics®Software

Sharing Models U

When working wit

Simscape editin

• The Restricted

does not requi

parameters, b

• TheFullmoder

license. It a

New SimHydr

The new bloc

• Centrifug

• Single-Ac

• Double-A

• Hydrauli

• Hydraul

• Valve Hy

• Spool Or

ctingRotaryActuator

c Single-Acting Valve Actuator

ic Double-Acting Valve Actuator

draulic Force

ifice Hydraulic Force

h SimHydraulics models, you now have a selection of two

g modes that allow full o r restricted editing of models.

mode requires SimHydraulics software to be installed, but

re a license. It allows you change a limited set of model

ut not the blocks or connections, in a SimHydraulics model.

equires SimHydraulics software to be installed with a

llows you to change anything in a SimHydraulics model.

aulics Blocks

ks introduced in Version 1.2 are listed below:

al Pump

ting Rotary A ctuator

sing the Simscape Editing Modes

Initia

Severa

use in

Note t

(V1.0

comp

the b

• Gas-

• Spr

• Con

• Va

l Conditions Added for Certain Blocks

l blocks now have a parameter that specifies the initial condition for

computing the block’s initial state at the beginning of a simulation run.

hat some of these blocks, which used to be included in SimHydraulics

and V1.1), are now part of Simscape product. The following is a

lete list of blocks where you can specify an initial condition through

lock dialog box:

Charged Accumulator

ing-Loaded Accumulator

stant Volume Chamber

riable Volume Chamber

21

Page 26

SimHydraulics®Release Notes

• Fluid Inertia

• Inertia

• Mass

• PS Integrator

• Rotational Spring

• Translational Spring

For details, see the block reference pages.

Compatibility Considerations

In this version, there is a difference in the way the initial conditions are

computed, and as a result, the blocks that have an initial condition parameter

work differently than they used to in the previous version.

Block Library Links Must Be Resolved

All SimHydraulics blocks in your models must n ow have resolved block

library links. You can neither disable nor break these library links. This is a

global requirement of Simscape modeling environment. Consult the Simscape

documentation for further details.

22

Compatibility Considerations

If you have an existing Sim Hydraulics model with disabled or broken lin ks

from SimHydraulics blocks to the SimHydraulics block library, you must

restore all the broken block library links for your model to be valid.

If you have disabled or broken the SimHydraulics library link for blocks that

you have customized and want to keep these modified blocks in your model,

you must move these modified blocks to your own custom library or libraries,

then copy the block instances that you need to your model.

You must still restore the block link to its parent library, whether that parent

library is SimHydraulics or your own.

Page 27

Version 1.2 (R2007a) SimHydraulics®Software

Changes to SimHy

The following de

Demo Name

HydraulicActuatorwithTwo-Chamber

Snubbers

(

sh_actuator_with_2_chamber_snubbers)

Digital Hydraulic Actuator

(

sh_digital_hydraulic_actuator)

mos have been added in Version 1.2:

draulics Demos

Description

The reciprocal actuator demonstrated in this

model is equipped with snubbers (cushions) on

both sides of the cylinder.

The d ig ita l hydraulic actuator consists of three

double-acting cylinders mounted in the same

shell and interconnected through the hard

stops.

HydraulicActuatorwithLoad-Sensing

Variable-Displacement Pump

(

sh_hydraulic_actuator_load_sensing_pump)

The circuit demonstrates usage of a

load-sensing and pressure-limiting unit in a

conventional reciprocal system with variable

load on the forward stroke.

HydraulicActuatorwithTelescopicCylinder

(

sh_hydraulic_actuator_telescopic_cylinder)

The actuator is built around a telescopic

hydraulic cylinder, which is equipped with

three rods interacting with each other through

hard stops.

Closed-Circuit Reciprocal Actuator

(

sh_hydraulic_closed_circuit_reciprocal_actuator)

The dem

rohydraulic actuator driven by a

elect

ble-velocity electrical motor.

varia

o illustrates a closed-circuit

r-Assisted Steering Mechanism

Powe

hydraulic_power_assisted_steering

(

sh_

The m

)

powe

all i

raulic System with Servo-Valve

Hyd

_hydraulic_system_with_servo_valve

(

sh

The

)

ser

val

am

draulic Transmission with Secondary

Hy

ntrol

Co

sh_hydraulic_transmission_secondary_control)

(

ydrostatic Transmission with Shuttle Valve

H

(

sh_hydrostatic_transmission_shuttle_valve)

Th

se

w

The circuit demonstrates a hydrostatic

transmission with a shuttle valve in the control

unit.

odel represents a simplified version of a

r-assisted steering mechanism showing

ts major parts.

demo represents the model of a two-stage

vo-valve with a 4-way, 3-position spool

ve in the power stage and a flapper-nozzle

plifier in th e pilot stage.

e system demonstrates usage of the so-called

condary control in hydrostatic transmissions

ith a variable-displacement motor.

23

Page 28

SimHydraulics®Release Notes

Hydraulic Circuit with Load-Sensing Velocity

Control

(

sh_load_sensing_velocity_control)

Oscillating Hydraulic Mechanism

(

sh_oscillating_hydraulic_mechanism)

Reciprocal Actuator with Counterbalance

Valves

(

sh_reciprocal_actuator_cntrb_valves)

Sequencing Circuit with Rotary Actuators

(

sh_sequencing_circuit_rotary_actuators)

The following demos that used to be in SimHydraulics 1.1 are now part

of Simscape product:

Demo Name

Simple Mechanical System

(

ssc_simple_mechanical_system)

The circuit is equipped with the load-sensing

velocity regulator installed between the pump

and directional valve.

The oscillating hydraulic m echanism consists

of a single-acting hydraulic rotary actuator,

winch, flow control valve, two-position

electrohydraulic valve, and power and control

units.

The actuator is built of a double-acting

cylinder, directional valve, flow control,

block of counterbalance valves, power unit,

replenishment arrangement, and a control

unit.

The sequence circuit is based on four check

valves installed in both pressure and return

lines of the second rotary actuator.

Description

This model is built of both rotational and

translational mechanical blocks to illustrate

their use in a system.

Mechanical System with Translational Friction

ssc_mechanical_system_translational_friction )

(

Mechanical System with Translational Hard

Stop

(

ssc_mechanical_system_translational_hardstop )

24

Thedemoillustratesamassloadedwitha

spring and viscous damper.

The demo illustrates two masses interacting

through a hard stop.

Page 29

Version 1.2 (R2007a) SimHydraulics®Software

Mechanical Rotational System with Stick-Slip

Motion

(

ssc_rot_system_stick_slip)

Linkage Mechanism

(

ssc_linkage_mechanism)

This model demonstrates a mechanical

rotational sy stem, where a load is driven by a

velocity source with a friction element between

them, and stick-slip motion is developed in the

regions of constant velocities.

The model demonstrates the use of the Lever

block in a linkage mechanism.

25

Page 30

SimHydraulics®Release Notes

Version 1.1 (R2006b) SimHydraulics Software

This table summarizes what’s new in Version 1.1 (R2006b):

New Features and

Changes

Yes

Details below

Version

Compatibility

Considerations

No Bug Reports

New features introduced in this version are described here.

Fixed Bugs an d

Known Problems

Includes fixes

Related

Documentation at

Web Site

No

Linearization Support

The Simulink linmod and dlinmod commands create continuous- or

discrete-time linear time-invariant (LTI) state-space models from Simulink

models. You can now use these commands to generate an LTI state-space

model from a model containing SimHydra u li cs components.

There are two basic ways

of linearization differs depending on which method is chosen. If

is called (that is, the arguments for time, state, and input are not provided),

then consistent initial conditions are solved for in the same way as on the first

step of a simulation. If you call

important to provide it with a consistent state to linearize about. For more

information, see “Linearizing at an O pe rating Point” in the Simscape User’s

Guide.

linmod and dlinmod can be used, and the behavior

linmod(mdl)

linmod(mdl, t, x, u), it is particularly

26

New Solver Option Allows Starting Transient

Analysis from a Steady State

A new solver option allows you to specify that simulation starts from a steady

state. Steady state means that the system variables are no longer changing

with time.

If you select the Start simulation from steady state check box in the

Solver block dialog, the solver attempts to find the steady state that would

Page 31

Version 1.1 (R2006b) SimHydraulics®Software

result if the inputs to the system were held constant for a sufficiently large

time, starting from the initial state obtained from the initial conditions

computation. Although the solv er tries to find the particular steady state

resulting from the given initial conditions, it is not guaranteed to do so. All

that is guaranteed is that if the steady-state solve succeeds, the state found

is a steady state (within tolerance). Simulation then starts from this steady

state.

Note If the simulation fails at or near the start time when you use the Start

simulation from steady state option, consider clearing the check box and

simulating with the plain initial conditions computation only.

Extended Functionality for Working with Physical

Units

Version 1.1 provides the following commands that help you specify the

physical units for your system:

•

pm_adddimension

• pm_addunit

• pm_getunits

Unit names are defined in the pm_units.m file, which is shipped with the

product. You can open this file to see how the physical units are defined, and

also as an example when adding your own units. This file is located in the

directory

Use the

defined in your unit registry. Use the

commandstodefineadditionalunits.

matlabroot\toolbox\physmod\pm_util\pm_util.

pm_getunits command to get an up-to-date list of units currently

pm_adddimension and pm_addunit

New SimHydraulics Blocks

The new blocks introduced in Version 1.1 are listed below:

• Annular Orifice

• Cylinder Friction

27

Page 32

SimHydraulics®Release Notes

• Reservoir

• Elbow

• Pipe Bend

• T-junction

• Gradual Area Change

• Sudden Area Change

• Variable-Displacement Motor

• Variable-Displacement Pump

• Shuttle Valve

• PS Product

• PS Divide

28

Page 33

Version 1.0 (R2006a+) SimHydraulics®Software

Version 1.0 (R2006a+) SimHydraulics Software

This table summarizes what’s new in Version 1.0 (R2006a+):

New Features and

Changes

Yes

Details below

Version

Compatibility

Considerations

Not applicable

New features introduced in this version are described here.

Fixed Bugs an d

Known Problems

Bug Reports No

Related

Documentation at

Web Site

Product Introduction

SimHydraulics software is a modeling environment for the engineering design

and simulation of hydraulic power and control systems within Simulink

and MATLAB. It is based on the Physical Network approach and contains

a comprehensive library of hydraulic blocks, as well as one-dimensional

translational and rotational mechanical elements and utility blocks.

SimHydraulics software key features are:

• Enables modeling and simulation of hydraulic power and control systems

in Simulink

• Provides intuitive and convenient description of multidomain models based

on physical networks

• Includes a library of hydraulic components, such as pumps, valves,

accumulators, and pipelines, that account for effects such as fluid

compressibility, turbulence transition, and fluid inertia

• Provides foundation library of hydraulic building blocks, as well as

fundamental mechanical and mathematical elements, to enable efficient

extension and customization of models

• Provides customizable library of hydraulic fluids

SimHydraulics software employs a network approach to model building.

Components in the network correspond to physical elements, such as pumps,

29

Page 34

SimHydraulics®Release Notes

motors, valves, etc. The lines that join the components correspond to physical

connections that transmit power between components. Unlike traditional

Simulink block diagrams, these connections are non-directional and do not

require the user to resolve the causality of the system while building the

model. SimHydraulics libraries containmorethan75modelsofhydraulic

and mechanical components. All the models were developed to be easily

characterized by data normally available in manufacturer’s catalogs or data

sheets. Building a model of a system is analogous to assembling the actual

physical sy stem with off-the-shelf components. The end result is a hydraulic

circuit schematic in concurrence with ISO 1219 Fluid Power Standard.

SimHydraulics limitations are:

• Explicit solvers are not currently supported. Only the following solvers are

• A SimHydraulics physical network should not exist within a Simulink

supported:

ode15s, ode23t,andode14x.

algebraic loop. This means that you should not directly connect an output

of a PS-Simulink Converter block to an input of a Simulink-PS Converter

block of the same physical network.

30

• Code generation is not currently supported.

Page 35

Compatibility Summary for SimHydraulics®Software

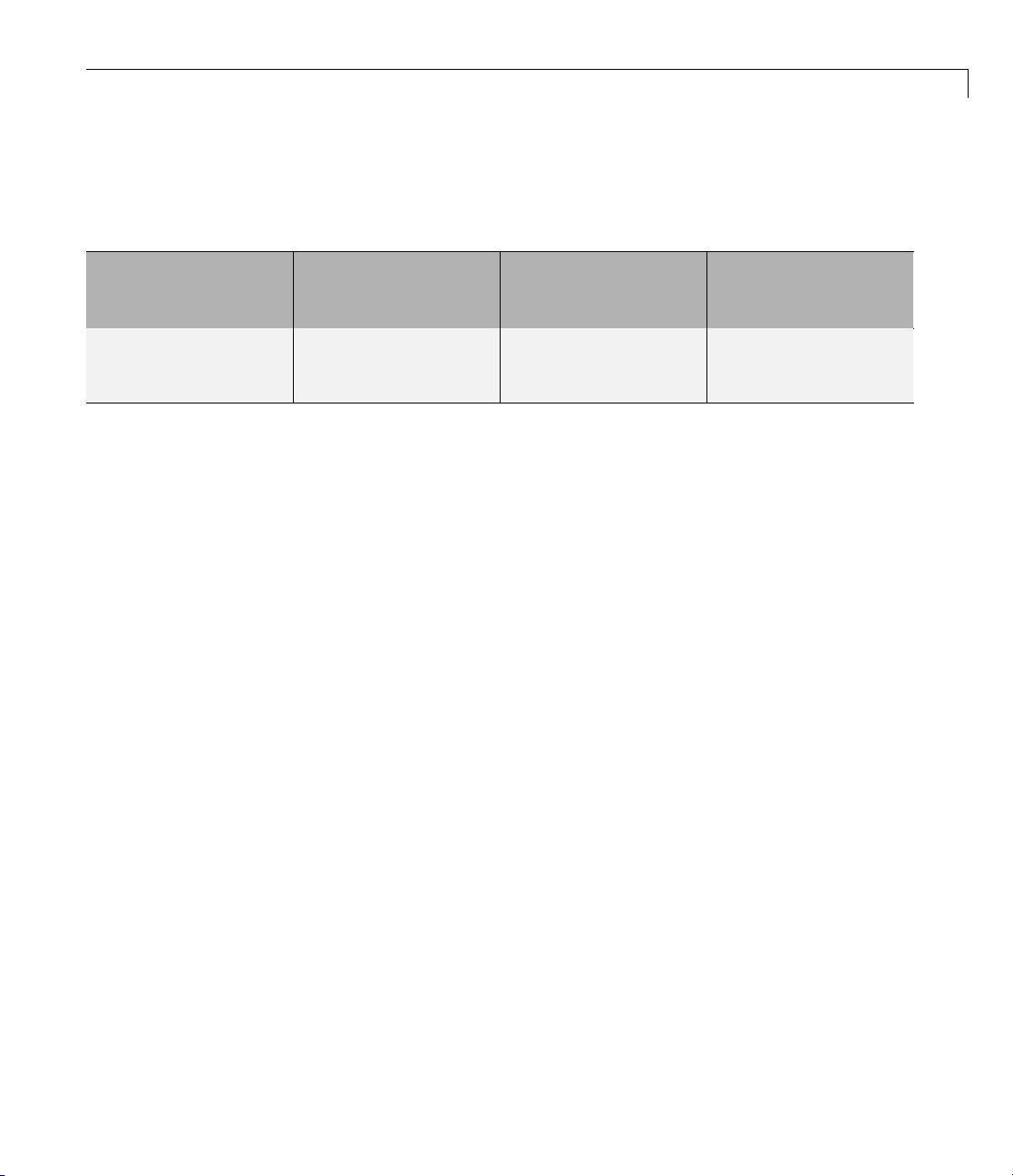

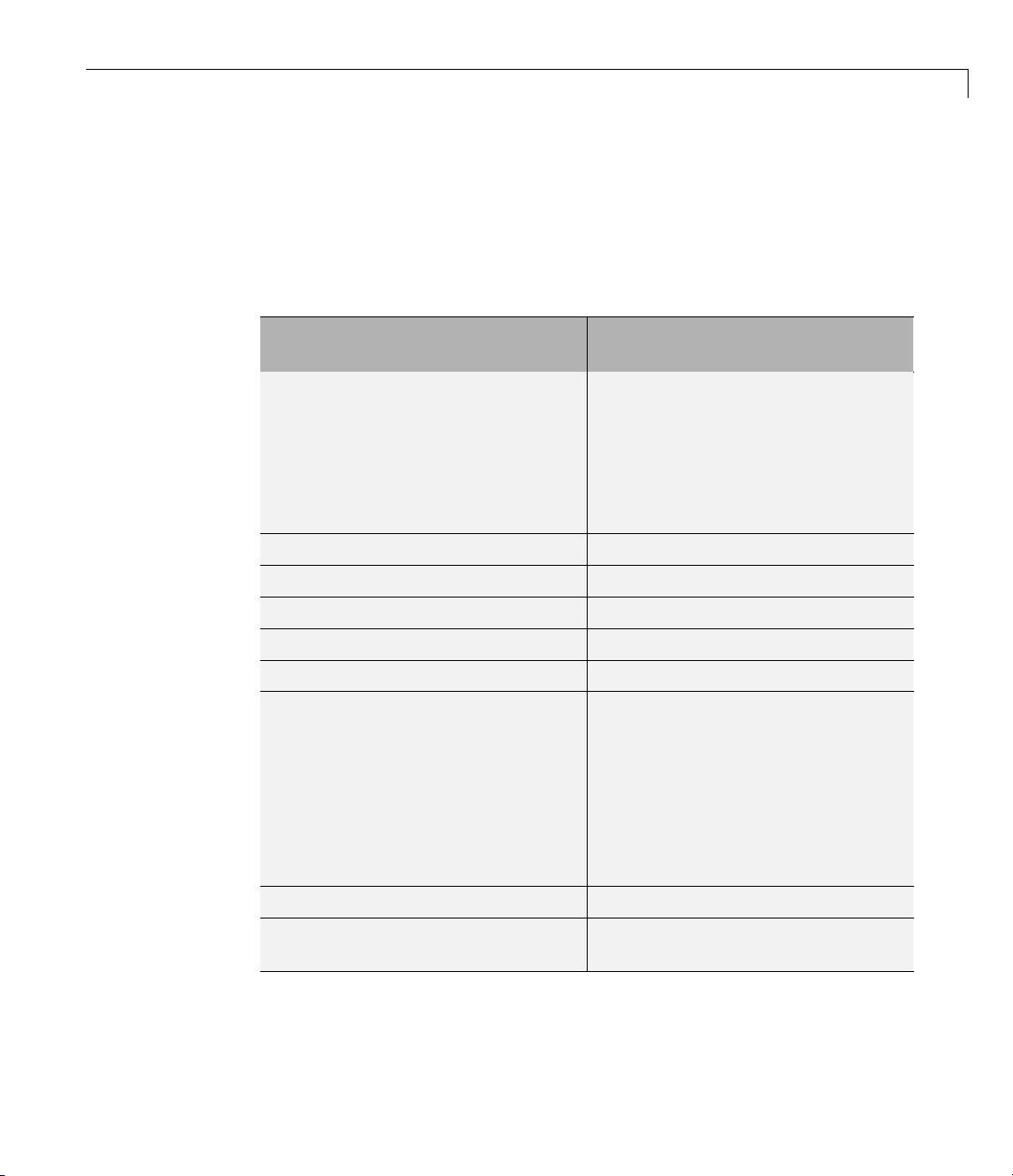

Compatibility Summar y for SimHydraulics Software

This table summarizes new features and changes that might cause

incompatibilities when you upgrade from an earlier version, or wh en you

use files on multiple versions. Details are provided in the description of the

new feature or change.

Version (Release) New Features and Changes with

Version Compatib ility Impact

Latest Version

V1.7 (R2010a)

V1.6 (R2009b)

V1.5 (R2009a)

V1.4 (R2008b)

V1.3 (R2008a)

V1.2.1 (R2007b)

V1.2 (R2007a) See the Compatibility

V1.1 (R2006b)

See the Compatibil ity

Considerations subheading

for this new feature or change:

• “Initial Piston Position in the

Single-Acting H ydraulic Cylinder

Block” on page 6

None

None

None

None

None

Considerations subheading

for these new features or changes:

• “Initial Conditions Added for

Certain Blocks” on page 21

• “Block Library Links Must Be

Resolved” on page 22

None

V1.0 (R2006a+)

Not applicable

31

Loading...

Loading...