Page 1

SimDriveline™ 1

User’s Guide

Page 2

How to Contact The MathWorks

www.mathworks.

comp.soft-sys.matlab Newsgroup

www.mathworks.com/contact_TS.html Technical Support

suggest@mathworks.com Product enhancement suggestions

bugs@mathwo

doc@mathworks.com Documentation error reports

service@mathworks.com Order status, license renewals, passcodes

info@mathwo

com

rks.com

rks.com

Web

Bug reports

Sales, prici

ng, and general information

508-647-7000 (Phone)

508-647-7001 (Fax)

The MathWorks, Inc.

3 Apple Hill Drive

Natick, MA 01760-2098

For contact information about worldwide offices, see the MathWorks Web site.

SimDriveline™ User’s Guide

© COPYRIGHT 2004–20 10 by The MathWorks, Inc.

The software described in this document is furnished under a license agreement. The software may be used

or copied only under the terms of the license agreement. No part of this manual may be photocopied or

reproduced in any form without prior written consent from The MathW orks, Inc.

FEDERAL ACQUISITION: This provision applies to all acquisitions of the Program and Documentation

by, for, or through the federal government of the United States. By accepting delivery of the Program

or Documentation, the government hereby agrees that this software or documentation qualifies as

commercial computer software or commercial computer software documentation as such terms are used

or defined in FAR 12.212, DFARS Part 227.72, and DFARS 252.227-7014. Accordingly, the terms and

conditions of this Agreement and only those rights specified in this Agreement, shall pertain to and govern

theuse,modification,reproduction,release,performance,display,anddisclosureoftheProgramand

Documentation by the federal government (or other entity acquiring for or through the federal government)

and shall supersede any conflicting contractual terms or conditions. If this License fails to meet the

government’s needs or is inconsistent in any respect with federal procurement law, the government agrees

to return the Program and Docu mentation, unused, to The MathWorks, Inc.

Trademarks

MATLAB and Simulink are registered trademarks of The MathWorks, Inc. See

www.mathworks.com/trademarks for a list of additional trademarks. Other product or brand

names may be trademarks or registered trademarks of their respective holders.

Patents

The MathWorks products are protected by one or more U.S. patents. Please see

www.mathworks.com/patents for more information.

Page 3

Revision History

August 2004 Online only New for Version 1.0 (Release 14+)

October 2004 Online only Revised for Version 1.0.1 (Release 14SP1)

March 2005 Online only Revised for Version 1.0.2 (Release 14SP2)

April 2005 Online only Revised for Version 1.1 (Release 14SP2+)

September 2005 O nline only Revised for Version 1.1.1 (Release 14SP3)

March 2006 First printing Revised for Version 1.2 (Release 2006a)

September 2006 O nline only Revised for Version 1.2.1 (Release 2006b)

March 2007 Online only Revised for Version 1.3 (Release 2007a)

September 2007 O nline only Revised for Version 1.4 (Release 2007b)

March 2008 Online only Revised for Version 1.5 (Release 2008a)

October 2008 Online only Revised for Version 1.5.1 (Release 2008b)

March 2009 Online only Revised for Version 1.5.2 (Release 2009a)

September 2009 O nline only Revised for Version 1.5.3 (Release 2009b)

March 2010 Online only Revised for Version 1.5.4 (Release 2010a)

Page 4

Page 5

Introducing SimDriveline Software

1

Product Overview ................................. 1-2

Product Definition

Driveline Simulation and Physical Modeling

................................. 1-2

........... 1-2

Contents

Related Products

Required Products

Other Related Products

Running a Demo Model

What the Model Represents

What the Model Illustrates

Opening the Model

Running the Model

Modifying the Model

What Can You Do with SimDriveline Software?

About SimDriveline Software

Modeling Drivetrains

Connector Ports and Connection Lines

Inertias and Gears

Complex Driveline Elements

Actuating and Sensing Motion

Simulating and Analyzing Motion

Learning M ore

Using the MATLAB Help System for Documentation and

Demos

Finding Special SimDriveline Help

........................................ 1-25

.................................. 1-4

................................. 1-4

............................ 1-4

............................ 1-6

......................... 1-6

.......................... 1-6

................................ 1-7

................................ 1-11

............................... 1-15

........................ 1-20

.............................. 1-20

................ 1-21

................................ 1-22

........................ 1-22

....................... 1-23

.................... 1-24

.................................... 1-25

................... 1-25

...... 1-20

v

Page 6

Simple Models

2

Introducing the SimDriveline Block Libraries ........ 2-2

About the SimDriveline Block Library

Accessing the Libraries

Using the Libraries

............................. 2-2

................................ 2-4

................ 2-2

Essential Steps to Building a Driveline Model

Representing and Transferring D riv e line Motion and

Torque

About Inertia, Motion, and Gears

Coupling Rotational Motion with Gears

Coupling Two Spinning Inertias with a Simple Gear

Coupling Two Spinning Inertias with a Variable Gear

Coupling Three Spinning Inertias with a Planetary

Gear

Actuating Drivelines with Torques and Motions

About Torques, Motions, and Actuation

Modeling the Effect of a Variable Inertia

Actuating a Driveline with Torques

Actuating a Driveline with Motion s

Setting the Motion Initial Conditions of a Driveline

Controlling Gear Couplings with Clutches

About Motion, Gears, and Clutches

Engaging a nd Disengaging Gears with Clutches

Modeling Realistic Clutch Systems with Loss

Braking Motion with Clutches

Modeling Friction Clutches at a Fundamental Level

......................................... 2-9

.................... 2-9

............... 2-9

.......................................... 2-17

............... 2-22

.............. 2-24

................... 2-25

................... 2-26

................... 2-28

....................... 2-37

........ 2-7

..... 2-11

...... 2-22

...... 2-26

........... 2-28

........ 2-28

........... 2-34

..... 2-41

... 2-16

vi Contents

Combining Clutches and Gears into T ransmissions

About Gears, Clutches, and Transmissions

Modeling a Simple Two-Speed Transmission with

Braking

Introducing the Transmission Templates Library

Modeling a CR-CR 4-Speed Transmission Driveline with

Braking

....................................... 2-43

....................................... 2-51

............. 2-42

....... 2-50

... 2-42

Page 7

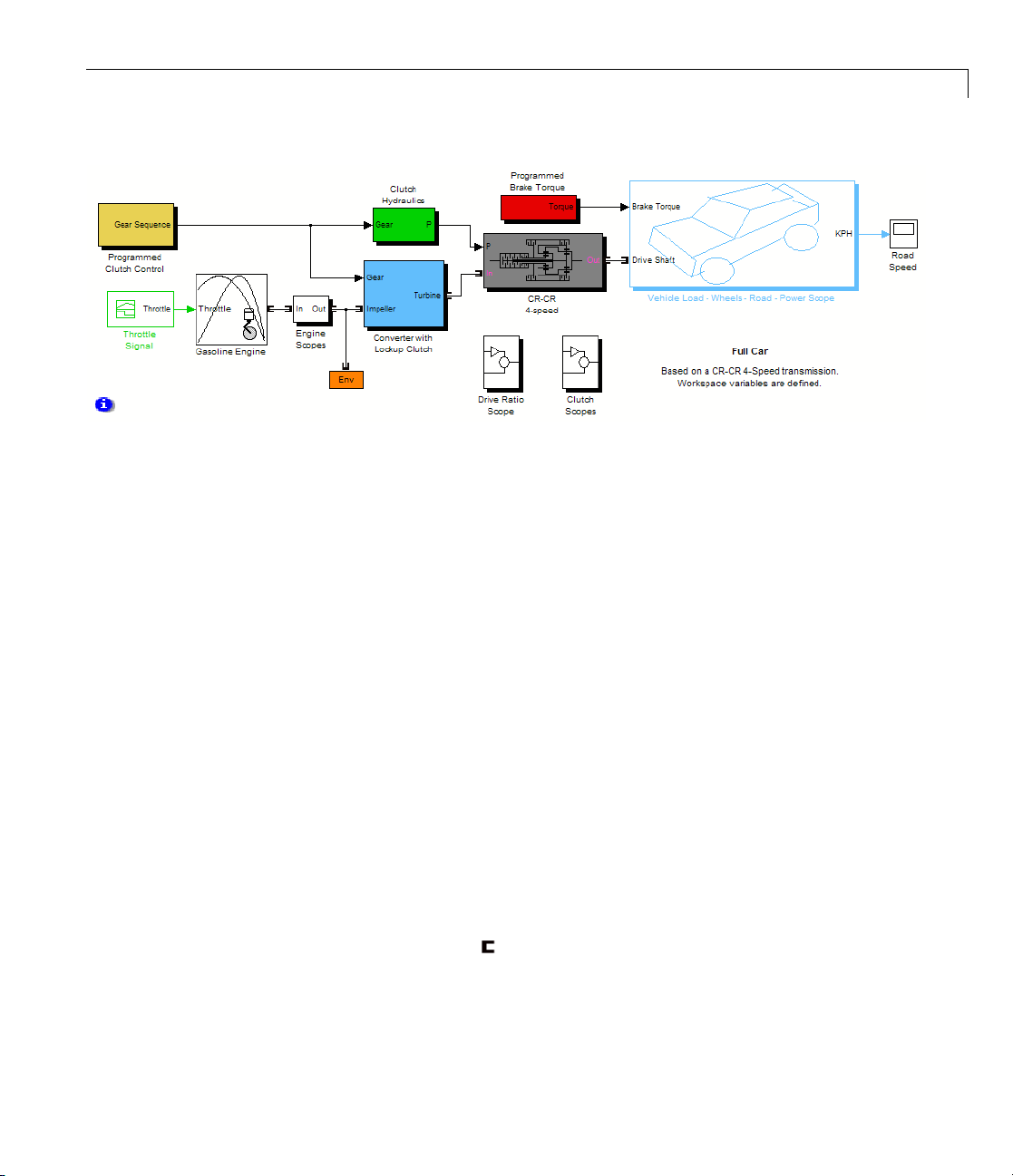

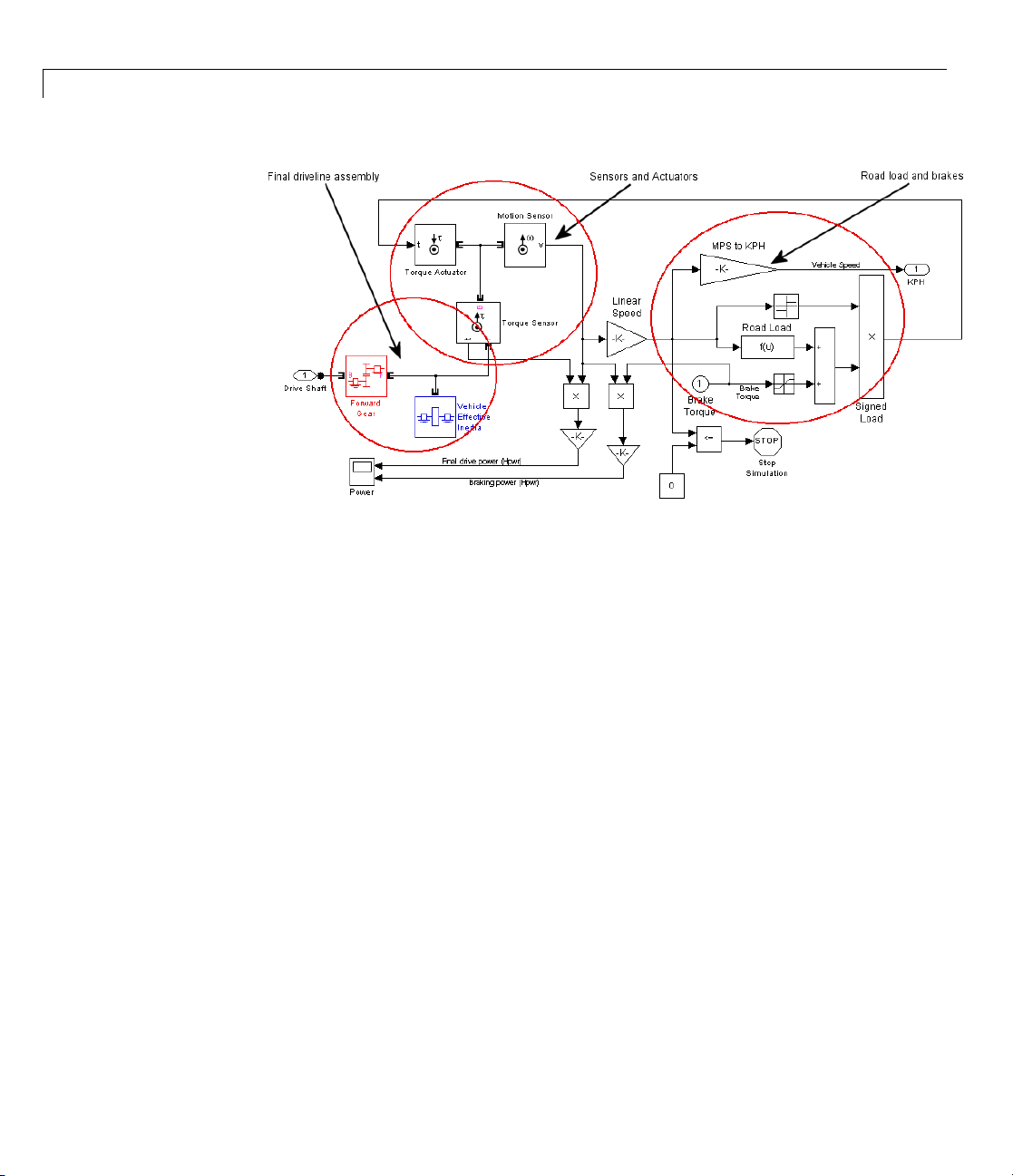

Modeling and Simulating a Complete Car ............ 2-58

About the Full Car Model

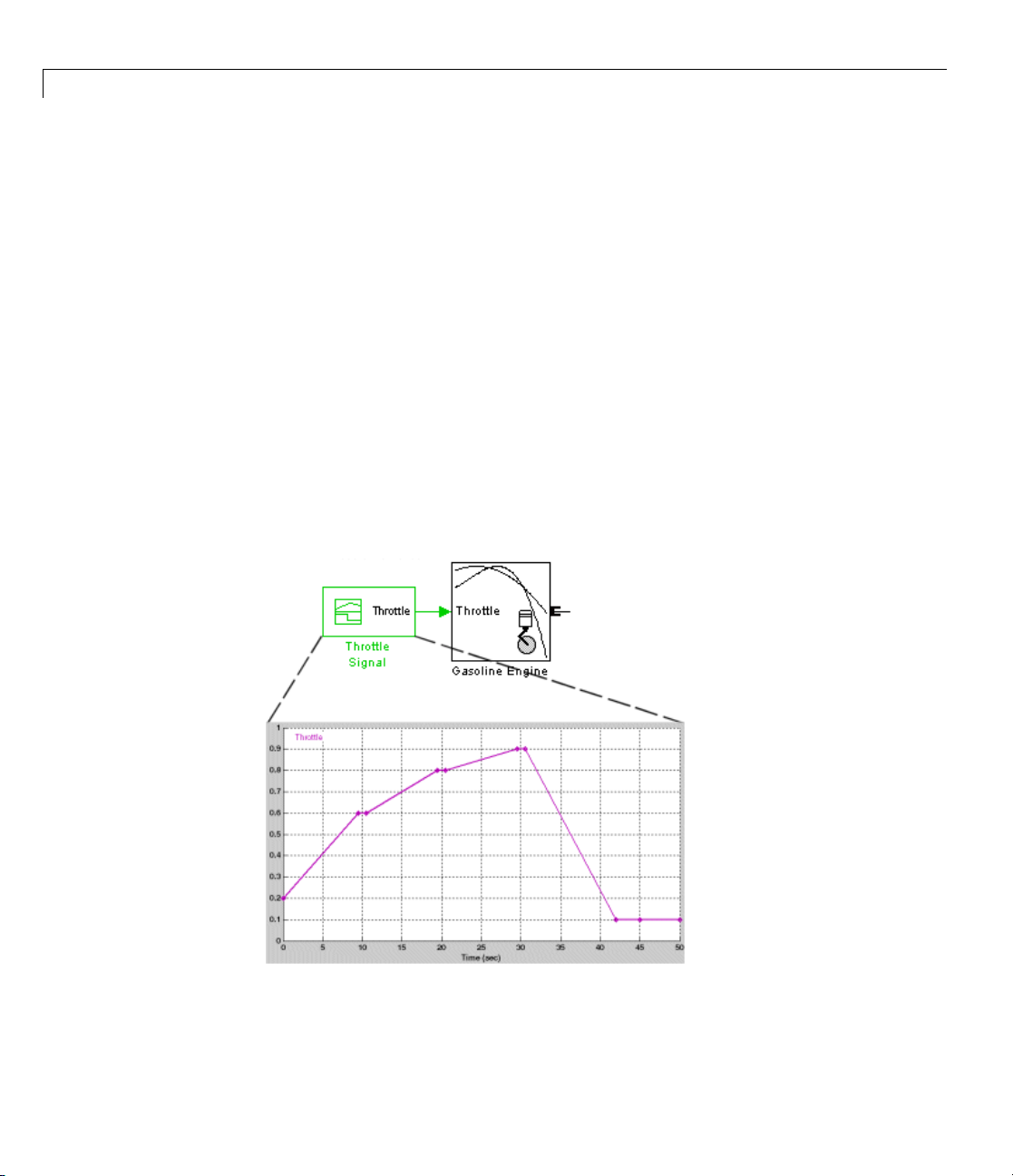

Modeling the Engine

Modeling the Transmission

Coupling the Engine to the Transmission

Modeling the Wheel Ass embly and Road Coupling

Controlling the Clutches and Braking

Running the Model

........................... 2-58

............................... 2-59

......................... 2-61

.............. 2-62

....... 2-63

................. 2-67

................................ 2-70

Advanced Methods

3

Using the Simscape Editing Mode ................... 3-2

Accessing and Changing the Simscape Configuration

Parameters

Editing Block Parameters in Restricted Mode

.................................... 3-2

.......... 3-3

Improving Performance

Simulating Drivelines within the Simulink

Environment

Increasing Accuracy and Speed

Optimizing Clutch Mode Changes and Fixed-Step

Solvers

Troubleshooting Simulation Errors

Analyzing Degrees of Freedom

About Drive line Degrees of Freedom and Constraints

Identifying Degrees of Freedom

Fundamental Degrees of Freedom

Connected Deg rees of Freedom

Constrained Deg rees of Freedom

Actuating, Sensing, and Terminating Degrees of

Freedom

Counting Independent Degrees of Freedom

Counting Degrees of Freedom in a Simple Driveline with a

Clutch

Trimming and Linearizing Driveline Models

About Trimming, Inverse Dynamics, and Linearization

................................... 3-5

........................................ 3-8

....................................... 3-23

........................................ 3-26

............................ 3-5

...................... 3-5

................... 3-11

...................... 3-14

...................... 3-15

.................... 3-15

...................... 3-18

..................... 3-19

............ 3-25

......... 3-31

.... 3-14

.. 3-31

vii

Page 8

Finding and Using Driveline States .................. 3-34

Trimming a Driveline with Inverse Dynamics

Linearizing a Driveline Model

Counting Driveline States in a Full Car

Trimming a Full Car to Rest

Linearizing a Full Car at Rest

....................... 3-37

........................ 3-43

....................... 3-45

.......... 3-35

............... 3-38

How Sim Driveline Software Works

About Driveline Simulation

State, Constraint, and Motion Actuation Identification

Independent State Selection and Initialization

Dependent State Selection and Initialization

Torque Analysis and Dynamical Simulation

Clutch Mode Iteration

Generating Code

About Code Generation from SimDriveline Models

Using Code-Related Products and Features

How SimDriveline Code Generation Differs from

Simulink

Using Run-Time Parameters in Generated Code

Limitations

About SimDriveline and Simulink Limitations

Continuous Sample Times Required

Restricted Simulink Tools

Unsupported Simulink Tool

Simulink Tools Not Compatible with SimDriveline

Blocks

Restrictions with Generated Code

........................................ 3-55

.................................. 3-50

...................................... 3-51

....................................... 3-54

......................... 3-48

.............................. 3-49

.......................... 3-54

......................... 3-55

.................. 3-48

.......... 3-49

........... 3-49

............ 3-49

............ 3-50

.................. 3-54

.................... 3-55

... 3-48

...... 3-50

........ 3-52

......... 3-54

viii Contents

Block Reference

4

Drivelines and Inertias ............................. 4-2

Gears

............................................. 4-2

Page 9

Dynamic Elements ................................. 4-3

Transmissions

Sensors and Actuators

Vehicle Components

Interface Elements

5

A

Drivel

ine Abbreviations and Conventions

Abbrev

Angula

Gear R

iations

rMotion

atios

..................................... 4-3

............................. 4-4

............................... 4-4

................................ 4-5

Blocks — Alphabetical List

Technical Conventions

...........

....................................

...................................

......................................

A-2

A-2

A-2

A-2

B

Drive

line Units

....................................

liography

Bib

I

A-4

ndex

ix

Page 10

x Contents

Page 11

Introducing SimDriveline Software

1

With SimDriveline™ software, you can model drivetrain and powertrain

systemsinaneasy,naturalwaywithinMATLAB

chapter introduces you to SimDriveline software, with an overview and an

example of modeling drivetrains.

• “Product Overview” on page 1-2

• “Related Products” on page 1-4

• “Running a Demo Model” on page 1-6

• “What Can You Do with Sim Driveline Software?” on page 1-20

• “Learning More” on page 1-25

®

and Simulink®.This

Page 12

1 Introduc ing SimDriveline™ Software

Product Overview

In this section...

“Product Definition” on page 1-2

“Driveline Simulation and Physical Modeling” on page 1-2

Product Definition

SimDriveline software is a block diagram modeling environment for the

engineering design and simulation of drivelines, or idealized powertrain

systems. A driveline propels a vehicle or craft by transferring its engine

torque and rotational power into vehicle kinetic energy and translational

momentum. The vehicle moves through or on a medium (air, water, ground)

which propels it by reaction forces an d which acts as a load on th e engine.

Drivelines consist of b odies spinning around fixed axes and subject to

Newton’s laws of motion. T he bodies can revolve about one axis, multiple

parallel axes, or multiple nonparallel axes. Simp l e and complex gears

constrain the bodies to revolve together and transfer torque up and down the

driveline axes. Locking and unlocking clutches switch the driveline from one

gear set to another. Gears and clutches make up transmissions.

1-2

With SimDriveline software, you represent a driveline with a connected

block diagram, like other Simulink models, and you can group blocks in to

hierarchical subsystems. You can initiate and maintain rotational motion in a

driveline with actuators wh ile measuring, via sensors, the motions of driveline

elements and the torques acting on them. You can return sensor signals to

the driveline via actuators, forming feedback loops and the basis for controls.

The SimDriveline libraries offer blocks to represent rotating bodies; gear

constraints among bodies; dynamic elements such as spring-damper forces,

rotational stops, and clutches; transmissions; and sensors and actuators.

You can also analyze linearized versions of your SimDriveline models and

generate code from them.

Driveline Simulation and Physical Modeling

SimDriveline software is based on the Simscape™ environment, the platform

product for the Simulink Physical Modeling family, encompassing the

Page 13

Product Overview

modeling and design of systems according to basic physical principles.

Simscape software runs within the Simulink environment and interfaces

seamlessly with the rest of Simulink and with MATLAB. Unlike other

Simulink blocks, which represent mathematical operations or operate on

signals, Simscape blocks represent physical components or relationships

directly.

Note This SimDriveline User’s Guide assumes that you have some

experience with modeling drivetrains and with building and running models

in Simulink.

1-3

Page 14

1 Introduc ing SimDriveline™ Software

Related Products

In this section...

“Required Products” on page 1-4

“Other Related Products” on page 1-4

Required Products

You must have current versions of the following products installed to use the

SimDriveline product:

• MATLAB

• Simulink

• Simscape

Other Related Products

The related products listed on the SimDriveline product page at the

MathWorks™ Web site include toolboxes and blocksets that extend the

capabilities of MATLAB and Simulink. These products will enhance your

SimDriveline experience in various applications.

1-4

Physical Modeling Product Family

Use the Physical Modeling product family to model physical systems in

Simulink. In addition to SimDriveline software, they include:

• Simscape, the platform and unifying environment for Physical Modeling

products

• SimElectronics

• SimHydraulics

• SimMechanics™, for modeling and simulating mechanical systems

• SimPowerSystems™, for modeling and simulating electrical power systems

®

, for modeling and simu l ati ng el ectronic systems

®

, for modeling and simulating hydromechanical systems

Page 15

Related Products

For Information About MathWorks Products

For more information about any MathWorks software products, see either

• The online documentation for that product if it is installed

• The MathWorks Web site at

www.mathworks.com; see the “Products” section

1-5

Page 16

1 Introduc ing SimDriveline™ Software

Running a Demo Model

In this section...

“What the Model Represents” on page 1-6

“What the Model Illustrates” o n page 1-6

“Opening the M odel” on page 1-7

“Running the Model” on page 1-11

“Modifying the Model” on page 1-15

What the Model Represents

The demo model of this section, drive_crcr_ideal, simulates a complete

drivetrain. This model will help you understand how to model driveline

components with SimDriveline blocks, connect them into a realistic model,

use Simulink blocks as well, and simulate and modify a drivetrain model.

1-6

The d riveline mechanism modeled here is part of a full vehicle, without the

engine or engine-drivetrain coupling, and without the final differential and

wheel assembly. The model includes an actuating torque, driver and driven

shafts, a four-speed transmission, and a braking clutch.

What the Model Illustrates

The drive_crcr_ideal model contains a driveline that accepts a driving torque

and transfers this torque and the associated angular motion from the input

or drive shaft to an output or driven shaft through a transmission. The

model includes a CR-CR (carrier-ring–carrier-ring) four-speed transmission

subsystem, based on two gears and four clutches. (The demo does not use

the reverse gear available in the CR-CR transmission.) You can set the

transmission to four different gear combinations, allowing four different

effective torque and angular velocity ratios. A fifth clutch, outside the

transmission, acts as a brake on the driven shaft.

The CR-CR 4-Speed Transmission subsystem illustrates a critical feature

of transmission design, the clutch schedule. Tobefullyengaged,the

transmission, with four clutches and two gears, requires two clutches to

be locked and the other two unlocked at any time. (The transmission’s

Page 17

Running a Demo Model

reverse clutch is not counted here.) The choice of which two clutches to lock

determines the effective gear ratio across the transmission. T he clutch

schedule is the table of locked and free clutches corresponding to different

gear settings. If all four clutches are unlocked, the transmission is in neutral.

If the clutches are completely disengaged, no torque or angular motion at all

is transferred across the transmission.

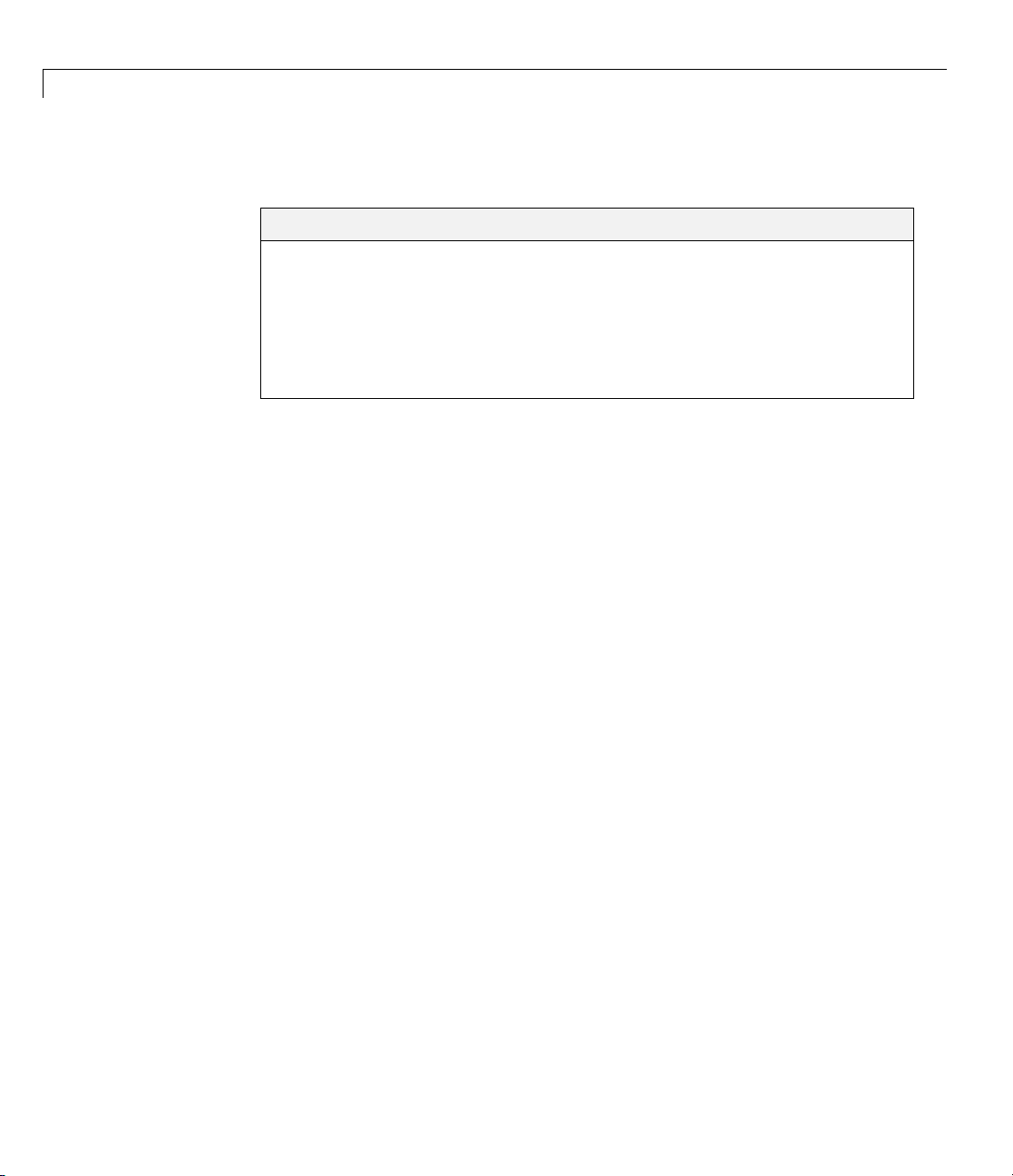

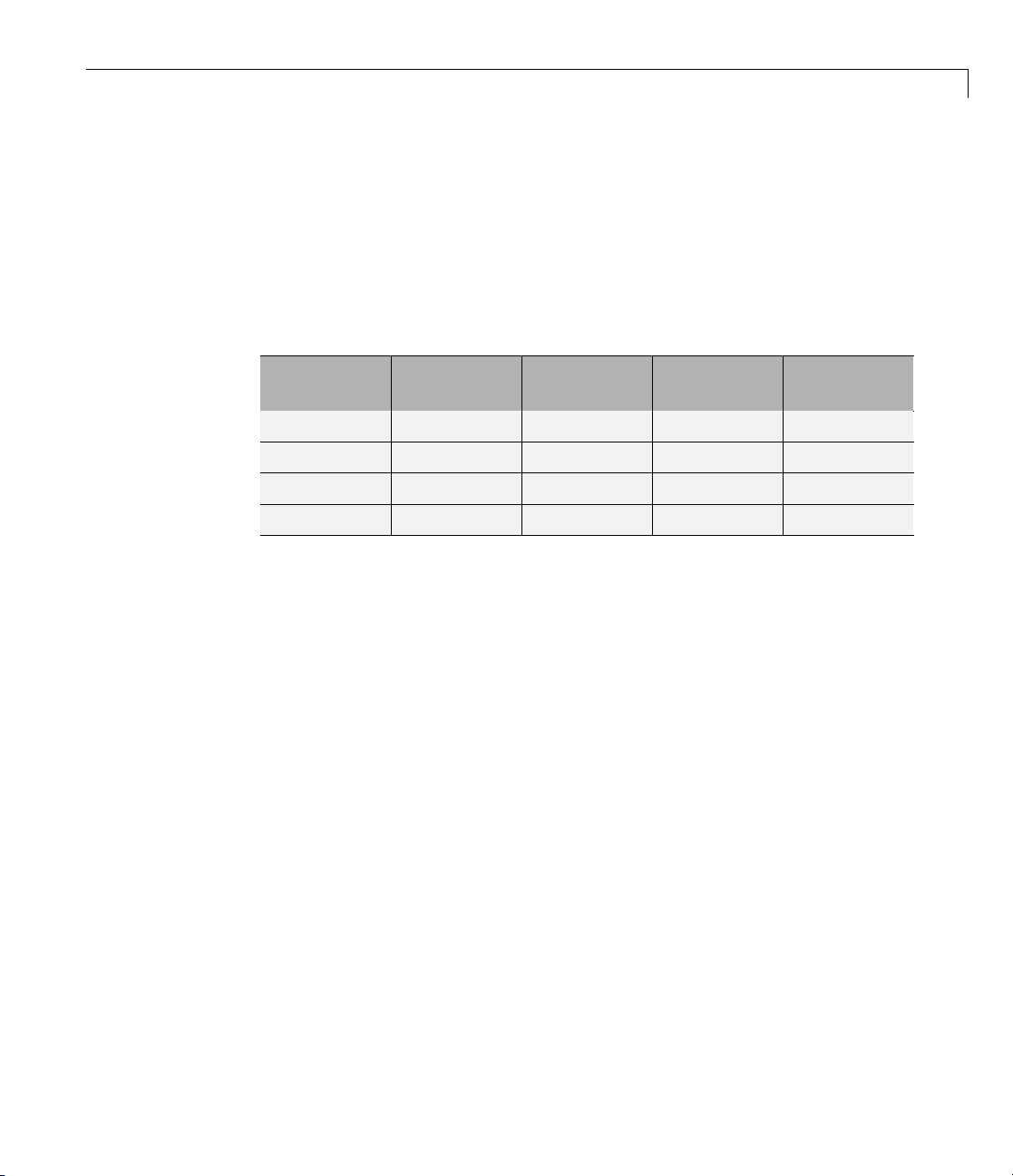

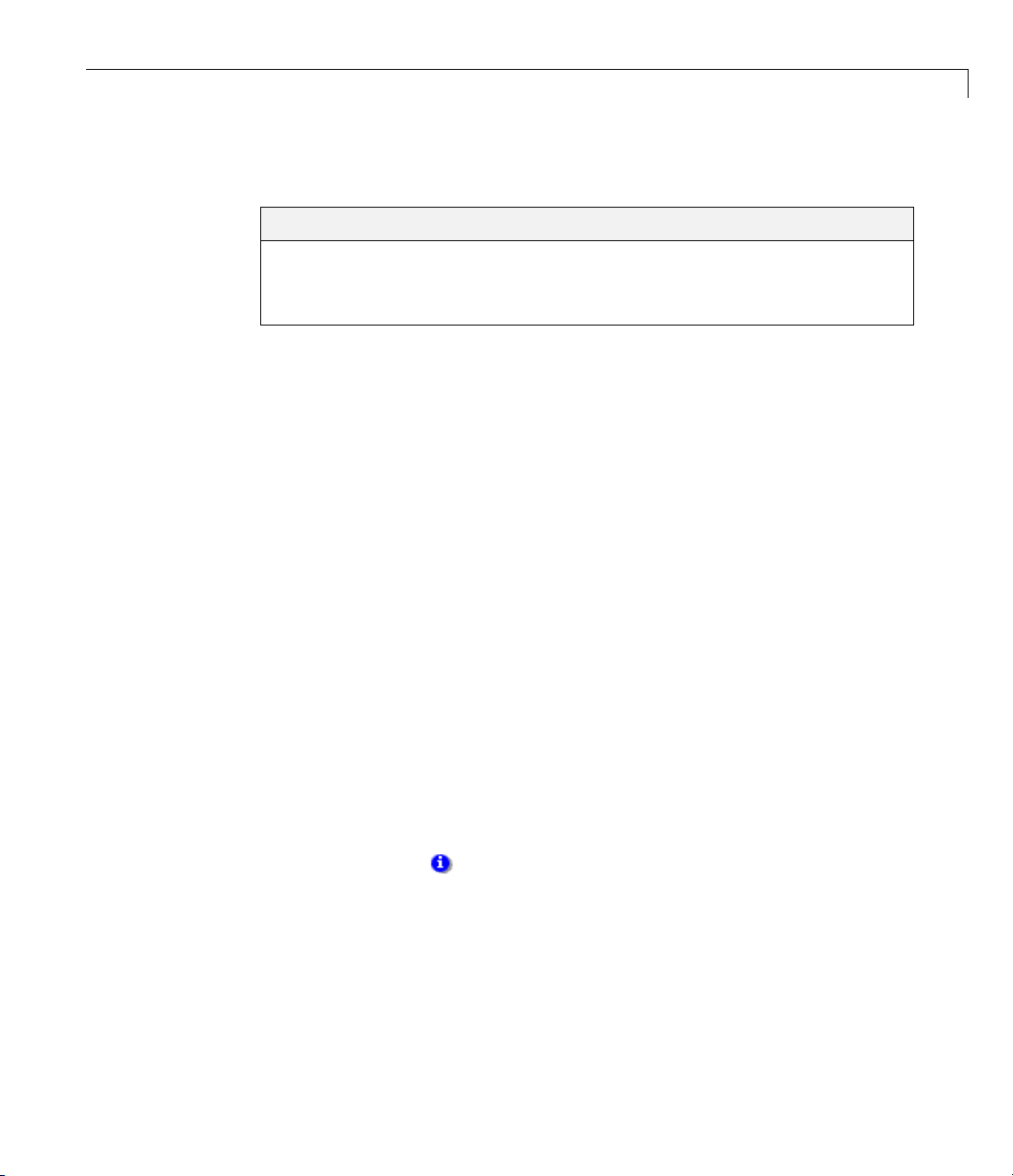

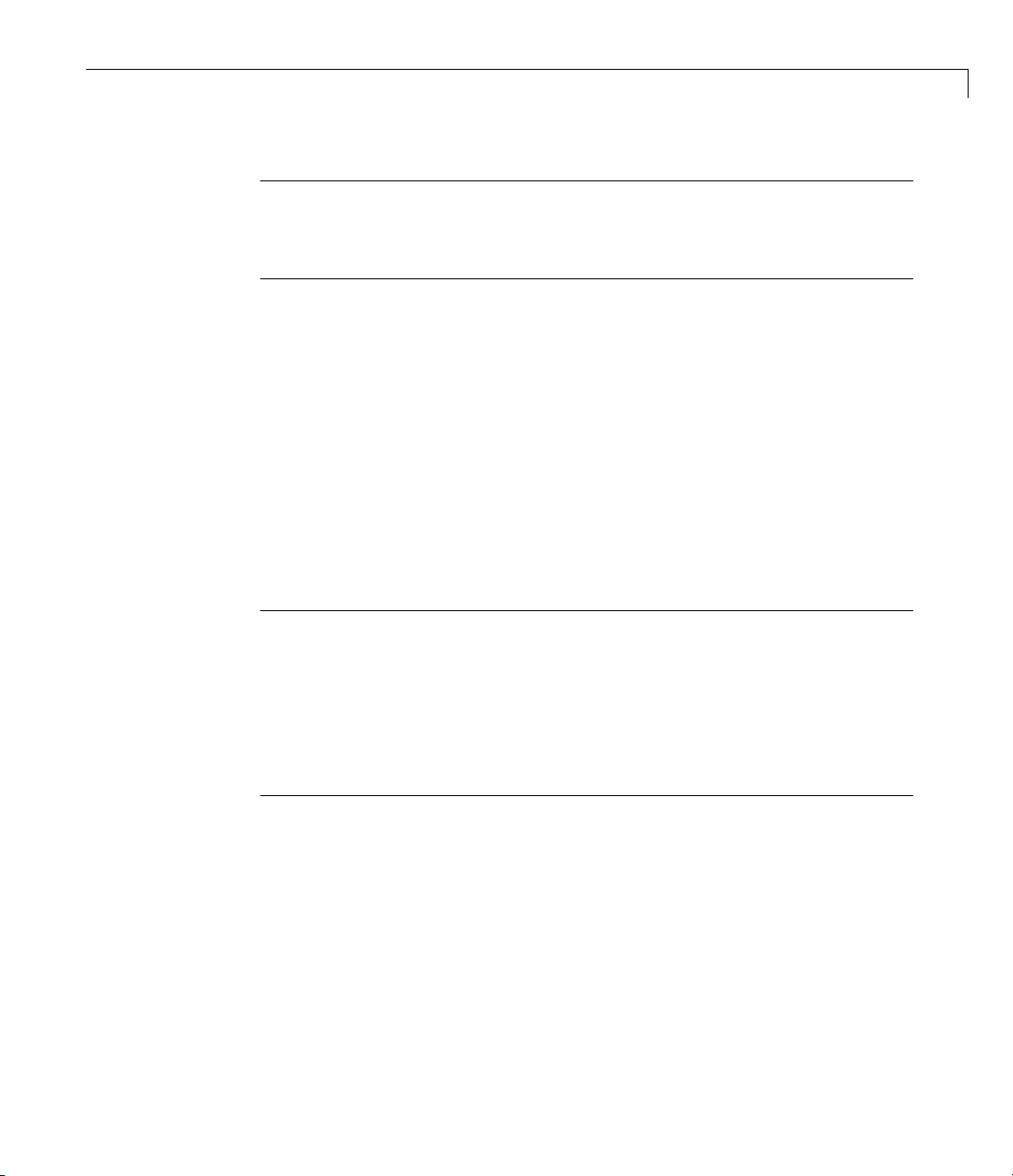

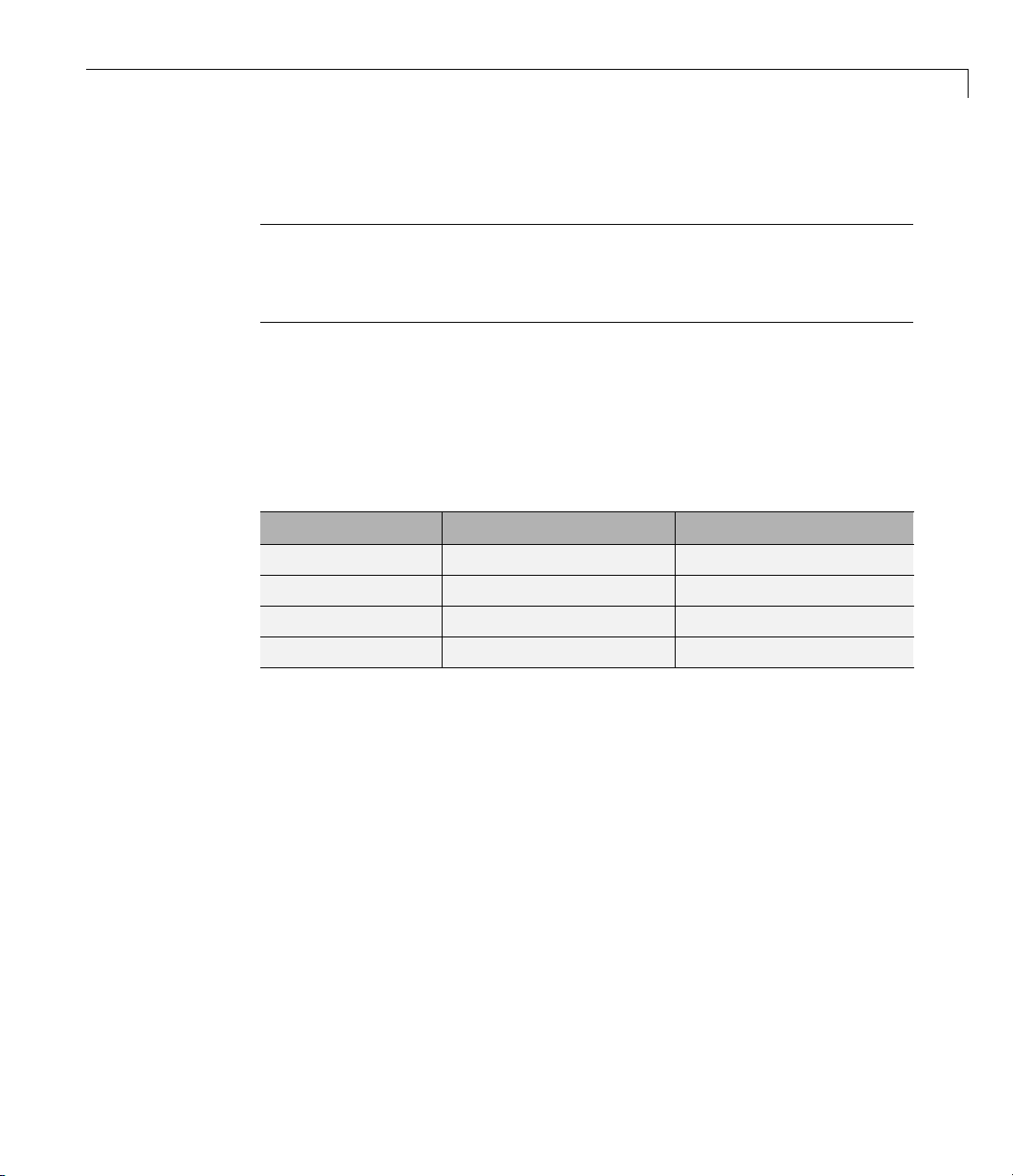

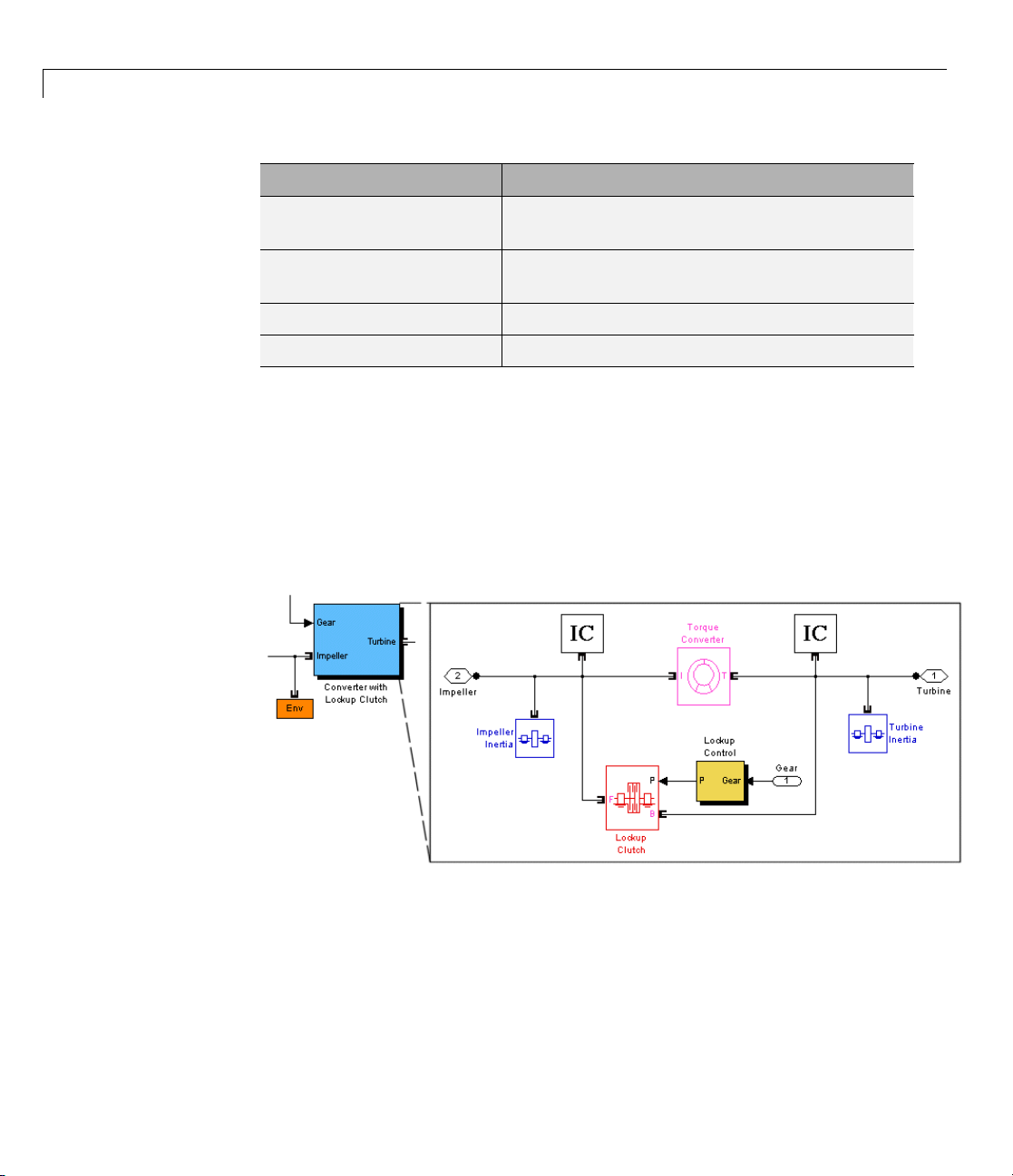

Clutch Schedule for the CR-CR 4-Speed Transmission

Gear

Setting

1

2

3

4

Clutch A

State

Clutch B

State

Clutch C

State

Clutch D

State

L FFL

L F L F

LLFF

F LLF

L = locked, F = free

Opening the Model

To get started q u ickly with the CR-CR transmission demo model, follow

either of these steps:

• Enter

• If you are working with the MATLAB Help browser, click the model name

Opening General SimDriveline Demos

You can open the complete SimDriveline demos list by:

drive_crcr_ideal at the MATLAB command line.

drive_crcr_ideal here.

1 Clicking the Start button on the lower left of the MATLAB desktop.

2 In the pop-up menu, selecting Simulink,thenSimDriveline,andthen

Demos.

This opens the SimDriveline demos list in the MATLAB Help browser.

1-7

Page 18

1 Introduc ing SimDriveline™ Software

You can locate and select any specific demo entry from the list of models.

Alternatively, you can open the same SimDriveline demos list by entering

demo simulink simdriveline or demo('simulink','simdriveline') at

the MATLAB command line.

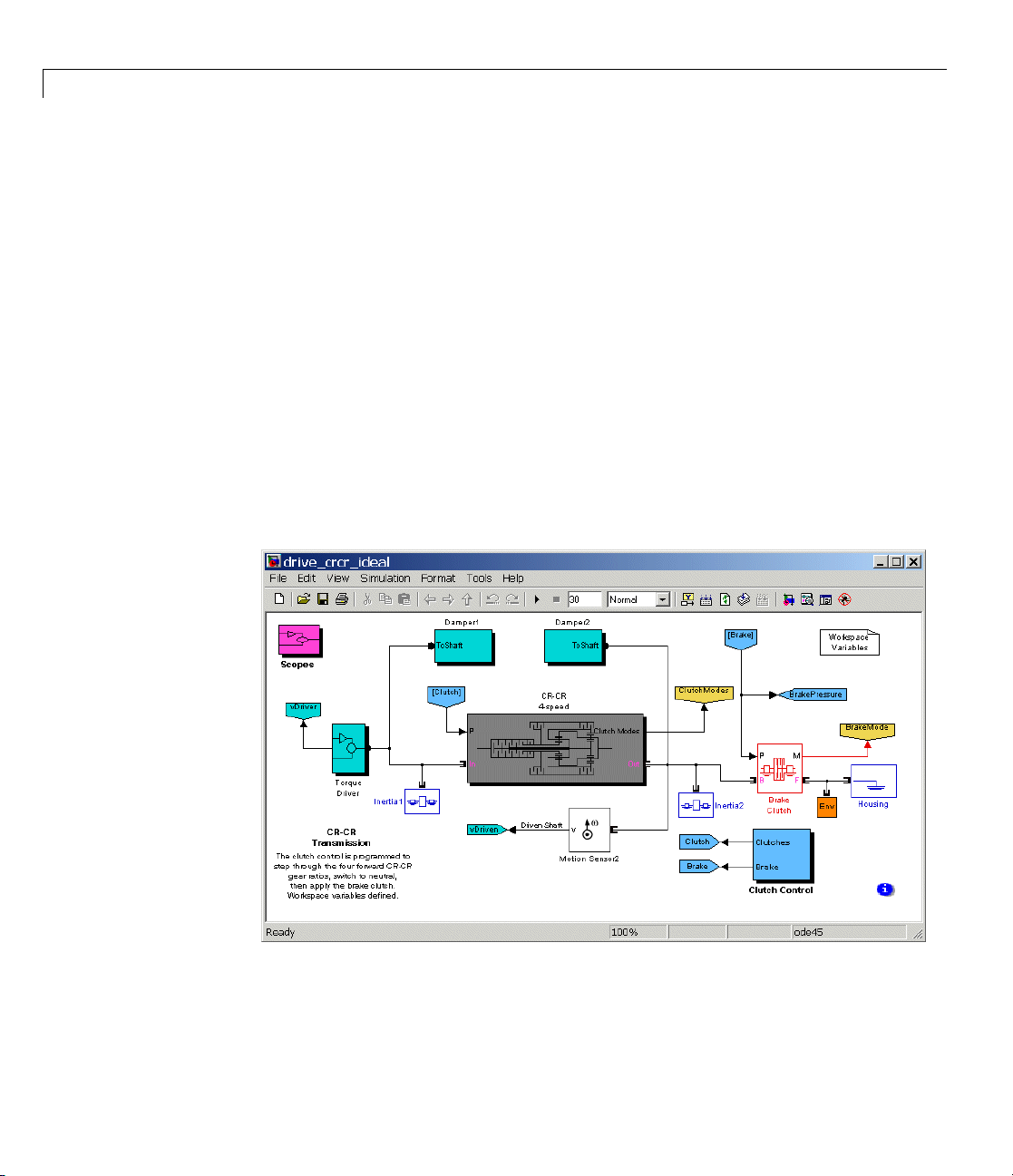

The Block Diagram Model

Examine the model and its structure. The main model window contains the

CR-CR transmission subsystem, the input or driver shaft assembly, and the

output or drive n shaft assembly. Each assembly consists of a wheel with

applied kinetic friction. The driver shaft transmits an externally specified

torque down the driveline.

The m ain model also includes a brake clutch. When this clutch is locked, the

driven shaft stops turning. This clutch must remain unlocked if the C R-C R

transmission is engaged.

1-8

nModelWindow

Mai

Page 19

Running a Demo Model

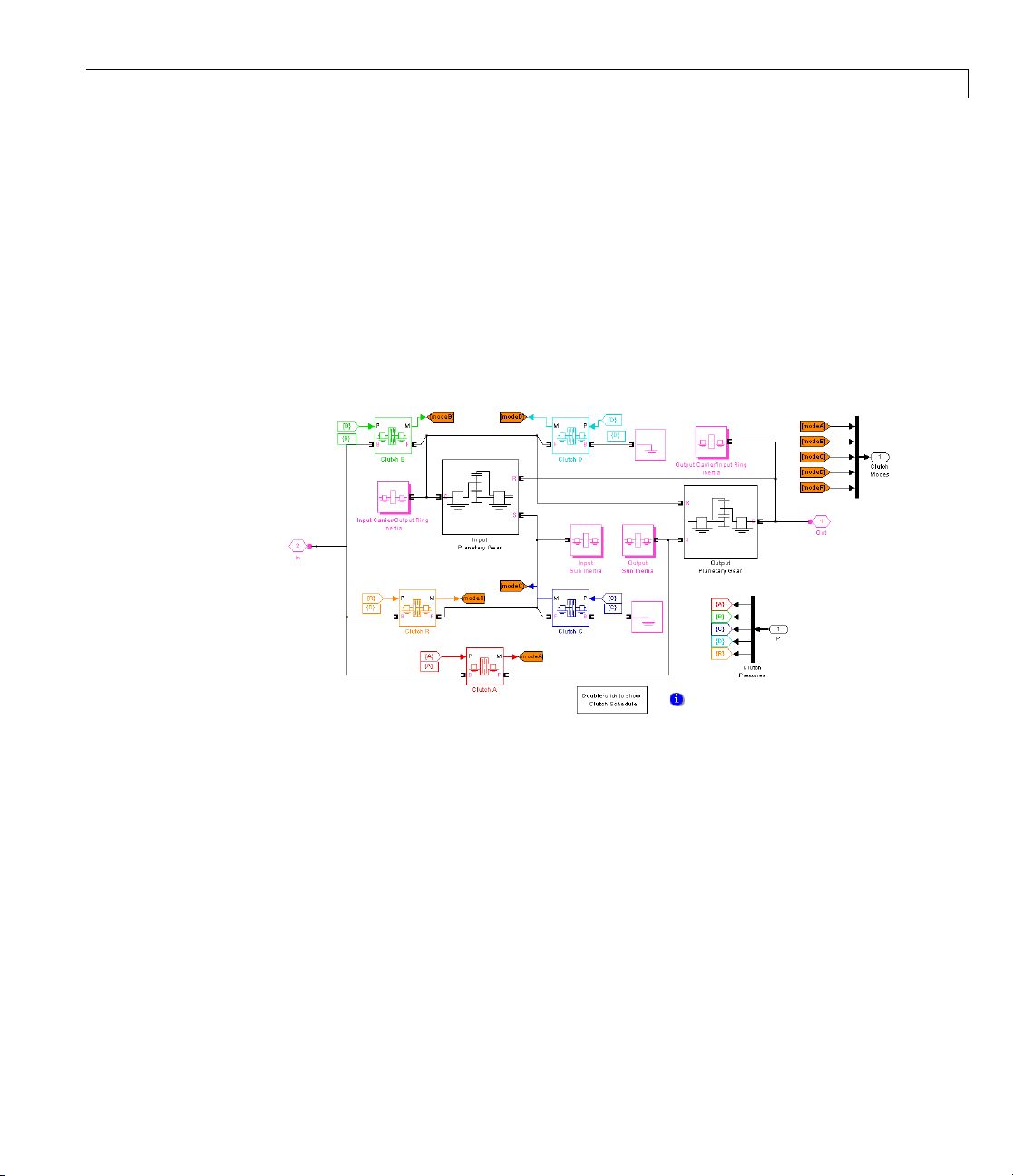

What the Model Contains — Opening the Subsystems

Open each subsystem in turn.

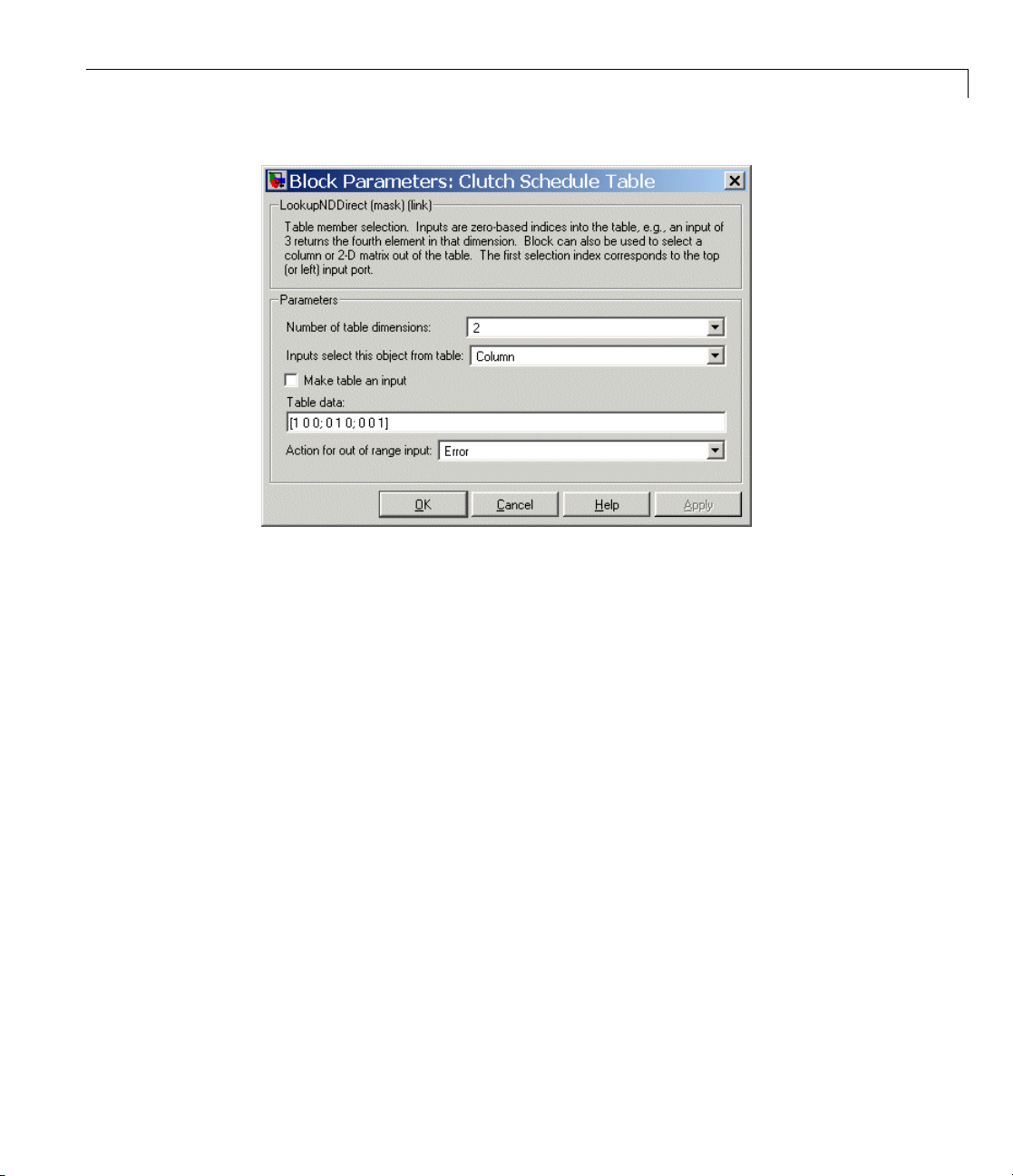

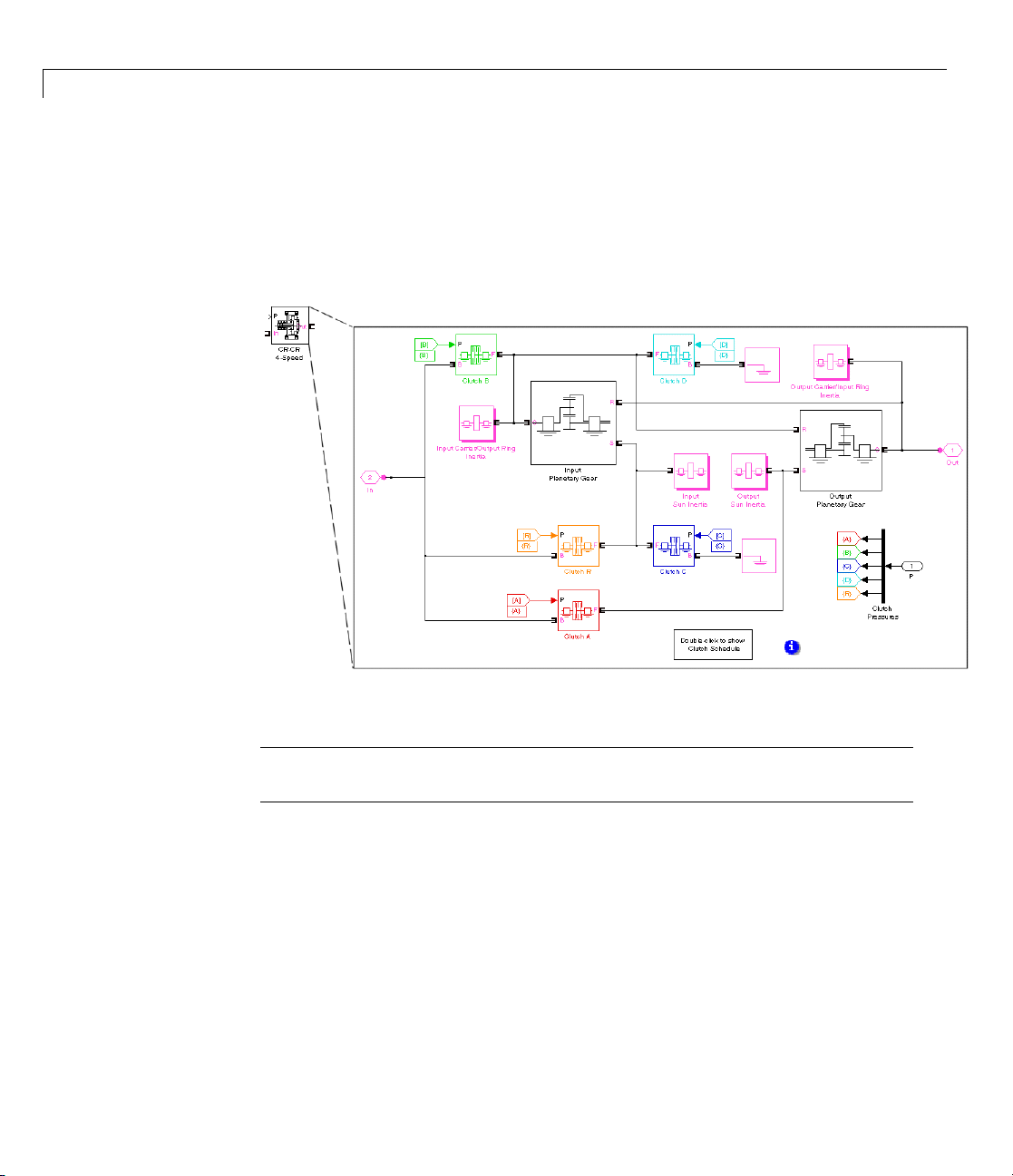

• The CR-CR 4-Speed Transmission subsystem is a set of fou r clutches,

two planetary gears, and four inertias (rotating bodies). (Ignore the

reverse gear and associated clutch.) Within the subsystem, open the

clutch schedule block to see the four possible (forward) gear settings for

the C R-CR 4-speed transmission. Exactly two clutches must be locked at

any one time for the transmission to be engaged and to avoid conflicting

constraints on the gear motions.

CR-CR 4-Speed Transmission Subsystem

1-9

Page 20

1 Introduc ing SimDriveline™ Software

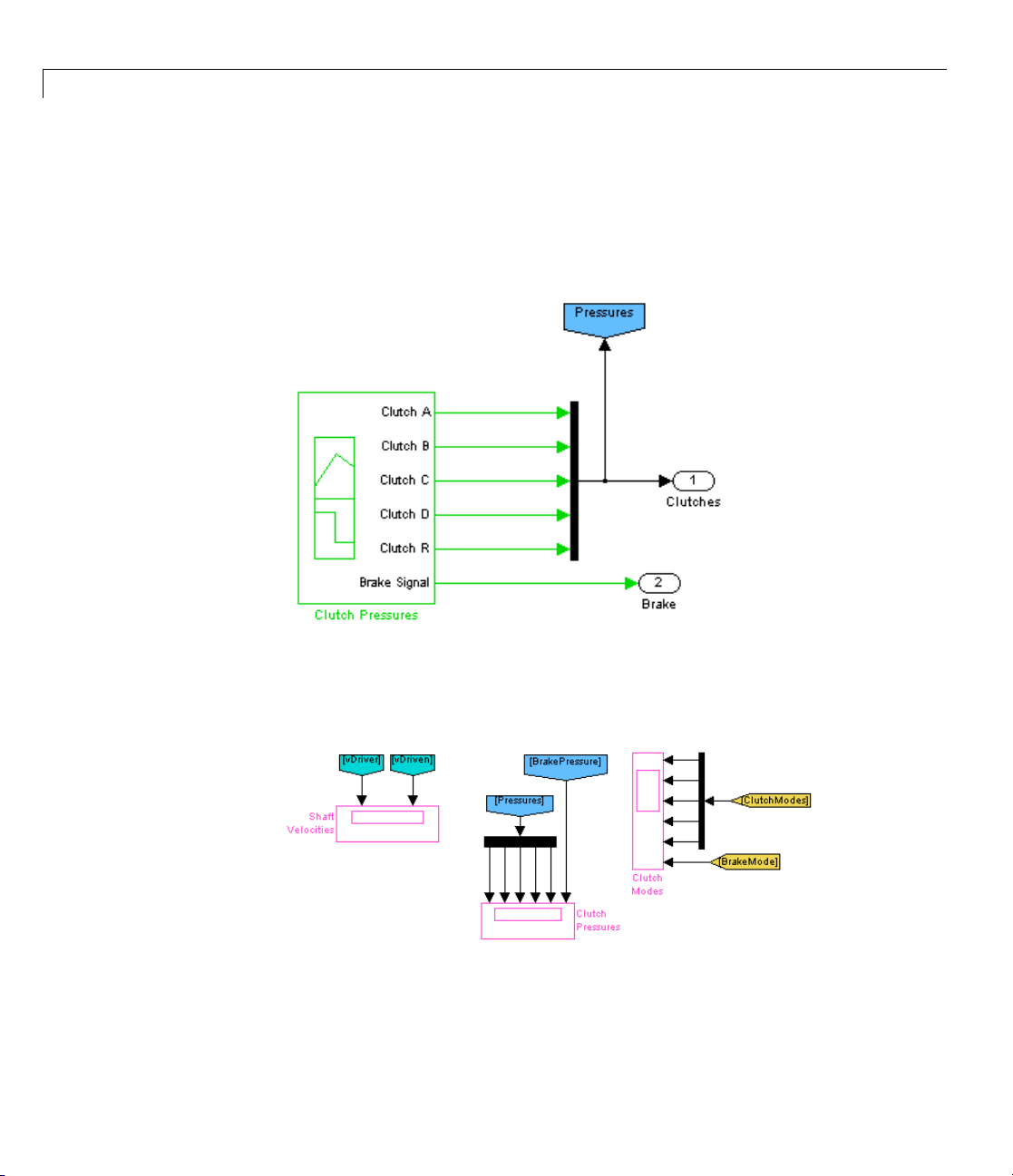

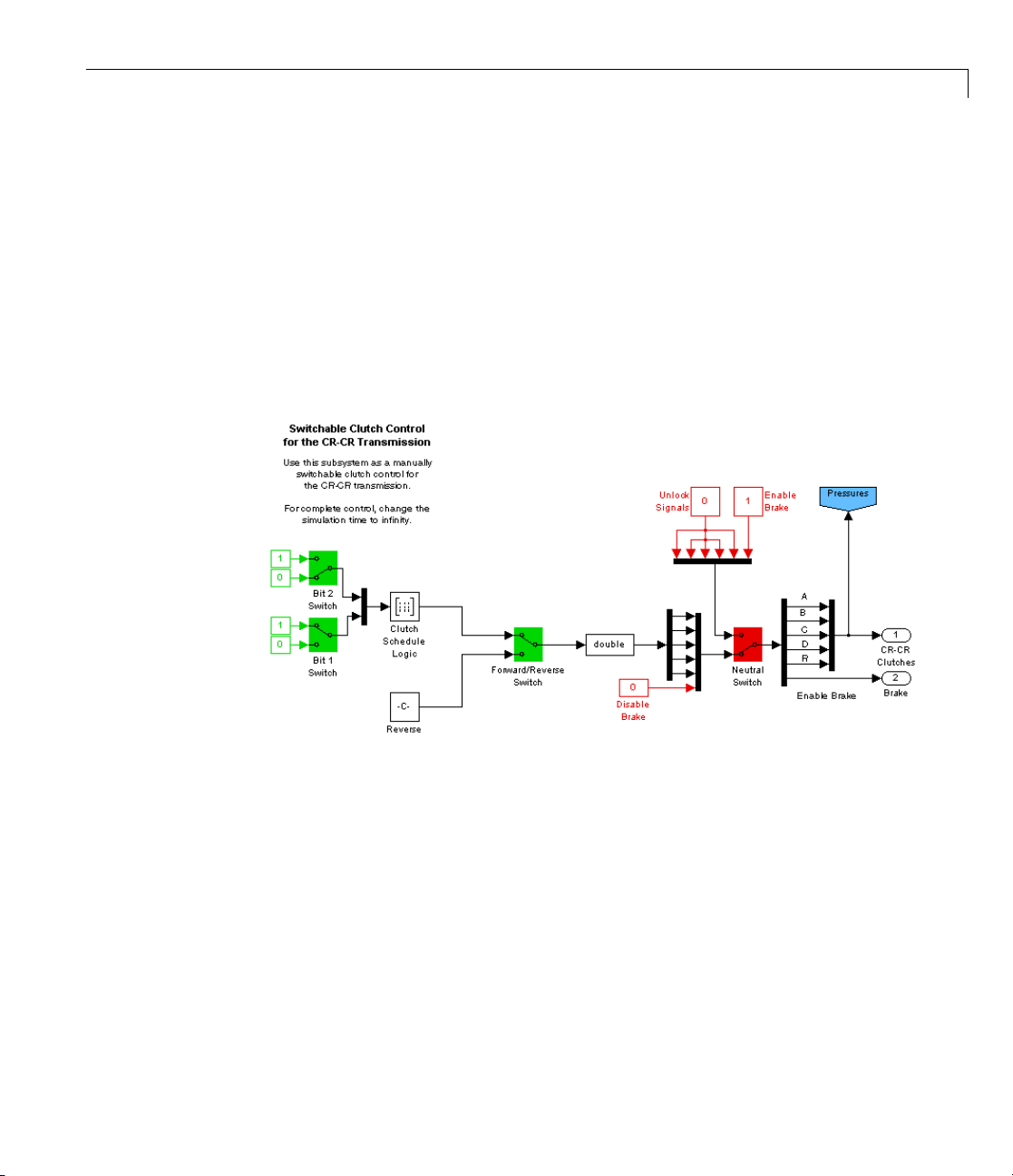

• The Clutch Control subsystem provides the pressures that lock the

necessary clutches. The clutch controller is programmed to move the

transmission through a fixed sequence of gears, then unlock all the

transmission clutches, allowing the driven shaft to “coast” for a time, and

then engage and lock the brake clutch to stop the driven shaft.

1-10

Clutch Control Subsystem

• The Scopes subsystem provides Scope blocks to display the clutch pressure,

driver and driven shaft velocity, and clutch mode signals.

Scopes Subsystem

Page 21

Running a Demo Model

Running the Mode

To display the CR

1 Open the Scopes

Scopes subsyst

2 Click Start. The model steps through the gears and then brakes.

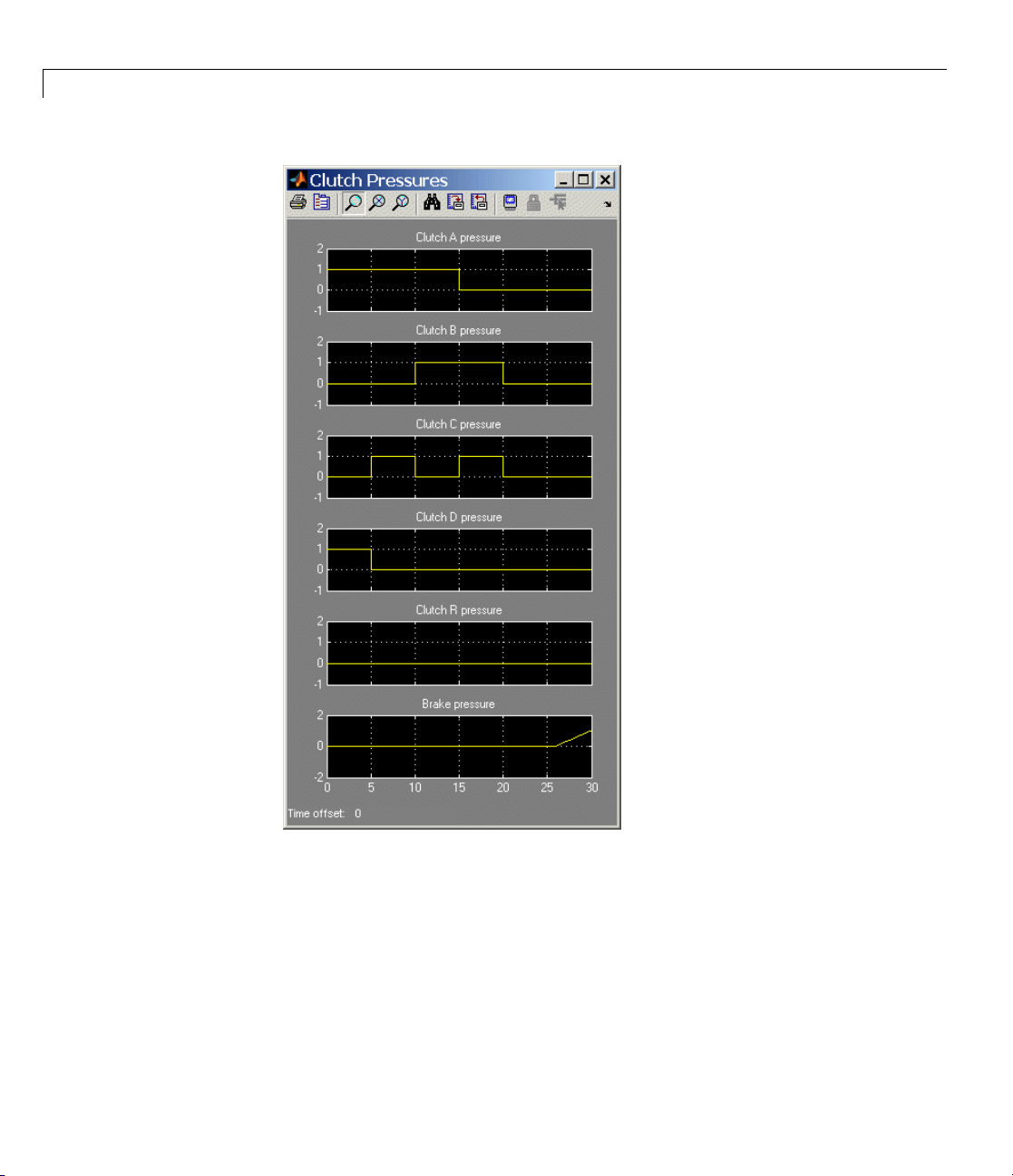

3 Observe how the clutch pressure signals move the transmission into

one gear after another, at 0, 5, 10, and 15 seconds of simulation time.

Compare these clutch pressure signals to the clutch schedule in the CR-CR

transmission subsystem to determine which gear settings the model is

implementing. (In fact, the model ste ps through gears 1, 2, 3, and 4, before

coasting and then braking.)

-CR driveline mo del’s behavior,

subsystem and then each of the Scope blocks. Close the

em.

l

1-11

Page 22

1 Introduc ing SimDriveline™ Software

1-12

Page 23

Running a Demo Model

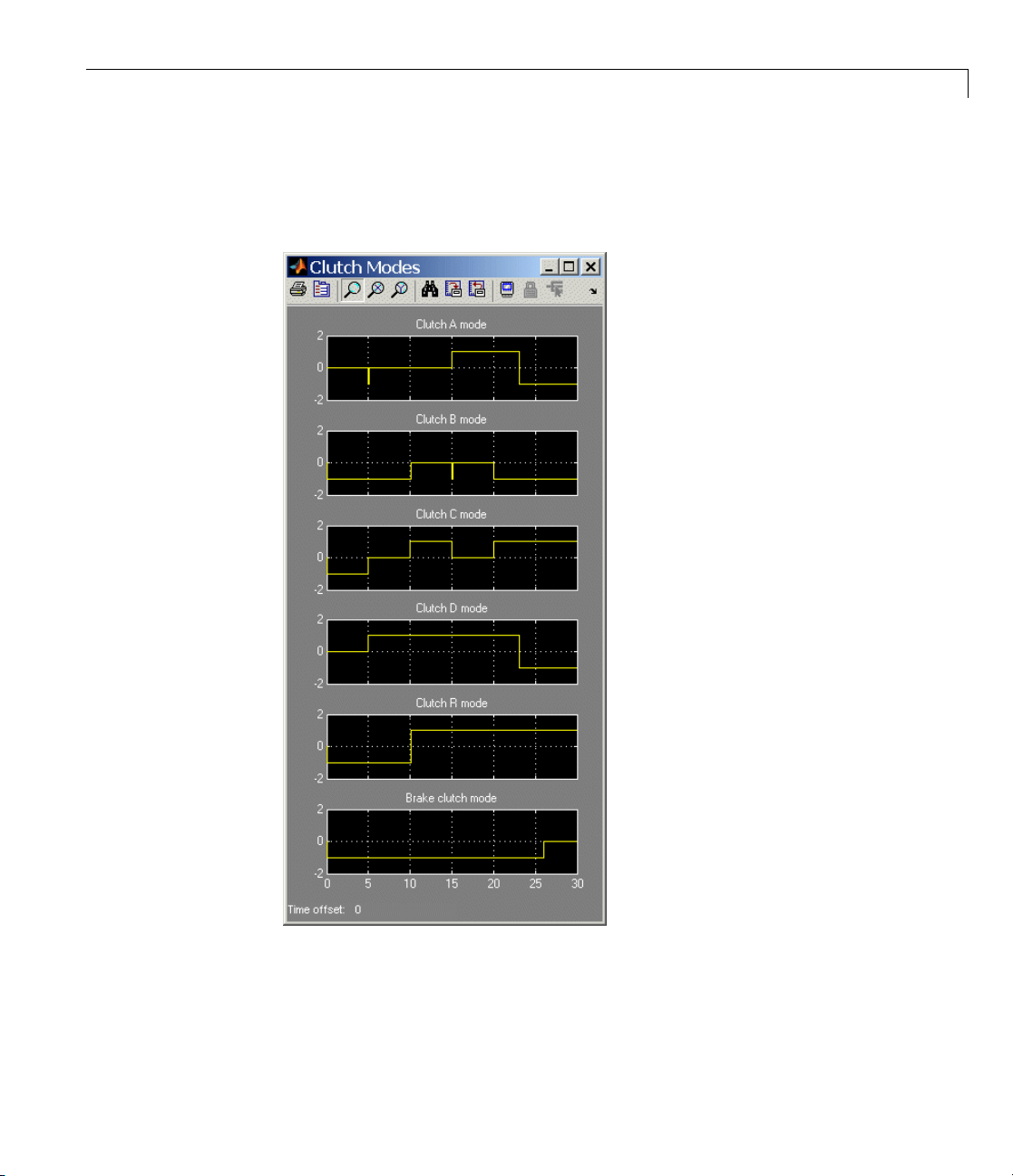

4 Observe the clutch modes at the same time. When a clutch mode is zero,

that clutch is locked. The sequence of clutch locking and unlocking matches

the sequence from the clutch schedule.

1-13

Page 24

1 Introduc ing SimDriveline™ Software

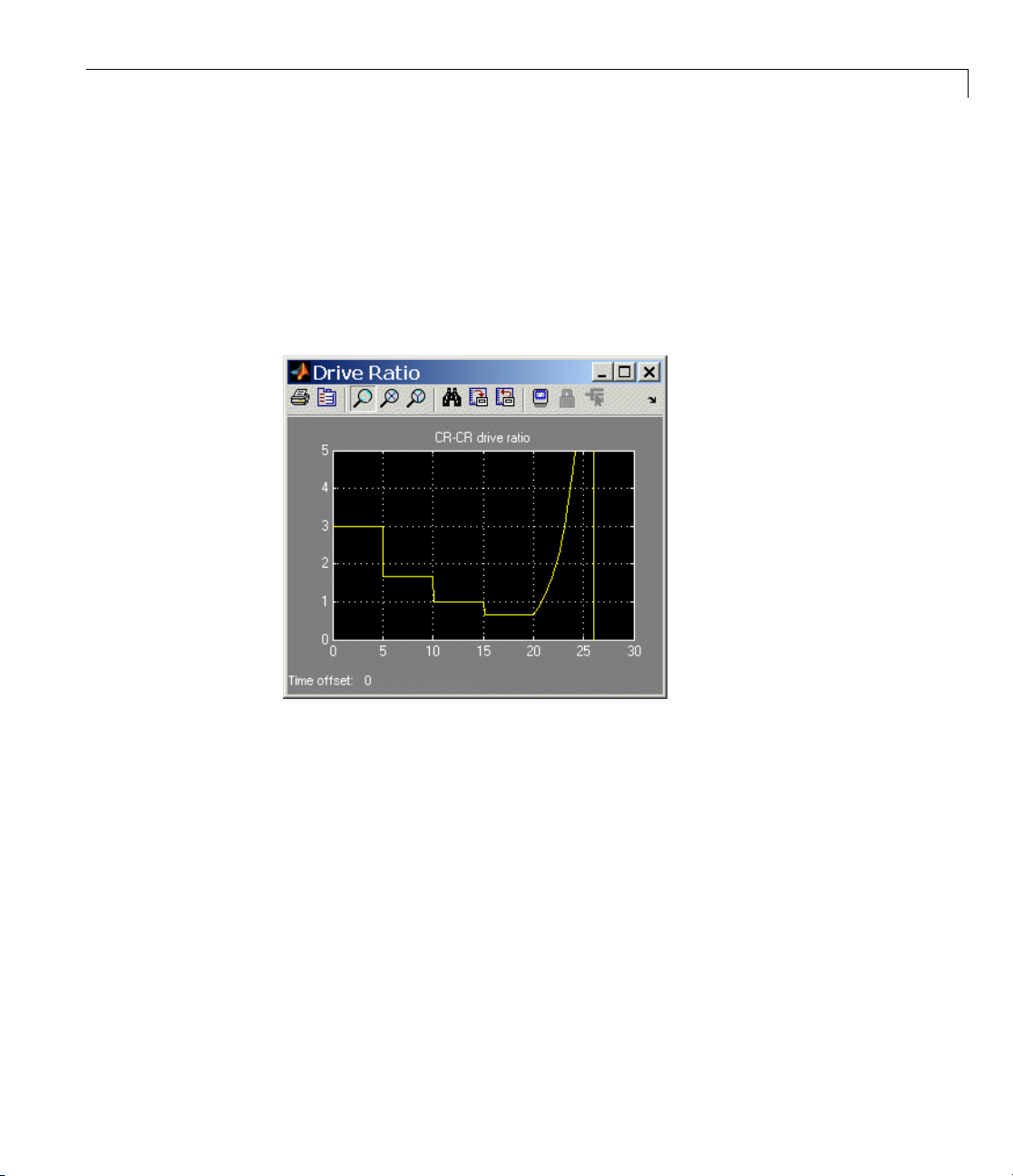

5 Compare the angular velocities of the driven and driver shafts. The effect

of the transmission is the result of the two planetary gears coupled in

different ways in the different gear settings. The effective drive ratio

of output to input shafts is the reciprocal of the ratio of output to input

angular velocities.

1-14

6 Observe what happens at 20 seconds. The transmission clutch pressures

drop to zero, and the transmission disengages. The transmission ceases

to transfer angular m otion and torque from the driver to the driven shaft,

and the driven shaft continues to spin simply from inertia. A small kinetic

friction damping gradually slows the driven shaft over the next 6 seconds.

Page 25

Running a Demo Model

7 At 26 seconds of simulation time, the brake clutch pressure begins to rise

from zero, and the brake clutch engages. The driven shaft decelerates more

drastically now. Between 26.0 and 26.1 seconds, the brake clutch locks,

and the driven shaft stops rotating completely.

Modifying the Model

You can modify this demo model to explore other SimDriveline features. Here

you modify and rerun the model to investigate two aspects of its motion.

• Measure the effective drive ratio of the CR-CR transmission in each gear

setting that it steps through.

• Change the gear sequence.

Measuring the Drive Ratio of the CR-CR Transmission States

The gear ratio (output to input) is the ratio of the output gear wheel radius to

the input gear radius. Equivalently, thegearratioistheratioofthenumber

of teeth on the output gear wheel to the number on the input wheel, or the

ratio of the output torque to the input torque. The ratio of the angular

velocities of output to input is the reciprocal of this gear ratio.

A transmission is a set of coupled gears. But for a particular transmission

gear setting, the ratio of driven (output) shaft velocity to the driver (input) is

fixed. Its reciprocal, the drive ratio, is like a gear ratio of an individ ual gear

coupling, but for the whole transmission.

1-15

Page 26

1 Introduc ing SimDriveline™ Software

Add and connect the Simulink blocks necessary to measure the drive ratio

of the transmission.

1 From the Simulink Math Op e ra tions lib rary, copy a Divide block and, from

the Simulink Sinks library, copy a Scope block.

2 From the Torque Driver subsystem outport, branch a signal line from

Motion Sensor1’s angular velocity output and connect it to the

on the Divid e block. From the velocity output of Motion Sensor2, on the

driven (output) shaft, again branch a signal line. Connect it to the ÷ inport

on the Divide block.

The effective output-to-input drive ratio is the ratio of input to output

velocities.

3 Connect the outport of the Divide block to the Scope. Rename Scope to

Drive Ratio.

X inport

1-16

CR-CR 4-Speed Model with Drive Ratio Measurement

Page 27

Running a Demo Model

4 OpentheDriveRatioscopeandrestartthedemo. Observehowthedrive

ratio steps through a sequence of five-second states, in parallel with the

clutch pressures and clutch modes, until it reaches 20 seconds. The

drive ratio measurement after 20 seconds is not meaningful because the

transmission is uncoupled.

Just after 26 seconds, the driven shaft velocity drops to zero, and the Div ide

block produces divide-by-zero warnings at the MATLAB command line.

5 Look inside the CR-CR 4-Speed Trans mission subsystem for the Clutch

Schedule block and open it. Consult the drive ratios for each gear, 1, 2,

3, and 4, in terms of the gear ratios of the transmission’s two Planetary

Gears. Determine the numerical values for these drive ratios for gear

settings1,2,3,and4andcheckthemagainstthevaluesdisplayedinthe

Drive Ratio scope.

The drive ratio sequence should be 3, 5/3, 1, and 2/3, respectively, for the

first, second, third, and fourth intervals of five seconds each.

nging the Transmission Gear Sequence

Cha

The d rive_crcr_ideal demo, when you open it, is programmed to step through

CR-CR gear settings 1, 2, 3, and 4, before disengaging. Modify it to step

through settings 1, 2, 3, and 1, then disengage. T he fourth gear requires

1-17

Page 28

1 Introduc ing SimDriveline™ Software

A, B, C, and D to be free, locked, locked, and free, respectively . You will

modify the clutch pressure signal sequence from 15 to 20 seconds so that the

transmission is set in first, not fourth, gear. The first gear requires clutches

A, B, C, and D to be locked, free, free, and locked, respectively.

1 Open the C lutch Control and CR-CR transmission subsystems. Within

the transmission, open the Clutch Schedule block and review the clutch

lockings for each gear setting.

2 Open the Signal Builder block, labeled Clutch Pressures, to view the clutch

pressure signals.

Modify clutch pressure signals A, B, C, and D so that, between 15 and 20

seconds, clutches A and D are locked (not free) and clutches B and C are

free (not locked). Sufficient pressure will lock the clutches, while zero input

pressure leaves a clutch unlocked.

1-18

Modified CR-CR 4-Speed Transmission Clutch Pressures

Page 29

Running a Demo Model

3 Restart the model. Observe that between 15 and 20 seconds of simulation

time the clutch pressures, the clutch modes, and the driven shaft velocity

are now different from the original version of the model.

Check the effective drive ratio between 15 and 20 seconds to confirm that

the CR-CR transmission during that time is set in gear 1, not gear 4. This

fourth interval of five seconds should exhibit a drive ratio of 3 instead of 2/3.

1-19

Page 30

1 Introduc ing SimDriveline™ Software

What Can You Do with SimDriveline Software?

In this section...

“About SimDriveline Software” on page 1-20

“Modeling Drivetrains” on page 1-20

“Connector Ports and Connection Lines” on page 1-21

“Inertias and Gears” on page 1-22

“Complex Driveline Elements” on page 1-22

“Actuating and Sensing Motion” on page 1-23

“Simulating and Analyzing Motion” on page 1-24

About SimDriveline Software

SimDriveline software is a set of block libraries and special simulation

features for use in the Simulink environment. You connect SimDriveline

blocks to normal Simulink blocks through Sensor and Actuator blocks.

1-20

The blocks in these libraries are the e lem ents you need to model driveline

systems consisting of any number of rotating inertias, rotating about one or

more axes, constrained to rotate together by gears, which transfer torque to

different parts of the driveline. You can represent drivelines with components

organized into hierarchical subsystems, as in normal Simulink models. You

can add complex dynamic elements such as clutches and transmissions,

actuate bodies with external torques or motions, integrate the Newtonian

rotational dynamics, and measure the resulting motions.

Modeling Drivetrains

SimDriveline software extends Simulink with blocks to specify a driveline’s

components and properties and to solve the equations of motion. The blocks

are similar to other Simulink blocksets, with some properties unique to

SimDriveline software.

These are the major steps you follow to build and run a SimDriveline model

representation of a driveline:

Page 31

What Can You Do with SimDriveline™ Software?

1 Specify rotational inertia for each body and connect the bodies with

driveline connection lines representing driveline axes. If needed, ground

the driveline to one or more housings fixed in space.

2 Constrain the driveline axes to rotate together by connecting them with

gears. Gears impose static constraints on driveline motions and transfer

torques at fixed ratios.

3 As necessary and desired, add dynamic driveline elements that transfer

torque and motion among driveline axes in a nonstatic way. These

elements include internal torque-generating components such as damped

springs, clutches and transmissions, and torque converters. You can also

construct and connect your own dynamic elements.

4 Setupactuatorsandsensorstoinitiateandrecordbodymotions,aswellas

apply external torques to the driveline.

5 Connect the Sim Driveline motion solv er to the driveline and configure it.

Start the simulation, calling the Simulink solvers to find the motions of the

system. Display and analyze the motion.

Connector Ports and Connection Lines

Most SimDriveline blocks have special driveline ports . You connect

driveline ports with driveline connection lines, distinct from normal Simulink

lines. Driveline connection lines represent physical rotation axes along which

torque is transferred and around which inertias rotate.

• You can connect driveline ports only to other driveline ports.

• The driveline connection lines that connect driveline ports together are

not normal Simulink lines, which carry signals or indicate mathematical

operations. You cannot connect driveline lines directly to Simulink inports

and outports >.

• Two directly connected driveline components must corotate at the same

angular velocity.

• You can branch SimDriveline connection lines. When you do so, components

directly connected with one another continue to share the same angular

velocity. The torque transferred along the driveline axis is divided among

the multiple components connected by the branches. How the torque is

divided is determined by the driveline dynamics.

1-21

Page 32

1 Introduc ing SimDriveline™ Software

The sum of all torques flowing into a branch point equals the sum of all

torques flowing out.

Inertias and Gears

SimDriveline software defines a drive line as a collection of bodies rotating

about driveline axes represented by connection lines. The bodies are defined

by their rotational inertias. The lines carry the rotational degrees of freedom

(DoF) and, unconstrained, rotate freely. Directly connecting one body to

another constrains both bodies to rotate at th e same angular velocity. A

torque applied to one body is effectively applied to both.

You can also ground driveline axes to housings that do not move and that

represent infinite effective inertia.

Note All SimDriveline rotational DoFs are ab sol ute and m easured with

respect to a single implicit global coordinate system at rest.

1-22

In a real driveline, the bodies can also be connected indirectly by gears that

couple driveline axes. The gears constrain the axes to rotate together. T hese

gears can be simple or complex and can couple two or more axes. The g ears

have two roles:

• They constrain the connected axes to corotate at angular velocities in

fixed ratio or ratios.

• They transfer the torques flowing along one or more axes to other axes,

also in fixed ratio or ratios.

Complex Driveline Elements

Tip These blocks serve as suggestions for developing variant or entirely new

models to simulate the same components. You can study these subsystems

by looking under their masks. If necessary, break the block’s library link

before modifying it, and then create your own version. Or create your own

completely new block from scratch.

Page 33

What Can You Do with SimDriveline™ Software?

Tocreatemorerealisticdrivelinemodels, you elaborate on simple drivelines

consisting of inertias and gears by adding complex mechanical elements

that generate torques internally within the driveline, between one axis and

another. Certain SimDriveline blocks encapsulate as subsystems entire

models of complex dri veline elements:

• Clutches that model the locking and unlocking of pairs of driveline axes by

applying kinetic and static friction.

Note In the default case, adding clutches introduces algebraic loops (mode

iterations), non-time-based simulation steps.

• Transmission models that incorporate multigear sets and clutches into a

single subsystem

• Vehicle component models that represent engines, tires, and vehicle

dynamics

• Specialized torque models, such as torque converters, bilateral stops, and

damped spring-like torsion

Actuating and Sensing Motion

Sensors and Actuators are the blocks you use to interface between

SimDriveline blocks and normal Simulink blocks:

• Actuator blocks impart motion to driveline axes, e ither at zero time or

through the course of a simulation, and impose externally defined torques

on the bodies of a driveline.

• Sensor blocks measure the motions of, and the torques transferred along,

theaxesofadrivelinesystem.

Actuating inputs and sensor outputs are Simulink signals that you can define

and use like any other Simulink signal. For example, you can connect a

Sensor output to a Simulink Scope block and display the torques in a driveline

as functions of time.

1-23

Page 34

1 Introduc ing SimDriveline™ Software

Simulating and A

Once you specify

the bodies with g

of finding the s

prepare it for s

environment.

Newtonian dyn

torques and co

Once your mod

motions and i

all the rotational inertias of the bodies and interconnect

ears and other driveline elements, the dynamical problem

ystem’s motion is solvable. To finish a driveline model and

imulation, you must connect the driveline to the SimDriveline

The environment defines the solver that integrates the

amics for the system, applying all internal and external

nstraints to find the motions of the bodies.

el is ready for simulation, you can run it and analyze its

nternal torques.

nalyzing Motion

Trimming and Linearizing the Motion

In many cas

of motions

torques, y

trajector

consists

Aspecial

searchi

acceler

tools in

how the

system

es, you do not know the torques necessary to produce a given set

. By motion-actuating your driveline and measuring the resulting

ou can find the torques necessary to produce a specified motion

y. This technique inverts the canonical approach to dynamics, which

of finding motions from torques.

case of inverse dynamics is trimming. This technique involves

ng for steady-state motions of the bodies, when their angular

ations and the torques they experience vanish. Using the linearization

Simulink, you can perturb such a steady motion state slightly to find

system responds to small disturbances. Theresponseindicatesthe

’s stability and suitability for controllers.

1-24

Generating Code — Clutches and Algebraic Loops

SimDr

Realvers

enha

The p

and

The

gen

iveline software is compatible with Simulink Acceleration modes,

Time Workshop

ions of the models you create originally in Simulink with block diagrams,

ncing simulation speed and model portability.

resence of clutches in a driveline model induces mode iterations

dynamical discontinuities and triggers algebraic loops in Simulink.

se discontinuities and algebraic loops place certain restrictions on code

eration.

®

and xPC Target™ software. They let you generate code

Page 35

Learning More

In this section...

“Using the MATLAB Help System for Documentation and Demos” on page

1-25

“Finding Special SimDriveline Help” on page 1-25

Using the MATLAB Help System for Documentation and Demos

Youcangethelponlineinanumberofwaystoassistyouwhileyouuse

SimDriveline software. The MATLAB help browser allows you to access the

documentation and demo models for a ll the MATLAB and Simulink based

products that you have installed. The online help includes an online index

and search system.

Consult the MATLAB Getting Started Guide for more about the MATLAB

help system.

Learning More

Finding Special SimDriveline Help

This user’s guide includes these reference chapters:

• Appendix A, “Technical Conventions” explains special conventions,

abbreviations, and units.

• Appendix B, “Bibliography” lists external references on driveline and

powertrain modeling and related topics.

In addition, many SimDriveline demos have help links represented by the

information symbol

in the Help browser.

. Click this symbol to open that demo’s documentation

1-25

Page 36

1 Introduc ing SimDriveline™ Software

1-26

Page 37

Simple Models

This chapter introduces you to modeling drivetrains in the SimDriveline

environment. After showing you how you how to access the SimDriveline

block library and reviewing the essential rules of connecting blocks and

transferring angular motion and torque, it moves you from modeling simple

gears to simulating a full car in a series of short tutorials.

• “Introducing the SimDriveline Block Libraries” on page 2-2

• “Essential Steps to Building a Driveline Model” on page 2-7

• “Representing and Transferring Driveline Motion and Torque” on page 2-9

2

• “Actuating Drivelines with Torques and Motions” on page 2-22

• “Controlling Gear Couplings with Clutches” on page 2-28

• “Combining Clutches and Gears into Transmissions” on page 2-42

• “Modeling and Simulating a Complete Car” on pag e 2-58

This user’s guide assumes that you are familiar with building models in

Simulink. If not, see the Simulink documentation.

Page 38

2 Simple Models

Introducing the SimDriveline Block Libraries

In this section...

“About the SimDriveline Block Library” on page 2-2

“Accessing the Libraries” on page 2-2

“Using the Libraries ” on page 2-4

About the SimDriveline Block Library

SimDriveline software is organized into a set of libraries of closely related

blocks. This section shows you how to opentheseSimDriveline block libraries

and explains the nature of each library.

Accessing the Libraries

There are several ways to open the SimDriveline block library.

2-2

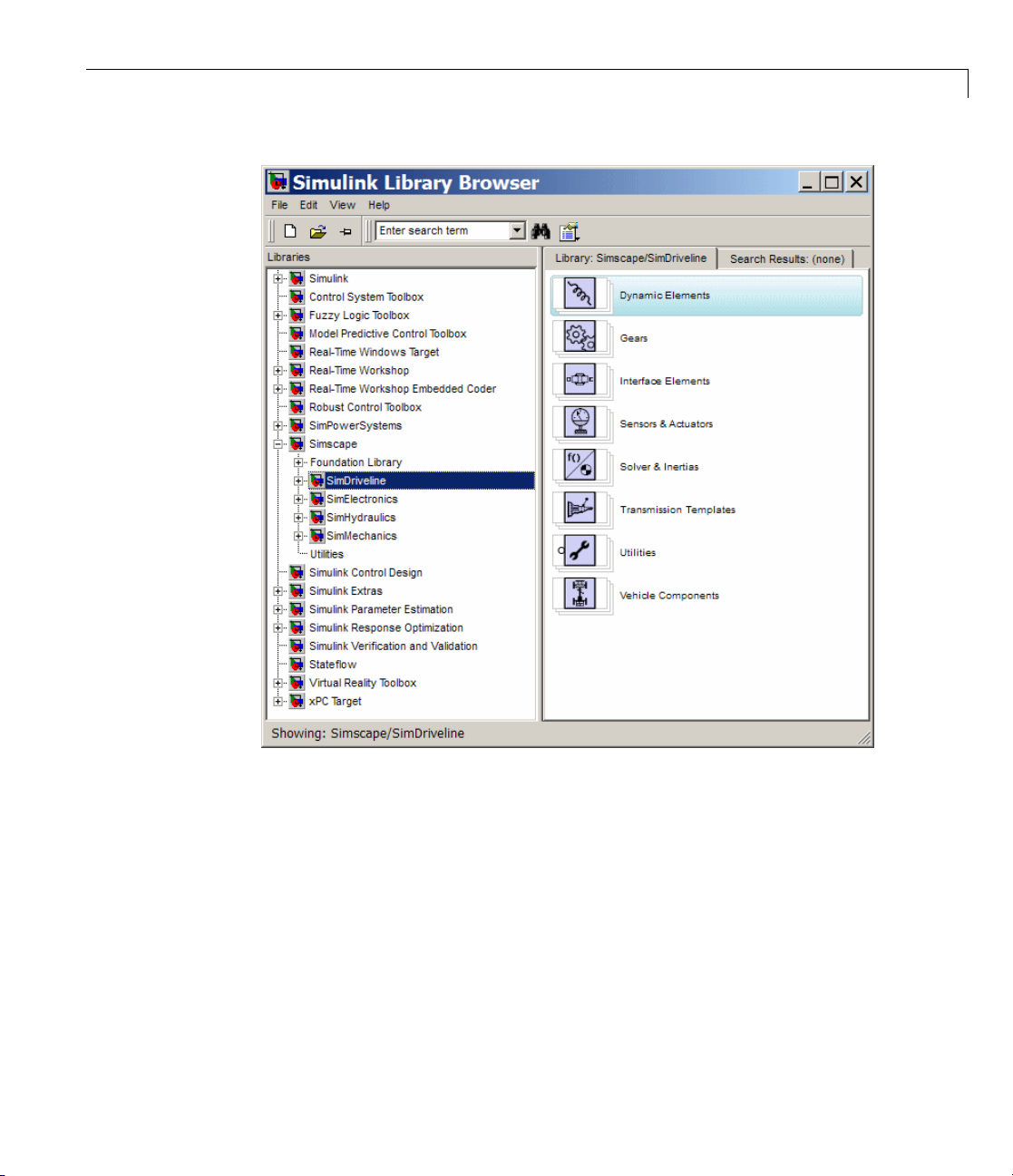

You can access the blocks through the Simulink Library Browser. Open the

browser by clicking the Simulink button

then the SimDriveline subentry, in the contents tree.

. Expand the Simscape entry,

Page 39

Introducing the SimDriveline™ Block Libraries

You can also access the blocks directly inside the SimDriveline library in

several ways:

• In the Simulink Library Browser, right-click the SimDriveline subentry

under Simscape and select Open SimDriveline Library. The library

appears.

• Click the Start button in the lower-left corner of your MATLAB desktop.

In the pop-up menu, select Simulink,thenSimDriveline,thenBlock

Library.

• Enter

drivelib at the MATLAB command line.

2-3

Page 40

2 Simple Models

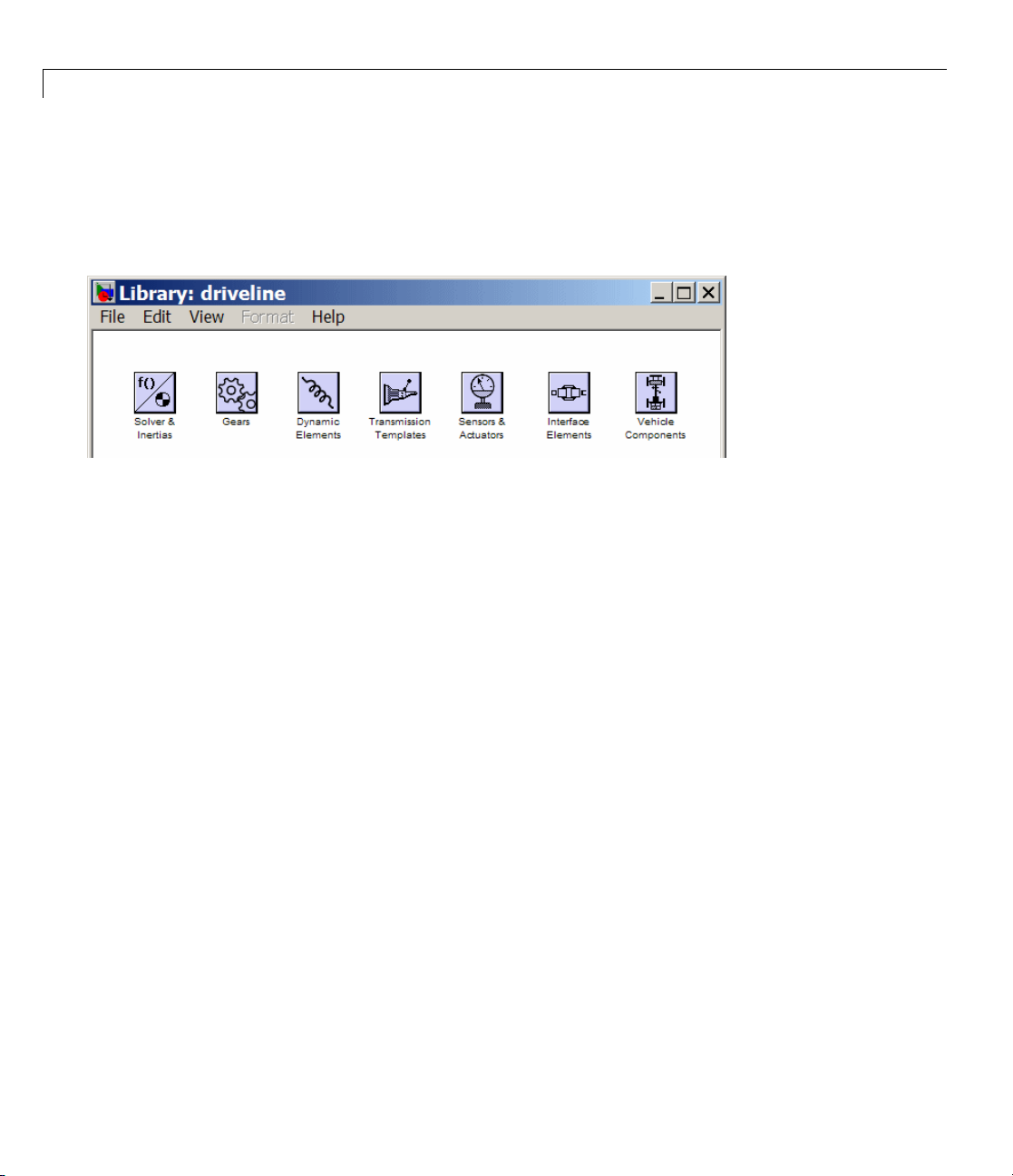

SimDriveline Library

Once you perform one of these steps, the SimDriveline library opens. This

library displays seven top-level block groups. You can expand each library

by double-clicking its icon.

The next section summarizes the blocks of each library and their use. For

explanations of individual blocks, consult the SimDriveline “Block Reference”

reference.

2-4

Using the Libraries

The SimDriveline block library is organized into separate libraries, each with

a different type of driveline block.

Solver & Inertias

The Solvers & Inertias library provides the Inertia block, which represents

a rotating body specified by its moment of inertia, the fundamental unit of

driveline modeling. It also contains the Housing block, which represents an

immobile rotational ground.

Finally, the library contains the Driveline Environment block, which

configures the driveline settings of a SimDriveline block diagram, and

the Shared Environment block, which allows you to connect two driveline

block diagrams in a nonphysical way so that they share the same driveline

environment settings.

Gears

The Gears library contains blocks that represent simple and complex gears,

driveline elements that couple distinct driveline axes and constrain their

Page 41

Introducing the SimDriveline™ Block Libraries

relative motions. The Gear blocks range from simple two-wheel gear couplings

with fixed and variable gear ratios, to complex multiwheel and multiaxis

gears such as planetary and differential gears.

Dynamic Elements

The Dynamic Elements library contains blocks that model such critical

drivetrain components as clutches, torque converters, damped springs, and

stops. Dynamic elements generate internal driveline torques.

The blocks of this library serve as suggestions for developing variant or

entirely new models to simulate the same components. Look under the block

mask, break the block’s library link before modifying it, and create your own

version.

Transmission Templates

The Transmission Templates are a set of predesigned transmission examples

constructed from gears, clutches, and inertias. You can copy and use these

examples in your drivetrain models.

Transmission templates copied into your model are not linked to the block

library. You can modify and rebuild these template copies at will.

Sensors & Actuators

The Sensors & Actuators library provides blocks for sensing and initiating the

motions of driveline axes and applying and sensing torques along those axes.

Interface Elements

The Interface Elements library enables connections between SimDriveline

driveshaft connection lines and Simscape mechanical rotational motion.

Vehicle Components

The Vehicle Components library contains blocks that represent components

of a full vehicle beyond the drivetrain itself. It includes models of engines,

wheeled vehicles, and tires in contact with the ground.

2-5

Page 42

2 Simple Models

The blocks of this library serve as suggestions for developing variant or

entirely new models to simulate the same components. Look under the block

mask, break the block’s library link before modifying it, and create your own

version.

2-6

Page 43

Essential Steps to Building a Driveline Model

Essential Steps to Building a Driveline Model

The demo model of Chapter 1, “Introducing SimDriveline Software” illustrates

a typ ica l drivetrain system you can model with SimDriveline software. It also

illustrates the key rules for connecting driveline blocks to each other and the

dual roles of driveline connection lines: transferring torque and enforcing

angular velocity constraints. You should review these rules before building

and running the tutorial models of this chapter.

• Driveline blocks, in general, feature both driveline connector ports

regular Simulink inports and outports

one another and Simulink ports to one another. But you cannot connect a

drivelineporttoaSimulinkport.

• The driveline connection lines interconnecting driveline connector ports

represent driveline axes and enforce physical relationships. Unlike

Simulink lines, they do not represent signals or mathematical operations,

and they have no inherent directionality.

• A driveline connection line represents an idealized massless and perfectly

rigid spinning shaft. A driveline conne ction line between two ports enforces

the constraint that the two driveline components so connected rotate at

the same angular velocity. The connection line also transfers any torque

applied to a driveline component at one end to the component at the other

end.

• You can branch driveline connection lines. You must connect the end of

any branch of a driveline connection line to a driveline connector port

• Branching a driveline connection line modifies the physical constraints

that it represents. All driveline components connected to the ends of a

set of b ranched lines rotate at the same angular velocity. The torque

transferred along the input driveline axis is split up among the branches.

How the torque is split depends on the dynamical details of the system

that you are modeling.

>. You connect connector ports to

and

.

• Driveline connection lines satisfying the angular velocity constraint must

havethesameinitialangularvelocities.

2-7

Page 44

2 Simple Models

Branching Driveline Connection Lines

The Driveline Environment block does not use any torque. It does share the

angular velocity constraint from the branch point.

2-8

Symbolically, the branching conditions o n driveline connection lines are

ω = ω

τ = τ

= ω2= ω3...

1

+ τ2+ τ3...

1

The driveline axes have an implicit directionality. Torque and motion are

transferred “down” the driveline from input or drive shafts to output or

driven shafts. Certain SimDriveline blocks require explicit directionality and

represent it by designating one driveline connector port as the input base (B)

and the other a s the output follower (F). Relative motion of driveline axes or

shafts, when needed, is measured as follower relative to base.

Caution All motion in SimDriveline models, except when relativ e motion is

explicitly required, is measured in implicit absolute coordinates. An absolute

orientation defines zero angle, and an absolute reference frame defines zero

angular velocity. The Housing block implements the absolute zero angular

velocity and, if connected to a drivelineaxis,enforcesthiszero-motionstate

on that axis.

Page 45

Representing and Transferring Driveline Motion and Torque

Representing and Transferring Driveline Motion and

Torque

In this section...

“About Inertia, Motion, and Gears” on page 2-9

“Coupling Rotational Motion with Gears” on page 2-9

“Coupling Two Spinning Inertias with a Simple Gear” on page 2-11

“Coupling Two Spinning Inertias with a Variable Gear” on page 2-16

“Coupling Three Spinning Inertias with a Planetary Gear” on page 2-17

About Inertia, Motion, and Gears

The purpose of a gear set is to transfer rotational motion and torque at a

known ratio from one driveline axis to another. This section introduces you to

modeling gears and using them to couple bodies rotating on driveline axes.

Coupling Rotational Motion with Gears

A gear set consists of two or more meshed gears corotating at some specified

gear ratios. The ratios might or mightnotbeconstant. Thegearratios

determine how angular velocity and torque are transferred from one driveline

component to another.

Gear Coupling Rules

Ideal gears mesh and corotate at a point of contact without frictional loss

or slippage.

The simplest gear coupling consists of two circular gear wheels of radii r

r

, spinning with angular velocities ω1and ω2,respectively,andlyinginthe

2

same plane. Their connected shafts are parallel and carry torques τ

The gear ratio of gear 2 to gear 1 is the ratio of their respective radii: g

r

. The power transferred along either shaft is ω·τ.

2/r1

The gear couplin g is often sp ecified in terms of the number of gear teeth on

each gear, N

r

.

2/r1

and N2. The gear ratio of gear 2 to gear 1 is then g21= N2/N1=

1

and τ2.

1

21

1

and

=

2-9

Page 46

2 Simple Models

The fundamental conditions on the simple gear coupling of rotational motion

are ω

=±1/g21and τ2/τ1=±g21. That is, the ratio of angular velocities is the

2/ω1

reciprocal of the ratio of radii, while the ratio of torques is the ratio of radii.

The transferred power, being the product of angular velocity and torque,

isthesameoneithershaft.

The choic e of signs indicates that the gears ca n spin in the same or in opposite

directions. If the gears are external to one another (corotating on their

respective outside surfaces), they rotate in opposite directions. If the gears

are internal to one another (corota tin g with the outsid e of the smaller gear

meshing with inside of the larger gear) , they rotate in the same direction.

Warning Gear ratios should always be strictly positive. If a gear

ratio vanishes or becomes negative, the SimDriveline simulation

stops with an error.

Generalized Gear Coupling Rules

You need the general ideal gear coupling conditions if you are coupling gears

that are not constant in radii, not lying in the s ame plane, or not circular.

2-10

The general velocity constraint requires that the linear velocities of the gears

at the point of contact be the same. This is a vector condition on the angular

velocities ω

and ω2and the radius vectors r1and r2: ω

1

x r

= ω

x r

1

1

.The

2

2

alternative form in terms of the number of gear teeth is equivalent to this

linear velocity constraint. For the gear teeth to mesh, the number of teeth per

unit length of gear circumference must be the same on the two gears.

The g eneral torque condition arises from the force equilibrium at the point of

contact. If there is no linear motion of the w h ole gear a sse mbly, the forces at

contact F must be equal and opposite. The ratio of torque s is then:

|τ

|/|τ1|=|r

2

x F|/|r1x F|

2

The power transferred along either shaft is conserved across ideal gear

couplings:

ω

·(r

2

x F)=ω

2

·(r

x F)

1

1

Page 47

Representing and Transferring Driveline Motion and Torque

Coupling Two Spi

In this example,

(driveline axis

spinning along

velocities; an

spinning at di

most basic Sim

Environment.

you couple two spinning inertias, first, along a single shaft

), so that they spin with the same angular velocity; then

two shafts and coupled by a gear so that they spin at different

d finally, coupled by a gear and actuated by an external torque,

fferent rates and experiencing different torques. You use the

Driveline blocks, such as Inerti a, Simple Gear, and Driveline

nning Inertias with a Simple Gear

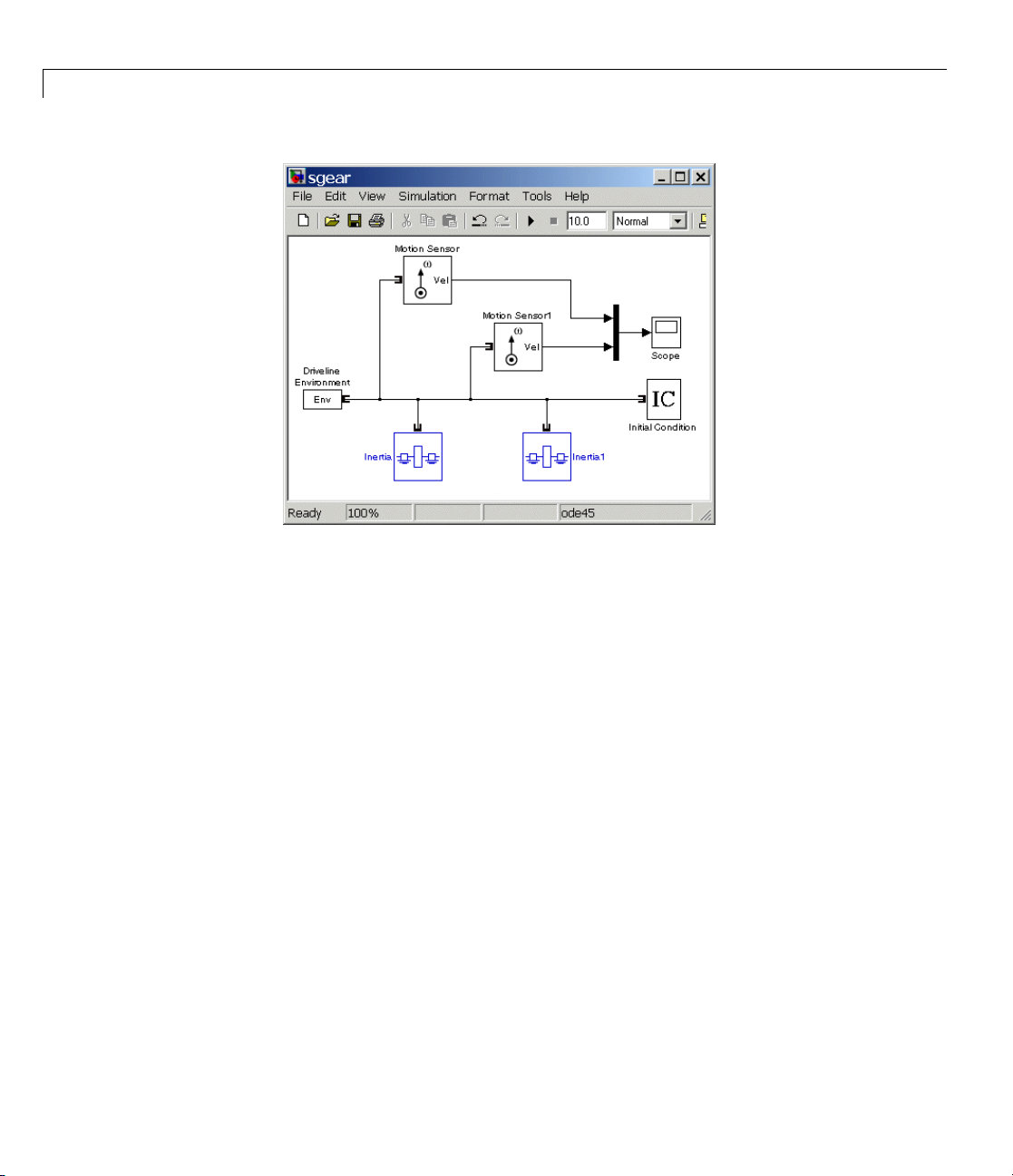

Modeling Two Spinning Inertias

Here you cre

spinning to

block libra

1 Drag and drop two Inertia, two Motion Sensor, and one Initial Condition

blocks into the model window.

2 Every topologically distinct driveline block diagram requires exactly one

Driveline Environment block, found in the SimDriveline Solver & Inertias

library. Copy one such block into your model.

3 From the

connect

ate the first version of the simplest driveline model, tw o inertias

gether along the same axis. Open the SimDriveline and Simulink

ries and a new Simulink model window.

Simulink library, drag and drop a Scope and a Mux block. Then

theblocksasshown.

2-11

Page 48

2 Simple Models

Two Spinning Inertias

2-12

4 Open the Initial Condition block. In the Initial angular velocity field,

replace its default

0 entry with pi radians/second (rad/s). Click OK.

If you do not connect an Initial Condition block to a driveline axis, the

axis by default starts the simulation with zero angular velocity. You must

ensure that the initial angular velocities of your coupled driveline axes are

consistent with one another. If they are not, the simulation stops with

an error.

5 Open the Scope block and start the simulation. The two angular velocities

are constant at 3.14 radians/second.

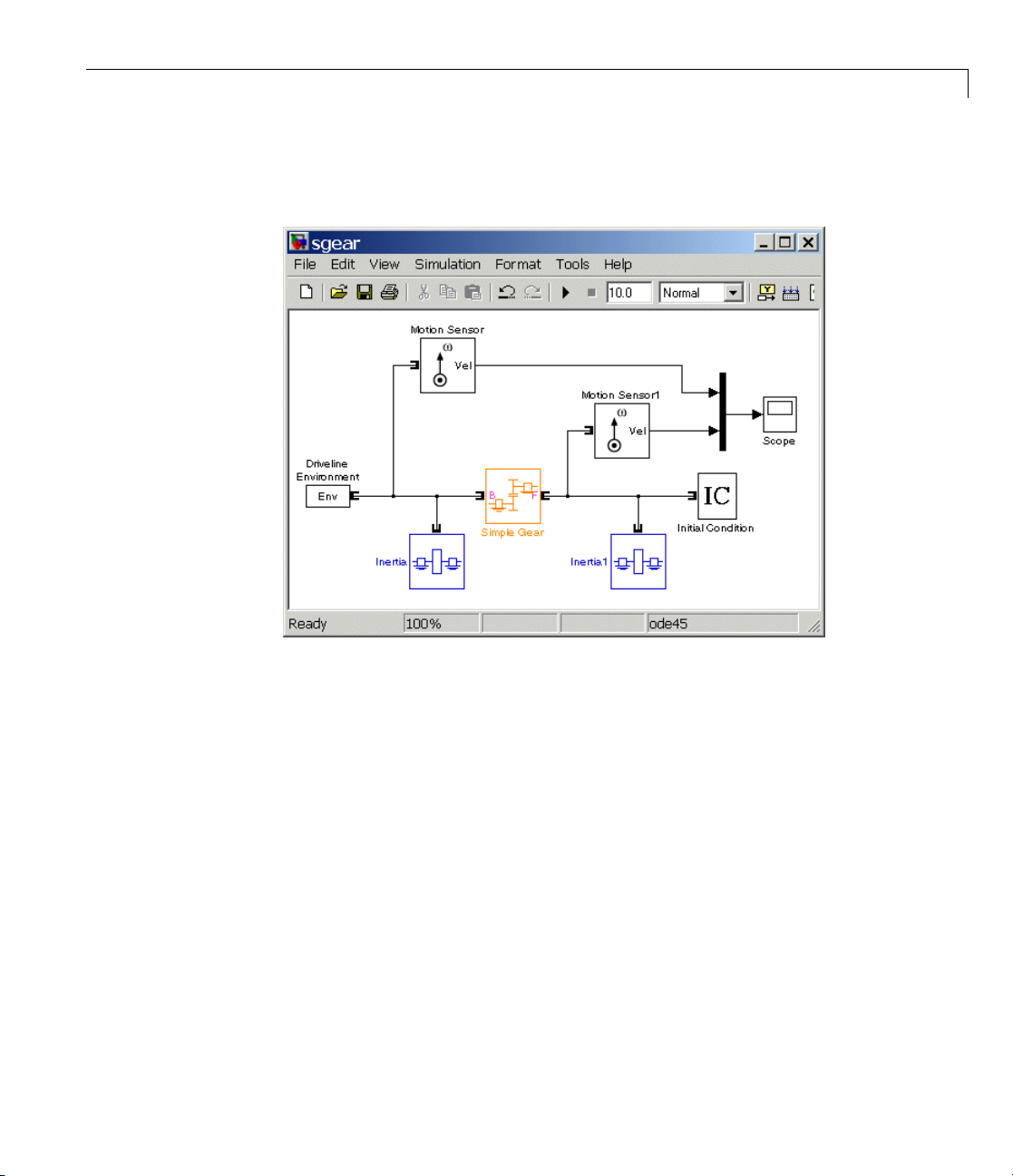

Coupling Two Spinning Inertias with a Simple Gear

Now you modify the model you just created by coupling the two spinning

inertias with a simple, ideal gear with a fixed gear ratio.

1 From the SimDriveline block library, drag and drop a Simple Gear block

into your model. Open the block. Leave the default follower-base gear ratio

value at

check box and click OK. The simple gear then represents two gear wheels

2.CleartheFollower and base rotate in opposite directions

Page 49

Representing and Transferring Driveline Motion and Torque

corotating in the sam e direction, with the sm aller wheel inside the larger.

Reconnect the b locks as shown.

Two Spinning Inertias Coupled by a Gear

Leave the initial angular velocities at pi in the Initial Condition block.

SimDriveline software automatically sets the correct initial angular

velocity for Inertia.

2 Open the Scope and start the simulation. The two angular velocities

are constant at 3.14 and 6.28 radians/second for Inertia1 and Inertia,

respectively. The fo llower-base gear ratio is 2, and the angular velocity of

Inertia is twice that of Inertia1, with the same sign, because the two bodies

are spinning in the same direction.

3 Now s

4 Restart the simulation. The two angular velocities are 3.14 and -6.28

elect the Follower and base r otate in opposite directions check

. The simple gear then becomes two w heels corotating in opposite

box

ections, with the two wheels meshed on their respective outer surfaces.

dir

radians for Inertia1 and Inertia, respectively. The second angular velocity

2-13

Page 50

2 Simple Models

is twice the first and with opposite sign, because the two bodies are

spinning in opposite directions.

5 Finally, again clear the Follower and base rotate in opposite

directions check box.

Torque-Actuating Two Coupled, Spinning Inertias

In the final version of the simple gear model, you actuate the inertias with an

external torque instead of starting them with fixed initial angular velocities.

The external torque varies sinusoidally. You can find a completed version of

this model in the demo drive_sgear.

1 From the SimDriveline block library, copy a Torque Actuator and two

Torque Sensor blocks. From the Sim ulink block library, drag and drop a

second Scope block, a second Mux block, and a Sine Wave block.

2 Disconnect the Inertia blocks from theSimpleGearandinserttheTorque

Sensors. Disconnect and delete the Initial Condition blo ck. The two axes

will now default back to zero angular velocities.

2-14

Connect the other blocks as shown.

Page 51

Representing and Transferring Driveline Motion and Torque

Two Spinn

3 Open both Scope blocks and start the simulation.

ing Inertias Coupled by a Gear and Actuated with Torque

The measured torques and angular velocities vary sinusoidally. The angular

velocity of Inertia1 is half that of Inertia, as you saw in the previous models.

But the torque in the second shaft is twice that in the first, as required by the

laws of gear coupling.

If you select the Follower and base rotate in opposite directions check

box in Simple Gear and restart the simulation, the same angular velocities

and torques result, except that the values associated with Inertia1 and the

second shaft are negative, because the second body and second shaft are

spinning in opposite directions.

Sensing and Actuating Motion and Torque

The Sensor and Actuator blocks you use in the preceding mo de ls illustrate

their dual nature: they act as driveline components themselves, but also let

you connect drivelin e blocks with the rest of Simulink.

2-15

Page 52

2 Simple Models

• Sensor & Actuator blocks have both driveline connector ports and normal

Simulink ports

Simulink outports. You can actuate motion or apply external torques by

feeding in actuation signals with a block’s Simulink inports.

Many other SimD r iveline blocks feature Simulink ports for inserting and

measuring signals.

• You connect a Torque Sensor along a driveline axis, by placing it in series

with other driveline components.

• You connect the other Sensor and Actuator blocks across a driveline axis,

by branching the driveline connectionlineofftoonesideandconnecting

this secondary line to the block; or by connecting the block to the end of

adrivelineaxis.

>. You can extract sensor signal information with a block’s

Coupling Two Spinning Inertias with a Variable Gear

You can modify the simple gear model further by replacing the fixed-ratio

gear with a gear whose gear ratio variesintime. Youspecifythegearratio

variation with a Simulink signal. Start with the simple gear model you built

in the preceding section or by opening and editing the drive_sgear demo.

2-16

1 From the SimDriveline block library, drag and drop a Variable Ratio Gear

block and replace the Simple Gear block with it. Open Variable Ratio Gear

and ensure that the Follower and base rotate in opposite directions

check box is selected (the default). The two shafts will spin in opposite

directions.

2 The Variable Ratio Gear block accepts the continuously varying gear ratio

as a Simulink signal through the extra inport labeled

create a S i m ulink signal f or the gear ratio with a Signal Builder block

from the Sim ul ink block library . Build a signal that rises with consta n t

slope from 1 to 2 over 10 seconds. Then connect the Signal Builder block

to the

r port.

r. For this ex ample,

Page 53

Representing and Transferring Driveline Motion and Torque

Simple Variable Ratio Gear Model

3 Leave the other, original settings of the simple gear m o del unchanged.

Open both Scopes and start the simulation.

The two shafts’ angular velocities and torques have opposite signs. Apart

from this sign difference, the ratios of angular velocities and torques start at

1, because the initial gear ratio is 1. But as the gear ratio increases toward

2, the angular velocity of Inertia1 becomes smaller than that of Inertia,

while the associated torque in the second shaft (apart from the opp osite s ign)

becomes larger than that in the first shaft. Because of the changing gear

ratio, the motion and the torques are no longer strictly sinusoidal, even

though the actuating external torque is.

The drive_vgear demo is a full model of this type. To learn more about how to

use variable gears, including the Coriolis acceleration, consult the Variable

Ratio Gear block reference page.

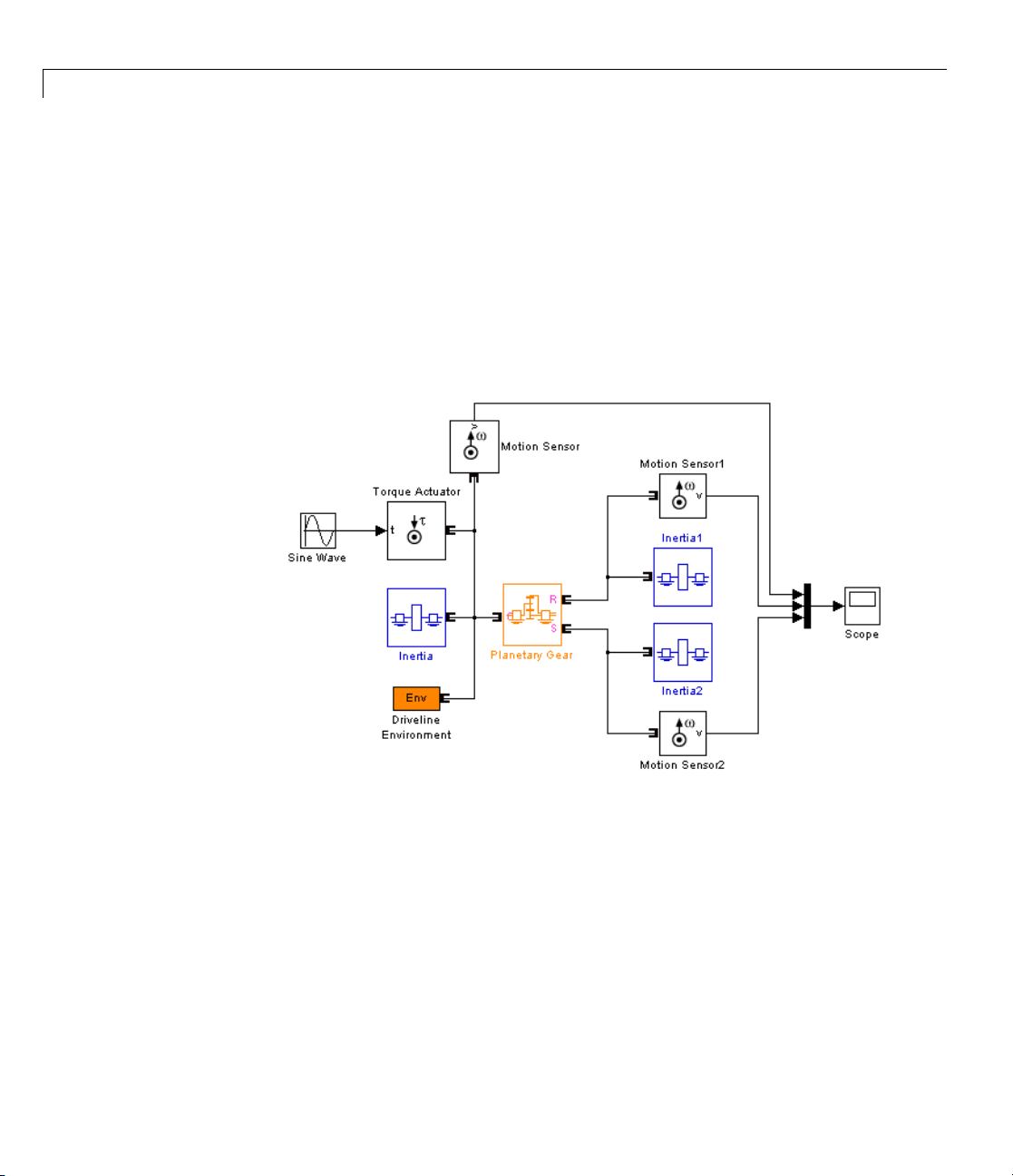

Coupling Three Spinning Inertias with a Planetary Gear

You can further modify the simple gear model and use it as a starting point for

studying more complex gear sets. One of the most important is the planetary

gear, which has three wheels, the ring, the sun, and the planet, all held in

place by a common carrier body. The planetary gear is inte resting in its own

2-17

Page 54

2 Simple Models

right, but also important because it is a common component in complex,

realistic transmissions.

1 Replace the Simple Gear in your model with a Planetary Gear from the

SimDriveline block library. A planetary gear splits input angular motion

from the carrier between the ring and sun wheels, each connected to their

respective bodies.

2 Copy another Inertia and another Motion Sensor as well. Connect the

blocks to form the new diagram as shown.

2-18

Simple Planetary Gear Model

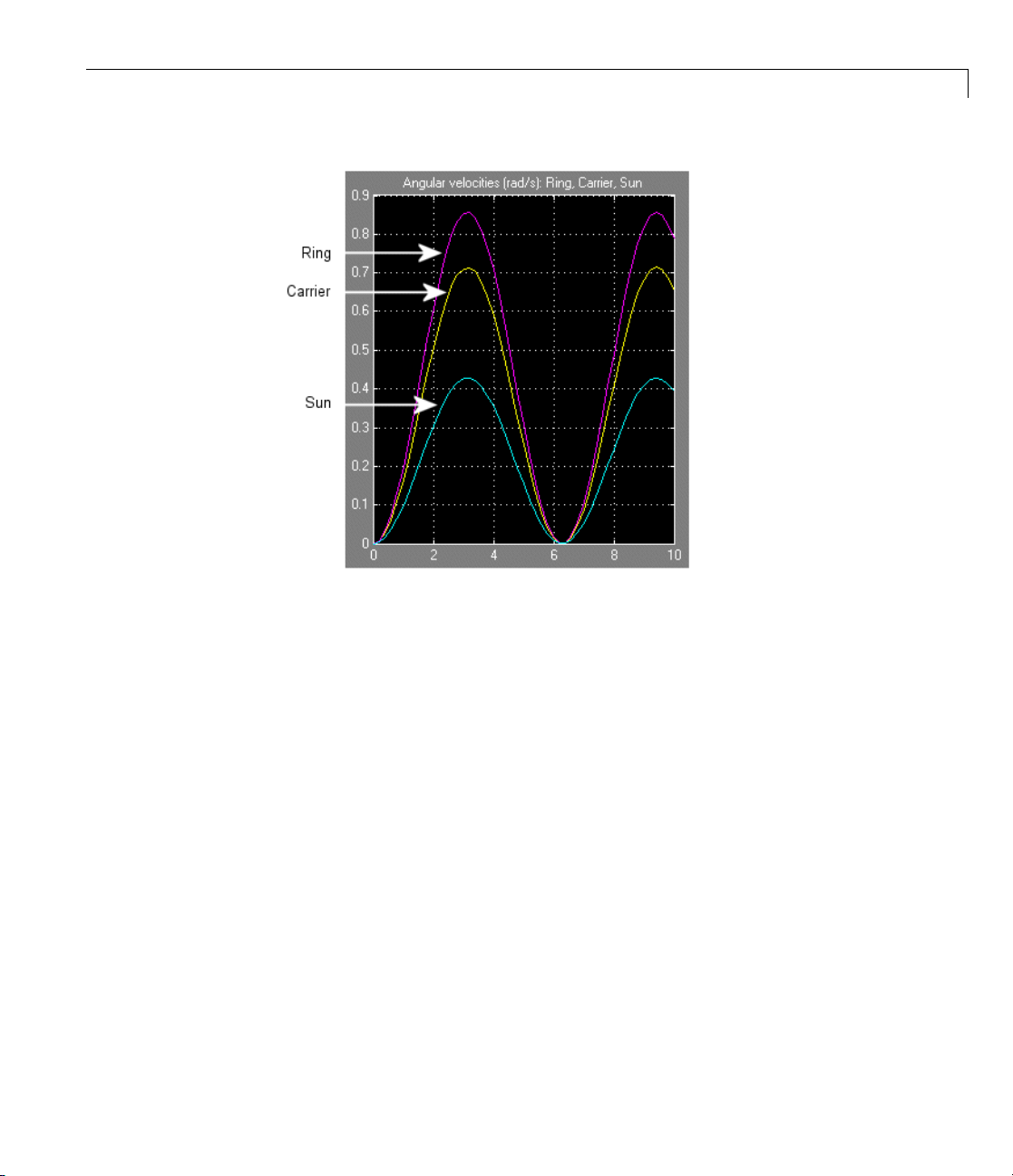

3 Enter 2 for the Ring/Sun gear ratio in Planetary Gear. Open the Scope

and start the simulation to observe the angular velocities of the ring,

carrier, and sun, from largest to smallest. The ratio of the ring to sun gear

velocities is always two.

Page 55

Representing and Transferring Driveline Motion and Torque

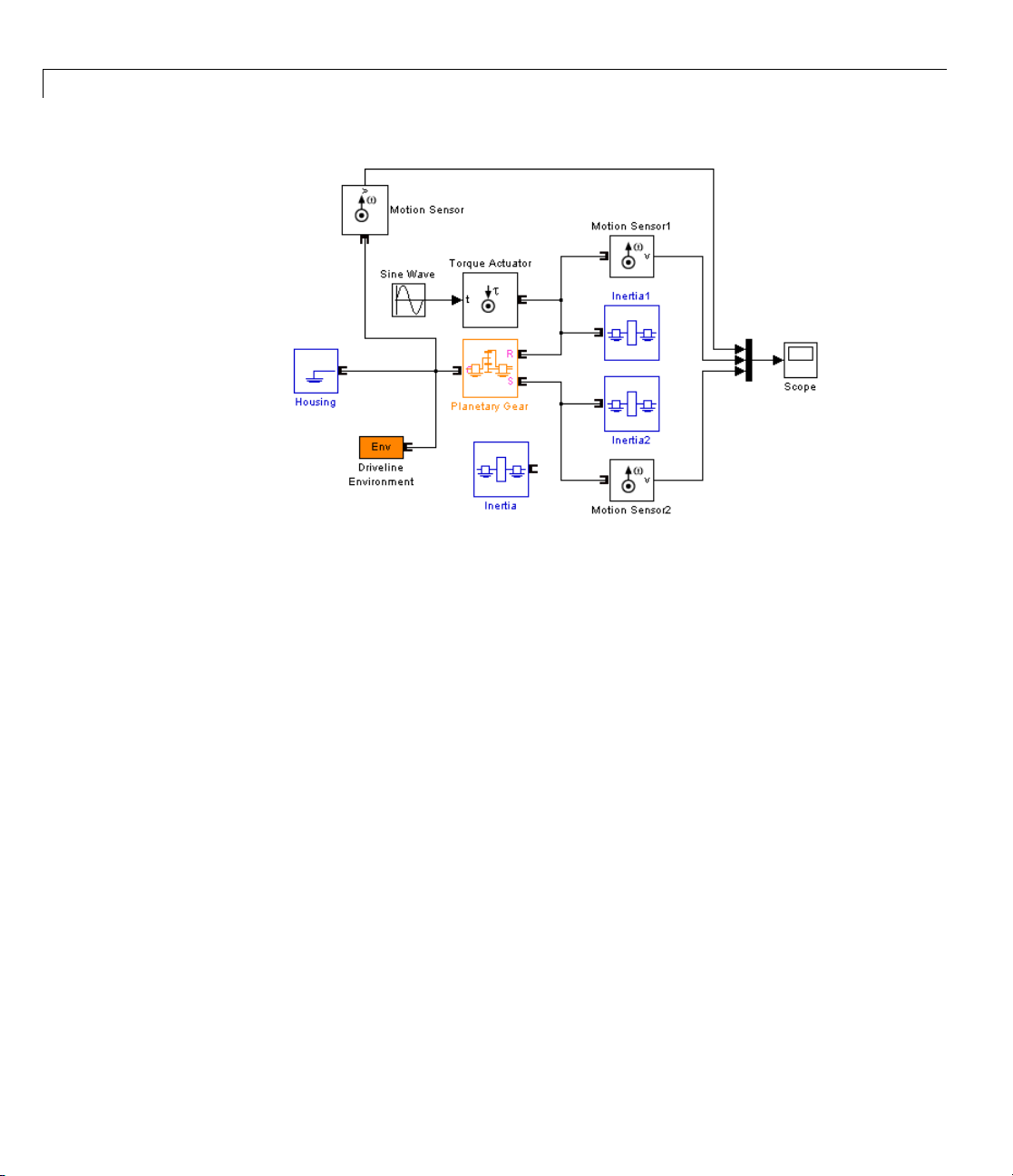

4 To see the ring and sun wheels spinning alone, you must lock the carrier.

In this case, you switch the torque actuation to the ring wheel. Copy

a Housing block from the SimDriveline block library. Disconnect and

delete Inertia, replacing it on the carrier driveline axis w ith Housing, and

reconnect the Driveline Environment block to this connection line.

5 Insert a Torque Actuator and move the Sine Wave block next to it. Connect

it to the inport.

2-19

Page 56

2 Simple Models

Simple Planetary Gear Model with Locked Carrier

2-20

6 Open the Scope and start your model. Observe the angular velocities of

the ring, carrier, and sun.

Page 57

Representing and Transferring Driveline Motion and Torque

The carrier, connected to Housing, does not move. The ring is driven with a

sinusoidal torque, and the sun responds by spinning in the opposite direction

(ring and sun g ear wheels are external to one another) at tw ice the rate. The

ring wheel has twice the radius (or twice the number of teeth) as the sun, so

itspinshalfasfast.

To learn more about modeling planetary gears, see the Planetary Gear block

reference page.

2-21

Page 58

2 Simple Models

Actuating Drivelines with Torques and Motions

In this section...

“About Torques, Motions, and Actuation” on page 2-22

“Modeling the Effect of a Variable Inertia” o n page 2-24

“Actuating a Driveline with Torques” on page 2-25

“Actuating a Driveline with Motions” on page 2-26

“Setting the Motion Initial Conditions of a Driveline” on page 2-26

About Torques, Motions, and Actuation

A SimDriveline simulation solves, from the torques applied to spinning

inertias, a driveline’s dynamics for its motions. H ow ev er, it can also accept

motions imposed on a driveline and solve for the torques needed to produce

those motions. A driveline simulation is typically a mixture of these two

requirements, solving dynamics both forward (torque to motion) and inverse

(motion to torque). Imposing motions and applying torques are together forms

of driveline actuation.

2-22

This section discusses actuating drivelines with time-varying inertias,

torques, motions, and motion initial conditions. All of these actuation

types (except for initial conditions) require input Simulink signals to define

time-varying functions.

Torque and Motion Actuation are Complementary and

ally Exclusive

Mutu

In all cases, you should exercise care as you apply a mixture of actua tion s to

a driveline and its degrees of freedom (DoFs), as discussed in greater detail

by the section, “Analyzing Degrees of Freedom” on page 3-14. The complete

effect of the actuations must be such that

• Driveline DoFs actuated by torques are not also subject to motion

actuations. (They can be subject to motion initial condition actuation.)

• Driveline DoFs actuated by motions are not also subject to torque

actuations.

Page 59

Actuating Drivelines with Torques and Motions

For a SimDriveline model to successfully simulate nontrivial motion, torque

and motion actuations must exactly complement one another to account

consistently for the motion of all the DoFs, no more and no less. If this

criterion is not satisfied, one of these outcomes results.

• The motion of the driveline is trivial, staying in its initial motion state for

the entire simulation.

• The actuations are inconsistent with each other, and the simulation stops

with an error.

• The actuations leave the driveline underdetermined or overdetermined,

and the simulation stops with an error.

For more about driveline simulation errors, see “Troubleshooting Simulation

Errors” on page 3-11.

Stabilizing Numerical Derivatives in Actuator Signals

To actuate a phys ical system m od eled by blocks, you often need to differentiate

an incoming Simulink actuation signal.

Simulink provides a Derivative block for numerical differentiation of a signal.

However, this block’s output is sometimes not stable or accurate enough for

Physical Modeling purposes. Recommended alternatives to the Derivative

block include the following.

Integrating Higher Derivative Signals. Start by specifying the highest

derivative signal (such as an acceleration), then integrate this signal to obtain

lower derivative signals (such as a velocity) using the Integrator block.

Transforming Signals with Transfer Functions. To differentiate a signal,

use a transfer function block (Transfer Fcn). This block actually performs a

Laplace transform convolution to smooth the output, which is not exactly

the derivative.

You can eliminate this drawback by filtering the original signal f,then

defining exact derivatives dF/dt, etc., of the filtered signal F by adding higher

orders to the transfer function numerator. The order of the denominator

should be equal to or greater than the number of output signals. Use the

filtered signal F (instead of f), as well as the filtered derivatives.

2-23

Page 60

2 Simple Models

In this example, the constant τ represents a smoothing time. The transfer

functions define a filtered signal and its first derivative, two signals in all.

Therefore, the transfer function deno minator should be seco nd order or high er.

Modeling th

You cannot

However, y

Ratio Gear

momentum

1 Place a Va

2 Connect this constant Inertia to the Gear’sbase(B)orfollower(F)port.

3 Vary the gear ratio of the Variable Ratio Gear with an incoming Simulink

signal.

By changing the gear ratio, you change the effective inertia on the shaft from

the constant Inertia.

• Effective inertia = (constant inertia)•(variable gea r ratio)

if the B port is connected to Inertia

• Effective inertia = (constant inertia)/(variable gear ratio)

if the F port is connected to Inertia

e Effect of a Variable Inertia

vary the inertia value of an Inertia block during a simulation.

ou can model a time-varying inertia indirectly with a Variable

block. This method relies on the conservation of angular

.

riable Ratio Gear between a shaft and an Inertia.

2-24

Page 61

Actuating Drivelines with Torques and Motions

Effective Variable Inertia with a Variable Ratio Gear

Actuating a Driveline with Torques

You can apply a torque to a driveshaft

• Directly, with a Torque Actuator block

• Indirectly, with a block that generates torque, using a Torque Actuator as

part of a larger subsystem. Such blocks include:

- Dynamic elements such as clutches, torque converters, and engines

- Transmissions, which contain clutches

In any case, a Torque Actuator accepts an incoming Simulink signal and

originates, from its driveline connector port, a driveline connection l in e

carrying that torque.

The SimDriveline simu la t ion so lves for the motion of the spinning driveshaft,

given the torque it is subject to. Therefore you cannot, in addition, subject

that same driveshaft to motion actuation.

2-25

Page 62

2 Simple Models

Caution A driveline actuated by a torque must have a nonzero inertia,

represented by one or more connected Inertia blocks. A torque-actuated

driveline without any inertia experiences a singular acceleration. In this case,

the SimDriveline simulation will stop with an error.

Actuating a Driveline with Motions

You can apply a motion to a driveshaft directly, with a Motion Actuator block.

A Motion Actuator accepts an incoming Simulink signal and originates,

from its driveline connector port, a driveline connection lin e spinning with

the specified motion.

TheSimDrivelinesimulationsolvesforthetorquecarriedbythespinning

driveshaft, given its motion. Therefore you cannot, in addition, subject that

same driveshaft to torque actuation.

2-26

Setting the Motion Initial Conditions of a Driveline

When driveline simulation starts, the c omplete driveline determines the

initial motion of all dri veshafts by a combination of constra in ts, motio n

actuators, and initial condition actuators. If, after the application of the

complete driveline’s con strai nts and actuators, one or more of the driveshaft

motions remain undetermined, these driveshafts start simulation with zero

angular velocity by default.

You can exercise direct control over how a driveshaft starts motion during

simulation by connecting it to an Initial Condition actuation block. You set

the initial velocity of the driveshaft in the block’s dialog.

For more about constraints and degrees of freedom, see “Analyzing Degrees of

Freedom” on page 3-14.

Page 63

Actuating Drivelines with Torques and Motions

Caution You must ensure that whatever initial conditions you impose on

the driveshafts in yo ur driveline are consistent with all of the driveline’s

constraints and motion actuators. If an inconsistency occurs, the SimDriveline

simulation stops with error.

Resolving Undetermined Motions in Complex Gears

A simple gear has two ports and imposes one constraint between them,

leaving one independent DoF. Once one port is connected to a driveshaft, the

motion of the other port’s driveshaft is determined.

A complex gear has three or more ports and imposes one or more constraints

among them. A complex gear can have any number of independent DoFs,

including none.

For more about complex gears, see “Representing and Transferring Drivel ine

Motion and Torque” on page 2-9.

Tip If a simulation apportions the initial motions of a complex gear in an

unsatisfactory way, determine how you want the overall initial motion divided

up and enforce that division with one or more Initial Condition blocks on one

or more of the complex gear shafts.

However you divide the initial motion among the gear shafts, ensure that

this division is consistent with all constraints in your driveline, as well as

any motion actuators.

2-27

Page 64

2 Simple Models

Controlling Gear Couplings with Clutches

In this section...

“About M otion, Gears, and Clutches” on page 2-28

“Engaging and Disengaging Gears with Clutches” on page 2-28

“Modeling Re alistic Clutch Systems with Loss” on page 2-34

“Braking Motion with Clutches” on page 2-37

“Modeling Friction Clutches a t a F undamental Level” on page 2-41

About Motion, Gears, and Clutches

The most important requirement of a practical drivetrain is the ability

to transfer rotational motion and torque among spinning components at

different speeds and gear ratios. A single set of gears is usually not sufficient

to accomplish this. Clutches are the critical components that allow the

drivetrain to selectively transfer mot ion and torque at different gear ratios

under manual or automatic control.

2-28

This section e xplains how to model and use clutches in driveline models

without and with frictional losses and braking.

Engaging and Disengaging Gears with Clutches

A common problem in drivetrain design is transferring motion and torque at

different fixed gear ratios. Drivetrains are typically designed to switch among

a set of discrete gear ratios. Implementing the switch from one gear ratio to

another requires gradually disengaging one set of driveline couplings and

engaging another set. Clutches allow you to gradually engage and disengage

driveline shafts from one another.

The Controllable Friction Clutch block represents a standard surface

friction-based clutch that models this behavior and requires no more than

modest preparation to use. This section uses this block. You also can model

clutches in greater detail u sing the Fundamental Friction Clutch block, which

requires you to specify the static and kinetic clutch friction more completely.

See “Modeling Friction Clutches at a Fundamental Level” on page 2-41.

Page 65

Controlling Gear Couplings with Clutches

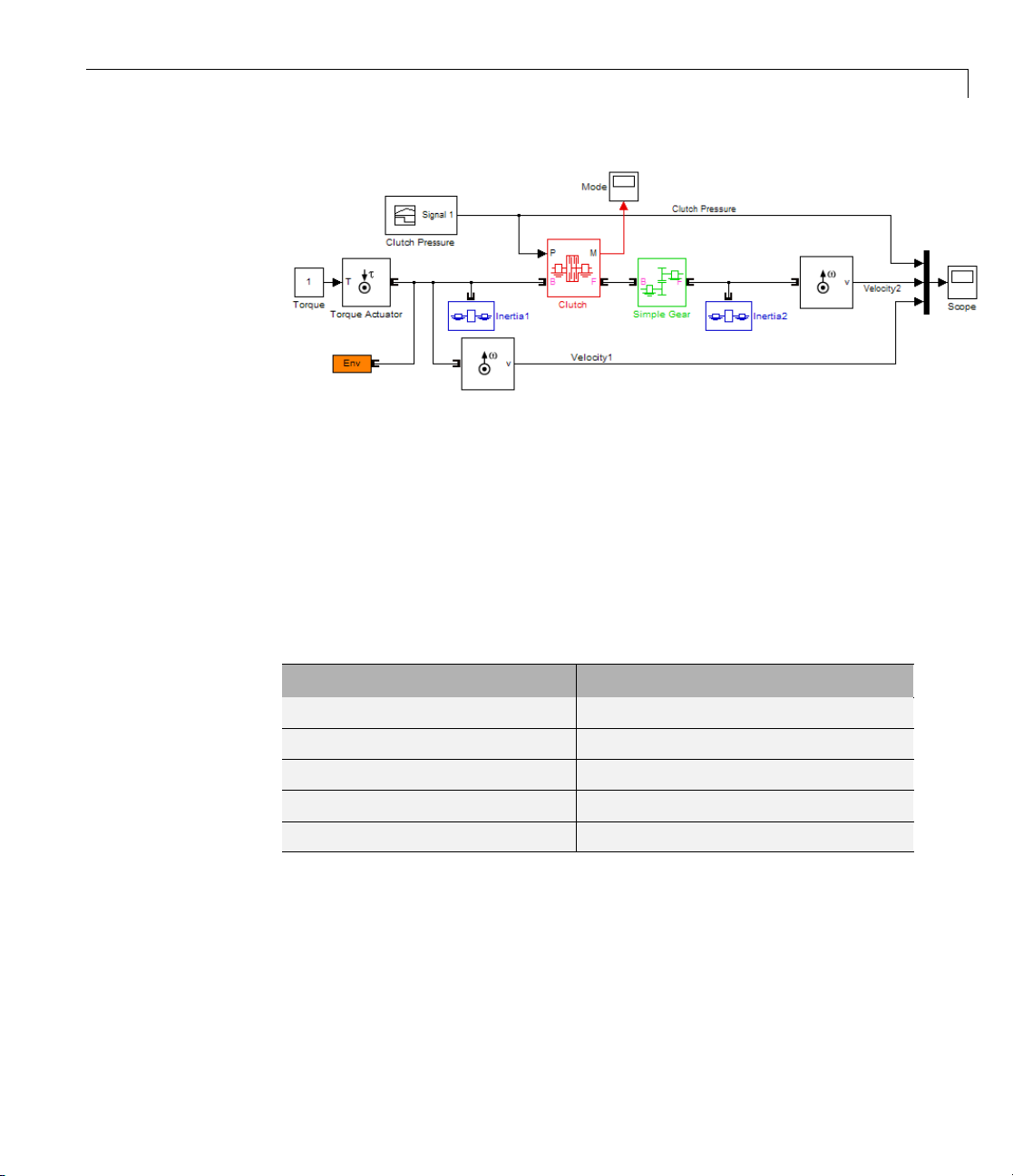

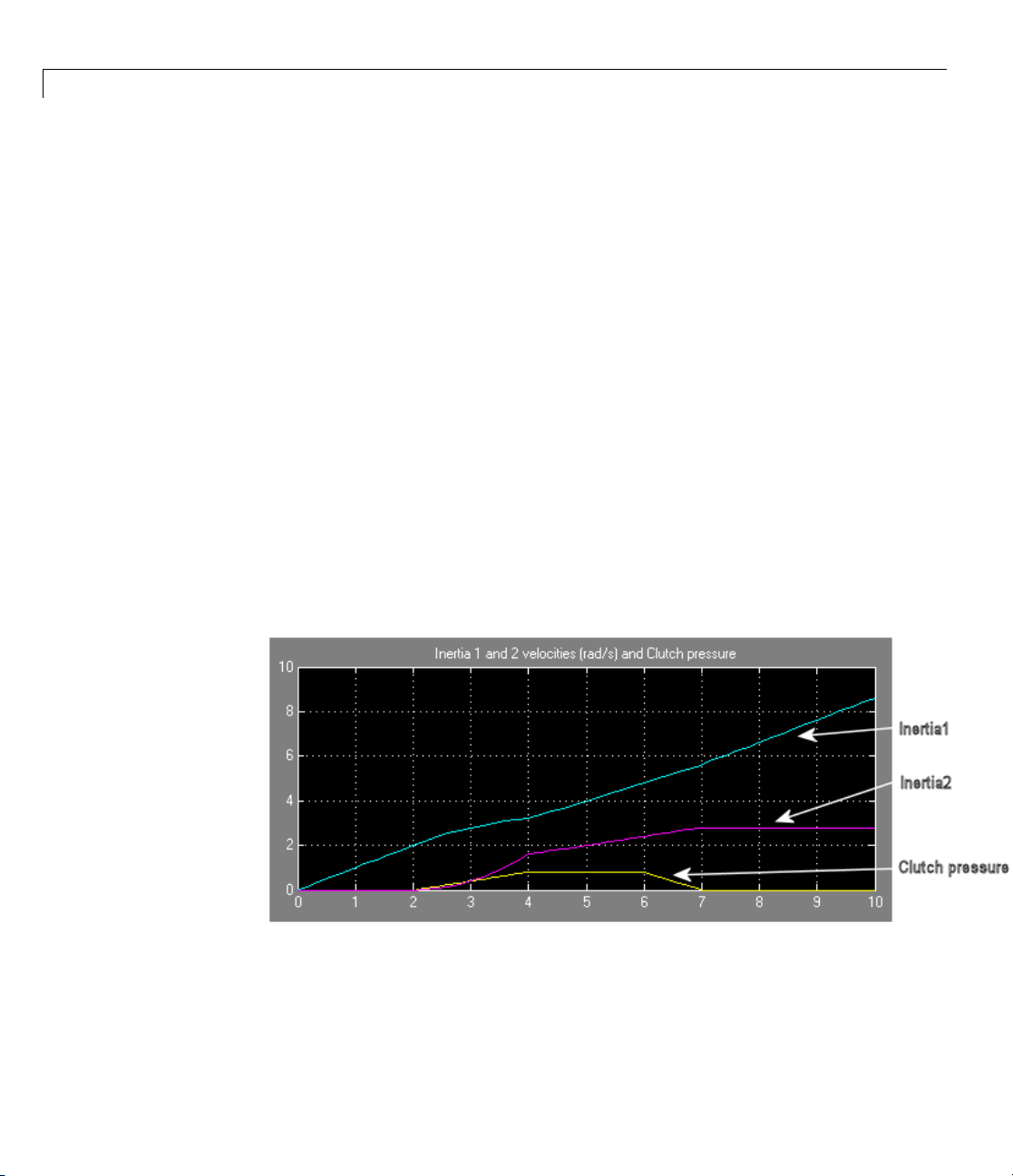

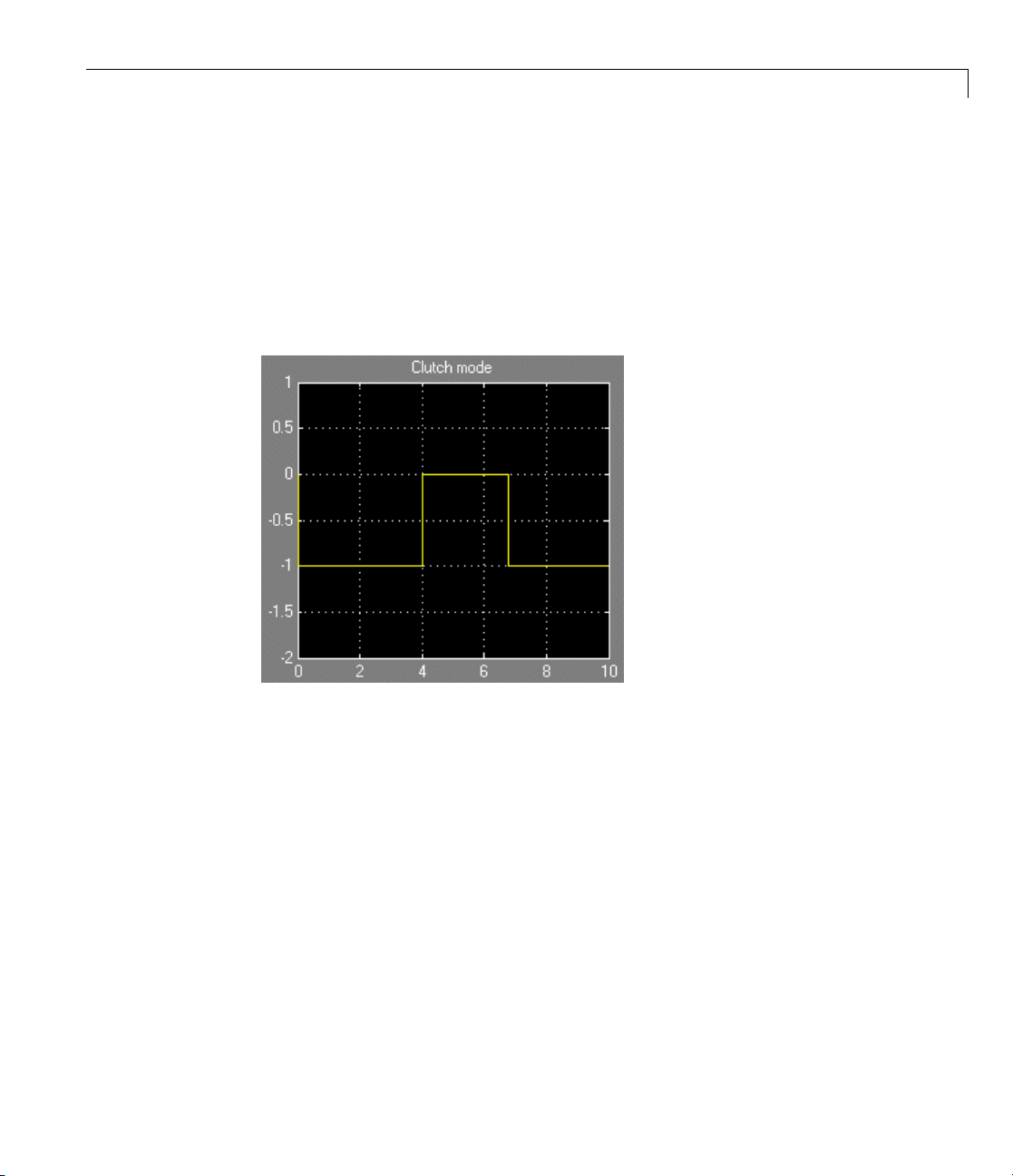

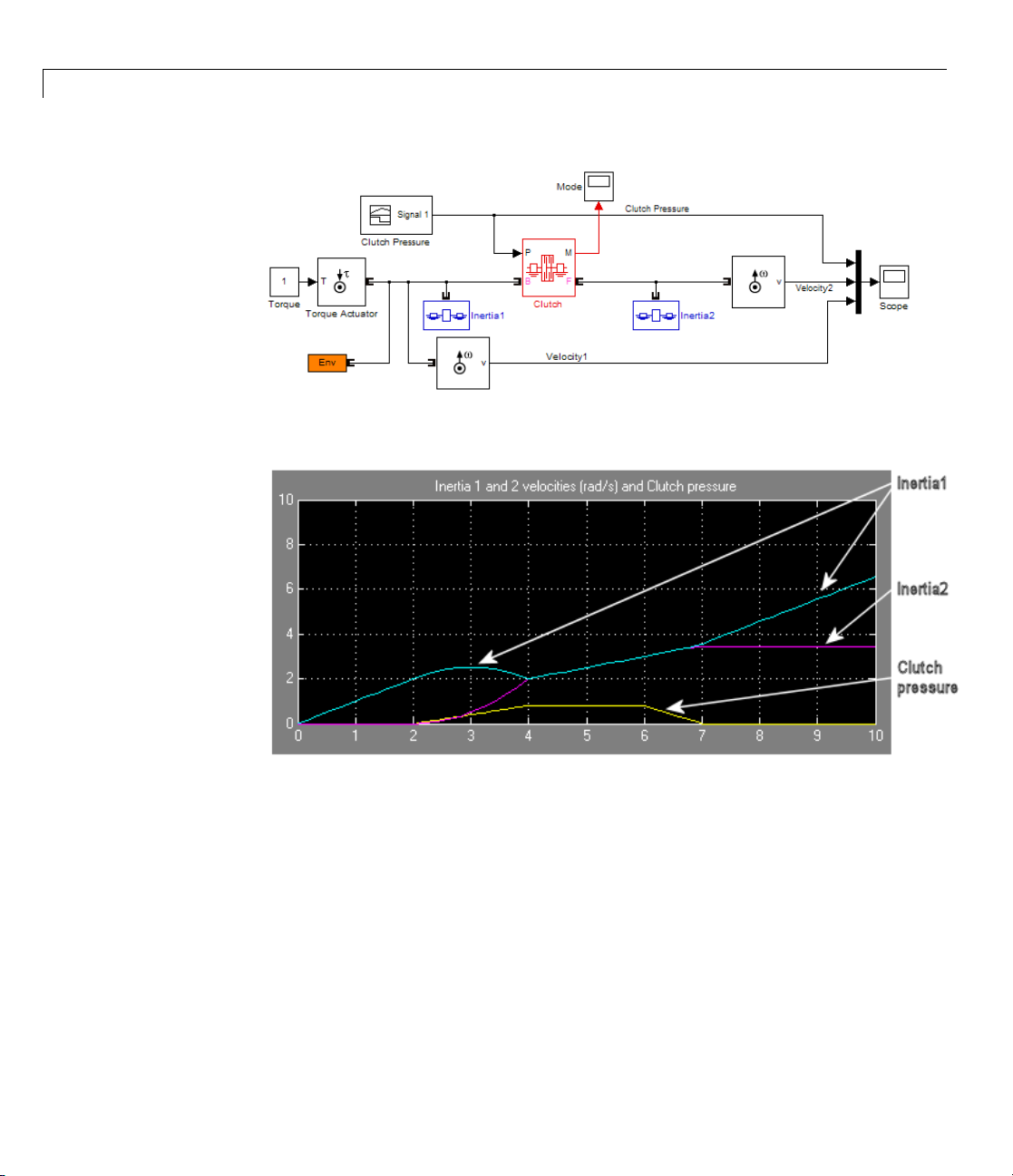

Tip You can model continuous motion-torque transfer with the Torque