Page 1

Control System Too

Getting Started Guide

lbox™ 9

Page 2

How to Contact MathWorks

www.mathworks.

comp.soft-sys.matlab Newsgroup

www.mathworks.com/contact_TS.html Technical Support

suggest@mathworks.com Product enhancement suggestions

bugs@mathwo

doc@mathworks.com Documentation error reports

service@mathworks.com Order status, license renewals, passcodes

info@mathwo

com

rks.com

rks.com

Web

Bug reports

Sales, prici

ng, and general information

508-647-7000 (Phone)

508-647-7001 (Fax)

The MathWorks, Inc.

3 Apple Hill Drive

Natick, MA 01760-2098

For contact information about worldwide offices, see the MathWorks Web site.

Control System Toolbox™ Getting Started Guide

© COPYRIGHT 2000–2010 by The MathWorks, Inc.

The software desc ribed in this document is furnished under a license agreeme nt. The software may be used

or copied only under the terms of the license agreement. No part of this manual may be photocopied or

reproduced in any form without prior written consent from The MathWorks, Inc.

FEDERAL ACQUISITION: This provision applies to all acquisitions of the Program and Documentation

by, for, or through the federal government of the United States. By accepting delivery of the Program

or Docum entation, the government hereby agrees that this software or documentation qualifies as

commercial computer software or commercial computer software documentation as such terms are used

or defined in FAR 12.212, DFARS Part 227.72, and DFARS 252.227-7014. Accordingly, the terms and

conditions of this Agreement and only those rights specified in this Agreement, shall pertain to and govern

theuse,modification,reproduction,release,performance,display,anddisclosureoftheProgramand

Documentation by the federal government (or other entity acquiring for or through the federal governme nt)

and shall supersede any conflicti ng contractual terms or conditions. If this License fails to meet the

government’s needs or is inconsistent in any respect with federal procurement law, the government agrees

to return the Program and Documentation, unused , to The MathWorks, Inc.

Trademarks

MATLAB and Simulink are registered trademarks of The M athWorks, Inc. See

www.mathworks.com/trademarks for a list of additional trademarks. Other product or brand

names may be trademarks or registered trademarks of their respective holders.

Patents

MathWorks products are protected by one or more U.S. patents. Please see

www.mathworks.com/patents for more information.

Page 3

Revision History

November 2002 First printing New Version 5.0 (Release 12)

June 2001 Second printing Revised for Version 5.1 (Release 12.1)

July 2002 Online only Revised for Version 5.2 (Release 13)

June 2004 Online only Revised for Version 6.0 (Release 14)

March 2005 Online only Revised for Version 6.2 (Release 14SP2)

September 2005 O nline only Revised for Version 6.2.1 (Release 14SP3)

March 2006 Online only Revised for Version 7.0 (Release 2006a)

September 2006 Online only Revised for Version 7.1 (Release 2006b)

March 2007 Online only Revised for Version 8.0 (Release 2007a)

September 2007 O nline only Revised for Version 8.0.1 (Release 2007b)

March 2008 Online only Revised for Version 8.1 (Release 2008a)

October 2008 Third printing Revised for Version 8.2 (Release 2008b)

March 2009 Online only Revised for Version 8.3 (Release 2009a)

September 2009 Online only Revised for Version 8.4 (Release 2009b)

March 2010 Online only Revised for Version 8.5 (Release 2010a)

September 2010 Online only Revised for Version 9.0 (Release 2010b)

Page 4

Page 5

1

Contents

Product Overview

Why Use This Too

Using the Docu

Related Prod

mentation

ucts

lbox?

.............................

..........................

..................................

Building M

2

Linear (LTI) Models ................................ 2-2

What Is a Plant?

Linear Model Representations

SISO Example: The DC Motor

Building SISO Models

Constructing Discrete Time Systems

Adding Delays to Linear Models

LTI Objects

MIMO Models

MIMO Example: State-Space Model of Jet Transport

Aircraft

Constructing MIMO Transfer Functions

Accessing I/O Pairs in MIMO Systems

.................................. 2-2

....................... 2-2

....................... 2-3

.............................. 2-6

.................. 2-9

..................... 2-10

...................................... 2-10

..................................... 2-13

....................................... 2-13

............... 2-15

................ 2-17

1-2

1-3

1-4

odels

Arrays of Linear Models

Model Characteristics

Interconnecting Linear Models

............................ 2-18

.............................. 2-21

..................... 2-23

v

Page 6

Arithmetic Operations for Interconnecting Models ...... 2-23

Feedback Interconnections

Converting Between Continuous- and Discrete- Time

Systems

Available Commands for Continuous/Discrete

Conversion

Available Methods for Continuous/Discrete Conversion

Digitizing the Discrete DC Motor Model

........................................ 2-26

..................................... 2-26

.......................... 2-24

.. 2-26

............... 2-26

Reducing Model Order

Model Order Reduction Commands

Techniques for Reducing Model Order

Example: Gasifier Model

............................. 2-29

................... 2-29

................. 2-29

........................... 2-30

Analyzing Models

3

Quick Start for Performing Linear Analysis Using the

LTI Viewer

LTI Viewer

Plot Types Available in the LTI Viewer

Example: Time and Frequency Responses of the DC

Motor

Right-Click Menus

Displaying Response Characteristics on a Plot

Changing Plot Type

Showing Multiple Response Types

Comparing Multiple Models

...................................... 3-2

........................................ 3-7

................ 3-7

......................................... 3-8

................................ 3-10

................................ 3-14

.................... 3-16

......................... 3-17

.......... 3-11

vi Contents

Simulating Models with Arbitrary Inputs and Initial

Conditions

What is the Linear Simulation Tool?

Opening the Linear Simulation Tool

Working with the Linear Simulation Tool

Importing Input Signals

Example: Loading Inputs from a Microsoft

Spreadsheet

...................................... 3-22

.................. 3-22

.................. 3-22

.............. 3-23

............................ 3-26

®

Excel

.................................... 3-28

Page 7

Example: Importing Inputs from the Workspace ........ 3-29

Designing Input Signals

Specifying Initial Conditions

............................ 3-33

........................ 3-35

Functions for Time and Frequency Response

When to Use F unctions for Time and Frequency

Response

Time and Frequency Response Functions

Plotting MIMO Model Responses

Data Markers

Plotting and Comparing Multip le Systems

Creating Custom Plots

...................................... 3-37

.............. 3-37

..................... 3-40

.................................... 3-42

............................. 3-47

........ 3-37

............. 3-44

Designing Compensators

4

Designing PID Controllers ......................... 4-2

Designing PID Controllers with the PID Tuner GUI

Designing PID Controllers at the Command Line

SISO Design Tool

Quick Start for Tuning Compensator Parameters Using the

SISO Design Tool

Components of the SISO Tool

Design Options in the SISO Tool

Opening the SISO Design Tool

Using the SISO Design Task Node in the Control and

Estimation Tools Manager

Importing Models into the SISO Design Tool

Feedback Structure

Analysis Plots for Loop Responses

Using the Graphical Tuning Window

Exporting the Compensator and Models

Storing and Retrieving Intermediate Designs

.................................. 4-15

............................... 4-15

........................ 4-26

..................... 4-26

....................... 4-27

........................ 4-29

................................ 4-34

.................... 4-36

................. 4-42

............... 4-49

....... 4-14

........... 4-30

........... 4-51

..... 4-2

Bode Diagram Design

What Is Bode Diagram Design?

Example: DC Motor

Adjusting the Compensator Gain

.............................. 4-55

............................... 4-55

...................... 4-55

..................... 4-56

vii

Page 8

Adjusting the Bandwidth ........................... 4-57

Adding an Integrator

Adding a Lead Network

Moving Compensator Poles and Zeros

Adding a Notch Filter

Modifying a Prefilter

.............................. 4-59

............................ 4-63

................. 4-68

.............................. 4-71

............................... 4-76

Root Locus Design

What Is Root Locus Design?

Example: Electrohydraulic Servomechanism

Changing the Compensator Gain

Adding Poles and Zeros to the Compensator

Editing Compensator Pole and Zero Locations

Viewing Damping Ratios

Nichols Plot Design

What Is Nichols Plot Desig n?

DC Motor Example

Opening a Nichols Plot

Adjusting the Compensator Gain

Adding an Integrator

Adding a Lead Network

Automated Tuning Design

Supported Automated Tuning Methods

Loading and Displaying the DC Motor Example for

Automated Tuning

Applying Automated PID Tuning

Multi-Loop Compensator Design

When to Use Multi-Loop Compensator Design

Workflow for Multi-Loop Compensator Design

Example: Position Control of a DC Motor

................................. 4-81

......................... 4-81

..................... 4-88

............ 4-91

........................... 4-100

................................ 4-103

........................ 4-103

................................ 4-103

............................. 4-104

..................... 4-105

.............................. 4-108

............................ 4-110

.......................... 4-114

................ 4-114

.............................. 4-114

..................... 4-116

.................... 4-120

.............. 4-120

........... 4-82

.......... 4-96

.......... 4-120

.......... 4-120

viii Contents

Control Design Analysis of Multiple Models

Multiple Models Represent Sy stem Variations

Control Design Analysis Using the SISO Design Tool

Specifying a Nominal Model

Frequency Grid for Multimodel Computations

How to Analyze the Controller Design for Multiple

Models

........................................ 4-137

......................... 4-133

.......... 4-132

.......... 4-132

.... 4-132

.......... 4-136

Page 9

Functions for Compensator Design .................. 4-147

When to Use Functions for Compensator Design

Root Locus Design

Pole Placement

Linear-Quadratic-Gaussian (LQG) Design

Example — Designing an LQG Regulator

Example — Designing an LQG Servo Controller

Example—DesigninganLQRServoControllerin

Simulink

................................. 4-147

................................... 4-148

.............. 4-162

...................................... 4-168

........ 4-147

............. 4-151

........ 4-165

Index

ix

Page 10

x Contents

Page 11

Product Overview

• “Why Use This Toolbox?” on page 1-2

• “Using the Documentation” on p age 1-3

• “Related Products” on page 1-4

1

Page 12

1 Product Overview

Why Use This Toolbox?

The Control System Toolbox™ product extends the MATLAB®software to

provide functions designed specifically for control engineering.

This toolbox lets you construct and analyze linear models of dynamic systems.

Use Control System Toolbox functions to model dynamic systems as transfer

functions, in state-space form, or as arrays of frequency response data. Plot

the time and frequency responses of your system to understand how your

system behaves.

You can also use the toolbox to design and tune single-loop or multiple -loop

control systems using various classical and state-space techniques.

1-2

Page 13

Using the Documentation

If you are new to Control System Toolbox, review the Control System Toolbox

Getting Started Guide to learn how to:

• Build and manipulate linear time-invariant models of dynamical systems

• Analyze such models and plot their time and frequency responses

• Design compensators using root locus and pole placement techniques

This guide also discusses model order reduction and linear quadratic

Gaussian (LQG) control design techniques with examples.

Other documentation available for this toolbox includes:

• Release Notes — Highlights new and changed features in the latest product

release.

• Creating and Manipulating Models — In-depth information about creating,

manipulating, and analyzing linear models and linear time-invariant

(LTI) arrays. You can use LTI arrays to store collections of linear models

in one variable.

Using the Documentation

• Customization — Information about setting plot properties, including

setting preferences that persist from session to session.

• Control System Toolbox Design Case Studies —Workedexamples

of control design problems, including Kalman filtering and

Linear-Quadratic-Gaussian design. The examples illustrate

design techniques in both single-input/single-output (SISO) and

multiple-input/multiple-output (MIMO) systems.

• Control System Toolbox Reliable Computations — Discussion of numerical

stability and accuracy in computation

• Using the SISO Design Tool and the LTI Viewer — Complete descriptions

of the LTI Viewer and SISO Design Tool. These tools help you analyze

systems and design SISO compensators.

• Function Reference — D escribes the purpose, syntax, and options for each

function.

1-3

Page 14

1 Product Overview

Related Products

ThefollowingtablesummarizesMathWorks®products that extend and

complement the Control System Toolbox software. For current information

about these products and other MathWorks products, point your Web browser

to:

www.mathworks.com

Product

ulink

®

®

Control Design™

Simulink

Fuzzy Logic Toolbox™

Model Predictive Control Toolbox™

Robust Control Toolbox™

Sim

Description

Provides blocks for simulating

models you create and analyze

using the Control System Toolbox

software.

Complements Control System

Toolbox software with tools for

modeling complex systems based on

fuzzy logic.

Helps you design and simulate model

predictive controllers for linear plant

models created using Control System

Toolbox functions.

Helps

syste

creat

Tool

to as

conf

mod

Let

lin

tu

you design robust control

ms based on plant models

ed using the Control System

box software. Enables you

sess robustness based on

idence bounds for your plant

els.

s y ou use Control System Toolbox

ear control to ols to analyze and

ne Simulink models.

1-4

Page 15

Related Products

Product

Simulink®Design Optimization™

“System Identification Toolbox™”

Description

Helps you improve controller

designs by estimating and tuning

model parameters using numerical

optimization.

Helps you estimate linear and

nonlinear mathematical models of

dynamic systems from measured

data. Use the Control System

Toolbox software to analyze and

design controllers for resulting

linear mo dels.

1-5

Page 16

1 Product Overview

1-6

Page 17

Building Models

• “Linear (LTI) Models” on page 2-2

• “MIMO Models” on page 2-13

• “Arrays of Linear Models” on page 2 -18

• “Model Characteristics” on page 2-21

• “Interconnecting Linear Models” on page 2-23

• “Converting Between Continuous- and Discrete- Time Systems” on page

2-26

2

• “Reducing Model Order” on page 2-29

Page 18

2 Building Models

Linear (LTI) Models

In this section...

“What Is a Plant?” on page 2-2

“Linear Model Representatio ns” on page 2-2

“SISO Example: The DC Motor” on page 2-3

“Building SISO M odels ” on page 2-6

“Constructing Discrete Time Systems” on page 2-9

“Adding Delays to Linear Models” on page 2-10

“LTI Objects” on page 2-10

What Is a Plant?

Typically, control engineers begin by developing a mathematical description of

thedynamicsystemthattheywanttocontrol. Thesystemtobecontrolledis

called a plant. As an example of a plant, this section uses the DC motor. This

section develops the differential equations that describe the electromechanical

properties of a DC motor with an inertial load. It then shows you how to

use the Control System Toolbox functions to build linear models based on

these equations.

2-2

Linear Model Representations

You can use Control Sy stem Toolbox functions to create the follow ing model

representations:

• State-space models (SS) of the form

dx

Ax Bu

=+

dt

yCxDu

=+

where A, B, C,andD are matrices of appropriate dimensions, x is the state

vector, and u and y are the input and output vectors.

• Transfer functions (TF), for example,

Page 19

Linear (LTI) Models

s

Hs

()=

• Zero-pole-gain (ZPK) models, for exam ple,

Hz

()

• Frequency response data (FRD) models, which consist of sampled

measurements of a system’s frequency response. For example, you can

store experimentally collected frequency response data in an FRD model.

Note The design of FRD models is a specialized subject that this guide

does not address. See “Creating Frequency Response Data (FRD) Models”

for a discussion of this topic.

+

2

ss

++210

zjzj

()()

++ +−

=

11

3

zz

(.)(.)

++

02 01

SISO Example: The DC Motor

A simple model of a DC motor driving an inertial load shows the angular rate

υ

ω()t

of the load,

ultimate goal of this example is to control the angular rate by varying the

applied voltage. This figure shows a simple model of the DC motor.

A Simple Model of a DC Motor Driving an Inertial Load

, as the output and applied voltage,

t()

,astheinput. The

app

2-3

Page 20

2 Building Models

In this model, the dynamics of the motor itself are idealized; for instance,

themagneticfieldisassumedtobeconstant. Theresistanceofthecircuit

is denoted by R and the self-inductance of the armature by L. If you are

unfamiliar with the basics of DC motor modeling, consult any basic text on

physical modeling. With this simple model and basic laws of physics, it is

possible to develop differential equations that d escri be the behavior of this

electromechanical system. In this example, the relationships between electric

potential and mechanical force are Faraday’s law of induction and Ampère’s

law for the force on a conductor moving through a magnetic field.

Mathematical Derivation

The torqueτseen at the shaft of the motor is proportional to the current i

induced by the applied voltage,

τ() ()tKit

=

m

where Km, the armature constant, is related to physical properties of the

motor, such as magnetic field strength, the number of turns of wire around

2-4

the conductor coil, and so on. The back (induced) electromotive force,

a voltage proportional to the angular rate

υω

tKt() ()=

emf b

where Kb, the emf constant, also depends on certain physical properties

of the motor.

The mechanical part of the motor equations is derived using Newton’s law,

which states that th e inertial load J times the derivative of angular rate

equals the sum of all the torques about the motor shaft. The result is this

equation,

dw

J

==− +

∑

dt

where

Finally, the electrical part of the motor equations can be described by

Kfω

is a linear approximation for viscous friction.

KtKit

τω() ()

if m

ω

seen at the shaft,

υ

emf

,is

Page 21

Linear (LTI) Models

υυ

ttL

app emf

di

dt

Ri t() () ()−=+

or, solving for the applied voltage and substituting for the back emf,

υω

app b

di

tL

dt

Ri t K t() () ()=++

This sequence of equations leads to a set of two differential equat ions that

describe the behavior of the motor, the first for the induced current,

di

dt

R

=− − +() () ()ωυ

L

it

K

b

L

1

t

L

app

t

and the second for the resulting angular rate,

d

ω

11

KtJKit

ω=− +

() ()

dt J

fm

State-Space Equations for the DC Motor

Given the two differential equations derived in the last section, you can now

develop a state-space representation of the DC motor as a dynamic system.

The current i and the angular rate ω are the two states of the system. The

applied voltage,

υ

, is the input to the system, and the angular velocity

app

ω is the output.

K

R

⎡

−−

⎢

i

⎡

⎤

d

⎢

ωω

dt

⎣

yt

() ()=

State-Space Representation of the DC Motor Exam ple

L

⎢

=

⎥

K

⎢

⎦

m

⎢

J

⎣

i

⎡

⋅

[]

⎢

⎣

−

⎤

⎥

⎦

L

K

J

+

[]

⎤

b

⎥

⎡

⎥

⋅

⎢

⎥

f

⎣

⎥

⎦

⋅01 0ωυ

i

app

1

⎤

⎡

⎤

⎥⎥

⎢

⋅υ

+

L

⎥

⎥

⎢

⎦

0

⎥

⎢

⎦

⎣

app

t()

t

2-5

Page 22

2 Building Models

Building SISO Mo

After you develo

can construct SI

p a set of differential equations that describe your plant, you

SO models using simple commands. The following sections

dels

discuss

• Constructing

• Converting be

• Creating tra

a state-space model of the DC motor

tween model representations

nsfer function and zero/pole/gain models

Constructing a State-Space Model of the DC Motor

Enter the fo

R= 2.0 % Ohms

L= 0.5 % Henrys

Km = .015 % torque constant

Kb = .015 % emf constant

Kf = 0.2 % Nms

J= 0.02 % kg.m^2

Given th

represe

A = [-R/L -Kb/L; Km/J -Kf/J]

B = [1/L; 0];

C = [0 1];

D = [0];

sys_dc = ss(A,B,C,D)

llowing nominal values for the various parameters of a DC motor.

ese values, you can construct the numerical state-space

ntation using the

ss function.

2-6

These

a=

b=

commands return the following result:

x1 x2

x1 -4 -0.03

x2 0.75 -10

u1

Page 23

Linear (LTI) Models

x1 2

x2 0

c=

x1 x2

y101

d=

u1

y1 0

Converting Between Model Representations

Now that you have a state-space representation of the DC motor, y ou can

convert to other model representations, including transfer function (TF) and

zero/pole/gain (ZPK) models.

Transfer Function Representation. You can use

tf to convert from the

state-space representation to the transfer function. For example, use this code

to convert to the transfer function representation of the DC motor.

sys_tf = tf(sys_dc)

Transfer fu nction:

1.5

-----------------s^2 + 14 s + 40.02

Zero/Pole/Gain Representation. Similarly, the zpk function converts

from state-space or transfer function representations to the zero/pole/gain

format. Use this code to convert from the state-space representation to the

zero/pole/gain form for the DC motor.

sys_zpk = zpk(sys_dc)

Zero/pole/gain:

1.5

2-7

Page 24

2 Building Models

------------------(s+4.004) ( s+9.996)

Note The state-space representation is best suited for numerical

computations. For highest accuracy, convert to state space prior to combining

models and avoid the transfer function and zero/pole/gain representations,

except for model specif ication and inspection. See Reliable Computations for

more information on numerical issues.

Constructing Transfer Function and Zero/Pole/Gain Models

In the DC motor example, the state-space approach produces a set of matrices

that represents the model. If you choose a different approach, you can

construct the corresponding models using

sys = tf(num,den) % Transfer function

sys = zpk(z,p,k) % Zero/pol e/gain

sys = ss(a,b,c,d) % State-sp ace

sys = frd(response,fre quencies) % Frequency response data

tf, zpk, ss,orfrd.

2-8

For example, you can create the transfer function by specifying the numerator

and denominator with this code.

sys_tf = tf(1.5,[1 14 40.02])

Transfer fu nction:

1.5

-----------------s^2 + 14 s + 40.02

Alternatively, if you want to create the transfer function of the DC motor

directly, use these commands.

s = tf('s');

sys_tf = 1.5/(s^2+14*s +40.02)

These commands result in this transfer function.

Transfer f unction:

Page 25

Linear (LTI) Models

1.5

-------------------s^2 + 14 s + 40.02

To build the zero/pole/gain model, use this command.

sys_zpk = zpk([],[-9. 996 -4.004], 1.5)

This command returns the following zero/pole/gain re pre sentation.

Zero/pole/gain:

1.5

------------------(s+9.996) ( s+4.004)

Constructing Discrete Time Systems

The Control System Toolbox software provides full support for discrete-time

systems. You can create discrete systems in the same way that you create

analog systems; the only difference is that you must specify a sample time

period for any model you build. For example,

sys_disc = tf(1, [1 1], .01);

creates a SISO model in the transfer function format.

Transfer f unction:

1

----z+1

Sampling ti me: 0.01

Adding Time Delays to Discrete-Time Models

Youcanaddtimedelaystodiscrete-timemodelsbyspecifyinganinputdelay,

output delay, or I/O delay when building the model. The time delay m ust be

a nonnegative integer that represen ts a multiple of the sampling time. For

example,

sys_delay = tf(1, [1 1], 0.01,'ioDelay',5)

2-9

Page 26

2 Building Models

returns a system with an I/O delay of 5 s.

Transfer f unction:

1

z^(-5) * -----

z+1

Sampling ti me: 0.01

Adding Delays to Linear Models

You can add time delays to linear models by specifying an input delay, output

delay, or I/O delay when building a m odel. F or example, to add an I/O delay to

the DC motor, use this code.

sys_tfdelay = tf(1.5, [1 14 40.02],'ioDelay',0.05 )

This command constructs the DC motor transfer function, but adds a 0.05

second delay.

2-10

Transfer f unction:

1.5

exp(-0.05*s) * ------- -----------

s^2 + 14 s + 40.02

For a complete description of adding time de lays to models and closing loops

with time delays, see Time Delays.

LTI Objects

For convenience, the Control System Toolbox software uses custom data

structures called LTI objects to store model-related data. For example, the

variable

There are also TF, ZPK, and FRD objects for transfer function, zero/pole/gain,

and frequency data response models respectively. The four LTI objects

encapsulate the model data and enable you to manipulate linear systems as

single entities rather than as collections of vectors or matrices.

To see what LTI objects contain, use the

the contents of

sys_dc created for the DC motor example is called an SS object.

get command. This code describes

sys_dc from the DC motor example.

Page 27

get(sys_dc)

a: [2x2 double]

b: [2x1 double]

c: [0 1]

d: 0

e: []

StateName: {2x1 cell}

InternalDelay: [0x1 do uble]

Ts: 0

InputDelay: 0

OutputDelay: 0

InputName: {''}

OutputName: {''}

InputGroup: [1x1 struct ]

OutputGroup: [1x1 st ruct]

Name: ''

Notes: {}

UserData: []

Linear (LTI) Models

You can manipulate the data contained in LTI o bjects using the set command;

see the Control System Toolbox online reference pages for descriptions of

set and get.

Another convenient way to set or retrieve LTI model properties is to access

them directly using dot notation. For example,ifyouwanttoaccessthevalue

of the

A matrix, instead of using get,youcantype

sys_dc.a

at the MATLAB prompt. This notation returns the A matrix.

ans =

-4.0000 -0.0300

0.7500 -10.0000

Similarly, if you want to change the values of the A matrix, you can do so

directly, as this code show s.

A_new = [-4.5 -0.05; 0.8 -12.0];

2-11

Page 28

2 Building Models

sys_dc.a = A_new;

For more information on LTI properties, type ltiprops at the MATLAB

prompt. F or a complete description of LTI objects, see Creating and

Manipulating Models.

2-12

Page 29

MIMO Models

In this section...

“MIMO Example: State-Space Model of Jet Transport Aircraft” on page 2-13

“Constructing MIMO Transfer Functions” on page 2-15

“Accessing I/O Pairs in MIMO Systems” on page 2-17

MIMO Example: State-Space Model of Jet Transport Aircraft

You can use the same functions that apply to SISO systems to create

multiple-input, multiple-output (MIMO) models. This example shows how

to build a MIMO model of a jet transport. Because the development of a

physical model for a jet aircraft is lengthy, only the state-space equations

are presented here. See any standard text in aviation for a more complete

discussion of the physics behind aircraft flight.

MIMO Models

The jet model during cruise flight at MACH = 0.8 and H = 40,000 ft. is

A = [-0.0558 -0.9968 0.0802 0.0415

0.5980 -0.1150 -0.0318 0

-3.0500 0.3880 -0.4650 0

0 0.0805 1.0000 0];

B = [ 0.0073 0

-0.4750 0.0077

0.1530 0.1430

00];

C=[0100

0001];

D=[0 0

00];

Use the following commands to specify this state-space model as an LTI object

and attach names to the states, inputs, and outputs.

2-13

Page 30

2 Building Models

states = {'beta' 'yaw' 'roll' 'phi'};

inputs = {'rudder' 'aileron'};

outputs = {'yaw rate' 'bank angle'};

sys_mimo = ss(A,B,C,D, 'statename',states,...

'inputname',inputs,...

'outputname',outputs);

You can display the LTI model by typing sys_mimo.

sys_mimo

a=

beta yaw roll phi

beta -0.0558 -0.9968 0.0802 0.0415

yaw 0.598 -0.115 -0.0318 0

roll -3.05 0.388 -0.465 0

phi 0 0.0805 1 0

2-14

b=

rudder ailer on

beta 0.0073 0

yaw -0.475 0.0077

roll 0.153 0.143

phi00

c=

beta yaw roll phi

yawrate0100

bankangle0001

d=

rudder ailer on

yawrate00

bank angle 0 0

Continuous-time model.

Page 31

MIMO Models

The model has two inputs and two outputs. The units are radians for beta

(sideslip angle) and phi (bank angle) and radians/sec for yaw (yaw rate) and

roll (roll rate). The rudde r and aileron deflections are in degrees.

As in the SISO case, use

tf(sys_mimo)

Transfer fu nction from input "rudder" to output...

yaw rate: ---------------------------------------------------

s^4 + 0.6358 s^3 + 0.9389 s^2 + 0.5116 s + 0.003674

bank angl e: ---------------------------------------------------

Transfer fu nction from input "aileron" to output...

0.0077 s^3 - 0.0005372 s^2 + 0.008688 s + 0.004523

yaw rate: ---------------------------------------------------

s^4 + 0.6358 s^3 + 0.9389 s^2 + 0.5116 s + 0.003674

bank angl e: ---------------------------------------------------

tf to derive the transfer function representation.

-0.475 s ^3 - 0.2479 s^2 - 0.1187 s - 0.05633

0.1148 s ^2 - 0.2004 s - 1.373

s^4 + 0.6358 s^3 + 0.9389 s^2 + 0.5116 s + 0.003674

0.1436 s^ 2 + 0.02737 s + 0.1104

s^4 + 0.6358 s^3 + 0.9389 s^2 + 0.5116 s + 0.003674

Constructing MIMO Transfer Functions

MIMO tra nsfer functions are two-dimensional arrays of elementary SISO

transferfunctions. TherearetwowaystospecifyMIMOtransferfunction

models:

• Concatenation of SISO transfer function models

• Using

tf with cell array arguments

Concatenation of SISO Models

Consider the following single-input, two-output transfer function.

2-15

Page 32

2 Building Models

⎡

⎢

s

()=

⎢

s

⎢

2

⎢

ss

++

⎣

Hs

You can specify H(s) by concatenation of its SISO entries. For instance,

h11 = tf([1 -1],[1 1]);

h21 = tf([1 2],[1 4 5]);

or, equivalently,

s = tf('s')

h11 = (s-1)/(s+1);

h21 = (s+2)/(s^2+4*s+5 );

can be concatenated to form H(s).

H = [h11; h21]

⎤

⎥

1

+

⎥

2

+

⎥

⎥

45

⎦

1

s

−

2-16

This syntax mimics standard matrix concatenation and tends to be easier

and more readable for MIMO systems with m any inputs and/or outputs. See

Model Interconnection Functions for more details on concatenation operations

for LTI systems.

Using the tf Function with Cell Arrays

Alternatively, to define MIMO transfer functions using tf, you need two cell

arrays (say,

polynomials, respectively. See Cell Arrays in the MATLAB documentation for

more details on cell arrays.

For example, for the rational transfer matrix H(s), the two cell arrays

should contain the row-vector representations of the polynomial entries of

Ns

() ()=

You can specify this MIMO transfer matrix H(s)bytyping

N and D) to represent the sets of numerator and denominator

s

−

1

⎡

⎤

⎢

⎥

s

+

2

⎣

⎦

Ds

s

⎡

=

⎢

2

ss

++

⎣

+

1

⎤

⎥

45

⎦

N and D

Page 33

MIMO Models

N = {[1 -1];[1 2]}; % Cell arr ay for N(s)

D = {[1 1];[1 4 5]}; % Cell array for D(s)

H = tf(N,D)

These commands return the following res ult:

Transfer f unction from input to output...

s-1

#1: -----

s+1

s+2

#2: -------------

s^2+4s+5

Notice that both N and D havethesamedimensionsasH. For a general MIMO

transfer matrix H(s), the cell array entries

row-vector representations of the numerator and denominator of H

N{i,j} and D {i,j } should be

(s), the

ij

ijth entry of the transfer matrix H(s).

Accessing I/O Pairs in MIMO Systems

After you define a MIMO system , y ou can access and manipulate I/O pairs by

specifying input and output pairs of the system. For instance, if

MIMO system with two inputs and three outputs,

sys_mimo(3,1)

extracts the subsystem, mapping the first input to the third output. Row

indices select the outputs and column indices select the inputs. Similarly,

sys_mimo(3,1) = tf(1, [1 0])

redefines the transfer function between the first input and third output as

an integrator.

sys_mimo is a

2-17

Page 34

2 Building Models

Arrays of Linear Models

You can specify and manipulate collections of linear models as single entities

using LTI arrays. For example, if you want to vary the

for the DC motor and store the resulting state-space models, use this code.

K = [0.1 0.15 0.2]; % Sev eral values for Km and Kb

A1 = [-R/L -K(1)/L; K(1)/J -Kf/J];

A2 = [-R/L -K(2)/L; K(2)/J -Kf/J];

A3 = [-R/L -K(3)/L; K(3)/J -Kf/J];

sys_lti(:,:,1)= ss(A1,B,C,D);

sys_lti(:,:,2)= ss(A2,B,C,D);

sys_lti(:,:,3)= ss(A3,B,C,D);

The number of inputs and outputs must be the same for all linear models

encapsulated by the LTI array, but the model order (number of states) can

vary from model to model within a single LTI array.

Kb and Km parameters

The LTI array

Type

sys_lti to see the contents of the LTI array.

Model sys_ lti(:,:,1,1)

======================

a=

.

.

.

Model sys_l ti(:,:,2,1)

======================

a=

.

.

sys_lti contains the state-space models for each value of K.

x1 x2

x1 -4 -0.2

x2 5 -10

x1 x2

x1 -4 -0.3

x2 7.5 -10

2-18

Page 35

Arrays of Linear Models

.

Model sys_l ti(:,:,3,1)

======================

a=

x1 x2

x1 -4 -0.4

x2 10 -10

.

.

.

3x1 array of continuous-time state-space models.

You can manipulate the LTI array like any other object. For example,

step(sys_lti)

produces a plot containing step responses for all three state-space models.

Step Responses for an LTI Array Containing Three Models

2-19

Page 36

2 Building Models

LTIarraysareusefulforperformingbatchanalysisonanentiresetofmodels.

For more information, see Arrays of LTI Models.

2-20

Page 37

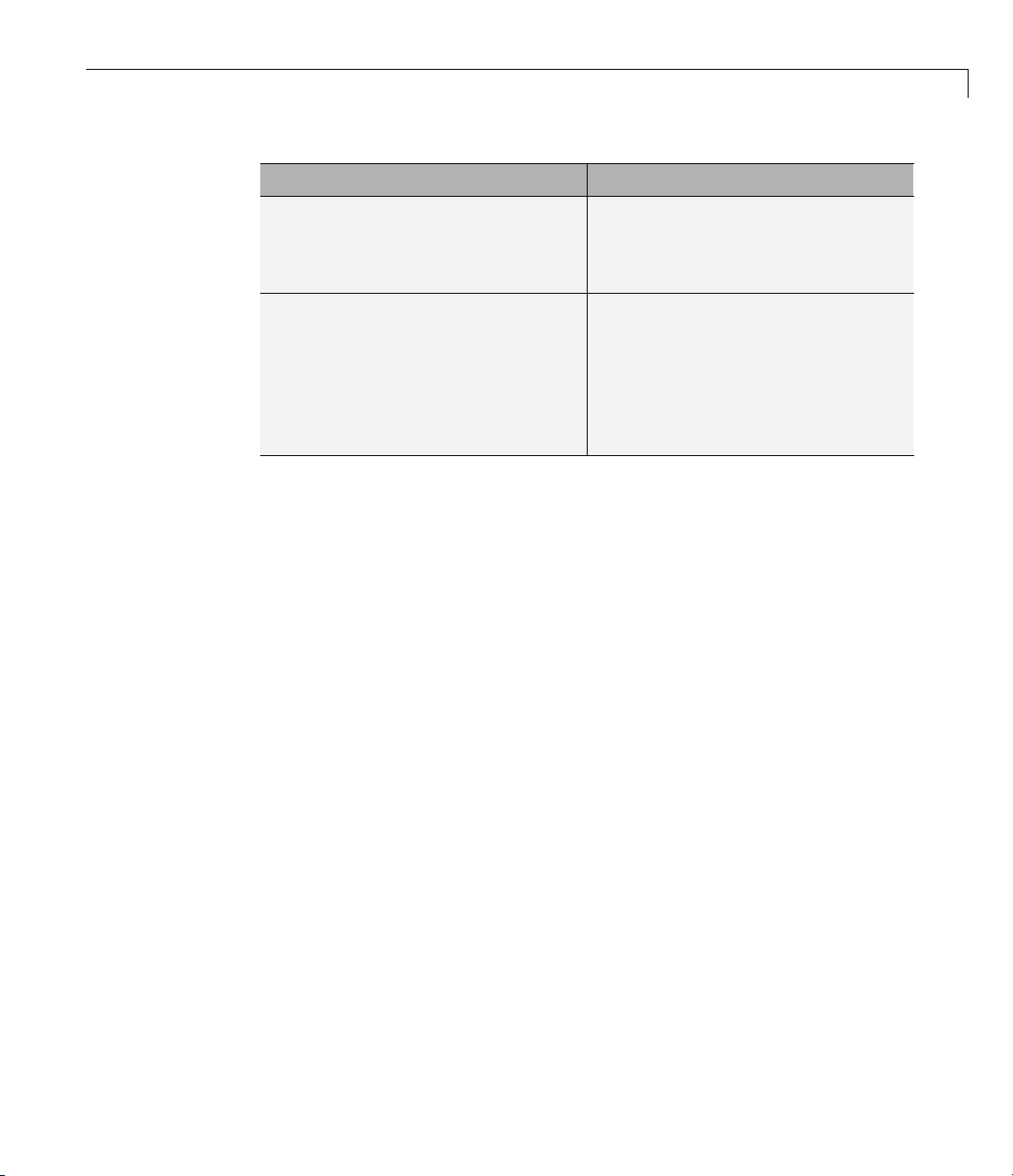

Model Characteristics

You can use the Control System Toolbox commands to query model

characteristics such as the I/O dimensions, poles, zeros, and DC gain.

These commands apply to both continuous- and discrete-time models. Their

LTI-basedsyntaxissummarizedinthetablebelow.

Commands to Query Model Characteristics

Command Description

size(model_name) Number of inputs and outputs

ndims(model_name) Number of dimensions

isct(model_name) Returns 1 for continuous systems

isdt(model_name) Returns 1 for discrete systems

hasdelay(model_name)Trueifsystemhasdelays

pole(model_name)Systempoles

Model Characteristics

zero(model_name) System (transmission) zeros

dcgain(model_name)DCgain

norm(model_name)Systemnorms(H

covar(model_name,W) Covariance of response to white noise

bandwidth(model_name)

lti/order(model_name)

pzmap(model_name) Compute pole-zero map of LTI models

mp

(model_name)

da

Frequency response bandwidth

model order

LTI

tural frequency and damping of system

Na

oles

p

and L∞)

2

2-21

Page 38

2 Building Models

Commands to Query Model Characteristics (Continued)

Command Description

class(model_name) Create object or return class of object

isa(model_name) Determine whether input is object of given

class

isempty(model_name)

isproper(model_name)

issiso(model_name)

Determine whether LTI model is empty

Determine w

hether LTI model is proper

Determine w hether LTI model is

single-input/single-output (SISO)

ble

lti/issta

reshape(model_name) Change shape of LTI array

(model_name)

Determine whether system is stable

2-22

Page 39

Interconnecting Linear Models

In this section...

“Arithmetic Operations for Interconnecting Models” on page 2-23

“Feedback Interconnections” on page 2-24

Arithmetic Operations for Interconnecting Models

You can perform arithmetic on LTI models, such as addition, multiplication,

or concatenation. Addition performs a parallel interconnection. For example,

typing

tf(1,[1 0] ) + tf([1 1],[1 2]) % 1/s + (s+1)/(s+2)

produces this transfer function.

Transfer f unction:

s^2 + 2 s + 2

------------s^2+2s

Interconnecting Linear Models

Multiplication performs a series interconnection. For example, typing

2 * tf(1,[1 0])*tf([1 1],[1 2]) % 2*1/s*(s+1)/(s+2)

produces this cascaded transfer function.

Transfer f unction:

2s+2

---------

s^2 + 2 s

If the operands are models of different types, the resulting model type is

determined by precedence rules; see “Precedence and Property Inheritance”

for more information. State-space models have the highest precedence while

transfer functions have the lowe st precedence. Hence the sum of a transfer

function and a state-space model is always a state-space model.

2-23

Page 40

2 Building Models

Other available operations include system inversion, transposition, and

pertransposition; see Arithmetic Operations. You can a ls o perform matrix-like

indexing for extracting subsystems; see Extracting and Modifying Subsystems

for more information.

You can also use the

multiplication and addition, respectively.

Equivalent Ways to Interconnect Systems

Operator Function Resulting Transfer Function

sys1 + sys2 parallel(sys1,sys2)

sys1 - sys2 parallel(sys1,-sys2)

sys1 * sys2 series(sys2,sys1)

series and parallel functions as substitutes for

Systems in parallel

Systems in parallel

Cascaded systems

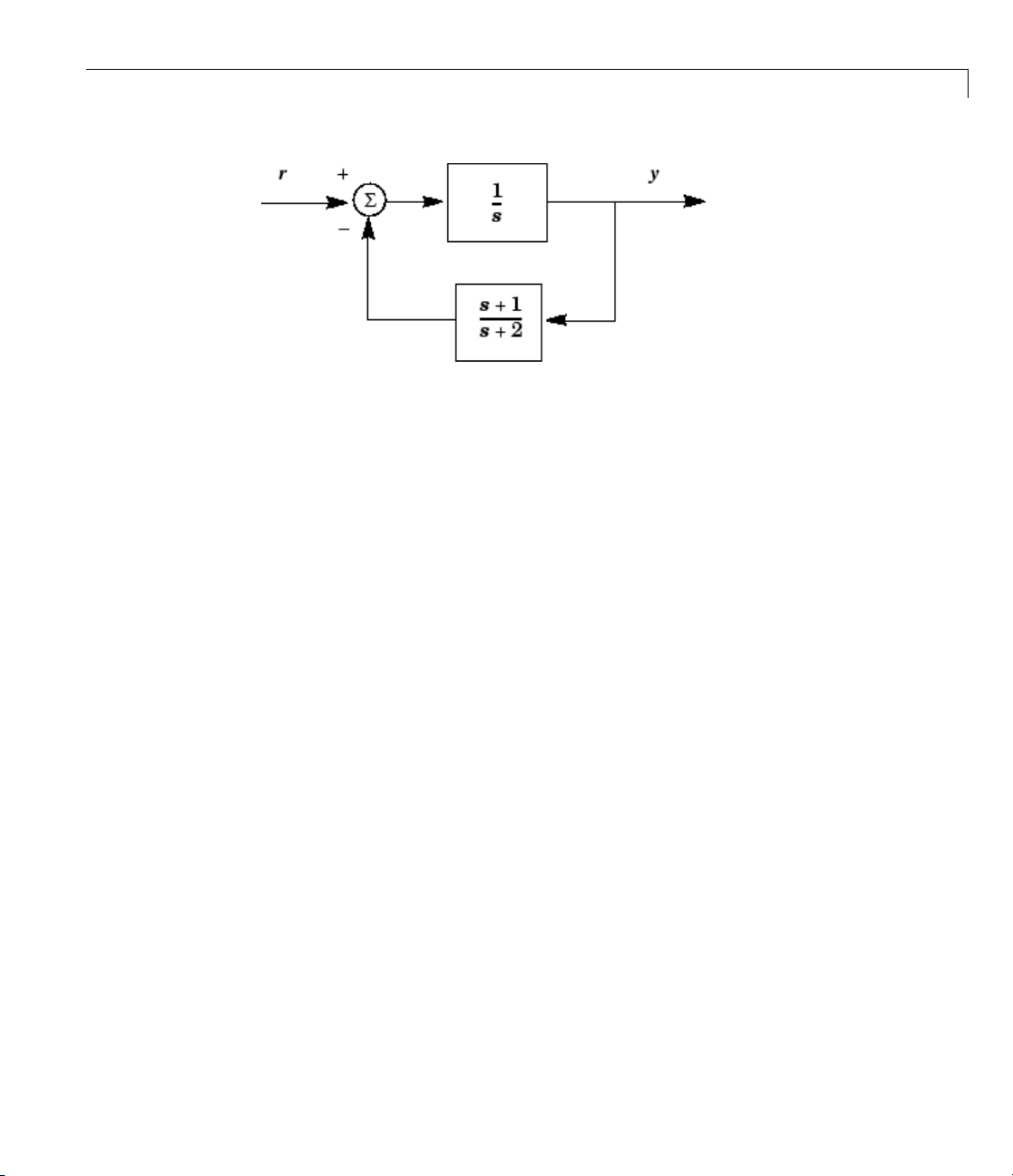

Feedback Interconnections

You can use the feedback and lft functions to d erive closed-loop models.

For example,

sys_f = feedback(tf(1 ,[1 0]), tf([1 1],[1 2])

computes the closed-loop transfer function from r to y for the feedback loop

shown below. The result is

Transfer f unction:

s+2

-------------

s^2 + 3 s + 1

2-24

This figure shows the interconnected system in block diagram format.

Page 41

Interconnecting Linear Models

Feedback Interconnection

You can use the lft function to create more complicated feedback structures.

This function constructs the linear fractional transformation of two systems.

See the reference page for more information.

2-25

Page 42

2 Building Models

Converting Between Continuous- and Discrete- Time Systems

In this section...

“Available Commands for Continuous/Discrete Conversion” on page 2-26

“Available Methods for Continuous/Discrete Conversion” on page 2-26

“Digitizing the Discrete DC Motor Model” on page 2-26

Available C

Conversio

The comman

continuou

sysd = c2d(sysc,Ts) % Discretization w/ sample period Ts

sysc = d2c(sysd) % Equivalent continuous -time model

sysd1= d2d( sysd,Ts) % Resampling at the period Ts

s, and discrete to discrete (resampling) conversions, respectively.

Available Met

ommands for Continuous/Discrete

n

ds

c2d, d2c,andd2d perform continuous to discrete, discrete to

hods for Continuous/Discrete

Conversion

Various discr

zero-order h

without prew

sysd = c2d(sysc,Ts,'f oh') % Uses first-order hold

sysc = d2c(sysd,'tusti n') % Uses Tustin approximation

Digitizing the Di

You can digitize

appropriate sam

factors, includ

constant in your

to run. For this

Example: The DC

sys_dc.

etization/interpolation methods are available, including

old (default), first-order hold, Tustin approximatio n with or

arping, and matched zero-pole. For ex ample,

screte DC Motor Model

the DC motor plant using the

ple time. Choosing the rig ht sample time involves many

ing the performance you want to achieve, the fastest time

system, and the spe ed at which you expect your controller

example, choose a time constant of 0.01 second. See “SISO

Motor” on page 2-3 for the cons truction of the SS object

c2d function and selecting an

2-26

Ts=0.01;

Page 43

sysd=c2d(sys_dc,Ts)

a=

x1 0.96079 -0.00027976

x2 0.006994 0.90484

b=

x1 0.019605

x2 7.1595e-005

c=

y101

Converting Between Continuous- and Discrete- Time Systems

x1 x2

u1

x1 x2

d=

u1

y1 0

Sampling ti me: 0.01

Discrete-time model.

To see the discrete-time zero-pole gain for the digital DC motor, use zpk to

convert the model.

fd=zpk(sysd)

Zero/pole/gain:

7.1595e-005 (z+0.9544)

------------------------

(z-0.9608) (z-0.9049)

Sampling ti me: 0.01

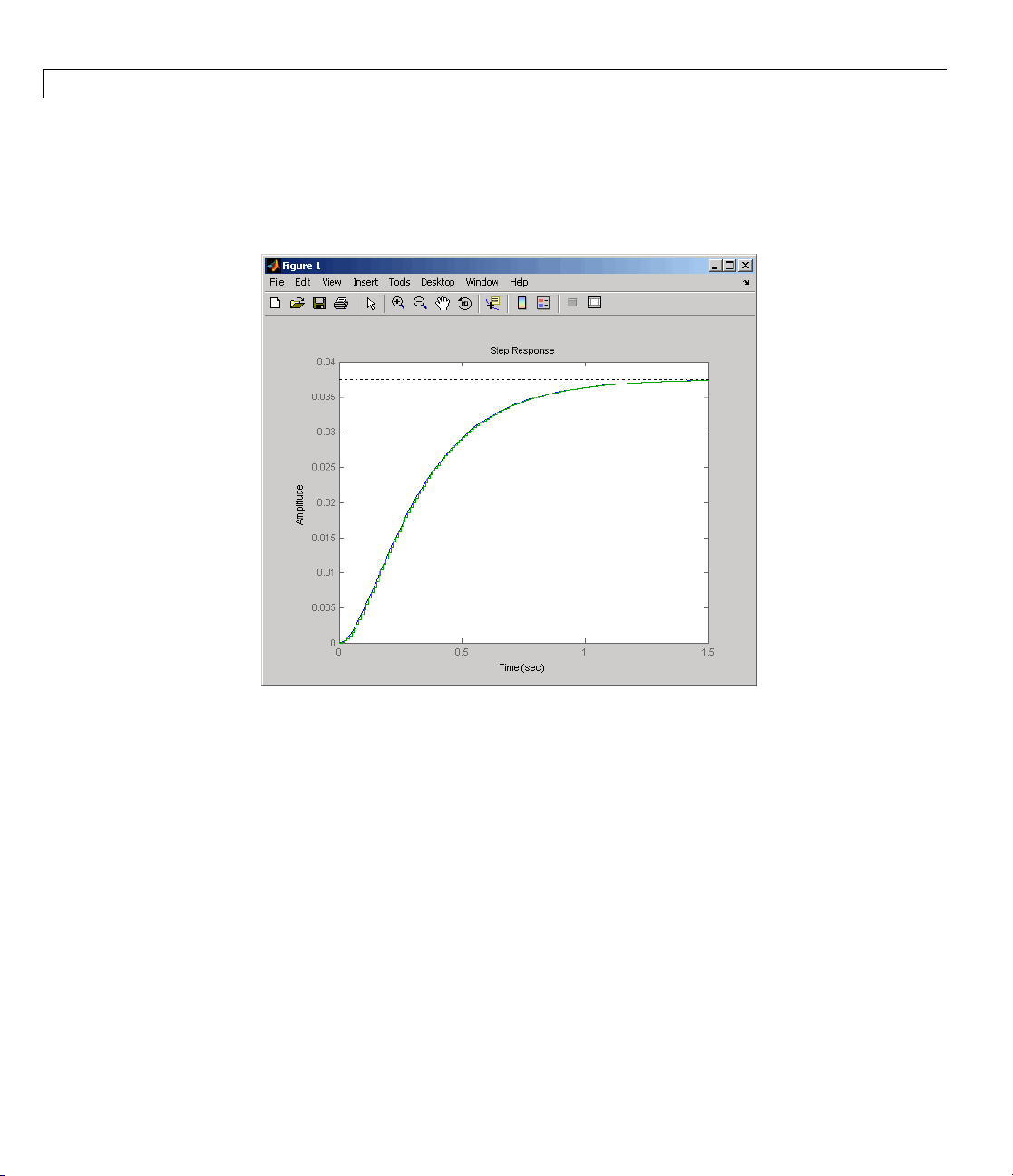

You can compare the step responses of sys_dc and sysd by typing

2-27

Page 44

2 Buildin g Models

step(sys_dc,sysd)

This figure shows the result.

2-28

Note the s t ep response match. C ontinuous and FOH-discretized step

responses match for models without internal delays.

Page 45

Reducing Model Order

In this section...

“Model Order Reduction Commands” o n page 2-29

“Techniques for Reducing Model Order” on page 2-29

“Example: Gasifier Model” on page 2-30

Model Order Reduction Commands

You can derive reduced-order SISO and MIMO models with the commands

shown in the following table.

Model Order Reduction

Commands

hsvd

balred

minreal

balreal

modred

sminreal

Reducing Model Order

Compute Hankel singular values of LTI model

Reduced-order model approximation

Minimal realization (pole/zero cancellation)

Compute input/output balanced realization

State deletion in I/O balanced realization

Structurally minimal realization

hniques for Reducing Model Order

Tec

educe the order of a model, you can perform any of the following actions:

To r

iminate states that are structurally disconnected from the inputs or

• El

tputs using

ou

iminating structurally disconnected states is a good first step in model

El

duction because the process is cheap and does not involve any numerical

re

omputation.

c

ompute a low-order approximation of your model using

• C

liminate cancelling pole/zero pairs using

• E

sminreal.

balred.

minreal.

2-29

Page 46

2 Buildin g Models

Example: Gasifier Model

This example presents a model of a gasifier, a device that converts solid

materials into gases. The original m odel is nonlinear.

Loading the Model

To load a linearized version of the model, type

load ltiex amples

at the MATLAB prompt; the gasifier example is stored in the variable named

gasf.Ifyoutype

size(gasf)

you get in return

State-space model wit h 4 outputs, 6 inputs, and 25 states.

2-30

SISO Model Order Reduction

You can reduce the order of a single I/O pair to understand how the model

reduction tools work before attempting to reduce the full MIMO model as

described in “MIMO Model Order Reduction” on page 2-34.

This example focuses on a single input/output pair of the gasifier, input

to output 3.

sys35 = gasf(3,5);

Before attempting model order reduction, inspect the pole and zero locations

by typing

pzmap(sys35)

Zoom in near the origin on the resulting plo t using the zoom feature or by

typing

axis([-0.2 0.05 -0.2 0.2])

The following figure shows the results.

5

Page 47

Reducing Model Order

Pole-Zer

Because

for mode

To find

1 Select

o Map of the Gasifier Model (Zoomed In)

the m odel displays near pole-zero cancellations, it is a good candidate

l reduction.

a low-order reduction of this SISO model, perform the following steps:

an appropriate orde r for your reduced system by examining the

ve amount of energy per state using a Hankel singular value (HSV)

relati

Type the command

plot.

hsvd(sys35)

eate the HSV plot.

to cr

Changing to log scale using the right-click menu results in the following

plot.

2-31

Page 48

2 Buildin g Models

2-32

Small Hankel singular values indicate that the associated states contribute

little to the I/O behavior. This plot shows that discarding the last 10 states

(associated with the 10 sma llest Hankel singular values) has little impact

on the approximation error.

2 To remove the last 10 states and create a 15th order approximation, type

rsys35

= balred(sy s35,15);

You can type s ize (rsys35) to see that your reduced system contains only

15 states.

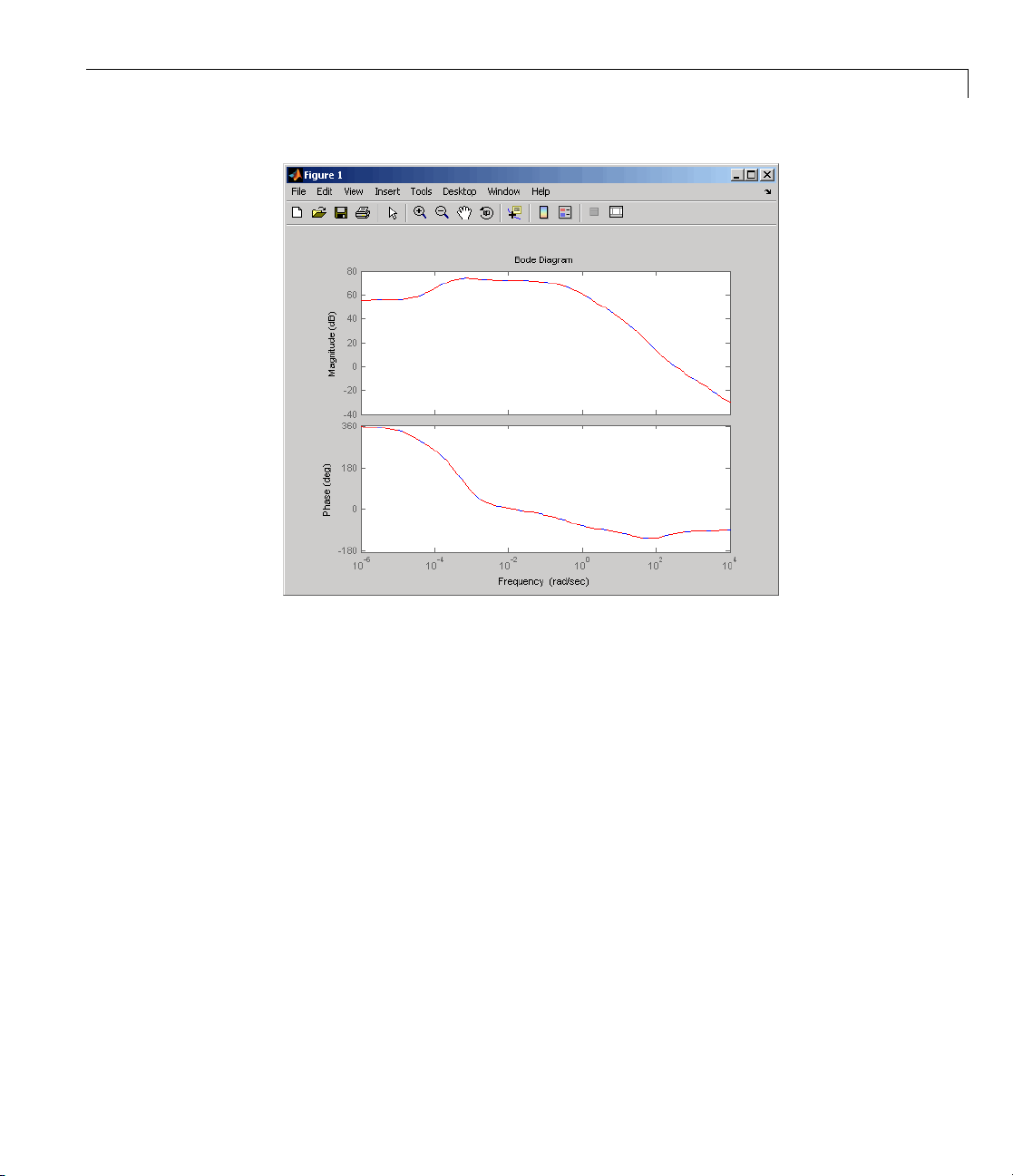

3 Comp

are the Bode response of the full-order and reduced-order models

g the bode command:

usin

bode(sys35,'b',rsys35,'r--')

s figure shows the result.

Thi

Page 49

Reducing Model Order

As the overlap of the curves in the figure shows, the reduced m odel provides

a good approximation of the original system.

You can try reducing the model order further by repeating this process and

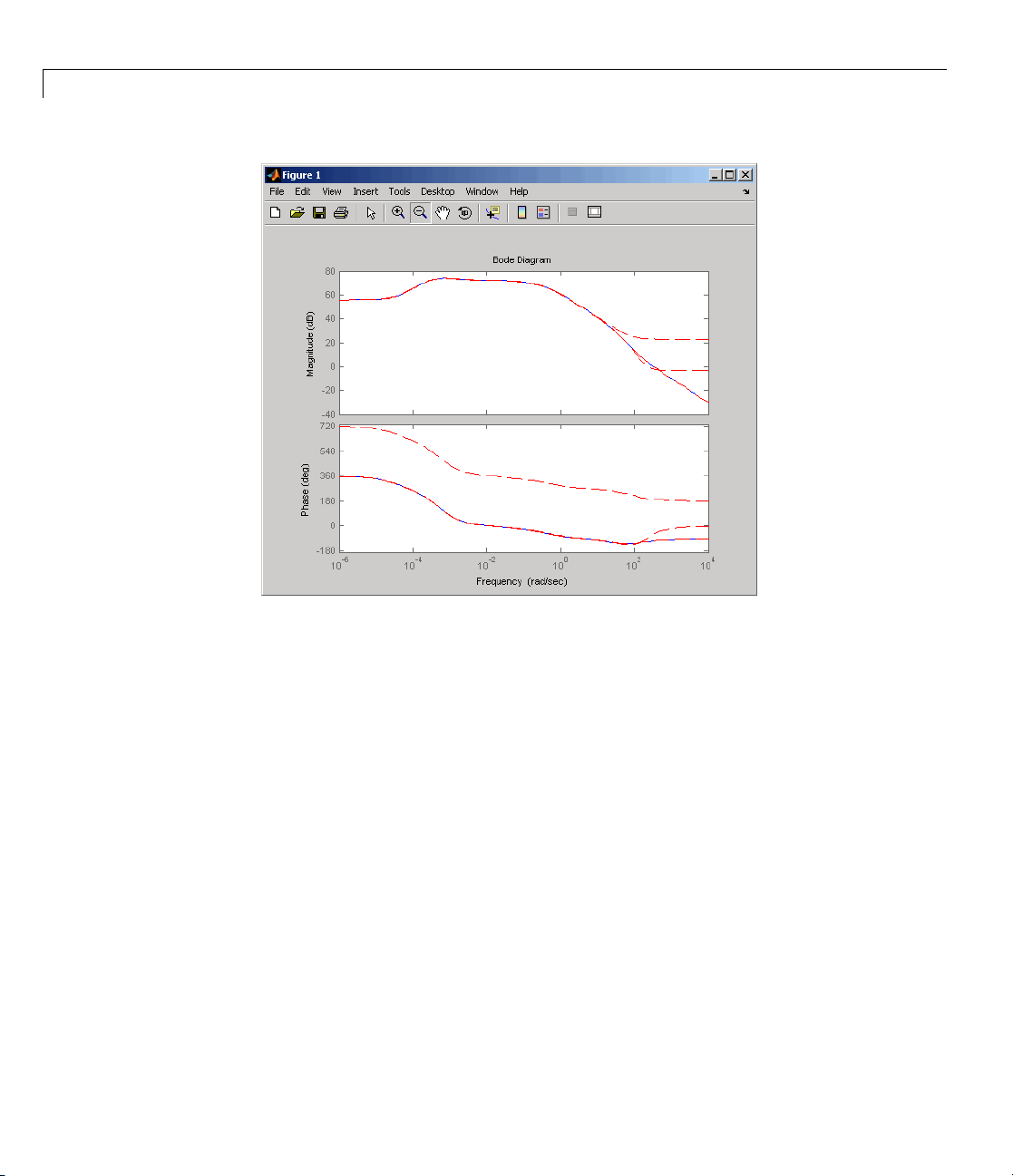

removing more states. Reduce the

gasf model to 5th, 10th, and 15th orders

allatoncebytypingthefollowingcommand

rsys35 = balred(sys35 ,[5 10 15]);

Plot a bode diagram of these three reduced syste ms along with the full order

system by typing

bode(sys35,'b',rsys35,'r--')

2-33

Page 50

2 Buildin g Models

2-34

Observe h

ow the error increases as the order decreases.

MIMO Model Order Reduction

You can a

follow

1 Select

relati

plot.

Type

to create the HSV plot.

pproximate MIMO models using the same steps as SISO models as

s:

an appropriate orde r for your reduced system by examining the

ve amount of energy per state using a Hankel singular value (HSV)

hsvd(gasf)

Page 51

Reducing Model Order

Discarding the last 8 states (associat ed with the 8 smallest Hankel singular

values) should have little impact on the error in the resulting 17th order

system.

2 To remove the last 8 states and create a 17th order MIMO system, type

rsys=b

alred(gasf,17);

You can type size(gasf) to see that your reduced system contains only

17 states.

3 To fac

ilitate visual inspection of the approximation error, use a singular

e plot rather than a MIMO Bode plot. Type

valu

sigma(gasf,'b',gasf-rsys,'r')

reateasingularvalueplotcomparingtheoriginalsystemtothe

to c

uction error.

red

2-35

Page 52

2 Buildin g Models

2-36

The reduction e rror is small compared to the original system so the reduced

order model provides a good approximation of the original model.

Acknowledgment

MathWorks thanks ALSTOM®Power UK for permitting use of their gasifier

model for this example. This model was issued as part of the ALSTOM

Benchmark Challenge on Gasifier Control. For more details see Dixon, R.,

(1999), "Advanced Gasifier Control," Computing & Control Engineering

Journal, IEE, Vol. 10, No. 3, pp. 92–96.

Page 53

Analyzing Models

• “Quick Start for Performing Linear Analysis Using the LTI Viewer” on

page 3-2

• “LTI Viewer” on page 3-7

• “Simulating Models with Arbitrary Inputs and Initial Conditions” on page

3-22

• “Functions for Time and Frequency Response” on page 3-37

3

Page 54

3 Analyzing Models

Quick Start for Performing Linear Analysis Using the LTI Viewer

In this Quick Start, you learn how to analyze the time- and frequency-d omain

responses of one or more linear models using the LTI Viewer GUI.

Before you can perform the analysis, you must have already created linear

models in the MATLAB workspace. For information on how to create a model,

see Chapter 2, “Building Models”.

To perform linear analysis:

1 Open the LTI Viewer showing one or more models using the following

syntax:

ltiview(model1,model2,...,modelN)

By default, this syntax opens a step response plot of your models, as shown

in the following figure.

3-2

Page 55

Quick Start for Performing Linear Ana lysi s Using the LTI Viewer

Click to add a legend

3-3

Page 56

3 Analyzing Models

2 Add more plots to the LTI Viewer.

a Select Edit > Plot Configurations.

b In the Plot Configurations dialog box, select the number of plots to open.

3-4

Select the

number of

plots to open

Page 57

Quick Start for Performing Linear Ana lysi s Using the LTI Viewer

3 To view a different type of response on a plot, right-click and select a plot

type.

Right-click

to select

a plot type

3-5

Page 58

3 Analyzing Models

4 Analyze system performance. For example, you can analyze the peak

response in the Bode plot and settling time in the step response plot.

a Right-click to select performance characteristics.

b Click on the dot that appears to view the characteristic value.

Right-click to show

performance

characteristics

Click dot to

view value

3-6

Page 59

LTI Viewer

LTI Viewe r

In this section...

“Plot Types Available in the LTI Viewer” on page 3-7

“Example: Time and Frequency Responses of the DC Motor” on page 3-8

“Right-Click Menus” on page 3-10

“Displaying Response Characteristics on a Plot” on page 3-11

“Changing Plot Type” on page 3-14

“Showing Multiple Response Types” on page 3-16

“Comparing Multipl e Models” on page 3-17

Plot Types Available in the LTI Viewer

The LTI Viewer is a GUI for vie wing and manipulating the response plots of

linear models. You can display the following plot types for linear models

using the LTI Viewer:

• Step and impulse responses

• Bode and Nyquist plots

• Nichols plots

• Singular values of the frequency response

• Pole/zero plots

• Response to a general input signal

• Unforced response starting from given initial states (only for state-space

models)

Note that time responses and pole/zero plots are not available for FRD models.

Note The LTI Viewer displays up to six different plot types simultaneously.

You can also analyze the response plots of several linear models at once.

3-7

Page 60

3 Analyzing Models

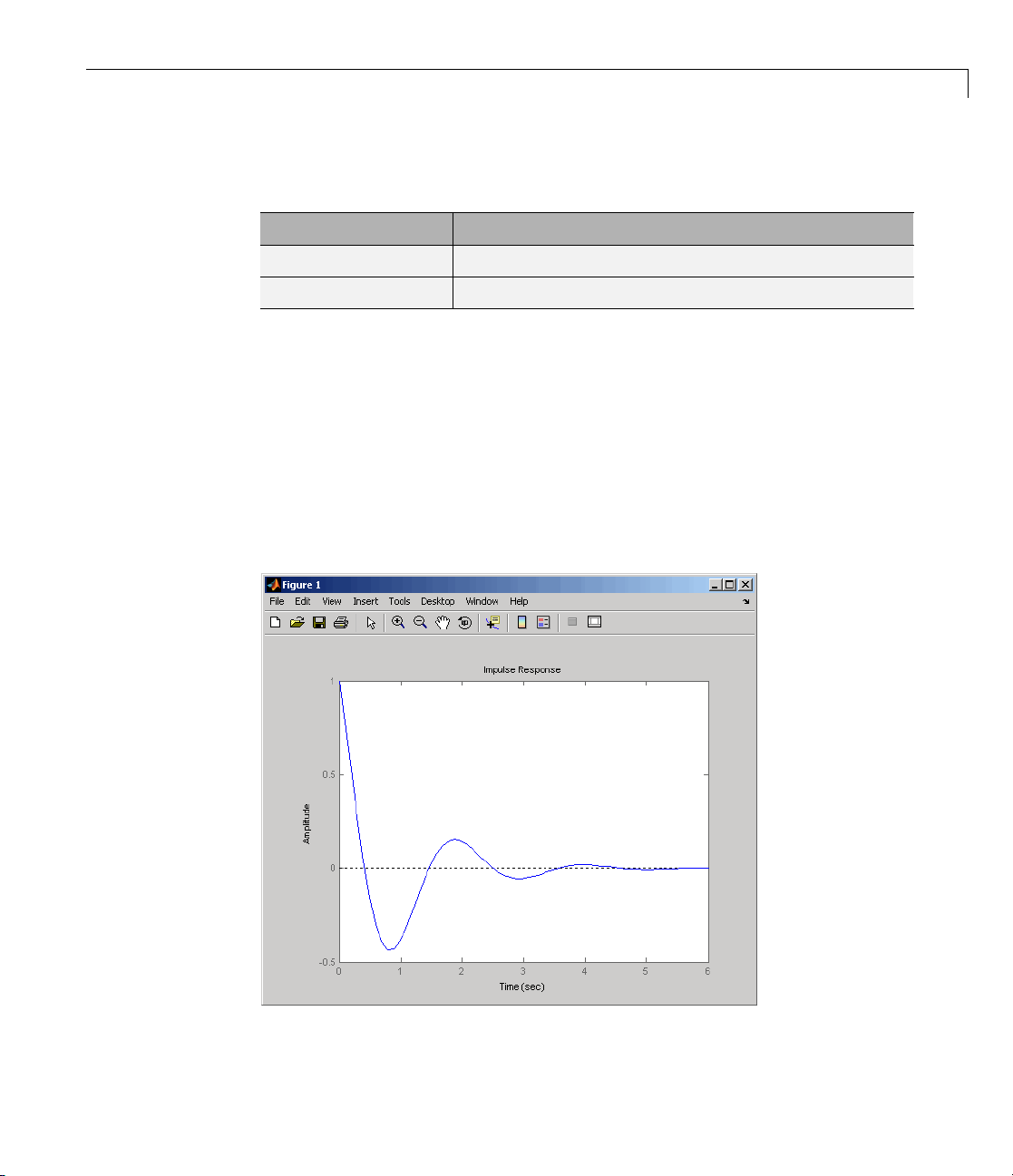

This figure shows an LTI Viewer with two response plots.

The LTI Viewer with Step and Impulse Response Plots

The next section presents an example that shows you how to import a system

into the LT I Viewer and how to customize the viewer to fit your requirements.

Example: Time and Frequency Responses of the DC Motor

“SISO Example: The DC Motor” on page 2-3 presents a DC motor example. If

you have not yet built that example, type

ltiexamples

load

at the MATLAB prompt. This loads several LTI models, including a

state-space representation of the DC motor called

3-8

sys_dc.

Page 61

LTI Viewe r

Opening the LTI Viewer

To open the LTI Viewer, type

ltiview

This opens an LTI Viewer with an empty step response plot window by default.

Importing Models into the LTI Viewer

To import the DC motor model, select Import under the File m enu. This

opens the Import System Data dialog box, which lists all the models available

in your MATLAB workspace.

Import System Data Dialog Box w ith the DC Motor M od el Selected

Select sys_dc from the list of available models and click OK to close the

browser. This im po rts the DC motor model into the LTI Viewer.

To select more than one model at a time, do the follow ing:

• To select individual (noncontiguous) models, select one model and hold

down the Ctrl key while selecting additional models. To clear any models,

hold down the Ctrl k ey while you click the highlighted model nam es.

• To select a list of contiguous models, select the first mode l and hold down

the Shift key while selecting the last model you want in the list.

3-9

Page 62

3 Analyzing Models

The figure below shows the LTI Viewer with a step response for the DC

motor example.

3-10

Step Response for the DC Motor Example in the LTI Viewer

Alternatively, you can open the L TI Viewer and import the DC mo to r example

directly from the MATLAB prompt.

ltiview('step', sys_dc)

See the ltiview reference page for a complete list of options.

Right-Click Menus

The LTI Viewer provides a set of controls and options that you can access by

right-clicking your mouse. Once you have imported a model into the LTI

Viewer, the options you can select include

• Plot Types — Change the plot type. Available types include step, impulse,

Bode,Bodemagnitude,Nichols,Nyquist,andsingularvaluesplots.

Page 63

• Systems — Select or clear any models that you included when you created

theresponseplot.

• Characteristics — Add information about the plot. The characteristics

available change from plot to plot. For example, Bode plots have stability

margins available, but step responses have rise time and steady-state

values available.

• Grid —Addgridstoyourplots.

• Normalize — Scale responses to fit the view (only available for

time-domain plot types).

• Full View — Use automatic limits to make the entire curve visible.

• Properties — Open the Property Editor.

LTI Viewe r

You can use this editor to customize various attributes of your plot. See

Customizing Plot Properties and Preferences for a full description of the

Property Editor.

Alternatively, you can open the Property Editor by double-clicking in an

empty region of the response plot.

Displaying Response Characteristics on a Plot

Forexample,toseetherisetimeforthe DC m otor step response, right-click

and select Characteristics > Rise Time.

3-11

Page 64

3 Analyzing Models

3-12

Using Rig

By defau

respons

range in

proper

The LTI

e to go from 10% to 90% of the steady-state value. You can change this

ty editor, see Customizing Plot Properties and Pre ferences.

ht-Click Menus to Display the Rise Time for a Step Response

lt, the rise time is defined as the amount of time it takes the step

the options tab of the property editor. For more information on the

Viewer calculates and displays the rise time for the step response.

Page 65

LTI Viewe r

DC Motor S

To displ

your mou

data mar

persis

For exa

respon

tep Response with the Rise Time Displayed

ay the values of any plot characteristic marked on a plot, place

se on the blue dot that marks the characteristic. This opens a

ker with the relevant information displayed. To make the marker

tent, left-click the blue dot.

mple, this figure shows the rise time value for the DC motor step

se.

3-13

Page 66

3 Analyzing Models

3-14

Using You

Note tha

respons

over the

For mor

Chang

You ca

examp

sele

r Mouse to Get th e Rise Time Values

t you can left-click anyw here on a particular plot line to see the

e values of that plot at that point. You must either place y our cursor

bluedotorleft-click,however,ifyouwanttoseetherisetimevalue.

e information about data markers, see “Data Markers” on page 3-42.

ing Plot Type

n view other plots using the right-click menus in the LTI Viewer. For

le, if you want to see the open loop Bode plots for the DC motor model,

ct Plot Type and then Bode from the right-click menu.

Page 67

LTI Viewe r

Changing

Selecti

ng Bode changes the step response to a Bode plot for the DC motor

model.

the Step Response to a Bode Plot

3-15

Page 68

3 Analyzing Models

3-16

Bode Plot

for the DC Motor Model

Showing

If you wa

the sam

respon

Edit me

nt to see, for example, both a step response and a Bode plot at

e time, you have to reconfig ure the LTI View er. To view different

se types in a single LTI Viewer, select Plot Configurations under the

nu. This opens the Plot Configurations dialog box.

Multiple Response Types

Page 69

Using the Plot Configurations Dialog Box to Reco nfigure the LTI Viewer

You can select up to six plots in one viewer. Choose the R esponse type for

each plot area from the right-side menus. There are nine available plot types:

• Step

LTI Viewe r

• Impulse

• Linear Simulation

• Initial Condition

• Bode (magnitude and phase)

• Bode Magnitude (only)

• Nyquist

• Nichols

• Singular Value

• Pole/Zero

• I/O pole/zero

Comparing Multiple Models

This section shows you how to import and manipulate multiple models in

one LTI Viewer. For example, if you h ave designed a set of compensators to

control a system, you can compare the closed-loop step responses and Bode

plots using the LTI Viewer.

3-17

Page 70

3 Analyzing Models

A sample set of clo sed-loo p transfer function models is included (along with

some other models) in the MAT-file

load ltiex amples

to load the provided transfer functions. The three closed-loop transfer function

models,

Gcl1, Gcl2,andGcl3, are for a satellite attitude controller.

ltiexamples.mat.Type

In this example, you analyze the response plots of the

functions.

Gcl1 and Gcl2 transfer

Initializing the LTI Viewer with Multiple Plots

To load the two models Gcl1 and Gcl2 into the LTI Viewer, select Import

under the File menu and select the desired models in the LTI Browser. See

“Importing Models into the LTI Viewer” on page 3-9 for a description of how

to select groups of models. If necessary, you can reconfigure the viewer to

display both the step responses and the Bode plots of the two systems using

the Viewer Configuration dialog box. See“ShowingMultipleResponseTypes”

on page 3-16 for a discussion of this feature.

Alternatively, you can open an LTI Viewer with both systems and both the

step responses and Bode plots displayed. To do this, type

ltiview({'step';'bode'},Gcl1,Gcl2)

Either approach opens the following LTI Viewer.

3-18

Page 71

LTI Viewe r

Multiple

Response Plots in a Single LTI Viewer

Inspecting Response Characteristics

To mark t

do the f

• Right-

opens t

• Selec

To mar

sele

Your

he settling time on the step responses presented in this example,

ollowing:

click anywhere in the plot region of the step response plots. This

he right-click menu list in the plot region.

t Characteristics > Settling Time.

k the stability margins of the Bode plot in this example, right-click and

ct Characteristics > Minimum Stability Margins.

LTI Viewer should now look like this.

3-19

Page 72

3 Analyzing Models

3-20

Multiple

The mini

gain mar

diagram

right-

Plots with Response Characteristics Added

mum stability margins, meaning the smallest magnitude phase and

gins, are displayed as green and blue markers on the Bode phase

. Ifyouwanttoseeallthegainandphasemarginsofasystem,

click and select Characteristics > Minimum Stability Margins.

Toggling Model Visibility

have imported more than one model, you can s elect and clear which

If you

s to plot in the LTI Viewer using right-click menus. For example, if you

model

t the following three models into the viewer, you can choose to view any

impor

ination of the three you want.

comb

s=tf('s');

sys1=1/(s^2+s+1);

sys2=1/(s^2+s+2);

sys3=1/(s^2+s+3);

Page 73

LTI Viewe r

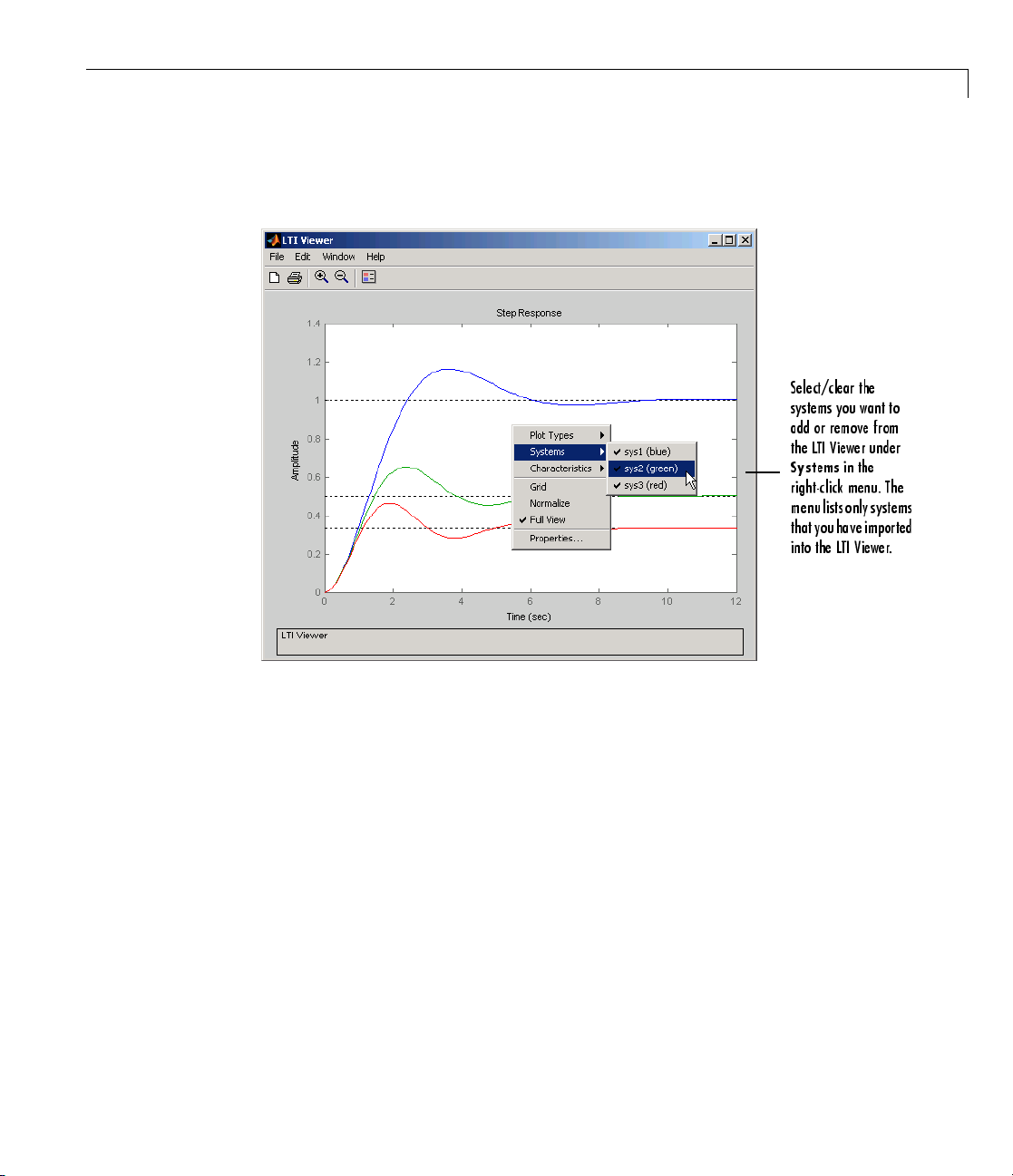

This figure shows how to clear the second of the three models using right-click

menu options.

Using Right-Click Menus to Select/Clear Plotted Systems

The Systems menu lists all the imported models. A system is selected if a

check mark is visible to the left of the system name.

3-21

Page 74

3 Analyzing Models

Simulating Models with Arbitrary Inputs and Initial Conditions

In this section...

“What is the Linear Simulation Tool?” on page 3-22

“Opening the Linear Simulation Tool” on page 3-22

“Working with the Linear Simulation Tool” on page 3-23

“Importing Input Signals” on page 3-26

“Example: Loading Inputs from a M icrosoft®Excel Spreadsheet” on page

3-28

“Example: Importing Inputs from the W orkspace” on page 3-29

“Designing Input Signals” on page 3-33

“Specifying Initial Conditions” on page 3-35

3-22

What is

You can

rary input s i gn als and ini tia l conditions.

arbit

The Li

• Impo

• Impo

ASC

• Gen

pfunction,orwhitenoise.

ste

ecify initial states for state-space models.

• Sp

fault initial states are zero.

De

pening the Linear Simulation Tool

O

o open the Linear Simulation Tool, do one of the following:

T

the Linear Simulation Tool?

use the Linear Simulation Tool to simulate linear models with

near Simulation Tool lets you do the following:

rt input signals from the MATLA B workspace.

rt input signals from a MAT-file, Microsoft

II flat-file, comma-separated variable file (CSV), or text file.

erate arbitrary input signals in theformofasinewave,squarewave,

®

Excel®spreadsheet,

Page 75

Simulating Models with Arbitrary Inputs and Initial Conditions

• In the LTI Viewer, right-click the plot area and select Plot Types >

Linear Simulation.

• Use the

lsim function at the MATLAB prompt:

lsim(modelname)

• IntheMATLABFigurewindow,right-click a response plot and select

Input data .

Working with the Linear Simulation Tool

The Linear Simulation Tool contains two tabs, Input signals and Initial

states.

After opening the Linear Simulation Tool (as described in “Opening the Linear

Simulation Tool” on page 3-22), follow these steps to simulate your model:

1 Click the Input signals tab, if it is not displayed.

3-23

Page 76

3 Analyzing Models

2 In the Timing area, specify the simulation time vector by doing one of

the following:

• Import the time vector by clicking Import time.

• Enter the end time and the time interval in s econds. The start time

is set to

3 Specify the input signal by doing one of the following:

0 seconds.

• Click Import signal to import it from the MATLAB workspace or a file.

For more information, see “Importing Input Signals” on page 3-26.

• Click Design signal to create your ow n inputs. For more information,

see “Designing Input Signals” on page 3-33.

4 If you have a state-space model and want to specify init ial conditions, click

the Initial states tab. By default, all initial states are set to zero.

You can either enter state values in the Initial value column, or import

values by clicking Import state vector. For more information about

entering initial states, see “Specif yi n g In iti al Conditions” on page 3-35.

3-24

Page 77

Simulating Models with Arbitrary Inputs and Initial Conditions

5 For a con

the Inte

• Zero or

• First o

• Autom

hold a

Note

mode

ck Simulate.

6 Cli

tinuous model, select one of the following interpolation methods in

rpolation method list to be used by the simulation solver:

der hold

rder hold (linear interpolation)

atic (Linear Simulation Tool selects first order hold or zero order

utomatically, based on the smoothness of the input)

The interpolation method is not used when simulating discrete

ls.

3-25

Page 78

3 Analyzing Models

Importing Input

You can import in

the Linear Simul

page 3-22). You ca

spreadsheet, A

For informati

Signals” on pa

Tool, see “Wo

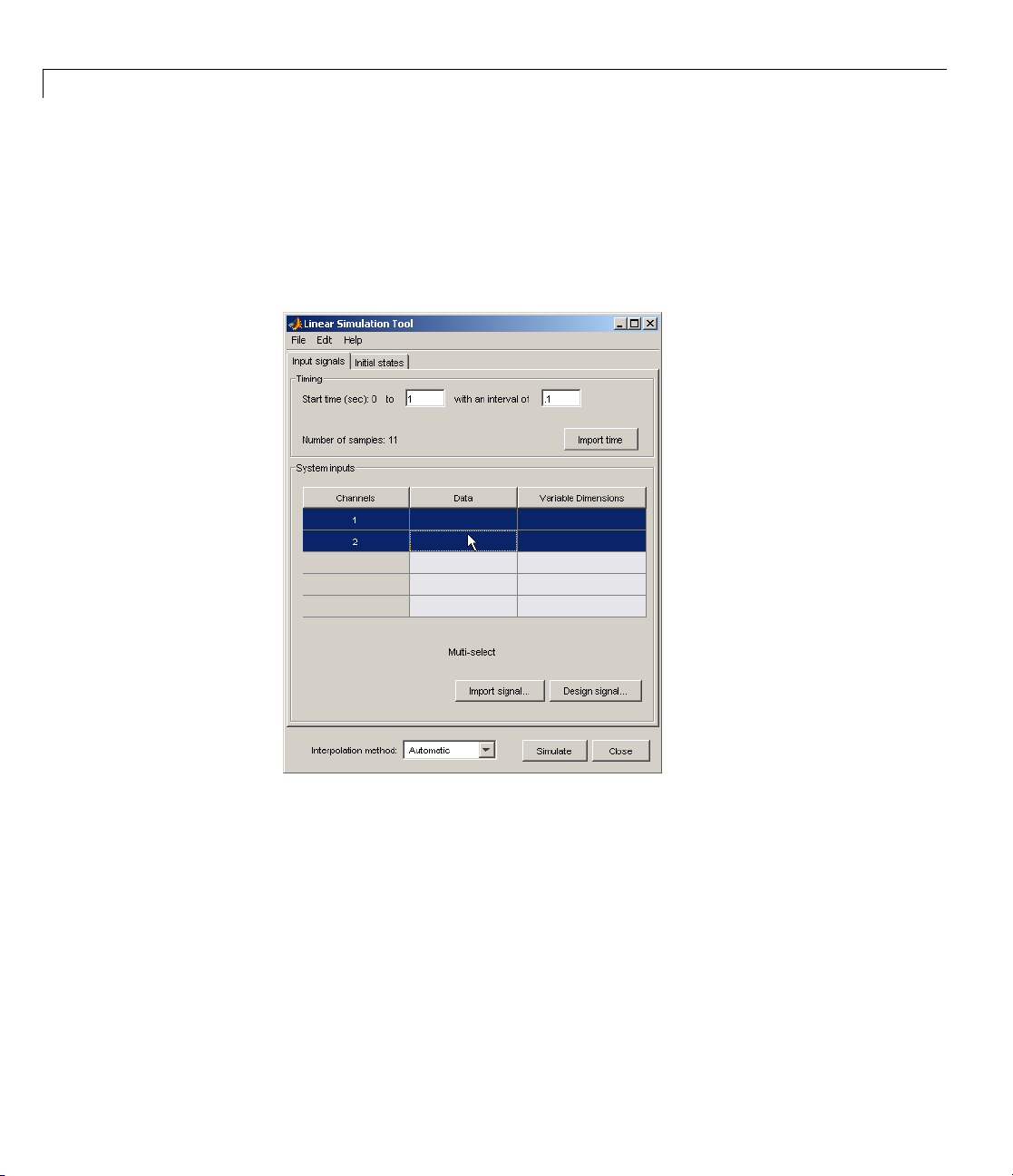

To import one

1 In the Linea

displayed.

2 Specify the simulation time in the Timing area.

3 Select one or mo re rows for the input channels you want to import. The

following figure shows an example with two selected channels.

ation Tool (see “Opening the Linear Simulation Tool” on

SCII flat-file, comma-separated variable file (CSV), or text file.

on about creating your own inputs, see “D esigning Input

ge 3-33. For an overview of w ork ing with the Linear Simulation

rking with the Line ar Simulation Tool” on page 3-23.

or more input signals:

r Simulation Tool, click the Input signals tab, if it is not

Signals

put signals from the MATLAB workspace after opening

n also import inputs from a MAT-file, Microsoft Excel

3-26

Page 79

Simulating Models with Arbitrary Inputs and Initial Conditions

4 Click Import signal to open the Data Import dialog box. The following

figure shows an example of the Data Import dialog box.

3-27

Page 80

3 Analyzing Models

5 In the Import from list, select the source of the input signals. It can be

one of the following:

•

Workspace

• MAT file

• XLS file

• CSV file

• ASCII file

6 Select the data you want to import. The Data Import dialog box contains

different options depending on which source format you selected.

7 Click Import.

For an example of importing input signals, see the foll owing:

• “Example: Loading Inputs from a Microsoft

®

Excel Spreadsheet” on p ag e

3-28

• “Example: Importing Inputs from the Workspace” on page 3-29

Example: Loading Inputs from a Microsoft Excel Spreadsheet

To load inputs from a Microsoft Excel (XLS) spreadsheet:

1 In the Linear Simu lation Tool, click Impo r t signal in the Input signals

tab to ope n the Data Import dialog box .

2 Select XLS file in th e Import from list.

3 Click Browse.

4 Select the file you want to import and click Open. This populates the Data

Import dialog box with the data from the Microsoft Excel spreadsheet.

3-28

Page 81

Simulating Models with Arbitrary Inputs and Initial Conditions

Example: Importing Inputs from the Workspace

To load an input signal from the M ATLAB workspace:

1 Enter this code to open a response plot with a second-order system:

s=tf('s');

ss=(s+2)/(s^2+3*s+2);

lsim(ss,randn(100,1),1:100);

2 Right-click the plot background and select Input data.

3-29

Page 82

3 Analyzing Models

3-30

This opens the Linear Simulation Tool with default input data.

Page 83

Simulating Models with Arbitrary Inputs and Initial Conditions

3 Create an input signal for your system in the MATLAB Command Window,

such as the following:

new_signal=[-3*ones(1,20) 2*ones(1,30) 0.5*ones(1,50)]';

4 In the Linear Simulation Tool, click Import signal.

5 In the Data Imp ort dialog box, click, Assign columns to assign the first

column of the input signal to the selected channel.

3-31

Page 84

3 Analyzing Models

6 Click Import. This imports the new signal into the Linear Simulation Tool.

3-32

Page 85

Simulating Models with Arbitrary Inputs and Initial Conditions

7 Click Simulate to see the response of your second-order system to the

imported signal.

Designing Input Signals

You can generate arbitrary input signals in the form of a sine wave, square

wave, step function, or white noise after opening the Linear Simulation Tool

(see “Opening the Linear Simulation Tool” on page 3-22).

For information about importing inputs from the MATLAB workspace or from

a file, see “Importing Input Signals” on page 3-26. For an overview of working

with the Linear Simulation Tool, see “W orking with the Linear Simulation

Tool” on page 3-23.

To design one or more input signals:

1 In the Linear Simulation Tool, click the Input signals tab (if it is not

displayed).

3-33

Page 86

3 Analyzing Models

2 Specify the simulation time in the Timing area. The time interval (in

seconds) is used to evaluate the input signal you design in later steps of

this procedure.

3 Select one or more rows for the signal channels you want to design. The

following figure shows an example with two selected channels.

3-34

4 Click Design signal to open the Signal Designer dialog box. The following

figure shows an example of the Signal Designer dialog b ox.

Page 87

Simulating Models with Arbitrary Inputs and Initial Conditions

5 In the Signa

can be one o

•

Sine wav e

• Square wa

• Step func

• White no

6 Specify the signal characteristics. The Signal Designer dialog box contains

ltypelist, select the type of signal you want to create. It

f the following:

ve

tion

ise

different options depending on which signal type you selected.

7 Click Insert. This brings the new signal into the Linear Simulation Tool.

8 Click S

Speci

If you

afte

Tool

For a

wit

You

imulate in the Linear Sim u la t ion T o o l to view th e system response.

fying In itial Conditions

r system is in state-space form, you can enter or import initial states

r opening the Linear Simulation Tool (see “Opening the Linear Simulation

”onpage3-22).

n overview of working with the Linear Simulation Tool, see “Working

h the Linear Simulation Tool” on page 3-23.

can also import initial states from the MATLAB workspace.

3-35

Page 88

3 Analyzing Models

To import one or more initial states:

1 In the Linear Sim ulation Tool, click the Initial s tates tab (if it is not

already displayed).

2 In the Selected system list, select the system for which you want to

specify initial conditions.

3 You can either enter state values in the Initial value column, or import

values from the MATLAB workspace by clicking Import state vector.

The following figure shows an example of the import window:

3-36

Note For

4 After s

Tool to

n-states, your initial-condition vector must have n entries.

pecifying the initial states, click Simulate in the Linear Simulation

view the system response.

Page 89