Part # 740.0000

2016-03

Processes

Plasma

110-240VAC Plasma System

.

2016.03

MATCO MA48

PCA48 PFC

AIR PLASMA CUTTER

IMPORTANT: Read th is Owner’s Manual Completely before attempting to use this

equipment. Save this manual and keep it handy for quick reference. Pay particular

attention to the safety instructions we have provided for your protection. Contact your

distributor if you do not fully understand this manual.

OPERATOR’S MANUAL

II

CONTENT

§1 SAFETY ................................................................................................................................. 1

§2 TECHNOLOGY PARAMETERS ........................................................................................... 3

§2.1

PARAMETERS .................................................................................................................... 3

§3 INSTALLATION ..................................................................................................................... 4

§3.1

UNPACKING ....................................................................................................................... 4

3.2

INPUT POWER CONNECTIONS ............................................................................................... 4

§3.3

GAS CONNECTIONS ........................................................................................................... 4

§4 OPERATION .......................................................................................................................... 5

§4.1

LAYOUT FOR THE FRONT REAR PANEL(T AKE THE CUT40 FOR EXAMPLE) ............................... 5

§4.2

CUTTING PREPARATION ..................................................................................................... 6

§4.3C

UTTING OPERATION ......................................................................................................... 6

§5 MAINTENANCE .................................................................................................................... 7

§5.1

BASIC TROUBLESHOOTING GUIDE ...................................................................................... 7

§5.2

TROUBLESHOOTING PRINCIPLE .......................................................................................... 8

§5.3

NPT48 PLASMA TORCH CONSUMABLES ........................................................................... 10

§5.2

ELECTRICAL PRINCIPLE DRAWING ..................................................................................... 11

§5.3

PARTSLISTING ................................................................................................................. 11

Antimon

Chromium

Mercury

Beryllium

Arsenic

Cobalt

Nickel

Lead

Barium

Copper

Selenium

Silver

Cadmiu

Manganes

Vanadium

§1 SAFETY

Important Safety Precautions

OPERATION AND MAINTENANCE OF PLASMA ARC EQUIPMENT CAN BE DANGEROUS AND

HAZARDOUS TO YOUR HEALTH.

Plasma arc cutting produces intense elec tric and magnetic emissions that may interf ere with the proper

function of cardiac pacemakers, hearing aids, or other elect ronic health eq uipment. Pers ons who wo rk near

plasma arc cutting applications should consult their medical health professional and t he manufacturer of the

health equipment to deter- mine whether a hazard exists.

To prevent possible injury, read, understand and follow all warnings, safety precautions and instructions

before using the equipment.

GASES AND FUMES

Gases and fumes produced during the plasma cutting proces s can be dangerous and hazardous to

your health.

• Keep all fumes and ga ses from the breathing area. Keep your head out of the cutting fume plume.

• Use an air-supplied respirator if ventilation is not adequate to remove all fumes and gases.

• The kinds of fumes and gases from the plasma arc depend on the kind of metal being used, coatings

on the metal, and the different processes. Y ou must be very careful when cutting or cutting any metals which

may contain one or more of the following:

Always read the Material Safety Data Sheets (MSDS) that should be supplied with the material you are

using. Thes e MSDSs will give you the informati on regarding the kind and amount of fumes and gases that

may be dangerous to your health.

• Use special equipment, such as water or down draft cutting tables, to capture fumes and gas es.

• Do not use the plasma torch in proximity to combustible or explosive gases or materials.

• Phosgene, a toxic gas, is generated f rom t he vapors of chlorinat ed s olv ents and cleansers . Rem ove

all sources of these vapors.

ELECTRIC SHOCK

Electric Shock can injure or kill. The plasma arc process uses and produces high voltage electrical

energy. This el ectric energy can cause severe or fatal shock to the operator or others i n the workplace.

• Never touch any parts that are electrically “live” or “hot.”

1

1

2

• Wear dry gloves and clothing. Ins ulate yourself from the work piece and live torch parts.

• Repair or replace all worn or damaged parts.

• Extra care must be taken when the workplace is moist or damp.

• Disconnect power source before performing any service or repairs.

• Read and follow all the instructions in the Operating Manual.

FIRE AND EXPLOSION

Fire and explosion can be caused by hot slag, sparks, or t he pl asma arc.

• Be sure there is no com bustible or flammable material in the workplace.

• Ventilate all flammable or explosive vapors from the workplace.

• Do not cut or weld on containers that m ay have held combustibles.

• Provide a fire watch when working in an area where fire hazards may exist.

• Hydrogen gas may be formed and trapped under aluminum work-pieces when they are cut

underwater or while using a water table. DO NOT cut aluminum alloys underwater or on a water table unless

the hydrogen gas can be eliminated or dissipated. Trapped hydrogen gas that is ignited will cause an

explosion.

NOISE

Noise can cause permanent hearing loss. Plasm a arc processes can cause noise levels to exceed

safe limits. You must protect your ears from loud noise to prevent permanent loss of hearing.

• Operator should wear protective ear plugs and/or ear muffs. Protect others in the workplace.

• Noise levels s houl d be measured to be sure the decibels (sound) do not exceed saf e l evel s.

PLASMA AR C RAYS

Plasma Arc Rays can injure your eyes and burn your skin. The plasma arc process produces very bright

ultra violet and infrared light. These arc rays will damage your eyes and burn your skin if you are not properly

protected.

• Wear safety glasses with specified UV/IR DIN 1.7-6.0 with side shields other protective eye wear.

• Wear cutting gloves and suitable clothing t o protect your skin from the arc rays and sparks.

• Keep helmet and saf ety glasses in good condition. Replace lenses when cracked, chipped or dirty.

• Protect others in the work area from the arc rays. Use protective booths, sc reens or shields.

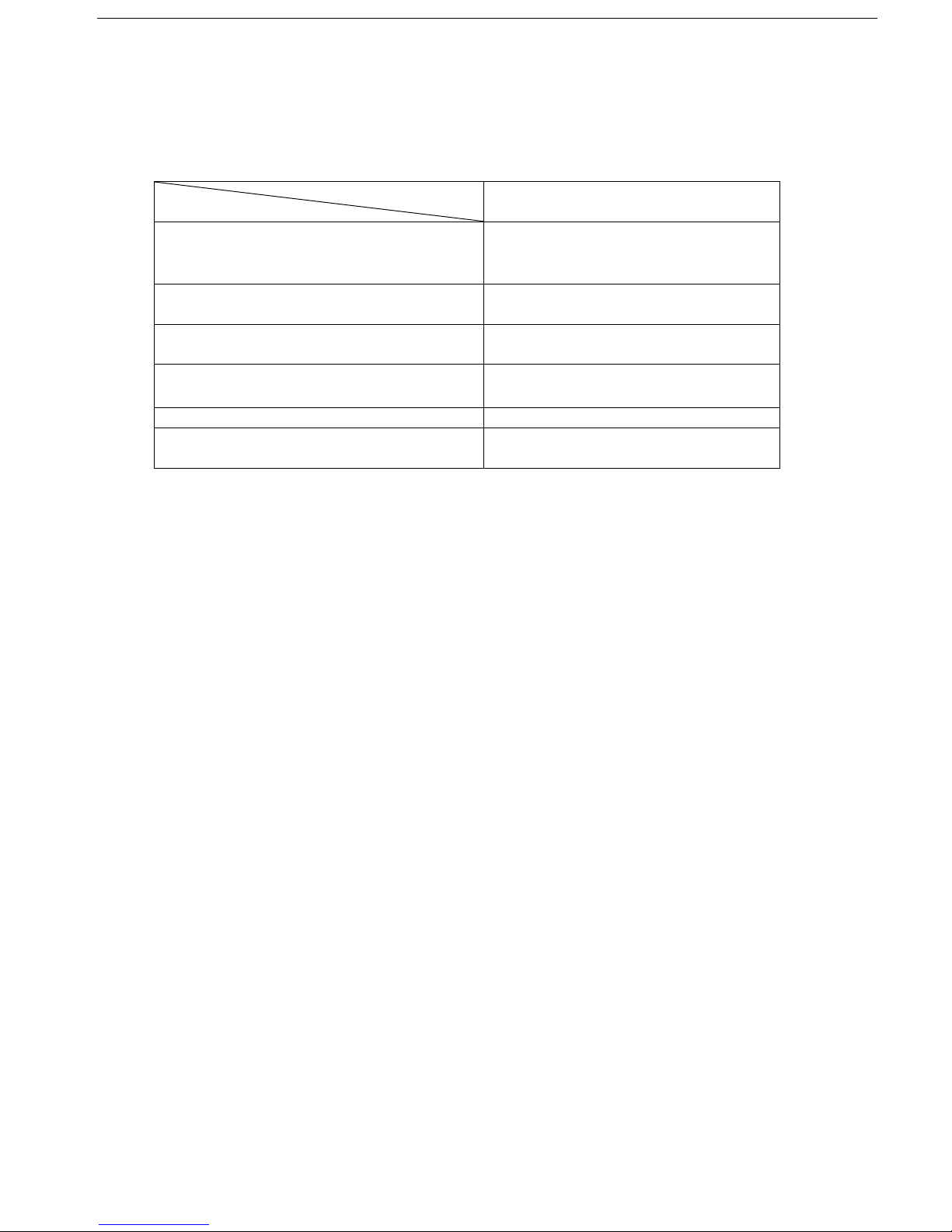

3

Models

Parameters

21(220V)

31(110V)

4.7(220V)

3.4(110V)

20~40(220V)

20~30(110V)

Max. no-load voltage (V)

320

50%(220V)

50%(110V)

§2.1 Parameters

Input power 110-220VAC, Single-Phase,50/60Hz

Rated input current(A)

Rated input power(KW)

Adjustment range of current(A)

Duty cycle(40℃ @ 10 minutes)

§2 Technology Parameters

PCA48 PFC

Note: The above parameters are subject to change with the improvement of mac hines.

§3 Installation

3.1 Unpacking

Identify and account for each item per the followi ng l i st:

1) PCA48 Power source (with NEMA6-50 power cord and compressed air regulator/dryer)

2) NPT48 Plasma Torch (with central adaptor cable connector)

3) Earth Clamp Cable (with 200-amp clamp and 25-10 c abl e connector)

4) Spare Consumables (with 3 spare Electrodes and 5 spare Cutting tips)

5) Operator Manual

Inspect each item for pos sible shi pping damage. If damage is evident, c ontact your distributor an d / or

shipping company before proceeding with the installation.

3.2 Plasma Torch & Earth Clamp Connections

Install the NPT48 plasma torch by first removing the plastic cap on t he brass machine plug. Insert the

plug into the female socket on the front panel being c ertain to align the collar with the pin detents. Screw

locking collar in place to secure torch.

Install the earth clamp cable by inserting the brass plug into the female socket on the front panel being

certain to align the tab with the channel and “TWIST-LOCK” into place to secure.

4

3.3 Input Power Connections

The PCA48 PFC plasma cutting machine features electronic switching power supply allowing it to be

connected to any 110-240VAC, 1-Phase LINE power outlet.

208-240VAC LINE CONNECTION: Machine is provided with NEMA 6-50P LINE Service cord to be

plugged into any 6-50R outlet with 208-240VAC, single-phase power and 50-amp circuit breaker.

110-120VAC LINE CONNECTION: Machine is provided with NEMA 6-50R to NEMA 5-15P “Jumper”

Service cord. This allows machine to be plugged into any 5-15R standard outlet with 110-120VAC,

single-phase power and 20-amp circuit breaker.

In the event NEMA6-50R or 5-15R outlets, with rated LINE circuit breaker amperage are not

available, they should be installed by a licensed electrician in accordance to all national & local

codes.

In the event LINE power supply is over voltage (>245) or under voltage (<195), protection circ uit inside

the machine will illuminate alarm light and current will be cut off.

If the power supply voltage continually goes beyond the safe work voltage range, it will short en the life

of the machine. If this occurs, the below measures s houl d be taken:

Change the LINE power supply. Such as, connect the welder to a dedicated circuit.

Shut off other machines using LINE power supply at the same time as wel di ng.

WARNING: Any modification or removal of factory installed service power cords will VOID

MACHINE WARRANTY!

3.3 Input Gas Connections

The PCA48 PFC plasma cutter is supplied wi th a compressed air filter/dryer and adjustable air flow

knob. The air hose from the compressor should be connected directly to this air regulator. Connecting

additional regulator on line can reduce air flow to the cutting torch and damage the system.

The pressure regulator should be set ~70 psi (4.8 bar) and flow rate should be 210 SCFH (100 lpm)

minimum with ¼” (6mm) minimum hose diameter at 1/ 4G regulator input.

WARNING: Maximum Line air pressure should not exceed 125 PSI (8.6 bar)

5

§4 Operation

4.1 Layout of Front and Rear Panel

1. Power pilot LED Illuminates when machine power is switched ON

2. Alarm pilot LED Illuminates when machines exceeds duty-cyc l e operation (auto reset)

3. Current regulator Allows operator adjustment of output cutting current

4. Earth cable connector Connect earth cable from machine to the work-piece

5. Torch cable connector Connect plasma cutting torch cable to the power source

6. Compressed air fitting Connect compressed ai r hose to regulator (125 PSI maximum)

7. Power switch Flip toggle to turn line power ON or OFF to machine

8. Power cord Connected plug end to the appreciate power outlet (3.3 Above)

9. Torch / Air pilot LED Illuminates when shield cap is removed or air pressure below 30 psi

10. DC output pilot LED Illuminates when trigger is closed and DC current is flowing to torch.

11. RUN / SET switch Flip toggle to SET to purge air in torch. Flip to RUN to begin cutting.

6

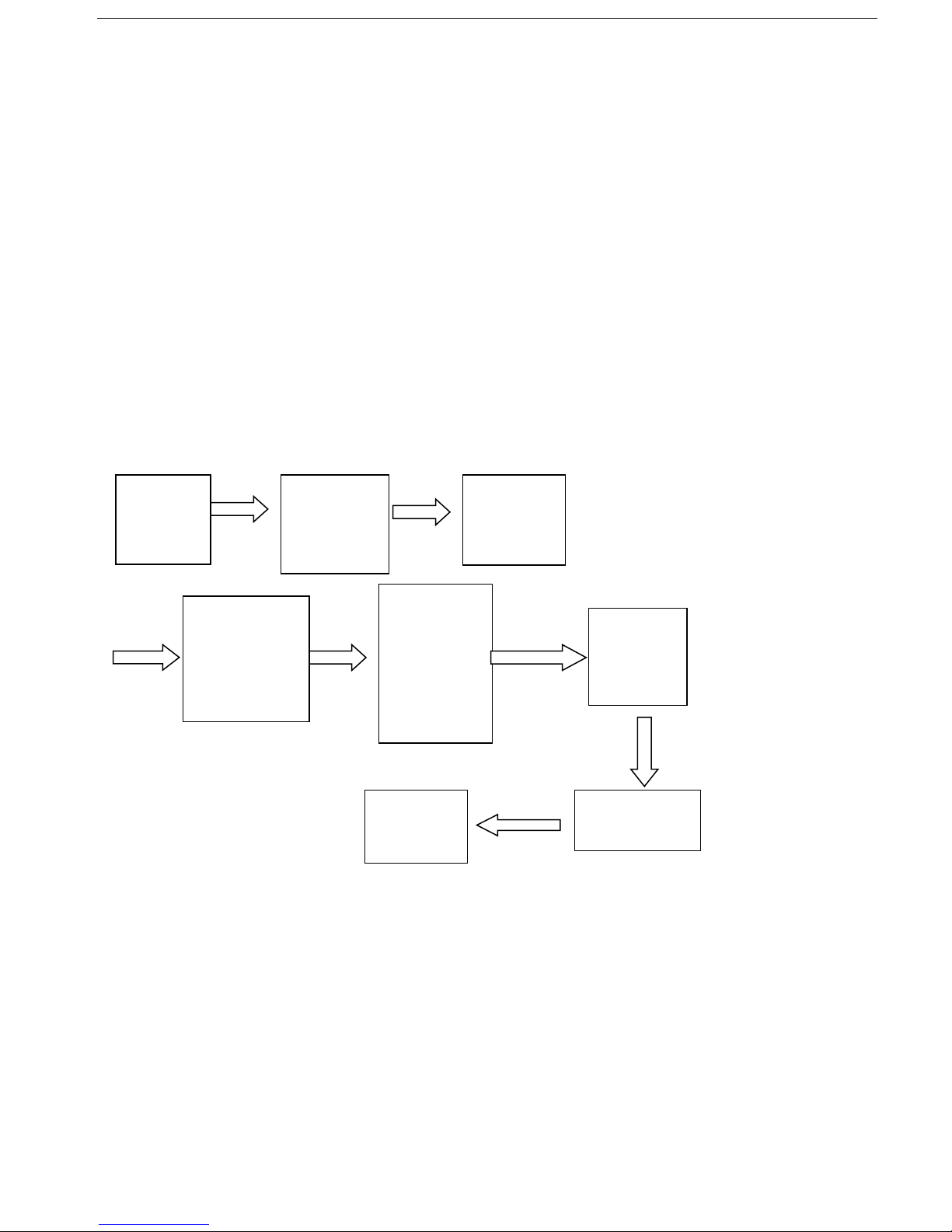

Turn ON

Release

Tip finishes

Place

Press

Post-gas

Slide tip to

Arc

4.2 Cutting Preparation

1、Connect the power cable to electrical outlet (t he input voltage, refer to the section 3).

2、Connect the air hose to the air supply equipment and set pressure to ~60 psi (4.2 bar).

3、Connect the earth cable to the workpiece not being removed with cut.

4、Make certain operator is wearing proper safety glasses (1.7-6.0 DIN) gloves and protective clothi ng.

5、Make certain work area is clean and free of all hazordous liqui ds & gases.

6、Turn ON the power switch and check the power pilot lamp is illuminated.

7、Flip RUN/SET switch to SET position for 10 seconds to purge any moisture from the torc h cable.

8、Flip RUN/SET switch to RUN and machine is ready to cut.

4.3 Cutting Operation

the power

source

work-piece,

changing the

pilot arc into

cutting arc

cutting tip

on edge of

surface

cut on the

work-piece,

the cutting

arc changes

into pilot arc

trigger to

ignite the

pilot arc

torch

trigger to

stop arc

again

cooling for

extinguished

10 seconds

Notes: (1) In the event of alarm lamp ON when cutting, release torch trigger and allow unit to cool until

the alarm resets and lamp goes OFF, then press on the switch to start cutting again.

(2) In the automatic air purge mode (SET), press ing trigger will not ignite arc.

(3) In the event less than 30 psi air pressure is supplied to t he machine, pressing trigger will

not ignite arc.

(4) After extended usage, nozzle and electrode should be changed to insure optimum cutting

performance.

(5) The al arm lamp will illuminate when shield c up is removed from torch head and torch will

not arc. Shiled cap must be re-installed securely in place and lamp will turn off.

7

§5 Maintenance

5.1 Cutting To rch Maintenance

Plasma cutting torches use ionized air (plasma) as the arc that “melts” the metal and is pushed away by

the compressed air. This plasma arc exceeds 50,000°F (28,000°C) when it is pushed through

the .030”-.040” (0.8-1.0mm) hole in the berylium copper cutting tip. Considering these extreme temperatures,

it is easy to understand the need to replace tip s & electrodes, as they become worn, and to check that all

cooling air ports are clear to allow maximum air flow.

Changing Tip & Electrodes: When reduced cut ting performance is observed by the op erator, worn tips and

electrodes must be replaced. A simple visual inspection will determine need for replacement.

To replace tips & electrode, complete the following steps:

1) Turn power switch to OFF position, making certain power pilot LED on panel is OFF (wait 5 secs.)

2) Move torch head to clean work benchtop area and, wi th tip pointing up, remove shield cap.

3) Remove cutting tip and swirl ring by lifting off electrode and place both on bench.

4) Locate electrode wrench and remove electrode by rotating counter-clockwise (RH thread).

5) Inspect torch head for clogged air ports or damage.

6) Replace elctrode with new part and tighten with wrench. It is important to secure wit h wrench as

electrode transfers very high DC current at vert high temperatures. A loose electrode will damage

the torch head.

7) Inspect the swirl ring for any damage and replace if necessary.

8) Install the new cutting tip making sure to align with the step i n the swirl ring.

9) Inspect the shield cap, making certain no melted outer covering is blocking cooling air ports. If shield

cap is burned or cover is melted, replace.

10) Reinstall shield cap, making certain it is securely turned down to the base making contact with

safety pins located in handle.

Inspecting Cables & Hoses: Upon completing torch consumable replacement, check all power cables,

hoses and the regulator glass bowl (empty water if necessary) to mak e certain there is no damage. In the

event of damaged insualtion on a cabl e, repair with proper electrical tape or shrink tubing or repalce with

new assembly.

8

5.2 Trouble Shooting Principle

WARNING

There are extremely dangerous voltage and power levels present inside this unit. Do not attempt to

diagnose or repair unless you have had training in power electronics measurement and

troubleshooting techniques.

A. The cutting torch fails to ignite the arc when torch trigger depressed, DC pilot light on.

1. Gas pressure too high, gas test then adjust gas pressure 60 psi (to 4.2 bar).

B. The cutting torch fails to ignite the arc, when torch trigger depressed, torch/air pilot light flashes.

1. The shield cup improper installation, turn off the power source, install and screw it down properly, then turn

on the power source.

C. The cutting torch fails to ignite the arc, when torch trigger depressed, DC pilot light ON and air

intermittently.

flows

1.The electrode or nozzle improper installation, turn off the power source, install the electrode or nozzle, and

screw shield

cup down properly, then turn on the power source.

D .The cutting torch fail to ignite the arc, when torch tr igger depressed, DC pilot light ON and air

flows

intermittently.

1. Short-circuit for burned-out and other abnorma l situation, turn off the power source to change the

electrode and nozzle.

E. Power lamp and temperature lamp ON.

1. Air flow blocked, check for blocked air fl ow around the unit and correct condition.

2. Fan block ed, check and correct condition.

3. Unit is overheated, let unit cool down for at least 5 minutes. Make s ure the unit has not been operated

beyond Duty Cycle limit, refer to technology parameters in Section 2.

4. Faulty components in unit, return for repair or have qualified technician repair per Service Manual.

F. Torch fails to ignite the arc when torch switch is activated

1. System is in SET mode. Change to RUN mode.

2. Faulty torch parts, inspect torc h parts and replace if necessary.

3. Gas press ure too high or too low, adjust to proper pressure.

9

G. No gas flow w ith the power lamp ON and fan operating

1. Gas not connected or pressure too low, check gas connections. Adjust gas pressure to

proper setting.

2. Faulty components in unit, return for repair or have qualified technician repair.

L. Torch cuts but low quality

1. Current (A) control set too low, increase current setting.

2. Torch is being moved too fast across work-piece, reduce cutting speed.

3. Excessive oil or moisture in torch, hold torch 1/8 inch (3 mm) from c lean surface while

purging and observe oil or moisture buildup (do not activate torch). If there are contaminants in the

gas, additional filtering may be needed.

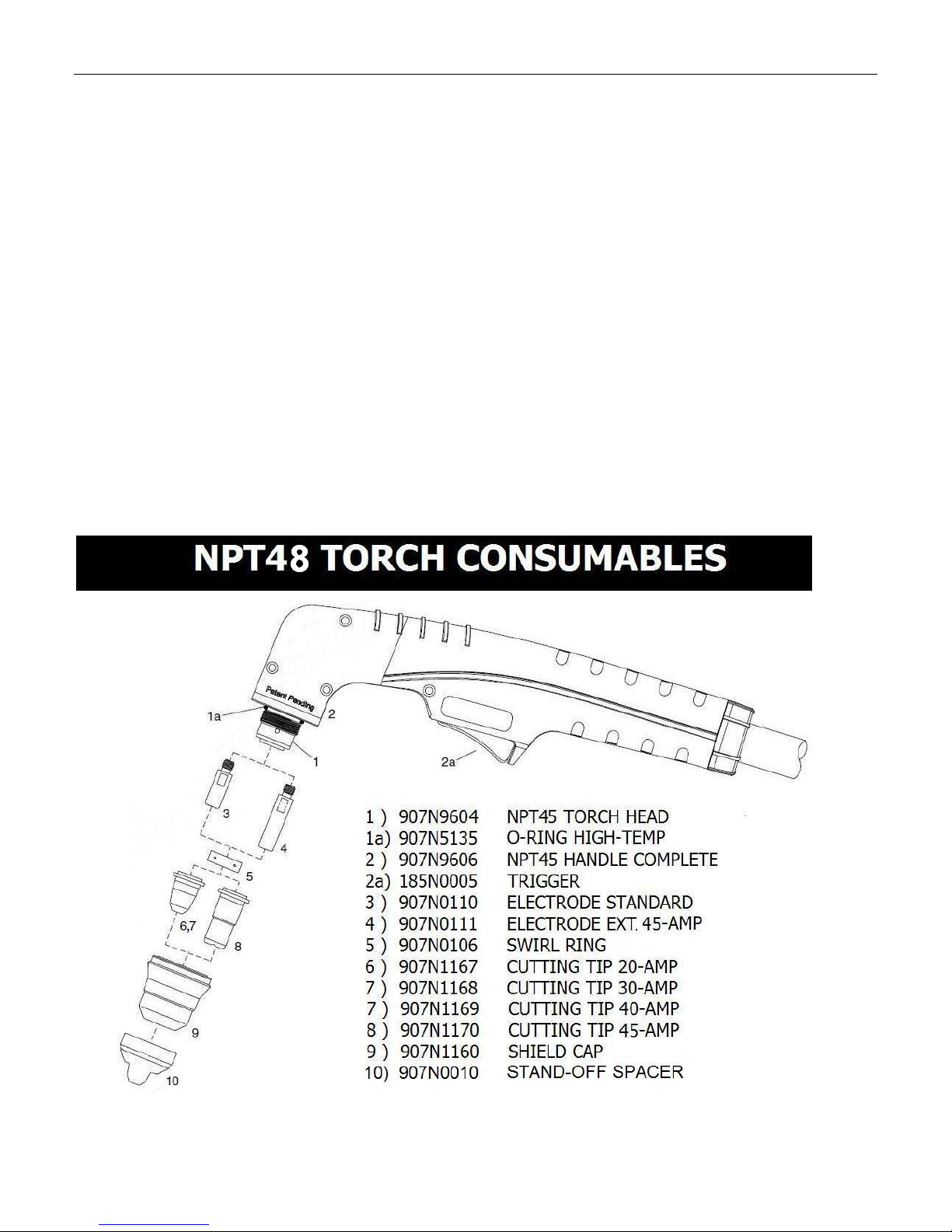

5.3 NPT48 Torch Consumables

5.4 Electrical principle drawing

5.5 PCA48 Parts Drawing

Loading...

Loading...