REV. 12 (SW33)

MasterLan

INSTRUCTION MANUAL

pCO5/PGD1 DIGITAL CONTROLLER

HEAT PUMPS

MasterTherm

MASTERTHERM CZ s.r.o.

Václavské náměstí 819/43, 110 00 Praha 1

tel.:+ 420 311 516 567

e-mail: info@mastertherm.cz, www.mastertherm.cz

MasterLAN –INSTRUCTION MANUAL

TABLE OF CONTENTS:

1 Introduction ........................................................................................................................... 3

2 Terms definition ....................................................................................................................3

3 Hardware configuration.........................................................................................................3

3.1 pLAN address table ....................................................................................................... 4

3.2 Setting of the pCO pLAN address..................................................................................4

3.2.1 Protocol Set menu .................................................................................................. 5

3.3 Setting of the pDG pLAN address..................................................................................5

3.4 Setting communication between pCO and pGD ............................................................5

3.4.1 Single controller unit ............................................................................................... 6

3.4.2 Double controller unit..............................................................................................6

3.5 Setting summary............................................................................................................6

3.6 Wiring ............................................................................................................................7

3.6.1 MasterLAN wiring diagram .....................................................................................8

4 Software configuration .......................................................................................................... 9

4.1 Main Menu mask ...........................................................................................................9

4.2 Setting masks ................................................................................................................ 9

4.2.1 Master/Slave setting mask......................................................................................9

4.2.2 Master setting masks............................................................................................10

4.2.3 Source Control Masks ..........................................................................................13

4.2.4 OFFLINE configuration.........................................................................................14

4.2.5 Remote Functions ................................................................................................15

4.3 Control principle........................................................................................................... 16

4.3.1 Proportional control (recommended) ....................................................................16

4.3.2 PI control .............................................................................................................. 16

4.3.3 PID control............................................................................................................ 17

5 Alarms MasterLAN masks ..................................................................................................17

6 Additional notes ..................................................................................................................18

7 Revision history .................................................................................................................. 18

Revison 1.1, Ing. Jiří Jiránek 2

MasterLAN –INSTRUCTION MANUAL

1 Introduction

MasterLan is used for control of the multiple units installation. MasterLan requires specific

hardware and software configuration.

2 Terms definition

Explanation of some important terms and names used in the MasterLan description.

pCO5:

PLC controller used in the MasterTherm CZ heat pumps.

pGD1:

Semigraphical terminal used for communication with user. (pCO Graphic Display).

pLAN:

Carel based protocol dedicated for communication between pCO controllers and pGD displays.

(pCO Local Area Network). Principle of data transmision is based on RS485 standard.

pLAN address:

Address of each unit in the pLAN. Each pCO controller and pGD terminal has its own pLAN

address.

MasterLan:

MasterTherm heat pumps hardware and software solution used for multiple heat pumps

installation. Control is based on Master/Slave principle. One unit is configured like Master and

all other units are configured like Slaves. Maximum 16 compressor circuits could be controlled

in the MasterLan.

Single controller machine:

Heat pump with one refrigerant circuit and one pCO5 controller.

Double controller machine:

Heat pump with 2 compressor circuits, 2 controllers and 1 pGD terminal. Switching of the

display between 2 controllers is made by pressing PRG and ENTER keys simultaneously

3 Hardware configuration

Each compressor of the heat pump circuit is controlled by one pCO5 controller.

Single controller heat pump is also equipped with single pGD terminal. Double controller heat

pump is equipped with 2 pCO5 controllers and single pGD display, which is used for

communicating with both compressor circuits of the unit. Switching of the display between 2

controllers is made by pressing PRG and ENTER keys simultaneously. In the double heat

pump 2 controllers are already interconnected with pLAN protocol. Connection is made by 3

wires between terminals 61(Rx-/Tx-), 62(Rx+/Tx+) and 63(GND). Terminals are interconnected

with J11 pLAN connector of pCO5.

IMPORTANT: BEFORE ADDRESS SETTING IT IS ABSOLUTLY NECESSARY TO

DISCONNECT J11 pLAN CONNECTOR FROM ALL CONTROLLERS.

Revison 1.1, Ing. Jiří Jiránek 3

MasterLAN –INSTRUCTION MANUAL

3.1 pLAN address table

Single compressor units:

Unit type pCO controller

pLAN address

Master 1 32

Slave 1 2 31

Slave 2 3 30

Slave 3 4 29

Slave 4 5 28

Slave 5 6 27

Slave 6 7 26

Slave 7 8 25

This text type is default factory setting.

Double compressor units:

Unit type pCO controller

pLAN address

Master 1 32

Slave 1 2 -

Slave 2 3 31

Slave 3 4 Slave 4 5 30

Slave 5 6 Slave 6 7 29

Slave 7 8 -

This text type is default factory setting.

pGD terminal

pLAN address

pGD terminal

pLAN address

3.2 Setting of the pCO pLAN address

IMPORTANT: BEFORE ADDRESS SETTING IT IS ABSOLUTLY NECESSARY TO

DISCONNECT J11 pLAN CONNECTOR FROM ALL CONTROLLERS.

• Disconnect J11 connector from all pCO controllers

• Power ON the pCO controller

• Enter menu "Protocol Set"

• Set the address according to the table

• Repeat this procedure for all units controllers

Revison 1.1, Ing. Jiří Jiránek 4

MasterLAN –INSTRUCTION MANUAL

Display address

3.2.1 Protocol Set menu

List password mask and enter the OEM Expert password code. Enter menu and list "Protocol

Set", confirm ENTER and find following mask using UP key.

Jump with cursor to "pCO Address" and set address according to table above. Address is

changed immediately.

Use ESC to return to the menu.

3.3 Setting of the pDG pLAN address

Each pCO controller and pGD display address must be set according to the table above.

• Connect pGD display to the pCO controller

• Power ON pCO

• Press “UP”+“ENTER“+”DOWN” keys simultaneously until following display appears

Setting…………..: xx

I/O Board address:xx

• Use keys “UP”/”DOWN” to change address of the pGD according to the table above.

• Confirm selection pressing „ENTER“ key

3.4 Setting communication between pCO and pGD

This procedure requires correct setting of the pCO according to the pLAN address table.

Revison 1.1, Ing. Jiří Jiránek 5

MasterLAN –INSTRUCTION MANUAL

Display address

Terminal config

P:xx Adr Priv/Shared

3.4.1 Single controller unit

• Connect the pGD to the pCO controller

• Power ON the pCO, wait for pCO initialization, it takes cca 1 minute.

• Press “UP”+“ENTER“+”DOWN” keys simultaneously until following display appears

• Use keys “UP”/”DOWN” to change address of the pGD according to the pLAN address

table

• Confirm selection pressing „ENTER“ key

• Wait until I/O Board address appears beside “--” symbol

• Confirm pressing ENTER key, following screen will appear

• Pressing ENTER key, following screen will appear

• Set Trm1 address according to the unit You are setting, confirm ENTER

• Set type of terminal to “Pr”, confirm ENTER until You reach Yes/No array

• Change array to “Yes” and confirm ENTER

Setting…………..: xx

I/O Board address:xx

Press ENTER

to continue

Trm1 xx Pr

Trm2 xx -Trm3 xx -- Ok? Yes

3.4.2 Double controller unit

Do procedure as for single compressor circuit, but set type of terminal to Shared, “Sh”. You

have to do it for both controllers in the unit.

3.5 Setting summary

• Disconnect all J11 terminals from all controllers

• Set pCO address for all controllers

• Set pGD address for all pGDs

• Set commincation between pCO and pGD

• Switch all controllers OFF

• Return J11 connectors to the pCO controllers

Revison 1.1, Ing. Jiří Jiránek 6

MasterLAN –INSTRUCTION MANUAL

3.6 Wiring

For correct function make wiring connection using twisted pair shielded cable between 61, 62

and 63 terminals of all electric control boards.

NOTE: For correct pLAN function at least one pGD must be installed.

Please see following wiring diagram for proper installation.

Revison 1.1, Ing. Jiří Jiránek 7

MasterLAN –INSTRUCTION MANUAL

3.6.1 MasterLAN wiring diagram

Revison 1.1, Ing. Jiří Jiránek 8

MasterLAN –INSTRUCTION MANUAL

4 Software configuration

For the access to the MasterLAN configuration You have to enter the OEM password.

4.1 Main Menu mask

MasterLAN masks could be found in the main mask loop, using the UP and DOWN keys from

„ICON“ mask.

Master Slaves 1 to 7

Compressor

status 0 - OFF

1 - ON

Heater

status

Slaves 8 to 15

4.2 Setting masks

To enter MasterLAN setting displays please press PRG button on the main MasterLAN display.

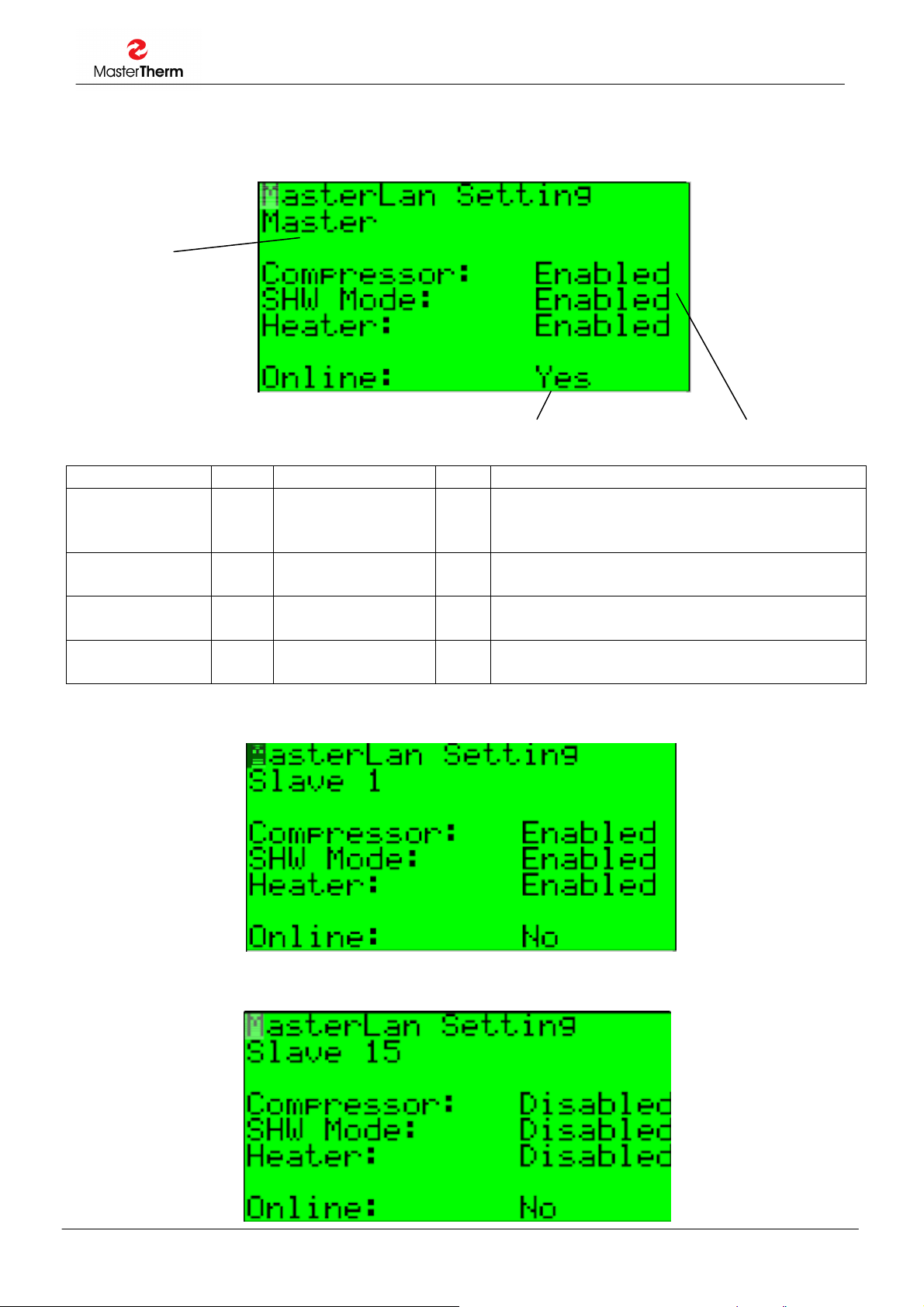

4.2.1 Master/Slave setting mask

MasterLAN control Enabled/Disabled

Unit in the MasterLAN system Compressor steps Heater steps

Master/Slave1/Slave2/…/SlaveX

You can Enable or Disable MasterLAN control on this mask. No more masks are available if the

unit is Slave.

Press ESC key for return to the main mask loop.

Revison 1.1, Ing. Jiří Jiránek 9

MasterLAN –INSTRUCTION MANUAL

4.2.2 Master setting masks

Using keys UP and DOWN you have access to the following masks.

Unit in the MasterLAN

system

Master/Slave1/Slave2

/........./Slave15

Yes/No Enabled/Disabled

Parameter: SP Range/F.: Unit Description

Compressor B440

-455

SHW Mode - Enabled/Disabled

Heater B460

-475

Online - Yes/No - If the unit is communicating in MasterLAN

Similar masks appearing for each unit .........

Enabled/Disabled

F: Enabled

F: Enabled

Enabled/Disabled

F: Enabled

- Allows compressor to be controlled by

MasterLAN control in Heating/Cooling

mode.

- Unit is enabled for SHW Mode. When

Disabled, unit will not run in SHW Mode.

- Enabling heater for MasterLAN control in

heating mode.

network (unit is present and online).

.

.

.

Revison 1.1, Ing. Jiří Jiránek 10

MasterLAN –INSTRUCTION MANUAL

Parameter: SP Range/F.: Unit Description

Compressor

Control

Proportional

Band

Integration

Time

Derivative Time I137 0-9999

I133 P, PI, PID

F: P

A94 0.0-99.9

F: 3.0

I135 0-9999

F: 0

- Compressor control mode.

°C Control proportional band.

s Integration time of PI or PID control mode

s Derivative time of PID control mode

F: 0

Parameter: SP Range/F.: Unit Description

Rotation B409 FIFO/LIFO

F: FIFO

- Compressor rotation system

FIFO = first in, first out

LIFO = last in, first out

1 Compressor

Off Time

I139 0-999

F: 360

s Minimum compressor Off time. Minimum

time compressor must stay Off before

starting after stop command.

1 Comprressor

On Time

2 Compressors

Off Start

1 Compressor

Off Start

I141 0-999

F: 10

I143 0-999

F: .30

I145 0-999

F: .360

s Minimum time compressor must stay On

after start command.

s Minimum time between starts of 2 different

compressors.

s Minimum time between 2 starts of the same

compressor.

Revison 1.1, Ing. Jiří Jiránek 11

MasterLAN –INSTRUCTION MANUAL

Parameter: SP Range/F.: Unit Description

Heater Control I134 P, PI, PID

- Auxiliary heater control mode.

F: P

Proportional

Band

Integration

Time

Derivative Time I138 0-9999

A95 0.0-99.9

F: 3.0

I136 0-9999

F: 0

°C Heater Control proportional band.

s Integration time of PI or PID heater control

mode

s Derivative time of PID heater control mode

F: 0

Parameter: SP Range/F.: Unit Description

Rotation - FIFO/LIFO

F: FIFO

- Heater rotation system

FIFO = first in, first out

LIFO = last in, first out

1 Heater Off

Time

I140 0-999

F: 360

s Minimum heater Off time. Minimum time

heater must stay Off before starting after

stop command.

1 Heater On

Time

2 Heaters Off

Start

1 Heater Off

Start

I142 0-999

F: 10

I144 0-999

F: .30

I146 0-999

F: .360

s Minimum time heater must stay On after

start command.

s Minimum time between starts of 2 different

heaters.

s Minimum time between 2 starts of the same

heater.

Revison 1.1, Ing. Jiří Jiránek 12

MasterLAN –INSTRUCTION MANUAL

4.2.3 Source Control Masks

Source control allows cascade control according to the source temperature as well.

Parameter: SP Range/F.: Unit Description

Source Control

Enabled

Source Control

Active

Control Probe - B1-5/pCO5

Setpoint A434 -99.9 / +99.9

Real

Temperature

Compressors H I411 0-99 °C Requested Compressors Heating

Compressors S I412 0-99 °C Requested Compressors Source

Parameter: SP Range/F.: Unit Description

Source Control I410 P, PI, PID

Proportional

Band

Integration

Time

Derivative Time I409 0-9999

- Yes/No

- Enabling Source Control

F: No

B429 Yes/No - Source Control Active, Enabled + Probe OK

- Choice of Source Control probe.

B1-4/pCOe

F: Not Used

°C Source Control Setpoint

F: 5.0

A433 -99.9 / +99.9 °C Real Source Temperature

- Compressor Source control mode.

F: P

A529 0.0-99.9

°C Source Control proportional band.

F: 5.0

I408 0-9999

F: 0

s Integration time of PI or PID Source control

mode

s Derivative time of PID Source control mode

F: 0

Revison 1.1, Ing. Jiří Jiránek 13

MasterLAN –INSTRUCTION MANUAL

4.2.4 OFFLINE configuration

In case, unit losses bus communication with Master unit, it starts working in OFFLINE mode,

according to actual settings. It is possible to choose relay, activated in case of OFFLINE

situation.

Parameter: SP Range/F.: Unit Description

Master Online

Delay

Master Offline

Delay

Rele - Relay 1-8/pCO5

P - 0/1

Online B480 Yes/No - Master Online

Active B427 Yes/No - Master Online and MasterLAN control active

I406 0-999

F: 60

I407 0-999

F: 60

Relay 1-4/pCOe

F: Not Used

F: 0

s Delay of MasterLAN control activation, after

Master unit is Online.

s Delay of MasterLAN control deactivation,

after Master unit is Offline.

- Choice of relay activated, in case Master is

Offline.

- Master Offline Relay polarity

Revison 1.1, Ing. Jiří Jiránek 14

MasterLAN –INSTRUCTION MANUAL

4.2.5 Remote Functions

This is the setup of services used on Slave unit provided remotely by Master unit. Each Slave

could be set separately.

Parameter: SP Range/F.: Unit Description

Outdoor Probe:

Value:

SHW Probe:

Value:

SHW Mode:

Active

B203

B204

B205

-

0/1 (No/Yes)

F: 0 (No)

0/1 (No/Yes)

F: 0 (No)

0/1 (No/Yes)

F: 0 (No)

0/1 (No/Yes)

-

°C

-

°C

-

-

No = Slave unit uses own outdoor

temperature probe (recommended)

Yes = Slave unit uses outdoor temperature

probe from Master unit

Shows actual Master value

No = Slave unit uses own Hot Water

temperature probe

Yes = Slave unit uses Hot Water

temperature probe from Master unit

Shows actual Master value

This function is usable, when each unit has

its own Hot Water 3way valve or charging

pump.

No = Slave unit activates Hot Water mode

by its own control

Yes = Slave unit activates Hot Water mode

according to order from Master unit and by

its own control, if it is configured.

Shows actual Master value

Revison 1.1, Ing. Jiří Jiránek 15

MasterLAN –INSTRUCTION MANUAL

4.3 Control principle

Control automaticaly balances the operating hours and sequence of the compressors.

MasterLAN setpoint for compressors and heaters are automatically transferred from Master

unit. Although Slaves are switched On and Off via MasterLAN, they still keep they own setting.

Therefore Slaves setpoints must be highest possible for heating mode and lowes possible for

cooling mode.

4.3.1 Proportional control (recommended)

Proportional control works very simply. Proportional band is divided between compressor steps.

Proportional control is stable but always works with steady state error, so the system is not able

to reach exactly the setpoint. This is not a problem, cause compressors are controlled by On/Off

principle. Disadvantage is, that “band”is relatively big, cause You can not set band per one

compressor less than 1K. This could be the problem for more than 4 compressors.

Example:

Compressors: 4 Proportional band: 4 Requested temperature: 40 °C

Starting temperature: 30 °C

All compressors are running.

When the temperature reaches 37°C, 1st compressor is switched Off.

When the temperature reaches 38°C, 2nd compressor is switched Off.

When the temperature reaches 39°C, 3rd compressor is switched Off.

When the temperature reaches 40°C, the last compressor is switched Off.

Starting temperature: 40 °C

All compressors are Off.

When the temperature reaches 39°C, 1st compressor is switched On.

When the temperature reaches 38°C, 2nd compressor is switched On.

When the temperature reaches 37°C, 3rd compressor is switched On.

When the temperature reaches 36°C, the last compressor is switched On.

4.3.2 PI control

PI control is able to work almost without steady state error, but it’s more sensible for unstability.

It requires more time during commisioning for proper setting of the P and I constants.

Revison 1.1, Ing. Jiří Jiránek 16

MasterLAN –INSTRUCTION MANUAL

4.3.3 PID control

This is the best control method for the more than 4 compressors in the MasterLAN. In reality

You are able to have almost continuous and very accurate control of the requested water

temperature. Begin with the setting of the P/I/D = 50K / 100s / 10s.

If the systém is not stable, increase P.

5 Alarms MasterLAN masks

To find information about Slaves alarms, press ALARM button on the MasterLAN mask.

Press ALARM button to see Slaves alarm status......

Pressing the ENTER key You can edit and change Slave unit. After change for the Slave unit

please wait some time to allow the system to read the data from the Slave unit (30s

recommended).

If You press ALARM button on this mask, Master will send RESET command to all Slaves.

Revison 1.1, Ing. Jiří Jiránek 17

MasterLAN –INSTRUCTION MANUAL

6 Additional notes

• For heating mode all Slaves must have maximum water requested temperature settings

in the menu “Heating Set”, 47.5°C recommended both for point A and B.

- this is not neccessary from SW revision 33 (document revision 12)

• For cooling mode all Slaves must have minimum water requested temperature settings in

the menu “Cooling Set”, 14.5°C recommended both for point A and B.

• Control of the Sanitary Hot Water must be performed by Master unit only.

• All requested temperature settings must be done in the Master unit ONLY. (“Master”

displayed in the right top corner of the display in the ICON mask.

• Internet connection if it is used, must be in the Master unit.

7 Revision history

REV.10

REV 11

Source Control Mode

OFFLINE Management

REV 12

Remote Functions

Automatic maximum setpoint activation for slave units

Revison 1.1, Ing. Jiří Jiránek 18

MasterLAN –INSTRUCTION MANUAL

Revison 1.1, Ing. Jiří Jiránek 19

Registered trade marks and l

ogos used in the

MasterLAN –INSTRUCTION MANUAL

MASTERTHERM CZ s.r.o.

NOTES:

text are owned by the appropriate companies.

All rights are reserved.

Unauthorized modifications are not permitted.

Václavské náměstí 819/43, 110 00 Praha 1

tel.:+ 420 311 516 567

e-mail: info@mastertherm.cz, www.mastertherm.cz

Loading...

Loading...