Page 1

PORTABLE

FORCED

AIR HEATER

OWNER’S MANUAL

R

Model BH150CE

Heater Size: 44 kW (150,000 BTU/Hr)

IMPORTANT

Read and understand this manual before assembling, starting or servicing

heater. Improper use of heater can cause serious injury. Keep this manual

for future reference.

Page 2

CONTENTS

SECTION PAGE

Safety Information.........................................................................3

Product Identification .................................................................... 4

Unpacking......................................................................................4

Assembly .......................................................................................5

Theory of Operation ......................................................................6

Fuels .............................................................................................. 6

Ventilation .....................................................................................7

Operation .......................................................................................7

Storage ........................................................................................... 8

Preventative Maintenance Schedule..............................................8

Troubleshooting.............................................................................9

Service Procedures ........................................................................ 10

Upper Shell Removal .............................................................. 10

Fuel Filter................................................................................10

Spark Plug ............................................................................... 11

Air Output, Air Intake, and Lint Filters ..................................11

Pump Pressure Adjustment ..................................................... 12

Nozzle ..................................................................................... 12

Pump Rotor ............................................................................. 13

Fan...........................................................................................14

Specifications.................................................................................15

Wiring Diagram.............................................................................15

Illustrated Parts Breakdown and Parts List....................................16, 17

Wheels and Handles................................................................ 18

Accessories .................................................................................... 18

Warranty and Repair Service......................................................... Back Cover

2

101487

Page 3

SAFETY

WARNINGS

INFORMATION

IMPORTANT: Read this owner’s manual carefully and completely

before trying to assemble, operate, or service this heater. Improper

use of this heater can cause serious injury or death from burns, fire,

explosion, electrical shock, and carbon monoxide poisoning.

DANGER

Carbon monoxide poisoning may lead to death!

Carbon Monoxide Poisoning: Early signs of carbon monoxide poisoning

resemble the flu, with headaches, dizziness, or nausea. If you have these signs, the

heater may not be working properly. Get fresh air at once! Have heater serviced.

Some people are more affected by carbon monoxide than others. These include

pregnant women, persons with heart or lung disease or anemia, those under the

influence of alcohol, and those at high altitudes.

Make certain you read and understand all warnings. Keep this manual for

reference. It is your guide to safe and proper operation of this heater.

• Use only kerosene or No. 1 fuel oil to avoid risk of fire or explosion. Never

use gasoline, naphtha, paint thinners, alcohol, or other highly flammable

fuels.

• Never use heater where gasoline, paint thinner, or other highly flammable

vapors are present.

• Follow all local ordinances and codes when using heater.

• Use only in well-vented areas. Provide at least a 2800 square cm (3-squarefoot) opening of fresh, outside air for each 29.3 kW (100,000 BTU/Hr) of

rating.

• Use only in places free of flammable vapors or high dust content.

• Use only with the electrical voltage and frequency specified on model plate.

• Use only a three-prong, grounded (earthed) extension cord.

• Minimum heater clearances from combustibles:

Outlet: 250 cm (8 Ft.) Sides, Top, and Rear: 125 cm (4 Ft.)

• Locate heater on a stable and level surface while hot or running or a fire may

occur.

• When moving or storing heater, keep heater in a level position or fuel

spillage may occur.

• Keep children and animals away from heater.

• Unplug heater when not in use.

• When used with thermostat, heater may start anytime.

• Never use heater in living or sleeping areas.

• Never block air inlet (rear) or air outlet (front) of heater.

• Never move, handle, refuel, or service a hot, operating, or plugged-in heater.

• Never attach duct work to front or rear of heater. Using duct work could

reduce the necessary air flow of heater. Heater would produce excessive

carbon monoxide.

101487

3

Page 4

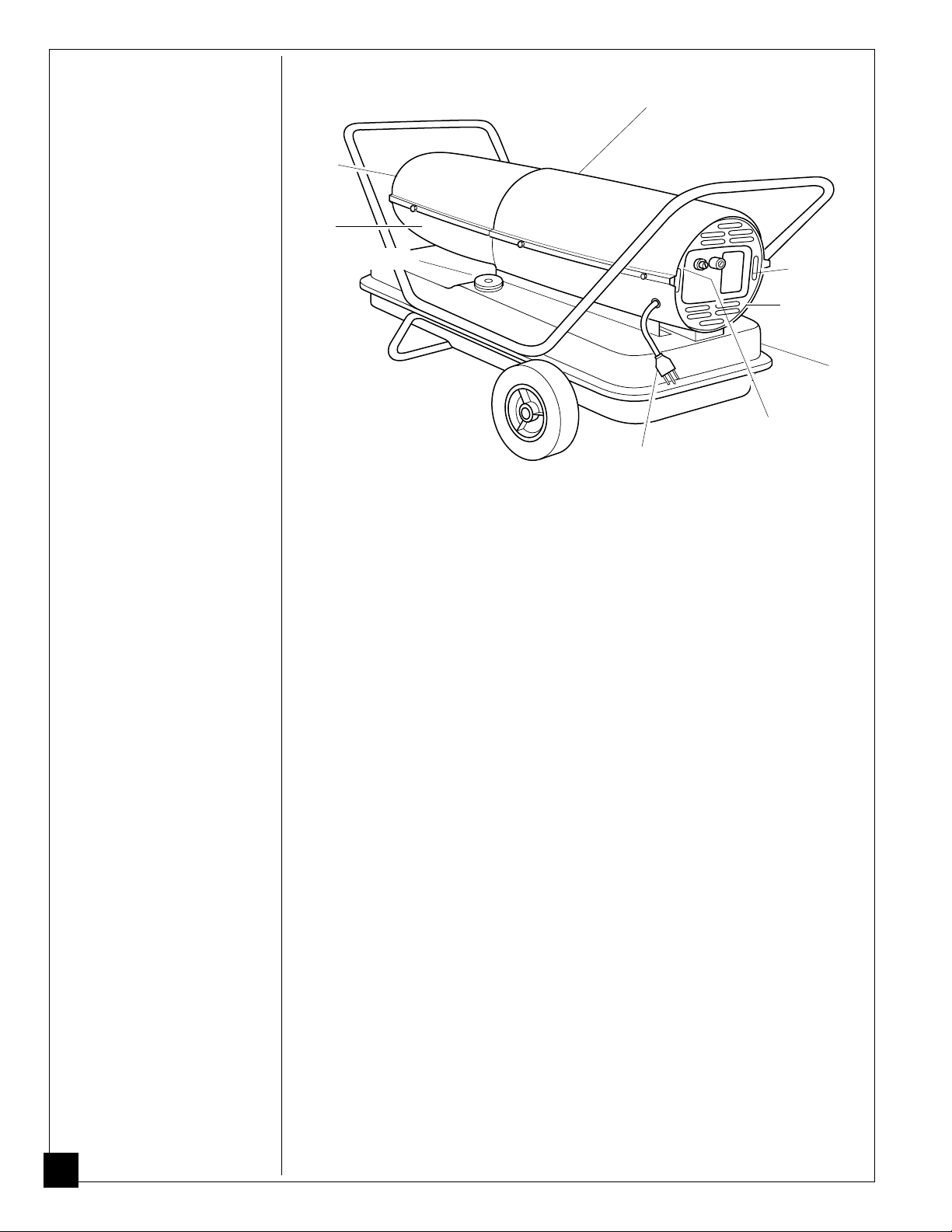

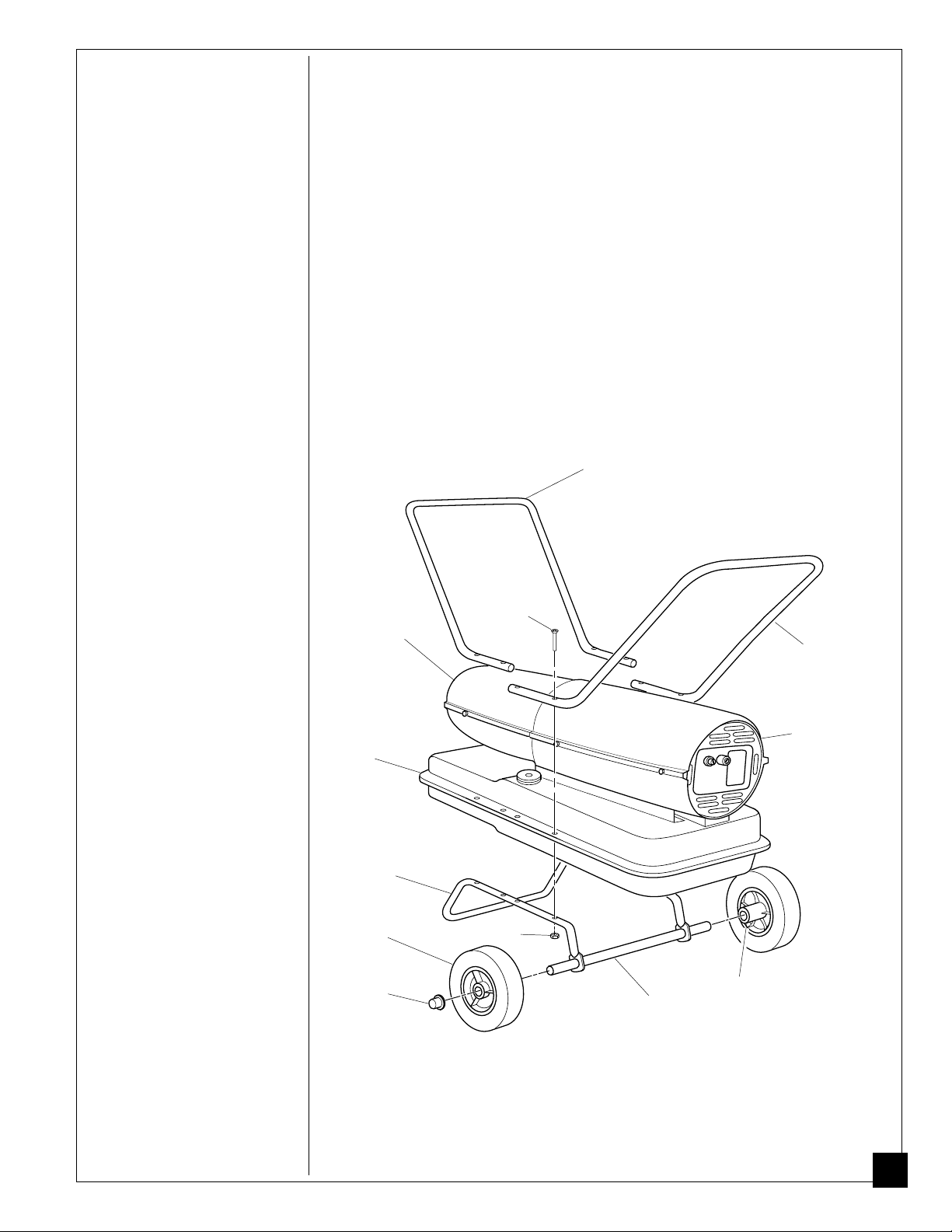

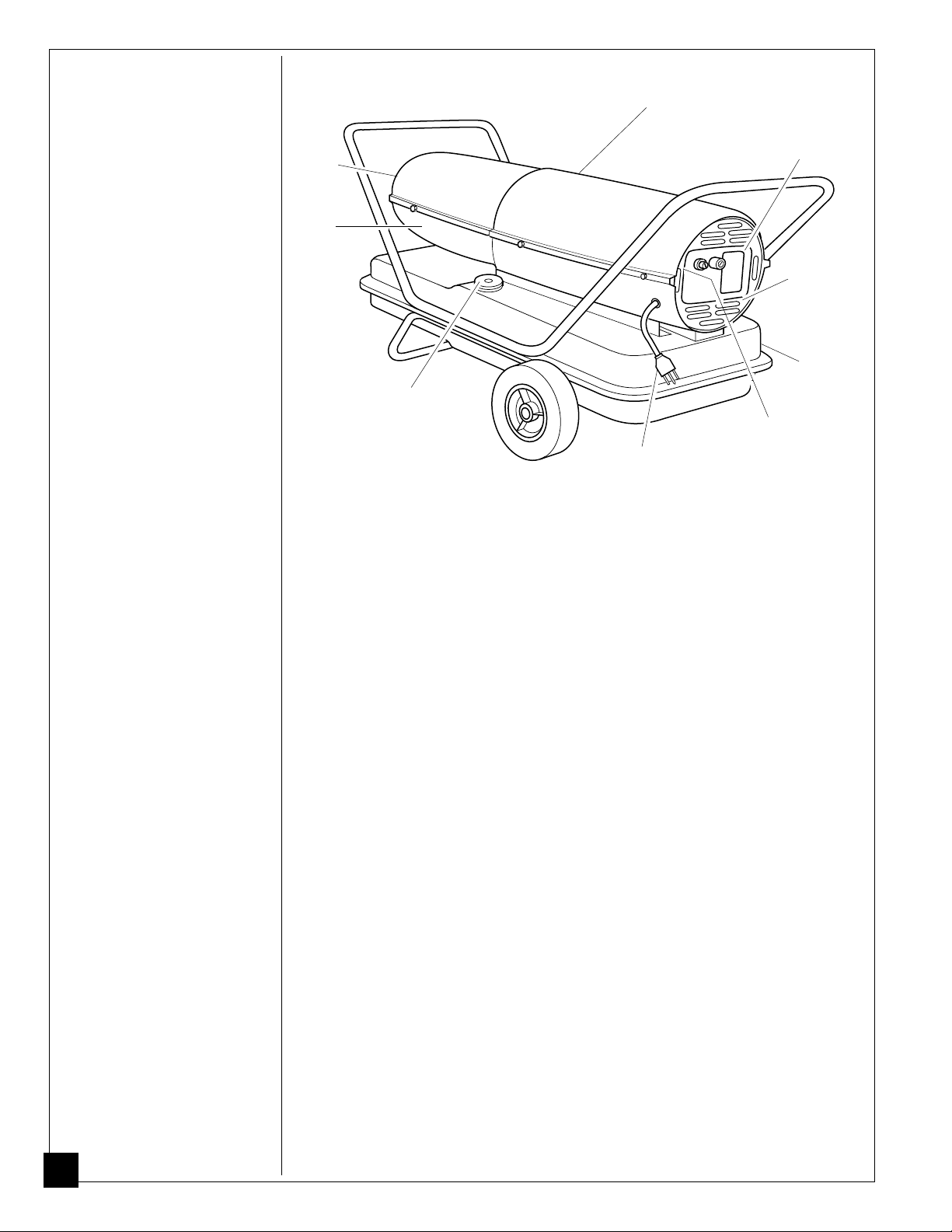

PRODUCT

IDENTIFICATION

Hot Air

Outlet

Lower

Shell

Fuel Cap

Upper Shell

Power Cord

Figure 1 - 44 kW (150,000 BTU/Hr) Model

Air Filter

End Cover

Fan Guard

Fuel

Tank

Flame-Out Control

Reset Button

UNPACKING

1. Remove all packing items applied to heater for shipment.

2. Remove all items from carton.

3. Check items for any shipping damage. If heater is damaged, promptly inform

dealer where you bought heater.

4

101487

Page 5

ASSEMBLY

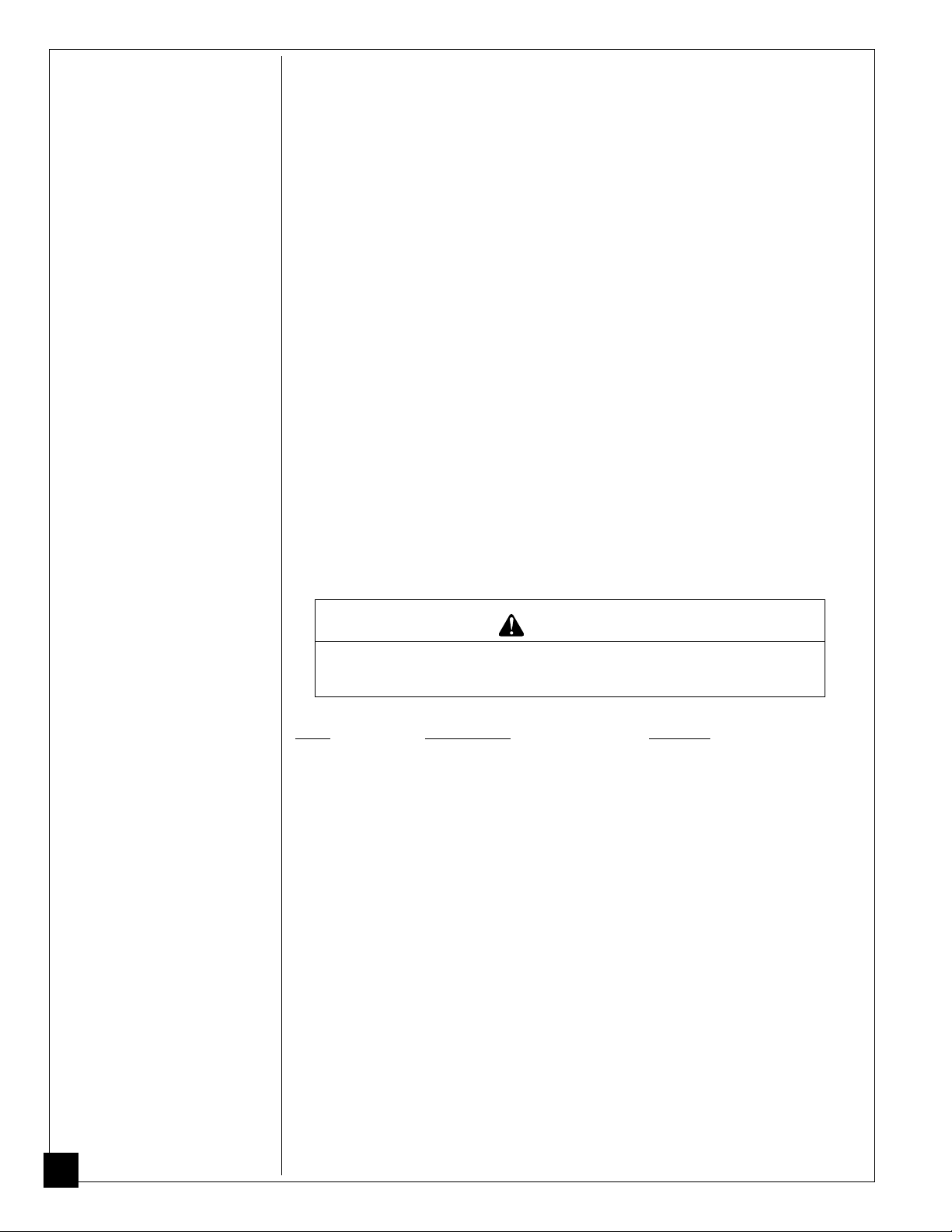

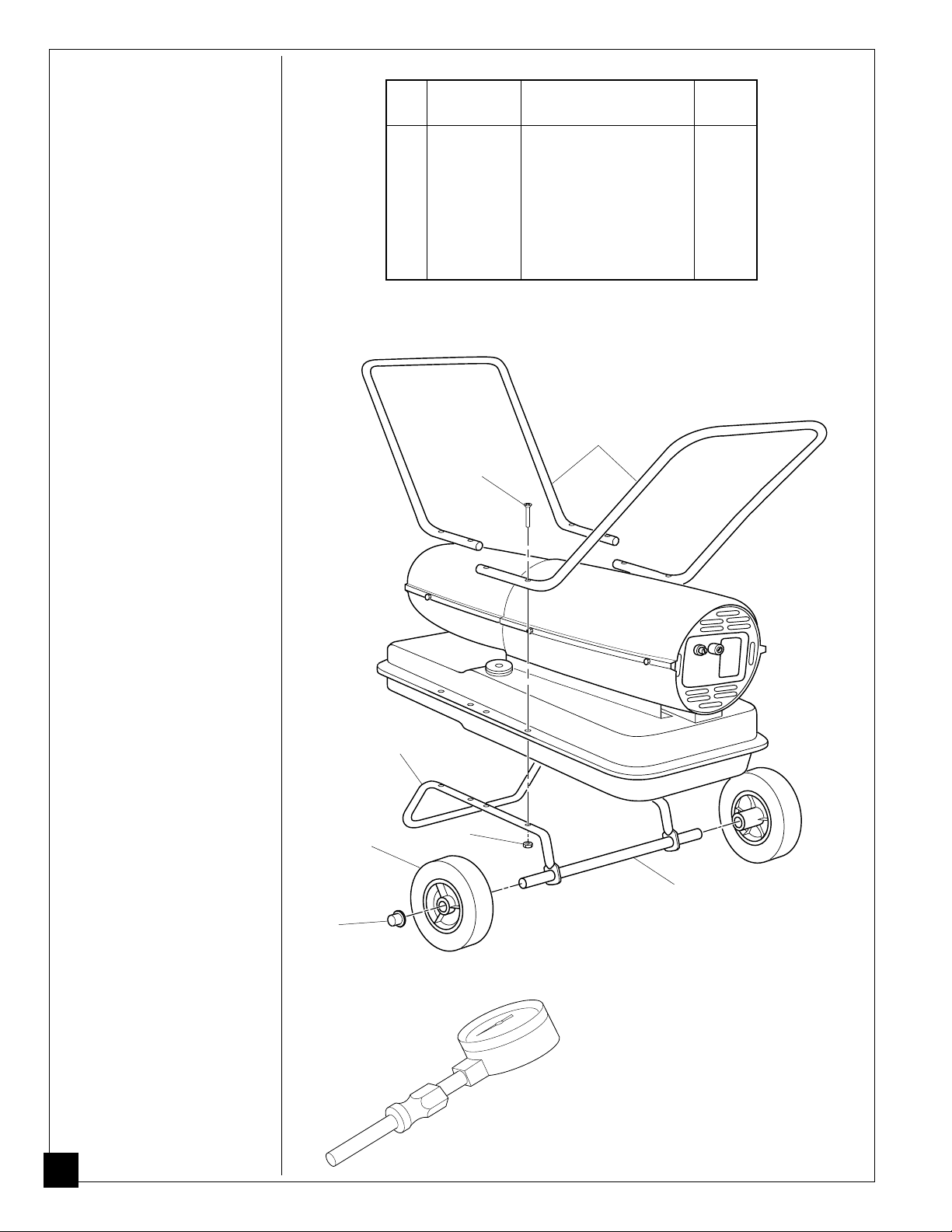

These models are furnished with wheels and handles. Wheels, handles, and the

mounting hardware are found in the shipping carton.

Tools Needed

• Medium Phillips Screwdriver

• 3/8" Open or Adjustable Wrench

• Hammer

1. Slide axle through wheel support frame. Install wheels on axle.

I

MPORTANT:

wheel support frame (see Figure 2).

2. Place cap nuts on axle ends. Gently tap with hammer to secure.

3. Place heater on wheel support frame. Make sure air inlet end (rear) of heater is over

wheels. Line up holes on fuel tank flange with holes on wheel support frame.

4. Place front handle and rear handle on top of fuel tank flange. Insert screws

through handles, fuel tank flange, and wheel support frame. Attach nut finger

tight after each screw is inserted.

5. After all screws are inserted, tighten nuts firmly.

When installing wheels, point extended hub of wheels toward

Front Handle

Hot Air

Outlet

Fuel

Tank

Flange

Wheel

Support

Frame

Wheel

Cap Nut

Screw

Nut

Axle

Rear

Handle

Air

Inlet

Extended

Hub

101487

Figure 2 - Wheel and Handle Assembly

5

Page 6

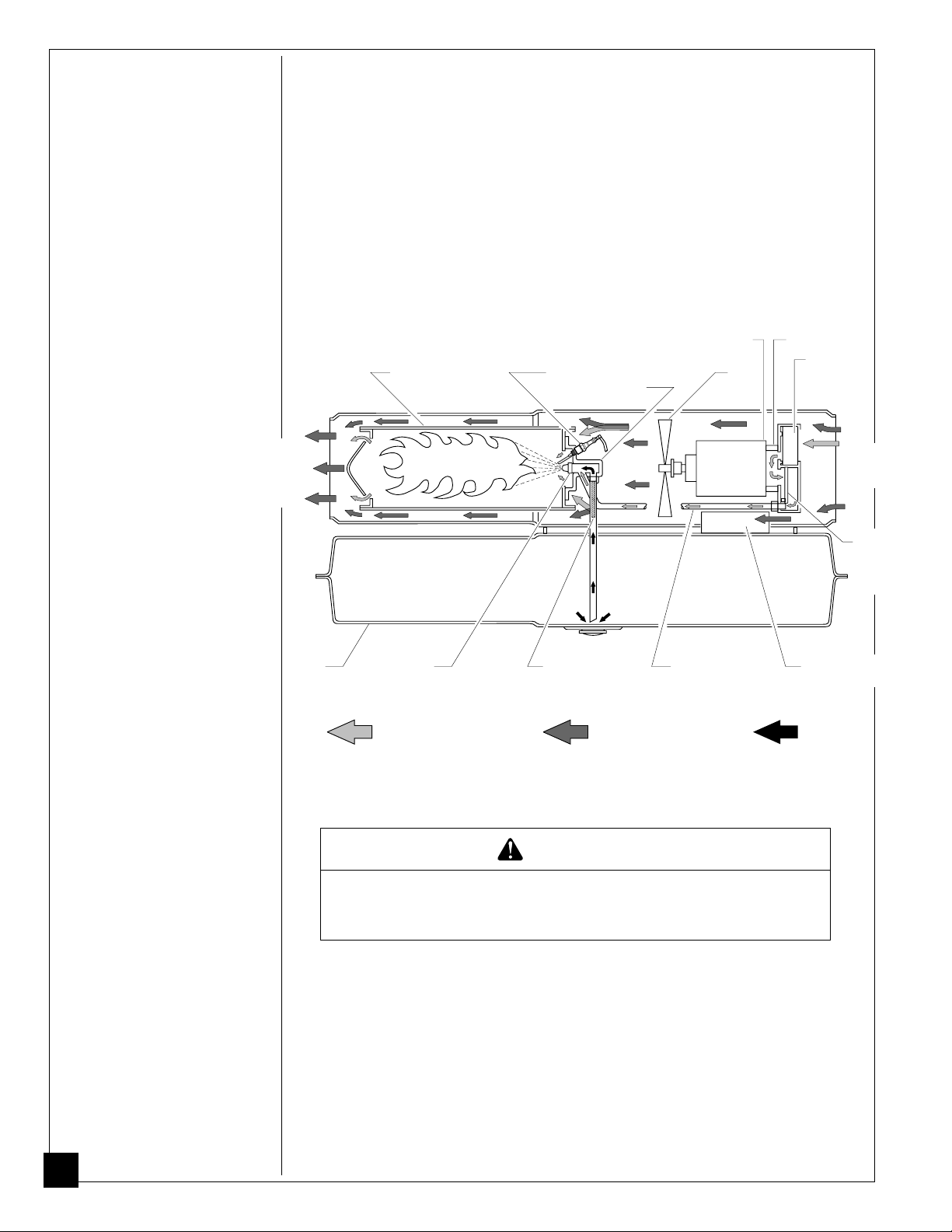

THEORY OF

OPERATION

The Fuel System: The air pump forces air through the air line. The air is then

pushed through the burner head nozzle. This air causes fuel to lift from the tank. A

fine mist of fuel is sprayed into the combustion chamber.

The Air System: The motor turns the fan. The fan pushes air into and around

the combustion chamber. This air is heated and provides a stream of clean, hot air.

The Ignition System: The electronic ignitor sends voltage to the spark plug.

The spark plug ignites the fuel and air mixture.

The Flame-Out Control System: This system causes the heater to shut down

if the flame goes out.

Clean

Heated

Air Out

Fuel

Tank

Combustion

Chamber

Nozzle

Air For Fuel

System

Figure 3 - Cross Section Operational View

Spark

Plug

Fuel

Filter

Motor

Burner

Head

Air line

To Burner

Air For Combustion

And Heating

Fan

Air Pump

Intake

Air

Filter

Cool

Air

In

Output

Air

Filter

Electronic

Ignitor

Fuel

FUELS

WARNING

Use only kerosene or No. 1 fuel oil to avoid risk of fire or

explosion. Never use gasoline, naphtha, paint thinners,

alcohol or other highly flammable fuels.

Do not use heavy fuels such as No. 2 fuel oil or No. 2 Diesel. Using heavy fuels

will result in:

• clogged fuel filter and nozzle

• carbon build up on spark plug

• use of non-toxic anti-icer in fuel during very cold weather

IMPORTANT:

clean. Foreign matter such as rust, dirt, or water will cause the flame-out control to

shut down heater. Foreign matter may also require you to clean fuel system often.

6

Use a KEROSENE ONLY container. Be sure storage container is

101487

Page 7

VENTILATION

WARNING

Follow the minimum fresh, outside air ventilation

requirements. If proper fresh, outside air ventilation is not

provided, carbon monoxide poisoning can occur. Provide

proper fresh, outside air ventilation before running heater.

Provide a fresh air opening of at least 2800 square cm (3 square feet) for each 29.3

kW (100,000 BTU/Hr) rating. Provide extra fresh air if more heaters are being

used.

OPERATION

Example:

A 44 kW (150,000 BTU/Hr) heater requires one of the following:

• a 4.88 m (16 foot) wide two-car garage door raised 8.59 cm (3.38 inches)

• a 2.75 m (9 foot) wide single-car garage door raised 15.24 cm (6 inches)

• two, 76.20 cm (30 inch) wide windows raised 28 cm (11 inches)

WARNING

Review and understand the warnings in the

Information Section.

heater. Follow all local codes when using this heater.

They are needed to safely operate this

To Start Heater

1. Follow all ventilation and safety information.

2. Fill fuel tank with kerosene or No. 1 fuel oil.

3. Attach fuel cap.

4. Plug power cord of heater into standard 230 volt/50 hertz, grounded (earthed)

outlet. Use an extension cord if needed. Use only a three-prong, grounded

(earthed) extension cord.

Extension Cord Wire Size Requirements

Up to 30.5 meters (100 feet) long, use 1.0 mm2 (16 AWG) conductor

30.6 to 61 meters (101 to 200 feet) long, use 1.5 mm2 (14 AWG) conductor

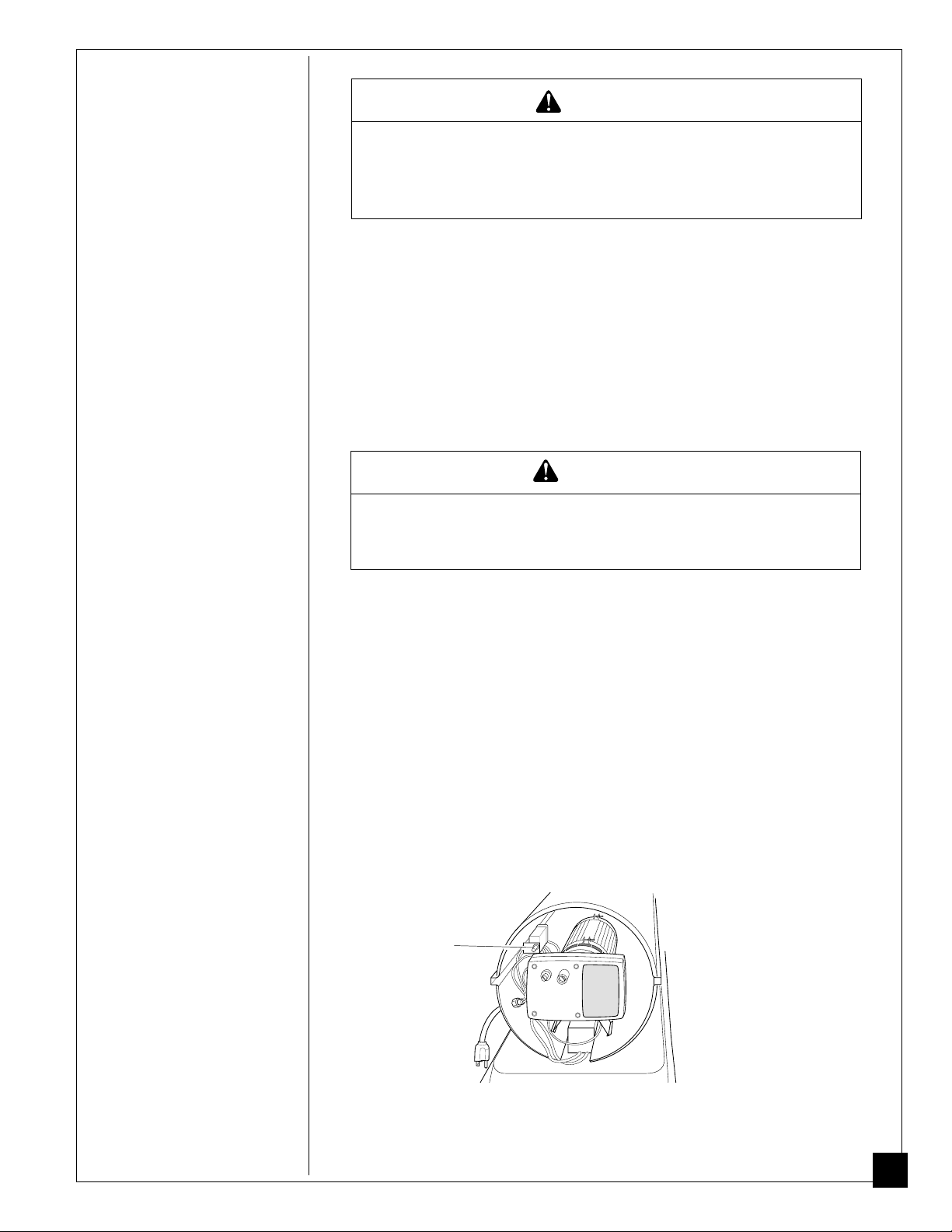

Heater will start when power cord is plugged into outlet. If not, push in flame-

out control reset button (see Figure 4).

Safety

101487

Flame-Out

Control

Reset Button

(Fan Guard

Removed)

Figure 4 - Flame-Out Control Reset Button

Continued

7

Page 8

OPERATION

Continued

To Stop Heater

1. Unplug power cord from outlet.

To Restart Heater

1. Wait 2 minutes after stopping heater.

2. Repeat steps under To Start Heater, page 7.

STORAGE

PREVENTATIVE

MAINTENANCE

SCHEDULE

1. Drain fuel tank.

Note:

Some models have drain plug on underside of fuel tank. If so, remove

drain plug to drain all fuel. If heater does not have drain plug, drain fuel

through fuel cap opening. Be sure all fuel is removed.

2. Replace drain plug if used.

3. Add 4 liters (one gallon) of clean kerosene to fuel tank.

4. Attach fuel cap.

5. Move heater forwards and backwards to stir fuel.

6. Remove fuel cap or drain plug and drain fuel tank. Be sure all fuel is removed.

7. Replace fuel cap or drain plug. Properly dispose of old and dirty fuel.

8. Store heater in dry place. Make sure storage place is free of dust and corrosive

fumes.

IMPORTANT:

heating season. Using old fuel could damage heater.

Do not store kerosene over summer months for use during next

WARNING

Never service heater while it is plugged in, operating, or

hot. Severe burns and electrical shock can occur.

Item How Often How To

Fuel tank Flush every 150-200 hours See Storage above.

of operation or as needed.

Air output and Replace every 500 hours of See Air Output, Air Intake,

lint filters operation or once a year. and Lint Filters, page 11.

Air intake Wash and dry with soap and See Air Output, Air Intake,

filter water every 500 hours of and Lint Filters, page 11.

operation or as needed.

Fuel filter Clean twice a heating season See Fuel Filter, page 10.

or as needed.

Spark plug Clean and regap every 600 See Spark Plug, page 11.

hours operation or replace

as needed.

Fan blades Clean every season or as needed. See Fan, page 14.

Motor Not required/permanently lubricated

8

101487

Page 9

TROUBLE-

SHOOTING

WARNING

Never service heater while it is plugged in, operating, or hot.

Severe burns and electrical shock can occur.

OBSERVED FAULT POSSIBLE CAUSE REMEDY

Heater ignites, but

flame-out control

shuts off heater after

a short period of

time.

Wrong pump pressure

Dirty air output, air intake,

and lint filters

Dirty fuel filter

Dirt in nozzle

Dirty photocell lens

Bad flame-out control

See Pump Pressure

Adjustment, page 12.

See Air Output, Air Intake

and Lint Filters, page 11.

See Fuel Filter, page 10.

See Nozzle, page 12.

Clean photocell lens.

Replace flame-out control.

Heater will not

ignite, but motor runs

for a short period of

time.

Motor does not start

when heater is

plugged in, fan

rotates slowly or

does not turn.

Wrong pump pressure

Carbon deposits on spark

plug and/or improper gap

Dirty fuel filter

Dirt in nozzle

Water in fuel tank

WARNING: High voltage!

Electronic ignitor not

grounded (earthed)

Bad electronic ignitor

Flame-out control not reset

Binding pump rotor

See Pump Pressure

See Spark Plug, page 11.

See Fuel Filter, page 10.

See Nozzle, page 12.

Drain and flush fuel tank

Make sure electronic

Replace electronic

Reset flame-out control

If fan is hard to turn, see

Adjustment, page 12.

with clean kerosene. See

Storage, page 8.

ignitor mounting is tight.

ignitor.

button, see Figure 4,

page 7.

Pump Rotor, page 13.

101487

9

Page 10

SERVICE

PROCEDURES

WARNING

Never service heater while it is plugged in, operating, or

hot. Severe burns and electrical shock can occur.

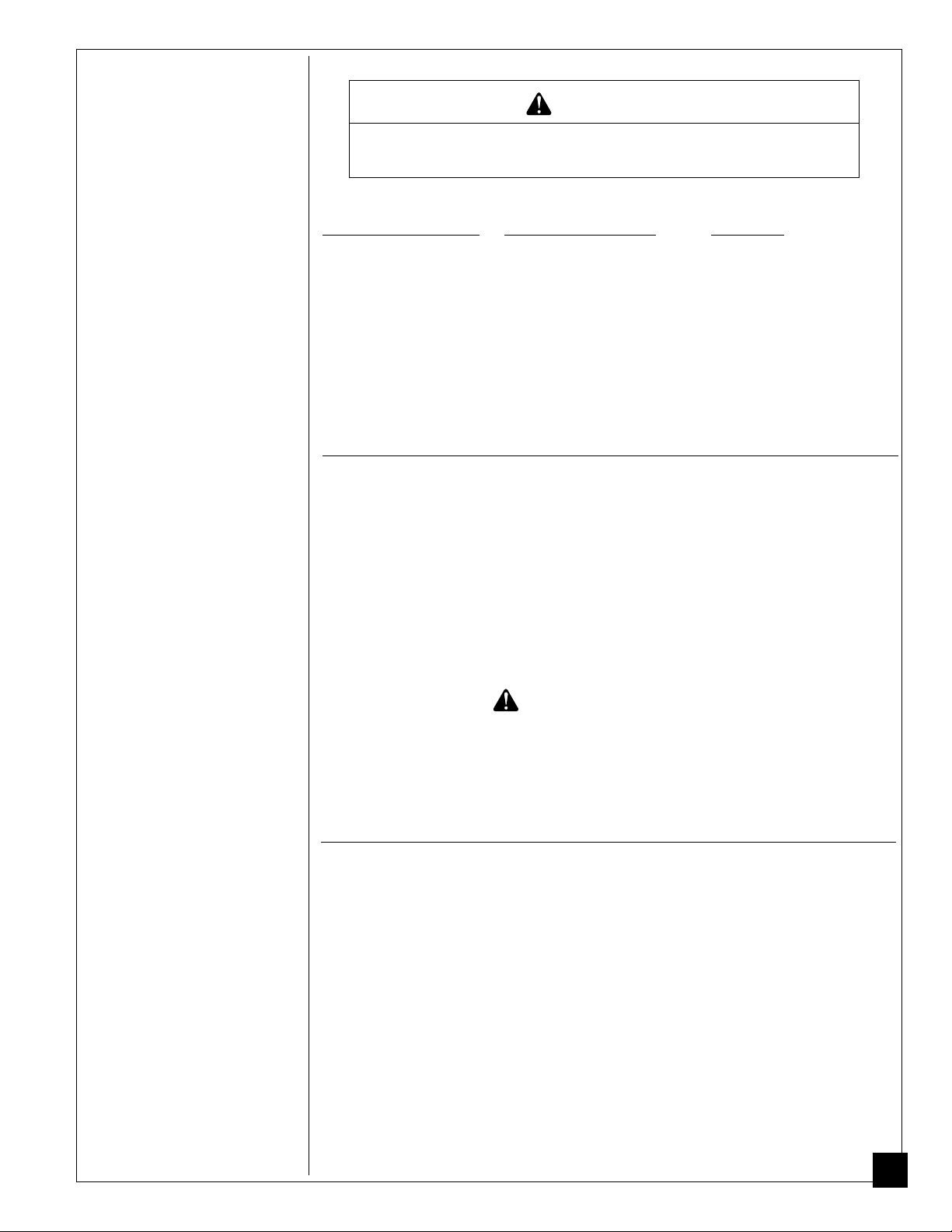

Upper Shell Removal

1. Remove screws along each

side of heater using 5/16"

nut-driver. These screws

attach upper and lower

shells together.

2. Lift upper shell off.

3. Remove fan guard.

Fuel Filter

1. Remove upper shell (see

page 10).

2. Remove fan (see page 14).

3. Loosen flare nut using 3/4"

open-end wrench. Push fuel

tube down, away from

burner head. Fuel filter is

located inside of fuel tube.

4. Lift out fuel filter.

5. Wash fuel filter with clean

fuel and replace in fuel

tube.

6. Connect fuel tube to burner

head. Attach flare nut until

nut seats against fuel tube

and fitting. Tighten 1/4 turn

more using 3/4" open-end

wrench (11.3-14.7 n-m/

100-130 inch-pounds).

7. Replace fan (see page 14).

8. Replace fan guard and

upper shell.

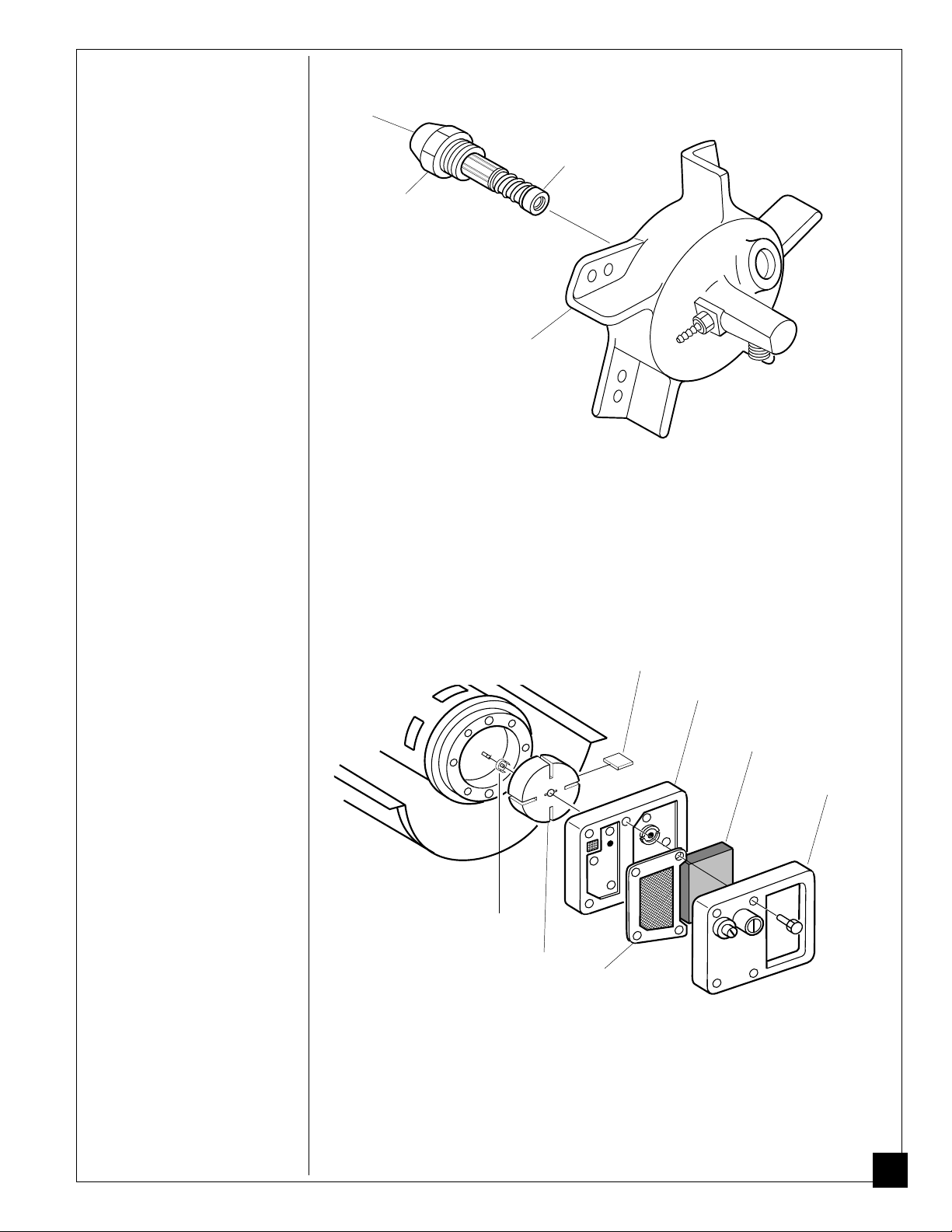

Fuel Filter

Fuel Tube

Flare Nut

Upper

Shell

Fan Guard

Figure 5 - Upper Shell Removal

Combustion

Chamber

Burner

Head

Figure 6 - Fuel Filter Removal

10

101487

Page 11

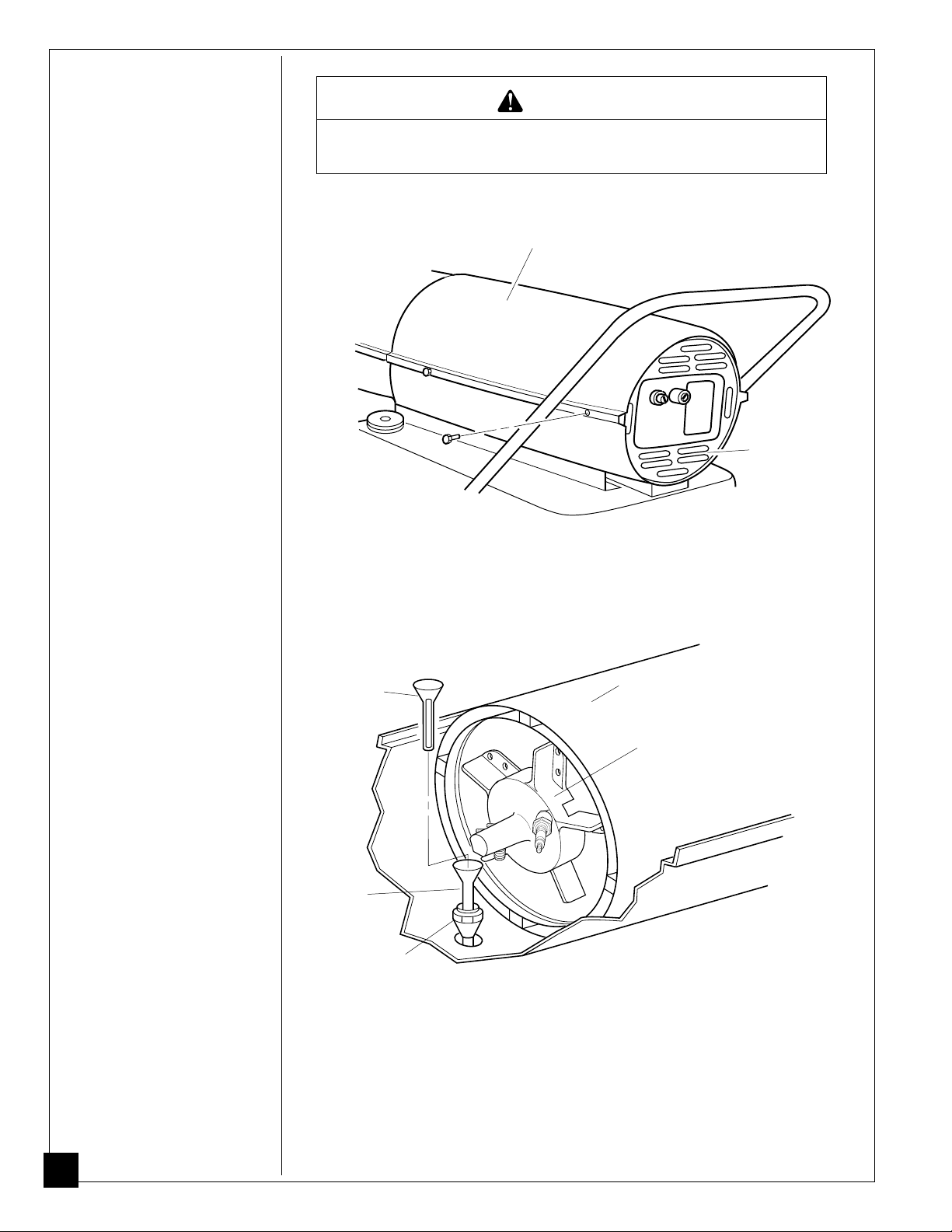

Spark Plug

1. Remove upper shell (see

page 10).

2. Remove fan (see page 14).

3. Remove spark plug wire

from spark plug.

4. Remove spark plug from

burner head using 13/16"

open-end wrench.

5. Clean and regap spark plug

electrodes to 1.4 mm

(.055") gap.

6. Install spark plug in burner

head.

7. Attach spark plug wire to

spark plug.

8. Replace fan (see page 14).

9. Replace fan guard and

upper shell.

Burner

Head

Spark Plug

Wire

Spark

Plug

Figure 7 - Spark Plug Removal

Bend Here

to Adjust

Gap

Air Output, Air Intake,

and Lint Filters

1. Remove upper shell (see

page 10).

2. Remove filter end cover

screws using 5/16" nutdriver.

3. Remove filter end cover.

4. Replace air output and lint

filters.

5. Wash or replace air intake

filter (see Preventative

Maintenance Schedule,

page 8).

6. Replace filter end cover.

7. Replace fan guard and

upper shell.

1.4 mm

(.055" )

Gap

Figure 8 - Spark Plug Gap

Air Intake Filter

Filter End

Cover

Fan Guard

(Not Shown)

Lint Filter

Air Output

Filter

Figure 9 - Air Output, Air Intake, and Lint Filters

IMPORTANT:

101487

Do not oil filters

11

Page 12

Pump Pressure

g

F

F

Adjustment

1. Remove pressure gauge

plug from filter end cover.

2. Install accessory pressure

gauge (part number

HA1180).

3. Start heater (see Operation,

page 7). Allow motor to

reach full speed.

4. Adjust pressure. Turn relief

valve to right to increase

pressure. Turn relief valve

to left to decrease pressure.

Set pump pressure at 4.9

psi.

5. Remove pressure gauge.

Replace pressure gauge

plug in filter end cover.

Pressure

Gauge

Relief

Valve

Pressure

Gauge

Plug

150 PRESSURE ADJUSTMENT Plu

Figure 10 - Pressure Gauge Plug Removal

P

Nozzle

1. Remove upper shell (see

page 10).

2. Remove fan (see page 14).

3. Remove spark plug wire

from spark plug.

4. Remove spark plug from

burner head using 13/16"

open-end wrench.

5. Loosen flare nut using

3/4" open-end wrench.

Push fuel tube down.

6. Remove air line hose from

burner head.

7. Remove three screws

using 5/16" nut-driver and

remove burner head from

combustion chamber.

8. Place burner head into vise

and lightly tighten.

9. Carefully remove nozzle

from burner head using

5/8" socket wrench (see

Figure 13).

10. Blow compressed air thru

face of nozzle. This will

free any dirt in nozzle area.

11. Inspect nozzle seal for

damage.

Combustion

Chamber

Screw

Air Line Hose

150 PRESSURE ADJUSTMENT P

Figure 11 - Adjusting Pump Pressure

Burner Head

Flare Nut

Fuel Tube

Spark Plug

Wire

Spark

Plug

12

Figure 12 - Removing Burner Head

101487

Page 13

12.Replace nozzle into burner

head and tighten firmly

(9.1-12.4 n-m/80-110

inch-pounds).

13.Attach burner head to

combustion chamber.

14.Install spark plug in burner

head.

15.Attach spark plug wire to

spark plug.

16.Attach fuel tube and

airline hose to burner

head. Attach flare nut until

nut seats against fuel tube

and fitting. Tighten 1/4

turn more using 3/4" openend wrench (11.3-14.7 nm/100-130 inch-pounds).

17.Replace fan (see page 14).

18.Replace fan guard and

upper shell.

Nozzle

Face

Nozzle

Seal

Nozzle

Burner

Head

Figure 13 - Removing Nozzle

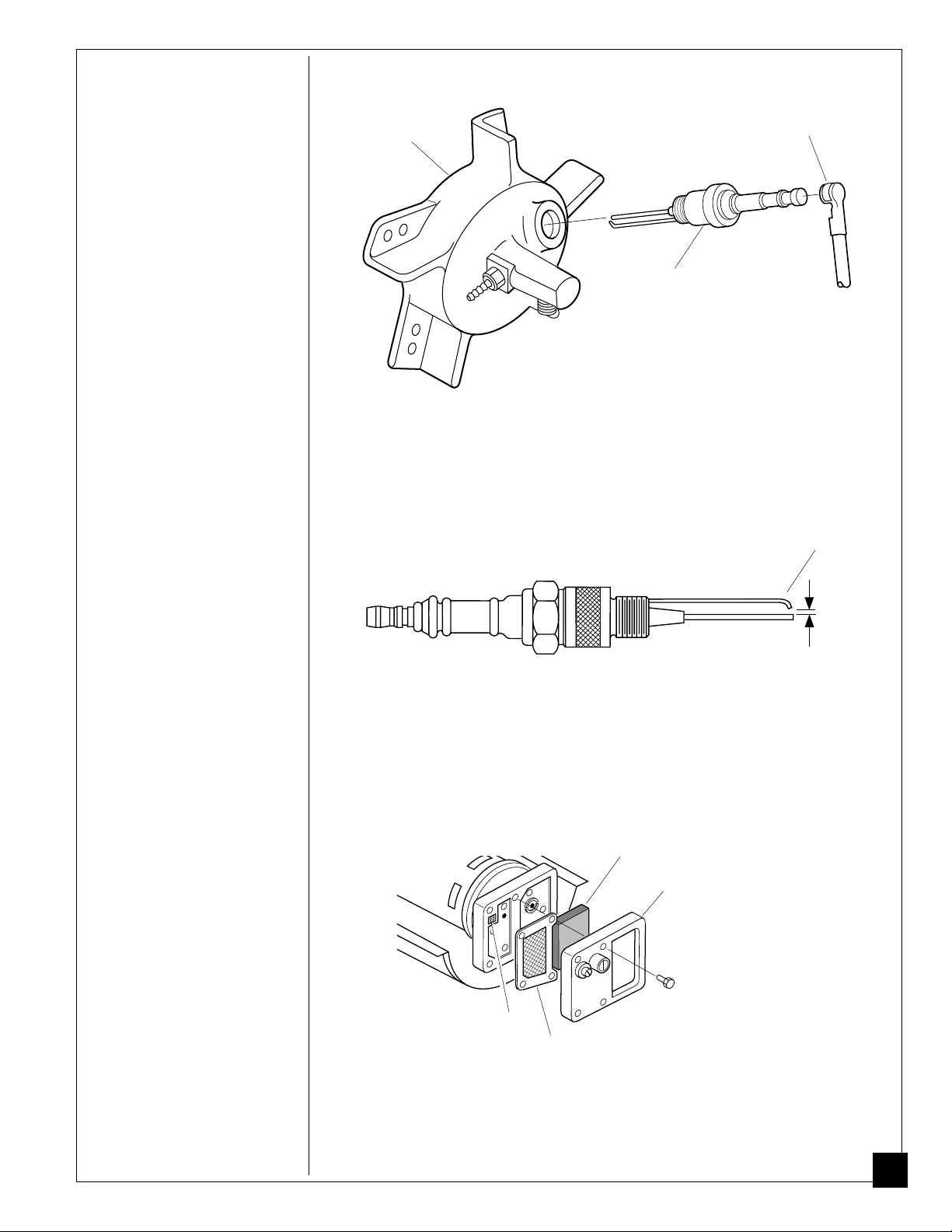

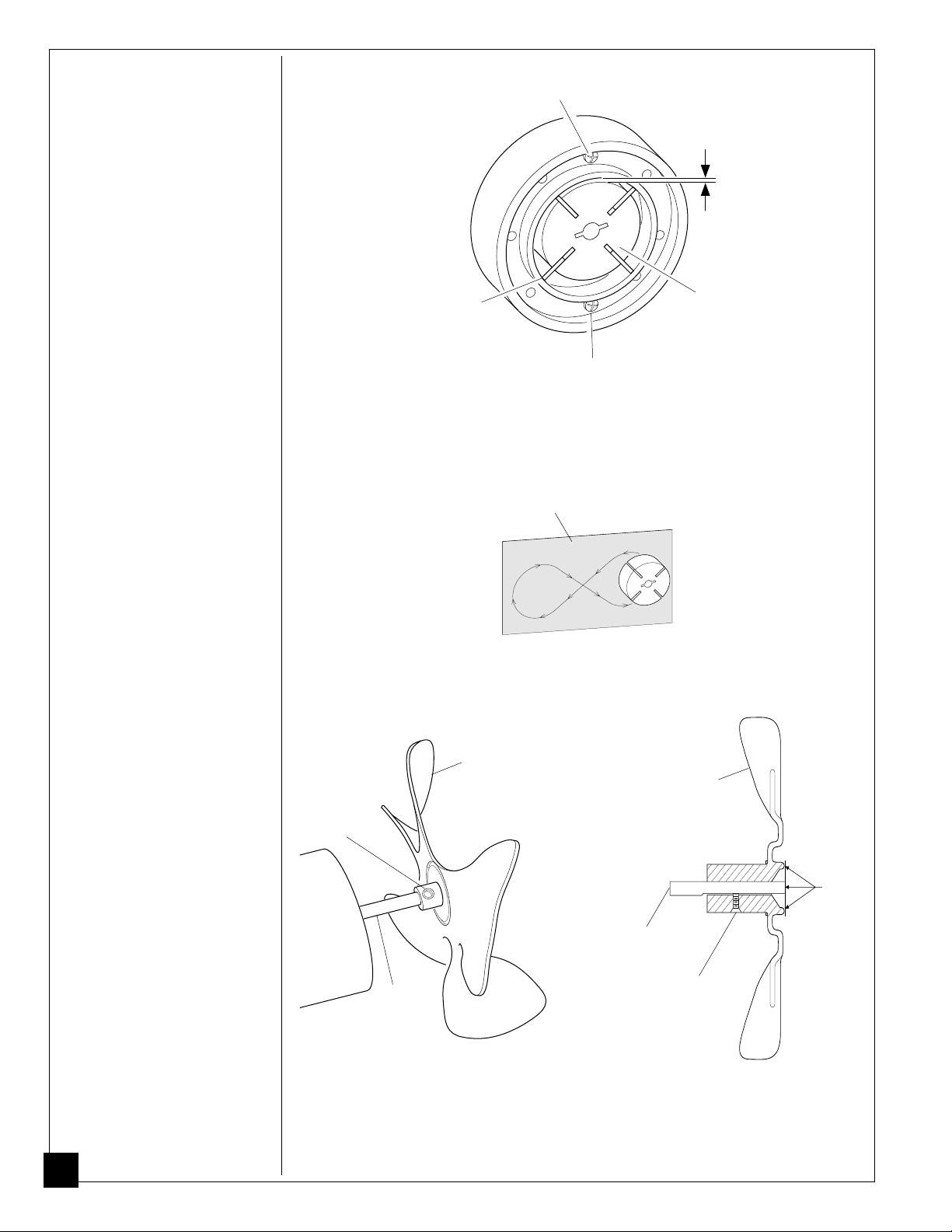

Pump Rotor

(Procedure if rotor is binding)

1. Remove upper shell (see

page 10).

2. Remove filter end cover

screws using 5/16" nutdriver.

3. Remove filter end cover

and air filters.

4. Remove pump plate

screws using 5/16" nutdriver.

5. Remove pump plate.

6. Remove rotor, insert, and

blades.

7. Check for debris in pump.

If debris is found, blow

out with compressed air.

8. Install insert and rotor.

9. Check gap on rotor.

Adjust to .076/.101 mm

(.003"/.004") if needed

(see Figure 15).

Note:

Rotate rotor one

full turn to insure the gap is

.003"/.004" (.076/.101 mm) at

tightest position. Adjust if

needed.

101487

Blade

Insert

Rotor

Figure 14 - Rotor Location

Air

Output

Filter

Pump

Plate

Air

Intake

Filter

Filter End

Cover

Fan Guard

(Not Shown)

13

Page 14

10.Install blades, pump plate,

air filters, and filter end

cover.

11.Replace fan guard and

upper shell.

12.Adjust pump pressure (see

page 12).

Note:

If rotor is still binding,

proceed as follows.

Gap Adjusting

Screw

.076/.101 mm

(.003"/.004") Gap

Measured With

Feeler Gauge

13.Perform steps 1 through 6,

page 13.

14.Place fine grade sandpaper

(600 grit) on flat surface.

Sand rotor lightly in

“figure 8” motion four

times (see Figure 16).

15.Reinstall insert and rotor.

16.Perform steps 10 through

12 above.

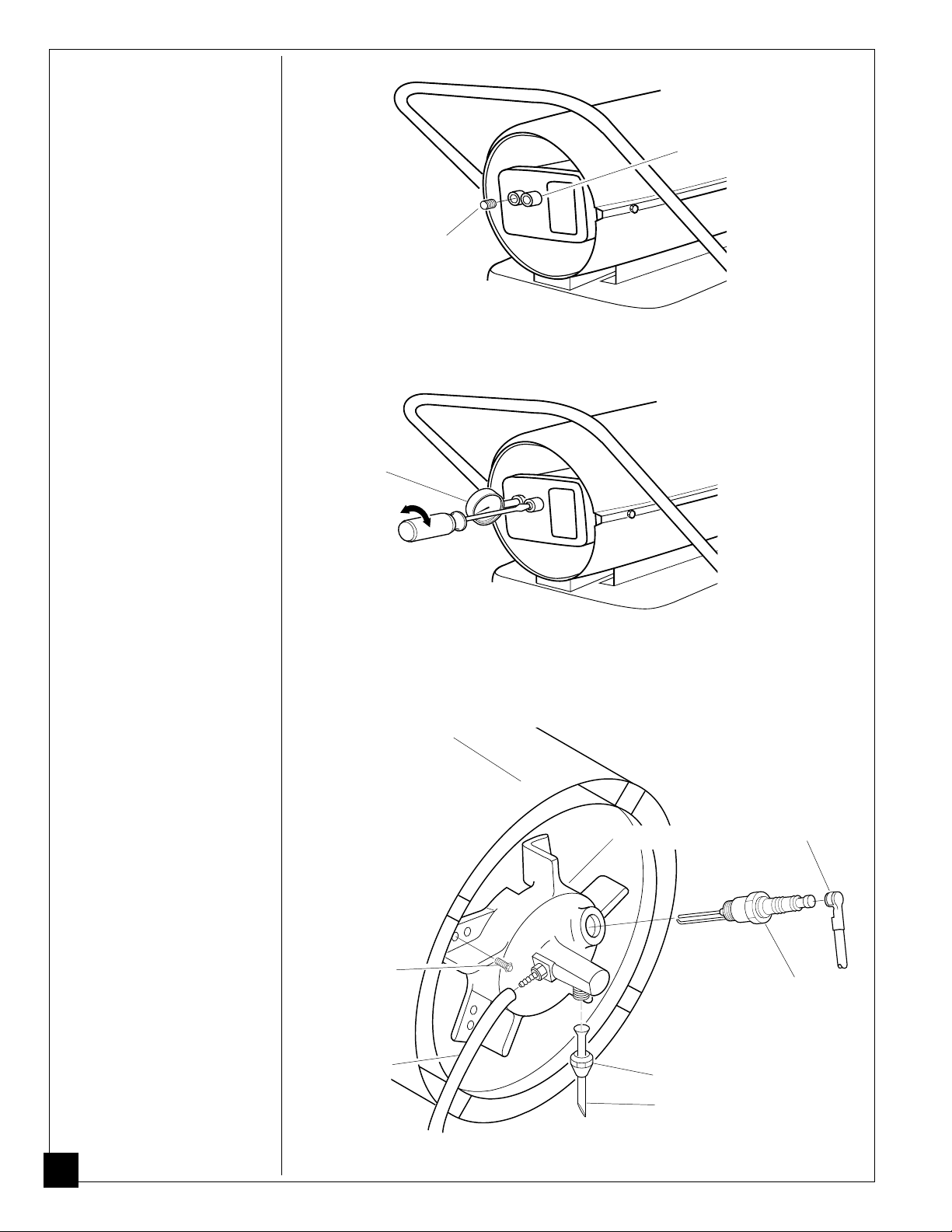

Fan

IMPORTANT:

from motor shaft before

removing motor from heater.

The weight of the motor

resting on the fan could

damage the fan pitch.

Remove fan

Blade

Gap

Adjusting

Screw

Figure 15 - Gap Adjusting Screw Locations

Sandpaper

Figure 16 - Sanding Rotor

Rotor

1. Remove upper shell (see

page 10).

2. Use 1/8" allen wrench to

loosen setscrew which

holds fan to motor shaft.

3. Slip fan off motor shaft.

4. Clean fan using a soft cloth

moistened with kerosene or

solvent.

5. Dry fan thoroughly.

6. Replace fan on motor

shaft. Place fan hub flush

with end of motor shaft

(see Figure 18).

7. Place setscrew on flat of

shaft. Tighten setscrew

firmly (4.5-5.6 n-m/40-50

inch-pounds).

8. Replace fan guard and

upper shell.

14

Fan

Setscrew

Motor

Shaft

Figure 17 - Fan, Motor Shaft, and

Setscrew Location

Fan

Flush

Motor

Shaft

Setscrew

Figure 18 - Fan Cross Section

101487

Page 15

SPECIFICATIONS

Output Rating (kW / BTU/Hr) 44kW/150,000

Fuel Use Only Kerosene or No. 1 Fuel Oil

Fuel Tank Capacity

(Liters/U.S. Gal.) 51.09/13.5

Fuel Consumption

(Liters Per Hr./Gal. Per Hr.) 4.16/1.10

Electric Requirements 230 V/50 Hz

Amperage (Normal Run) 1.5

Hot Air Output (CMM/CFM) 17/600

RPM 2850

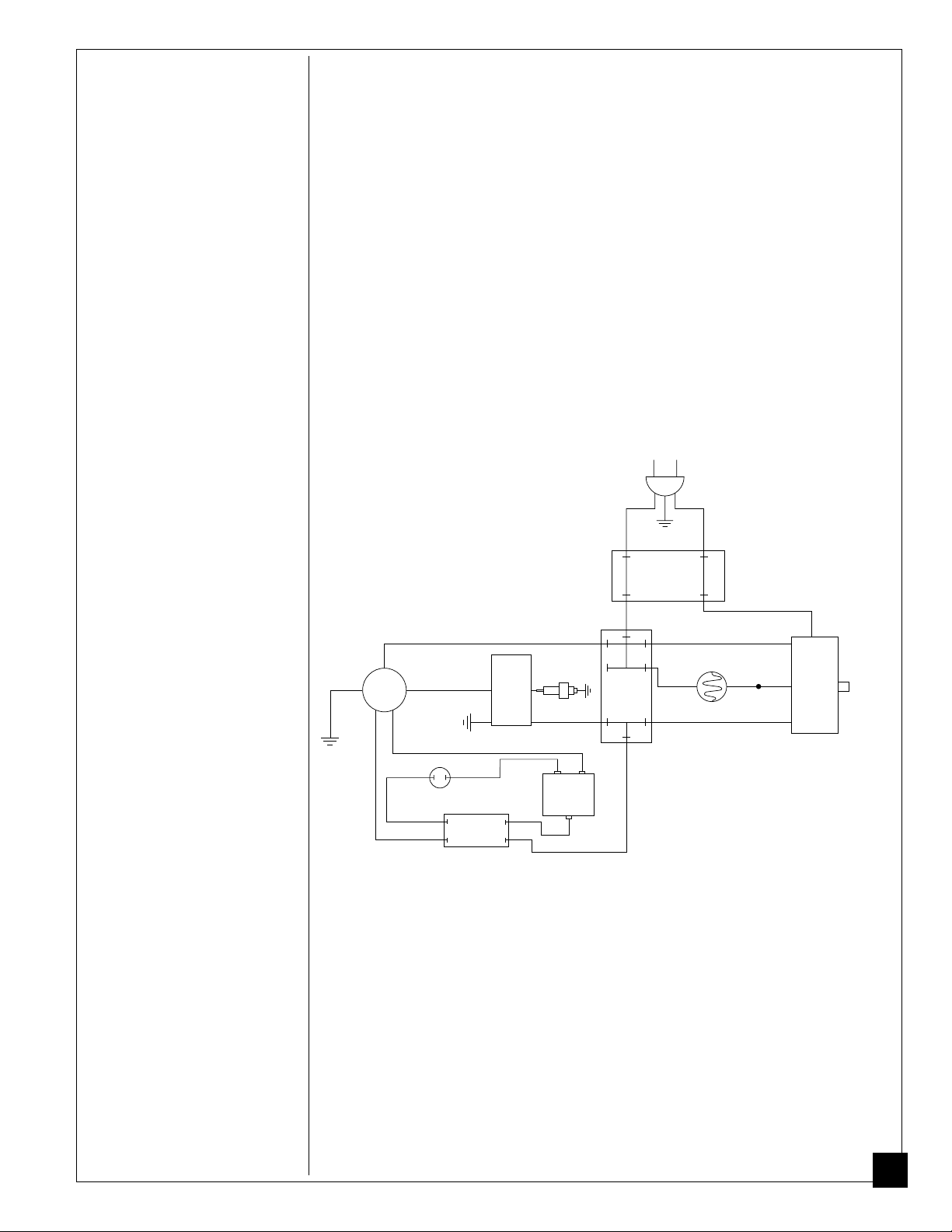

WIRING

DIAGRAM

Green/

Yellow

Motor

Black

Black

Orange

Start

Capacitor

Capacitor

Black

Run

230V/50Hz

Blue

Green/

Yellow

Terminal

Blue

White

Ignitor

Red

S or 2 M or 3

Black

Spark Plug

Motor

Start

Relay

Red

L or 1

Terminal

Board

Red

Figure 19 - Wiring Diagram

Board

White

Brown

Red

Brown

White

Blue

Photocell

Blue

B

Safety

Control

R

Reset

Button

101487

15

Page 16

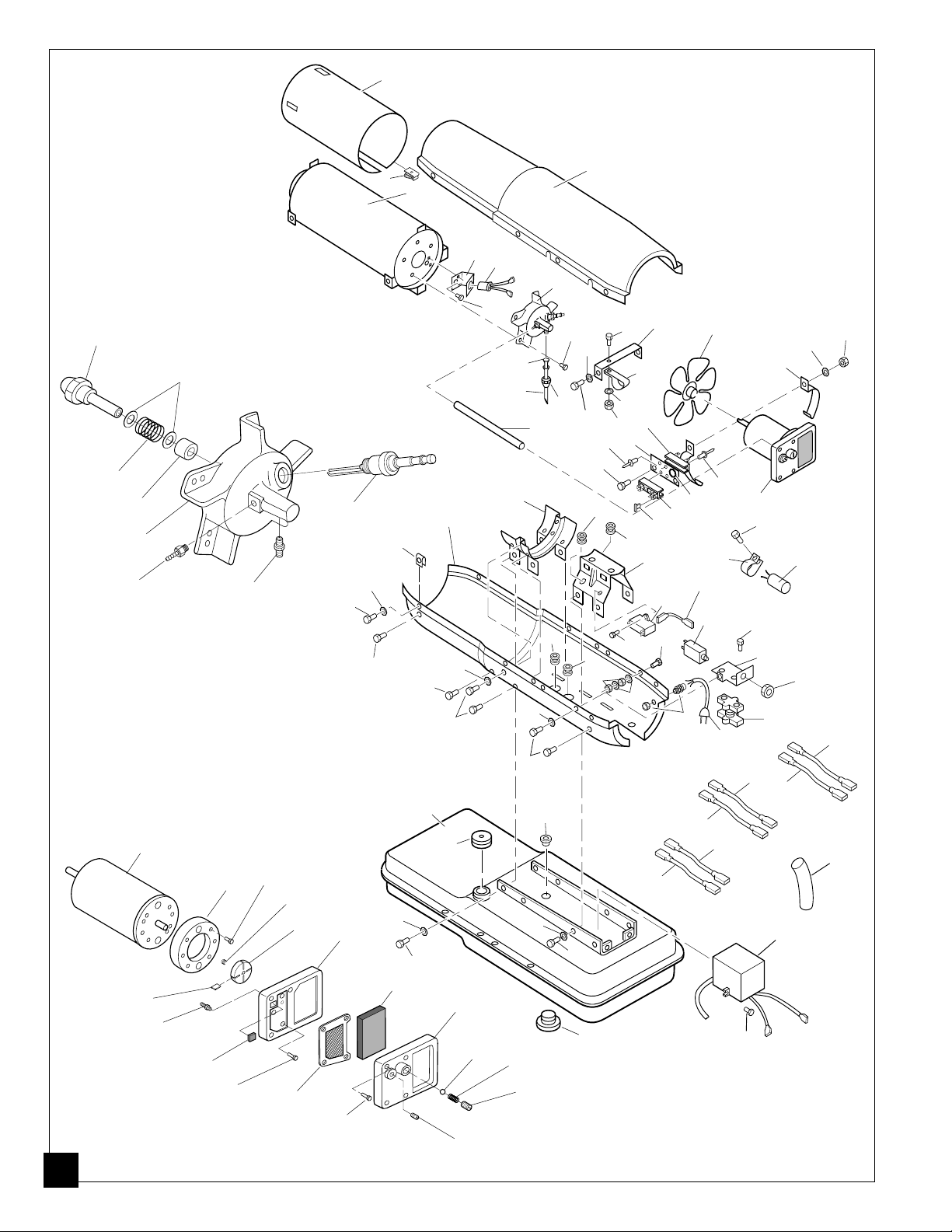

ILLUSTRATED

PARTS

2

BREAKDOWN

8-1

8-2

8-3

8-4

8-5

8-6

Burner Head Assembly

22-1

22-18

22-17

22-16

8-7

22-2

22-15

22-3

22-14

22-4

22-5

8-8

13

22-6

63

32

17

31

63

22-7

1

3

4

5

8

46

9

7

9

63

10

11

12

16

25

30

63

9

32

47

22-8

22-9

63

9

63

22-10

22-11

9

39

21

26

33

33

64

45

9

48

59

56

58

29

38

52

63

57

53

27

50

14

61

28

62

15

20

39

34

23

49

43

22

32

40

9

35

36

37

54

44

26

6

51

42

41

24

65

19

18

55

60

16

22-13

22-12

Motor and Pump Assembly

101487

Page 17

P ARTS LIST

This list contains replaceable parts used in your heater. When ordering parts,

be sure to provide the correct model and serial numbers (from the model plate),

then the part number and description of the desired part.

KEY PART PART

NO. NUMBER DESCRIPTION QTY.

1 098511-58 Upper Shell 1

2 098068-01 Heat Detector 1

3 098512-02 Combustion Chamber 1

4 M16660 Photocell Bracket 1

5 HA3019 Photocell Assembly 1

6 099125-02 Terminal Board 1

7 M10908-2 Screw, #6-32 x 3/8" 2

8 ** Burner Head Assembly 1

8-1 M18022 Nozzle 1

8-2 M10659-1 Nozzle Seal Washer 2

8-3 M10809-1 Nozzle Seal Spring 1

8-4 M8882 Nozzle Seal Sleeve 1

8-5 M50924-01 Burner Head Body 1

8-6 M50820-02 Barb Fitting 1

8-7 079685-01 Male Connector 1

8-8 M10962-2 Spark Plug 1

9 M11084-27 Screw, #10-16 x 1/2" 19

10 M19630 Fuel Filter 1

11 M16790-12 Fuel Tube 1

12 M50660-05 Flared 45° Nut 1

13 100647-01 Screw, #10-16 x 1/2" 8

14 M16871 Retainer Strap 1

15 M17920 Fan 1

16 M50814-03 Air Line 1

17 M50873-01 Clip 9

18 NPC-4C Hex Nut, 1/4-20 2

19 WLM-4 Lockwasher, 1/4" 2

20 M16661-1 Motor Clamp 4

21 M51043-01 Bolt, 1/4-20 x 1 1/2" 2

22 ** Motor and Pump Assembly 1

22-1 098784-03 Motor (230V/50Hz) 1

22-2 079975-04 Pump Body 1

22-3 FHPF3-7C Screw, #10-32 x 7/8" 2

22-4 M22009 Insert 1

22-5 M22456-3 Rotor 1

22-6 M50545 End Pump Cover 1

22-7 M12179 Intake Filter 1

22-8 M16545 End Filter Cover 1

22-9 M8940 Steel Ball (1/4" Dia.) 1

22-10 M10993-1 Pressure Relief Spring 1

22-11 M27694 Adjusting Screw 1

22-12 M22997 Plug 1

22-13 M12461-31 Screw, #10-32 x 1" 4

22-14 M12244-1 Output Filter 1

22-15 M12461-34 Screw, #10-32 x 1 1/2" 6

22-16 M11637 Lint Filter 1

22-17 M50820-02 Barb Fitting 1

22-18 M8643-3 Blade 4

23 M12651-1 Capacitor Clamp 1

24 M12650-3 Capacitor 1

25 M12828 Shell Support Bracket 1

26 M30865-04 Open/Closed Bushing 2

KEY PART PART

NO. NUMBER DESCRIPTION QTY.

27 M16645 Motor Support Bracket 1

28 M51357-01 Capacitor (Run) 1

29 M15823-39 Screw, #8-18 x 1/2" 1

30 M16810-06AB Lower Shell 1

31 M11271-8 Nut Clip 9

32 M11084-29 Screw, #10-16 x 3/4" 8

33 M50104-03 Shorty Bushing 2

34 097630-02 Flame-Out Control 1

35 M12461-13 Screw, #8-32 x 1/4" 2

36 097060-01 Mounting Bracket 1

37 M12462-13 Relay-Motor Start 1

38 099607-02 Terminal Board Bracket 1

39 099157-01 Rivet 2

40 M9900-183 Wire Assembly (black 6") 1

41 M9900-184 Wire Assembly (black 15") 1

42 M50400 Strain Relief Bushing 1

43 079673-03 Power Cord 1

44 098557-07 Electronic Ignitor 1

45 M10990-3 Rubber Bushing 1

46 098513-08 Fuel Tank 1

47 097702-01 Fuel Tank Cap 1

48 M27417 Drain Plug 1

49 079010-14 Wire Assembly (red 8 7/8") 1

50 M9900-77 Wire Assembly (black 15") 1

51 M16841-57 Wire Assembly (red 8 1/2") 1

52 M30865-02 Open/Closed Bushing 1

53 099125-08 Terminal Board 1

54 079010-23 Wire Assembly (blue 9") 1

55 079010-24 Wire Assembly (brown 12") 1

56 M12461-27 Screw, #10-32 x 1/2" 1

57 101488-01 Airline Clamp 1

58 WLM-3 Lock Washer, #10 1

59 NPF-3C Hex Nut, 10-32 1

60 101578-01 Sleeving 1

61 078918-01 Terminal Board Tab Cap 1

62 RF3-5B Screw, #10-32 x 5/8" 1

63 WLE-3 Lock Washer, #10 23

64 NPF-3B Hex Nut, 10-32 2

65 099177-01 Hex Nut, 3/8x27 1

PARTS AVAILABLE - NOT SHOWN

101639-01 Warning Decal 1

098892-02 Fan Guard Bracket 1

M50140 Fan Guard 1

097650-01 Tradename Decal 1

HA2210 Filler Neck Screen 1

098235-25 General Info. Decal

(English & French) 1

098235-26 General Info. Decal

(German & Dutch) 1

**Not available as an assembly, order parts separately.

101487

17

Page 18

WHEELS AND

HANDLES

KEY PART PART

NO. NUMBER DESCRIPTION QTY.

1 HA2205 Handles 2

2 M12345-33 Screw, #10-24 x 1 3/4" 8

3 M12831-3 Wheel Support Frame 1

4 NTC-3C Hex Nut, #10-24 8

5 097896-01 Wheel 2

6 M28526 Cap Nut 2

7 M16801-2 Axle 1

1

2

ACCESSORY

Purchase accessory from your

local dealer.

18

3

5

6

4

7

AIR GAUGE KIT - HA1180

For all models. Special tool to

check pump pressure.

101487

Page 19

NOTES

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

101487

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_____________________________________________________________

19

Page 20

WARRANTY AND REPAIR SERVICE

CERTIFICATE OF GENERAL EQUIPMENT -

LIMITED 90 DAY WARRANTY

DESA International warrants new Products sold by it to be

free from defects in material or workmanship for a period of

ninety days after date of delivery to the first user and subject to

the following conditions:

DESA International's obligation and liability under this

Warranty is expressly limited to repairing or replacing at DESA

International's option, any parts which appear to DESA International upon inspection to have been defective in material or

workmanship when shipped from the factory. Such parts shall

be provided at no cost to the user, at the business establishment

of any factory authorized service center or the factory during

regular working hours. The Warranty shall not apply to component parts or accessories of Products not manufactured by

DESA International and which carry the warranty of the manufacturer thereof, or to normal maintenance (such as pressure

adjustments) or to normal maintenance parts (such as filters

and spark plugs). Replacement or repair parts installed in the

Product covered by this Warranty are warranted only for the

remainder of this Warranty as if such parts were original components of said Product. DESA INTERNATIONAL MAKES NO

OTHER EXPRESS WARRANTY. TO THE EXTENT PERMITTED BY LAW DESA INTERNATIONAL MAKES NO IMPLIED

WARRANTY AND MAKES NO WARRANTY OF MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PUR-

POSE. IN ANY EVENT IMPLIED WARRANTIES INCLUDING

THOSE OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE LIMITED TO THE DURATION OF

THIS EXPRESS WARRANTY.

Any transportation charges, costs of installation, duty,

taxes or any other charges whatsoever must be borne by the

user. DESA International's obligation under this limited Warranty shall not include any liability for direct, indirect, incidental,

or consequential damage or delay. If requested by DESA

International, Products or parts for which a warranty claim is

made are to be returned transportation prepaid by user to the

factory. Any improper use, including operation after discovery

of defective or worn parts, operation beyond capacity, substitution of parts not approved by DESA International, or any

alteration or repair by others in such manner as in DESA

International's judgement affects the Product materially and

adversely, shall void this Warranty.

NO EMPLOYEE OR REPRESENTATIVE IS AUTHORIZED

TO CHANGE THIS WARRANTY IN ANY WAY OR GRANT

ANY OTHER WARRANTY UNLESS SUCH CHANGE IS

MADE IN WRITING AND SIGNED BY AN OFFICER OF DESA

INTERNATIONAL AT ITS HOME OFFICE.

WARRANTY SERVICE

Always specify model and serial numbers when communicating

with the factory.

We reserve the right to amend these specifications at any time

without notice. The only Warranty applicable is our standard

written Warranty. We make no other Warranty, expressed or

implied.

A Service Manual is available by writing to the Technical Service

Department at:

Corporate Headquarters

2701 Industrial Drive

P.O. Box 90004

Bowling Green, KY 42102-9004

U.S.A.

Printed in U.S.A.

20

101487-01

Rev. B

9/94

101487

Page 21

R

APPAREIL DE

CHAUFFAGE

INDIVIDUEL À AIR

FORCÉ

MANUEL D’UTILISATION

Modèle BH150CE

Puissance de l’appareil : 44 kW (150,000 BTU/Hr)

IMPORTANT

Veiller à lire et comprendre ce manuel avant de monter, mettre en marche ou

effectuer l’entretien de cet appareil. Une mauvaise utilisation de cet appareil

pourrait causer des blessures graves. Conserver ce manuel pour s’y reporter

plus tard.

Page 22

TABLE DES

SECTION PAGE

MATIÈRES

Notes sur la sécurité....................................................................... 2

Nomenclature des pièces ............................................................... 4

Déballage ....................................................................................... 4

Montage ......................................................................................... 5

Principes de fonctionnement ......................................................... 6

Carburants...................................................................................... 6

Ventilation ..................................................................................... 7

Fonctionnement ............................................................................. 7

Remisage ....................................................................................... 8

Tableau d’entretien préventif.........................................................8

Dépannage ..................................................................................... 9

Procédures d’entretien ................................................................... 10

Dépose du couvercle ............................................................... 10

Filtre à carburant ..................................................................... 10

Bougie ..................................................................................... 11

Filtres de sortie d’air, d’entrée d’air et à peluche ................... 11

Réglage de la pression de la pompe ........................................ 12

Gicleur..................................................................................... 12

Rotor de la pompe ................................................................... 14

Ventilateur............................................................................... 15

NOTES SUR LA

SÉCURITÉ

Vue éclatée et liste des pièces........................................................16, 17

Roues et guidons ..................................................................... 18

Accessoires .................................................................................... 18

Spécifications ................................................................................ 19

Schéma électrique.......................................................................... 19

Garantie et réparations................................................................... Dos du manuel

AVERTISSEMENTS

IMPORTANT : Veiller à lire ce manuel d’utilisation attentivement et

complètement avant de tenter de monter, de faire fonctionner ou

d’effectuer l’entretien de cet appareil. Une mauvaise utilisation de cet

appareil de chauffage peut causer des blessures graves, voire la mort

par brûlures, incendie, explosion, électrocution et intoxication par

l’oxyde de carbone.

DANGER

L’intoxication par l’oxyde de carbone peut entraîner la mort !

Voir page suivante

2

101487

Page 23

NOTES SUR LA

AVERTISSEMENTS

Suite

SÉCURITÉ

Suite

Intoxication par l’oxyde de carbone : Les premiers signes d’intoxication par

l’oxyde de carbone ressemblent à ceux de la grippe : maux de tête, vertiges ou

nausée. Si l’on ressent ces symptômes, il se peut que l’appareil de chauffage ne

fonctionne pas correctement. Aller immédiatement respirer de l’air frais ! Faire

réparer l’appareil de chauffage. Certaines personnes sont plus susceptibles que

d’autres aux effets de l’oxyde de carbone, par exemple les femmes enceintes, les

personnes souffrant de maladies cardiaques ou pulmonaires, d’anémie, celles sous

l’effet de l’alcool ou celles se trouvant à haute altitude.

Veiller à lire et comprendre tous les avertissements. Conserver ce manuel pour s’y

reporter plus tard. C’est un guide pour l’utilisation correcte et sans danger de cet

appareil de chauffage.

• Ne se servir que de kérosène ou de fioul n 1 pour éviter les risques d’incendie ou

d’explosion. Ne jamais utiliser d’essence, de naphte, de diluants à peinture,

d’alcool ou d’autres combustibles hautement inflammables.

• Ne jamais se servir de l’appareil dans des endroits contenant des vapeurs

d’essence, de diluant à peinture, d’alcool ou d’autres combustibles hautement

inflammables.

• Se conformer à tous les règlements et codes locaux lors de l’utilisation de

l’appareil.

• Ne le faire fonctionner que dans des endroits bien aérés. Une ouverture d’au moins

2800 cm

chaque indice de 29,3 kW (100,000 BTU/Hr) de rendement nominal.

• Ne le faire fonctionner que dans des endroits sans vapeurs inflammables et sans

poussière.

• N’utiliser que les tension et fréquence spécifiées sur la plaque signalétique.

• N’utiliser qu’une rallonge à trois broches avec mise à la terre.

• Distance minimale entre l’appareil et tout matériau combustible :

Sortie : 2,5 m (8 ft) Côtés, dessus et arrière: 1,25 m (4 ft)

• Placer l’appareil de chauffage sur une surface stable et horizontale lorsqu’il est

chaud ou en marche pour éviter de provoquer un incendie.

• Lors du déplacement ou du remisage de l’appareil, le maintenir horizontal pour

éviter de renverser du carburant.

• Maintenir enfants et animaux éloignés de l’appareil de chauffage.

• Débrancher l’appareil lorsqu’on ne s’en sert pas.

• S’il est muni d’un thermostat, l’appareil peut se mettre en marche à n’importe quel

moment.

• Ne jamais utiliser l’appareil dans les salles de séjour ou dans les chambres à

coucher.

• Ne jamais bloquer l’entrée d’air (arrière) ou la sortie d’air (avant) de l’appareil.

• Ne jamais déplacer, manipuler, faire le plein ou effectuer l’entretien d’un appareil

chaud, en marche ou branché.

• Ne jamais monter de canalisation de distribution d’air à l’avant ou à l’arrière de

l’appareil. Cela risquerait de diminuer l’écoulement d’air nécessaire à l’appareil,

qui produirait alors un excès d’oxyde de carbone.

2

(3 sq. ft) laissant passer l’air frais de l’extérieur est nécessaire pour

101487

3

Page 24

NOMENCLA-

Couvercle

TURE DES

PIÈCES

Sortie

d’air

chaud

Boîtier

Bouchon du réservoir

de carburant

Bouton de

Cordon

électrique

Figure 1 - Modèle de 44 kW (150,000 BTU/Hr)

réarmement du

détecteur

d’extinction de

flamme

Cachefiltre

Grille de

protection

du

ventilateur

Réservoir

de

carburant

DÉBALLAGE

1. Retirer tous les emballages de protection utilisés pour le transport.

2. Retirer tous les éléments contenus dans la boîte.

3. Vérifier s’ils ont été endommagés pendant le transport. Si l’appareil est

endommagé, avertir au plus tôt le concessionnaire qui l’a vendu.

4

101487

Page 25

MONTAGE

Ces modèles sont livrés avec des roues et des guidons. Ces derniers et leur

boulonnerie de montage se trouvent dans la boîte d’expédition.

Outils nécessaires

• Tournevis cruciforme de taille moyenne

• Clé plate ou à molette de 3/8 in.

• Marteau

1. Faire passer l’essieu dans le berceau. Installer les roues sur l’essieu.

I

MPORTANT :

berceau (voir figure 2).

2. Placer les écrous borgnes sur les extrémités de l’essieu. Taper légèrement

dessus avec le marteau pour les mettre en place.

3. Placer l’appareil de chauffage sur le berceau. S’assurer que le côté entrée d’air

(arrière) de l’appareil se trouve au-dessus des roues. Aligner les trous du

rebord du réservoir de carburant avec les trous du berceau.

4. Placer les guidons avant et arrière sur le rebord du réservoir de carburant. Faire

passer les vis à travers les guidons, le rebord du réservoir et le berceau. Ceci

fait, serrer à la main un écrou sur chaque vis.

5. Une fois toutes les vis en place, serrer fermement les écrous.

Installer les roues avec le côté allongé du moyeu tourné vers le

Guidon avant

Sortie

d’air

chaud

Rebord

du

réservoir

de

carburant

Berceau

Roue

Écrou

borgne

Vis

Écrou

Essieu

Guidon

arrière

Entrée

d’air

Moyeu

allongé

101487

Figure 2 - Montage des roues et des guidons

5

Page 26

PRINCIPES DE

FONCTION-

NEMENT

Sortie

d’air

chaud

non

pollué

Circuit d’alimentation en carburant : La pompe à air force l’air dans la conduite

d’air. L’air passe ensuite par le gicleur du brûleur. La dépression causée par l’air

fait monter le carburant du réservoir. Un fin nuage de carburant est vaporisé dans

la chambre de combustion.

Circuit d’air : Le moteur fait tourner le ventilateur. Celui-ci pousse l’air dans et

autour de la chambre de combustion. Cet air est chauffé et produit un jet d’air

chaud non pollué.

Dispositif d’allumage : L’allumeur électronique envoie le courant à la bougie.

Celle-ci enflamme le mélange de carburant et d’air.

Détecteur d’extinction de flamme : Ce dispositif arrête l’appareil de chauffage si

la flamme s’éteint.

Chambre de

combustion

Bougie

Moteur

Ventilateur

Brûleur

Pompe à air

Filtre à

air

d’entrée

Entrée

d’air

frais

Filtre

à air

de

sortie

CARBURANTS

6

Réservoir

de

carburant

Gicleur

Air pour le circuit

d’alimentation en

carburant

Figure 3 - Coupe, fonctionnement

Filtre à

carburant

Air de combustion

et de chauffage

Conduite d’air

vers brûleur

Allumeur

électronique

Carburant

AVERTISSEMENT

Ne se servir que de kérosène ou de fioul n 1 pour éviter les

risques d’incendie ou d’explosion. Ne jamais utiliser

d’essence, de naphte, de diluants à peinture, d’alcool ou

d’autres combustibles hautement inflammables.

Ne pas se servir de carburants lourds tels que le fioul n 2 ou le carburant diesel

n 2. L’utilisation de carburants lourds peut donner lieu :

• au colmatage du filtre à carburant et du gicleur

• à l’accumulation de carbone sur la bougie

• au besoin d’ajouter au carburant des produits antigel non toxiques durant les

périodes de grand froid.

IMPORTANT :

KÉROSÈNE. S’assurer que le récipient de stockage est propre. Les matières

étrangères telles que la rouille, la poussière ou l’eau provoquent l’arrêt de

l’appareil par le détecteur d’extinction de flamme. En outre, elles peuvent exiger

un nettoyage plus fréquent du circuit d’alimentation en carburant.

Se servir d’un bidon utilisé EXCLUSIVEMENT pour du

101487

Page 27

VENTILATION

AVERTISSEMENT

Respecter les règles minimales de ventilation en air frais

extérieur. Sans ventilation adéquate en air frais extérieur, il

y a risque d’intoxication par l’oxyde de carbone. S’assurer

que ces règles sont bien suivies avant de faire fonctionner

l’appareil de chauffage.

FONCTION-

NEMENT

Assurer l’entrée d’air frais extérieur par une ouverture d’au moins 2800 cm

ft) pour chaque 29,3 kW (100,000 BTU/Hr) de rendement nominal. Prévoir

davantage d’air frais si plusieurs appareils sont utilisés.

Exemple :

dans l’une des conditions suivantes :

• une porte double de garage de 4,88 m (16 ft) de large relevée de 8,59 cm (3,38 in.)

• une porte simple de garage de 2,75 m (9 ft) de large relevée de 15,24 cm (6 in.)

• deux fenêtres à guillotine de 76,20 cm (30 in.) de large relevées de 28 cm (11 in.)

Un appareil de chauffage de 44 kW (150,000 BTU/Hr) doit fonctionner

2

(3 sq.

AVERTISSEMENT

Veiller à revoir et à bien comprendre les avertissements qui

se trouvent dans la section

nécessaire pour faire fonctionner cet appareil en toute

sécurité. Respecter tous les règlements locaux lors de

l’utilisation de cet appareil.

Mise en marche de l’appareil

1. Suivre les instructions concernant la ventilation et la sécurité.

2. Faire le plein du réservoir avec du kérosène ou du fioul n 1.

3. Remettre le bouchon du réservoir.

4. Brancher le cordon électrique de l’appareil dans une prise standard de 230

Volts et 50 Hz avec prise de terre. Se servir d’une rallonge si nécessaire.

N’utiliser qu’une rallonge à trois broches avec mise à la terre.

Notes sur la sécurité

. Cela est

101487

Conditions requises pour les rallonges électriques

Pour des longueurs atteignant 30,5 m (100 ft), rallonge de calibre 1,0 mm

(16 AWG)

De 30,6 à 61 m (101 à 200 ft), rallonge de calibre 1,5 mm2 (14 AWG)

L’appareil démarre lorsque le cordon électrique est branché dans la prise.

Sinon, appuyer sur le bouton de réarmement du détecteur d’extinction de

flamme (voir figure 4).

Bouton de

réarmement du

détecteur d’extinction

de flamme (Grille de

protection du

ventilateur déposée)

Figure 4 - Bouton de réarmement du détecteur d’extinction de flamme

Voir page suivante

2

7

Page 28

FONCTION-

NEMENT

Suite

Pour arrêter l’appareil de chauffage

1. Débrancher le cordon électrique de la prise.

Pour remettre l’appareil en marche

1. Attendre 2 minutes après l’arrêt de l’appareil.

2. Répéter les opérations indiquées page 7 sous la rubrique Mise en marche.

REMISAGE

TABLEAU

D’ENTRETIEN

PRÉVENTIF

8

1. Vidanger le réservoir de carburant.

Note :

Sur certains modèles, il y a un bouchon de vidange sous le réservoir. Si

c’est le cas, le retirer et vidanger tout le carburant. S’il n’y a pas de bouchon de

vidange, vidanger le carburant par l’orifice de remplissage. S’assurer que tout

le carburant est vidangé.

2. Remettre le bouchon de vidange en place le cas échéant.

3. Verser 4 litres (1 gal.) de kérosène propre dans le réservoir.

4. Remettre le bouchon du réservoir.

5. Déplacer l’appareil d’avant en arrière pour remuer le carburant.

6. Enlever le bouchon du réservoir ou le bouchon de vidange et vidanger le

carburant. S’assurer que tout le carburant est vidangé.

7. Remettre le bouchon du réservoir ou le bouchon de vidange. Se débarrasser du

carburant usé et sale de manière appropriée.

8. Remiser l’appareil dans un endroit sec, à l’abri de la poussière et des vapeurs

corrosives.

IMPORTANT :

période de chauffage suivante. L’usage de carburant ancien risque d’endommager

l’appareil.

Ne pas stocker le kérosène pendant l’été pour l’utiliser durant la

AVERTISSEMENT

Ne jamais effectuer l’entretien de l’appareil de chauffage s’il

est branché, en marche ou chaud. Cela peut entraîner des

brûlures graves ou l’électrocution.

Élément

Réservoir de carburant

Filtres de sortie d’air et

à peluche

Filtre d’entrée d’air

Filtre à carburant

Bougie

Pales du ventilateur

Moteur

Périodicité

Rincer toutes les 150 à 200

heures de fonctionnement

ou selon le besoin.

Remplacer toutes les 500

heures de fonctionnement

ou une fois par an.

Le laver à l’eau savonneuse

et le sécher toutes les 500

heures de fonctionnement

ou selon le besoin.

Le nettoyer deux fois par

période de chauffage ou

selon le besoin.

Nettoyer et régler l’écart

toutes les 600 heures de

fonctionnement ou

remplacer selon le besoin.

Les nettoyer chaque saison

ou selon le besoin.

Aucun entretien nécessaire.

Lubrification permanente.

Opération

Voir Remisage,

ci-dessus.

Voir Filtres de sortie

d’air, d’entrée d’air et

à peluche, page 11.

Voir Filtres de sortie

d’air, d’entrée d’air et

à peluche, page 11.

Voir Filtre à carburant,

page 10.

Voir Bougie, page 11.

Voir Ventilateur, page

15.

101487

Page 29

DÉPANNAGE

AVERTISSEMENT

Ne jamais effectuer l’entretien de l’appareil de chauffage s’il

est branché, en marche ou chaud. Cela peut entraîner des

brûlures graves ou l’électrocution.

ANOMALIE

OBSERVÉE

L’appareil s’allume,

mais le détecteur

d’extinction de

flamme l’arrête après

quelques instants.

L’appareil ne

s’allume pas, mais le

moteur tourne

pendant quelques

instants.

CAUSE

PROBABLE

Pression incorrecte de la

pompe

Filtres de sortie d’air,

d’entrée d’air et à

peluche encrassés

Filtre à carburant

encrassé

Gicleur encrassé

Lentille de cellule

photoélectrique sale

Détecteur d’extinction de

flamme défectueux

Pression incorrecte de la

pompe

Dépôts de carbone sur la

bougie et/ou écart incor-

rect

Filtre à carburant encrassé

Gicleur encrassé

Eau dans le réservoir de

carburant

AVERTISSEMENT : Haute tension !

L’allumeur électronique

n’est pas mis à la masse (à

la terre)

Allumeur électronique

défectueux

REMÈDE

Voir Réglage de la

pression de la pompe,

page 12.

Voir Filtres de sortie

d’air, d’entrée d’air et

à peluche, page 11.

Voir Filtre à carburant,

page 10.

Voir Gicleur, page 12.

La nettoyer.

Le remplacer.

Voir Réglage de la

pression de la pompe,

page 12.

Voir Bougie, page 11.

Voir Filtre à carburant,

page 10.

Voir Gicleur, page 12.

Vidanger et rincer le

réservoir avec du

kérosène propre. Voir

Remisage, page 8.

S’assurer que le montage

de l’allumeur

électronique est bien

serré.

Le remplacer.

101487

Le moteur ne

démarre pas quand

l’appareil est

branché, le

ventilateur tourne

lentement ou pas du

tout.

Le détecteur d’extinction de

flamme n’est pas réarmé

Rotor de pompe grippé

Réarmer le bouton du

détecteur d’extinction

de flamme ; voir figure

4, page 7.

Si le ventilateur tourne

avec difficulté, voir

Rotor de la pompe,

page 14.

9

Page 30

PROCÉDURES

D’ENTRETIEN

AVERTISSEMENT

Ne jamais effectuer l’entretien de l’appareil de chauffage

s’il est branché, en marche ou chaud. Cela peut entraîner

des brûlures graves ou l’électrocution.

Dépose du couvercle

1. Enlever les vis se trouvant

de chaque côté de

l’appareil à l’aide d’une clé

à douille de 5/16 in. Ces

vis retiennent le couvercle

sur le boîtier.

2. Enlever le couvercle.

3. Retirer la grille de protection du ventilateur.

Filtre à carburant

1. Déposer le couvercle (voir

page 10).

2. Déposer le ventilateur (voir

page 15).

3. Desserrer l’écrou évasé à

l’aide d’une clé plate de

3/4 in. Pousser le tube

d’arrivée du carburant vers

le bas pour l’éloigner du

brûleur. Le filtre à

carburant se trouve à

l’intérieur du tube.

4. Retirer le filtre à carburant.

5. Laver le filtre à carburant

avec du carburant propre et

le remettre dans le tube.

6. Brancher le tube sur le

brûleur. Serrer l’écrou

évasé jusqu’à ce qu’il

touche le tube d’arrivée du

carburant et le raccord. Le

serrer d’un quart de tour

supplémentaire avec la clé

plate de 3/4 in. (11,3 à 14,7

Nm [100 à 130 lb.-in.]).

7. Remonter le ventilateur

(voir page 15).

8. Remonter la grille du

ventilateur et le couvercle.

Filtre à

carburant

Tube

d’arrivée

de

carburant

Couvercle

Grille de

protection

du

ventilateur

Figure 5 - Dépose du couvercle

Chambre de

combustion

Brûleur

Écrou

évasé

Figure 6 - Dépose du filtre à carburant

10

101487

Page 31

Bougie

1. Déposer le couvercle (voir

page 10).

2. Déposer le ventilateur (voir

page 15).

3. Débrancher le fil de la

bougie.

4. Retirer la bougie du brûleur

à l’aide d’une clé plate de

13/16 in.

5. Nettoyer les électrodes et

en régler l’écart à 1,4 mm

(.055 in).

6. Remettre la bougie dans le

brûleur.

7. Rebrancher le fil à la

bougie.

8. Remonter le ventilateur

(voir page 15).

9. Remonter la grille de

protection du ventilateur et

le couvercle.

Brûleur

Fil de

bougie

Bougie

Figure 7 - Dépose de la bougie

Plier ici

pour régler

l’écart

Filtres de sortie d’air,

d’entrée d’air et à

peluche

1. Déposer le couvercle

(voir page 10).

2. Retirer les vis du

cache-filtre à l’aide d’une

clé à douille de 5/16 in.

3. Déposer le cache-filtre.

4. Remplacer les filtres de

sortie d’air et à peluche.

5. Laver ou remplacer le

filtre d’entrée d’air (voir

Tableau d’entretien

préventif, page 8).

6. Remonter le cache-filtre.

7. Remonter la grille de

protection du ventilateur

et le couvercle.

IMPORTANT :

les filtres.

101487

Ne pas huiler

Figure 8 - Écart des électrodes de la bougie

Filtre d’entrée d’air

Cache-filtre

Grille de

protection du

ventilateur (non

Filtre à

peluche

Figure 9 - Filtres de sortie d’air, d’entrée d’air et à peluche

Filtre de

sortie d’air

illustrée)

Écart de

1,4 mm

(.055 in.)

11

Page 32

g

F

F

Réglage de la pression

de la pompe

1. Retirer le bouchon du trou

du manomètre du

cache-filtre.

2. Installer le manomètre

(numéro de pièce

HA1180).

3. Mettre l’appareil en

marche (voir

Fonctionnement, page 7).

Attendre que le moteur

atteigne son régime

maximum.

4. Régler la pression. Tourner

le clapet de décharge vers

la droite pour augmenter la

pression et vers la gauche

pour la diminuer. Régler la

pression de la pompe à

33,78 kPa (0,34 bar) (4,9

psi).

5. Retirer le manomètre et

remettre le bouchon du

trou du manomètre sur le

cache-filtre.

Bouchon de

manomètre

Manomètre

Clapet de

décharge

150 PRESSURE ADJUSTMENT Plu

Figure 10 - Dépose du bouchon du trou du manomètre

150 PRESSURE ADJUSTMENT P

Figure 11 - Réglage de la pression de la pompe

P

Gicleur

1. Déposer le couvercle (voir

page 10).

2. Déposer le ventilateur

(voir page 15).

3. Détacher le fil de la

bougie.

4. Retirer la bougie du

brûleur à l’aide d’une clé

plate de 13/16 in.

5. Desserrer l’écrou évasé à

l’aide d’une clé plate de

3/4 in. Pousser le tube

d’arrivée de carburant vers

le bas.

6. Débrancher du brûleur le

flexible de la conduite

d’air.

7. Enlever les trois vis à

l’aide d’une clé à douille

de 5/16 in. et enlever le

brûleur de la chambre de

combustion.

12

Chambre de

combustion

Vis

Flexible de

conduite d’air

Brûleur

Écrou évasé

Tube d’arrivée du

carburant

Figure 12 - Dépose du brûleur

Fil de

bougie

Bougie

101487

Page 33

8. Placer le brûleur dans un

étau et le serrer

légèrement.

9. Enlever avec précaution le

gicleur du brûleur à l’aide

d’une clé à pipe de 5/8 in.

(voir figure 13).

10.Souffler de l’air comprimé

par l’avant du gicleur pour

en déloger toute saleté.

11.Vérifier le bon état du

joint d’étanchéité du

gicleur.

12.Remettre le gicleur dans le

brûleur et le serrer

fermement (9,1 à 12,4 Nm

[80 à 100 lb.-in.]).

13.Remonter le brûleur sur la

chambre de combustion.

14.Poser la bougie dans le

brûleur.

15.Rebrancher le fil à la

bougie.

16.Rebrancher le tube

d’arrivée du carburant et le

flexible de la conduite

d’air au brûleur. Serrer

l’écrou évasé jusqu’à ce

qu’il touche le tube

d’arrivée du carburant et le

raccord. Le serrer d’un

quart de tour

supplémentaire avec la clé

plate de 3/4 in. (11,3 à

14,7 Nm [100 à 130 lb.in.]).

17.Remonter le ventilateur

(voir page 15).

18.Remonter la grille de

protection du ventilateur et

le couvercle.

Avant

du

gicleur

Joint

d’étanchéité

du gicleur

Gicleur

Brûleur

Figure 13 - Dépose du gicleur

101487

13

Page 34

Rotor de la pompe

(Procédure en cas de grippage)

1. Déposer le couvercle (voir

page 10).

2. Retirer les vis du

cache-filtre à l’aide d’une

clé à douille de 5/16 in.

3. Déposer le cache-filtre et

les filtres à air.

4. Retirer les vis de la plaque

de la pompe à l’aide d’une

clé à douille de 5/16 in.

5. Déposer la plaque de la

pompe.

6. Enlever rotor, pièce

encastrée et pales.

7. Vérifier s’il y a des corps

étrangers dans la pompe.

S’il y en a, les chasser à

l’air comprimé.

8. Installer la pièce encastrée

et le rotor.

9. Vérifier le dégagement du

rotor. Si nécessaire, le

régler de 0,076 à 0,101

mm (.003 à .004 in.) (voir

figure 15).

Note :

Faire faire un tour

complet au moteur pour

s’assurer que l’écart à

l’endroit le plus serré est de

0,076 à 0,101 mm (.003 à

.004 in.). Refaire le réglage si

nécessaire.

10.Remonter pales, plaque de

pompe, filtres à air et

cache-filtre.

11.Remonter la grille de

protection et le couvercle.

12.Régler la pression de la

pompe (voir page 12).

Pale

Pièce

encastrée

Rotor

Filtre de

sortie d’air

Figure 14 - Emplacement du rotor

Vis de réglage

de l’écart

Pale

Vis de

réglage

de l’écart

Figure 15 - Emplacement des vis de réglage de l’écart

Plaque de

pompe

Filtre

d’entrée

d’air

Grille de

protection du

ventilateur (non

illustrée)

Écart de 0,076 à

0,101 mm (.003 à

.004 in.) mesuré

avec une jauge

d’épaisseur

Rotor

Cache-filtre

Note :

Si le rotor est toujours

grippé, procéder comme suit.

13.Effectuer les opérations 1

à 6 ci-dessus.

14

Papier de

verre

Figure 16 - Ponçage du rotor

101487

Page 35

14.Placer une feuille de

papier de verre fin (600)

sur une surface plate.

Poncer légèrement le rotor

sur la feuille d’un

mouvement en forme de

« 8 » (voir figure 16).

Répéter quatre fois.

15.Remonter la pièce

encastrée et le rotor.

16.Effectuer les opérations 10

à 12 (voir page 14).

Ventilateur

IMPORTANT :

ventilateur de l’arbre du

moteur avant de retirer ce

dernier de l’appareil. Le poids

du moteur sur le ventilateur

peut en fausser les pales.

1. Déposer le couvercle (voir

page 10).

2. Utiliser une clé coudée de

1/8 in. pour desserrer la

vis d’arrêt qui maintient le

ventilateur sur l’arbre du

moteur.

3. Retirer le ventilateur en le

faisant glisser sur l’arbre

du moteur.

4. Nettoyer le ventilateur

avec un chiffon propre

préalablement mouillé

avec du kérosène ou du

diluant.

5. Sécher complètement le

ventilateur.

6. Replacer le ventilateur sur

l’arbre du moteur. Placer

le moyeu du ventilateur au

ras de l’extrémité de

l’arbre du moteur (voir

figure 18).

7. Positionner la vis d’arrêt

sur le méplat de l’arbre. La

serrer fermement (de 4,5 à

5,6 Nm/40 à 50 in-lb).

8. Remonter la grille de

protection du ventilateur et

le couvercle.

101487

Retirer le

Ventilateur

Vis d’arrêt

Arbre du

moteur

Figure 17 - Emplacement du ventilateur,

de l’arbre du moteur et de la vis d’arrêt

Ventilateur

Au

ras

Arbre du

moteur

Vis d’arrêt

Figure 18 - Coupe du ventilateur

15

Page 36

VUE ÉCLATÉE

8-1

8-2

8-3

8-4

8-5

8-6

Ensemble brûleur

22-1

22-18

22-17

22-16

22-2

22-15

8-7

22-3

22-4

22-14

22-5

8-8

13

22-6

63

32

17

2

31

63

22-7

1

3

4

5

8

7

14

10

11

16

12

9

56

63

57

58

9

39

59

53

38

15

20

19

18

21

39

22

9

30

25

26

61

26

6

52

27

23

24

51

28

34

33

63

9

33

64

63

32

29

63

62

42

43

35

36

65

37

55

9

40

54

46

47

45

41

49

60

50

63

9

22-8

9

48

22-9

22-10

22-11

44

32

16

Ensemble moteur et pompe

22-13

22-12

101487

Page 37

LISTE DES

PIÈCES

Cette liste comprend les pièces de l’appareil de chauffage qui peuvent être

remplacées. Lors de la commande de pièces détachées, veiller à inclure le

numéro de modèle et les numéros de série corrects (pris sur la plaque

signalétique), puis le numéro de pièce et la désignation de la pièce désirée.

N DE NUMÉRO

RÉF. DE PIÈCE DÉSIGNATION QTÉ

1 098511-58 Couvercle 1

2 098068-01 Bouclier thermique 1

3 098512-02 Chambre de combustion 1

4 M16660 Support de cellule

photoélectrique 1

5 HA3019 Ensemble cellule

photoélectrique 1

6 099125-02 Planche à bornes 1

7 M10908-2 Vis n 6-32 x 3/8 in. 2

8 ** Ensemble brûleur 1

8-1 M18022 Gicleur 1

8-2 M10659-1 Rondelle d’étanchéité de gicleur 2

8-3 M10809-1 Ressort d’étanchéité de gicleur 1

8-4 M8882 Manchon d’étanchéité

de gicleur 1

8-5 M50924-01 Corps de brûleur 1

8-6 M50820-02 Raccord à griffes 1

8-7 079685-01 Connecteur mâle 1

8-8 M10962-2 Bougie 1

9 M11084-27 Vis n 10-16 x 1/2 in. 19

10 M19630 Filtre à carburant 1

11 M16790-12 Tube de carburant 1

12 M50660-05 Écrou évasé à 45 1

13 100647-01 Vis n 10-16 x 1/2 in. 8

14 M16871 Bande de retenue 1

15 M17920 Ventilateur 1

16 M50814-03 Conduite d’air 1

17 M50873-01 Attache 9

18 NPC-4C Écrou hexagonal, 1/4-20 2

19 WLM-4 Rondelle de blocage, 1/4 in. 2

20 M16661-1 Attache de moteur 4

21 M51043-01 Boulon 1/4-20 x 1 1/2 in. 2

22 ** Ensemble moteur et pompe 1

22-1 098784-03 Moteur (230 V/50 Hz) 1

22-2 079975-04 Corps de pompe 1

22-3 FHPF3-7C Vis n 10-32 x 7/8 in. 2

22-4 M22009 Pièce encastrée 1

22-5 M22456-3 Rotor 1

22-6 M50545 Couvercle de pompe 1

22-7 M12179 Filtre d’entrée 1

22-8 M16545 Cache-filtre 1

22-9 M8940 Bille en acier (1/4 in. de diam.) 1

22-10 M10993-1 Ressort de décharge

de pression 1

22-11 M27694 Vis de réglage 1

22-12 M22997 Bouchon 1

22-13 M12461-31 Vis n 10-32 x 1 in. 4

22-14 M12244-1 Filtre de sortie 1

22-15 M12461-34 Vis n 10-32 x 1 1/2 in. 6

22-16 M11637 Filtre à peluche 1

22-17 M50820-02 Raccord à griffes 1

22-18 M8643-3 Pale 4

23 M12651-1 Bride de condensateur 1

24 M12650-3 Condensateur 1

25 M12828 Support de boîtier 1

26 M30865-04 Bague fermée/ouverte 2

27 M16645 Support de moteur 1

N DE NUMÉRO

RÉF. DE PIÈCE DÉSIGNATION QTÉ

28 M51357-01 Condensateur (marche) 1

29 M15823-39 Vis n 8-18 x 1/2 in. 1

30 M16810-06AB Boîtier 1

31 M11271-8 Attache 9

32 M11084-29 Vis n 10-16 x 3/4 in. 8

33 M50104-03 Bague courte 2

34 097630-02 Détecteur d’extinction

de flamme 1

35 M12461-13 Vis n 8-32 x 1/4 in. 2

36 097060-01 Ferrure de montage 1

37 M12462-13 Relais - démarrage du moteur 1

38 099607-02 Ferrure de planche à bornes 1

39 099157-01 Rivet 2

40 M9900-183 Ensemble de fil (noir 6 in.) 1

41 M9900-184 Ensemble de fil (noir 15 in.) 1

42 M50400 Bague anti-tension 1

43 079673-03 Cordon électrique 1

44 098557-07 Allumeur électronique 1

45 M10990-3 Bague en caoutchouc 1

46 098513-08 Réservoir de carburant 1

47 097702-01 Bouchon de réservoir

de carburant 1

48 M27417 Bouchon de vidange 1

49 079010-14 Ensemble de fil (rouge 8 7/8 in.) 1

50 M9900-77 Ensemble de fil (noir 15 in.) 1

51 M16841-57 Ensemble de fil (rouge 8 1/2 in.) 1

52 M30865-02 Bague ouverte/fermée 1

53 099125-08 Planche à bornes 1

54 079010-23 Ensemble de fil (bleu 9 in.) 1

55 079010-24 Ensemble de fil (marron 12 in.) 1

56 M12461-27 Vis n 10-32 x 1/2 in. 1

57 101488-01 Collier de conduite d’air 1

58 WLM-3 Rondelle de blocage n 10 1

59 NPF-3C Écrou hexagonal, 10-32 1

60 101578-01 Matériau de gainage 1

61 078918-01 Fiche de planche à bornes 1

62 RF3-5B Vis n 10-32 x 5/8 in. 1

63 WLE-3 Rondelle de blocage n 10 23

64 NPF-3B Écrou hexagonal, 10-32 2

65 099177-01 Écrou hexagonal, 3/8x27 1

PIÈCES DISPONIBLES - NON ILLUSTRÉES

101639-01 Autrocollant d’avertissement 1

098892-02 Support de grille de protection

de ventilateur 1

M50140 Grille de protection

de ventilateur 1

097650-01 Autocollant de marque déposée 1

HA2210 Crépine de goulotte de

remplissage 1

098235-25 Autocollant d’informations

générales (Anglais et français) 1

098235-26 Autocollant d’informations

générales (Allemand et

néerlandais) 1

**N’est pas disponible monté, commander les pièces séparément.

101487

17

Page 38

ROUES ET

GUIDONS

N NUMÉRO

RÉF DE PIÈCE DÉSIGNATION QTÉ

1 HA2205 Guidons 2

2 M12345-33 Vis n 110-24 x 1 3/4 in. 8

3 M12831-3 Berceau 1

4 NTC-3C Écrou hexagonal n 10-24 8

5 097896-01 Roue 2

6 M28526 Écrou borgne 2

7 M16801-2 Essieu 1

1

2

ACCESSOIRE

Se procurer les accessoires

auprès du concessionnaire

18

local.

3

5

6

4

7

JEU DE MANOMÈTRE - HA1180

Pour tous les modèles. Outil

conçu pour vérifier la pression de

la pompe.

101487

Page 39

SPÉCIFICA TIONS

SCHÉMA

Rendement nominal de sortie (kW/BTU/Hr) 44 kW/150 000

Carburant N’employer que du

kérosène ou du fioul n 1

Contenance du réservoir de carburant (l/U.S. Gal.) 51,09/13.5

Consommation de carburant (l/h/Gal./h) 4,16/1.10

Électricité requise 230 V/50 Hz

Intensité (A) (Fonctionnement normal) 1,5

3

Débit d’air chaud (m

/min ; ft3/min) 17/600

Régime moteur (tr/min) 2850

230V/50Hz

ÉLECTRIQUE

Vert/

Jaune

Moteur

Noir

Orange

Noir

Allumeur

Rouge

Noir

Condesateur

de démarrage

Condensateur

de marche

S ou 2

Noir

Blanc

Bougie

Rouge

Relais de

démarrage

du moteur

L ou 1

Bleur

Planche

à bornes

M ou 3

Bleur

Rouge

Vert/

Jaune

Planche

à bornes

Blanc

Rouge

Marron

Cellule

Photoélectrique

Bleur

Marron

Blanc

Bleur

B

Détecteur

d'extinction

de flamme

R

Bouton de

réarmement

101487

19

Page 40

GARANTIE ET RÉPARATIONS

CERTIFICAT RELATIF AU MATÉRIEL GÉNÉRAL -

GARANTIE LIMITÉE DE 90 JOURS

Les produits neufs vendus par la société DESA International sont garantis pièces et main-d’oeuvre contre les vices de

matériaux et de fabrication, pour une période de quatre-vingtdix jours à compter de la date de livraison, et ce, au premier

utilisateur et sous réserve des conditions suivantes :

Les obligations et la responsabilité de la société DESA

International en vertu de la présente garantie se limitent

expressément à la réparation ou au remplacement, à la

discrétion de la société, de toute pièce qui lui semblerait, après

inspection, défectueuse au moment de l’expédition de l’usine en

raison d’un vice de matériau et de fabrication. La ou lesdites

pièces seront remplacées gratuitement et mises à la disposition

de l’utilisateur dans les locaux de tout centre d’entretien dûment

autorisé par l’usine de fabrication, ou à l’usine même, et ce

durant les heures normales d’ouverture. La présente garantie

ne couvre pas les pièces et accessoires non fabriqués par

DESA International et couverts par la garantie de leur propre

fabricant ; elle ne couvre pas non plus l’entretien habituel (par

exemple, les réglages de la pression) ni les pièces d’entretien

habituelles (telles que les filtres et les bougies). Les pièces de

remplacement ou de réparation posées sur le produit couvert

par la présente garantie ne seront elles-mêmes couvertes que

pour la durée restante de la garantie, tout comme si elles avaient

été des pièces d’origine dudit produit. AUCUNE AUTRE

GARANTIE EXPRESSE N’EST ÉMISE PAR LA SOCIÉTÉ

DESA INTERNATIONAL. DANS LES LIMITES PRESCRITES

PAR LA LOI, DESA INTERNATIONAL N’ÉMET AUCUNE

GARANTIE IMPLICITE, NI AUCUNE GARANTIE DE QUALITÉ

LOYALE ET MARCHANDE OU DE CONFORMITÉ À

L’UTILISATION PRÉVUE. QUOI QU’IL EN SOIT, LES

GARANTIES IMPLICITES, Y COMPRIS LES GARANTIES DE

QUALITÉ LOYALE ET MARCHANDE OU DE CONFORMITÉ

À L’UTILISATION PRÉVUE, SONT LIMITÉES À LA DURÉE

DE LA PRÉSENTE GARANTIE EXPRESSE.

Tous les frais de transport et d’installation, les droits, les

impôts ou tout autre frais de quelque nature que ce soit seront

à la charge de l’utilisateur. La société DESA International ne

saurait être responsable, en vertu de la présente garantie

limitée, de quelque dommage direct, indirect ou accessoire

que ce soit, ou de retards. Les produits ou pièces faisant l’objet

d’une demande en vertu de la présente garantie devront être

renvoyés à l’usine par l’utilisateur en port payé, à la demande

de la société DESA International. La présente garantie sera

réputée nulle et de nul effet en cas d’usage abusif, y compris

en cas d’utilisation après la découverte des pièces

défectueuses ou usées, d’utilisation au-delà des capacités du

produit, de substitution de pièces non approuvées par DESA

International, ou encore en cas de modification ou de

réparation, de quelque nature que ce soit, effectuée par un tiers

d’une façon telle que, selon DESA International, le produit en

est affecté matériellement et défavorablement.

LES EMPLOYÉS OU MANDATAIRES NE SONT EN

AUCUN CAS AUTORISÉS À MODIFIER EN QUOI QUE CE

SOIT LA PRÉSENTE GARANTIE, NI À ACCORDER UNE

AUTRE GARANTIE DE QUELQUE NATURE QUE CE SOIT,

SANS L’AUTORISATION PRÉALABLE ÉCRITE ET SIGNÉE

PAR UN MEMBRE DU BUREAU DE LA SOCIÉTÉ DESA

INTERNATIONAL, À SON SIÈGE SOCIAL.

Printed in U.S.A.

20

SERVICES FOURNIS AU TITRE DE LA GARANTIE

Toujours indiquer le modèle et les numéros de série dans la

correspondance avec l’usine.

Nous nous réservons le droit de modifier à tout moment les