Page 1

R

PORTABLE

FORCED

AIR HEATERS

OWNER’S MANUAL

Heater Sizes: 35,000 70,000 100,000 150,000 Btu/Hr

Models: B35CEA, B70CEA, B100CEA, and B150CEA

IMPORTANT: Read and understand this manual before assembling, starting or

servicing heater. Improper use of heater can cause serious injury. Keep this manual

for future reference.

Page 2

R

PORTABLE FORCED AIR HEATERS

SAFETY

INFORMATION

WARNINGS

IMPORTANT: Read this Owner’s

Manual carefully and completely

before trying to assemble, operate, or service this heater. Improper use of this heater can

cause serious injury or death from

burns, fire, explosion, electrical

shock, and carbon monoxide

poisoning.

DANGER: Carbon monoxide

poisoning may lead to death!

Carbon Monoxide Poisoning: Early

signs of carbon monoxide poisoning resemble the flu, with headaches, dizziness,

and/or nausea. If you have these signs, the

heater may not be working properly. Get

fresh air at once! Have heater serviced.

Some people are more affected by carbon

monoxide than others. These include pregnant women, persons with heart or lung

disease or anemia, those under the influence

of alcohol, and those at high altitudes.

Make certain you read and understand all

Warnings. Keep this manual for reference.

It is your guide to safe and proper operation

of this heater.

• Use only kerosene or No. 1 fuel oil to

avoid risk of fire or explosion. Never use

gasoline, naphtha, paint thinners, alcohol, or other highly flammable fuels.

• Fueling

a) Personnel involved with fueling shall

be qualified and thoroughly familiar

with the manufacturer's instructions

and applicable regulations regarding the safe fueling of heating units.

b)Only the type of fuel specified on the

heater's data plate shall be used.

c) All flame, including the pilot light, if

any, shall be extinguished and the heater

allowed to cool, prior to fueling.

d)During fueling, all fuel lines and fuel-

line connections shall be inspected for

leaks. Any leaks shall be repaired prior

to returning the heater to service.

e) At no time shall more than one day's

supply of heater fuel be stored inside

a building in the vicinity of the heater.

Bulk fuel storage shall be outside the

structure.

f) All fuel storage shall be located a

minimum of 762cm (25 feet) from

heaters, torches, welding equipment,

and similar sources of ignition (exception: the fuel reservoir integral

with the heater unit).

g)Whenever possible, fuel storage shall

be confined to areas where floor penetrations do not permit fuel to drip

onto or be ignited by a fire at lower

elevation.

h)Fuel storage shall be in accordance

with the authority having jurisdiction.

• Never use heater where gasoline, paint

thinner, or other highly flammable vapors are present.

• Follow all local ordinances and codes

when using heater.

• Heaters used in the vicinity of tarpaulins, canvas, or similar enclosure materials shall be located a safe distance

from such materials. The recommended

minimum safe distance is 304.8cm (10

feet). It is further recommended that

these enclosure materials be of a fire

retardant nature. These enclosure materials shall be securely fastened to prevent them from igniting or from upsetting the heater due to wind action.

• Use only in well-vented areas. Before

using heater, provide at least a 2800

square cm (three-square-foot) opening

of fresh, outside air for each 100,000

Btu/Hr of rating.

• Use only in places free of flammable

vapors or high dust content.

• Use only the electrical voltage and frequency specified on model plate.

• Use only a three-prong, grounded extension cord.

• Minimum heater clearances from combustibles:

Outlet: 250 cm (8 Ft.)

Sides, Top, and Rear: 125 cm (4 Ft.)

• Locate heater on a stable and level surface if heater is hot or running or a fire

may occur.

• When moving or storing heater, keep

heater in a level position or fuel spillage may occur.

• Keep children and animals away from

heater.

• Unplug heater when not in use.

• When used with thermostat, heater may

start anytime.

• Never use heater in living or sleeping

areas.

• Never block air inlet (rear) or air outlet

(front) of heater.

• Never move, handle, refuel, or service

a hot, operating, or plugged-in heater.

• Never attach duct work to front or rear

of heater. Using duct work could reduce

the necessary air flow of heater. Heater

would produce excessive carbon monoxide.

2

104468

Page 3

OWNER’S MANUAL

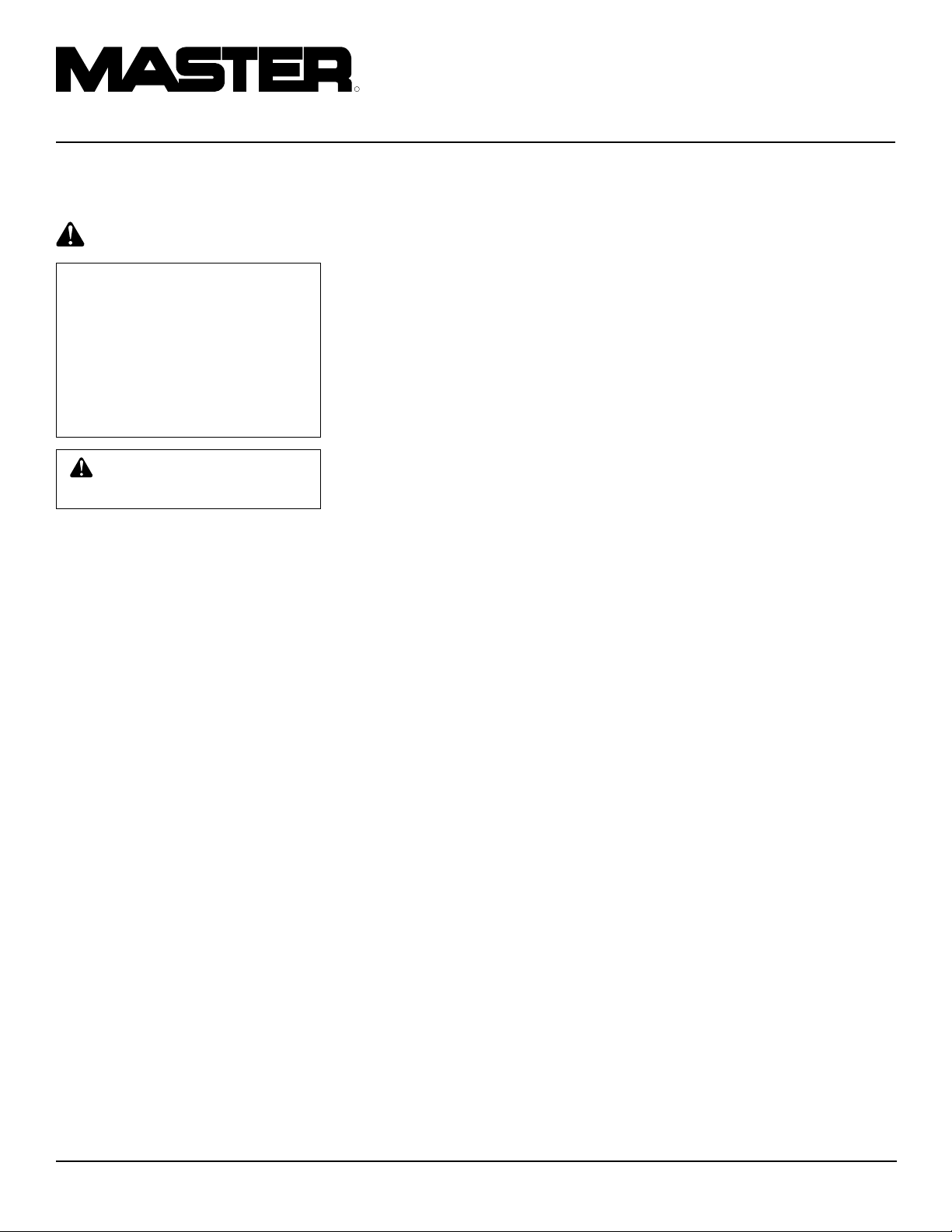

PRODUCT

IDENTIFICATION

Hot Air Outlet

Upper Shell

Lower Shell

Fuel Tank

Side Cover

Flame-Out

Control Reset

Button

Figure 1 - 35/70,000 Btu/Hr Models

Hot Air

Outlet

Power

Cord

Handle

Upper Shell

UNPACKING

1. Remove all packing items applied to

heater for shipment.

2. Remove all items from carton.

3. Check items for any shipping damage.

If heater is damaged, promptly inform

dealer where you bought heater.

Fan Guard

Air Filter

End Cover

Fuel Cap

Lower

Shell

Fuel Cap

Side Cover

Figure 2 - 100/150,000 Btu/Hr Models

Flame-Out

Control Reset Button

Fan Guard

Fuel Tank

Power Cord

104468

3

Page 4

R

PORTABLE FORCED AIR HEATERS

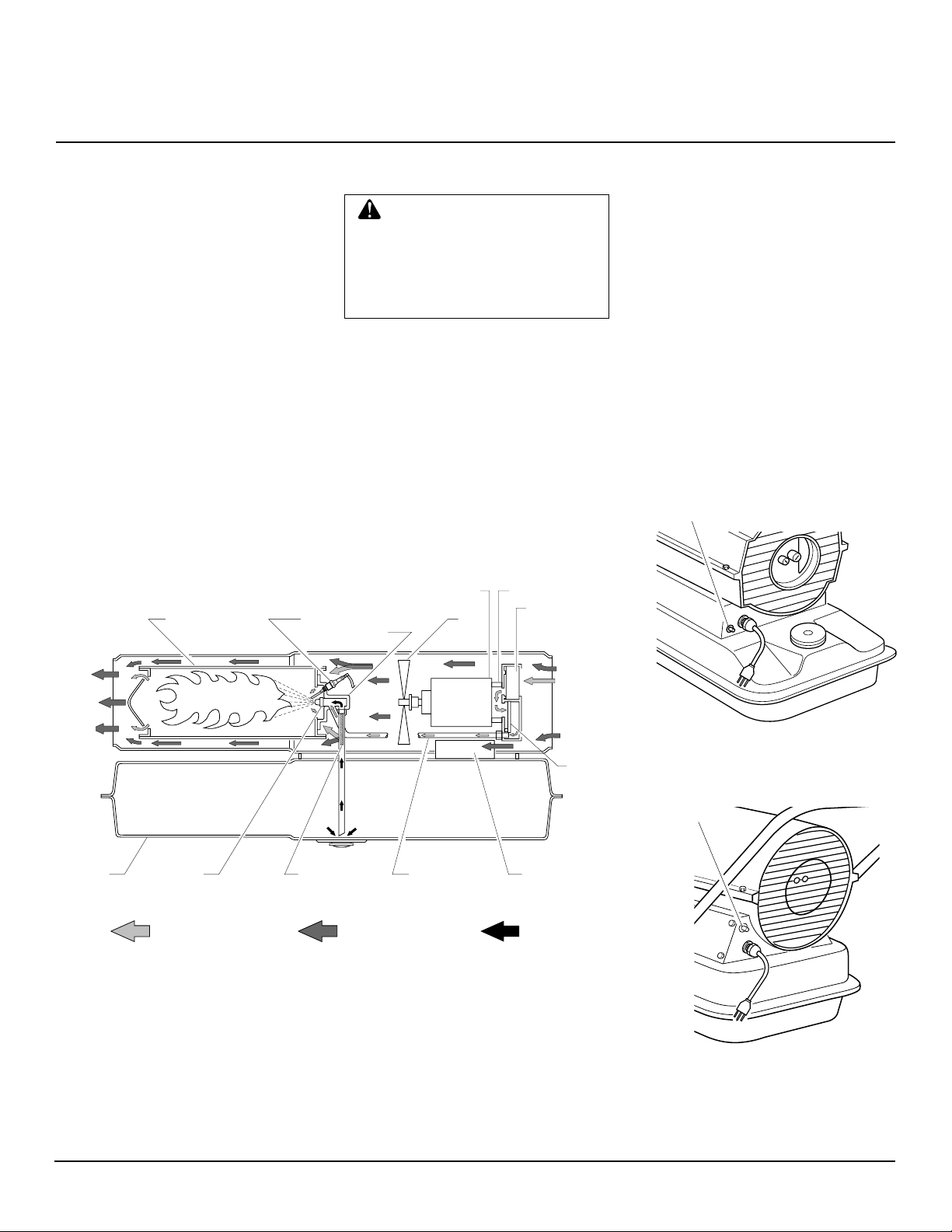

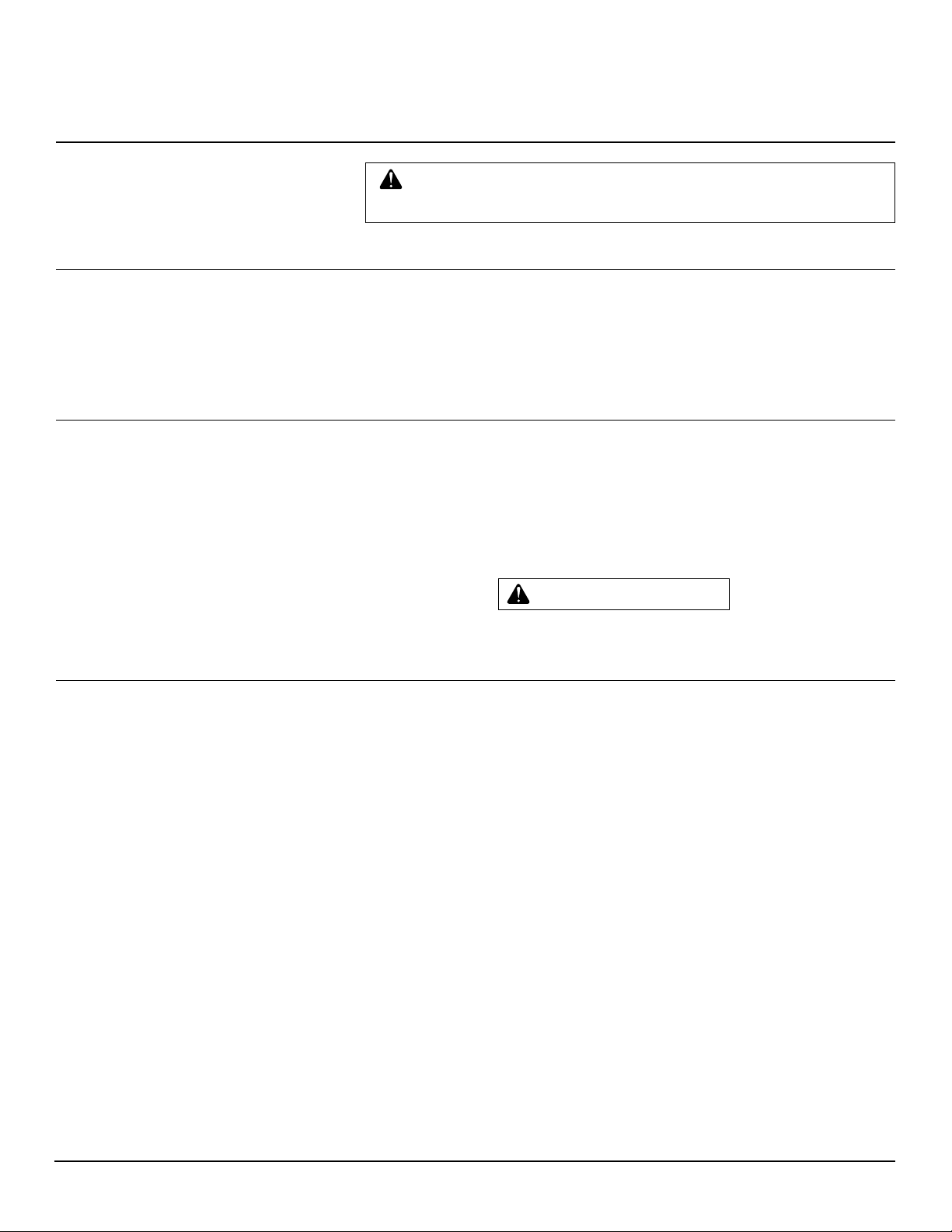

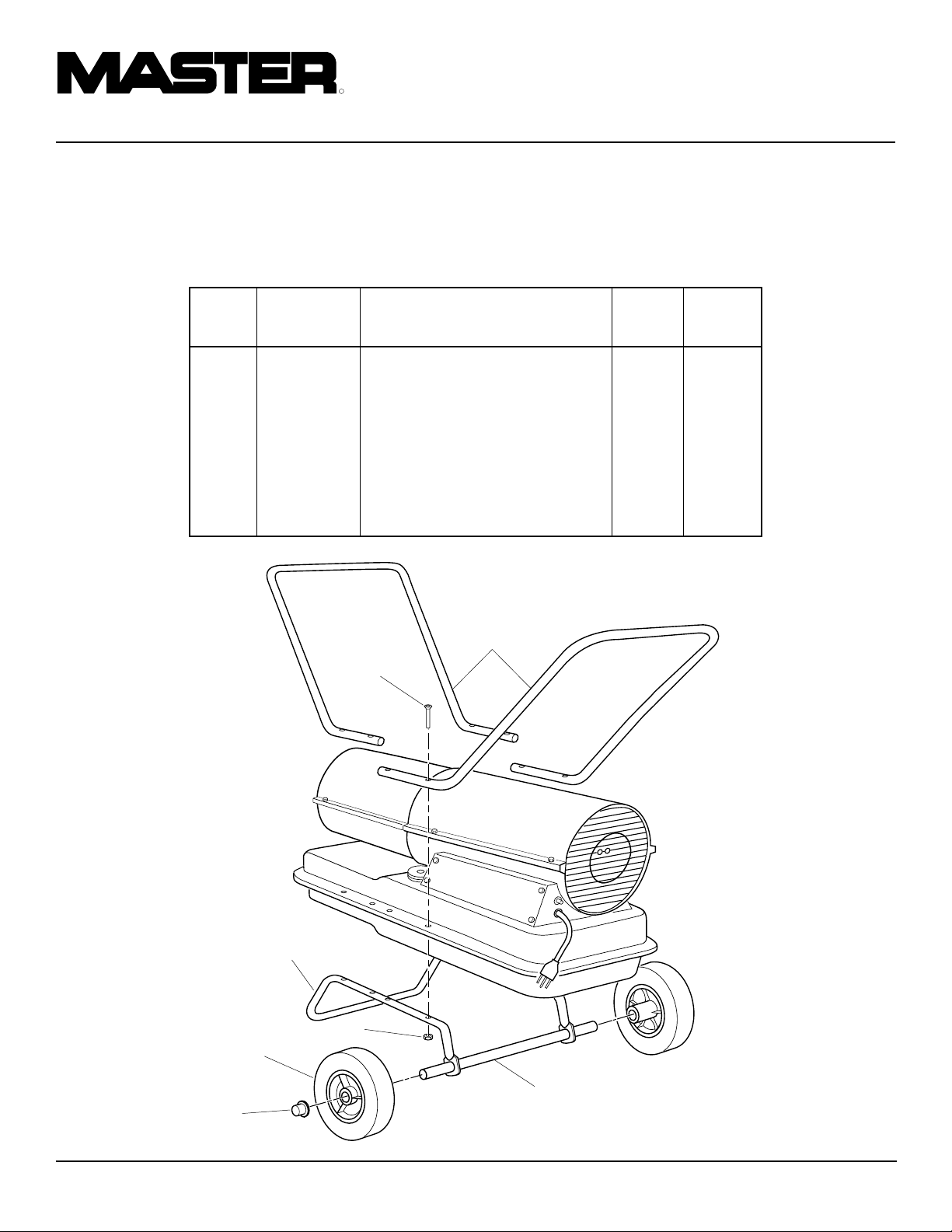

ASSEMBLY

(FOR 100,000 AND 150,000

BTU/HR MODELS ONLY)

These models are furnished with wheels and

handles. Wheels, handles, and the mounting

hardware are found in the shipping carton.

Tools Needed

• Medium Phillips Screwdriver

• 3/8" Open or Adjustable Wrench

• Hammer

1. Slide axle through wheel support

frame. Install wheels on axle.

IMPORTANT:

wheels, point extended hub of wheels

toward wheel support frame (see Figure 3).

When installing

2. Place cap nuts on axle ends. Gently tap

with hammer to secure.

3. Place heater on wheel support frame.

Make sure air inlet end (rear) of heater

is over wheels. Line up holes on fuel

tank flange with holes on wheel support frame.

4. Place front handle and rear handle on

top of fuel tank flange. Insert screws

through handles, fuel tank flange, and

wheel support frame. Attach nut finger

tight after each screw is inserted.

5. After all screws are inserted, tighten

nuts firmly.

Front Handle

FUELS

WARNING: Use only kerosene

or No. 1 fuel oil to avoid risk of fire

or explosion. Never use gasoline, naphtha, paint thinners, alcohol or other highly flammable

fuels.

Do not use heavy fuels such as No. 2 fuel oil

or No. 2 Diesel. Using heavy fuels will

result in:

• clogged fuel filter and nozzle

• carbon build up on spark plug

• use of non-toxic anti-icer in fuel during

very cold weather

IMPORTANT:

container. Be sure storage container is clean.

Foreign matter such as rust, dirt, or water

will cause the flame-out control to shut

down heater. Foreign matter may also require you to clean fuel system often.

Use a KEROSENE ONLY

Hot Air

Outlet

Fuel Tank

Flange

Wheel

Support

Frame

Wheel

Cap Nut

Screw

Nut

Axle

Extended

Hub

Rear

Handle

Air

Inlet

VENTILATION

WARNING: Follow the minimum fresh, outside air ventilation requirements. If proper fresh,

outside air ventilation is not provided, carbon monoxide poisoning can occur. Provide proper

fresh, outside air ventilation before running heater.

Provide a fresh air opening of at least 2800

square cm (three square feet) for each

100,000 Btu/Hr rating. Provide extra fresh

air if more heaters are being used.

Example:

quires one of the following:

• a 4.88 m (16 foot) wide two-car garage

door raised 8.59 cm (3.38 inches)

• a 2.75 m (9 foot) wide single-car garage

door raised 15.24 cm (six inches)

• two, 76.2 cm (thirty-inch) windows

raised 30.48 cm (twelve inches)

A 150,000 Btu/Hr heater re-

Figure 3 - Wheel and Handle Assembly, 100/150,000 Btu/Hr Models Only

4

104468

Page 5

OWNER’S MANUAL

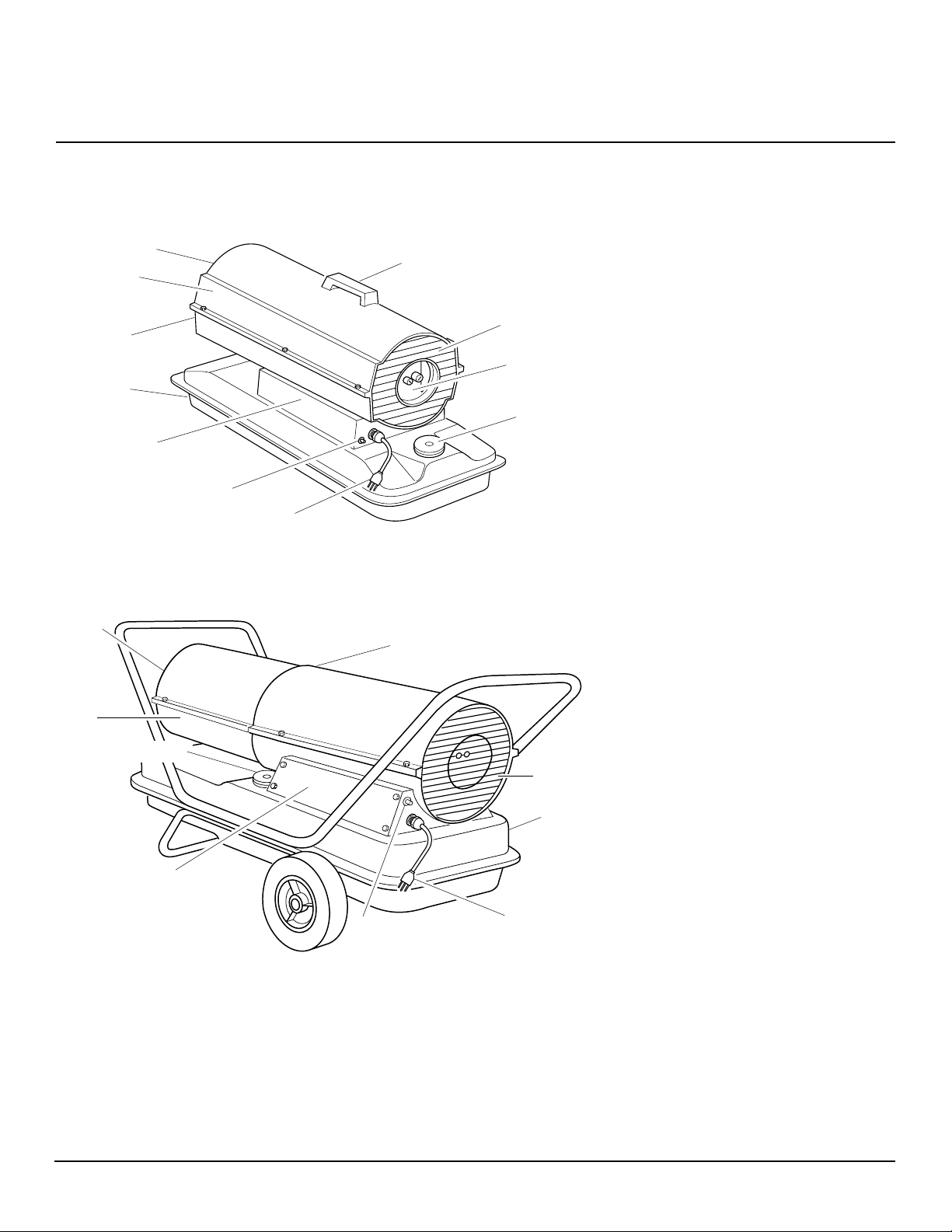

THEORY OF

OPERATION

The Fuel System: The air pump forces

air through the air line. The air is then

pushed through the burner head nozzle. This

air causes fuel to lift from the tank. A fine

mist of fuel is sprayed into the combustion

chamber.

The Air System: The motor turns the fan.

The fan pushes air into and around the

combustion chamber. This air is heated and

provides a stream of clean, hot air.

The Ignition System: The electronic

ignitor sends voltage to the spark plug. The

spark plug ignites the fuel and air mixture.

The Flame-Out Control System: This

system causes the heater to shut down if the

flame goes out.

Combustion

Chamber

Spark

Plug

OPERATION

WARNING: Review and understand the warnings in the

Safety Information Section. They

are needed to safely operate this

heater. Follow all local codes

when using this heater.

To Start Heater

1. Follow all ventilation and safety information.

2. Fill fuel tank with kerosene or No. 1

fuel oil.

3. Attach fuel cap.

4. Plug power cord of heater into standard

230 volt/50 hertz, grounded (earthed)

outlet. Use an extension cord if needed.

Use only a three-prong, grounded

(earthed) extension cord.

Air Pump

Intake

Air

Filter

Burner

Head

Motor

Fan

Extension Cord Wire Size

Requirements

Up to 30.5 meters (100 feet) long, use 1.0

2

mm

(16 AWG) conductor 30.6 to 61 meters

(101 to 200 feet) long, use 1.5 mm2 (14

AWG) conductor

Heater will start when power cord is plugged

into outlet. If not, push in flame-out control

reset button (see Figures 5 and 6).

To Stop Heater

1. Unplug power cord from outlet.

To Restart Heater

1. Wait 2 minutes after stopping heater.

2. Repeat steps under To Start Heater.

Flame-Out Control

Reset Button

Clean

Heated

Air Out

Fuel

Tank

Figure 4 - Cross Section Operational View

Nozzle

Air For Fuel

System

Fuel

Filter

Air line

To Burner

Air For Combustion

And Heating

Cool

Air

In

Output

Air

Filter

Electronic

Ignitor

Fuel

Figure 5 - Flame-Out Control Reset

Button, 35/70,000 Btu/Hr

Flame-Out Control

Reset Button

Figure 6 - Flame-Out Control Reset

Button, 100/150,000 Btu/Hr

104468

5

Page 6

R

PORTABLE FORCED AIR HEATERS

STORING,

TRANSPORTING,

OR SHIPPING

Note:

If shipping, transport companies re-

quire fuel tanks to be empty.

1. Drain fuel tank.

Note:

Some models have drain plug on

underside of fuel tank. If so, remove

drain plug to drain all fuel. If heater

does not have drain plug, drain fuel

through fuel cap opening. Be sure all

fuel is removed.

2. Replace drain plug if provided.

3. If any debris is noted in old fuel, add 1

or 2 quarts of clean kerosene to tank,

stir, and drain again. This will prevent

excess debris from clogging filters during future use.

4. Replace fuel cap or drain plug. Properly dispose of old and dirty fuel. Check

with local automotive service stations

that recycle oil.

5. If storing, store heater in dry place.

Make sure storage place is free of dust

and corrosive fumes.

IMPORTANT:

summer months for use during next heating

season. Using old fuel could damage heater.

Do not store kerosene over

PREVENTATIVE

MAINTENANCE

SCHEDULE

Item

Fuel tank

Air output and

lint filters

Air intake filter

Fuel filter

Spark plug

Fan blades

Motor

How Often

Flush every 150-200 hours of operation or as needed.

Replace every 500 hours of, operation or once a year.

Wash and dry with soap and water

every 500 hours of operation or as

needed.

Clean twice a heating season or as

needed.

Clean and regap every 600 hours

operation or replace as needed.

Clean every season or as needed.

Not required/permanently lubricated

WARNING: Never service heater while

it is plugged in, operating, or hot. Severe

burns and electrical shock can occur.

How To

See Storing, Transporting or

Shipping,column 1

See Air Output, Air Intake,

and Lint Filters, page 10.

See Air Output, Air Intake,

and Lint Filters, page 10.

See Fuel Filter, page 8.

See Spark Plug, page 9.

See Fan, page 13.

6

104468

Page 7

OWNER’S MANUAL

TROUBLESHOOTING

OBSERVED FAULT

Heater ignites, but flame-out control shuts

off heater after a short period of time.

Heater will not ignite, but motor runs for a

short period of time.

WARNING: Never service heater while it is plugged in, operating,

or hot. Severe burns and electrical shock can occur.

POSSIBLE CAUSE

1. Wrong pump pressure

2. Dirty air output, air intake, and lint filters

3. Dirty fuel filter

4. Dirt in nozzle

5. Dirty photocell lens

6. Bad flame-out control

1. Wrong pump pressure

2. Carbon deposits on spark plug and/or

improper gap

3. Dirty fuel filter

4. Dirt in nozzle

5. Water in fuel tank

WARNING: High voltage!

REMEDY

1. See Pump Pressure

Adjustment, page 10.

2. See Air Output, Air Intake and Lint Filters, page 10.

3. See Fuel Filter, page 8.

4. See Nozzle, page 11.

5. Clean photocell lens.

6. Replace flame-out control.

1. See Pump Pressure Adjustment, page 10.

2. See Spark Plug, page 9.

3. See Fuel Filter, page 8.

4. See Nozzle, page 11.

5. Drain and flush fuel tank with clean

kerosene. See Storing, Transporting, or

Shipping, page 6.

Motor does not start when heater is plugged

in, fan rotates slowly or does not turn.

6. Electronic ignitor not grounded (earthed)

7. Bad electronic ignitor

1. Flame-out control not reset

2. Binding pump rotor

6. Make sure electronic ignitor mounting

is tight.

7. Replace electronic ignitor.

1. Reset flame-out control button, see Figures 5 and 6, page 5.

2. If fan is hard to turn, see Pump Rotor,

page 12.

104468

7

Page 8

R

PORTABLE FORCED AIR HEATERS

SERVICE

PROCEDURES

WARNING: Never service

heater while it is plugged in, operating, or hot. Severe burns and

electrical shock can occur.

Upper Shell Removal

1. Remove screws and lock washers along

each side of heater using 5/16" nutdriver. These screws attach upper and

lower shells together.

2. Lift upper shell off.

3. Remove fan guard.

Fuel Filter

(35/70,000 Btu/Hr Models)

1. Remove side cover screws using 5/16"

nut-driver.

2. Remove side cover.

3. Pull rubber fuel line off fuel filter neck.

4. Carefully pry bushing and fuel filter out

of fuel tank.

5. Wash fuel filter with clean fuel and replace in tank.

6. Attach rubber fuel line to fuel filter

neck.

7. Replace side cover.

Fuel Filter

(100/150,000 Btu/Hr Models)

1. Remove side cover screws using 5/16"

nut-driver.

2. Remove side cover.

3. Pull upper fuel line off fuel filter neck.

4. Carefully pry bushing, lower fuel line,

and fuel filter out of fuel tank.

5. Wash fuel filter with clean fuel and replace in tank.

6. Attach upper fuel line to fuel filter neck.

7. Replace side cover.

Upper Shell

Fan Guard

Figure 7 - Upper Shell Removal, 35/70,000

Btu/Hr Models

Fuel Filter

Side Cover

Fuel Line

Figure 9 - Fuel Filter Removal, 35/70,000 Btu/Hr Models

Fuel Filter, Bushing, and

Lower Fuel Line

Upper

Shell

Figure 8 - Upper Shell Removal, 100/

150,000 Btu/Hr Models

Fan

Guard

Upper

Fuel

Line

Side Cover

Figure 10 - Fuel Filter Removal, 100/150,000 Btu/Hr Models

8

104468

Page 9

OWNER’S MANUAL

SERVICE

PROCEDURES

Continued

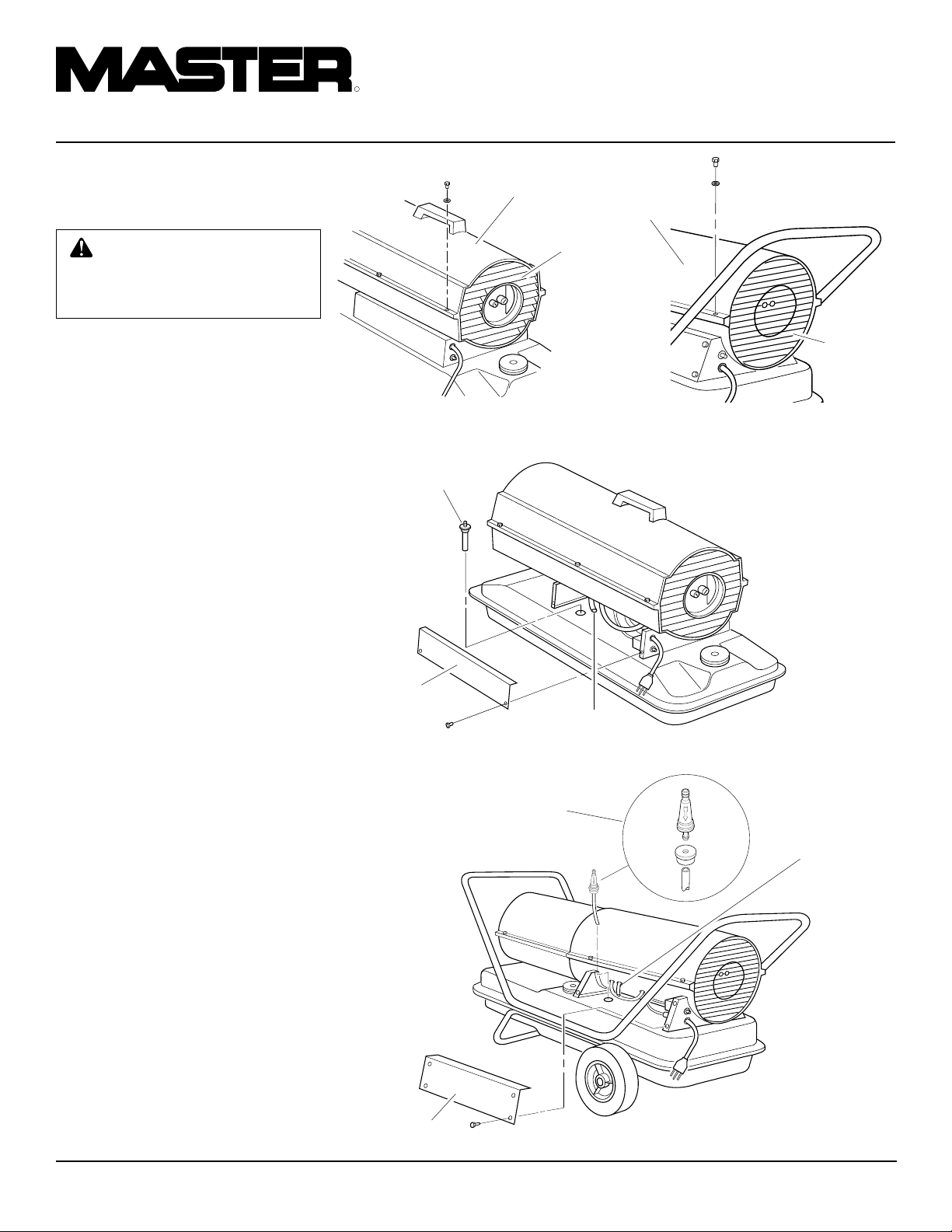

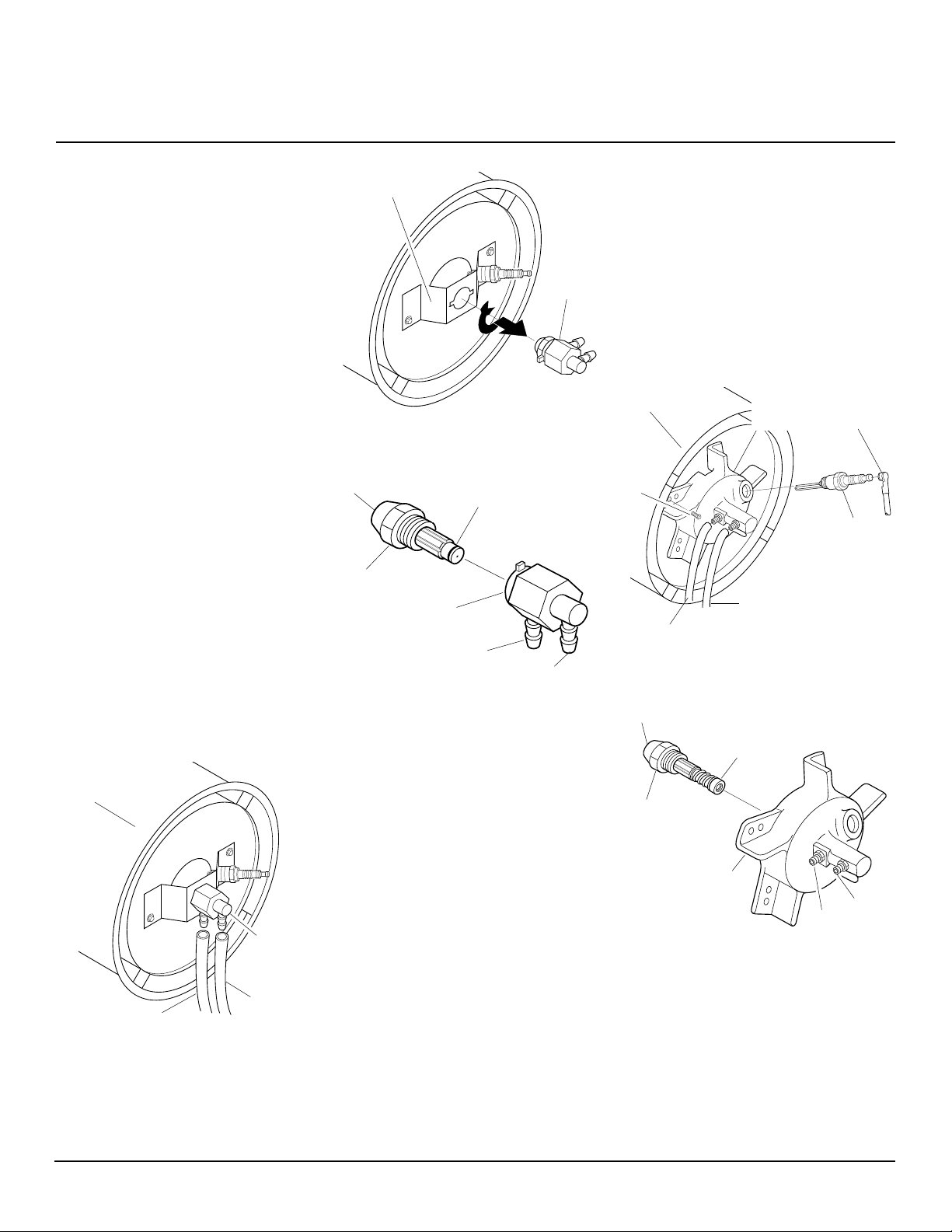

Spark Plug

(35,000 Btu/Hr Model)

1. Remove upper shell (see page 8).

2. Remove fan (see page 13).

3. Remove fuel and air line

hoses from nozzle assembly.

4. Remove spark plug wire from spark plug.

5. Remove two screws using 5/16" nutdriver and remove burner strap.

6. Place hex-body of spark plug into vise

and tighten.

7. Remove spark plug mounting nut using 11/16" open-end wrench.

8. Remove burner strap from spark plug.

9. Clean and regap spark plug electrodes

to 1.4 mm (.055") gap.

10. Replace burner strap onto spark plug.

Rotate burner strap to position spark

plug electrodes (see Figure 13).

11. Tighten spark plug with spark plug

mounting nut.

12. Release hex-body of spark plug from vise.

13. Replace burner strap onto combustion

chamber.

14. Attach spark plug wire to spark plug.

15. Attach fuel and air line hoses to nozzle

assembly.

16. Replace fan (see page 13).

17. Replace fan guard and upper shell.

Combustion

Chamber

Air Line Hose

Figure 11 - Spark Plug Removal, 35,000

Btu/Hr Model

Figure 12 - Spark Plug Gap, 35,000 Btu/Hr

Model

Burner Strap

Figure 13 - Spark Plug Rotation, 35,000

Btu/Hr Model Only

Spark Plug

Mounting Nut

Burner

Strap

Spark

Plug

Spark

Plug

Wire

Nozzle

Assembly

Fuel Line Hose

Bend Here to

Adjust Gap

1.4 mm

(.055") Gap

Spark Plug

(70/100/150,000 Btu/Hr Models)

1. Remove upper shell (see page 8).

2. Remove fan (see page 13).

3. Remove spark plug wire from spark plug.

4. Remove spark plug from burner head

using 13/16" open-end wrench.

5. Clean and regap spark plug electrodes

as follows:

70/100,000 Btu/Hr Models:

1.9 mm (.075") gap

150,000 Btu/Hr Model:

2.8 mm (.110") gap

6. Install spark plug in burner head.

7. Attach spark plug wire to spark plug.

8. Replace fan (see page 13).

9. Replace fan guard and upper shell.

Burner Head

Spark Plug Wire

Spark

Plug

Figure 14 - Spark Plug Removal, 70/100/

150,000 Btu/Hr Models

Bend Here to

Adjust Gap

Gap

Figure 15 - Spark Plug Gap, 70/100/150,000

Btu/Hr Models

104468

Continued

9

Page 10

R

PORTABLE FORCED AIR HEATERS

SERVICE

PROCEDURES

Continued

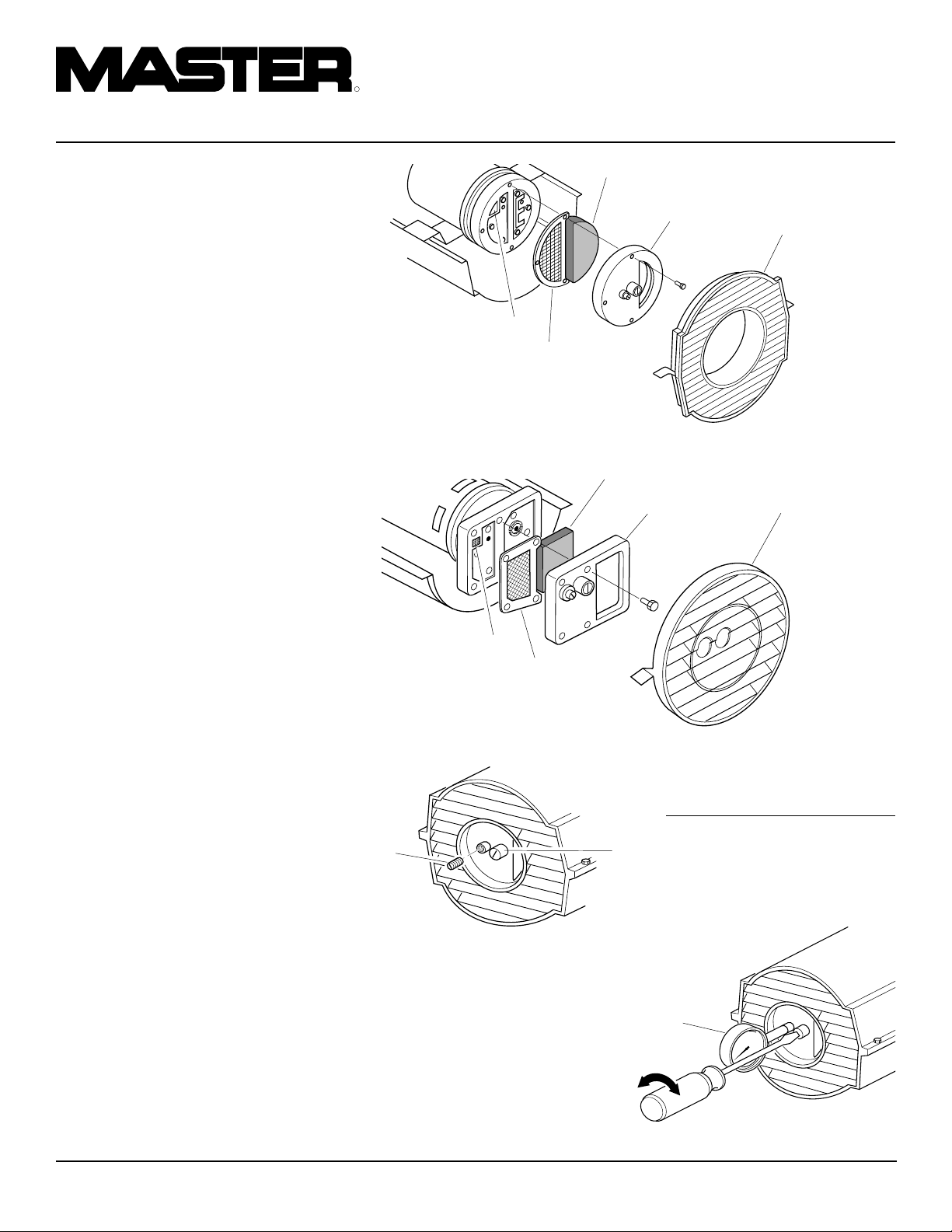

Air Output, Air Intake, and Lint

Filters

1. Remove upper shell (see page 8).

2. Remove filter end cover screws using

5/16" nut-driver.

3. Remove filter end cover.

4. Replace air output and lint filters.

5. Wash or replace air intake filter (see

Preventative Maintenance Schedule,

page 6).

6. Replace filter end cover.

7. Replace fan guard and upper shell.

IMPORTANT:

Pump Pressure Adjustment

1. Remove pressure gauge plug from filter

end cover.

2. Install accessory pressure gauge (part

number HA1180).

3. Start heater (see Operation, page 5).

Allow motor to reach full speed.

4. Adjust pressure. Turn relief valve to

right to increase pressure. Turn relief

valve to left to decrease pressure. See

specifications at right for correct pressure for each model.

5. Remove pressure gauge. Replace pressure gauge plug in filter end cover.

Do not oil filters

Air Intake Filter

Filter End

Cover

Lint Filter

Air Output

Filter

Figure 16 - Air Output, Air Intake, and Lint Filters, 35/70,000 Btu/Hr Models

Air Intake Filter

Filter End

Cover

Lint Filter

Air Output

Filter

Figure 17 - Air Output, Air Intake, and Lint Filters, 100/150,000 Btu/Hr Models

Fan Guard

Fan Guard

Model Pump Pressure

(PSI/Bar)

Pressure

Gauge

Plug

Relief

Valve

35,000 Btu/Hr 2.9/0.20

70,000 Btu/Hr 3.8/0.26

100,000 Btu/Hr 3.9/0.27

150,000 Btu/Hr 4.8/0.33

Figure 18 - Pressure Gauge Plug Removal

(35/70,000 Btu/Hr Models Shown)

10

Pressure

Gauge

Figure 19 - Adjusting Pump Pressure

104468

Page 11

OWNER’S MANUAL

SERVICE

PROCEDURES

Continued

Nozzle

(35,000 Btu/Hr Model)

1. Remove upper shell (see page 8).

2. Remove fan (see page 13).

3. Remove fuel and air line hoses from

nozzle assembly.

4. Turn nozzle assembly 1/4 turn to left

and pull toward motor to remove.

5. Place plastic hex-body into vise and

lightly tighten.

6. Carefully remove nozzle from the

nozzle adapter using 5/8" socket

wrench.

7. Blow compressed air thru face of nozzle.

This will free any dirt in nozzle area.

8. Inspect nozzle seal for damage.

9. Replace nozzle into nozzle adapter until nozzle seats. Tighten 1/3 turn more

using 5/8" socket wrench (4.5-5.1 n-m/

40-45 inch-pounds).

10. Attach nozzle assembly to burner strap.

11. Attach fuel and airline hoses to nozzle

assembly.

12. Replace fan (see page 13).

13. Replace fan guard and upper shell.

Combustion

Chamber

Nozzle

Assembly

Fuel Line

Air Line Hose

Figure 20 - Removing Air and Fuel Line

Hoses, 35,000 Btu/Hr Model

Hose

Burner

Strap

Nozzle

Assembly

Figure 21 - Removing Nozzle Assembly,

35,000 Btu/Hr Model

Nozzle

Face

Nozzle

Air line Fitting

Figure 22 - Nozzle and Nozzle Adapter,

35,000 Btu/Hr Model

Nozzle Seal

Nozzle

Adapter

Fuel line Fitting

Nozzle

(70/100/150,000 Btu/Hr Models)

1. Remove upper shell (see page 8).

2. Remove fan (see page 13).

3. Remove fuel and air line hoses from

burner head.

4. Remove spark plug wire from spark plug.

5. Remove spark plug from burner head

using 13/16" open-end wrench.

6. Remove three screws using 5/16" nutdriver and remove burner head from

combustion chamber.

7. Place burner head into vise and lightly

tighten.

8. Carefully remove nozzle from burner

head using 5/8" socket wrench (see Figure 24).

9. Blow compressed air thru face of nozzle.

This will free any dirt in nozzle area.

10. Inspect nozzle seal for damage.

11. Replace nozzle into burner head and

tighten firmly (9.1-12.4 n-m/80-110

inch-pounds).

12. Attach burner head to combustion

chamber.

13. Install spark plug in burner head.

14. Attach spark plug wire to spark plug.

15.

Attach fuel and airline hoses to burner head.

16. Replace fan (see page 13).

17. Replace fan guard and upper shell.

Combustion

Chamber

Screw

Air Line Hose

Figure 23 - Removing Burner Head,

70/100/150,000 Btu/Hr Models

Nozzle

Face

Nozzle

Burner

Head

Figure 24 - Removing Nozzle, 70/100/

150,000 Btu/Hr Models

Burner

Head

Fuel Line Hose

Nozzle

Seal

Spark Plug

Wire

Spark

Plug

Air line

Fitting

Fuel line

Fitting

104468

Continued

11

Page 12

R

PORTABLE FORCED AIR HEATERS

SERVICE

PROCEDURES

Continued

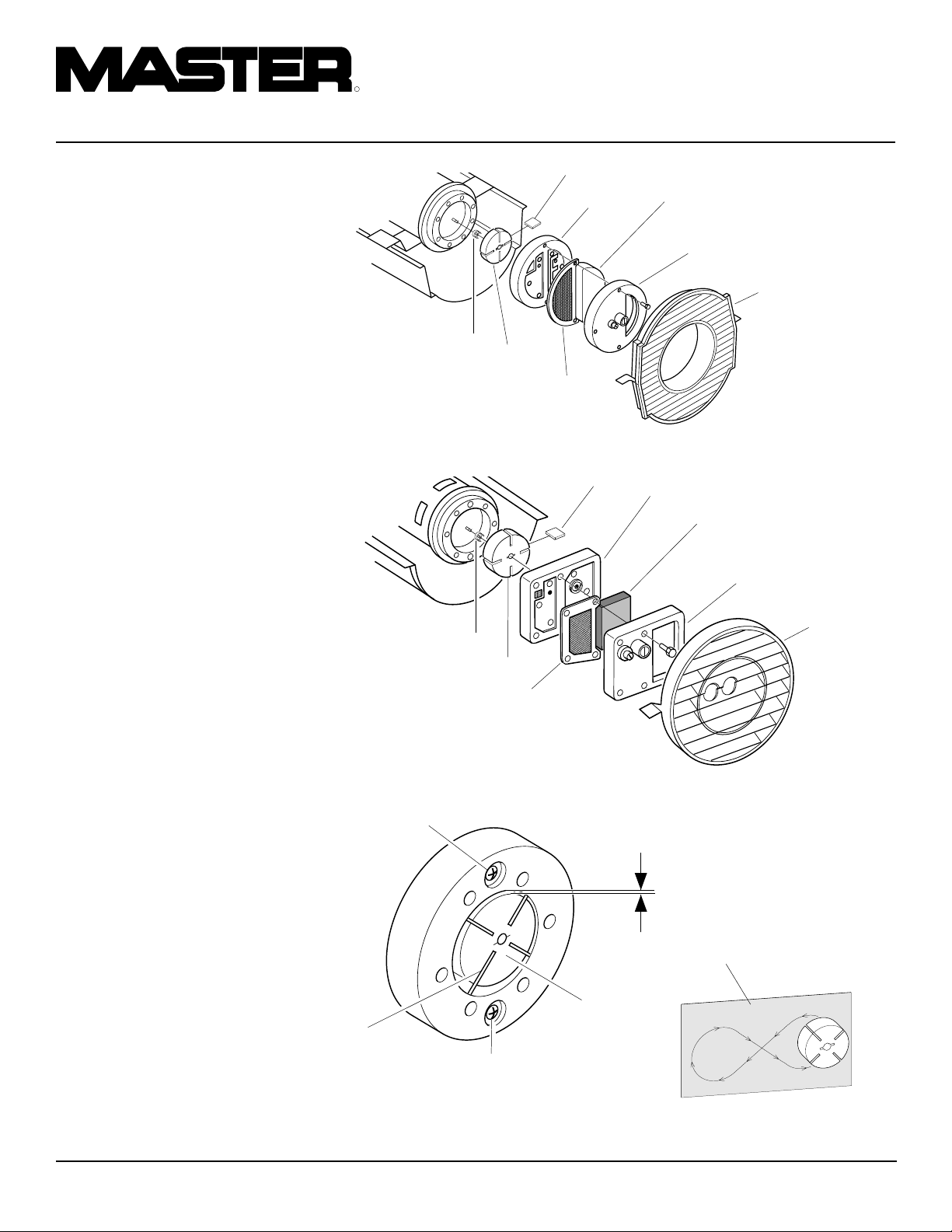

Pump Rotor

(Procedure if rotor is binding)

1. Remove upper shell (see page 8).

2. Remove filter end cover screws using

5/16" nut-driver.

3. Remove filter end cover and air filters.

4. Remove pump plate screws using 5/16"

nut-driver.

5. Remove pump plate.

6. Remove rotor, insert, and blades.

7. Check for debris in pump. If debris is

found, blow out with compressed air.

8. Install insert and rotor.

9. Check gap on rotor. Adjust to .076/.101

mm (.003"/.004") if needed (see Figure 27).

Note:

Rotate rotor one full turn to insure the

gap is .076/.101 mm (.003"/.004") at tightest position. Adjust if needed.

10. Install blades, pump plate, air filters,

and filter end cover.

11. Replace fan guard and upper shell.

12. Adjust pump pressure (see page 10).

Note:

If rotor is still binding, proceed as

follows.

13. Perform steps 1 through 6 above.

14. Place fine grade sandpaper (600 grit)

on flat surface. Sand rotor lightly in

“figure 8” motion four times (see Figure 28).

15. Reinstall insert and rotor.

16. Perform steps 10 through 12 above.

Blade

Pump

Plate

Insert

Rotor

Air Output

Filter

Figure 25 - Rotor Location, 35/70,000 Btu/Hr Models

Blade

Insert

Rotor

Air Output

Filter

Figure 26 - Rotor Location, 100/150,000 Btu/Hr Models

Gap Adjusting

Screw

Air

Intake

Filter

Filter End

Cover

Pump

Plate

.076/.101 mm (.003"/.004") Gap

Measured With Feeler Gauge

Fan Guard

Air Intake

Filter

Filter End

Cover

Fan Guard

Rotor

Blade

Gap Adjusting

Screw

Figure 27 - Gap Adjusting Screw

Locations

12

Sandpaper

Figure 28 - Sanding Rotor

104468

Page 13

OWNER’S MANUAL

SERVICE

PROCEDURES

Continued

Fan

IMPORTANT:

shaft before removing motor from heater.

The weight of the motor resting on the fan

could damage the fan pitch.

1. Remove upper shell (see page 8).

2. Use 1/8" allen wrench to loosen set-

screw which holds fan to motor shaft.

3. Slip fan off motor shaft.

4. Clean fan using a soft cloth moistened

with kerosene or solvent.

5. Dry fan thoroughly.

6. Replace fan on motor shaft. Place fan

hub flush with end of motor shaft (see

Figure 30).

7. Place setscrew on flat of shaft. Tighten

setscrew firmly (40-50 inch-pounds/

4.5-5.6 n-m).

8. Replace fan guard and upper shell.

Remove fan from motor

SPECIFICATIONS

Output Rating (Btu/Hr) 35,000 70,000 100,000 150,000

Fuel Use Only Kerosene or No. 1 Fuel Oil

Fuel Tank Capacity

(U.S. Gal./Liters) 3.0/11.4 5.0/18.9 9.0/34 13.5/51.1

Fuel Consumption

(Gal. Per Hr./Liters Per Hr.) .26/1.0 .49/1.85 .70/2.7 1.1/4.1

Electric Requirements 230 V/50 Hz (Same All Models)

Amperage (Normal Run) .8 1.0 1.2 1.2

Hot Air Output (CFM/CMM) 140/4 225/6.4 425/12 500/14.2

RPM 1425 2850 2850 2850

WIRING DIAGRAMS

230V/50Hz

BrownBlue

RFI Filter

Black

White

Black

Green/Yellow

White

B

Setscrew

Motor

Shaft

Fan

Figure 29 - Fan, Motor Shaft, and Setscrew

Location

Fan

Flush

Motor

Shaft

Setscrew

Green/

Yellow

Orange Terminal

Motor

Ignitor

Spark Plug

Red

Board

Red

White

Red

Figure 31 - Wiring Diagram, 35/100/150,000 Btu/Hr Models

230V/50Hz

BrownBlue

RFI Filter

Green/

Yellow

Motor

Orange

Black

Spark Plug

Ignitor

Red

S or 2 M or 5

Motor

Start

Relay

White

Red

L or 1

Black

Terminal

Board

Red

White

Black

Green/Yellow

Red

Blue

Photocell

White

Blue

Photocell

Blue

Blue

Flame-

Out

Control

R

B

Flame-

Out

Control

R

Reset

Button

Reset

Button

Figure 30 - Fan Cross Section

104468

Figure 32 - Wiring Diagram, 70,000 Btu/Hr Model

13

Page 14

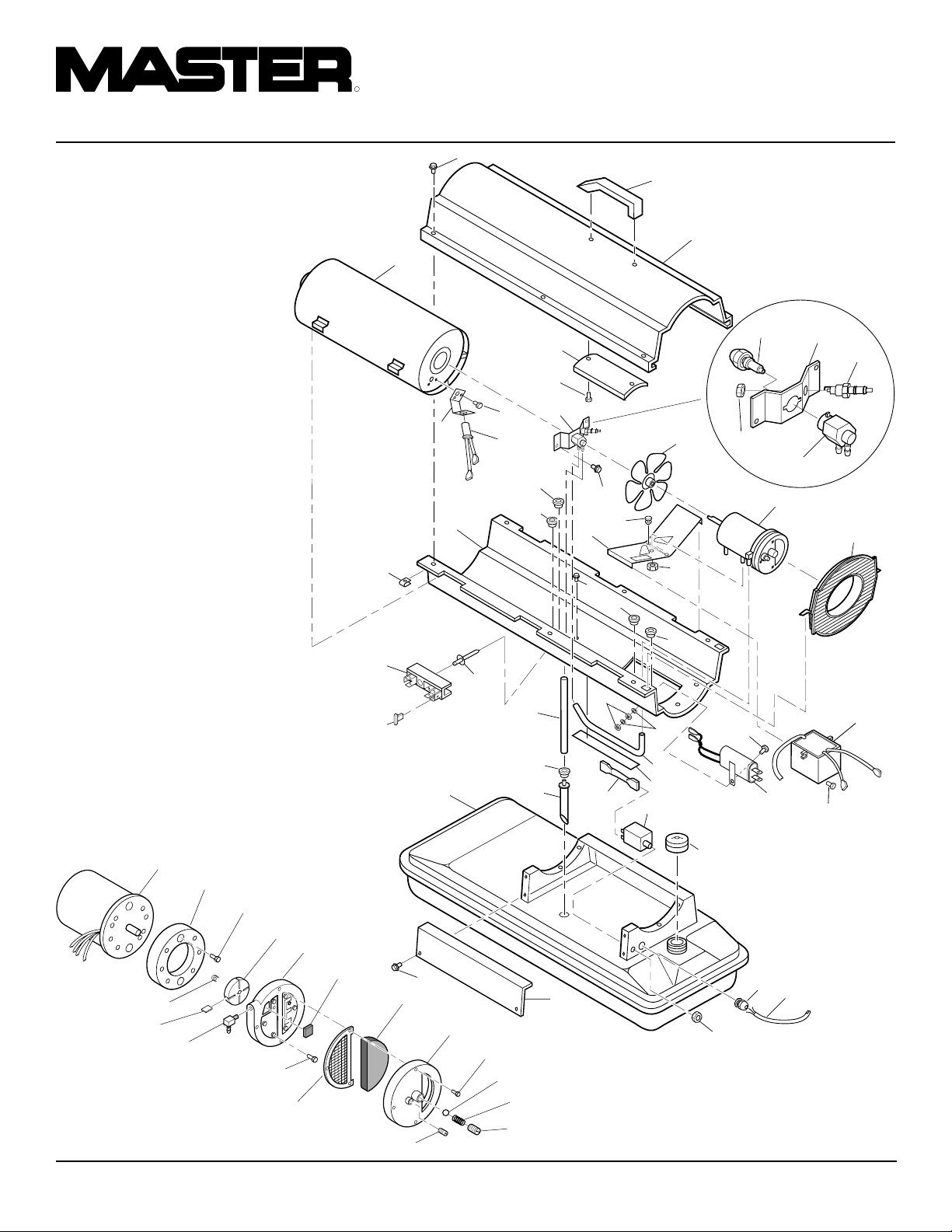

R

PORTABLE FORCED AIR HEATERS

3

ILLUSTRATED

PARTS

1

BREAKDOWN

35,000 BTU/HR

24

33

41

2

4

11-5

5

6

27

13

13

11

17

22

22

39

16

21

43

21

20

15

11-4

25

7

23

8

9

34

11-1

11-2

11-3

18

19

31

18-1

18-2

18-3

18-17

18-16

Motor and Pump Assembly

18-18

18-15

18-4

18-14

18-5

18-6

18-7

18-13

22

37

18-8

14

18-9

18-10

29

30

18-11

18-12

38

28

35

26

42

36

40

14

12

32

10

104468

Page 15

OWNER’S MANUAL

PARTS LIST

35,000 BTU/HR

KEY PART PART

NO. NUMBER DESCRIPTION QTY.

1 M51104-01 Handle 1

2 098511-54 Upper Shell 1

3 102432-01 Screw/Lockwasher, 1/2" 6

4 098512-43 Combustion Chamber 1

5 M51108-01 Heat Shield 1

6 M11084-29 Screw, #10-16 x 3/4" 2

7 M16660 Photocell Bracket 1

8 M10908-2 Screw, #6-32 x 3/8" 2

9 HA3019 Photocell Assembly 1

10 079673-06 Power Cord 1

11 ** Burner Strap Assembly 1

11-1 097124-01 Bracket 1

11-2 HA3013 Spark Plug 1

11-3 079980-01 Nozzle Adapter 1

11-4 M29824 Nut, 14mm 1

11-5 HA3006 Nozzle 1

12 102801-01 Power Line RFI Filter 1

13 M30865-02 Bushing 2

14 M50400 Strain Relief Bushing 1

15 M30884 Fan 1

16 M50631 Rubber Bumper 2

17 101205-01 Motor Bracket 1

18 ** Motor and Pump Assembly 1

18-1 098642-02 Motor (230V/50Hz) 1

18-2 079975-03 Pump Body 1

18-3 M22009 Insert 1

18-4 M22456-2 Rotor 1

18-5 M29608 End Pump Cover 1

18-6 M29632 Lint Filter 1

18-7 M29633 Intake Filter 1

18-8 M29609 End Filter Cover 1

18-9 M12461-31 Screw, #10-32 x 1" 3

18-10 M8940 Steel Ball (1/4" Dia.) 1

18-11 M10993-1 Pressure Relief Spring 1

18-12 M27694 Adjusting Screw 1

18-13 M22997 Plug 1

18-14 M29612-01 Output Filter 1

18-15 M12461-32 Screw, #10-32 x 1 1/8" 6

This list contains replaceable parts used in your heater. When ordering parts, be sure to

provide the correct model and serial numbers (from the model plate), then the part number

and description of the desired part.

KEY PART PART

NO. NUMBER DESCRIPTION QTY.

18-16 M50016 Elbow, 90˚ (Barb Fitting) 1

18-17 M8643-2 Blade 4

18-18 FHPF3-6C Screw, #10-32 x 3/4" 2

19 M51105-01 Fan Guard 1

20 NTC-4C Hex locknut 2

21 M50104-02 Bushing (wires) 2

22 102431-01 Screw/Lockwasher, 1/2" 10

23 098511-12 Lower Shell 1

24 M11271-8 Clip Nut 6

25 RF3-6B Screw, #10-32 x 3/4" 1

26 M29652-04 Rubber Airline 1

27 M29652-05 Fuel Line 1

28 M16841-57 Wire Assembly (red 8 1/2") 1

29 M10990-3 Rubber Bushing 1

30 M50876-04 Fuel Filter Assembly 1

(Includes bushing)

31 102482-02 Electronic Ignitor 1

32 M11084-29 Screw, #10-16 x 3/4" 2

33 099125-02 Terminal Board 1

34 099157-01 Rivet 1

35 097630-02 Flame-Out Control 1

36 097702-01 Fuel Tank Cap 1

37 098513-73 Fuel Tank 1

38 M50899-03AA Side Cover 1

39 NPF-3B Nut, #10-32 3

40 099177-01 Hex Nut 1

41 078918-01 Terminal Board Tab Cap 1

42 097785-01 Vinyl Foam Gasket 1

43 WLE-3 Lock Washer, #10 2

PARTS AVAILABLE - NOT SHOWN

HA2210 Filler Neck Screen 1

097649-01 Tradename Decal 2

M9900-192 Combustion Chamber

Ground Wire 1

102944-01 Decal Package 1

**Not available as an assembly, order parts separately.

104468

15

Page 16

R

PORTABLE FORCED AIR HEATERS

3

ILLUSTRATED

PARTS

1

BREAKDOWN

70,000 BTU/HR

Burner Head Assembly

10-1

10-2

10-4

10-3

10-6

18-1

18-2

18-18

18-3

18-17

18-16

Motor and Pump Assembly

18-4

18-15

18-14

10-5

10-7

18-5

18-6

4

24

35

43

40

18-7

18-13

11

39

6

18-8

23

36

16

8

18-9

18-10

7

18-11

18-12

12

12

31

32

29

10

2

5

14

11

25

17

30

41

21

15

38

16

45

28

44

26

20

21

11

22

37

42

18

19

27

33

34

13

9

104468

Page 17

OWNER’S MANUAL

PARTS LIST

70,000 BTU/HR

KEY PART PART

NO. NUMBER DESCRIPTION QTY.

1 M51104-01 Handle 1

2 098511-54 Upper Shell 1

3 102432-01 Screw/Lockwasher, 1/2" 6

4 098512-44 Combustion Chamber 1

5 M11084-29 Screw, #10-16 x 3/4" 2

6 M16660 Photocell Bracket 1

7 M10908-2 Screw, #6-32 x 3/8" 2

8 HA3019 Photocell Assembly 1

9 079673-06 Power Cord 1

10 ** Burner Head Assembly 1

10-1 HA3008 Nozzle 1

10-2 M10659-1 Nozzle Seal Washer 2

10-3 M10809-1 Nozzle Seal Spring 1

10-4 M8882 Nozzle Seal Sleeve 1

10-5 M51098-02 Burner Head Body 1

10-6 M50820-01 Barb Fitting 2

10-7 HA3012 Spark Plug 1

11 102431-01 Screw/Lockwasher, 1/2" 11

12 M30865-02 Bushing 2

13 M50400 Strain Relief Bushing 1

14 M30884 Fan 1

15 M50631 Rubber Bumper 2

16 M12461-13 Screw, #8-32 x 1/4" 2

(holds relay in position)

17 101205-01 Motor/Relay Bracket 1

18 ** Motor and Pump Assembly 1

18-1 102001-16 Motor (230V/50Hz) 1

18-2 079975-02 Pump Body 1

18-3 M22009 Insert 1

18-4 M22456-1 Rotor 1

18-5 M29608 End Pump Cover 1

18-6 M29632 Lint Filter 1

18-7 M29633 Intake Filter 1

18-8 M29609 End Filter Cover 1

18-9 M12461-31 Screw, #10-32 x 1" 3

18-10 M8940 Steel Ball (1/4" Dia.) 1

18-11 M10993-1 Pressure Relief Spring 1

18-12 M27694 Adjusting Screw 1

18-13 M22997 Plug 1

18-14 M29612-01 Output Filter 1

This list contains replaceable parts used in your heater. When ordering parts, be sure to

provide the correct model and serial numbers (from the model plate), then the part number

and description of the desired part.

KEY PART PART

NO. NUMBER DESCRIPTION QTY.

18-15 M12461-31 Screw, #10-32 x 1" 6

18-16 M50016 Elbow, 90˚ (Barb Fitting) 1

18-17 M8643 Blade 4

18-18 FHPF3-5C Screw, #10-32 x 5/8" 2

19 M51105-01 Fan Guard 1

20 NTC-4C Hex locknut 2

21 M50104-02 Bushing (wires) 2

22 102801-01 Power Line RFI Filter 1

23 098511-12 Lower Shell 1

24 M11271-8 Clip Nut 6

25 098136-05 Relay (motor start) 1

26 M16841-58 Wire Assembly (red 9 1/2") 1

27 RF3-6B Screw, #10-32 x 3/4" 1

28 M29652-04 Rubber Airline 1

29 079973-01 Fuel Line 1

30 M16841-57 Wire Assembly (red 8 1/2") 1

31 M10990-3 Rubber Bushing 1

32 M50876-05 Fuel Filter Assembly 1

(Includes bushing)

33 102482-02 Electronic Ignitor 1

34 M11084-29 Screw, #10-16 x 3/4" 2

35 099125-02 Terminal Board 1

36 099157-01 Rivet 1

37 097702-01 Fuel Tank Cap 1

38 097630-02 Flame-Out Control 1

39 098513-74 Fuel Tank 1

40 M50899-03AA Side Cover 1

41 NPF-3B Nut, #10-32 3

42 099177-01 Hex Nut 1

43 078918-01 Terminal Board Tab Cap 1

44 097785-01 Vinyl Foam Gasket 1

45 WLE-3 Lock Washer, #10 2

PARTS AVAILABLE - NOT SHOWN

HA2210 Filler Neck Screen 1

097649-01 Tradename Decal 2

M9900-192 Combustion Chamber

Ground Wire 1

102944-02 Decal Package 1

**Not available as an assembly, order parts separately.

104468

17

Page 18

R

PORTABLE FORCED AIR HEATERS

ILLUSTRATED

PARTS

BREAKDOWN

100,000 BTU/HR

8-1

8-2

8-4

8-3

8-5

8-7

2

1

3

4

5

31

30

8

7

9

15

10

26

11

25

17

28

20

12

13

14

21

8-6

Burner Head Assembly

13-1

13-2

13-18

13-17

13-16

13-15

Motor and Pump Assembly

13-3

13-4

13-5

13-14

13-6

13-13

42

27

23

24

36

44

16

9

13-7

13-8

13-9

13-12

37

13-10

13-11

35

33

34

18

19

38

39

6

9

43

40

22

32

29

41

18

104468

Page 19

OWNER’S MANUAL

PARTS LIST

100,000 BTU/HR

KEY PART PART

NO. NUMBER DESCRIPTION QTY.

1 098511-138 Upper Shell 1

2 102432-01 Screw/Lockwasher, 1/2" 8

3 098512-31 Combustion Chamber 1

4 M16660 Photocell Bracket 1

5 HA3019 Photocell Assembly 1

6 M27417 Drain Plug 1

7 M10908-2 Screw, #6-32 x 3/8" 2

8 ** Burner Head Assembly 1

8-1 100735-15 Nozzle 1

8-2 M10659-1 Nozzle Seal Washer 2

8-3 M10809-1 Nozzle Seal Spring 1

8-4 M8882 Nozzle Seal Sleeve 1

8-5 M50924-03 Burner Head Body 1

8-6 M50820-02 Barb Fitting 2

8-7 HA3012 Spark Plug 1

9 102431-01 Screw/Lockwasher, 1/2" 13

10 M50814-06 Air Line 1

11 M51345-01 Fuel Line 1

12 102042-01 Fan 1

13 ** Motor and Pump Assembly 1

13-1 102001-03 Motor with capacitor

(230V/50Hz) 1

13-2 079975-02 Pump Body 1

13-3 FHPF3-5C Screw, #10-32 x 5/8" 2

13-4 M22009 Insert 1

13-5 M22456-1 Rotor 1

13-6 M50545 End Pump Cover 1

13-7 M12179 Intake Filter 1

13-8 M16545 End Filter Cover 1

13-9 M8940 Steel Ball (1/4" Dia.) 1

13-10 M10993-1 Pressure Relief Spring 1

13-11 M27694 Adjusting Screw 1

13-12 M22997 Plug 1

13-13 M12461-31 Screw, #10-32 x 1" 4

13-14 M12244-1 Output Filter 1

13-15 M12461-31 Screw, #10-32 x 1" 6

13-16 M11637 Lint Filter 1

13-17 M50820-02 Barb Fitting 1

13-18 M8643 Blade 4

14 M51114-01 Fan Guard 1

This list contains replaceable parts used in your heater. When ordering parts, be sure to

provide the correct model and serial numbers (from the model plate), then the part number

and description of the desired part.

KEY PART PART

NO. NUMBER DESCRIPTION QTY.

15 M50631 Rubber Bumper 2

16 097468-01 Edge Liner 1

17 101206-01 Motor and Relay

Bracket Assembly 1

18 WLE-3 Lock Washer, #10 2

19 NPF-3B Nut, #10-32 3

20 NTC-4C Hex locknut 2

21 102482-02 Electronic Ignitor 1

22 M11084-29 Screw, #10-16 x 3/4" 2

23 099125-02 Terminal Board 1

24 099157-01 Rivet 1

25 M50104-03 Bushing 1

26 M50104-03 Bushing 1

27 M50104-01 Bushing 2

28 099213-01 Button Plug 1

29 102801-01 Power Line RFI Filter 1

30 098511-191 Lower Shell 1

31 M11271-8 Clip Nut 8

32 RF3-6B Screw, #10-32 x 3/4" 1

33 M51150-01 Fuel filter 1

34 M10990-3 Rubber Bushing 1

35 M51151-01 Fuel Line 1

36 098513-75 Fuel Tank 1

37 097702-01 Fuel Tank Cap 1

38 M16841-57 Wire Assembly (red 8 1/2") 1

39 097630-02 Flame-Out Control 1

40 M50400 Strain Relief Bushing 1

41 079673-06 Power Cord 1

42 M51077-01AA Side Cover 1

43 099177-01 Hex Nut 1

44 078918-01 Terminal Board Tab Cap 1

PARTS AVAILABLE - NOT SHOWN

HA2210 Filler Neck Screen 1

097650-01 Tradename Decal 2

M9900-192 Combustion Chamber

Ground Wire 1

102944-03 Decal Package 1

**Not available as an assembly, order parts separately.

104468

19

Page 20

R

PORTABLE FORCED AIR HEATERS

ILLUSTRATED

PARTS

BREAKDOWN

150,000 BTU/HR

8-1

8-2

8-4

8-3

8-5

8-7

2

1

3

4

5

31

30

8

7

9

15

10

26

25

11

17

46

28

12

20

13

14

21

8-6

Burner Head Assembly

13-1

13-2

13-18

13-17

13-16

13-15

Motor and Pump Assembly

13-3

13-14

13-4

13-5

13-6

13-13

42

16

23

43

13-7

44

13-8

13-12

20

24

36

13-9

37

13-10

13-11

35

33

34

38

19

27

9

18

39

45

40

6

22

32

29

41

104468

Page 21

OWNER’S MANUAL

PARTS LIST

150,000 BTU/HR

KEY PART PART

NO. NUMBER DESCRIPTION QTY.

1 098511-138 Upper Shell 1

2 102432-01 Screw/Lockwasher, 1/2" 8

3 098512-36 Combustion Chamber 1

4 099229-01 Photocell Bracket 1

5 HA3019 Photocell Assembly 1

6 M27417 Drain Plug 1

7 M10908-2 Screw, #6-32 x 3/8" 2

8 ** Burner Head Assembly 1

8-1 100735-11 Nozzle 1

8-2 M10659-1 Nozzle Seal Washer 2

8-3 M10809-1 Nozzle Seal Spring 1

8-4 M8882 Nozzle Seal Sleeve 1

8-5 M50924-08 Burner Head Body 1

8-6 M50820-02 Barb Fitting 2

8-7 HA3012 Spark Plug 1

9 102431-01 Screw/Lockwasher, 1/2" 9

10 M50814-06 Air Line 1

11 M51345-01 Fuel Line 1

12 102042-01 Fan 1

13 ** Motor and Pump Assembly 1

13-1 102001-03 Motor (with capacitor) 1

13-2 079975-03 Pump Body 1

13-3 FHPF3-6C Screw, #10-32 x 3/4" 2

13-4 M22009 Insert 1

13-5 M22456-2 Rotor 1

13-6 M50545 End Pump Cover 1

13-7 M12179 Intake Filter 1

13-8 M16545 End Filter Cover 1

13-9 M8940 Steel Ball (1/4" Dia.) 1

13-10 M10993-1 Pressure Relief Spring 1

13-11 M27694 Adjusting Screw 1

13-12 M22997 Plug 1

13-13 M12461-31 Screw, #10-32 x 1" 4

13-14 M12244-1 Output Filter 1

13-15 M12461-32 Screw, #10-32 x 1 1/8" 6

13-16 M11637 Lint Filter 1

13-17 M50820-02 Barb Fitting 1

13-18 M8643-2 Blade 4

14 M51114-01 Fan Guard 1

15 M50631 Rubber Bumper 2

This list contains replaceable parts used in your heater. When ordering parts, be sure to

provide the correct model and serial numbers (from the model plate), then the part number

and description of the desired part.

KEY PART PART

NO. NUMBER DESCRIPTION QTY.

16 097468-01 Edge Liner 1

17 101206-01 Motor Bracket 1

18 WLE-3 Lock Washer, #10 2

19 NPF-3B Nut, #10-32 3

20 NTC-4C Hex locknut 2

21 102482-02 Electronic Ignitor 1

22 M11084-29 Screw, #10-16 x 3/4" 2

23 099125-02 Terminal Board 1

24 099157-01 Rivet 1

25 M50104-03 Bushing 1

26 M50104-03 Bushing 1

27 M50104-01 Bushing 2

28 099213-01 Button Plug 1

29 102801-01 Power Line RFI Filter 1

30 098511-191 Lower Shell 1

31 M11271-8 Clip Nut 8

32 RF3-6B Screw, #10-32 x 3/4" 1

33 M51150-01 Fuel filter 1

34 M10990-3 Rubber Bushing 1

35 M51151-02 Fuel Line 1

36 098513-76 Fuel Tank 1

37 097702-01 Fuel Tank Cap 1

38 M16841-57 Wire Assembly (red 8 1/2") 1

39 097630-02 Flame-Out Control 1

40 M50400 Strain Relief Bushing 1

41 079673-06 Power Cord 1

42 M51077-01AA Side Cover 1

43 M11084-27 Screw, #10-16 x 1/2" 4

44 078918-01 Terminal Board Tab Cap 1

45 099177-01 Hex Nut 1

46 097785-04 Vinyl Foam Gasket 2

PARTS AVAILABLE - NOT SHOWN

HA2210 Filler Neck Screen 1

097650-01 Tradename Decal 2

M9900-192 Combustion Chamber

Ground Wire 1

102944-04 Decal Package 1

**Not available as an assembly, order parts separately.

104468

21

Page 22

R

PORTABLE FORCED AIR HEATERS

WHEELS AND

HANDLES

100,000 AND 150,000 BTU/HR

MODELS

KEY PART PART 100,000 150,000

NO. NUMBER DESCRIPTION QTY. QTY.

1 HA2203 Handles 2 —

HA2204 Handles — 2

2 M12345-33 Screw, #10-24 x 1 3/4" 8 8

3 M12342-3 Wheel Support Frame 1 —

M12831-3 Wheel Support Frame — 1

4 NTC-3C Hex Nut, #10-24 8 8

5 097896-03 Wheel 2 2

6 M28526 Cap Nut 2 2

7 M51015-01 Axle 1 —

M16801-2 Axle — 1

1

2

3

5

6

4

7

22

104468

Page 23

ACCESSORIES

Purchase accessories from your local dealer.

AIR GAUGE KIT - HA1180

For all models. Special tool to check pump

pressure.

OWNER’S MANUAL

STANDARD WHEELS AND

HANDLE KIT - HA1206

Makes heater even more portable and convenient. Easy to assemble.

For 35/70,000 Btu/Hr models.

HEAVY DUTY WHEELS AND

HANDLE KIT - HA1202

For heavy duty applications. Makes your heater

even more portable and convenient.

For 35/70,000 Btu/Hr models.

104468

23

Page 24

WARRANTY AND REPAIR SERVICE

CERTIFICATE OF GENERAL

EQUIPMENT - LIMITED 90 DAY WARRANTY

DESA International warrants new Products sold by it to be

free from defects in material or workmanship for a period of

ninety days after date of delivery to the first user and subject to

the following conditions:

DESA International's obligation and liability under this

Warranty is expressly limited to repairing or replacing at DESA

International's option, any parts which appear to DESA International upon inspection to have been defective in material or

workmanship when shipped from the factory. Such parts shall

be provided at no cost to the user, at the business establishment

of any factory authorized service center or the factory during

regular working hours. The Warranty shall not apply to component parts or accessories of Products not manufactured by

DESA International and which carry the warranty of the manufacturer thereof, or to normal maintenance (such as pressure

adjustments) or to normal maintenance parts (such as filters

and spark plugs). Replacement or repair parts installed in the

Product covered by this Warranty are warranted only for the

remainder of this Warranty as if such parts were original components of said Product. DESA INTERNATIONAL MAKES NO

OTHER EXPRESS WARRANTY. TO THE EXTENT PERMITTED BY LAW DESA INTERNATIONAL MAKES NO IMPLIED

WARRANTY AND MAKES NO WARRANTY OF MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PUR-

POSE. IN ANY EVENT IMPLIED WARRANTIES INCLUDING

THOSE OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE LIMITED TO THE DURATION OF

THIS EXPRESS WARRANTY.

Any transportation charges, costs of installation, duty,

taxes or any other charges whatsoever must be borne by the

user. DESA International's obligation under this limited Warranty shall not include any liability for direct, indirect, incidental,

or consequential damage or delay. If requested by DESA

International, Products or parts for which a warranty claim is

made are to be returned transportation prepaid by user to the

factory. Any improper use, including operation after discovery

of defective or worn parts, operation beyond capacity, substitution of parts not approved by DESA International, or any

alteration or repair by others in such manner as in DESA

International's judgement affects the Product materially and

adversely, shall void this Warranty.

NO EMPLOYEE OR REPRESENTATIVE IS AUTHORIZED

TO CHANGE THIS WARRANTY IN ANY WAY OR GRANT

ANY OTHER WARRANTY UNLESS SUCH CHANGE IS

MADE IN WRITING AND SIGNED BY AN OFFICER OF DESA

INTERNATIONAL AT ITS HOME OFFICE.

WARRANTY SERVICE

Always specify model and serial numbers when communicating

with the factory.

We reserve the right to amend these specifications at any time

without notice. The only Warranty applicable is our standard

written Warranty. We make no other Warranty, expressed or

implied.

A Service Manual is available by writing to the Technical Service

Department at:

Corporate Headquarters

2701 Industrial Drive

P.O. Box 90004

Bowling Green, Kentucky 42102-9004

U.S.A.

Printed in U.S.A.

Page 25

R

CALENTADORES

PORTATILES DE AIRE

FORZADO

MANUAL DEL PROPIETARIO

Tamaños: 10,2 (35.000) 20,5 (70.000) 29,3 (100.000) 44 kW (150.000 Btu/hr)

Modelos: B35CEA, B70CEA, B100CEA, Y B150CEA

IMPORTANTE: Lea y comprenda este manual antes de armar, encender o dar servicio

al calentador. El uso indebido del calentador puede causar lesiones graves. Guarde

este manual para referencia futura.

104468 01

NOT A UPC

104468-01

Rev. A

12/97

Page 26

R

CALENTADORES PORTATILES DE AIRE FORZADO

INFORMACION DE

SEGURIDAD

ADVERTENCIAS

IMPORTANTE: Lea este manual

del propietario detenida y completamente antes de intentar armar, usar o dar servicio al calentador. El uso indebido de este

calentador puede causar lesiones graves o la muerte a causa

de las quemaduras, incendios,

explosiones, choques eléctricos

y envenenamiento por monóxido

de carbono.

PELIGRO: El envenenamiento por monóxido de carbono puede causar la muerte.

Envenenamiento por monóxido de

carbono: Los primeros síntomas del enve-

nenamiento por monóxido de carbono son

parecidos a los de la gripe e incluyen dolores

de cabeza, mareos o náuseas. Si se experimentan estos síntomas, el calentador podría

estar funcionando mal. ¡Busque aire fresco

de inmediato! Solicite la reparación del

calentador. Algunos individuos se ven más

afectados por el monóxido de carbono que

otros. Estos incluyen las mujeres embarazadas, individuos con padecimientos del corazón o los pulmones o con anemia, individuos bajo los efectos del alcohol e individuos a grandes alturas.

Asegúrese de leer y comprender todas las

advertencias. Guarde este manual para referencia. Es su guía para el uso seguro y

adecuado de este calentador.

• Para evitar el riesgo de incendio o explosión, use sólo keroseno o fueloil No.

1. Nunca use gasolina, nafta, diluyentes

de pintura, alcohol u otros combustibles muy inflamables.

• Abastecimiento de combustible

a) El personal involucrado en el abas-

tecimiento del combustible deberá

ser calificado y estar plenamente familiarizado con las instrucciones del

fabricante y los reglamentos aplicables en cuanto al abastecimiento seguro de combustible de las unidades

de calefacción.

b)Sólo se debe utilizar el tipo de com-

bustible especificado en la chapa de

datos del calentador.

c) Se deberá extinguir toda llama, in-

cluyendo la luz piloto en su caso, y

permitir que el calentador se enfríe

antes de abastecerlo de combustible.

d)Durante el abastecimiento de com-

bustible, todas las líneas y conexiones de combustible deberán

inspeccionarse en busca de fugas.

Todas las fugas deberán repararse

antes de volver a poner en servicio

el calentador.

e) En ningún momento se deberá alma-

cenar una cantidad de combustible

mayor que la necesaria para un día

de funcionamiento en el interior de

un edificio en las cercanías del calentador. El depósito de abasto de

combustible deberá estar ubicado

fuera de la estructura.

f) Todo el combustible almacenado

deberá ubicarse a un mínimo de 762

cm (25 pies) de los calentadores,

sopletes, equipo de soldadura y otras

fuentes similares de inflamación (excepción: el tanque de combustible

incorporado en el calentador).

g)Siempre que sea posible, el almace-

namiento de combustible deberá confinarse a zonas donde las aberturas

en el suelo no permitan que el combustible gotee sobre una llama o sea

inflamado por una llama ubicada a

una altura más baja.

h)El almacenamiento del combustible

deberá efectuarse según las disposiciones de las autoridades competentes.

• Nunca use el calentador en presencia de

vapores de gasolina, de diluyente de pintura u otros vapores muy inflamables.

• Respete todos los reglamentos y códigos locales al usar el calentador.

• Los calentadores utilizados en las cercanías de alquitranado, lonas o materiales

de envoltura similares deberán ubicarse

a una distancia segura de tales materiales. La distancia mínima recomendada es

304,8 cm (10 pies). Además, se recomienda que tales materiales tengan propiedades retardantes a las llamas. Estos materiales de envoltura deberán fijarse de

modo seguro para impedir su combustión o que volteen el calentador debido a

la acción del viento.

• Utilícelo solamente en lugares con buena ventilación. Deje una abertura de por

lo menos 2800 cm2 (3 ft2) para la entrada de aire fresco exterior por cada 29,3

kW (100.000 Btu/hr) de capacidad.

• Utilícelo solamente en lugares exentos

de vapores inflamables o contenido elevado de polvo.

• Use solamente el voltaje eléctrico y la

frecuencia especificados en la chapa del

número de modelo.

• Use solamente un cordón de extensión

de tres clavijas con puesta a tierra.

• Los espacios mínimos entre el calentador y materiales combustibles son:

Salida: 250 cm (8 ft)

Lados, partes superior y trasera: 125 cm

(4 ft)

• Coloque el calentador en una superficie estable y nivelada mientras el calentador está caliente o funcionando, de

lo contrario podría ocurrir un incendio.

•

Para trasladar o guardar el calentador, manténgalo en posición nivelada, de lo contrario podría derramarse el combustible.

• Deje el calentador fuera del alcance de

los niños y animales.

• Desenchufe el calentador cuando no

esté en uso.

• Cuando se usa con termostato, el calentador puede arrancar en cualquier

momento.

• Nunca use el calentador en habitaciones o dormitorios.

• Nunca bloquee la entrada de aire (trasera) ni la salida de aire (delantera) del

calentador.

• Nunca mueva, manipule, reabastezca

de combustible ni dé servicio a un calentador caliente, en funcionamiento o

enchufado.

• Nunca conecte ductos a la parte delantera o trasera del calentador. El uso de

ductos podría reducir el flujo de aire

que el calentador necesita. El calentador entonces produciría monóxido de

carbono en exceso.

2

104468

Page 27

MANUAL DEL PROPIETARIO

IDENTIFICACION

DEL PRODUCTO

Salida de aire

caliente

Casco

superior

Casco inferior

Tanque de

combustible

Cubierta lateral

Botón de reposición

del control de

extinción de llamas

Figura 1 - Modelos de 10,2/20,5 kW (35.000/70.000 Btu/hr)

Salida

de aire

caliente

Asa

Casco superior

Protector del

ventilador

Cubierta del

extremo del filtro

de aire

Tapa de

combustible

Cordón

eléctrico

DESEMBALAJE

1. Quite todo el material de embalar aplicado al calentador para el transporte.

2. Saque todos los componentes de la caja.

3. Inspeccione los componentes en busca

de daños ocurridos durante el transporte. Si el calentador ha sufrido daños,

informe oportunamente al concesionario donde se compró el calentador.

Casco

inferior

Tapa de

combustible

Cubierta

lateral

Botón de reposición

del control de

extinción de llamas

Figura 2 - Modelos de 29,3/44 kW (100.000/150.000 Btu/hr)

Protector del

ventilador

Tanque de

combustible

Cordón

eléctrico

104468

3

Page 28

R

CALENTADORES PORTATILES DE AIRE FORZADO

ARMADO

(SÓLO PARA MODELOS DE

29,3 Y 44 KW [100.000 Y

150.000 BTU/HR])

Estos modelos se proveen con ruedas y asas.

Las ruedas, asas y la tornillería de montaje

se encuentran en la caja de embalaje.

Herramientas necesarias

• Destornillador Phillips mediano

• Llave ajustable o de boca de 3/8"

• Martillo

1. Deslice el eje a través del bastidor de

soporte de las ruedas. Instale las ruedas en el eje.

IMPORTANTE:

oriente el cubo extendido de las ruedas

hacia el bastidor de soporte de las ruedas (vea la Figura 3).

Al instalar las ruedas,

2. Coloque las tuercas ciegas en los extremos del eje. Martíllelas suavemente

para fijarlas.

3. Coloque el calentador sobre el bastidor de soporte de las ruedas. Asegúrese que el extremo de entrada de aire

(posterior) del calentador esté sobre las

ruedas. Alinee los agujeros de la pestaña del tanque de combustible con los

agujeros del bastidor de soporte de las

ruedas.

4. Coloque el asa delantera y el asa trasera encima de la pestaña del tanque de

combustible. Inserte los tornillos a través de las asas, de la pestaña del tanque de combustible y del bastidor de

soporte de las ruedas. Ponga una tuerca apretada a mano en cada tornillo

después de insertarlo.

5. Después de insertar todos los tornillos,

apriete las tuercas firmemente.

Asa delantera

COMBUSTIBLES

ADVERTENCIA: Para evitar el

riesgo de incendio o explosión, use

sólo keroseno o fueloil No. 1. Nunca use gasolina, nafta, diluyentes

de pintura, alcohol u otros combustibles muy inflamables.

No use combustibles pesados como el fueloil

No. 2 ó diesel No. 2. El uso de estos combustibles causará:

• taponamiento del filtro de combustible

y de la boquilla

• depósitos de carbón en la bujía

• necesidad de usar aditivo anticongelador

no tóxico en el combustible durante el

tiempo muy frío

IMPORTANTE:

macenar KEROSENO SOLAMENTE.

Asegúrese que el envase esté bien limpio.

Las materias extrañas tales como óxido, tierra o agua harán que el control de extinción de

llamas apague el calentador. Las materias

extrañas también harán necesaria la limpieza

frecuente del sistema de combustible.

Utilice un envase para al-

Salida de

aire caliente

Pestaña del

tanque de

combustible

Bastidor de

soporte de

las ruedas

Rueda

Tuerca

ciega

Figura 3 - Conjunto de ruedas y asas, sólo modelos de 29,3/44 kW

(100.000/150.000 Btu/hr)

Tornillo

Tuerca

Eje

Cubo

extendido

4

Asa trasera

Entrada

de aire

VENTILACION

ADVERTENCIA: Observe los

requisitos mínimos de ventilación

de aire fresco exterior. Si no se

provee la ventilación debida con

aire fresco exterior, podría ocurrir

el envenenamiento por monóxido

de carbono. Antes de hacer funcionar el calentador, asegúrese de

proporcionar buena ventilación

con aire fresco exterior.

Deje una abertura de por lo menos 2800 cm

(3 ft2) por cada 29,3 kW (100.000 Btu/hr) de

capacidad para la entrada de aire. Proporcione aire fresco adicional si se usan más

calentadores.

Ejemplo:

Btu/hr) requiere una de las siguientes aberturas:

• puerta de garaje para dos carros de 4,88

• puerta de garaje para un carro de 2,75 m

• dos ventanas de 76,20 cm (30 in.) de ancho

Un calentador de 44 kW (150.000

m (16 ft) de ancho levantada por lo menos 8,59 cm (3,38 in.)

(9 ft) de ancho levantada por lo menos

15,24 cm (6 in.)

levantadas por lo menos 30,48 cm (12 in.)

104468

2

Page 29

MANUAL DEL PROPIETARIO

TEORIA DE

FUNCIONAMIENTO

Sistema de combustible: La bomba de

aire fuerza el paso del aire por la línea de

aire. De allí, el aire es empujado a través de

la boquilla del quemador. Este aire hace que

el combustible del tanque suba. Un vapor

fino de combustible es rociado en la cámara

de combustión.

Sistema de aire: El motor hace girar el

ventilador. El ventilador empuja el aire al

interior y alrededor de la cámara de combustión. Este aire se calienta y proporciona un

chorro de aire caliente y limpio.

Sistema de encendido: El ignitor electrónico envía voltaje a la bujía. La bujía

enciende la mezcla de combustible y aire.

Sistema de control de extinción de

llamas: Este sistema apaga el calentador

en caso de extinguirse la llama.

Cámara de

combustión

Salida

de aire

caliente

y limpio

FUNCIONAMIENTO

ADVERTENCIA: Estudie y

comprenda las advertencias dadas en la sección Información de

seguridad. Son necesarias para

el funcionamiento sin peligro de

este calentador. Respete todos

los códigos locales al usar este

calentador.

Para encender el calentador

1. Observe toda la información sobre ventilación y seguridad.

2. Llene el tanque de combustible con

keroseno o fueloil No. 1.

3. Ponga la tapa de combustible.

4. Enchufe el cordón eléctrico del calentador en un tomacorriente estándar de 230

V/50 Hz con puesta a tierra. Utilice un

cordón de extensión si es necesario. Use

solamente un cordón de extensión de tres

clavijas con puesta a tierra.

Bomba de

aire

Bujía

Quemador

Motor

Ventilador

Filtro de

admisión

de aire

Entrada

de aire

frío

Requisitos del calibre del

alambre del cordón de

extensión

Hasta 30,5 m (100 ft) de largo, use conductores de 1,0 mm2 (16 AWG); de 30,6 a 61 m

(101 a 200 ft), use conductores de 1,5 mm

(14 AWG)

El calentador arrancará al enchufar el cordón eléctrico en el tomacorriente. De lo

contrario, oprima el botón de reposición del

control de extinción de llamas (vea las Figuras 5 y 6).

Para apagar el calentador

1. Desenchufe el cordón eléctrico del

tomacorriente.

Para volver a encender el

calentador

1. Espere 2 minutos después de apagar el

calentador.

2. Repita los pasos bajo Para encender el

calentador.

Botón de

reposición del

control de

extinción de

llamas

2

Tanque de

combustible

Figura 4 - Vista en corte transversal del funcionamiento

104468

Boquilla

Aire para el sistema

de combustible

Filtro de

combustible

Aire para combustión

y calefacción

Línea de aire

al quemador

5

Filtro de

aire de

salida

Ignitor

electrónico

Combustible

Figura 5 - Botón de reposición del control

de extinción de llamas, modelos de 10,2/

20,5 kW (35/70.000 Btu/hr)

Botón de

reposición del

control de

extinción de

llamas

Figura 6 - Botón de reposición del control

de extinción de llamas, modelo de 29,3/

44 kW (100.000/150.000 Btu/hr)

Page 30

R

CALENTADORES PORTATILES DE AIRE FORZADO

ALMACENAMIENTO,

TRANSPORTE O

EMBARQUE

Nota:

Si se está despachando la unidad para

embarque, las compañías transportistas exigen que los tanques de combustible estén

vacíos.

1. Vaciar el tanque de combustible.

Nota:

Algunos modelos tienen el tapón

de vaciado en el lado inferior del tanque de combustible. De ser así, sacar

el tapón para vaciar todo el combustible. Si el calentador no tiene tapón de

vaciado, vaciar el combustible por la

abertura de la tapa de combustible.

Asegurarse de haber extraído todo el

combustible.

2. Volver a colocar el tapón de vaciado,

si lo tiene.

3. Si se observa la presencia de basura en

el combustible viejo, añadir 1 ó 2 litros

de keroseno al tanque, agitarlo y volver a vaciarlo. Esto ayuda a impedir que

el exceso de basura tapone los filtros

en el futuro.

4. Volver a colocar la tapa del tanque de

combustible o el tapón de vaciado.

Desechar el combustible viejo de manera adecuada. Consultar a una estación

de servicio local que efectúe el reciclaje

de derivados del petróleo.

5. Si se está almacenando la unidad,

almacenarla en un lugar seco. Asegurarse que el lugar de almacenamiento esté

libre de polvo y vapores corrosivos.

IMPORTANTE:

durante el verano para usarlo en la siguiente

temporada fría. El usar keroseno viejo podría dañar el calentador.

No almacenar el keroseno

PROGRAMA DE

MANTENIMIENTO

PREVENTIVO

Item

Tanque de combustible

Filtros de salida de

aire y de pelusa

Filtro de admisión de

aire

Filtro de combustible

Bujía

Paletas del ventilador

Motor

Intervalo

1

Enjuáguelo cada 150-200 horas de

funcionamiento o según sea necesario.

Cámbielos cada 500 horas de funcionamiento o anualmente.

Lávelo con agua y jabón y séquelo

cada 500 horas de funcionamiento

o según sea necesario.

Límpielo dos veces por temporada

de frío o según sea necesario.

Límpiela y ajuste el espacio entre

electrodos cada 600 horas de funcionamiento o según sea necesario.

Límpielas cada temporada o según

sea necesario.

No requerido/lubricado permanentemente.

ADVERTENCIA: Nunca repare el

calentador mientras está enchufado, en funcionamiento o caliente.

Podrían ocurrir graves quemaduras

y electrochoque.

Procedimiento

Vea Almacenamiento,

Transporte o Embarque,

más arriba.

Vea Filtros de salida de aire,

de admisión de aire y de

pelusa, página 10.

Vea Filtros de salida de aire,

de admisión de aire y de

pelusa, página 10.

Vea Filtro de combustible,

página 8.

Vea Bujía, página 9.

Vea Ventilador, página 13.

6

104468

Page 31

MANUAL DEL PROPIETARIO

LOCALIZACION DE

AVERIAS

AVERIA OBSERVADA

El calentador se enciende, pero el control de

extinción de llamas lo apaga después de un

rato corto.

El calentador no enciende, pero el motor

funciona por un rato corto.

ADVERTENCIA: Nunca repare el calentador mientras está enchufado,

en funcionamiento o caliente. Podrían ocurrir graves quemaduras y

electrochoque.

CAUSA POSIBLE

1. Presión incorrecta de la bomba

2. Filtros de salida de aire, de admisión de

aire y de pelusa sucios

3. Filtro de combustible sucio

4. Tierra en la boquilla

5. Cristal de la fotocélula sucio

6. Control de extinción de llamas defectuoso

1. Presión incorrecta de la bomba

2. Depósitos de carbón en la bujía y/o espacio entre electrodos inapropiado

3. Filtro de combustible sucio

4. Tierra en la boquilla

5. Agua en el tanque de combustible

SOLUCION

1. Vea Ajuste de la presión de la bomba,

página 10.

2. Vea Filtros de salida de aire, de admi-

sión de aire y de pelusa, página 10.

3. Vea Filtro de combustible, página 8.

4. Vea Boquilla, página 11.

5. Limpie el cristal de la fotocélula.

6. Sustituya el control de extinción de llamas.

1. Vea Ajuste de la presión de la bomba,

página 10.

2. Vea Bujía, página 9.

3. Vea Filtro de combustible, página 8.

4. Vea Boquilla, página 11.

5. Vacíe y enjuague el tanque de combustible con keroseno limpio. Vea Almace-

namiento, Transporte o Embarque, página 6.

El motor no arranca al enchufar el calentador, el ventilador gira lentamente o no gira.

ADVERTENCIA: ¡Alto voltaje!

6. Ignitor electrónico no conectado a tierra

7. Ignitor electrónico defectuoso

1. El control de extinción de llamas no está

reposicionado

2. Rotor de la bomba atascado

6. Asegúrese que el montaje del ignitor

electrónico esté firmemente apretado.

7. Sustituya el ignitor electrónico.

1. Oprima el botón del control de extinción

de llamas, vea las Figuras 5 y 6 en las

página 5.

2. Si el ventilador gira con dificultad, vea

Rotor de la bomba, página 12.

104468

7

Page 32

R

CALENTADORES PORTATILES DE AIRE FORZADO

PROCEDIMIENTOS

DE SERVICIO

ADVERTENCIA: Nunca repare el calentador mientras está

enchufado, en funcionamiento o

caliente. Podrían ocurrir graves

quemaduras y electrochoque.

Remoción del casco superior

1. Quite los tornillos a lo largo de cada lado

del calentador con una llave de tuercas

de 5/16". Estos tornillos sujetan juntos

los cascos superior e inferior.

2. Levante y quite el casco superior.

3. Quite el protector del ventilador.

Filtro de combustible

(Modelos de 10,2/20,5 kW [35.000/

70.000 Btu/hr])

1. Quite los tornillos de la cubierta lateral

con una llave de tuercas de 5/16".

2. Quite la cubierta lateral.

3. Quite la línea de combustible de caucho

del cuello del filtro de combustible.

4. Palanquee cuidadosamente el buje y el

filtro de combustible para sacarlos del

tanque de combustible.

5. Lave el filtro de combustible con combustible limpio y vuelva a colocarlo en

el tanque.

6. Sujete la línea de combustible de caucho al cuello del filtro de combustible.

7. Vuelva a colocar la cubierta lateral.

Filtro de combustible

(Modelo de 29,3/44 kW [100.000/

150.000 Btu/hr])

1. Quite los tornillos de la cubierta lateral

con una llave de tuercas de 5/16".

2. Quite la cubierta lateral.

3. Quite la línea de combustible superior

del cuello del filtro de combustible.

4. Palanquee cuidadosamente el buje, la

línea de combustible inferior y el filtro

de combustible para sacarlos del tanque de combustible.

5. Lave el filtro de combustible con combustible limpio y vuelva a colocarlo en

el tanque.

6. Sujete la línea de combustible superior

al cuello del filtro de combustible.

7. Vuelva a colocar la cubierta lateral.

Casco

superior

Casco

superior

Protector

del

ventilador

Protector del

ventilador

Figura 7 - Remoción del casco superior,

modelos de 10,2/20,5 kW (35.000/70.000

Btu/hr)

Filtro de

combustible

Cubierta

lateral

Figura 9 - Remoción del filtro de combustible, modelos de 10,2/20,5 kW (35.000/70.000 Btu/hr)

Filtro de combustible, buje

y línea de combustible

inferior

Cubierta lateral

Figura 10 - Remoción del filtro de combustible, modelo de 29,3/44 kW (100.000/150.000 Btu/hr)

Figura 8 - Remoción del casco superior,

modelo de 29,3/44 kW (100.000/150.000

Btu/hr)

Línea de

combustible

Línea de

combustible

superior

8

104468

Page 33

MANUAL DEL PROPIETARIO

PROCEDIMIENTOS

DE SERVICIO

Continuación

Bujía

(Modelo de 10,2 kW [35,000 Btu/hr])

1. Quite el casco superior (vea la página 8).

2. Quite el ventilador (vea la página 13).

3. Quite las mangueras de las líneas de

aire y de combustible del conjunto de

la boquilla.

4. Quite el cable de la bujía.

5. Quite los dos tornillos con una llave de

tuercas de 5/16" y quite la banda

fijadora del quemador.

6. Coloque el cuerpo hexagonal de la bujía en una prensa y apriétela.

7. Quite la tuerca de montaje de la bujía

con una llave de boca de 11/16".

8. Quite la banda fijadora del quemador

de la bujía.

9. Limpie la bujía y ajuste el espacio entre electrodos a 1,4 mm (0.055 in.).

10. Vuelva a colocar la banda fijadora del

quemador en la bujía. Gire la banda

fijadora del quemador para posicionar los

electrodos de la bujía (vea la Figura 13).

11. Apriete la bujía con la tuerca de montaje.

12. Suelte el cuerpo hexagonal de la bujía

de la prensa.

13. Vuelva a colocar la banda fijadora del

quemador en la cámara de combustión.

14. Conecte el cable de la bujía.

15. Sujete las mangueras de las líneas de

aire y de combustible al conjunto de la

boquilla.

16. Vuelva a colocar el ventilador (vea la

página 13).

17. Vuelva a colocar el protector del ventilador y el casco superior.

Cámara de

combustión

Tuerca de

montaje de

la bujía

Manguera de aire

Figura 11 - Remoción de la bujía, modelo

de 10,2 kW (35.000 Btu/hr)

Figura 12 - Espacio entre electrodos de la

bujía, modelo de 10,2 kW (35.000 Btu/hr)

Banda fijadora

del quemador

Figura 13 - Rotación de la bujía, modelo

de 10,2 kW (35.000 Btu/hr)

Banda fijadora

del quemador

Bujía

Cable de

la bujía

Conjunto

de boquilla

Manguera de

combustible

Doble aquí para

ajustar el espacio

Espacio de 1,4 mm

(0,055 in.)

Bujía

(Modelos de 20,5/29,3/44 kW [70.000/

100.000/150.000 Btu/hr])

1. Quite el casco superior (vea la página 8).

2. Quite el ventilador (vea la página 13).

3. Quite el cable de la bujía.

4. Quite la bujía del quemador con una

llave de boca de 13/16".

5. Limpie la bujía y ajuste el espacio entre electrodos:

20,5/29,3 kW (70/100.000 Btu/hr)

Modelos:

1,9 mm (,075 in.) espacio

44 kW (150.000 Btu/hr) Modelo:

2,8 mm (,110 in.) espacio

6. Instale la bujía en el quemador.

7. Conecte el cable de la bujía.

8. Vuelva a colocar el ventilador (vea la

página 13).

9. Vuelva a colocar el protector del ventilador y el casco superior.

Quemador

Cable de la bujía

Bujía

Figura 14 - Remoción de la bujía, modelos

de 20,5/29,3/26,4/44 kW (70.000/100.000/

150.000 Btu/hr)

Doble aquí para

ajustar el espacio

Espacio

Figura 15 - Espacio entre electrodos de la

bujía, modelos de 20,5/29,3/26,4/44 kW

(70.000/100.000/150.000 Btu/hr)

104468

Continúa

9

Page 34

R

CALENTADORES PORTATILES DE AIRE FORZADO

PROCEDIMIENTOS

DE SERVICIO

Continuación

Filtros de salida de aire, de

admisión de aire y de pelusa

1. Quite el casco superior (vea la página 8).

2. Quite los tornillos de la cubierta del

extremo del filtro con una llave de

tuercas de 5/16".

3. Quite la cubierta del extremo del filtro.

4. Reemplace los filtros de salida de aire

y de pelusa.

5. Lave o reemplace el filtro de admisión

de aire (vea Programa de mantenimien-

to preventivo, página 6).

6. Vuelva a colocar la cubierta del extremo del filtro.

7. Vuelva a colocar el protector del ventilador y el casco superior.

IMPORTANTE:

Ajuste de la presión de la

bomba

1. Quite el tapón para manómetro de la

cubierta del extremo del filtro.

2. Instale el manómetro accesorio (No. de

pieza HA1180).

3. Encienda el calentador (vea Funciona-

miento, página 5). Permita que el motor alcance su velocidad plena.

4. Ajuste la presión. Gire la válvula de

alivio hacia la derecha para aumentar

la presión. Gire la válvula de alivio

hacia la izquierda para reducir la presión. Vea las especificaciones a la derecha para obtener la presión correcta

para cada modelo.

5. Quite el manómetro. Vuelva a colocar