Page 1

EASY-LO AD®3PUMP HEADS

Model Numbers 77800-50, -52, -60 and -62

®

Operating Manual

A-1299-5093

Edition 05

Cole-Parmer

1-800-MASTERFLEX (627-8373) (U.S. and Canada only)

11 (847) 549-7600 (Outside U.S.) • (847) 549-7600 (Local)

www.masterflex.com • techinfo@coleparmer.com

Thermo Fisher Scientific

1-800-637-3739 (U.S. and Canada only)

11 (847) 381-7050 (Outside U.S.) • (847) 381-7050 (Local)

www.thermo.com • bar.barnant@thermofisher.com

Page 2

WARNING: To reduce risk of electrical shock, connect only to a

properly grounded, grounding-type receptacle.

WARNINGS: Turn drive off before removing, adjusting or installing

tubing. Fingers or loose clothing could be caught

in the rollers.

(The rotor is partially exposed when the Actuator

lever is in the open position.)

Do not remove back cover. The strong spring inside

may cause injury.

Tubing breakage may result in fluid being sprayed

from pump. Use appropriate measures to protect

operator and equipment.

WARNING: Risk of crushing. Keep fingers away from rotor while

pump is in operation. Stop pump before loading or

unloading tubing.

Fingers may be trapped between rollers on the

pump rotor.

2

SAFETY PRECAUTIONS

NOTE:

Use only MASTERFLEX precision tubing with MASTERFLEX

pumps to ensure optimum performance. Use of other tubing

may void applicable warranties.

WARNING : PRODUCT U SE LIMITATION

This product is not designed for, nor intended for use

in, patient-connected applications, including, but not

limited to medical and dental use and, accordingly,

has not been submitted for FDA approval.

EX PL ANATIO N O F SYM BOL S

WARNING: This word and symbol are needed in safety messages for

hazards that are not immediately accessible, but that

present a probability of serious personal injury if the

hazards are not avoided. These safety messages describe

precautions that must be taken to avoid hazards.

WARNING or DANGER: Warning or Danger with this symbol indicates

probability of serious injury exists if crushing hazard is

not avoided.

C-FLEX — Reg TM Consolidated Polymer Technologies, Inc.

Norprene, PharMed, Tygon — Reg TM Saint-Gobain Performance Plastics Corp.

VITON — Reg TM E.I. duPont DeNemours & Co.

Trademarks bearing the ® symbol in this publication are registered in the U.S. and in other countries.

U.S. patent pending on the pump products described in this manual.

Page 3

3

Number of rollers: 3

Maximum pump speed (rpm): 600

Maximum torque load—Starting: 400 oz-in (29 kg-cm)

Maximum torque load—Running: Up to 180 oz-in (13 kg-cm)

Housing materials: Glass-filled polypropylene (PP), polyphenylene

sulfide (PPS), nylon (PA)

Roller materials: Cold-rolled steel (CRS) / Stainless steel (SS)

Bearing materials: Carbon steel / sealed stainless steel

Rotor materials: Stainless steel

Chemical resistance: Most substances, except strong acids or alkalis,

organic solvents or hydrocarbons.

Operating Temperature

‡

: 32°F to 104°F (0°C to 40°C)

Storage Temperature: –49°F to 149°F (–45°C to 65°C)

Humidity: 10% to 90% (non-condensing)

Altitude: 2000 m or less

Dimensions (W × H × D): (Excluding shaft and cosmetic cover)

Operating: 3.45" × 4.75" × 3.08" (8.8 cm × 12.1 cm × 7.8 cm)

Open: 3.45" × 5.65" × 3.08" (8.8 cm × 14.4 cm × 7.8 cm)

Weight: 1.1 lb (0.5 kg)

*

For NORPRENE®, PHARMED®BPT, and TYGON®tubing.

Values will be less with silicone, C-FLEX

®

, and Viton®.

Flow rate and discharge pressure will vary based on tubing size, formulation, and operating temperature.

The chart above is only a guide.

‡

Use in this temperature range for continuous duty operation with no decrease in performance or product life.

Pump Heads will work outside this range with some possible reductions in performance or product life.

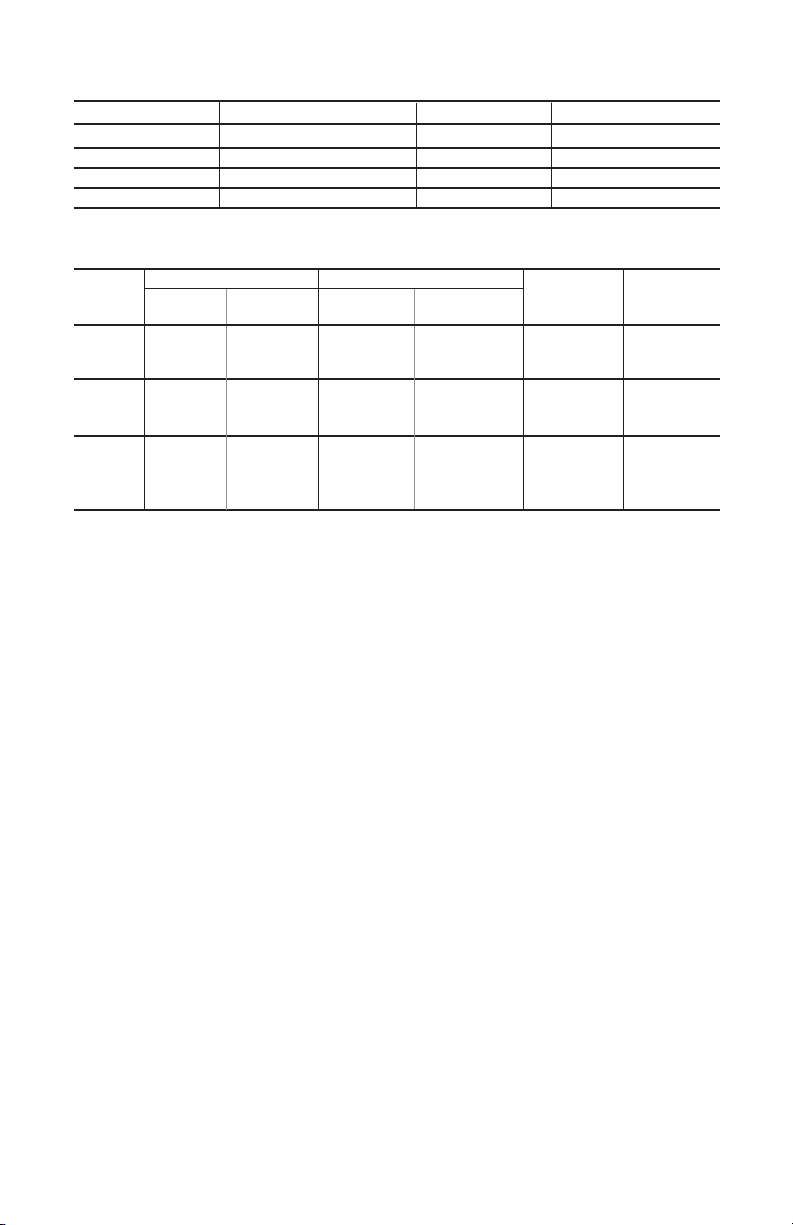

Pump Head Number Roller and Bearing Material Number of Rollers L/S®Tubing

77800-50 CRS and Carbon Steel 3 L/S®13, 14, 16, 25, 17, 18

77800-52 CRS and Carbon Steel 3 L/S®15, 24, 35, 36

77800-60 Stainless Steel 3 L/S®13, 14, 16, 25, 17, 18

77800-62 Stainless Steel 3 L/S®15, 24, 35, 36

SPECIFICATIONS

Typical Flow, Pressure and Vacuum Data—3 roller pumps

LS

®

FLOW RATE*DISCHARGE PRESSURE* Vacuum* Suction Lift*

Tubing

@ 1 rpm @ 600 rpm Continuous Intermittent @ 600 rpm @ 600 rpm

mL/Rev mL/min psig (bar) psig (bar) in (mm) Hg ft (m) H

2

0

L/S

®

13 0.06 36 25 (1.7) 40 (2.7) 26 (660) 29 (8.8)

L/S

®

14 0.22 130 25 (1.7) 40 (2.7) 26 (660) 29 (8.8)

L/S®16 0.80 480 25 (1.7) 40 (2.7) 26 (660) 29 (8.8)

L/S

®

25 1.7 1000 20 (1.4) 35 (2.4) 26 (660) 29 (8.8)

L/S

®

17 2.8 1700 15 (1.0) 20 (1.4) 20 (510) 22 (6.7)

L/S®18 3.8 2300 10 (0.7) 15 (1.0) 20 (510) 22 (6.7)

L/S

®

15 1.7 1000 25 (1.7) 30 (2.7) 26 (660) 29 (8.8)

L/S

®

24 2.8 1700 25 (1.7) 30 (2.7) 26 (660) 29 (8.8)

L/S

®

35 3.8 2300 20 (1.4) 25 (2.4) 26 (660) 29 (8.8)

L/S®36 4.8 2900 15 (1.0) 20 (1.4) 24 (610) 27 (8.3)

Page 4

INTROD UC TION AND GENERAL DESCRIPTION

This L/S®EASY-LOAD®3 Pump Head, when combined with a MASTERFLEX L/S drive or

compatible system, is designed to provide a simple, easy-to-use peristaltic pump system.

The Pump Head accepts several different tub ing sizes for a wide range of flow rates. The

unique lever actuator design and automatic tubing retention allow quick tubing changes.

This pump is designed to transfer or dispense liquids of various viscosities, as well as solids

suspended in liquids. It is NOT intended to pump flammable or explosive substances.

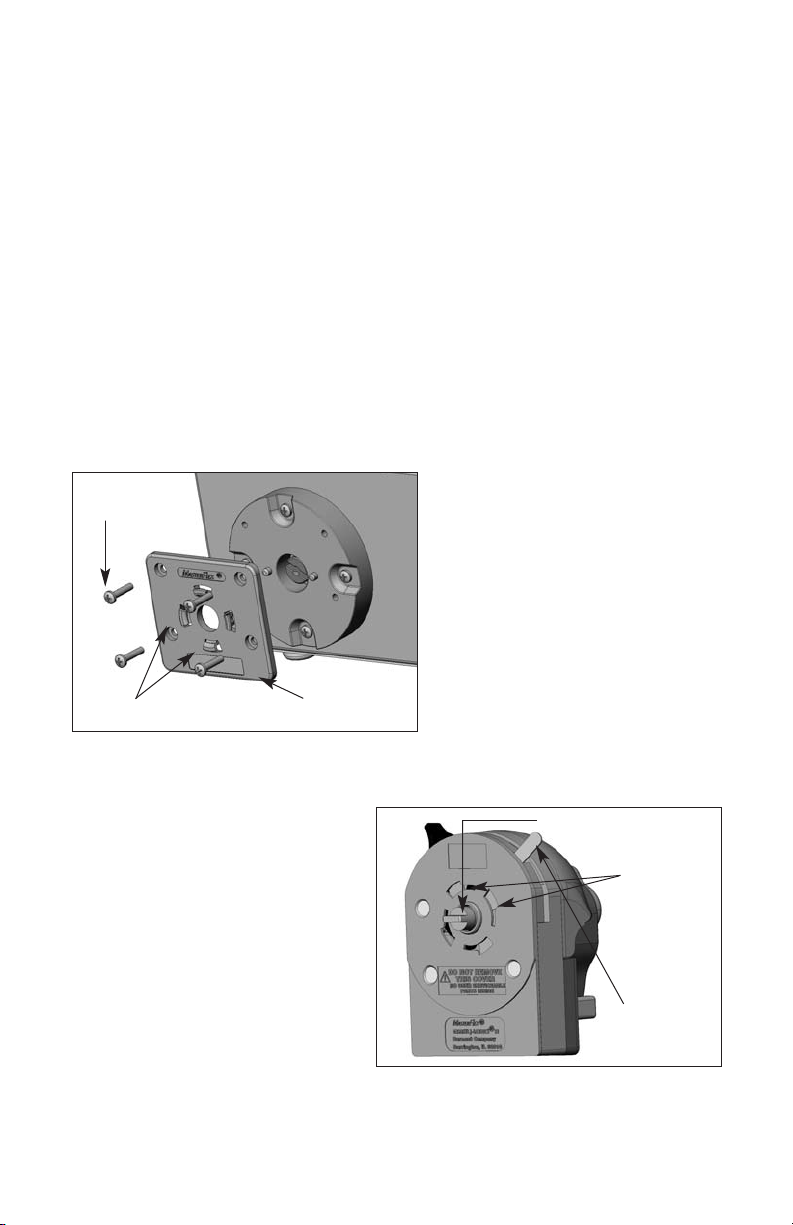

A mounting kit adapts this pump to MASTERFLEX L/S drives. The kit includasterflexting plate

and four screws, which are used to attach the mounting plate to a drive. Pumps are easily

and quickly attached to the mounting plate, or another pump, by means of the bayonet feature

on the back of the pump. The pump may be mounted with tubing entering and exiting to the

left, right, up or down. Mounting orientation options may be limited with some drives. Pumps

are just as easily removed, using the one-finger release lever on the upper left side of the

pump. The tang on the pump shaft couples the pump to standard MASTERFLEX drives, for

power transmission.

Each pump is supplied complete with a 17-inch (43-cm) length of tubing, one mounting kit and

this manual. A Phillips screwdriver is required to complete installation.

4

FIGURE 1

Attaching Mounting Plate to Drive

FIGURE 2

Back of EASY-LOAD 3 Pump

Pump Shaft with Tang

Bayonet

Features

Bayonet Lock

Lever-in Rear,

Locked Position

(4) screws

Bayonet Tabs

Mounting Plate

Page 5

INSTALLATION a nd REMOVAL

Attach the mounting plate to the MASTERFLEX drive, with the four Phillips head screws provided

in the mounting kit. (See Figure 1.) Orient the pump with its back facing the drive. Insert the tang

on the pump shaft into the slot in the shaft on the drive. Align the bayonet features on the pump

back with the bayonet tabs on the front of the mounting plate. (See Figures 1, 2 and 3.) The pump

should be tilted about 30 degrees counter-clockwise from the intended installed orientation.

Finally, press the pump firmly against the drive and rotate clockwise, until no more rotation is

possible (about 30 degrees). (See Figure 4.) The bayonet lock lever will snap toward the back

of the pump and automatically lock the pump to the mounting plate.

To remove the pump from the drive, pull the bayonet lock lever forward. Hold the lever forward

while rotating the pump as far counterclockwise as possible (approximately 30 degrees).

Then pull the pump away from the drive. The actuator lever should be in the far right position

when removing the pump. (See Figure 5.)

WARNING: Stop the drive before installing or removing

the pump from a drive

FIGURE 3

Position for Engaging Bayonet Feature

for Horizontal Mounting

FIGURE 4

Pump Bayonet Feature Locked

in Horizontal Pump Orientation

Approximately 30°

5

Page 6

TUBING LOADING a nd UN LOADING

To load tubing, open the pump by moving the actuator lever counterclockwise (left, if pump is

mounted vertically). (See Figures 5 and 6.) Insert a loop of tubing into one open tubing

retainer, between the occlusion bed and the rollers and into the other tubing retainer. (See

Figure 7.) Position the tubing so that it is firmly against the rollers and centered on the length

of the roller. While holding the tubing ends, move the actuator lever back to the far clockwise

(right) position, as shown in Figure 5. The pump will automatically grip the tubing. Tubing sizes

L/S

®

13, L/S®14, L/S®16, L/S®25, L/S®17 and L/S® 18 (thin wall) will automatically be

stretched by the pump. Approximately 5 pounds of force must be applied to the actuator lever

to fully close the pump and place the lever in its locked position (far right position) or to fully

open the pump (far left position). NOTE: It is not necessary to have an end of the tubing free to

load or unload tubing from the pump. A length of tubing, attached to other devices, may be

loaded into the pump, without disconnecting the tubing from adjacent devices.

WARNING: Stop the drive before installing or removing

tubing from the pump.

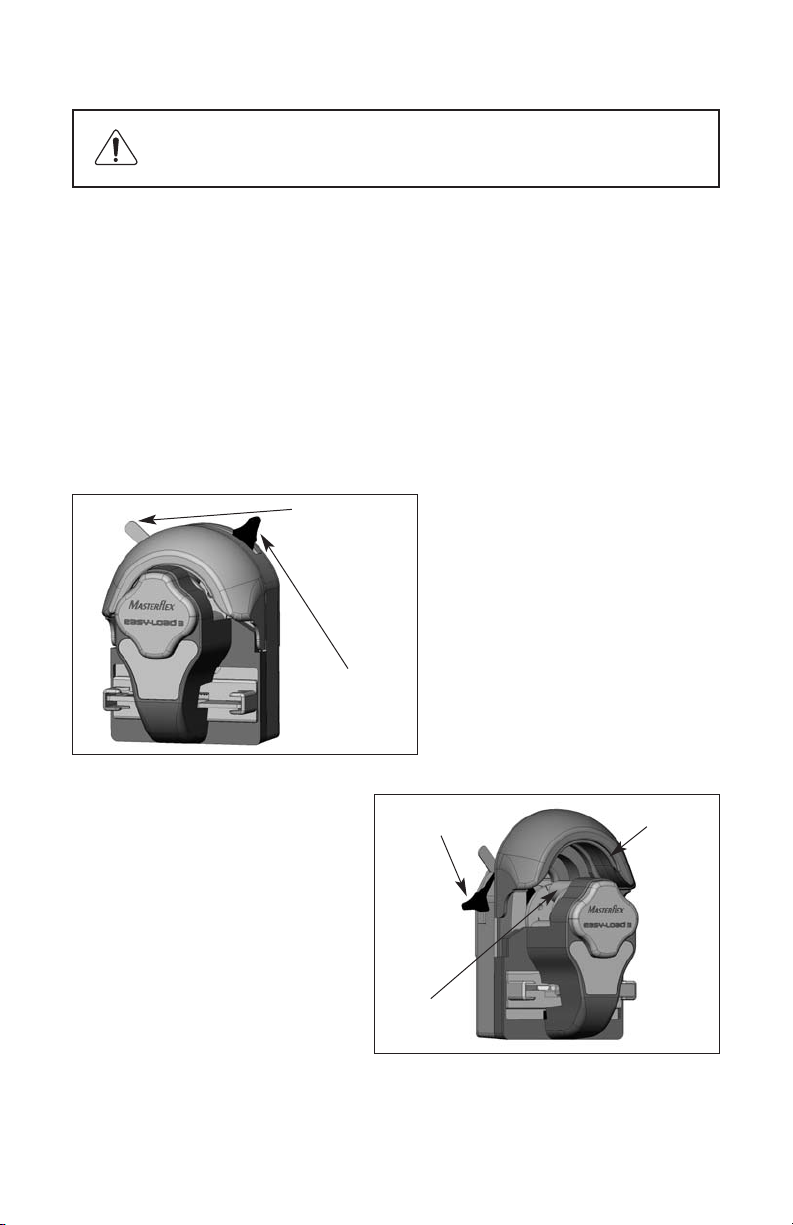

FIGURE 5

EASY-LOAD 3 Pump

in Fully Closed Position

FIGURE 6

EASY-LOAD 3 Pump

in Fully Open Position

Bayonet Lock

Lever-Pull

Forward

to Release

Actuator Lever-Far

Left Position

Actuator

Lever-Far

Right Position

Occlusion Bed

Roller

(one of 3 or 6)

6

Page 7

7

FIGURE 7

Tubing Path Through Pump—During Loading

Tubing

Retainer

(one per side)

To unload tubing from the pump, turn off the drive. Then open the pump by moving the

actuator lever counterclockwise (left), as described above. The pump will automatically open

the tubing retainers, as well as lifting the occlusion bed away from the tubing. Then pull the

tubing away from the pump front.

Occlusion

Bed

NOTE: When pump is not being used, store with actuator lever halfway between far left and

far right positions. (See figures 5 and 6.)

Page 8

8

MULTI-C HANNEL MOUNTING

L/S EASY-LOAD 3 Pump Heads can be mounted in tandem (up to three), depending on the

torque capabilities of the drive. (See Figures 8, 9 and 10.) Once the mounting plate is

attached to a drive, no other mounting hardware is required. To use 4 pumps on one drive,

call dealer for recommendations.

To install a second pump, the cosmetic cover must be removed from the first pump.

Grasp the cover by the notches and pull it off. (See Figure 8.) Align the second pump

to the first, as if the first pump were a drive. Follow single pump mounting instructions

in ”INSTALLATION AND REMOVAL“. (See Figures 9 and 10.)

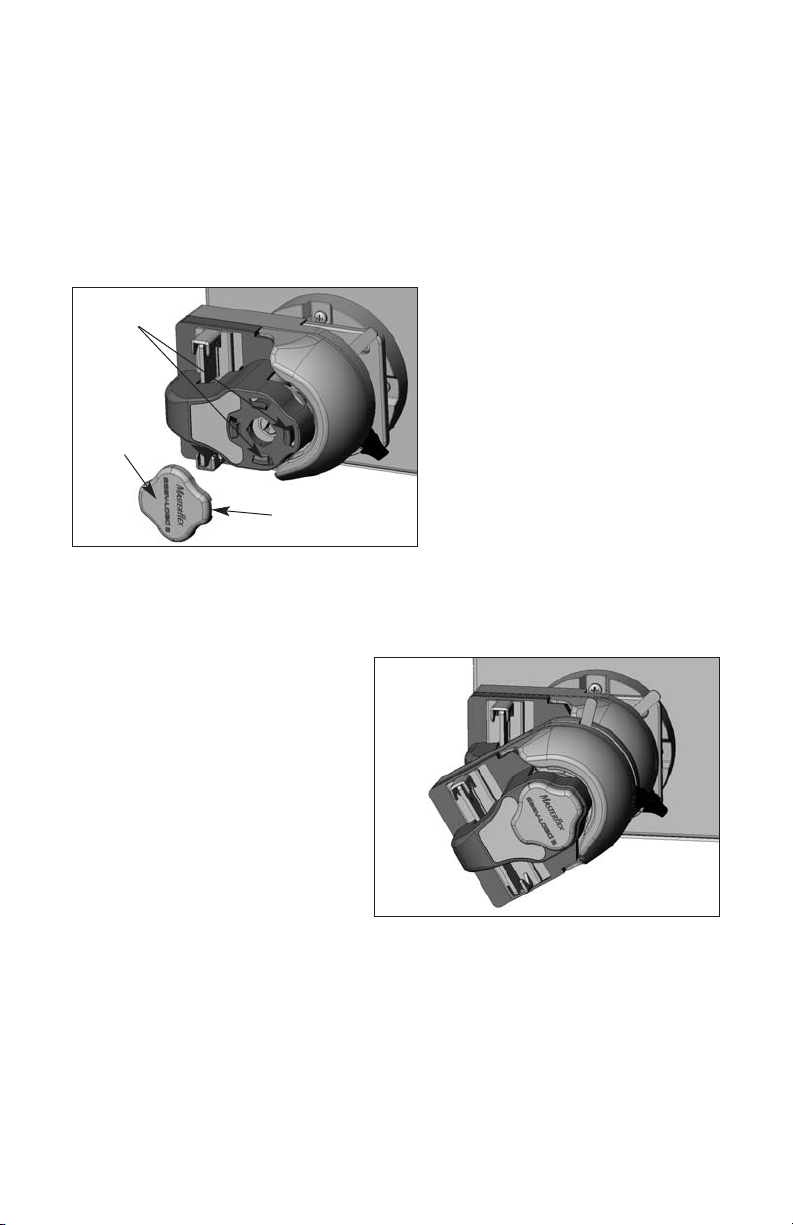

FIGURE 8

Preparation to Mount a Second Pump

Cosmetic

Cover

Notch (here and

on opposite edge)

Bayonet Tabs

on Pump Front

FIGURE 9

Engaging Bayonet Feature of Second

Pump to Bayonet Tabs on First Pump

Page 9

9

CAUTION:

Be sure that bayonet features on back of each

pump are fully engaged with bayonet tabs on

front of mounting plate or adjacent pump front

before operating pump. Bayonet lock lever

(see Figure 5) will snap back when bayonet

features engage completely.

NOTE: The tubing on the inside L/S EASY-LOAD 3 Pump Head(s)

can be changed without removing the outside Pump Head(s)

from the drive.

FIGURE 10

Drive with 2 Pumps Locked in Position

Page 10

10

MAINTENANCE AND CLEANING

■

No lubrication is required for the L/S EASY-LOAD 3 Pump Head.

■

Use a mild detergent solution or 70% isopropyl alcohol only to clean the Pump Head.

■

Do not immerse nor use excessive fluid.

■

This pump requires no maintenance, other than cleaning. There are no

user serviceable or replaceable parts inside.

REPLACEMENT PARTS AND ACCESSORIES

Mounting Plate Kit for L/S EASY-LOAD 3 Pump Heads: 77800-00

Kit contains (4) 8-32 screws and the mounting plate.

This kit adapts the EASY-LOAD 3 Pump Head to MASTERFLEX L/S pump drives.

Page 11

11

Printed in U.S.A.

WARRANTY

The Manufacturer warrants this product to be free from significant deviations from published specifications. If repair or adjustment is necessary

within the warranty period, the problem will be corrected at no charge if it

is not due to misuse or abuse on your part as determined by the

Manufacturer. Repair costs outside the warranty period, or those resulting

from product misuse or abuse, may be invoiced to you.

The warranty period for this product is two (2) years from the date of

purchase.

PRODUCT RETURN

To limit charges and delays, contact the seller or Manufacturer for authorization and shipping instructions before returning the product, either within or outside of the warranty period. When returning the product, please

state the reason for the return. For your protection, pack the product carefully and insure it against possible damage or loss. Any damages resulting

from improper packaging are your responsibility.

TECHNICAL ASSISTANCE

If you have any questions about the use of this product, contact the

Manufacturer or authorized seller.

Cole-Parmer

1-800-MASTERFLEX (627-8373) (U.S. and Canada only)

11 (847) 549-7600 (Outside U.S.)

(847) 549-7600 (Local)

www.masterflex.com

techinfo@coleparmer.com

Thermo Fisher Scientific

1-800-637-3739 (U.S. and Canada only)

11 (847) 381-7050 (Outside U.S.)

(847) 381-7050 (Local)

www.thermo.com

bar.barnant@thermofisher.com

Loading...

Loading...