Page 1

FOR ALL MODELS OF

EASY-LOAD

®

PUMP HEADS

®

®

OPERATING MANUAL

A-1299-1149

Edition 02

(US & Canada only) Toll Free 1-800-MASTERFLEX ● 1-800-637-3739

(Outside US & Canada) 1-847-549-7600 ● 1-847-381-7050

www.masterflex.com ● techinfo@masterflex.com

®

Page 2

EXPLANATION OF SYMBOLS

CAUTION: Risk of danger. Consult the Operator's Manual for

nature of hazard and corrective actions.

CAUTION: Risk of crushing. Keep fingers away from rotor while

pump is in operation. Stop pump before loading or unloading tubing.

2 7

NOTE: Use only MASTERFLEX precision tubing with MASTERFLEX pumps to

ensure optimum performance. Use of other tubing may void applicable

warranties.

WARNING: PRODUCT USE LIMITATION

This product is not designed for, nor intended for use in patient

connected applications; including, but not limited to, medical and dental use,

and accordingly, has not been submitted for FDA approval.

Printed in U.S.A.

C-FLEX, NORPRENE, PHARMED, TYGON — Reg TM Saint-Gobain Performance Plastics Corp.

Trademarks bearing the ® symbol in this publication

are registered in the U.S. and in other countries.

SAFETY PRECAUTIONS

WARNINGS: Turn drive off before removing or installing tubing. Fingers or loose

clothing could be caught in the rollers.

Stop the drive when changing the tubing or its position in the rotor

mechanism (the rotor is partially exposed when the LOADING LEVER is

in the open position).

CAUTION: DO NOT OVERTIGHTEN SCREWS OR WING NUTS.

PUMP FOR LIQUIDS

ORIGINAL INSTRUCTIONS

(US & Canada only) Toll Free 1-800-MASTERFLEX • 1-800-637-3739

(Outside US & Canada) 1-847-549-7600 • 1-847-381-7050

www.masterflex.com • techinfo@masterflex.com

*EN809 manufactured by:

Cole-Parmer Instrument Company

28W092 Commercial Avenue

Barrington, IL 60010

®

Page 3

3

WARRANTY

Use only MASTERFLEX precision tubing with MASTERFLEX pumps to ensure

optimum performance. Use of other tubing may void applicable warranties.

The Manufacturer warrants this product to be free from significant deviations from

published specifications. If repair or adjustment is necessary within the warranty

period, the problem will be corrected at no charge if it is not due to misuse or abuse

on your part, as determined by the Manufacturer. Repair costs outside the warranty

period, or those resulting from product misuse or abuse, may be invoiced to you.

The warranty period for this product is two (2) years from the date of

purchase.

PRODUCT RETURN

To limit charges and delays, contact the seller or Manufacturer for authorization

and shipping instructions before returning the product, either within or outside of

the warranty period. When returning the product, please state the reason for the

return. For your protection, pack the product carefully and insure it against

possible damage or loss. Any damages resulting from improper packaging are your

responsibility.

TECHNICAL ASSISTANCE

If you have any questions about the use of this product, contact the Manufacturer

or authorized seller.

6

INTRODUCTION AND GENERAL DESCRIPTION

This EASY-LOAD Pump Head when combined

with a MASTERFLEX®I/P®drive or compatible

system is designed to provide a simple easy-to-use

peristaltic pump system. The Pump Head accepts

3 different tubing sizes for a wide range of flow

rates. The unique over-center cam design and

automatic tubing retention allows quick tubing

changes and greatly reduced maintenance time.

Each pump is supplied complete with a 20 in

(50-cm) length of tubing, one mounting hardware package and this manual. A flat-bladed

screwdriver is required to complete installation.

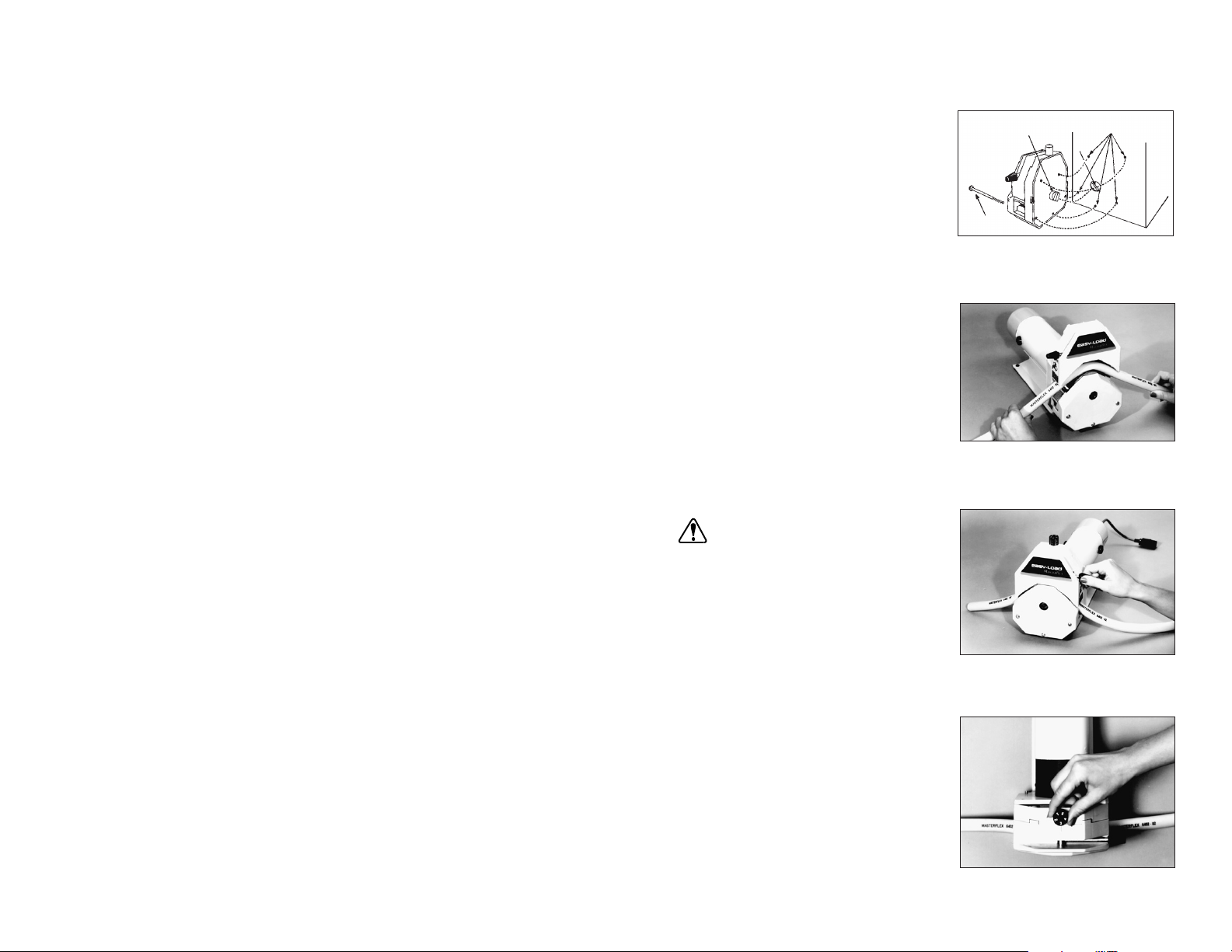

DRIVE COMPATIBILITY AND SETUP

The I/P EASY-LOAD Pump Head is available in two

drive shaft lengths depending upon the drive

chosen. The short shaft versions have a standard

tang interface. Mount the Pump Head using the

5 screws provided. (See Figure #1.)

NOTE: Raise occlusion bed to expose mounting

holes for top 2 short screws.

TUBE LOADING

1. Be sure the pump drive is turned off.

2. Move the lever to the left to open the pump.

3. Load the correct tubing. (Figure #2.)

4. Move the lever to the right to close. (Fig. #3.)

WARNING: Stop the drive when changing the

tubing or its position in the rotor

mechanism (the rotor is partially exposed

when the LOADING LEVER is in the open

position).

NOTE: For optimum tubing life, keep tubing

straight when entering and exiting the pump.

OCCLUSION ADJUSTMENT

Adjust occlusion setting on top of Pump H ead.

(Figure #4.)

“3” for nominal performance;

“4” or “5” for increased pressure/vacuum with

reduced tubing life;

“1” or “2” for longer life with less pressure

and vacuum.

NOTE: For optimum performance turn knob to

“1” after loading. Start drive and adjust knob until

pump primes and fluid begins to flow.

NOTE: Occlusion usually does not need to be

readjusted when changing tubing.

NOTE: After operation for some time, the retainer

teeth may scratch or mark the surface of the

tubing. This is normal and will not cause leaks or

otherwise reduce tubing life.

Figure #1. Setup

Figure #2. Open and Load

Figure #3. Close Pump

Figure #4. Adjust Occlusion

Mounting

Holes

Mounting Bolt

Motor

Shaft

Pump Shaft Tang

Page 4

Pump Head number Housing Material Shaft Length Tubing

77602-00 PPS/CRS Short

I/P ®26, 73, 82

77602-10 PPS/SS Short I/P

®

26, 73, 82

77602-02 PPS/CRS Long I/P

®

26, 73, 82

77602-12 PPS/SS Long I/P

®

26, 73, 82

77601-60 PPS/SS Short I/P

®

26, 73, 82

77601-62 PPS/SS Long I/P

®

26, 73, 82

4

MAINTENANCE AND CLEANING

No lubrication is required for the I/P EASY-LOAD Pump Head. Use a mild detergent solution

to clean the Pump Head. Inspect the tang boot after 1,000 hours of operation and replace

if necessary.

REPLACEMENT PARTS AND ACCESSORIES

A. Main body assembly (occlusion bed with rear bearings).

Pump Head number PPS order number Pump Head number PPS order number

77602-00, -02 77602-07 — —

77602-10, -12 77602-17 77601-60,-62 77601-67

B. Rotor/bearing support assembly.

D. Mounting hardware for I/P EASY-LOAD

pump heads.

Number of heads Stainless steel

to be mounted order number

1 77601-95

2 77601-96

Figure #5.

C. Tubing retainer kit 77601-06

Includes two retainer assemblies, back plate and screws.

MULTI-CHANNEL MOUNTING

I/P EASY-LOAD Pump Heads can be mounted in

tandem depending upon the torque capabilities of

the drive. A standard short shaft Pump Head is

required for the add-on head along with special

mounting hardware. (See Figure #5.)

See REPLACEMENT PARTS AND ACCESSORIES for

mounting hardware.

CAUTION: DO NOT OVERTIGHTEN

SCREWS OR WING NUTS.

NOTE: The tubing on the inside EASY-LOAD Pump

Head can be changed without removing the

outside Pump Head.

Mounting

Holes For

Tandem Units

Pump Head number Short shaft order No. Pump Head number Long shaft order No.

77602-00 77602-08 77602-02 77602-28

77602-10 77602-18 77602-12 77602-38

77601-60 77601-68 77601-62 77601-88

C

D

C

B

A

5

SPECIFICATIONS

I/P ®26, I/P ® 73 I/P ®82

Maximum discharge pressure—

psi (bar): 40 (2.7)* 20 (1.4)*

Maximum vacuum: 660 mm (26) in Hg* 610 mm (24) in Hg*

Maximum suction lift: 8.8 m (29 ft) H2O* 8.2 m (27 ft) H2O*

Number of rollers: 3

Occlusion: Adjustable (with Knob on top of Pump Head)

Maximum pump speed (rpm): 650

Nominal torque load-Starting: up to 13 kg-cm (180 oz-in)

Nominal torque load-Running: up to 9 kg-cm (120 oz-in)

Housing material: Polyphenylene sulfide (PPS), Polyester, Aluminum, Nylon

Roller/rotor materials: Cold-rolled steel (CRS) or Stainless steel (SS)

Operating temperature‡ : 0 to 40°C (32 to 104°F)

Noise level: <70 dBA @ 1 meter

Compliance (for CE mark): EN809 (EU Machinery Directive)

* Testing with NORPRENE®, PHARMED®BPT and TYGON®tubing. Values will be less with silicone and C-FLEX®.

‡ Use in this temperature range for continuous duty operation with no decrease in performance

or product life. Pump heads will work outside this range with some possible reductions in

performance or product life.

E

E. Tang Boot. Order number 77600-02

(pkg. of 2) or 77600-03 (pkg. of 10)

Loading...

Loading...