Page 1

OPERATING MANUAL

HIGH-PERFORMANCE

HAZARDOUS-DUTY

PUMP HEAD

Model 77250-82

®

®

A-1299-5133

Edition 03

1-800-MASTERFLEX (627-8373) (U.S. and Canada only)

11 (847) 549-7600 (Outside U.S.) • (847) 549-7600 (Local)

www.masterflex.com • techinfo@coleparmer.com

Page 2

2

WARNINGS: Turn drive off before removing or installing tubing. Fingers

or loose clothing could be caught in the rollers.

Periodically examine bearings and moving parts for excessive wear that can cause overheating of surfaces from friction.

Select tubing for chemical compatibility. Ground or

electrically bond containers during fluid transfer to avoid

electrostatic charge buildup that can ignite vapors when

discharged. Refer to NFPA 77.

ATEX Ratin g: The models are rated as Group II, Category 3 (Zone 2) equipment

using constructional safety (c) protection, with a T6 (<85° C) temperature

classification for use in Gas Group IIC (acetylene) environments:

EXPLANATIO N OF SYMBO LS

CAUTION: Risk of danger. Consult the Operator's Manual for

nature of hazard and corrective actions.

CAUTION: Risk of crushing. Keep fingers away from rotor while

pump is in operation. Stop pump before loading or unloading tubing.

WARNING: Risk of Ignition. Periodically examine bearings and

moving parts for excessive wear that can cause overheating of surfaces

from friction. Ground or electrically bond containers during fluid transfer

to avoid electrostatic charge buildup that can ignite vapors when

discharged.

WARNING: PROD UCT USE LIMITATION

This product is not designed for, nor intended for use in patient

connected applications; including, but not limited to, medical and dental use,

and accordingly, has not been submitted for FDA approval.

E II 3 G c IIC T6

North American Rating: Class I, Division 2, Groups A, B, C, & D, T6

MASTERFLEX, L/S, EASY-LOAD – Reg TM Cole-Parmer

C-FLEX, NORPRENE, PHARMED, TYGON – Reg TM Saint-Gobain Performance Plastics Corp.

Trademarks bearing the ® symbolin this publication are registered

in the U.S. and in other countries.

PUMP FOR LIQUIDS

ORIGINAL INSTRUCTIONS

Page 3

3

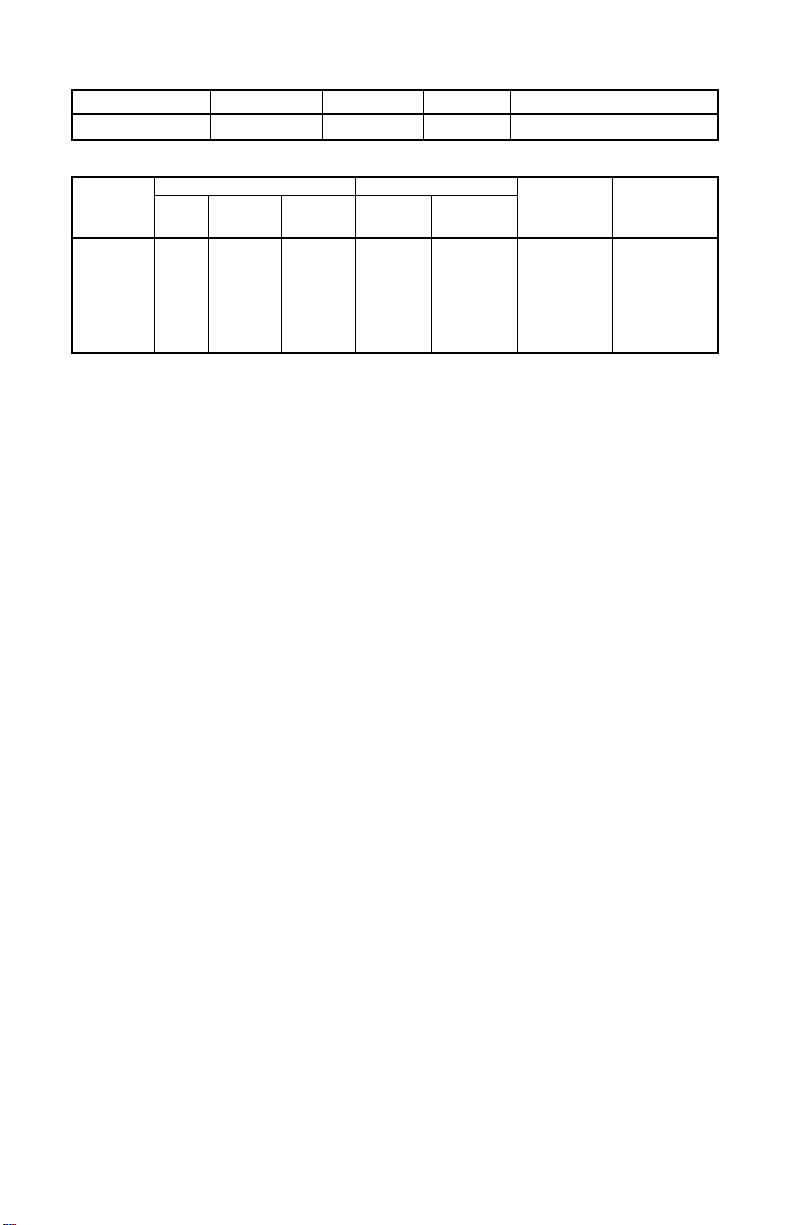

SPECIFICATIONS

Typical Flow, Pressure and Vacuum Data:

L/S

®

Flow rate (cw) Discharge Pressure* Vacuum* Suction Lift*

Tubing @ 1 rpm @ 100 rpm @ 600 rpm Continuous Intermittent @ 600 rpm @ 600 rpm

mL/min mL/min mL/min psig (bar) psig (bar) in (mm) Hg ft (m) H

2

0

L/S

®

16HP** .9 90 — 100 (6.8) 125 (8.5) — —

L/S

®

15HP** 1.7 170 — 80 (5.5) 100 (6.8) — —

L/S

®

15 1.8 — 1100 25 (1.7) 40 (2.7) 26 (660) 29 (8.8)

L/S

®

24 3.0 — 1800 25 (1.7) 40 (2.7) 26 (660) 29 (8.8)

L/S

®

35 4.3 — 2600 20 (1.4) 35 (2.4) 26 (660) 29 (8.8)

L/S

®

36 5.8 — 3400 15 (1.0) 20 (1.4) 24 (610) 27 (8.3)

Number of rollers: 3

Occlusion: Fixed

Maximum pump speed (rpm): 600

Nominal torque load—Running: up to 180 oz-in (13 kg•cm)

Housing materials: Stainless steel (SS), polyester (PE) body,

polyphenylene sulfide (PPS) tubing bed,

polypropylene (PP) knob

Roller/bearing materials: Stainless Steel (SS)/Sealed Stainless Steel

Rotor materials: Stainless Steel (SS)

Operating Temperature

‡

: 32°F to 104°F (0°C to 40°C)

Storage Temperature: –40°F to 149°F (–40°C to 65°C)

Humidity: 5% to 95% (non-condensing)

Dimensions (W

×H ×

D):

Operating: 3.7 in

×

3.5 in ×3.0 in (94 mm ×89 mm ×76 mm)

Open: 4.5 in

×

3.5 in ×5.1 in (114 mm ×89 mm ×130 mm)

Weight: 2.1 lb (0.96 kg)

Noise level: <70 dBA @ 1 meter

Compliance (for CE mark): EN809 (EU Machine Directive)

* As tested with NORPRENE®, PHARMED®BPT, and TYGON®tubing.

Values will be less with silicone and C-FLEX

®

.

** L/S

®

15HP and L/S® 16HP tubing are for use only with the MASTERFLEX®L/S®High-Performance Pump Head

and any MASTERFLEX

®

L/S®1 to 100 rpm drive capable of running two or more pump heads.

‡ Use in this temperature range for continuous duty operation with no decrease in performance or product life.

Pump heads will work outside this range with some possible reductions in performance or product life.

Pump Head Number Pump Material Occlusion Shaft Length L/S®Tubing

77250-82 PPS/PE/SS Fixed Short L/S

®

15, 24, 35, 36, 16HP, 15HP

Page 4

INTRODUCTION

The MASTERFLEX®L/S®High-Performance Pump Head delivers in excess of

3 L/min flow at normal MASTERFLEX operating speeds and pressures. It is

designed for optimal pumping in the clockwise direction. There are two mounting

positions. Tubing entry and exit are either on the left side or on top of the pump

when mounted on a MASTERFLEX

®

L/S®Drive. The pump will operate with any

MASTERFLEX

®

L/S®drive with 180 oz-in (13 kg•cm) or more output torque.

SETU P AND O PERATION

Pump Drive Compatibility

The High-Performance Pump Head has a standard shaft interface to

accommodate MASTERFLEX

®

L/S®Pump Drives. Pump drive must provide

180 in-oz (13 kg•cm) torque. (NOTE: These drives are usually designated as

capable of driving two or more pump heads.)

Mounting Pump Head to Drive

1. Check that pump drive is turned OFF.

2. Align pump shaft tang with slot in motor shaft.

3. If pump drive has alignment pins, slide Pump Head alignment holes over

pins.

4. Secure pump to pump drive with the two mounting screws (furnished).

a. For left side tubing entry and exit, use round mounting holes.

(Labeled "A" in Figure 1.)

b. For top tubing entry and exit, use hexagonal mounting holes.

(Labeled "B" in Figure 1.)

Selecting Tubing

Pumps accept only L/S®15, L/S®24, L/S®35 and L/S®36, L/S®16HP, L/S®15HP

tubing. Use only MASTERFLEX tubing that is surface-printed with the tubing

designation.

4

Figure 1. Mounting Holes

A

A

B

B

Page 5

Loading Tubing

WARNING: Turn off drive before removing or installing tubing.

Fingers or loose clothing could be caught in the rollers.

1. Rotate tubing retainer knob, Figure 2, counterclockwise to release retainer,

then pull to open cover.

2. Lift latch to open occlusion bed.

Figure 2. High-Performance Pump Head

5

Page 6

3. Insert the MASTERFLEX tubing inside tubing guide and around rotor with the

ends of the tubing extending out of the tubing entrance and tubing exit as

shown in Figure 3. Center tubing on roller.

4. Press the occlusion bed against the tubing, and snap the latch closed.

5. Close the cover, then pull the tubing snug (do not stretch) around the rotor

assembly. Tighten the tubing retainer by rotating the tubing retainer knob

clockwise sufficiently to prevent the tube from moving. Pump is now ready

for operation.

Figure 3. Loading Tubing

Operation

1. Connect pump tubing to desired source and destination.

2. Start pump drive and set desired speed.

6

Page 7

MAINTENANCE

Maintenance is limited to replacement of the parts listed in the replacement

parts list and cleaning the pump head.

Replacement Parts

REF DESCRIPTION ORDER NUMBER

A Rotor Assembly with Clip 77250-69

B Tubing Retainer Kit 77250-66

C Occlusion Bed Assembly Kit 77250-67

D Mounting Screws (not shown) 77250-01

Figure 4. Exploded View of Pump

Cleaning Pump Head

Use mild detergent with water to clean the pump and rotor assembly. Do not

immerse nor use excessive fluid.

7

A

B

C

Page 8

8

Printed in U.S.A.

WARRANTY

Use only MASTERFLEX precision tubing with MASTERFLEX pumps to

ensure optimum performance. Use of other tubing may void applicable

warranties.

The Manufacturer warrants this product to be free from significant deviations from

published specifications. If repair or adjustment is necessary within the warranty

period, the problem will be corrected at no charge if it is not due to misuse or

abuse on your part, as determined by the Manufacturer. Repair costs outside the

warranty period, or those resulting from product misuse or abuse, may be

invoiced to you.

The warranty period for this product is 2 years from the date of

purchase.

RETURN OF ITEMS

To limit charges and delays, contact the seller or Manufacturer for authorization

and shipping instructions before returning the product, either within or outside of

the warranty period. When returning the product, please state the reason for the

return. For your protection, pack the product carefully and insure it against

possible damage or loss. Any damages resulting from improper packaging are

your responsibility.

TECHNICAL ASSISTANCE

If you have any questions about the use of this product, contact the Manufacturer

or authorized seller.

1-800-MASTERFLEX (627-8373) (U.S. and Canada only)

11 (847) 549-7600 (Outside U.S.)

(847) 549-7600 (Local)

www.masterflex.com

techinfo@coleparmer.com

*EN809 manufactured by:

Thermo Fisher Scientific

28W092 Commercial Avenue

Barrington, IL 60010

1-800-637-3739 (U.S. and Canada only)

11 (847) 381-7050 (Outside U.S.)

(847) 381-7050 (Local)

www.thermoscientific.com

fluidhandling@thermoscientific.com

Loading...

Loading...