Page 1

OPERATING MANUAL

Composite Sampler

07580-00

& accessories

Model No.

Cole-Parmer Instrument Co.

1-800-MASTERFLEX (627-8373) (U.S. and Canada only)

11 (847) 549-7600 (Outside U.S.) • (847) 549-7600 (Local) • www.masterflex.com

Barnant Company

1-800-637-3739 (U.S. and Canada only)

11 (847) 381-7050 (Outside U.S.) • (847) 381-7050 (Local) • www.barnant.com

A-1299-1015

Edition 01-11-11-02

Page 2

TABLE OF CONTENTS

Title Page

SAFETY PRECAUTIONS......................................................3

INTRODUCTION

General..................................................................................4

Suction Lift............................................................................4

Scope ....................................................................................4

SETUP

Unpacking ............................................................................5

Assembly ..............................................................................5

Tubing Selection ..................................................................5

INSTALLATION

Site Requirements................................................................5

Power Requirements ..........................................................5

DESCRIPTION

Functional Description ........................................................6

Wetted Parts ........................................................................6

Controls, Indicators and Connectors ................................6

Familiarization System Features ........................................7

INITIAL OPERATION

System Boot-up Internal Battery........................................8

System Boot-up External Power ........................................9

Battery Charging................................................................10

Setting Time and Date ......................................................10

Security ..............................................................................10

OPERATION

Description of Programming ............................................11

Starting & Stopping Program............................................11

Menu....................................................................................12

Navigation ..........................................................................14

GLOBAL SETTINGS

General................................................................................14

Global Settings Tour ..........................................................14

VIEW/EDIT PROGRAMS

General................................................................................19

Program Menu Tour ..........................................................19

SAMPLING PROGRAM MENU OPTIONS

General................................................................................22

Program Start ....................................................................22

Sample Volume ..................................................................23

# of Contact Closures........................................................24

Default Program Settings..................................................25

Save Program ....................................................................25

Hot Keys..............................................................................26

CALIBRATING THE SYSTEM

General................................................................................26

Minimum Sample Size ......................................................26

Required Equipment..........................................................26

Calibration Procedure........................................................26

Previous Calibrations ........................................................27

CYCLING THE SYSTEM ....................................................27

MAINTENANCE

Sample Reservoir ..............................................................27

Tubing..................................................................................27

TROUBLESHOOTING

General................................................................................28

Error/Status Messages & Solutions................................28

USER REPLACEMENT PARTS SERVICING

Internal Battery Replacement ..........................................29

Motor Brush Replacement/Check....................................30

USER REPLACEMENT PARTS ..........................................31

SPECIFICATIONS ..............................................................32

WARRANTY ........................................................................33

PRODUCT RETURN ..........................................................33

TECHNICAL ASSISTANCE ................................................33

ACCESSORY OPERATING INSTRUCTIONS

07571-50 Automotive Power Adapter ..............................34

07571-52 & -54 Auxiliary Power-Pak................................35

07580-60 Remote Contact Closure Cable ......................38

07580-65 RS-232 Adapter..................................................38

2

NORPRENE, PHARMED, TYGON—Reg TM Norton Co.

WINDOWS—Reg TM Microsoft Corp

Trademarks bearing the ® symbol in this publication are registered in the U.S. and in other countries

Page 3

3

SAFETY PRECAUTIONS

DANGERS: NEVER apply AC voltages directly to the EXTERNAL POWER INPUT receptacle on the front

panel. The application of AC voltages can result in injury and death of the operator and

destruction of the unit. Use only the AC/DC Universal Power Supply/Converter supplied

with the unit to power unit from an AC source.

NEVER short or connect the terminals of the battery terminals together. Shorting of the

battery terminals causes rapid internal heating of the battery resulting in the explosion of

the battery and severe injury to or the death of the operator.

The AC/DC Universal Power Supply/Converter is rated for INDOOR USE ONLY. DO NOT use

the AC/DC Power Supply/Converter in an outdoor environment to either charge the battery

or power the drive. Electrical shock, severe injury and/or death are possible if this warning

is ignored.

DO NOT BURN OR INCINERATE THE BATTERY. THE BATTERY MAY EXPLODE CAUSING

SEVERE INJURY OR DEATH OF THE PERSONNEL IN THE AREA. (Dispose of the old battery

by recycling.)

CAUTIONS: Do not reverse the connections to the battery. If the battery connections are reversed,

damage to the unit will occur.

Fully charge the unit before using for the first time. Damage to the internal battery can result

if the battery is in a fully discharged state and operation of the unit is attempted.

Immersion or submersion of the unit will result in improper operation and possible damage to

the unit.

Use of pump heads, tubing sizes and formulations other than those specified in this manual,

or the mounting and use of two or more pump heads concurrently will result in improper

operation and possible damage to the unit.

WARNINGS: Tubing breakage may result in fluid being sprayed from the pump. Use appropriate measures

to protect the operator and equipment.

Turn drive off, remove all the power to the unit, including the AC/DC Power Supply/Converter,

Automotive Power Adapter or other external power source if present before removing or

installing pump head or tubing. This will help prevent accidental activation of the drive

mechanism so fingers or loose clothing will not get caught in the pump drive mechanism.

WARNING: PRODUCT USE LIMITATION

This product is not designed for, nor intended for use in, patient-connected applications, including, but not

limited to, medical and dental use and, accordingly, has not been submitted for FDA approval.

Page 4

4

INTRODUCTION AND GENERAL DESCRIPTION

GENERAL

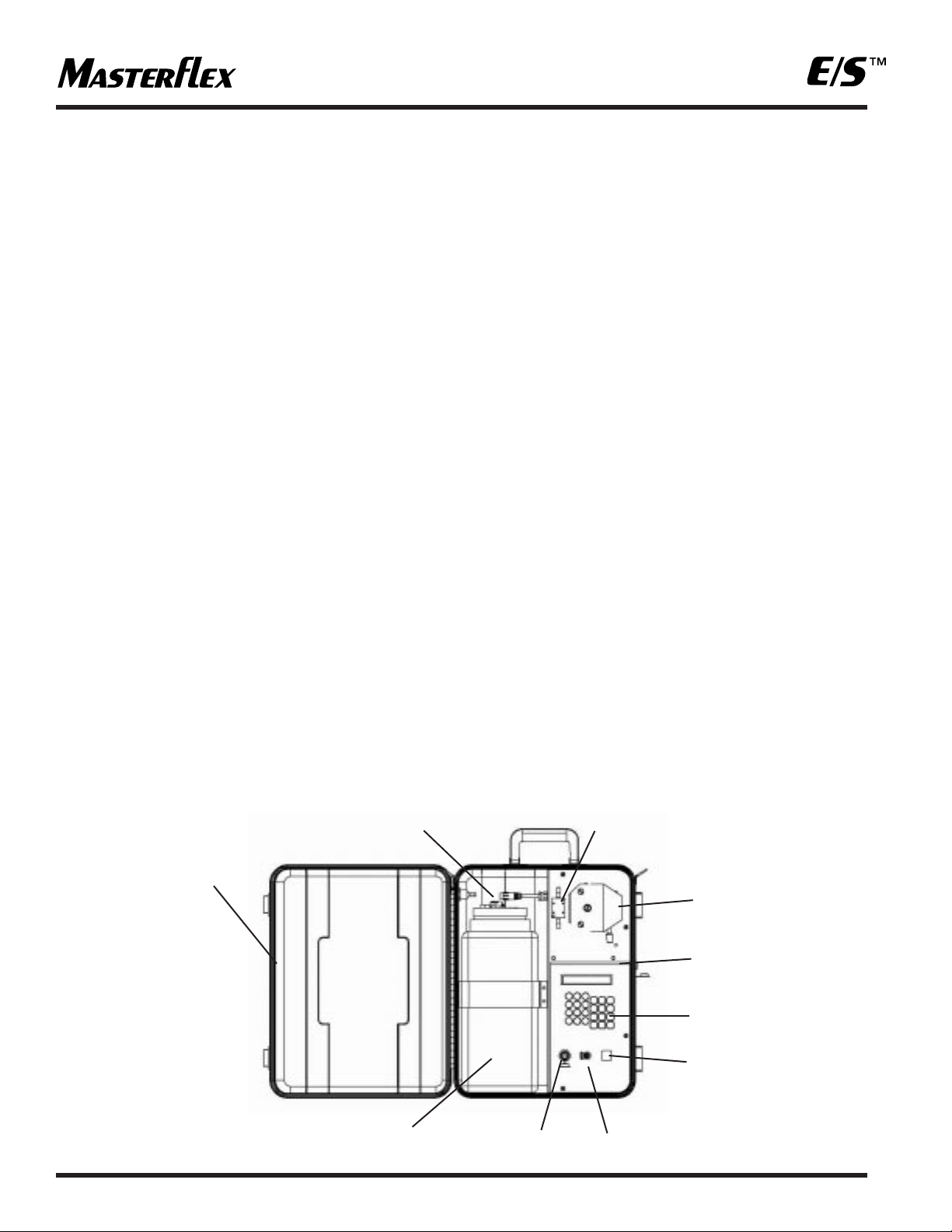

The Masterflex®E/S™Composite Sampler is a DSP controlled,

portable, self-contained, programmable peristaltic pump

system designed to meet EPA, NPDES guidelines for the

sampling of storm and waste water.

The Masterflex

®

E/S™Composite Sampler as shown in Figure

1, consists of an exterior housing, a controls console which

contains the internal power source, pump drive system and

system controls, a Masterflex

®

L/S®Easy-Load®peristaltic

pump head and a sealed and vented sample reservoir. The

drive system is capable of operating one Masterflex

®

L/S

®

Standard®, L/S®Easy-Load® or L/S® PTFE pump head.

The Masterflex®E/S™Composite Sampler is current limited,

protected from reverse power supply polarity and transient

voltages.

You may operate the Masterflex

®

E/S™Composite Sampler on

the internal battery, an external 12V DC source or indoors

using the 115V AC or 230V AC with the AC/DC Universal

Power Supply/Converter supplied with the unit.

The system features a built-in spill-proof gel battery and

recharging system allowing the unit to be recharged from an

AC power source using the supplied AC/DC Universal Power

Supply/Converter or from an automotive 12V DC electrical

system if used with the Automotive Power Adapter accessory.

It is designed and programmed to accept, control and power

one Masterflex

®

L/S®Easy-Load®, Standard or PTFE Tubing

pump head for fluid transfer and sampling in the field.

The unit is housed in a high visibility, protective polyethylene

housing. The control panel and the drive controls have an

environmental protection rating of IP56.

When closed and latched, the drive will float for a minimum of 30

minutes if dropped into a lake or stream to allow recovery of the unit.

SUCTION LIFT

The Masterflex®E/S™ Composite Sampler is capable of lifting

a sample of water up to twenty-five (25) feet vertically. This

capability is called suction lift and is measured from the

surface of the liquid to the pump head.

If the liquid to be sampled has a viscosity or density greater

than water, this lifting capability is reduced or diminished.

This lifting capability is also diminished as altitude above

sea level increases.

SCOPE OF THE MANUAL

This manual contains instructions for installing, setting up,

programming, operating and maintaining the sampling

system. It is intended for use by technicians and operators

as well as maintenance personnel. The TROUBLESHOOTING

section contains a list of possible problems, their probable

causes, and actions to take to remedy each problem.

Instructions for replacing user-serviceable parts and a list of

parts that can be ordered are included.

The ACCESSORIES section lists all available accessories for

the Masterflex

®

E/S™Composite Sampler.

EXTERIOR

HOUSING

LEVEL

SENSOR

KEYPAD

ON/OFF 0-1

STATUS

SWITCH

EXTERNAL

POWER IN

RECEPTACLE

RS-232

CONNECTOR

SAMPLE

RESERVOIR

FLOW

DETECTOR

MASTERFLEX

EASY-LOAD

PERISTALTIC PUMP

CONTROL

CONSOLE

FIGURE 1

Page 5

5

SETUP

UNPACKING

Care has been taken in the packaging of the Masterflex®E/S

™

Composite Sampler to protect it in transit to its final destination.

After opening the carton, save the packing material until proper

product operation has been verified.

The Masterflex

®

E/S™Composite Sampler consists of the

following items:

(1) Sampling Unit

(1) AC/DC Universal Power Supply/Converter

(1) Sample Line Tubing Connector

(2) Keys for the locking latches

(1) 25 feet of Masterflex

®

L/S®24 size peroxide-cured

silicone tubing

(1) Operator's Manual CD

(1) Warranty Card

ASSEMBLING

Unit is shipped fully assembled and plumbed with Masterflex

®

L/S® 24 size silicone peroxide-cured tubing. The operator only

needs to connect an external sample line using the supplied

tubing connector into Sample Line Inlet bulkhead connector

shown in Figure 2.

TUBING SELECTION

The flow rate at which a sample can be taken is dependent

on the tubing size, tubing material and the height the sample

must be raised to enter the sample reservoir. The purity of

the sample is dependent on the formulation of the tubing

material. The Composite Sampler is supplied with L/S

®

24

size tubing made of peroxide cured silicone resins. The tubing

supplied with the unit has been selected based on its purity

versus flow and lift performance. Optimum lift and flow

performance can be had by using Tygon

®

LFL or Lab tubing.

See Table 1 for other tubing materials and sizes available for

operation with the Composite Sampler.

INSTALLATION

SITE REQUIREMENTS

The E/S Composite Sampler is designed to operate in most

outdoor conditions. Ensure that the work area temperature

range is between 1°C to 50°C (39°F to 122°F) and that the

relative humidity remains between 10% and 90%.

Position the sampler in an upright position with the carrying

handle at the top of the case (as shown), preferably on a firm

level surface, adjacent to the source to be sampled. The

sampler may also be suspended or attached to a vertical

support using the D-rings at the top of the exterior housing.

POWER REQUIREMENTS:

The Masterflex®Composite Sampler is internally powered by a

12 V sealed gel battery. The unit may also be operated or

charged in an outdoor environment using the Automotive

Power Adapter Accessory 07571-50 Auxiliary Power Pack

07571-52 or 07571-54, or any DC source supplying 11-18 volts.

Sampler can be operated or charged indoors from a 115

(90-130) VAC or 230 (180-260) VAC 50/60 Hz incoming power

using the AC/DC Universal Power Supply/Converter (supplied).

DANGER: NEVER apply AC voltages directly

to the EXT PWR IN receptacle on

the front panel. The application of

AC voltages can result in injury

and death of the operator and

destruction of the unit. Use only

the AC/DC Universal Power Supply/

Converter supplied with the unit to

power unit from an indoor AC

source.Fully charge the unit before

using for the first time. Damage to

the internal battery can result if the

battery is fully discharged and

operation of the unit is attempted.

Tubing formulation L/S®15 L/S®24

Silicone, peroxide-cured 96400-15 96400-24

Tygon, Lab

®

06409-15 06409-24

Tygon LFL

®

06429-15 06

429-24

PharMed

®

06485-15 06485-24

TABLE 1 Tubing Materials

Page 6

6

DESCRIPTION

FUNCTIONAL DESCRIPTION

The control console of the Composite Sampler provides the

operator interface for programming, control and charging of the

sampling system. The DSP in the control console scans the

keypad, communicates to the display, communicates with the

integral pump drive, assesses the state of and controls

charging of the battery.

The system is preprogrammed with one (1) fluid transfer

program and five (5) sampling programs. All of the factorysupplied sampling programs can be modified by the operator

and saved without modifying or destroying the factory

supplied programming. The factory supplied programming

and operational parameters are stored in non-volatile flash

memory within the DSP controller.

Program options and instructions from the operator are

stored in non-volatile memory consisting of an EEPROM

which supplements the flash memory of the DSP.

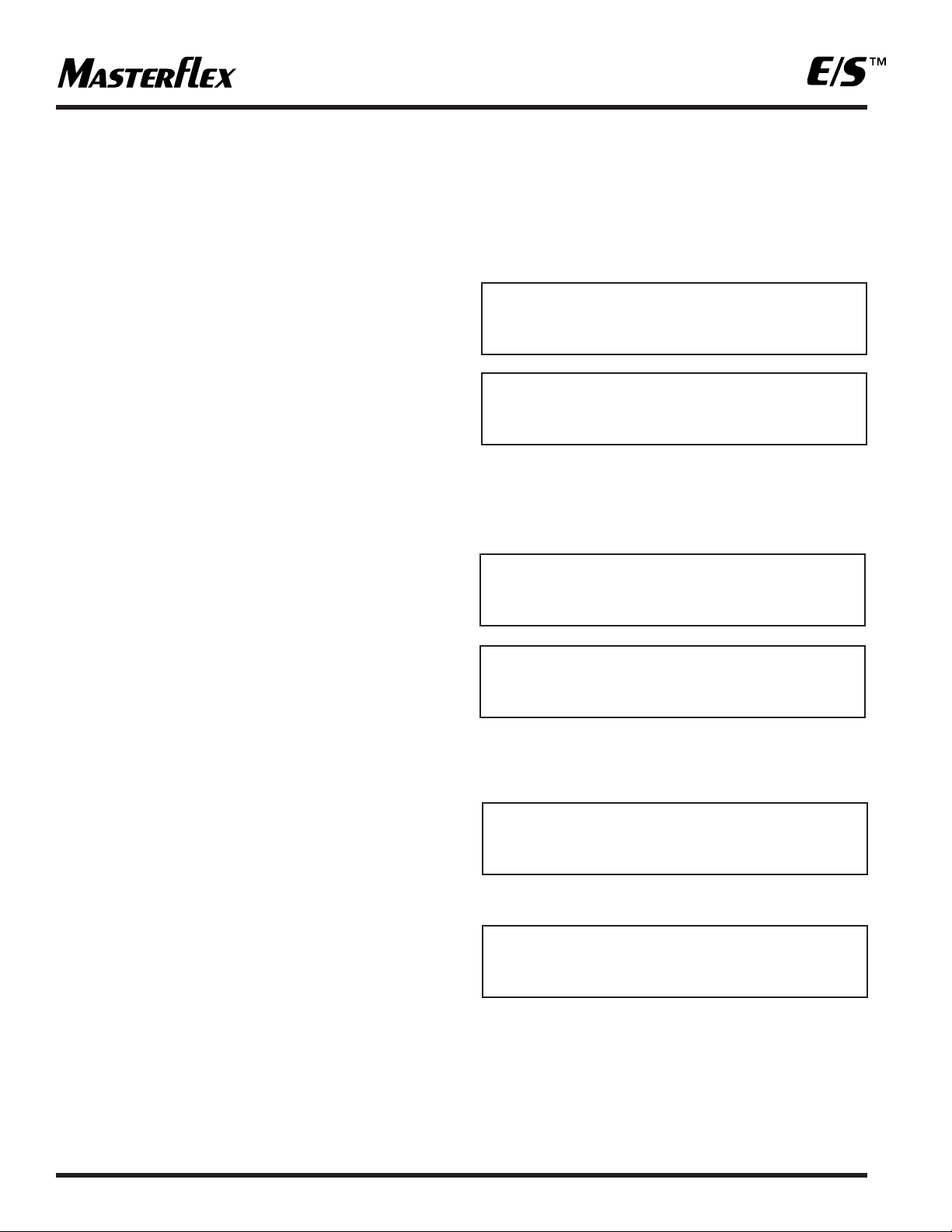

CONTROLS, INDICATORS AND

CONNECTORS

All the controls, connectors, and indicators on the controls

console and exterior housing are shown in Figure 2 and 3.

Table 2 lists all of the operator controls and indicators.

WETTED PARTS

All parts in direct contact with the sample being taken are

considered wetted parts. The following is a listing of the

wetted parts and their associated materials.

Sample intake tubing: Unit is supplied with

1

⁄4" ID 25 feet of

Masterflex

®

L/S®24 size peroxide-cured silicone tubing.

Sample intake tubing connectors: Delrin®acetal co-polymer

T ubing: Masterflex®L/S®24 size peroxide-cured Silicone

tubing.

Flow detector: PVC and stainless steel

Flow detector tubing connectors: polycarbonate and Viton

®

Discharge tubing: Masterflex®L/S®24 size peroxide-cured

silicone tubing.

Discharge tubing fittings: Delrin

®

acetal co-polymer

Sample reservoir: HDPE (high density polyethylene)

Sample reservoir cap: polypropylene

Breather vents, sample reservoir: medical grade ABS/Teflon

®

SAMPLE

LINE INLET

REMOTE CONTACT

CLOSURE

CONNECTOR

RS232

CONNECTOR

EXTERNAL POWER IN

RECEPTACLE

11-18VDC

ON-OFF

0-1/ STATUS

SWITCH

FIGURE 2

Page 7

7

Control or indicator Description and function

0-1/ STATUS Use to turn the unit ON, OFF, check unit status or awaken unit from an inactive mode

DISPLAY 24 character by two-line LCD that displays all menus needed for programming and operating

the system.

MENU Use to access the menu.

Selection arrow keys Use to navigate menu options shown on the display.

Numeric keypad 0-9 Use for numeric entry.

START/STOP Use to initiate program or to stop a program which is running.

CANCEL Cancels any changes that were made to the current menu selection and returns to previous menu

ENTER Accepts the selected item and moves down to the next menu level. If there is not a lower menu

level, it will return to the top level for the selected item.

CLOCK Used to set date and time. The date is displayed in a MM:DD:YY format. The time format is a

24hour clock displayed in a HH:MM:SS..

TIME Used access the time settings in the loaded program.

SAMP. VOL Used to access the sample volume parameter in the loaded program without going through the

menu.

LIFT HEIGHT Used to access the lift height parameter in the loaded program without going through the menu

CYCLE TEST Used to verify unit operation in the field.

CAL Used to verify and calibrate unit in the field for accurate sample delivery.

TABLE 2 Operator Controls and Indicators

FIGURE 3

FAMILIARIZATION WITH

SYSTEM FEATURES

The system has unique features with which the operator needs to

become familiar during the course of system operation. Understanding

the features will enable the operator to know if the system is

operating properly and effectively. These features are as follows:

1. Automatic Power-Up: Any time an external power source is

connected to the EXT POWER IN receptacle located on the front

of the control console, the system will power up and go through a

boot up routine or display a system message as to system status.

If no action is taken, the system will charge the battery.

2. Automatic Power Conservation: If the system is not implementing an internal command or the operator has not pressed a

key on the control console for 10 minutes the system to conserve

power will POWER DOWN. The LCD display will display a message

for 5 seconds:

POWERING DOWN

Page 8

8

After which the display will blank. If an external power source

is connected at the time, the battery will continue to charge

while the display is blank. If a sampling program was running

or in process at the time of power down the system will

continue to run the program. The display panel will show a

message when the unit starts to take a sample and show

the time until the next sample is to be taken. The display will

remain active for an additional 5-10 seconds before returning

to a powered down state.

If the display panel is not active, press the 0-1/STATUS key

on the control console to awaken the system.

3. Automatic Battery Charging: System will automatically

charge the internal battery any time an external power source

such as the AC/DC Universal Power Supply/Converter or

Automotive Power Adapter is plugged into the EXT PWR IN

receptacle. The rate at which the internal battery is charged

will vary with other system operations. Once the battery is

fully charged, the integral battery charging circuit will place

the battery on a floating or maintenance charge to maintain

the battery in a fully charged state.

4. Automatic Purging: The system will automatically purge

the sample intake line prior to the taking of any sample or the

occurrence of a rinse cycle. This is to ensure that the sample

inlet line is free of any obstructions or debris.

5. Glow-In-Dark Keypad: The keypad is printed with

phosphorescent pigments. These pigments will glow for up

to 20 minutes if exposed to ultraviolet radiation from the sun

or a krypton flashlight. This feature is helpful in low ambient

light conditions. The LCD display is backlightable and when

used with keys that glow in the dark, this lessens the need for

external lighting in dim and dark areas.

INITIAL OPERATION

SYSTEM BOOT—INTERNAL BATTERY

Press the 0-1/STATUS button on the control console. The

LCD display will activate and display the following messages:

System will power up the drive system to place the internal

battery under load and verify its condition.

The LCD panel will display one of the following messages,

depending upon battery condition.

If the battery is fully charged or you pressed cancel when

notified the battery is low, the system will complete boot-up

and display the following on the LCD screen:

If the message displayed is:

The system should not be operated until the battery has been

charged or an external power source has been connected to

the unit. Proceed to the BATTERY CHARGING section of the

manual on page 10.

SAMPLER ON VERSION X.X

CHECKING BATTERY

PRESS CANCEL TO QUIT

BATTERY FULLY CHARGED

BATTERY IS LOW

CHARGING IS RECOMMENDED

SAMPLER SYSTEM READY

HH:MM:SS MM/DD/YYYY

BATTERY IS VERY LOW

MUST CHARGE BATTERY!

Page 9

SYSTEM BOOT—

EXTERNAL POWER

Open the exterior housing, connect the AC/DC Universal

Power Supply/Converter into the EXT PWR IN receptacle on

the front. Then connect the AC plug into an AC receptacle.

The system will come on automatically. The first screen displayed on the LCD panel will be:

This will be followed by another screen:

Remove the plug from the EXT PWR IN receptacle on the

control console. LCD will change to read:

The system will power up the drive system to place the

internal battery under load and verify its condition. After the

drive system has stopped, you may reconnect the external

power to the EXT PWR IN receptacle. The LCD panel will

display one of the following messages, depending upon

battery condition.

If the battery is fully charged or you pressed cancel when

notified the battery is low, the system will complete boot-up

and display the following on the LCD screen:

If the message displayed is:

The system should not be operated until the battery has been

charged. Proceed to the BATTERY CHARGING section of the

manual on page 10.

SAMPLER ON VERSION X.X

REMOVE EXT PWR TO CHECK

BATTERY—CANCEL TO SKIP

CHECKING BATTERY

PRESS CANCEL TO QUIT

BATTERY IS FULLY CHARGED

BATTERY IS LOW

CHARGING IS RECOMMENDED

BATTERY IS VERY LOW

MUST CHARGE BATTERY!

SAMPLER SYSTEM READY

HH:MM:SS MM/DD/YYYY

9

Page 10

10

SAMPLER SYSTEM READY

HH:MM:SS MM/DD/YYYY

BATTERY CHARGING

The Composite Sampler is equipped with an internal four

state battery charger capable of diagnosing and automatically

charging the internal battery. The operator only needs to

connect the AC/DC Universal Power Supply/Converter or

Automotive Power Adapter accessory. The sampler system

will automatically power up and begin charging the battery.

After 10 minutes the LCD display on the control console will

power down, going blank. The battery will continue to charge

until it has reached is full potential. Once the battery is fully

charged, the battery will be placed on a float or maintenance

charge until the external power source is disconnected.

The system may run or be programmed while the unit is

charging. Battery charging will continue in the background

while other operations are taking place. Allow a minimum of

8 hours to fully charge the battery from a fully discharged

state with no other operations occurring. During battery

charging all functions of the sampler are operational.

WARNING! The AC/DC Power Supply/Converter

is rated for INDOOR USE ONLY.

DO NOT use the AC/DC Power

Supply/Converter in an outdoor

environment to either charge the

battery or power the drive. Electrical

shock, severe injury and/or death is

possible if this warning is ignored.

SETTING THE TIME AND DATE

Press the keypad's CLOCK key. The display will read:

TIME

The clock used in the Composite Sampler is a 24-hour clock,

does not use an AM or PM notation and shows the time in

an HH:MM:SS format. The clock displays 12:00 AM midnight

as 00:00:00 (the starting point of the clock), 6:00:00 AM as

06:00:00, 12:00:00 PM (or noon) as 12:00:00 and 6:00 PM

as 18:00:00.

If a sample was taken at 3:00 PM the clock will read 15:00:00.

The Composite Sampler clock was set at the factory based

upon our local time. The time is expressed as hour, hour,

minute, minute, second, second. If the current time on the

clock is correct, bypass setting the time by pressing ENTER

or CANCEL and you will be taken to the screen where you

may change the date. See the screen below.

If you need to correct the time shown on the clock, use the

numeric keypad to enter the current time and press ENTER.

The display will change to the date correction screen as

shown below.

DATE:

The calendar date is expressed as month, month, day, day,

year, year.

If the date is correct, press ENTER or CANCEL and you will

be taken back to the system prompt.

If you need to correct the date shown, use the numeric

keypad, enter the date and press ENTER.

EXAMPLE: To enter January 1, 2003, press 10103 on the

numeric keypad and press ENTER.

To enter December 31, 2002, press 123102 on

the numeric keypad and press ENTER.

You will then be taken back to the system prompt screen

which will now display the current time and date.

SECURITY

The Composite Sampler will be exposed to an outdoor

environment in which the operator may or may not be

present or in attendance. To protect the unit from tampering

by unauthorized individuals the sampler housing may be

locked using the two locking latches on the exterior of

the housing.

In addition a security feature has been incorporated into

the Composite Sampler to lock the keypad.

SET TIME (HR:MIN:SEC)

20:30:57 (23:59:59)

SET DATE (MON/DAY/YR)

09/21/02 (MM/DD/YY)

Page 11

11

LOCKING THE KEYPAD

The Composite Sampler keypad may be locked to ensure

that running programs are not inadvertently terminated or to

restrict access to the system. The only key which is functional

when the keypad lockout is enabled is the 0-1/STATUS key.

Pressing this key will not disable or interfere with any program

which is running. To lock the keypad, perform the following

procedure either from a system prompt or after you have

pressed the START/STOP key to start a program. The keypad

lockout cannot be enabled or disabled during programming

or the editing of a program.

1. Ensure that the control console is in a system ready prompt

or a program is running.

2. Enter 847 on the numeric keypad and press ENTER.

3. The following display appears for approximately five

seconds. The display reappears anytime a non-numeric

key is pressed and the LCD display is active.

4. To unlock the keypad, enter the same code and press

ENTER. The following display appears:

OPERATION

The unit is operated through the use of a menu system and

various hot buttons on the keypad located on the control

console face. The menus and their options are shown as words

and numbers used in everyday oral communications or

speech without the need for decryption or an additional legend.

This equipment should not be operated on a "learn as you

go" basis. Make sure to become familiar with and practice all

safety procedures presented in the SAFETY section before

operating the Composite Sampling System.

DESCRIPTION OF PROGRAMMING

The Composite Sampler can be operated using any of the

six (6) factory supplied programs through the menu system.

The five (5) sampling programs can be modified or edited and

stored for future use. Editing the factory supplied programs

and saving them as modified programs will temporarily

overwrite the factory program. The factory programs can be

individually restored to their original default settings upon

operator demand through the menu system.

NOTE: One program is always present or selected to run

whenever the unit is on. When received from the factory the

default program selected to be run is PROGRAM #1.

STARTING/STOPPING A PROGRAM

To start or stop a program press the START/STOP key.

Programs can only be started from a SAMPLER SYSTEM

READY prompt. Sampling programs can be stopped at any

time the display is active by pressing CANCEL. If the display

is inactive, press the 0-1/STATUS key to awaken the system

and then press CANCEL. The CONTINUOUS PUMPING

program can be stopped at any time. Stopping a program is

equivalent to canceling the program. Programs that have

been stopped cannot be restarted from the point at which

they were stopped. When you start the program again, it will

begin at the beginning of the program.

HINT: If the program you stopped was taking a sample, it

may be necessary to empty or clear the sample reservoir

prior to starting the program again.

CANCELING A PROGRAM

To cancel a program that has started, press the CANCEL

key. Canceling a program is the same as stopping a program

as described above. Pressing the CANCEL key does not

deselect the program selected to be run. It only cancels the

program schedule that has started.

HINT : The program will show up on the data log as a cancelled

program. If you do not want this record to appear on the data

log, clear the data log prior to starting the program again.

ACCESSING THE MENU

Operation of the system and editing programs is menu driven.

To access the menu press the MENU button on the control

console. The LCD display will show the following.

KEYPAD LOCKOUT ENABLED

KEYPAD LOCKOUT DISABLED

g GLOBAL SETTINGS

c VIEW/EDIT PROGRAMS

Page 12

12

MENU

The menu is divided into two main sections or categories: GLOBAL SETTINGS and VIEW/EDIT PROGRAMS.

GLOBAL SETTINGS

This section consists of operational parameters related to the

Composite Sampler system as follows:

• DISPLAY CONTRAST

• SAMPLING LOCATION NUMBER

• PUMP HEAD SELECTION

• TUBING SIZE SELECTION

• TUBING FORMULATION SELECTION

• RINSE CYCLES

• VOLUME UNITS

• DISTANCE UNITS

• LIFT HEIGHT

• TUBING LENGTH

• LCD BACKLIGHTING

• DATA LOGGING

• DEFAULT GLOBAL SETTINGS

VIEW/EDIT PROGRAMS

The VIEW/EDIT PROGRAMS section consists of parameters

related to the sampling programs as follows:

• SELECT HOW PROGRAM IS STARTED

• SAMPLE VOLUME

• NUMBER OF SAMPLES

• TIME INTERVAL BETWEEN SAMPLES

EQUAL OR UNEQUAL

• # OF CONTACT CLOSURES

• DEFAULT THE PROGRAM SETTING

• SAVE USER PROGRAM

See Table #3 for menu categories and selections.

Page 13

TABLE #3 MENU SELECTIONS

Defaults are shown in BOLD type or noted

13

CATEGORY SELECTION CHOICES SUB SELECTIONS

DISPLAY CONTRAST UP & DOWN ARROWS TO ADJUST

LOCATION NUMBER ENTER 0-99999999

PUMP HEAD

Easy-Load/Standard

SIZE 24

TYGON LFL

TYGON LAB

SIZE 15

SILICONE TUBING

PHARMED TUBING

PTFE TUBING PUMP

PTFE 4 MM

PTFE 6 MM

RINSE CYCLES ENTER NUMBER 0-5 Default is 0

VOLUME UNITS

MILLILITERS

GALLONS

DISTANCE UNITS

FEET

GLOBAL

METERS

LIFT HEIGHT ENTER NUMBER Default is 6 feet or 1.8 meters

TUBING LENGTH ENTER NUMBER Default is 12 feet or 3.6 meters

LCD BACKLIGHTING

NONE—POWER SAVER

BACKLIGHT ON KEY PRESS

KEY PRESS AND SAMPLING

CONTINUOUS BACKLIGHT

LOG DATA

VIEW LOG DATA

PRINT LOG DATA

CLEAR LOG DATA

CLEAR ALL LOG DATA

DON'T CLEAR LOG DATA

DEFAULT GLOBAL SETTINGS

RESET GLOBAL SETTINGS

DON'T RESET SETTINGS

PROGRAM START

DELAYED START HHH:MM (0-167.59)

REMOTE & DELAYED START HHH:MM (0-167.59)

MAINTAINED CONTACT

PULSED CONTACT

SAMPLE VOLUME ENTER NUMBER (1-9,000)

NUMBER OF SAMPLES ENTER NUMBER (1-99)

EQUAL INTERVALS HH:MM (0-99:59)

HH:MM (0-99:59)

#1 HH:MM (0-99:59)

#2 HH:MM (0-99:59)

#3 HH:MM (0-99:59)

#4 HH:MM (0-99:59)

#5 HH:MM (0-99:59)

VIEW/EDIT

TIME BETWEEN SAMPLES

UNEQUAL INTERVALS

#6 HH:MM (0-99:59)

PROGRAMS

#7 HH:MM (0-99:59)

#8 HH:MM (0-99:59)

#9 HH:MM (0-99:59)

#10 HH:MM (0-99:59)

#11 HH:MM (0-99:59)

#12 HH:MM (0-99:59)

# OF CONTACT CLOSURES

ENTER NUMBER Only appears if MAINTAINED is not

(0-9999) Default is 0 chosen under PROGRAM START/REMOTE & DELAYED START

DEFAULT PROGRAM RESET PROGRAM SETTINGS

SETTINGS DON'T RESET SETTINGS

USER PROG #1

USER PROG #2

SAVE USER PROGRAM USER PROG #3

USER PROG #4

USER PROG #5

Page 14

14

NAVIGATION

Looking at the LCD display screen below:

1. The MENU key takes you to the top level of the menu as

shown above.

2. The arrows in the first display column indicates which way

the user can go from each menu selection.

3. Solid box in second column indicates selected menu item,

empty box is an unselected menu item.

NOTE: Only one selection is allowed in each menu option.

4. UP/DOWN arrow keys on the control console move the

solid box to select a menu item and scroll the display if

more menu items are available.

5. The ENTER key accepts the selected item and moves

down to the next menu level. If there is not a lower menu

level, it will return to the top level for the selected item. For

example, if selecting a tubing material, pressing ENTER will

return back to the PUMP HEAD menu selection.

6. CANCEL key cancels any changes that were made to the

current menu selection and returns to previous menu.

7. CANCEL key will back up to previous menu level and exit

the menus when at the top level.

8. Display is 2 lines by 24 characters so only 2 lines of the

menu are seen at one time.

GLOBAL SETTINGS

GENERAL

The GLOBAL SETTINGS are not saved in memory like

multiple sampling programs. The only settings available are

those currently loaded into the non-volatile memory.

Selecting a menu option or setting using the up and down

arrow keys does not load that option or setting in memory

until the ENTER key is pressed.

Settings must be modified as necessary to suit the sampling

site and equipment used. Many of these settings may use the

default values, such as pump head selection, tubing size or

formulation. Other parameters such as lift height and tubing

length or location will vary with the sampling site and will be

changed frequently.

GLOBAL SETTINGS TOUR

The tour of the GLOBAL SETTINGS menu will take the operator

through each of the menu selection display screens. Going

through the entire menu is not necessary each time a change

to one or two GLOBAL SETTINGS parameters is made. It is

recommended that you take the tour to familiarize yourself

with all of the options and screens available.

Select GLOBAL SETTINGS by pressing the ENTER key.

The display will now show the following choices:

DISPLAY CONTRAST

Allows adjustment of the display contrast for readability.

ADJUSTING THE DISPLAY

CONTRAST

To adjust the contrast of the LCD display, select DISPLAY

CONTRAST and press the ENTER key. The following menu

will be displayed:

View the display and use the up and down arrow keys to

adjust the contrast. Press the up arrow key to increase

contrast or the down arrow key to decrease contrast. When

you have achieved the desired contrast, press the ENTER

key. This will save the contrast setting you have selected

for the display. The system will return you to the following

display.

DISPLAY CONTRAST

g DISPLAY CONTRAST

c LOCATION NUMBER

g

GLOBAL SETTINGS

c

VIEW/EDIT PROGRAMS

g

DISPLAY CONTRAST

c

LOCATION NUMBER

g

GLOBAL SETTINGS

c

VIEW/EDIT PROGRAMS

Page 15

15

Use the down arrow to select LOCATION NUMBER, the filled

in box will switch from DISPLAY CONTRAST to LOCATION

NUMBER and press ENTER. The display will change to read:

LOCATION NUMBER

Allows the input of up to a 9 digit number to identify the

sampling site. You do not have to erase or delete the number

(site identifier) that may already be there.

INPUTTING A LOCATION NUMBER

Enter the number and press ENTER. The new site

identification number will be entered and the display will

change to:

Use the down arrow to decrement the menu to and select

PUMP HEAD by pressing ENTER.

The display changes to read:

PUMP HEAD

Multiple option screens which allow the operator to select the

pump head, tubing size and tubing formulation or material.

EASY-LOAD is the default pump head supplied with the

Composite Sampler for your convenience in changing the

tubing when needed. If you intend to use the pump head

supplied with the unit press ENTER.

If you wish to use a PTFE TUBING PUMP proceed to the

description of this menu option on page 16.

The display will change to read:

Size 24 is the default tubing size. The tubing supplied with

the Composite Sampler is L/S

®

24 peroxide cured silicone

Model No. 96400-24. This tubing size will deliver an average

flow of 1,700 ml/min. @ 0 lift.

Size 15 is an alternate tubing size offered for use with the

Easy-Load

®

pump head supplied with the Composite

Sampler. This size option is offered for circumstances where

the use of L/S

®

24 in certain formulations may not be practical.

The average flow of L/S

®

15 tubing is 1,000 ml/min. @ 0 lift.

Select the appropriate tubing size and press the ENTER key.

The display will change to the tubing formulation menu.

NOTE: the display is only 2 lines, so you will only see 2

choices at one time. Remember the arrow in the first column

indicates whether there are choices above or below the ones

you are viewing.

The tubing formulations shown are available in either

SIZE 24 or SIZE 15. See Table 1 Tubing Materials in the

SETUP section of this manual for tubing model numbers.

LOCATION NUMBER

________ _(0-999999999)

c DISPLAY CONTRAST

g LOCATION NUMBER

c

LOCATION NUMBER

g

PUMP HEAD

g EASY-LOAD/STANDARD

c PTFE TUBING PUMP

g SIZE 24

c SIZE 15

c TYGON LFL TUBING

c TYGON LAB TUBING

g SILICONE TUBING

c PHARMED

Page 16

16

PTFE TUBING PUMP

This pump head is offered as an option for those sampling

applications such as toxic fluids and oily waste water where

only the use of Teflon“ tubing will perform adequately for the

application.

Use the up and down arrow keys to navigate and select the

PTFE TUBING PUMP and press ENTER. The display will

change to show the tubing sizes available for use with the

PTFE TUBING PUMP.

Selection of the tubing formulation for sizes 24 and 15 or the

selection of the PTFE tubing sizes will return the display to

read:

Use the down arrow keys to navigate and select RINSE

CYCLES and press ENTER. The display will change to read:

RINSE CYCLES

This sets the number of rinses (0-5) that the Composite Sampler

will perform prior to the taking of each sample. The default is

zero (0). The purpose of the rinse cycle is to remove or rinse

away any contaminants or residues in the sample intake lines

from a previous sampling site or cycle. The tubing will first be

purged of any fluid. Then fluid from the sampling site will be

drawn into the sample intake lines until the fluid is detected by

the flow sensor . The system will then stop and r everse the drive

to expel the fluid. This completes one rinse cycle.

To accept the default setting press either CANCEL or ENTER.

To change the number of cycles, enter the number of cycles

desired and press ENTER.

The display will change to read:

Use the down arrow key to navigate and select VOLUME

UNITS and press ENTER. The display will change to read:

VOLUME UNITS

Allows the user to select the units in which the sample will be

measured. The default is MILLILITERS. The two options are:

MILLILITERS

Displays the sample volume from 1-9000 milliliters.

GALLONS

Displays the sample volume from 0.001 to 2.377 gallons.

To accept the default press either CANCEL or ENTER. To

change the VOLUME UNITS from MILLILITERS to GALLONS,

use the arrow key to navigate and select GALLONS and press

ENTER. The display will change to read:

Use the down arrow key to navigate and select DISTANCE

UNITS and press ENTER. The display will change to read:

c PTFE 4 MM

c PTFE 6 MM

g PUMP HEAD

c RINSE CYCLES

RINSE CYCLES

0 (0-5)

c EASY-LOAD/STANDARD

g PTFE TUBING PUMP

c RINSE CYCLES

g VOLUME UNITS

g MILLILITERS

c GALLONS

g VOLUME UNITS

c DISTANCE UNITS

g FEET

c METERS

Page 17

17

DISTANCE UNITS

Allows the user to select English or metric distance measurement

units. The default is feet.

The two options are:

FEET

Displays the VERTICAL LIFT (1-25) and TUBING LENGTH

(1-99) in whole feet.

METERS

Displays the VERTICAL LIFT (0.3-7.6) and TUBING LENGTH

(.3 to 30.1) in tenths of a meter.

To accept the default press either CANCEL or ENTER. To

change the DISTANCE UNITS from FEET to METERS, use the

arrow key to navigate and select METERS and press ENTER.

The display will change to read:

Use the down arrow key to navigate and select LIFT HEIGHT

and press ENTER. The display will change to read:

LIFT HEIGHT

Sets the draw or lift height to which the sample must be lifted

to enter the sample reservoir.

This parameter allows the system to accurately calculate the

sample volume for each revolution of the pump head at a

specific height. Sample volume decreases as lift height

increases. This parameter will be expressed in feet or meters

depending upon your earlier choice of DISTANCE UNITS. The

default is 6 feet or 1.8 meters. Enter the number and press

enter. The acceptable values will be shown in parenthesis on

the 2nd line on the right side of the display.

Once you press enter the display will change to:

Use the down arrow key to navigate and select TUBING

LENGTH and press ENTER. The display will change to read:

TUBING LENGTH

Sets the length of tubing through which the sample volume

must be drawn. Setting the tubing length allows the system

to calculate the correct amount of time for purging the tubing

prior to taking a sample. This parameter will be expressed in

feet or meters depending upon your earlier choice of DIST ANCE

UNITS. The default is 12 feet or 3.6 meters. Enter the number

and press enter. The acceptable values will be shown in

parentheses on the second line on the right side of the display.

Once you press enter the display will change to:

Use the down arrow key to navigate and select LCD BACKLIGHT and press ENTER. The display will change to read:

NOTE: the display is only 2 lines, so you will only see 2

choices at one time. Remember the arrow in the first column

indicates whether there are choices above or below the ones

you are viewing.

LCD BACKLIGHT

Sets the conditions under which the display is backlit for

optimum readability. There are four choices of backlighting.

LIFT HEIGHT

6 FEET (0-25)

g LIFT HEIGHT

c TUBING LENGTH

g DISTANCE UNITS

c LIFT HEIGHT

TUBING LENGTH

12 FEET (1-99)

g TUBING LENGTH

c LCD BACKLIGHT

c NONE—POWER SAVER

g BACKLIGHT ON KEY PRESS

c KEY PRESS AND SAMPLING

c CONTINUOUS BACKLIGHT

Page 18

18

NONE—POWER SAVER

The display will not be backlit under any circumstance. This

is the default setting and is used to conserve power. If the

LCD display can be read without difficulty in the sampling

environment, then this is adequate.

BACKLIGHT ON KEY PRESS

The LCD will be backlit for 10 seconds when any key is

pressed. After 10 seconds the display will return to its normal

unlit state. This setting can be useful during programming

since it improves the readability of the display without wasting power and provides backlighting during programming or

selecting menu options in low ambient light conditions.

KEY PRESS AND SAMPLING

The LCD will be backlit for 10 seconds when any key is

pressed or whenever a sample is to be taken. Ten (10)

seconds after the last key is pressed or after the sampling

cycle is completed the display will return to its normal unlit

state. This setting can be useful during programming since it

improves the readability of the display and allows monitoring

of the sampling process in low ambient light conditions.

If the Composite Sampler will be left unattended during the

sampling process this setting is not recommended.

CONTINUOUS BACKLIGHT

The LCD will always be backlit as long as the display is active.

HINT: The system's automatic power conservation feature blanks

the LCD display if no key has been pressed for 10 minutes.

Blanking of the LCD also occurs 10 seconds after the system

has taken a sample or processed an internal instruction while

running a program. See the FAMILIARIZATION WITH

SYSTEM FEATURES section on page 7.

It is recommended that you experiment with the various

backlighting options to determine your preference. You can

always return to the menu option by pressing enter once you

have made your selection and pressed enter, because the

display will change to read:

Proceeding down the menu, use the down arrow key to

navigate and select the next menu option LOG DATA and

press ENTER. The display will change to read:

HINT: the display is only 2 lines, so you will only see 2

choices at one time. Remember the arrow in the first column

indicates whether there are choices above or below the ones

you are viewing.

LOG DATA

The system logs all events, such as: sample location, cycle

date and time, sample volume, and any faults which may

occur during the sampling process. The system is capable of

logging 300 events. This log is stored in non-volatile memory

outside of the DSP. This log may be viewed or printed.

Viewing or printing the log does not erase or clear the log

from memory. The log may only be erased through the use of

the CLEAR LOG DATA menu option.

NOTE: should you forget to clear the logged data, the system

will begin to overwrite the oldest data first. This occurs only

once the capacity of the non-volatile memory log has been

exceeded.

VIEW LOG DATA

Allows the user or operator to view the data log. This does

not erase or clear the data log.

This is the default option for LOG DATA.

PRINT LOG DATA

Allows the printing of the data log. This menu option requires

the use of the RS 232 cable accessory catalog no. 07580-65.

See the ACCESSORY section for details. Printing of the data

log does not erase or clear the data log.

c LCD BACKLIGHT

c LOG DAT A

c VIEW LOG DAT A

c PRINT LOG DAT A

c PRINT LOG DAT A

c CLEAR LOG DAT A

Page 19

19

CLEAR DATA LOG

Allows the operator to clear the data log. This is the only way

the data log may be cleared or erased. Once you have

selected the menu option and pressed ENTER, you will be

taken to a confirmation screen as shown below:

The default selection will not clear the data log. You must use

the up arrow to select "CLEAR ALL LOG DATA" and press

ENTER. Once the ENTER key has been pressed, the log will

be erased and the display will change to read:

Use the down arrow key to navigate and select DEFAULT

GLOBAL SETTINGS and press ENTER. The display will

change to read:

DEFAULT GLOBAL SETTINGS

Allows the operator to return all of the GLOBAL SETTINGS to

their default values.

If you have made changes to the GLOBAL SETTINGS and

lost track of the changes you have made or would just like to

start your changes from some common point, this option will

prove to be helpful. This option allows resetting of the

GLOBAL SETTINGS without having to track your changes or

remember what the default was.

To reset the GLOBAL SETTINGS you must use the up arrow

key to navigate and select RESET GLOBAL SETTINGS and

press ENTER. This confirmation of your selection to return

the settings to their default value is done to prevent accidental

or unintended changes to the global settings. Once you press

the enter key your previous changes will be lost and cannot

be recovered.

HINT: To exit the menu and return to a system ready prompt

use the cancel key.

HOT KEY

One option of the GLOBAL SETTINGS menu is also accessible

via a "Hot Key" located on the control console keypad. The

key is round, blue in color and labeled LIFT HEIGHT. This key

allows the operator to access the lift height setting in the

GLOBAL SETTINGS without going through the menu.

VIEW/ EDIT PROGRAMS

GENERAL

There are a total of 6 programs supplied with the Composite

Sampler. One program is a fluid transfer program called

CONTINUOUS PUMPING, this program cannot be modified.

The other 5 programs are fluid sampling programs. These

programs are numbered 1 through 5. All programs can be

accessed through the menu system of the Composite

Sampler. The 5 sampling programs can be edited to create

your own sampling programs. Edited or modified programs

must be saved before they can be run. Modifying the factory

supplied programs and saving them as modified programs

will temporarily overwrite the factory program. The factory

programs can be individually restored to their original default

settings upon demand.

Only (1) one program can be loaded and used at a time. A

program is always loaded into memory of the Composite

Sampler.

PROGRAM MENU TOUR

Operation of the system is menu driven. To access the menu,

if not presently displayed, press the MENU button on the

control console. The LCD display will show the following.

Use the down arrow key to navigate and select VIEW/EDIT

PROGRAMS and press ENTER. The display will change to read:

HINT: the display is only 2 lines, so you will only see 2

choices at one time. Remember the arrow in the first column

indicates whether there are choices above or below the ones

you are viewing.

c CLEAR ALL LOG DAT A

g

DON’T CLEAR ALL LOG DA TA

g LOG DAT A

c DEF AULT GLOBAL SETTINGS

c RESET GLOBAL SETTINGS

g DON’T RESET SETTINGS

g GLOBAL SETTINGS

c VIEW/EDIT PROGRAMS

g PROGRAM #1

c PROGRAM #2

Page 20

20

Navigate further into the program options by using the ⁄ down

arrow key.

LOADED PROGRAMS

One of the available programs is always loaded into the

memory for use. How do you verify which program is loaded

for operation of the Composite Sampler? To verify which

program is loaded for operation of the unit, access the menu

by pressing the MENU key and selecting VIEW/EDIT

PROGRAMS, then press the ENTER key.

The display will change to show 2 program options. One of

these options will show a darkened or filled in box next to the

program name. This is the program which is loaded for operation.

See the example below.

In this case PROGRAM #3 is loaded for operation as shown

in the above example.

CONTINUOUS PUMPING

This program is for fluid transfer in the field. The pump will

start when the START/STOP button is pressed or the REMOTE

CONTACT CLOSURE is closed. The pump will stop when

the same button is pressed again, the REMOTE CONTACT

CLOSURE opens or the fluid level sensor in the sample

reservoir causes the system to stop because the reservoir

is full. This program cannot be modified in any manner.

This program selection is not visible when you first access

the program menu. Select VIEW/EDIT PROGRAMS and press

ENTER. The display will change to read as follows.

The arrow at the far left of the display on line 1 shows a

bi-directional arrow, indicating there is an available option

above PROGRAM #1.

Use the up arrow key to navigate upward in the menu. The

display will change to read:

You may now select CONTINUOUS PUMPING by pressing

the ENTER key.

c PROGRAM #2

c PROGRAM #3

c PROGRAM #3

c PROGRAM #4

c PROGRAM #4

c PROGRAM #5

g PROGRAM #3

c PROGRAM #4

g PROGRAM #1

c PROGRAM #2

g CONTINUOUS PUMPING

c PROGRAM #1

Page 21

21

SAMPLING PROGRAMS #1-5

The attached summary shows the default values for the 5 factory sampling programs

PARAMETER PROGRAM 1 PROGRAM 2 PROGRAM 3 PROGRAM 4 PROGRAM 5

PROGRAM START

DELAYED START HR:MIN 0-167:59 00:00 01:00

REMOTE & DELAYED START 00:00 167:59 01:00

MAINTAINED CONTACT X X

PULSED CONTACT X

SAMPLE VOLUME 1-9000ml 500 500 375 500 375

NUMBER OF SAMPLES 1-99 18 12 24 18 24

TIME BETWEEN SAMPLES

EQUAL INTERVALS HH:MM 00:15 00:00 01:00 01:00

UNEQUAL INTERVALS HH:MM X

#1 00:15

#2 00:30

#3 00:45

#4 01:00

#5 01:15

#6 01:30

#7 01:45

#8 02:00

#9 02:15

#10 02:30

#11 02:45

#12 03:00

# OF CONTACT CLOSURES 0 Not Visible 5 0 Not Visible

Page 22

22

SAMPLING PROGRAM

MENU OPTIONS

GENERAL

All of the sampling programs have the same menu options.

Programs are constructed or built by editing the existing

program sampling menu options and saving those changes

as a modified program. The sampling menu options are

accessed through any of the sampling programs, shown in

the VIEW/EDIT PROGRAMS menu. Select a sampling

program such as PROGRAM #1 and press the ENTER key.

The display will change to read:

NOTE: You may make only one selection in each menu

option.

Select PROGRAM START and press ENTER. The

display will change to read:

PROGRAM START

Allows the operator to change how the program starts:

immediately, with a delay or through the use of another

device. There are two options; DELAYED START and

REMOTE & DELAYED START.

Select DELAYED START and press ENTER: The display will

change to:

DELAYED START

Allows the operator to input the time delay for starting the

program once the START button is pressed. The parameter is

hours and minutes 0-167:59. If you want the program to start

immediately upon pressing the START button input 0 and

press ENTER. To start after a delay or waiting period input

the desired time. If the desired delay time is 40 hours and

0 minutes input 4000 and press enter. If the desired time is

5 minutes of delay time input 5 and press enter.

REMOTE & DELAYED START

Allows the operator to start the Composite Sampler through

the use of another instrument using the REMOTE CONTACT

CLOSURE (see Figure 2) located on the exterior right hand

side of the unit. The other instrument must be able to either

close or short the contacts (dry contact closure) or generate a

pulse. Some of the instruments or devices that may be used

to start the Composite Sampler remotely are: level sensors or

float switches, pH meters or flowmeters.

Using the remote start component of this feature you can

sample a water source upon the occurrence of an event such

as a rain storm or increase in water flow or pH.

The delayed start component of this feature allows the operator

to add a time delay once the contact closure or remote signal

has activated the unit. This feature can be used to delay the

start of a sampling program until an event causes the water

source being sampled to change. An example of this would

be a rainstorm upstream of a water source. It may take 15

minutes before the water from the rainstorm affects the water

source you are sampling. You do not want to

sample the water source until it is affected by the incoming

water. You can use a float or level switch to sense an increase

of water level and remotely turn on the Composite Sampler

and the time delay to cause the program to wait before taking

the first sample to allow the waters to mix. The use of this

feature requires the Remote Contact Closure Accessory

Model No. 7580-60.

See the ACCESSORY section for details.

When you select REMOTE & DELAYED START and press

ENTER, the display changes to:

g PROGRAM START

c SAMPLE VOLUME

g DELAYED ST AR T

c REMOTE & DELAYED ST AR T

DELAYED ST AR T

000:00 HR/MN (0-167:59)

DELAYED ST AR T

000:00 HR/MN (0-167:59)

Page 23

23

MAINTAINED CONTACT

This is the default type of signal that is continuous or level related.

There is continuous continuity between the contacts, like a short.

When this option is selected the REMOTE CONT ACT CLOSURE

must remain closed during the entire sample program. If the

REMOTE CONT ACT CLOSURE should open during the program; the

program will stop after taking the next scheduled sample.

PULSED CONTACT

This type of signal is not continuous. It goes on and off and

the system is able to count the number of pulses or signals to

perform various functions.

Select the appropriate type of contact using the arrow keys

and press ENTER. The display will return you to:

Use the down arrow key to navigate and select SAMPLE

VOLUME and press ENTER. The display will change to read:

SAMPLE VOLUME

Allows the operator to enter the desired sample volume.

Volume units that were selected in the GLOBAL SETTINGS

menu option is what will appear. If you selected gallons, then

GAL (representing gallons) will appear on the display screen.

The minimum sample volume that can be taken will vary with

tubing size. Trying to pump a 1 mL sample with L/S

®

24 size

tubing is not practical. Use smaller tubing for pumping

smaller sample volumes. See the SPECIFICATION section for

the minimum volume required for calibration accuracy.

HINT: If you will be taking small sample volumes such as 100

mL and or require high lifts greater than 12 feet than you

should consider using L/S

®

15 size tubing. This will improve

the performance and accuracy of the sample volume taken.

Enter the desired sample volume and press ENTER. The

display will return you to:

Use the down arrow key to navigate and select NUMBER OF

SAMPLES and press ENTER. The display will change to read:

NUMBER OF SAMPLES

Allows the operator to set the number of samples to be

taken. Select NUMBER OF SAMPLES and press ENTER.

The display will change to read:

HINT: If the number of samples times the sample volume

exceeds the reservoir capacity you will receive an error

message asking you to decrease one or the other when you

try to save the program. You must correct the problem before

you can save the program.

After entering the NUMBER OF SAMPLES press the enter

key. The display will return you to:

Use the down arrow key to navigate and select TIME

BETWEEN SAMPLES and press ENTER.

g MAINTAINED CONT ACT

c PULSE CONTACT

g PROGRAM START

c SAMPLE VOLUME

SAMPLE VOLUME

500 ML (1-9000)

c PROGRAM START

g SAMPLE VOLUME

c SAMPLE VOLUME

g NUMBER OF SAMPLES

NUMBER OF SAMPLES

XX (1-99)

c SAMPLE VOLUME

g NUMBER OF SAMPLES

c NUMBER OF SAMPLES

g TIME BETWEEN SAMPLES

Page 24

24

TIME BETWEEN SAMPLES

Allows the operator to input the desired time between samples.

When TIME BETWEEN SAMPLES is selected and you press

ENTER two choices will presented for your selection.

EQUAL INTERVALS

Allows the operator to input the desired time between samples

in an hours:minutes format. All time intervals will be the same

or equal. You can select any time period between 0 minute to

99 hours 59 minutes. The time for this option should be set

to a value greater than 0 except for applications where the

number the # CONTACT CLOSURES is chosen to control time

between samples. The display appears as follows:

NOTE: If your are using the # CONTACT CLOSURES menu

option the time in this option should be set to 00:00 HR:MN,

otherwise the two features will interact. This will cause the

timer to enact a sampling cycle rather than the set number of

contact closures if the time interval occurs before the # OF

CONTACT CLOSURES..

UNEQUAL INTERVALS

Allows the operator to input desired time between samples

in an hours:minutes format where the time between samples

can vary. The operator is allowed a maximum of 12 different

time periods between samples. If more than 12 samples were

selected in NUMBER OF SAMPLES menu option the remaining

time periods will repeat time period #12.

If only 5 samples were selected in NUMBER OF SAMPLES

only 5 time periods will appear in the selection menu. The

display appears as follows:

HINT: the display is only 2 lines, so you will only see 2

choices at one time. Remember the arrow in the first column

indicates whether there are choices above or below the ones

you are viewing.

Once you have made your selections and pressed enter the

display changes to read:

Use the down arrow key to navigate and select # OF CONTACT

CLOSURES and press ENTER. The display changes to read:

# OF CONTACT CLOSURES

This menu option will not be visible if you selected REMOTE &

DELAYED START in the PROGRAM START option and selected

the MAINTAINED CONTACT menu option. The system will be

started by a single contact closure. The system will be take a

sample after the specified number of contact closures occurs.

The number of contact closures available is 0-9999. The

default is 0.

Once you have made your selections and pressed enter the

display changes to read:

Use the down arrow key to navigate and select DEFAULT

PROG SETTINGS and press ENTER.

g EQUAL INTERVALS

c UNEQUAL INTERVALS

EQUAL INTERVALS

00:15 HR:MN (0-99:59)

g #1 00:15 HR:MN

c #2 00:30 HR:MN

c #2 00:45 HR:MN

c #3 01:00 HR:MN

c #11 02:45 HR:MN

g #12 03:00 HR:MN

g TIME BETWEEN SAMPLES

c # OF CONTACT CLOSURES

# OF CONTACT CLOSURES

(0-9999)

g TIME BETWEEN SAMPLES

c DEFAULT PROG SETTINGS

Page 25

25

DEFAULT PROGRAM SETTINGS

Allows to the operator to return the program being edited to

its factory default settings. This only affects the program

being edited. The other sampling programs are unaffected.

Upon selecting this menu option and pressing ENTER, the

display will change to:

The default selection will not reset the program settings. You

must use the up arrow to select "RESET PROGRAM SETTINGS" and press ENTER. Once the ENTER key has been

pressed, the display will change to:

HINT: If you have returned a program to its default settings,

there is no need to save it.

SAVE PROGRAM

Allows the operator to save an edited program under one of

the five program numbers.

The program being edited does not have to be saved under

the program number you are editing.

If you are editing program #1, this edited program could be

saved as program #5. You will be overwriting whatever program was there. Factory default programs can be restored,

modified programs cannot be restored once over written.

Use the down arrow key to navigate and select SAVE

PROGRAMS and press ENTER. The display will change to:

HINT: The display is only 2 lines, so you will only see 2

choices at one time. Remember the arrow in the first column

indicates whether there are choices above or below the ones

you are viewing.

Once you have selected the program number under which the

edited program will be saved and pressed ENTER. The display

will return you to the program selection screen as shown below .

The LCD display will show you the program number you have

saved the edited program under with a date at the far right of

the screen. This date indicates that the program is an edited

or modified program and the date it was saved. Programs

using factory supplied defaults will not display a date to the

right of the program number. In this way you can differentiate

between a factory program and an edited one.

HINT: If you attempt to exit the VIEW/EDIT PROGRAMS

menu without saving the program the following display screen

will appear.

This is to confirm your choices and prevent accidental loss of

desired changes to a program.

HINT: Edited programs can only be run once they are saved.

If you do not save the edited program, it cannot be run and

your edits will be lost.

HINT: To exit the menu and return to a system ready prompt

use the cancel key.

c RESET PROG SETTINGS

g DON’T RESET SETTINGS

g DEFAULT PROG SETTINGS

c SAVE PROGRAM

c SAVE PROGRAM #4

c SAVE PROGRAM #5

c PROGRAM #X 09/23/02

c PROGRAM #X

PROGRAM NOT SAVED

ENTER=SAVE CANCEL=NO SAVE

g SAVE PROGRAM #1

c SAVE PROGRAM #2

c SAVE PROGRAM #2

c SAVE PROGRAM #3

Page 26

26

HOT KEYS

Three of the VIEW/EDIT PROGRAMS menu options are also

accessible via "Hot Keys" located on the control console

keypad. The keys are round, blue in color and labeled SAMP.

VOL., TIME, and DELAY START. These keys allow the operator

to access the sample volume, time between samples and

delay starting time for the program currently selected to run

without going through the menu.

HINT: To save the program setting you have just modified

using the HOT KEYS you must save the program or your

change will be lost.

CALIBRATING THE

SYSTEM

GENERAL

The Composite Samplers' non-volatile memory contains flow

data related to sample volume flow per pump head revolution

versus sample lift height. This information is used to calculate

the correct sample volume being taken by the system at a

specific lift height. Due to the number of variables and

variations possible with use of the Composite Sampler in the

field, the stated accuracy of the unit is achieved only when

the unit is calibrated at the field site after setup of the sampler

as it will be used.

MINIMUM SAMPLE SIZE

The stated accuracy of the sample volume being taken is

predicated on a minimum sample size versus the tubing size

used to take the sample.

For L/S

®

15 size tubing the minimum sample size for stated

calibrated sample accuracy is 167 milliliters.

For L/S

®

24 size tubing the minimum sample size for stated

calibrated sample accuracy is 270 milliliters.

REQUIRED EQUIPMENT

To calibrate the Composite Sampler you will need a graduated

cylinder with a minimum volume of 250ml for use with L/S

®

15

tubing or 500 mL for use with L/S

®

24 tubing. The graduated

cylinder is not supplied with the sampler system and is the

users’ responsibility to provide one. See the ACCESSORIES

section for recommended graduated cylinders.

CALIBRATION PROCEDURE

1. Setup the Composite Sampler on site as it will be used

for sampling.

2. Verify that the global settings for lift height and tubing

length have been entered.

3. Disconnect the sample hose from the sample reservoir

quick disconnect fitting.

4. Have the graduated cylinder ready.

5. Press the CAL key.

The display will change to read:

6. Press the ENTER key and hold the sample hose to the

graduated cylinder.

7. The system will first purge the sample intake line and then

take a calibration volume. When the sample has completed

taking a calibration volume, the display will change to read:

8. Read the volume from the graduated cylinder and enter the

volume measured on the numeric keypad and press the

ENTER key. EXAMPLE: If the volume was 10.5 ml enter 105

and press enter. If the measured volume was 267.5 ml

enter 2675 and press enter.

9. The system will then return to a system ready prompt on

the LCD display.

c START TUBE CALIBRATION

USING FACTORY CAL

ENTER MEASURED VOLUME

_ _ _ . _ ML (1-999.9)

SAMPLER SYSTEM READY

HH:MM:SS MM/DD/YYYY

Page 27

27

PREVIOUS CALIBRATIONS

If the Composite Sampler System was previously calibrated

on another site, the recommendation is to restore the factory

calibration prior to calibrating the system at another site. To

restore the factory calibration press the CAL key. The display

will change to read:

Use the down arrow key to navigate and select RESTORE

FACTORY CAL and press ENTER. The Display will change to

request a confirmation of requested action and will read as

shown below.

Navigate using the up arrow to select RESTORE FACTORY

CAL and press ENTER.

The display will change to read as shown at the beginning of

the calibration procedure.

CYCLING THE SYSTEM

The operational readiness of the system and sample lines

can be checked prior to starting the sampling program. The

operator can perform this check by:

1. Disconnecting the sample line from the sample reservoir at

the quick disconnect fitting on the reservoir cap. Point the

end of the sample line away from the unit.

2. Press CYCLE TEST key.

3. The unit will go through a through a purge cycle, a single

rinse cycle if one or more are programmed, and draw a

single sample of the volume programmed.

4. Reconnect the sample line to the sample reservoir cap

once you have completed this check.

MAINTENANCE

WARNING: Disconnect the Composite Sample

from any external power source

before cleaning. A shock hazard

exists when using water on powered

equipment.

CLEANING:

Keep the exterior housing and sample reservoir clean by

using a mild detergent and soap solution. Never immerse the

unit in water or use excessive fluid when cleaning the system.

Dry the cleaned parts before restoring external power.

SAMPLE RESERVOIR VENTS

The sample reservoir cap contains two breather vents

allowing the reservoir to be filled with fluid, while expelling

air. These vents can become clogged by particulate matter

present in the fluid samples taken at various sites.

To clean the vents apply a vacuum source to the inside bore

of the vent to remove any contaminants or foreign matter. If

cleaning is unsuccessful in unclogging the vents, they will

have to be replaced.

Refer to USER REPLACEMENT PARTS for the part numbers

of all user replacement parts.

TUBING

The tubing will occasionally have to be replaced due to wear

at the pump head and fouling.

The routing of the tubing is important, since it will change the

performance of the product if not performed correctly.

The correct routing of the tubing is as follows:

1. From the Sample Inlet bulkhead connector to the bottom of

the Flow Detector. A tubing length of 18" is required.

2. From the top of the Flow Detector through the pump to the

Sample Reservoir. A tubing length of 17.63" is required.

g START TUBE CALIBRATION

c USING FACTORY CAL

c RESTORE FACTORY CAL

g DON’T RESTORE CAL

Page 28

28

DISPLAY READS DESCRIPTIONS & REMEDIES

BAD GLOBAL SETUP Global setup data from EEPROM corrupted, reset GLOBAL SETTINGS to their defaults.

USING DEFAULTS

BAD USER CAL DATA User field cal Data from EEPROM corrupted,reset to factory cal.

USING DEFAULTS

REAL TIME CLOCK ERROR Run data in RTC RAM corrupted, program running status lost. Charge or replace battery

CHECK BATTERY as necessary.

BATTERY FULLY CHARGED During battery check, voltage under load ≥ 12.5

BATTERY LOW During battery check, voltage under load < 12.5. Strongly recommend you charge

CHARGING IS RECOMMENDED the battery. You may not have enough power to run a complete sampling program

sequence. Charge the battery.

BATTERY IS VERY LOW During battery check, voltage under load <11.9V. You must charge the battery!

MUST CHARGE BATTERY! Damage to unit can result if run in a discharged state.

CAN'T CHARGE BATTERY Battery was in trickle charge state for over 4 hours (< 10.5V). Replace the battery.

MUST REPLACE BATTERY

ERROR: NO BATTERY Detected battery voltage over 16V. Check battery connections. If connected, replace

MUST REPLACE BATTERY the battery. Contact factory for further assistance if needed.

BAD FLASH CHECKSUM Bad program checksum in flash. Operation of unit is disabled. Internal system problem.

SERVICE REQUIRED Contact factory for assistance.

NO MOTOR FEEDBACK No encoder pulses detected. Internal system problem, contact the factory for assistance.

SERVICE REQUIRED

MOTOR OVER SPEED Motor running too fast. If any servicing of the motor took place recently, the motor leads

SERVICE REQUIRED may have been reversed. Check that the polarity of the motor leads matches the coding

next to the terminal. Red lead to terminal marked red, black to black. Contact the factory