Page 1

®

OPERATING MANUAL:

®

LS® & I/P

PUMP DRIVES

DIGITAL

Model Nos.

07551-50

®

®

MASTERFLEXLIVE

®

L/S

®

07551-50

07551-60

07575-70

07575-72

77420-50

77420-60

(US & Canada only) Toll Free 1-800-MASTERFLEX • 1-800-637-3739

(Outside US & Canada) 1-847-549-7600 • 1-847-381-7050

www.masterflex.com • techinfo@masterflex.com

A-1299-1169

Edition 02

Page 2

© 2020 Cole-Parmer Instrument Company. All rights reserved.

Masterflex – Reg TM Cole-Parmer Instrument Company.

Trademarks bearing the ® symbol in this publication are registered in the U.S. and in other countries.

®

Digital Pump Drive Operating Manualii

MasterflexMASTERFLEXLIVE

Page 3

Safety Precautions

Preface

SAFETY

PRECAUTIONS

DANGER: High voltages exist and are accessible. Use extreme caution when

servicing internal components.

WARNINGS: Tubing breakage may result in fluid being sprayed from pump. Use

!

appropriate measures to protect operator and equipment.

Turn drive off before removing or installing tubing. Fingers or loose clothing

could get caught in drive mechanism.

WARNINGS: Do not operate the pump drive in a manner not specified in the

documentation. Misuse of the pump drive may result in a hazard and may

compromise the safety protection built into the pump drive. If the pump drive is

damaged, turn it off and not use it until service-trained personnel can check

its safety.

Single-Phase Only. Not to be used with Split-Phase lines.

The Power switch on the Back Panel is not the main disconnect. Main

disconnect is accomplished by disconnecting the detachable power supply

cord at the appliance coupler or at the main plug. Ensure the power cord is

easily accessible and removable, in the event of an emergency, which requires

immediate disconnection.

The operator should check the detachable power supply cord condition. The

equipment should not be operated if the power supply cord is cracked or

broken. Any obvious damage to the enclosure (from a drop or fall) should be

checked by service personnel for loose or damaged parts inside.

CAUTIONS: Power must be turned off before connecting the external remote

!

control cable to prevent damage to the drive.

Do not contaminate the lubricant in the container, on the shaft or on the seal

with foreign material. Failure to observe this precaution may result in damage

to the seal and premature failure of the seal.

No foreign matter should be allowed under the gasket on the back of the front

plate or under the heads of the screws. Failure to observe this precaution may

result in leakage during wash down of the drive.

Do not block the rear panel of the pump drive. The power switch must always

be easy to access. The power cord must always be easy to disconnect.

Replace the power cord only with one of the same type and rating. The

minimum power ratings are stated on the rear panel.

The power cord set supplied with your pump drive meets the requirements of

the country where you purchased the pump drive. If you use the pump drive in

another country, you must use a power cord set that meets the requirements

of that country.

When using hazardous chemical and biological agents, take all suitable

protective measures, such as wearing protective glasses and gloves resistant

to the substances used. Follow local and/or national regulations for safe

operation and maintenance of the system.

®

Digital Pump Drive Operating ManualMasterflex

iiiMASTERFLEXLIVE

Page 4

Preface

Safety Precautions

SAFETY

PRECAUTIONS

(continued)

Explanation of

Symbols

WARNING:

Production Use

CAUTION: To avoid electrical shock, the power cord protective grounding

conductor must be connected to ground. Not for operation in wet

locations as defined by EN61010-1.

CAUTIONS: Keep fingers away from rotor while pump is in operation.

Stop pump before loading or unloading tubing.

To reduce the possibility of tipping, use the stacking clip provided with

the unit.

CAUTION: Risk of Danger. Consult Operator’s manual for nature of hazard

!

and corrective actions.

CAUTION: Risk of crushing. Keep fingers away from rotor while pump is

in operation. Stop pump before loading or unloading tubing.

CAUTION: Hot Surface. Do not touch.

CAUTION: Risk of electric shock. Consult Operator’s manual for nature of

hazard and corrective actions.

This product is not designed for, nor intended for use in patient connected

applications; including, but not limited to, medical and dental use, and

accordingly has not been submitted for FDA approval.

Limitation

This product is not designed for, nor intended for use in hazardous duty

areas as defined by ATEX or the NEC (National Electrical Code); including,

but not limited to use with flammable liquids. Consult the factory for

products suitable for these types of applications.

®

Digital Pump Drive Operating Manualiv

MasterflexMASTERFLEXLIVE

Page 5

Table of Contents

Section 1

Section 2

Section 3

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Application Solutions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INSTALLATION AND SETUP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Before Starting the Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mounting the Pump Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Turning On the Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Priming the Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tubing Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Continuous Mode Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Continuous Mode Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Time Dispense Mode Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Time Dispense Mode Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Copy Dispense Mode Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Copy Dispense Mode Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Copy Setting Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Copy Setting Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Volume Dispense Mode Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Volume Dispense Mode Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remote Control Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DB-25 Pin Configuration with Wiring Scheme . . . . . . . . . . . . . . . . . . . . . .

31-Pin Configuration with Wiring Scheme. . . . . . . . . . . . . . . . . . . . . . . . . .

Remote Control Inputs and Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Open Collector Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Anti-Drip Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Communication Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1

1-1

1-2

2-1

2-1

2-2

3-1

3-1

3-2

3-2

3-3

3-4

3-6

3-7

3-8

3-9

3-10

3-12

3-13

3-15

3-16

3-17

3-18

3-20

3-23

3-24

3-25

3-26

3-27

3-28

®

Digital Pump Drive Operating ManualMasterflex

vMASTERFLEXLIVE

Page 6

Table of Contents

Table of Contents

(continued)

Section 4

Page

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Replacement Parts and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Fuse Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Gear Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Shaft Seal Inspection (Stainless Steel and Powder Coated Steel

Enclosures Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Section 5

Section 6

Section 7

Section 8

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Troubleshooting Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Error Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

WARRANTY, PRODUCT RETURN, and TECHNICAL ASSISTANCE . . . 8-1

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Product Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Technical Assistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

®

Digital Pump Drive Operating Manualvi

MasterflexMASTERFLEXLIVE

Page 7

Figures

Figures

Page

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Continuous Mode Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Continuous Mode Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Time Dispense Mode Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Time Dispense Mode Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Copy Dispense Mode Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Copy Dispense Mode Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

COPY Setting Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

COPY Setting Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Volume Dispense Mode Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Volume Dispense Mode Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Remote Control Menu Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

DB-25 Pin Configuration with Wiring Scheme . . . . . . . . . . . . . . . . . . . . . . . 3-23

31-Pin Configuration with Wiring Scheme . . . . . . . . . . . . . . . . . . . . . . . . . .

3-24

Terminating Open Collector Outputs to a PLC . . . . . . . . . . . . . . . . . . . . . . . 3-26

Anti-Drip Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

Anti-Drip Degrees Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

Fuse Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Shaft Seal Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

®

Digital Pump Drive Operating ManualMasterflex

viiMASTERFLEXLIVE

Page 8

Tables

Tables

Page

Continuous Mode Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

Dispense Mode Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

Remote Control Inputs and Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

®

Digital Pump Drive Operating Manualix

MasterflexMASTERFLEXLIVE

Page 9

Section 1 Introduction

e Digital drive controls the speed of MASTERFLEX® Pump Heads to

provide flow rates from 0.001 to 3400 mL/min for L/S drives and from

0.01 to 19 L/min for I/P drives.

Mount up to 2 (600 rpm) or 4 (100 rpm) MASTERFLEX L/S Pump

Heads and all MASTERFLEX L/S-compatible Pump Heads on L/S drives

and up to 2 MASTERFLEX I/P EASY-LOAD® or MASTERFLEX I/P

Standard Pump Heads or 1 MASTERFLEX High-Performance I/P Pump

Head. Advantages of Peristaltic Pumps:

Application Solutions

• Handle abrasive slurries and corrosive fluids with minimal wear. Ideal for

titanium dioxide or diatomaceous earth filter aid applications.

• No seals in contact with the medium pumped.

• No valves to clog.

• Inner surfaces are smooth and easy to clean.

• Fluid contacts only the tubing or tube material.

• Suction lift and priming up to 8m water column at sea level.

• Low shearing for handling the most shear sensitive of fluids like latex or

fire fighting foam.

• Capable of running dry and pumping fluids with high quantities of

entrained air, such as black liquor soap.

• High volumetric efficiency allows operation in metering or dosing

applications where high accuracy is required.

• Handle extremely viscous fluids.

• Tubing and tube materials are available that are suitable for food and

pharmaceutical use.

®

Digital Pump Drive Operating ManualMasterflex

1-1MASTERFLEXLIVE

Page 10

Section 1

Introduction

General Description

e MASTERFLEX Digital Peristaltic Pump Drives offer flow rate

capacities from 0.001 mL/min to 19 L/min using MASTERFLEX Stan-

dard, EASY-LOAD® or High-Performance Pump Heads. Even lower flow

rates can be achieved with our multichannel and cartridge Pump Heads.

Features include a small footprint, plus non-stainless steel drives that are

stackable.

e MASTERFLEX digital pump provides a motor speed repeatability of

+/-0.1 percent to maximize productivity in precision liquid dosing, batch

dispensing and filling applications. A turndown ratio up to 6500-to-1,

bidirectional flow and self-priming capabilities allow for smooth, seamless

operation and an extremely broad flow range within one tubing size.

In addition to high accuracy, precision, repeatability and resolution of

speed (or flow rate), the MASTERFLEX drive features a multi-language,

intuitive, man/machine interface with a four-line graphical LCD display

providing direct readout of pump speed (rpm), flow rate (user-selected

units), number of dispenses, and menu options.

e easy-to-use keypad eliminates setpoint overshoot and provides easy

navigation through menu options that include a number of on-screen

programming features.

ese drives use high precision, no-maintenance brushless motors for

improved reliability. is, combined with its high turndown, superior

accuracy, and intuitive interface make the MASTERFLEX drives ideally

suited where ultra-precise, repeatable flow control is required. e pump

accommodates a variety of product fill volumes and batch dispensing profiles, and fluid only contacts the tubing, providing for contamination-free

pumping.

MASTERFLEX pumps are self-priming, can operate dry without damage,

are suitable for most chemicals and contain no valves or seals. See Pump

Head and Tubing Guides within this CD.

®

Digital Pump Drive Operating Manual1-2

MasterflexMASTERFLEXLIVE

Page 11

Before Starting Drive

!

!

Section 2 Installation and Setup

• e drive should be mounted on a flat horizontal surface, and no more

than two (2) Pump Heads should be added for 600 rpm drives or four

(4) pump Heads for 100 rpm drives.

• e ambient air temperature should not exceed 104° F (40° C) and

adequate air flow should be provided for.

CAUTION: Do not block the rear panel of the pump drive. The power

switch must always be easy to access. The power cord must

always be easy to disconnect.

• Tubing should be clean and routed so that bend radii are at a

minimum four (4) times the tube diameter and as short as possible.

WARNING: Turn drive off before removing or installing tubing. Fingers

or loose clothing could get caught in drive mechanism.

• Use a tube size of appropriate diameter for the flow rate and viscosity

required.

• To maintain the best accuracy of flow rates, re-calibrate tubing regularly.

See Tubing Calibration Section of this manual.

• For tubing selection and compatibility, see Tubing Selection Guide within

this CD.

• For Pump Head information, see Pump Head information within this CD.

• When cleaning or performing maintenance, please remove power from

the drive.

CAUTION: The power cord set supplied with your pump drive meets the

!

requirements of the country where you purchased the pump drive. If you

use the pump drive in another country, you must use a power cord set

that meets the requirements of that country.

DANGER: High voltages exist and are accessible. Use extreme caution

when servicing internal components.

®

Digital Pump Drive Operating ManualMasterflex

2-1MASTERFLEXLIVE

Page 12

Section 2

Installation and Setup

Mounting the

Pump Head

!

• Mount Pump Head and load tubing (See Pump Head information within

this CD). Check to make sure that rollers are clean and free of defects.

CAUTION: When using hazardous chemical and biological agents, take

all suitable protective measures, such as wearing protective glasses

and gloves resistant to the substances used. Follow local and/or

national regulations for safe operation and maintenance of the system.

®

Digital Pump Drive Operating Manual2-2

MasterflexMASTERFLEXLIVE

Page 13

Section 3 Operation

Turning On the Drive

WARNING: Do not operate the pump drive in a manner not specified in the documentation. Misuse of the pump drive may result in

a hazard and may compromise the safety protection built into the

pump drive. If the pump drive is damaged, turn it off and not use it

until service-trained personnel can check its safety.

1. Plug the power cord into the IEC Connector, located on the rear of the

drive. Plug the opposite end of the power cord into an electrical outlet.

2. Flip the power switch located on the rear of the drive.

3. Upon turning on the drive for the first time you will be prompted to

select a language. e selected language will be set as the default but

can be changed at any time by selecting “LANGUAGE” on the main

menu.

4. After selecting your language, the Main Menu will now appear on the

LCD screen. (NOTE: Each start-up after the initial will revert to the

mode of operation screen previously in use.)

5. If the language is accidently changed and the user would like to reset

it to the default language (English), press and hold the UP/DOWN

(▲/▼) keys during power up.

6. To restore drive to default settings, press and hold the LEFT/RIGHT

(◄/►) keys during power up.

CAUTION: To avoid electrical shock, the power cord protective

grounding conductor must be connected to ground. Not for operation in wet locations as defined by EN61010-1.

CAUTION: Power must be turned off before connecting the

!

external remote control cable to prevent damage to the drive.

WARNING: Tubing breakage may result in fluid being sprayed

!

from pump. Use appropriate measures to protect operator and

equipment.

®

Digital Pump Drive Operating ManualMasterflex

3-1MASTERFLEXLIVE

Page 14

Section 3

Operation

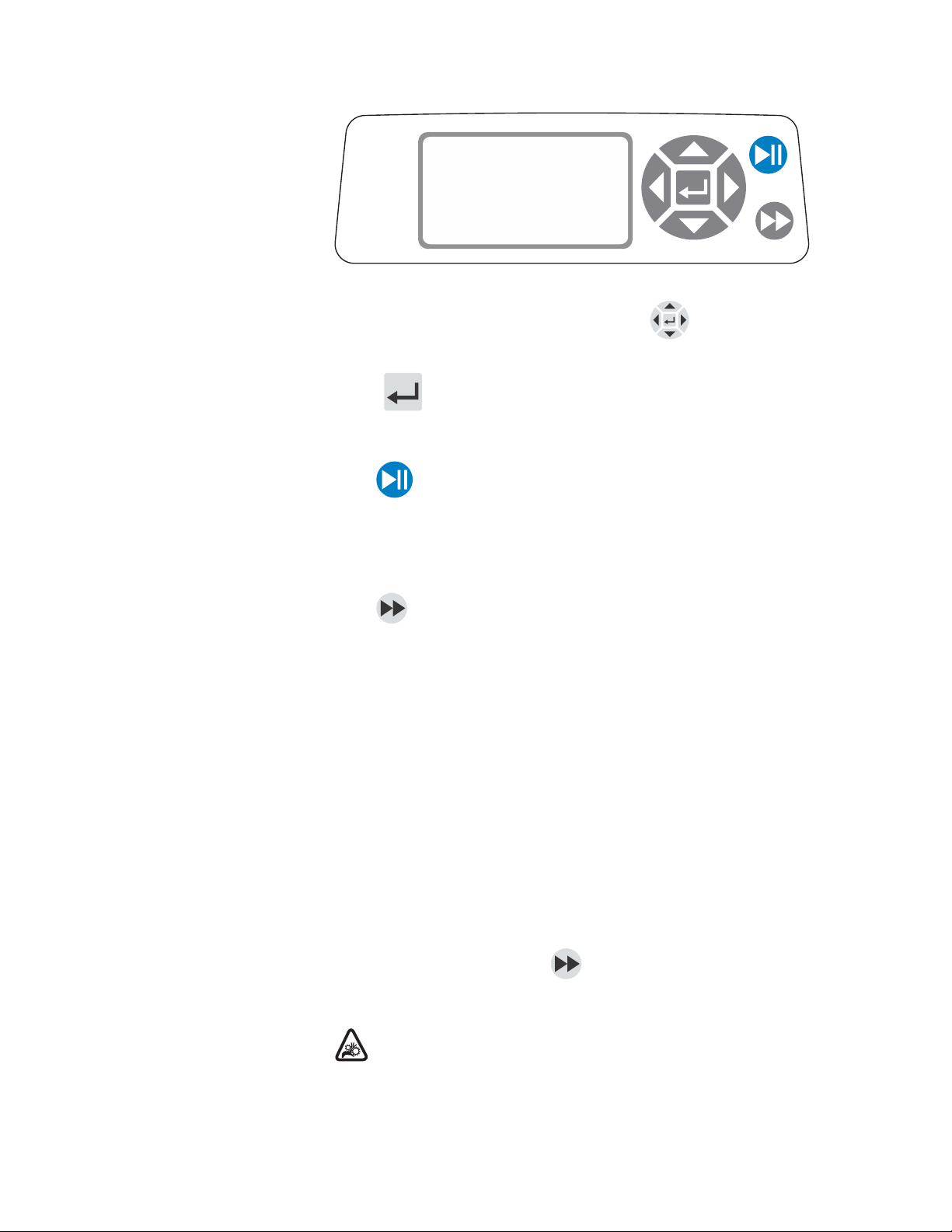

Control Panel

Figure 3-1. Control Panel

• To navigate all menus on the drive use the directional pad

directly to the right of the LCD screen.

• e (ENTER) key located in the middle of the directional pad is used

to enter or select a highlighted field or option. is key is often referred to

as the ENTER key in this manual.

• e (START/STOP) key located at the top right of the control panel is

used to start and pause the drive. is key is functional only when in one of

the four operating modes: Continuous, Time Dispense, Copy Dispense, or

Volume Dispense. is key is often referred to as the START/STOP key in

this manual.

Priming the Pump

• e (PRIME) key located at the bottom right of the control panel issued

to access the prime (fast forward) function. While pressed, this key operates

the drive at the maximum allowed speed/flow rate and in the direction

shown on the display. When released, the drive returns to its original speed

or flow rate.

1. Mount Pump Head to drive.

2. Insert appropriate tubing into Pump Head.

3. Insert tube inlet into supply fluid.

4. Insert supply outlet into desired container.

5. Turn on pump using switch located on the back of the drive.

6. Press and hold the PRIME key on the drive console to prime the

pump. Priming will stop when key is released.

CAUTION: Keep fingers away from rotor while pump is in

operation. Stop pump before loading or unloading tubing.

®

Digital Pump Drive Operating Manual3-2

MasterflexMASTERFLEXLIVE

Page 15

Section 3

Operation

Main Menu

CONTINUOUS MODErefer to Continuous Mode in this manual.

TIME DISPENSE MODErefer to Time Dispense Mode in this manual.

COPY DISPENSE MODErefer to Copy Dispense Mode section in this

manual.

VOLUME DISPENSE MODErefer to Volume Dispense Mode section in

this manual.

REMOTE CONTROL MODErefer to Remote Control Mode section in

this manual.

CUMULATIVE VOLUME:e drive stores and displays the cumulative

volume in units based on flow rate units (see SETUP MENU in this section). e Cumulative Volume can also be reset to zero.

NOTE:e Cumulative Volume is dependent on the Tubing Size selected.

(See SETUP MENUin this section.)

SOUNDS:An audible “beep” can be enabled to indicate a keypad press, the

end of a dispense and/or the end of a batch.

AUTOSTART:By default the drive will not restart when power is applied.

To enable this feature select AUTOSTART and then ON. e drive will

now restart when power is reapplied.

DISPLAY CONTRAST: is display can be adjusted using the

UP/DOWN( / ) arrows after selecting this menu item.

LANGUAGE:After selecting this menu, the user will be able to select one

of seven different languages.

NOTE:If the language is accidentally changed and the user would like to

reset it to the default language (English), press and hold the UP/DOWN

( / ) keys when power is reapplied.

DEFAULT SETTINGS: Selecting this menu item and pressing the

ENTER key will restore default settings. To restore drive to default settings

the user may also press and hold the LEFT/RIGHT ( / ) keys when

power is reapplied.

®

Digital Pump Drive Operating ManualMasterflex

3-3MASTERFLEXLIVE

Page 16

Section 3

Operation

Tubing Calibration 1. Mount Pump Head to drive.

2. Insert appropriate tubing into Pump Head.

3. Insert tube inlet into supply fluid.

4. Insert tube outlet into desired container. Container should be a

graduated container or a container placed on a scale may be used for

increased accuracy.

If using a scale, an acceptable weight to volume conversion for water

is 1 gram = 1 mL.

5. Turn on drive using power switch located on the rear of the drive.

6. Go to the Main Menu or Mode Setup Menu by selecting the SETUP

icon and pressing the ENTER key. Use the UP and DOWN keys

to highlight TUBING CAL in the Main or Setup Menu and press

the ENTER key.

7. Set the drive for the desired flow direction, tube size, and flow rate.

Note that these settings are retained and transferred to other mode

screens when entering or leaving the TUBING CAL screen.

• e flow direction is set using the directional keypad to highlight

the directional arrow. Pressing ENTER will toggle arrow between CW and CCW.

• e tube size is set using the directional keypad to highlight the

tube size field. Press ENTER and use the UP/DOWN keys to

select the tube size. Press ENTER to SAVE the selection and

return to TUBING CAL screen.

• e estimated flow rate is set using the directional keypad to

highlight the flow rate field. Press ENTER and use the

LEFT/RIGHT keys to select the digit to be changed. Use the

UP/DOWN keys to adjust the flow rate value. Press ENTER to

SAVE the setting and EXIT field using arrow keys. e drive will

adjust this flow rate after calibration is complete.

• Note that the calibration volume is fixed and cannot be changed.

8. Press and hold the prime key on the drive console to prime the

pump. Priming will stop when key is released.

9. Place a measuring container at the pump outlet. Highlight the START

field and press the ENTER key. e drive will run based on the

default volume at the estimated flow rate selected.

®

Digital Pump Drive Operating Manual3-4

MasterflexMASTERFLEXLIVE

Page 17

Section 3

Operation

Tubing Calibration

(continued)

10. Upon completion of the calibration run period, the CAL VOLUME

field will be highlighted. Press the ENTER key and adjust the CAL

VOLUME to the measured quantity. Use the LEFT/RIGHT keys to

select digit to be changed, use the UP/DOWN keys to adjust the value,

and press ENTER to SAVE setting and EXIT the field.

A lower case “c” should now be displayed when the calibrated tubing

size is selected. e volume units will depend on the flow rate units. e

flow rate unit mL/min will result in a volume unit of mL; oz/min will

result in a volume unit of oz.

Tubing Calibration Notes

• If the drive is stopped during calibration, empty the container and restart the procedure.

• Calibration time at maximum allowable flow rate (default max flow

rate) is 5-10 seconds and at minimum allowable flow rate (approximately 4% of the maximum flow rate) is 4 minutes. Select the

CUSTOM tube size for other tubing sizes or lower flow rates.

• Minimum and maximum flow rates will change after a tubing calibration due to a re-calculation of the vol/rev.

• Optimum results are best obtained after tubing has been broken in by

running in pump for at least 10 minutes. Steps 8-10 can be repeated

as necessary to optimize the accuracy of the tubing cal.

CAL RUN TIME FORMULA

60 / (flow rate [mL/min] / cal volume [mL]) = cal run time (seconds)

INVALID CAL RUN TIME EXAMPLE

• tube size 13 flow rate range is 0.006 mL/min – 36.0 mL/min

• at flow rate of 1 mL/min, cal run time calculation is as follows:

60 / (1 mL/min / 6 mL) = 360 seconds 360 seconds exceed the max

run time of 4 minutes (240 seconds)

®

Digital Pump Drive Operating ManualMasterflex

3-5MASTERFLEXLIVE

Page 18

Section 3

Operation

Setup Menu

All four operation mode screens contain a SETUP icon in the upper

right hand that gives quick access to the SETUP menu. e exact options

that can be accessed through the SETUP menu will depend on the operating

mode currently in use:

1. Selecting the SETUP Menu:In any of the four operating modes, use the

directional pad and enter key to select the SETUP icon from the mode

operation screen.

2. Navigating the SETUP Menu: Use the directional pad and the

ENTER key to select desired setting.

A breakdown of the setting features common to all modes follows. Other

settings are related to the specific operating mode currently in use and can be

accessed through the mode operation screen as well.

Flow Unit:Select desired flow unit to be displayed.

Tubing Size:Size and Maximum Flow Rate are displayed. Select desired tubing size.

Flow Rate:Set the flow rate in flow unit listed at the top of the screen.

(NOTE:To change flow unit, see Flow Unit above.) When the entire rate field

is highlighted, press ENTER. e digits can be navigated individually using

the UP/DOWN arrows; switch between digits using the LEFT/RIGHT arrows. After selecting an optimal flow rate, press ENTER again to validate.

Tubing Calibration:See Tubing Calibration.

Pump Direction: Select the direction of the pump flow.

Sounds: Select a beep for keypad, end of dispenses, and batches.

Remote Control:See Remote Control.

Keypad Lockout:Allows for the keypad to be locked and unlocked.

Cumulative Volume:View and reset cumulative volume.

Main Menu: Return to the Main Menu.

Exit:Return to the Mode Operation screen.

®

Digital Pump Drive Operating Manual3-6

MasterflexMASTERFLEXLIVE

Page 19

Section 3

Operation

Continuous Mode

Screen

Display Legend: Below is a screenshot of the screen display for the drive in

Continuous Mode. An explanation of the information on the screen follows.

A B

I

G

H

CONTINUOUS MODE

100.00

or

F

mL/min

17

C

D

E

Figure 3-2. Continuous Mode Screen

A. Mode Display: Current operating mode in which the drive will oper-

ate. Pressing ENTER key when highlighted will cycle through the

different operation modes.

B. Setup : Pressing the ENTER key on this icon goes to the Setup

screen. e Setup screen contains most functions that can be accessed

from the Continuous Mode operation screen, including: flow units,

tubing size, flow rate, pump direction, remote control, and keypad

lockout. e Setup screen also provides access to tubing calibration,

sounds, cumulative volume and the Main Menu.

C. Flow Direction:Pressing the ENTER key on this icon toggles between

clockwise and counterclockwise flow direction.

D. Flow Units:Pressing the ENTER key on this icon goes to the Flow Unit

selection screen. NOTE:% and rpm are available in Continuous Mode only.

When switching to Copy Dispense or Volume Dispense Modes % and rpm

units will change to mL/min with values dependent on tubing size selected.

E. Tubing Size:Pressing the ENTER key on this icon goes to the tubing

size selection screen.

F. Current Flow Rate: e center digits show the flow rate of the drive in

the unit of measure selected and shown to the right (see position D, Figure

3-2).

G. Local/Remote or :Pressing the ENTER key on this icon goes to

the Remote Control setup screen. is icon indicates whether your drive

is in local or remote control mode. If the solid rectangle appears in the

center of the figure the drive is set to be operated locally. If the solid

rectangle does not appear in the center of the figure the drive is set to be

operated by remote control.

H. Key Pad Lock :Pressing the ENTER key on this icon goes to the

Keypad Lockout screen. Locking the keypad will prevent someone from

changing the settings on the drive. When locked this icon changes to .

®

Digital Pump Drive Operating ManualMasterflex

3-7MASTERFLEXLIVE

Page 20

Section 3

Operation

Continuous Mode

Operation

CONTINUOUS MODE

100.00

Figure 3-3. Continuous Mode Operation

1. Getting Started:From the Main Menu, use the ENTER key to select

Continuous Mode to enter the Continuous Mode Operation screen.

2. Calibrating Tubing:Before operating the pump, insert desired tubing into

the Pump Head. For more information, see “Tubing Calibration”.

3. Preparing External Supplies:Insert tube inlet into supply fluid. Next,

insert tube outlet into desired container.

4. Starting the Drive:From this operation screen, simply pressing the

START/STOP key will start the drive at the speed/flow rate and direction shown. In Continuous Mode the drive will operate at the displayed speed/flow rate and direction continuously.

mL/min

17

5. Stopping the Drive:To pause or stop the drive, press the START/

STOP key in the top right hand corner of the console.

6. Changing Speed/Flow Rate:To change the speed/flow rate of the drive,

use the directional pad to highlight the numeric field in the center of

the display and press the ENTER key. is puts you in a position to

change the speed/flow rate of the drive at the farthest digit to the right

(tenths, hundredths, thousandths, etc depending on flow unit). Pressing

the UP arrow on the directional pad will increase the speed/flow rate by

one value and pressing the DOWN arrow will decrease the speed/flow

rate by one value. Pressing the ENTER key again will show all the possible digits that can be manipulated for the specific flow unit currently

in use; use the LEFT/RIGHT arrows on the directional pad to move

between digits and the UP/DOWN arrows to increase or decrease the

value, respectively. Once desired speed/flow rate is selected, press ENTER key a final time to set the drive to operate at that speed/flow rate.

7. Changing Flow Unit:To change the flow unit of the drive pause the drive

using the START/STOP key. Next, use the directional pad to select the

Flow Units icon and press the ENTER key. Use the UP/DOWN arrow

on the directional pad to select the desired flow unit and press the ENTER key to choose that unit. e drive will now operate in that flow

unit. Press the START/STOP key to resume operating the drive.

®

Digital Pump Drive Operating Manual3-8

MasterflexMASTERFLEXLIVE

Page 21

Section 3

Operation

Time Dispense Mode

Screen

Display Legend:Below is a screenshot of the screen display for the drive in

Time Dispense Mode. An explanation of the information on the screen fol-

lows.

I

G

H

A

TIME DISP. MODE

B

00:00:00

1000/2000

or

F

C

D

ON

E

OFF

Figure 3-4. Time Dispense Mode Screen

A. Mode Display: Current operating mode.

B. Setup: e Setup screen can be used to select flow units, tubing size,

flow rate, tubing calibration, sounds, cumulative volume, and Main

Menu. e Setup screen contains some functions that can be accessed

from the Time Dispense Mode operation screen, including: pump direction, on/off time, batch count, remote control, and keypad lockout.

C. Flow Direction:Pressing the ENTER key on this icon toggles between

clockwise and counterclockwise flow direction.

D. Pump ON Time:When this field is highlighted the drive is ON.

NOTE: e drive will not show 00:00 when switching from ON to

OF time.

E. Pump OFF Time: When this field is highlighted the drive is OFF.

F. Batch Count: Displays the number of cycles dispensed in the batch.

G. Local/Remote or : Pressing the ENTER key on this icon goes to the

Remote Control setup screen. is icon indicates whether your drive

is in Local or Remote Control mode. If the solid rectangle appears in

the center of the figure the drive is set to be operated locally. If the solid

rectangle does not appear in the center of the figure the drive is set to be

operated by remote control.

H. Key Pad Lock : Pressing the ENTER key on this icon goes to the

Keypad Lockout screen. Locking the keypad will prevent someone from

changing the settings on the drive. When locked this icon changes to .

I. Time Display: e center digits show the remaining time of the drive

in the ON or OFF Time highlighted on the right of the display

(position D or E, Figure 3-4).

®

Digital Pump Drive Operating ManualMasterflex

3-9MASTERFLEXLIVE

Page 22

Section 3

Operation

Time Dispense

Mode Operation

TIME DISP. MODE

00:00:00

ON

1000/2000

Figure 3-5. Time Dispense Mode Operation

1. Getting Started:From the Main Menu, use the enter key to select Time

Dispense Mode to enter the Time Dispense Mode Operation screen.

2. Calibrating Tubing: Before operating the pump, insert desired tubing

into the Pump Head. For more information, see “Tubing Calibration”.

3. Choosing Settings:Select desired flow unit, tube size, flow rate, pump

direction, etc. For more information see “SETUP Menu.”

4. Preparing Tubing: Insert tube inlet into supply fluid. Next, insert tube

outlet into desired container.

5. Selecting Flow Rate:Use the directional pad and ENTER key to select

the Setup icon. Use the UP/DOWN arrows on the directional pad to

select Flow Rate. In the Flow Rate selection screen, press the ENTER

key and then use the UP/DOWN arrows on the directional pad to select a desired flow rate. For faster entry, use the LEFT/RIGHT arrows

on the directional pad to move between digits and the UP/DOWN

arrows to increase or decrease the value, respectively. Press ENTER one

more time to validate the selected flow rate. Use the directional pad to

select EXIT to return to the Time Dispense Mode Setup Screen.

OFF

6. Setting ON Time:To set the ON Time, use the directional pad and

ENTER key to select the ON field (see position D, Figure 3-4). Doing

so will highlight the timer in the center of the screen (see position I,

Figure 3-4). Pressing ENTER again, allows the timer to be set using the

UP/DOWN arrows. Switch between digits using the LEFT/RIGHT

arrows. Having selected an optimal ON Time, press ENTER again to

validate. e drive will now run for the time appearing in the center of

the screen.

®

Digital Pump Drive Operating Manual3-10

MasterflexMASTERFLEXLIVE

Page 23

Section 3

Operation

Time Dispense Mode

Operation (continued)

7. Setting OFF Time:To set the OFF Time, use the directional pad and

ENTER key to select the OFF field (see position E, Figure 3-4). Doing so will highlight the timer in the center of the screen (see position

I, Figure 3-4). Pressing ENTER again, allows the timer to be set using

the UP/DOWN arrows. Switch between digits using the LEFT/RIGHT

arrows. Having selected an optimal OFF Time, press ENTER again

to validate. e drive will stop running for the time appearing in the

center of the screen. NOTE: If the OFF Time is set to 00:00:00, the drive

requires a START/STOP input from the keypad or the remote I/O

Connector to start the next dispense.

8. Selecting Batch Size:Before running the drive at the selected ON/ OFF

Times, select a batch size for the operation. To do so, use the directional

pad and the ENTER key to select the BATCH icon (see position F,

Figure 3-4). In the Batch Count screen, press the ENTER key and then

use the UP/DOWN arrows on the directional pad to select a batch size.

Switch between digits using the LEFT/RIGHT arrows. Press ENTER

one more time to validate the selected batch size. When set to zero (0)

the drive will run for an infinite number of cycles and the symbol is

displayed. Use the directional pad to select EXIT to return to the Time

Dispense Operation Screen.

9. Starting the Drive:e drive is now set to operate, press the START/

STOP key in the upper right hand corner to start the drive. e drive

can be paused at any time throughout the batch to adjust flow direction, tubing size, flow units, flow rate, etc.

10. Resetting Batch:To reset a batch, use the directional pad and the ENTER key to select the BATCH icon (see position F, Figure 3-4). In the

Batch Count screen, use directional pad to select RESET and press the

ENTER key to reset the batch count, select EXIT to return to the main

Time Dispense Mode operation screen.

®

Digital Pump Drive Operating ManualMasterflex

3-11MASTERFLEXLIVE

Page 24

Section 3

Operation

Copy Dispense Mode

Screen

Display Legend:Below is a screenshot of the screen display for the drive in

Copy Dispense Mode. An explanation of the information on the screen

follows.

A

COPY DISP. MODE

J

100.00

I

or

H

G

53 %

1000/2000

F

B

COPY

C

K

D

E

OFF

Figure 3-6. Copy Dispense Mode Screen

A. Mode Display:Current operating mode.

B. Setup : e Setup screen can be used to select flow units, tubing size,

flow rate, tubing calibration, sounds, cumulative volume, and Main

Menu. e Setup screen contains some functions that can be accessed

from the Time Dispense Mode operation screen, including:

pump direction, on/off time, batch count, remote control, and keypad

lockout.

C. Flow Direction:Pressing the ENTER key on this icon toggles between

clockwise and counterclockwise flow direction.

D. Copy Amount Screen: See Copy Setting Screen, Figure 3-8.

E. Pump OFF Time:Highlighted when the drive is OFF.

F. Batch Count: Displays the number of cycles dispensed in the batch.

G. Local/Remote or :Pressing the ENTER key on this icon goes to the

Remote Control setup screen. is icon indicates whether your drive is in

local or remote control mode. If the solid rectangle appears in the center

of the figure the drive is set to be operated locally. If the solid rectangle

does not appear in the center of the figure the drive is set to be operated

by remote control.

H. Keypad Lock : Pressing the ENTER key on this icon goes to the

Keypad Lockout screen. Locking the keypad will prevent someone

from changing the settings on the drive. When locked this icon

changes to .

I. Percentage Completed: is icon displays the portion of fluid

dispensed as a percentage.

J. Copy Volume:Displays the Copy Volume while dispensing or the

OFF Time.

K. Anti-Drip:A waterdrop icon present indicates that the Anti-Drip function

is on. For further information see Anti-Drip Function page 3-27.

®

Digital Pump Drive Operating Manual3-12

MasterflexMASTERFLEXLIVE

Page 25

Section 3

Operation

Copy Dispense Mode

Operation

COPY DISP. MODE

100.00

53 %

1000/2000

Figure 3-7. Copy Dispense Mode Operation

1. Getting Started: From the Main Menu, use the ENTER key to select

Copy Dispense Mode to enter the Copy Dispense Mode operation

screen.

2. Calibrating Tubing: Before operating the pump, insert desired tubing

into the Pump Head. For more information, see “Tubing Calibration”.

3. Choosing Settings: Select desired flow unit, tube size, flow rate, pump

direction, etc. For more information see “Using the SETUP Menu.”

4. Preparing Tubing: Insert tube inlet into supply fluid. Next, insert tube

outlet into desired container.

COPY

OFF

5. Setting Copy Amount: See Copy Setting Operation.

6. Setting OFF Time: Use the directional pad and ENTER key to select

OFF on the display to enter the Pump OFF Time. Use the directional

pad and ENTER key to set the Pump OFF Time. e timer in the

center of the screen will be highlighted, and using the UP/DOWN arrows will increase/decrease the farthest right digit of the time interval.

Switch between digits using the LEFT/RIGHT arrows. After selecting

an optimal OFF Time, press ENTER again to validate. e drive will

now rest for the time appearing in the center of the screen.

NOTE:If the OFF Time is set to 00:00:00, the drive requires a START/

STOP input from the keypad or the remote I/O Connector to start

the next dispense.

7. Setting Batch Size: Use the directional pad and ENTER key to select

the Batch Count icon from the operation screen (see position F, Figure

3-6). From Batch Count screen use the UP/DOWN arrows to select

batch size. Press ENTER to validate batch size. When set to zero (0)

the drive will run for an infinite number of cycles and the symbol is

displayed. Select EXIT to return to the Copy Dispense Mode screen.

• Batch count may be reset from BATCH COUNT screen by

selecting RESET.

®

Digital Pump Drive Operating ManualMasterflex

3-13MASTERFLEXLIVE

Page 26

Section 3

Operation

Copy Dispense Mode

Operation (continued)

8. Operating Drive: Press the START/STOP key to operate the drive at the

settings selected and displayed on the screen. Press again to pause or stop

the drive. Drive will automatically stop once batch is complete.

9. Reset Batch Count: Use the directional pad and the ENTER key to select

the BATCH COUNT icon (see position F, Figure 3-6). In the BATCH

COUNT screen, select RESET and press the ENTER key to reset the

batch count. Select EXIT to return to the Copy Mode Operation screen.

10. Maximum Dispense Time: e specification for the maximum dispense

in Copy Mode is over 80+ hours at 600 rpm for L/S drives or 77 hours @

650 rpm for I/P drives. Actual maximum volume is dependant on tubing

size and flow units selected.

®

Digital Pump Drive Operating Manual3-14

MasterflexMASTERFLEXLIVE

Page 27

Section 3

Operation

COPY Setting Screen

Display Legend: Below is a screenshot of the screen display for the drive in

Copy Setting Mode. An explanation of the information on the screen follows.

A

COPY

H

10000

EXIT

G F

CLEAR

B

START

C

D

mL/min

E

STOP

Figure 3-8. COPY Setting Screen

A. Mode Display: Current operating mode.

B. START: is icon will start drive allowing for copy volume to be set.

C. Flow Direction: Pressing the ENTER key on this icon toggles between

clockwise and counterclockwise flow direction.

D. Volume Unit: is is dependent on the flow rate selected.

E. STOP: is stops the Copy and sets the volume to be dispensed. It is

displayed in position H.

F. CLEAR: Selecting this will clear the number displayed on the screen

and will allow for a new copy volume to be selected.

G. EXIT: Return to Copy Dispense Mode.

H. Volume: is is the amount that was dispensed during the copy.

®

Digital Pump Drive Operating ManualMasterflex

3-15MASTERFLEXLIVE

Page 28

Section 3

Operation

COPY Setting

Operation

COPY

10000

EXIT

Figure 3-9. COPY Setting Operation

1. Getting Started: From the COPY DISPENSE MODE Screen select

COPY and ENTER.

2. Clear Volume:Using the directional Keypad select CLEAR and ENTER.

3. Establish Copy Volume:3 methods are available to the user.

a. Place the desired container at the tubing outlet. Press the START/

STOP keyto initiate the dispensing of fluid. When you have

reached the desired volume press the START/STOP keyagain.

Select EXIT and press ENTER. e drive will store the value of

the copy in memory and use that value in the COPY DISPENSE

MODE.

CLEAR

START

mL/min

STOP

b. Place the desired container at the tubing outlet. Select the START

field on the screen and press the ENTER key to initiate the dispensing of fluid. e drive will now highlight the STOP field on

the screen. When you have reached the desired volume press the

ENTER key to stop. Select EXIT and press ENTER. e drive

will store the value of the copy in memory and use that value in the

COPY DISPENSE MODE.

c. Place the desired container at the tubing outlet. Close the contacts

on the START/STOP input to initiate the dispensing of fluid.

When you have reached the desired volume, close and release the

contacts on the START/STOP input. Select EXIT and press ENTER. e drive will store the value of the copy in memory and use

that value in the COPY DISPENSE MODE.

NOTE: e value displayed as the volume in the COPY SETTING screen

and the COPY DISPENSE Mode screen depend on the flow units selected. RPM, and % are invalid. If these units have been selected the drive will

display a volume in mL, in the COPY DISPENSE MODE, that is dependent on the tubing size selected.

See TUBING CALIBRATION to improve the accuracy of this conversion.

®

Digital Pump Drive Operating Manual3-16

MasterflexMASTERFLEXLIVE

Page 29

Section 3

Operation

Volume Dispense

Mode Screen

Display Legend: Below is a screen shot of the screen display for the drive in

Volume Dispense Mode. An explanation of the information on the screen

follows.

A

VOL DISP. MODE

I

G

100.00

H

1000/2000

or

B

C

J

D

mL

E

OFF

F

Figure 3-10. Volume Dispense Mode Screen

A. Mode Display: Current operating mode.

B. Setup : e Setup screen can be used to select flow units, tubing size,

flow rate, tubing calibration, sounds, cumulative volume, and Main

Menu. e Setup screen contains some functions that can be accessed

from the Time Dispense Mode operation screen, including: pump direction, on/off time, batch count, remote control, and keypad lockout.

C. Flow Direction: Pressing the ENTER key on this icon toggles between

clockwise and counterclockwise flow direction.

D. Flow Units: Select desired flow unit.

E. Pump OFF Time: Highlighted when the drive is OFF.

F. Batch Count: Displays the number of cycles dispensed in the batch.

G. Local/Remote or : Pressing the ENTER key on this icon goes to

the Remote Control setup screen. is icon tells you whether your

drive is in local or remote control mode. If the solid rectangle appears

in the center of the figure the drive is set to be operated locally. If the

solid rectangle does not appear in the center of the figure the drive is

set to be operated by remote control.

H. Keypad Lock: Pressing the ENTER key on this icon goes to the Key-

pad Lockout screen. Locking the keypad will prevent someone from

changing the settings on the drive. When locked this icon changes to .

I. Volume: Displays the Volume while dispensing or the OFF Time.

J. Anti-Drip: A water drop icon present indicates that the Anti-Drip

function is on. For further information see Anti-Drip Function page

3-27.

®

Digital Pump Drive Operating ManualMasterflex

3-17MASTERFLEXLIVE

Page 30

Section 3

Operation

Volume Dispense

Mode Operation

VOL DISP. MODE

100.00

1000/2000

Figure 3-11. Volume Dispense Mode Operation

1. Getting Started: From the Main Menu, use the ENTER key to select

Volume Dispense Mode to enter the Volume Dispense Mode operation

screen.

2. Calibrating Tubing: Before operating the pump, insert desired tubing

into the Pump Head. For more information, see “Tubing Calibration”.

3. Choosing Settings: Select desired flow unit, tube size, flow rate, pump

direction, etc. For more information see “SETUP Menu.”

4. Preparing Tubing: Insert tube inlet into supply fluid. Next, insert tube

outlet into desired container.

mL

OFF

5. Setting Desired Volume: Using the directional pad highlight the numeric field in the center of the display and press the ENTER key. is puts

you in a position to change the fluid volume of the drive at the farthest

digit to the right (tenths, hundredths, thousandths, etc., depending on

your volume unit). Pressing the UP arrow on the directional pad will

increase the volume by one value and pressing the DOWN arrow will

decrease the volume by one value. Pressing the ENTER key again will

show all the possible digits that can be manipulated for the specific

volume unit currently in use; use the LEFT/RIGHT arrows on the

directional pad to move between digits and the UP/DOWN arrows

to increase or decrease the value, respectively. Once desired volume is

selected, press ENTER a final time to set the drive to operate at that

volume. Press the START/STOP key to resume operating the drive.

6. Setting Pump OFF Time: Use the directional pad and ENTER key to

select OFF on the display (see position E, Figure 3-10) to enter the

OFF TIME. Use the directional pad and ENTER key to set the pump

rest time. e timer in the center of the screen will be highlighted, and

using the UP/DOWN arrows will increase/decrease the farthest right

digit of the time interval. If ENTER is pressed a second time while the

timer is highlighted, the digits can be navigated individually using the

UP/DOWN arrows; switch between digits using the LEFT/RIGHT

arrows. After selecting an optimal OFF time, press ENTER again to

validate. e drive will now rest for the time appearing in the center of

the screen. NOTE:If the OFF Time is set to 00:00:00, the drive requires

a START/STOP input from the keypad or the remote I/O Connector

to start the next dispense.

®

Digital Pump Drive Operating Manual3-18

MasterflexMASTERFLEXLIVE

Page 31

Section 3

Operation

Volume Dispense

Mode Operation

(continued)

7. Setting Batch Size: Use the directional pad and ENTER key to select

the Batch Count icon from the operation screen (see position F, Figure

3-10). From Batch Count screen use the UP/DOWN arrows to select

batch size. Press ENTER to validate batch size. When set to zero (0)

the drive will run for an infinite number of cycles and the ∞ symbol is

displayed. Select EXIT to return to drive operation screen.

• Batch count may be reset from the Batch Count screen by selecting

RESET.

8. Operating the Drive: Press the START/STOP key to operate the drive

continuously at the settings selected and displayed on the screen. Press

again to pause or stop the drive. Drive will automatically stop once

batch is complete.

9. Reset Batch Count: Use the directional pad and the ENTER key to

select the BATCH COUNT icon (see position F, Figure 3-10). In the

BATCH COUNT screen, select RESET and press the ENTER key

to reset the batch count. Select EXIT to return to the COPY MODE

OPERATION screen.

10. Maximum Dispense Time: e specification for the maximum dispense

volume in Volume Mode is over 80+ hours at 600 rpm for L/S drives or

77 hours @ 650 rpm for I/P drives. Actual maximum volume is dependant on tubing size and flow units selected.

®

Digital Pump Drive Operating ManualMasterflex

3-19MASTERFLEXLIVE

Page 32

Section 3

Operation

Remote Control Menu

REMOTE CONTROL

LOCAL

CURRENT INPUT

CURRENT OUTPUT

VOLTAGE INPUT

VOLTAGE OUTPUT

START/STOP

EXIT

Figure 3-12. Remote Control Menu Screen

NAVIGATION: From the Main Menu or SETUP Menu select REMOTE

CONTROL and ENTER.

LOCAL: When this is selected the drive is controlled by the front panel

keypad, Start/Stop Input, Directional Input or Prime Input.

CURRENT INPUT: When this is selected, the drive is in remote control.

is allows the user to input a current signal to control the flow. e user

has an option to adjust the minimum, maximum and middle set points

for current and flow. By default the minimum (MIN) current is set to 4.2

mA and the flow is set to 0. e maximum (MAX) is set to 20 mA and the

flow is set to maximum. e middle (MID) is auto calculated for a current and flow that is centered between the MIN and the MAX. e MID

can be adjusted if other profiles are needed. e scaling can be inverted if

necessary. To confirm CURRENT INPUT MODE is selected, select EXIT

after returning to the Remote Control Menu, then select CONTINUOUS

PUMP MODE. To deselect Remote Current Input Mode select LOCAL

and ENTER.

NOTE: When Current Input is selected the drive will not start until the

REMOTE CONTROL MODE is exited and CONTINUOUS PUMP

MODE is selected.

CURRENT OUTPUT: is allows the user to adjust the current output

for a given flow. e user has an option to adjust the minimum, maximum

and middle setpoints for current and flow. By default the minimum (MIN)

flow is set to 0.00 and the current is set to 4.0 mA. e maximum (MAX)

is set to maximum flow and the current is set to 20.0 mA. e middle

(MID) is auto calculated for a current and flow that is centered between the

MIN and the MAX. e MID can be adjusted if other profiles are needed.

is allows for a three-point calibration of the current output. e flow is

linear between these points. e scaling can be inverted if necessary. NOTE:

Selecting Current Output will not put user into REMOTE CONTROL

MODE. Only selecting VOLTAGE INPUT or CURRENT INPUT will

put the user into Remote Control Mode, as indicated by the empty house

icon (see position G, Figure 3-2). NOTE:e Current Output indicates the

Running Command Speed. Use the Motor Running contacts (normally

open/closed) to indicate if pump is running.

®

Digital Pump Drive Operating Manual3-20

MasterflexMASTERFLEXLIVE

Page 33

Section 3

Operation

Remote Control Menu

(continued)

VOLTAGE INPUT: When this is selected, the drive is in remote control.

is allows the user to input a voltage signal to control the flow. e user

has an option to adjust the minimum, maximum and middle set points for

voltage and flow. By default the minimum (MIN) voltage is set to 00.1

V DC and the flow is set to 00.0. e maximum (MAX) is set to 10.0 V

DC and the flow is set to maximum. e middle (MID) is auto-calculated

for a voltage and flow that is centered between the MIN and the MAX.

e MID can be adjusted if other profiles are needed. e scaling can be

inverted, if necessary. To confirm VOLTAGE INPUT MODE is selected,

select EXIT after returning to the Remote Control Menu, then select CONTINUOUS PUMP MODE. To deselect Remote Voltage Input Mode select

Local and ENTER.

NOTE: When Voltage Input is selected the drive will not start until the

REMOTE CONTROL MODE is exited and CONTINUOUS PUMP

MODE is selected.

VOLTAGE OUTPUT: is allows the user to adjust the voltage output for

a given flow. e user has an option to adjust the minimum, maximum and

middle set points for voltage and flow. By default the minimum (MIN)

flow is set to 00.00 and the voltage is set to 00.0V DC. e maximum

(MAX) is set to maximum flow and the voltage is set to 10.0V DC. e

middle (MID) is auto calculated for a voltage and flow that is centered between the MIN and the MAX. e MID can be adjusted if other profiles are

needed. is allows for a three point calibration of the voltage output. e

flow is linear between these points. e scaling can be inverted if necessary.

NOTE: Selecting Voltage Output will not put the user into Remote Control

Mode. Only selecting Voltage Input or Current Input will put the user into

Remote Control Mode, as indicated by the empty house icon (see position

G, Figure 3-2). NOTE: e Voltage Output indicates the Running Command Speed. Use the Motor Running contacts (normally open/closed) to

indicate if pump is running.

START/STOP: e START/STOP input can be configured to be OFF

(factory default), or ON for the drive to run.

With the OFF selected (factory default), use of the START/STOP input

is optional. When the START/STOP input is open, the drive can still be

started using the START/STOP key, PRIME key, or PRIME input. In

remote modes the drive will also run if there is sufficient current or voltage

at the input.

Closing the START/STOP input will cause the drive to run until the

START/STOP input opens or the START/STOP key is pressed. In Time

dispense, Copy dispense, and Volume dispense mode, only a momentary

START/STOP closure is needed to start the drive. If the drive is already

running in one of the dispense modes, a momentary START/STOP closure

will stop the drive. In SET COPY MODE, the START/STOP input functions the same as in CONTINUOUS MODE; closing it will cause the drive

to run until it opens.

®

Digital Pump Drive Operating ManualMasterflex

3-21MASTERFLEXLIVE

Page 34

Section 3

Operation

Remote Control Menu

(continued)

e function of the START/STOP input is considerably simplified when

the ON is selected. e drive will not run under any condition unless the

START/STOP input is closed.

Table 3-1. Continuous Mode Operation

MENU SETTINGS

SETUP OPTIONS

AUTO

START/STOP

START

REQUIRED

OFF OFF OPEN Running Not running Not running

OFF OFF OPEN Not running Not running Not running

OFF OFF CLOSED Forced run due to

OFF ON OPEN Forced not running

OFF ON CLOSED Forced run due to

ON OFF OPEN Running Running Running

ON OFF OPEN Not running Not running Running

ON OFF CLOSED Forced run due to

ON ON OPEN Forced not running

ON ON CLOSED Forced run due to

NOTE: In Continuous Mode when using the START/STOP input the drive is started with a closed contact and

stopped when the contacts are opened.

START/STOP

INPUT

Drive State When

Powered OFF

S/S CLOSED

due to S/S OPEN

S/S CLOSED

S/S CLOSED

due to S/S OPEN

S/S CLOSED

INTERNAL MODE mA or V MODE

Drive Response When

Powered ON

Not running Not running

Not running Not running

Not running Not running

Running Running

Not running Not running

Running Running

Drive Running

(sufficient level)

When Powered OFF

Drive Response when

Powered ON

(sufficient level present)

Table 3-2. Dispense Mode Operation

MENU SETTING SETUP OPTIONS START/STOP

AUTO START START/STOP

REQUIRED

OFF OFF OPEN Running Not running

OFF OFF OPEN Not running Not running

OFF OFF CLOSED* Forced run due to S/S

OFF ON OPEN Forced not running due

OFF ON CLOSED Forced run due to S/S

ON OFF OPEN Running Running

ON OFF OPEN Not running Not running

ON OFF CLOSED* Forced run due to S/S

ON ON OPEN Forced not running due

ON ON CLOSED Forced run due to S/S

* NOTE: In Dispense Modes and START/STOP MENU SETUP Option OFF the drive will start a dispense with

a momentary contact closure and stop with a momentary contact closure during both the dispense period

and interval period.

INPUT

Drive State When

Powered OFF

CLOSED

to S/S OPEN

CLOSED

CLOSED

to S/S OPEN

CLOSED

Drive Response When

Powered ON

Not running

Not running

Not running

Running

Not running

Running

®

Digital Pump Drive Operating Manual3-22

MasterflexMASTERFLEXLIVE

Page 35

Section 3

Operation

DB-25 Pin

Configuration with

Wiring Scheme

Contact Arrangements

M

13 1 12 11 10 9 8 7 6 5 4 3 2

25 24 23 22 21 20 19 18 17 16 15 14

K

A. START/STOP

B. CW/CCW

C. OUTPUT 0-20mA; 4-20mA

D. INPUT 0-20mA; 4-20mA

E. INPUT 0-10V

F. OUTPUT 0-10V

G. TACH OUTPUT

L

H. PRIME

I. MOTOR RUNNING N.O. (1A @ 24 V)

J. MOTOR RUNNING N.C. (1A @ 24 V)

K. 24V (150mA max.)

L. General Alarm

M. Local/Remote Indicator

I

J

G

H

Figure 3-13. DB-25 Pin Configuration with Wiring Scheme

Pin No. Description

DB-25

1 Speed Control Voltage Input (0-10 V)

2 Speed Control Current Input (0-20 mA)

3 Speed Control Input Ground Return

4 Speed Signal Current Output (0-20 mA)

5 Speed Signal Output Ground Reference

6 (Motor Running N.O. Default) 1A @24 V (Open Collector)

7 Motor Running Ground Return

8 (Motor Running N.C. Default) 1A @24 V (Open Collector)

14 Speed Signal Voltage Output (0-10 V)

15 Remote Start/Stop Input

16 Remote CW/CCW Input

17 Remote Start/Stop, CW/CCW, Prime Grnd Ref.

18 Tach Ground Reference

19 Tach Output (open collector)

20 Remote Prime Input

9 Reserved – Not Used

10 Reserved – Not Used

11 Auxiliary Input (Computer Compatible Drive Only)

12 Auxiliary Input Return (Computer Compatible Drive Only)

21 Auxiliary Output #1 (Computer Compatible Drive Only)

22 Auxiliary Output #2 (Computer Compatible Drive Only)

23 General Alarm (Open Collector)

24 Local.Remote Indicator (Open Collector)

25 Aux 24V+ (150 mA)

13 Aux 24V- (150 mA)

F

C

D

B

A

E

NOTE: Pins 5, 13, 17, and 18 are at earth ground, all are suitable for use

with START/STOP, PRIME, Direction, Tach, LOCAL/REMOTE, General Alarm Signals and Current and Voltage Outputs.

CAUTION: Power must be turned off before connecting the

!

external remote control cable to prevent damage to the drive.

NOTE: Open collector outputs in “low impedance” state are at earth ground

and when in “high impedance” state are essentially floating. See Open Collector page following.

®

Digital Pump Drive Operating ManualMasterflex

3-23MASTERFLEXLIVE

Page 36

Section 3

Operation

31-Pin

Configuration with

Wiring Scheme

Contact Arrangements

14

18

31- #20

13

8

3

1

2

7

19

25

30

31

29

24

Figure 3-14. 31-Pin Configuration with Wiring Scheme

Pin No. Description

1 Speed Control Voltage Input (0-10 V)

2 Speed Signal Voltage Output (0-10 V)

3 Speed Control Current Input (0-20 mA)

4 Remote Start/Stop Input

5 Speed Control Input Ground Return

6 Remote CW/CCW Input

7 Speed Signal Current Output (0-20 mA)

8 Remote Start/Stop, CW/CCW, Prime Grnd Ref.

9 Speed Signal Output Ground Reference

10 Tach Ground Reference

11 (Motor Running N.O. Default) 1A @24 V (Open Collector)

12 Tach Output (open collector)

13 Motor Running Ground Return

14 Remote Prime Input

15 (Motor Running N.C. Default) 1A @24 V (Open Collector)

16 Reserved – Not Used

17 Reserved – Not Used

18 Reserved – Not Used

19 Reserved – Not Used

20 General Alarm (Open Collector)

21 Reserved – Not Used

22 Local.Remote Indicator (Open Collector)

23 Reserved – Not Used

24 Aux 24V+ (150 mA)

25 Aux 24V- (150 mA)

26 Reserved – Not Used

27 Reserved – Not Used

28 Reserved – Not Used

29 Reserved – Not Used

30 Reserved – Not Used

31 Reserved – Not Used

NOTE: Pins 8, 9, 10, and 25 are at earth ground, all are suitable for use

with START/STOP, PRIME, Direction, Tach, LOCAL/REMOTE, General Alarm Signals and Current and Voltage Outputs.

CAUTION: Power must be turned off before connecting the

!

external remote control cable to prevent damage to the drive.

NOTE: Open collector outputs in “low impedance” state are at earth

ground and when in “high impedance” state are essentially floating. See

Open Collector page following.

®

Digital Pump Drive Operating Manual3-24

MasterflexMASTERFLEXLIVE

Page 37

Section 3

Operation

Remote Control Inputs

and Outputs

INPUTS

Remote CW/CCW, Remote Start/Stop, Remote Prime, & Aux. In:

e remote control inputs work with current sinking outputs (open-collector NPN transistor outputs without passive pull-up resistors) or contact

closures to DC common (earth ground). A continuous active low to the

Remote Start/Stop inputcauses the drive to run, while a continuous active

low to the Remote CW/CCW input causes the drive to run CCW. e

motor is brought to a controlled stop before reversing direction. A continuous active low to the Remote Prime input causes the drive to run at full

rated speed.

Table 3-3. Remote Control Inputs and Outputs

CURRENT CLOSED INPUT 1 mA TYP

VOLTAGE OPEN INPUT 3.2 V TYP

THRESHOLD CURRENT TO ACTIVATE 0.5 mA TYP

Remote Analog Input:

4-20 mA Input: 250 ohms typical input impedance ref. to signal

ground. 4 mA, Stop; 20 mA, Full Speed (Default Settings) 10 Bit Resolution

Overload Capability: 10 V or 40 mA max.

0-10 V Input: 10 K ohms typical input impedance ref. to signal

ground. 0 V, Stop; 10 V, Full Speed (Default Settings) 10 Bit Resolution

OUTPUTS

4-20 mA Output: 0 to 600 ohms max. load referenced to earth

ground.

4 mA, Stop; 20 mA, Full Speed (Default Settings) 10 Bit Resolution

0-10 V Output: 1.0 K ohms min. load referenced to earth ground.

0 V, Stop; 10 V, Full Speed (Default Settings) 10

Bit Resolution

Tach Output: Open Collector, 1.0A @ 28V DC

Frequency range: L/S: 100 to 6000 Hz or 100 to 1000 Hz,

50% Duty Cycle. (10 Hz = 1 pump rpm)

I/P: 100 to 6500 Hz,

50% Duty Cycle. (10 Hz = 1 pump rpm)

Logic Outputs: Open Collector, 1.0 A @ 28V DC

Motor Running Outputs: Normally Open and Normally Closed when drive

is running.

General Alarm Output: Open (High Impedance) when an alarm is displayed.

Local/Remote Indicator: Open (High Impedance) when in remote

control mode (Voltage Input or Current Input).

®

Digital Pump Drive Operating ManualMasterflex

3-25MASTERFLEXLIVE

Page 38

Section 3

Operation

Open Collector

Outputs

Some remote outputs on this drive (Tachometer, Local/Remote, Motor Running and Alarm) are “open collector” type outputs and cannot be wired in

the same manner as relay outputs. An open collector output is not isolated

and must be configured differently than a relay output.When the open collector output is active, the output is effectively switched to earth ground and

if improperly terminated could result in damage to the drive and/or external

equipment.

Recommendation

When connecting to open collector outputs, the output should be connected

to a current limiting resistor and then to a positive supply source which is less

than 28V DC. Typically this would be connected to a 24V PLC input (see

Figure 3-15).

NOTE: when using the 24V supply on the interface connector, current

draw must be limited to 150 mA.

NOTE: DO NOT connect 120V supply lines to open collector outputs!

+24V

10k

Output

To PLC

Figure 3-15. Terminating Open Collector Outputs to a PLC

®

Digital Pump Drive Operating Manual3-26

MasterflexMASTERFLEXLIVE

Page 39

Section 3

Operation

Anti-Drip Function

e same drive offers an Anti-Drip feature. e tendency of fluid to drip

after a dispense is dependant on several factors including tubing size, tubing

orientation, and the viscosity of the fluid. To minimize this drip the drive

will reverse direction after a dispense to draw the fluid back at the end of the

tubing.

To access this feature select in either Copy Dispense Mode or Volume

Dispense Mode ANTI-DRIP.

ANTI-DRIP

ON

OFF

EXIT

Figure 3-16. Anti-Drip Screen

If the ANTI-DRIP function is desired, select ON and a second screen will

appear which will allow the user to input how many degrees of reverse

rotation the drive will perform. Typical values range from 5 to 45 degrees.

To exit without changing the current setup select EXIT.

ANTI-DRIP

45

EXIT

Figure 3-17. Anti-Drip Degrees Screen

With the number highlighted press the ENTER key and use the UP and

DOWN, and RIGHT and LEFT arrows to change the digits. Press the

ENTER key and then select EXIT to save the setting. e drive will now

reverse after every dispense.

°

®

Digital Pump Drive Operating ManualMasterflex

3-27MASTERFLEXLIVE

Page 40

Section 3

Operation

Communication

Specification

Physical Connections

Pump drives that are equipped with the MASTERFLEXLIVE

Communication feature have two available physical connections – USB,

and Ethernet.

USB

e USB port is USB 1.1 Full Speed, 12 Mbit/s, compatible. As a

Communication Device Class (CDC) device, the pump will appear as

a virtual COM port on the host computer. e COM port settings are

115,200 baud, 8 data bits, 1 stop bit, no parity, no flow control.

Ethernet

e Ethernet port is a 10/100 port, supporting data transfer rates of 10

and 100 Mbit/s. e MASTERFLEX Network Setup application is used

to obtain the pump’s IP address. By default, the pump implements a

20 second TCP connection timeout. If the pump does not receive data

during this period, it will automatically close the connection. e TCP

timeout period can be changed or disabled by using the MASTERFLEX

Network Setup application. e browser-based Network Setup can be

used as well.

®

Digital Pump Drive Operating Manual3-28

MasterflexMASTERFLEXLIVE

Page 41

Section 4 Maintenance

Replacement Parts

and Accessories

WARNINGS: The Power switch on the Back Panel is not the

main disconnect. Main disconnect is accomplished by disconnecting the detachable power supply cord at the appliance

coupler or at the main plug. Ensure the power cord is easily

accessible and removable, in the event of an emergency, which

requires immediate disconnection.

The operator should check the detachable power supply cord

condition. The equipment should not be operated if the power

supply cord is cracked or broken. Any obvious damage to the enclosure (from a drop or fall) should be checked by service personnel for loose or damaged parts inside.

CAUTIONS: Replace the power cord only with one of the same type and

rating. The minimum power ratings are stated on the rear panel.

The power cord set supplied with your pump drive meets the re-

!

quirements of the country where you purchased the pump drive. If

you use the pump drive in another country, you must use a power

cord set that meets the requirements of that country.

L/S Replacement Parts

Description Part Number

Fuse-T3.15A, 5 x 20 mm 77500-25

Gear Service Kit (600) 07553-06

Gear Only (600 rpm) 07553-09

Gear Service Kit (100 rpm) 07553-08

Replacement seal kit (NEMA)* 07575-01

Replacement gear and shaft kit (NEMA)* 07575-02

*For washdown drives only

I/P Replacement Parts

Description Part Number

Fuse-T6.3A, 5 x 20 mm 77500-24

®

Digital Pump Drive Operating ManualMasterflex

4-1MASTERFLEXLIVE

Page 42

Section 4

Maintenance

Fuse Replacement

1. Place the power switch in the off position.

2. Disconnect the AC power input line cord from the receptacle.

3. Remove and check the fuse and replace if defective.

A

E

G

Style “A”