Page 1

AFETY,

S

OPERATION AND

MAINTENANCE

MANUAL

/ PARTS LIST

W

DRY VACUUM

CLEANER

This unit is intended for commercial use.

READ & FOLLOW ALL

INSTRUCTIONS,WARNINGS & CAUTIONS

BEFORE USING THIS VACUUM

This vacuum will afford you many years of

trouble-free operating satisfaction, provided it is give proper care. All parts have

passed rigid quality control standards prior

to their being assembled to produce the

finished product. Prior to packaging, your

vacuum was again inspected for assurance of flawless assembly.

This vacuum is protectively packed to prevent damage in shipment. We recommend

that upon delivery, unpack the unit and

inspect it for any possible damage. Only a

visual examination will reveal damage that

may have occurred.

If damage is discovered, immediately notify the transportation company that delivered your vacuum. As a shipper, we are

unable to report any claim for damage.

You must originate any claim within 5

days.

This manual is for you protection and information. PLEASE READ CAREFULLY since

failure to follow precautions could result in

discomfort or injury. Read this manual

completely before operation this vacuum. It

is important to follow the instruction in this

manual to prevent the possibility of injury

.or damage to the user and/or vacuum.

PLEASE READ

CAREFULLY

BEFORE

OPERATING

SAVE THESE INSTRUCTIONS

PAGE 1

PN 415731 Rev B - QuietMaster Manual - Printed in USA 01/29/04

Page 2

IMPORTANT

WARNING:

SAFETY

INSTRUCTIONS

To Reduce the Risk of Fire, Electric Shock or Injury:

Electric shock could occur if used on wet surfaces.

DO NOT expose to rain. Store indoors.

When using this vacuum basic precautions should always

be followed, including the following:

1] DO NOT leave the vacuum when

plugged in. Unplug from the outlet when

not in use and before servicing.

2] To avoid electric shock, DO NOT expose

to rain. Store indoors. DO NOT use on wet

surfaces.

3] This is NOT a toy. Close attention is

necessary when used around or near children.

4] Use only as described in this safety

manual. Use only manufacturer's recommended attachments and accessories.

5] DO NOT use this vacuum with damaged

cord or plug. If the vacuum is not working

as it should, because it has been dropped,

damaged, left outdoors or dropped into

water, contact an authorized service center or factory.

6] DO NOT pull or carry by the cord, use

cord as a handle, close a door on cord or

pull cord around sharp edges and corners.

DO NOT run vacuum over cord. Keep cord

away from heated surfaces.

7] DO NOT unplug the vacuum by pulling

on the cord. To unplug, grasp the plug, not

the cord.

11] DO NOT pick up anything that is burning or smoking, such as cigarettes, matches, or hot ashes.

12] DO NOT use without dust bag and/or

filters in place.

13] DO NOT use the vacuum to pick up

flammable or combustible liquids such as

gasoline or use in areas where they may

be present.

14] Use extra care when cleaning on

stairs.

15] DO NOT use where anesthetics and

oxygen are used.

16] Turn OFF all controls before unplugging.

17] DO NOT use an extension cord unless

absolutely necessary. If an extension cord

is used, then wire size must be #14 or

larger and should not exceed 50 feet in

length. The extension cord must be a

three-wire type to insure grounding protection.

18] Replace damaged or worn parts

immediately with genuine original equipment parts to maintain safety and to protect your limited warranty.

8] DO NOT handle the plug of the vacuum

with wet hands.

9] DO NOT put any objects into the openings. DO NOT use with any opening

blocked; keep free of dust, lint, hair and

anything that may reduce air flow.

10] Keep hair, loose clothing, fingers, and

all parts of body away from openings and

moving parts.

SAVE THESE INSTRUCTIONS

PAGE 2

If you vacuum has a outlet for a motorized

power nozzle, always turn OFF vacuum

before connecting or disconnecting the

motorized nozzle.

This vacuum must be connected to a properly grounded outlet only. (See grounded

instructions). When not in use the power

cord should be wrapped around the motor

head cord holder for storage.

Page 3

DANGER:

GROUNDING

Improper use of the grounding plug can result in a

risk of electric shock.

Electrical equipment must be grounded. If

it should mal-function or breakdown,

grounding provides a path of least resistance for electrical current to reduce the

risk of electric shock. The vacuum is

equipped with a cord having an equipmentgrounding conductor and grounding plug.

The plug must be inserted into an appropriate outlet that is properly installed and

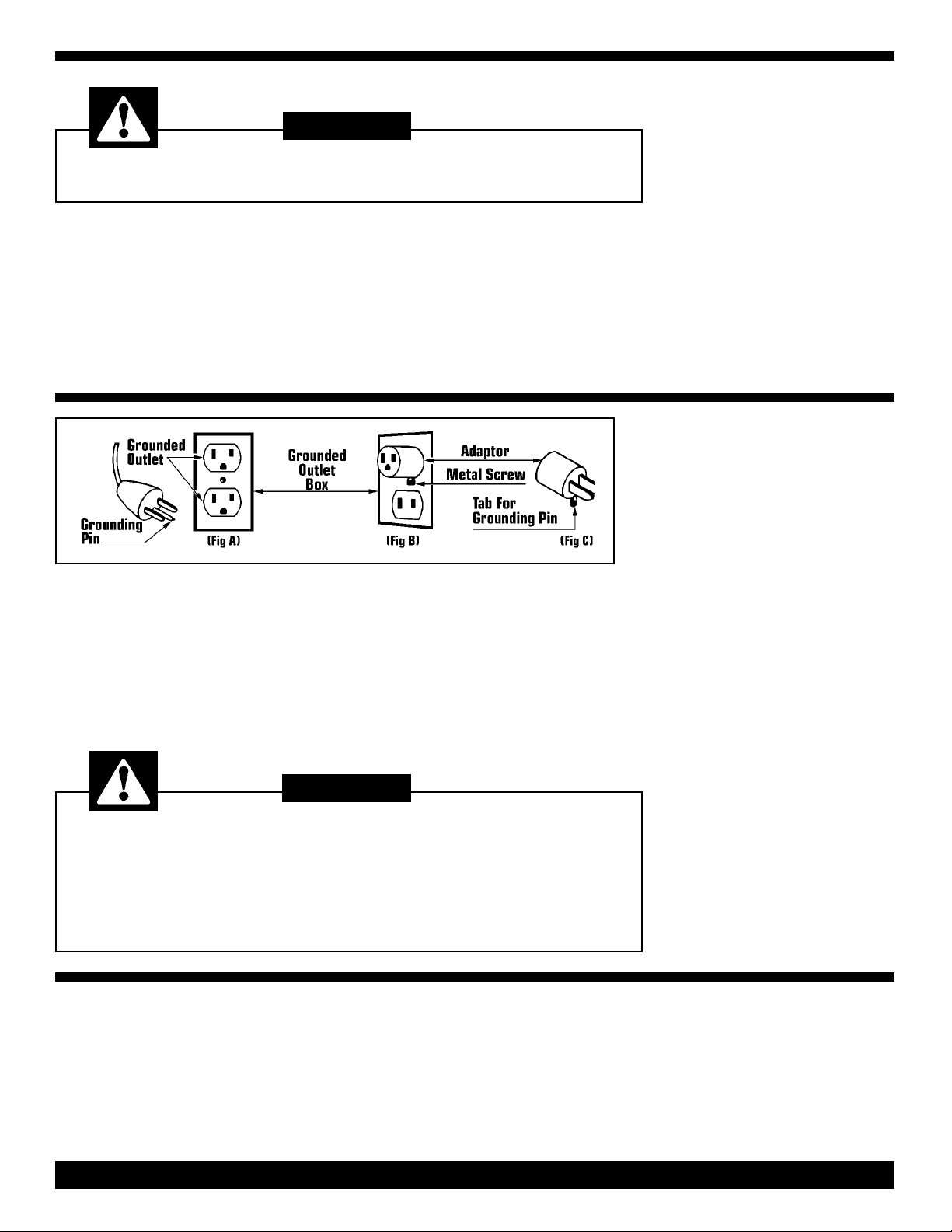

This electric equipment is for use on a

nominal 120 volt circuit, and has a

grounded plug that looks like the plug illustrated in (Fig A). A temporary adaptor that

looks like the adaptor illustrated in (Fig B

& C) may be used to connect this plug to

a 2-pole receptacle as shown in (Fig B) if a

properly grounded outlet is not available.

INSTRUCTIONS

grounded in accordance with all local

codes and ordinances.

If repair or replacement of the cord or plug

is necessary, DO NOT connect the grounded wire to either flat blade terminal. The

wire with insulation having an outer surface that is green with or without yellow

stripes is the grounding wire.

GROUNDING

METHODS

The temporary adaptor should be used

only until a properly grounded outlet (Fig A)

can be installed by a qualified electrician.

The green color rigid ear, lug or the like

extending from the adaptor must be connected to a permanent ground such as a

properly grounded outlet box cover.

Whenever the adaptor is used, it must be

held in place by a metal screw (Fig C).

WARNING:

Improper connection of the equipment-grounding conductor can result

in a risk of electric shock. Check with a qualified electrician or service person if you

are in doubt as to whether the outlet is properly grounded.

DO NOT modify the plug provided with the equipment. If it will not fit the outlet,

have a proper outlet installed by a qualified electrician.

Note: In Canada, the use of a temporary adaptor is not permitted

by the Canadian Electrical Code.

Treat your vacuum cleaner as you would

any other high grade precision made product. Dropping, unreasonable bumping

across thresholds and other misuses may

result in a damaged unit which will not be

covered by warranty.

PAGE 3

CARE OF

VACUUM

Page 4

FILTER

INSTALLATION

& REMOVAL

This vacuum is shipped assembled. It is

equipped with a air-thru motor, designed

for dry pickup only.

The paper filter bags and a impact filter

shipped with the vacuum MUST be

installed before operating the vacuum.

Paper Filter Bag Installation:

(A) Press the holdown clamp upward and

remove the motor head and set aside.

(B) Remove the cloth filter assembly (F),

set aside.

Impact Filter Installation:

1) Place the impact filter around the

perimeter of the tank.

Paper Filter Bag Removal:

1) Pull the paper filter bag out of tank using care

not to puncture bag with inlet tube. Install a new

bag and dispose of the full bag.

(C) Expand the bag pleats to form full

shape of bag. Position hole in collar to end

of inlet tube and pull forward until collar is

completely on the tube and as close to the

tank wall as possible.

2) Replace cloth filter

assembly and secure clamps.

2) Replace impact filter and dry filter assembly.

3) Replace motor head on tank and close clamps.

CAUTION:

Always exercise caution when handling the motor head.

Dropping the motor head may cause permanent damage to internal components.

PAGE 4

Page 5

F

AINTENANCE

M

ILTER

Cloth

Filter

Assembly

In order to maintain maximum efficiency of

this vacuum it is important to clean the

cloth filter each time the tank is emptied.

To clean the cloth filter, shake off loose particles and vacuum the cloth or, for a more

thorough cleaning wash and allow to dry

Note: Water temperature should be not

more than 72°F when washing the cloth

filter.

Hose &

Swivel

Connector

Motor

Filter

Clean the filter (E) after changing the paper

filter bag. After 10 paper bag changes

replace the filter. The blue side of the filter

must be visible.

Wand,

Tools &

Hose

ATTACHMENT

INSTALLATION

Wand

Vacuum

Control

The vacuum hose and swivel connector

are preassembled at the factor. To

attach the swivel connector to the

intake fitting on the vacuum tank.

1) Line up the slots in the swivel connector with retaining rivets on inlet.

2) Insert swivel connector and twist

clockwise until the rivets reset against

slot ends.

This vacuum is equipped with a thermal cut-off. If the thermal cut-off shuts OFF the

vacuum, change the filter bag and make sure there is nothing lodged in the hose or

wand. The thermal cut-off may take up to 20 minutes to reset itself.

1) Firmly connect wand pieces and tool

required for your cleaning operation.

2) Insert vacuum hose into wand elbow.

3) Plug in power cored and turn on the

vacuum switch.

CAUTION:

PAGE 5

1) The vacuum control located on the

upper part of the wand adjusts the vacuum power for cleaning different types

of surfaces.

Page 6

REPLACEMENT

PARTS LIST

TANK ASSEMBLY & FILTERS

__________________________________

Ref Part Description Part

No No

__________________________________

1 Filter Cage 409243

2 Cloth Filter 409251

3A Vacuum Tank 417939

3B Vacuum Tank Assembly 419869

4 Swivel Caster 418374

8 Paper Bag (5/Pk) 408239

9 Impact Filter (1/Pk) 408328

10 Metal Inlet Fitting w/Gasket 356298

11 M5 X 12 MM Screw (3) 374733

12 Metal Plate 417955

__________________________________

DOME ASSEMBLY

_______________________________

Ref Part Description Part

No No

_______________________________

1 Handle 417971

2 Dome 418366A

3 Tumbler Switch 415235

4 KA40 X 12 Screw 418005

5 Silencing Foam 418013

6 Holdown Pin 418021

7 Pin 418048

8 Latch 418056

9 30 Ft Line Cord 318647

14 Female Pig Tail 369160

15 Strain Relief Assy 443379

17 M12 X 16MM Screw 457034

23 Piggy Back Terminal (2) 437298

24 Orange Wire Nut 398985

25 Insulated Terminal (2) 394041

26 Thermal Cut Off 300578

_______________________________

PAGE 6

Page 7

REPLACEMENT PARTS LIST

MOTOR ASSEMBLY

__________________________________

Ref Part Description Part

No No

__________________________________

1 Screw, KA40 X12 418005

2 Motor Cover 418161

3 Top Motor Gasket 418188

4A 120V Vacuum Motor 373893

(Includes Nos: 5; 11; 12; 15; 16; 17)

4B 230V Vacuum Motor 393045

(Includes Nos: 5; 11; 12; 15; 16; 17)

5 Carbon Brush (120V Mtr - 2) 449296

6 Lower Motor Gasket 364177

7 Silencing Foam 418234

8 Cover 418242

9 Silencing Gasket 418250

10 Motor Filter 418269

11 Thermal Cut Off 300578

12 Insulated Terminal (2) 394041

13 Cable Lock 436992

14 Cable Lock Screws (2) 437026

15 #6-10 X .37 Screw 349011

16 Flag Terminal 379166

17 #14 X 9” White Lead 335754

__________________________________

HOSE, WAND & TOOLS

______________________________

Ref Part Description Part

No No

______________________________

1 Hose Assembly 413216A

2 Vacuum Hose 400661

3 Hose Cuff 378038

4 Straight Wand (2 Required) 408212

5 Wand Elbow 418331

6 Slide 418358

7 Upholstery Tool 409146

8 Crevice Tool 409154

9 Brush, Dusting 409162

10 Tool, Carpet/Floor 409170

11 1

12 Power Nozzle* 408379

13 Air Power Brush* 408360

______________________________

*Optional Accessories

1

/

2

” Hose Connector 349445

PAGE 7

Page 8

TROUBLE

SHOOTING

GUIDE

CAUTION

Always disconnect power cord before servicing vacuum.

PROBLEM: Loss of Vacuum.

Possible Cause: Possible Solution:

1. Motor head not placed on vacuum 1. Remove motor head and re-adjust on

tank properly. vacuum tank.

2. Dry filter assembly is dirty. 2. Clean cloth filter.

3. Faulty vacuum motor. 3. Call manufacturer or service center.

4. Full paper filter bag. 4. Replace paper filter bag.

5. Clogged hose or wand. 5. Remove obstruction.

6. Loose or broken fan. 6. Contact manufacturer or service center.

PROBLEM: Motor is not running.

Possible Cause: Possible Solution:

1. Faulty ON/OFF switch. 1. Contact manufacturer or service center.

2. Power cord defective. 2. Contact manufacturer or service center.

3. Loose connection or wiring. 3. Contact manufacturer or service center.

3. Motor defective. 4. Contact manufacturer or service center.

4. Blown fuse or tripped circuit breaker. 5. Replace fuse or reset circuit breaker.

PROBLEM: Dust blowing from vacuum.

Possible Cause: Possible Solution:

1. Full paper filter bag. 1. Replace filter bag.

2. Paper filter bag not installed 2. Reinstall or replace paper filter bag.

properly or off inlet tube.

3. Cloth filter bag dirty. 3. Clean cloth filter bag.

4. Cloth or paper filter bag is torn. 4. Replace.

WARNING:

Repairs should only be performed by an

authorized service center.

Address:

777 South Street, Newburgh, NY 12550- 0606

TEL:

(800) 835-7812 (845) 565-8850

FAX:

(800) 752-6883 (845) 565-9392

URL:

www.mastercraftusa.com

E-mail:

mail@mastercraftusa.com

PN 415731 Rev B - QuietMaster Manual - Printed in USA 01/29/04

PAGE 8

Loading...

Loading...