Page 1

READ AND FOLLOW ALL

COMPRESSED

AIR-OPERATED

ACUUM CLEANERS

V

SAFETY,

PERATION &

O

AINTENANCE

M

MANUAL

This unit is intended for commercial use.

INSTRUCTIONS, WARNINGS & CAUTIONS

BEFORE USING THIS VACUUM.

This vacuum will afford you many years of

trouble-free operating satisfaction, provided

it is given proper care. All parts have passed

rigid quality control standards prior to being

assembled to produce the finished product.

Prior to packaging, this vacuum was again

inspected for assurance of flawless assembly.

This vacuum is protectively packed to prevent damage in shipment. We recommend

that upon delivery, unpack the unit and

inspect it for any possible damage. Only a

visual examination will reveal damage that

may have occurred.

If damage is discovered, immediately notify

the transportation company that delivered

your vacuum. As a shipper, we are unable to

report any claim for damage. You must originate any claim within 5 days of delivery.

This manual is for you protection and information. PLEASE READ CAREFULLY since

failure to follow precautions could result in

discomfort or injury. Read this manual completely before operating this vacuum. It is

important to follow instructions in this manual to prevent the possibility of injury or damage to the user and/or vacuum.

Treat this vacuum as you would any other

high grade precision made product.

Dropping, unreasonable bumping across

thresholds and other misuses may result in

a damaged unit which will not be covered by

the warranty.

PLEASE READ

CAREFULLY

EFORE

B

PERATION

O

SAVE THESE INSTRUCTIONS

PAGE 1

Air Vacuum Manual - PN 313491 Rev B - Printed in USA 04/26/05

Page 2

IMPORTANT

SAFETY

INSTRUCTIONS

VACUUM

SSEMBLY

A

1. Air supply should not exceed 150 PSI.

2. Use compressed air line rated for 200

PSI or better.

3. Water separator must be used on compressed air line.

4. DO NOT used to pickup flammable

and/or combustible materials.

6. Air control valve must be OFF before connecting to compressed air line, than open

valve slowly making sure not exceed the 150

PSI rated pressure.

5. When the unit is ON, never allow hair,

fingers, or loose clothing to come near

intake, suction ports or nozzle.

7. The cloth filter must be in place for dry

pick-up to prevent clogging and contamination to venturi and exhaust filter. When use

for liquid pick-up a wet adaptor must be

used.

8. Replace damaged or worn parts immediately with genuine original equipment parts

to maintain safety and to protect your limited

warranty.

CAUTION:

The air supply must be turned OFF when the vacuum action is stopped.

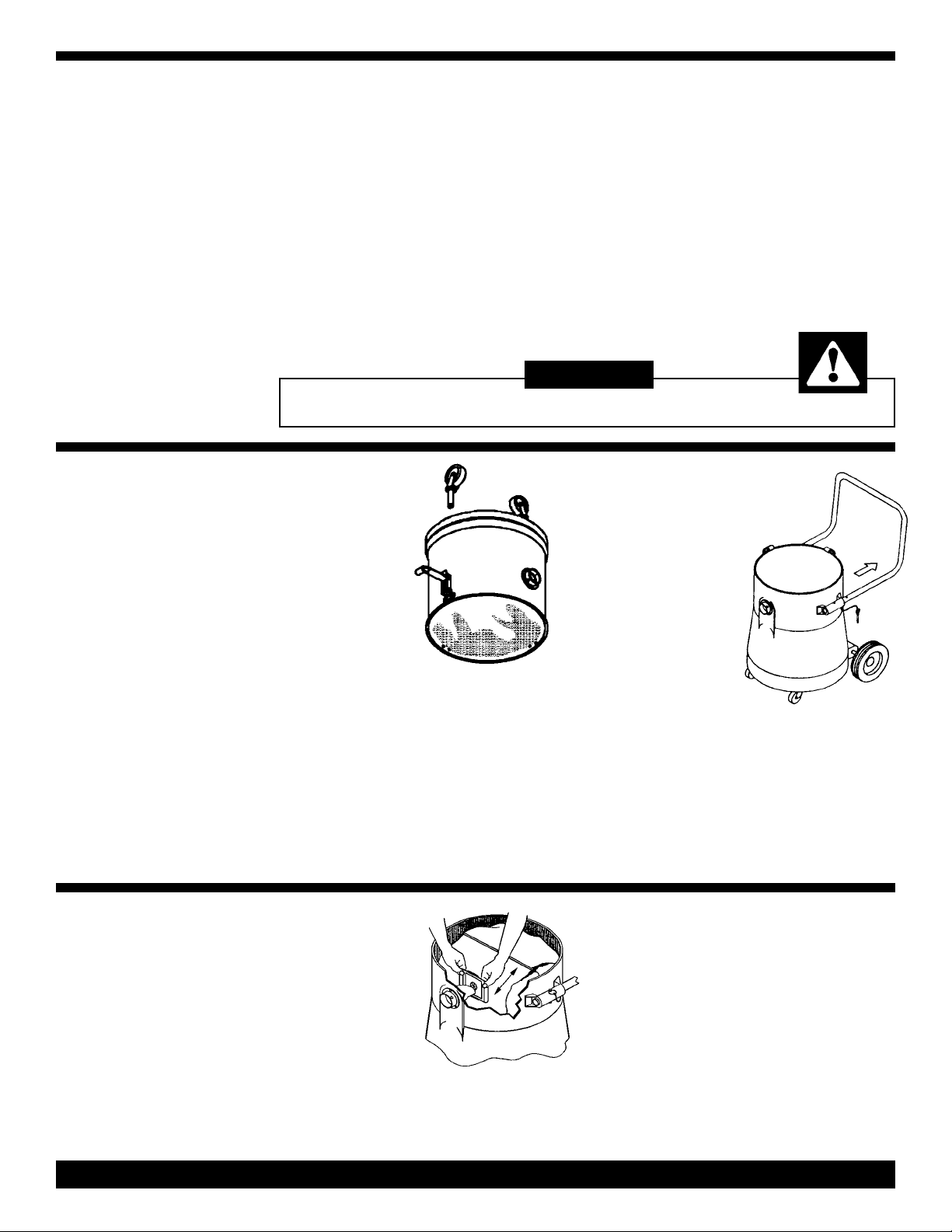

4-Caster

Tanks

Glidemobile

Style

w/Handle

FILTER

INSTALLATION

This vacuum

requires some

assembly.

1] Carefully remove and set aside motor

head and filter assembly

2] Turn tank upside down.

Poly Tanks: Press caster into plastic socket

until bottom of stem fits flush against plastic

socket.

Steel Tanks: Insert casters into caster

mount assemblies.

Cloth and

Paper Bag

Filter:

1) Disengage the

holdown clamps.

2) Remove the air head and set aside.

This vacuum is

shipped with the

handle in the storage

position and it must

be moved to the

operating position.

1) Firmly grasp the speed pins on each side

of handle and pull up and out.

2) Pulling the handle slowly away from tank,

align front handle holes with the holes in the

handle bracket.

3) Insert speed pins through holes on both

sides, locking handle in position.

4) Expand filter bag pleats, then grasp

scored ends of the cardboard and pull forward completely onto inlet tube as close to

tank wall as possible.

5) Position cloth filter assembly on the tank,

then place motor head on tank and close

clamps.

3) Empty filters, hose and other attachments that may be packed in the tank.

PAGE 2

Page 3

Paper Filter

Bag Removal:

DRY FILTER

REMOVAL &

MAINTENANCE

Dry Filter Assembly

Maintenance

In order to maintain maximum efficiency of

the vacuum cleaner it is important to clean

the cloth filter each time the tank is emptied. To clean the cloth filter, shake off loose

particles and brush exposed surface with a

soft bristle brush

NOTE: DO NOT WASH, shrinkage to the

cloth and damage to the gasket can occur.

This air vacuum is designed for wet or dry

pick-up. In order to use this vacuum for wet

pickup you must order the optional wet pickup adaptor.

1) Remove the motor head

and cloth filter assembly.

Set aside.

2) Lay vacuum tank on its side with inlet

tube on top.

3) Pull the bag out of tank, using care not to

puncture bag with inlet tube.

4) Reseal the cardboard flap that covered filter bag opening.

Install a new paper filter bag.

Removal of Liquid From

Vacuum Tank:

Tank Without Drains

1) Disengage the holdown clamps on tank.

2) Remove air head and wet pickup adaptor,

carefully place to one side.

ET

W

OPERATION

Wet Pick-Up

Adaptor Installation:

The safety float located in the protective

frame of the wet adaptor stops the vacuum

action of air head when maximum recovery

of liquid is reached.

1) Disengage the holdown clamps. Remove

air head, dry filter assembly and disposable

paper filter bag.

2) Set wet adaptor on tank, replace air head

and snap down clamps.

Wet Pickup

Maintenance:

DO NOT store the vacuum with any liquid

inside the tank. Before storing or converting

over for dry pickup, run the emptied vacuum

for approximately five minutes to eliminate

moisture in the tank, hose and attachments.

3) Pour liquid from tank into suitable drain.

Tanks w/Drain Valves

1) Center the drain valve over a drain in the

floor.

2) Open drain valve by turning valve counterclockwise and continue turning until the

desired flow is reached.

3) After tank is drained, and before closing

the drain valve check for any obstruction

that will prevent valve from sealing. Turn the

valve clockwise until it is fully closed and

sealed.

Tanks w/Gate Valves

1) Center the tank's gate valve over a floor

drain.

2) Pull up on the gate valve handle to empty

the tank.

PAGE 3

Page 4

TOOLS & ATTACHMENT ASSEMBLY

Hose & Swivel

Connector

The hose and swivel connector are preassembled at the factory. To attach the

swivel connector to intake fitting on vacuum tank:

1) Line up the slots in the swivel connector with retaining rivets on the intake.

2) Insert swivel connector and twist

clockwise until rivets reset against slot

end.

Wand

TROUBLE

PROBLEM:

SHOOTING

GUIDE

Assembly

1) Align the button lock of the upper

wand section with the opening for button

lock in the lower wand section.

2) Push sections together, until the lock

is accomplished.

3) To attach hose to wand, slide free

end of hose onto the grooved end of

upper wand.

Assembly

1) Turn the wand nut counterclockwise

approximately four (4) complete turns.

2) Insert the tool into wand and coupling.

3) While holding the tool in place, turn

nut clockwise until wand nut is fully

locked.

Tool

Loss of vacuum.

CAUSE: SOLUTION:

1. Full paper filter bag. 1. Replace the paper filter bag.

2. Dry filter assembly clogged. 2. Clean the cloth filter.

3. Clogged hose, wand, or air supply. 3. Remove obstruction.

4. Tank rim damaged. 4. Replace the tank.

5. Air supply stops. 5. Check for a blockage and remove.

6. Loss of air supply. 6. Check to see if there is a minimum

operating pressure of 90 PSI.

7. Gasket worn. 7. Replace the gasket.

8. Float not functioning. 8. Check to see if the ball on the rod

moves freely or tank is fill.

PROBLEM:

CAUSE: SOLUTION:

1. Full paper filter bag. 1. Replace the paper filter bag.

Address:

777 South Street

Newburgh, NY 12550-0606

TEL:

(800) 835-7812

(845) 565-8850

FAX:

(800) 752-6883

(845) 565-9392

URL:

www.mastercraftusa.com

E-Mail:

techsupport@mastercraftusa.com

Air Vacuum Manual - PN 313491 Rev B - Printed in USA 04/26/05

2. Paper filter bag not installed 2. Reinstall or replace the paper filter

properly or off the inlet tube. bag properly.

3. Cloth filter is dirty. 3. Clean cloth filter.

4. Cloth filter or paper filter bag is torn. 4. Replace damaged filter.

5. Paper filter bag is not installed. 5. Install paper filter bag.

PROBLEM:

CAUSE: SOLUTION:

1. Tank is full of liquid. 1. Empty the tank.

2. Foamy liquid is being picked up. 2. Add defoamer to the tank.

Dust blowing from vacuum when running.

Water blowing from vacuum when running.

PAGE 4

Loading...

Loading...