Page 1

READ & FOLLOW

SAFETY,

ALL INSTRUCTIONS,

ARNINGS & CAUTIONS

W

BEFORE USING THIS VACUUM

PERATION &

O

MAINTENANCE

MANUAL

/PARTS

W

LIST

WET/DRY

POLY VACUUMS

These units are intended for commercial use.

IT1-1566

This vacuum will afford you many years of

trouble-free operating satisfaction, provided it is given proper care. All parts have

passed rigid quality control standards prior

to being assembled to produce the finished product. Prior to packaging, the vacuum was again inspected for assurance of

flawless assembly.

Your vacuum is protectively packed to prevent damage in shipment. We recommend

that upon delivery, unpack the vacuum and

inspect it for any possible damage. Only a

visual examination will reveal damage that

may have occurred.

IT2--1567

If damage is discovered, immediately notify the transportation company that delivered your vacuum. As a shipper, we are

unable to report claims for concealed

damage. You must originate any claims

within 5 days.

This manual is for your protection and

information.

PLEASE READ CAREFULLY since failure

to follow precautions could result in discomfort or injury.

READ ALL

INSTRUCTIONS

BEFORE

OPERATION

SAVE THESE INSTRUCTION

PAGE 1

IT-Vac Manual - PN 412600 Rev A - Printed in USA 03/22/05

Page 2

MPORTANT

I

WARNING:

AFETY

S

INSTRUCTIONS

To reduce the risk of fire, Electric Shock or Injury:

DO NOT expose to rain - Store Indoors

When using this electric vacuum, basic precautions should

always be followed,

1. DO NOT leave the vacuum when

plugged in. Unplug it from the outlet

when not in use and before servicing.

2. This is NOT a toy. Close attention is

necessary when used around or near

children.

3. Use only as described in this safety

manual. Use only manufacturer’s recommended attachments and accessories.

4. DO NOT use this vacuum with damaged cord or plug. If the vacuum is not

working as it should, because it has

been dropped, damaged, left outdoors

or dropped into water, contact an

authorized service center or factory.

5. DO NOT pull the vacuum by the cord,

use cord as a handle, close a door on

the cord or pull cord around sharp

edges and corners. DO NOT run the

vacuum over the cord. Keep cord away

from heated surfaces.

including the following:

10. Keep hair, loose clothing, fingers,

and all parts of your body away from

openings and moving parts.

11. DO NOT pick up anything that is

smoking or burning such a cigarettes,

matches, or hot ashes.

12. When used for dry pickup DO NOT

use without dust bag or filters in place.

13. Use extra care when cleaning on

stairs.

14. DO NOT use this vacuum to pick up

flammable or combustible liquids such

as gasoline or use in areas where they

may be present.

15. DO NOT use where anesthetics and

oxygen are used.

16. Replace damaged or worn parts

immediately with genuine original equipment parts to maintain safety and to

protect your limited warranty.

6. DO NOT unplug the vacuum by pulling

on the cord. To unplug, grasp the plug,

not the cord.

7. DO NOT handle the vacuum plug or

vacuum with wet hands.

8. DO NOT put any objects into openings. DO NOT use with any openings

blocked; keep free of dust, lint hair, and

anything that may reduce air flow.

9. Tu rn OFF all controls before unplugging.

SAVE THESE INSTRUCTIONS

PAGE 2

17. DO NOT use an extension cord

unless absolutely necessary. If an extension cord is used, then wire size must

be #14 gauge or larger and should not

exceed 50 feet in length. Use only (3)

conductor grounding extension cord to

insure GROUNDING protection.

This vacuum must be connected to a

properly grounded outlet only. See

grounding instructions (Page 3)

Page 3

DANGER:

Improper use of the grounding plug can result in a

risk of electric shock.

GROUNDING

INSTRUCTIONS

Electrical equipment must be grounded. If

it should mal-function or breakdown,

grounding provides a path of least resistance for electrical current to reduce the

risk of electric shock. This vacuum is

equipped with a cord having an equipment-grounding conductor and grounding

plug. The plug must be inserted into an

appropriate outlet that is properly installed

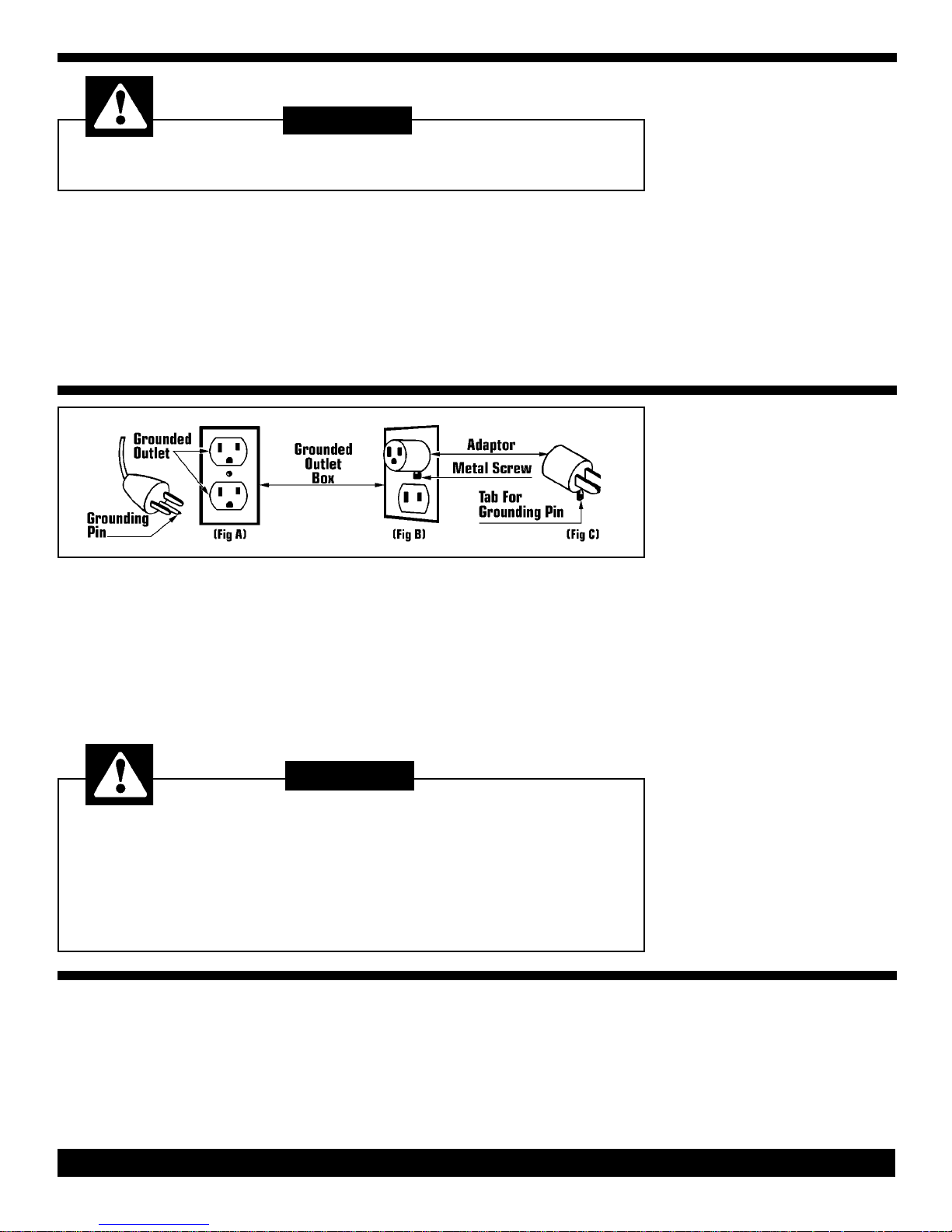

This electric equipment is for use on a

nominal 120 volt circuit, and has a

grounded plug that looks like the plug illustrated in (Fig A). A temporary adaptor that

looks like the adaptor illustrated in (Fig B

& C) may be used to connect this plug to

a 2-pole receptacle as shown in (Fig B) if

a properly grounded outlet is not available.

The temporary adaptor should be used

and grounded in accordance with all local

codes and ordinances.

If repair or replacement of the cord or

plug is necessary, DO NOT connect the

grounded wire to either flat blade terminal. The wire with insulation having an

outer surface that is green with or without

yellow stripes is the grounding wire.

GROUNDING

METHODS

only until a properly grounded outlet (Fig

A) can be installed by a qualified electrician. The green color rigid ear, lug or the

like extending from the adaptor must be

connected to a permanent ground such

as a properly grounded outlet box cover.

Whenever the adaptor is used, it must be

held in place by a metal screw (Fig 3).

WARNING:

Improper connection of the equipment-grounding conductor can result in a risk

of electric shock. Check with a qualified electrician or service person if you are

in doubt as to whether the outlet is properly grounded.

DO NOT modify the plug provided with the equipment. If it will not fit the outlet,

have a proper outlet installed by a qualified electrician.

Note: In Canada, the use of a temporary adaptor is not permitted by the

Canadian Electrical Code.

Treat this vacuum as you would any other

high grade precision made product.

Dropping, unreasonable bumping across

thresholds and other misuses may result

in a damaged to the unit which will not be

covered by warranty.

Read this manual completely before operating the vacuum. It is important to follow

instructions in this manual to prevent the

possibility of injury or damage to the user

and/or vacuum.

PAGE 3

CARE OF THIS

ACUUM

V

Page 4

RY & WET

D

PERATION

O

The IT-Vacs are equipped with by-pass

motors, designed for dry or wet pickup.

They are shipped assembled with the

hose, wand and tools packed in the shipping carton.

Dry Operation

This vacuum is shipped with the dry filter

in place and is set up for dry pickup.

Dry Setup

After Wet

Pickup

1. Remove the motor head and set

aside.

2. Lift up on the front handle and tilt

tank back and empty contents into a

suitable drain.

3. Set dry filter assembly on tank,

replace motor head and snap down

clamps.

HOSE, WAND & TOOLS INSTALLATION

Setup

for Wet Operation

When using this vacuum for wet pickup

the dry filter must be removed. The float

cage is attached to the bottom of motor

head and remains in place for dry and

wet operation.

1. Disengage holdown clamps remove

motor head and set aside.

2. Remove dry filter, set aside.

3. Replace the motor head, and snap

down clamps.

1. Hose to Inlet:

Push the red button on the inlet to the

left and insert hose. Release button and

the hose is connected.

2. Wand Assembly

Push straight ends of wands together.

3. Hose to Wand:

Slide the free end of hose onto one end

of the wand.

VACUUM MAINTENANCE

Dry Filter

In order to maintain maximum efficiency

of this vacuum cleaner it is important to

clean the cloth filter each time the tank is

emptied.

To clean the cloth filter, shake off loose

particles and brush exposed surface

with a soft bristle brush.

Always exercise CAUTION when handling the motor head.

Dropping the motor head may cause damage to the internal components.

Wet Pickup

DO NOT store this vacuum with any liquids inside the vacuum. Before storing

or converting over for dry pickup run

emptied vacuum for approximately five

minutes to eliminate moisture in the

tank, hose and attachments

4. Wand to Tool:

Select the required tool for vacuuming

and attach it to the free end of wand.

Empty liquids from Tank

1. Remove the motor head and dry filter

.Set aside.

2. Lift up on the front handle and tilt the

tank back to empty the contents.

Note: The tank can also be removed

from the dolly by rotating the quick

release system.

CAUTION:

PAGE 4

Page 5

15 GALLON POLY TANK

________________________________

Ref Part Description Qty Part

No No

________________________________

TANK & TROLLEY

REPLACEMENT

PARTS LIST

TANK TROLLEY

_________________________________

Ref Part Description Qty Part

No No

_________________________________

1 Dolly Handle 1 417270

2 Spacer 2 417084

3 Spiral Spring 2 416983

4 Pivot Hinge 2 417009

5 Support Rod 1 417300

6 Clamp 2 417297

7 5 X 25 Phillips Hd Screw 4 416975

8 Axle Shaft 1 417262

9 Axle Retainer 2 417114

10 5 X 30 Phillips Hd Screw 8 416746

11 Plastic Washer 6 417203

12 5 X 35 Phillips Hd Screw 2 416762

13 M5 X 40 Screw 12 416754

14 Front Caster 2 417025

15 5 X 20 Phillips Hd Screw 8 416703

16 Bushing 2 417211

17 Wheel Spacer 2 417084

18 Rear Wheel 2 416673

19 Washer 2 417017

20 Cap Nut 2 417343

21 Dolly Base 1 417335

_________________________________

1 5 X 30 Phillips Hd Screw 4 416746

2 Poly Tank 1 417327

3 Inlet Gasket 1 417041

4 Inlet Gasket 1 417165

5 Hose Release Button 1 417076

6 Spring 1 417092

7 Tank Inlet 1 417033

8 Inlet Deflector 1 417068

9 Front Handle 1 417238

10 Plastic Washer 2 417203

11 5 X 25 Phillips Hd Screw 2 416975

12 Tank Trim 1 417319

13 Holdown Clamps 2 416967

14 Tank Hinge 1 416991

NS Disposable Filter Bags

(5/Pk) 1 432423

________________________________

PAGE 5

Page 6

SINGLE MOTOR HEAD

REPLACEMENT

PARTS LIST

________________________________

Ref Part Description Qty Part

No No

________________________________

1 Motor Head Handle 1 417246

2 Dome Cover 1 416053

3 5 X 20 Phillips Hd Screw 11 416703

4 5 X 30 Phillips Hd Screw 2 416746

5 Terminal Block 1 416665

6 Vacuum Cap 2 438723

7 Dome 1 416843

8 Anti-Splash Switch 1 416584

9 Motor Holdown 1 416851

10 Silencing Foam 3 416894

11 Plastic Ring 1 416568

12 Gasket 6 416525

13 11/2 HP,120 Volt Motor 1 416797

14 Washer 2 416711

15 M4 X 8 Screw 2 416770

16 Automatic Valve 2 416606

17 Motor Base Assembly 1 416657

18 5 X 14 Phillips Hd Screw 12 416681

19 Plastic Motor Spacer 2 438758

20 Deadening Triangle

21 Gasket 1 416576

22 Foam Filter 3 438731

23 27 Ft, 3/16 Power Cord 1 416827

24 5 X 35 Phillips Hd Screw 8 416762

25 Locknut 1 416541

27 Strain Relief 1 416533

28 Motor Cap 2 438766

________________________________

(Base) 3 416940

TOOL, HOSE AND WAND

1

5

3

4

2

6

PAGE 6

Page 7

DUAL MOTOR HEAD

REPLACEMENT

PARTS LIST

___________________________________

Ref Part Description Qty Part

No No

___________________________________

1 Motor Head Handle 1 417246

2 Dome Cover 1 416053

3 5 X 20 Phillips Hd Screw 11 416703

4 5 X 30 Phillips Hd Screw 2 416746

5 Terminal Block 1 416665

6 Dome 1 416843

7 Anti-splash Switch 2 416649

8 Gasket 1 416576

9 Motor Holdown 1 416851

10 Silencing Foam 3 416894

11 Plastic Ring 2 416568

12 Motor Gasket 4 416525

13 2 - 1 HP, 120 Volt Motor 2 416789

14 Washer 2 416711

15 M4 X 8 Screw 2 416770

16 Automatic Valve 2 416606

17 Motor Base Assembly 1 416657

18 Motor Cap 1 438766

19 Motor Spacer 1 438758

20 Deadening Triangle 3 416940

21 Vacuum Cap 1 438723

22 Foam Filter 3 438731

23 5 X 35 Phillips Hd Screw 8 416762

24 Cord Clamp 1 416541

25 4.3 X 22 Screw 2 416738

26 Strain Relief 1 416533

27 27 Ft, 3/16 Power Cord 1 416827

28 5 X 14 Ph Hd Screw 12 416681

___________________________________

_____________________________

Ref Part Description Qty Part

No No

_____________________________

1 3 Piece Plastic Wand 1 456020

2 10 Ft Vinyl Hose 1 422576

3 Dusting Brush 1 432830

4 16" Squeegee Tool 1 435503

5 Crevice Tool 1 422533

6 16" Floor Tool 1 433187

N/S Reducer 1 433268

_____________________________

TOOL, HOSE AND

WAND PARTS LIST

PAGE 7

Page 8

DRY FILTER AND

FLOAT CAGE

REPLACEMENT

______________________________

Ref Part Description Qty Part

No No

______________________________

PARTS LIST

ROUBLE

T

SHOOTING

GUIDE

1 Wire Mesh Filter 1 417254

2 Float 1 417106

3 Spacer 1 417351

4 5 X 25 Screw 4 417289

5 Float Cage 1 417122

6 Plastic Frame 1 417130

7 Filter Ring 1 416630

8 Cloth Filter Bag 1 417157

Optional Filter

9 Cartridge Filter 1 417173

10 Cartridge Filter Ring 1 417181

______________________________

PROBLEM: Lose of vacuum.

POSSIBLE CAUSE: POSSIBLE SOLUTION:

1. Cloth filter clogged. 1. Clean cloth filter.

2. Clogged hose or wand. 2. Remove obstruction.

3. Tank rim damaged 3. Replace tank.

4. Loose or broken fan. 4. Contact manufacturer or service center.

5. Motor not working. 5. Contact manufacturer or service center.

6. Float not functioning. 6. Check to see if float moves freely.

7. Tank full. 7. Drain dirty water from tank.

PROBLEM: Motor or pump is not running.

POSSIBLE CAUSE: POSSIBLE SOLUTION:

1. Broken switch. 1. Contact manufacturer or service center.

2. Power cord defective. 2. Contact manufacturer or service center.

3. Motor or pump defective. 3. Contact manufacturer or service center.

4. Blown fuse or tripped circuit 4. Replace fuse or reset circuit breaker.

breaker.

Address:

777 South Street

P.O. Box 2310

Newburgh, NY 12550-0606

TEL:

(800) 835-7812

(845) 565-8850

FAX:

(800) 752-6883

(845) 565-9392

URL:

www.mastercraftusa.com

E-mail:

mail@mastercraftusa.com

IT-Vac Manual - PN 412600 Rev A - Printed in USA 03/22/05

PROBLEM: Dust blowing from vacuum when running.

POSSIBLE CAUSE: POSSIBLE SOLUTION:

1. Cloth filter bag dirty. 1. Clean cloth filter bag.

2. Cloth filter bag is torn or missing. 2. Replace.

PROBLEM: Water blowing from vacuum when running.

POSSIBLE CAUSE: POSSIBLE SOLUTION:

1. Tank is full of liquid. 1. Empty tank.

2. Sudsy or foamy liquid is being 2. Add defoamer to tank.

picked up.

PAGE 8

Loading...

Loading...