Page 1

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described.

Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or

property damage! Retain instructions for future reference.

Operating Instructions and Parts Manual WS0973, 58-8023-2

Arc Welder

Description

This Mastercraft Arc Welder is designed to

be used on standard 115 V household

current. It is equipped with an output

control to accurately select the proper

current needed for various welding

conditions. Internal components are

thermostatically protected.

This welder can weld up to 1/8” steel in a

single pass. Recommended electrode size

is 1/16” diameter for 15 A circuits, up to

5/64” diameter for 20 A circuits. For

replacement electrodes, call 1-866-2202097 for the nearest authorized service

centre.

Unpacking

When unpacking, inspect carefully for any

damage that may have occurred during

transit. Report any damaged or missing

items by calling 1-866-220-2097.

Circuit Requirements

This equipment

requires a

dedicated 115 V circuit. Refer to the

following chart for the correct circuit

breaker or fuse rating. Do not run other

appliances, lights, or tools on this

circuit while operating this equipment.

Extension cords are not recommended.

Blown fuses or tripped circuit breakers

can result from failure to comply with

this recommendation.

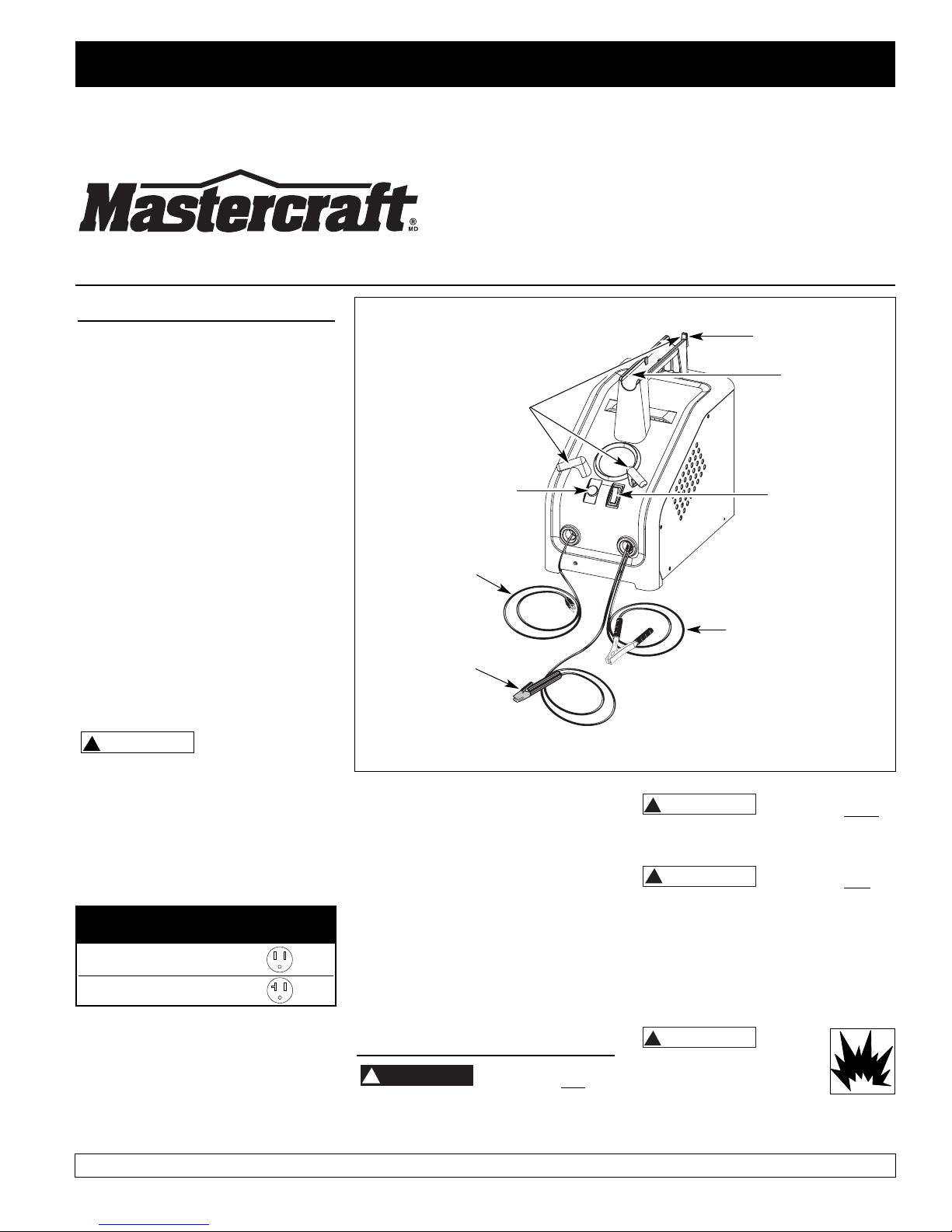

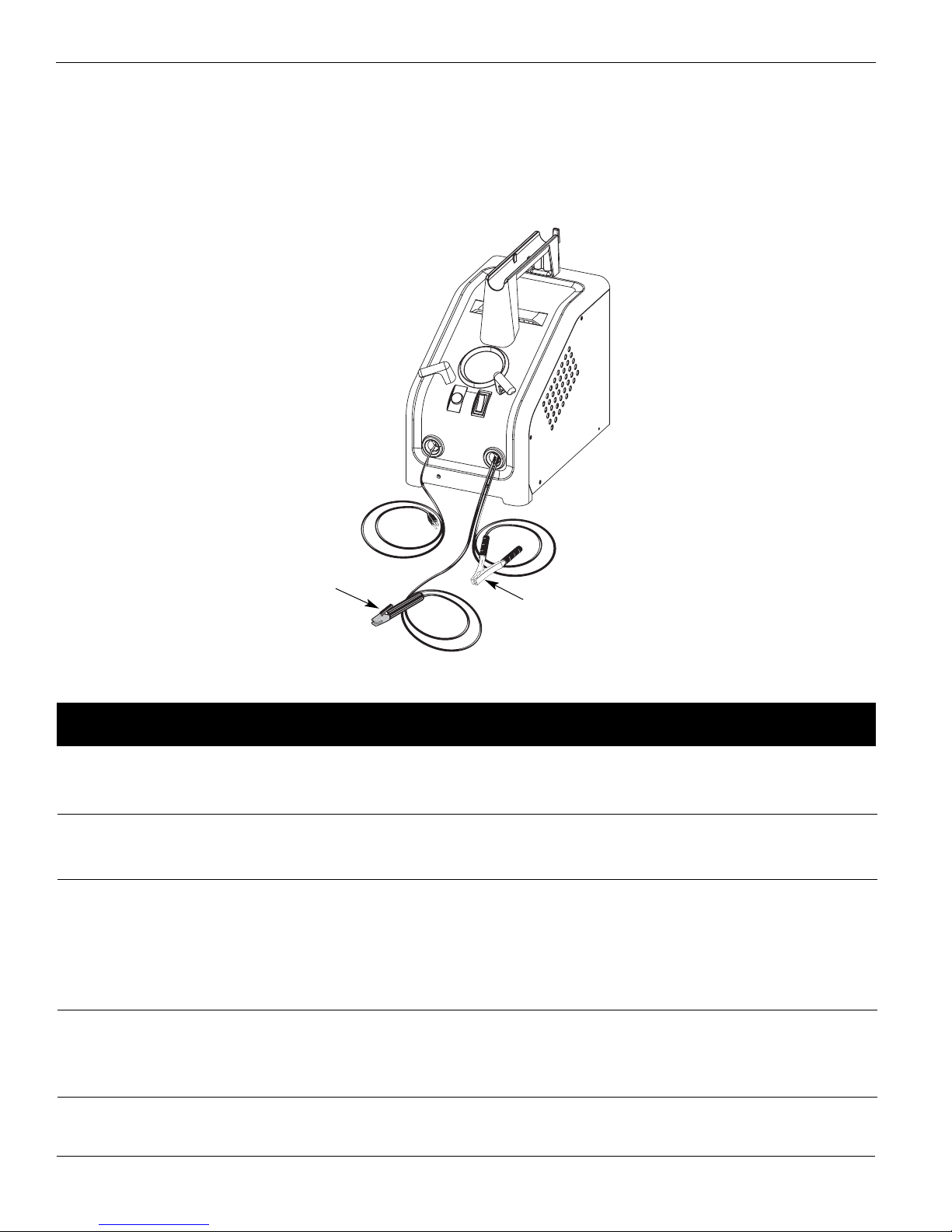

Components and Controls

1. Work Clamp- connect to workpiece

2. Electrode Holder - holds electrode

welding rod

3. Power Cord - plug into 115 V outlet.

4. Power Switch - High/Off/Low.

5. Indicator Light - light activates if

thermostat has automatically shut unit

off.

6. Hand-shield hook - for hanging the

hand-shield for storage and transport.

7. Cable Keepers - for wrapping the

cables during storage and transport.

8. Storage Pocket - for storing the

chipping hammer/brush. Also can be

used for storing a tube of welding

rods.

General Safety

Danger means a

hazard that will

cause death or serious injury if the

warning is ignored.

Warning means a

hazard that could

cause death or serious injury if the

warning is ignored.

Caution means a

hazard that may

cause minor or moderate injury if the

warning is ignored. It also may mean a

hazard that will only cause damage to

property.

NOTE: Note means any additional

information pertaining to the product

or its proper usage.

Always keep a fire

extinguisher accessible

while performing arc

welding operations.

Figure 1 - Welder Components and Controls

IN972300AV 7/04

Low 15 A

High 20 A

Heat Circuit Breaker or

Setting Slow Blow Fuse

1

2

3

4

5

6

7

REMINDER: Keep your dated proof of purchase for warranty purposes! Attach it to this manual or file it for safekeeping.

8

!

CAUTION

!

DANGER

!

WARNING

!

CAUTION

!

WARNING

Page 2

2

Arc Welder

General Safety

(Continued)

Before starting or servicing any

electric arc welder, read and

understand all instructions. Failure

to follow safety precautions or

instructions can cause equipment

damage and or serious personal

injury or death.

All installation, maintenance, repair

and operation of this equipment

should be performed by qualified

persons only in accordance with

national, provincial, and local codes.

Improper use of electric arc

welders can cause electric

shock, injury, and death!

Take all precautions

described in this manual to reduce the

possibility of electric shock.

Verify that all components of the

arc welder are clean and in good

condition prior to operating the

welder. Be sure that the insulation

on all cables, electrode holders, and

power cords is not damaged.

Always repair or replace damaged

components before operating the

welder. Always keep welder panels,

shields, etc. in place when operating

the welder.

Always wear dry protective clothing

and welding gloves, and insulated

footwear.

Always operate the welder in a

clean, dry, well-ventilated area. Do

not operate the welder in humid,

wet, rainy, or poorly ventilated

areas.

Be sure that the workpiece is

properly supported and grounded

prior to beginning any electric arc

welding operation.

Coiled welding cable should be spread

out before use to avoid overheating

and damage to insulation.

Never immerse the

electrode or

electrode holder in water. If the welder

becomes wet for any reason, be

absolutely certain that it is completely

clean and dry prior to attempting use!

Always shut the equipment off and

unplug the power prior to moving

the unit.

Always attach the work lead first.

Verify that the workpiece is securely

grounded.

Always shut off electric arc welding

equipment when not in use and

remove the electrode from the holder.

Never allow any part of the body to

touch the electrode and ground or

grounded workpiece at the same time.

Awkward welding conditions and

positions can be electrically hazardous.

When crouching, kneeling or at

elevations, be sure to insulate all

conductive parts, wear appropriate

protective clothing, and take

precautions to prevent injury from falls.

Never attempt to use this

equipment at current settings or

duty-cycles higher than those

specified on the equipment labels.

Never use an electric arc welder to

thaw frozen pipes.

Flying sparks and hot metal

can cause injury. As welds

cool, slag can be thrown off.

Take all precautions described in this

manual to reduce the possibility of

injury from flying sparks and hot metal.

Wear ANSI approved face shield or

safety glasses with side shield

protection when chipping or

grinding metal parts.

Wear ear plugs when welding

overhead to prevent spatter or slag

from falling into ears.

Electric arc welding

operations produce intense

light and heat and ultraviolet

(UV) rays. This intense light and UV rays

can cause injury to eyes and skin. Take

all precautions described in this manual

to reduce the possibility of injury to

eyes and skin.

All persons operating this

equipment or in the area while

equipment is in use must wear

protective welding gear including:

welding helmet or shield with at

least shade 10, flame resistant

clothing, leather welding gloves,

and full foot protection.

Never look at arc

welding operations

without eye protection as described

above. Never use a shade filter lens

that is cracked, broken, or rated below

number 10. Warn others in the area not

to look at the arc.

Electric arc welding

operations cause sparks and

heat metal to temperatures

that can cause severe burns! Use

protective gloves and clothing when

performing any metal working

operation. Take all precautions

described in this manual to reduce the

possibility of skin and clothing burns.

Make sure that all persons in the

welding area are protected from

heat, sparks, and ultraviolet rays.

Use additional face shields and

flame resistant barriers as needed.

Never touch workpieces until

completely cooled.

Heat and sparks produced

during electric arc welding

and other metal working

operations can ignite

flammable and explosive materials!

Take all precautions described in this

manual to reduce the possibility of

flames and explosions.

Remove all flammable materials

within 35 feet (10.7 metres) of

welding arc. If removal is not

possible, tightly cover flammable

materials with fire proof covers.

Do not operate any electric arc

welder in areas where flammable or

explosive vapours may be present.

Take precautions to be sure that

flying sparks and heat do not cause

flames in hidden areas, cracks,

behind bulkheads, etc.

Fire hazard! Do not weld on

containers or pipes that

contain or have contained

flammable materials or gaseous or

liquid combustibles.

Arc welding closed cylinders

or containers such as tanks

or drums can cause

!

WARNING

!

DANGER

!

WARNING

!

WARNING

!

WARNING

!

WARNING

!

WARNING

!

WARNING

!

WARNING

Page 3

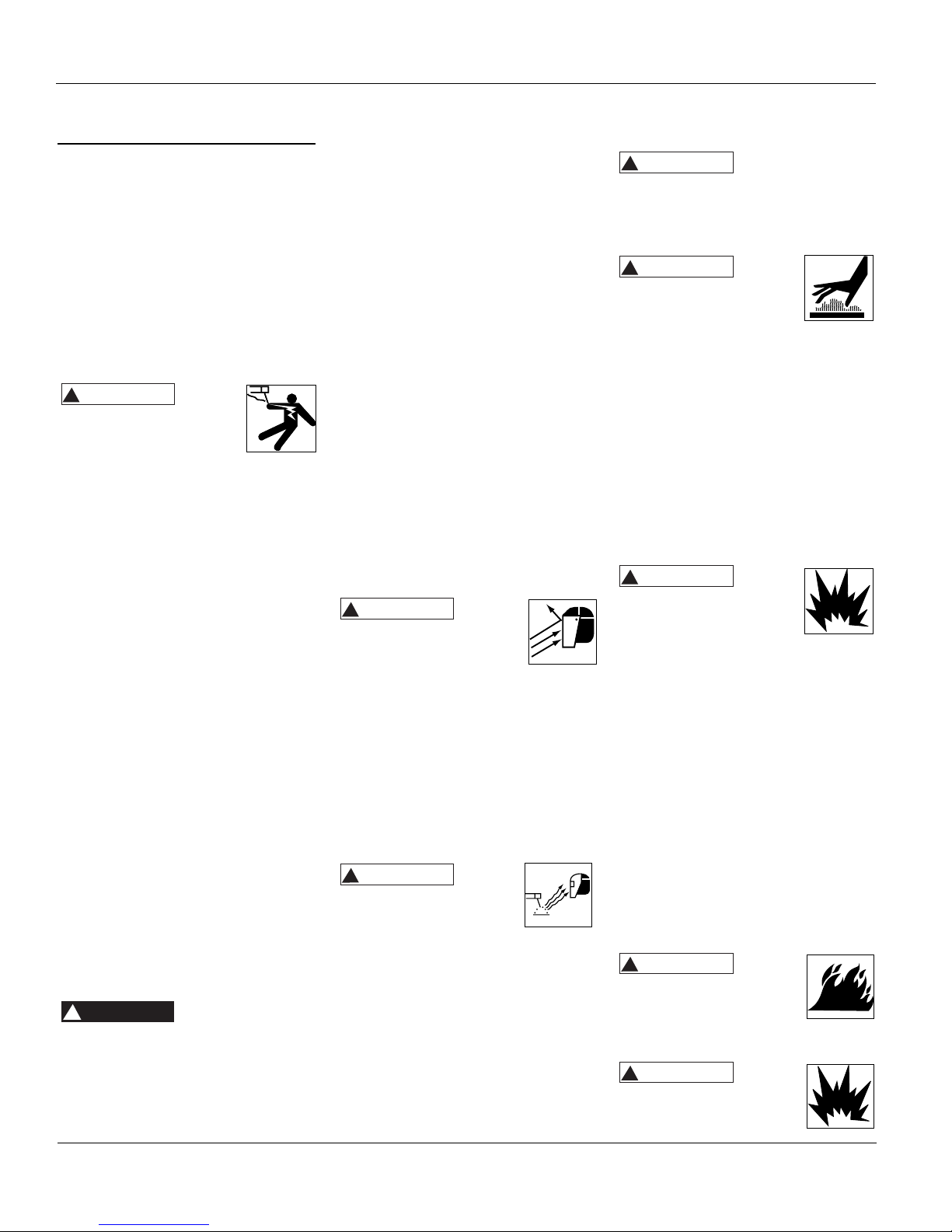

2. Insert filter lens.

3. To attach the handle, place shield on

a flat surface and press handle into

place (See Figure 5).

NOTE: If you have never welded before

or have little experience, a full face

helmet is recommended. Both hands

are needed to stabilize and control the

angle and arc length of the electrode.

General Safety

(Continued)

explosion if not properly vented!

Verify that any cylinder or container to

be welded has an adequate ventilation

hole, so that expanding gases can be

released.

Do not breathe fumes that

are produced by the arc

welding operation. These

fumes are dangerous. If the welding

area cannot be adequately ventilated,

be sure to use an air-supplied

respirator.

Keep the head and face out of the

welding fumes.

Do not perform electric arc welding

operations on metals that are

galvanized or cadmium plated, or

contain zinc, mercury, or beryllium

without completing the following

precautions:

a. Remove the coating from the

base metal.

b. Make sure that the welding area

is well-ventilated.

c. Use an air-supplied respirator.

Extremely toxic fumes are created

when these metals are heated.

The electromagnetic field

that is generated during arc

welding may interfere with

the operation of various electrical and

electronic devices such as cardiac

pacemakers. Persons using such devices

should consult with their physician

prior to performing any electric arc

welding operations.

Route the electrode and work

cables together and secure with

tape when possible.

Never wrap arc welder cables

around the body.

Always position the electrode and

work leads so that they are on the

same side of the body.

Exposure to electromagnetic fields

during welding may have other

health effects which are not known.

Always be sure

that the welding

area is secure and free of hazards

(sparks, flames, glowing metal or slag)

prior to leaving. Be sure that

3

WS0973, 58-8023-2

equipment is turned off and electrode

is removed. Be sure that cables are

loosely coiled and out of the way. Be

sure that all metal and slag has cooled.

ADDITIONAL SAFETY STANDARDS

Code for Safety in Welding and

Cutting

CSA Standard W117.2, from Canadian

Standards Association, Standards Sales,

178 Rexdale Boulevard, Rexdale,

Ontario, Canada M9W 1R3

ANSI Standard Z49.1 from American

Welding Society, 550 N.W. LeJune Rd.

Miami, FL 33126

Safe Practices For Occupational And

Educational Eye And Face

Protection

ANSI Standard Z87.1, from American

National Standards Institute, 1430

Broadway, New York, NY 10018

Refer to the Material Safety Data

Sheets and the manufacturers

instructions for metals, electrodes,

coatings and cleaners.

Installation

Location

Selecting the proper location can

significantly increase performance,

reliability and life of the arc welder.

For best results locate the welder in

an environment that is clean and

dry. Dust and dirt in the welder

retain moisture and increase wear

of moving parts.

Store electrodes in a clean, dry

location with low humidity to

preserve the flux coating.

The receptacle used for the welder

must be properly grounded and the

welder must be the only load on the

power supply circuit. Refer to the

Circuit Amperage chart on page 1

for correct circuit capacity.

The use of an extension cord is not

recommended for arc welding

machines. Extension cord use will

significantly degrade the

performance of the welder.

Assembly

HANDSHIELD

1. Cut detachable handle away from

shield. Trim the excess plastic to

remove sharp edges.

Figure 2

Figure 3

Figure 4

Figure 5

!

WARNING

!

WARNING

!

WARNING

Page 4

The electrode

holder and rod are

electrically “live” (current potential)

when the welder is on.

Grounding against

any metallic

surface may produce an arc which could

cause sparks and damage eyesight.

6. Hold the electrode away from the

grounded workpiece or workbench.

Turn on the welder to either High

or Low. Refer to the following chart

for proper output setting.

7. Position the electrode to begin

weld, lower the welding helmet or

position the hand shield, and strike

an arc. Adjust output setting as

needed.

8. When finished welding, turn welder

off and store properly.

DUTY-CYCLE / THERMOSTATIC

PROTECTION

Welder duty-cycle is the percentage of

actual weld time that can occur in a

ten minute interval. For example, at a

10% duty-cycle, actual welding can

occur for one minute, then the welder

must cool for nine minutes.

Internal components of this welder are

protected from overheating with an

automatic thermal switch. A yellow

lamp is illuminated on the front panel

if the duty-cycle is exceeded. Welding

operations may continue when the

yellow lamp is no longer illuminated.

4

Arc Welder

Operation

1. Be sure to read,

understand, and comply

with all precautions in the

General Safety

Information section. Be sure to read

the entire section entitled Welding

Guidelines prior to using this

equipment.

2. Turn welder off and plug into

appropriate receptacle:

115 V 15 A - Low

115 V 20 A - High

3. Verify that the surfaces of metals to

be joined are free from dirt, rust,

paint, oil, scale or other contaminants.

These contaminants make welding

difficult and cause poor welds.

All persons

operating this

equipment or in the area while

equipment is in use must wear

protective welding gear including: eye

protection with minimum shade 10

lens, flame resistant clothing, leather

welding gloves, and full foot

protection.

If heating, welding, or

cutting materials that are

galvanized, zinc plated, lead, or

cadmium plated refer to the General

Safety Information Section for

instructions. Extremely toxic fumes are

created when these metals are heated.

4. Connect the work clamp to the

workpiece. Make sure the contact is

on bare metal and not obstructed

by paint, varnish, corrosion, or nonmetallic materials.

5. Insert the exposed part of the

electrode rod (the end with no flux)

into the jaws of the electrode

holder.

Maintenance

Disconnect power

supply and turn

machine off before inspecting or

servicing any components.

Before every use:

1. Check condition of weld cables and

immediately repair or replace any

cables with damaged insulation.

2. Check condition of power cord and

immediately repair or replace any

cord if damaged.

3. Check condition of electrode holder

insulating pieces and immediately

replace cracked or missing

insulators. Verify that all fasteners

are tight and insulated.

Do not operate this

welding machine

with cracked or missing insulation on

welding cables, electrode holder, or

power cord.

Every 3 months:

Replace any unreadable labels on the

welder. Use compressed air to blow all

dust and lint from the ventilation

openings.

Electrode Output

Diameter Setting

1/16" (1.6 mm) Low

5/64" (2 mm) High

!

WARNING

!

WARNING

MANUAL

!

WARNING

!

WARNING

!

WARNING

!

WARNING

Page 5

5

Welding Guidelines

General

This welding machine utilizes a process

known as Shielded Metal-Arc Welding

(SMAW). This process is used to bond

metals by heating them with an electric

arc created between the electrode and

the workpiece.

Electrodes used for shielded metal arc

welding have two parts. The inner core is

a metal rod or wire that should be similar

in composition to the base metal. The

outer coating is called flux. Various types

of flux exist. Each coating is used for a

particular welding situation.

While the metal is molten, it can be

contaminated by elements in the air. This

contamination could weaken the weld.

The flux coating creates a protective

barrier called slag that protects the

molten metal from contaminants.

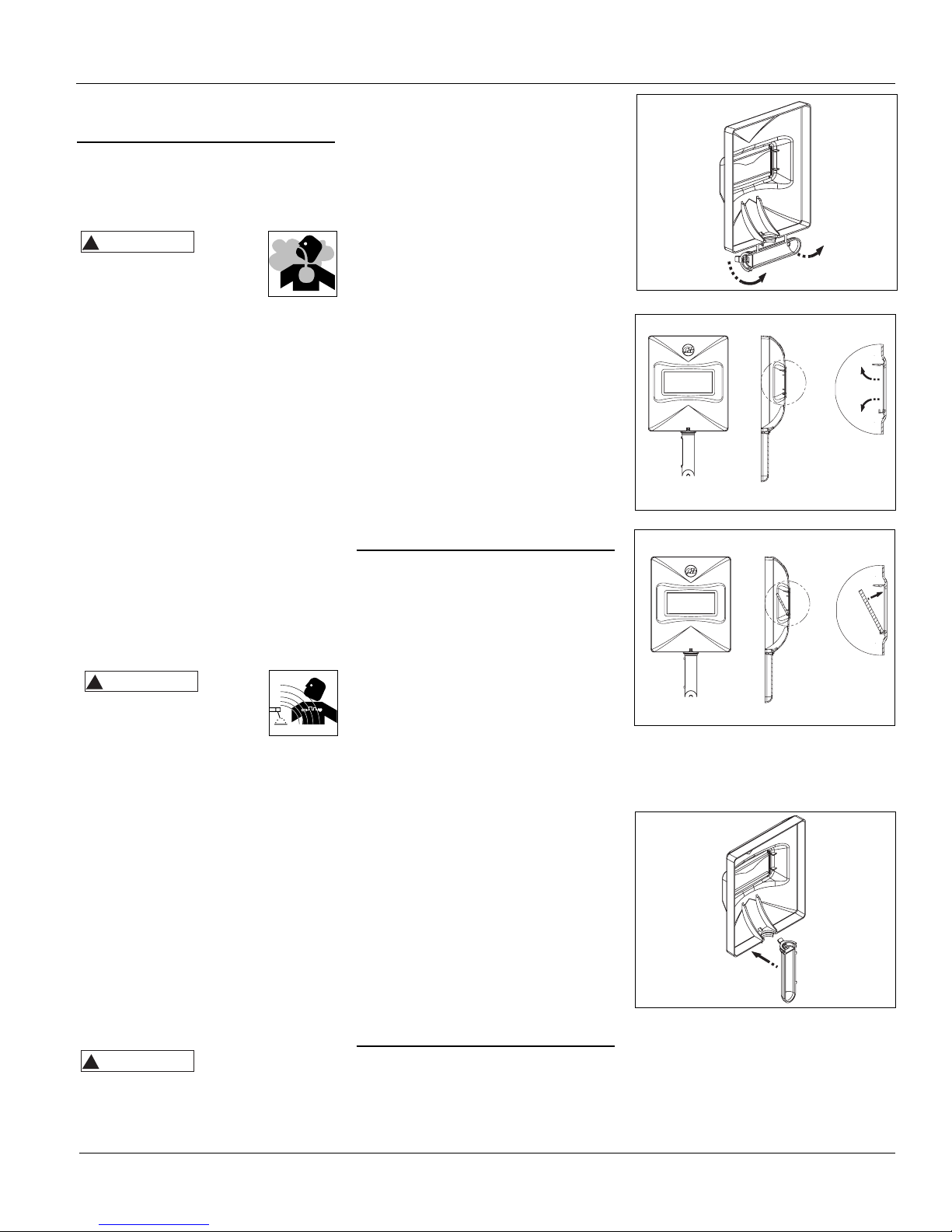

When current (amperage) flows through

the circuit to the electrode, an arc is

formed between the end of the electrode

and the workpiece. The arc melts the

electrode and the workpiece. The melted

metal of the electrode flows into the

molten crater and forms a bond with the

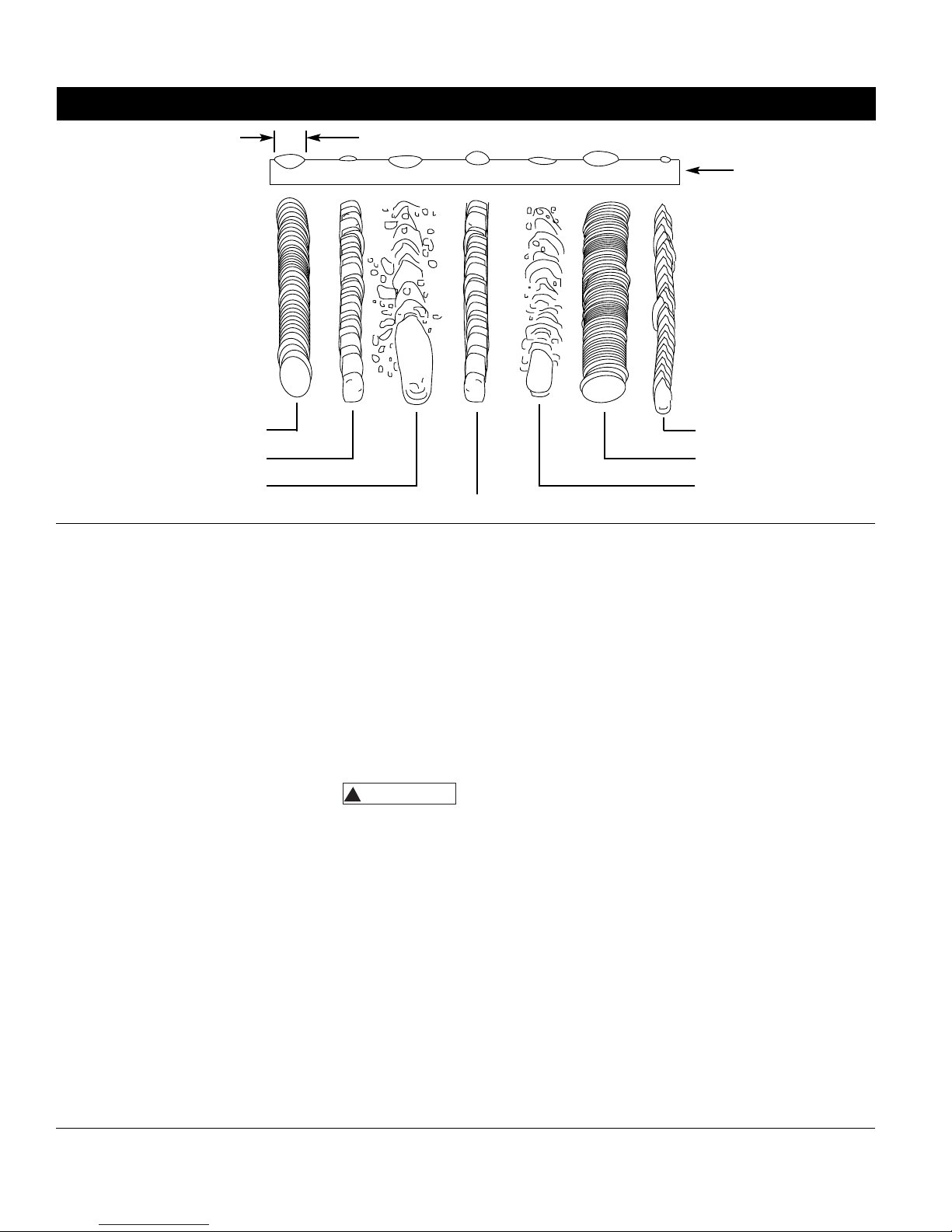

workpiece as shown in Figure 6.

NOTE: Discontinue using and discard

electrodes that burn down to 1 to 2

inches from the electrode holder.

STRIKING AN ARC

Attach work clamp to workpiece. The

jaws of the work clamp must make good

contact with clean bare metal of the

workpiece for good welding results.

Place the bare end of the electrode in the

holder. Grip the holder lightly to reduce

tiring of the hand and arm.

NOTE: Always keep the jaws of the

holder clean to ensure good electrical

contact with the electrode.

Be careful not to

touch the workpiece

or welding bench with the electrode as

this causes arc flashes.

The best method of striking an arc is the

scratching method. Drag the electrode at

an angle along the surface much like

striking a match. Upon contact with the

plate, lift the electrode approximately

1/16” off the surface or it will stick (See

Figure 7).

NOTE: Should the electrode stick to the

workpiece, break it loose by quickly

twisting or bending at the holder while

pulling upward. If the electrode does not

break loose, disengage the electrode by

releasing it from the holder.

ELECTRODE TYPE AND SIZE

Two types of electrodes are

recommended for this welder. The

electrodes are designated as follows:

1. E-6013 GENERAL PURPOSE

• All position, smooth deposit rod with

low spatter.

• For all mild steel and general purpose

work.

2. E-7014 FAST FILL

• Smooth bead and fast deposition

• Ideal for joints with poor fitup and

general repair work

NOTE: E-6011 and E-7018 are not

recommended for use with these

welders. Recommended electrode

diameter is 1/16” or 5/64”. Call

1-866-220-2097 for availability.

Arc Welding Basics

Four basic techniques affect weld

quality. These are: amperage setting,

weld angle, arc length, and travel

speed. Proper use of these techniques is

necessary for good weld quality.

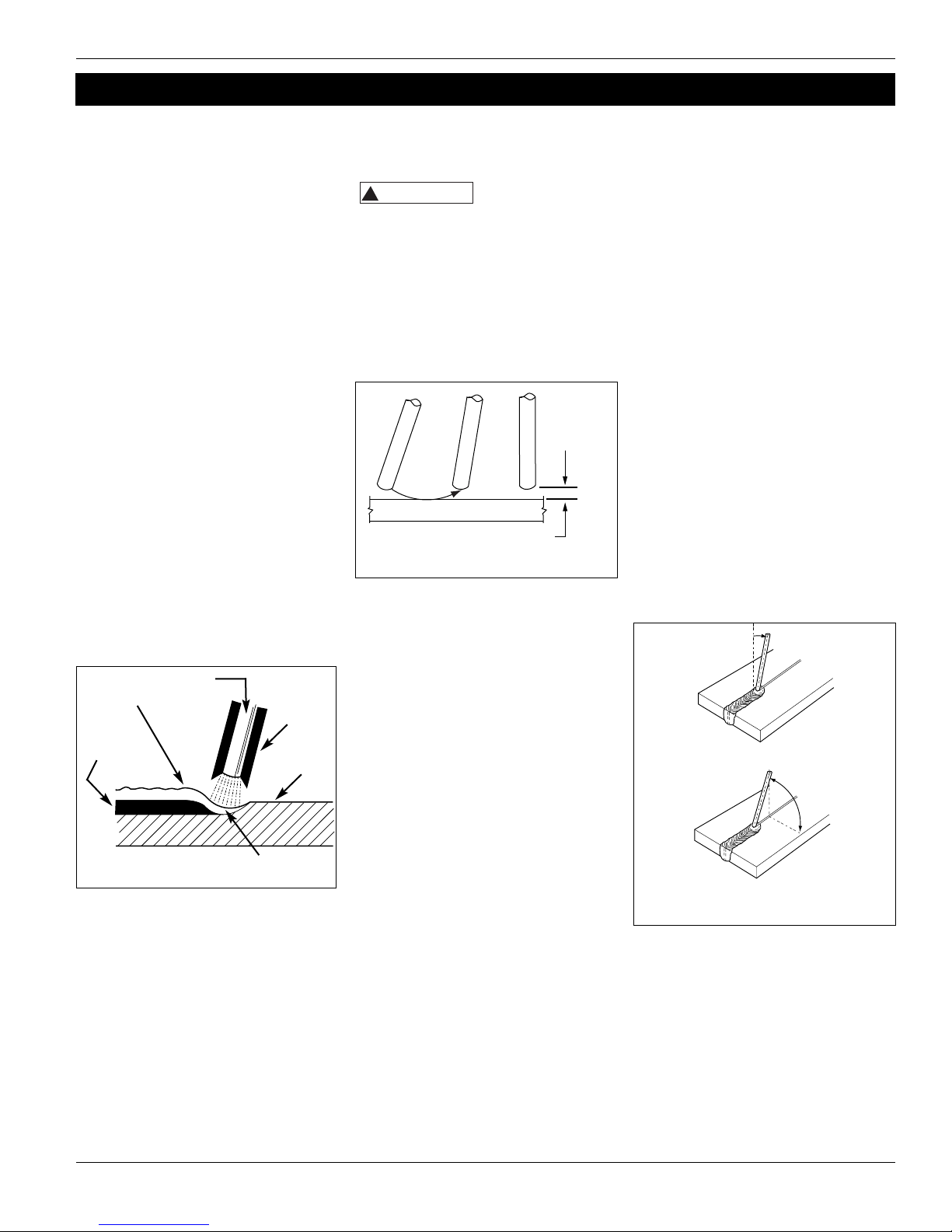

AMPERAGE SETTING

The correct amperage involves the

adjustment of the welding machine to

the required amperage setting. This is

regulated by selecting the appropriate

high or low setting. The amperage

required depends on the size

(diameter) of electrode used and the

thickness of the workpiece.

Excessive currents burn through light

metals and the weld bead is flat and

porous (See Figure 9). The bead

appears high and irregular if the

current is too low.

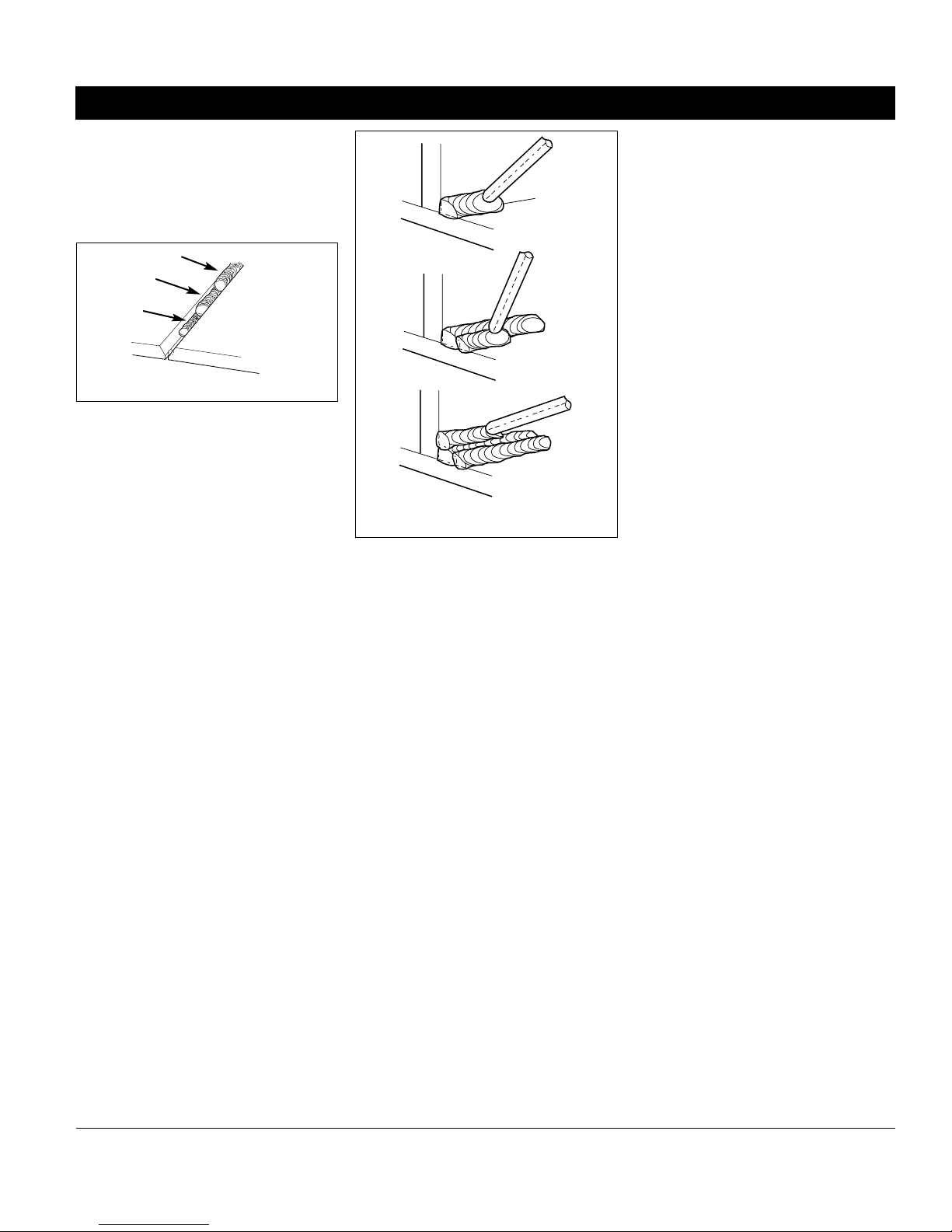

WELD ANGLE

Weld angle is the angle at which the

electrode is held during the welding

process. Using the correct angle ensures

proper penetration and bead formation.

Electrode angle involves two positions travel angle and work angle (See Figure

8).

Travel angle is the angle in the line of

welding and may vary from 5º to 45º

from the vertical, depending on

welding conditions.

Work angle is the angle from

horizontal, measured at right angles to

the line of welding.

For most applications, a 45º travel

angle and 45º work angle is sufficient.

For specific applications, consult an arc

welding handbook.

Slag

Weld

Wire

Flux

Workpiece

Crater

Figure 6 - Weld Components

Same as Electrode Diameter

Figure 7 - Scratching Method

WS0973, 58-8023-2

Figure 8 - Weld Angle

5o - 45

o

Travel Angle

Work Angle

!

WARNING

1/16"

Page 6

6

Arc Welder

NOTE: Right handed welders should

weld from left to right. Left handed

welders should weld from right to left.

The electrode should always point into

the weld puddle as shown.

ARC LENGTH

Arc length is the distance from the

workpiece to the tip of the electrode,

the distance which the arc must travel.

A proper arc length is essential to

generate the heat needed for welding

(See Figure 9). An arc that is too long

produces an unstable arc, reduces

penetration, increases spatter, and

causes flat and wide beads. Too short

an arc does not create enough heat to

melt the workpiece, the electrode has a

tendency to stick, penetration will be

poor, and uneven beads with irregular

ripples result. A proper arc should be

no longer than the diameter of the rod.

The sound of a proper arc is a steady,

crisp sizzle, similar to bacon frying.

TRAVEL SPEED

The travel speed is the rate at which

the electrode is moved across the weld

area (See Figure 9). When the speed is

too fast, the bead is narrow and bead

ripples are pointed as shown. When the

speed is too slow, the weld metal piles

up and the bead is high and wide. To

control travel speed, watch the width

of the weld bead (not the arc) when

welding. The weld bead is the orange,

molten metal behind the arc. The width

should be approximately twice the

diameter of the welding rod. Control

travel speed to obtain a consistent

bead width.

SLAG REMOVAL

Wear ANSI

approved safety

glasses (ANSI Standard Z87.1) and

protective clothing when removing

slag. Hot, flying debris can cause

personal injury to anyone in the area.

After completing the weld, wait for the

welded sections to cool. A protective

coating called slag now covers the weld

bead which prevents contaminants in

the air from reacting with the molten

metal. Once the weld cools to the point

that it is no longer glowing red, the

slag can be removed. Removal is done

with a chipping hammer. Lightly tap

the slag with the hammer and break it

loose from the weld bead. The final

clean-up is done with a wire brush.

When making multiple weld passes,

remove the slag between each pass.

WELDING POSITIONS

Four basic welding positions can be used;

flat, horizontal, vertical, and overhead.

Welding in the flat position is easier than

any of the others because welding speed

can be increased, the molten metal has

less tendency to run, better penetration

can be achieved, and the work is less

fatiguing.

Other positions require different

techniques such as a weaving pass,

circular pass, and jogging. A higher skill

level is required to complete these welds.

All work should be performed in the

flat position if possible. For specific

applications, consult an arc welding

handbook.

WELD PASSES

Sometimes more then one pass is

necessary to fill the joint. The root pass

is first, followed by filler passes and the

Welding Guidelines (Continued)

Normal Amperage,

Arc Length, Speed

Amperage Too Low

Amperage Too High

Arc Length Too Short

Arc Length Too Long

Speed Too Slow

Speed Too Fast

Workpiece

NOTE: Weld bead width (W)

should be approximately

twice the diameter fo the

electrode rod used.

W

Figure 9 - Weld Appearance

!

WARNING

Page 7

7

Welding Guidelines (Continued)

cover pass (See Figure 10). If the pieces

are thick, it may be necessary to bevel

the edges that are joined at a 60º

angle. Remember to remove the slag

between each pass.

Figure 10 - Weld Passes

Cover

Filler

Root

Figure 11 - Multiple Weld Passes

WS0973, 58-8023-2

Page 8

8

Troubleshooting Chart - Welder

Symptom Possible Cause(s) Corrective Action

1. No power at receptacle

2. Broken or damaged power

cable

1. Inadequate current at electrode

2. Poor connections at welder

1. Accidental contact with

workpiece

2. Current leakage caused by

moist clothing or work area

1. Use of extension cord

2. Electrode diameter too large

3. Overloaded circuit

1. Wrong type of electrode

2. Electrode diameter too large

3. Workpiece not properly

grounded

4. Heavy loads making power line

voltage low

For Information About This Product, Call 1-866-220-2097

1. Check circuit fuse or circuit breaker

2. Power cable requires service

1. Check work clamp, cable and connection to workpiece.

Check electrode cable and clamp

2. Check all welder external connections

1. Avoid contact with workpiece

2. Make sure clothing and work area are dry

1. If possible, relocate welder to avoid use of extension cord. If

relocation of welder is not possible, use thicker (lower gauge

number) extension cord

2. Use smaller diameter electrode

3. Welder requires a dedicated 115 V circuit

1. Verify that electrode is for alternating current (AC) use

2. Use smaller diameter electrode

3. Verify proper grounding. (No paint, varnish or corrosion)

4. Run welder on dedicated 115 V circuit

Welder does not hum when

turned on

Welder hums but does not

weld

Welder gives trickle shocks

Welder overheats - blows

fuses, trips circuit breaker

Arc difficult to strike

Bead is intermittently too

thin or too thick

Ragged depressions at edge

of weld

Weld bead does not

penetrate workpiece

Electrode sticks to

workpiece

Electrodes sputter and stick

1. Inconsistent travel speed

2. Output amperage setting

incorrect

1. Travel speed too fast

2. Arc length too short

3. Output amperage setting too

high

1. Inconsistent travel speed

2. Output amperage setting too

low

3. Electrode diameter too large

1. Arc length short

2. Amperage setting low

Damp electrodes

Troubleshooting Chart - Welds

Symptom Possible Cause(s) Corrective Action

1. Carefully watch and control the width of the molten weld

bead

2. Adjust output amperage setting or change to smaller

diameter electrode

1. Watch orange molten weld puddle and control bead width

2. Practice running electrode across workpiece with welder

OFF

3. Reduce output amperage setting

1. Decrease and maintain constant travel speed

2. Increase output amperage setting or change to smaller

diameter electrode

3. Recommend either 1/16” or 5/64” diameter electrodes

1. Lift electrode to correct arc length as soon as arc is struck

2. Increase amperage setting or change to smaller diameter

electrode

Use dry electrodes and store in dry location

Arc Welder

Page 9

9

Limited Warranty

This Mastercraft product carries a three (3) year replacement warranty against defects in workmanship and materials.

Mastercraft Canada agrees to replace the defective product free of charge within the stated warranty period, when returned

by the original purchaser with proof of purchase. This product is not guaranteed against wear or breakage due to misuse

and/or abuse. Accessories carry a one (1) year warranty against defects in workmanship and materials.

WS0973, 58-8023-2

Page 10

10

For Replacement Parts, call 1-866-220-2097

Please provide following information:

- Model number

- Serial number (if any)

- Part description and number as

shown in parts list

2

1

Arc Welder

1 Electrode holder assembly – cord not included WC200000AV 1

2 Work clamperage – cord not included WC100000AV 1

3 Safety decal (not shown) DK687500AV 1

4 Chipping hammer/brush (not shown) WC803000AV 1

5 Hand shield (not shown) WC801700AV 1

6 Hand shield lens (not shown) WC801100AV 1

7 Welding electrodes (not shown)

1/16” E6013 (8 oz. tube) WE103501AV +

5/64” E6013 (8 oz. tube) WE103001AV +

1/16” E7014 (8 oz. tube) WE105501AV +

5/64” E7014 (8 oz. tube) WE105001AV +

1/16” Autostrike (5 oz. tube) WE110001AV +

8 Welding helmet (not shown)

2” x 4 1/4” Viewing area WT100500AV +

4 1/2” x 5 1/4” Viewing area WT101000AV +

Auto-darkening WT100600AV +

+ Optional accessories (not included with welder)

Ref

No. Description Part Number Qty

Replacement Parts List - WS0973, 58-8023-2

Page 11

11

WS0973, 58-8023-2

Notes

Page 12

12

Arc Welder WS0973, 58-8023-2

Glossary of Welding Terms

AC or Alternating Current - electric

current that reverses direction

periodically. Sixty cycle current travels

in both directions sixty times per

second.

Arc Length - the distance from the end

of the electrode to the point where the

arc makes contact with the work

surface.

Base Metal - the material to be

welded.

Butt Joint - a joint between two

members aligned approximately in the

same plane.

Crater - a pool, or pocket, that is

formed as the arc comes in contact with

the base metal.

DC or Direct Current - electric current

which flows only in one direction. The

polarity (+ or -) determines which

direction the current is flowing.

DC Reverse Polarity - occurs when

the electrode holder is connected to

the positive pole of the welding

machine. Reverse Polarity directs more

heat into melting the electrode rather

then the workpiece. It is used on

thinner material.

DC Straight Polarity - occurs when

the electrode holder is connected to

the negative pole of the welding

machine. With straight polarity more

heat is directed to the workpiece for

better penetration on thicker material.

Electrode - a coated metal wire having

approximately the same composition as

the material being welded.

Fillet Weld - approximately a triangle

in cross-section, joining two surfaces at

right angles to each other in a lap, T or

corner joint.

Flux - the coating on arc-welding rods

and in flux-cored welding wire that is

consumed in the arc to produce a

shielding gas. This gas displaces air and

impurities from around the weld.

Flux Cored Arc Welding (FCAW) also called Gasless, is a welding process

used with a wire-feed welding

machine. The weld wire is tubular with

flux material contained inside for

shielding.

Gas Metal Arc Welding (GMAW) also called MIG, is a welding process

used with a wire feed welding

machine. The wire is solid and an inert

gas is used for shielding.

Gas Tungsten Arc Welding (GTAW) also called TIG, is a welding process

used with welding equipment with a

high frequency generator. The arc is

created between a non-consumable

tungsten electrode and the workpiece.

Filler metal may or may not be used.

Lap Joint - a joint between two

overlapping members in parallel

planes.

Open Circuit Voltage (OCV) - the

voltage between the electrode and the

work clamperageof the welding

machine when no current is flowing

(not welding). The OCV determines

how quickly the arc is struck.

Overlap - occurs when the amperage is

set too low. In this instance, the molten

metal falls from the electrode without

actually fusing into the base metal.

Porosity - gas pockets, or cavities,

formed during weld solidification. They

weaken the weld.

Penetration - the depth into the

workpiece that has been heat effected

by the arc during the welding process.

A good weld achieves 100%

penetration meaning that the entire

thickness of the workpiece has been

heated and resolidified. The heat

effected area should be easily seen on

the opposite side of the weld.

Shielded Metal Arc Welding

(SMAW) - also called Stick, is a welding

process which uses a consumable

electrode to support the arc. Shielding

is achieved by the melting of the flux

coating on the electrode.

Slag - a layer of flux soot that protects

the weld from oxides and other

contaminants while the weld is

solidifying (cooling). Slag should be

removed after weld has cooled.

Spatter - metal particles thrown from

the weld which cool and harden on the

work surface. Spatter can be minimized

by using a spatter resistant spray on the

workpiece before welding.

Tack Weld - weld made to hold parts

in proper alignment until final welds

are made.

Travel Angle - the angle of the

electrode in the line of welding. It

varies from 5º to 45º depending on

welding conditions.

T Joint - made by placing the edge of

one piece of metal on the surface of

the other piece at approximately a 90º

angle.

Undercut - a condition that results

when welding amperage is too high.

The excessive amperage leaves a

groove in the base metal along both

sides of the bead which reduces the

strength of the weld.

Weld Pool or Puddle - a volume of

molten metal in a weld prior to its

solidification as weld metal.

Weld Bead - a narrow layer or layers of

metal deposited on the base metal as

the electrode melts. Weld bead width is

typically twice the diameter of the

electrode.

Work Angle - the angle of the

electrode from horizontal, measured at

right angles to the line of welding.

Page 13

Description

Ce soudeur à arc Mastercraft est conçu

pour un courant résidentiel standard de

115 V. Il est doté d'un contrôle de sortie

pour choisir avec exactitude le bon

courant nécessaire pour diverses

conditions de soudage. Les pièces

internes sont protégées par un

thermostat.

Ce soudeur peut souder de l’acier jusqu’à

3,2 mm (1/8 po) en une passe. La taille

d’électrode recommandée est 1,6 mm

(1/16 po) de diamètre pour un circuit de

15 A, jusqu’à 1,98 mm (5/64 po) de

diamètre pour les circuits de 20 A. Pour

des électrodes de rechange, composer le

1-866-220-2097 pour le centre de service

après-vente autorisé dans votre région.

Déballage

Lors du déballage, l’examiner soignusement pour rechercher toute trace de

dommage susceptible de s’être produit

en cours de transport. Rapporter tout

dommage ou pièces manquantes en

composant le 1-866-220-2097.

Exigences de circuit

Cet équipe- ment requiert un circuit de

115 V unique. Se reporter au tableau

suivant pour le disjoncteur ou la

classification de fusible correcte. Ne pas

faire fonctionner autres appareils,

lampes, ou outils sur ce circuit pendant

l’utilisation de cet équipement. Les

cordons prolongateurs ne sont pas

recommandés. Le non-respect de ces

recommandations peut avoir comme

résultat fusibles sautés et disjoncteurs

déclenchés.

8. Pochette d'entreposage - pour ranger

le marteau/brosse de piquage. Peut

aussi servir pour ranger un tube de

baguettes de soudure.

Généralités sur la

sécurité

Le non-respect de cet avertissement de

danger causera perte de vie ou

blessures graves.

Le non-respect de cet avertissement

peut causer perte de vie ou blessures

graves.

13 Fr

IN972300AV 7/04

Figure 1 - Piéces détachées et commandes du soudeur

Pièces détachées et

commandes

1. Collier de mise à la terre - fixer à

l’objet de travail.

2. Porte-électrode - tient l’électrode.

3. Cordon d’alimentation - brancher dans

une prise de courant de 115 V.

4. Interrupteur - High/Off/Low

(élevé/arrêt/bas).

5. Voyant - le voyant s'active si le

thermostat éteint automatiquement

l'appareil.

6. Crochet de masque de soudage à

main - pour suspendre le masque de

soudage à main pour le ranger et le

transporter.

7. Porte-câbles - pour enrouler les câbles

pendant l'entreposage et le transport.

Guide d’utilisation et des pièces WS0973, 58-8023-2

Poste de

soudage à l’arc

Réglage Disjoncteur ou

de chaleur fusible à retardement

S’il vous plaît lire et conserver ces instructions. Lire attentivement avant de monter, installer, utiliser ou de procéder à l’entretien du produit

décrit. Se protéger ainsi que les autres en observant toutes les instructions de sécurité, sinon, il y a risque de blessure ou dégâts matériels!

Conserver ces instructions comme référence.

Bas 15 A

Élevé 20 A

1

2

3

4

5

6

7

REMARQUE: Gardez votre preuve d'achat datée jusqu’à la fin de la garantie!

Joignez-la à ce manuel ou classez-la dans un dossier pour plus de sécurité.

8

!

ATTENTION

!

DANGER

!

AVERTISSEMENT

Page 14

Généralités sur la

sécurité (suite)

Le non-respect de cet avertissement

d’attention peut causer des blessures

(petites ou moyennes) ou du dommage

matériel.

REMARQUE : Remarque indique de

l’information additionnelle concernant

le produit ou son utilisation.

Toujours avoir un extincteur

d’incendie disponible

pendant le soudage à arc.

Lire et comprendre toutes les

instructions avant de démarrer un

soudeur à l’arc électrique ou de

procéder à son entretien.

Le non-respect des précautions et

instructions de sécurité peut avoir

comme résultat : blessures graves,

perte de vie ou dommage à

l’équipement.

Tout installation, entretien,

réparation et utilisation de cet

équipement doit être effectué par

les personnes qualifiées

conformément aux codes

nationaux, provinciaux et locaux.

L’utilisation incorrecte des

soudeurs à l’arc peut avoir

comme résultat secousse

électrique, blessure et perte de vie!

Suivre toutes les précautions indiquées

dans ce manuel afin de réduire le

risque de secousse électrique.

S’assurer que toutes les pièces

détachées du soudeur à l’arc sont

propres et en bon état avant

d’utiliser le soudeur. S’assurer que

l’isolation sur tous câbles, porteélectrodes et cordons d’alimentation

n’est pas endommagée. Toujours

réparer ou remplacer les pièces

détachées endommagées avant

d’utiliser le soudeur. Toujours garder

les panneaux et couvercles de

soudage en place pendant le

fonctionnement du soudeur.

Toujours porter des vêtements

protecteurs, gants de soudage secs

et chaussures isolantes.

Toujours utiliser le soudeur dans un

endroit propre, sec et bien ventilé.

Ne jamais utiliser un soudeur dans

un endroit humide, trempe,

pluvieux ou mal ventilé.

S’assurer que l’objet sur lequel vous

travaillez est bien fixé et mis à la

terre correctement avant de

commencer votre soudage

électrique à l’arc.

Le câble de soudage roulé devrait

être étendu avant l’utilisation afin

d’éviter la surchauffe et le

dommage à l’isolation.

Ne jamais immerger l’électrode ou le

porte-électrode dans l’eau. Si le

soudeur devient trempe, il est

nécessaire qu’il soit complètement sec

et propre avant l’utilisation!

Toujours mettre l’équipement hors

circuit (off) et le débrancher avant

de le déplacer.

Toujours brancher le conducteur de

travail en premier lieu.

Vérifier que l’objet de travail est mis

à la terre correctement.

Toujours mettre l’équipement de

soudage électrique à l’arc hors

circuit s’il n’est pas en usage et

enlever l’électrode du porteélectrode.

Ne jamais permettre que votre

corps touche l’électrode et le

contact à la terre, ni l’objet de

travail mis à la terre simultanément.

Les conditions et positions de

soudage difficiles peuvent poser des

hasards électriques. Si vous êtes

accroupis, à genoux ou situé à

élévation, s’assurer que toutes les

pièces conductrices sont isolées.

Porter des vêtements protecteurs

convenables et prendre ses

précautions contre les chutes.

Ne jamais essayer d’utiliser cet

équipement aux réglages de

courant ou facteurs d’utilisation

plus élevés que ceux indiqués sur les

étiquettes de l’équipement.

Ne jamais utiliser un soudeur

électrique à l’arc pour dégeler les

tuyaux congelés.

Les étincelles volantes et le

métal chaud peuvent causer

des blessures. La scorie peut

s’échapper pendant le refroidissement des

soudures. Suivre toutes les directives et

précautions indiquées dans ce manuel pour

réduire la possibilité de blessures causées

par les étincelles volantes et le métal

chaud.

Porter un masque de soudure

approuvé par ANSI ou des lunettes

protectrices avec écrans protecteurs de

bords pendant le burinage ou

l’ébarbage des pièces en métal.

Utiliser des protège-tympans pour le

soudage aérien afin d’éviter que la scorie

ou la bavure tombe dans les oreilles.

Le soudage électrique à l’arc

produit de la lumière et de la

chaleur intense ainsi que des

rayons ultraviolets (UV). Cette lumière

intense et ces rayons UV peuvent causer des

blessures aux yeux et à la peau. Prenez

toutes les précautions indiquées dans ce

manuel afin de réduire la possibilité de

blessures aux yeux et à la peau.

Toute personne qui utilise cet

équipement ou qui est présente là où

l’équipement est utilisé doi porter des

vêtements de soudage protecteurs y

compris : masque ou casque de

soudeur ou écran avec lentille filtrante

de classification d’au moins 10,

vêtements incombustibles, gants de

soudeur en cuir et protection

complète pour les pieds.

Ne jamais observer le soudage sans

protection pour les yeux indiqué cidessus. Ne jamais utiliser une lentille

filtrante qui est fendue, cassée, ou

classifiée moins que le numéro 10. Avertir

les personnes présentes de ne pas

observer l’arc.

Le soudage électrique à l’arc

produit des étincelles et chauffe

le métal aux tempéra-tures qui

peuvent causer des brûlures sévères! Utiliser

des gants et vêtements protecteurs pendant

n’importe quel travail de métal. Prenez toutes

les précautions indiquées dans ce manuel afin

de réduire la possibilité de brûlures de peau

ou de vêtements.

14 Fr

Poste de soudage à l’arc

!

ATTENTION

!

AVERTISSEMENT

!

AVERTISSEMENT

!

DANGER

!

AVERTISSEMENT

!

AVERTISSEMENT

!

AVERTISSEMENT

!

AVERTISSEMENT

Page 15

Généralités sur la

sécurité (suite)

S’assurer que toute personne dans

l’endroit de soudage est protégée

contre la chaleur, les étincelles et les

rayons ultraviolets. Utiliser des

écrans de visage additionnels et

écrans coupe-feu là où nécessaire.

Ne jamais toucher les objets de travail

avant qu’ils se refroidissent

complètement.

La chaleur et les étincelles qui

sont produits pendant le

soudage électrique à l’arc et autres

travaux de métal peuvent allumer les

matériaux inflammables et explosifs!

Prenez toutes les précautions indiquées

dans ce manuel afin de réduire la

possibilité de flammes et d’explosions.

Enlever tous les matériaux

inflammables à moins de 35 pieds

(10,7 mètres) de l’arc de soudage. Si

cela n’est pas possible, couvrir les

matériaux inflammables avec des

couvertures incombustibles.

Ne pas utiliser un soudeur

électrique à l’arc dans les endroits

qui contiennent des vapeurs

inflammables ou explosives.

Prenez toutes les précautions pour

s’assurer que les étincelles volantes

et la chaleur ne produisent pas de

flammes dans des endroits cachés,

fentes, a l’arrière des cloisons, etc.

Risque d’incendie! Ne pas

souder les récipients ni les

tuyaux qui contiennent ou ont

contenu des matériaux inflammables

ou combustibles gazeux ou liquides.

Le soudage à l’arc des

cylindres ou récipients fermés

tels que les réservoirs ou

bidons peuvent causer une explosion

s’ils ne sont pas bien ventilés! Vérifier

qu’il y a un trou de ventilation

suffisant dans n’importe quel cylindre

ou récipient pour permettre la

ventilation des gaz en expansion.

Ne pas inspirer les vapeurs

qui sont produites par le

soudage à l’arc. Ces vapeurs

sont dangereuses. Utiliser un

respirateur si l’endroit de soudage

n’est pas bien ventilé.

Garder la tête et le visage hors des

vapeurs de soudage.

Ne pas exécuter le soudage

électrique à l’arc sur les métaux qui

sont galvanisés ou plaqués en

cadmium, ou qui contiennent zinc,

mercure, ou beryllium sans suivre

les précautions suivantes :

a. Enlever l’enduit du métal

commun.

b. S’assurer que l’endroit de

soudage est bien ventilé.

c. Utiliser le respirateur à air fourni.

Des vapeurs extrèmement toxiques

sont produites pendant le

chauffage de ces métaux.

Le mperageélectromagnétique

qui est produit pendant le

soudage à l’arc peut causer de

l’interférence avec le fonctionnement de

plusieurs appareils électriques tels que

les pacemakers cardiaques. Toute

personne qui utilise ces appareils doit

consulter son médecin avant d’exécuter

le soudage électrique à l’arc.

Router l’électrode et les câbles

ensemble et les fixer avec du ruban

adhésif là où possible.

Ne jamais envelopper les câbles de

soudage à l’arc autour de votre

corps.

Toujours situer l’électrode et les

conducteurs de terre afin qu’ils

soient sur le même côté de votre

corps.

L’exposition aux champerage

électromagnétiques peut avoir

d’autres réactions inconnues

concernant la santé.

Toujours s’assu-rer que l’endroit de

soudage est en état sûr et sans risque

(étincelles, flammes, métal chauffé au

rouge ou scorie) avant de partir.

S’assurer que l’équipement est hors

circuit et que l’électrode est enlevée.

S’assurer que les câbles soient roulés

(sans serrer) et hors du chemin.

S’assurer que tout métal et scorie sont

refroidis.

NORMES DE SÉCURITÉ ADDITIONNELLES

Norme ANSI Z49.1 de l’American

Welding Society, 550 N.W. LeJune Rd.

Miami, FL 33126

Code for Safety in Welding and

Cutting (Code de sécurité pour le

soudage et le coupage)

Norme CSA W117.2, de la Canadian

Standards Association, Standards Sales,

178 Rexdale Boulevard, Rexdale,

Ontario, Canada M9W 1R3

Safe Practices For Occupational

And Educational Eye And Face

Protection (Règlements

professionnels et d’éducation de

sécurité pour la protection des

yeux et du visage)

Norme ANSI Z87.1, de l’American

National Standards Institute, 1430

Broadway, New York, NY 10018

Se reporter aux Material Safety Data

Sheets (fiches signalétiques) et aux

instructions du fabricant pour métaux,

électrodes, enduits et produits pour le

nettoyage.

Installation

ENDROIT

La sélection d’un bon endroit peut

augmenter rendement, sûreté de

fonctionnement et vie du soudeur à

arc.

Pour un meilleur résultat, situer le

soudeur dans un endroit propre et

sec. La poussière et la saleté dans le

soudeur conservent l’humidité et

augmentent l’usure des pièces

mobiles.

Entreposer les électrodes dans un

endroit propre et sec avec humidité

basse pour conserver le fini du flux.

Le récipient utilisé pour le soudeur

doit être mis à la terre correctement

et le soudeur doit être le seul

appareil de charge sur le circuit. Se

reporter au tableau d’intensité de

circuit à la page 1 pour la capacité

correcte du circuit.

L’usage d’un cordon prolongateur

n’est pas recommandé pour les

15 Fr

WS0973, 58-8023-2

!

AVERTISSEMENT

!

AVERTISSEMENT

!

AVERTISSEMENT

!

AVERTISSEMENT

!

AVERTISSEMENT

!

AVERTISSEMENT

Page 16

REMARQUE : Si vous n’avez jamais

utilisé un soudeur ou si vous avez peu

d’expérience, il est recommandé que

vous utilisiez un masque qui couvre

complètement votre visage. Les deux

mains sont nécessaires pour stabiliser et

contrôler l’angle et la longeur de l’arc

de l’électrode.

Fonctionnement

1. Lire, comprendre et

suivre toutes les

précautions dans la

section Généralités sur

la sécurité de ce

manuel. Lire la section Directives de

soudage dans ce manuel avant

d’utiliser l’équipement.

2. Couper la puissance au soudeur et le

brancher dans la prise approprié :

115 V 15 A - Bas

115 V 20 A - Élevé

3. Vérifier que les surfaces du métal

sont libres de saleté, rouille,

peinture, huile, écailles ou autres

polluants avant de les souder

ensemble. Ces polluants peuvent

causer de mauvaises soudures.

Toutes les personnes utilisant cet

équipement ou près de l'équipement en

marche doivent porter une protection

pour la soudure y compris une protection

oculaire avec lentille ombre teinte 10 au

moins, des vêtements ignifuges, des

gants de soudure de cuir et une

protection complète pour les pieds.

Pour le chauffage, soudage

ou coupage des matériaux

galvanisés, plaqué en zinc,

plomb, ou en cadmium, se reporter à la

Installation (suite)

soudeurs électriques à l’arc. La perte

de tension dans le cordon

prolongateur peut réduire le

rendement du soudeur.

Montage

MASQUE À MAIN

1. Éloigner la poignée amovible du

masque. Couper l’excès de plastique

pour enlever les bords tranchants.

2. Introduire la lentille filtrante.

3. Pour fixer le manche, placer le

masque à main sur une surface

nivelée et appuyer sur le manche

jusqu’à ce qu’il soit en place (voir

figure 5).

16 Fr

Poste de soudage à l’arc

section Généralités sur la sécurité pour

plus d’information. Les vapeurs

extrêmement toxiques sont produites

pendant le chauffage de ces métaux.

4. Raccorder la pince de soudeur à

l’objet de travail. S’assurer que le

contact est au métal nu, non pollué

par la peinture, le vernis, la

corrosion ou autres matériaux non

métalliques.

5. Loger la pièce exposée de

l’électrode (le bout sans flux) dans

les mâchoires du porte-électrode.

Le porte-électrode et l’éctrode sont

maintenant “chauds” (courant actif)

quand le soudeur est en marche.

La mise à la terre contre n’importe

quelle surface métallique peut produire

un arc qui peut causer des étincelles et

endommager les yeux.

6. Tenir l'électrode loin de l'établi et

de la pièce de travail mise à la terre.

Mettre le soudeur à Élevé ou Bas. Se

reporter au tableau suivant pour le

réglage de sortie approprié.

7. Tenir l’électrode en position de

soudage, baisser le casque de

soudeur ou mettre le masque à

main en position et amorcer un

arc. Ajuster le réglage de sortie au

besoin.

8. Mettre le soudeur hors circuit et

l’entreposer correctement lorsque

vous avez fini de souder.

FACTEUR D’UTILISATION /

PROTECTION THERMOSTATIQUE

Le facteur d’utilisation de soudage est le

pourcentage du temps de soudage actuel

qui peut se passer dans un intervalle de dix

minutes. Par exemple, le soudage actuel

peut se produire pour une minute à un

facteur d’utilisation de 10 %, et ensuite, le

soudeur doit se refroidir pour neuf minutes.

Les pièces détachées internes de ce soudeur

Figure 2

Figure 3

Figure 4

Figure 5

Diamètre Réglage

d’électrode de sortie

1/16 po (1,6 mm) Bas

5/64 po (2 mm) Élevé

!

AVERTISSEMENT

!

AVERTISSEMENT

MANUEL

!

AVERTISSEMENT

!

AVERTISSEMENT

Page 17

Fonctionnement

(suite)

sont protégées contre la surchauffe avec un

interrupteur automatique thermique. Un

voyant jaune s'allume sur le panneau

avant si le cycle de service est dépassé.

Continuer avec le soudage quand la lampe

n’est pas allumée.

Entretien

Débrancher et mettre la machine hors

circuit avant de vérifier ou de

procéder à l’entretien de n’importe

quelle pièce détachée

Avant chaque usage :

1. Vérifier la condition des câbles de

soudage et réparer ou remplacer

immédiatement les câbles qui ont

de l’isolation endommagée.

mâchoires de la pince doivent être en

contact avec le métal nu propre de la

pièce à travailler pour de bons résultats

de soudure.

Placer le bout nu de l’électrode dans le

porte-électrode. Tenir le porteélectrode légèrement afin de réduire la

fatigue à votre main et bras.

REMARQUE : Toujours tenir les

mâchoires du porte-électrode propres

pour assurer un bon contact électrique

avec l’électrode.

Prendre soin de ne pas toucher l’atelier

de soudage ni l’objet de travail avec

l’électrode. Cela peut causer des

étincelles.

La meilleure méthode d’amorcer un arc

est la méthode d’égratignure. Tirer

l’électrode à un angle le long de la

surface comme vous frotteriez une

allumette pour l’allumer. Lorsque vous

contactez la plaque, soulevez

l’électrode d’environ 1,6 mm (1/16 po)

17 Fr

2. Vérifier la condition du cordon

d’alimentation et le réparer ou

remplacer immédiatement si

endommagée.

3. Vérifier la condition des pièces

isolantes du porte-électrode et

remplacer les isolateurs fendus ou

manquants immédiatement.

S’assurer que toutes les attaches

sont serrées et isolées.

Ne pas utiliser ce soudeur si l’isolation

sur les câbles de soudage, le porteélectrode ou le cordon d’alimentation

est fendue ou manquante.

Chaque 3 mois :

Remplacer toutes étiquettes qui ne

sont pas lisibles sur le soudeur. Utiliser

de l’air comprimé pour souffler toute la

poussière des ouvertures de

ventilation.

Quand le courant (intensité) passe du

circuit à l’électrode, un arc est produit

entre le bout de l’électrode et l’objet de

travail. L’arc fond l’électrode et la pièce

de travail. Le métal fondu de l’électrode

s’écoule dans le cratère fondu et

produit un adhérence à l’objet comme

indiqué dans la figure 6.

REMARQUE : N’utiliser pas et mettre

au rebut les électrodes qui se sont

brûlées 1 à 2 pouces du porte-électrode

AMORÇAGE D’UN ARC

Fixer la pince de travail à la pièce. Les

Généralités

Cet appareil de soudage utilise une

procédure connue sous le nom de

soudage avec électrodes enrobées

(Shielded Metal-Arc Welding SMAW). Ce

procédé est utilisé pour unir des

métaux en les rechauffant d’un arc

électrique crée entre une électrode et

l’objet sur lequel vous travaillez.

Les électrodes utilisées pour le soudage

à l’arc au métal couvert ont deux

pièces. Le centre est une baguette en

métal ou un fil qui devrait être

semblable en composition au métal

commun. L’enrobage extérieur est

appelé le flux. Une variété de flux peut

être utilisée selon la situation.

Une fois fondu, le métal peut devenir

contaminé par les éléments dans l’air.

Cette contamination peut afaiblir la

soudure. L’enrobage de flux crée une

barrière protectrice appelée scorie qui

protège le métal fondu contre les

polluants.

Directives de soudage

Scorie

Soudure

Flux

Objet de

travail

Cratère

Fil

Figure 6 - Composantes de la soudure

WS0973, 58-8023-2

!

AVERTISSEMENT

!

AVERTISSEMENT

!

AVERTISSEMENT

Page 18

l’électrode utilisée et de l’épaisseur de

l’objet de travail.

Des courants excessifs brûlent les

métaux légers et le boudin de soudure

est plat et poreux (voir la figure 9). Le

boudin semble haut et irrégulier si le

courant est trop faible.

ANGLE DE SOUDURE

L’angle de soudure est l’angle de

l’électrode pendant le soudage.

L’utilisation de l’angle correct assure la

pénétration et la formation du cordon

de soudure exigé. L’angle de l’électrode

comprend deux positions - l’angle de

18 Fr

Intensité, longueur de l’arc et vitesse

normaux

Intensité trop basse

Intensité trop élevée

Longueur d’arc trop courte

Longueur d’arc trop longe

Vitesse trop lente

Vitesse trop rapide

Objet de travail

REMARQUE : La largeur du

cordon de soudure (W) devrait

être environ deux fois le

diamètre de la baguette de

l’électrode utilisée.

W

Figure 9 - Apparance de la soudure

de la surface, sinon elle se collera (voir

figure 7).

REMARQUE : Si l’électrode se colle à

l’objet de travail, la dégager en

tortillant rapidement ou en pliant et

levant à l’endroit du porte-électrode. Si

l’électrode ne se dégage pas, la

débrayer en la lâchant du porteélectrode.

TYPE ET TAILLE D’ÉLECTRODE

Deux types d’électrodes sont

recommandés pour l’usage avec ce

soudeur :

1. E-6013 TOUT USAGE

• Pour toutes positions, dépôt lisse et

peu d’éclaboussures

• Pour tous types d’acier doux et pour

les travaux généraux.

2. E-7014 REMPLISSAGE RAPIDE

• Cordon de soudure lisse et dépôt

rapide

• Idéal là où les joints ne se

rencontrent pas parfaitement et

pour les réparations générales.

REMARQUE : E-6011 et E-7018 ne sont

pas recommandés pour l’usage avec ces

soudeurs. Le diamètre d’électrode

recommandé est 1,6 mm (1/16 po) ou

1,98 mm (5/64 po). Composer le

1-866-220-2097 pour leur disponibilité.

Généralités de soudage à

l’arc

Il y a quatre techniques de base qui

agissent sur la qualité de soudure :

réglage de l’intensité, angle de

soudure, longueur de l’arc et vitesse de

déplacement. De bonnes techniques

sont nécessaires pour des soudures de

bonne qualité.

RÉGLAGE D’INTENSITÉ

L’intensité correcte implique l’ajustement

du soudeur au réglage en ampères

requis. Pour ce faire choisir le réglage

approprié (bas ou élevé). L’intensité

dépend de la taille (diamètre) de

Directives de soudage (suite)

Figure 8 Angle de

soudure

5o - 45

o

Angle de déplacement

Angle de travail

Poste de soudage à l’arc

Égal au diamétre de l’électrode

Figure 7 - Méthode d’égratignure

Page 19

PASSES DE SOUDAGE

Quelques fois il est nécessaire d’utiliser

plus d’une passe pour remplir le joint. La

première passe est la passe de base, suivie

par la passe de remplissage et la passe de

finition (voir figure 10). Si les morceaux

sont épais, il peut être nécessaire de

biseauter les bords qui sont joints à un

angle de 60º. Se rappeler d'enlever les

scories entre chaque passe.

Figure 10 - Passes de soudage

Finition

Remplissage

Base

Figure 11 - Passes multiples de

soudage

déplacement et l’angle de travail (voir

figure 8).

L’angle de déplacement est l’angle

situé dans la ligne de la soudure et

peut varier entre 5º à 45º du vertical

selon les conditions de soudage.

L’angle de travail est l’angle de

l’horizontal, mesuré aux angles droits à

la ligne de soudage.

Un angle de travail de 45º et un angle

de déplacement de 45º sont suffisant

pour la plupart des applications. Pour

les usages spécifiques, consulter un

manuel d’enseignement de soudage.

REMARQUE : Les soudeurs droitiers

devraient souder de la gauche à la

droite. Les soudeurs gauchers

devraient souder de la droite à la

gauche. L’électrode devrait toujours

être dirigée vers la flaque de la

soudure comme indiqué.

LONGUEUR DE L’ARC

La longueur de l’arc est la distance de

l’objet de travail jusqu’au bout de

l’électrode; la distance de voyage de

l’arc. Une longueur d’arc correcte est

nécessaire pour la production de la

chaleur exigée pour le soudage (voir

figure 9). Un arc qui est trop long

produit un arc instable, réduit la

pénétration, augmente l’éclaboussage

et produit des cordons de soudure

plats et larges. Un arc trop court ne

produit pas assez de chaleur pour

fondre l’objet de travail, l’électrode se

colle facilement, la pénétration n’est

pas suffisante et les cordons de

soudure sont inégaux avec des

ondulations irrégulières. L’arc ne

devrait pas être plus large que le

diamètre de la baguette de l’électrode et

son bruit devrait être un grésillement

constant comme le grésillement du bacon.

VITESSE DE DÉPLACEMENT

La vitesse de déplacement indique la

vitesse que l’électrode est dirigée au

long de la surface de soudage (voir

figure 9). Si la vitesse est trop rapide, le

cordon est étroit et les ondulations du

cordon sont pointues comme indiqué.

Si la vitesse est trop lente, la soudure se

tasse et le cordon est haut et large.

Pour régler la vitesse de déplacement,

observer la largeur du cordon de

soudure (et non l’arc) pendant la

soudure. Le cordon de soudure est le

métal fondu orange derrière l’arc. Il

devrait être deux fois le diamètre de la

baguette d’électrode. Régler la vitesse de

déplacement afin d’obtenir un cordon de

largeur uniforme.

ENLEVAGE DE SCORIE

Porter des lunettes protectrices

approuvées ANSI (ANSI Standard Z87.1)

et des vêtements protecteurs pendant

l’enlevage de la scorie chaude. Le débris

chaud et volant peut causer des blessures

aux personnes présentes.

Après avoir complété la soudure,

attendre que les sections de soudage se

refroidissent. Une couche protectrice

appelée scorie couvre le cordon de

soudure qui empêche la réaction du

métal fondu avec les polluants dans l’air.

La scorie peut être enlevée une fois que

la soudure s’est refroidie jusqu’à ce

qu’elle ne soit plus rouge. Enlever la

scorie avec un marteau à buriner. Frapper

la scorie légèrement avec le marteau et la

dégager du cordon de soudure. Finir avec

une brosse métallique. Pour plusieurs

passes de soudure, retirer les scories

entre chaque passe.

POSITIONS DE SOUDAGE

Il y a quatre positions générales de

soudage : plate, horizontale, verticale et

aérienne. Le soudage dans une position

plate est le plus facile car la vitesse peut

être augmentée, le métal fondu coule

moins, une meilleure pénétration est

possible et le travail est moins fatiguant.

D’autres positions exigent d’autres

techniques teles que tissage, passe

circulaire et jogging. Un niveau élevé

de compétence est exigé pour ces

soudures.

Tout travail devrait être effectué dans

la position plate, si possible. Pour des

applications particulières, consulter un

guide de soudure à l’arc.

Directives de soudage (suite)

19 Fr

WS0973, 58-8023-2

!

AVERTISSEMENT

Page 20

Le cordon de soudure est

trop mince ou trop épais

par intervalles.

Enfoncements en lambeaux

au bord de la soudure.

Le cordon de soudure ne

pénètre pas l’objet de

travail.

L’électrode se colle à

l’objet de travail.

Les électrodes crachent et

se collent.

1. Vitesse de déplacement

irrégulière

2. Réglage incorrect d’intensité de

sortie

1. Vitesse de déplacement trop

rapide

2. L’arc est trop court.

3. Réglage de l’intensité de sortie

trop haut

1.Vitesse de déplacement

irrégulière

2. Réglage de l’intensité de sortie

trop bas

3. Diamètre d’électrode trop large

1. Arc trop court

2. Intensité trop basse

Électrodes humides

1. Observer avec attention et contrôler la largeur du

cordon de soudure.

2. Régler l’intensité de sortie ou utiliser une électrode

ayant un diamètre plus petit.

1. Observer le dépôt de soudure en fusion orange et

contrôler la largeur du cordon de soudure.

2. Se pratiquer en passant l’électrode sur l’objet de travail

lorsque le soudeur est hors circuit (OFF).

3. Réduire le réglage de l’intensité de sortie.

1. Diminuer et conserver une vitesse de déplacement

constante.

2. Augmenter le réglage d’intensité de sortie ou changer à

une électrode de diamètre plus petit.

3. Électrodes recommandées d'un diamètre de 1/16 po ou

5/64 po.

1. Soulever l’électrode pour corriger la longueur de l’arc

aussitôt que l’arc se colle.

2. Augmenter le réglage d’intensité ou changer à une

électrode de diamètre plus petit.

Utiliser des électrodes sèches et les entreposer dans un

endroit sec.

1. Manque de puissance à la prise

de courant

2. Cordon d’alimentation

endommagé

1. Courant insuffisant à l’électrode

2. Mauvais raccordements au

soudeur

1. Contact accidentel avec l’objet

de travail

2. Perte de courant causé par les

vêtements ou endroit de travail

humides

1. Utilisation d’un cordon

prolongateur

2. Diamètre d’électrode trop large

3. Circuit surchargé

1. Électrode incorrecte

2. Diamètre d’électrode trop large

3. Objet de travail pas mis à la

terre correctement

4. Basse tension causée par la

surcharge

1. Vérifier le fusible de circuit ou le disjoncteur.

2. Faire réparer le cordon d’alimentation.

1. Vérifier le collier de mise à la terre, le câble et son

raccordement à l’objet de travail. Vérifier le câble

d’électrode et le collier.

2. Vérifier tous les raccordements externes du soudeur.

1. Éviter le contact avec l’objet de travail.

2. S’assurer que vos vêtements et l’endroit de travail sont

secs.

1. Déplacer le soudeur si possible afin d’éviter l’usage d’un

cordon prolongateur, sinon, utiliser un cordon

prolongateur plus épais (nº de calibre plus bas).

2. Utiliser une électrode de diamètre plus petit.

3. Le soudeur requiert un circuit unique de 115 V.

1. Vérifier que l’électrode est fabriquée pour l’usage avec

un courant alternatif (c.a.).

2. Utiliser une électrode de diamètre plus petit.

3. Vérifier la mise à la terre correcte (pas de peinture,

vernis ou corrosion).

4. Faire fonctionner le soudeur sur un circuit unique de

115 V.

Le soudeur ne ronronne

pas quand il est mis en

marche.

Le soudeur ronronne, mais

ne soude pas.

Le soudeur donne des

chocs à goutte.

Le soudeur surchauffe fait sauter les fusibles,

déclenche le disjoncteur.

Arc difficile à amorcer.

20 Fr

Guide de dépannage - soudeur

Symptôme Cause(s) possible(s) Mesures correctives

Pour plus d’informations, composer 1-866-220-2097

Guide de dépannage - soudures

Symptôme Cause(s) possible(s) Mesures correctives

Poste de soudage à l’arc

Page 21

21 Fr

WS0973, 58-8023-2

Garantie Limitée

Cet article Mastercraft comporte une garantie de remplacement de trois (3) ans contre les défauts de fabrication et de

matériau(x). Mastercraft Canada consent à remplacer l'article défectueux sans frais lorsqu'il est retourné, accompagné de la

preuve d'achat, par l'acquéreur initial. Exclusion : usure ou bris causés par un usage abusif ou inapproprié. Les accessoires

sont garanties pour un (1) an contre les défauts de fabrication et de matériau(x).

Page 22

2

1

Pour pièces de rechange, composer 1-866-220-2097

S’il vous plaît fournir l’information

suivante :

- Numéro de modèle

- Numéro de série (si applicable)

- Numéro et description de la pièce

22 Fr

Poste de soudage à l’arc

1 Montage de porte-électrode – cordon non compris WC200000AV 1

2 Pince de soudeur – cordon non compris WC100000AV 1

3 Décalcomanie de sécurité (non illustré) DK687500AV 1

4 Marteau/brosse de piquage (non illustré) WC803000AV 1

5 Masque de soudage à main (non illustré) WC801700AV 1

6 Lentille de masque de soudage à main (non illustré) WC801100AV 1

7 Électrodes de soudure (non illustré)

1/16 po E6013 (tube de 8 oz) WE103501AV +

5/64 po E6013 (tube de 8 oz) WE103001AV +

1/16 po E7014 (tube de 8 oz) WE105501AV +

5/64 po E7014 (tube de 8 oz) WE105001AV +

1/16 po autoamorçage (tube de 5 oz) WE110001AV +

8 Casque de soudure (non illustré)

2 po x 4 1/4 po, zone d'observation WT100500AV +

4 1/2 po x 5 1/4 po, zone d'observation WT101000AV +

Auto noircissement WT100600AV +

+ Accessoires optionnels (non inclus avec le soudeur)

Nº de

réf. Description Nº de pièce Qté

Liste de pièces de rechange - WS0973, 58-8023-2

Page 23

WS0973, 58-8023-2

23 Fr

Notes

Page 24

24 Fr

c.a. ou courant alternatif - courant

électrique qui change de direction

périodiquement. Le courant à soixante

cycles voyage dans les deux directions

soixante fois par seconde.

Longueur de l’arc - la distance du

bout de l’électrode jusqu’au point où

l’arc contacte la surface de travail.

Métal commun - le matériau qui doit

être soudé.

Joint en bout - un joint entre deux

pièces qui sont alignées

approximativement dans le même plan.

Cratère - une flaque ou poche qui est

produite quand l’arc contacte le métal

commun.

c.c. ou courant continu - courant

électrique d’une direction seulement.

La polarité (+ ou -) détermine la

direction du courant.

Polarité inversée (c.c.) - quand le

porte-électrode est branché au pôle

positif du soudeur. La polarité inversée

dirige plus de chaleur dans l’électrode

plutôt que sur l’objet de travail pour

l’utilisation sur les matériaux plus

minces.

Polarité ordinaire (c.c.) - quand le

porte-électrode est branché au pôle

négatif du soudeur. Plus de chaleur est

dirigée vers l’objet de travail pour une

meilleure pénétration des matériaux

épais.

Électrode - un fil en métal enrobé

ayant approximativement la même

composition que le matériau qui doit

être soudé.

Soudure en cordon - dimension

approx. d’un triangle, profil en travers,

qui uni les deux surfaces à angles droits

en soudure à recouvrement, en T ou en

coin.

Flux - l’enduit sur les électrodes de

soudage à l’arc et sur le fil de soudage

fourré en flux qui est consommé dans

l’arc afin de produire un gaz

protecteur. Ce gaz déplace l’air et les

polluants autour de la soudure et sert à

protéger la soudure.

Soudure à l’arc fourré de flux

(FCAW) - ou sans-gaz est une méthode

de soudage utilisée avec un soudeur à

alimentation en fil. Le fil de soudage

est tubulaire avec du flux à l’intérieur

pour protection.

Soudure à l’arc MIG (GMAW) - est

une méthode utilisée avec un soudeur à

alimentation en fil. Le fil est solide et

un gaz inerte est utilisé pour

protection.

Soudure à l’arc tungstène au

chalumeau (TIG) (GTAW) - est une

méthode de soudage utilisée avec de

l’équipement de soudage qui a une

génératrice à haute fréquence. L’arc est

crée entre une électrode tungstène

non-usable et l’objet de travail. Un

bouche-pores peut être utilisé.

Soudure à recouvrement - un joint

entre deux pièces en chevauchement.

Tension au repos (OCV) - la tension

entre l’électrode et le collier de mise à

la terre quand il n’y a pas de flux de

courant (pas de soudage). Cela

détermine la vitesse à la quelle l’arc est

amorçé.

Chevauchement - se produit quand le

réglage d’intensité est trops bas. En ce

cas, le métal fondu tombe de

l’électrode sans se fondre dans le métal

commun.

Porosité - des soufflures ou creux

formés pendant la solidification de la

soudure qui affaiblissent la soudure.

Pénétration - la profondeur d’entrée

de la chaleur pendant la soudure. Une

soudure de haute qualité est celle qui

atteint 100 % de pénétration. C’est à

dire que l’objet de travail en entier a

été chauffé et solidifié à nouveau. Les

endroits affectés par la chaleur

devraient être visibles sur l’endos de la

soudure.

Soudure à l’arc au métal enrobé

(SMAW) - est une méthode de soudage

qui utilise une électrode usable pour

soutenir un arc. L’enduit de flux fondu

sur l’électrode fournit la protection.

Scorie - une couche d’encrassement de

flux qui protège la soudure des oxydes

et autres polluants pendant le

refroidissement de la soudure. Enlever

la scorie après que la soudure s’est

refroidie.

Bavure - particules métalliques

volantes qui se refroidissent sur la

surface de travail. La bavure peut être

diminuée si vous utilisez un agent