Page 1

Multi-attachment Rotary Tool System

54-4790-6

Owner’s Manual

Imported by Trileaf Distribution Trifeuil Toronto, Canada M4S 2B8

SPECIFICATIONS

Motor:

Permanent magnet, 120 V AC, 60 Hz, 2 A

Variable speeds:

5,000 to 35,000 RPM (no load)

Collets:

1/8, 3/32, 1/16" (3, 2.5, 1.5 mm)

Weight:

1 lb 12 oz (780 g)

TOLL FREE HELPLINE 1-800-689-9928

Page 2

2

Specifications ………….…………………………………………………………………..

1

Table of contents …………………………………………………………………….……

2

Safety warnings …………………………………………………………………………...

3–4

Eye, ear, and lung protection ……………………………………………………. ……..

3–4

Electrical safety ……………………………………………………………….. …………

4

Power tool safety ……………………………………………………………………….…

5–6

General safety rules …………………………………………………………... ………..

5

Work area ………………………………………………………………….…... …………

5

Electrical safety ……………………………………………………………….. …………

5

Personal safety ……………………………………………………………….. ………….

5–6

Use and care of power tools……………………………………………………………..

6

Service …………………………………………………………………………… ……….

6

Specific safety rules ………………………………………………………………………

7

Extension cord safety ……………………………………………………………….……

8

Symbols ……………………………………………………………………………………

9

Diagram and location of parts …………………………………………………………...

10–11

Accessories and Contents …………………………………………………………….. ..

12

Accessories ……………………………………………………………………………….

12

Contents ……………………………………………………………………………………

12–13

Contents of the accessory kit ……………………………………………………………

14–16

Description and use of the accessory kit……………………………………………….

16–17

Assembly and Operating instructions …………………………………………………..

18–35

Changing the collet ……………………………………………………….….…………...

18

Installing accessories …………………………………………………………. ………...

18–19

Connecting the flexible shaft to the tool …………………………………….. ………...

19–20

Changing the collet and accessories in the flexible shaft ……………….…... ………

20

Assembling the rotary tool stand ………………………………………………. ………

21

Installing the right angle attachment ………………………………………… ………...

22–23

Installing the angle guide and the vacuum adapter ………………………………. ….

23–24

Installing the sander attachment …………………………………………….. …………

24–25

Installing sandpaper …………………………………………………………... ………...

26

Installing the pad onto the sander ………………………………………………………

26–27

Sanding wood ……………………………………………………………………………..

27

Sanding tips ……………………………………………………………………………….

27–28

Installing the mini circular saw attachment …………………………………………….

28–29

Installing a saw blade …………………………………………………….….…………...

30

Cutting wood ………………………………………………………………….…………...

31–32

Assembling the LED worklight …………………………………………………………..

32

Selecting the proper speed…………………………….…………………………………

33

Digital motor control ………………………………………………………….…………...

34

ON/OFF switch ……………………………………………………………….…………...

34

Adjusting the speed ………………………………………………………………………

34–35

Speed memory ……………………………………………….…………………………...

35

Maintenance ……………………………………………………………………………….

36

Exploded view ……………………………………………………………………………..

37

Parts list ……………………………………………………………………………………

38

Warranty ……………………………………………………………………….…………..

39

TABLE OF CONTENTS

Page 3

3

EYE, EAR, AND LUNG PROTECTION

This Owner's Manual contains the following information:

General Safety Rules

Specific Safety Rules and Symbols

Functional Description

Assembly Instructions

Operating Instructions

Maintenance

Accessories

!

WEAR EYE PROTECTION THAT CONFORMS WITH CSA

REQUIREMENTS or ANSI SAFETY STANDARD Z87.1

FLYING DEBRIS can cause permanent eye damage. Prescription

eyeglasses ARE NOT a replacement for proper eye protection.

WARNING: Non-compliant eyewear can cause serious injury if

it breaks while the wearer is operating a power tool.

KEEP THIS OWNER'S MANUAL IN A SAFE PLACE FOR FUTURE REFERENCE

WARNING: Use hearing protection, especially when operating the tool

for an extended period and when performing a noisy operation.

!

SAFETY WARNINGS

CAUTION: Read this Owner's Manual carefully before using this tool or

any of its accessories, and follow all Safety Rules and Operating

instructions.

!

Page 4

4

ELECTRICAL SAFETY

WARNING: Use proper circuit protection in order to avoid electrical

hazards, fire hazards, or damage to the rotary tool.

This rotary tool is wired at the factory for 110–120 V operation. It must be

connected to a 110–120 V 15 A time-delayed fuse or circuit breaker. In order

to avoid shock or fire, replace the power cord immediately if it is worn, cut, or

damaged in any way.

WEAR A DUST MASK THAT IS DESIGNED TO BE USED WHEN

OPERATING A POWER TOOL IN A DUSTY ENVIRONMENT.

WARNING: Dust that is created by power sanding, sawing, grinding,

drilling, and other construction activities may contain chemicals that are

known to cause cancer, birth defects. or other genetic abnormalities. These

chemicals include:

Lead from lead-based paints

Crystalline silica from bricks, cement, and other masonry products

Arsenic and chromium from chemically-treated lumber

The level of risk from exposure to these chemicals varies according to how

often this type of work is performed. In order to reduce exposure to these

chemicals, work in a well-ventilated area, and use approved safety

equipment, such as a dust mask that is specifically designed to filter out

microscopic particles.

!

SAFETY WARNINGS

Page 5

5

GENERAL SAFETY RULES

WARNING: Read all instructions

carefully and understand them

completely. Failure to follow all of the

instructions listed below may result in

electric shock, fire, and/or serious personal

injury.

WORK AREA

Keep the work area clean and well lit.

Cluttered benches and dark areas invite

accidents.

Do not operate a power tool in a potentially

explosive environment, such as in the

presence of flammable liquids, gas, or

dust. Power tools create sparks that may

ignite the dust or fumes.

Keep bystanders, children, and visitors

away while operating a power tool.

Distractions can cause the operator to lose

control.

ELECTRICAL SAFETY

Double insulated tools are equipped with a

polarized plug (one blade is wider than the

other). This plug will only fit into a

polarized outlet one way.

If the plug does not fit into the outlet

properly, reverse the plug. If it still does not

fit, contact a qualified electrician in order to

install a polarized outlet. Do not alter the

plug in any way. Double insulation

eliminates the need for the three-pronged

grounded power cord and grounded power

supply system.

Avoid contact between the operator's body

and grounded surfaces such as pipes,

radiators, ranges, and refrigerators. There

is an increased risk of electric shock if the

operator's body is grounded.

Do not expose power tools to rain or wet

conditions. Water entering the power tool

will increase the risk of electric shock.

Do not abuse the cord. Do not use the

power cord to carry the tool or to pull the

plug out of the outlet. Keep the power cord

away from heat, oil, sharp edges, and

moving parts. Replace a damaged power

cord immediately. A damaged power cord

increases the risk of electric shock.

When operating a power tool outdoors,

use an outdoor extension cord that is

marked “W-A” or “W”. These cords are

rated for outdoor use, and they reduce the

risk of electric shock.

PERSONAL SAFETY

Stay alert, be aware of the surroundings,

and use common sense when operating a

power tool. Do not use a power tool while

tired or under the influence of drugs,

alcohol, or medication. A moment of

inattention while operating a power tool

could result in serious personal injury.

Dress properly. Do not wear loose clothing

or jewellery.

Contain long hair. Keep hair, clothing, and

gloves away from moving parts. Loose

clothing, jewellery, or long hair can get

caught in moving parts.

!

POWER TOOL SAFETY

Page 6

6

PERSONAL SAFETY – cont’d

Avoid accidental start-ups. Verify that the

switch is in the OFF position before

plugging the tool in. Carrying a power tool

with a finger on the switch or plugging in a

tool that has the switch in the ON position

invites accidents.

Remove adjusting keys and wrenches

before turning the tool ON. A wrench or

key that is left attached to a rotating part of

the tool may result in personal injury.

Do not overreach. Keep proper footing and

balance at all times. Proper footing and

balance allows the operator to maintain

better control of the tool in unexpected

situations.

Use safety equipment. Always wear eye

protection.

Use a dust mask, non-skid safety shoes, a

hardhat, or hearing protection when

appropriate.

USE AND CARE OF POWER TOOLS

Use clamps or another practical means to

secure and support the workpiece to a

stable platform. Holding the work in a hand

or against the body is not stable, and may

lead to loss of control.

Do not force the tool. Use the correct tool

for the application. The correct tool will do

the job better and safer when it is used at

the rate that it was designed to work at.

Do not use a power tool if it cannot be

turned ON or OFF using the power switch.

A tool that cannot be controlled using the

switch is dangerous, and must be repaired.

Disconnect the plug from the outlet before

making any adjustments, changing

accessories, or storing the tool. Such

preventive safety measures reduce the risk

of accidental start-ups.

When power tools are not in use, store

them out of the reach of children and other

untrained persons. Tools are dangerous in

the hands of untrained users.

Maintain tools with care. Keep cutting tools

sharp and clean. Properly maintained

cutting tools with sharp cutting edges are

less likely to bind, and are easier to

control.

Inspect the tool for misalignment or binding

of moving parts, broken parts, and any

other condition that may affect the

operation of the tool. If it is damaged, have

the tool serviced before using it. Many

accidents are caused by poorly maintained

tools.

Use only accessories that are

recommended by the manufacturer for this

model. Accessories that are suitable for

one tool may become hazardous when

used with another tool.

SERVICE

Tools must be serviced by qualified

personnel. Service or maintenance

performed by non-qualified personnel

could result in a risk of injury.

When servicing a tool, use only identical

replacement parts. Follow the instructions

in the Maintenance section of this Manual.

The use of unauthorized parts, or failure to

follow the instructions in the Maintenance

section of this Manual may create a risk of

electric shock or injury.

POWER TOOL SAFETY

Page 7

7

WARNING: For safety reasons,

read this Owner's Manual carefully and

understand it thoroughly before

plugging in the rotary tool.

Hold the tool by the insulated gripping

surfaces when performing any operation

where the cutting tool may coming into

contact with hidden wiring or its own power

cord. Contact with a “live” wire will make

the exposed metal parts of the tool “live”,

which could shock the operator.

Verify that the work surface is free of nails

and other foreign objects. Cutting into a

nail may cause the bit and the tool to jump,

and could damage the bit.

Do not hold the workpiece in one hand and

the tool in the other hand while using the

tool. Do not place the hands near or below

the cutting surface. It is much safer to

clamp the material and to guide the tool

using both hands.

Do not lay the workpiece on a hard surface

such as concrete, stone, etc. The

protruding cutting bit may cause the tool to

jump.

Wear safety goggles and a dust mask.

Work only in a well-ventilated area. Using

personal safety devices and working in a

safe environment reduces the risk of injury.

Verify that the collet nut and all other

adjustment devices are securely tightened

after changing bits and accessories or

making adjustments. Loose adjustment

devices may be thrown violently when the

tool is turned ON.

Be sure to use the correct collet size. If the

collet size is larger than the accessory's

shank, it will not grip the shank properly,

which could result in injury to the operator

or damage to the tool.

Inspect accessory bits, grinding stones,

cut-off wheels, etc. for damage before

each use. A damaged accessory can

break during use, which could cause

serious injury.

Do not use dull or damaged bits. Handle

sharp bits with care. A damaged bit can

snap during use. A dull bit requires more

force in order to push the tool, which could

cause the bit to break.

Do not touch the bit during or immediately

after use. After use, the bit is hot enough

to burn bare skin.

Do not operate the flexible shaft with a

bend radius of less that 6” (15.2 cm). A

shorter bend radius will damage the

flexible shaft and the motor of the rotary

tool.

SPECIFIC SAFETY RULES

!

Page 8

8

WARNING: Keep the extension

cord clear of the work area. Position the

cord so that it will not get caught on the

workpiece, a tool, or any other obstruction

while the power tool is in use.

If an extension cord is used with this rotary

tool, verify that it is in good condition.

When using an extension cord, be sure to

use one that is heavy enough to carry the

current that the tool will draw. An

undersized cord will cause a drop in line

voltage, which will result in a loss of power

and overheating.

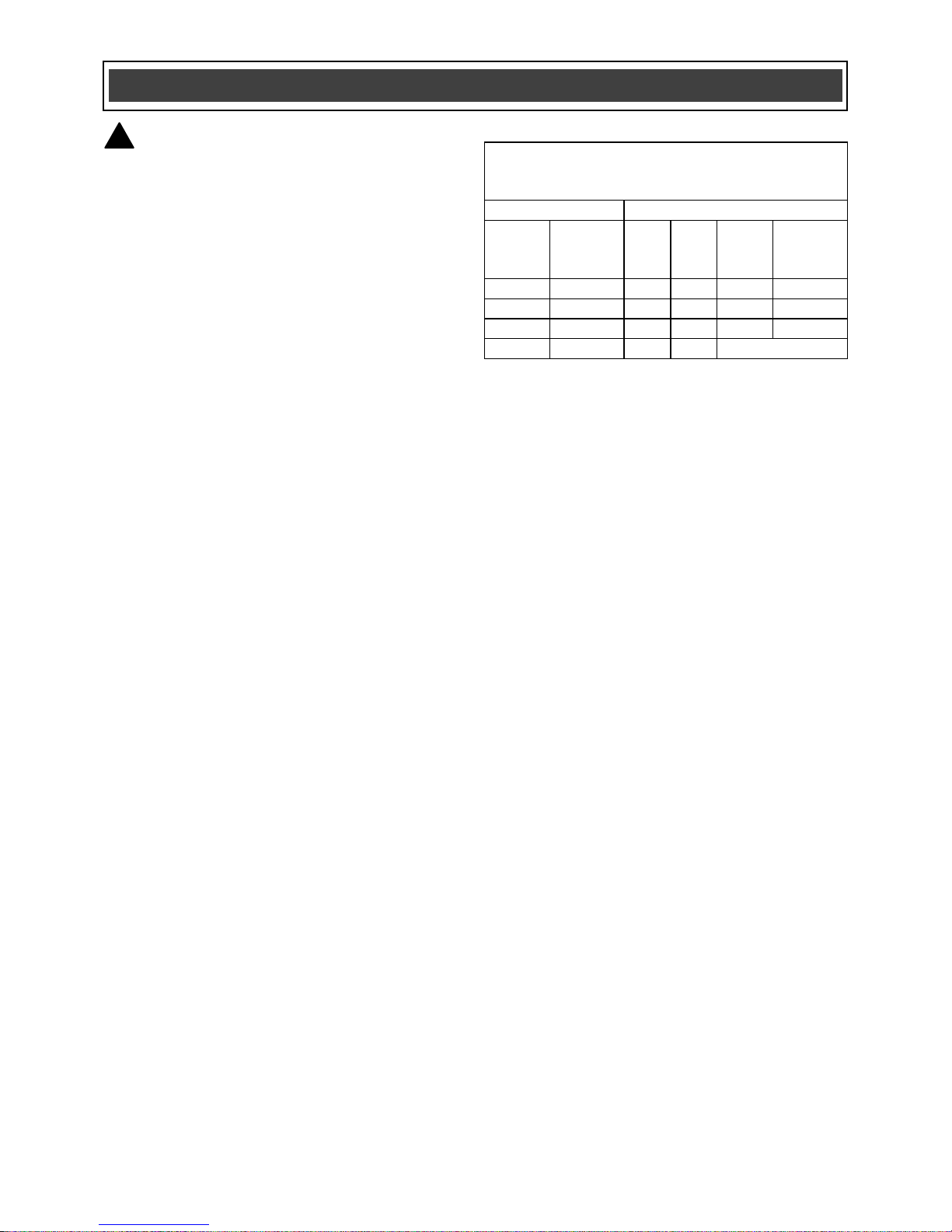

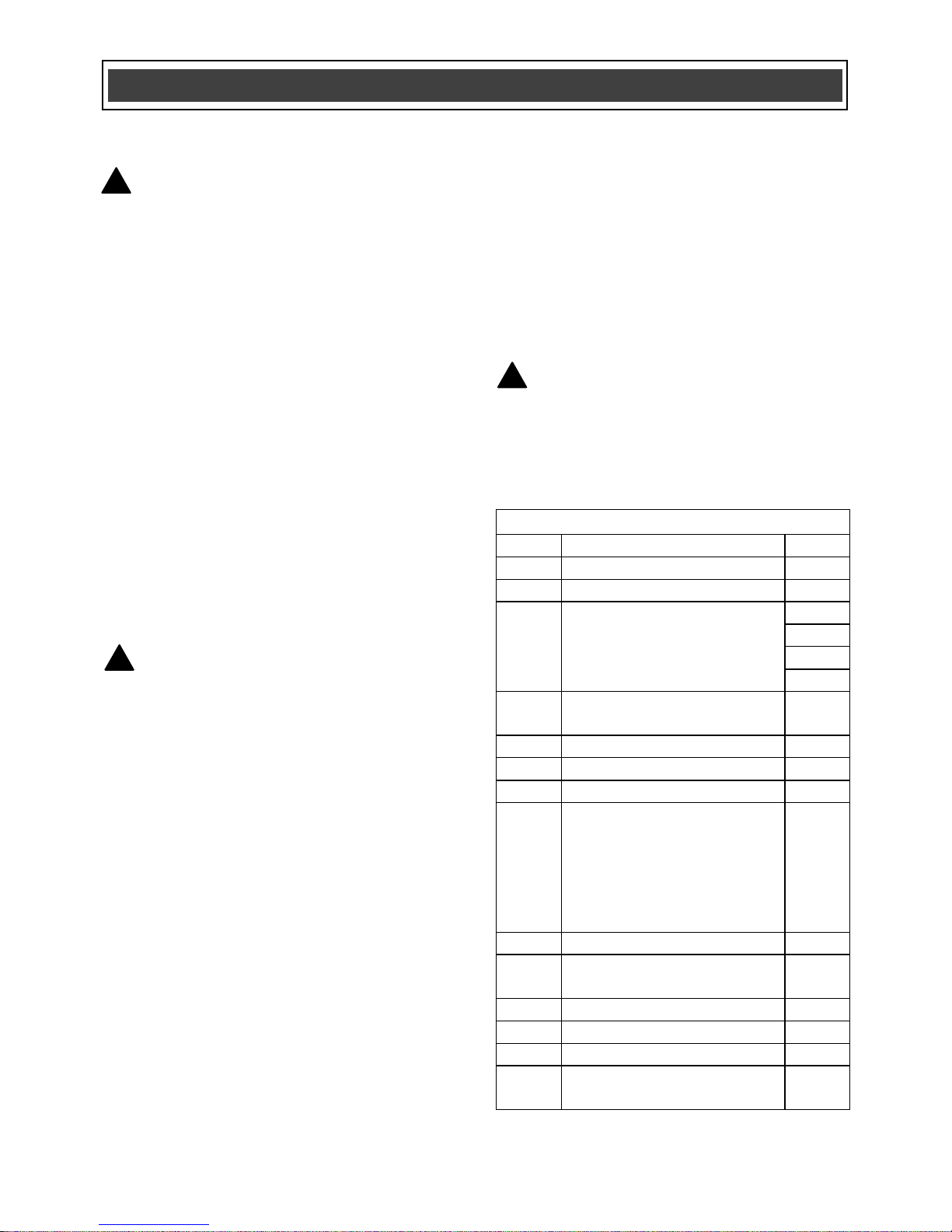

The following table shows the correct size

to use according to cord length and the

amperage rating that is listed ton the tool's

nameplate. When in doubt, use the next

heavier gauge. The smaller the gauge

number, the heavier the cord.

Verify that the extension cord is properly

wired and in good condition. Replace a

damaged extension cord immediately, or

have it repaired by a qualified electrician

before using it. Keep the extension cord

away from sharp objects, excessive heat,

and damp or wet areas.

Use a separate electrical circuit for power

tools. This circuit must consist of not less

than 14 gauge wire, and should be

protected by either a 15 A time-delayed

fuse or a circuit breaker. Before connecting

the power tool to the outlet, verify that the

switch is in the OFF position, and that the

voltage of the power source is the same as

the voltage that is indicated on the tool's

nameplate. Running this rotary tool at

lower voltage will damage the motor.

MINIMUM GAUGE (AWG) EXTENSION

CORDS

(120 V use only)

Ampere Rating

Total length in feet

More

Than

Not

More

Than

25’ 50’ 100’ 150’ 0 6

18

16

16

14 6 10

18

16

14

12

10

12

16

16

14

12

12

16

14

12

Not Applicable

!

EXTENSION CORD SAFETY

Page 9

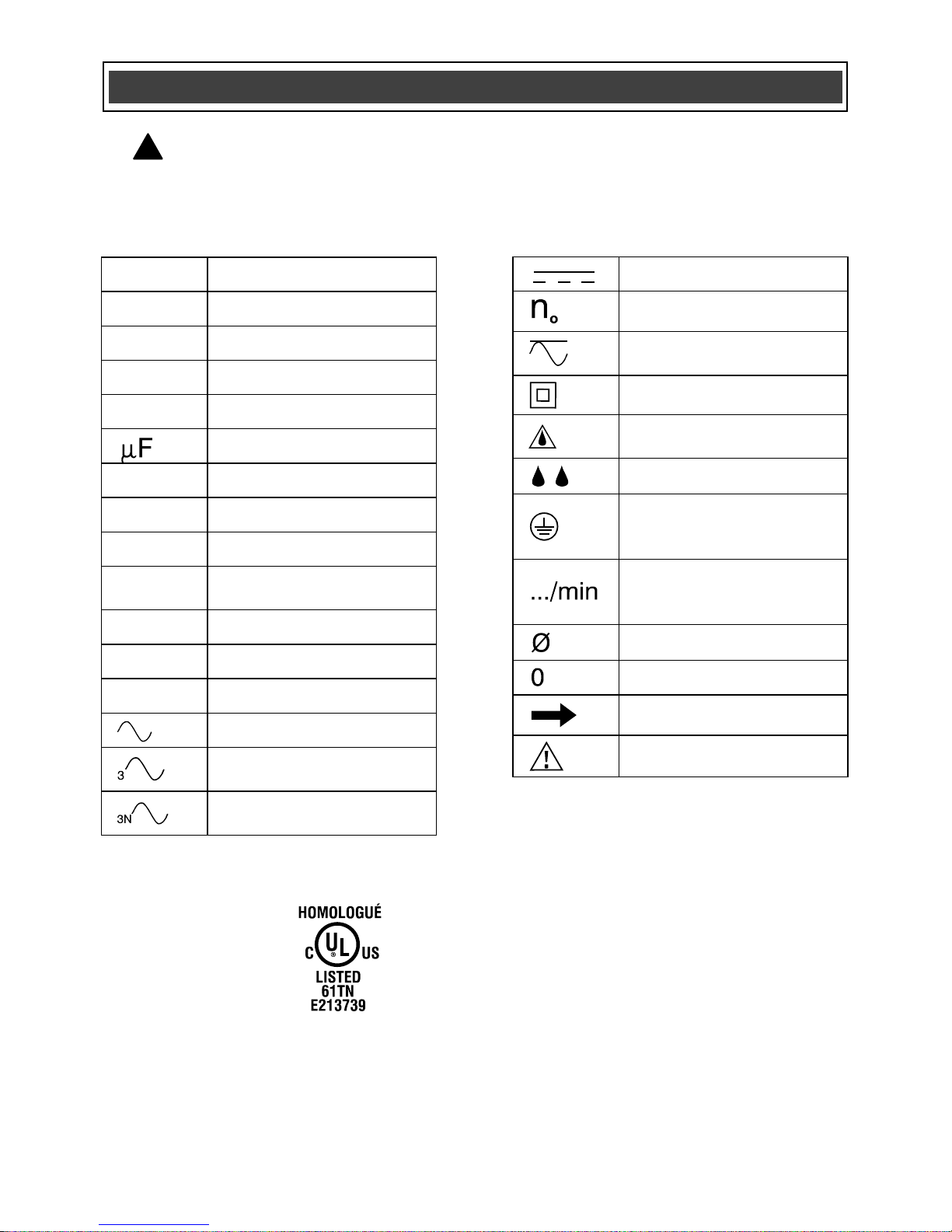

9

V

Volts

A

Amperes

Hz

Hertz

W

Watts

kW

Kilowatts

Microfarads

L

Litres

kg

Kilograms

H

Hours

N/cm2

Newtons per square

centimeter

Pa

Pascals

Min

Minutes

S

Seconds

Alternating current

Three-phase alternating

current

Three-phase alternating

current with neutral

Direct current

No load speed

Alternating or direct

current

Class II construction

Splash-proof

construction

Watertight construction

Protective grounding at

earthing terminal, Class I

tools

Revolutions or

reciprocations per

minute

Diameter

Off position

Arrow

Warning symbol

WARNING: Some of the following symbols may appear on the rotary

tool. Study these symbols and learn their meaning. Proper interpretation of

these symbols will allow for more efficient and safer operation of this tool.

!

SYMBOLS

This symbol indicates that this

tool is listed by Underwriters

Laboratories as meeting both

Canadian and U.S.

requirements.

Page 10

10

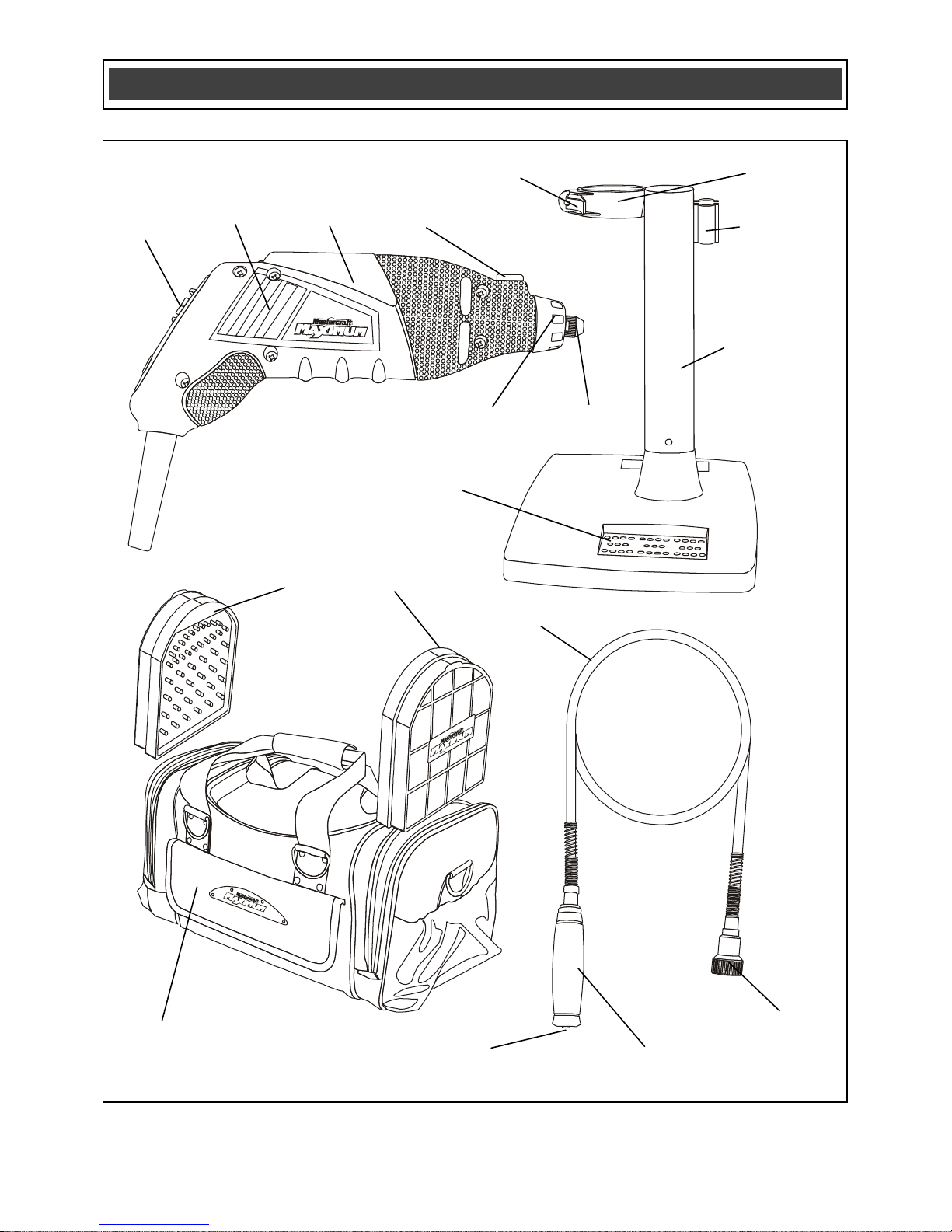

DIAGRAM AND LOCATION OF PARTS

Rotary tool

clamp

Release

lever

Carry bag

Accessory

storage trays

Rotary tool

hanger

Bit storage

Flexible shaft

hanger

Flexible shaft

locking collar

Motor

controls

Rotary

tool

Spindle

lock

Spindle

nut

Collet

nut

Flexible shaft

collet nut

Flexible shaft

mounting nut

Flexible shaft

Cooling

vents

Page 11

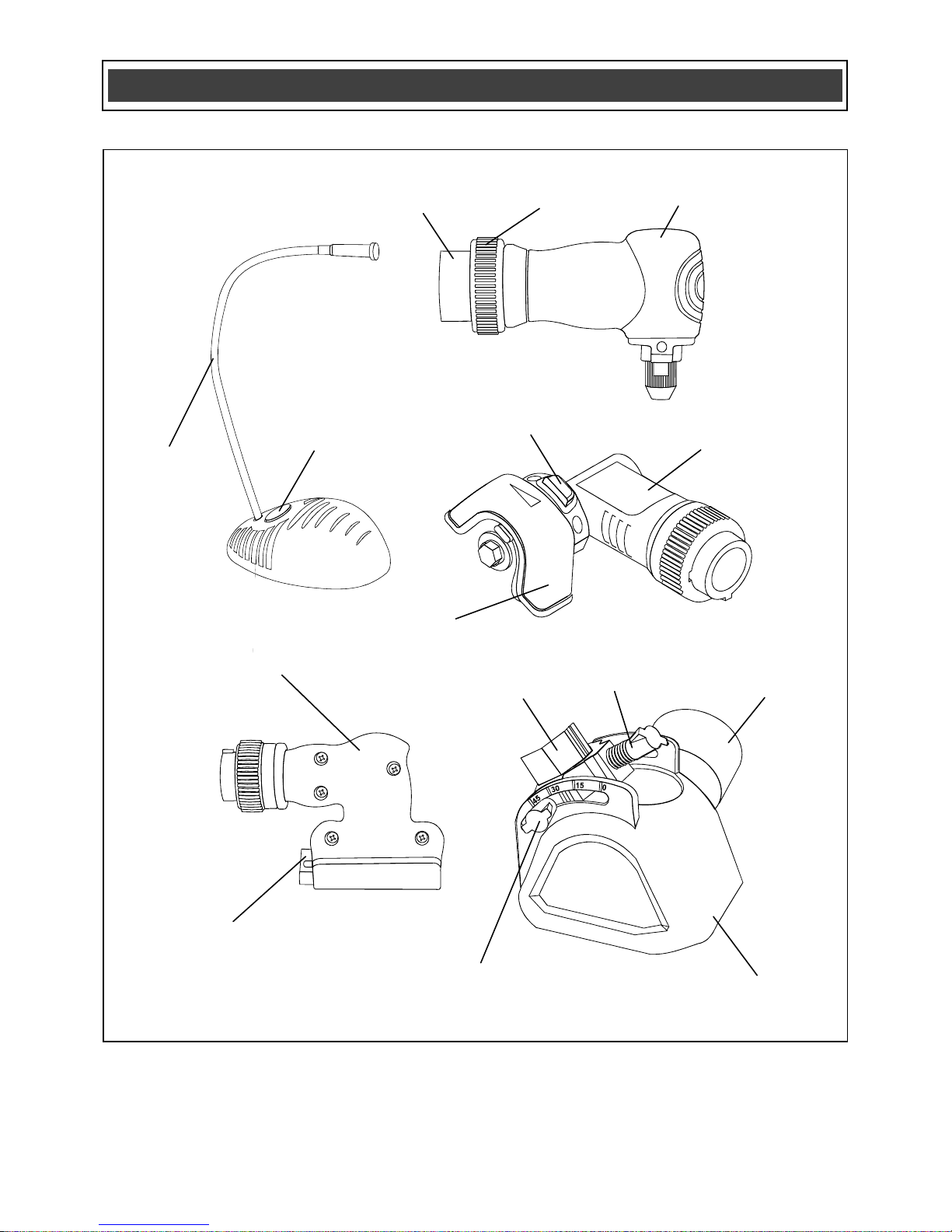

11

DIAGRAM AND LOCATION OF PARTS

Connecting

adapter

Blade

guard

Mini circular saw

attachment

Right angle

attachment

Vacuum

adaptor

Sanding

attachment

LED

worklight

Connecting

collar

Height

adjusting screw

Rotary tool

connector

Angle adjustment

screw

Angle guide

Clamping

lever

Guard

rotation lock

ON/OFF

button

Page 12

12

AVAILABLE ACCESSORIES

WARNING: Use only accessories

that are recommended for this rotary

tool. Follow the instructions that

accompany the accessories. The use of

improper accessories may result in

injury to the operator or damage to the

rotary tool.

Before using any accessory, carefully read

the instructions or the owner’s manual for

the accessory.

● Grinding stones

● Cut-off wheels

● Polishing wheels

● Wire brushes

● Bristle brushes

● Sanding drums

● Cutting bits

● Drill bits

● Dressing stones

WARNING: If any part is missing or

damaged, do not plug the rotary tool into

the outlet until the missing or damaged

part has been replaced.

CONTENTS

Carefully unpack the rotary tool and all of

its components. Compare the contents

against the following chart entitled “Rotary

Tool Components”.

NOTE: See the illustrations of the rotary

tool and accessories on the following

pages.

WARNING: In order to avoid the risk

of fire or toxic reaction, do not use

gasoline, naphtha, acetone, lacquer

thinner, or similar highly volatile solvents to

clean the rotary tool.

! ! !

ACCESSORIES AND CONTENTS

ROTARY TOOL COMPONENTS

KEY

DESCRIPTION

QTY

A

Rotary cutting tool

1

B

Detail sanding pad

1

C

Contour sanding pads

● Wedge

● Convex

● Concave

1 1 1

D

Batteries for the LED

worklight

2

E

Stand assembly

1

F

LED worklight assembly

1

G

Flexible shaft

1

H

Slide-out storage

containers with

accessories

● See the following

pages for the list of

accessories

2

I

Tote bag

1

J

Angle attachment with

vacuum adaptor

1

K

Circular saw attachment

1

L

Sander attachment

1

M

Right angle attachment

1

Owner’s Manual

(not shown)

1

Page 13

13

CONTENTS

0

A

D

B

C

E

F

G

H

I

J

K

L

M

Page 14

14

Illustration

Item

Description / Size

Qty

Aluminium oxide

grinding stone

Cylinder 3/8" (9 mm)

1

Aluminium oxide

grinding stone

Circular grinding stone

5/8" (16 mm) radial

1

Aluminium oxide

grinding stone

Cylinder with pointed

end 1/4" (6 mm)

1

Aluminium oxide

grinding stone

Parabolic 3/8" (9 mm)

1

Aluminium oxide

grinding stone

Grinding wheel 1"

(25 mm)

1

Aluminium oxide

grinding stone

Cone 5/8" (16 mm)

1

Aluminium oxide

grinding stone

Abrasive wheel 3/4"

(19 mm)

2

Silicon carbide

grinding stone

Cylinder with pointed

end 3/16" (5 mm)

1

Silicon carbide

grinding stone

Cylinder with pointed

end 3/32" (2.5 mm)

1

Silicon carbide

grinding stone

Wheel 3/8" (9 mm)

1

Silicon carbide

grinding stone

Wheel 5/8" (16 mm)

1

Silicon carbide wheel

Abrasive wheel 3/4"

(19 mm)

2

Super duty cut-off

wheel

Fibreglass-reinforced

wheel 1 1/4 " (32 mm)

3

Heavy duty cut-off

wheel

15/16 x .031"

(24 x .8 mm) thick

60

Regular duty cut-off

Wheel

15/16 x .025"

24 x .6 mm) thick

60

Bristle brush

3/4" (19 mm) radial

1

Bristle brush

1/2" (13 mm) axial

1 Stainless steel brush

1/2" axial (13 mm)

1

Stainless steel brush

3/4" (19 mm) radial

1

Brass brush

1/2" (13 mm) axial

1

Felt polishing wheel

1/2" (13 mm)

18

ACCESSORY KIT CONTENTS

Page 15

15

Illustration

Item

Description / Size

Qty

Felt polishing

wheel

1" (25 mm)

1

Felt polishing tip

Pointed tip 3/8"

(9 mm)

1

Cloth wheel

1" (25 mm)

1 Sanding band

60 grit 1/4" (6 mm)

10

Sanding band

120 grit 1/4"

(6 mm)

10

Sanding band

60 grit 1/2"

(13 mm)

10

Sanding band

120 grit 1/2"

(13 mm)

10

Drum sander

1/4"(6 mm) with

1/8" (3 mm) shank

1

Drum sander

1/2" (13 mm) with

1/8" (3 mm) shank

1

Sanding disc

100 grit 3/4"

(19 mm)

80

Sanding disc

220 grit 3/4"

(19 mm)

80

Sanding disc

240 grit 3/4"

(19 mm)

80

Flap wheel

1/4" (6 mm)

1

Diamond wheel

point

Taper point 3/32"

(2.5 mm)

1

Diamond wheel

point

Ball 5/64" (2 mm)

1

Diamond wheel

point

Ball 11/64"

(4.5 mm)

1

Carbide grout

cutter

1/16" (1.5 mm)

1

HSS cutter

Cylinder 1/8"

(3 mm)

1

Collet

1/8" (3 mm)

1 Collet

3/32" (2.5 mm)

1

Collet

1/16" (1.5 mm)

1

ACCESSORY KIT CONTENTS

Page 16

16

Illustration

Item

Description / Size

Qty

Screw mandrel

1/8" (3 mm)

10

Mandrel

For felt wheels

1/8" (3 mm)

10

Wrench

For collet nut and

drum sander

1

Dressing stone

Rectangular 3/8 x

1" (9 x 25 mm)

1

Hook & loop

sandpaper

For detail sander

4

Hook & loop

sandpaper

For contour

sanders

6

Circular saw

blade

48 teeth

2

L-key

For attachments

1

Description

Uses

High-speed steel cutter

Shaping, hollowing, grooving, slotting, and making

tapered holes in soft metals, plastics, and wood.

Carbide grout cutter

Cutting wall and floor grout.

Multi-purpose bit

Cutting wood, plastic, fibreglass, drywall, laminate, and

aluminium and vinyl siding.

Screw mandrel

Holding sanding discs, felt wheels, polishing wheels,

grinding wheels, and cut-off wheels.

Mandrel for emeryimpregnated polishing wheel

Holding the emery-impregnated polishing wheel.

Mandrel for cloth wheel

Holding sanding discs, polishing wheels, grinding

wheels, and cut-off wheels.

Collet

Holding accessories in position.

Collet wrench

Tightening & loosening the collet nut and the screw for

drum sanders.

Dressing stone

Cleaning grinding wheels and stones, and shaping or

reshaping stones for desired applications.

L-key

Locking the flexible shaft in position when loosening or

tightening the collet nut.

Aluminum oxide

Grinding stones

Grinding wheels

Abrasive wheels

Sharpening, de-burring, removing rust , and generalpurpose grinding of most materials, including metals,

castings, welded joints, and rivets.

ACCESSORY KIT CONTENTS

DESCRIPTION AND USE OF ACCESSORIES

Page 17

17

Description

Uses

Silicon carbide

Stones

Wheels

General-purpose grinding of stone, glass, ceramics,

porcelain, and non-ferrous metals.

Cut-off wheel

Cutting, grooving, and trimming all kinds of materials,

including metal, wood, and ceramics; cutting screws

and rusted bolts, making slots in screw heads,

trimming castings, etc.

Polishing wheel

Emery-

impregnated

Cleaning and polishing coarse surfaces.

Polishing wheel

Felt & cloth

Polishing most metal surfaces and plastics. Can be

used with a polishing compound.

Bristle brush

Light de-burring, cleaning, and polishing of silverware,

jewellery, and other precious metals. Can be used with

a polishing compound.

Stainless steel brush

Light de-burring, cleaning, and polishing of corrosionresistant materials like pewter, aluminium, and

stainless steel. Does not cause "after-rust".

Brass brush

Light de-burring, cleaning, and polishing of soft metals

such as gold, copper, brass, etc. Non-sparking, and

does not scratch.

Sanding band

Rough shaping and smoothing of wood and fibreglass,

removing rust from metal surfaces, and shaping rubber

surfaces. Sanding bands are easily replaceable on

drums.

Sanding wheel

Rough shaping and smoothing of wood and fibreglass,

removing rust from metal surfaces, shaping rubber

surfaces, etc.

Flap wheel

Grinding and polishing flat or contoured surfaces.

Finishing surfaces after heavier sanding and material

removal has been completed.

Diamond wheel point

Cutting, sawing, and carving hard materials such as

marble, concrete, brick, porcelain, ceramics, hard

epoxy, and soft and hard wood.

Engraving Cutter

Detailed engraving, carving, and routing in wood,

fibreglass, plastic, and soft metals.

Tungsten-carbide cutter

Shaping, smoothing, and removing material from

hardened steel, stainless steel, cast iron, non-ferrous

metals, fired ceramics, plastics, hard wood, and other

hard materials.

Hook & loop detail sheets

Sanding wood. Used with the detail sander.

Sandpaper for contour sander

Sanding wood. Used with the contour sander.

Circular blade

Cutting wood. Used with the mini circular saw.

DESCRIPTION AND USE OF ACCESSORIES

Page 18

18

CHANGING THE COLLET

Different accessories require the use of

different sized collets. The most common

collet sizes are 1/8, 3/32, and 1/16" (3, 2.5,

and 1.5 mm). It is important to ensure that

the collet size matches the shank of the

accessory.

WARNING: If the collet is too

large for the accessory, the accessory

could be thrown from the tool, which

could cause serious injury.

1. Turn the switch to the OFF position, and

disconnect the plug from the outlet.

2. Depress the spindle lock button (1), and

slowly turn the collet nut (2) until the

spindle lock button locks the spindle in

place (Fig. 1).

3. Hold the spindle lock button down, and

turn the collet nut counter-clockwise using

the collet wrench until it comes free.

4. Remove the collet (3) by pulling it out of

the spindle (4).

5. Insert the replacement collet into the

spindle, and tighten the collet nut by

turning it clockwise while holding the

spindle lock button down.

NOTE: Do not tighten the collet nut without

an accessory installed in the collet. Doing

so will damage the collet.

INSTALLING ACCESSORIES

1. Turn the switch to the OFF position, and

disconnect the plug from the outlet.

!

ASSEMBLY AND OPERATING INSTRUCTIONS

Fig. 1

Page 19

19

INSTALLING ACCESSORIES – cont’d

2. Depress the spindle lock button (1), and

slowly turn the collet nut (2) until the

spindle lock button locks the spindle in

place (Fig. 2).

3. Hold the spindle lock button down, and

turn the collet nut counter-clockwise until

the collet is loose inside the collet nut.

4. Insert the shank of the accessory (3)

into collet.

NOTE: Verify that the proper collet is used

for the accessory. If the collet is too large,

replace it with the next smaller size.

5. Press the spindle lock button, and

engage it in the spindle. While holding the

spindle lock button down, turn the collet

clockwise by hand in order to tighten it .

NOTE: Do not use pliers to tighten the

collet nut. Use the collet wrench that is

provided. Over-tightening the collet will

damage the tool.

6. Pull on the accessory in order to verify

that it is held securely in position.

CONNECTING THE FLEXIBLE SHAFT

TO THE TOOL

WARNING: Do not bend the

flexible shaft to a radius of less than 6”

(15.2 cm) when using it with the rotary

tool. Store the flexible shaft carefully

when it is not in use, avoiding sharp

bends.

!

ASSEMBLY AND OPERATING INSTRUCTIONS

Fig. 2

Page 20

20

CONNECTING THE FLEXIBLE SHAFT TO THE

TOOL – cont’d

1. Remove the collet nut (1) and the

spindle nut (2) from the tool by turning

them counter-clockwise (Fig. 3).

2. Remove the collet from motor shaft (3).

3. Insert the the inner cable of the flexible

shaft (4) into the motor shaft until the

stopper (5) comes into contact with the

motor shaft.

4. Thread the flexible shaft collet nut (6)

onto the motor shaft by turning it

clockwise. Tighten it using the collet

wrench.

5. Thread the flexible shaft nut (7) onto the

tool housing (8) by turning it clockwise.

NOTE: Tighten the flexible shaft nut by

hand only. Do not use pliers or a wrench.

CHANGING THE COLLET AND

ACCESSORIES IN THE FLEXIBLE

SHAFT

In order to change the collet or to install an

accessory in the flexible shaft, follow the

steps listed in the sections entitled

“Changing the collet” and “Installing

accessories”. In order to lock the shaft in

place, pull back on the flexible shaft grip

(1) and rotate the collet until the shaft grip

locks the shaft in place (Fig. 4). The

flexible shaft grip will return to its normal

position when it is not being held in the

locked position.

NOTES:

a) Do not attempt to loosen or tighten the

collet without locking the shaft in place as

described above. Doing so will damage the

flexible shaft.

b) Do not over-tighten the collet nut.

ASSEMBLY AND OPERATING INSTRUCTIONS

Fig. 4

Fig. 3

Page 21

21

ASSEMBLING THE ROTARY TOOL

STAND

The rotary tool stand is used to hold the

rotary tool while using the flexible shaft.

1. Insert the bottom end of the tool holder

(1) into the matching slots (2) in the base

of the stand (3) (Fig. 5).

NOTE: Rotate the tool holder in order to

position the tool clamp (4) toward the front

of the base.

2. Rotate the tool holder 90° clockwise in

order to secure it to the base.

3. Install the flexible shaft on the rotary tool

(Fig. 3).

4. Pull out on the tool holder clamp lever

(5) in order to open the tool holder clamp

(4) (Fig. 6).

5. Insert the flexible shaft (7) through the

tool holder clamp, and insert the rotary tool

(6) into its clamp (4).

NOTE: Verify that the rotary tool is

inserted fully into the clamp.

6. Push the tool holder clamp lever toward

the tool until it snaps into place and holds

the tool securely in place.

7. If the tool is left installed in the stand

with the flexible shaft installed, hang the

collet end of the flexible shaft

in the slotted holder (8) that is located at

the right side of the stand.

8. Accessories can be stored in the base

of the stand, in the spaces that are

provided (9).

ASSEMBLY AND OPERATING INSTRUCTIONS

Fig. 5

Fig. 6

Page 22

22

INSTALLING THE RIGHT ANGLE

ATTACHMENT

1. Remove the collet nut and the collet

from the motor shaft.

NOTE: Engage the spindle lock button in

order to hold the spindle in place while

loosening and tightening the collet nut.

2. Remove the spindle nut (1) from the tool

by turning it counter-clockwise (Fig. 7).

3. Insert the short end of the drive shaft (2)

into the motor shaft (3) until the stopper (4)

comes into contact with the shaft.

4. Slide the collet nut (6) over the drive

shaft (5), and thread it onto the motor shaft

by turning the collet nut clockwise. Tighten

the collet nut using the collet wrench.

5. Remove the right angle attachment

adaptor (7) and the collar (8) from the right

angle attachment (9) by turning the collar

counter-clockwise.

6. Fasten the right angle attachment

adaptor and the collar to the tool (10) by

turning the right angle attachment adaptor

clockwise.

NOTE: Tighten by hand only. Do not use

pliers or a wrench.

7. Insert the end of the drive shaft into the

hole in the right angle attachment (11).

ASSEMBLY AND OPERATING INSTRUCTIONS

Fig. 7

Page 23

23

INSTALLING THE RIGHT ANGLE

ATTACHMENT – cont’d

NOTE: Rotate the right angle attachment

collet nut (12) while pushing the right angle

attachment onto the adaptor until the

square end of the drive shaft is inserted

into the corresponding square in the right

angle attachment.

8. Once the drive shaft is fully engaged

into the right angle attachment, lock the

right angle attachment to the

adaptor by turning the adaptor collar

clockwise.

NOTE: Tighten by hand only. Do not use

pliers or a wrench.

Follow the basic procedures that are

described in the section entitled Changing

the collet and accessories in the flexible

shaft (Fig. 4) in order to change the collet

and accessories in the right angle

attachment. In order to lock the spindle,

rotate the collet nut (12) until the L-key

(13) can be inserted into the hole in the

shaft (14) (Fig. 7A).

INSTALLING THE ANGLE GUIDE AND

THE VACUUM ADAPTER

The angle guide is used to hold the tool at

a specific angle while cutting or grinding.

1. Remove the spindle nut (1) from the tool

by turning it counter-clockwise (Fig. 8).

2. Install the appropriate bit in the rotary

tool (Fig. 2).

3. Install the angle guide (2) onto the tool

by turning the base clockwise onto the

threaded portion of the tool spindle (3).

NOTE: Do not overtighten.

ASSEMBLY AND OPERATING INSTRUCTIONS

Fig. 7A

Fig. 8

Fig. 7

Page 24

24

INSTALLING THE ANGLE GUIDE – cont’d

4. In order to set the cutting angle, loosen

the two angle-adjusting thumb screws (4)

that are located on the sides of the base,

move base to desired angle, and then

retighten the thumb screws.

NOTE: Do not overtighten the thumb

screws.

5. In order to set the cutting depth, loosen

the height-adjusting thumb screw (5), slide

the tool up or down in the base until it is at

the desired cutting depth, and then

retighten the thumb screw.

6. When working with dusty applications,

attach a vacuum to the vacuum adaptor (6)

(Fig 8A). In order to install the vacuum

adaptor, insert the small end of the adaptor

(7) into the vacuum port (8) that is located

on the side of the angle guide.

NOTE: Align the two slots (9) in the

vacuum adaptor with the corresponding

keys (10) in the vacuum port. Turn the

vacuum adaptor clockwise in order to lock

it in position.

INSTALLING THE SANDER

ATTACHMENT

1. Remove the collet nut (1) and the collet

from the motor shaft (2) (Fig. 9).

NOTE: Engage the spindle lock button in

order to hold the spindle in place while

loosening and tightening the collet nut.

2. Remove the spindle nut (3) from the tool

by turning it counter-clockwise.

ASSEMBLY AND OPERATING INSTRUCTIONS

Fig. 8

Fig. 9

Fig. 8A

Page 25

25

INSTALLING THE SANDER ATTACHMENT –

cont’d

3. Insert the short end of the drive shaft (4)

into the motor shaft until the stopper (5)

comes into contact with the shaft.

4. Slide the collet nut over the drive shaft,

and thread it onto the motor shaft by

turning the collet nut clockwise. Tighten

the collet nut using the collet wrench.

5. Remove the sander attachment adaptor

(6) and the collar (7) from the sander

attachment by turning the collar counterclockwise.

6. Fasten the sander attachment adaptor

and the collar to the tool (8) by turning the

sander attachment adaptor clockwise.

NOTE: Tighten by hand only. Do not use

pliers or a wrench.

7. Insert the square end of the drive shaft

(9) into the hole in the sander attachment

(10).

NOTE: Rotate the drive shaft while

pushing the sander attachment onto the

adaptor until the square end of the drive

shaft is inserted into the corresponding

square in the sander attachment.

8. Once the drive shaft is inserted fully into

the sander attachment, secure the sander

attachment to the adaptor by turning the

adaptor collar clockwise onto the sander

attachment threads (11).

NOTE: Tighten by hand only. Do not use

pliers or a wrench.

ASSEMBLY AND OPERATING INSTRUCTIONS

Fig. 9

Page 26

26

INSTALLING SANDPAPER

In order to properly adhere to the

accessories, the sandpaper that is used for

the detail and contour sander accessories

must be of the hook & loop design. The

following instructions describe how to

apply the sandpaper to each type of

sanding accessory.

Detail sander pad

Sandpaper pads are pre-cut to fit the

triangular shape of the detail sander

accessory. In order to apply the

sandpaper, align the pre-cut sandpaper (1)

with the bottom of the detail sander

accessory, and press it firmly onto the

base (2) (Fig. 10).

Contour sanding pads

Sandpaper pads are pre-cut into

rectangular pieces that will fit the shape of

the various contour sander accessories. In

order to apply the sandpaper, align the

pre-cut sandpaper with the “hooked”

bottom and side surfaces of the selected

contour accessory, and press it firmly onto

the hooked surfaces (Fig. 11, 12 & 13).

NOTES:

a) Apply the sandpaper to the accessory

so that it extends to the top of the rubber

pad.

b) If the sheet of sandpaper is too large to

fit the contour accessory properly, trim the

sandpaper to the proper size using an old

pair of scissors.

INSTALLING THE PAD ONTO THE

SANDER

1. Rotate the pad locking lever (1) counterclockwise in order to open the pad clamp

(2) (Fig. 14).

ASSEMBLY AND OPERATING INSTRUCTIONS

Fig. 10

Fig. 11

Fig. 12

Fig. 13

Fig. 14

Page 27

27

INSTALLING THE PAD ONTO THE SANDER –

cont’d

2. Insert the top of the pad and the

sandpaper into the open clamp.

NOTE: Verify that the top of the pad is

centered in the clamp, and that the clamp

grips the sandpaper.

3. Rotate the pad clamp lever clockwise in

order to secure the pad and sandpaper in

position.

SANDING WOOD

WARNING: Wear safety goggles,

hearing protection, and a dust mask

when performing sanding operations.

Failure to use adequate protection may

result in serious injury.

Use the sander in the same manner as

any other finishing sander.

SANDING TIPS

1. Use coarse sandpaper to remove

material from gouges and rough areas

more quickly. Coarse paper lasts longer,

and is less likely to get clogged up with

wood resin and surface finishes.

2. Use fine sandpaper for a smoother

finish.

3. In order to improve sanding action,

verify that the sandpaper is firmly pressed

onto the “hook” area of the sanding pad.

4. Turn rotary tool on before the sandpaper

comes into contact with the workpiece.

!

ASSEMBLY AND OPERATING INSTRUCTIONS

Fig. 14

Page 28

28

SANDING TIPS – cont’d

NOTE: Setting the rotary tool at a faster

speed will produce smoother sanding

action.

5. Keep the rotary tool moving while the

sandpaper is in contact with the workpiece

in order to avoid removing excess material

from the workpiece.

INSTALLING THE MINI CIRCULAR SAW

ATTACHMENT

1. Remove the collet nut (1) and the collet

from the motor shaft (2) (Fig. 15).

NOTE: Engage the spindle lock button in

order to hold the spindle in place while

loosening and tightening the collet nut.

2. Remove the spindle nut (3) from the tool

by turning it counter-clockwise.

3. Insert the short end of the drive shaft (4)

into the motor shaft until the stopper (5)

comes into contact with the shaft.

4. Slide the collet nut over the drive shaft

(9), and thread it onto the motor shaft by

turning the collet nut clockwise. Tighten

the collet nut using the collet wrench.

5. Remove the saw attachment adaptor (6)

and the collar (7) from the circular saw

attachment by turning the collar counterclockwise.

ASSEMBLY AND OPERATING INSTRUCTIONS

Fig. 15

Page 29

29

INSTALLING THE MINI CIRCULAR SAW

ATTACHMENT – cont’d

6. Fasten the saw attachment adaptor and

the collar to the tool (8) by turning the saw

attachment adaptor clockwise.

NOTE: Tighten by hand only. Do not use

pliers or a wrench.

7. Insert the square end of the drive shaft

(9) into the hole in the saw attachment

(10).

NOTE: Rotate the saw blade screw (11)

while pushing the saw attachment onto the

adaptor until the square end of the drive

shaft is inserted into the corresponding

square in the saw attachment.

8. Position the saw blade to the LEFT side

of the rotary tool. The hexagonal

positioning locks will engage when the

body of the saw attachment is in the

proper position.

9. Once the drive shaft and positioning

locks are fully engaged, secure the saw

attachment to the adaptor by turning the

adaptor collar clockwise.

NOTE: Tighten by hand only. Do not use

pliers or a wrench. Loosen adaptor collar

when removing the circular saw

attachment from the rotary tool.

10. Rotate the saw guard assembly until

the bottom sliding surface of the guard

assembly and the rotary tool are in the

desired position. In order to rotate the

guard assembly, press the release button

(12) and rotate the guard assembly until

the release button snaps into the next

locked position.

ASSEMBLY AND OPERATING INSTRUCTIONS

Fig. 15

Page 30

30

INSTALLING A SAW BLADE

1. Lock the saw attachment shaft in place.

in order to lock the shaft in place, rotate

the screw that holds the blade onto the

shaft until the hole in the shaft is aligned

with the hole in the saw attachment body

(1) (Fig. 16). Insert the L-Key (2) through

the holes in order to lock the shaft in place.

NOTE: Do not attempt to loosen or tighten

the blade screw without locking the shaft

as described above. Doing so will damage

the flexible shaft.

2. Remove the saw blade screw (1), the

locking washer (2), and the large washer

(3) by turning the screw clockwise using a

5/16" (8 mm) wrench (Fig. 16A). The screw

has a left-hand thread.

3. Rotate the blade guard lever (4)

forward.

4. Place the saw blade onto the spindle

(5).

NOTE: Verify that the teeth on the bottom

of the saw blade are pointing forward.

5. Secure the saw blade in position by

replacing the large washer, the locking

washer, and the saw blade screw in the

proper order.

NOTES:

a) Place the hollow side of the large

washer against saw blade.

b) Lock the saw blade shaft using the

L-Key.

c) Tighten the saw blade screw by turning

it counter-clockwise. The screw has a lefthand thread.

d) Do not overtighten the saw blade screw.

Doing so will damage the threaded

spindle.

ASSEMBLY AND OPERATING INSTRUCTIONS

Fig. 16A

Fig. 16

Page 31

31

CUTTING WOOD

WARNING: Wear safety goggles,

hearing protection, and a dust mask when

performing sawing operations. Failure to

use adequate protection could result in

serious injury.

WARNING: Do not place hands

near or below the cutting line.

The mini circular saw attachment is

designed to make smooth cuts in

extremely thin pieces of wood. Verify that

the saw blade is not in contact with

anything, and that the operator's hands are

clear of the blade before turning the rotary

tool on.

1. Turn rotary tool on.

2. Set the speed to 25,000 RPM.

3. Position the saw attachment on the

edge of the workpiece, with the blade

aligned with the cutting line.

4. Slowly move the blade toward the

cutting line until it comes into contact with

the workpiece.

5. Once the blade begins to cut, move the

blade into the workpiece at a slow and

steady pace, following the cutting line.

NOTE: The mini circular saw attachment is

designed to cut straight lines only. It is not

designed to cut curves.

Moving the saw at a slow and steady pace

will produce a smooth cut. Forcing the

blade to cut too quickly will cause it to

overheat, which will result in burn marks

on the wood, a rough cut, and a dull blade.

!

!

ASSEMBLY AND OPERATING INSTRUCTIONS

Page 32

32

CUTTING WOOD – cont’d

WARNING: Once the cutting

operation is complete, verify that the saw

blade has come to a complete stop before

setting the rotary tool down.

WARNING: Do not touch the blade

immediately after cutting, because it will be

hot enough to cause burns.

ASSEMBLING THE LED WORKLIGHT

This rotary tool is equipped with a freestanding LED worklight that can be placed

on any flat surface near the workpiece.

The flexible arm can be bent in order to

focus the light on the desired location.

Install the batteries into the base of the

LED worklight as follows:

1. Turn the worklight upside down.

2. Remove the battery cover (1) from the

base of the worklight (2) by lifting the side

where the slot (3) is located (Fig. 17).

3. Install two AAA alkaline batteries (4) into

the battery compartment.

NOTE: Position the batteries with the

positive (+) end of each battery as

illustrated in the picture that is in the

battery compartment.

4. Re-install the cover of the battery

compartment.

5. Turn the LED worklight on or off using

the ON/OFF button (5) that is located on

the top of the base (Fig. 17A). Push the

button once in order to turn the light on.

Push it again to turn the light off.

!

!

ASSEMBLY AND OPERATING INSTRUCTIONS

Fig. 17

Fig. 17A

Page 33

33

SELECTING THE PROPER SPEED

The different types of operations that can

be performed require that the rotary tool be

used at different speeds. The following

chart outlines some of the basic speed

settings:

OPERATION

SPEED

(RPM)

Sanding

13,000

Cutting metal

35,000

Sanding wood

13,000

Cutting hard metal

29,000

Engraving metal

27,000

Sawing

25,000

De-burring

19,000

Drilling holes

17,000

Removing rust

13,000

Sharpening

9,000

Polishing

9,000

WARNING: For safety reasons, the operator must read the sections of this

Owner's Manual entitled “GENERAL SAFETY WARNINGS”, “POWER TOOL

SAFETY”, “SPECIFIC SAFETY RULES”, EXTENSION CORD SAFETY” and

“SYMBOLS” before using this rotary tool.

Verify the following every time the rotary tool is used:

1. All accessories that are being used are in good condition and are not

damaged in any way.

2. The workpiece is properly secured and the accessory is securely installed.

3. The operator is wearing safety glasses.

Failure to observe these safety rules will significantly increase the risk of injury.

!

ASSEMBLY AND OPERATING INSTRUCTIONS

Page 34

34

DIGITAL MOTOR CONTROL

This rotary tool features advanced digital

controls, including an LCD (liquid crystal

display) speed indicator and a speed

memory function. The following sections

describe how these functions work.

ON/OFF SWITCH

WARNING: Verify that the bit is

securely installed in the collet and that the

cutting accessory is not in contact with

anything before turning the switch to the

“ON” position.

1. Push the left side of the switch in order

to turn it to the "ON" position (1) (Fig. 18).

NOTE: The tool will start, and the digital

display (2) will indicate the speed that was

previously set. The indicated speed will be

between “05” and “35” (5,000 and 35,000

RPM).

2. Push the right side of the switch in order

to turn it to the "OFF" position (3) (Fig. 19).

NOTE: The digital display will go blank.

ADJUSTING THE SPEED

The speed of the tool can be adjusted from

5,000 RPM to 35,000 RPM in order to

accommodate the various types of

operations.

NOTE: The motor is equipped with a soft

start feature. When the switch is turned to

the "ON" position, the motor will start

slowly, and will increase in speed until the

preset speed is attained.

ASSEMBLY AND OPERATING INSTRUCTIONS

Fig. 18

Fig. 19

!

Page 35

35

ADJUSTING THE SPEED – cont’d

1. Turn the switch to the "ON" position.

The rotary tool will start slowly, and will

increase in speed until the preset speed is

attained. The display will read between

“05” and “35” (5,000 and 35,000 RPM).

2. In order to increase the speed of the

tool, press the “+” speed control button (4)

once (Fig. 20). The speed of the tool will

increase by “02” (2,000 RPM).

3. Continue to increase the speed of the

tool by pressing the “+” speed control

button several times (Fig. 21). The speed

of the tool will increase by “02” (2,000

RPM) each time the “+” speed control

button is pressed, until it reaches the

maximum speed of “35” (35,000 RPM).

4. In order to decrease the speed of the

tool, press the “–” speed control button (5).

NOTE: Each time the “–“ speed control

button is pressed, the speed of the tool will

decrease by “02” (2,000 RPM).

SPEED MEMORY

The digital controls of this rotary tool

include a “memory” function. When the tool

is turned on, the tool will automatically start

at the speed that was set the last time the

tool was turned off. This function is

particularly useful when the tool is turned

off in order to change cutting bits.

Adjust the speed to the desired setting

each time the tool is turned on.

ASSEMBLY AND OPERATING INSTRUCTIONS

Fig. 20

Fig. 21

Page 36

36

WARNING: When servicing, use

only identical replacement parts. The use

of any other part may create a hazard or

damage the rotary tool.

Do not abuse power tools. Abusive

practices can damage the tool and the

workpiece.

WARNING: Do not attempt to

modify this rotary tool or to create

accessories. Any such alteration or

modification is considered to be misuse,

and could result in a hazardous condition

that may lead to serious injury. Doing so

will also void the warranty.

CLEANING

Do not use solvents to clean plastic parts.

Many plastics are susceptible to damage

from various types of commercial solvents.

Use a clean cloth to remove dirt, dust, oil,

grease, etc.

WARNING: Do not allow brake

fluids, gasoline, petroleum-based products,

penetrating oils, etc. to come into contact

with plastic parts. These substances

contain chemicals that can damage,

weaken, or destroy plastic.

Power tools are subjected to accelerated

wear and possible premature failure when

they are used on fiberglass boats and

sports cars, wallboard, spackling

compounds, or plaster. The chips and

grindings from these materials are

extremely abrasive to some parts of power

tools, including bearings, brushes,

commutators, etc. Therefore, it is

recommended that this tool not be used for

extended work on any fiberglass material,

wallboard, spackling compound, or plaster.

If this rotary tool is used on these

materials for an extended period, it must

be cleaned frequently by blowing it out with

an air jet.

WARNING: Wear safety goggles or

safety glasses that have side shields

whenever performing any operation

with a rotary tool. It is also critical to wear

safety goggles or safety glasses that have

side shields, as well as a dust mask, when

blowing dust out of the tool using an air jet.

Failure to observe these safety

precautions could result in permanent eye

or lung damage.

LUBRICATION

All of the bearings in this rotary tool have

been lubricated with a sufficient quantity of

high-grade lubricant for the life of the tool

under normal conditions. No further

lubrication is required.

!

!

MAINTENANCE

! ! !

Page 37

37

EXPLODED VIEW

Page 38

38

WARNING: When servicing, use only Mastercraft® replacement parts. The use of

any other parts may create a safety hazard or cause damage to the rotary tool.

Any attempt to repair or replace electrical parts on this rotary tool may create a safety

hazard unless repairs are performed by a qualified technician. For more information, call

the Toll-Free Helpline, at 1-800-689-9928.

Always order by PART NUMBER, not by key number.

Key #

Part #

Part Name

Quantity

1

313300

Accessory collar

1 2 215100

Collet nut

1 3 216506

1/8" collet

1

4

213016

Output shaft

1

5

520008

Bearing 626RS

2 6 314009

Fan 1 7

134008

Armature

1 8 138008

Stator

1

9

321006

Bearing sleeve

1

10

500843

Screw M3 x 10

2

11

504000

Spring washer 3

2

12

503008

Small washer 3

2

13

215014

Locking pin

1

14

221286

Washer

1

15

240824

Locking pin spring

1

16

312934

Spindle lock button

1

17

300076

Housing (right)

1

18

234033

Aluminium cover (right)

1

19

500001

Tapping screw ST2.9 x 16

6

20

162853

Rectifying PCB

1

21

500409

Tapping screw ST2.2 x 16

3

22

162852

V.S. PCB

1

23

242553

Hanging loop

1

24

312098

Back cover

1

25

317013

"-" speed control button

1

26

317012

"+" speed control button

1

27

500006

Tapping screw ST2.9 x 12

2

28

224455

Cord clamp

1

29

322006

Cord guard

1

30

160205

Cord set

1

31

314527

Brush holder support

2

32

222827

Brush holder

2

33

342027

Carbon brush

2

34

300076

Housing (left)

1

35

234033

Aluminium cover (left)

1

!

PARTS LIST

Page 39

39

Rev 1.3 13/07/2008

WARRANTY

*Limited 5-year Replacement Warranty

This Mastercraft Maximum product carries a five (5) year replacement

warranty against defects in workmanship and materials. Mastercraft

Canada agrees to replace the defective product free of charge with

the same model or one of equal value or specification, within the

stated warranty period, when returned by the original purchaser with

proof of purchase. The case carries a two (2) year replacement

warranty against defects in workmanship and materials. This product

is not guaranteed against wear or breakage due to misuse and/or

abuse.

This product is not guaranteed if used for industrial or

commercial purposes.

Loading...

Loading...