Page 1

model no. 062-3404-4

R

Submersible

SUMP PUMP

IMPORTANT:

Please read this manual carefully before installing

or operating this sump pump. Save this manual for

future reference.

INSTRUCTION

MANUAL

Page 2

headline bars

Page 3

TABLE OF CONTENTS

Technical Specifications 4

Safety Guidelines 6

Installation Instructions 8

Operation and Maintenance 9

Key Parts Diagram 10

Troubleshooting 11

Warranty Information 12

3

TABLE OF CONTENTS

NOTE:

If any parts are missing or damaged, or if you have any questions, please call our

toll-free helpline at 1-800-689-9928.

SAVE THESE INSTRUCTIONS

This manual contains important safety and operating instructions.

Read all instructions and follow them with use of this product.

Page 4

headline bars

headline bars

4

TECHNICAL SPECIFICATIONS

model no. 062-3404-4 | contact us: 1-800-689-9928

MOTOR SPECIFICATIONS

Horsepower 1/3

Voltage 115

Amps 4.1

Hertz 60 Hz

Phase Single

RPM 3450 RPM

Motor Type Permanent split capacitor (PSC)

Insulation Class A

Circuit Requirements 15 A (min) individual circuit

Duty Rating Continuous*

Shaft Seal Carbon/ceramic and stainless steel

Motor Shaft Stainless steel

Upper Motor Bearing Ball bearing

Lower Motor Bearing Ball bearing

Cooling Oil cooled

Motor Protection Auto reset thermal overload protector

*For continuous operation, the water depth must be at least 6” (15.24 cm) to prevent the motor

from overheating.

PUMP SPECIFICATIONS

Discharge Size 1 1/2” FNPT (3.8 cm)

Cord Length 10’ (3 m)

Cord Type SJTW, UL listed, 3-wire, 18 gauge

Pump Housing Cast iron

Pump Base Cast iron

Impeller Material Stainless steel

Impeller Type Non-clogging

Gasket Buna-N

Solids Handling 3/8” Spherical (9.5mm)

Liquid Temp. Range 32–120°F (0–49°C)

Operation Automatic or non-automatic

Fasteners Stainless steel

Max Flow Rate 2760 U.S. GPH (10,448 L/hr)

Maximum Head 25’ (8 m)

Max Pressure 10.8 PSI (74.5 kPa)

Weight 17 lb (7.71 kg)

Page 5

AUTOMATIC FLOAT SWITCH SPECIFICATIONS

Type Vertical with piggy-back plug

Switch on point* (factory set) 6” (15.24 cm)

Switch off point* (factory set) 2” (5.08 cm)

Material Polypropylene

Cord Length 10’ (3.05 m)

Cord Type SJOW, UL listed, 2-wire, 18 gauge

*Adjustable by changing tether length

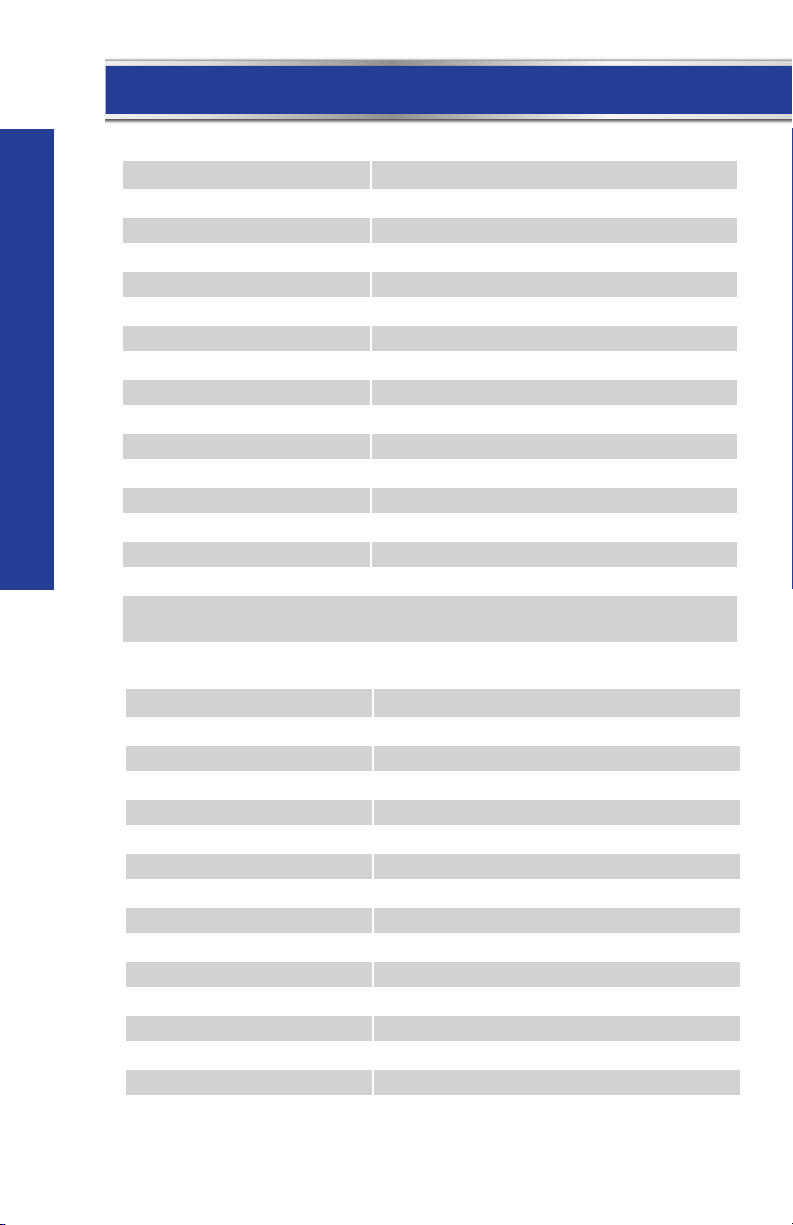

PERFORMANCE CHART

Lift 0’

(0 m)

Flow 2760 U.S. GPH

(10,448 L/Hr)

*Friction loss in piping not included in measurement

5’

(1.5 m)

2160 U.S. GPH

(8,176 L/Hr)

10’

(3 m)

1800 U.S. GPH

(6,813 L/Hr)

15’

(4.6 m)

1500 U.S. GPH

(5,678 L/Hr)

20’

(6 m)

720 U.S. GPH

(2,725 L/Hr)

DIMENSIONS

5

25’

(7.6 m)

60 U.S. GPH

(227 L/Hr)

TECHNICAL SPECIFICATIONS

310 mm

12 3/16”

8 3/8”

214 mm

3 1/2”

89 mm

6”

152 mm

7 3/4”

197 mm

100 mm

7 3/4”

197 mm

3 7/8”

Page 6

headline bars

headline bars

6

model no. 062-3404-4 | contact us: 1-800-689-9928

SAFETY GUIDELINES

Carefully read, understand and follow all safety instructions in this manual. This

is the safety alert symbol. When you see this symbol, look for one of the following signal

words.

Indicates a hazardous situation which, if not avoided, will result in death or

serious injury.

Indicates a hazardous situation which, if not avoided, could result in death or

serious injury.

Indicates a hazardous situation which, if not avoided, could result in minor or

moderate injury.

Indicates important information, that if not followed, may result in damage to

the equipment.

Safety Information

Read these warnings carefully. Know the application and limitations of this pump. Failure to

follow these warnings could result in serious bodily injury and/or property damage.

RISK OF ELECTRIC SHOCK. Disconnect and lockout power supply before

SAFETY GUIDELINES

removing old pump or installing or servicing this pump.

RISK OF ELECTRIC SHOCK. This pump is supplied with a grounding

conductor and grounding type attachment plug. To reduce the risk of electric

shock, be certain that it is connected only to a properly grounded, grounding type receptacle.

For added safety, it is highly recommended to connect this pump to a GFCI (Ground Fault Circuit

Interrupter) outlet. Connect only to a receptacle that is adequately rated for the voltage and

amperage of this pump.

The installation of this pump must be in accordance with the Canadian

Electrical Code (CE code), National Plumbing Code of Canada (NPC),

International Plumbing Code (IPC) as well as all applicable local codes and ordinances.

Do not install this pump in any location classified as hazardous by the

Canadian Electrical Code (CE code)

Do not use this pump to pump flammable or explosive fluids such as gasoline,

kerosene, etc. Do not use this pump in flammable or explosive environments.

Use only with liquids compatible with pump component materials.

RISK OF ELECTRIC SHOCK. This pump has not been investigated for use in

swimming pool or marine areas.

RISK OF ELECTRIC SHOCK. DO NOT use the power cord to remove or lower

the pump into the basin. The cord may pull apart exposing bare wires which

could cause a fire or electrical shock. Use the handle supplied with the pump for installing and

removing the pump from the basin.

Do not run the pump dry. This pump relies on water for cooling. Running the

pump dry can cause the pump to overheat and the possibility of burns to

anyone that handles the pump. Running the pump dry will void the warranty.

Do not use this pump for potable/drinking water. Use only in applications for

which the pump is designed.

Do not expose pump to freezing temperatures. Discharge lines exposed to

freezing temperatures should be positioned with a downward slope to prevent

freezing.

Page 7

SAFETY GUIDELINES (CONTINUED)

DO NOT UNDER ANY CIRCUMSTANCES REMOVE THE GROUND PIN. The

3-prong plug must be inserted into a mating 3-prong grounded receptacle.

If the installation does not have such a receptacle, it must be changed to the proper type, wired

and grounded in accordance with the Canadian Electrical Code and all applicable local codes and

ordinances.

All wiring must be performed by a qualified electrician.

Keep hands clear of suction and discharge openings. To prevent injury, never

insert fingers into pump while it is plugged in.

Sump basins must be vented according to local plumbing codes.

Do not handle this pump with wet hands or while standing on wet or damp

surfaces or in water.

If a flexible discharge hose is used, make sure the pump is secured in the

basin to prevent movement. Failure to secure the pump could result in

flooding from switch malfunction.

This pump motor is equipped with an automatic resetting thermal protector

and may restart unexpectedly.

Please read this before installing or operating pump. This information is provided for your

SAFETY and to PREVENT EQUIPMENT PROBLEMS. Most accidents can be avoided by using COMMON SENSE.ts.

• Always wear appropriate safety gear, such as safety glasses, when working on the pump

or piping.

• Only qualified personnel should install, operate, and repair pump.

• Make sure lifting handle is securely fastened each time before lifting.

• Do not lift pump by the power cord.

• Do not exceed manufacturer’s recommendation for maximum performance, as this could cause the

motor to overheat.

• Secure the pump in its operating position so it cannot tip over, fall, or slide.

• Keep hands and feet away from impeller when power is connected.

• Any wiring of pumps should be performed by a qualified electrician.

• Cable should be protected at all times to avoid punctures, cuts, and abrasions. Inspect frequently.

• Do not remove cord and strain relief.

• Mastercraft® Canada is not responsible for losses, injury, or death resulting from a failure to observe

these safety precautions, or misuse or abuse of pumps or equipment.

7

SAFETY GUIDELINES

CAUTION!

• Do not wear loose clothing that may become entangled in the impeller or other moving parts.

• Pumps generate heat and pressure during operation. Allow time for pumps to cool before handling or servicing.

• Keep clear of suction and discharge openings. Do not insert fingers in pump with power connected.

• Never operate a pump with a power cord that has frayed or brittle insulation.

WARNING!

• To reduce risk of electric shock, all wiring and junction connections should be made per the Canadian Electrical Code

(CEC) and applicable provincial and local codes. Requirements may vary depending on usage and location.

• To reduce risk of electric shock, always disconnect the pump from the power source before handling or servicing.

Page 8

headline bars

headline bars

8

model no. 062-3404-4 | contact us: 1-800-689-9928

UNPACKING

• Upon receiving the pump, it should be inspected for damage or missing parts. If you have

concerns please contact customer support at 1-800-689-9928.

REMOVING OLD PUMP (IF NECESSARY)

1. Remove the old pump from the basin. If you need to cut the old discharge pipe to remove

the pump, cut it as close to floor level as possible. If a check valve is attached to the pump,

be prepared for water to leak from the pipe. Allow water to drain into the sump basin.

2. Inspect the basin for accumulated mud, sand, silt or small stones. Clean out the basin if

necessary.

INSTALL NEW PUMP

1. Connect the discharge pipe to the pump discharge. Do not use pipe joint compound on

plastic pipe or plastic pump threads as this can degrade the plastic. Use non-stick tape if

necessary.

2. Install a full flow, swing type check valve (sold separately) either directly into the pump

discharge or on the discharge pipe. Make sure the check valve is positioned in the correct

INSTALLATION INSTRUCTIONS

direction of flow.

3. Place the pump on a solid, level surface in the basin. Use bricks or blocks to raise the

pump off the bottom surface. Do not place the pump directly in mud, sand, silt or on rocky

surfaces as these materials can clog or damage the pump. Do not lower the pump into the

basin by the power cord or discharge pipe; use the attached handle.

4. Position the pump in the basin making sure that the float switch will operate freely without

coming in contact with the sides of the basin.

5. Once the pump is positioned in the basin, mark and cut your existing discharge pipe to

fit the height of the pump or continue installation of discharge pipe to the outside of the

building.

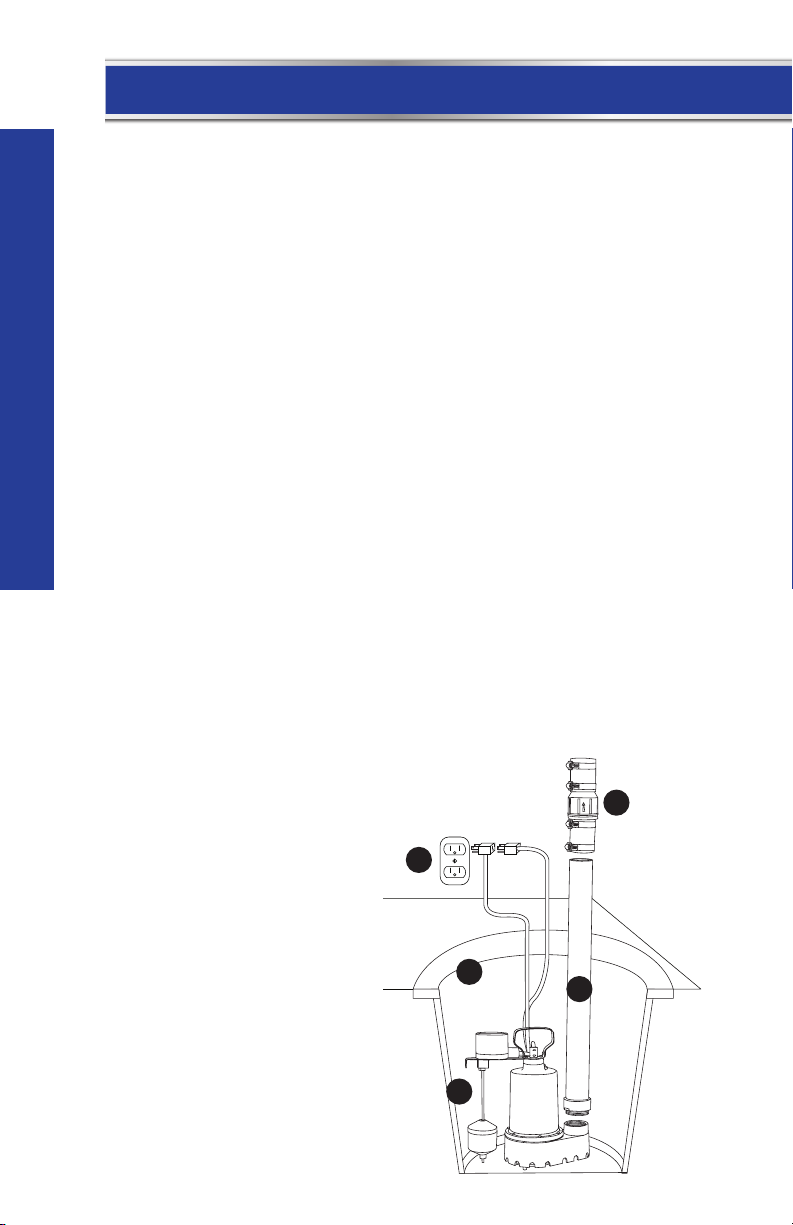

INSTALLATION DIAGRAM

A. Grounded outlet. A

GFCI outlet is strongly

recommended.

B. Discharge pipe

C. Full-flow swing type check

valve

D. Sump basin

E. Position pump so the float

switch operates freely

without touching the sides

of the basin.

C

A

D

B

E

Page 9

OPERATION

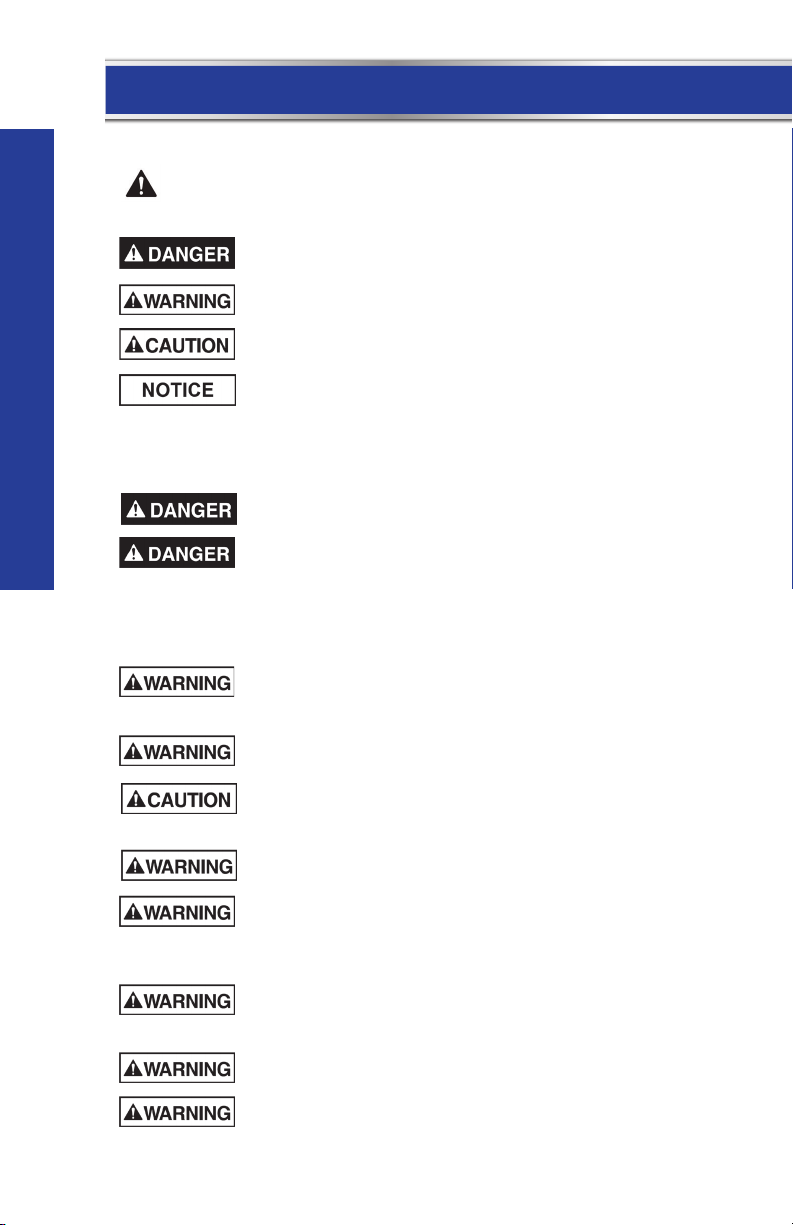

1. See Figure 2 for pump plug-in instructions.

• Automatic: Plug the piggy-back plug of the float

switch into a 115 V grounded outlet. The use of a

GFCI is strongly recommended. Plug the pump plug

into the back of the piggy-back float switch plug.

• Manual: Plug the pump plug into a 115 V grounded

outlet. The use of a GFCI is strongly recommended.

2. Test your installation by filling the basin with water. Observe the float switch through at least

one complete cycle to ensure it operates freely and does not contact the sides of the basin. If

necessary, adjust the float switch or reposition the pump to ensure proper operation.

3. This pump is equipped with an anti-airlock hole. A stream of water will emit from this hole

when the pump is operating. This is a normal feature of this pump. The anti-airlock hole

should be cleaned periodically to prevent the pump from becoming air-locked.

4. Do not let the pump run dry. The pump depends on water for cooling and lubrication.

Operating the pump without water may cause the motor to overheat or cause damage to

internal parts. It may also shorten the life of your pump.

5. Your pump motor is thermally protected. It is not recommended for pumping liquids over

120°F (49°C). The thermal overload protector will automatically shut down the pump in an

overheat situation. The pump will reset itself once the pump cools down. This overload is

designed as a safety device and it will fail after repeated use. Normal operation is for fluids

between 32 and 120°F (0 and 49°C).

Risk of electric shock. Always disconnect the power supply before attempting

to install, service or perform maintenance on the pump.

All repairs must be made by an authorized service centre.

This submersible pump contains oil which may become pressurized and hot

under normal operating conditions – allow the pump to cool for 2–3 hours

before servicing.

FIGURE 2

AUTOMATIC

MANUAL

MAINTENANCE

1. The pump motor is hermetically sealed in the housing and does not require any service.

Disassembly of the motor housing or modification of the power cord voids the warranty.

2. Periodically check the sump basin for accumulation of mud, silt, sand and foreign objects. Clean

the basin as needed to prevent damage or clogging of the pump.

3. Periodically check the removable intake screen for obstructions. Clean if necessary.

4. Periodically inspect and clean the anti-airlock hole.

5. Inspect the float switch for any accumulated debris that may inhibit it from operating properly.

Clean if necessary.

6. Inspect the impeller for signs of wear and obstructions.

7. Inspect the power cord for signs of damage or wear. Do not operate the pump if the cord is

damaged or worn.

8. In applications where the pump may not activate for extended periods of time, it is recommended

to cycle the pump at least once per month to ensure the pumping system is working properly when

needed.

9

OPERATION AND MAINTENANCE

Page 10

headline bars

10

headline bars

model no. 062-3404-4 | contact us: 1-800-689-9928

PARTS LIST

No. Description Qty.

1 Power Cord 1

2 Handle 1

3

4 Float Switch 1

5 Shaft Seal 1

6 Impeller 1

7 Gasket 1

8 Base / Volute 1

9 Intake Screen 1

10 Motor 1

11 Float Switch

KEY PARTS DIAGRAM

*If motor fails, replace

entire pump.

Oil Fill Plug

with O-Ring

Bracket

11

1

1

2

3

1

4

10

*

5

6

7

8

9

Page 11

TROUBLESHOOTING

Problem Possible Causes Solution

The pump does not

start or run.

The pump starts and

stops too often.

The pump runs but

moves little or no

water.

Pump is not plugged in, switch or

breaker is off.

Check for blown fuses or tripped

circuit breakers or tripped GFCI

outlets.

Float switch is defective.

Motor thermal protector tripped.

Float is stuck or obstructed. Remove obstruction or position the pump so it

Backflow of water from discharge

hose/pipe.

Float switch is defective. Replace float switch.

Clogged discharge hose/pipe. Remove clog.

Frozen discharge hose/pipe. Allow hose/pipe to thaw.

Pump is air locked. Check airlock hole for clogs and clean if

Low line voltage. Check wire size and increase if necessary.

Check valve is stuck in the closed

position.

Check valve is installed backwards. Make sure valve is installed in the correct

Worn, damaged or clogged pump

parts.

Discharge head exceeds pump

capacity.

Plug pump in or turn on switch/breaker.

Replace fuse, reset breaker, reset GFCI outlet.

Check and replace if necessary.

Allow pump to cool. Pump will reset

automatically.

will not become stuck.

Install or replace check valve.

necessary.

Inspect, repair or replace if necessary.

direction of flow.

Inspect for wear, damage or clog and clean or

replace if necessary.

See performance chart for pump limitations,

see page 5.

11

TROUBLESHOOTING

Pump does not

shut off.

Float is obstructed or stuck. Remove obstruction.

Pump plug is not plugged into piggy-

back float switch plug.

Defective switch. Replace float switch.

Plug pump plug into float switch plug for

automatic operation. See page 9.

NOTE: Not all problems and corrections will apply to each pump. model.

CAUTION!

• Always disconnect the pump from the electrical power source before handling. If the system fails to operate

properly, carefully read instructions and perform maintenance recommendations. If operating problems persist, the

troubleshooting chart above may be of assistance in identifying and correcting them.

Page 12

headline bars

12

WARRANTY INFORMATION

This Mastercraft product is guaranteed for a period of three (3) years from the date of original retail

purchase against defects in materials and workmanship.

Subject to the conditions and limitations described below, this product, if returned to us with proof of purchase

within the stated warranty period and if covered under this warranty, will be repaired or replaced (with the same

model, or one of equal value or specification), at our option. We will bear the cost of any repair or replacement and

any costs of labour relating thereto.

These warranties are subject to the following conditions and limitations:

a. A bill of sale verifying the purchase and purchase date must be provided;

b. This warranty will not apply to any product or part thereof which is worn or broken or which has become

inoperative due to abuse, misuse, accidental damage, neglect or lack of proper installation, operation or

maintenance (as outlined in the applicable owner’s manual or operating instructions) or which is being used

for industrial, professional, commercial or rental purposes;

c. This warranty will not apply to normal wear and tear or to expendable parts or accessories that may be

supplied with the product which are expected to become inoperative or unusable after a reasonable period

of use;

d. This warranty will not apply to routine maintenance and consumable items such as, but not limited to, fuel,

lubricants, vacuum bags, blades, belts, sandpaper, bits, fluids, tune-ups or adjustments;

e. This warranty will not apply where damage is caused by repairs made or attempted by others (i.e., persons

not authorized by the manufacturer);

f. This warranty will not apply to any product that was sold to the original purchaser as a reconditioned or

refurbished product (unless otherwise specified in writing);

g. This warranty will not apply to any product or part thereof if any part from another manufacturer is installed

therein or any repairs or alterations have been made or attempted by unauthorized persons;

h. This warranty will not apply to normal deterioration of the exterior finish, such as, but not limited to,

scratches, dents, paint chips, or to any corrosion or discolouring by heat, abrasive and chemical cleaners;

and

i. This warranty will not apply to component parts sold by and identified as the product of another company,

which shall be covered under the product manufacturer’s warranty, if any.

Additional Limitations

This warranty applies only to the original purchaser and may not be transferred. Neither the retailer nor the

manufacturer shall be liable for any other expense, loss or damage, including, without limitation, any indirect,

incidental, consequential or exemplary damages arising in connection with the sale, use or inability to use this

product.

Notice to Consumer

This warranty gives you specific legal rights, and you may have other rights, which may vary from province to

province. The provisions contained in this warranty are not intended to limit, modify, take away from, disclaim or

exclude any statutory warranties set forth in any applicable provincial or federal legislation.

Page 13

N° de modèle : 062-3404-4

R

POMPE DE VIDANGE

Immergée

IMPORTANT :

Veuillez lire ce guide attentivement avant de

procéder à l’installation ou à l’utilisation de cette

pompe. Conservez ce guide pour toute consultation

ultérieure.

GUIDE

D’UTILISATION

Page 14

headline bars

Page 15

TABLE DES MATIÈRES

Fiche technique 4

Consignes de sécurité 6

Instructions d'installation 8

Fonctionnement et entretien 9

Schéma des pièces clés 10

Dépannage 11

Garantie 12

15

TABLE DES MATIÈRES

REMARQUE :

Si des pièces sont manquantes ou endommagées, ou si vous avez des questions,

veuillez appeler notre service d’assistance téléphonique sans frais au 1 800 689-

9928.

CONSERVEZ CES CONSIGNES

Le présent guide d’utilisation contient un mode d’emploi et des consignes de sécurité

importants. Lisez et respectez toutes les instructions lorsque vous utilisez ce produit.

Page 16

headline bars

headline bars

16

N° de modèle : 062-3404-4 | Communiquez avec nous au 1 800 689-9928

FICHE TECHNIQUE DU MOTEUR

Puissance 1/3 HP

Tension 115 V

Ampères 4,1 A

hertz 60 Hz

Courant Monophasé

Tr/min 3 450

Type de moteur Condensateur auxiliaire permanent

Isolation Classe A

Exigences du circuit Circuit individuel de 15 A (min)

Cycle de travail Continu*

Joint d'arbre Carbone/céramique et acier inoxydable

Arbre du moteur Acier inoxydable

Palier supérieur du moteur Roulement à billes

Palier inférieur du moteur Roulement à billes

FICHE TECHNIQUE

Refroidissement Refroidissement à l'huile

Protection du moteur Circuit de protection thermique intégré à réinitialisation

*Pour assurer un fonctionnement continu, la profondeur d'eau doit être d'au moins 6 po (15, 24

cm) pour éviter toute surchauffe du moteur.

automatique

FICHE TECHNIQUE DE LA POMPE

Diamètre du raccord de refoulement 1 1/2 po (38,1 mm) à filetage femelle NPT

Longueur du cordon 10 pi (3 m)

Type de cordon SJTW, homologué UL, 3 fils, calibre 18

Boîtier de pompe Fonte

Pied de la pompe Fonte

Matériau de la tête de pompe Acier inoxydable

Type de tête de pompe Résistant au colmatage

Joint d'étanchéité Buna-N

Acceptant les matières solides Turbine d'un diamètre de 3/8 po (9,5 mm)

Températures des liquides 32 à 120 °F (0 à 49 °C)

Fonctionnement Automatique ou manuel

Dispositifs de fixation Acier inoxydable

Débit maximal 2 760 gal US/h (10 448 L/h)

Colonne d'eau maximale 25 pi (8 m)

Pression maximale 10,8 lb/po² (74,5 kPa)

Poids 17 lbs (7,71 kg)

Page 17

FICHE TECHNIQUE DU CONTACTEUR À FLOTTEUR CAPTIF

Type Interrupteur verticalet fiche à prise arrière intégrée.

Point d'activation (réglé en usine) 10 po (25,4 cm)

Point d'inactivation (réglé en usine) 2 po (5,08 cm)

Matériau Polypropylène

Longueur du cordon 10 pi (3 m)

Type de cordon SJOW, homologué UL, 2 fils, calibre 18

*Réglable en modifiant la longueur du contacteur

TABLEAU DE RENDEMENT

Hauteur de

refoulement

Débit 2 760 gal US/h

*La mesure ne tient pas compte de la perte de pression dans le tuyau

DIMENSIONS

0 pi

(0 m)

(10 448 L/h)

5 pi

(1,5 m)

2 160 gal US/h

(8 176 L/h)

10 pi

(3 m)

1 800 gal US/h

(6 813 L/h)

15 pi

(4,6 m)

1 500 gal US/h

(5 678 L/h)

20 pi

(6 m)

720 gal US/h

(2 725 L/h)

17

25 pi

(7,6 m)

60 gal US/h

(227 L/h)

FICHE TECHNIQUE

310 mm

12 3/16 po

214 mm

8 3/8 po

89 mm

3 1/2 po

6 po

152 mm

7 3/4 po

197 mm

3 7/8 po

100 mm

7 3/4 po

197 mm

Page 18

headline bars

headline bars

18

N° de modèle : 062-3404-4 | Communiquez avec nous au 1 800 689-9928

CONSIGNES DE SÉCURITÉ

Lisez attentivement, comprenez et suivez toutes les consignes de sécurité dans

ce guide. Ceci est un symbole d’avertissement. Lorsque vous apercevez ce symbole,

recherchez l’un des mots d’avertissement suivants.

Indique une situation dangereuse qui, si elle n’est pas évitée, entraînera la

mort ou des blessures graves.

Indique une situation dangereuse qui, si elle n’est pas évitée,

pourrait entraîner la mort ou des blessures graves.

Indique une situation dangereuse qui, si elle n’est pas évitée, pourrait

entraîner des blessures légères ou modérées.

Indique la présence de renseignements importants qui, s’ils ne sont pas suivis,

pourraient entraîner des dommages à l’équipement.

Consignes de sécurité

Lisez attentivement ces avertissements. Prenez connaissance des applications et des contraintes

de cette pompe. Le non-respect de ces avertissements pourrait entraîner des blessures

corporelles graves et/ou des dommages matériels.

RISQUE DE CHOC ÉLECTRIQUE. Coupez et verrouillez l’alimentation

CONSIGNES DE SÉCURITÉ

électrique avant de retirer une pompe usagée, d’en installer une neuve ou

d’effectuer toute tâche d’entretien.

RISQUE DE CHOC ÉLECTRIQUE. Cette pompe est munie d’un conducteur

de mise à la terre et d’une fiche de mise à la terre. Pour réduire le risque

de choc électrique, assurez-vous de brancher la pompe uniquement à une prise correctement

mise à la terre. Pour une sécurité accrue, nous vous recommandons fortement de brancher cette

pompe à une prise équipée d’un disjoncteur de fuite de terre. Branchez-la uniquement à une prise

adaptée à la tension et à l’intensité de cette pompe.

L’installation de cette pompe doit être conforme au Code

canadien de l’électricité, au Code national de plomberie du

Canada, au Code international de la plomberie et tous les autres codes et règlements municipaux

en vigueur.

N’installez pas cette pompe dans un endroit classé comme

dangereux par le Code canadien de l’électricité.

N’utilisez pas cette pompe pour l’aspiration de substances inflammables

ou explosives, comme l’essence, le kérosène, etc. N’utilisez pas la pompe

dans des milieux inflammables et explosifs. N’utilisez la pompe qu’avec des liquides compatibles

avec les matériaux de ses composants.

RISQUE DE CHOC ÉLECTRIQUE. Cette pompe n’a pas été

conçue pour une utilisation dans les piscines ou les zones

maritimes.

RISQUE DE CHOC ÉLECTRIQUE. N’utilisez PAS le cordon

d’alimentation pour monter ou descendre la pompe dans le

bassin. Le cordon pourrait se déchirer, exposant ainsi des fils nus qui pourraient poser un risque

d’incendie ou de décharge électrique. Utilisez la poignée fournie avec la pompe lorsque vous

montez et descendez la pompe du bassin.

Ne faites pas tourner la pompe à sec. Cette pompe emploie

de l’eau pour le refroidissement. Faire tourner la pompe à sec

pourrait causer sa surchauffe et un risque de brûlure pour toute personne qui la manipule. Faire

tourner la pompe à sec annulera sa garantie.

Page 19

CONSIGNES DE SÉCURITÉ (SUITE)

N’utilisez pas cette pompe pour aspirer de l’eau potable. Utilisez-la

uniquement aux fins prévues.

N’exposez pas la pompe au point de congélation. Les tuyaux

de refoulement exposés au point de congélation doivent être

positionnés vers le bas pour prévenir toute congélation.

VOUS NE DEVEZ JAMAIS, SOUS AUCUN PRÉTEXTE, RETIRER

LA BROCHE DE MISE À LA TERRE. La fiche à 3 broches doit être

insérée dans une prise mise à la terre correspondante à 3 fentes. Si vous ne possédez pas ce type

de prise, vous devez la remplacer par une prise adéquate, câblée et mise à la terre conformément

au Code canadien de l’électricité et tout autre code municipal en vigueur.

Tout le câblage doit être effectué par un électricien qualifié.

Tenez vos mains à l’écart des orifices d’aspiration et de

refoulement. Pour prévenir les blessures, n’insérez jamais vos

doigts dans la pompe lorsqu’elle est branchée.

Ne manipulez pas cette pompe avec des mains mouillées ou

lorsque vous avez les pieds sur des surfaces mouillées ou

humides ou dans l’eau.

Si vous utilisez un tuyau de refoulement flexible, assurez-vous

de bien raccorder la pompe au bassin pour éviter que la pompe

se déplace. Le non-respect de cette consigne pourrait entraîner une inondation causée par une

anomalie du contacteur.

Le moteur de cette pompe est muni d’un circuit de protection thermique

intégré à réinitialisation automatique et pourrait redémarrer inopinément.

Veuillez lire les consignes suivantes avant de procéder à l’installation ou à l’utilisation de la pompe.

Ces renseignements sont fournis pour votre sécurité et pour ÉVITER LES PROBLÈMES D’ÉQUIPEMENT. La plupart

des accidents peuvent être évités en utilisant le BON SENS.

• Portez toujours de l’équipement de sécurité adéquat, comme des lunettes de sécurité, lorsque vous travaillez

avec la pompe ou de la tuyauterie.

• Seules les personnes qualifiées sont autorisées à installer, utiliser et réparer la pompe.

• Assurez-vous, en tout temps, que la poignée de transport est bien fixée avant de soulever l’appareil.

• Ne soulevez pas la pompe par le cordon d’alimentation.

• N’excédez pas le rendement maximal recommandé par le fabricant, car cela pourrait causer la surchauffe du

moteur.

• Fixez la pompe dans sa position de travail de sorte qu’elle ne puisse basculer, chuter ou glisser.

• Tenez les mains et les pieds à l’écart de la tête de pompe lorsque l’appareil est branché.

• Tout câblage de pompe doit être effectué par un électricien qualifié.

• Les câbles doivent être protégés en tout temps pour éviter les perforations, les coupures et l’abrasion.

Examinez l’appareil régulièrement.

• Ne retirez pas le cordon ou le serre-câble.

• MastercraftMD Canada ne peut pas être tenue responsable des dommages, blessures ou de la mort découlant

du non-respect de ces consignes, ou d’une utilisation inadéquate ou abusive de pompes et d’équipement.

19

CONSIGNES DE SÉCURITÉ

ATTENTION!

• Ne portez pas des vêtements amples qui risquent de se prendre dans la tête de pompe ou d’autres pièces mobiles.

• Les pompes produisent de la chaleur et de la pression durant leur utilisation. Laissez les pompes refroidir avant de les

manipuler ou d’effectuer toute tâche d’entretien.

• Restez à l’écart des orifices d’aspiration et de refoulement. N’insérez jamais vos doigts dans la pompe lorsqu’elle est

branchée.

• N’utilisez jamais une pompe munie d’un cordon d’alimentation dont l’isolation est dénudée ou se détériore.

AVERTISSEMENT!

• Pour réduire le risque de choc électrique, tout le câblage et tous les raccordements de jonction doivent être effectués

conformément au Code canadien de l’électricité et tous les autres codes provinciaux et municipaux en vigueur. Les

exigences peuvent varier selon l’usage et l’emplacement.

• Pour réduire le risque de choc électrique, débranchez toujours la pompe de la source d’alimentation avant de manipuler

l’appareil ou d’effectuer toute tâche d’entretien.

Page 20

headline bars

headline bars

20

CONSIGNES D’INSTALLATION

N° de modèle : 062-3404-4 | Communiquez avec nous au 1 800 689-9928

DÉBALLAGE

• Lorsque vous recevez la pompe, examinez-la pour repérer tout dommage ou toute pièce

manquante. Pour toute question, veuillez communiquer avec le service à la clientèle en

composant le 1 800 689-9928.

RETRAIT D’UNE POMPE USÉE (AU BESOIN)

1. Retirez la pompe usée du bassin. Si vous avez besoin de couper l’ancien tuyau de

refoulement pour retirer la pompe, coupez-le le plus près du plancher que possible. Si un

clapet de non-retour est raccordé à la pompe, de l’eau coulera du tuyau. Laisser l’eau couler

dans le bassin.

2. Examinez le bassin pour toute accumulation de boue, de sable, de limon et de cailloux.

Nettoyez le bassin, au besoin.

INSTALLATION D’UNE POMPE NEUVE

1. Raccordez le tuyau de refoulement à l’orifice de refoulement de la pompe. N’utilisez pas un

composé de scellement sur les joints filetés en plastique du tuyau ou de la pompe car cela

causera sa dégradation. Utilisez du ruban pour joints filetés, au besoin.

2. Raccordez un clapet de non-retour à battant de plein débit (vendu séparément) soit

directement à l’orifice de refoulement de la pompe ou au tuyau de refoulement. Assurezvous de raccorder le clapet de non-retour dans le bon sens, en suivant le flux.

3. Placez la pompe sur une surface plane et solide dans le bassin. Utilisez des briques ou des

blocs pour surélever la pompe du fond du bassin. Ne placez pas la pompe directement dans

la boue, le sable, le limon, ou sur toute surface rocheuse, car ces matières peuvent colmater

et endommager la pompe. Ne descendez pas la pompe dans le bassin à l’aide du cordon

d’alimentation ou du tuyau de refoulement; utilisez la poignée fournie.

4. Placez la pompe dans le bassin en vous assurant que le flotteur puisse monter et descendre

librement sans toucher les parois du bassin.

5. Une fois que la pompe est positionnée dans le bassin, marquez et coupez votre tuyau de

refoulement actuel de sorte qu’il corresponde à la hauteur de la pompe ou installez le tuyau

de refoulement en l’orientant vers l’extérieur de l’immeuble.

SCHÉMA D’INSTALLATION

A. Prise de mise à la terre.

Nous vous recommandons

fortement d’utiliser un

disjoncteur de fuite de terre.

B. Tuyau de refoulement

C. Clapet de non-retour à

battant de plein débit

D. Bassin de puisard

E. Positionnez la pompe de

sorte que le contacteur à

flotteur monte et descende

sans toucher les parois du

bassin.

C

A

D

B

E

Page 21

FONCTIONNEMENT

• Consultez la Figure 2 pour les consignes relatives au

branchement de la pompe.

• Automatique : Branchez la fiche à prise arrière

intégrée du contacteur à flotteur à une prise mise à la

terre de 115 V. Nous vous recommandons fortement

d’utiliser un disjoncteur de fuite de terre. Branchez la

fiche de la pompe au dos de la fiche à prise arrière

intégrée.

• Manuel : Branchez la fiche de la pompe à une prise mise à la terre de 115 V. Nous vous

recommandons fortement d’utiliser un disjoncteur de fuite de terre.

2. Testez l’installation en remplissant le bassin avec de l’eau. Observez le contacteur à flotteur

pendant un cycle complet pour vous assurer qu’il monte et descend librement et ne touche

pas aux parois du bassin. Réglez le contacteur à flotteur ou repositionnez la pompe pour

assurer un fonctionnement adéquat, au besoin.

3. Cette pompe est munie d’un trou d’échappement. Un jet d’eau sortira de ce trou lorsque la

pompe est en marche. Ceci est une caractéristique normale. Le trou d’échappement doit être

nettoyé régulièrement pour éviter que la pompe se verrouille.

4. Ne faites pas tourner la pompe à sec. Cette pompe emploie de l’eau pour le refroidissement

et la lubrification. Faire tourner la pompe à sec pourrait causer sa surchauffe et endommager

des pièces internes. Ceci pourrait aussi réduire la durée de vie de votre pompe.

5. Le moteur de la pompe est muni d’une protection thermique. Nous vous déconseillons de

procéder à l’aspiration de liquides d’une température supérieure à 120 °F (49 °C). Le circuit

de protection thermique arrêtera la pompe automatiquement si cette dernière surchauffe.

Elle se réinitialisera après le refroidissement. Le circuit de protection thermique est un

dispositif de sécurité qui cessera de fonctionner si utilisé à répétition. En temps normal, la

pompe peut être utilisée pour aspirer des liquides d’une température entre 32 et 120 °F (0 et

49 °C).

FIGURE 2

AUTOMATIQUE

MANUEL

21

FONCTIONNEMENT ET ENTRETIEN

Risque de choc électrique. Débranchez toujours la source d’alimentation

avant d’installer la pompe ou d’effectuer des réparations ou des tâches

d’entretien.

Toutes les réparations doivent être effectuées dans un centre de

service autorisé.

Cette pompe immergée contient de l’huile qui pourrait devenir chaude et

sous pression dans des conditions de fonctionnement normal – Laissez la

pompe se refroidir 2 à 3 heures avant d’effectuer toute tâche d’entretien.

ENTRETIEN

1. Le moteur de la pompe est scellé hermétiquement dans le boîtier et ne nécessite aucun entretien.

Tout démontage du boîtier du moteur ou toute modification apportée au cordon d’alimentation

annulera la garantie.

2. Examinez régulièrement le bassin pour toute accumulation de boue, de limon, de sable et de corps

étrangers. Nettoyez le bassin, au besoin, pour prévenir tout dommage ou colmatage de la pompe.

3. Examinez régulièrement la crépine d’aspiration pour toute obstruction. Nettoyez-la au besoin.

4. Examinez et nettoyez le trou d’échappement régulièrement.

5. Examinez le contacteur à flotteur pour toute accumulation de débris qui pourrait empêcher la pompe

de fonctionner adéquatement. Nettoyez-la au besoin.

6. Examinez la tête de pompe pour toute trace d’usure et d’obstruction.

7. Examinez le cordon d’alimentation pour toute trace d’endommagement ou d’usure. N’utilisez pas la

pompe si le cordon d’alimentation est endommagé ou usé.

8. Lorsque vous n’utilisez pas la pompe pendant des périodes prolongées, nous vous recommandons

d’utiliser la pompe au moins une fois par mois pour assurer l’efficacité du système d’aspiration.

Page 22

headline bars

22

headline bars

N° de modèle : 062-3404-4 | Communiquez avec nous au 1 800 689-9928

LISTE DES PIÈCES

N° Description Qté

1 Cordon

d’alimentation

2 Guidon 1

3 Bouchon de

remplissage

d'huile avec

joint torique

4 Contacteur à

flotteur

5 Joint de

l’arbre

6 Tête de

pompe

SCHÉMA DES PIÈCES CLÉS

7 Joint

d'étanchéité

8 Base/sortie 1

9 Crépine

d'aspiration

10 Moteur 1

11 Support

D’interrupteur

à Flotteur

*Si le moteur ne

fonctionne pas, remplacez

complètement la pompe.

1

1

1

1

1

1

1

1

11

1

2

4

5

6

3

10

*

7

8

9

Page 23

DÉPANNAGE

Problème Causes possibles Solution

La pompe ne

démarre pas ou ne

fonctionne pas.

La pompe démarre

et s’arrête trop

fréquemment.

La pompe fonctionne

mais n’aspire que

de petites quantités

d’eau ou pas d’eau

du tout.

La pompe ne

s’éteint pas.

La pompe n'est pas branchée.

L'interrupteur ou le disjoncteur

est éteint.

Repérez tout fusible grillé,

tout disjoncteur et toute prise

à disjoncteur de fuite de terre

déclenchés.

Le contacteur à flotteur est

défectueux.

Le circuit de protection thermique

s'est déclenché.

Le flotteur est coincé ou obstrué. Éliminez l'obstruction ou positionnez la pompe

Il y a un refoulement d'eau provenant

du tuyau/conduit de refoulement.

Le contacteur à flotteur est défectueux. Remplacez-le.

Le tuyau/conduit de refoulement est

bouché.

Le tuyau/conduit de refoulement est

gelé.

La pompe est étanche. Vérifiez le trou d'échappement pour tout

La tension est faible. Vérifiez le calibre du cordon et remplacez-le

Le clapet de non-retour est bloqué en

position fermée.

Le clapet de non-retour est posé à

l'envers.

Certaines pièces sont usées,

endommagées ou colmatées.

La hauteur de refoulement excède la

capacité de la pompe.

Le flotteur est coincé ou obstrué. Éliminez l'obstruction.

La fiche de la pompe n'est pas

branchée à la fiche à prise arrière

intégrée du contacteur à flotteur.

Contacteur défectueux. Remplacez-le.

Branchez la pompe et allumez l'interrupteur ou

le disjoncteur.

Remplacez le fusible, réinitialisez le disjoncteur

et réinitialisez la prise à disjoncteur de fuite

de terre.

Vérifiez et remplacez si nécessaire.

Laissez la pompe se refroidir. Elle se

réinitialisera automatiquement.

de sorte que le flotteur ne reste pas coincé.

Installez ou remplacez le clapet de non-retour.

Débouchez le tuyau/conduit.

Laissez le tuyau/conduit dégeler.

colmatage, puis nettoyez-le au besoin.

par un nouveau de calibre plus élevé, au

besoin.

Examinez, réparez et remplacez au besoin.

Assurez-vous de poser le clapet dans le bon

sens, en suivant le flux.

Inspectez l'appareil pour toute trace d'usure,

d'endommagement et de colmatage, puis

nettoyez ou remplacez la pièce, au besoin.

Consultez le tableau de rendement à la page 5

pour connaître les limites de la pompe.

Branchez la fiche de la pompe à la prise du

contacteur à flotteur pour un fonctionnement

automatique. Voir la page 9.

23

DÉPANNAGE

REMARQUE : Tous les problèmes et toutes les corrections ne s’appliqueront pas nécessairement à votre pompe.model.

ATTENTION!

• Débranchez toujours la pompe de la source d’alimentation électrique avant de la manipuler. Si le système ne

fonctionne pas correctement, lisez attentivement les consignes et effectuez des recommandations d’entretien.

Si les problèmes de fonctionnement persistent, le tableau de dépannage ci-dessus peut vous aider à les

identifier et à les corriger.

Page 24

headline bars

24

GARANTIE

Le présent produit Mastercraft est garanti pour une période de trois (3) ans à compter de la date de

l’achat au détail original contre les vices de matériau(x) et de fabrication.

Sous réserve des conditions et restrictions énoncées ci-dessous, le présent produit sera réparé ou remplacé (par

un produit du même modèle ou par un produit ayant une valeur égale ou des caractéristiques identiques), à notre

discrétion, pourvu qu’il nous soit retourné avec une preuve d’achat à l’intérieur de la période de garantie prescrite

et qu’il soit couvert par la présente garantie. Nous assumerons le coût de tout remplacement ou réparation ainsi

que les frais de main-d’œuvre s’y rapportant.

La présente garantie est assujettie aux conditions et restrictions qui suivent:

a. Un contrat de vente attestant l’achat et la date d’achat doit être fourni;

b. La présente garantie ne s’applique à aucun produit ou pièce d’un produit qui est usé ou brisé, qui est devenu

hors d’usage en raison d’un emploi abusif ou inapproprié, d’un dommage accidentel, d’une négligence ou

d’une installation, d’une utilisation ou d’un entretien inapproprié (selon la description figurant dans le guide

d’utilisation ou le mode d’emploi applicable) ou qui est utilisé à des fins industrielles, professionnelles,

commerciales ou locatives;

c. La présente garantie ne s’applique pas à l’usure normale ou aux pièces ou accessoires non réutilisables qui

sont fournis avec le produit et qui deviendront vraisemblablement inutilisables ou hors d’usage après une

période d’utilisation raisonnable;

d. La présente garantie ne s’applique pas à l’entretien régulier et aux articles de consommation comme le

carburant, les lubrifiants, les sacs d’aspirateur, les lames, les courroies, le papier abrasif, les embouts, les

mises au point ou les réglages;

e. La présente garantie ne s’applique pas lorsque les dommages sont causés par des réparations ou des

tentatives de réparation faites par des tiers (c’est à dire des personnes non autorisées par le fabricant);

f. La présente garantie ne s’applique à aucun produit qui a été vendu à l’acheteur original à titre de produit

remis en état ou remis à neuf (à moins qu’il n’en soit prévu autrement par écrit);

g. La présente garantie ne s’applique à aucun produit ou pièce de produit lorsqu’une pièce d’un autre fabricant

est installée dans celui-ci ou que des réparations ou modifications ou tentatives de réparation ou de

modification ont été faites par des personnes non autorisées;

h. La présente garantie ne s’applique pas à la détérioration normale du fini extérieur, notamment les éraflures,

les bosses et les éclats de peinture, ou à la corrosion ou à la décoloration causée par la chaleur, les produits

abrasifs et les produits de nettoyage chimiques;

i. La présente garantie ne s’applique pas aux pièces vendues par une autre entreprise et décrites comme

telles, lesquelles pièces sont couvertes par la garantie du fabricant s’y rapportant, le cas échéant.

Restrictions supplémentaires

La présente garantie s’applique uniquement à l’acheteur original et ne peut être transférée. Ni le détaillant ni

le fabricant ne sont responsables des autres frais, pertes ou dommages, y compris les dommages indirects,

accessoires ou exemplaires liés à la vente ou à l’utilisation du présent produit ou à l’impossibilité de l’utiliser.

Avis au consommateur

La présente garantie vous accorde des droits précis et il se peut que vous ayez d’autres droits, lesquels peuvent

varier d’une province à l’autre. Les dispositions énoncées dans la présente garantie ne visent pas à modifier,

à restreindre, à éliminer, à rejeter ou à exclure les garanties énoncées dans les lois fédérales ou provinciales

applicables.

Loading...

Loading...