Page 1

model no. 058-9816-0

AIR-POWERED

COIL ROOFING NAILER

IMPORTANT :

For your own safety, read and follow all of the Safety Guidelines

and Operating Instructions before operating this nailer. Keep this

manual for future reference.

OPERATING

MANUAL

Page 2

TABLE OF CONTENTS

3

TECHNICAL SPECIFICATIONS

SAFETY GUIDELINES

KEY PARTS DIAGRAM

TECHNICAL INFORMATION

TYPES OF NAILS

OPERATING INSTRUCTIONS

MAINTENANCE

TROUBLESHOOTING

EXPLODED VIEW

PARTS LIST

WARRANTY

10

13

14

21

24

26

27

28

4

5

9

TABLE OF CONTENTS

Page 3

model no. 058-9816-0 | contact us 1-800-689-9928

54

TECHNICAL SPECIFICATIONS

LOADING CAPACITY

FASTENER DETAILS

OPERATING PRESSURE

AIR CONSUMPTION

WEIGHT

AIR INLET

CF: Cubic Feet (the volumetric flow rate of air corrected to standardized conditions of

temperature and pressure).

NPT: National Pipe Thread.

120 Nails (1 coil)

15° Wire-collated coil nails (3/4 - 1 3/4")

70 - 110 PSI (4.8 - 7.5 bar)

0.043 CF/cycle @ 90 PSI

5 Ib 11 oz (2.58 kg)

3/8" NPT

TECHNICAL SPECIFICATIONS

SAFETY GUIDELINES

This manual contains information that relates to PROTECTING PERSONAL SAFETY and

PREVENTING EQUIPMENT PROBLEMS. It is very important to read this manual carefully and

understand it thoroughly before using the product. The symbols listed below are used to

indicate this information.

DANGER!

Potential hazard that will result in serious

injury or death.

WARNING!

Potential hazard that could result in

serious injury or death.

CAUTION!

Potential hazard that may result in

injury or damage to equipment.

PERSONAL SAFETY

These precautions are intended for the personal safety of the user and others working with the

user. Please take time to read and understand them.

Make sure you read and understand this manual before using this tool. Make sure other users

read and understand this manual before they use the tool.

SAFETY GUIDELINES

Note: The word “Note” is used to inform the readers of something

they need to know about the tool.

Page 4

model no. 058-9816-0 | contact us 1-800-689-9928

76

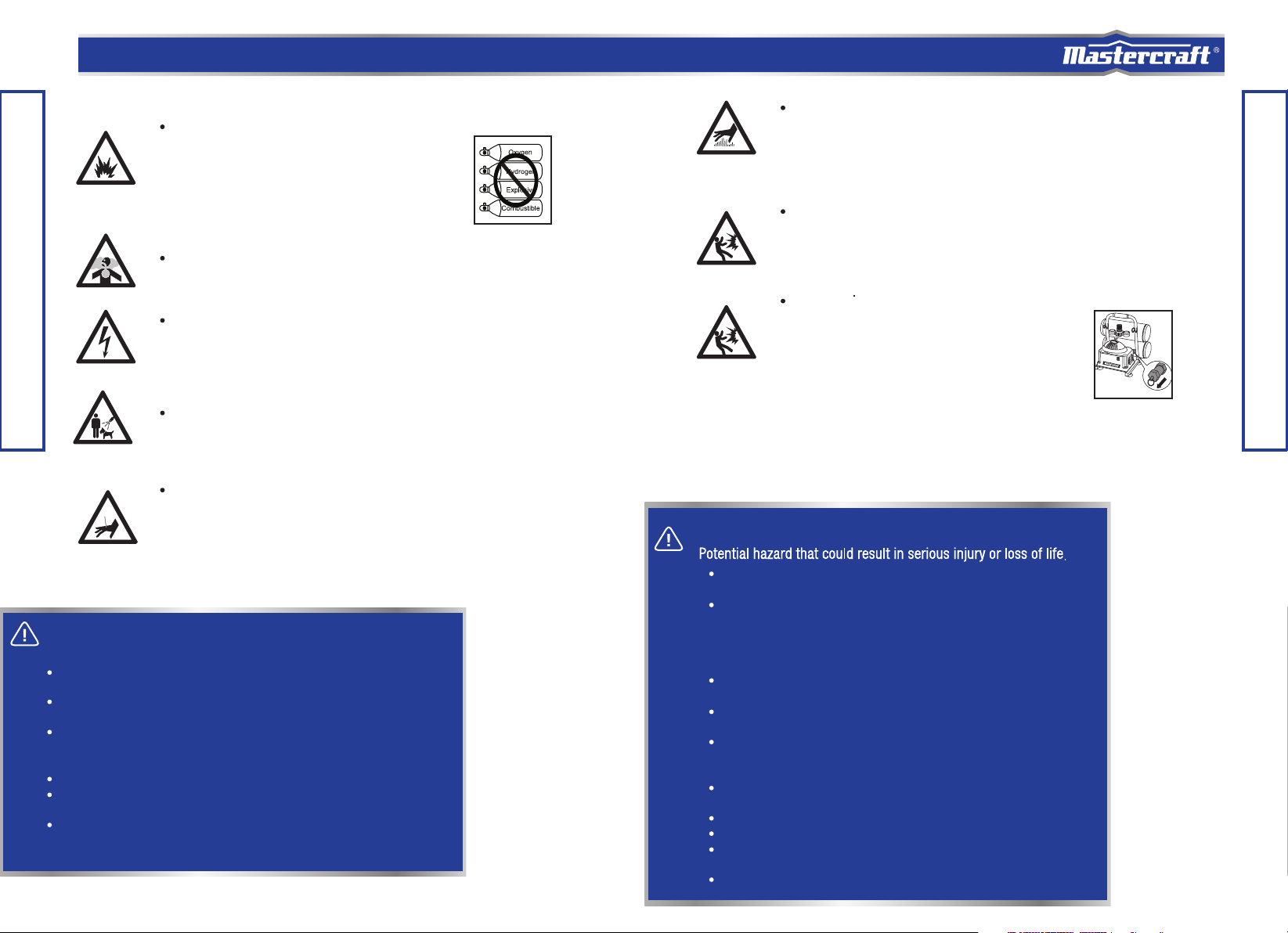

SAFETY GUIDELINES

Do not use oxygen or any other combustible or bottled

gas to power air-powered tools. Failure to observe this

warning can cause explosion and serious personal

injury or death. Use only compressed air to power

air-powered tools. Use a minimum of 25' (7.6 m) of

hose to connect the tool to only compressor. Failure to

comply will result in serious injury or death.

Risk of inhalation: Never directly inhale the air produced by the

compressor.

Risk of electric shock: Do not expose a compressor to rain.

Store it indoors. Disconnect the compressor from the power

source before servicing. The compressor must be grounded.

Do not use grounding adaptors.

Risk of personal injury: Do not direct compressed air from the air hose

SAFETY GUIDELINES

towards the user or other people or animal.

Never point nailer toward yourself or anyone else.

Always assume the nailer contains fasteners. Never point the nailer

toward yourself or anyone else, whether it contains fasteners or not.

If fasteners are mistakenly driven, it can lead to severe injuries.

Never engage in horseplay with the nailer. Respect the nailer as a

working implement.

DANGER!

Potential hazard that will result in serious injury or death.

Keep children away from the work area. Do not allow children to handle

power tools.

Do not use this tool in the presence of flammable liquids or gases. Sparks

that are created during use may ignite gases.

Do not point the tool towards yourself or other people, even when the tool

has stopped. Keep hands, feet, and all other parts of the body clear from

work area.

Do not attempt to clear nailer jams while the air hose is connected.

Do not keep the trigger or the safety stand pressed while loading nails.

Unintentional firing of a nail could cause serious personal injury or death.

Do not disconnect or reconnect the air hose with the trigger pressed. The

air-powered coil roofing nailer may fire when it is reconnected to the air

supply.

Risk of burns: The pump and the manifold generate high temperatures. In

order to avoid burns or other injuries, do not touch the pump, the manifold,

or the transfer tube while the compressor is running. Allow the parts to cool

down before handling or servicing. Keep children and pets away from the

compressor at all times.

Risk of bursting: Do not adjust the pressure switch or safety valve for any

reason. They have been preset at the factory for this compressor’s maximum

pressure. Tampering with the pressure switch or the safety valve may cause

personal injury or property damage.

Risk of bursting: Make sure the regulator is adjusted

so that the compressor outlet pressure is set lower

than the maximum operating pressure of the tool.

Before starting the compressor, pull the ring on the

safety valve to make sure the valve moves freely.

Drain water from the tank after each use. Do not weld

nor repair the tank. Relieve all pressure in the hose

before removing or attaching accessories.

SAFETY GUIDELINES

WARNING!

Do not allow inexperienced or untrained individuals to operate an airpowered coil roofing nailer or any other air-powered tool.

Keep hands and other parts of the body away from the firing head

during use. Keep hands, feet, and all other parts of the body at least

8" (20 cm) away from the firing head. Nails or objects in the

workpiece can cause serious injury if they are deflected by the

workpiece or if they are driven away from the point of entry.

Do not overload the tool. Allow the tool to operate at its optimum

speed for maximum efficiency.

Locate the compressor in a well-ventilated area for cooling, at a

minimum of 12" (30 cm) away from the nearest wall.

Protect the air hose and the power cord from damage and puncture.

Inspect them for weak or worn spots before every usage, and replace

them if necessary.

Always wear eye and hearing protection when using the air compressor. Failure to do so may result in hearing loss.

Do not carry the compressor while it is running.

Do not operate the compressor if it is not in a stable position.

Do not operate the compressor on a rooftop or in an elevated position

that could allow the unit to fall or be tipped over.

Always replace a damaged gauge before operating the unit again.

Page 5

model no. 058-9816-0 | contact us 1-800-689-9928

CAUTION!

Potential hazard that may result in injury or damage to

equipment.

Disconnect the tool from the air supply and turn off the

compressor before performing any maintenance,

loading or changing nails, when the tool is not in use,

when it is being handed to another person, and when it

is left unattended. Failure to comply may result in injury

or damage to equipment.

98

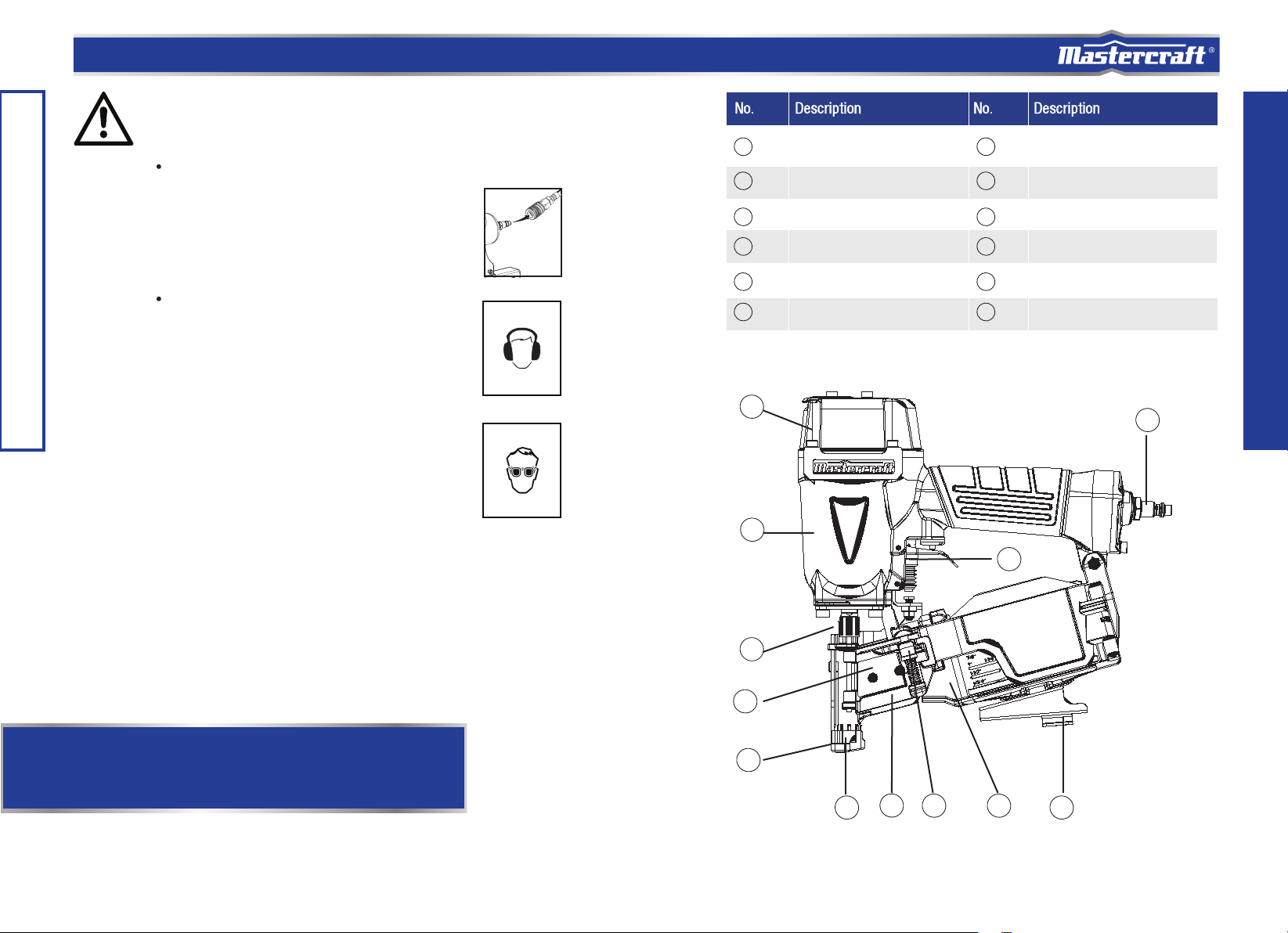

1

2

3

4

Exhaust Cover

Nose

Feeder

Push Lever

10

7

8

9

Knob

Magazine

Shingle Guide

Gun Body

Use safety goggles and ear protection:

Wear safety glasses with side shields when operating

the tool and verify that others in the work area are also

wearing safety glasses. Safety glasses must conform to

American National Standards Institute (ANSI Z87.1)

requirements and must provide protection from flying

particles from the front and the sides.

Air-powered tools are loud and the sound can cause

SAFETY GUIDELINES

hearing damage. Always wear ear protection to help

prevent hearing damage and loss. Failure to comply may

result in injury.

5

6

1

10

2

3

Outlet (Firing Head)

Nail Guide

11

12

12

Air plug

Trigger

11

KEY PARTS DIAGRAM

Note: Recycle unwanted materials rather than disposing of them as waste. Sort

the tools, hoses, and packaging in specific categories and take them to the local

recycling centre or dispose of them in an environmentally safe way.

4

6

5

7

8

9

Page 6

model no. 058-9816-0 | contact us 1-800-689-9928

model no. 058-9809-8 | contact us 1-800-689-9928

Compatible compressors

GUIDELINES FOR PROPER USE AND OPERATION

Be sure to use a proper air compressor with Mastercraft

should be able to supply a minimal air delivery of 4.7 CFM @ 90 PSI to ensure the compressor

can run continuously with the Mastercraft

®

Air-powered Coil Roofing Nailer.

®

air-powered tools. The compressor

General use

This Mastercraft® Air-powered Coil Roofing Nailer drives 3/4 to 1 3/4" wire-collated coil nails.

The tool is lightweight and durable, stands up to the elements and provides consistently

accurate results over the life of the tool. An ideal tool for a variety of construction projects,

including installation of asphalt roofing shingles and insulation boards, and features a

high-capacity side-load magazine, adjustable drive depth, durable construction, and more.

1110

Air Compressor

Size and Power

4–6 Gallons

8–11 Gallons

TECHNICAL INFORMATION

15+ Gallons

Wood Density

>0.6 g/cm

≤0.6 g/cm

3

3

1 1/2–2 HP 2 1/2 HP 3+ HP

Light-duty and

intermittent use

Light-duty and

intermittent use

Medium-duty and

intermittent use

Nail Size Compressor Air Pressure

<1" (25 mm)

≥1" (25 mm)

<1" (25 mm)

≥1" (25 mm)

Light-duty and

intermittent use

Medium-duty and

intermittent use

Heavy-duty and

continuous use

Light-duty and

intermittent use

Medium-duty and

intermittent use

Heavy-duty and

continuous use

90 PSI (6.3 bar)

120 PSI (8.3 bar)

75 PSI (5.2 bar)

110 PSI (7.5 bar)

Air-powered

MASTERCRAFT

Coil Roofing Nailer

Quick connector

Quick coupler

Air hose

Lubricator

®

Regulator (0 to 8.5 bar)

Filter

Cut-off valve

Air compressor

Air system

Always use clean, dry, regulated, compressed air at 4.8 to 7.5 bar (70 to 110 PSI).

Do not exceed the maximum or minimum pressures. Operating the tool at the wrong

pressure (too low or too high) will cause excessive noise or rapid wear.

WARNING!

Potential hazard that could result in serious injury or death.

Keep hands and other parts of the body away from the tool’s discharge

and working areas when connecting the air supply. Failure to comply

could lead to serious injury or death.

TECHNICAL INFORMATION

Page 7

model no. 058-9816-0 | contact us 1-800-689-9928

model no. 058-9809-8 | contact us 1-800-689-9928

1312

•

It is recommended that a filter-regulator-lubricator be used and be located as close to the tool

as possible.

•

If a filter-regulator-lubricator is not installed, place up to 6 drops of compressor oil into the air

inlet plug before each use.

•

If a filter-regulator-lubricator is installed, keep the air filter clean. A dirty filter will reduce the

air pressure to the tool, which will cause a reduction in power, efficiency, and general

performance.

•

For optimal performance, install a quick connector to the tool and a quick coupler on the

hose, if applicable.

•

Verify that all of the connections in the air supply system are sealed in order to prevent air

leakage.

Read this Instruction Manual carefully before using the air-powered roofing nailer.

• Read and follow all the safety instructions at the beginning of this manual. Inspect the

air-powered coil roofing nailer prior to each use in order to:

– ensure that the proper power source is being used.

– verify that the tool is in proper working order.

TECHNICAL INFORMATION

This Mastercraft® Air-powered Coil Roofing Nailer drives 3/4 to 1 3/4" wire-collated coil nails.

ACCEPTABLE NAILS

Length: 3/4 - 1 3/4"

1 3/4

"

(45 mm)

3/4"

(19 mm)

NAIL TYPE ICONS

These icons are used to select the proper nails for this specific nailer.

TYPES OF NAILS

WARNING!

Potential hazard that could result in serious injury or death.

• Do not use the tool if it is not in proper working order.

• Do not use oxygen or any other combustible or bottled gas to

power this tool.

• Do not use this tool in the presence of any flammable liquids or

gases.

• Keep hands and other parts of the body away from the firing

head during use.

• Do not point the tool towards the operator or other people.

• Do not attempt to clear a jammed nail when the air hose is

connected.

• Do not drive a nail on top of an existing nail. Failure to comply

could lead to serious injury or loss of life.

Note: Icons are colour coded. Please refer to the actual tool for the

specific colour.

WARNING!

Potential hazard that could result in serious injury or death.

• The use of any other types of nails will cause the nailer to

jam and could lead to serious injury or death.

Page 8

14

model no. 058-9816-0 | contact us 1-800-689-9928

model no. 058-9338 | contact us 1-800-689-9928

15

Loading nails

1. Disconnect the tool (1) from the air

supply (2) (Fig. A).

Fig. B

Knob

Nail guide

Magazine cover

2. Grip the nail guide and knob with finger.

Press the knob down, swing the nail

guide open and open the magazine cover

(Fig. B).

Fig. A

OPERATING INSTRUCTIONS

3. Adjust the position of the nail holder to

correspond with the nail length. The nail

will not feed smoothly if the nail holder is

not correctly adjusted.

① Turn the nail holder about 90°

counter-clockwise.

② Move the nail holder up and down to align

the plate of the nail holder with the mark on

the magazine that correspond with the

length of the nails being used.

③ Turn the nail holder 90° clockwise until

you hear “click” (Fig. C).

DANGER!

Potential hazard that will result in serious injury or death.

Disconnect the tool from the compressed air source before

loading nails.

Do not point the tool towards the operator or other people while

changing nails.

Do not hold the tool with the trigger pressed while changing

nails. Failure to comply will lead to serious injury or death.

Note:

Before loading nails in the magazine, adjust the nail holder. If the magazine

cover is forcibly closed without adjusting the nail holder correctly, the nail

holder may be damaged.

Do not deform the collated wires and do not disengage the nails with the

guide surface. Otherwise, the nail guide will not close correctly.

Fig. C

For 7/8, 1 and

1 1/4"

(22, 25, 32 mm)

For 1 1/2" (38 mm)

For 1 3/4" (45 mm)

Magazine

Plate

1

Nail holder

Fig. D

First Nail

2

Nail Guide

Driving Hole

Guide Surface

Guide Slot

32

Pawl

①

4

Feeder

4. Place the nails in the magazine. Insert the

first nail coil into the magazine opening.

① Uncoil enough nails to reach the driving hole.

② Insert the first nail into the driving hole and

the second nail between the two pawls of

the feeder.

③ Fit the nail heads in the guide slot.

④ Pull the nails to the right. After checking

and making sure that the magazine cover is

closed, hook your fingers on the nail guide

and knob, turn the nail guide clockwise while

pressing the knob downward, and then close

the nail guide completely.

⑤ Lock the knob completely (Fig. D).

OPERATING INSTRUCTIONS

DANGER!

Potential hazard that will result in serious injury or death.

Never place your hands or feet closer than 8" (20 cm) from firing

head when using.

Do not drive nails on top of other nails or with nailer at too steep

an angle. Nails can ricochet and hurt someone.

In order to avoid double fire or unwanted ejection of a nail due to

bouncing of the nailer, do not push nailer on workpiece using

strong force, take nailer away from workpiece using recoil,

release trigger quickly when performing trigger fire.

Do not drive nails from both sides of a wall at the same time.

Nails can be driven into and through the wall and hit a person on

the opposite side.

Never drive nails into thin boards or near corners and edges of

workpiece. Nails can be driven through or away from workpiece

and hit someone.

Never use nailer which is defective or operating abnormally.

Never use nailer as hammer.

Page 9

model no. 058-9816-0 | contact us 1-800-689-9928

model no. 058-9809-8 | contact us 1-800-689-9928

Testing the nailer

Before actually beginning the nailing work, test the nailer by using the check list below. Conduct the

tests in the following order. If abnormal operation occurs, stop using the nailer and contact a service

centre immediately.

1. DISCONNECT AIR HOSE FROM NAILER. REMOVE ALL NAILS FROM NAILER.

● All screws must be tightened. If any

screws are loose, tighten them

Fig. F

2. Adjust the air pressure to 70 PSI (4.9 bar or

5 kgf/cm

OPERATING INSTRUCTIONS

2

). Connect the air hose.

Do not load any nails in the nailer

● THE NAILER MUST NOT LEAK AIR.

Hold the nailer downward and pull

the trigger.

● THE NAILER MUST NOT OPERATE.

Fig. I

Depress

push lever

(Fig. F).

(Fig. H).

● The push lever and trigger must move

smoothly

Fig. G

Push lever

Fig. H

3. With finger off the trigger, depress the

push lever against the workpiece

● THE NAILER MUST NOT OPERATE.

(Fig. G).

Trigger

Pull trigger

Do not

connect

air hose

(Fig. I).

Firing modes

The Mastercraft® Air-powered Coiled Roofing Nailer has two firing modes: sequential fire for single firing,

or bump fire for repetitive, fast firing of nails. The bump fire trigger kit comes installed on the nailer, and

the sequential fire trigger kit is included as replacement parts. See page 18 for instructions on how to

change from one mode to the other.

METHODS OF OPERATION

This nailer is equipped with a push lever at the nailing point and will not operate unless the push lever is

depressed (pushed upwards).

Each mode requires a different method of operation:

1. Sequential fire (single shot)

① Position the nail outlet on the workpiece with finger

off the trigger.

② Push the nailer down until the push lever is

completely depressed.

③ Pull the trigger to drive a nail.

④ Remove finger from the trigger.

⑤ To drive another nail, move the nailer along the

workpiece, repeating steps 1 to 4 as required (Fig. J).

Fig. K

Previously pull

the trigger

3

1

Fig. J

Push lever

2

3

Trigger

2. Bump fire (multiple shots)

① Pull the trigger with the nailer off the workpiece.

② Drive a nail by pressing the nailer against the

workpiece to depress the push lever.

③ Drive additional nails by moving the nailer along

the workpiece with a bouncing motion. Each

depression of the push lever will drive a nail.

When the required nails have been driven,

remove finger from the trigger (Fig. K).

1716

OPERATING INSTRUCTIONS

Do not pull trigger

4. Without touching the trigger, depress the push lever against the workpiece.

Pull the trigger.

● THE NAILER MUST OPERATE.

5. With the nailer off the workpiece, pull the trigger. Depress the push lever against the

workpiece.

● THE NAILER MUST OPERATE.

6. If no abnormal operation is observed, you may load nails in the nailer.

Drive nails into a test piece that is the same type of material that will be used in the

actual application.

● THE NAILER MUST OPERATE PROPERLY.

WARNING!

● Never use nailer unless push lever is operating properly.

Always wear eye protection.

Note: Be aware that the final nail can fall out or be driven at an irregular angle.

WARNING!

Potential hazard that may result in moderate injury or

damage to equipment.

Keep your finger off the trigger except when nailing. Serious

injury could result if the push lever accidentally contacts you or

others in work area.

Keep hands and body away from the discharge area. This

Mastercraft

and unexpectedly drive another nail, possibly causing injury.

Some types of loaded nails can spark out of the muzzle during

a nail driving operation. Exercise caution!

®

nailer may bounce from the recoil of driving a nail

Page 10

model no. 058-9816-0 | contact us 1-800-689-9928

model no. 058-9809-8 | contact us 1-800-689-9928

1918

The installed sequential fire (single shot) mechanism is useful for when precision nail placement

is desired. It may also reduce the possibility of bodily injury to you or others in the work area as

it is less likely to drive an unwanted nail by accidentally bumping the push lever while the trigger

is pulled. The bump fire (multiple shot) mechanism is useful when repetitive, fast firing is required.

Replace Sequential Trip Mechanism Parts

1. Insert a rod into the trigger hole, tapping the rod

with two pins and remove the trigger and the

trigger plunger (Fig. L).

Fig. M

OPERATING INSTRUCTIONS

3. Remove the trigger valve bushing assembly

and the urethane ball (Fig. N).

Fig. L

2. Use a M5 hex wrench to remove the screw as

shown, releasing the magazine and nail guide

assembly (Fig. M).

Fig. N

Pin 3x30

Trigger plunger

Trigger

Fig. O

Part#111

Adjusting the nailing depth

To assure that each nail penetrates to the same depth, be sure that:

① The air pressure to the nailer remains constant (regulator is installed and working properly).

② The nailer is always held firmly against the workpiece. If nails are driven too deep or too shallow into the

workpiece, adjust the nailing depth using the following instructions.

1. Disconnect air hose from nailer (Fig. P).

2a. If the nails are driven too deep, pull the adjuster

downward and turn counter-clockwise (Fig. Q).

4. Remove the contact trip valve seat components

(including plunger and plunger spring), and then

changed into sequential trip valve seat components

and grease the o-rings (Fig. O).

5. Reassemble by comleting step 1 to 3 in reverse order.

Fig. P

Adjuster

Disconnect air hose

2b. If nails are driven too shallow, pull the adjuster

downward and turn clockwise (Fig. R).

OPERATING INSTRUCTIONS

Ball

NOTE:

The standard CONTACT TRIP MECHANISM and the optional SQUENTIAL

TRIP MECHANISM are safe if used as described above and according to

all warnings and instructions.

Always handle nails and container carefully. If nails are dropped, collating

wire may be damaged and cut, which will cause mis-feeding and jamming.

After nailing: disconnect air hose from the nailer, remove all nails from the

nailer, add 5-10 drops of pneumatic tool lubricant into the air plug in the

nailer and open the petcock on the air compressor tank to drain any

moisture.

Fig. Q

When the adjuster is released it will spring back up and can be set with a click at each 1/4 rotation. The

adjuster changes the nailing depth approximately 0.25 mm per 1/4 rotation.

3. Connect the air hose and perform a nailing test. ALWAYS WEAR EYE PROTECTION.

4. If additional adjustments are necessary, DISCONNECT AIR HOSE FROM NAILER and repeat step 2.

Turn adjuster

hsulFpeed ooT

2

Fig. R

Too shallow Flush

Turn adjuster

2

Page 11

model no. 058-9816-0 | contact us 1-800-689-9928

model no. 058-9809-8 | contact us 1-800-689-9928

2120

Using the shingle guide

The shingle guide can be used to control shingle spacing.

① Disconnect air hose from nailer.

② Loosen the shingle guide bolt with the accessory hex wrench.

③ Place the shingle guide against the bottom of the first row of shingles.

④ Adjust the distance between the outlet and the shingle guide to the proper shingle exposure by

sliding the shingle guide.

⑤ Tighten the shingle guide bolt.

Second row

First row

Outlet

OPERATING INSTRUCTIONS

Proper shingle

exposure

Shingle guide

2

4

3

Shingle guide

bolt

1

Disconnect

air hose

Clearing a jammed nail

To clear a jammed nail

● Disconnect the tool from the air supply line.

● Open the nail guide and insert a rod into the outlet. Tap the rod with a hammer.

● Remove the jammed nail with a slotted screwdriver.

● Cut the deformed collated wire with snips. Correct the deformation.

● Remove the non-jammed nails that are stored in the tool’s magazine.

● Operate the magazine latch and slide the pusher back to open the magazine for checking the

jammed nails.

● Use pliers or any appropriate tool to remove the jammed nails.

● Close the magazine cover and slide the pusher to its original position.

● Reload the nails into the tool magazine.

● Reconnect the air supply line to the tool’s air inlet.

● Test fire 3 to 5 nails into a piece of scrap wood in order to ensure proper operation.

Cold weather operation

When operating any air-powered tool below freezing temperature:

● Verify if the compressor tank has been properly drained prior to use.

● Keep tools as warm as possible using any safe, convenient method.

● Place up to 6 drops of pneumatic tool oil into the tool’s air inlet.

● Adjust the air pressure to 80 PSI or lower.

● Load the nails into the magazine (if required).

● Actuate the tool 5 to 6 times into a scrap wooden piece in order to lubricate the O-rings.

● Adjust the air pressure to the operating level (do not exceed 120 PSI) and use the tool

normally.

● Relubricate the tool, as described in the maintenance section.

● Drain the compressor tank at least once per day.

MAINTENANCE

Note: The proper shingle exposure will depend on the type of shingle

and the manufacturer's specifications.

The shingle guide is not to be utilized as an indicator of nail location.

Note: If the nails continue to jam, call 1-800-689-9928.

WARNING!

Potential hazard that will result in serious injury or death.

Disconnect the tool from the air supply line before clearing a

jammed nail. Failure to comply could cause them to be fired

out of the tool causing serious injury.

Do not point the tool towards the operator or other people.

Serious personal injury could result if these instructions are

not followed.

Page 12

model no. 058-9816-0 | contact us 1-800-689-9928

model no. 058-9809-8 | contact us 1-800-689-9928

INSPECTION

1. Inspect the push lever and feeders.

● Disconnect air hose.

● Clean the knob sliding part and lubricate it with pnenumatic tool lubricant.

● Open the nail guide and remove dust. Lubricate the nose opening and feeder shaft.

● Lubricate the feeding surface of the nose and the nail guide after cleaning. This promotes

smooth operation and prevents rust.

2. Clean and remove tar and dirt.

Tar and dirt may build up on the nose and push lever. This can prevent correct operation.

● Disconnect air hose.

● Clean and remove tar and dirt with kerosene, #2 fuel oil or diesel fuel. CAUTION! Excess

vapour from these products could be ignited by a spark produced during nailing and

cause an explosion.

● Immerse only the area around the outlet in solvent. Do not immerse the magazine or

body. Plastic parts and O-ring may be damaged.

● Dry off the nailer before use. Any oil film left after cleanup will accelerate tar

buildup and nailer will require more frequent cleaning.

● Make sure the push lever operates properly.

3. Inspect the magazine.

● Disconnect air hose.

● Clean the magazine. Remove paper chips or wooden chips which may have accumulated

in the magazine.

MAINTENANCE

STORING

● When not in use for an extended period, apply a thin coat of lubricant to the steel

parts to avoid rust.

● Do not store the nailer in a cold weather environment.

● When not in use, the nailer should be stored in a warm and dry place. Keep out of reach

children.

Maintenance

MAINTENANCE

REQUIRED

General inspectionfree movement

In-depth inspection

Replace worn or

broken parts

Lubrication

DESCRIPTION

Trigger, spring,

safety mechanism

Worn or broken

parts

See below X

TOOLS OR

MATERIALS

REQUIRED

None

Pneumatic tool

oil

• Lubrication: If the air-powered coil roofing

nailer and the compressor are not equipped

with an in-line lubrication system, place up

to 6 drops of pneumatic tool oil into the air

inlet before each work day or after every 2

hours of continuous use, depending on the

characteristics of the workpiece and type

of fasteners used.

• Air-operated tools must be inspected periodically and worn or broken parts must be

replaced to ensure that the tools are operating safely and efficiently.

• Inspect and replace worn or damaged O-rings, seals, etc. Tighten all screws and caps

frequently in order to help prevent personal injury.

• Keep the magazine of the tool clean and free of any dirt or abrasive particles.

MAXIMUM SERVICE INTERVAL

Each Use or

Every 2 Hrs

X

Monthly

As

Needed

X X

X

2322

MAINTENANCE

Note: Solvent sprayed on the nose to clean and free up the push lever

may have the opposite effect.The solvent may soften the tar on the

shingles and cause tar buildup to be accelerated. Dry operation is better.

CAUTION!

Check that the main nail stopper and sub nail stopper slide

smoothly by pushing them with finger. If not smooth, nails can

be driven at an irregular angle and hurt someone.

Never use gasoline or other highly flammable liquids.

Never use nailer unless push lever is operating properly.

Note: When temperatures are below freezing, keep the tools warm

using any safe, convenient method.

DANGER!

Potential hazard that will result in serious injury or death.

Disconnect the tool from the air compressor before performing maintenance/service, adjusting, clearing jams, reloading,

and when it is not in use.

Repairs must be performed by a qualified service technician

only. Failure to comply will lead to serious injury or death.

Page 13

model no. 058-9816-0 | contact us 1-800-689-9928

24

model no. 058-9809-8 | contact us 1-800-689-9928

The following chart lists common issues and solutions. Please read it carefully and

follow all instructions carefully.

Disconnect the tool from the air supply before making any adjustments.

PROBLEM POSSIBLE CAUSES SOLUTIONS

Air leakage at the

top of the tool or in

the trigger area.

Air leakage near the

bottom of the tool.

TROUBLESHOOTING

Air leakage between

the bottom and the

cylinder cap.

The nails are being

driven too deep.

1.

O-rings in the trigger valve are

damaged.

2.

The trigger valve heads are

damaged.

3.

Trigger valve stem, seal, or

O-rings are damaged.

1.

The screws are loose.

2.

The O-rings or the bumper are

worn or damaged.

1.

The screws are loose.

The O-rings or the seals are worn

2.

or damaged.

1.

The bumper is worn.

2.

The air pressure is too high.

3.

The depth adjustment knob is not

adjusted properly.

1.

Inspect and replace the O-ring.

2.

Inspect and replace trigger valve heads.

3.

Inspect and replace the trigger valve stem,

seal, or O-ring.

Have the tool serviced by a qualified service

technician.

1.

Tighten the screws.

2.

Inspect and replace the O-rings or the

bumper.

Have the tool serviced by a qualified service

technician.

Tighten the screws.

1.

Inspect and replace the O-rings or the seals.

2.

Have the tool serviced by a qualified service

technician.

1.

Replace the bumper.

2.

Adjust the air pressure.

3.

Adjust the depth setting by turning the depth

adjustment knob counter-clockwise (see

section “Adjusting nail depth” for more

detailed instructions).

PROBLEM POSSIBLE CAUSES SOLUTIONS

The tool does not

operate properly, it

does not drive the

nails or operates

sluggishly.

The tool skips nails.

The tool jams.

Air exhaust is being

directed towards the

operator.

1.

The air supply is inadequate.

2.

Lubrication is inadequate.

3.

The O-rings or seals are worn or

damaged.

4.

The exhaust deflector in the

cylinder head is blocked.

1.

The bumper is worn or the spring

is damaged.

2.

There is dirt in the front plate.

3.

Nails cannot move freely in the

magazine due to dirt or wear.

4.

The O-ring on the piston is worn

or dry or lubrication is insufficient.

5.

The cylinder cover seal Is leaking.

Improper nails are used, or nails are

1.

damaged.

The driver guide is damaged or worn.

2.

The magazine screw is loose.

3.

There is dirt in magazine.

4.

The direction of the exhaust

deflector requires adjustment.

1.

Verify that the air supply is adequate.

2.

Pour up to 6 drops of oil into the air inlet.

3.

Inspect and replace O-rings or seals.

4.

Replace the damaged internal parts.

Have the tool serviced by a qualified service

technician.

1.

Replace the bumper or spring.

2.

Clean the drive channel on the front plate.

3.

Clean the magazine.

4.

Replace the O-ring.

5.

Replace the sealing washer.

Have the tool serviced by a qualified service

technician.

Use proper nails.

1.

(see section “Clearing a jammed nail.”)

Inspect and replace the driver.

2.

Tighten the magazine.

3.

Open and clean the magazine.

4.

Direct the exhaust deflector away from the

operator.

25

TROUBLESHOOTING

DANGER!

Potential hazard that will result in serious injury or death.

If any of the following symptoms appear while the tool is in use,

turn it off and disconnect it from the air supply immediately.

Failure to comply will lead to serious injury or death.

Repairs must be performed by a qualified service technician

only.

Note: For further repair information, please call 1-800-689-9928.

Page 14

model no. 058-9816-0 | contact us 1-800-689-9928

2726

1

2

3

4

1

5

6

7

8

9

10

EXPLODED VIEW

11

12

13

14

15

1

2

3

4

5

6

7

8

9

10

16

17

18

13

19

20

21

13

Bolt M5 x 30

Top cover

Bolt M5 x 6

Exhaust cover

Logo

Body guard

Cover gasket

Packing

Exhaust valve

Head cap

21

O-ring 47 x 2.4

22

Body assembly (includes 37)

23

O-ring 43.5 x 2.65

24

104 105 106 107 108 109 110

111

41

42

40

31

36

22

23

24

25

26

27

28

30

31

33

32

34

35

43

59

58

66

70

71

67

68

69

6

1

2

1

2

2

1

1

1

1

39

38

37

63

62

61

60

76

75

29

82

72

73

74

11

12

13

14

15

16

17

18

19

20

65

64

77

78

79

80

83

84

85

O-ring 30.5 x 3.5

Piston

O-ring 65 x 2

O-ring 41.5 x 2.4

Cylinder plate

Cylinder

Cylinder ring

Cylinder spring

O-ring 56 x 2.4

Cylinder guide

44

45

46

47

48

81

86

57

49

50

48

51

52

53

54

55

56

57

100

101

102

103

65

87

88

89

90

91

92

43

34

93

94

95

34

69

96

97

98

99

1

1

3

1

1

1

1

1

1

1

Piston bumper

25

Bumper sheet

26

Housing gasket

27

Bolt M5 x 8

28

Guard

29

Nose

30

Nose guard

31

Bolt M5 x 25

32

Spring

33

Bolt M5 x16

34

Nut M5

35

Pushing lever

36

Washer

37

Grip rubber

38

Cap sealing gasket

39

Cap

40

Bolt M5 x 20

41

Air plug (NPT 3/8")

42

Plug protector

43

Pin 3 x 30

44

Plunger spring

45

O-ring 3 x 1.8

46

Plunger (A)

47

Valve bushing

48

O-ring 11.8 x 1.5

49

Valve packing

50

Urethane ball

51

Valve plate

52

Trigger valve bushing

53

Trigger plunger

54

O-ring 2.8 x 1.8

55

Trigger

56

Plunger (B)

57

Valve rubber cover

58

O-ring 8.75 x 1.8

59

O-ring 14.2 x 1.9

60

Feed piston

61

O-ring 11.2 x 1.8

62

Cover sealing ring

63

Feed piston cover

64

Magazine bushing

65

Bolt M5 x 10

66

Feeder spring

1

1

1

1

1

1

2

1

1

2

5

1

1

3

1

1

1

1

1

3

1

1

2

1

1

1

1

3

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

3

1

67

Feeder

68

Feeder shaft

69

Feeder shaft ring

70

Shaft ring

71

Nail guide shaft

72

Adjuster

73

Adjuster spring

74

Bolt M6 X 18

75

Nail guide

76

Lock shaft

77

Guide lock

78

Pin 3 x 10

79

Guide lock spring

80

Main stopper spring

81

Bolt M4 x 10

82

Roll pin 3 x 28

83

Main nail stopper

84

Nail stopper

85

Sub stopper spring

86

Nail guide cover

87

Magazine cover

88

Holder cap

89

Screw M4 x 50

90

Spring washer D=4

91

Washer D=4

92

Holder shaft

93

Sleeve

94

Ratchet spring

95

Nail holder

96

Magazine

97

Pin

98

Nylon Nut M4

99

Magazine guard

100

Plate nut

101

Guide base

102

Bolt M5 x 14

103

Shingle guide

104

Plunger spring II

105

O-ring 3.55 x 2

106

Plunger (A) II

107

Valve bushing II

108

O-ring 11.8 x 1.5

109

Plunger (B) II

110

Plunger III

111

Sequential fire trigger assembly

(includes 57, 104 -110)

1

1

2

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

PARTS LIST

1

1

1

1

1

2

1

1

1

1

1

1

1

1

2

1

1

1

1

1

2

1

1

1

Page 15

model no. 058-9816-0 | contact us 1-800-689-9928

model no. 058-9809-8 | contact us 1-800-689-9928

2928

3-Year Limited Warranty

This product is guaranteed for a period of 3 years from the date of original retail purchase

against defects in workmanship and materials, except for the following component:

Component A: Accessories, which are guaranteed for a period of 1-year from the date of

original retail purchase against defects in workmanship and materials.

Subject to the conditions and limitations described below, this product, if returned to us

with proof of purchase within the stated warranty period and if covered under this

warranty, will be repaired or replaced (with the same model, or one of equal value or

specification), at our option. We will bear the cost of any repair or replacement and any

costs of labour relating thereto.

These warranties are subject to the following conditions and limitations:

a)

A bill of sale verifying the purchase and purchase date must be provided.

b)

This warranty will not apply to any product or part thereof which is worn or broken or

which has become inoperative due to abuse, misuse, accidental damage, neglect, or lack

of proper installation, operation, or maintenance (as outlined in the applicable instruction

WARRANTY

manual or operating instructions), or which is being used for industrial, professional,

commercial, or rental purposes.

c)

This warranty will not apply to normal wear and tear or to expendable parts or accessories

that may be supplied with the product which are expected to become inoperative or

unusable after a reasonable period of use.

d)

This warranty will not apply to routine maintenance and consumable items such as, but

not limited to, fuel, lubricants, vacuum bags, blades, belts, sandpaper, bits, fluids,

tune-ups, or adjustments.

e)

This warranty will not apply where damage is caused by repairs made or attempted by

others (i.e., persons not authorized by the manufacturer).

g)

This warranty will not apply to any product or part thereof if any part from

another manufacturer is installed therein or any repairs or alterations have

been made or attempted by unauthorized persons.

This warranty will not apply to normal deterioration of the exterior finish, such

h)

as, but not imited to, scratches, dents, paint chips, or to any corrosion or

discolouring by heat, or abrasives and chemical cleaners.

This warranty will not apply to component parts sold by and identified as the

i)

product of another company, which shall be covered under the product

manufacturer’s warranty, if any.

Additional limitations

This warranty applies only to the original purchaser and may not be

transferred. Neither the retailer nor the manufacturer shall be liable for any

other expense, loss or damage, including, without limitation, any indirect,

incidental, consequential, or exemplary damages arising in connection with

the sale, use, or inability to use this product.

Notice to consumer

This warranty gives you specific legal rights, and you may have other rights,

which may vary from province to province. The provisions contained in this

warranty are not intended to limit, modify, take away from, disclaim, or

exclude any statutory warranties set forth in any applicable provincial or

federal legislation.

Made in China

Imported by Mastercraft Canada Toronto, Canada M4S 2B8

WARRANTY

f)

This warranty will not apply to any product that was sold to the original purchaser as a

reconditioned or refurbished product (unless otherwise specified in writing).

Loading...

Loading...