Page 1

INSTRUCTION MANUAL

AIR-POWERED

SIPHON-FEED SPRAY GUN

058-9336-2

6852-06302012

Page 2

TABLE OF CONTENTS

1

AIR-POWERED SIPHON-FEED SPRAY GUN 058- 9336-2

QUICK START GUIDE

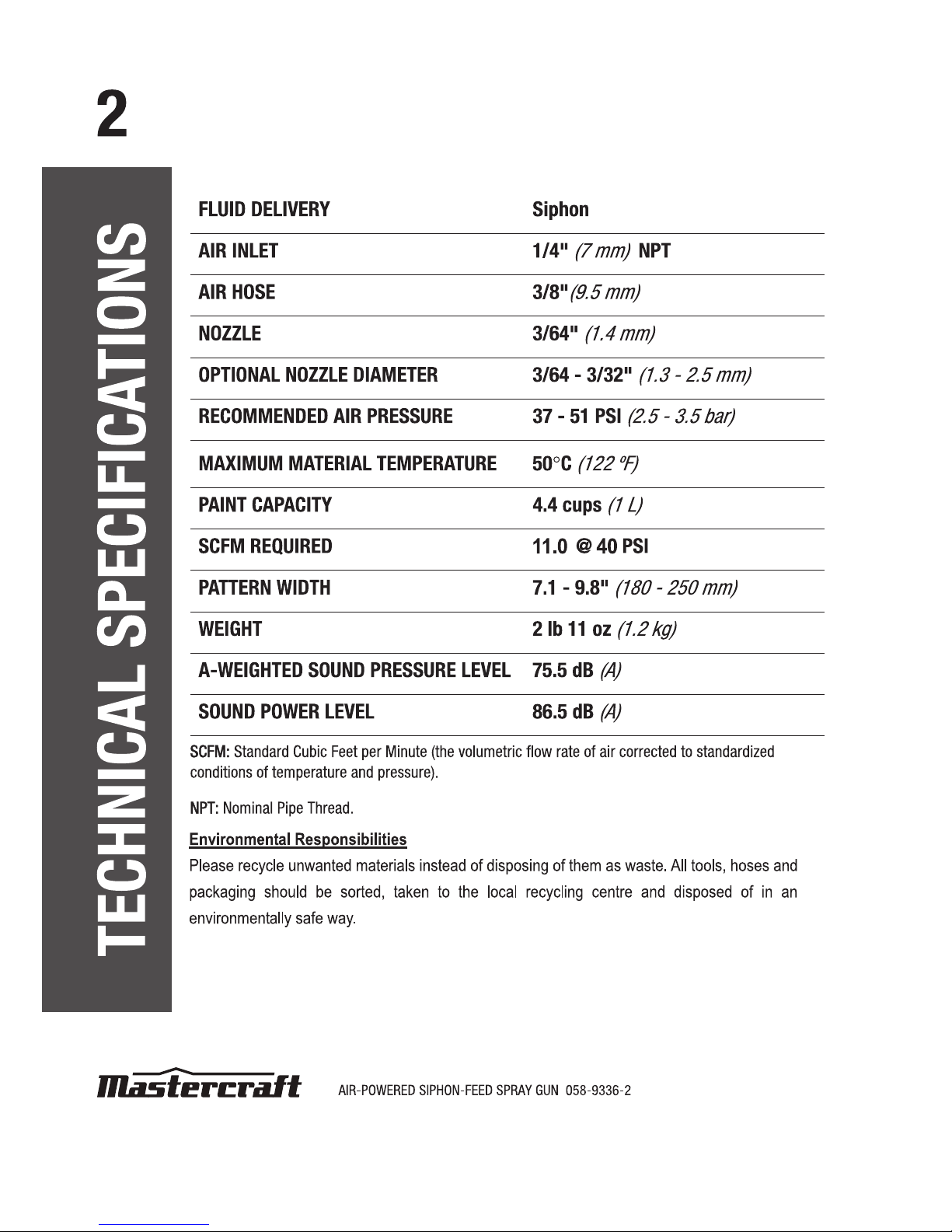

TECHNICAL SPECIFICATIONS 2

SAFETY GUIDELINES 3–8

KEY PARTS DIAGRAM 9

IMPORTANT INFORMATION 10

OPERATING INSTRUCTIONS 11–16

MAINTENANCE 17–18

TROUBLESHOOTING 19–21

EXPLODED VIEW 22

PARTS LIST 23–24

WARRANTY 25–26

Page 3

Page 4

SAFETY GUIDELINES

3

AIR-POWERED SIPHON-FEED SPRAY GUN 058- 9336-2

This manual contains information that relates to PROTECTING PERSONAL SAFETY and PREVENTING

EQUIPMENT PROBLEMS. It is very important to read this manual carefully and understand it

thoroughly before using the product. The symbols listed below are used to indicate this information.

Note- The word “Note” is used to inform the

reader of something he/she needs to know about

t

he tool.

PERSONAL SAFETY

These precautions are intended for the personal safety of the user and others working with the user.

Please take time to read and understand them.

SAFETY GUIDELINES

N

ote: Carefully read and understand all the instructions in this manual before using the spray gun.

Ensure that operator of the tool has read and understood these instructions.

DANGER!

P

otential hazard that will result in serious

injury or loss of life.

WARNING!

P

otential hazard that could result in

serious injury or loss of life.

CAUTION!

P

otential hazard that may result in

m

oderate injury or damage to equipment.

Page 5

SAFETY GUIDELINES

4

AIR-POWERED SIPHON-FEED SPRAY GUN 058-9336-2

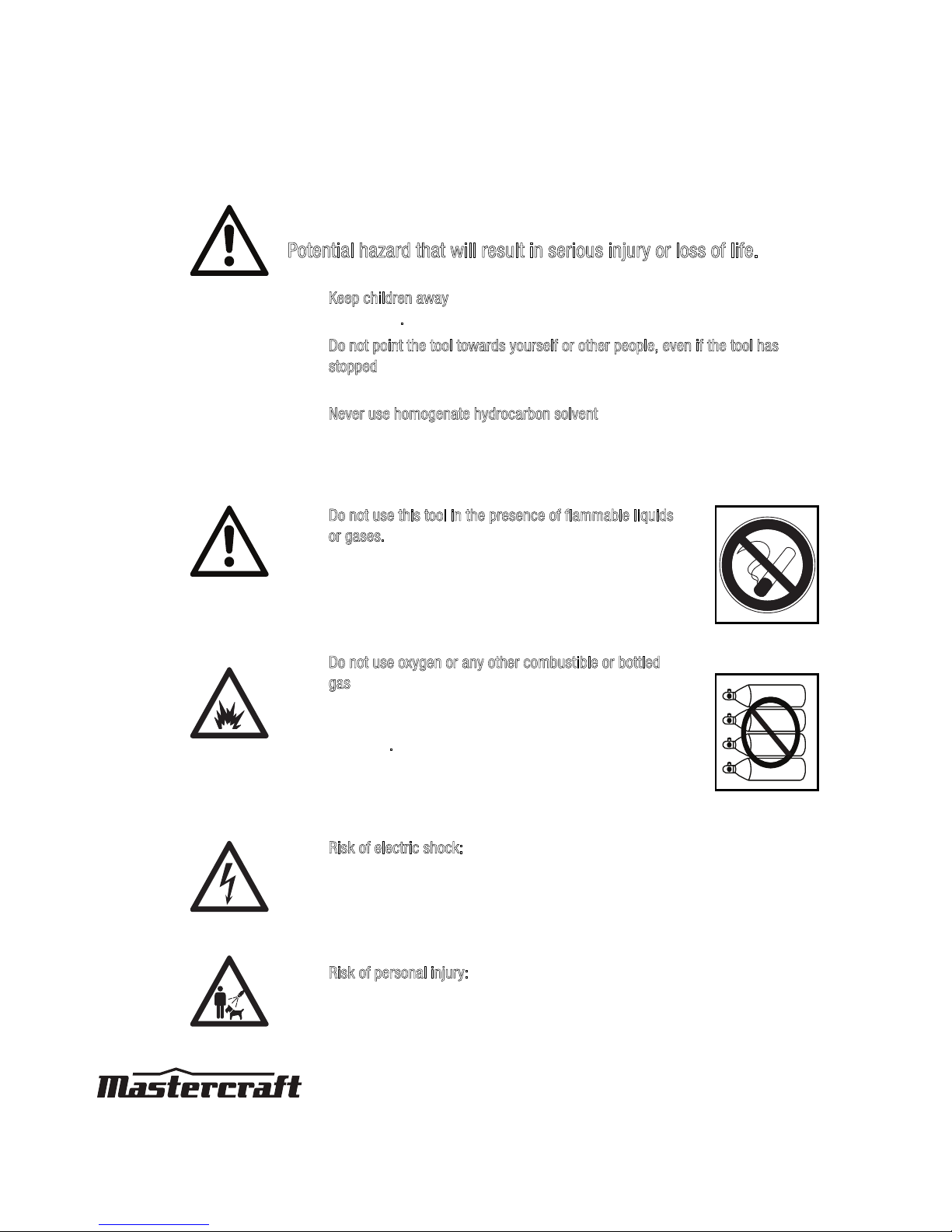

DANGER!

Potential hazard that will result in serious injury or loss of life.

• Keep children away from the work area. Do not allow children to handle

power tools.

• Do not point the tool towards yourself or other people, even if the tool has

s

topped. Keep hands, feet, and all other parts of the body clear from work

area.

• N

ever use homogenate hydrocarbon solvent, which can chemically react

with aluminium and zinc parts and which is not chemically compatible with

aluminium and zinc parts.

• Do not use this tool in the presence of flammable liquids

o

r gases. Sparks that are created during use may ignite

gases. Please use the tool in well-ventilated area only

and avoid any ignition sources such as smoking and open

flames.

• Do not use oxygen or any other combustible or bottled

g

as to power air-powered tools. Failure to observe this

warning can cause explosion and serious personal injury

or death. Use only compressed air to power the air-powered tools.

Use a minimum of 25' (7.6 m) of hose to connect the tool to the compressor. Failure to comply will

result in serious injury or loss of life.

• Risk of electric shock: Do not expose a compressor to rain. Store it indoors.

Disconnect the compressor from power source before servicing. Compressor

must be grounded. Do not use grounding adaptors.

• Risk of personal injury: Do not direct compressed air from the air hose

towards the user or other persons.

MC-OM-05

Oxygen

Hydrogen

Explosive

Combustible

MC-OM-02

Page 6

SAFETY GUIDELINES

5

AIR-POWERED SIPHON-FEED SPRAY GUN 058-9336-2

• Risk of inhalation: Never directly inhale the air produced by the compressor

and the spray gun. Always use the spray gun in a well ventilated area.

Use protective respirator: Toxic vapors produced by spraying certain materials can cause serious damage to health.

Always wear safety es, gloves, and respirator to prevent the

hazard caused by inhalation of toxic vapor or contact of solvent and paint with eyes or skin. Failure to comply will result

in moderate injury.

• Risk of burns: The pump and the manifold generate high temperatures. In

order to avoid burns or other injuries, do not touch the pump, the manifold,

or the transfer tube while the compressor is running. Allow the parts to cool

down before handling or servicing. Keep children away from the compressor

at all times.

• Risk of bursting: Do not adjust the pressure switch or

safety valve for any reason. They have been preset at the

factory for this compressor’s maximum pressure.

Tampering with the pressure switch or the safety valve

may cause personal injury or property damage. Make

sure the regulator is adjusted so that the compressor

outlet pressure is set lower than the maximum operating

pressure of the tool. Before starting the compressor, pull

the ring on the safety valve to make sure the valve

moves freely. Drain water from tank after each use. Do

not weld or repair tank. Relieve all pressure in the hose

before removing or attaching accessories.

• Use compressed air at regulated pressure: Always use

clean, dry, and compressed air at regulated pressure. Do

not exceed the maximum operating pressure of 8.3 bar

(120 PSI)

. Failure to comply will lead to serious injury or

loss of life.

MC-OM-04

MC-OM-22

MC-OM-06

Page 7

SAFETY GUIDELINES

6

AIR-POWERED SIPHON-FEED SPRAY GUN 058-9336-2

WARNING!

Potential hazard that could result in serious injury or loss of life.

• Do not allow unskilled or untrained individuals to operate the Air-powered

Siphon-feed Spray Gun.

• U

se components recommended by manufacturers: Never modify the tool for

other applications. Use only parts, nozzles, and accessories with

specifications as mentioned in this manual

(see section “Technical

specifications”)

.

• Some solvents and chemicals used in the spray gun may pose a risk of

personal injury or death, or may pose a threat to the environment. The

operator should read the associated Material Safety Data Sheet (MSDS),

understand all warnings, wear suitable personal protective equipment, and

follow safe handling and application procedures, before using the spray gun.

• I

nspect the tool components and attachments before operation and ensure

that they are assembled properly and are not damaged. Failure to comply

will lead to serious injury or loss of life.

• L

ocate the compressor in a well-ventilated area for cooling, a minimum of

12" (31 cm) away from the nearest wall.

• P

rotect the air hose and the power cord from damage and puncture. Inspect

t

hem for weak or worn spots every week, and replace them if necessary.

• A

lways wear hearing protection when using the air compressor. Failure to do

so may result in hearing loss.

• D

o not carry the compressor while it is running.

• D

o not operate the compressor if it is not in a stable position.

• D

o not operate the compressor on a rooftop or in elevated position that

could allow the unit to fall or be tipped over.

Page 8

SAFETY GUIDELINES

7

AIR-POWERED SIPHON-FEED SPRAY GUN 058- 9336-2

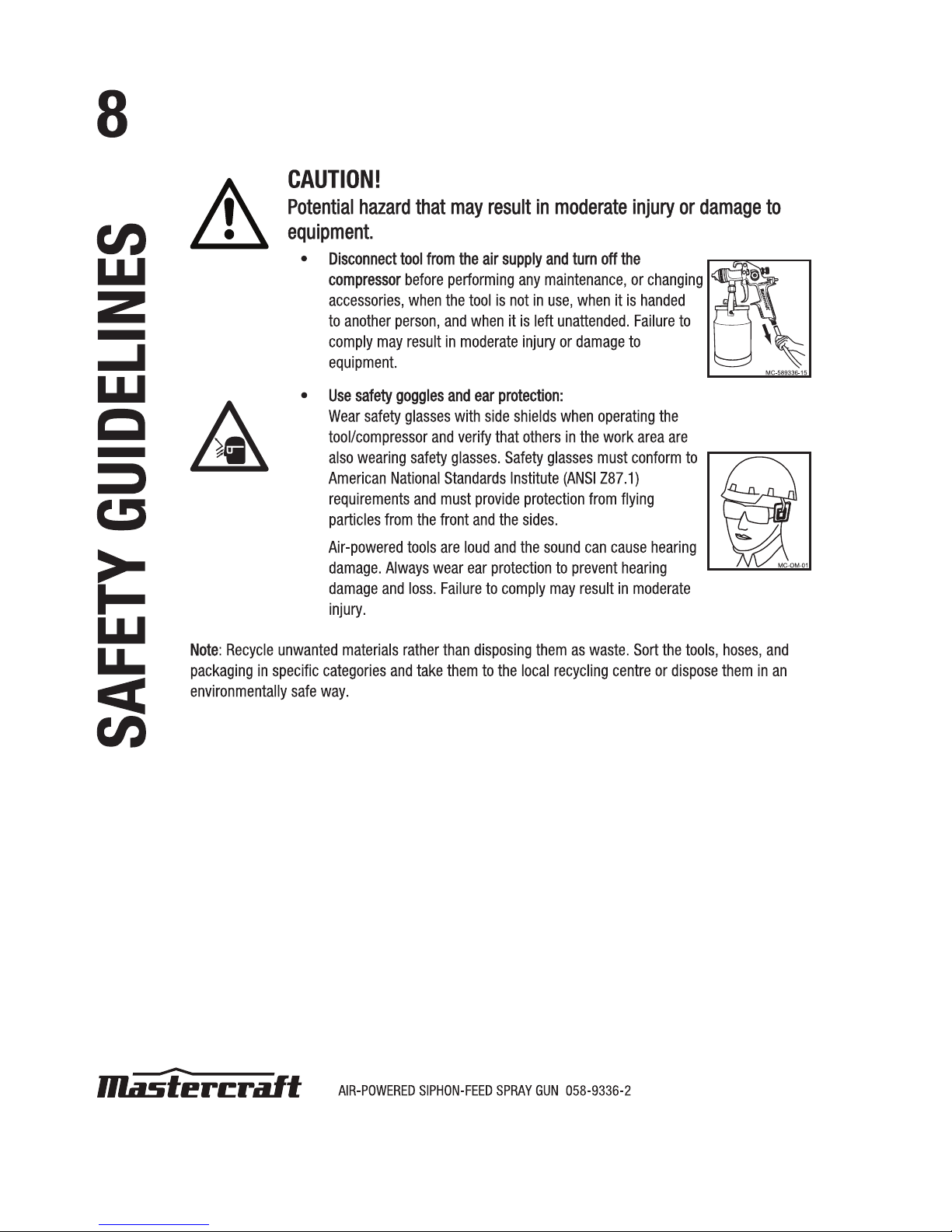

CAUTION!

Potential hazard that may result in moderate injury or damage to

e

quipment.

• Keep proper footing at all times in order to ensure correct balance.

• Do not use a tool that is leaking air, with missing or damaged parts, or that

requires repairs. V

erify that all screws are securely tightened.

• For optimal safety and tool performance, i

nspect the tool daily in order to

ensure free movement of the trigger, safety mechanisms, and springs.

• E

nsure proper tool operation before painting. Before painting, inspect to

ensure free movement of the trigger and nozzle.

• C

heck the tightness of screws before operating the tool. Before operating

the tool, make sure all the screws and caps are securely tightened to

prevent leakage.

• K

eep the work area clean. A cluttered or dirty workbench may lead to an

accident. Floors should be kept clear.

• H

andling and storage of oil: Use with adequate ventilation. Avoid contact of

oil with eyes, skin, and clothing. Avoid breathing spray or mist. Store in a

tightly closed container in a cool, dry, well-ventilated area free from

incompatible substances.

• D

o not use the tool near or below freezing temperatures, as doing so may

cause tool failure.

• D

o not store the tool in a freezing environment to prevent ice formation on

the operating valves of the tool, as that may cause tool failure.

Page 9

Page 10

Page 11

IMPORTANT INFORMATION

10

AIR-POWERED SIPHON-FEED SPRAY GUN 058-9336-2

Compatible compressors and air tool

GUIDELINES FOR PROPER USE AND OPERATION

Be sure to use the proper air compressor with Mastercraft

®

air-powered tools. The compressor

should be able to supply a minimal air delivery of 7.1 SCFM @ 51PSI to ensure the compressor can

run continuously with the Mastercraft Air-powered Siphon-feed Spray Gun. Using tools or

combinations of tools that together or separately require more than the air compressor can deliver

will reduce performance and could void the compressor or tool guarantee/warranty.

General Description

This Mastercraft® Air-powered Siphon-feed Spray Gun operates at 37 PSI (low pressure). The spray

gun uses an air cap which forms a easily-controllable soft spray and generates less overspray and

high transfer efficiency. The spray gun has adjustable knobs to control paint output, pattern

formation, and air outflow. This spray gun is designed to provide uniform atomization and particle

size for painting any type of surface. The stainless steel needle, nozzle, and precision air cap setting

are provided for a variety of coatings. The lightweight, ergonomic design and easy trigger pivot

enable user-friendly operation, reducing operator fatigue.

Air Compressor

Size and Power

1 1/2–2 HP 2 1/2 HP 3 HP and more

5–6 Gallons

Light-duty and

intermittent use

Light-duty and

intermittent use

Light-duty and

intermittent use

8–11 Gallons

Light-duty and

intermittent use

Medium-duty and

intermittent use

Medium-duty and

intermittent use

15 Gallons

and more

Medium-duty and

intermittent use

Heavy-duty and

continuous use

Heavy-duty and

continuous use

Page 12

OPERATING INSTRUCTIONS

11

AIR-POWERED SIPHON-FEED SPRAY GUN 058-9336-2

Before using the spray gun

• After unpacking the spray gun, inspect

carefully and check thoroughly to see if

there is any damage that may have

occurred during transit. Ensure the

tightness of fittings, bolts, etc., before

performing any operation.

• After connecting the gun to air supply,

ensure the tight connection of the fluid

cap, canister, and air hose with the Airpowered Siphon-feed Spray Gun.

• Use a piece of cardboard or other scrap

material as target for trial spray and

adjust for best spray pattern.

WARNING!

Potential hazard that could result in serious injury or loss of life.

• Do not exceed the maximum pressure of spray gun or any other parts in the

compressor system. Failure to comply could lead to serious injury or loss of life.

• Never aim or spray at yourself or anybody else which could cause serious

injury. Failure to comply could lead to serious injury or loss of life.

Page 13

Page 14

Page 15

Page 16

Page 17

Page 18

Page 19

MAINTENANCE

18

AIR-POWERED SIPHON-FEED SPRAY GUN 058-9336-2

• Pour out the remaining paint into another container.

• Disassemble the Air-powered Siphon-feed Spray Gun.

• Clean all paint passages, nozzle, and other components using a brush dipped in cleaning

solvent.

• Reassemble the spray gun and spray small quantity of solvent in the paint passages to

remove any paint residue.

Storage

• Rotate the paint adjustment knob in counter-clockwise direction and open the knob when the

gun is not in use. This will reduce spring tension on the needle fluid tip.

• Clean the Air-powered Siphon-feed Spray Gun thoroughly and slightly lubricate it, after using

and before storing.

WARNING!

Potential hazard that could result in serious injury or loss of life.

• Do not use metal or other objects that could damage the holes in nozzle and

cap.

• Never immerse the spray gun completely in solvent.

• Do not use components or parts that are not recommended. Failure to comply

could lead to serious injury or loss of life.

Page 20

TROUBLESHOOTING

19

AIR-POWERED SIPHON-FEED SPRAY GUN 058-9336-2

Troubleshooting

The following chart lists common issues and solutions. Please read it carefully and follow all

instructions closely.

• Disconnect electrical plug and air supply from the tool before making any adjustments.

• Repairs must be performed by a qualified service technician only.

WARNING!

Potential hazard that could result in serious injury or loss of life.

• If any of the following symptoms appears while the tool is in use, turn it off and

disconnect it from the air supply immediately. Failure to heed this warning

could result in serious personal injury.

PROBLEM POSSIBLE CAUSES SOLUTIONS

Fluttering or spitting

1. Paint level inside the canister

is too low.

2. Canister is not placed on a

planar surface.

3. Fluid inlet connection is loose.

4. Fluid tip/seat is loosened or

damaged.

5. The fluid needle nut is dry or the

round nut is loose.

6. Air vent is clogged.

1. Add paint inside the canister.

2. Place the canister on a planar surface.

3. Tighten the connection.

4. Adjust or replace.

5. Lubricate the fluid adjustment needle and/or

tighten the round nut.

6. Clear the vent hole.

Arc-shaped pattern

1. Fluid nozzle is worn or loose.

2. Paint has built up on air cap.

1. Tighten or replace fluid nozzle.

2. Remove obstructions from holes, but don’t

use metal objects to clean it.

MC-OM-08

MC-OM-09

Page 21

TROUBLESHOOTING

20

AIR-POWERED SIPHON-FEED SPRAY GUN 058-9336-2

Pattern is not spread

uniformly

1. Paint has built up on air cap.

2. Fluid nozzle is dirty or worn.

1. Clean or replace air cap.

2. Clean or replace fluid nozzle.

Centre of pattern is

too narrow

1. Paint is too thin or not

sufficient.

2. Atomization air pressure is too

high.

1. Regulate paint viscosity.

2. Reduce air pressure.

Width of spray

pattern is too narrow

1. Paint is too thick.

2. Atomization air pressure is too

low.

1. Regulate paint viscosity.

2. Increase the air pressure.

Air leakage from air

cap when trigger is

not pressed

1. Air valve stem is stuck.

2. Air valve or seat is contaminated.

3. Air valve or seat is worn or

damaged.

4. Air valve spring is broken.

5. Air valve stem is bent.

1. Lubricate the air valve stem.

2. Clean the air valve or seat.

3. Replace the air valve or seat.

4. Replace the air valve spring.

5. Replace the air valve stem.

Fluid leakage from

packing nut

1. Packing nut is loose.

2. Packing nut is worn or dry.

1. Tighten the packing nut, but do not restrict

needle.

2. Replace or lubricate the packing nut

(use non-silicone oil).

PROBLEM POSSIBLE CAUSES SOLUTIONS

MC-OM-10

MC-OM-11

MC-OM-12

Page 22

TROUBLESHOOTING

21

AIR-POWERED SIPHON-FEED SPRAY GUN 058-9336-2

Excessive overspray

1. Atomization pressure is too high.

2. Work surface is too far.

3. Improper stroking (arcing, gun

motion too fast).

1. Reduce pressure.

2. Adjust to proper distance.

3. Move at moderate pace, parallel to work

surface.

No spray

1. No pressure in gun.

2. Fluid control is not properly

opened.

3. Fluid is too heavy.

1. Check air lines.

2. Open fluid control.

3. Thin fluid or change to pressure feed system.

PROBLEM POSSIBLE CAUSES SOLUTIONS

Page 23

Page 24

PARTS LIST

23

AIR-POWERED SIPHON-FEED SPRAY GUN 058-9336-2

No. Description Qty. No. Description Qty.

1 Filter 1 27 Trigger pin II 1

2 Paint straw 1 28 Trigger 1

3 Canister 1 29 Snap retainer 3

4 Pin 2 30 Trigger washer 1

5 Pin sleeve 2 31 O-ring 6 X 2 1

6 Washer 1 32 Pattern adjusting bolt 1

7 Handle 1 33 Brass washer 1

8 Anti-leaking washer 1 34 Pattern adjusting bolt seat 1

9 Hanger 1 35 Pattern adjusting nut 1

10 Paint inlet plug 1 36 Bolt M4 X 7 1

11 Nut 1 37 Paint adjusting bolt 1

12 Paint inlet seat 1 38 Paint adjusting nut 1

13 Air cap retainer 1 39 Needle spring 1

14 Round nut 1 40 Needle 1

15 Air cap washer 1 41 Fluid adjusting knob 1

16 Air cap 1 42 Trigger spring 1

17 Nozzle 1 43 Valve stopper 1

18 Nozzle housing 1 44 O-ring 4.5 X 1.8 1

19 Washer 1 45 Valve stem 1

20 Washer 1 46 Hex bolt 1

21 Position bolt 1 47 Compressed spring 1

22 Needle sealing washer 1 48 Brass washer 1

23 Washer 1 49 O-ring 2.5 X 1.2 1

24 Compressed spring 1 50 O-ring 9 X 1.2 1

25 Washer 1 51 Valve seat 1

26 Trigger pin I 1 52 Bolt 1

Page 25

PARTS LIST

24

AIR-POWERED SIPHON-FEED SPRAY GUN 058-9336-2

If any parts are missing or damaged, or if you have any questions, please call 1-800-689-9928.

53 Gun body 1 55 Wrench 1

54 Air inlet plug 1 56 Brush 1

No. Description Qty. No. Description Qty.

Page 26

WARRANTY

25

AIR-POWERED SIPHON-FEED SPRAY GUN 058-9336-2

Mastercraft® limited warranty

These warranties are subject to the following conditions and limitations:

a. A bill of sale verifying the purchase and purchase date must be provided.

b. This warranty will not apply to any product or part thereof which is worn or broken or which

has become inoperative due to abuse, misuse, accidental damage, neglect, or lack of proper

installation, operation, or maintenance (as outlined in the applicable instruction manual or

operating instructions), or which is being used for industrial, professional, commercial, or

rental purposes.

c. This warranty will not apply to normal wear and tear or to expendable parts or accessories

that may be supplied with the product which are expected to become inoperative or unusable

after a reasonable period of use.

d. This warranty will not apply to routine maintenance and consumable items such as, but not

limited to, fuel, lubricants, vacuum bags, blades, belts, sandpaper, bits, fluids, tune-ups, or

adjustments.

e. This warranty will not apply where damage is caused by repairs made or attempted by others

(i.e., persons not authorized by the manufacturer).

f. This warranty will not apply to any product that was sold to the original purchaser as a

reconditioned or refurbished product (unless otherwise specified in writing).

This Mastercraft

®

product is guaranteed for a period of 3

years from the date of original retail purchase against

defects in workmanship and materials, except for the

following component:

Component A: Accessories, which are guaranteed for a

period of 1-year from the date of original retail purchase

against defects in workmanship and materials.

Subject to the conditions and limitations described below,

this product, if returned to us with p

roof of purchase within

the stated warranty period and if covered under this

warranty, will be repaired or replaced (with the same model,

or one of equal value or specification), at our option. We will

bear the cost of any repair or replacement and any costs of

labor relating thereto.

Page 27

WARRANTY

26

AIR-POWERED SIPHON-FEED SPRAY GUN 058-9336-2

g. This warranty will not apply to any product or part thereof if any part from another

manufacturer is installed therein or any repairs or alterations have been made or attempted by

unauthorized persons.

h. This warranty will not apply to normal deterioration of the exterior finish, such as, but not

limited to, scratches, dents, paint chips, or to any corrosion or discoloring by heat, or

abrasives and chemical cleaners.

i. This warranty will not apply to component parts sold by and identified as the product of

another company, which shall be covered under the product manufacturer’s warranty, if any.

Additional limitations

This warranty applies only to the original purchaser and may not be transferred. Neither the retailer

nor the manufacturer shall be liable for any other expense, loss or damage, including, without

limitation, any indirect, incidental, consequential, or exemplary damages arising in connection with

the sale, use, or inability to use this product.

Notice to consumer

This warranty gives you specific legal rights, and you may have other rights, which may vary from

province to province. The provisions contained in this warranty are not intended to limit, modify, take

away from, disclaim, or exclude any statutory warranties set forth in any applicable provincial or

federal legislation.

Loading...

Loading...