Page 1

model no. 058-8691-0

OPERATING

MANUAL

IMPORTANT:

For your own safety, read and follow all of the Safety Guidelines

and Operating Instructions before operating this nailer. Keep this

manual for future reference.

AIR-POWERED BRAD NAILER

Page 2

3

TABLE OF CONTENTS

4

5

9

10

13

14

19

20

22

23

24

TABLE OF CONTENTS

TECHNICAL SPECIFICATIONS

SAFETY GUIDELINES

KEY PARTS DIAGRAM

TECHNICAL INFORMATION

TYPES OF NAILS

OPERATING INSTRUCTIONS

MAINTENANCE

TROUBLESHOOTING

EXPLODED VIEW

PARTS LIST

WARRANTY

Page 3

54

SAFETY GUIDELINES

TECHNICAL SPECIFICATIONS

TECHNICAL SPECIFICATIONS

These precautions are intended for the personal safety of the user and others working with the

user. Please take time to read and understand them.

Make sure you read and understand this manual before using this tool. Make sure other users

read and understand this manual before they use the tool.

SAFETY GUIDELINES

PERSONAL SAFETY

Potential hazard that will result in serious

injury or death.

Potential hazard that could result in

serious injury or death.

Potential hazard that may result in

injury or damage to equipment.

Note: The word “Note” is used to inform the readers of something

they need to know about the tool.

WARNING!

CAUTION!

DANGER!

This manual contains information that relates to PROTECTING PERSONAL SAFETY and

PREVENTING EQUIPMENT PROBLEMS. It is very important to read this manual carefully and

understand it thoroughly before using the product. The symbols listed below are used to

indicate this information.

100 Nails

18–gauge brad nails (5/8–2")

70–110 PSI (4.8 - 7.5 bar)

120 PSI (8.3 bar)

0.03 CF/cycle @ 90 PSI

1/4" (6.4 mm) – 18 NPT

3 lb 6 oz (1.55 kg)

CAPACITY (QTY.)

NAIL SIZE

OPERATION PRESSURE

MAXIMUM PRESSURE

AIR CONSUMPTION

AIR INLET

WEIGHT

CF : Cubic Feet (the volumetric flow rate of air corrected to standardized conditions of

temperature and pressure).

NPT: National Pipe Thread.

model no. 058-8691-0 | contact us 1-800-689-9928

Page 4

76

Do not use oxygen or any other combustible or bottled

gas to power air-powered tools. Failure to observe this

warning can cause explosion and serious personal

injury or death. Use only compressed air to power

air-powered tools. Use a minimum of 25' (7.6 m) of

hose to connect the tool to only compressor. Failure to

comply will result in serious injury or death.

Risk of inhalation: Never directly inhale the air produced by the

compressor.

Risk of electric shock: Do not expose a compressor to rain.

Store it indoors. Disconnect the compressor from the power

source before servicing. The compressor must be grounded.

Do not use grounding adaptors.

Keep children away from the work area. Do not allow children to handle

power tools.

Do not use this tool in the presence of flammable liquids or gases. Sparks

that are created during use may ignite gases.

Do not point the tool towards yourself or other people, even when the tool

has stopped. Keep hands, feet, and all other parts of the body clear from

work area.

Do not attempt to clear nailer jams while the air hose is connected.

Do not keep the trigger or the safety stand pressed while loading nails.

Unintentional firing of a nail could cause serious personal injury or death.

Do not disconnect or reconnect the air hose with the trigger pressed. The

Air-powered Brad Nailer may fire when it is reconnected to the air supply.

Risk of personal injury: Do not direct compressed air from the air hose

towards the user or other people or animal.

Risk of burns: The pump and the manifold generate high temperatures. In

order to avoid burns or other injuries, do not touch the pump, the manifold,

or the transfer tube while the compressor is running. Allow the parts to cool

down before handling or servicing. Keep children and pets away from the

compressor at all times.

Risk of bursting: Do not adjust the pressure switch or safety valve for any

reason. They have been preset at the factory for this compressor’s maximum

pressure. Tampering with the pressure switch or the safety valve may cause

personal injury or property damage.

Risk of bursting: Make sure the regulator is adjusted

so that the compressor outlet pressure is set lower

than the maximum operating pressure of the tool.

Before starting the compressor, pull the ring on the

safety valve to make sure the valve moves freely.

Drain water from the tank after each use. Do not weld

nor repair the tank. Relieve all pressure in the hose

before removing or attaching accessories.

Do not allow inexperienced or untrained individuals to operate an Airpowered Brad Nailer or any other air-powered tool.

Keep hands and other parts of the body away from the firing head

during use. Keep hands, feet, and all other parts of the body at least

8" (20 cm) away from the firing head. Nails or objects in the

workpiece can cause serious injury if they are deflected by the

workpiece or if they are driven away from the point of entry.

Do not overload the tool. Allow the tool to operate at its optimum

speed for maximum efficiency.

Locate the compressor in a well-ventilated area for cooling, at a

minimum of 12" (30 cm) away from the nearest wall.

Protect the air hose and the power cord from damage and puncture.

Inspect them for weak or worn spots before every usage, and replace

them if necessary.

Always wear eye and hearing protection when using the air

compressor. Failure to do so may result in hearing loss.

Do not carry the compressor while it is running.

Do not operate the compressor if it is not in a stable position.

Do not operate the compressor on a rooftop or in an elevated position

that could allow the unit to fall or be tipped over.

Always replace a damaged gauge before operating the unit again.

SAFETY GUIDELINES

WARNING!

DANGER!

SAFETY GUIDELINES

SAFETY GUIDELINES

model no. 058-8691-0 | contact us 1-800-689-9928

Potential hazard that will result in serious injury or death.

Page 5

98

CAUTION!

Potential hazard that may result in injury or damage to

equipment.

Disconnect the tool from the air supply and turn off the

compressor before performing any maintenance,

loading or changing nails, when the tool is not in use,

when it is being handed to another person, and when it

is left unattended. Failure to comply may result in injury

or damage to equipment.

Use safety goggles and ear protection:

Wear safety glasses with side shields when operating

the tool and verify that others in the work area are also

wearing safety glasses. Safety glasses must conform to

American National Standards Institute (ANSI Z87.1)

requirements and must provide protection from flying

particles from the front and the sides.

Air-powered tools are loud and the sound can cause

hearing damage. Always wear ear protection to help

prevent hearing damage and loss. Failure to comply may

result in injury.

Note: Recycle unwanted materials rather than disposing of them as waste. Sort

the tools, hoses, and packaging in specific categories and take them to the local

recycling centre or dispose of them in an environmentally safe way.

SAFETY GUIDELINES

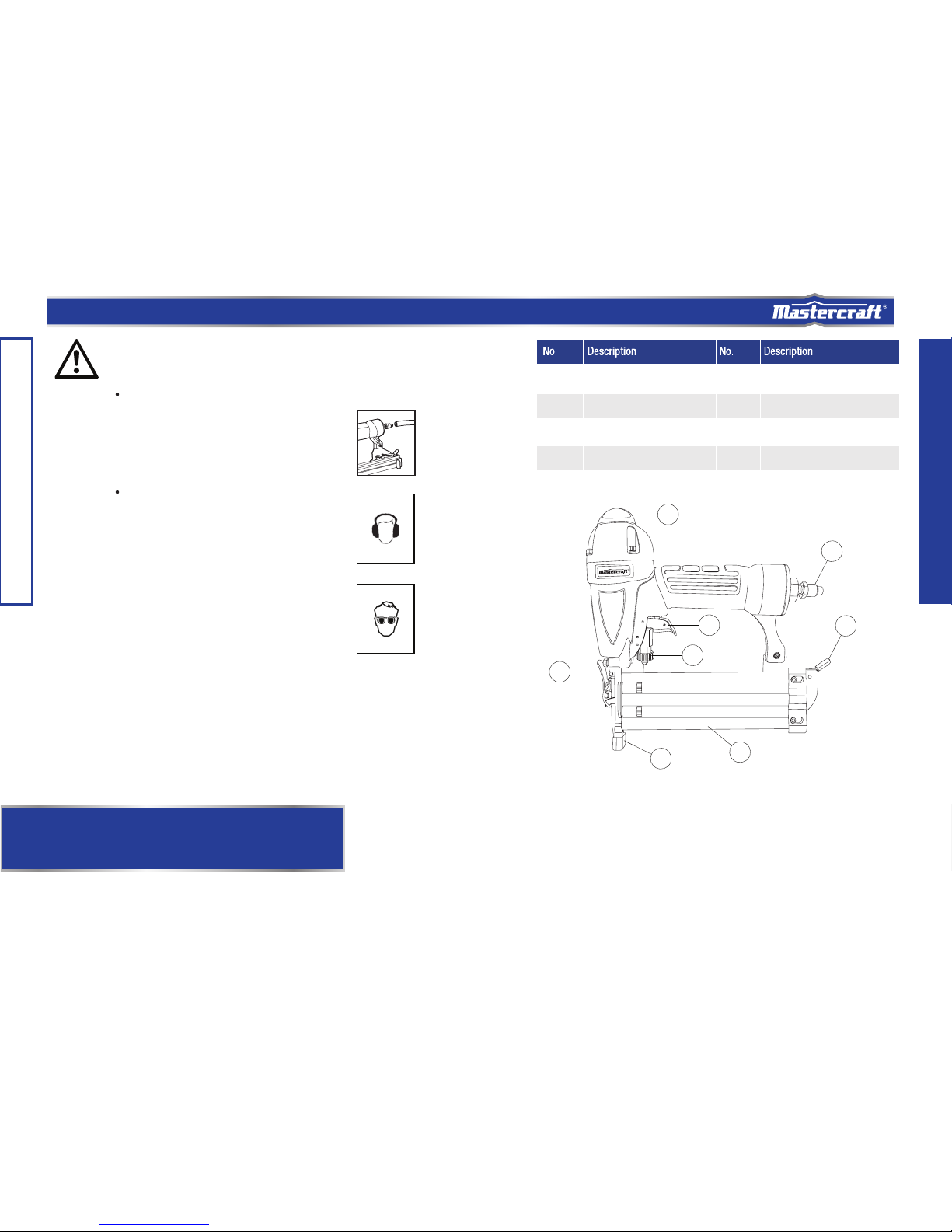

KEY PARTS DIAGRAM

3

4

3

2

1

6

5

3

7

3

8

Air inlet plug

Magazine latch

Magazine

Safety tip

1

2

3

4

5

6

7

8

Quick release handle

Depth adjustment dial

Trigger

Air deflector

model no. 058-8691-0 | contact us 1-800-689-9928

Page 6

1110

Compatible compressors

Air system

General use

GUIDELINES FOR PROPER USE AND OPERATION

Potential hazard that could result in serious injury or death.

Be sure to use a proper air compressor with Mastercraft

®

air-powered tools. The

compressor should be able to supply a minimal air delivery of 2.0 CFM@ 90 PSI to ensure

the compressor can run continuously with the Mastercraft

®

Air-powered Pin Nailer.

Air Compressor

Size and Power

Wood Density Nail Size Compressor Air Pressure

0.6g/cm

3

0.6g/cm

3

Quick connector

Quick coupler

Air hose

Lubricator

Regulator (0 to 8.5 bar)

Filter

Cut-off valve

Air compressor

Always use clean, dry, regulated, compressed air at 4.8 to 7.5 bar (70 to 110 PSI).

Do not exceed the maximum or minimum pressures. Operating the tool at the wrong

pressure (too low or too high) will cause excessive noise or rapid wear.

WARNING!

Keep hands and other parts of the body away from the tool’s discharge

and working areas when connecting the air supply. Failure to comply

could lead to serious injury or death.

Heavy-duty and

continuous use

Medium-duty and

intermittent use

Light-duty and

intermittent use

Light-duty and

intermittent use

Light-duty and

intermittent use

Light-duty and

intermittent use

Medium-duty and

intermittent use

Medium-duty and

intermittent use

Medium-duty and

intermittent use

15+ Gallons

8–11 Gallons

2–6 Gallons

1/3–1 1/3 HP 1 1/2–2 HP 2+HP

TECHNICAL INFORMATION

TECHNICAL INFORMATION

90 PSI (6.3 bar)

100 PSI (7 bar)

70 PSI (4.8 bar)

90 PSI (6.3 bar)

Mastercraft® Air-powered Brad Nailer

<1 1/4”(32 mm) brad nails

<1 1/4”(32 mm) brad nails

<1 1/4”(32 mm) brad nails

<1 1/4”(32 mm) brad nails

model no. 058-8691-0 | contact us 1-800-689-9928

This Mastercraft® Air-powered Brad Nailer includes a die cast aluminum body that is strong and

lightweight, and a comfort grip rubber handle for improved control and comfort, even during

extended use. The tool has a magazine that accepts 18-gauge and 5/8 - 2" (15 to 50 mm) long

brad nails, without adjustment. A hardened one-piece drive blade is provided for professional

application, and an adjusting wheel for controlling the depth of the nails. A touch-strike security

system is included for ensuring safety of the operator. The tool features a 360º air deflector that

is adjustable in any direction, and a quick-release handle for clearing jams. The Air-powered

Brad Nailer is best suited for installing door and window trim, decorative trim, cabinet work,

finish paneling, framing, scribe molding, upholstery, beading, chair rail, flooring works, etc.

Page 7

1312

ACCEPTABLE NAILS

NAIL TYPE ICON

WARNING!

WARNING!

It is recommended that a filter-regulator-lubricator be used and be located as close to the tool

as possible.

If a filter-regulator-lubricator is not installed, place up to 6 drops of compressor oil into the air

inlet plug before each use.

If a filter-regulator-lubricator is installed, keep the air filter clean. A dirty filter will reduce the

air pressure to the tool, which will cause a reduction in power, efficiency, and general

performance.

For optimal performance, install a quick connector to the tool and a quick coupler on the

hose, if applicable.

Verify that all of the connections in the air supply system are sealed in order to prevent air

leakage.

Read this Instruction Manual carefully before using the Air-powered Pin Nailer.

• Read and follow all the safety instructions at the beginning of this manual. Inspect the

Air-powered Pin Nailer prior to each use in order to:

– ensure that the proper power source is being used.

– verify that the tool is in proper working order.

•

•

•

•

•

Potential hazard that could result in serious injury or death.

• Do not use the tool if it is not in proper working order.

• Do not use oxygen or any other combustible or bottled gas to

power this tool.

• Do not use this tool in the presence of any flammable liquids or

gases.

• Keep hands and other parts of the body away from the firing

head during use.

• Do not point the tool towards the operator or other people.

• Do not attempt to clear a jammed nail when the air hose is

connected.

• Do not drive a nail on top of an existing nail. Failure to comply

could lead to serious injury or loss of life.

Note: Icons are colour coded. Please refer to the actual tool for the

specific colour.

Potential hazard that could result in serious injury or death.

• The use of any other types of nails will cause the nailer to

jam and could lead to serious injury or death.

OPERATING INSTRUCTIONS

TYPES OF NAILS

2”

5/8”

Length: 5/8 - 2" (15 to 50 mm)

These Icons are used to select the proper nails for this specific nailer.

model no. 058-8691-0 | contact us 1-800-689-9928

Page 8

1514

Potential hazard that will result in serious injury or death.

DANGER!

fig. A

Loading nails

1. Disconnect the tool (1) from the air

supply (2) (Fig. A).

fig. B

fig. C

fig. D

5.

Disconnect the tool from the compressed air source before

loading nails.

Do not point the tool towards the operator or other people while

changing nails.

Do not hold the tool with the trigger pressed while changing

nails. Failure to comply will lead to serious injury or death.

OPERATING INSTRUCTIONS

OPERATING INSTRUCTIONS

2

1

1

2

Hold the Air-powered Brad Nailer firmly

with one hand, and use the other hand

to press the latch (1) on the magazine

(2) and slide it back (fig B).

1

2

1

fig. E

1

Insert a strip of nails (1) into the

magazine. After ensuring that the points

of the nails are facing down, close the

magazine. The tool is now ready for use

(fig C).

Plug in compressor, turn it on, set the

pressure regulator to 90 PSI, attach one

end of the air hose to the compressor

and the other end of the air hose (1) to

the tool (2). Use plumber’s tape to

prevent air leaks (fig D).

Test the driving depth of the tool against

a sample piece of wood by pressing the

trigger (1) before working on the

workpiece. If the nails are being driven

too deep or not deep enough, adjust the

regulator in the air supply in order to

provide more or less air pressure, as

required (fig E).

model no. 058-8691-0 | contact us 1-800-689-9928

Page 9

1716

WARNING!

Potential hazard that will result in serious injury or death .

Potential hazard that may result in moderate injury or

damage to equipment.

Fasteners depth adjustment

fig. F

The safety tip must be in contact with the workpiece before

activating the tool.

Do not operate the tool if the nails are not loaded, as doing so

may damage the tool.

Do not fire nails into the air, as doing so may cause injury to

the operators or others, apart from damaging the tool.

Load the correct type of nails only. Failure to comply could lead

to serious injury or loss of life.

When operating any air-powered tool below freezing temperature:

CAUTION!

Operate the tool with utmost care when connected with the

air compressor. Failure to comply may result in moderate

injury or damage to equipment.

Cold weather operation

OPERATING INSTRUCTIONS

OPERATING INSTRUCTIONS

• Verify that the compressor tanks have been properly drained prior to use.

• Keep the tool as warm as possible using any safe, convenient method.

• Place up to 6 drops of pneumatic tool oil into the tool’s air inlet.

• Maintain the operating level of the air pressure as recommended (see section “Technical

specification”).

• Load the nails into the magazine (if required).

• Actuate the tool 5 to 6 times into a scrap wooden piece in order to lubricate the O-rings.

• Adjust the pressure up to the operating level (do not exceed 120 PSI) and use the tool normally.

• Relubricate the tool, as described in the maintenance section.

• Drain the compressor tanks at least once per day.

fig. G fig. H

The Mastercraft® Air-powered Brad Nailer

has a depth adjustment dial below the trigger

to adjust the firing depth of the fasteners.

Note: Refer to the graphic imprinted below

the trigger and adjust the firing depth

accordingly (fig F).

DECREASING FASTENER DEPTH INCREASING FASTENER DEPTH

Turn the depth adjustment dial

counterclockwise (with the discharge area of

the tool facing away from the operator) (fig G).

Turn the depth adjustment dial clockwise (with

the discharge area of the tool facing away from

the operator) (fig H).

model no. 058-8691-0 | contact us 1-800-689-9928

Page 10

1918

Note: If the nails continue to jam, call 1-800-689-9928.

Note: When temperatures are below freezing, keep the tools warm

using any safe, convenient method.

WARNING!

DANGER!

Potential hazard that will result in serious injury or death .

Potential hazard that will result in serious injury or death .

Clearing a jammed nail

Disconnect the tool from the air supply line before clearing a

jammed nail. Failure to comply could cause them to be fired

out of the tool causing serious injury.

Do not point the tool towards the operator or other people.

Serious personal injury could result if these instructions are

not followed.

Disconnect the tool from the air supply line.

Remove the non-jammed nails that are stored in the tool’s magazine.

Operate the magazine latch and slide the pusher back to open the magazine for checking the

jammed nails.

Use pliers or any appropriate tool to remove the jammed nails.

Close the magazine cover and slide the pusher to its original position.

Reload the nails into the tool magazine.

Reconnect the air supply line to the tool’s air inlet.

Test fire 3 to 5 nails into a piece of scrap wood in order to ensure a proper operation.

To clear a jammed nail

None X

X X

X

See below X

MAINTENANCE

REQUIRED

TOOLS OR

MATERIALS

REQUIRED

DESCRIPTION

Each Use or

every 2 Hrs

MAXIMUM SERVICE INTERVAL

Monthly

As

Needed

General inspectionfree movement

In-depth inspection

Replace worn or

broken parts

Lubrication

Trigger, spring,

safety mechanism

Worn or broken

parts

Pneumatic tool

oil

Maintenance

Lubrication: If the Air-powered Pin Nailer and the

compressor are not equipped with an in-line

lubrication system, place up to 6 drops of

pneumatic tool oil into the air inlet before each

work day or after every 2 hours of continuous use,

depending on the characteristics of the workpiece

and type of nails used.

Air-operated tools must be inspected periodically and worn or broken parts must be

replaced in order to keep tools operating safely and efficiently.

Inspect and replace worn or damaged O-rings, seals, etc. Tighten all screws and caps

frequently in order to help prevent personal injury.

Inspect the trigger, spring, and safety mechanism for free movement on a regular basis in

order to ensure that the safety system is fully functional. Verify that no parts are lose or

missing and no parts are sticking or jammed.

Keep the magazine and the safety tip of the tool clean and free of any dirt or abrasive

particles.

Disconnect the tool from the air compressor before

performing maintenance/service, adjusting, clearing jams,

reloading, and when it is not in use.

Repairs must be performed by a qualified service technician

only. Failure to comply will lead to serious injury or death.

OPERATING INSTRUCTIONS

MAINTENANCE

model no. 058-8691-0 | contact us 1-800-689-9928

Page 11

21

20

Note: For further repair information, please call 1-800-689-9928.

DANGER!

Potential hazard that will result in serious injury or death .

The following chart lists common issues and solutions. Please read it carefully and

follow all instructions carefully.

Air leakage at the

top of the tool or in

the trigger area.

The tool does not

operate properly - it

does not drive the

nails or operates

sluggishly.

The tool skips nails.

The tool jams.

Air leakage between

the bottom and the

cylinder cap.

Air leakage near the

bottom of the tool.

O-rings in the trigger valve are

damaged.

The trigger valve heads are

damaged.

Trigger valve stem, seal, or

O-rings are damaged.

The screws are loose.

The O-rings or the bumper are

worn or damaged.

The screws are loose.

The O-rings or the seals are worn

or damaged.

1.

2.

3.

1.

2.

3.

4.

1.

2.

3.

1.

2.

Tighten the screws.

Inspect and replace the O-rings or the seals.

1.

2.

Tighten the screws.

Inspect and replace the O-rings or the

bumper.

1.

2.

1.

2.

Inspect and replace the O-ring.

Inspect and replace trigger valve heads.

Inspect and replace the trigger valve stem,

seal, or O-ring.

Disconnect the tool from the air supply before making any adjustments.

If any of the following symptoms appear while the tool is in use,

turn it off and disconnect it from the air supply immediately.

Failure to comply will lead to serious injury or death.

Repairs must be performed by a qualified service technician

only.

PROBLEM POSSIBLE CAUSES SOLUTIONS

PROBLEM POSSIBLE CAUSES SOLUTIONS

The nails are being

driven too deep.

The bumper is worn.

The air pressure is too high.

The depth adjustment knob is not

adjusted properly.

1.

2.

3.

1.

2.

3.

Replace the bumper.

Adjust the air pressure.

Adjust the depth setting by turning the depth

adjustment knob counterclockwise (see

section “Adjusting nail depth” for more

detailed instructions).

The air supply is inadequate.

Lubrication is inadequate.

The O-rings or seals are worn or

damaged.

The exhaust deflector in the

cylinder head is blocked.

1.

2.

3.

4.

5.

1.

2.

3.

4.

1.

2.

3.

4.

The bumper is worn or the spring

is damaged.

There is dirt in the front plate.

Nails cannot move freely in the

magazine due to dirt or wear.

The O-ring on the piston is worn

or dry or lubrication is insufficient.

The cylinder cover seal Is leaking.

Improper nails are used, or nails are

damaged.

The driver guide is damaged or worn.

The magazine screw is loose.

There is dirt in magazine.

1.

2.

3.

4.

Verify that the air supply is adequate.

Pour up to 6 drops of oil into the air inlet.

Inspect and replace O-rings or seals.

Replace the damaged internal parts.

1.

2.

3.

4.

5.

Replace the bumper or spring.

Clean the drive channel on the front plate.

Clean the magazine.

Replace the O-ring.

Replace the sealing washer.

Use proper nails.

(see section “Clearing a jammed nail.”)

Inspect and replace the driver.

Tighten the magazine.

Open and clean the magazine.

TROUBLESHOOTING

TROUBLESHOOTING

model no. 058-8691-0 | contact us 1-800-689-9928

Page 12

2322

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

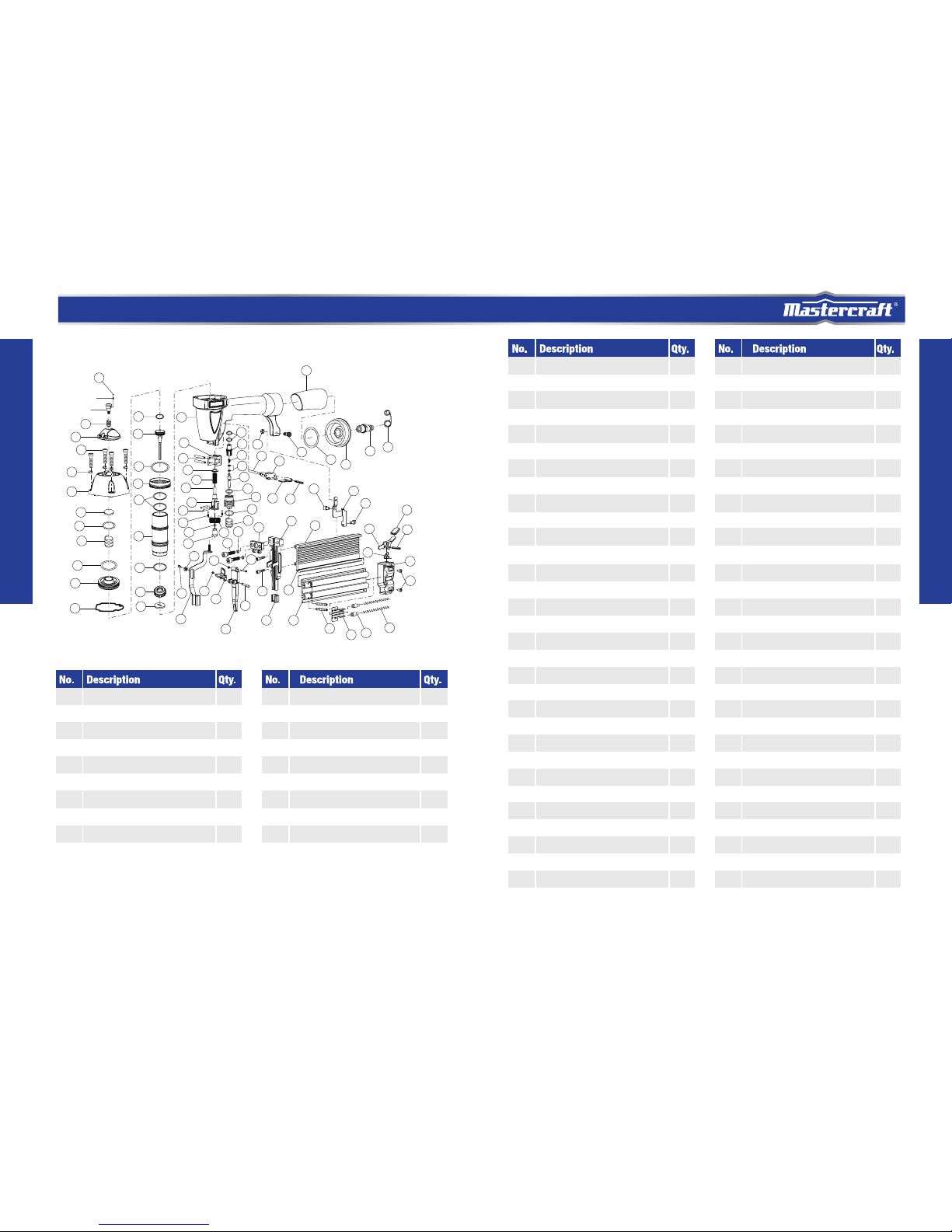

EXPLODED VIEW&PARTS LIST

PARTS LIST

2

15

22

25

27

28

29

30

32

33

35

34

36

26

24

23

16

17

18

19

12

20

21

12

4

5

6

6

8

9

10

11

12

13

14

1

82

81

80

78

79

74

73

69

70

68

55

72

66

77

76

67

65

64

63

62

61

60

59

5856

52

51

53

57

71

54

50

48

47

31

49

7

46

45

44

43

42

41

37

38

39

40

24

75

16

23

42

43

44

45

46

51

52

53

54

47

49

50

17 24

25

18

19

20

21

22

8

9

12

13

6

26

27

28

29

30

31

32

33

34

35

36

37

39

40

55

38

48

60

61

62

63

67

71

72

73

70

74

75

76

77

80

81

82

83

84

77

85

86

94

78

79

2

15

22

25

27

28

29

30

32

33

35

34

36

26

24

23

16

17

18

19

12

20

21

12

4

5

6

6

8

9

10

11

12

13

14

1

82

81

80

78

79

74

73

69

70

68

55

72

66

77

76

67

65

64

63

62

61

60

59

5856

52

51

53

57

71

54

50

48

47

31

49

7

46

45

44

43

42

41

37

38

39

40

24

75

Ball Dw=2.5

Compressed Spring A

Bolt

Compressed Spring

Air deflector

Bolt M5 x 20

Spring Washer 5

Cylinder Cover

Sealing Washer

O-ring 17 x 2.65

3

1

1

1

1

4

6

1

1

1

Compressed Spring

O-ring 33.6 x 2

Switch Valve

Washer

O-ring 24.2 x 3.1

Main Piston

Sealing washer

Collar

Cylinder

Bumper

1

4

1

1

1

1

1

1

1

1

Sealing Washer

Gun Body

Guide Stand

Pin 3 x 26

Washer II

Compressed Spring

Pusher Pipe

Adjustable Stand

Norm Pin 1.5 x 8

Compressed spring B

Adjustable Nut

Snap retainer 2

Adj. stem

Safety Stand

Guide Sleeve

Bolt M3 x 8

O-ring 7 x 1.5

Trigger Valve Guide

Screw Spring

O-ring 1.9 x 1.1

Switch Lever

O-ring 11.2 x 1.6

Trigger Valve Seat

O-ring 11.7 x 2.4

Compressed Spring

Fixed Driver Guide Cover

Bolt M5 x 25

Pin Sleeve

Pin

Bolt M4 x 16

Quick Release Handle

1

1

1

3

1

1

1

1

2

2

1

1

1

1

1

1

2

1

1

2

1

1

1

1

1

1

2

1

1

2

1

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

Movable Driver Guide Cover

O-RING 1.9 x 1.2

Pin

Driver Guide

Safety Nozzle

Inlay Slice

Movable Magazine

Bolt M4 x 12

Pusher A

Pusher Pipe

Compressed Spring

Bolt M4 x 10

Position Seat

Torsion spring

Pin 3 x 18

Fixed Lever

Fixed Lever Jacket

Bolt M4 x 8

Fixed Seat

Bolt M4 x 6

Fixed Magazine

Pin 3 x 17.5

Safety Spacer

Trigger II

Nut M4

Bolt M4 x 14

Rubber Handle Case

O-ring 36.3 x 3.55

End Cap

Air Inlet Plug

Air Inlet Plug Cap

1

1

1

1

1

1

1

2

1

2

2

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

model no. 058-8691-0 | contact us 1-800-689-9928

Page 13

2524

3-Year Limited Warranty

This product is guaranteed for a period of 3 years from the date of original retail purchase

against defects in workmanship and materials, except for the following component:

Component A: Accessories, which are guaranteed for a period of 1-year from the date of

original retail purchase against defects in workmanship and materials.

Subject to the conditions and limitations described below, this product, if returned to us

with proof of purchase within the stated warranty period and if covered under this

warranty, will be repaired or replaced (with the same model, or one of equal value or

specification), at our option. We will bear the cost of any repair or replacement and any

costs of labor relating thereto.

These warranties are subject to the following conditions and limitations:

A bill of sale verifying the purchase and purchase date must be provided.

This warranty will not apply to any product or part thereof which is worn or broken or

which has become inoperative due to abuse, misuse, accidental damage, neglect, or lack

of proper installation, operation, or maintenance (as outlined in the applicable instruction

manual or operating instructions), or which is being used for industrial, professional,

commercial, or rental purposes.

This warranty will not apply to normal wear and tear or to expendable parts or accessories

that may be supplied with the product which are expected to become inoperative or

unusable after a reasonable period of use.

This warranty will not apply to routine maintenance and consumable items such as, but

not limited to, fuel, lubricants, vacuum bags, blades, belts, sandpaper, bits, fluids,

tune-ups, or adjustments.

This warranty will not apply where damage is caused by repairs made or attempted by

others (i.e., persons not authorized by the manufacturer).

This warranty will not apply to any product that was sold to the original purchaser as a

reconditioned or refurbished product (unless otherwise specified in writing).

a)

b)

c)

d)

e)

f)

This warranty will not apply to any product or part thereof if any part from

another manufacturer is installed therein or any repairs or alterations have

been made or attempted by unauthorized persons.

This warranty will not apply to normal deterioration of the exterior finish, such

as, but not imited to, scratches, dents, paint chips, or to any corrosion or

discoloring by heat, or abrasives and chemical cleaners.

This warranty will not apply to component parts sold by and identified as the

product of another company, which shall be covered under the product

manufacturer’s warranty, if any.

g)

h)

i)

This warranty applies only to the original purchaser and may not be

transferred. Neither the retailer nor the manufacturer shall be liable for any

other expense, loss or damage, including, without limitation, any indirect,

incidental, consequential, or exemplary damages arising in connection with

the sale, use, or inability to use this product.

This warranty gives you specific legal rights, and you may have other rights,

which may vary from province to province. The provisions contained in this

warranty are not intended to limit, modify, take away from, disclaim, or

exclude any statutory warranties set forth in any applicable provincial or

federal legislation.

Additional limitations

Notice to consumer

Made in China

Imported by Mastercraft Canada Toronto, Canada M4S 2B8

WARRANTY

WARRANTY

model no. 058-8691-0 | contact us 1-800-689-9928

Loading...

Loading...