Page 1

INSTRUCTION MANUAL

MIG/FLUX-CORE WIRE FEED

WELDER KIT

058-8195-2

Page 2

Quick Start Guide

If any parts are

missing or damaged,

or if you have any

questions, please call

1-800-689-9928.

Read and understand this instruction manual

thoroughly before using the product. It contains

important information for your safety as well as

operating and maintenance advice.

Keep this instruction manual for future use. Should

this product be passed on to a third party, then this

instruction manual must be included.

MIG/FLUX-CORE WIRE FEED WELDER KIT 058-8195-2

Page 3

QUICK START GUIDE

MIG/FLUX-CORE WIRE FEED WELDER KIT 058-8195-2

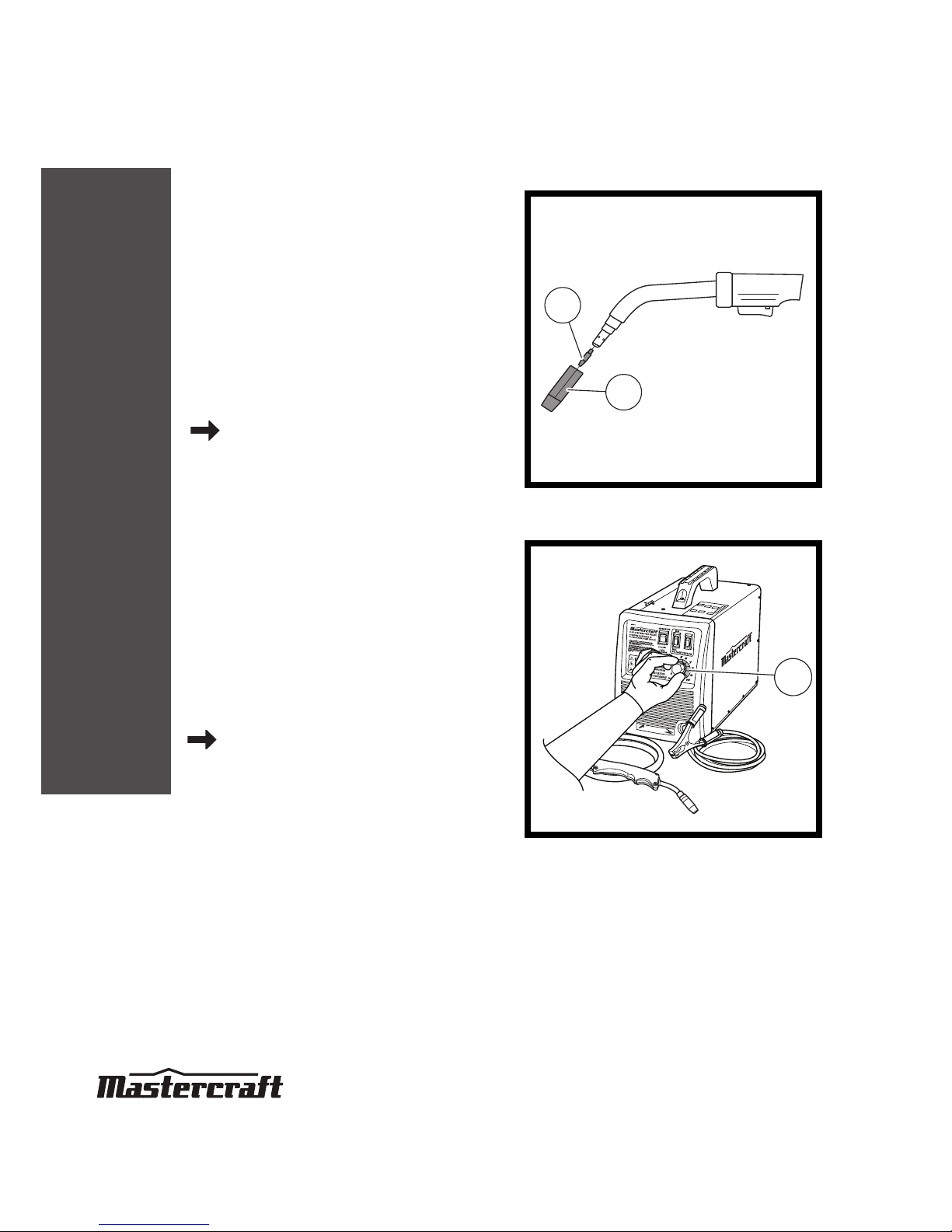

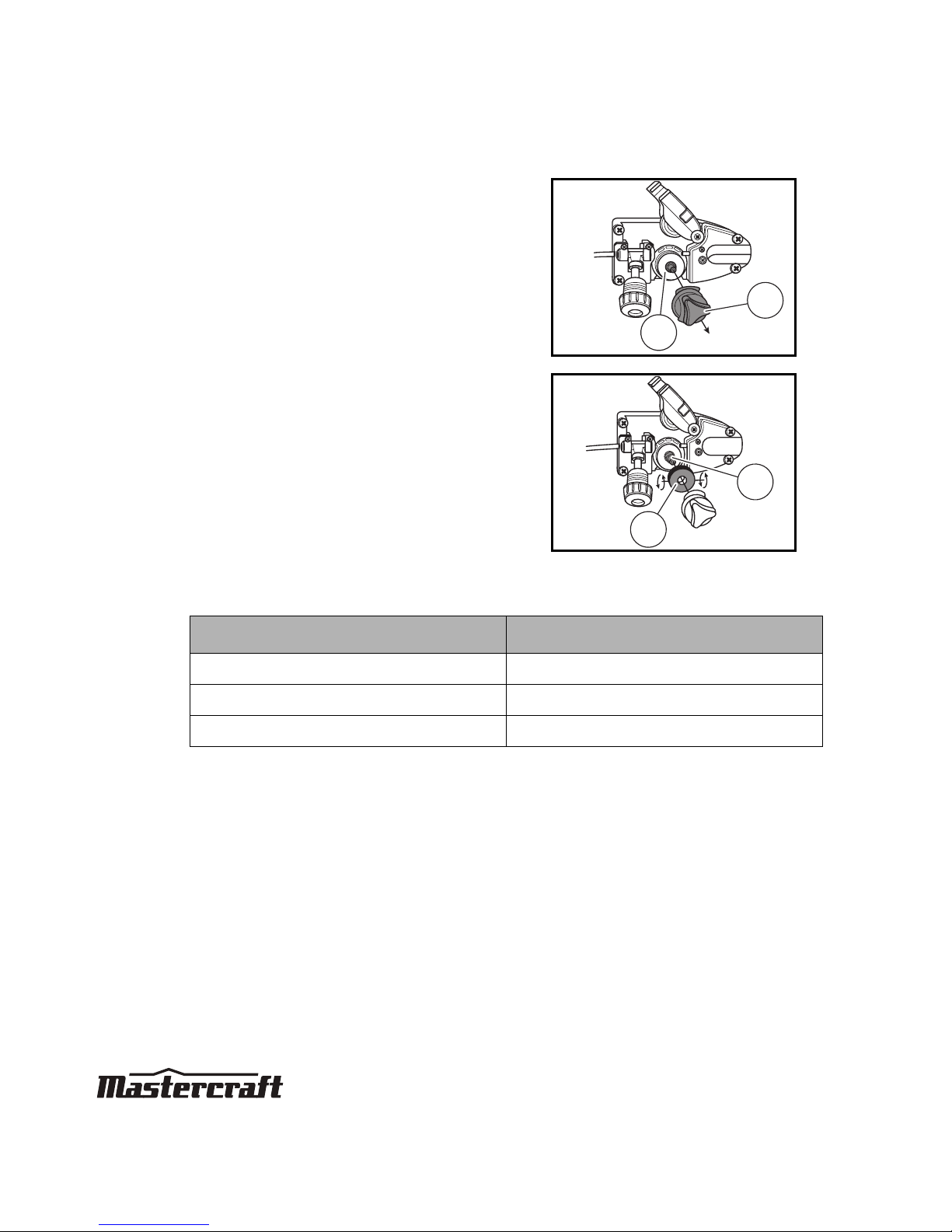

STEP 1

Installing the wire

Remove the nozzle (1) and contact tip (2) from

the end of the torch assembly. Identify the

leading end of the wire secured on the edge of

the wire spool. Place the spool on the hub with

the wire passing from the bottom of spool into

the drive mechanism.

pages 16-17, steps 1-4

STEP 2

Setting the wire tension

Press the trigger on the gun. Turn the drive

tension adjustment knob (1) clockwise, and

increase the drive tension until the wire seems

to feed smoothly without slipping.

page 18, steps 1-2

MC-588195-06

1

2

MC-588195-24

1

Page 4

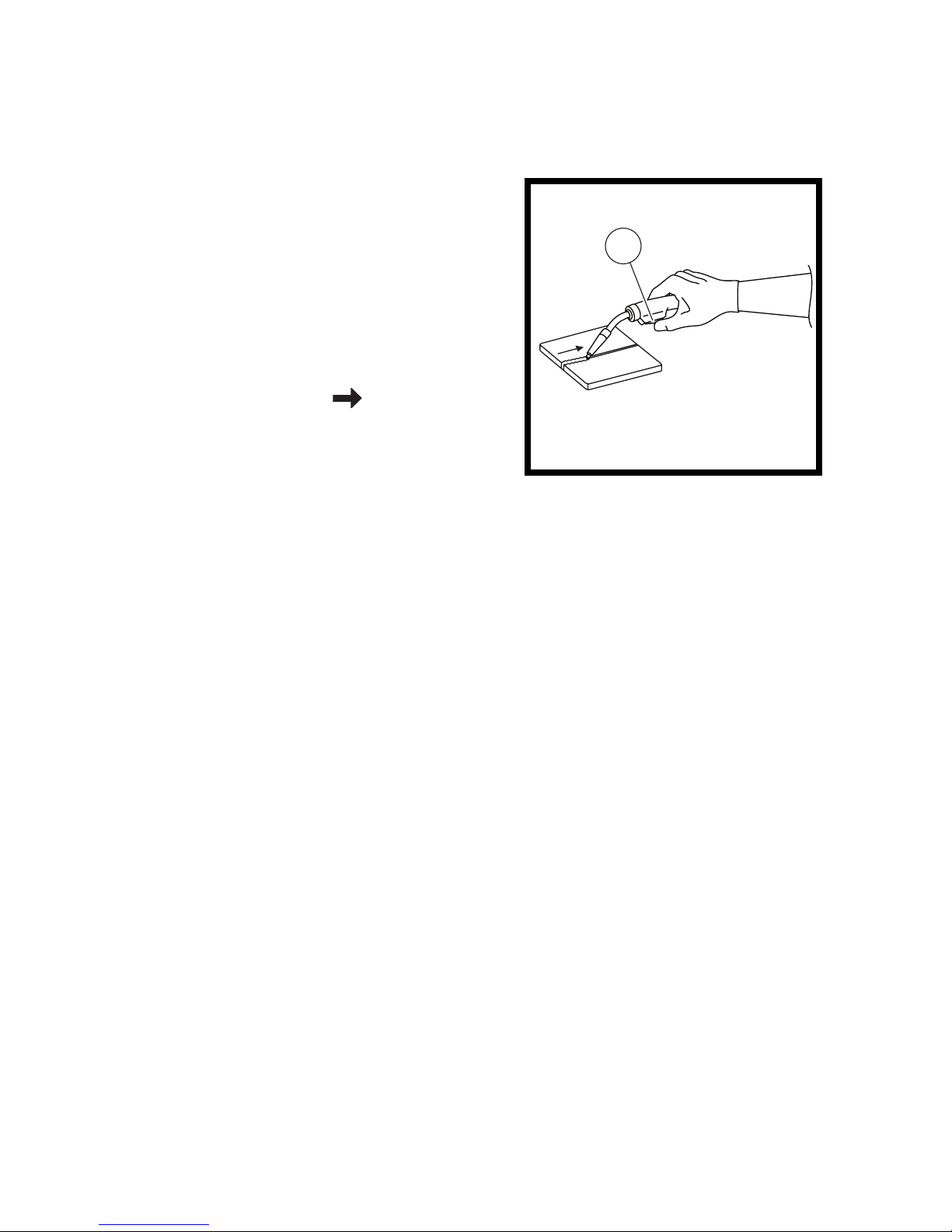

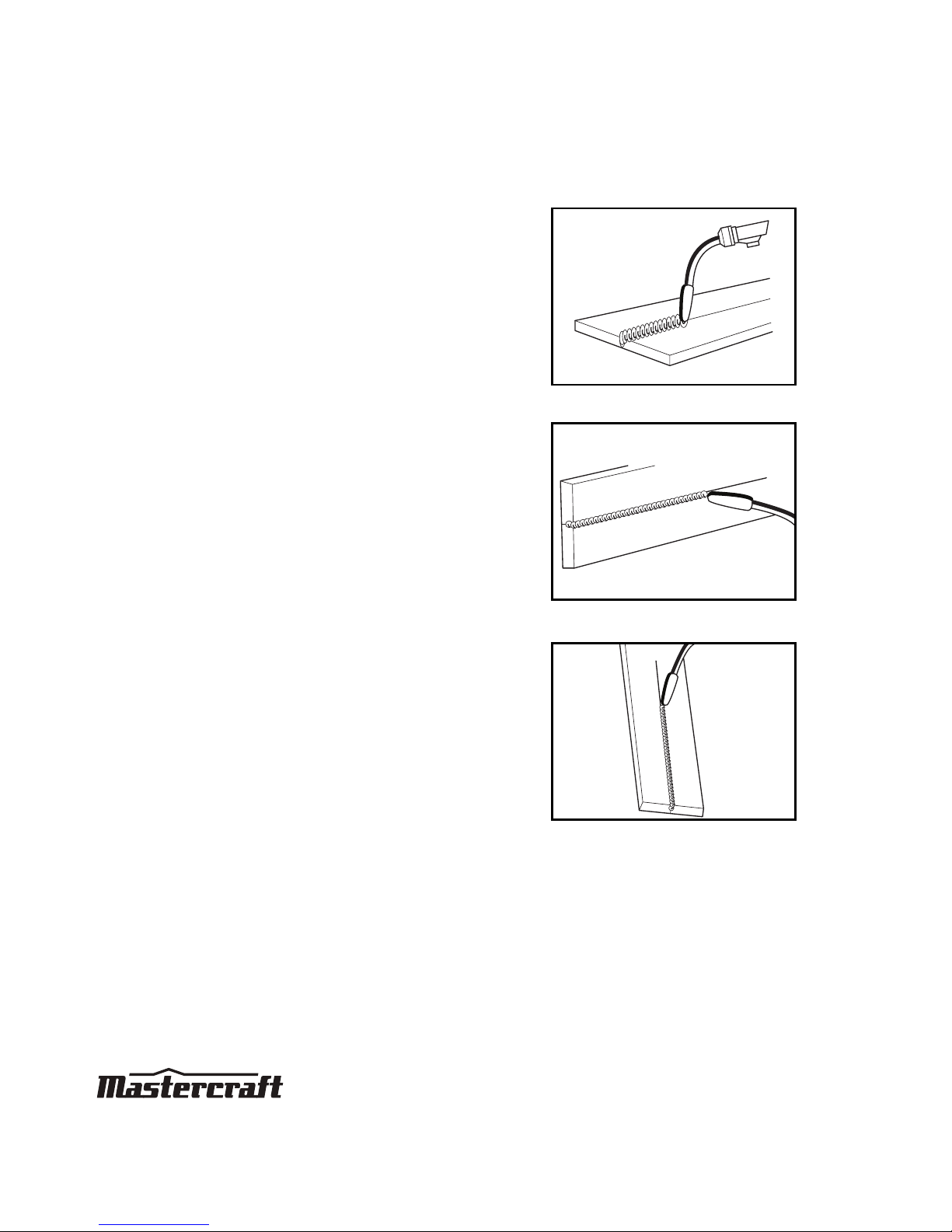

STEP 3

Operation

Hold the torch in one hand and turn the wire

speed dial with the other hand to its maximum

position. Pull the trigger (1) on the torch to

start an arc. Drag the torch toward the user

while simultaneously turning the wire speed

dial counterclockwise. page 20,

steps 4-5

(Please see page 21 for welding techniques if

needed.)

MC-588195-25

1

Page 5

TABLE OF CONTENTS

MIG/FLUX-CORE WIRE FEED WELDER KIT 058-8195-2

2

QUICK START GUIDE

TECHNICAL SPECIFICATIONS 3

SAFETY GUIDELINES 4–8

KEY PARTS DIAGRAM 9

IMPORTANT INFORMATION 10–13

ASSEMBLY INSTRUCTIONS 14–18

OPERATING INSTRUCTIONS 19–27

MAINTENANCE 28

TROUBLESHOOTING 29–30

MAIN CIRCUIT CHART 31

EXPLODED VIEW 32

PARTS LIST 33

WARRANTY 34–35

Page 6

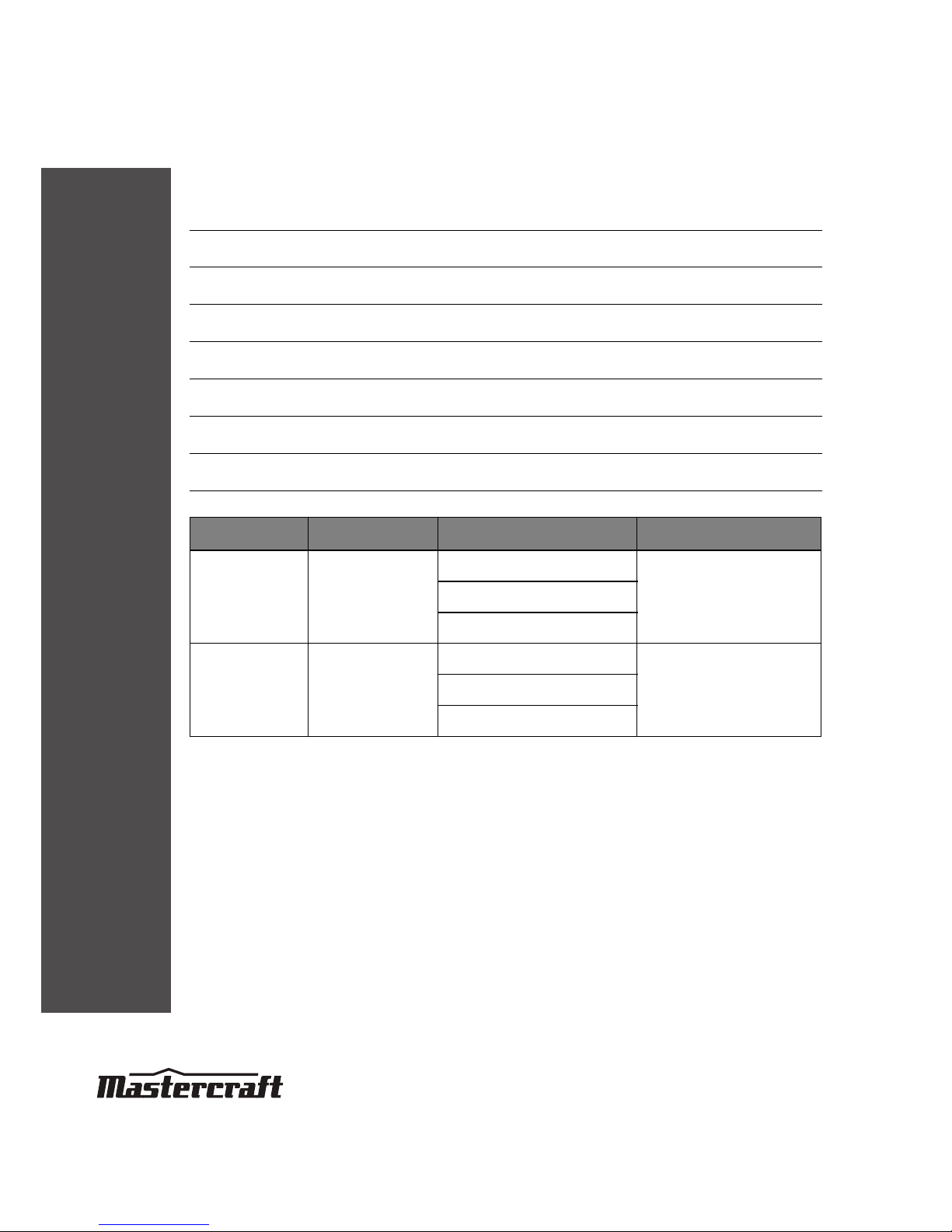

TECHNICAL SPECIFICATIONS

3

MIG/FLUX-CORE WIRE FEED WELDER KIT 058-8195-2

POWER SUPPLY single-phase, 120 V, 60 Hz

NO-LOAD VOLTAGE 30V

OUTPUT CURRENT 35-80 A (Peak 130 A)

DUTY CYCLE 20% @ 80 A

WIRE USED MIG and flux-core wire

WIRE DIAMETER 0.023", 0.030", 0.035"

DIMENSIONS (L x W x H) 17.6" x 9.4" x 14.5"

WEIGHT 62 lb 10 oz

(28.42 kg)

Welding mode Materials For metal thickness Use wire size

Flux core Steel

20-gauge-5/32"

0.03" (1/32") 0.8 mm

0.035" (5/128") 0.9 mm

5/128-5/32"

1.0-4.0 mm

MIG Steel, Stainless steel

20-gauge-1/8"

0.03" (1/32") 0.8 mm

0.023" (3/128") 0.6 mm

5/128-1/8"

1.0-3.0 mm

Page 7

SAFETY GUIDELINES

4

MIG/FLUX-CORE WIRE FEED WELDER KIT 058-8195-2

This manual contains information that relates to PROTECTING PERSONAL SAFETY and PREVENTING

EQUIPMENT PROBLEMS. It is very important to read this manual carefully and understand it

thoroughly before using the product. The symbols listed below are used to indicate this information.

Note- The word “Note” is used to inform the

reader of something he/she needs to know about

the tool.

PERSONAL SAFETY

These precautions are intended for the personal safety of the user and others working with the user.

Please take time to read and understand them.

DANGER!

Potential hazard that will result in serious

injury or loss of life.

WARNING!

Potential hazard that could result in

serious injury or loss of life.

CAUTION!

Potential hazard that may result in

moderate injury or damage to equipment.

Page 8

SAFETY GUIDELINES

5

MIG/FLUX-CORE WIRE FEED WELDER KIT 058-8195-2

DANGER!

Potential hazard that will result in serious injury or loss of life.

• Keep children or other personnel away from the work area while welding. Do

not allow children to handle the welder.

• Do not use the welder in the presence of flammable liquids or gases. Sparks

that are created during use may ignite gases.

• Do not operate the welder in humid, wet, or poorly ventilated areas.

• Use appropriate shield to prevent other personnel from being affected by

harmful rays.

• Always ensure that a fire extinguisher is available in adequate distance

within the welding environment.

• Do not repair or maintain the welder while the power is on.

• Risk of electric shock: Do not touch electrical live parts or metal

components connected to the welding wire, as doing so may cause fatal

shock and severe burns. Secure the ground lead before welding. Wear dry

protective apparel like coat, shirt, gloves, and insulated footwear.

• Risk for breathing: Never directly inhale the emission of harmful fumes when

welding on coated materials like galvanized, cadmium plated or contacting

zinc, mercury, or barium.

• Risk of fire: Do not weld on containers or pipes that contain flammable,

gaseous, or liquid combustibles. Remove all flammable materials within 35

feet of the welding arc or tightly cover the flammabe materials with fireproof

covers. To prevent any unintended arcs after welding, cut off the excess wire

that extends past the end of the nozzle more than ¼".

• Risk of burns: Do not touch the welded materials with bare hands, as the

welded materials are hot and can cause severe burns

.

Page 9

SAFETY GUIDELINES

6

MIG/FLUX-CORE WIRE FEED WELDER KIT 058-8195-2

• Risk of explosion: Keep high pressure shielding gas cylinder away from

welding or electrical circuits. Do not touch the cylinder with MIG gun and do

not weld on the cylinder. Use proper regulators, gas hoses, and fittings for

the specific application.

• Do not expose the welder to rain.

• Risk of UV and IR arc rays: Do not look at the welding arc without proper eye

protection, as the welding arc produces ultraviolet (UV) and infrared (IR) rays.

Use screens or other barriers to protect other personnel from the rays.

Page 10

SAFETY GUIDELINES

7

MIG/FLUX-CORE WIRE FEED WELDER KIT 058-8195-2

WARNING!

Potential hazard that could result in serious injury or loss of life.

•

Do not allow unskilled or untrained individuals to install and operate this

welder.

• Before operating the welder, check the insulation of the ground cable, power

cord, and welding cable for damage. Replace or repair the damaged

components before using the welder.

• Keep hands and fingers away from moving parts and stay away from the

drive rolls while the welder is in use.

• Do not allow any body part of the user to come in contact with the welding

wire while holding the welding gun.

• Do not allow the user to drape cables over or around the body.

• Do not point MIG gun toward the user or other personnel.

• Do not allow a person to use electronic devices such as pacemakers in the

welding area.

• Consult a doctor before using any electric arc welder or cutting device.

Page 11

SAFETY GUIDELINES

8

MIG/FLUX-CORE WIRE FEED WELDER KIT 058-8195-2

Note: Recycle the unwanted materials rather than disposing of it as waste. Sort the tools, hoses, and

packaging in specific categories and take to the local recycling center or dispose of it in an

environmentally safe way.

CAUTION!

Potential hazard that may result in moderate injury or damage to

equipment.

• Do not operate the welder if the output cable electrode, MIG gun, wire or

wire feed system is wet. All the components and the welder must be

completely dry before attempting to use the welder.

• Keep the welder in the OFF position when it is not in use.

• Do not wear watches, rings, bracelets, or loose clothing when using the

welder.

• Maintain a correct position while using the welder. Mount the welder on a

secure bench or cart to prevent if from tipping over or falling.

• Connect the ground lead as close to the area being welded to ensure proper

ground connection.

• Wear a full covered helmet, proper gloves, and protective clothing such as

leather shirt, coat, pant, and insulated footwear to prevent the skin from

being exposed to hot metals while welding.

• Do not overload the welder to prevent it from being heated. Allow proper

cooling time between duty cycles.

• Use safety goggles and ear protection:

Wear safety glasses with side shields when operating the

tool and verify that others in the work area are also wearing

safety glasses. Safety glasses must conform to American

National Standards Institute (ANSI Z87.1) requirements and

must provide protection from flying particles from the front

and the sides.

Always wear ear protection to help prevent hearing damage

and loss. Failure to comply may result in moderate injury.

MC-OM-01

Page 12

KEY PARTS DIAGRAM

9

MIG/FLUX-CORE WIRE FEED WELDER KIT 058-8195-2

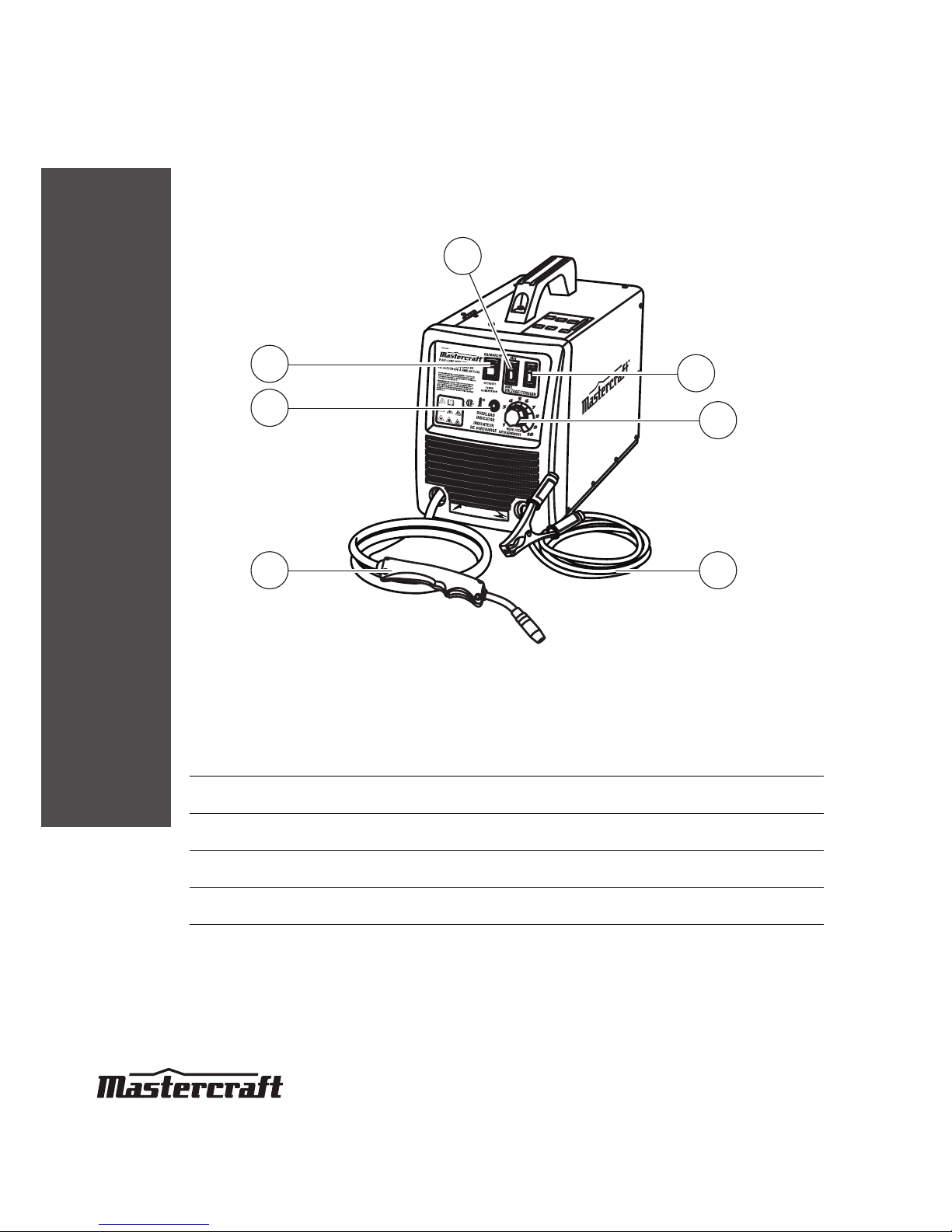

No. Description No. Description

1 MIN/MAX voltage setting 5 MIG torch

2 1/2 voltage setting 6 Thermal overload indicator

3 Wire feed setting 7 ON/OFF switch

4 Ground cable and clamp

1

6

7

2

3

4

MC-588195-01

5

Page 13

IMPORTANT INFORMATION

10

MIG/FLUX-CORE WIRE FEED WELDER KIT 058-8195-2

General usage description

The Mastercraft® portable and gasless MIG/Flux-Core Wire Feed Welder Kit uses AC single phase

120V, 60 Hz/20A with a time delayed fuse or circuit breaker. The kit provides two heat settings,

infinite wire speed control, overload and thermal protection. The welder kit can be used for welding

mild steel 20 gauge to 1/8" using flux core wire only in light industrial applications.

Guidelines for proper usage and description

REMOVING FROM CARTON

1. Remove cartons, bags, or styrofoam containing the welder and accessories.

2. Check the contents with the packaging list below.

After unpacking the welder unit, inspect for any damage that may have occurred during transit.

Check for loose, missing, or damaged parts. A shipping damage claim must be filled with carrier.

ON/OFF switch

This switch is used to turn the power supply of the welder kit ON and OFF through the main

transformer and control circuit.

MIN/MAX 1/2 voltage setting

Two adjustment switches are provided on the front panel of the welder kit, for setting the minimum

and maximum values of votage and tension. Refer to the set up chart for initial adjustment of the

voltage setting.

ITEM QTY.

Portable MIG welder 1 unit

Contact tip, 0.023" 0.030" 0.035" 1 pc

Sample spool flux core wire, 0.030" 1 LBS

Sample spool solid wire, 0.023" 1/2 LBS

Welding mask 1 pc

Chipping hammer/wire brush 1 pc

Instruction manual 1 manual

Handle 1 pc

Page 14

IMPORTANT INFORMATION

11

MIG/FLUX-CORE WIRE FEED WELDER KIT 058-8195-2

Wire feed setting

This setting adjusts the wire feed speed.

Ground cable and clamp

The ground cable and the clamp are attached to the workpiece to form a closed circuit which allows

the flow of current needed to weld.

Welding Cable and MIG gun/torch

The welding wire is driven through the welding cable and the MIG gun/torch to the workpiece. It is

attached to the drive system and the gun trigger activates the drive motor.

Thermal Indicator

If the duty cycle of the welder kit exceeds the maximum level, the internal temperature of the welder

kit will exceed the allowable operating range, which in turn makes the thermal overload light glow

and the welder kit to be shut down automatically. Allow the welder kit to cool down for 20 minutes

until the thermal overload light turns OFF automatically. The temperature of the welder kit is then

within the allowable operating range.

Power cord

The power cord connects the welder to the 120 V power supply. Connect the 15 A plug into a

120 V/20 A receptacle to supply power to the welder.

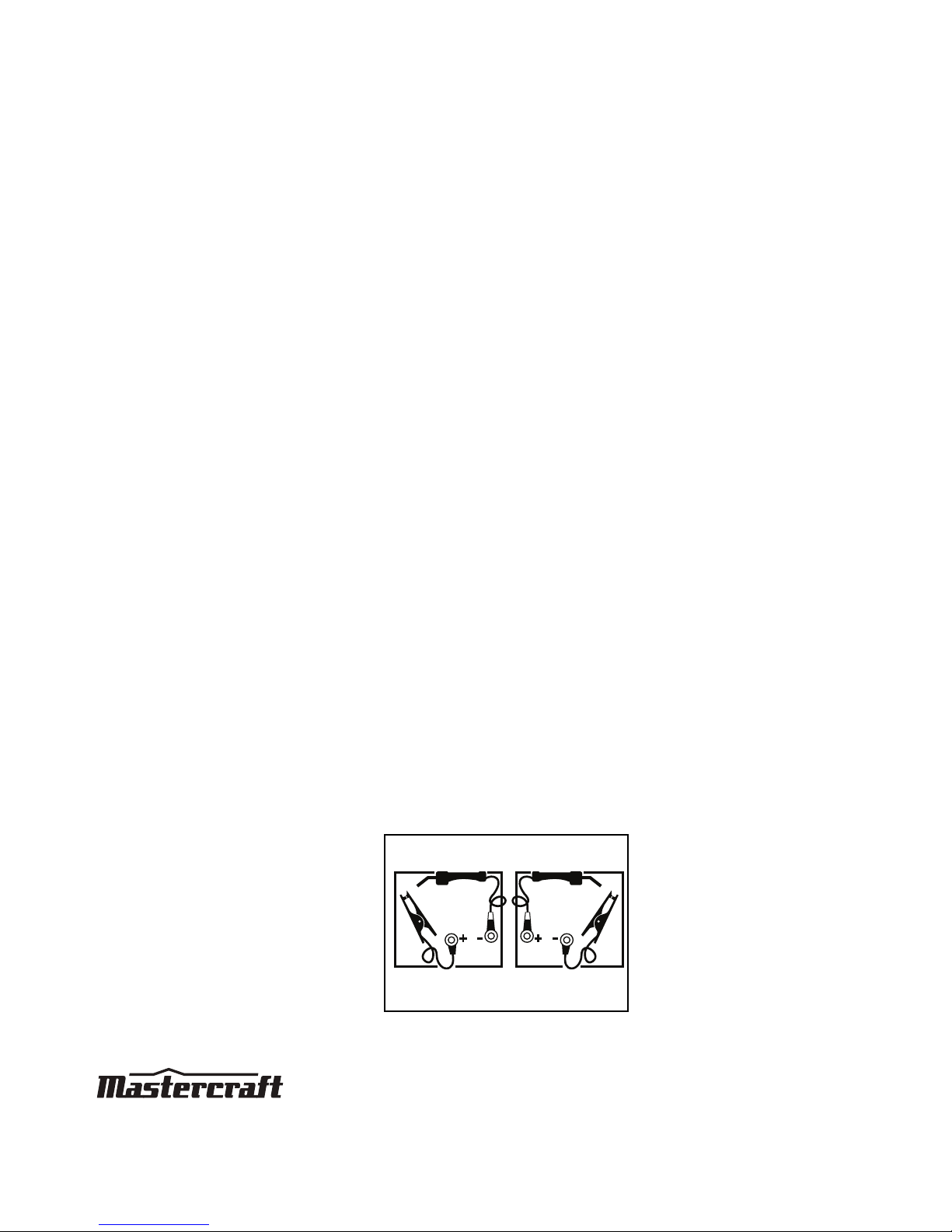

Polarity changing

Factory polarity setting (electrode negative) is for flux core welding (no shielding gas is required). In

this process the RED gun lead is connected to negative ("-") polarity terminal and the ground cable

is connected to the positive ("+") terminal.

For MIG welding (solid wire) using shielding gas, the RED gun lead is connected to positive ("+") and

the ground cable is connected to negative ("-").

NO

GAS

GAS

MC-588195-22

Page 15

IMPORTANT INFORMATION

12

MIG/FLUX-CORE WIRE FEED WELDER KIT 058-8195-2

Gas hoses, regulator and gas cylinder connections

• Connect the gas hose to the gas solenoid valve on the back panel of the welder.

• Connect the other end to the regulator connected to the shielding gas cylinder.

• Slowly open the cylinder valve by turning it counterclockwise until the cylinder pressure gauge

fixes the cylinder pressure.

• Slowly turn the adjustment knob clockwise to increase gas flow to 20 cfm. Turn it

counterclockwise to reduce the gas flow.

• Gas flow can be heard at the end of the gun when the trigger is activated.

Note: If there is no gas flow, harsh arc with excessive spatter will be found and a smooth weld bead

will not be obtained.

Gas selection

Different materials require different shielding gas when MIG welding. Refer to the set up chart inside

the wire drive compartment.

Mild steel: Use 75% Argon and 25% for reduced spatter and reduced penetration for thinner

materials. Use CO

2

for deeper penetration and increased spatter.

Note: Do not use argon gas concentrations higher than 75% on steel. The result will be extremely

poor penetration, porosity, and brittleness of weld.

Stainless steel: Use a mixed gas consisting of Helium, Argon, and CO

2

.

Aluminum or bronze: Use 100% Argon feed compartment.

No. Description No. Description

1 Gas cylinder 5 Regulator

2 Cylinder valve 6 Adjustment knob

3 Cylinder pressure gauge 7 Gas hose

4 Gas flow gauge

Regulator

1

23456 7

MC-588195-23

MACHINE

Page 16

IMPORTANT INFORMATION

13

MIG/FLUX-CORE WIRE FEED WELDER KIT 058-8195-2

Wire drive compartment

The wire drive compartment has wire feed components (1) such as wire feeder and spool hub, and a

set up chart (2).

1 2 3

4 56

MC-588195-25

1

2

Page 17

ASSEMBLY INSTRUCTIONS

14

MIG/FLUX-CORE WIRE FEED WELDER KIT 058-8195-2

Assembly Instructions

Installing the handle:

1. Line up the holes in the handle with the

holes on the top of the welder.

2. Place a lock washer (1) and a washer (2)

onto the welder handle screws.

3. Insert a screw with the washers through

the holes on the handle and into the top

of the welder, and tighten the screw

(fig A)

.

Installing the wire roller:

1. Open the wire drive compartment.

2. Remove the drive tension by loosening

the drive tension adjusting knob (1) and

lifting the drive tension adjustor and

drive tension arm (2) away from the

drive roller

(fig B)

.

3. Put an end of the wire into the hole on

outside edges of the wire spool and

bend it over to hold the wire in place.

Remove the wire spool from the wire

drive compartment.

Note: If the wire is already installed in the welder, roll the wire back onto the wire spool by manually

rotating the wire spool clockwise. Do not allow the wire to come out of rear end of the inlet guide

tube.

2

3

MC-588195-02

fig A

1

fig B

2

1

MC-588195-03

Page 18

ASSEMBLY INSTRUCTIONS

15

MIG/FLUX-CORE WIRE FEED WELDER KIT 058-8195-2

4. Rotate the drive roller cap (1)

counterclockwise and remove it from the

drive roller (2)

(fig C)

.

5. Pull the drive roller (1) from the drive

roller shaft (2)

(fig D)

.

Based on the wire diameter, select the correct groove using the following table:

Note: When installing the drive roller, the number stamped on the drive roller should face the user.

Push the drive roller onto the drive roller shaft.

6. Reinstall the drive roller cap and lock in place by turning it clockwise. Close the wire drive

compartment.

0.6

fig C

1

2

MC-588195-04

1

2

fig D

MC-588195-05

Wire Diameter

Roller Groove

0.023" 0.023"

0.030" 0.030"

0.035" 0.035"

Page 19

ASSEMBLY INSTRUCTIONS

16

MIG/FLUX-CORE WIRE FEED WELDER KIT 058-8195-2

Installing the wire:

Select the type of wire using the following table:

1. Remove the nozzle (1) and contact tip (2)

from the end of the torch assembly

(fig E)

.

2. Ensure proper groove on the drive roller

is in place for the wire to be installed.

3. Remove the packaging from the wire

spool and identify the leading end of the

wire secured on the edge of the spool.

Do not unhook it at this time.

WARNING!

Potential hazard that could result in serious injury or loss of life.

• Always switch off the power and unplug the power cord from the AC power

source before installing the wire.

• Remove any wire or wire spool that is rusty.

• Do not weld metal thinner than 18 gauge, as doing so may burn the metal.

• Before installing, remove any old wire from the MIG gun assembly to prevent

the wire from being jammed inside the gun liner.

• Use extreme caution when removing the welding nozzle, as the contact tip

on the welder is live whenever the torch trigger is pulled.

Wire Type

Availability

0.23" MIG wire Yes

0.30" MIG wire Yes

Flux Core wire 0.030" Yes

Flux Core wire 0.035" Yes

fig E

1

2

MC-588195-06

Page 20

ASSEMBLY INSTRUCTIONS

17

MIG/FLUX-CORE WIRE FEED WELDER KIT 058-8195-2

4. Place the spool on the hub with the

wire passing from the bottom of spool

into the drive mechanism

(fig F)

.

Note: The welder can use either 4" or 8"

spool. The 8" spool requires an adaptor. The

wing nut controls the tension on the spool.

5. Setting the wire spool tension:

a. Turn the wire spool with one hand.

b. Increase the spool tension by tightening the wing nut while turning the spool. Turn the

spool until it slows down.

c. Stop tightening the wing nut. Repeat these steps until proper spool tension is achieved.

Note: If high tension is applied to the wire spool, the wire slips on the drive roller or will not be able

to feed. If less tension is applied, the wire spool unspools itself when the trigger is released.

Readjust the spool tension using the wing nut if the tension is high or low.

6. Disconnect the welder from the power source, and remove the leading end of the wire from

the spool.

7. Cut off any bent portion of the wire using a wire cutter.

8. Loosen the tension adjusting knob holding the drive tension arm in place and lift the tension

arm up off the drive roller.

9. Insert the wire into the inlet guide tube, and feed it of about six inches across the drive roller

and into the torch assembly.

10. Line up the wire with the correct groove in the drive roller.

11. Place the drive tension arm back above the drive roller.

12. Tighten the drive tension adjusting knob until the tension roller is applying enough force on

the wire to prevent it from slipping in the drive roller.

13. Plug in and turn the welder ON. Set the voltage switch to the voltage setting recommended for

the gauge of metal that is to be welded. Refer to the set up chart on the back side of the wire

drive compartment.

14. Set the wire speed control

. Straighten the MIG gun cable and pull the trigger in the gun

handle to feed the wire through the torch assembly

.

X

fig F

MC-588195-07

Page 21

ASSEMBLY INSTRUCTIONS

18

MIG/FLUX-CORE WIRE FEED WELDER KIT 058-8195-2

15. Turn the power switch to the OFF position. Select a contact tip having the diameter same as

the wire being used

.

Note: Due to inherent variances in flux cored welding wire, it is necessary to use a contact tip of size

larger than the wire.

16. Slide the contact tip over the wire, thread the contact tip into the end of the gun and tighten

securely.

17. Install the nozzle on the gun assembly, and cut off excess wire that extends past the end of

the nozzle.

Setting the wire tension:

1. Press the trigger on the gun.

2. Turn the drive tension adjustment knob

(1) clockwise, and increase the drive

tension until the wire seems to feed

smoothly without slipping

(fig G)

.

WARNING!

Potential hazard that could result in serious injury or loss of life.

• Ensure that wire passing out of the end of the torch does not contact with

the workpiece, ground clamp or any grounded material during the drive

tension setting process, as doing so may reduce the risk of arc flash.

MC-588195-24

fig G

1

Page 22

OPERATING INSTRUCTIONS

19

MIG/FLUX-CORE WIRE FEED WELDER KIT 058-8195-2

Operation

Holding the torch (MIG gun):

• While using the welder, experiment holding the torch in different positions until finding a

suitable position.

Distance from the workpiece:

• If the nozzle is held off the workpiece, the distance between the nozzle and the workpiece

should be kept constant and should not exceed ¼".

Tuning in the wire speed:

This is one of the most important parts of the MIG welder operation and must be done before

starting each welding job or whenever any of the following variables are changed: heat setting, wire

diameter, or wire type.

1. Connect the ground clamp to a scrap piece of the same type of the material to be welded.

Note: The thickness of the scrap piece should be equal to or greater than the thickness of the actual

workpiece, and free of oil, paint, and rust.

2. Select the heat setting.

3. Hold the torch in one hand, and allow the nozzle to rest on the edge of the workpiece farther

from the user and at an angle similar to that which will be used when welding.

There are two angles of the torch nozzle in relation to the workpiece that must be considered

when welding.

WARNING!

Potential hazard that could result in serious injury or loss of life.

• Prolonged exposure to the welding arc can cause blindness and burns.

• Never strike the arc or start welding until the user is adequately protected.

• Wear flameproof welding gloves, heavy long sleeved shirt, trousers with out

cuffs, high topped shoes, and welding helmet.

Page 23

OPERATING INSTRUCTIONS

20

MIG/FLUX-CORE WIRE FEED WELDER KIT 058-8195-2

4. Turn the wire speed dial with the other hand to its maximum position and continue to hold

onto the knob.

5. Pull the trigger (1) on the torch to start an arc. Drag the torch toward the user while

simultaneously turning the wire speed dial counterclockwise

(fig J)

.

6. When the wire speed decreases, the sound that the arc makes will change from a sputtering

sound to a high-pitched buzzing sound. The correct setting is the point where the high-pitched

buzzing sound is achieved.

Use the wire feed control to slightly increase or decrease the heat and penetration by

selecting higher or lower wire feed settings. Repeat this tune-in procedure if a new heat

setting, a different diameter wire, or a different type of welding wire is selected.

Angle A Angle B

• Angle A can be varied, but in most

cases the optimum angle will be 60

degrees (the point at which the torch

handle is parallel to the workpiece). If

angle A is increased, penetration will

increase, and if it is decreased

penetration will decrease

(fig H)

.

• Angle B can be varied to improve the

visibility of the arc in relation to the weld

puddle and to direct the force of the arc

(fig I)

.

60

fig H

MC-588195-09

30

45

fig I

MC-588195-10

MC-588195-25

1

fig J

Page 24

OPERATING INSTRUCTIONS

21

MIG/FLUX-CORE WIRE FEED WELDER KIT 058-8195-2

Welding techniques:

• Torch travel: The movement of the torch along the weld joint. For a solid weld bead, the

welding torch should be moved steadily and at the right speed along the weld joint. Moving

the torch too fast, too slow, or erratically prevents proper fusion or creates a lumpy, uneven

bead.

• Travel direction: The direction of the torch moving along the weld joint in relation to the weld

puddle. The torch is either pushed into the weld puddle or pulled away from the weld puddle.

For most welding jobs, pull the torch along the weld joint for greater weld puddle visibility

(fig K)

.

• Travel speed: The rate at which the torch is being pushed or pulled along the weld joint. For a

fixed heat setting, if the travel speed is faster, the penetration will be low and the finished

weld bead will be low and narrow. Likewise, if the travel speed is slow, the penetration will be

deep and the finished weld bead will be high and wide.

WARNING!

Potential hazard that could result in serious injury or loss of life.

• Prolonged exposure to the welding arc can cause blindness and burns.

• Do not perform any welding while standing, kneeling, or lying on the grounded

area. Failure to comply could result in serious injury or loss of life.

fig K

MC-588195-12

Page 25

OPERATING INSTRUCTIONS

22

MIG/FLUX-CORE WIRE FEED WELDER KIT 058-8195-2

Types of welding beads:

Stringer bead Weave bead

• The stringer bead is formed by

travelling with the torch in a straight

line while keeping the wire and nozzle

centered over the weld joint

(fig L)

.

• The weave bead is made by weaving the

wire from side to side while moving with

the torch

(fig M)

.

fig L

MC-588195-13

fig M

MC-588195-14

Page 26

OPERATING INSTRUCTIONS

23

MIG/FLUX-CORE WIRE FEED WELDER KIT 058-8195-2

Welding position:

1. Flat position: This position is easiest and

most commonly used. It is best to weld

in the flat position to achieve good

results

(fig N)

.

2. Horizontal position: This position

prevents the weld puddle from running

downward while allowing slow and

enough travel speed. For this position,

angle B should be about 30 degrees

downward from being perpendicular to

the workpiece

(fig O)

.

3. Vertical position: The torch can be easily

pulled from top to bottom in this

position, though it is difficult to prevent

the puddle from running downward.

Pushing the torch from bottom to top

provides better puddle control and

allows slower rates of travel speed to

achieve deeper penetration. For this

position, angle B should be zero and

angle A will vary from 45 to 60 degrees

to provide better puddle control

(fig P)

.

fig N

MC-588195-15

fig O

MC-588195-16

fig P

MC-588195-17

Page 27

OPERATING INSTRUCTIONS

24

MIG/FLUX-CORE WIRE FEED WELDER KIT 058-8195-2

4. Overhead position: This is the most

difficult welding position. For this

position, angle A should be maintained

at 60 degrees

. Maintaining this angle

will reduce falling of molten metal into

the nozzle

(fig Q)

.

Angle B should be zero degrees so that

the wire is aiming directly into the weld

joint. If excessive dripping of the weld

puddle occurs, select a lower heat

setting.

fig Q

MC-588195-18

Page 28

OPERATING INSTRUCTIONS

25

MIG/FLUX-CORE WIRE FEED WELDER KIT 058-8195-2

Multiple pass welding:

• Butt weld joint: When butt welding

thicker materials, prepare the edges of

the material to be joined by grinding a

bevel on the edges of the metal pieces

being joined. When it is done, a "V" is

created between the two metal pieces.

In most cases, more than one pass or

bead will need to be laid into the joint to

close the "V"

(fig R)

.

Note: When using self-shielding flux core wire,

it is necessary to thoroughly chip and brush the

slag off each completed weld bead before

making another pass.

• Fillet weld joint: Most fillet weld joints on

metals of moderate to heavy thickness

will require multiple pass welds to

produce strong joint. The sequence of

lying multiple pass beads into a T fillet

joint and a lap fillet joint is shown

(fig S)

.

fig R

1

2

1

1

23

First or

Root Pass

Second

Pass

Third

Pass

MC-588195-19

Finished

Weld

fig S

1

1

2

3

2

3

Lap Joint Welded

In Three Passes

T Join in

Three Passes

MC-588195-20

Page 29

OPERATING INSTRUCTIONS

26

MIG/FLUX-CORE WIRE FEED WELDER KIT 058-8195-2

Spot welding:

There are three methods of spot welding:

1. Burn-through method: In this method,

two overlapped metal pieces are welded

together by burning through the top

piece and into the bottom piece. The

wire suitable for this method is 0.035

inch self-shielding, flux core wire.

Always select the high heat setting for

this method and tune in the wire speed

prior to making a spot weld

(fig T)

.

Note: Do not use 0.030 inch self-shielding flux

core wires when using this method unless the

metal is very thin or excessive filler metal and

minimal penetration is acceptable.

2. Punch and fill method: This method

produces a weld with the most finished

appearance. In this method, a hole is

punched or drilled into the top piece of

metal and the arc is directed through the

hole to penetrate into the bottom piece.

The puddle is allowed to fill up the hole

leaving a spot weld that is smooth and

flush with the surface of the top piece

(fig U)

.

3. Lap spot method: The welding arc is

directed to penetrate the bottom and top

pieces at the same time, and along each

side of the lap joint seam. Select the

wire diameter, heat setting, and tune in

the wire speed in such a way suitable

for welding the material with a

continuous bead

(fig V)

.

fig T

MC-588195-21

fig U

MC-588195-22

fig V

MC-588195-23

Page 30

OPERATING INSTRUCTIONS

27

MIG/FLUX-CORE WIRE FEED WELDER KIT 058-8195-2

Instructions to be followed for the spot welding methods:

1. Select the wire diameter and heat setting recommended above for the intended method of

spot welding.

2. Tune in the wire speed as if a continuous weld is to be performed.

3. Hold the nozzle piece completely perpendicular to and about ¼ inch off the workpiece.

4. Pull the trigger on the torch and release it when the desired penetration is achieved.

5. Make practice spot welds on scrap metal and vary the duration of time of holding the trigger

until a desired spot weld is made.

6. Make spot welds on the actual workpiece at desired locations.

Page 31

MAINTENANCE

28

MIG/FLUX-CORE WIRE FEED WELDER KIT 058-8195-2

Maintenance

The welder needs regular maintenance as following:

• Clean the dust, dirt, and grease periodically from the welder.

• Every six months, remove the front panel from the welder to clear the accumulated dust and

dirt.

• Replace power cord, ground cable, ground clamp, or electrode assembly when damaged or

worn.

• Repairs must be performed by a qualified service technician only.

Storage

• Store the welder in a clean and dry location away from corrosive gas and excess dust at a

temperature of 10°F

-120°F and relative humidity of less than 90%.

• It is recommended to repack the welder when transporting or storing the welder after use.

• Cleaning is required before storage.

WARNING!

Potential hazard that could result in serious injury or loss of life.

• Unplug the welder before performing any maintenance or service.

• Only use the welder after replacing or repairing any damaged parts or

accessories.

• Use only recommended and properly rated replacement parts. Failure to

comply could lead to serious injury or loss of life.

MAINTENANCE

REQUIRED

DESCRIPTION

TOOLS OR

MATERIALS

REQUIRED

MAXIMUM SERVICE INTERVAL

Each Use or

every 2 Hrs

Monthly

As

Needed

In-depth inspection

Worn or broken

parts

X X

Replace worn or

broken parts

X

Page 32

TROUBLESHOOTING

29

MIG/FLUX-CORE WIRE FEED WELDER KIT 058-8195-2

Troubleshooting

The following chart lists common issues and solutions. Please read it carefully and follow all

instructions closely.

WARNING!

Potential hazard that could result in serious injury or loss of life.

• If any of the following symptoms appears while the welder is in use, turn it off

and disconnect it from the power supply immediately. Failure to heed this

warning will result in serious personal injury or loss of life.

• Repairs must be performed by a qualified service technician only.

PROBLEM POSSIBLE CAUSES SOLUTIONS

The welder does not

work when the main

switch is turned on.

1. No power input.

2. Power cord or power plug is

broken.

3. Main switch is broken.

4. Transformer is broken.

1. Check the circuit or fuse of the power supply.

2. Replace the power cord.

3. Replace the main switch.

4. Replace the transformer.

The welder does not

weld.

1. Incorrect power input.

2. Inadequate current at the output.

3. Poor connection of output cable.

4. Dirty surfaces.

5. Wrong welding wire.

1. Check the power source.

2. Check for proper grounding to the workpiece.

3. Check the output connection.

4. Clean the surfaces.

5. Use the correct wire.

If the problem persists, send it for servicing or

return back to the store.

Blown fuse or

tripped circuit

breaker.

Inadequate fuse or circuit breaker. Check whether the fuse in power supply is 20 A.

If the problem persists, send it for servicing or

return back to the store.

Arc is hard to start.

1. Wrong welding wire.

2. Base metal not grounded

properly.

1. Use the correct wire.

2. Make sure the connection is good.

If the problem persists, send it for servicing or

return back to the store.

Page 33

TROUBLESHOOTING

30

MIG/FLUX-CORE WIRE FEED WELDER KIT 058-8195-2

Note: For further repair information, please call 1-800-689-9928.

Inconsistent arc or

wire feed.

1. Not enough drive roller pressure.

2. Spool hub tension too tight or

loose.

3. Contact tip worn or wrong size.

4. Rusty or corroded wire.

1. Tighten the drive tension adjustor on wire

feeder.

2. Adjust the wing nut on the spool holder.

3. Replace the contact tip.

4. Replace the wire.

PROBLEM POSSIBLE CAUSES SOLUTIONS

Page 34

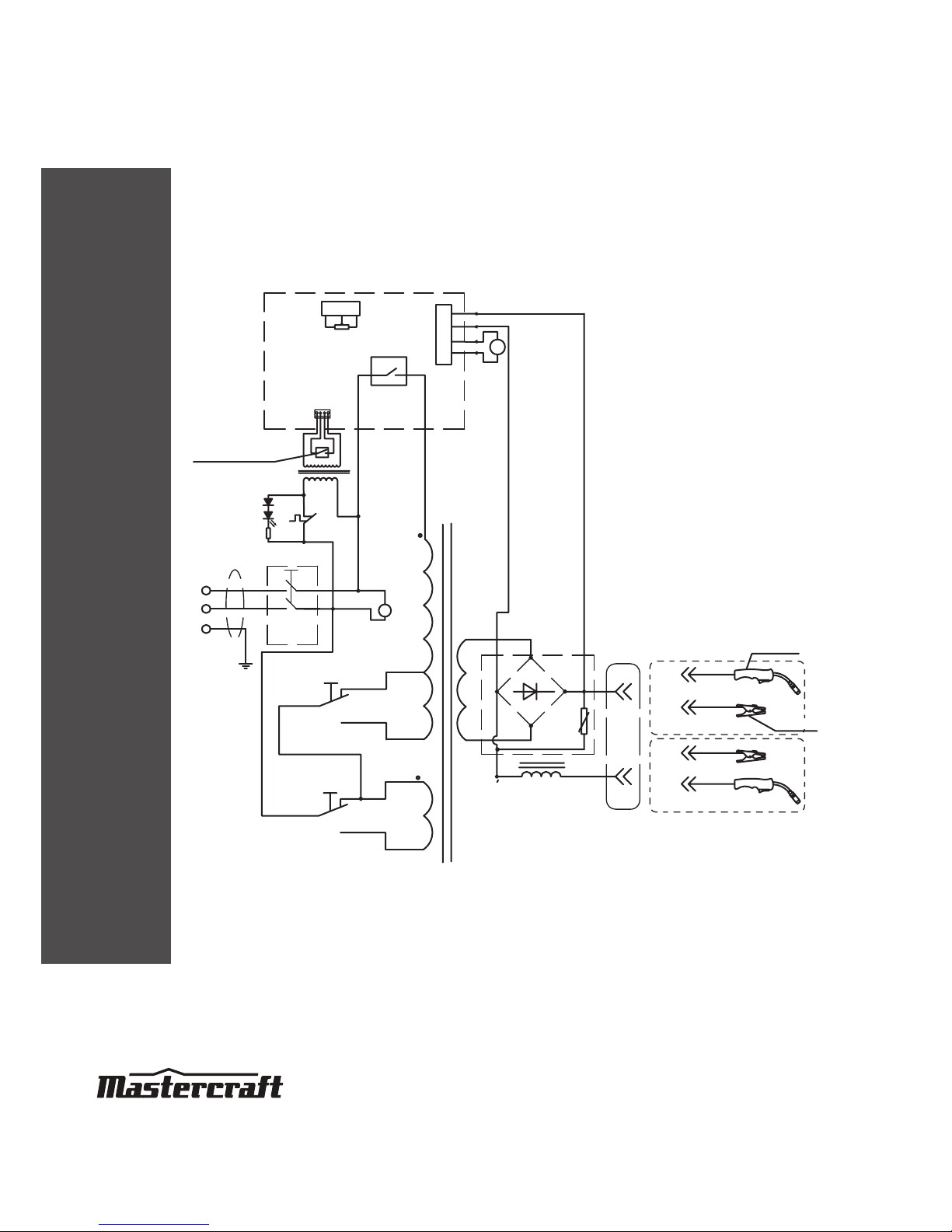

MAIN CIRCUIT CHART

31

MIG/FLUX-CORE WIRE FEED WELDER KIT 058-8195-2

Welding gun switch

Welding gun

2

3

4

5

2

1

2

1

+

_

_

+

+

+

_

_

223

34

1

1

S1

T1

J

G

L

S2

S3

PCB

MAX

fan

TR1

24V

MIN

+

_

NO GAS

GAS

Earth champ

MC-588195-24

Page 35

EXPLODED VIEW

32

MIG/FLUX-CORE WIRE FEED WELDER KIT 058-8195-2

28

1

4

8

9

6

7

31

12

34

37

27

26

25

22

21

20

19

24

23

10

29

32

33

35

36

2

3 5

11

13

14

18

15

16

17

30

MC-588195-25

Page 36

PARTS LIST

33

MIG/FLUX-CORE WIRE FEED WELDER KIT 058-8195-2

If any parts are missing or damaged, or if you have any questions, please call 1-800-689-9928.

No. Description Qty. No. Description Qty.

1 Ground cable and clamp 1 20 Cable holder 1

2 Wire feed setting knob 1 21 Back panel 1

3 Torch cable holder 1 22 Gas hose connector 1

4 Cable holder 1 23 Rectifier 1

5 Front panel 1 24 Rectifier bracket 1

6 PCB support 1 25 Vertical middle panel 1

7 PCB 1 26 Spool holder 1

8 Bottom 1 27 Plastic hinge 2

9 Feet 1 28 Left panel 1

10 Control transformer 4 29 Fuse 1

11 Thermal relay 1 30 Red terminal 1

12 Circuit breaker 1 31 Black terminal 1

13 Main transformer 1 32 Door bolt 1

14 Fan bracket 1 33 Wire feeder 1

15 Fan 2 34 MIN/MAX 1/2 voltage switch 2

16 Fan blade 1 35 ON/OFF switch 1

17 Handle 1 36 Overload indicator 1

18 Right panel 1 37 MIG torch 1

19 Power cord 1

Page 37

WARRANTY

34

MIG/FLUX-CORE WIRE FEED WELDER KIT 058-8195-2

Mastercraft® limited warranty

This warranty is subject to the following conditions and limitations:

a. A bill of sale verifying the purchase and purchase date must be provided.

b. This warranty will not apply to any product or part thereof which is worn or broken or which

has become inoperative due to abuse, misuse, accidental damage, neglect, or lack of proper

installation, operation, or maintenance (as outlined in the applicable instruction manual or

operating instructions), or which is being used for industrial, professional, commercial, or

rental purposes.

c. This warranty will not apply to normal wear and tear or to expendable parts or accessories

that may be supplied with the product which are expected to become inoperative or unusable

after a reasonable period of use.

d. This warranty will not apply to routine maintenance and consumable items such as, but not

limited to, fuel, lubricants, vacuum bags, blades, belts, sandpaper, bits, fluids, tune-ups, or

adjustments.

e. This warranty will not apply where damage is caused by repairs made or attempted by others

(i.e., persons not authorized by the manufacturer).

f. This warranty will not apply to any product that was sold to the original purchaser as a

reconditioned or refurbished product (unless otherwise specified in writing).

g. This warranty will not apply to any product or part thereof if any part from another

manufacturer is installed therein or any repairs or alterations have been made or attempted by

unauthorized persons.

This Mastercraft

®

product is guaranteed for a period of

three (3) years from the date of original retail purchase

against defects in workmanship and materials.

Subject to the conditions and limitations described below,

this product, if returned to us with proof of purchase within

the stated warranty period and if covered under this

warranty, will be repaired or replaced (with the same model,

or one of equal value or specification), at our option. We will

bear the cost of any repair or replacement and any costs of

labor relating thereto.

Page 38

WARRANTY

35

MIG/FLUX-CORE WIRE FEED WELDER KIT 058-8195-2

h. This warranty will not apply to normal deterioration of the exterior finish, such as, but not

limited to, scratches, dents, paint chips, or to any corrosion or discoloring by heat, or abrasive

and chemical cleaners.

i. This warranty will not apply to component parts sold by and identified as the product of

another company, which shall be covered under the product manufacturer’s warranty, if any.

Additional limitations

This warranty applies only to the original purchaser and may not be transferred. Neither the retailer

nor the manufacturer shall be liable for any other expense, loss, or damage, including, without

limitation, any indirect, incidental, consequential, or exemplary damages arising in connection with

the sale, use, or inability to use this product.

Notice to consumer

This warranty gives you specific legal rights, and you may have other rights, which may vary from

province to province. The provisions contained in this warranty are not intended to limit, modify, take

away from, disclaim, or exclude any statutory warranties set forth in any applicable provincial or

federal legislation.

Loading...

Loading...