Page 1

model no. 055-6755-8

TABLE SAW

WITH HEAVY-DUTY

STEEL STAND

IMPORTANT:

Please read this manual carefully before using this table

saw and save it for reference.

INSTRUCTION

MANUAL

Page 2

TABLE OF CONTENTS

Quick Start Guide

Specifications

Safety Guidelines

Know Your Table Saw

Assembly Instructions

Operating Instructions

Maintenance

Troubleshooting

Exploded View

Parts List

Warranty

3

4

5

6-11

12-16

17-35

36-43

44

45-46

47-50

51-53

54

TABLE OF CONTENTS

NOTE:

If any parts are missing or damaged, or if you have any questions, please call our

toll-free helpline at 1-800-689-9928

SAVE THESE INSTRUCTIONS

This manual contains important safety and operating instructions. Read all

instructions and follow them when using this product.

Page 3

4

model no. 055-6755-8 | contact us 1-800-689-9928

5

QUICK START GUIDE

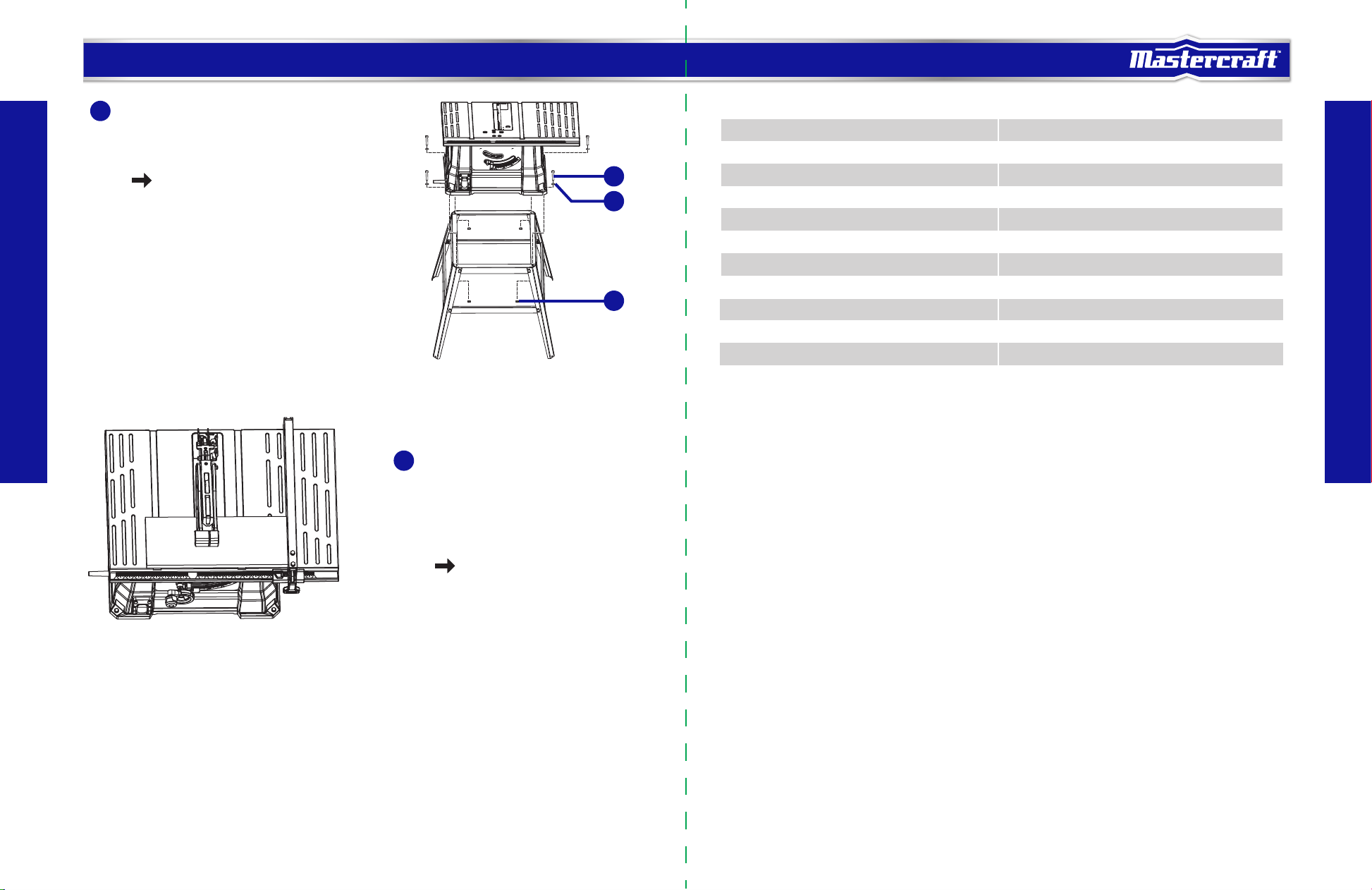

• Place the table saw on top of the stand, aliging the

1

holes in the base with the holes in the stand.

• Insert four hex bolts M6 x 25 (1) along with flat

washers (2) into the aligned holes.

see page 22

• Adjust the blade so that it is approximately

2

1/8" (3.2 mm) higher than the workpiece.

• Hold the workpiece flat on the table and

against the fence. Keep the workpiece

approximately 1" (2.5 cm) away from the

blade.

see page 39

SPECIFICATIONS

Motor

Speed

1

2

3

Blade

Arbor size

Table size

Table height

Depth of cut at 90°

Depth of cut at 45°

Rip capacity

Bevel range

Mitre range

Weight

120 V, 60 Hz, 15A

4700 RPM (no load)

10" (25.4 cm) 24-tooth carbide-tipped

5/8" (1.6 cm)

25 x 17" (63.5 x 43.2 cm)

35 1/4" (89.5 cm)

3" (7.6 cm)

2 1/2" (6.4 cm)

13" (33 cm) right; 8" (20.3) left

0-45°

0-45°, right & left

43 lb 3 oz (19.6 kg)

SPECIFICATIONS

Page 4

6

model no. 055-6755-8 | contact us 1-800-689-9928

7

SAFETY GUIDELINES

This manual contains information that relates to PROTECTING PERSONAL SAFETY and PREVENTING

EQUIPMENT PROBLEMS. It is very important to read this manual carefully and understand it thoroughly before

using the product. The symbols listed below are used to indicate this information.

DANGER!

Potential hazard that will result in serious injury or loss of life.

WARNING!

Potential hazard that could result in serious injury or loss of life.

CAUTION!

Potential hazard that may result in moderate injury or damage to equipment.

Note: The word “Note” is used to inform the reader of something the operator needs to know about the tool.

SAFETY RECOMMENDATIONS

These precautions are intended for the personal safety of the operator and others working with the operator.

Failure to follow these instructions may result in a permanent loss of vision, serious personal or even fatal

SAFETY GUIDELINES

injury, property damage and/or tool damage. Please take time to read and understand these instructions.

Safety is a combination of common sense, staying alert and knowing how your table saw works.

GENERAL SAFETY RULES

• Store all safety guidelines and instructions for future use.

• This device is not intended for use by people (including children) lacking experience with electrical power

tools unless they have received some instruction about how the device is to be used. Children have to be

supervised to ensure that they do not play with the device.

• Store the operating instructions so that they are always available to the user of the tool when it is being

operated.

• Remove the protective padding around the motor before using.

• Pay close attention to instructions on reducing the risk of kickback.

• Always use push sticks when ripping narrow workpieces and when making non-through cuts.

WARNING!

Read all the safety guidelines and instructions before you use this electric power tool!

WARNING!

When using electric power tools, the following essential safety measures have to be observed

to prevent electric shocks, injury and fire hazards. Failure to adhere to the safety guidelines and

instructions can cause electric shock, fire and/or severe injuries.

• If you lend this device to other people, always hand over these operating instructions to ensure safe use.

Instruct inexperienced people in accordance with these safety instructions.

• Keep your work area tidy. Untidiness in your work area can cause accidents.

• Pay attention to the surrounding conditions. Do not expose the electric power tool to rain. Do not use

electric power tools in damp or wet conditions. Ensure that the work area is well lit.

Do not use electric power tools where there is a danger of fire or explosion.

• Protect yourself against electric shocks. Avoid bodily contact with earthed parts (e.g. pipes, radiators,

electric hobs or cooling appliances).

• Keep other people away from the work area. Do not let other people, especially children, touch the

electric power tool or the power cable. Keep them away from your work area.

• Store unused electric power tools safely. Unused electric power tools should be stored in a dry, high-lying

or locked place, out of the reach of children.

• Do not overload your electric power tool. It works better and more securely within the stated output

range.

• Use the correct electric power tool. Do not use inefficient machines for heavy work. Do not use the

electric power tool for purposes for which it was not intended. For example, do not use circular saws to

cut wooden masts or logs.

• Wear suitable clothing. Do not wear baggy clothing or jewellery, as they can be caught by moving parts.

When working outdoors, anti-slip shoes are recommended. If you have long hair, wear a hair net.

• Wear safety equipment. Wear safety goggles. If the work creates dust, wear a dust mask.

• Attach the dust extraction unit. If there are connections for dust extraction and collection equipment, then

make sure that the equipment is correctly attached and used.

• Never use the cable for purposes for which it is not intended. Do not use the cable to pull the plug out of

the power socket. Protect the cable from heat, oil and sharp edges.

• Secure the workpiece. When necessary, use clamping devices to secure the workpiece. The workpiece is

secured better that way than by hand.

• Avoid taking abnormal stances. Make sure you stand securely and keep your balance at all times.

• Look after your tool with care. Keep the cutting tool sharp and clean so that you are able to work better

and more safely with it. Observe the guidelines on lubrication and exchanging tools. Check the power

cable of the electric power tool regularly. In case of damage, let a qualified specialist repair it. Check

extension cords regularly and replace them if they are damaged. Keep the handles dry, clean and free of

oil and grease.

• Pull the plug out of the power socket when the electric power tool is not in use, before maintenance and

when exchanging tools, such as saw blades, drills and mills.

• Do not leave keys in the device. Before you switch the device off, check that keys and setting tools have

been removed.

• Avoid starting the device accidentally. Make sure that when you insert the plug into the power socket,

the power switch is turned off.

SAFETY GUIDELINES

Page 5

8

model no. 055-6755-8 | contact us 1-800-689-9928

9

• Use an extension cord when working outdoors. Only use extension cords outdoors that are authorized

for outdoor use and are correspondingly marked.

• Be attentive. Be careful. Carry out your work sensibly.

• Check the electric power tool for any sign of damage. Before continuing work with the electric power tool,

safety devices or easily damaged parts have to be carefully checked to ensure that they function properly

and are not defective. Check that moving parts are working properly and are not jammed or damaged.

All parts must be correctly assembled by an experienced individual, unless stated otherwise in the

operating instructions, and meet all required conditions in order to guarantee that the electric power tool

functions without a problem. Damaged switches have to be replaced by a qualified electrician. Do not

use electric power tools if the power switch cannot be turned on and off.

• Let a qualified electrician repair your electric power tool. This electric power tool meets applicable

safety standards. Repairs are only allowed to be carried out by a qualified electrician, using original

replacement parts; otherwise accidents may occur.

SPECIFIC SAFETY RULES FOR TABLE SAW

• No other people may stand in the direct vicinity of the machine when it is in use. People not operating the

machine must maintain a suitable, safe distance away.

• Never lay the power cable over the machine table.

SAFETY GUIDELINES

• Use the push rod to pass the workpiece safely into the saw blade. Do not come too close to the saw

blade.

• Make sure that the thickness of the material to be cut is less than the maximum possible cutting depth.

• Never cut “hands-free”. The workpiece must always lie level on the machine table and be moved along

the stop. The workpiece must always be pressed hard against the stop.

• Never cut workpieces that are so small that they cannot be safely pressed against the stop and could

turn.

• Never cut workpieces that are so small that they cannot be moved by the push rod at a safe distance

from the saw blade.

• Only cut one workpiece at a time. Never cut several workpieces simultaneously. Workpieces must not be

placed behind or on top of each other. There is a danger of the workpiece “jamming” and slipping away.

• Make sure that the workpiece cannot slip while being cut or get jammed in the saw blade.

• Clean the work area and the workpiece after each cut.

• Never reach into the openings of the device. Never insert objects into the openings of the device (e.g. the

saw blade casing, dust extraction adaptor). There is a danger of being cut. Never reach around or over

saw blade.

• Never remove the cutting piece if the machine is still switched on or running. There is a danger of cutting

yourself.

• Cut workpieces may have sharp edges, ridges or wooden splinters. There is a danger of cutting injuries.

• Always switch the machine off and remove the power plug when you leave the machine.

• Never expose the device to rain or extreme moisture.

• Do not perform any cuts with this table saw other than those described in these operating instructions.

Do not saw seams and notches.

• Table saws must not be used for slitting (notches that end in the workpiece).

• Failure to comply with these warnings may result in serious personal injury.

USE SAFETY GOGGLES AND EAR PROTECTION:

ALWAYS WEAR EYE PROTECTION THAT CONFORMS WITH CUL REQUIREMENTS. FLYING

DEBRIS can cause permanent eye damage.

The tool is loud and the sound can cause hearing damage. Always wear ear protection to help

prevent hearing damage and loss. Failure to comply may result in moderate injury.

USE DUST MASK:

Some dust created by sawing contains chemicals that are known to cause cancer, birth defects

or other reproductive harm. Some examples of these chemicals come from lead-based paints,

crystalline silica from bricks, cement and other masonry products, arsenic and chromium from

chemically treated lumber. To reduce exposure to these chemicals, work in a well-ventilated

area with approved safety equipment, such as dust masks that are specially designed to filter out microscopic

particles.

ELECTRICAL SAFETY

GUIDELINES FOR USING EXTENSION CORDS:

In the event of a malfunction or breakdown, grounding provides a path of least resistance for electric current

to reduce the risk of electric shock. This tool is equipped with an electric cord having an equipment-grounding

conductor and a grounding plug. The plug must be plugged into a matching outlet that is properly installed

and grounded in accordance with all local codes and ordinances.

SAFETY GUIDELINES

WARNING!

The use of other insertion tools and accessories can present a danger of injury.

WARNING!

Switch the device off, remove the plug from the power socket and let the machine come to a

standstill. No foreign bodies are allowed to be on the workpiece or the machine table! Cut

pieces of the workpiece can be caught by the rotating cutting disc and be flung from the tool

and work area.

Page 6

10

model no. 055-6755-8 | contact us 1-800-689-9928

11

Do not modify the plug provided. If it will not fit the outlet, have the proper outlet installed by a qualified

electrician.

Improper connection of the equipment-grounding conductor

can result in a risk of electric shock. The conductor with

a green outer surface, with or without yellow stripes, is the

equipment-grounding conductor. If repair or replacement of

the electric cord or plug is necessary, do not connect the

equipment-grounding conductor to a live terminal.

Check with a qualified electrician or service technician if

the grounding instructions are not completely understood,

or if in doubt as to whether the tool is properly grounded.

Use only three-wire extension cords that have three-prong

grounding plugs and three-pole receptacles that accept the

tool’s plug, as shown in Fig. 1. Repair or replace a damaged or worn cord immediately.

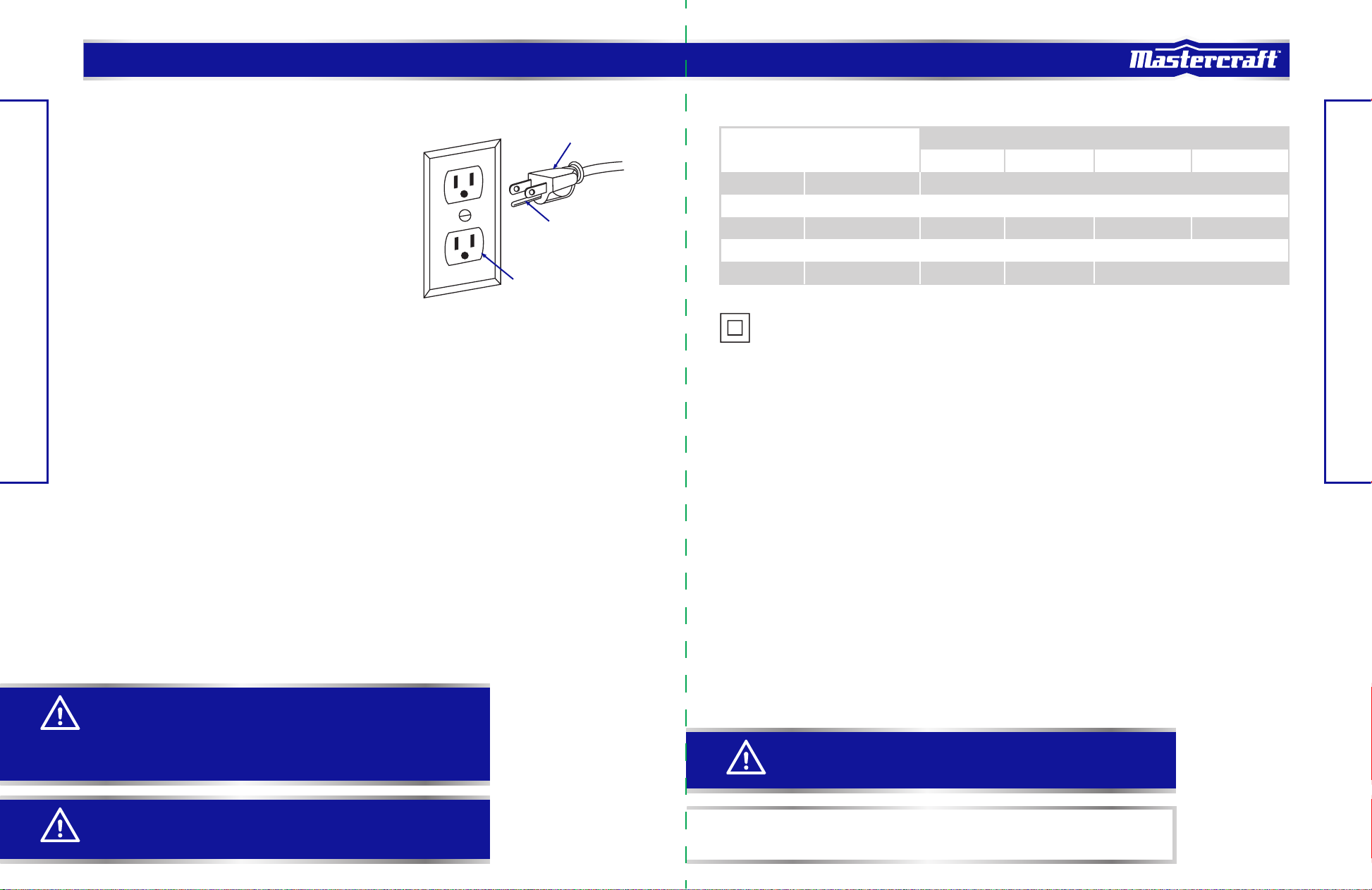

GROUNDING INSTRUCTIONS:

• Make sure the extension cord is in good condition. When using an extension cord, be sure to use one

that is heavy enough to carry the current that your product will draw. An undersized cord will cause a

drop in line voltage, which will result in loss of power and overheating. The table on the next page shows

SAFETY GUIDELINES

the correct size to be used according to cord length and nameplate ampere rating. When in doubt, use

the next heavier gauge. The smaller the gauge number, the heavier the cord.

• Make sure your extension cord is properly wired and in good condition. Always replace a damaged

extension cord, or have it repaired by a qualified person before using it. Protect your extension cords from

sharp objects, excessive heat, and damp or wet areas.

• Use a separate electrical circuit for your tools. This circuit must consist of not less than #12 wire with a

20 A time-delayed fuse or a #14 wire with a 15 A time-delayed fuse. Before connecting the motor to the

power line, make sure the switch is in the Off position and the electric current is rated the same as the

current stamped on the motor nameplate. Running at a lower voltage will damage the motor.

Three-prong plug

Grounding prong

Properly grounded outlet

Fig. 1

Recommended size for extension cords

AMPERAGE RATING OF THE TOOL

(120 V CIRCUIT ONLY)

MORE THAN

0

6

10

12

Double-insulated construction.

NOT MORE THAN

6

10

12

16

25' (7.6 m)

TOTAL LENGTH OF THE EXTENSION CORD

50' (15.2 m)

MINIMUM GAUGE FOR THE EXTENSION CORD (AWG)

18

18

16

14

16

16

16

12

100' (30.5 m)

16

14

14

Not recommended

150' (45.7 m)

14

12

12

SAFETY GUIDELINES

WARNING!

• Use the proper extension cord. Make sure to use an extension cord that is heavy enough to carry

the current required by the tool. An undersized cord will cause a drop in line voltage, resulting in

loss of power and overheating of the tool.

• Use the extension cord only for intended purpose. Do not pull the extension cord to remove it

from the power socket.

CAUTION!

In all cases, verify that the outlet in question is properly grounded. If you are not sure, have a

licensed electrician check the outlet.

WARNING!

This tool must be grounded while in use in order to protect the operator from electric shock.

NOTE:

Recycle unwanted materials rather than disposing of them as waste. Sort the tool and its components in

specific categories and take to the local recycling centre or dispose of them in an environmentally safe way.

Page 7

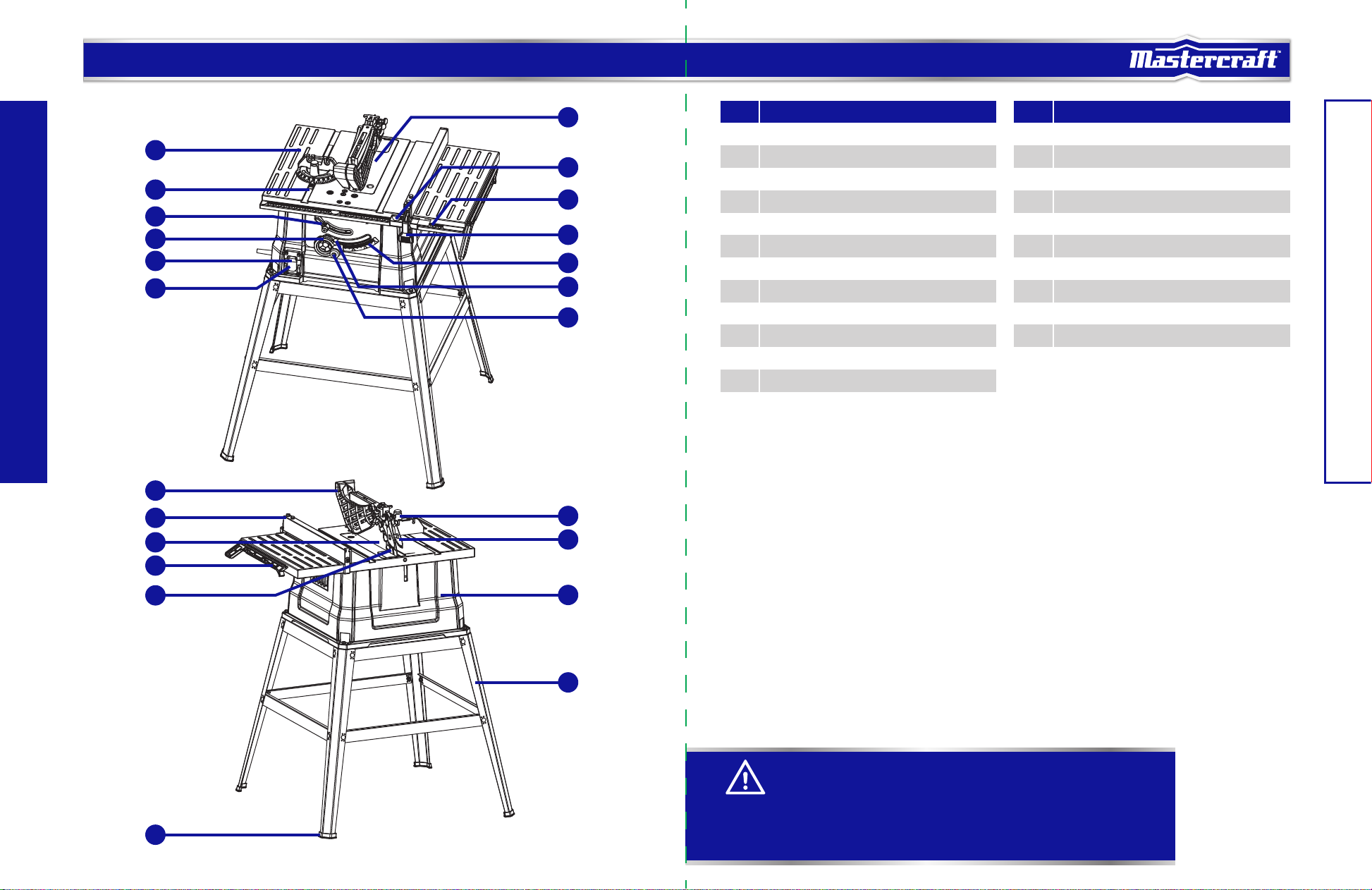

12

model no. 055-6755-8 | contact us 1-800-689-9928

23

22

21

20

19

18

KNOW YOUR TABLE SAW

17

16

15

14

13

1

2

3

4

5

6

7

8

9

10

No.

Description

1

Table insert

2

Rip fence indicator and scale

3

Front rail

4

Rip fence locking handle

5

Bevel scale

6

Bevel indicator

7

Height adjustment knob

8

Mitre gauge

9

Anti-kickback pawls

10

Cabinet

11

Stand

12

Rubber foot

Anti-kickback pawls:

Kickback is a hazard in which the workpiece is thrown back toward the operator. The teeth on the

anti-kickback pawls point away from the workpiece. If the workpiece should be pulled back toward the

operator, the teeth dig into the wood to help prevent or reduce the possibility of kickback.

Bevel scale and bevel indicator:

The easy-to-read scale and indicator on the front of the cabinet shows the exact blade angle.

Saw blade:

For maximum performance, it is recommended that you use the 24-tooth, 10" (25.4 cm) carbide-tipped

combination blade provided with your saw. The blade is raised and lowered with the height/bevel adjusting

handwheel. Bevel angles are locked with the bevel-locking lever.

No.

Description

13

Riving knife

14

Push stick

15

Saw blade

16

Rip fence

17

Blade guard

18

On/Off switch

19

Safety key

20

Height/bevel adjusting handwheel

21

Bevel-locking lever

22

Mitre gauge groove

23

Working table

13

KNOW YOUR TABLE SAW

12

11

Blade guard:

The guard is installed over the riving knife. It protects the operator’s hand from being cut while providing a

clear view of the material to be cut during through-sawing cuts.

Bevel-locking lever:

This lever under the work table surface on the front of the cabinet, locks the angle setting of the blade.

WARNING!

• Use only 10" (25.4 cm) diameter blades rated at maximum safe operating speeds of

4700 RPM or higher. Failure to heed this warning could result in personal injury.

• The blades should always be kept sharp. Use a reputable sharpening service to sharpen

the blades when needed.

• Never store the blades stacked on top of one another. Place material such as cardboard

between them to keep the blades from coming into contact with one another.

Page 8

14

model no. 055-6755-8 | contact us 1-800-689-9928

15

Height/bevel adjusting handwheel:

Located on the front of the cabinet, this handwheel is used to lower and raise the blade for adjustments or

blade replacement. The handwheel also makes the adjustment for bevel angles easy.

Rip fence locking handle:

The handle on the front of the rip fence releases or locks the rip fence with respect to the work table.

Mitre gauge:

This mitre gauge aligns the wood for a cross cut. The easy-to-read indicator shows the exact angle for a

mitre cut.

Mitre gauge grooves:

The mitre gauge rides in these grooves on either side of the blade.

Front rail:

Front rail provides support for the rip fence.

Rip fence:

The rip fence is a sturdy metal fence that can be locked to the work table to guide the workpiece securely.

KNOW YOUR TABLE SAW

Scale:

Located on the front rail, the easy-to-read scale provides precise measurements for rip cuts.

Riving knife:

The riving knife is a metal piece, slightly thinner than the saw blade, used to keep the kerf open to prevent

kickback.

Switch assembly:

This saw has an easy-access power switch. The switch located on the front of the cabinet allows the operator

to turn the table saw On/Off easily. To lock the switch in the Off position, remove the safety key from the

switch. Place the key in a location that is inaccessible to children and others not qualified to use the tool.

Arbor:

The arbor is a shaft on which a blade is mounted.

Wooden spacer:

The wooden spacer is attached on one side of the rip fence to prevent the material from being caught

between the bottom of the rip fence and the work table, when ripping material such as thin paneling.

Work table:

The surface to which the workpiece is attached while cutting.

Operating components:

The upper portion of the blade projects up through the table and is surrounded by an insert called the table

insert. The height of the blade is set with a handwheel on the front of the cabinet.

Detailed instructions are provided in the “Operating Instructions” section of this manual for the basic cuts:

cross cuts, mitre cuts, bevel cuts, and compound cuts.

The rip fence is used to position work for lengthwise cuts. A scale on the front rail shows the distance

between the rip fence and the blade.

It is very important to use the blade guard assembly for all through-sawing operations. The blade guard

assembly includes: riving knife, anti-kickback pawls, and plastic blade guard.

Applications:

You can use this tool for the purposes listed below:

• Straight-line cutting operations such as cross cutting, ripping, mitreing 0-45° mitre angle, bevel

crosscutting 0-45° blade bevel and 90° mitre angle and 0-45° blade bevel and 0-45° mitre angle.

• Cabinet making and woodworking.

Causes of kickback:

Kickback can occur when the blade stalls or binds, causing the workpiece to be kicked back toward the

operator with great force and speed. If your hands are near the saw blade, they may be jerked loose from

the workpiece and come into contact with the blade. Obviously, kickback can cause serious injury, and it is

well worth using precautions to avoid the risks.

Kickback can be caused by any action that pinches the blade in the wood, such as the following:

• Making a cut with incorrect blade depth.

• Sawing into knots or nails in the work piece.

• Twisting the wood while making a cut.

• Failing to support the workpiece.

• Forcing a cut.

• Cutting warped or wet lumber.

• Using the wrong blade for the type of cut.

• Not following correct operating procedures.

• Misusing the saw.

• Failing to use the anti-kickback pawls.

• Cutting with a dull, gummed-up, or improperly set blade.

KNOW YOUR TABLE SAW

NOTE:

This table saw is designed to cut wood and wood composition products only. It is not designed for cutting

large panels. Depending on the shape of the panel, use the rip fence or mitre gauge.

Page 9

16

model no. 055-6755-8 | contact us 1-800-689-9928

17

Avoiding kickback:

• Always use the correct blade depth setting. The top of the blade teeth should clear the workpiece by

1/8 - 1/4" (3.2 - 6.4 mm).

• Inspect the workpiece for knots or nails before beginning a cut. Knock out any loose knots with a

hammer. Never saw into a loose knot or nail.

• Always use the rip fence when rip cutting and the mitre gauge when crosscutting. This helps to prevent

twisting the wood in the cut.

• Always use clean, sharp, and properly set blades. Never make cuts with dull blades.

• To avoid pinching the blade, support the work properly before beginning a cut.

• When making a cut, use steady, even pressure. Never force cuts.

• Do not cut wet or warped lumber.

• Always hold the workpiece firmly with both hands or with push sticks. Keep your body in a balanced

position to be ready to resist kickback should it occur. Never stand directly in line with the blade.

• Use the right type of blade for the cut being made.

KNOW YOUR TABLE SAW

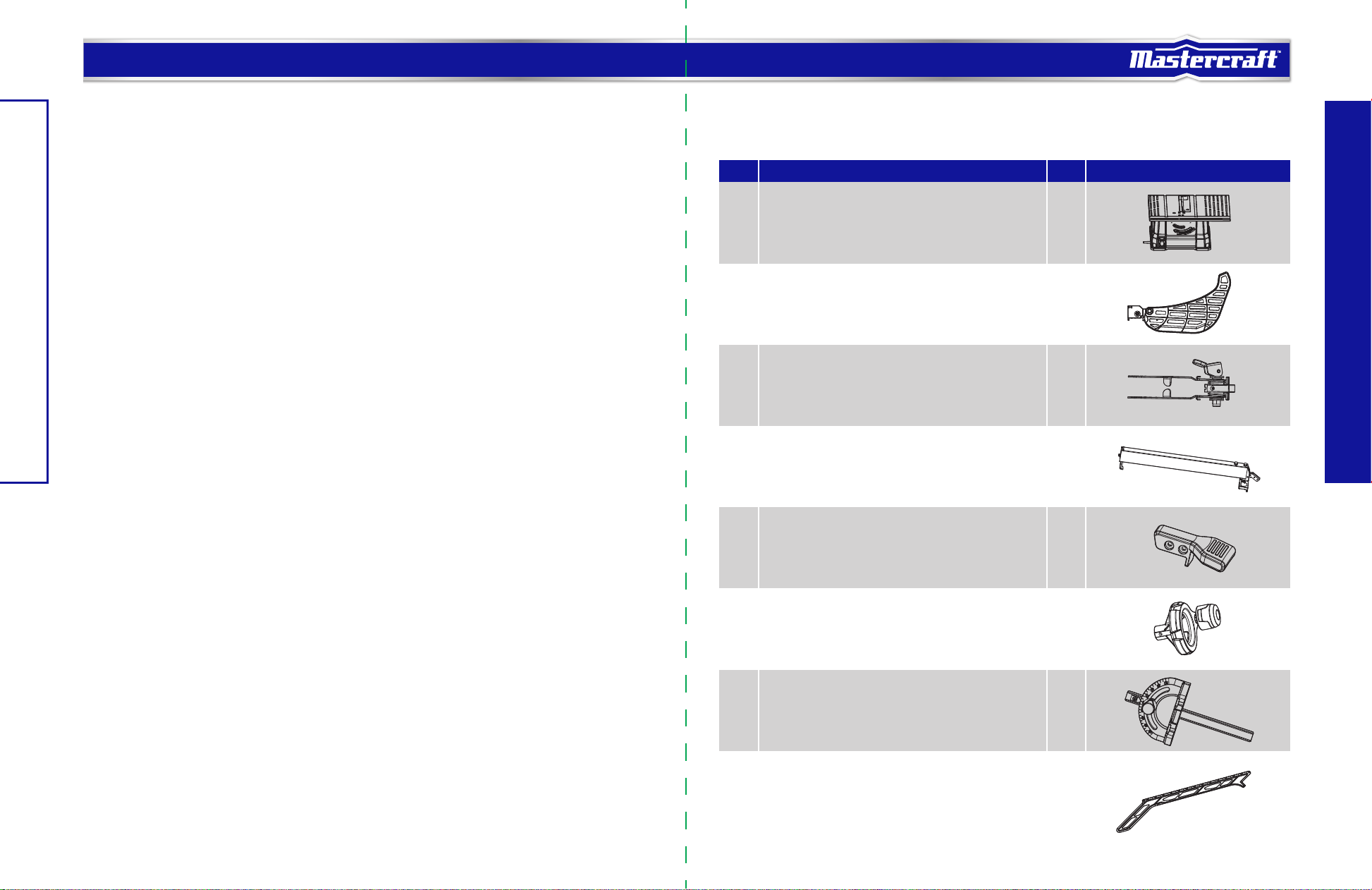

PACKAGE CONTENTS

FOR TABLE SAW

No. Description Qty Illustration

Table saw assembly

1

Blade guard assembly

2

Anti-kickback pawls assembly

3

Rip fence

4

1

1

1

1

ASSEMBLY INSTRUCTIONS

Rip fence locking handle

5

Bevel adjusting handwheel

6

Mitre gauge

7

Push stick

8

1

1

1

1

Page 10

18

model no. 055-6755-8 | contact us 1-800-689-9928

19

No. Description Qty Illustration

Blade wrenches

9

Screws ST 3.9 x 19

10

Screw M4 x 12 with flat washer 4

11

Push stick storage screws

12

ASSEMBLY INSTRUCTIONS

Hex bolts M6 x 25 with nuts M6 , flat washers 6

13

No. Description Qty Illustration

Short top leg brackets

2

2

1

2

3

Short bottom leg brackets

4

Long bottom leg brackets

5

Rubber feet

6

2

2

2

4

ASSEMBLY INSTRUCTIONS

Screws M6 x 12 with nuts M6 , flat washers 6

4

7

and spring washers 6

16

FOR STAND

TOOLS NEEDED FOR ASSEMBLY

No. Description Qty Illustration

Stand legs

1

Long top leg brackets

2

4

2

Screwdriver Framing square

Star-head screwdriver

Wrench

Triangle square

Page 11

20

model no. 055-6755-8 | contact us 1-800-689-9928

21

UNPACKING

Do not use this product if any parts of the package contents are already assembled to your product when you

unpack it. Package contents are not assembled to the product by the manufacturer and require customer

installation. Use of a product that may have been improperly assembled could result in serious personal injury.

• Carefully remove the table saw from the carton and remove the protective polyfoam around the motor.

• Inspect the tool carefully to make sure no breakage or damage occurred during shipping.

• Do not discard the packing material until you have carefully inspected and satisfactorily operated the tool.

• The saw is factory set for accurate cutting. After assembling it, check for accuracy. If shipping has

influenced the settings, refer to specific procedures explained in this manual.

• If any parts are damaged or missing, please call 1-800-689-9928 for assistance.

MOUNTING HOLES (Fig. 2)

The table saw must be mounted to a firm supporting

surface such as workbench or leg stand. Four bolt holes

have been provided in the saw’s base for this purpose.

ASSEMBLY INSTRUCTIONS

Each of the four mounting holes (1) should be bolted securely

using 1/4" machine bolts, lock washers, and hex nuts (not

included). Bolts should be of sufficient length to

accommodate the saw base, lock washers, hex nuts, and

the thickness of the workbench. Tighten all four bolts

securely.

Carefully check the workbench after mounting to make sure

that no movement can occur during use. If any tipping,

sliding, or walking is noted, secure the workbench to the

floor before operating.

TO ASSEMBLE THE LEG STAND (Fig. 3-6)

• Unpack all parts, and group them by type and size.

Refer to the section “package contents” for correct

quantities.

• Attach one long top leg bracket (1) to the top of one

leg (2) using a screw, flat washer, spring washer and

hex nut. (Fig. 3)

• Attach other end of the long top leg bracket (1) to top

of another leg (2) using using a screw, flat washer,

spring washer and hex nut.

• Attach one long bottom leg bracket (3) to the centre of

each leg (2) using a screw, flat washer, spring washer

and hex nut. This completes the front frame section.

(Fig. 4)

• Assemble the rear frame section in exactly the same

manner.

• Join the front and rear frame assemblies to the two

short upper supports (4) and two short bottom

supports (5) using a screw, flat washer, spring

washer and hex nut. (Fig. 5)

2

2

3

1

Fig. 3

1

2

ASSEMBLY INSTRUCTIONS

Fig. 4

3

1

1

Fig. 2

2

4

4

1

2

WARNING!

If any parts are damaged or missing do not operate this tool until the parts are replaced. Use of

this product with damaged or missing parts could result in serious personal injury.

• Do not attempt to modify this tool or create accessories not recommended for use with this tool.

Any such alteration or modification is misuse and could result in a hazardous condition leading

to possible serious personal injury.

• Do not connect to power supply until assembly is complete. Failure to comply could result in

accidental starting and possible serious personal injury.

• Risk of injury! Always pull out the mains plug (disconnect the product from its power supply)

before commencing work on the product.

NOTE:

Do not tighten the bolts until the stand is properly aligned (see step #8).

5

2

3

5

2

Fig. 5

Page 12

22

model no. 055-6755-8 | contact us 1-800-689-9928

23

• Insert the rubber foot (6) into the bottom of each leg.

(Fig. 6)

• Place the stand on a level surface, and adjust it so that

all of the legs are contacting the floor and are at

similar angles to the floor. Tighten all of the screws.

ATTACH THE TABLE SAW TO THE STAND (Fig. 7)

• Place the stand on a level surface and level the stand to

ASSEMBLY INSTRUCTIONS

the floor.

• Place the table saw on top of the stand, aliging the

holes in the base with the holes in the stand.

• Insert four hex bolts M6 x 25 (1) along with flat washers

(2) into the aligned holes.

• Tighten all four hex nuts M6 (3) and hex bolts (1).

6

Fig. 6

1

2

TO REMOVE/REPLACE/ALIGN THE TABLE INSERT (Fig. 8)

• Turn the height-adjusting knob counter-clockwise to

lower the blade.

• Lock the blade by turning bevel-lock lever clockwise.

• To remove the table insert: Place your index finger

in the hole and lift the front end, pulling the table

insert (1) out toward the front of the saw.

• To reinstall the table insert: Slip the tab into the

slot at the back of the saw and push down to secure

in place.

TO INSTALL THE HEIGHT/BEVEL ADJUSTING HANDWHEEL (Fig. 9)

Attach the height/bevel adjusting wheel (1) into the fix pole.

Use the screw (2) and washer (3) to lock the control wheel.

3

1

1

Fig. 8

2

ASSEMBLY INSTRUCTIONS

Fig. 9

NOTE:

The stand should not rock after all of the bolts have been tightened.

Screw: M6 x 12, flat washer 6, spring washer 6 and hex nut M6.

WARNING!

Do not operate this machine on the floor, as that is a very dangerous position.

NOTE:

Do not over-tighten the bolts that hold the saw to the stand. Doing so will damage the saw base.

3

Fig. 7

TO USE HEIGHT/BEVEL ADJUSTING HANDWHEEL (Fig. 10)

• Turn the height-adjusting knob (1) clockwise to raise

the blade, and counter-clockwise to lower the blade.

• Turn the handwheel (2) clockwise, and move along

the arc rail, then the blade will bevel from 0-45°,

or turn counter-clockwise.

• Secure the blade bevel-locking lever (3) when the bevel

angle pointer points at desired angle on scale. To lock

the blade, turn blade bevel-lock lever clockwise.

To unlock the blade, turn it counter-clockwise.

1

3

2

Fig. 10

Page 13

24

model no. 055-6755-8 | contact us 1-800-689-9928

25

ADJUSTING THE RIVING KNIFE (Fig. 11-13)

This saw is shipped with the riving knife placed in “down”

position.

• Unplug the saw.

TO PLACE IN THE HIGHEST POSITION FOR ALL

THROUGH CUTS (WITH BLADE GUARD AND

ANTI-KICKBACK PAWLS):

• Remove the table insert.

• Set the saw blade angle to 0°.

• Raise the saw blade to the uppermost positon by

turning the height-adjusting knob clockwise.

• Unlock the release lever by pushing the lever up (1).

• Grasp the riving knife (2) and push it toward the right

to unlock it from the pins (3). Pull it up until the

pins are re-engaged (riving knife (2) has two holes (4)

on its lower end that match with two pins (3) on the

inner side board (5) and the riving knife is in “up”

ASSEMBLY INSTRUCTIONS

position.

• Lock the release lever by pushing the lever down (6).

• Reinstall the table insert.

TO PLACE IN “DOWN” POSITION FOR FOR

2

7

Fig. 11

4

2

1

NON-THROUGH CUTTING, E.G. MAKING CHANNEL

(WITH BLADE GUARD AND ANTI-KICKBACK PAWLS

REMOVED):

• Remove the table insert.

• Set the saw blade angle to 0°.

• Raise the saw blade to the uppermost positon by

turning the height-adjusting knob clockwise.

• Unlock the release lever by pushing the lever up (1).

• Grasp the riving knife (2) and push it toward the right

to unlock it from the pins (3) then pull it down until the

pins are re-engaged (riving knife (2) has two holes (7)

on its middle position that match with two pins (3) on

the inner side board (5) and the riving knife is in

“down” position.

• Lock the release lever by pushing the lever down (6).

• Reinstall the table insert.

5

3

Fig. 13

ASSEMBLY INSTRUCTIONS

2

WARNING!

Riving knife has four holes for two positions. The highest position is for all through cuts.

The lower position is for rabbets and other non-through cuts (with blade guard and

anti-kickback pawls removed).

• Make sure locking pin is aligned with riving knife hole and secure in position by

pushing the lever down.

• Riving knife must be in line with blade. Make sure riving knife sits flat against outer

side board (7) and inner side board (5).

6

Fig. 12

TO INSTALL THE ANTI-KICKBACK PAWLS AND BLADE GUARD (Fig. 14-17)

• Unplug the saw.

• Set the blade angle to 0°.

• Raise the saw blade to maximum height by turning

height-adjustment knob clockwise.

• Place the riving knife in the highest position.

NOTE:

Anti-kickback pawls should only be installed for through cuts.

Anti-kickback pawls notch

Riving knife

Blade guard notch

Fig. 14

Page 14

model no. 055-6755-8 | contact us 1-800-689-9928

2726

TO INSTALL ANTI-KICKBACK PAWLS: (Fig. 14-15)

• Unplug the saw.

• Place the anti-kickback pawls assembly (1) onto riving

knife (2) at notches indicated. The spring pin (3) is

placed in the front notch (4) and bolt (5) is placed in the

rear notch (6).

• Press anti-kickback pawls assembly completely down

and push latch (7) down to secure in position.

TO INSTALL THE BLADE GUARD: (Fig. 14-16)

• Unplug the saw.

• Place the slot (8) of blade guard assembly (9) over the

riving knife (2). Slot (10) of bushing is placed in the

notch (11) indicated in Figure 16.

• The bushings have a beveled edge and must be

located in the centre of the notch to lock properly.

• Pull guard fully down onto knife and push latch (12)

down to lock guard into position.

ASSEMBLY INSTRUCTIONS

4

10

11

13

3

1

7

5

6

2

Fig. 15

12

9

8

2

Fig. 16

14

CHECK AND ALIGN THE RIVING KNIFE AND SAW BLADE (Fig.18-19)

TO CHECK THE ALIGNMENT OF THE RIVING KNIFE:

• Unplug the saw.

• Raise the saw blade to maximum height by turning

height-adjustment knob clockwise.

• Remove the anti-kickback pawls, and place a

framing square (1) or straight edge against both the

saw blade and the riving knife.

Make sure that you place the framing square between the

carbide teeth, and measure from the blade.

This step will ensure that the framing square is square

against the blade from the front to the back of the blade.

• The saw blade and riving knife are aligned when the

framing square contacts the blade and the riving knife

evenly, with no gaps.

TO ADJUST:

• Unplug the saw.

• Insert the hex key (not included) through the slot on

the back of the saw. Two adjustment screws (2) can

be accessed through the slot.

• Turn the adjustment screws (2) to reposition the riving

knife left or right as needed to align the riving knife

with the saw blade.

• Once properly aligned, securely retighten the screws.

1

Fig. 18

2

ASSEMBLY INSTRUCTIONS

NOTE:

Blade guard body should be parallel to the table. If not, adjust the set screw (13) as necessary. (Fig. 17)

NOTE:

The teeth of anti-kickback pawls should touch table surface. Use set screw (14) to adjust if needed. (Fig. 17)

Fig. 17

Fig. 19

NOTE:

If the riving knife is out of alignment with the saw blade, adjustment is needed.

NOTE:

The blade guard and riving kinfe must always be correctly aligned so that the cut workpiece will pass on

either side of the riving knife without binding or twisting to the side.

WARNING!

Improper riving knife alignment can cause kickback and serious injury.

Page 15

28

model no. 055-6755-8 | contact us 1-800-689-9928

29

TO CHECK SAW BLADE INSTALLATION (Fig. 20)

The saw is shipped with the blade installed. Prior to initial

use, it is recommended that you check the blade installation

as instructed below.

• Unplug the saw.

• Lower the saw blade and remove the table insert.

• Set the saw blade angle to 0°.

• Turn the bevel-locking lever clockwise to tighten it

securely. Raise the saw blade to its full height by

turning the height-adjusting knob clockwise.

TO LOOSEN THE BLADE:

• Using one opened-ended blade wrench (1), place the

flat open end on the flats on the outer blade flange.

• Using the other opened-ended blade wrench (2), place

the flat open end on the flats on the arbor nut (3).

Holding both wrenches firmly, pull the opened-ended

blade wrench on the arbor nut forward to the front of

ASSEMBLY INSTRUCTIONS

the machine.

TO TIGHTEN THE BLADE:

• Using one opened-ended blade wrench (1), place the

flat open end on the flats on the outer blade flange.

• Using the other opened-ended blade wrench (2), place

the flat open end on the flats on the arbor nut (3).

Holding both wrenches firmly, pull the opened-ended

blade wrench (2) on the arbor nut forward to the back

of the machine. Make sure the arbor nut is securely

tightened. Do not overtighten.

• Check all clearances for free blade rotation.

TO REPLACE THE BLADE (Fig. 20-21)

When you need replace the saw blade, please follow the

1

2

3

Fig. 20

procedure below:

• Unplug the saw.

• Remove blade guard assembly and pawl assembly.

• Turn height-adjustment knob counter-clockwise to

drop the saw blade to lowest position, and remove the

table insert.

• Turn height-adjustment knob clockwise to raise blade

to maximum height.

• Using one opened-ended blade wrench, place the flat

open end on the flats on the outer blade flange (1).

• Using the other opened-ended blade wrench, place

the flat open end on the flats on the arbor nut (2).

Holding both wrenches firmly, pull the opened-ended

blade wrench on the arbor nut forward to the front of

the machine.

• Remove arbor nut (2), outer blade flange (1) and saw

blade (3).

• Place one new blade on arbor (4). Make sure saw

blade teeth point down at the front side of saw table.

Place outer flange (1) and nut (2) on arbor and use

blade wrenches to tighten nut securely. Verify that

large, flat surface of the outer flange faces the saw

blade and the saw blade (3) is firmly seated aganist

the inner flange (5).

• Lower the saw blade to lowest position and replace

table insert.

• Replace blade guard assembly and pawl assembly.

5

3

1

2

4

Fig. 21

ASSEMBLY INSTRUCTIONS

CAUTION!

To work properly, the saw blade teeth must point down toward the front of the saw. Failure to

heed this instruction could cause damage to the saw blade, the saw or the workpiece.

NOTE:

Arbor shaft has left-hand threads.

WARNING!

Be extremely careful when loosening arbor nut.

Keep firm grasp on both wrenches. Do not allow hands to slip and contact blade.

Page 16

30

model no. 055-6755-8 | contact us 1-800-689-9928

31

ÉLÉVATION DE LA LAME (Fig. 22)

The saw blade depth should be set so that the outer points

of the saw blade are higher than the workpiece by

approximately 1/8-1/4" (3.2 - 6.4 mm), but the lowest

points (gullets) (1) are below the top surface.

• Unplug the saw.

• Turn the bevel-locking lever clockwise to tighten it

securely.

• Raise the blade by turning the height-adjusting knob

clockwise, or lower it by turning the knob

counter-clockwise.

CHANGING THE BLADE ANGLE (Fig. 23)

This table saw has a rack-and-pinion bevel control that

allows you make angled cuts from 90-45°.

ASSEMBLY INSTRUCTIONS

• Unplug the saw.

• Loosen the bevel-locking lever (1) by turning it

counter-clockwise.

• To adjust the bevel angle, turning the height/bevel

adjusting handwheel (2) counter-clockwise increases

the angle of the blade, bringing it closer to 45°. Turning

it clockwise decreases the angle, bringing the blade

closer to 90°.

• Lock by turning the bevel-locking lever (1) clockwise.

1

Fig. 22

1

2

Fig. 23

ADJUSTING THE BEVEL STOPS (Fig. 24-26)

This saw has positive stops that will quickly position the

saw blade at 90° or 45° to the table.

The angle settings of the saw have been set at the factory

and, unless damaged in shipping, should not require

setting during assembly. After extensive use, it may need

to be checked. Make adjustments only if necessary.

• Unplug the saw.

• Remove the anti-kickback pawls assembly and blade

guard assembly.

• Raise the blade to the maximum height by turning the

height-adjusting knob clockwise.

• Using a framing square (3), set the blade to exactly

90°.

• If the blade stops bevelling before it gets to 90°,

loosen the 90°-stop set screw (1) (located at the left

of the table insert), and then adjust it to 90°.

• With the blade set at 90°, slowly turn the 90°-stop set

screw (1) until you feel resistance. Bevel the blade

away from 90° a little and then back to the stop.

• Re-measure the angle, and repeat the stop

adjustment as necessary, until the blade stops at 90°.

• Set the 45° stop in the same way. The 45°-stop set

screw (2) is located at the right of table insert. Use

the triangle square (4).

• Replace the anti-kickback pawls assembly and blade

guard assembly.

• Make a test cut.

1

2

Fig. 24

3

ASSEMBLY INSTRUCTIONS

Fig. 25

4

NOTE:

A 90° cut has a 0° bevel and a 45° cut has a 45° bevel.

Fig. 26

Page 17

32

model no. 055-6755-8 | contact us 1-800-689-9928

33

ADJUSTING THE BEVEL INDICATOR (Fig. 27)

If the bevel indicator (1) is not at 0° when the saw blade is

at 90°, adjust the indicator (1) by loosening the cross screw

(2) with a star-head screwdriver and setting it to 0° on the

bevel scale.

Retighten the cross screw (2).

Make sure that you make a trial cut on a scrap piece of

wood before making critical cuts. Measure for

exactness.

TO INSTALL THE RIP FENCE LOCKING HANDLE (Fig. 28)

ASSEMBLY INSTRUCTIONS

• Slide the locking handle (1) over the exposed end of

the rip fence (2), making certain the handle is inserted

as far as possible.

• Align the holes in the rip fence and the holes in the

handle. Secure using the screws (3).

CHECKING THE ALIGNMENT OF THE RIP FENCE TO THE BLADE (Fig. 29)

• Unplug the saw.

• Remove the blade guard assembly and anti-kickback

pawls assembly.

2

1

Fig. 27

• Raise the locking handle (1) to allow the rip fence (2)

to be moved.

• Place the framing square (3) beside the blade, and

move the rip fence up to the square. Note the

measurement on the rip scale.

• Move the fence back and rotate the framing square

(3) 180° to check the other side.

• If the two measurements are not the same, loosen the two socket head bolts (4) on the rip fence and then

align it.

• Retighten the two socket head bolts (4).

• Replace the blade guard assembly and anti-kickback pawls assembly.

• Make two or three test cuts using scrap wood. If the cuts are not true, repeat the process.

3

2

1

2

Fig. 29

ASSEMBLY INSTRUCTIONS

2

1

3

Fig. 28

USING THE RIP FENCE (Fig. 30)

• Unplug the saw.

• Place the rear lip of the rip fence (1) on the rear of the

saw table and push it slightly toward the back of the

unit.

• Lower the front end of the rip fence onto the guide

surfaces on top of the front rail.

• With the rip fence flat on the saw table, push the fence

toward the front rail to align the fence to the saw

table.

• Push the locking handle (2) down to align and secure the fence.

Check for a smooth gliding action. If adjustments are needed, see the previous section: “Checking the

alignment of the rip fence to the blade.”

• Make two or three test cuts using scrap wood. If the cuts are not true, repeat the process.

2 1 3

Fig. 30

CAUTION!

To prevent personal injury:

• Always disconnect the plug from the power source when making any adjustments.

• The adjustment must be correct. If it is not, kickback could result in a serious injury and inability

to make accurate cuts.

NOTE:

The rip fence must be secure when the locking handle is engaged. To increase the grip of the rip fence on the

rear lip of the table, tighten the clamp screw (3) on the rear of the rip fence by turning it clockwise.

Page 18

34

model no. 055-6755-8 | contact us 1-800-689-9928

35

USING THE MITRE GAUGE (Fig. 31)

The mitre gauge provides greater accuracy in angled cuts.

For very close tolerances, test cuts are recommended.

There are two mitre gauge grooves, one on either side of

the saw blade. When making a 90° crosscut, use either

mitre gauge groove. When making a bevel crosscut (the

blade tilted in relation to the table), the mitre gauge should

be located in the groove on the right so that the blade is

tilted away from the mitre gauge and away from your

hands.

The mitre gauge can turned 60° to the right or left.

• Slide the mitre gauge in the mitre gauge groove (1).

• Loosen the locking handle (2).

• With the mitre gauge in the mitre gauge groove,

rotate the gauge until the desired angle is reached on

the scale.

• Retighten the locking handle (2).

ASSEMBLY INSTRUCTIONS

TO ADJUST MITRE GAUGE (Fig. 32)

• Loosen the lock handle in order to allow the mitre body

to rotate freely. Position the mitre body at 90°, so that

the positive detent secures its position. Tighten the

lock handle in order to hold the mitre body in position.

• If the pointer requires adjustment, loosen the screw (1)

on the pointer using a screwdriver. Adjust the pointer

to 90° on the scale, and then firmly tighten screw (1).

PUSH STICK STORAGE (Fig. 33)

• Insert the push stick storage screws (1) into the holes

on the side of the saw table. Use a screwdriver to

2

Fig. 31

1

tighten screws securely.

• Place the slots in the push stick (2) over the screws

and slide the push stick towards the back of the saw.

1

2

Fig. 33

ASSEMBLY INSTRUCTIONS

1

Fig. 32

Page 19

36

model no. 055-6755-8 | contact us 1-800-689-9928

37

BASIC OPERATION OF THE TABLE SAW

The three-prong plug must be plugged into a matching outlet that is properly installed and grounded according

to all local codes and ordinances. Improper connection of the equipment can result in electric shock. Do not

modify the plug if it will not fit the outlet. Have the correct outlet installed by a qualified electrician. Refer to

the electrical safety section in this manual.

ON/OFF SWITCH (Fig. 34)

The On/Off switch has a removable safety key (1). With

the key removed from the switch, unauthorized and

hazardous use by children and others is minimized.

• To turn the saw On, insert the key into the slot in the

switch. Move the switch upward to the On position.

• To turn the saw Off, move the switch downward.

• To lock the switch in the Off position, grasp the end

(or yellow part) of the safety key and pull it out.

• The switch will not operate with the safety key

OPERATING INSTRUCTIONS

removed.

• If the safety key is removed while the saw is running,

it can be turned Off, but it cannot be restarted without

inserting the safety key.

Make sure that you always remove the safety key when the tool is not in use, and keep the safety key in a

safe place. In the event of a power failure, turn the switch Off and remove the key. This action will prevent the

tool from accidentally starting when the power returns.

ALWAYS make sure that your workpiece is not in contact with the blade before operating the switch to start

the tool. Failure to heed this warning may cause the workpiece to be kicked back toward the operator, and

may result in serious personal injury.

To reduce the risk of accidental starting, always make sure the switch is in the Off position before plugging

the tool into the power source.

MAKING CUTS

Before using the table saw, polish the table with an automotive wax in order to keep it clean and make it

easier to slide the workpiece.

There are two basic types of table saw cuts: ripping and crosscutting. In general, ripping means cutting with

the grain, along the length of the workpiece. Crosscutting means either cutting across the width or across the

grain of the workpiece. However, with man-made materials, this distinction can be difficult to make.

Therefore, cutting a piece of wood to a different width is ripping and cutting across the short dimension is

crosscutting. Neither ripping nor crosscutting operations can be performed safety freehand: Ripping requires

the use of the rip fence, and crosscutting requires the use of the mitre gauge.

1

Fig. 34

OPERATING INSTRUCTIONS

WARNING!

Overheating may be caused by misaligned parts or by a dull blade. Inspect the saw for proper

setup before using it again.

WARNING!

• Do not allow familiarity with tools to make you careless. Remember that a careless fraction

of a second is sufficient to inflict severe injury.

• Always wear eye protection that conforms with CUL requirements. Failure to do so could

result in objects being thrown into your eyes, resulting in possible serious injury.

• Do not use any attachments or accessories not recommended by the manufacturer of this

tool. The use of attachments or accessories not recommended can result in serious personal

injury.

• Although many of the illustrations in this manual are shown with the blade guard removed

for clarity, do not operate the saw without the blade guard unless specifically instructed

to do so.

WARNING!

Do not use blades rated less than the speed of this tool. Failure to heed this warning could

result in personal injury.

CAUTION!

Make sure you read the general safety guidelines for the table saw before operating it. Your

safety depends on it. Verify the following every time the saw is used:

• The blade is tight.

• The bevel angle locking knob is tight.

• If ripping, the fence locking handle is tight, the fence is parallel and the mitre gauge

locking hanle is tight.

• If crosscutting, the mitre gauge knob is tight.

• The blade guard and riving knife are in place and are working properly.

• Safety glasses are being worn.

Failure to adhere to these safety rules can greatly increase the chances of injury.

Page 20

38

model no. 055-6755-8 | contact us 1-800-689-9928

39

PUSH STICK (Fig. 35)

Push sticks are devices used for safely pushing a workpiece through the blade instead of using your hands.

They can be made from scrap wood in various sizes and shapes to be used in a specific project. The stick

must be narrower than the workpiece, with a 90° notch in one end and shaped for a grip on the other end.

• Use good quality plywood or solid wood

• Use 1/2" (1.27 cm) or 3/4" (1.9 cm) material

• Push stick MUST be thinner than the width

of material being cut

OPERATING INSTRUCTIONS

15 3/4" (40 cm)

Drill hole

for hanging

Notch to

prevent hand

from slipping

RIPPING (Fig. 36)

• Remove the mitre gauge, and secure the rip fence to

table.

• Adjust the blade so that it is approximately 1/8"

(3.2 mm) higher than the workpiece.

• Hold the workpiece flat on the table and against the

fence. Keep the workpiece approximately 1" (2.5 cm)

away from the blade.

• Turn the saw On, and allow the blade to come up to

full speed.

• Slowly feed the workpiece into the blade by pushing

forward only on the section of the workpiece that will

pass between the blade and the fence.

• Keep your thumbs off the table top. When both of your

thumbs touch the front edge of the table, complete the

cut using a push stick.

• The push stick should always be used when the ripped

workpiece is 2" (5 cm) wide or narrower.

• Continue to push the workpiece with the push stick

until it passes the blade guard and clears the rear of

the table.

• Never pull the workpiece back while the blade is

turning. Turn the switch Off. When the blade comes

to a complete stop, raise the anti-kickback pawls on

either side of the riving knife, if necessary, and then

slide the workpiece out.

Fig. 36

OPERATING INSTRUCTIONS

20°-30°

90°

Cut here to push

1/2" (1.27 cm) wood

Cut here to push

3/4" (1.9 cm) wood

Fig. 35

WARNING!

To prevent serious injury:

• Never use the mitre gauge when ripping.

• Never use more than one rip fence during a single cut.

• Do not allow familiarity with or frequent use of your table saw to cause careless mistakes.

Remember that even a fraction of a second of carelessness is enough to cause a severe injury.

• Keep both hands away from the blade and path of the blade.

• When ripping, the workpiece must have a straight edge against the fence, and must not be

warped, twisted, or bowed.

CAUTION!

Avoid kickback by pushing only on the section of workpiece that will pass between the blade

and the fence.

Page 21

40

model no. 055-6755-8 | contact us 1-800-689-9928

41

BEVEL RIPPING

This operation is the same as ripping, except that the bevel angle is set to an angle other than 0°.

Make sure that you only cut with the workpiece and the fence on the right-hand side of the blade.

RIPPING SMALL PIECES (Fig. 37)

• It is not safe to rip small pieces. It is not safe to put

your hands close to the blade. In order to ensure your

safety, rip the small piece from a larger piece.

• When a small width is to be ripped and your hand

cannot be safely put between the blade and the rip

fence, use one or more push sticks. Use the push stick

to hold the workpiece against the table top and the

fence, and to push the workpiece completely past the

blade.

Avoid injury resulting from contact with the blade. Never

make through-cuts narrower than 3/4" (1.9 cm) wide.

OPERATING INSTRUCTIONS

Fig. 37

CROSSCUTTING (Fig. 38)

• Remove the rip fence, and place the mitre gauge in

one of the mitre gauge grooves on the table.

• Adjust the blade height so that it is 1/8" (3.2 mm)

higher than the top of the workpiece.

• Hold the workpiece firmly against the mitre gauge,

with the blade path in line with the desired cut

location. Move the workpiece to within 1" (2.5 cm) of

the blade.

• Start the saw, and wait for the blade to come up to

full speed. Never stand directly in line with the path

of the saw blade.

• Keep the workpiece against the face of the mitre

gauge and flat against the table. Slowly push the

workpiece through the blade.

• Do not attempt to pull the workpiece backward while

the blade is turning. Turn the switch Off, and wait

until the blade has come to a complete stop before

carefully sliding the workpiece out.

Fig. 38

OPERATING INSTRUCTIONS

CAUTION!

To prevent serious injury:

• Do not allow familiarity with or frequent use of your table saw to cause careless mistakes.

Remember that even a fraction of a second of carelessness is enough to cause a severe injury.

• Keep both hands away from the blade and the path of the blade.

• Never attempt to pull the workpiece backward during a cutting operation. This will cause

kickback, and serious injury to the user can occur.

WARNING!

In order to avoid instability, always place the larger surface of the workpiece on the table when

crosscutting and/or bevel crosscutting.

Page 22

42

model no. 055-6755-8 | contact us 1-800-689-9928

43

BEVEL CROSSCUTTING 0-45° BLADE BEVEL AND 90° MITRE ANGLE (Fig. 39)

This cutting operation is the same as crosscutting, except

that the blade is at a bevel angle other than 0°.

This operation must be performed with mitre gauge in the

right side groove.

• Adjust the blade to the desired angle, and then tighten

the blade bevel-locking lever.

• Tighten the mitre lock handle at 90°.

• Hold the workpiece firmly against the face of the mitre

gauge throughout the cutting operation.

Make sure that you always work to the right side of the

blade during this type of cut. The mitre gauge must be in

the right side groove, because the bevel angle may cause

the blade guard to interfere with the cut if it is used in the

left side groove.

OPERATING INSTRUCTIONS

0-45° BLADE BEVEL AND 0-45° MITRE ANGLE (Fig. 40)

This sawing operation combines a mitre angle with a bevel

angle. This operation must be performed with the mitre

gauge in the right side groove.

• Set the mitre gauge to the desired angle.

• Place the mitre gauge in the right side groove of the

table.

• Set the blade bevel to the desired bevel angle, and

tighten the blade bevel-locking lever.

• Hold the workpiece firmly against the face of the mitre

gauge throughout the cutting operation.

Make sure that you always work to the right side of the

blade during this type of cut. The mitre gauge must be in

the right side groove, because the bevel angle may cause

the blade guard to interfere with the cut if it is used in the

left side groove.

Fig. 39

Fig. 40

MITREING 0-45° MITRE ANGLE (Fig. 41)

This sawing operation is the same as crosscutting, except

that the mitre gauge is locked at an angle other than 90°.

• Set the blade to the 0° bevel angle, and then tighten

the blade bevel-locking lever.

• Set the mitre gauge to the desired mitre angle, and

lock it in position by tightening the mitre gauge

locking handle.

• Hold the workpiece firmly against the face of the

mitre gauge throughout the cutting operation.

USING WOOD FACING ON THE RIP FENCE (Fig. 42)

When performing certain special cutting operations, add a

wood facing to either side of the rip fence.

• Use a smooth, straight, 3/4" (1.9 cm) thick wooden

facing (1) that is as long as the rip fence.

• Attach the wood facing (1) to the rip fence (2) using

wood screws (3) (not included) through the hole in the

fence. A wood facing should be used when ripping

material such as thin paneling, in order to prevent the

material from catching between the bottom of the

fence and the table.

1

Fig. 41

3

2

Fig. 42

OPERATING INSTRUCTIONS

Page 23

44

model no. 055-6755-8 | contact us 1-800-689-9928

Avoid using solvents when cleaning plastic parts. Most plastics are susceptible to damage from various types

of commercial solvents and may be damaged by their use. Use clean cloths to remove dirt, dust, oil, grease,

etc.

• Periodically check all clamps, nuts, bolts and screws for tightness and condition. Make sure the table

insert is in good condition and in position.

• Check the blade guard assembly.

• To maintain the table surfaces, fence, and rails, periodically apply paste wax to them and buff them to

provide smooth functioning.

• Protect the blade by cleaning out sawdust from underneath the table and in the blade teeth. Use a resin

solvent on the blade teeth.

• Clean plastic parts only with a soft, damp cloth. DO NOT use any aerosol or pertoleum solvents.

LUBRICATION

All of the bearings in this tool are lubricated with a sufficient amout of high-grade lubricant for the life of the

unit under normal operating conditions. Therefore, no further lubrication is required.

MAINTENANCE

TROUBLESHOOTINGGENERAL MAINTENANCE

PROBLEM Possible Causes Solution

Saw will not start. • Overload tripped.

• Saw is not plugged in.

• Fuse blown or circuit breaker

tripped.

• Cord is damaged.

Does not make 45° and 90°

rip cuts.

Material pinches blade

when ripping.

• Positive stop not adjusted correctly.

• Bevel angle pointer not set

accurately.

• Rip fence not be properly aligned.

• Rip fence not aligned with blade.

• Warped wood, edge against fence

is not straight.

• Allow motor to cool and reset by

pushing reset switch.

• Plug in saw.

• Replace fuse or reset circuit

breaker.

• Have the cord replaced by a

qualified electrician.

• Check blade with square and adjust

positive stop.

• Check blade with square and adjust

to zero.

• Align the rip fence with the mitre

gauge slot.

• Check and adjust rip fence.

• Select another piece of wood.

45

TROUBLESHOOTING

WARNING!

• When servicing, use only identical replacement parts. Use of any other parts may create a

hazard or cause product damage.

• For your own safety, turn the switch Off and remove the key. Remove the plug from the

power source before performing maintenance on or lubricating your saw.

• Before performing any maintenance, make sure the tool is unplugged from the power supply

and the switch is in the Off (O) position. Failure to heed this warning could result in serious

personal injury.

WARNING!

Do not at any time let brake fluids, gasoline, petroleum-based products, penetrating oils, etc.,

come in contact with plastic parts. Chemicals can damage, weaken or destory plastics which

may result in serious personal injury.

Material binds on riving

knife.

Saw makes unsatisfactory

cuts.

• Riving knife not aligned correctly

with blade.

• Dull blade.

• Blade mounted backwards.

• Gum or pitch on blade.

• Incorrect blade for work being

done.

• Gum or pitch on blade causing

erratic feed.

• Check and align riving knife with

blade.

• Replace blade.

• Turn the blade around.

• Remove the blade and clean with

turpentine and coarse steel wool.

• Change the blade.

• Clean table with turpentine and

steel wool.

Page 24

46

model no. 055-6755-8 | contact us 1-800-689-9928

PROBLEM Possible Causes Solution

Material kicked back from

blade.

Blade does not raise or tilt

freely.

Blade does not come up to

TROUBLESHOOTING

speed or reset trips too

easily.

Machine vibrates

excessively.

Does not make accurate

45° and 90° cuts.

• Rip fence out of adjustment.

• Align rip fence with mitre gauge

slot.

• Riving knife not aligned with blade.

• Feeding stock without rip fence.

• Riving knife not in place.

• Align riving knife with blade.

• Install and use rip fence.

• Install and use riving knife (with

guard).

• Dull blade.

• The operator letting go of material

before it is past saw blade.

• Mitre angle lock knob is not tight.

• Sawdust and dirt in elevation/tilting

mechanisms.

• Extension cord too light or too long.

• Low house voltage.

• The saw is not mounted securely to

• Replace blade.

• Push material all the way past saw

blade before releasing work.

• Tighten knob.

• Brush or blow out loose dust and

dirt.

• Replace with adequate size cord.

• Contact your electric company.

• Tighten all mounting hardware.

the stand.

• Stand is on uneven floor.

• Damaged saw blade.

• Reposition on flat level surfece.

• Replace blade.

• Mitre gauge out of adjustment. • Adjust mitre gauge.

1 2 3 4 5 6 7 8

47

9

10

11

12

13

14

15

16

22

17

18

19

20

21

9

23

24

25

10

31

26

27

28

29

30

20

21

9

9

6

32

33

EXPLODED VIEW

34

35

36

37

45

44

43

42

41

39

40

7

3

38

24

Page 25

48

model no. 055-6755-8 | contact us 1-800-689-9928

49

EXPLODED VIEW

81

82

46

47

48

49

53

54

55

56

6

24

58

80

79

78

58

50

51

52

57

59

60

61

62

6

58

3

63

64

66

65

76

77

24

75

73

74

67

3

68

69

70

71

72

83

152

3

6

5

148

149

58

151

24

6

88

87

58

86

85

84

145

146

147

9

9

90

89

6150

102 121

9291

121

144

143

100

142

141

140

139

138

137

136

100

121

135

134

133

132

131

130

126

96

122

127

125

124

99

98

100

84

101

103

123

102

121

9

100

6

120

111

105

104

106

110

107

119

9

118

112

108

113

95

117

24

38

24

116

115

114

109

9

100

93

94

95

382421

6

38

37

24

129

128

24

97

EXPLODED VIEW

Page 26

50

model no. 055-6755-8 | contact us 1-800-689-9928

51

PARTS LIST

EXPLODED VIEW

158

157

159

156

155

No.

Description

1

Mitre guage rod

2

Pointer

3

Flat washer 4

4

Mitre gauge

5

Spring washer 4

6

Big flat washer 6

7

Bolt M4x6

8

Knob for mitre gauge

9

Hex locking nut M6

10

Washer (C)

11

Uncork ring 9

153

6

38

58

154

12

Limited piece (B)

13

Compaction cover (B)

14

Support base for limited piece

15

Torsional spring

16

Bolt M3x8

17

Spring pin 4x30

18

Limited piece (right)

19

Connect shaft (B)

20

Circumgyrate wrench parts

21

Spring pin 4x12

22

Riving knife

23

Screw M6x58

24

Flat washer 6

25

Press block

26

Blade guard (left)

27

Support board cover

28

Guard support board

29

Bolt M4x10

30

Bolt M5x15

31

Guard support base

Qty

1

1

5

1

2

11

2

1

11

4

2

1

2

1

1

1

1

1

1

2

5

1

1

36

2

1

2

2

6

2

1

No.

Description

32

Gasket

33

Connection shaft

34

Blade guard (right)

35

Press board

36

Compression spring

37

Rubber washer

38

Pole

39

Rip fence

40

Screw M6x16

41

Spring washer 6

42

Pointer

43

Guide pipe fixed seat

44

Locking handle

45

Spring pin 4x20

46

Locking handle cover

47

Bolt ST3.9x19

48

Washer

49

Table insert

50

Bolt M8x30

51

Bolt M6x25

52

Scale label

53

Main working table

54

Push stick storage

55

Fix seat (B)

56

Fix seat (A)

57

Rotation axis compress board (B)

58

Rotation axis compress board (A)

59

Bolt M6x16

60

Hex nut M6

61

Reinforced side board

62

Cabinet

Qty

1

1

1

1

1

1

1

1

2

23

1

1

1

1

1

2

1

1

2

4

1

1

2

1

1

2

2

4

27

1

1

PARTS LIST

Page 27

52

model no. 055-6755-8 | contact us 1-800-689-9928

53

No.

Description

63

Main label

64

Hex locking nut

65

Angle pointer

66

Locking handle for angles

67

Bolt M4x8

68

Compression spring

69

Rotation wheel

70

Bolt M4x12

71

Locking cover

72

Rotation knob

73

Screw for handle

74

Switch

75

PARTS LIST

Bolt ST2.9x20

76

Switch board

77

Switch box

78

Screw M6x25

79

Rubber ring

80

Bolt ST3.5x19

81

Press wire block

82

Cord inlet

83

Plug cord

84

Angle pointer base

85

Square screw M6×85

86

Up-down adjustment screw

87

Bolt M4x10

88

Bushing (B)

89

Square screw M6x42

90

Up-down adjustment seat

91

Moving support assembly (A)

92

Square screw M6x16

93

Moving support (C)

Qty

1

1

1

1

1

1

1

1

1

1

1

1

4

1

1

4

2

2

1

1

1

1

2

1

1

1

1

1

1

1

1

No.

Description

94

Moving support (B)

95

Limited block

96

Screw M6x18

97

Bushing (A)

98

Motor connection seat

99

Down blade guard

100

Adjustment washer

101

Flat washer 5

102

Screw M6x12

103

Bolt M5x16

104

Blade guard support

105

Connection pole

106

Gear cover screw

107

Inner flange

108

Saw blade

109

Outer flange

110

Thin hex nut M16

111

Locking compression board

112

Locking plate

113

Riving knife compression board

114

Cam handle

115

Special screw

116

Riving knife support base assembly

117

Reset spring

118

Bolt M6x20

119

Compression cover

120

Rotation shaft

121

Reinforcement support

122

Bolt M5x10

123

Gear cover

124

Bearing 6003

Qty

1

1

4

1

1

1

1

11

1

3

1

1

3

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

2

1

1

No.

Description

125

Ring for shaft or hole 35

126

Output shaft

127

Half-round key 5x6.5x16

128

Gear

129

Ring for shaft 16

130

Self-lubricating bearing

131

Front cover

132

Inside track

133

Bearing 6201

134

Rotor assembly

135

Bolt ST5x60

136

Spring washer 5

137

Stator assembly

138

Bearing 6001

139

Absorbed ring

140

Motor body

141

Brush holding

142

Carbon brush

Qty

1

1

1

1

1

1

1

1

1

1

2

7

1

1

1

1

2

2

No.

Description

143

Nut

144

Bolt M5x8

145

Cover board

146

Bolt M5x35

147

Bolt M5x8

148

Press wire block

149

Bolt ST4.9x10

150

Motor cord

151

Thin hex nut M6

152

Square screw M6x12

153

Connection pole (A)

154

Spring pin 8x90

155

Leg

156

Support (D)

157

Support (C)

158

Rubber foot

159

Support (B)

160

Support (A)

Qty

2

2

1

4

2

1

2

1

1

17

1

1

4

2

2

4

2

2

PARTS LIST

Page 28

54

3-Year Limited Warranty

This Mastercraft product is guaranteed for a period of 3 years from the date of original retail purchase against

defects in workmanship and materials, except for the following component:

Component A: Accessories, which are guaranteed for a period of 1-year from the date of original retail

purchase against defects in workmanship and materials.

Subject to the conditions and limitations described below, this product, if returned to us with proof of purchase

within the stated warranty period and if covered under this warranty, will be repaired or replaced (with the

same model, or one of equal value or specification), at our option. We will bear the cost of any repair or

replacement and any costs of labour relating thereto.