Page 1

INSTRUCTION

MANUAL

BAND SAW WITH

EXTENSION TABLE

IMPORTANT:

Please read this manual carefully before running this band saw

and save it for reference.

model no. 055-6748-6

Page 2

3

TABLE OF CONTENTS

SAVE THESE INSTRUCTIONS

This manual contains important safety and operating instructions. Read all

instructions and follow them when using this product.

NOTE:

If any parts are missing or damaged, or if you have any questions, please call our

toll-free helpline at 1-800-689-9928

TABLE OF CONTENTS

Quick Start Guide

Specifications

Safety Guidelines

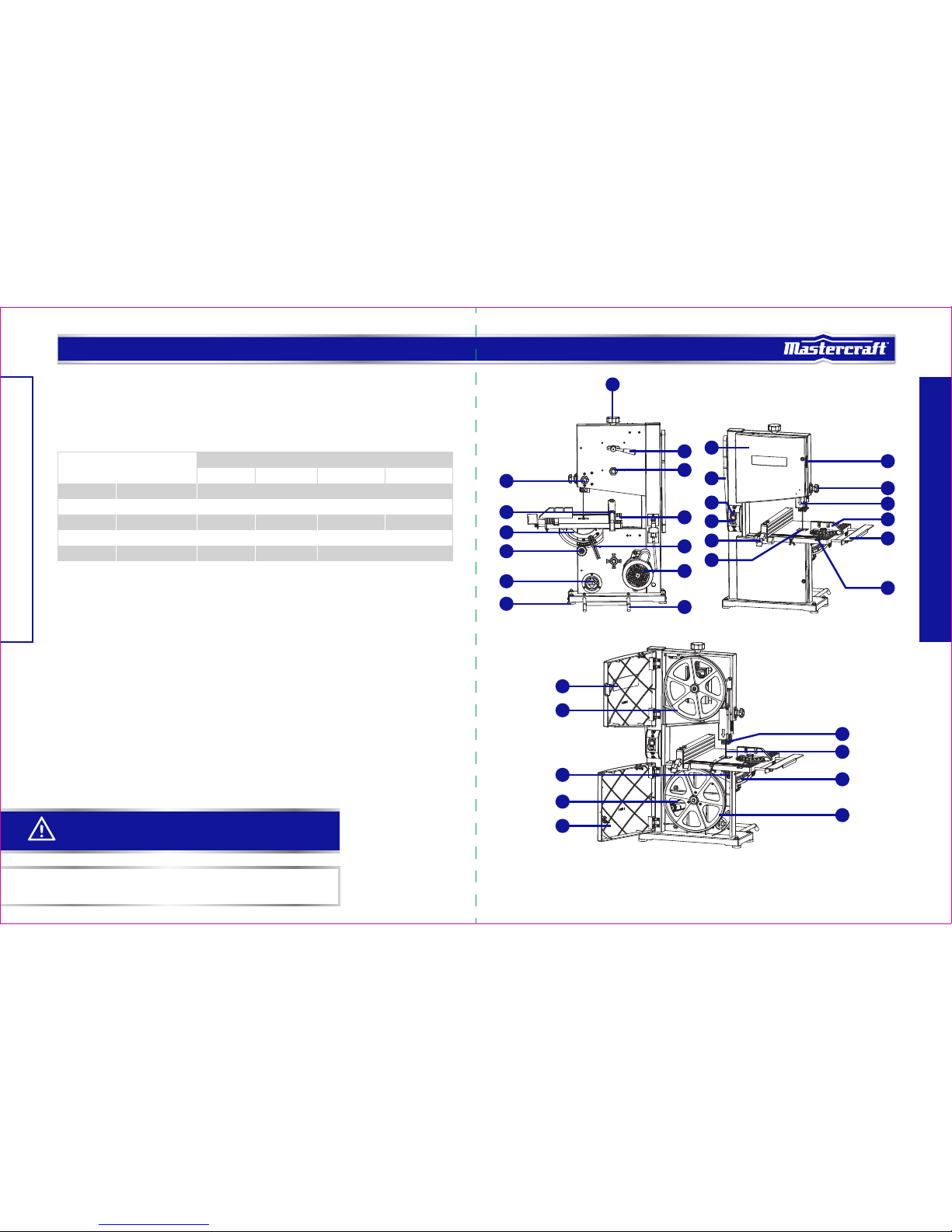

Know Your Band Saw

Assembly Instructions

Operating Instructions

Maintenance

Troubleshooting

Exploded View

Parts List

Warranty

4

5

6-10

11-15

16-26

27-29

30

31-33

34-35

36-38

39

Page 3

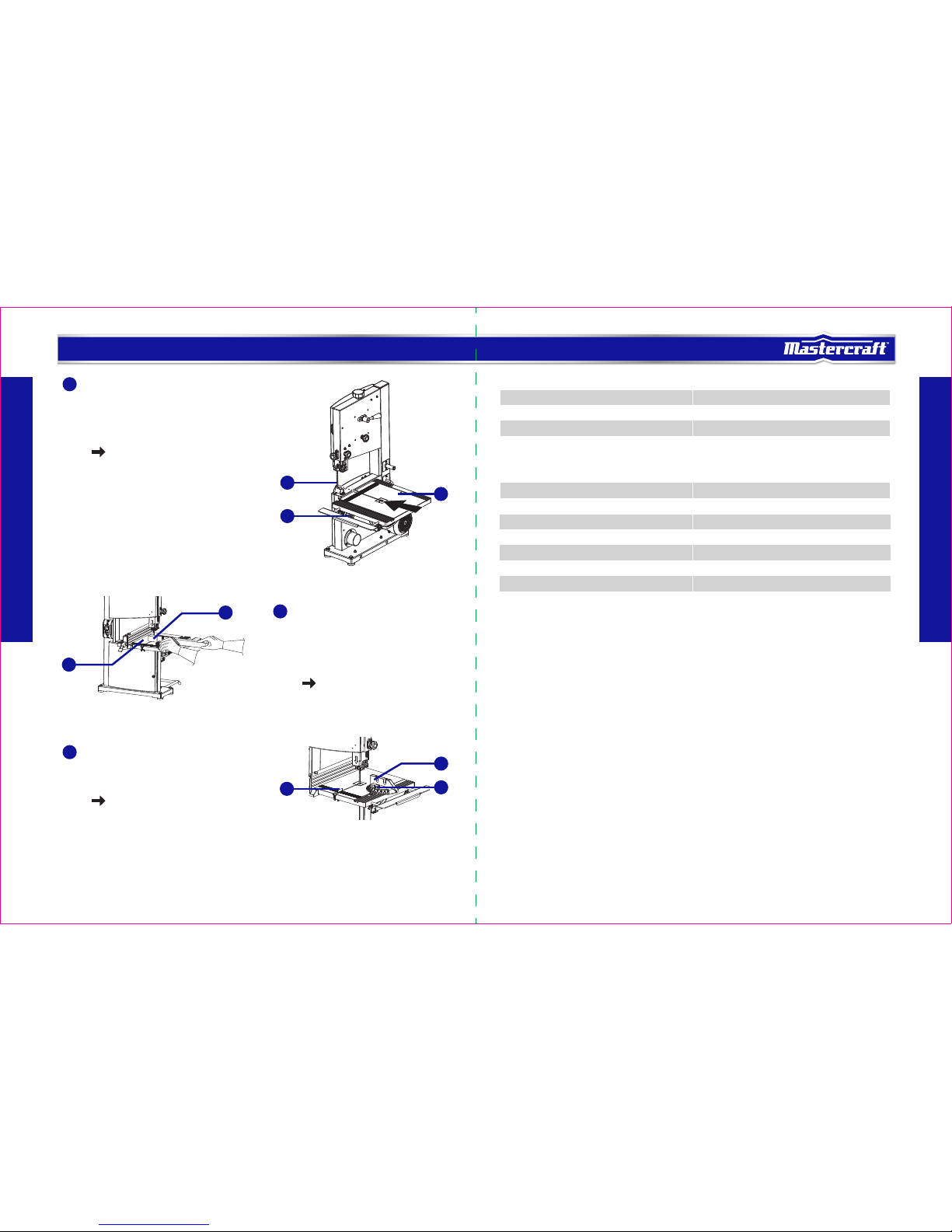

• Holding the work table with your left

hand while pulling the table, tilt

adjustment knob (6) away from the saw

frame, align the teeth on the table

support assembly (7) with the teeth on

the table tilt adjustment knob (6).

see page 21

1

• Use both hands to hold the workpiece (3)

flat against the work table (4) and to guide

along desired path.

• Turn the band saw On. Wait until the band

saw reaches maximum speed (refer

section “Specifications”).

see page 29

2

model no. 055-6748-6 | contact us 1-800-689-9928

SPECIFICATIONS

Motor

Motor speed

Blade length

width

teeth

thickness

Main table size

Extension table size

Table Tilting Range

Max. extension table range

Max. cutting depth

Max. cutting width

Weight

120 V, 60 Hz, 2.5A

2556 SFM (no load)

62" (157.5 cm)

1/4" (6.35 mm)

6 TPI

1/64" (0.3 mm)

11 3/4 x 11 3/4" (30 x 30 cm)

11 3/4 x 1 9/16" (30 x 4 cm)

0°-45°

2 5/32" (5.2 cm)

3 1/8" (8 cm)

9" (23 cm)

40 lb 13 oz (18.5 kg)

5

SPECIFICATIONS

4

QUICK START GUIDE

• Place the mitre gauge (1) on the mitre

gauge slot of the work table (2).

• Use the gauge knob (3) to set the desired

angle on the gauge scale.

see page 29

3

5

4

6

3

2

1

3

4

Page 4

WARNING!

To avoid mistakes that could cause serious injury, do not plug in the band

saw until you have read and understood the following rules.

DANGER!

Potential hazard that will result in serious injury or loss of life.

WARNING!

Potential hazard that could result in serious injury or loss of life.

CAUTION!

Potential hazard that may result in moderate injury or damage to equipment.

model no. 055-6748-6 | contact us 1-800-689-9928

7

SAFETY GUIDELINES

6

SAFETY GUIDELINES

SAFETY GUIDELINES

This manual contains information that relates to PROTECTING PERSONAL SAFETY and PREVENTING

EQUIPMENT PROBLEMS. It is very important to read this manual carefully and understand it thoroughly before

using the product. The symbols listed below are used to indicate this information.

Note: The word “Note” is used to inform the reader of something the operator needs to know about the tool.

SAFETY RECOMMENDATIONS

These precautions are intended for the personal safety of the operator and others working with the operator.

Failure to follow these instructions may result in a permanent loss of vision, serious personal or even fatal

injury, property damage and/or tool damage. Please take time to read and understand them.

Safety is a combination of common sense, staying alert, and knowing how your band saw works.

• READ and become familiar with this entire instruction manual. LEARN the tool’s applications, limitations,

and possible hazards.

• AVOID DANGEROUS CONDITIONS. DO NOT use power tools in wet or damp areas, and DO NOT expose

them to rain. Keep work areas well lit. Attach the dust extraction unit. If there are connections for dust

extraction and collection equipment, then make sure that the equipment is correctly attached and used.

• DO NOT use power tools in the presence of flammable liquids or gases.

• ALWAYS keep your work area clean, uncluttered and well lit. DO NOT work on floor surfaces that are

slippery with sawdust or wax.

• KEEP BYSTANDERS AT A SAFE DISTANCE FROM the work area, especially when tool is operating. NEVER

allow children or pets near the tool.

• DO NOT FORCE THE TOOL to do a job that it was not designed to do.

• DRESS FOR SAFETY. DO NOT wear loose clothing, gloves, neckties, or jewellery (rings, watches, etc.)

when operating the tool. Inappropriate clothing and items can get caught in moving parts and pull you in.

ALWAYS wear non-slip footwear, and tie back long hair.

• WEAR A FACE MASK OR DUST MASK. Sawing operations produce dust.

Dust generated from certain materials can be hazardous to your health. Always operate the band saw in

a well-ventilated area, and provide for proper dust removal. Wear a face mask or dust mask when

operating.

• ALWAYS remove the power cord plug from the electric outlet when making adjustments, changing parts,

cleaning or working on the tool.

• KEEP GUARDS IN PLACE AND IN WORKING ORDER.

• AVOID ACCIDENTAL START-UPS. Turn the power switch to the Off position before plugging in the power

cord.

• REMOVE ADJUSTMENT TOOLS. ALWAYS make sure all adjustment tools are removed from the band saw

before turning it on.

• NEVER LEAVE A RUNNING TOOL UNATTENDED. Turn the power switch to the OFF position. DO NOT leave

tool until it has come to a complete stop.

• NEVER STAND ON THE TOOL. Serious injury could result if the tool tips or is accidentally jarred. DO NOT

store anything above or near the tool.

• DO NOT OVERREACH. Keep proper footing and balance at all times. Wear oil-resistant, rubber-soled

footwear. Keep the floor clear of oil, scraps and other debris.

• MAINTAIN TOOLS PROPERLY. ALWAYS keep tools clean and in good working order. Follow instructions for

lubricating and changing accessories.

• CHECK FOR DAMAGED PARTS. Check for alignment of moving parts, jamming, binding, breakage,

improper mounting or any other conditions that may affect the operation. Any part that is damaged

should be properly repaired or replaced before use.

• MAKE THE WORKSHOP CHILDPROOF. Use padlocks and master switches, and ALWAYS remove starter

keys.

• DO NOT operate the tool if you are under the influence of any drugs, alcohol or medication that could

affect your ability to use the tool properly.

ADDITIONAL SAFETY GUIDELINES FOR BAND SAW

• TO AVOID INJURY FROM UNEXPECTED MOVEMENT, make sure the saw is on a firm, level surface and

that it is properly secured to prevent rocking. Make sure there is adequate space for operations. Bolt the

saw to a support surface to prevent slipping or sliding during operation.

• TURN OFF AND UNPLUG the saw before moving it.

• USE THE CORRECT SIZE AND STYLE OF BLADE.

• MAKE SURE THE BLADE TEETH POINT DOWN AND TOWARD THE TABLE.

• BLADE GUIDE, SUPPORTS, BEARINGS AND BLADE TENSION must be properly adjusted in order to avoid

accidental blade contact, and to minimize blade breakage. To maximize blade support, always adjust the

upper blade guide and blade guard so that it barely clears the workpiece.

• TABLE LOCK HANDLE SHOULD BE TIGHT.

• USE EXTRA CAUTION with very large, very small, or awkward workpieces.

Page 5

WARNING!

For your own safety, read the instruction manual before operating the band saw.

• Wear eye protection.

• Do not wear gloves, a necktie or loose clothing.

• Make sure the saw is on a firm, level surface and that it is properly secured.

• Use only the recommended accessories.

• Use extra caution with very large, very small or awkward workpieces.

• Keep your hands away from the blade at all times in order to prevent accidental injury.

WARNING!

• Use the proper extension cord. Make sure to use an extension cord that is heavy enough to carry

the current required by the tool. An undersized cord will cause a drop in line voltage, resulting in

loss of power and overheating of the tool.

• Use the extension cord only for intended purpose. Do not pull the extension cord to remove it

from the power socket.

CAUTION!

This band saw is intended for indoor use only. Do not expose it to rain or use in damp locations.

model no. 055-6748-6 | contact us 1-800-689-9928

9

SAFETY GUIDELINES

8

SAFETY GUIDELINES

• USE EXTRA SUPPORTS to prevent workpieces from sliding off the tabletop. Never use another person in

place of a table extension, or to provide additional support for the workpiece.

• WORKPIECES SHOULD BE SECURED so that they do not twist, rock, or slip while being cut.

• PLAN INTRICATE OR SMALL WORK CAREFULLY in order to avoid pinching the blade. Avoid awkward

operations and hand positions in order to prevent accidental contact with the blade.

• SMALL PIECES SHOULD BE SECURED with clamps or fixtures. Do not hold small pieces with your hand,

because your fingers might go under the blade guard.

• SUPPORT ROUND WORK PROPERLY (use a V block or press it against the mitre gauge) to prevent it from

rolling and the blade from biting.

• CUT ONLY ONE WORKPIECE AT A TIME. Make sure the table is clear of everything except the workpiece

and its guides before you turn the saw on.

• ALWAYS WATCH THE SAW RUN BEFORE EACH USE. If there is excessive vibration or unusual noise, stop

immediately. Turn the saw off and unplug it immediately. Do not start the saw again until the problem

has been located and corrected.

• TO FREE JAMMED MATERIAL, turn the switch off. Remove the switch key and unplug the saw. Wait for

all moving parts to stop before removing the jammed material.

• DON’T LEAVE THE WORK AREA UNTIL ALL MOVING PARTS HAVE STOPPED. Shut off the power to master

switches. Remove the switch key from the band saw and store it in a safe place, away from children.

Childproof the workshop!

USE SAFETY GOGGLES AND EAR PROTECTION:

ALWAYS WEAR EYE PROTECTION THAT CONFORMS WITH CUL REQUIREMENTS. FLYING

DEBRIS can cause permanent eye damage.

The tool is loud and the sound can cause hearing damage. Always wear ear protection to help

prevent hearing damage and loss. Failure to comply may result in moderate injury.

USE DUST MASK:

Some dust created by sawing contains chemicals that are known to cause cancer, birth defects

or other reproductive harm. Some examples of these chemicals come from lead-based paints,

crystalline silica from bricks, cement and other masonry products, arsenic and chromium from

chemically treated lumber. To reduce exposure to these chemicals, work in a well-ventilated

area with approved safety equipment, such as dust masks that are specially designed to filter out microscopic

particles.

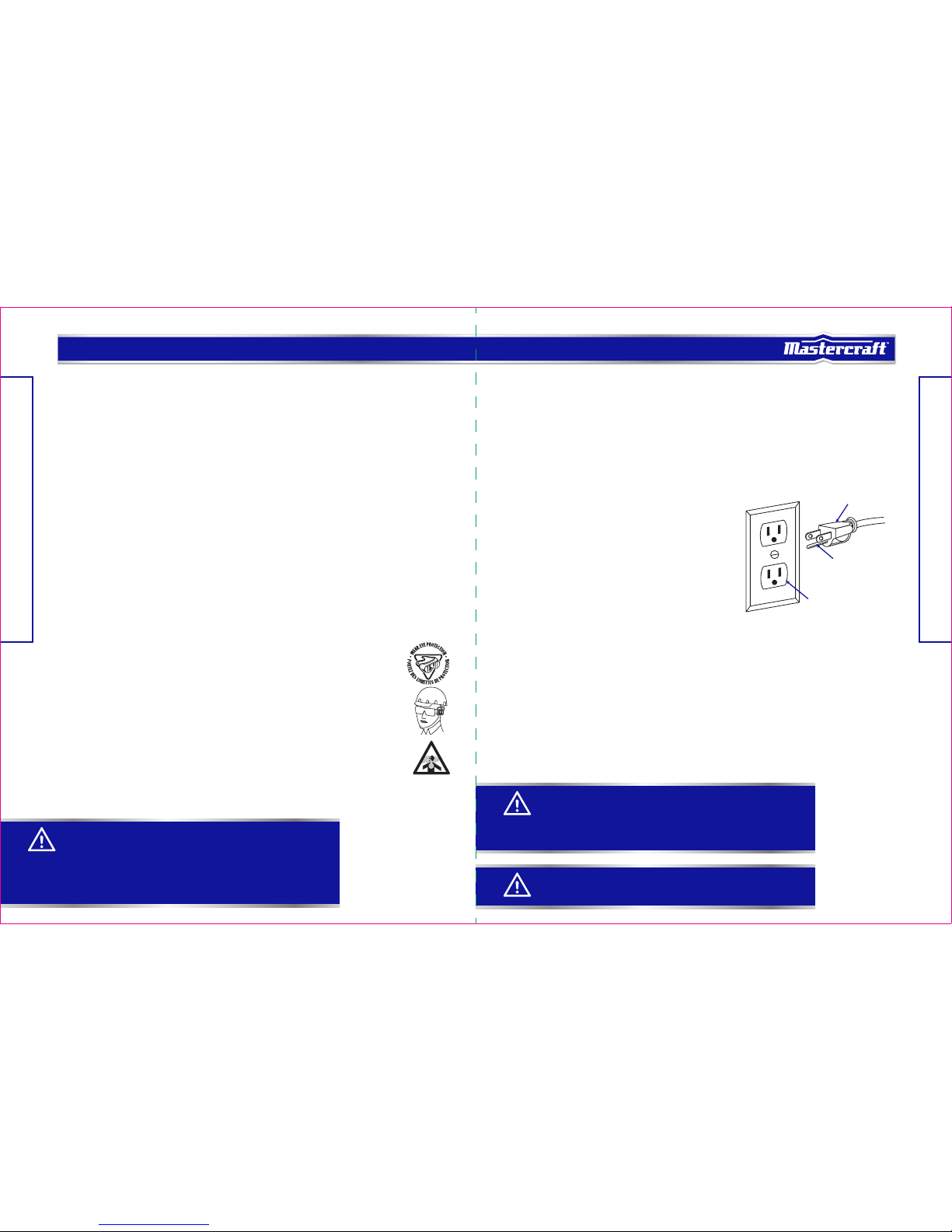

ELECTRICAL SAFETY

GUIDELINES FOR USING EXTENSION CORDS:

In the event of a malfunction or breakdown, grounding provides a path of least resistance for electric current

to reduce the risk of electric shock. This tool is equipped with an electric cord having an equipment-grounding

conductor and a grounding plug. The plug must be plugged into a matching outlet that is properly installed

and grounded in accordance with all local codes and ordinances.

Do not modify the plug provided. If it will not fit the outlet, have the proper outlet installed by a qualified

electrician.

Improper connection of the equipment-grounding conductor

can result in a risk of electric shock. The conductor with

a green outer surface, with or without yellow stripes, is the

equipment-grounding conductor. If repair or replacement

of the electric cord or plug is necessary, do not connect the

equipment-grounding conductor to a live terminal.

Check with a qualified electrician or service technician if

the grounding instructions are not completely understood,

or if in doubt as to whether the tool is properly grounded.

Use only three-wire extension cords that have three-prong

grounding plugs and three-pole receptacles that accept the

tool's plug, as shown in Fig. 1. Repair or replace a damaged or worn cord immediately.

GROUNDING INSTRUCTIONS:

• Make sure the extension cord is in good condition. When using an extension cord, be sure to use one

that is heavy enough to carry the current that your product will draw. An undersized cord will cause a

drop in line voltage, which will result in loss of power and overheating. The table on the next page shows

the correct size to be used according to cord length and nameplate ampere rating. When in doubt, use

the next heavier gauge. The smaller the gauge number, the heavier the cord.

• Make sure your extension cord is properly wired and in good condition. Always replace a damaged

extension cord, or have it repaired by a qualified person before using it. Protect your extension cords from

sharp objects, excessive heat, and damp or wet areas.

Fig. 1

Three-prong plug

Grounding prong

Properly grounded outlet

Page 6

NOTE:

Recycle unwanted materials rather than disposing of them as waste. Sort the tool and its components in

specific categories and take to the local recycling centre or dispose of them in an environmentally safe way.

AMPERAGE RATING OF THE TOOL

(120 V CIRCUIT ONLY)

MORE THAN

0

6

10

12

NOT MORE THAN

6

10

12

16

25’ (7.6 m)

18

18

16

14

50’ (15.2 m)

16

16

16

12

100’ (30.5 m)

16

14

14

Not recommended

150’ (45.7 m)

14

12

12

TOTAL LENGTH OF THE EXTENSION CORD

MINIMUM GAUGE FOR THE EXTENSION CORD (AWG)

WARNING!

This tool must be grounded while in use in order to protect the operator from electric shock.

model no. 055-6748-6 | contact us 1-800-689-9928

11

KNOW YOUR BAND SAW

10

SAFETY GUIDELINES

Recommended size for extension cords

• Use a separate electrical circuit for your tools. This circuit must consist of not less than #12 wire with a

20 A time-delayed fuse or a #14 wire with a 15 A time-delayed fuse. Before connecting the motor to the

power line, make sure the switch is in the Off position and the electric current is rated the same as the

current stamped on the motor nameplate. Running at a lower voltage will damage the motor.

2

14

17

18

27

28

29

30

31

32

33

34

26

19

15

16

3

13

12

11

9

8

10

4

5

6

20

21

23

22

24

25

7

1

Page 7

model no. 055-6748-6 | contact us 1-800-689-9928

13

KNOW YOUR BAND SAW

12

KNOW YOUR BAND SAW

Table tilt locking knob:

Loosening the table tilt locking knob allows the work table to be tilted at different angles. Tightening the table

tilt locking knob locks the work table in place.

Tracking knob:

Adjusts tracking knob to keep blade centred on the wheels.

Tracking window:

The tracking window makes tracking adjustments easier to see.

Blade tension knob:

Controls blade tension when changing blades and making adjustments for various sawing applications.

Mitre gauge:

This mitre gauge aligns the wood for a crosscut. The easy-to-read indicator shows the exact angle for a mitre

cut at 90° and 45°.

Dust collection system:

The system is connected with a dust extraction port at the motor side of the band saw. If the band saw is

operated without this system, some of the dust will be blown out.

Blade guides:

Upper and lower blade guides help keep the blade from twisting during operation.

Blade guard:

The guard is attached to the upper blade guide. It protects the operator from coming in contact with the blade.

Table tilt adjustment knob:

The adjustment knob is located under the work table, to adjust the work table to a desired angle.

Table tilt locking knob:

The locking wheel is located under the work table, to lock the work table at a desired angle.

Push stick:

Always use the push stick to feed the workpiece until it is clear of the table.

Fence locking lever:

The lever is located on the front of the rip fence to release or lock the rip fence with respect to the work table.

Blade tension lever:

This lever is located at the back of the tool to apply tension on the blade.

Blade cleaning brush:

The brush is used to remove foreign particles from the drive wheel by contacting the blade.

Blade:

The blade furnished with the band saw is a carbide-tipped combination blade, 62" (157.5 cm) long and 1/4"

(6.35 mm) wide, used for producing a good quality cut for many applications.

Blade pitch:

The blade pitch is the number of teeth per inch or tooth size. A blade with more teeth per inch produces a

smoother cut. The type of material to be cut determines the number of teeth that should be in contact with

the workpiece. When cutting soft materials, use a proper blade having six to eight teeth per inch. When

cutting hard materials, where vibration is more detrimental, use a blade with eight to twelve teeth per inch.

The blade vibration occurs when the pitch is too large. This vibration can strip the teeth from blade.

Blade thickness:

The blade thickness is the distance between sides of blade. A thicker blade has more rigidity and stronger

teeth. A narrow thick blade is used to make curves and a wide thin blade is used to make long, straight cuts.

Table insert:

The table insert is located on the table slot to support the workpiece with respect to the blade. It prevents the

movement of the workpiece from the work table.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

No.

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

Description

Extension table

Mitre gauge groove

Table insert

Fence locking lever

Safety key

On/Off switch assembly

Push stick

Cabinet

Upper blade guide

Blade

Table support assembly

Lower drive wheel

Lower door

Drive belt

Lower blade guide

Upper idler wheel

Upper door

Description

Blade tension knob

Blade tension lever

Tracking knob

Work table

Table tilt locking knob

Motor assembly

Additional support

Rubber feet

Dust extraction port

Table tilt adjustment knob

Table tilt gauge

Rip fence

Blade tracking knob

Tracking window

Upper guide knob

Blade guard

Mitre gauge

Page 8

WARNING!

Do not keep your hands near the saw blade. There is a chance of your hands suddenly slipping

from the workpiece and coming into contact with the blade.

WARNING!

• Use only blades at maximum safe operating speeds of 2556 SFM. Failure to heed this warning

could result in personal injury.

• The blades should always be kept sharp. Use a reputable sharpening service to sharpen the

blades when needed.

• Never store the blades stacked on top of one another. Place material such as cardboard

between them to keep the blades from coming into contact with one another.

model no. 055-6748-6 | contact us 1-800-689-9928

15

KNOW YOUR BAND SAW

14

KNOW YOUR BAND SAW

Drive belt:

The drive belt is fitted onto the lower drive wheel. The belt must be properly tensioned to enable smooth

operation of the drive wheel.

Lower drive wheel:

The lower drive wheel drives the blade in an endless loop.

Rubber feet:

The rubber feet are provided on four corners of the table base.

Table tilt gauge:

The tilt gauge is provided below the work table. The gauge has a scale that enables the operator to set the

work table at required angle between 0 to 45°.

Upper idler wheel:

The upper idler wheel can be adjusted to apply tension on the blade.

Upper and lower doors:

The upper and lower doors cover the upper idler wheel and lower drive wheel, respectively.

On/Off switch assembly:

The switch assembly located on the front of the cabinet allows the operator to easily turn On/Off the band

saw. To lock the switch in the Off position, remove the switch key from the switch. Place the key in a

location that is not accessible to children and others who are not qualified to use the tool.

Work table:

The surface where the workpiece rests while performing the cutting operation.

Table support assembly:

The support assembly attaches the work table with respect to the band saw.

Causes of kickback:

Kickback can be caused by any action that pinches the blade in the wood, such as the following:

• Incorrect blade depth

• Sawing into knots or nails in the workpiece

• Twisting the wood while making a cut

• Failing to support the workpiece

• Forcing the blade to cut the workpiece

• Cutting warped or wet lumber

• Not using the appropriate type of blade

• Not following correct operating procedures

• Misusing the band saw

• Cutting with a dull, gummed-up or improperly set blade

Avoiding kickback:

• Inspect the workpiece for knots or nails. Knock out any loose knots or remove any nails in the workpiece

with a hammer before cutting the workpiece. Never perform cutting operation into a loose knot or nail of

the workpiece.

• Always use the rip fence when rip cutting and the mitre gauge when crosscutting to prevent twisting of the

wood during cutting operation.

• Always use clean, sharp, and properly set blades. Never make cuts with dull blades.

• Support the workpiece properly before starting the cutting operation to avoid blade pinching.

• When cutting the workpiece, apply constant and uniform pressure to the workpiece. Never force the

workpiece while cutting.

• Do not cut wet or warped lumber.

• Use the correct type of blade according to the cut being made.

• Always hold the workpiece firmly with both hands or with push sticks. Keep your body in a balanced

position in order to resist kickback. Never stand directly in line with the blade.

Page 9

NO. Description Qty. Illustration

M6 Flat washers

M5 Flat washers

M5 Hex nuts

M6x30 Hex bolts

M5x20 Hex bolts

3, 4, 5 mm hex keys

M6 Cap nuts

Table tilt locking knob

9

10

11

12

13

14

15

16

4

2

2

4

2

3

4

1

PACKAGE CONTENTS

No. Description Qty Illustration

Band saw assembly

Mitre gauge

Rip fence

Additional support

Work table assembly

Push stick

Rubber feet

M8 Flat washer

1

2

3

4

5

6

7

8

1

1

1

1

1

1

4

1

model no. 055-6748-6 | contact us 1-800-689-9928

17

ASSEMBLY INSTRUCTIONS

16

ASSEMBLY INSTRUCTIONS

Page 10

NOTE:

All bolts should be inserted from the top. Install the lock washers and hex nuts from the underside of

the bench.

TOOLS NEEDED FOR ASSEMBLY

Star-head screwdriver Framing square

Wrench

WARNING!

If any parts are damaged or missing, do not operate this tool until the parts are replaced. Use of

this product with damaged or missing parts could result in serious personal injury.

• Do not attempt to modify this tool or create accessories not recommended for use with this tool.

Any such alteration or modification is misuse and could result in a hazardous condition leading

to possible serious personal injury.

• Do not connect to power supply until assembly is complete. Failure to comply could result in

accidental starting and possible serious personal injury.

• Risk of injury! Always pull out the mains plug (disconnect the product from its power supply)

before commencing work on the product.

• Never stand directly in line with the blade or allow hands to come within 3" (7.6 cm) of the

blade. Failure to heed this warning could result in serious injury.

• To avoid serious injury, always make sure the tool is securely mounted on the work table. Never

operate the tool on the floor.

UNPACKING

Do not use this product if any parts of the package contents are already assembled to your product when you

unpack it. Package contents are not assembled to the product by the manufacturer and require customer

installation. Use of a product that may have been improperly assembled could result in serious personal injury.

• Carefully lift the tool from the carton and place it on a level work surface.

• Inspect the tool carefully to make sure no breakage or damage occurred during shipping.

• Do not discard the packing material until you have carefully inspected and satisfactorily operated the tool.

• If any parts are damaged or missing, please call 1-800-689-9928 for assistance.

model no. 055-6748-6 | contact us 1-800-689-9928

19

ASSEMBLY INSTRUCTIONS

18

ASSEMBLY INSTRUCTIONS

MOUNTING RUBBER FEET ON THE BASE (Fig. 2)

• Insert the four rubber feet (1) into holes provided in

the four corners of saw base.

• Insert M6 hex bolts (2) into the holes and tighten them

with M6 flat washers (3) and M6 cap nuts (4).

MOUNTING BAND SAW TO WORKBENCH

If the band saw is to be used in a permanent location, the band saw must be mounted to a firm supporting

surface such as a workbench. Four bolt holes have been provided in the saw’s base for this purpose. Bolts

(not included) should be of sufficient length to accommodate the saw base, lock washers (not included), hex

nuts (not included), and the thickness of the workbench. Tighten all four bolts securely.

Carefully check the workbench after mounting to make sure that no movement can occur during use. If any

tipping, sliding, or walking is noted, secure the workbench to the floor before operating.

• Place band saw on the workbench. Using the saw base as a pattern, locate and mark the holes where the

band saw is to be mounted.

• Drill holes through the workbench.

• Place band saw on the workbench, aligning holes in the saw base with the holes drilled in the workbench.

• Insert bolts (not included) and tighten securely with lock washers and hex nuts (not included).

1

3

4

2

Fig. 2

CLAMPING BAND SAW TO WORKBENCH (Fig. 3)

If the band saw is to be used as a portable tool, it is recommended that you fasten it permanently to a

mounting board that can easily be clamped to a workbench or other supporting surface. The mounting board

should be of sufficient size to avoid tipping of the saw while in use. Any good grade plywood or chipboard

with a thickness of 3/4" (19 mm) is recommended.

Page 11

NOTE:

It may be necessary to countersink hex nuts and washers on bottom side of mounting board.

model no. 055-6748-6 | contact us 1-800-689-9928

21

ASSEMBLY INSTRUCTIONS

20

ASSEMBLY INSTRUCTIONS

If lag bolts are used, make sure they are long enough to go

through holes in the saw base and material the saw is being

mounted to. If machine bolts are being used, make sure

bolts are long enough to go through holes in the saw base,

the material being mounted to, and the lock washers and

hex nuts.

• Mount saw to board using holes in saw base as a

template for hole pattern. Locate and mark the holes

where the band saw is to be mounted.

• Follow the last three steps in the section MOUNTING

BAND SAW TO WORKBENCH.

ASSEMBLING THE WORK TABLE (Fig. 5-7)

• Remove the D-nut (1), flat washer (2) and wing screw

(3) from the hole located in the front edge of the work

table (4). (Fig. 4)

• Standing at the front of the band saw, slide the work

table (4) past the blade (5) and through the slot moving

from the right side of the work table to the left.

• Holding the work table with your left hand while pulling

the table tilt adjustment knob (6) away from the saw

frame, align the teeth on the table support assembly (7)

with the teeth on the table tilt adjustment knob (6).

Release the knob.

• Fit the pins on the frame into the slots of the table

support assembly (7)

• Insert the washer (8) on the threaded end of the table tilt

locking lever (9). Tighten the work table to the saw

frame by turning the table tilt locking lever (9)

clockwise.

• Attach the D-nut, flat washer and wing screw to the

work table.

Make sure that the wing screw goes below the saw table.

MOUNTING ADDITIONAL SUPPORT ON THE BASE (Fig. 4)

• Place the additional support (1) on the rear side of the

base.

• Align the two holes in the additional support with the

corresponding holes on the rear side of the saw base.

• Secure the additional support with two hexagon bolts

(2), two flat washers (3) and two nuts (4).

Fig. 3

Fig. 4

1

2

4

3

2

3

1

4

5

4

7

6

6

9

8

Fig. 5

Fig. 6

Fig. 7

6

8

9

Page 12

WARNING!

Never use miter gauge and rip fence at the same time. If you do, the blade may bind into the

workpiece, thereby resulting in the serious injury of the operator and/or damage to the workpiece.

NOTE:

Always make a test cut to insure the squareness of the blade prior to beginning any new project. If not

square, it may be necessary to loosen the screws under the work table to make the adjustment (mitre slot

must be parallel to the saw blade). Once square, retighten screws.

model no. 055-6748-6 | contact us 1-800-689-9928

23

ASSEMBLY INSTRUCTIONS

22

ASSEMBLY INSTRUCTIONS

SQUARING THE SAW TABLE TO THE BLADE (Fig. 8-9)

• Turn the blade tracking knob (1) counter-clockwise to

unlock the blade guide assembly (2). Turning the upper

guide knob (3) clockwise, raise the blade guide assembly

(2) as far as it will go. Turn the blade tracking knob

clockwise to retighten.

• Place a small combination square (4) on the saw table

beside the blade (5).

• Loosen the table tilt locking knob (6) and rotate the table

tilt adjustment knob (7) to tilt the work table up or down

to align table 90° to blade (0° position). Retighten the

table tilt locking knob (6).

• Using an adjustable wrench, loosen the locking nut (8).

• Turn the adjusting bolt (9) until the bolt just touches the

saw housing.

• Check squareness of the work table to the blade. Make

readjustments if necessary.

• Once squareness is confirmed, retighten the locking nut.

• Set scale indicator (10) to zero and tighten screw with

a star-head screwdriver.

WORK TABLE TILT ADJUSTMENT (Fig. 10)

Before adjusting the band saw, turn Off the band saw,

remove the safety key, and unplug the power cord from the

electrical outlet.

The work table can be tilted from 0° - 45° to the right side.

• Turn the table tilt locking knob (1) counter-clockwise.

• Rotate the table tilt adjustment knob (2) until the pointer

is at the desired angle on the table tilt gauge (3). Now the

work table is tilted to the desired angle.

• Tighten the table tilt locking knob in order to secure the

work table in position.

SETTING THE RIP FENCE ON THE WORK TABLE (Fig. 11)

• Raise the fence locking lever (1) on the rip fence (2).

• Place the rip fence on the work table (3) so that the

fence locking lever is at the front of the work table.

• Lower the fence locking lever in order to lock the rip

fence in position on the work table.

• To move the rip fence, raise the fence locking lever and

slide the fence to the desired location. Lower the fence

locking lever to lock the fence in position.

CONNECTING DUST EXTRACTION PORT TO DUST COLLECTION SYSTEM (Fig. 12)

Connect the dust extraction port (1) located on the motor

side of the band saw to the dust collection system by

connecting the inlet of the dust collection hose to the dust

extraction port.

Fig. 8

Fig. 9

Fig. 10

Fig. 11

Fig. 12

4

35

40

45

30

25

20

15

10

0

5

3

2

1

1

1

2

3

8

9

10

7

6

5

3

1

2

3

Page 13

NOTE:

Proper tracking is achieved only when upper idler wheel and lower drive wheel are aligned.

WARNING!

Always ensure correct tracking of the blade, as an improperly tracked blade may spring out from

the blade wheels, thereby causing serious injury. Do not perform the tracking adjustment while

band saw is operating.

model no. 055-6748-6 | contact us 1-800-689-9928

25

ASSEMBLY INSTRUCTIONS

24

ASSEMBLY INSTRUCTIONS

REMOVING AND INSTALLING THE BLADE (Fig. 13-15)

• Loosen and remove the D-nut, flat washer and wing

screw from the work table (1).

• Open the upper and lower door (2) by unscrewing the

cover locking screw (3).

• Turn the blade tracking knob (4) counter-clockwise to

unlock the blade guide assembly (5). Turning the upper

guide knob (6) (clockwise raises the blade guide

assembly (5); counter-closewise lowers it), position the

blade guide assembly (5) about halfway between the

work table and saw housing. Retighten the blade

tracking knob (4).

• Open the blade guard by pulling the left side of the

guard out and away from the idler wheel.

• Release all blade tension from the blade.

• Carefully remove the old blade (7).

• Wearing gloves, carefully uncoil the new blade at arms,

length. If the new blade was oiled to prevent rusting, it

may need to be wiped to keep the oil from your

workpiece. Carefully wipe in the same direction the

teeth are pointing so the rag does not catch on the teeth

of the saw blade.

The blade may need to be turned inside out if the teeth are

pointing In the wrong direction. Hold the blade with both

hands and rotate it inward.

• With the teeth of the blade toward the left of the saw

and facing downward, place the blade through the

lower blade guides (8) and around both idler wheels.

• Slowly turn the upper idler wheel (9) to the right or

clockwise by hand to centre the blade on the rubber

tires.

• Re-engagee the blade tension lever (10) then adjust the

blade tension; check or adjust the blade tracking.

• Adjust both upper and lower blade guides as explained

later in this manual.

• Re-attach the D-nut, flat washer and wing screw.

Tighten securely.

• Close the blade guard and upper and lower door.

Tighten the cover locking screw.

TRACKING THE BLADE (Fig. 16-17)

• Disconnect the band saw from power source.

• To check the position of the blade, rotate the lower

drive wheel (1) by hand in clockwise direction. View the

blade through tracking window.

• Loosen the blade tracking knob (2). If the blade rides

away from the cabinet, turn the tracking knob

clockwise. If the blade rides toward the cabinet, turn

the tracking knob counter-clockwise.

• Tighten the blade tracking knob to secure the blade in

the proper position.

Fig. 14

Fig. 15

Fig. 13

Fig. 16

Fig. 17

4

5

7

8

9

6

10

6

2

1

3

3

1

2

Page 14

WARNING!

• Always remove the switch key when the tool is not in use, and keep it in a safe place. In the

event of a power failure, turn Off the switch and remove the key, as doing so may prevent the

tool from accidentally starting when the power returns.

• Make sure the workpiece does not come into contact with the blade before operating the

switch. Failure to heed this warning may cause the workpiece to be kicked back toward the

operator, and could result in serious injury.

WARNING!

• Always handle the band saw with care. Failure to comply could cause serious injury.

• Always wear safety goggles or safety glasses with side shields when operating the tool, as

doing so may prevent flying particles from getting into eyes.

• Do not use any attachments or accessories that are not recommended by the manufacturer

of this tool. Failure to comply could result in serious injury.

• Do not operate the band saw without having the blade guard attached.

• Mount the band saw on a firm, supporting and waist-high surface. Failure to comply could result

in serious injury.

• Before using the band saw, check whether the power outlet is properly installed and grounded in

compliance with all local codes and ordinances. Improper connection could result in electric

shock.

• Do not alter three-pronged plug of the table saw. If the plug does not fit into the power outlet,

allow a qualified electrician to install the power outlet.

TRACKING THE BLADE (Fig. 18-19)

• Loosen the screws (1) to adjust guide pins (2) provided

on the blade sides.

• Use a feeler gauge to check that the guide pins are

0.002" away from the blade. Now tighten the screws

to lock the guide pins in the proper position.

• Adjust the ball bearing (3) at rear of blade by loosening

socket head bolt and repositioning the blade shaft.

• Use a feeler gauge to check that the ball bearing is

0.002" away from the back of blade. Secure the ball

bearing in position by tightening the socket head bolt.

• Loosen upper guide knob (4) to adjust the height of

upper blade guide (5) so that the blade guide is set at

a distance of 1/4" (6.35 mm) from the workpiece (6).

Tighten the upper guide knob after adjustment.

ADJUSTING THE LOWER BLADE GUIDE (Fig. 20)

• Loosen the screws (1) to move guide pins (2) away from

the blade sides.

• Loosen socket head bolts (3) and adjust the bearing (4)

so that the rear part of blade is positioned 0.002" away

from the bearing.

• Tighten the socket head bolts.

• Adjust the guide pins to the blade sides. Inserting a

playing card between guide and blade to check that

guide pins are 0.002" away from blade.

• Tighten the screws to lock the guide pins in proper

position.

ON/OFF SWITCH ASSEMBLY (Fig. 21)

• Insert switch key (1) into switch (2), and move the

switch to the On position to turn On the band saw.

• Move the switch (2) to the Off position to turn Off the

band saw.

• To lock the band saw, move the switch to the Off

position. Then remove the switch key (1) from the

switch and store the switch key in a safe and secure

location.

model no. 055-6748-6 | contact us 1-800-689-9928

27

OPERATING INSTRUCTIONS

26

ASSEMBLY INSTRUCTIONS

Fig. 18

Fig. 19

Fig. 20

Fig. 21

1

1/4"

1 1

2 2

4

5

6

3

1

4

1

2 2

3

SUR

DEHORS

(OFF)

(ON)

ON

REMOVE

TO LOCK

2

Page 15

NOTE:

The beveled cuts can be made freehand, or use the rip fence to guide and support the workpiece.

WARNING!

Use care when making this bevel cut freehand. The workpiece may slip from the work

table, thereby causing pressure on the blade, making it hard to follow the pattern line on the

workpiece and resulting in damage to the tool.

CAUTION!

• Never use mitre gauge and rip fence simultaneously, as the blade may bind into the workpiece

and could result in damage of the workpiece.

• Hold the workpiece firmly against the mitre gauge and feed the workpiece slowly into the blade

to restrict the movement of workpiece.

USING THE EXTENSION TABLE (Fig. 22)

When cutting a wider workpiece, you can use the extension.

The maximum extension table range is 2 5/32" (55 mm).

• Loosen the two wing screws (1) located underneath the

extension table (2).

• Pull the extension table to desired length.

• Tighten two wing screws (1).

CUTTING OPERATIONS

BEVEL CUTTING (Fig. 23-24)

• Unlock the work table (1) by loosening the table tilt

locking knob (2).

• Tilt the work table to desired position by rotating the

table tilt adjustment knob (3).

• Lock the work table in position by tightening the table

tilt locking knob.

• Adjust the upper blade guide (4) using the upper guide

knob (5) so that the upper blade guide is positioned at a

distance of 1/4" (6.35 mm) from the workpiece (6).

• Insert the switch key and turn On the band saw by

moving the switch to the On position. Wait until the

band saw reaches maximum speed. (Refer the

“Specifications” section.)

• Hold the workpiece firmly on the work table and against

the rip fence.

• Slowly feed the workpiece through the blade to make

beveled cuts on the workpiece.

CONTOUR CUTTING (Fig. 25-26)

• Adjust the upper blade guide (1) using the upper guide

knob (2) so that the upper blade guide is positioned at

a distance of 1/4" (6.35 mm) from the workpiece (3).

• Stand in front of the band saw and keep hands over

the work table exactly to the right of blade.

• Use both hands to hold the workpiece (3) flat against

the work table (4) and to guide it along the desired path.

• Turn the band saw on. Wait until the band saw

reaches maximum speed. (refer to the section

“Specifications” section.)

• Slowly feed the workpiece through the blade to cut

small corners of the workpiece. Continue the operation

until scrap is removed from the workpiece and desired

shape is obtained.

MITRING (Fig. 27-28)

This operation is performed by setting the mitre gauge to

an angle other than 0°.

• Place the mitre gauge (1) on the mitre gauge slot of

the work table (2).

• Use the gauge knob (3) to set the desired angle on the

gauge scale.

• Hold the workpiece (4) firmly against the mitre gauge

(1), and slowly feed the workpiece into the blade (5) .

model no. 055-6748-6 | contact us 1-800-689-9928

29

OPERATING INSTRUCTIONS

28

OPERATING INSTRUCTIONS

Fig. 25

Fig. 26

Fig. 27

Fig. 28

1/4"

1/4"

Fig. 23

Fig. 22

Fig. 24

5

4

6

1

3

2

1

1

2

1

3

2

2

1

3

5

2

4

1

4

3

Page 16

PROBLEM Possible Causes Solution

Excessive vibration. • Blade is out of balance.

• Blade is damaged.

• Saw accessories are not securely

mounted.

• The workpiece is not placed or

used on a flat surface.

• Blade is warped.

• Replace the blade.

• Replace the blade.

• Securely tighten all saw

accessories.

• Reposition the workpiece on a flat

surface.

• Replace the blade.

Rip fence does not move

smoothly.

• Rip fence is not mounted correctly. • Remount the rip fence in a correct

and stable position.

Excessive damage of

blade.

• Material is not secured on the work

table.

• Blade is too coarse.

• Teeth are in contact with the

workpiece before sawing.

• Blade guides are misaligned.

• Blade is thicker than the wheel

diameter.

• Crack occurs at weld.

• Place the workpiece firmly on the

work table.

• Use finer pitch blade.

• Allow the blade to contact the

workpiece only after the band saw

is started.

• Adjust the blade guides properly.

• Use thinner blade.

• Replace the blade.

Blade is dull. • Blade is too coarse.

• Inadequate workpiece feed

pressure.

• Hard spots or irregular layers

found on the workpiece.

• Blade is installed backwards.

• Use finer tooth blade.

• Gently increase the feed pressure.

• Increase rate of feed to remove the

layers and change the blades to

remove hard spots.

• Remove the blade, twist the blade

teeth inside and reinstall the blade.

Rough cuts. • Workpiece feeding rate is high.

• Blade is too coarse.

• Reduce the workpiece feeding rate.

• Use finer-tooth blade.

TROUBLESHOOTING

WARNING!

• Do not allow brake fluid, gasoline, petroleum-based products, penetrating oils, etc., to come

into contact with plastic parts. Failure to comply leads to tool damage, which in turn creates

a spark or fire resulting in serious personal injury.

• Make sure the tool is disconnected from power source before attempting to service or remove

any component.

GENERAL MAINTENANCE

Avoid using solvents when cleaning plastic parts. Most plastics are susceptible to damage from various types

of commercial solvents. Use a clean cloth to remove dirt, dust, oil, grease, etc.

• Periodically check all clamps, nuts, bolts, and screws for tightness and condition.

• Check and clean the blade guard periodically. Replace the blade guard if required.

• Clean the blades using a gum and pitch remover.

• To prevent the workpiece from slipping during cutting operations, do not wax the working face of the

mitre gauge.

• Protect the saw blade by cleaning sawdust accumulated under the work table and between the blade

teeth, and applying a resin solvent on the blade teeth.

• Clean plastic parts only with a soft damp cloth. Do not use any aerosol or petroleum solvents.

• Keep the upper and lower blade wheels clean. Debris on the wheels will cause poor tracking and blade

slippage.

LUBRICATION

• Apply small amount of machine oil to belt tension mechanisms and threaded or sliding surfaces.

• Lubricate all screw threads, nuts, and bearing points of the band saw (including the blade guard and the

mitre gauge).

• Apply a coat of paste wax to the tabletop to keep the work table slick and corrosion free.

SERVICE

• Replace the power cord if it is worn or damaged.

• Replace any damaged or missing part.

model no. 055-6748-6 | contact us 1-800-689-9928

31

TROUBLESHOOTING

30

MAINTENANCE

Page 17

model no. 055-6748-6 | contact us 1-800-689-9928

33

TROUBLESHOOTING

32

TROUBLESHOOTING

PROBLEM Possible Causes Solution

Saw does not start. • Motor cord or wall cord is not

plugged in.

• In-house circuit fuse is blown.

• In-house circuit breaker is tripped.

• In-house circuit switch is damaged.

• Improper electrical connections.

• Plug in the motor cord or wall cord.

• Replace the circuit breaker.

• Reset the circuit breaker.

• Repair or replace the in-house

circuit switch. Have the cord or

switch replaced by a qualified

service technician.

• Have a qualified technician check

the electrical connections.

PROBLEM Possible Causes Solution

Crooked cuts. • Workpiece is not placed properly

on the work table.

• Rate of feed of workpiece is too

high.

• Blade guides are not adjusted

properly.

• Upper blade guide is too far from

the workpiece.

• Blade is not sharp.

• Blade guide assembly or blade

thrust bearing is loosened.

• Use miter gauge to adjust tilt of the

work table to 90º.

• Reduce the rate of feed.

• Use feeler gauge to move the blade

guides within 0.002" from the

blade.

• Set the upper blade guide at a

distance of 1/4" (6.35 mm) from

the workpiece.

• Replace the blade.

• Tighten the blade thrust bearing

within 0.002" behind the back of

blade.

Twisting of the blade or

unusual wear on the

side/back of the blade.

• Blade binds into the workpiece.

• Blade guides or bearings are

damaged.

• Blade guides or bearings are not

adjusted properly.

• Blade guide brackets are loosened.

• Decrease the workpiece feed

pressure.

• Replace the blade guides or

bearings.

• Adjust the blade guides. (Refer to

the “Assembly Instructions”.)

• Tighten the blade guide brackets

properly.

Motor runs too hot. • Blade tooth is too coarse.

• Workpiece feed rate is high.

• Workpiece vibrates.

• Blade guide brackets are loosened.

• Use blade with finer teeth.

• Decrease the workpiece feed rate.

• Hold the workpiece firmly.

• Tighten the blade guide brackets

properly.

Ripping of the teeth from

the blade.

• Blade teeth are too coarse

especially when cutting pipe.

• Blade tooth is too fine especially

when cutting slick or soft material.

• Excessive dirt and chips on the

motor.

• Use blade with finer teeth.

• Use blade with coarser teeth.

• Clean the motor thoroughly.

Page 18

model no. 055-6748-6 | contact us 1-800-689-9928

35

EXPLODED VIEW

34

EXPLODED VIEW

2

3

4

5

6

7

10

4

28

27

26

18

19

20

21

24

6

25

31

44

39

40

43

41

39

38

37

42

36

34

33

40

4

4

4

54

52

51

50

49

48

11

47

46

43

40

39

61

6

60

59

58

57

56

55

26

28

63

6

29

62

25

67

69

84

6

11

13

11

13

11

78

115

113

110

111

112

103

11

106

108

108

10

10

11

9

8

11

53

40

39

42

66

105

106

107

68

49

64

32

35

105

109

6

104

24

65

10

48

116

32

81

6

45

4

166

17

22

23

9

8

11

12

11

3

29

6

30

24

10

12

166

14

4

1

15

16

11

11

3

114

6

154

1

119

54

55

118

121

122

123

117

78

120

56

98

99

100

102

101

125

126

127

28

124

6

81

32

78

4

155

69

80

81

82

83

6

84

85

86

88

6

11

13

32

87

89

32

81

4

4

4

65

70

72

73

75

71

32

6

74

66

67

68

46

76

11

81

147

79

149

94

93

92

91

90

77

78

148

11

46

95

96

119

142

140

78

143

144

145

151

150

153

152

97

78

137

138

139

140

141

6

32

158

136

146

67

133

134

128

6

129

130

131

135

156

46

11

49

132

157

159

160

161

162

163

164

165

Page 19

PARTS LIST

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

Qty

2

1

4

17

1

21

1

2

2

8

26

2

8

1

1

1

1

1

1

1

1

1

1

2

3

4

1

5

2

1

2

Description

Bolt

Lower bezel panel

Hinge

Cross-shaped sunk bolt

Brush

Flat washer

Cross-shaped self-tapping bolt

Door holder

Door lock spring

Nut

Flat washer

Pressing paw

Cross-shaped bolt

Upper bezel panel

Bezel panel lens

Cross-shaped self-tapping bolt

Shield

Spring

Cross-shaped self-tapping bolt

Sliding block (B)

Sliding block (C)

Sliding block (A)

Up-down part

Bolt

Bolt

Round pin

bracket (A)

Set screw

Bearing

Pin stop (B)

Bolt

No.

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

Qty

12

2

1

1

1

1

1

4

4

1

2

2

1

1

7

1

3

3

2

2

2

1

4

4

3

1

1

1

3

1

1

Description

Spring washer

Split washer

Fixed pin

Fixed block

Nut

Moving block

Shaft for driven wheel

Bearing

Retainer ring for hole

Driven wheel

Rubber band

Retainer ring for shaft

Blade

Lock switch

Cross-shaped bolt

Switch box

Cross-shaped bolt

Spring washer

Grounding terminal

Gear pad

Grounding signal

Locking plate

Flat washer

Spring washer

Bolt

Shaft for driving wheel

Synchronize wheel (B)

Synchronize belt

Cross-shaped self-tapping bolt

Driving wheel

Fixed pin (A)

No.

94

95

96

97

98

99

100

101

102

103

104

105

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

Qty

1

2

1

1

1

1

1

1

1

1

1

2

4

2

4

1

1

1

1

1

1

1

1

1

2

1

1

1

2

1

1

Description

Cord clip

Nut

Fine adjusting knob

Spring

Eccentricity shaft

Wave-shaped washer

Locating sleeve(B)

Compression handle

Roller

Block

Bolt

Box

Bolt

Cover

Bolt

Square-neck bolt

Compression spring

Swelling knob

Locknut

Lower shield(A)

Lower shield(B)

Bolt

Clamp handle

Spring round pin

Big flat washer

Connecting screw rod

Fixed pressing paw

Guide tube

Hexagon bolt

Connecting rod

Square washer (A)

No.

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

Qty

1

1

4

4

4

4

1

1

2

1

4

4

1

1

1

11

1

1

9

1

2

1

1

2

1

1

1

1

2

2

1

Description

Bracket (B)

Lower fixed block

Cap nut

Big flat washer

Footing

Hexagon bolt

Body

Supporting

Hexagon bolt

Clip

Hexagon bolt

Nut

Dust outlet

Angle adjusting gear

Spring

Flat washer

Bolt

Bolt

Bolt

Indicator

Locating sleeve

Adjusting gear

Locating sleeve(A)

Wave-shaped washer

Up-down knob

Protecting bush

Locking knob

Power cord

Bolt

Flat washer

Fixed plate assembly

model no. 055-6748-6 | contact us 1-800-689-9928

37

PARTS LIST

36

PARTS LIST

Page 20

3-Year Limited Warranty

This Mastercraft product is guaranteed for a period of 3 years from the date of original retail purchase against

defects in workmanship and materials, except for the following component:

Component A: Accessories, which are guaranteed for a period of 1-year from the date of original retail

purchase against defects in workmanship and materials.

Subject to the conditions and limitations described below, this product, if returned to us with proof of purchase

within the stated warranty period and if covered under this warranty, will be repaired or replaced (with the

same model, or one of equal value or specification), at our option. We will bear the cost of any repair or

replacement and any costs of labour relating thereto.

These warranties are subject to the following conditions and limitations:

a. a bill of sale verifying the purchase and purchase date must be provided;

b. this warranty will not apply to any product or part thereof which is worn or broken or which has become inoperative due

to abuse, misuse, accidental damage, neglect or lack of proper installation, operation or maintenance (as outlined in

the applicable owner’s manual or operating instructions) or which is being used for industrial, professional, commercial

or rental purposes;

c. this warranty will not apply to normal wear and tear or to expendable parts or accessories that may be supplied with the

product that are expected to become inoperative or unusable after a seasonable period of use;

d. this warranty will not apply to routine maintenance and consumable items such as, but not limited to, fuel, lubricants,

vacuum bags, blades, belts, sandpaper, bits, fluids, tune-ups or adjustments;

e. this warranty will not apply where damage is caused by repairs made or attempted by others (i.e. persons not

authorized by the manufacturer);

f. this warranty will not apply to any product that was sold to the original purchaser as a reconditioned or refurbished

product (unless otherwise specified in writing);

g. this warranty will not apply to any product or part thereof if any part from another manufacturer is installed therein or

any repairs or alterations have been made or attempted by unauthorized persons;

h. this warranty will not apply to normal deterioration of the exterior finish, such as, but not limited to, scratches, dents,

paint chips, or to any corrosion or discolouring by heat, abrasive and chemical cleaners; and

i. this warranty will not apply to component parts sold by and identified as the product of another company, which shall

be covered under the product manufacturer’s warranty, if any.

Additional Limitations

This warranty applies only to the original purchaser and may not be transferred. Neither the retailer nor the manufacturer

shall be liable for any other expense, loss or damage, including, without limitation, any indirect, incidental, consequential

or exemplary damages arising in connection with the sale, use or inability to use this product.

Notice to Consumer

This warranty gives you specific legal rights, and you may have other rights, which may vary from province to province.

The provisions contained in this warranty are not intended to limit, modify, take away from, disclaim or exclude any

statutory warranties set forth in any applicable provincial or federal legislation.

This product is not meant for industrial or commercial purposes. This product is for household

projects, read manual carefully

Made in China

Imported by Mastercraft Canada Toronto, Canada M4S 2B8

No.

126

127

128

129

130

131

132

133

134

135

136

137

138

139

140

141

142

143

144

145

Qty

1

1

1

1

1

1

1

1

1

1

1

1

1

1

6

4

1

1

1

1

Description

Spring

Movable clamp paw

Bolt

Knob for mitre angle

Mitre angle

Pointer

Fence

Worktable

Table insert

Bolt

Snap gauge

Bolt

Cushion cap

Wing bolt

Spring washer

Bolt

Mitre seat

Lock bolt

Securing handle

Compression spring

No.

146

147

148

149

150

151

152

153

156

157

158

159

160

161

162

163

164

165

166

Qty

2

1

1

1

2

1

1

1

1

2

1

2

2

2

1

2

2

2

4

Description

Bolt

Big flat washer

Synchronize wheel (A)

Motor

Bolt

Push stick

Spanner

Spanner

Scale label

Worktable steel board

Nut

Uncork pin

Butterfly bolt

Expand pole

Extension table

Washer

Spring washer

Lock nut

Star-head pan head screws

model no. 055-6748-6 | contact us 1-800-689-9928

39

WARRANTY

38

PARTS LIST

Loading...

Loading...