Page 1

TM

model no.: 055-6761-2

INSTRUCTION

MANUAL

IMPORTANT:

Please read this manual carefully before using this mitre saw and

save it for reference

SLIDING COMPOUND

MITRE SAW

Page 2

3

TABLE OF CONTENTS

TABLE OF CONTENTS

SPECIFICATIONS 4

SAFETY GUIDELINES 5

KEY PARTS DIAGRAM 11

ASSEMBLY AND ADJUSTMENTS 13

OPERATING INSTRUCTIONS 19

MAINTENANCE 29

TROUBLESHOOTING 31

EXPLODED VIEW

32

PARTS LIST 33

WARRANTY 36

NOTE:

If any parts are missing or damaged, or if you have any questions, please call our toll-free helpline at

1-800-689-9928.

SAVE THESE INSTRUCTIONS

This manual contains important safety and operating instructions. Read all

instructions and follow them when using this product.

Page 3

4 5

model no. 055-6761-2 | contact us 1-800-689-9928

SPECIFICATIONS

SAFETY GUIDELINES

SPECIFICATIONS SAFETY GUIDELINES

• Keep guards in place and in working order.

• Remove adjusting keys and wrenches. Form habit of checking to see that keys and adjusting

wrenches are removed from tool before turning it on.

• Keep work area clean. Cluttered areas and benches invite injuries.

• Don’t use in dangerous environment. Don’t use power tools in damp or wet locations, or expose

them to rain or snow. Keep work area well lighted.

• Keep children away. All visitors should be kept at a safe distance from work area.

• Make workshop childproof with padlocks, master switches, or by removing starter keys.

• Don’t force the tool. It will do the job better and safer at the rate for which it was designed.

• Use the right tool. Don’t force tool or attachment to do a job for which it was not designed.

• Wear proper apparel. Do not wear loose clothing, gloves, neckties, rings, bracelets, or other

jewellery which may get caught in moving parts. Non-slip footwear is recommended. Wear protective

hair covering to contain long hair.

• Always use safety glasses. Also use face or dust mask if cutting operation is dusty. Everyday

eyeglasses only have impact-resistant lenses, they are not safety glasses.

• Secure work. Use clamps or vise to hold work when practical. It’s safer than using your hand and it

frees both hands to operate tool.

• Don’t overeach. Keep proper footing and balance at all times.

• Maintain tools with care. Keep tools sharp and clean for best and safest performance. Follow

instructions for lubricating and changing accessories.

• Disconnect tools before servicing; when changing accessories, such as blades, clamps,

extensions, and the like.

• Reduce the risk of unintentional starting. Make sure the switch is in the OFF position before

plugging in.

• Use recommended accessories. Consult the owner’s manual for recommended accessories. The

use of improper accessories may cause risk of injury to persons.

Motor 120V AC, 60 Hz, 9.5A

Speed 5000 RPM (no load)

Blade 7 1/4” (18.4 cm) 24-tooth carbide-tipped

Arbor Size 5/8” (15.9 mm)

Cutting Capacity

2 x 8” (5.1 x 20.3 cm) crosscut at 0° mitre, 0° bevel

2 x 6” (5.1 x 15.2 cm) mitre cut at 45° mitre, 0° bevel

1 1/2 x 6” (3.8 x 15.2 cm) compound cut at 45° mitre, 45° bevel

1 1/2 x 8” (3.8 x 20.3 cm) cross cut at 45° bevel, left

Weight 19 lb 13 oz (9 kg)

WARNING!

To reduce the risk of injury, read the instruction manual.

WARNING!

Read and understand all instructions. Failure to follow the warnings and instructions listed below

may result in electrical shock, fire and/or serious injury.

Page 4

6 7

model no. 055-6761-2 | contact us 1-800-689-9928

SAFETY GUIDELINES

SAFETY GUIDELINES

• Never stand on tool. Serious injury could occur if the tool is tipped or if something unintentionally

comes into contact with the cutting tool.

• Check damaged parts. Before further use of the tool, a guard or other part that is damaged should

be carefully checked to determine whether it will operate properly and perform its intended function

- check for alignment of moving parts, binding of moving parts, breakage of parts, mounting, and any

other conditions that may affect its operation. A guard or other part that is damaged should be properly

repaired or replaced.

• Direction of feed. Feed work into a blade or cutter against the direction of rotation of the blade or

cutter only.

• Never leave tool running unattended. Turn power off. Don’t leave tool until it comes to a complete

stop.

DOUBLE-INSULATED TOOLS

• When servicing, use only identical replacement parts.

• Polarized Plugs: To reduce the risk of electric shock, this equipment has a polarized plug

(one blade is wider than the other). This plug will fit in a polarized outlet only one way. If the plug

does not fit fully into the outlet, reverse the plug. If it still does not fit, contact a qualified electrician to

install the proper outlet. Do not change the plug in any way.

ELECTRICAL SAFETY

• To reduce the risk of electric shock, double-insulated tools are equipped with a polarized

plug (one blade is wider than the other). This plug will fit into a polarized outlet only one way. If

the plug does not fit into the outlet properly, reverse the plug. If it still does

not fit, contact a qualified electrician to install a polarized outlet. Do not

change the plug in any way.

• Double insulation eliminates the need for the three-wire grounded

power cord and grounded power supply system. This compound

mitre saw is a double-insulated tool.

• Before plugging in the tool, BE SURE that the outlet voltage

supplied is within the voltage marked on the tool’s data plate. DO NOT use “AC only” rated

tools with a DC power supply.

• Avoid body contact with grounded surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric shock if your body is grounded.

• DO NOT expose power tools to rain or wet conditions and do not use power tools in wet

or damp locations. Water entering a power tool will increase the risk of electric shock. This tool is

intended for indoor use only.

• If operating a power tool in damp locations is unavoidable, ALWAYS USE a power supply for

your tool that is protected by a Ground Fault Circuit Interrupter. ALWAYS WEAR electrician’s

rubber gloves and footwear in damp conditions.

• Inspect tool cords for damage. Have damaged tool cords repaired by a qualied person. BE

SURE to stay constantly aware of the cord location, and keep it well away from the moving blade.

• Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the power

tool. Keep cord away from heat, oil, sharp edges and moving parts. Replace damaged cords

immediately. Damaged cords increase the risk of electric shock.

• Use proper extension cord. Make sure your extension cord is in good condition. When using an

extension cord, be sure to use one heavy enough to carry the current your product will draw. An

undersized cord will cause a drop in line voltage resulting in loss of power and overheating. The

following table shows the correct size to use depending on cord length and nameplate ampere rating.

If in doubt, use the next heavier gauge. The smaller the gauge number, the heavier the cord.

MINIMUM GAUGE FOR CORD SETS

Ampere rating of the tool

(120 V circuit only)

Total length of cord

25′′ (7.62 m) 50′′ (15.24 m) 100′ (30.48 m) 150′ (45.72 m)

more than not more than Minimum Gauge for the extension cord (AWG)

0 6 18 16 16 14

6 10 18 16 14 12

10 12 16 16 14 12

12 16 14 12 Not recommended

SPECIFIC SAFETY RULES FOR MITRE SAWS

• Always wear eye protection.

• Do not operate the saw without guards in place.

WARNING!

Do not permit fingers to touch the terminal or plug when installing or removing the plug from an

outlet.

WARNING!

For your own safety, read the Instruction Manual before operating the mitre saw.

WARNING!

Double insulation DOES NOT take the place of normal safety precautions when operating this tool.

Page 5

8 9

model no. 055-6761-2 | contact us 1-800-689-9928

SAFETY GUIDELINES

SAFETY GUIDELINES

• Be sure to turn the tool off and wait for the saw blade to stop before moving the workpiece or

changing settings.

• Be sure that the power is disconnected before changing the blade or servicing the saw.

• Do not expose to rain or use in a damp location.

• When servicing, use only identical replacement parts.

• Never reach around the saw blade.

• Do not perform any operation freehand. Always place the workpiece to be cut on the mitre saw

table and position it firmly against the fence as a backstop. Always use the fence.

• Always keep hands out of the path of the saw blade. Do not reach under the material being cut

or into the blade’s cutting path with your fingers or hand for any reason.

• To reduce the risk of injury, return the cutting head to the full rear position after each crosscut

operation.

• Always make sure that the mitre table and head assembly (bevel function) are locked in

position before operating your saw. Lock the mitre table by securely tightening the mitre locking

handle. Lock the head assembly (bevel function) by securely tightening the bevel locking knob.

• Be sure the blade path is free of nails. Always carefully inspect lumber and remove all nails

BEFORE cutting.

• Always be sure the blade clears the workpiece. Never start the saw with the blade touching the

workpiece. Always allow the motor to come up to full speed before starting a cut.

• Support long workpieces when cutting to minimize the risk of blade pinching or kickback.

The saw may slip, walk or slide while cutting long or heavy boards.

• Never use a length-stop on the free end of a clamped workpiece. Never hold onto or bind the

free end of the workpiece in any operation. If a clamp and length-stop are used together, they must

both be installed on the same side of the saw table to prevent the saw from catching the loose end and

kicking up.

• Never cut more than one piece at a time. Do not stack more than one workpiece on the worktable

at a time.

• Avoid awkward operations and hand positions where a sudden slip could cause your hand

to hit the blade. Always make sure you have good balance. Never operate your saw on the floor or in

a crouched position.

• Only use the correct blades. Use the correct blade size, style and cutting speed for the material and

the type of cut. Do not use blades with incorrect size holes. NEVER use blade washers or blade bolts

that are defective or incorrect. The maximum blade capacity for this saw is 7 1/4” (18.4 cm).

• Always keep blades clean, sharp and properly set. Sharp blades minimize stalling and kickback.

• Do not use dull or damaged blades. Bent blades can break easily or cause kickback.

• Never hold a workpiece by hand if it is too small to be clamped. Always keep your hands clear

of the “no hands” zone.

• Never apply lubricants to the blade when it is running.

• Never use solvents to clean plastic parts. Solvents could dissolve or otherwise damage the

material.

• Do not turn the motor switch on and off rapidly. This could cause the blade to loosen, which

could create a hazard. Should this ever occur, stand clear and allow the saw blade to come to a

complete stop. Disconnect the saw from the power source and tighten the blade bolt securely.

• Never leave the saw unattended while it is connected to a power supply.

• Keep the motor air slots clean and free of chips or dust. To avoid motor damage, the motor

should be blown out or vacuumed frequently. This keeps sawdust from interfering with the motor

ventilation.

• Never lift this tool by gripping the switch handle or by the mitre fence. This may cause

misalignment. Always lock the head assembly in the “Down” position and carry the saw by holding the

base or lift it using the carrying handle/support bracket.

ADDITIONAL RULES FOR SAFE OPERATION

• Know your power tool. Read the instruction manual carefully. Learn the applications and limitations,

as well as the specific potential hazards related to this tool. Following these rules will reduce the risk of

electric shock, fire or serious injury.

• Always wear safety glasses or eye shields when using this saw. Everyday eyeglasses have

only impact-resistant lenses; they are NOT safety glasses. All users and bystanders MUST wear eye

protection that conforms to ANSI Z87.1.

• Protect your lungs. Wear a face mask or a dust mask if the operation is dusty.

• Protect your hearing. Wear appropriate personal hearing protection during use. Under some

conditions and duration of use, noise from this product may contribute to hearing loss.

• All visitors and bystanders must wear the same safety equipment that the operator of the

saw wears.

• Inspect the tool cords periodically and, if damaged, have them repaired by a qualified person.

• Always check the tool for damaged parts. Before further use of the tool, a guard or other part that

is damaged should be carefully checked to determine whether it will operate properly and perform

its intended function. Check for misalignment or binding of moving parts, broken parts and any other

WARNING!

The use of this tool can generate and/or disburse dust, which may cause serious and permanent

respiratory or other injury. Always use NIOSH/OSHA approved respiratory protection appropriate

for dust exposure. Direct particles away from the face and body.

Page 6

10 11

model no. 055-6761-2 | contact us 1-800-689-9928

SAFETY GUIDELINES

KEY PARTS DIAGRAM

condition that may affect the tool’s operation. A guard or other part that is damaged should be properly

repaired or replaced by a qualified person.

• Save these instructions. Refer to them frequently and use them to instruct others who may

use this tool. If someone borrows this tool, make sure he or she has these instructions.

GLOSSARY OF WOODWORKING TERMS

• Spindle: The revolving shaft on which a blade or cutting tool is mounted.

• Spindle Lock: Allows the user to stop the blade from rotating while tightening or loosening the blade

screw during blade replacement or removal.

• Bevel Cut: A cutting operation made with the blade at any angle other than 90° to the mitre table.

• Chamfer Cut: A cut removing a wedge from a block of wood so the end (or part of the end) is angled

other than at 90°.

• Compound Mitre Cut: A cut made using both a mitre angle and a bevel angle at the same time.

• Crosscut: A cutting operation made across the grain of the workpiece.

• Freehand Cut: Performing a cut without using a fence, mitre gauge, fixture, work clamp, or other

proper device to keep the workpiece from twisting or moving during the cut. Do not perform any

operation freehand. Use a clamp or vice wherever possible.

• Kerf: The material removed by the blade in a through cut or the slot produced by the blade in a

non-through or partial cut.

• Kickback: A hazard that can occur when the blade binds or stalls, throwing the workpiece back

toward the operator.

• Mitre Cut: A cutting operation made with the blade at any angle other than 90° to the fence.

• No-Hands Zone: The area between the marked lines on the left and right side of the mitre table base.

This zone is identified by No-Hands Zone symbols inside the lines marked on the mitre table base.

• Non-through Cut: Any cutting operation where the blade does not extend completely through the

thickness of the workpiece.

• Revolutions Per Minute (RPM): The number of turns completed by a spinning object in one minute.

• Saw Blade Path: The area over, under, behind or in front of the blade, as it applies to the workpiece;

the area that will be or has been cut by the blade.

• Set: The distance that the saw blade tooth is bent (or set) outward from the face of the blade.

• Throat plate: A plate inserted in the mitre saw’s table that allows for blade clearance.

• Through Sawing: Any cutting operation where the blade extends completely through the thickness of

the workpiece.

• Workpiece or Material: The item on which the cutting operation is being done. The surfaces of a

workpiece are commonly referred to as faces, ends and edges.

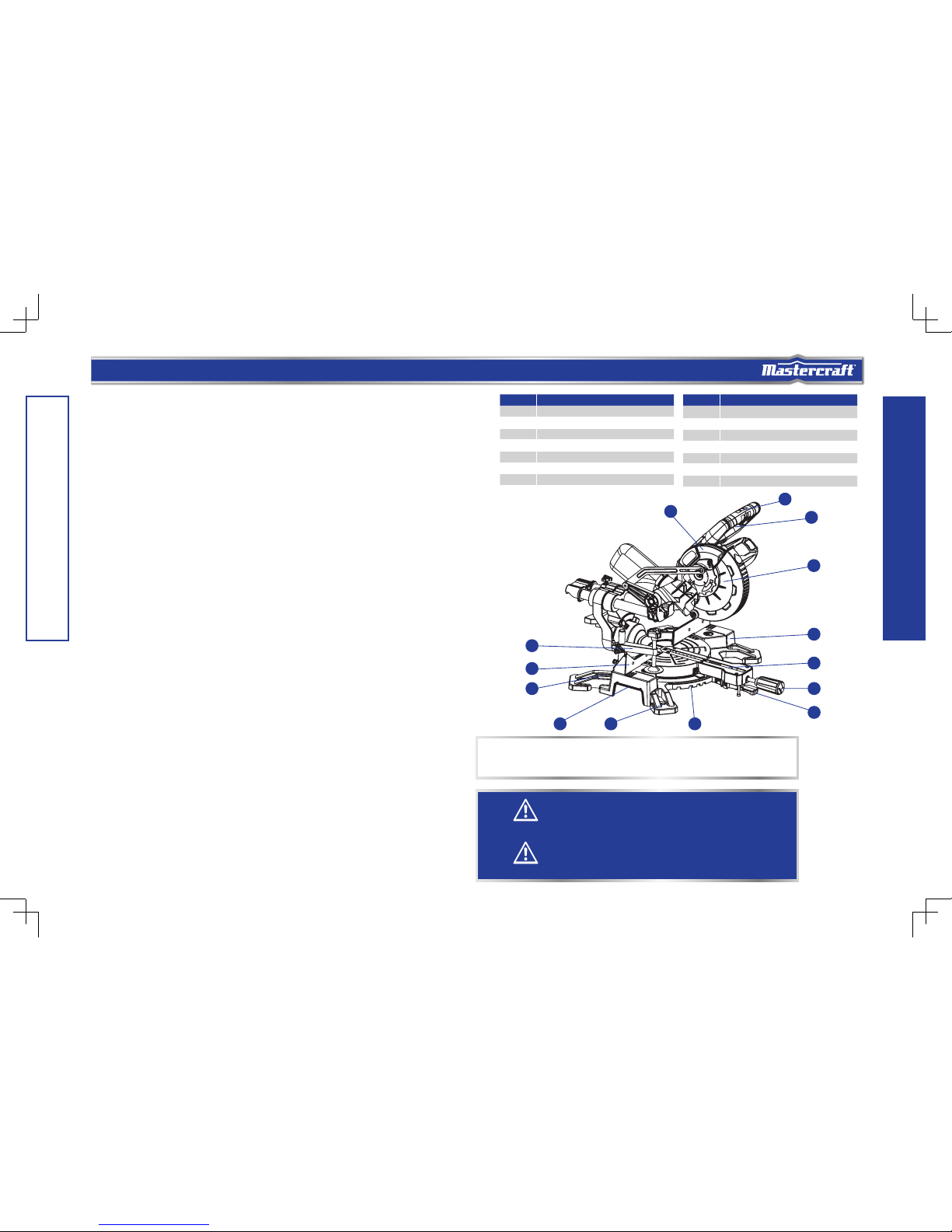

NOTE:

Before attempting to use your saw, familiarize yourself with all of the operating features and

safety requirements.

No. Description

1 Switch handle

2 On/Off trigger switch

3 Upper blade guard

4 Lower blade guard

5 Base

6 Table insert

7 Mitre handle

No. Description

8 Mitre stop locking lever

9 Positive mitre stop

10 Mounting hole

11 Hex wrench

12 Fence

13 Work clamp

14 Handhold for transportation

WARNING!

Carefully remove the tool and any accessories from the box. Make sure that all items listed in

the packing list are included. Inspect the tool carefully to make sure that no breakage or damage

occurred during shipping.

WARNING!

Do not discard the packing material until you have carefully inspected and satisfactorily operated

the tool.

1

2

3

4

5

6

7

8

12

13

11

910

14

Page 7

12 13

model no. 055-6761-2 | contact us 1-800-689-9928

KEY PARTS DIAGRAM

ASSEMBLY AND ADJUSTMENTS

REMOVING AND INSTALLING THE BLADE

Removing blade

(Fig. 1 to 4)

• Unplug the tool from the power source.

• Adjust the lock-down pin to raise the cutting head.

• Loosen the cover plate screw (1) about 4 turns with a

star-head screwdriver. Do not remove this screw from

the tool.

• Lift and hold up the lower blade guard (2) to expose

the threaded blade bolt (3).

• Press and hold the spindle-lock button (4) and

rotate the blade at the same time, until it is locked

in position.

• Continue to hold the spindle lock button to keep it

engaged, while using the wrench to turn the threaded

blade bolt clockwise and remove the threaded blade

bolt.

• Remove the outer flange (5) and the blade (6). Wipe

the flanges and spindle to remove any dust and debris.

Installing blade (Fig. 1 to 4)

Unplug the mitre saw before changing/installing the blade.

• Install a 7 1/4” (18.4 cm) blade with 5/8” (15.9 mm) arbor onto the arbor shaft (7). Match the arrow

on the blade with the arrow on the upper blade guard. Make sure that the blade teeth are pointing

downward.

No. Description

15 Spindle lock

16 Blade

17 Motor

18 Dust bag

19 Lock-down pin

No. Description

20 Sliding carriage lock knob

21 Bevel lock knob

22 Bevel scale

23 Table

24 Mitre scale

WARNING!

Always be sure that the tool is switched off and unplugged before adjusting or checking function

on the tool. Failure to switch off and unplug the tool may result in serious personal injury from

accidental start-up.

WARNING!

Only use a 7 1/4” (18.4 cm) diameter blade. To avoid injury from an accidental start, make sure

the switch is in the OFF position and the plug is not connected to the power source outlet.

NOTE:

Pay attention to the pieces being removed, noting their position and the direction they face. Wipe the blade

collar clean of any sawdust before installing a new blade.

WARNING!

Your saw should NEVER be connected to the power source when you are assembling

parts, making adjustments, installing or removing blades, cleaning, or when it it not in use.

Disconnecting the saw will prevent accidental starting, which could cause serious personal injury.

WARNING!

Do not allow familiarity with the mitre saw to cause a lack of alertness. A fraction of a second of

carelessness is enough to cause severe injury.

1

2

3

15

16

17

24

18

19

21

22

23

20

Page 8

14 15

model no. 055-6761-2 | contact us 1-800-689-9928

• Place the out flange against the blade and on the

arbor. Thread the blade bolt onto the arbor in a

counter-clockwise direction.

• Place the blade hex wrench into the blade bolt.

• Press the spindle lock button, holding it in firmly while

turning the blade counterclockwise. When spindle

lock engages, continue to press it in while tightening

the blade bolt securely.

• Rotate the lower blade guard back to its original

position until the slot in the cover plate engages with

the cover plate screw. While holding the lower blade

guard, tighten the screw with a Phillips screwdriver.

• Verify that the operation of the guard does not bind or

stick.

• Be sure the spindle lock is released so the blade turns

freely before operating the saw.

INSTALLING THE DUST BAG (Fig. 5)

• Squeeze the metal collar wings on the dust bag.

′• Place the dust bag neck opening around the exhaust

port on the mitre saw and release the metal collar

wings.

MITRE SCALE (Fig. 6)

The sliding compound mitre saw scale can be easily read,

showing mitre angles from 0° to 45° to the left, and 0°

to 45° to the right. The mitre saw table has nine of the

most common angle settings with positive stops at 0°,

15°, 22.5°, 31.6° and 45°. These positive stops position

the blade at the desired angle quickly and accurately.

Follow the process below for quickest and most accurate

adjustments.

This tool is carefully adjusted and aligned at the factory,

but rough handling may have affected the alignment. If

your tool is not aligned properly, perform the following as

needed.

To Adjust Mitre Angles:

• Unlock the table by turning the mitre handle (1)

counterclockwise.

• Move the table while lifting up on the positive stop locking lever (2) to align the indicator (3) to the

desired degree measurement.

• If the desired angle is one of the nine positive stops, release the positive stop locking lever, making

sure the lever snaps into position, and then secure by tightening the mitre handle.

• If the mitre angle desired is not one of the nine positive stops, simply lock the table into desired angle

position by turning the mitre handle in the clockwise direction.

ASSEMBLY AND ADJUSTMENTS

NOTE:

The lower blade guard must be in the right position to access the cover plate screw.

NOTE:

To empty the dust bag, remove it from exhaust port. Open zipper on underside of bag and empty into waste

container.

IMPORTANT:

Make sure the flats of the out flange are engaged with the flats on the arbor shaft. Also, the flat side of the

out flange collar must be placed against the blade.

IMPORTANT:

Check bag frequently and empty it before it gets full.

ASSEMBLY AND ADJUSTMENTS

WARNING!

• To avoid injury, never use the saw without the cover plate securely in place. It keeps the

blade bolt from falling out if it accidentally loosens and helps prevent the spinning blade from

coming off the saw.

• Make sure the anges are clean and properly arranged. Lower the blade into the lower table

and check for any contact with the metal base or the mitre table.

• To avoid injury from an accidental start, make sure the switch is in the OFF position and the

plug is not connected to the power source outlet.

• Never cut metals or masonry products with this tool. This mitre saw is designed for use on

wood and wood-like products only.

WARNING!

Do not use this saw to cut and/or sand metals. The hot chips or sparks may ignite sawdust from

the bag material.

3

5

6

Blade bolt

Out flange

Inner flange

Sawblade

Arborshaft

7

1

2

4

3

4

Page 9

16 17

model no. 055-6761-2 | contact us 1-800-689-9928

• If the blade is not 90° square with the table, loosen the bevel lock knob, tilt the cutting head to the left,

loosen the locknut (3) and turn the bevel angle adjustment bolt (4) in or out with a 3 mm hex wrench

until the blade is square with the table.

• Tilt the pivot arm back to the right at 90° (0°) bevel and recheck for alignment.

• Repeat steps if further adjustment is needed.

• Tighten bevel lock knob and locknut (3) when

alignment is achieved.

90° Bevel Pointer Adjustment (FIG. 9)

′When the blade is exactly 90° to the table, loosen the bevel

indicator screw (1) using a star-head screwdriver.

• Adjust bevel indicator (2) to the “0” mark on the bevel

scale and retighten the screw.

45° Bevel Adjustment (FIG. 10)

• Loosen the bevel lock knob (1) and tilt the cutting

head completely to the left.

• Using a combination square, check to see if the blade

is at a 45° angle to the table.

• If the blade is not at 45° to the mitre table, tilt the

pivot arm to the right, loosen the locknut (2) on the

bevel angle adjustment bolt (3) and use a 3 mm hex

wrench to the adjust bolt depth in or out to increase or

decrease the bevel angle.

• Tilt the cutting arm to the left to 45° bevel and

recheck for alignment.

• Repeat steps until the blade is at 45° to the mitre

table.

• Tighten bevel lock knob and locknut when alignment

is achieved.

MAXIMUM CUTTING DEPTH (FIG. 11)

The maximum depth travel of the cutting head was set at

the factory. Check to see that the blade does not extend

more than 5/16” (0.8 cm) below the table insert, and does

not touch the control arm throat or any part of the base or

table. If the maximum depth needs readjusting:

Mitre Angle Pointer Adjustment (Fig. 6)

• Move the table to the 0° positive stop.

• Loosen the screw (4) that holds the indicator with a Phillips screwdriver.

• Adjust the indicator (3) to the 0° mark and retighten the screw.

ADJUSTING FENCE SQUARENESS (Fig. 7)

• Lower the cutting head and lock in position.

• Using a square (1), lay the heel of the square against

the blade and the ruler against the fence (2) as

shown.

• Loosen the two fence locking bolts (3) with a 6 mm

hex wrench.

• Adjust the fence 90° to the blade and tighten the two

fence locking bolts.

• After fence has been aligned, make a cut at 90° using

a scrap piece of wood and check squareness on the

piece. Readjust if necessary.

BEVEL STOP ADJUSTMENT

This tool is carefully adjusted and aligned at the factory,

but rough handling may have affected the alignment. If

your tool is not aligned properly, perform the following as

needed.

90° (0°) Bevel Adjustment (Fig. 8)

• Loosen bevel lock knob (1) and tilt the pivot arm

completely to the right. Tighten the bevel lock knob.

• Place a combination square (2) on the mitre table with

the ruler against the table and the heel of the square

against the saw blade.

ASSEMBLY AND ADJUSTMENTS

ASSEMBLY AND ADJUSTMENTS

WARNING!

To avoid injury from an accidental start, make sure the switch is in the OFF position and the plug

is not connected to the power source outlet.

WARNING!

To reduce the risk of injury, wear safety goggles or glasses with side shields.

1

2

1

3

2

1

2

3 3

1

4

2

3

2

3

1

Page 10

18 19

model no. 055-6761-2 | contact us 1-800-689-9928

OPERATING INSTRUCTIONS

UNLOCKING AND LOCKING THE CUTTING

HEAD (Fig. 12)

To unlock: Press and lightly hold down the cutting head.

Pull out the lock-down pin (1) to release the cutting head.

The cutting head should freely move up.

To lock: Place the cutting head at the lowest position.

Secure the position and push the stop lock pin into the

locking position. Please note, if there is any cutting depth

setting, the lock in may not work. Release the cutting depth

limitation, and then lock the cutting head in.

UNLOCKING THE SLIDE CARRIAGE (Fig. 13)

After removing the saw from the carton, loosen the slide

carriage lock knob (1). When transporting or storing the

mitre saw, the slide carriage should always be locked in

position. The slide carriage lock knob is located on the

upper side of the slide carriage.

IMPORTANT:

To avoid damage, never carry the mitre saw by the switch handle, the cutting arm or the mitre table handle.

ALWAYS use the handholds for transportation.

CAUTION!

To avoid injury and damage to the saw, transport and store the mitre saw with the cutting head

locked in the down position. Never use the stop pin to hold the cutting head in a down position for

cutting operations.

• Loosen the lock nut (1) to free the depth screw (2).

• Move the cutting head down until the blade extends just 5/16” (0.8 cm) below the table insert.

• Adjust the depth screw to touch the stop plate (3), then tighten the lock nut to secured the depth

screw.

• Recheck the blade depth by moving the cutting head front to back through the full motion of a cut

along the control arm. If the blade touches the inside of the control arm, readjust the setting.

• When it is properly set, tighten the lock nut to lock the depth screw.

ASSEMBLY AND ADJUSTMENTS

CAUTION!

Always make sure that the spindle lock button is released so the blade can rotate freely. MAKE

SURE that the locking pin is loose and the cutting head moves freely up and down. ENSURE that

all clamps and locks are tightly in place, and that there is no excessive play in any parts.

WARNING!

Before each use, verify that the blade is free of cracks, loose teeth, missing teeth, or any other

damage. Do not use if damage is observed or suspected.

Always wait for the blade to stop completely, and unplug the tool before changing accessories or

making adjustments.

1

1

Page 11

20 21

model no. 055-6761-2 | contact us 1-800-689-9928

BENCH MOUNTING

(Fig. 14)

This tool should be bolted with four bolts to a level and

stable surface using the bolt holes (1) provided in the tool’s

base. This will help prevent tipping and possible injury.

INSTALLING THE WORK CLAMP (Fig. 15)

There are two mounting holes for the work clamp. These

are located just behind the fence on the left and right side

of the base.

•

Loosen the locking screw with a Phillips screwdriver.

• Place the work clamp in the desired mounting hole.

• Tighten the screw to hold the work clamp.

ON/OFF TRIGGER SWITCH (Fig. 16)

To turn the saw on, depress the trigger switch. To turn

the tool off, release the switch. There is no provision for

locking the switch on. To lock the saw off, place a padlock

in the hole provided in the trigger switch.

When the trigger switch is released, the blade will be

stopped within 10 seconds.

DRY RUN

For safe operation, it’s necessary to know where the blade

will contact the workpiece during the cutting process.

Always perform the simulated cutting process with the

switch off to check and understand the projected path of

the saw blade. Adjust the work clamps and fences to avoid

any contact with the lower guard and cutting action.

MITRE CUT (Fig. 17)

• When a mitre cut is required, unlock the table by

turning the mitre handle (1) counter-clockwise.

• While holding the mitre handle, lift up on the positive

stop locking lever (2).

• Rotate the table to the right or left with the mitre

handle.

• When the table is in the desired position, as shown

on the mitre scale (3), release the positive stop

locking lever and tighten the mitre handle. The table

is now locked at the desired angle. Positive stops are

provided at 0°, 15°, 22.5°, 31.6° and 45°.

BEVEL CUT (Fig. 18)

• When a bevel cut is required, loosen the bevel lock

knob (1) by turning it clockwise.

• Tilt the cutting head to the desired angle, as shown on

the bevel scale (2).

• The blade can be positioned at any angle, from a

90° straight cut (0° on the scale) to a 45° left bevel.

Tighten the bevel lock knob to lock the cutting head in

position. Positive stops are provided at 0° and 45°.

COMPOUND CUT (Fig. 19)

A compound cut is the combination of a mitre and a bevel

cut simultaneously.

• Loosen the bevel lock knob (1) and position the cutting

head at the desired bevel position. Lock the bevel lock

knob.

• Loosen the mitre handle (2). Lift up the positive stop

locking lever (3) and position the table at the desired

angle. Release the positive stop locking lever and lock

the mitre handle.

OPERATING INSTRUCTIONS

WARNING!

Ensure that the tool will not move on the supporting surface. Movement of the mitre saw on the

supporting surface while cutting may result in loss of control and serious personal injury.

WARNING!

• To avoid injury, after completing a cut and releasing the trigger switch, wait and conrm that

the blade has stopped before raising the cutting head.

′• To avoid injury, check and tighten the blade bolt periodically.

OPERATING INSTRUCTIONS

IMPORTANT:

Always tighten the mitre table lock handle before performing every cutting operation.

2

1

1 1

1 1

1

2

3

2

3

1

Page 12

1

2

3

4

22 23

model no. 055-6761-2 | contact us 1-800-689-9928

SLIDING CARRIAGE SYSTEM

(Fig. 20)

• For chop cutting operations on small workpieces,

slide the cutting head completely toward the rear of

the unit and tighten the carriage lock knob (1).

• To cut wide boards up to 8” (20.3 cm), the carriage

lock knob must be loosened to allow the cutting head

to slide freely.

SLIDE CUTTING WIDE BOARDS UP TO

8” (20.3 cm) WIDE

To avoid injury:

• Let the blade reach full speed before cutting. This will help reduce the risk of a thrown workpiece.

• Do not make crosscuts by lowering the blade and pulling the cutting head through the wood

toward you.

To Slide Cut Wide Boards (Fig. 21)

• Unlock the carriage lock knob (1) and allow the

cutting head assembly to move freely.

• Set both the desired bevel angle and/or the mitre

angle and lock into position.

• Use a work clamp (2) to secure the workpiece (3).

• Grasp and pull the switch handle (4) forward until

the centre of the saw blade is over the front of the

workpiece.

• Engage the trigger to turn the saw on.

• When the saw reaches full speed, slowly push the switch handle down, cutting through the leading

edge of the workpiece.

• Slowly move the switch handle toward the fence, completing the cut.

• Release the trigger and allow the blade to stop spinning before raising the cutting head and removing

the workpiece.

SETTING CUTTING DEPTH (Fig. 22)

The depth of cut can be preset for even and repetitive

shallow cuts.

• Slide the stop plate (1) towards the front position.

• Loosen the lock nut (2) to free the lock knob (3), turn

the stop knob until the cutting head down until the

teeth of the blade are at the desired depth.

• While holding the upper arm in that position, tighten

the lock nut to secured the stop knob.

• Recheck the blade depth by moving the cutting head

front to back through the full motion of typical cut

along the control arm.

CUTTING GROOVES (Fig. 23)

• Mark lines to identify the width and depth of the

desired cut on the workpiece and put the workpiece

on the table and aim the inside tip of the blade at the

line. Use a work clamp to secure the workpiece on the

table.

• Lower the cutting head so the tip of the blade touches

the top surface of the workpiece at the marked line.

• While holding the upper arm in position, loosen the

lock nut and turn the stop knob until it touches the

stop plate, then retighten the lock nut. (SEE “SETTING

CUTTING DEPTH”)

• Cut two parallel grooves as shown.

• Use a wood chisel or make multiple passes with a router to remove the material between the two

outside grooves to create the groove.

OPERATING INSTRUCTIONS

CAUTION!

To reduce the risk of injury, return carriage to the full rear position after each crosscut operation.

CAUTION!

Always use a work clamp to maintain control and reduce the risk of workpiece damage and

personal injury.

WARNING!

DO NOT USE A DADO BLADE, use only the standard saw blade for this operation.

OPERATING INSTRUCTIONS

NOTE:

Always perform a dry run cut so you can determine if the operation being attempted is possible before

power is applied to the saw.

1

2

3

1

Page 13

24 25

model no. 055-6761-2 | contact us 1-800-689-9928

CUTTING WARPED MATERIAL

(Fig. 24)

When cutting warped material, be sure that the convex

side is against the fence. If the workpiece is placed with

the concave side facing the fence, it will pinch the blade

near the completion of the cutting.

AUXILIARY WOOD FENCE (Fig. 25)

When making multiple or repetitive cuts that result in

cut-off pieces of 1” (2.5 cm) or less, it is possible for the

saw blade to catch the cut-off piece and throw it out of the

saw or into the blade guard and housing, possibly causing

damage or injury. To minimize this, an auxiliary wood fence

can be mounted to your saw. Holes are provided in the

saw fence to attach an auxiliary wood fence (this provides

additional depth of cut). This fence should be constructed

of straight auxiliary wood approximately 3/4” (1.9 cm)

thick by 1 1/2” (3.8 cm) high by 16” (40.6 cm) long. Attach

the wood fence securely and make a full depth cut to

make a blade slot. Check for interference between the

wood fence and the lower blade guard. Adjust if necessary.

CUTTING BASE MOULDING (Fig. 26)

Base mouldings and many other mouldings can be cut

on a compound mitre saw. The setup of the saw depends

on moulding characteristics and applications, as shown.

Perform practice cuts on scrap material to achieve best

results:

• Always make sure mouldings rest firmly against

the fence and table. Use hold-down or C-clamps,

whenever possible, and place tape on the area being

clamped to avoid marks.

• Reduce splintering by taping the cut area prior to

making cut. Mark cut line directly on the tape.

• Splintering typically happens due to wrong blade application and thinness of the material.

OPERATING INSTRUCTIONS

NOTE:

Always perform a dry run cut so you can determine if the operation being attempted is possible before

power is applied to the saw.

OPERATING INSTRUCTIONS

CUTTING CROWN MOULDING (Fig. 27, 28)

Your compound mitre saw is suited for the difcult task of

cutting crown moulding. To t properly, crown moulding

must be compound-mitreed with extreme accuracy. The

two surfaces on a piece of crown moulding that t at

against the ceiling and wall are at angles that, when added

together, equal exactly 90°.

Most crown moulding has a top rear angle (the section that

ts at against the ceiling) of 52° and a bottom rear angle

(the section that ts at against the wall) of 38°.

In order to accurately cut crown moulding for a 90° inside

or outside corner, lay the moulding with its broad back

surface at on the saw table. When setting the bevel and

mitre angles for compound mitres, remember the settings

are interdependent; changing one changes the other, as

well.

Bevel/Mitre Settings (when the angle between the walls equals 90°)

KEY BEVEL SETTING Mitre SETTING TYPE OF CUT

Inside corner - Left side

IL 33.9° 31.6° Right 1. Position top of moulding against fence.

2. Mitre table set at RIGHT 31.6°.

3. LEFT side is finished piece.

Inside corner - Right side

IR 33.9° 31.6° Left 1. Position bottom of moulding against

fence.

2. Mitre table set at LEFT 31.6°.

3. LEFT side is finished piece.

Outside corner - Left side

OL 33.9° 31.6° Left 1. Position bottom of moulding against

fence.

2. Mitre table set at LEFT 31.6°.

3. RIGHT side is finished piece.

Outside corner - Right side

OR 33.9° 31.6° Right 1. Position top of moulding against fence.

2. Mitre table set at RIGHT 31.6°.

3. RIGHT side is finished piece.

IL

IR

OL

OR

Inside

Corner

Outside

Corner

Fence

Mitre saw table

Workpiece

Mitre at 45°

bevel at 0°

Fence

Mitre saw table

Mitre at 0°

bevel at 45°

Workpiece

Fence

Mitre saw table

Workpiece

Fence

Mitre saw table

Workpiece

Page 14

26 27

model no. 055-6761-2 | contact us 1-800-689-9928

OPERATING INSTRUCTIONS

OPERATING INSTRUCTIONS

52/38° CROWN MOULDING 45/45° CROWN MOULDING

Angle Between

Walls

Mitre Setting Bevel Setting Mitre Setting Bevel Setting

104 25.69 29.02 28.92 25.81

105 25.29 28.67 28.48 25.50

106 24.89 28.31 28.05 25.19

107 24.49 27.96 27.62 24.87

108 24.10 27.59 27.19 24.56

109 23.71 27.23 26.77 24.24

110 23.32 26.87 26.34 23.93

111 22.93 26.51 25.92 23.61

112 22.55 26.15 25.50 23.29

113 22.17 25.78 25.08 22.97

114 21.79 25.42 24.66 22.66

115 21.42 25.05 24.25 22.33

116 21.04 24.68 23.84 22.01

117 20.67 24.31 23.43 21.68

118 20.30 23.94 23.02 21.36

119 19.93 23.57 22.61 21.03

120 19.57 23.20 22.21 20.70

121 19.20 22.83 21.80 20.38

122 18.84 22.46 21.40 20.05

123 18.48 22.09 21.00 19.72

124 18.13 21.71 20.61 19.39

125 17.77 21.34 20.21 19.06

126 17.42 20.96 19.81 18.72

127 17.06 20.59 19.42 18.39

128 16.71 20.21 19.03 18.06

129 16.37 19.83 18.64 17.72

130 16.02 19.45 18.25 17.39

131 15.67 19.07 17.86 17.05

132 15.33 18.69 17.48 16.71

133 14.99 18.31 17.09 16.38

134 14.66 17.93 16.71 16.04

135 14.30 17.55 16.32 15.70

136 13.97 17.17 15.94 15.36

137 13.63 16.79 15.56 15.02

138 13.30 16.40 15.19 14.62

139 12.96 16.02 14.81 14.34

140 12.63 15.64 14.43 14.00

141 12.30 15.25 14.06 13.65

142 11.97 14.87 13.68 13.31

143 11.64 14.48 13.31 12.97

144 11.31 14.09 12.94 12.62

145 10.99 13.71 12.57 12.29

CROWN MOULDING CHART

To aid in the correct setting, the compound angle setting chart below has been

provided.

52/38° CROWN MOULDING 45/45° CROWN MOULDING

Angle Between

Walls

Mitre Setting Bevel Setting Mitre Setting Bevel Setting

67 42.93 41.08 46.89 36.13

68 42.39 40.79 46.35 35.89

69 41.85 40.50 45.81 35.64

70 41.32 40.20 45.28 35.40

71 40.79 39.90 44.75 35.15

72 40.28 39.61 44.22 34.89

73 39.76 39.30 43.70 34.64

74 39.25 39.00 43.18 35.38

75 38.74 38.69 42.66 34.12

76 38.24 38.39 42.15 33.86

77 37.74 38.08 41.64 33.60

78 37.24 37.76 41.13 33.33

79 36.75 37.45 40.62 33.07

80 36.27 37.13 40.12 32.80

81 35.79 36.81 39.62 32.53

82 35.31 36.49 39.13 32.25

83 34.83 36.17 38.63 31.98

84 34.36 35.85 38.14 31.70

85 33.90 35.52 37.66 31.42

86 33.43 35.19 37.17 31.34

87 32.97 34.86 36.69 30.86

88 32.52 34.53 36.21 30.57

89 32.07 34.20 35.74 30.29

90 31.62 33.86 35.26 30.00

91 31.17 33.53 34.79 29.71

92 30.73 33.19 34.33 29.42

93 30.30 32.86 33.86 29.13

94 29.86 32.51 33.40 28.83

95 29.43 32.17 32.94 28.54

96 29.00 31.82 32.48 28.24

97 28.58 31.48 32.02 27.94

98 28.16 31.13 31.58 27.64

99 27.74 30.78 31.13 27.34

100 27.32 30.43 30.68 27.03

101 26.91 30.08 30.24 26.73

102 26.50 29.73 29.80 26.42

103 26.09 29.38 29.36 26.12

Page 15

28 29

model no. 055-6761-2 | contact us 1-800-689-9928

SAWDUST

Periodically, sawdust will accumulate under the table and base. This could cause difculty in the movement

of the table when setting up a mitre cut. Frequently blow out or vacuum up the sawdust.

LOWER BLADE GUARD

Do not use the saw without the lower blade guard.

The lower blade guard is attached to the saw for your protection. Should the lower guard become damaged,

do not use the saw until the damaged guard has been replaced. Check regularly to make sure the lower

guard is working properly. Clean the lower guard of any dust or buildup with a damp cloth.

REPLACING CARBON BRUSHES (Fig. 29)

Replace both carbon brushes when either has less than

1/4” (0.6 cm) length of carbon remaining, or if the spring or

wire is damaged or burned. To inspect or replace brushes,

rst unplug the saw. Remove the two screws on the back

cover of the motor and take the cover off. Move the coil

spring which press on the carbon brush to other side to

free the carbon brush. Pull out the brush and the wire

which connect to the holder. Replace it for a new carbon

brush. When replace for the other side. To reassemble,

reverse the procedure. Tighten two screws on the back

cover.

OPERATION INSTRUCTIONS

MAINTENANCE

WARNING!

• To avoid re or toxic reaction, never use gasoline, naphtha acetone, lacquer thinner or similar

highly volatile solvents to clean the mitre saw.

• To avoid injury from unexpected starting or electrical shock, unplug the power cord before

working on the saw.

• For your safety, this saw is double-insulated. To avoid electrical shock, re or injury, use

only parts identical to those identied in the parts list. Reassemble exactly to avoid electrical

shock.

CAUTION!

If blowing sawdust, wear proper eye protection to keep debris from blowing into eyes.

CAUTION!

• Do not use solvents on the guard. They could make the plastic cloudy and brittle.

• When cleaning the lower guard, unplug the saw to avoid unexpected start-up.

NOTE:

To reinstall the same brushes, first make sure the brushes go back in the way they came out.

52/38° CROWN MOULDING 45/45° CROWN MOULDING

Angle Between

Walls

Mitre Setting Bevel Setting Mitre Setting Bevel Setting

146 10.66 13.32 12.20 11.93

147 10.34 12.93 11.83 11.59

148 10.01 12.54 11.46 11.24

149 9.69 12.16 11.09 10.89

150 9.37 11.77 10.73 10.55

151 9.05 11.38 10.36 10.20

152 8.73 10.99 10.00 9.85

153 8.41 10.60 9.63 9.50

154 8.09 10.21 9.27 9.15

155 7.77 9.82 8.91 8.80

156 7.46 9.43 8.55 8.45

157 7.14 9.04 8.19 8.10

158 6.82 8.65 7.83 7.75

159 6.51 8.26 7.47 7.40

160 6.20 7.86 7.11 7.05

161 5.88 7.47 6.75 6.70

162 5.57 7.08 6.39 6.35

163 5.26 6.69 6.03 6.00

164 4.95 6.30 5.68 5.65

165 4.63 5.90 5.32 5.30

166 4.32 5.51 4.96 4.94

167 4.01 5.12 4.61 4.59

168 3.70 4.72 4.25 4.24

169 3.39 4.33 3.90 3.89

170 3.08 3.94 3.54 3.53

171 2.77 3.54 3.19 3.10

172 2.47 3.15 2.83 2.83

173 2.15 2.75 2.48 2.47

174 1.85 2.36 2.12 2.12

175 1.54 1.97 1.77 1.77

176 1.23 1.58 1.41 1.41

177 0.92 1.18 1.06 1.06

178 0.62 0.79 0.71 0.71

179 0.31 0.39 0.35 0.35

Page 16

30 31

model no. 055-6761-2 | contact us 1-800-689-9928

MAINTENANCE

This will avoid a break-in period that reduces motor performance and increases wear.

LUBRICATION (Fig. 30)

All the motor bearings in this tool are lubricated with a

sufcient amount of high-grade lubricant for the life of

the unit under normal operating conditions; therefore, no

further lubrication is required.

Lubricate the following as necessary:

Chop pivot: Apply light machine oil to points indicated in

illustration.

Central pivot of plastic guard: Use light household oil

(sewing machine oil) on metal-to-metal or metal-to-plastic

guard contact areas as required for smooth, quiet operation. Avoid excessive oil as sawdust will cling to it.

TROUBLESHOOTING

PROBLEM PROBABLE CAUSE

SUGGESTED CORRECTIVE

ACTION

Brake does not stop blade

within 10 seconds

Motor brushes not sealed or lightly

sticking

Inspect/clean/replace brushes

Motor brake overheated from use

of defective or wrong size blade or

rapid ON/OFF cycling

Use a recommended blade

Arbor bolt is loose Retighten

Motor does not start

Brush worn Replace brushes

Power source fuse or time delay

fuse

Check time delay fuse or circuit

breaker

Angle of cut inaccurate

Mitre table unlocked

Rotate the mitre locking handle all

the way to the right

Too much sawdust under table

Vacuum or blow out dust while

wearing eye protection

Head assembly cannot fully

raise or blade guard cannot fully close

Parts failure Contact service centre

Pivot spring not replaced properly

after service

Contact service centre

Sawdust build-up Clean and lubrica te moving parts

Lock-down pin not set properly

Check, adjust and properly set sawhead locking pin

Blade binds, jams or burns

wood

Improper operation

See OPERATING INSTRUCTIONS

section

Dull blade Replace or sharpen blade

Improper blade Replace blade

Warped blade Replace blade

Blade hits table Misalignment

See “Assembly and adjustments”

section

Brush sparks excessively

when switch is released

Brush worn/damaged Replace brushes

Saw vibrates or shakes

Saw blade damaged Replace blade

Saw blade loose Tighten black bolt

Saw not properly fastened down Fasten saw to stand, bench or table

Workpiece not properly supported

Properly support or clamp

workpiece

Page 17

32 33

model no. 055-6761-2 | contact us 1-800-689-9928

EXPLODED VIEW

PARTS LIST

MASTERCRAFT® 7 1/4” (18.4 CM) SLIDING MITRE SAW

When servicing the Mastercraft® Sliding Compound Mitre Saw, use only Mastercraft® replacement parts.

The use of any other parts may cause damage to the product. All servicing of the mitre saw should be

performed by a qualied service technician. For more information, call the Toll-Free Helpline at 1-800-689-

9928.

NO. Description Qty No. Description Qty

01 Screw 8 26 Inner ange 1

02 Self-tapping screw 8 27 Spindle 1

03 Top handle 1 28 Flat key 1

04 Trigger 1 29 Gear box cover 1

05 Rubber sleeve 1 30 Bearing 1

06 Cord press plate 1 31 Screw 2

07 Power cord sleeve 1 32 Spindle lock stop plate 1

08 Power cord and plug 1 33 Gear 1

09 Trigger spring 1 34 Criclip for shaft 1

10 Micro-switch 1 35 Copper sleeve 1

11 Screw 3 36 Spindle lock pin 1

12 Spring washer 11 37 Circlip 1

13 Washer 10 38 Spindle lock pin spring 1

14 Lower handle 1 39 Fixed guard 1

15 Locknut 2 40 Cuting depth adjustment screw 1

16 Moving guard cover plate 1 41 Socket head cap screw 1

17 Moving guard 1 42 Nut 4

18 Torsional spring 1 43 Knurled nut 1

19 Tooth screw 1 44 Setscrew 1

20 Screw 1 45 Bearing 1

21 Guard support 1 46 Rotor 1

22 Hex bolt 1 47 Bearing 1

23 Hex reverse screw 1 48 Fan guard 1

24 Outer ange 1 49 Self-tapping screw 2

25 Blade 1 50 Stator 1

1

1

2

3

4

9

10

14

8

7

11

6

12

13

111

2

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

35

36

37

38

39

40

41

42

43

44

46

47

48

49

50

51

52

53

54

55

56

57

58

59

64

63

65

66

67

68

69

7070

70707070

71

71

73

75

75

74

7676

81

77

78

79

80

86

87

8888

89

90

91

96

95

94

97

9898

82

83

85

99

100

100

101

101

102

103

104

105

106

107

60

61

108

109

110

111

115

117

112

113

5

33

34

45

126

72

84

8484

92

93

132

116

128

118

119

125

124

62

114

121

122

123

127

129

130

131

120

114

84

2

65

66

67

66

67

12

11

2

13

2

12

13

15

42

65

66

65

66

42

67

42

12

84

85

99

71

13

71

76

12

86

67

65

66

Page 18

34 35

model no. 055-6761-2 | contact us 1-800-689-9928

PARTS LIST

NO. Description Qty No. Description Qty

51 Motor housing 1 76 Half-round head screw 4

52 Brush holder 2 77 Cuting depth stop plate 1

53 Coil spring 2 78 Location pin 1

54 Carbon brush 2 79 O-ring 1

55 Self-tapping screw 4 80 Location pin knob 1

56 Motor housing cover 1 81 Support 1

57 Mitre lock handle 1 82 Shoulder screw 1

58 Mitre angle lock rod 1 83 Connection rod 1

59 Square nut 1 84 Wave washer 3

60 Location push button spring 1 85 Shoulder screw 2

61 Location push button 1 86 Buffer ring 2

62 Lock plate for mitre lock rod 1 87 Bearing cover 1

63 Screw 1 88 Straight bearing 2

64 Turntable 1 89 Bevel angle indication label 1

65 Screw 7 90 Crank arm 1

66 Spring washer 7 91 Short knob 2

67 Washer 5 92 Bevel lock knob 1

68 Mitre angle pointer 1 93 Hex bolt 1

69 Insert 1 94 Rotary shaft 1

70 Sunk screw 6 95 Washer 1

71 Washer 3 96 Locknut 1

72 Socket head cap screw 1 97 Guide rod support 1

73 Bevel angle pointer 1 98 Guide rod 2

74 Setscrew 1 99 Screw 2

75 Setscrew 2 100 Spring washer 2

PARTS LIST

NO. Description Qty No. Description Qty

101 Hex screw 2 117 Big torsional spring 1

102 Fence 1 118 Brand label 1

103 Base 1 119 Dust bag 1

104 Locknut 1 120 Inner hex screw 1

105 Mitre angle indication label 1 121 Rating label 1

106 Storage for hex key 1 122 Warning label 1

107 Hex key 1 123 Spring 1

108 Press plate of clamp 1 124 Locknut 1

109 Clamp arm 1 125 Socket head cap screw 1

110 Clamp screw knob 1 126 Mitre lock handle cover 1

111 Clamp rod 1 127 Inner wire sleeve 1

112 Inner tooth washer 1 128 Washer 1

113 Moving guard wheel 1 129 Terminal 1

114 Washer 2 130 Washer 1

115 Rotary shaft 1 131 Wave washer 1

116 Big torsional spring sleeve 1 132 Clamp lock knob 1

Page 19

36 37

model no. 055-6761-2 | contact us 1-800-689-9928

WARRANTY

WARRANTY

3-YEAR LIMITED WARRANTY

This Mastercraft product is guaranteed for a period of 3 years from the date of original retail purchase

against defects in workmanship and materials, except for the following component:

Component A: Accessories, which are guaranteed for a period of 1-year from the date of original retail

purchase against defects in workmanship and materials.

Subject to the conditions and limitations described below, this product, if returned to us with proof of

purchase within the stated warranty period and if covered under this warranty, will be repaired or replaced

(with the same model, or one of equal value or specification), at our option. We will bear the cost of any

repair or replacement and any costs of labour relating thereto.

These warranties are subject to the following conditions and limitations:

a) a bill of sale verifying the purchase and purchase date must be provided;

b) this warranty will not apply to any product or part thereof which is worn or broken or which has

become inoperative due to abuse, misuse, accidental damage, neglect or lack of proper installation,

operation or maintenance (as outlined in the applicable owner’s manual or operating instructions) or

which is being used for industrial, professional, commercial or rental purposes;

c) this warranty will not apply to normal wear and tear or to expendable parts or accessories that may

be supplied with the product that are expected to become inoperative or unusable after a seasonable

period of use;

d) this warranty will not apply to routine maintenance and consumable items such as, but not limited to,

fuel, lubricants, vacuum bags, blades, belts, sandpaper, bits, fluids, tune-ups or adjustments;

e) this warranty will not apply where damage is caused by repairs made or attempted by others (i.e.

persons not authorized by the manufacturer);

f) this warranty will not apply to any product that was sold to the original purchaser as a reconditioned or

refurbished product (unless otherwise specified in writing);

g) this warranty will not apply to any product or part thereof if any part from another manufacturer is

installed therein or any repairs or alterations have been made or attempted by unauthorized persons;

h) this warranty will not apply to normal deterioration of the exterior finish, such as, but not limited

to, scratches, dents, paint chips, or to any corrosion or discolouring by heat, abrasive and chemical

cleaners; and

i) this warranty will not apply to component parts sold by and identied as the product of another com-

pany, which shall be covered under the product manufacturer’s warranty, if any.

Additional limitations

This warranty applies only to the original purchaser and may not be transferred. Neither the retailer nor

the manufacturer shall be liable for any other expense, loss or damage, including, without limitation, any

indirect, incidental, consequential or exemplary damages arising in connection with the sale, use or inability

to use this product.

Notice to consumer

This warranty gives you specific legal rights, and you may have other rights, which may vary from province

to province. The provisions contained in this warranty are not intended to limit, modify, take away from,

disclaim or exclude any statutory warranties set forth in any applicable provincial or federal legislation.

Loading...

Loading...