Page 1

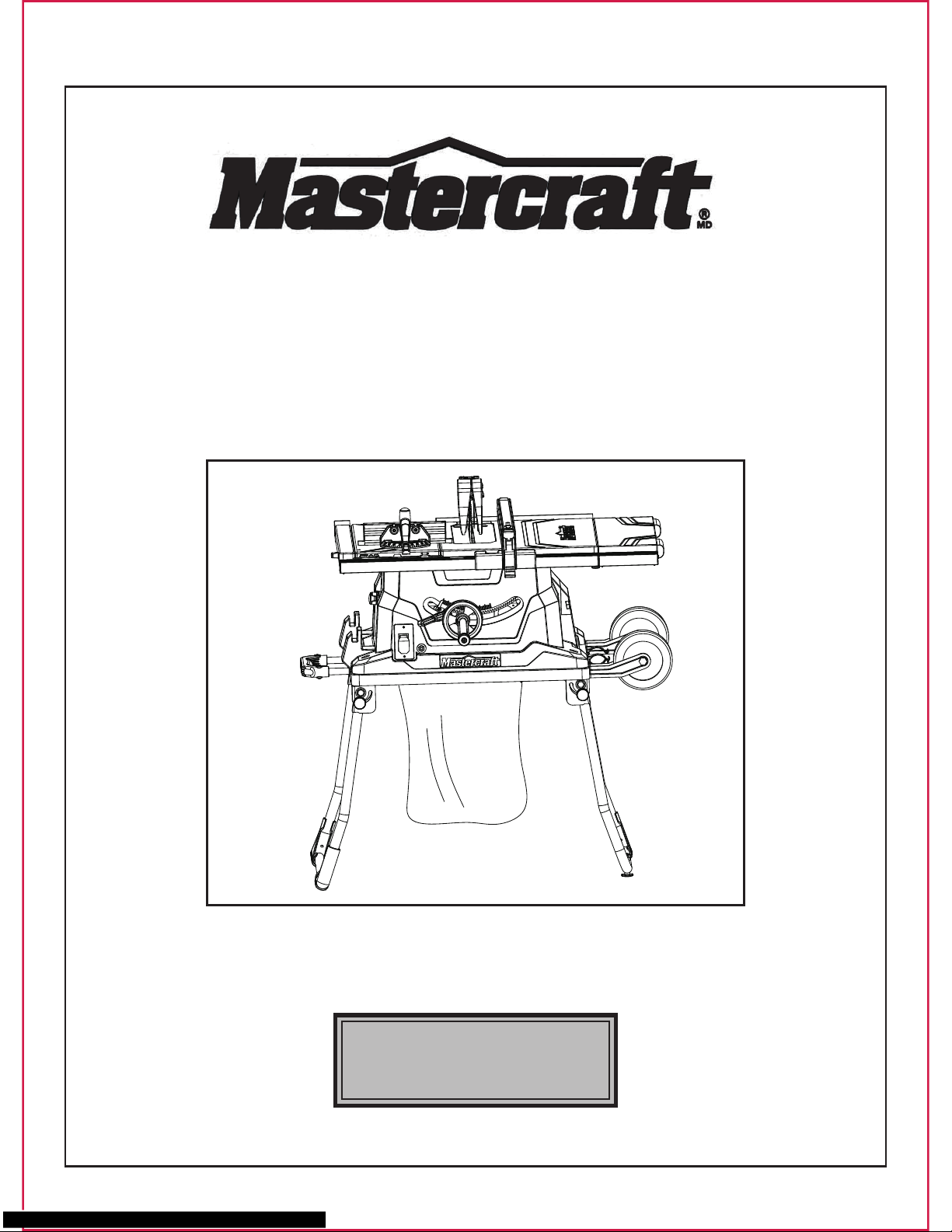

TABLE SAW

WITH SLIDING TABLE

055-6742-8

User Manual

Toll-free helpline

1-800-689-9928

Page 2

2

Table of contents

I.Specifications

SECTION

PAGE

I. Specifications

II. General safety guidelines

III. Electrical information

IV. Know your table saw

V. Assembly and adjustments

VI. Operating instructions

VII. Maintenance

VIII. Troubleshooting guide

IX. Warranty

X. Part list

Motor: 120 V, 60 Hz, 15 A,

Speed: 4500 RPM (no load)

Blade: 10” (25.4 cm) carbide-tipped

Right extension table: 19 11/16 x 6 1/10” (50 x 15.5 cm)

Main table size: 26 1/2 x 19 11/16” (67.3 x 50 cm)

Rear table size: 26 1/2 x 2 1/2” (67.3 x 6.4 cm)

Sliding tale size: 8 2/3” x 19 11/16” (22 x 50 cm)

Laser: Class IIIA

Laser wavelength: 630–665 nm

Laser outpower: <5 mW

Net weight: 75 lb (34 kg)

Depth of cut at 90°: 3 9/64” (8 cm)

Depth of cut at 45°: 2 5/32” (5.5 cm)

2

3

7

8

9

23

30

32

33

34

............................................................................................

........................................................................

..............................................................................

...............................................................................

......................................................................

............................................................................

..........................................................................................

..........................................................................

.................................................................................................

....................................................................................................

Page 3

1. 1. Store all safety guidelines and instructions for future use.

2. This device is not intended for use by people (including children) lacking experience with

electrical power tools unless they have received instructions about how the device is to be

used. Children have to be supervised to ensure that they do not play with the device.

3. Store the operating instructions so that they are always available to the user of the tool

when it is being operated.

4. If you lend this device to other people, then always hand over these operating instructions to

ensure safe use. Instruct inexperienced people in accordance with these safety instructions.

5. Keep your working area tidy. Untidiness in your work area can cause accidents.

6. Pay attention to the surrounding conditions. Do not expose the electric power tool to rain. Do

not use electric power tools in damp or wet conditions. Ensure that the work area is well lit.

Do not use electric power tools where there is a danger of fire or explosion.

7. Protect yourself against electric shocks. Avoid bodily contact with earthed parts (e.g. pipes,

radiators, electric hobs or cooling appliances).

8. Keep other people away from the work area. Do not let other people, especially children,

touch the electric power tool or the power cable. Keep them away from your work area.

9. Store unused electric power tools safety. Unused electric power tools should be stored in a

dry, high-lying or locked place, out of the reach of children.

10.Do not overload your electric power tool. It works better and more securely within the stated

output range.

11.Use the correct electric power tool. Do not use inefficient machines for heavy work. Do not

use the electric power tool for purposes which it was not intended for. For example, do not

use circular saws to cut wooden masts or logs.

12.Wear suitable clothing. Do not wear baggy clothing or jewellery, as they can be caught by

moving parts. When working outdoors, anti-slip shoes are recommended. If you have long

WARNING: Read all the safety guidelines and instructions before you use this electric power

tool!

3

WARNING! When using electrical power tools, the following essential safety measures have

to be observed to prevent electric shocks, injury and fire hazards. Failure to adhere to the

safety guidelines and instructions can cause electric shock, fire and/or severe injuries.

II. General safety guidelines

Page 4

hair, wear a hair net.

13.Wear safety equipment. Wear safety goggles. If the work creates dust, wear a dust mask.

14.Attach the dust extraction unit. If there are connections for dust extraction and collection

equipment, then make sure that the equipment is correctly attached and used.

15.Never use the cable for purposes which it is not intended for. Do not use the cable to pull the

plug out of the power socket. Protect the cable form heat, oil and sharp edges.

16.Secure the workpiece, when necessary use clamping devices to secure the workpiece.

The workpiece is thereby secured better than by hand.

17.Avoid taking abnormal stances. Make sure you stand securely and keep your balance at all

times.

18.Look after your tool with care. Keep the cutting tool sharp and clean so that you are able to

work better and safer with it. Observe the guidelines on lubrication and exchanging the tool.

Check the power cable of the electric power tool regularly and in case of damage let a

recognized specialist repair it. Check extension cables regularly and replace them if they are

damaged. Keep the handles dry, clean and free of oil and grease.

19.Pull the plug out of the power socket when the electric power tool is not in use, before

maintenance and when exchanging tools such as saw blades, drills and mills.

20.Do not leave keys in the device. Before you switch the device off, check that keys and setting

tools have been removed.

21.Avoid starting-up the device accidentally. Make sure that when you insert the plug into the

power socket, the power switch is turned off.

22.Use an extension cable when working outdoors. Only use extension cables outdoors which

are authorized for outdoor use and are correspondingly marked.

23.Be attentive. Be careful what you do. Carry out your work sensibly.

24.Check the electric power tool for any sign of damage. Before continuing work with electric

power tool, safety devices or easily damaged parts have to be carefully checked to ensure

that they function properly and are not defective. Check that the moving parts are working

properly and are not jammed, or whether the parts are damaged. All parts must be correctly

assembled by an experienced individual, unless stated otherwise in the operating instructions,

and meet all required conditions in order to guarantee that the electric power tool functions

without a problem. Damaged switches have to be replaced by a qualified electrician. Do not

use electric power tools if the power switch cannot be turned on and off.

II. General safety guidelines(continued)

4

Page 5

Additional safety guidelines for circular table saws

5

II. General safety guidelines(continued)

25.WARNING!The use of other insertion tools and accessories can present a danger of injury to

you.

26.Let a specialist electrician repair your electric power tool. This electric power tool corresponds

to the applicable safety conditions. Repairs are only allowed to be carried out by a specialist

electrician, using original replacement parts; otherwise accidents may occur.

27.No other people are allowed to stand in the direct vicinity of the machine when it is in use.

People not operating the machine must maintain a suitable safe distance!

28.Never lay the power cable over the machine table!

29.Use the push rod to pass the workpiece safely into the saw blade! Do not come too close to

the saw blade!

30.Make sure that the thickness of the material to be cut is less than the maximum possible

cutting depth.

31.Never cut “hands-free”! The workpiece must always lie level on the machine table and be

moved along the stop! The workpiece must always be pressed hard against the stop!

32.Never cut workpieces that are so small that they cannot be safety pressed against the stop

and could turn!

33.Never cut workpieces that are so small that they cannot be moved by the push rod at a safe

distance from the saw blade!

34.Only cut one workpiece at a time! Never cut several workpieces simultaneously! Workpiece

are not allowed to be placed behind or on top of each other!

35.There is a danger of the workpiece “jamming” and slipping away!

36.Make sure that the workpiece cannot slip while cutting or get jammed in the saw blade!

37.Clean the working area and the workpiece after each cut.

Warning! Switch the device off, remove the plug from the power socket and let the machine

come to a standstill! No foreign bodies are allowed to be on the workpiece or the machine

table! Cut pieces of the workpiece can be caught by the rotating cutting disc and be flung

away!

Page 6

KEEP THIS USER’S MANUAL IN A SAFE PLACE FOR FUTURE REFERENCE.

6

II. General safety guidelines(continued)

38.Never reach into the openings of the device! Never insert objects into the openings of the

device (e.g. the saw blade casing, dust extraction adaptor). Danger of cuts!

39.Never remove the cutting piece if the machine is still switched on or running! Danger of cutting

yourself!

40.Cut workpieces may have sharp edges, ridges or wooden splinters! Danger of cutting injuries!

41.Always switch the machine off and remove the power plug when your leave the machine.

42.Never expose the device to rain or extreme moisture!

43.Do not perform any cuts with this circular table saw, other than those described in these

operating instructions! Seams and notches are not allowed to be sawn!

44.Circular saws are not allowed to be used for slitting (notches which end in the workpiece)!

Page 7

III. Electrical information

7

Make sure your extension cord is properly wired and in good condition. Always replace a

damaged extension cord, or have it repaired by a qualified person before using it. Protect your

extension cords from sharp objects, excessive heat, and damp or wet areas.

Use a separate electrical circuit for your tools. This circuit must consist of not less than #12 wire

with a 20 A time-delayed fuse or a #14 wire with a 15 A time-delayed fuse. Before connecting the

motor to the power line, make sure the switch is in the OFF position and the electric current is

rated the same as the current stamped on the motor nameplate. Running at a lower voltage will

damage the motor.

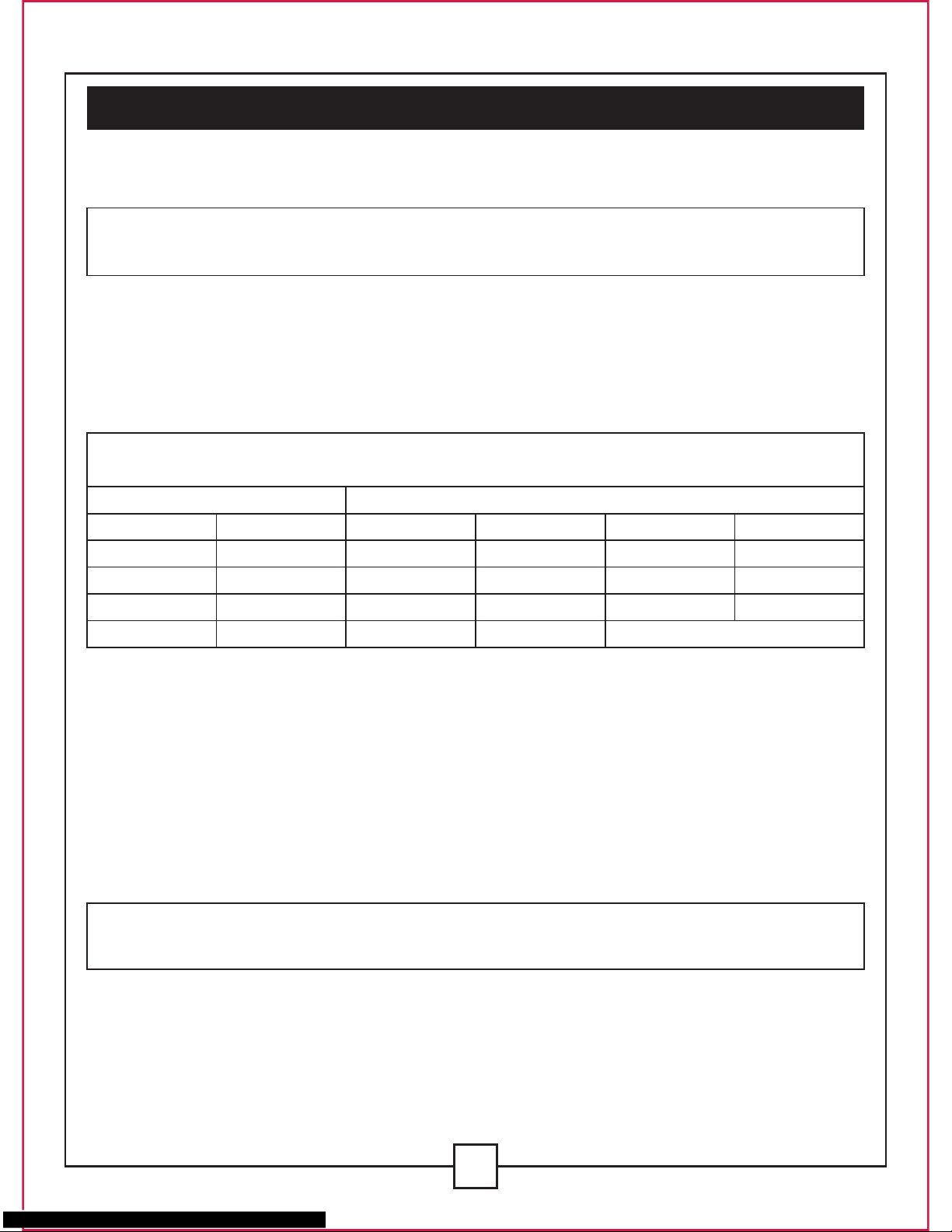

GUIDELINES FOR USING EXTENSION CORDS

WARNING: THIS TABLE SAW IS INTENDED FOR INDOOR USE ONLY. DO NOT EXPOSE

IT TO RAIN OR USE IT IN DAMP LOCATIONS.

Make sure the extension cord is in good condition. When using an extension cord, be sure to use

one that is heavy enough to carry the current that your product will draw. An undersized cord will

cause a drop in line voltage, which will result in loss of power and overheating. The table below

shows the correct size to be used according to cord length and nameplate ampere rating. When

in doubt, use the next heavier gauge. The smaller the gauge number, the heavier the cord.

MINIMUM GAUGE FOR EXTENSION CORDS(AWG)

(when using 120 V only)

Ampere Rating Total length of cord in feet (metres)

More Than Not More Than

0

6

10

12

6

10

12

16

25’ (7.6 m)

18

18

16

14

50’ (15.2 m)

16

16

16

12

100’ (30.5 m)

16

14

14

150’ (45.7 m)

14

12

12

Not Recommended

WARNING: THIS TOOL MUST BE GROUNDED WHILE IN USE IN ORDER TO PROTECT

THE OPERATOR FROM ELECTRIC SHOCK.

Page 8

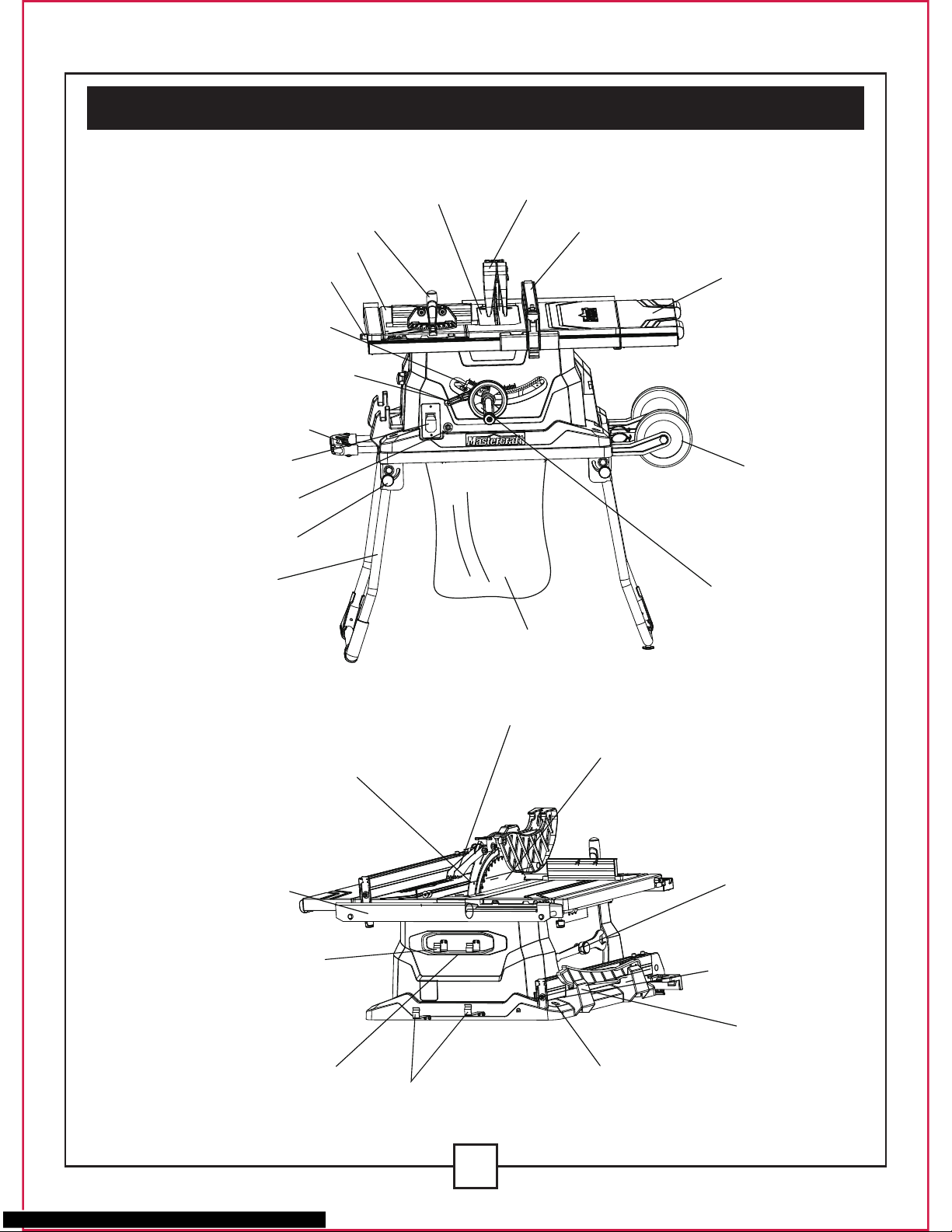

8

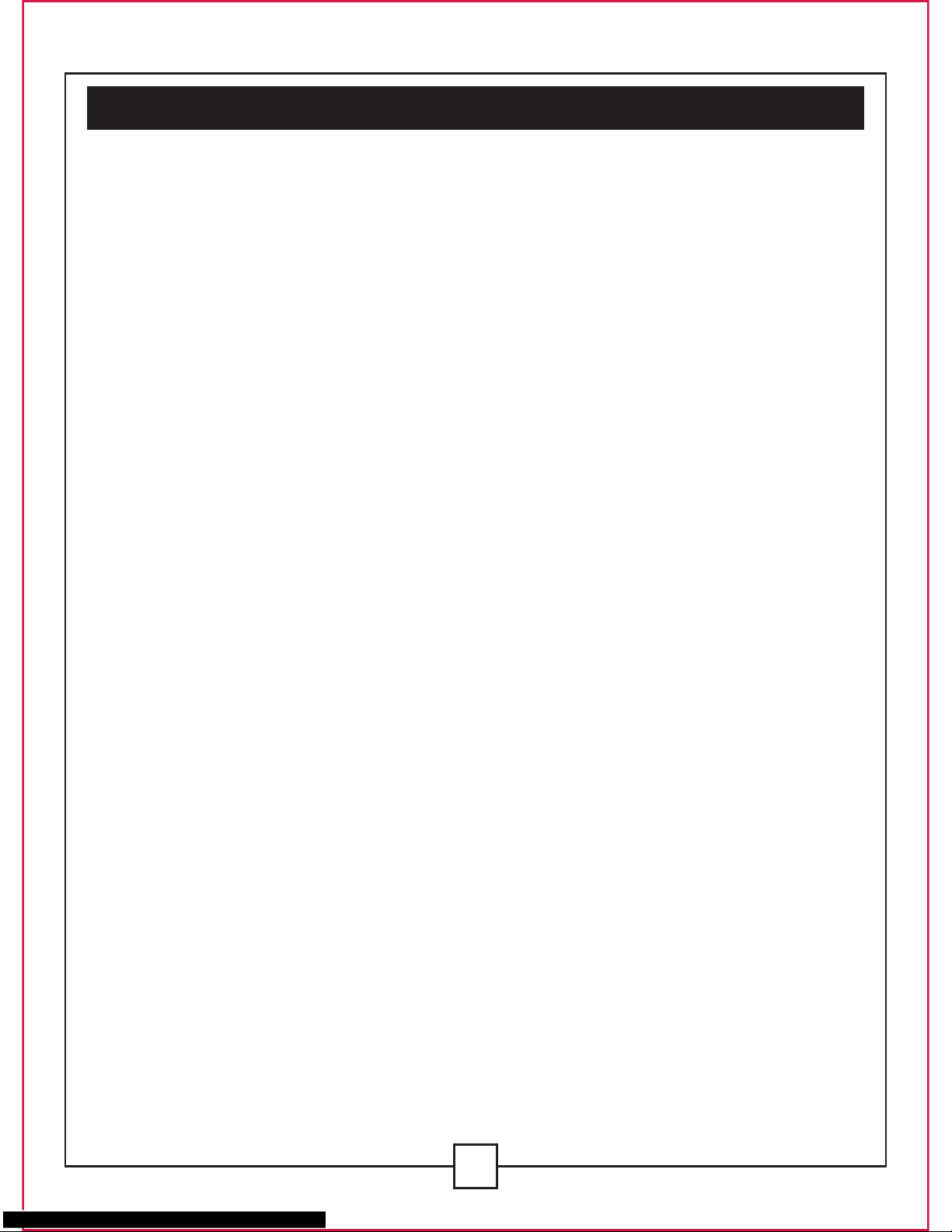

IV. Know your table saw

Mitre gauge

ON/OFF switch Key

Bevel angle

pointer and scale

Roller wheels

Rip fence

Blade guard

Table insert

Sliding mitre table

Sliding mitre table

locking lever

Fold and roll stand

Blade raising/tilting

control handle

Bevel angle

pointer and scale

Blade bevel

lock knob

Stand handle

Stand leg locking

lever

Dust bag

Side table

extension

Mounting

hole

Blade

Anti-Kickback pawls

Splitter

Rear

extension

table

Cord wrap

Limited hook

Guard pothook

Push

sticker

storage

Blade

storage

Rip fence

storage

Page 9

9

V. Assembly and adjustments

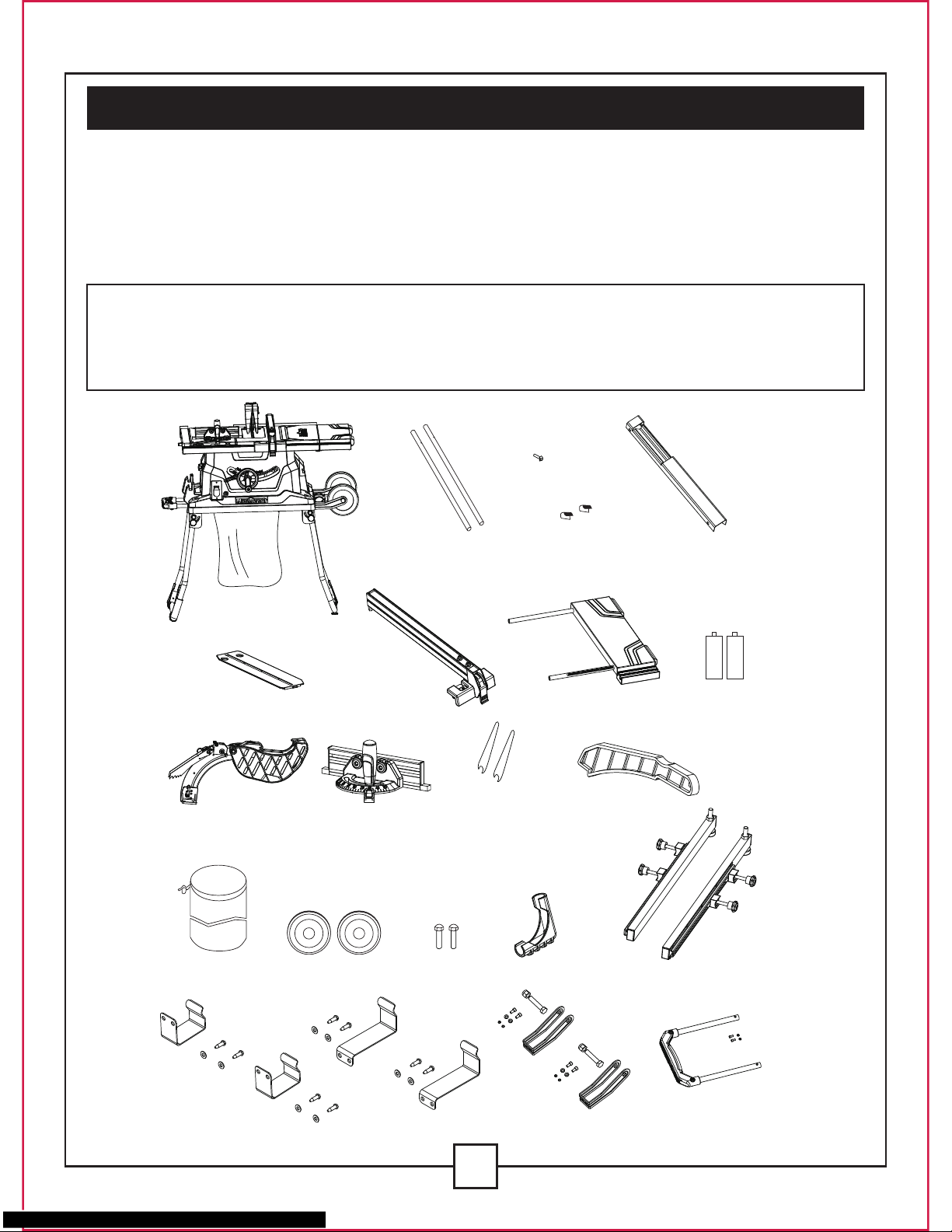

UNPACKING

1. Carefully remove the table saw from the carton.

2. Separate the parts.

3. Lay out all of the parts, and check them against the parts listed below. Examine all of the

parts carefully.

WARNING:

• IF ANY PART IS MISSING OR DAMAGED, DO NOT PLUG THE TABLE SAW IN UNTIL

THE MISSING OR DAMAGED PART HAS BEEN REPAIRED OR REPLACED.

• FOR MORE INFORMATION, CALL THE TOLL-FREE HELPLINE AT 1-800-689-9928.

Batteries

Table saw assembly

Dado insert

Blade guard

and splitter

Mitre gauge Blade wrenches

Dust bag

Limited hook Guard pothhook Wheel support Pull handle

Roller wheels Hex bolts Levelling pad Stand extension poles

Push sticker

Rip fence Right table extension

Rear table extension

tubes

Locating seats

Rear table

extension

Screw

Page 10

10

WARNING: The laser beam is emitted when the laser line is turned on. Do not stare into the

beam or view it directly using optical instruments. Do not remove the warning label that is

aaffixed to the laser cover. Avoid aiming the laser beam directly into the eyes. Caution-use of

controls or adjustments or performance of procedures other than those specified herein may

result in hazardous radiation exposure.

CAUTION-The use of optical instruments with this product will increase eye hazard.

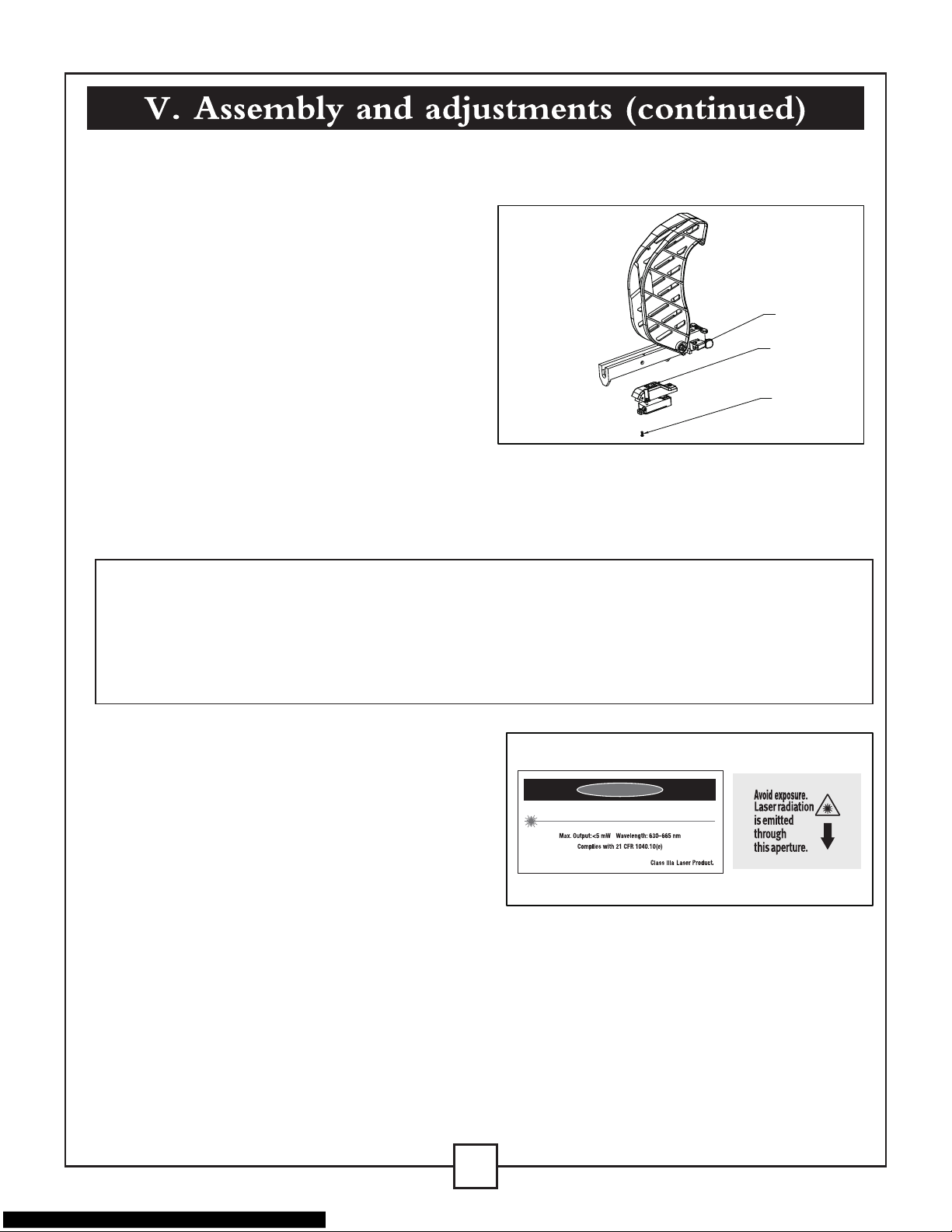

INSTALLING THE BATTERIES FOR THE LASER LINE (FIG. 1)

THE LASER LINE

1. Uninstall the blade guard component by

loosening the handle (1). Remove the

locking screw(2) on the battery box cover

with a screwdriver, and open the battery

compartment.

2. Install two “AAA” batteries.

3. Install the battery box cover by closing the

screw (2), tighten it securely.

4. Turn the switch (3) to the ON position in

order to activate the laser cutting guide.

This tool is equipped with a Hawkeye Laser Line, which is a battery-powered laser cutting guide.

The laser line allows the operator to anticipate the path of the saw blade on the workpiece before

beginning cutting.

Fig. 1

1

3

2

NOTE

• A laser beam is not a toy, and it should not be

used by children. Misuse of the laser line can lead

to irreparable eye damage.

• strongly recommend the use of laser protective

eyewear for the specific wavelength of emitted

light when working on or near reflective surfaces.

• Do not perform any adjustments that are intended

to increase the power of the laser.

• When using the laser line, do not point the laser beam at people and/or reflecting surfaces. Even

a low-intensity laser beam can cause eye damage. Do not look directly into the laser beam.

• If the laser line will not be used for more than three months, remove the batteries in order to

avoid damage from possible leakage.

• The laser line does not include any user-serviceable components. Do not open the housing in

an attempt to repair it.

• Repairs should only be carried out at a service centre or by an authorized service technician.

DANGER

LASER RADIATION-AVOID DIRECT EYE EXPOSURE

Page 11

2

1

Fig. 3

11

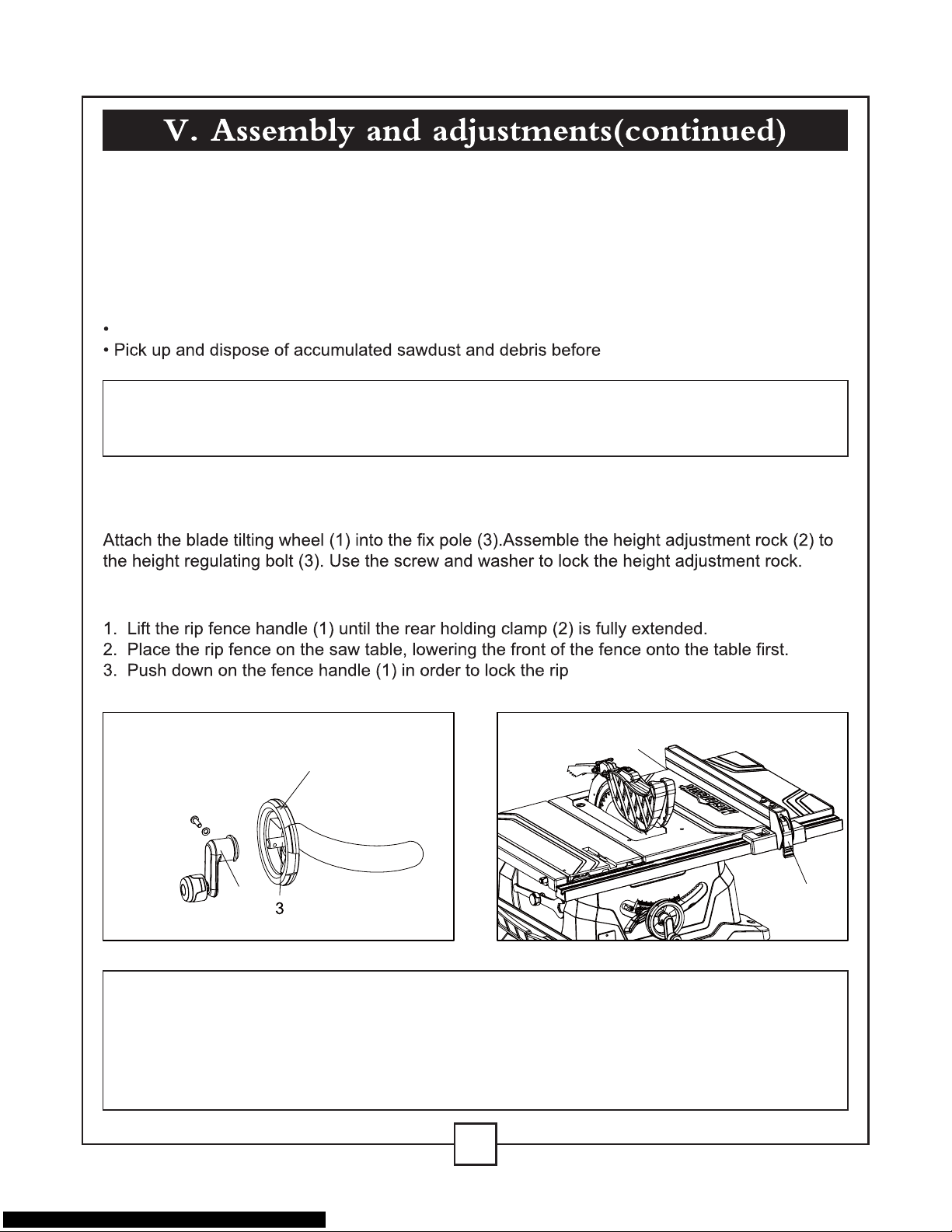

Keep Work Areas Clean

ASSEMBLING THE BLADE RAISING/

TILTING CONTROL HANDLE (FIG. 2)

RIP FENCE (FIG. 3)

WARNING: KEEP THE WORK AREA CLEAN, UNCLUTTERED, AND WELL-LIT. DO NOT

WORK ON A FLOOR SURFACE THAT IS SLIPPERY FROM ACCUMULATED SAWDUST,

DEBRIS OR WAX.

WARNING: IN ORDER TO AVOID INJURY FROM AN ACCIDENTAL START-UP, VERIFY

THAT THE POWER SWITCH IS IN THE “OFF” POSITION, THAT THE SAFETY KEY IS

REMOVED, AND THAT THE POWER CORD IS NOT PLUGGED INTO THE OUTLET. IN

ORDER TO AVOID SERIOUS INJURY, THE REAR OF THE TABLE INSERT MUST BE

FLUSH WITH THE TABLE DURING ALL SAWING OPERATIONS. A RUBBER ADJUSTING

SPACER IS PROVIDED UNDER THE REAR OF THE INSERT FOR THIS PURPOSE.

Accumulated sawdust and wood chips can pose a safety hazard.

each cutting operation.

fence in position.

Fig. 2

1

2

CAUTION

LASER RADIATION.

Do not stare into the beam or view it directly using optical instruments.

Maximum output: <5 mW Wavelength: 630-665 nm Protection Class: IIIA

Page 12

Fig. 4

2

1

3

V. Assembly and adjustments(continued)

12

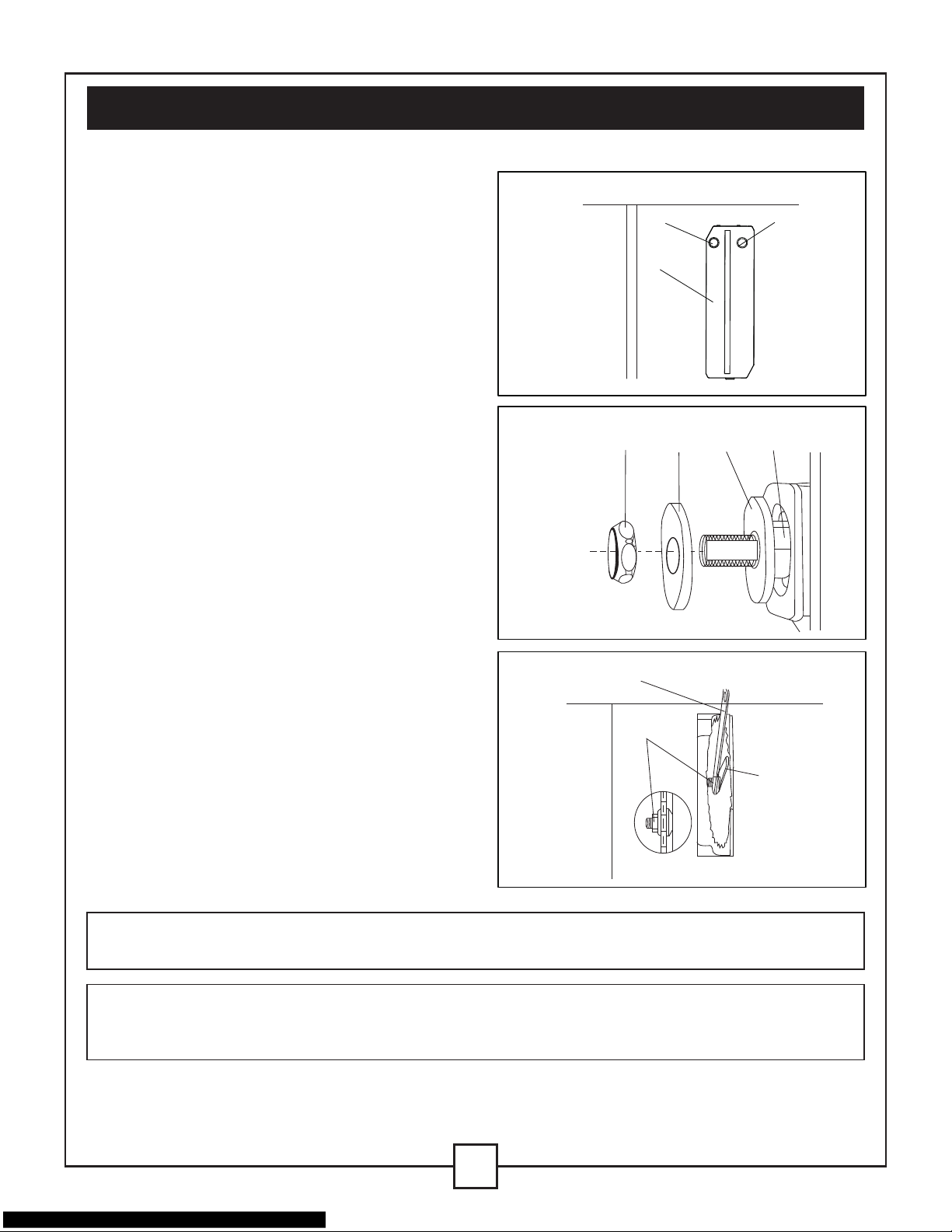

WARNING: VERIFY THAT THE SAW BLADE, THE ARBOR FLANGE, AND THE NUT ARE

PROPERLY SEATED, AND THAT THE ARBOR NUT IS TIGHTENED SECURELY.

WARNING: IN ORDER TO AVOID INJURY FROM AN ACCIDENTAL START-UP, VERIFY

THAT THE POWER SWITCH IS IN THE “OFF” POSITION, AND THAT THE POWER CORD

IS NOT PLUGGED INTO THE OUTLET.

INSTALLING THE BLADE TO THE

ARBOR (FIG. 4, 5, 6)

1. Remove the table insert(1)by inserting the

finger into the hole (2&3) (see Fig.4).

2. Raise the saw blade arbor (4) to its maximum

height by turning the blade raising control

handle counter-clockwise. Remove the arbor

nut (5) and the outer flange (6) from the saw

arbor.

3. Place the saw blade onto the arbor, with the

teeth of the blade pointing DOWN toward

the front of the saw.

4. Place the flange (6) and the arbor nut (5)

onto the arbor, and hand-tighten the nut.

Verify that the saw blade is firmly seated

against the inner flange (7) (Fig. 5).

NOTE: Verify that the large, flat surfaces

of the flange and the nut face INWARD,

toward the saw blade.

5. Place the open-ended blade wrench (8) on

the flat of the outer flange (6) in order to prevent

the arbor from turning while tightening.

Tighten the arbor nut by turning it clockwise

using the box-end blade wrench (9) (Fig. 6).

Fig. 5

Fig. 6

8

5

9

4

7

6

5

Page 13

WARNING:Improper alignment of the splitter can cause “kickback” and serious injury.

ASSEMBLING THE BLADE GUARD

(Fig. 7, 8 & 9)

V. Assembly and adjustments(continued)

13

VERIFY THAT THE SAW IS

DISCONNECTED FROM THE OUTLET

BEFORE INSTALLING THE BLADE

GUARD AND SPLITTER ASSEMBLY.

1. Use the handwheel to set the blade to

the maximum height and to set the tilt

to 0° on the bevel scale. Lock the

blade bevel locking knob.

3. Insert the blade guard assembly (1)

into the splitter bracket, as shown.

(Fig. 8)

4. Using a straight edge (2), verify

whether the blade guard splitter (3)

is aligned with the saw blade (4),

with the straight edge lying between

the teeth of the blade. (Fig. 9)

NOTE: The blade guard and splitter

must always be correctly aligned so

that the cut workpiece will pass on

either side of the splitter without

binding or twisting to the side.

Fig. 7

Fig. 8

Fig. 9

1

2

4

3

2. After loosing the knob (6),press the

device(5),the splitter (7) should be at

the highest position(Fig.7)

5

6

7

Page 14

ASSEMBLING THE TABLE

EXTENSION WING (FIG. 10, 11)

NOTE:

ADJUSTING THE TABLE EXTENSION

WING (FIG. 11)

WARNING:In order to avoid injury from an accidental start-up, verify that the power switch is

in the “OFF” position, and that the power cord is not plugged into the outlet.

A. Install the extension component (1) (2) into

the two holes at the side of the main table.

(Fig. 10)

B. Install the locking knobs (3) on the

aluminum extension wing. (Fig. 11)

INSTALLING THE MITRE GAUGE

(FIG. 12)

1. Position the mitre body (2) at 90°, and tighten

the handle (3) in order to secure the mitre

body in position.

2. Place the mitre gauge into the slot (4) of the

sliding mitre table (5).

3. Release the locking bolt (1) before using

the sliding mitre table.

Follow these steps to adjust the position of the

extension table

1. Unlock the locking knobs (3) on the two

extension tube brackets.

2. Slide the extension tubes in or out, until the

scale on the front tube is positioned at the

desired distance. Lock the locking knobs (3)

V. Assembly and adjustments(continued)

14

Fig. 10

Fig. 11

Fig. 12

1

2

2

3

1

5

4

2

1

3

Page 15

2

1

4

3

ADJUSTING THE MITRE GAUGE

(FIG. 13)

INSTALLING THE REAR TABLE

EXTENSION (FIG. 14)

ADJUSTING THE REAR TABLE EXTENSION

1. Loosen the locking handle (1) in order to

allow the mitre body (2) to rotate freely

(Fig. 13). Position the mitre body at 90°

so that the positive detent secures it in

position. Tighten the locking handle in order

to hold the mitre body securely in position.

2. If the pointer (3) requires adjustment, loosen

the screw that is located under the pointer

using a screwdriver.Adjust the pointer to 90°

on the scale, and then tighten the adjusting screw firmly.

3. In order to change the angle of the mitre gauge, loosen the locking handle (1) and the rotate

the mitre body to the desired angle, as indicated on the scale. Tighten the locking handle in

order to hold the mitre body securely in position.

1. Place the rear table extension onto the two

rear table extension tubes (1).

2. Snap the two locating seats (2) over the two

rear table extension tubes (1). Verify that the

locating pin in the locating seat fits into the

corresponding hole in the extension tube.

3. Insert the rear table extension tubes (1) into

the two holes in the rear of the saw table, and

into the extension tube brackets that are

located under the table. Position the rear table support so that the instruction labels are facing

up.

4. Tighten one extension wing stop screw (4) on the end of the left rear table extension tubes (1).

Verify that the screw is fully inserted into the corresponding hole (3) in the extension tube.

1. When ripping a short workpiece, the rear extension table should be positioned as close to the

rear of the main table as possible.

2. When ripping a long workpiece that requires extra support as the cut is completed, the rear

extension table should be pulled out as far as possible, until the locating seat prevents it from

moving out any further.

V. Assembly and adjustments(continued)

15

Fig. 13

Fig. 14

30

45

60

75

75

90

60

45

30

2

1

3

90°

Page 16

ADJUSTING THE RIP FENCE (FIG. 15)

1. Move the rip fence (1) by releasing the

handle (2) and sliding the fence to the

desired location. Push the handle down in

order to lock the fence into position.

2. Position the fence on the right side of the

table, and along the edge of the mitre gauge

groove.

3. Lock the fence handle. The fence should be

parallel to the mitre gauge groove.

4. If adjustment is required in order to make the

fence parallel to the groove, follow these

steps:

•Loosen the two bolts (3), and release the

handle (2).

•Hold the fence bracket (4) firmly on the front of the working table. Move the fence until it is

parallel to the mitre gauge groove.

•Push the handle down, and tighten both screws.

5. If the fence is loose when the handle is in the locked (down) position, follow these steps:

•Release the handle (2) and turn the adjusting nut (5) clockwise until the fence can be locked

on the table.

•Do not over-tighten the adjusting screw. Otherwise it will cause the fence to come out of the

table.

ADJUSTING THE RIP FENCE INDICATOR (FIG. 15)

1. The rip fence indicator (6) points to the measurement scale. The scale shows the distance

from the side of the fence to near side of the blade.

2. Measure the actual distance using a ruler. If there is a difference between the measurement

and the indicator, adjust the indicator (6).

3. Loosen the screw (7), and slide the indicator to the correct measurement on the scale.

Tighten the screw, and re-measure using the ruler.

RAPID BLADE TILTING (FIG. 16)

1. Loosen the blade bevel locking knob (2).

2. Slide the entire control handle assembly (3) to

the desired location.

3. Tighten the blade bevel locking knob (2).

Verify that the locking knob is tightened

securely before attempting a cut.

NOTE: The angle of the blade can be changed

without changing the height of the blade,

V. Assembly and adjustments(continued)

16

Fig. 15

5

1

3

4

2

6

7

Fig. 16

1

2

3

Page 17

WARNING: THE BLADE BEVEL LOCKING KNOB (2) MUST BE TIGHTENED SECURELY

AND LOCKED DURING ALL CUTTING OPERATIONS..

Turn the control handle (1) CLOCKWISE in order to raise the saw blade. Turn the control handle

(1) COUNTER-CLOCKWISE in order to lower the saw blade.

NOTE: It is not necessary to loosen the blade bevel locking knob (2) in order to raise or lower the

saw blade.

1. Raise the blade to the maximum height by

turning the control handle counter- clockwise.

2. Loosen the bevel angle locking knob.

3. Tilt the blade to the 90°(0°) bevel.

4. Using a square (1), verify that the blade is at a

90° (0°) angle to the table top.

5. If blade is not at a 90° (0°) angle to the table,

back off the adjustment screw (2).

6. Loosen the bevel locking knob and square the

blade 90° (0°) to the table.

7. Once the blade is at a 90° (0°) angle to the

table top, tighten the bevel angle locking knob.

8. Carefully tighten the adjusting screw (2) until

it touches the bevel stop. DO NOT OVERTIGHTEN.

9. Verify that the blade is still aligned at 90° (0°).

Once the blade has been set at a 90° (0°) angle

to the table top, as described in section above,

the angle pointer (1) may require adjustment.

If it does, follow these steps:

1. Loosen the pointer screw (2), and move the

pointer until it is aligned with 90° (0°) on the

bevel scale.

2. Retighten the pointer screw.

1. Raise the blade to the maximum height by

turning the control handle counter- clockwise.

2. Loosen the bevel angle locking knob.

3. Tilt the blade to the 45° bevel.

4. Using a square (1), verify that the blade is at

a 45° angle to the table top.

V. Assembly and adjustments(continued)

17

ADJUSTING THE BLADE HEIGHT

(FIG. 16)

90°(0°) BEVEL STOP (FIG. 17)

BEVEL POINTER ADJUSTMENT

(FIG. 18)

45° BEVEL STOP (FIG. 19)

Fig. 17

Fig. 19

Fig. 18

1

2

1

2

2

1

Page 18

ADJUSTING THE LASER GUIDE (FIG. 20)

WARNING: The laser beam is emitted when the laser guide is turned on. Do not stare into

beam or look directly at it using optical instruments. Do not remove the warning label that is

affixed to the blade guard. Do not direct the laser into the eyes.

strongly recommend the use of laser protective eyewear for the specific wavelength of

emitted light when working on or near reflective surfaces.

WARNING:DO NOT PLUG THE TABLE SAW INTO THE OUTLET UNTIL ALL

INSTALLATIONS AND ADJUSTMENTS HAVE BEEN COMPLETED AND THE SAFETY AND

OPERATIONAL INSTRUCTIONS IN THIS MANUAL HAVE BEEN READ CAREFULLY AND

UNDERSTOOD FULLY.

5. If blade is not at a 45° angle to the table, back off the adjustment screw (2).

6. Loosen the bevel locking knob and set the blade at a 45° angle to the table.

7. Once the blade is at a 45° angle to the table top, tighten the bevel angle locking knob

8. Carefully tighten the adjusting screw (2) until it touches the bevel stop. DO NOT

OVERTIGHTEN.

9. Verify that the blade is still aligned at 45°.

NOTE: All of the adjustments for the operation of

this machine have been carried out at the factory.

Occasional readjustments may be necessary as

a result of normal wear and use.

1. Turn the laser guide on. Place a straight edge

or ruler against the right side of the blade.

2. Verify whether the laser line is flush against

the right side of the blade, and against the

straight edge or ruler.

3. If the laser line is not flush, loosen the two

set screws (2) with a hex wrench, but do

not remove them.

4. Using a hex wrench (not provided), adjust the laser unit (1) until the laser line is

parallel with the blade.

NOTE: Be careful not to over-rotate the laser unit. Do not rotate the laser more than 1/8 of a turn

in either direction.

5. Adjust the set screw (2) on the left or right side in order to shift the laser line until it is flush

with the right side of the blade. Once proper alignment has been achieved, tighten the set

screw on the other side slowly, until it touches the laser, in order to lock the laser into position.

Turn the laser guide off.

V. Assembly and adjustments(continued)

18

Fig. 20

1

2

Page 19

ASSEMBLING THE

ROLLER WHEELS (FIG. 21)

Attach the roller wheels (7) to the

roller wheel supports (12) using hex

bolts (8) and nuts (9), as

illustrated. Do not over tighten,

because doing so will not allow

the wheels to turn.

Leveling pad (5) the is installed at

the four corners of stand by hex bolt.

stand extension poles (10) is

installed at the lateral of stand.

align two tips of pull handle (11) to

the holes in the stand bracket and

tighten them.

ATTACHING THE TABLE SAW TO THE

STAND (FIG. 22)

1. Place the stand on a level surface, and adjust

the right front adjustable stand pad (1) in

order to level the stand to the floor.

2. Place the table saw on top of the stand (1),

aligning the holes in the base with the holes

in the stand.

3. Insert four hex bolts (2) through flat washers

and through the holes in the base and the

stand.

4. Tighten all four bolts. NOTE: Do not over

tighten the bolts that hold the saw to the

stand. Doing so may damage the saw base.

V. Assembly and adjustments(continued)

19

UNFOLDING THE STAND (FIG. 21)

Fig. 21

Fig. 22

1. Release the knob (1)(2).

2. Lift the stand up, unfold the wider leg set (3)and unfold the narrower leg set (4).

3. Lock the locking knobs (1)(2).

NOTE: Verify that the stand is securely locked in position.

4. Attach the levelling pad (5) to the wider leg set (3) using the screw (6).

1

2

7

8

12

9

5

6

4

1

3

2

11

10

Page 20

V. Assembly and adjustments(continued)

20

NOTE:

Verify that the table saw is securely locked in position, and that the adjustable stand pad has

stabilized the table saw before operation.

FOLDING THE TABLE SAW/STAND (FIG. 23)

SETTING UP THE TABLE SAW/STAND (FIG. 23)

1. Rotate the stand locking hook to the left. Lift up the two right-side stand locking levers in

order to unlock, and lift the right side of the table saw up slightly off the floor (Fig. 23). Fold

the leg set on the right side up to the base of the saw until it snaps into position with the

spring clip (Fig. 23).

2. Slide the table extension toward the table until it rests against the saw table (Fig. 23-1).

3. Rest the right side of the saw onto the floor, release the two left-side stand locking levers,

and tilt the saw on its right side. Fold the left-side leg set up to the base (Fig. 23).

4. Secure the legs into position by rotating the stand locking hook to the right.

1. Rotate the stand locking lever to the left. Unfold the leg set, and lock the stand locking levers

in position by sliding the levers down the slots of the mounting brackets and pushing down in

order to lock it in position.

2. Rest the left side of the saw on the floor, lift up the right side of the stand, and unfold the

narrower right-side leg set (Fig. 23).

3. Secure the right-side legs in position by locking the stand locking levers in position, as

described in step 1

WARNING:Do not use this saw to cut metal. The hot chips or sparks may ignite sawdust or

the material of the bag.

Fig. 23 Fig. 23-1

FOLDING

SET-UP

1

1 2 3

2

Page 21

WARNING:FAILURE TO PROVIDE THE SAWDUST FALL-THROUGH AND REMOVAL

HOLE WILL CAUSE SAWDUST TO BUILD UP IN THE MOTOR AREA, WHICH MAY

RESULT IN A FIRE HAZARD OR CAUSE DAMAGE TO THE MOTOR.

proceed to step 5. If there is a hole that is large enough, proceed to step 7.

5. Mark a 11x11” (28x28 cm) square (2), centred between the four mounting holes (1).

6. Cut out and remove the square. This opening will allow sawdust to fall through the saw base.

7. Place the table saw on the workbench tabletop, and align the holes of the table saw with the

holes that were drilled in the workbench tabletop. Fasten the table saw to the workbench

using bolts and nuts.

IMPORTANT: When mounting the saw to the stand or workbench DO NOT over tighten the

mounting bolts.

NOTE: If the stand or the workbench tends to move while the table saw is in use, the stand or

workbench must be fastened to the floor.

V. Assembly and adjustments(continued)

21

INSTALLING THE DUST BAG (FIG. 24)

1. Place the dust bag around the neck of the

dust port. Tie the dust bag by pulling the

drawstring tight, and secure it using the

tie-clip.

MOUNTING THE TABLE SAW TO A

WORKBENCH (FIG. 24-1)

1. If the stand will not be used, the table saw

must be properly secured to a sturdy

workbench using the four mounting holes

on the base.

2. The workbench must have a hole that is

large enough to allow for sawdust fall through and removal.

3. Place the table saw in the centre of the

workbench tabletop, and mark the location

of the four 3/8” (9.5 mm) mounting holes

(1) on the workbench tabletop.

4. Drill four 3/8” (9.5 mm) holes in the

workbench tabletop.

NOTE: If there is not a hole that is large

enough for sawdust removal and fall through,

Fig. 24

Fig. 24-1

SQUARE

CUTOUT

1

2

Page 22

V. Assembly and adjustments(continued)

22

LIMITED HOOKS AND GUARD PATHHOOKS (Fig. A)

1. Align the holes in the limited hooks (1)and the body of table saw.

2. insert head srew through flat washer and the holes in limtted hooks.

3. Tighten the screws with cross screwdriver.

4. About guard pathhooks(2),pls follow the same assemble procedure of limited hooks.

Fig. A

1

2

Page 23

OVERLOAD PROTECTION (FIG. 24-3)

WARNING:IN ORDER TO AVOID INJURY AND PREVENT ACCIDENTAL START-UP WHEN

THE RESET BUTTON IS PUSHED, THE ON/OFF PADDLE SWITCH SHOULD BE IN THE

OFF POSITION, AND THE POWER CORD SHOULD BE UNPLUGGED FROM THE

OUTLET WHILE THE SAW IS COOLING DOWN. OVERHEATING MAY BE CAUSED BY AN

UNDER-SIZED EXTENSION CORD, AN EXTENSION CORD THAT IS TOO LONG,

MISALIGNED PARTS, OR A DULL BLADE. INSPECT THE SAW FOR PROPER SET-UP

BEFORE USING IT AGAIN.

This saw is equipped with a reset overload relay button (1) that will restart the motor after it shuts

off due to overloading or low voltage. If the motor stops during operation, move the ON/OFF

switch to the OFF position. Wait approximately five minutes for the motor to cool down, and then

push the reset button (1) and move the switch to the ON position.

23

RAISING THE BLADE (FIG. 24-2)

TILTING THE BLADE (FIG. 24-2)

ON/OFF PADDLE SWITCH (FIG. 24-3)

1. Loosen the blade bevel locking knob (2).

2. Slide the entire control handle assembly (1) to

the desired location.

3. Tighten the blade bevel locking knob (2). Verify

that the locking knob is fully tightened before

attempting a cut.

The ON/OFF paddle switch has a removable

safety key. The saw cannot be turned on when

the key is removed from the switch, which

minimizes unauthorized use.

1. To turn the saw ON, insert the safety key (2)

into the slot that is located above the switch,

and then move the paddle switch (3) up to the

ON position.

2. To turn the saw OFF, move the paddle switch

(3) down. (Fig. 24-3)

3. To lock the saw in the OFF position, grasp the

end of the safety key and pull it out.

4. The ON/OFF switch will not operate with the

safety key removed.

5. If the safety key is removed while the saw is running, the saw can be turned OFF, but it cannot

be restarted until the safety key (2) is reinserted.

Turn the blade raising control handle (1) COUNTER-CLOCKWISE in order to raise the blade.

NOTE: It is not necessary to loosen the blade tilting locking knob (2) when raising or lowering the

saw blade.

Fig. 24-2

Fig. 24-3

1

3

2

1

2

Page 24

WARNING:Do not use more than one rip fence or a combination of a mitre gauge and a rip

fence at the same time during a cutting operation.

VI. Operating instructions (continued)

24

WARNING:FOR SAFETY REASONS, VERIFY THAT THE OPERATOR HAS READ THE

SECTION ENTITLED GENERAL SAFETY GUIDELINES FOR THE TABLE SAW BEFORE

OPERATING THIS SAW. VERIFY THE FOLLOWING BEFORE EVERY TIME THE TABLE

SAW IS USED:

1. THE BLADE IS TIGHT.

2. THE BEVEL ANGLE LOCKING HANDLE IS LOCKED.

3. IF RIPPING, THE RIP FENCE LOCKING KNOB IS TIGHT, AND THE FENCE IS

PARALLEL TO THE MITRE GAUGE GROOVE AND THE BLADE.

4. IF CROSSCUTTING, THE MITRE GAUGE KNOB IS TIGHT.

5. THE BLADE GUARD AND SPLITTER ARE IN PLACE, AND ARE WORKING PROPERLY.

6. SAFETY GLASSES ARE WORN.

7. FAILURE TO ADHERE TO THESE SAFETY RULES WILL GREATLY INCREASE THE

CHANCES OF INJURY.

1. Unlock the table extension wing levers (2) on

the two extension tube brackets.

2. Slide the extension tubes in or out until the

scale on the front tube is positioned at the

desired distance. Lock the table extension

wing levers (2).

3. To adjust the position of the fence, loosen the

locking handles (2), and place the auxiliary

fence (1) in position.

4. Tighten the locking handles (2).

Before using the table saw, polish the tabletop with an automotive polishing wax in order to keep

it clean, and to make it easier to slide the workpiece.

There are two basic types of table saw cuts: ripping and crosscutting. Ripping refers to cutting

along the length of the grain and the workpiece. Crosscutting refers to either cutting across the

width or across the grain of the workpiece. This distinction may be hard to make with man made

materials. Therefore, cutting a piece of material to a different width is ripping, and cutting across

the short dimension is crosscutting. Neither operation can be performed safely freehand: ripping

requires the use of the rip fence, and crosscutting requires the use of the mitre gauge. Never use

the rip fence and the mitre gauge at the same time during the cutting operation.

USING THE TABLE EXTENSION WING

(FIG. 25)

Fig. 25

1

2

Page 25

RIPPING (FIG. 26, 26-1)

1. Remove the mitre gauge, and secure the rip fence to the table.

2. Raise the blade until it is approximately 1/8” (3.2 mm) above the top of the workpiece.

3. Place the workpiece flat on the table and against the fence so that the larger portion of the

workpiece is between the blade and the fence. Keep the workpiece approximately 1” (2.5 cm)

away from the blade.

4. Turn the saw ON, and wait for the blade to reach full speed.

5. Slowly feed the workpiece into the blade by pushing forward on the section of the workpiece

that will pass between the blade and the fence (Fig. 26). the pattern that is provided in this

manual. (Fig. 26-1)

VI. Operating instructions (continued)

1

3

2

CAUTION!To prevent serious injury:

• Do not allow frequent use of the table saw to cause complacency and careless mistakes.

Remember that it only takes a fraction of a second of carelessness to cause a severe injury.

• Keep both hands away from the blade and the path of the blade.

• The workpiece must have a straight edge against the fence, and must not be warped,

twisted, or bowed.

6. Do not place your thumbs on the table top. Always hold the workpiece (1) while the blade is

turning. Do not let go of it in order to reach for the push stick. When both thumbs touch the

front edge of the table (2), complete the cut using a push stick (3). Make a push stick using

7. Always use the push stick when performing ripping operations.

8. Continue to push the workpiece with the push stick until it passes the blade guard and clears

the rear of the table.

9. Do not pull the workpiece backward while the blade is turning. Turn the switch OFF, and

unplug the power cord. When the blade comes to a complete stop, raise the anti- kickback

pawls on each side of the splitter, if necessary, and slide the workpiece out.

Fig. 26 Fig. 26-1

1

25

Page 26

VI. Operating instructions (continued)

26

RIPPING SMALL PIECES

BEVEL RIPPING

1. It is not safe to rip small pieces. Instead, rip a larger piece in order to obtain the size of the

desired piece.

2. When ripping a small workpiece, it is not safe to place the hand between the blade and the rip

fence. Use one or more push sticks to push the workpiece completely past the blade.

(Fig. 26-1)

Bevel ripping is the same as ripping, except that the blade bevel angle is set to an angle other

than “0”.

CAUTION!THE WORKPIECE AND THE FENCE MUST BE ON THE RIGHT SIDE OF THE

BLADE WHEN CUTTING.

CAUTION!AVOID INJURY CAUSED BY CONTACT WITH THE BLADE. DO NOT USE THIS

SAW TO MAKE THROUGH-CUTS THAT ARE NARROWER THAN 1/2” (13 MM).

WARNING:

•DO NOT ATTEMPT TO PULL THE WORKPIECE BACKWARD WHILE THE BLADE IS

TURNING. TURN THE SWITCH OFF, AND WAIT UNTIL THE BLADE HAS COME TO A

COMPLETE STOP BEFORE CAREFULLY SLIDING THE WORKPIECE OUT.

•DO NOT PERFORM ANY OPERATION FREEHAND.

•AVOID KICKBACK BY KEEPING BLADES SHARP, VERIFYING THAT THE RIP FENCE IS

PARALLEL TO THE SAW BLADE, AND KEEPING THE SPLITTER, ANTI-KICKBACK

PAWLS, AND GUARDS IN PLACE, IN ALIGNMENT, AND FUNCTIONING PROPERLY.

Page 27

3

4

2

1

WARNING:In order to avoid instability, always place the larger surface of the workpiece on

the table when crosscutting and/or bevel crosscutting.

1. Remove the rip fence, place the mitre gauge

in the mitre gauge groove on the table, and

release the sliding mitre blade locking lever (4).

2. Raise the blade until it is approximately 1/8”

(3.2 mm) above the top of the workpiece.

3. Hold the workpiece firmly against the mitre

gauge, with the path of the blade in line with

the desired cutting line. Move the workpiece

to within 1” (2.5 cm) of the blade.

4. Start the saw, and wait for the blade (1) to

reach full speed. Do not stand directly in line

with path of the saw blade. Instead, stand to

the side of the blade, on the side where the cut is being made.

5. Keep the workpiece (2) against the face of the mitre gauge (3) and flat against the table.

Slowly push the workpiece through the blade.

6. Do not attempt to pull the workpiece backward while the blade is turning. Turn the switch OFF,

and wait until the blade has come to a complete stop before carefully sliding the workpiece out.

VI. Operating instructions (continued)

27

CAUTION!To prevent serious injury:

•Do not allow familiarity with or frequent use of the table saw to cause careless mistakes.

Remember that even a fraction of a second of carelessness is enough to cause a severe

injury.

•Keep both hands away from the blade and the path of the blade.

•Do not attempt to pull the workpiece backward during a cutting operation. This will cause

kickback, and may result in serious injury to the operator.

CROSSCUTTING (FIG. 27)

Fig. 27

Page 28

1

2

3

2

1

3

3

1

2

COMPOUND MITRE CROSSCUTTING

(FIG. 29)0° - 45° BLADE BEVEL &

0° - 45° MITRE ANGLE

This operation is the same as crosscutting,

except that the blade is at a bevel angle other

than 0°.

1. Adjust the blade (1) to the desired angle, and

then tighten the blade bevel locking knob.

2. Tighten the mitre locking handle (3) at 90°.

3. Hold the workpiece (2) firmly against the face

of the mitre gauge throughout the cutting

operation.

MITERING: 0° - 45° MITRE ANGLE

(FIG. 30)

This operation is the same as crosscutting,

except that the mitre gauge is locked at an angle

other than 90°.

1. Set the blade (1) to a 0° bevel angle, and

tighten the blade bevel locking knob.

2. Set the mitre gauge (3) to the desired mitre

angle, and secure it in position by tightening

the mitre gauge locking handle.

3. Hold the workpiece (2) firmly against the face

of the mitre gauge throughout the cutting

operation.

This sawing operation combines a mitre angle

with a bevel angle.

1. Set the mitre gauge (3) to the desired angle.

2. Set the blade (1) bevel to the desired bevel

angle, and tighten the blade bevel locking knob.

3. Hold the workpiece (2) firmly against the face

of the mitre gauge throughout the cutting

operation.

VI. Operating instructions (continued)

28

BEVEL CROSSCUTTING (FIG. 28) 0° 45° BLADE BEVEL & 90° MITRE

ANGLE

Fig. 28

Fig. 29

Fig. 30

Page 29

CAUTION!Be very careful when the dado blade is running. There is no guard to protect

the operator. Do not use adjustable or wobbling dado blades with this saw.

When performing certain cutting operations, it is

necessary to add a wood facing to either side of

the rip fence (2).

1. Use a smooth, straight, 3/4” (19 mm) thick

wooden board (1) that is as long as the rip fence.

2. Attach the wood facing to the fence using wood screws (3). A wood facing should be used

when ripping material such as thin paneling, in order to prevent the material from catching

between the bottom of the fence and the table.

DADO CUTTING (FIG. 32)

29

USING A WOOD FACING ON THE RIP

FENCE (FIG. 31)

Fig. 31

Fig. 32

Fig. 32-1

3

2

1

4

5

6

2

1

3

1. Unplug the power cord before removing

and/or installing dado blades.

2. When making dado cuts, a dado insert

plate must be installed in place of the

regular table insert.

3. Instructions for operating the dado are

packed with the dado set. (Purchased

separately)

4. The arbor (1) of this saw restricts the

maximum width of a dado cut to 1/2”

(1.3 cm) (Fig. 32). The flange (2) must

be installed prior to reinstalling and

tightening the arbor nut (3).

5. NOTE: Verify that the arbor nut is tight

and that at least one thread of the arbor

sticks out past the nut.

6. After loosing the knob (5),press the

device(4),the splitter (6) should be at

the lowest position,the purpose is not

intended to cut through the workpiece

the splitter is on the midlle position,the

purpose is for non-through operations.

Use only a stackable dado set, and keep

the width to 1/2” (1.3 cm) or less. It will be

necessary to remove the blade guard and kickback pawl when using the dado.

7. Use the correct number of round outside blades and chippers, as shown in the instruction

manual for the dado set. The total width of the blades and chippers must be as follows:

less than 1/2''(1.25cm) and less than 8''(20.32cm) in diameter.

8. Before starting the table saw, check to make sure the installed dado assembly will not strike

the motor, table, or table saw base when in operation.

Page 30

30

CAUTION: For safety reasons, turn the power switch OFF, remove the safety key, and unplug

the saw from the outlet before performing any maintenance or lubrication.

CAUTION: Electrical and mechanical repairs must be performed by a qualified repair

technician. Call the Tool-Free Helpline, at 1-800-689-9928. Use only identical replacement

parts. Using substitute parts may create a hazard.

CAUTION!In order to avoid injury, always replace the blade, the blade guard assembly, and

the table insert when once the dado cutting operation has been completed.

•Use a vacuum to clean out all sawdust that has accumulated inside the saw base and around

the motor on a regular basis.

•Use an automotive wax to polish the saw table in order to keep it clean, and to make it easier to

slide the workpiece.

•Clean the cutting blades using pitch and gum remover.

•Replace a worn, cut, or damaged power cord immediately.

Use liquid dishwashing detergent and water to clean all plastic parts. NOTE: the use of certain

cleaning chemicals may damage plastic parts.

Do not use the following cleaning chemicals or solvents on the table saw: gasoline, carbon

tetrachloride, chlorinated solvents, ammonia, or household detergents that contain ammonia.

The blade raising and tilting mechanisms should

be checked for looseness, binding, or other

abnormalities after every five hours of operation.

Unplug the table saw from the outlet, and turn it

upside down. Alternately pull up and down on the

motor unit. Observe any movement in the motor

mounting mechanism. (Fig. 33)

1.Turn the screw pole(1) in the fixed part(2)

connection with the wheel.

2.The power will be transferred by the taper

gear(3) and screw pole(4).

3.The pole (6) in the fixed part(5) will be moved

up and down.

DADO CUTTING

BLADE RAISING AND TILTING MECHANISM

All motor bearings are permanently lubricated at the factory, and do not require any additional

lubrication. Use graphite or silicone to lubricate all mechanical parts of the table saw where a

pivot or threaded rod is present. Dry lubricants do not hold sawdust like oil or grease.

LUBRICATION

Fig. 33

1

2

3

4

5

6

Page 31

31

PUSH STICK CONSTRUCTION

This is a full-size drawing (actual size)

Use good quality plywood or solid wood

Use 1/2 in. or 3/4 in.material

The push stick MUST be thinner than the

width of the material that is being cut

Drill Hole For

Hanging

Notch 0 Prevent

the Operator’

s Hand From

Slipping

Cut Here To

Push 1/2 in.

Wood

Cut Here To Push

3/4 in.Wood

Page 32

WARNING:In order to avoid injury from an accidental start-up, always turn the switch to the

OFF position and unplug the table saw before moving the table saw or the blade, replacing

the blade, or making adjustments to the table saw or the blade.

SYMPTOM

The saw will not start 1. The saw is not plugged in.

2. The fuse has blown or the

circuit breaker has tripped.

3. The cord is damaged.

1. Plug in the table saw.

2. Replace the fuse or reset

the circuit breaker.

3. Have the cord replaced by

a qualified electrician.

The saw does not make accurate

45° or 90° rip cuts

1. The positive stop is not adjusted

correctly.

2. The blade tilt pointer is not set

correctly.

3. The rip fence is not properly

aligned.

1. Check the blade with the square,

and adjust the positive stop.

2. Check the blade with the square,

and adjust the positive to zero.

3. Align the rip fence with the mitre

gauge slot.

The material pinches the blade

when ripping

1. The rip fence is not aligned with

the blade.

2. The wood is warped, or the edge

that is against the fence is not straight.

1. Check and adjust the rip fence.

2. Select another piece of wood

The material binds on the splitter 1. The splitter is not aligned correctly

with the blade.

1. Check and align the splitter with

the blade.

The saw makes unsatisfactory cuts 1. The blade is dull.

2. The blade is mounted backwards.

3. There is gum or pitch on the blade.

4. The blade is not appropriate for

the work that is being done.

5. There is gum or pitch on the table,

causing erratic feeding.

1. Replace the blade.

2. Turn the blade around.

3. Remove the blade, and clean it

with turpentine and coarse steel wool.

4. Change the blade.

5. Clean the table with turpentine and

coarse steel wool, and apply a coat

of automotive polishing wax.

The material kicks back from the

blade

1. The rip fence is out of alignment.

2. The splitter is not aligned correctly

with the blade.

3. The workpiece is being fed without

the rip fence.

4. The splitter is not in place.

5. The blade is dull.

6. The operator is letting go of the

material before it has passed the

saw blade.

7. The mitre angle locking knob is

loose.

1. Align the rip fence with the mitre

gauge slot.

2. Align the splitter with the blade.

3. Install and use the rip fence.

4. Install and use the splitter(with

the guard).

5. Replace the blade.

6. Push the material all the way past

the saw blade before releasing the

workpiece.

7. Tighten the knob.

The blade does not raise or tilt freely 1. There is sawdust and/or dirt in the

raising and tilting mechanisms.

1. Brush or blow out any loose dust

and dirt.

The blade does not reach full speed 1. The extension cord is too light or

too long.

2. The voltage from the outlet is too

low.

1. Replace with the proper size of

extension cord.

2. Contact the electricity supplier.

The saw vibrates excessively 1. The saw is not mounted securely

to the workbench.

2. The stand is on an uneven

surface.

3. The blade is damaged.

1. Tighten all mounting hardware.

2. Reposition the table saw on a flat

level surface.

3. Replace the blade.

POSSIBLE CAUSES CORRECTIVE ACTION

32

Page 33

This Mastercraft product carries a one ( 3 ) year repair warranty against defects in workmanship

and materials. At its discretion, Mastercraft Canada agrees to have any defective part(s) repaired

or replaced free of charge, within the stated warranty period, when returned by the original

purchaser with proof of purchase. This product is not guaranteed against wear or breakage due

to misuse and/or abuse.

This product is not guaranteed if used for commercial or industrial purposes.

33

Page 34

MASTERCRAFT TABLE SAW WITH SLIDING TABLE

WARNING:ANY ATTEMPT TO REPAIR OR REPLACE ELECTRICAL PARTS ON THIS

TABLE SAW MAY CREATE A HAZARD UNLESS THE REPAIRS ARE CARRIED OUT BY A

QUALIFIED SERVICE TECHNICIAN.

No

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

1

2

1

13

18

1

4

2

1

1

4

19

13

1

1

1

4

2

1

1

25

2

1

4

2

1

1

2

1

1

12

14

Screw

Locking ring

Compaction shaft

Bolt M4×10

Flat washer 4

Eccentricity handle

Bolt M4×8

Compaction washer

Rip fence fix seat

Pointer

Hex bolt M6×20

Spring washer 6

Big washer 6

Rip fence pipe

Rub washer

Compress spring

Press board

Locking nut M6

Mitre bar insert

Mitre guide knob cover

Mitre guide knob

Flat washer 6

Mitre guide locking knob

Mitre guide pointer

Bolt ST2.9×8

Washer 3

Rip fence

Mitre guide

Screw M6×25

Bevel bar

Sliding table

Bolt M5×10

Washer 5

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

2

1

1

1

2

1

1

2

2

1

1

1

1

1

1

2

3

2

2

2

2

1

3

1

1

1

1

1

2

1

1

2

Hex bolt M4×12

Guide (A)

Guide (B)

Table insert

Hex bolt M6×20

Main table

Washer board

Rear extension pole

Limited ring

Rear extension table

Screw M6×58

Blade guard (left)

Laser switch

Bolt M4×16

Laser seat

Hex bolt M5×6

Laser

Washer (C)

Compaction ring (A)

Bolt ST2.9×8

Hex bolt M4×15

Bolt M4×10

Guard support board

Support board ring

Gasket

Guard support seat

Connect shaft (A)

Battery dust cover

Battery box

Battery

Battery cover

Blade guard (right)

Circumgyrate wrench

Description Qty

34

When servicing this Mastercraft table saw, use only Mastercraft replacement parts.The use

of any other parts may cause damage to the product. All servicing should be performed by a

qualified service technician. To find the nearest technician, call the toll- free helpline, at

1-800-689-9928.

No Description Qty

Page 35

35

No

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106

107

108

2

2

2

1

2

1

1

1

2

2

2

12

2

1

8

2

1

5

5

1

1

1

1

4

8

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

4

10

Spring pin 4×12

Uncork ring 9

Limited piece

Spring pin 4×30

Compaction ring (B)

Limited support seat

Spring

Connect shaft (B)

Out handle

Hex bolt M14

Inside handle

Bolt ST4.2×12

Scale seat board (B)

Scale seat (B)

Bolt ST4.2×8

Scale seat board (A)

Scale label (B)

Square screw M6×16

Nut M6

Scale extension pole (right)

Scale label (C)

Extension table

Extension pole (right)

Extension pole knob

Bolt M6×20

Scale label (A)

Scale seat (A)

Orientation pin

Locking compress spring

Orientation block

Orientation pin knob

Bolt M3×18

Uncork ring 3.5

Locking nut M3

Adjustment pole

Motor parts

Rip knife base

Compress spring

Rip knife orientation pin

Rip knife

Bolt M5×20

Spring washer 5

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

127

128

129

130

131

132

133

134

135

136

137

138

139

140

141

142

143

144

145

146

147

148

149

150

2

1

1

2

1

2

1

2

2

1

1

1

1

4

2

2

2

2

2

1

1

1

1

1

1

1

10

2

1

4

1

1

1

2

1

1

1

4

4

1

3

1

Orientation shaft (A)

Rip knife press board

Rip knife locking knob

Up-down guide column

Up-down adjustment screw (B)

Flat key 4×8

Up-down adjustment seat

Taper gear

Ring for shaft 10

Fix seat (B)

Angle pointer

Spring washer 4

Up-down adjustment screw (A)

Bolt M6×16

Fix seat (B)

Screw M6×16

Clearance piece

Hex bolt M5×20

Sliding piece

Hex bolt M6×12

Body

Dust insert

Inside plywood

Blade

Outside plywood

Thin nut M16

Bolt ST2.9×10

Limited hook

Hook for cord

Big washer 4

Plug & cord

Press wire block

Cord inlet

Bolt ST4.2×16

Guard pothook (A)

Guard pothook (B)

Insert

Hex bolt M8×35

Washer 8

Miter guide board

Locking nut M5

Reinforce side board

Description Qty No Description Qty

Page 36

36

No

151

152

153

154

155

156

157

158

159

160

161

162

163

164

165

166

167

168

169

170

171

172

173

174

175

176

177

178

179

180

181

182

183

184

185

186

187

188

189

190

191

192

193

194

1

3

1

1

1

2

1

2

1

1

4

2

1

1

1

1

1

2

1

1

1

1

1

1

6

1

1

1

1

1

1

1

2

1

1

3

1

2

4

4

1

1

1

4

Rack (B)

Bolt M5×16

Overloading protection

Junction box groupware

Switch box cover

Rubber ring

Custer brand

Wire block

Overloading nut

Switch

Bolt M5×8

Bolt M4×12

Switch board

Overloading label

Case

Screw M8×30

Locking ring

Blade wrench

Blade knob

Push sticker

Main label

Washer ring

Locking compress spring

Compaction screw

Nut M5

Locking handle

Hex bolt M5×12

Circumgyrate wheel

Circumgyrate handle

Circumgyrate knob

Handle bolt

Bolt M5×16

Feet (A)

Adjustment feet

Locking knob (B)

Bolt M6×40

Stand (A)

Wheel

Screw M8×45

Nut M8

Dust collection ring

Rubber feet (B)

Stand (B)

Stand knob

195

196

197

198

199

200

201

202

203

204

205

206

207

208

209

210

211

212

213

214

215

216

217

218

219

220

221

222

223

224

225

226

227

228

229

230

231

232

233

234

235

236

237

238

2

2

2

1

2

2

2

1

4

1

1

1

1

2

1

1

1

2

2

2

1

2

1

1

1

1

1

1

1

1

1

1

3

2

2

4

1

1

4

1

2

1

4

4

Wheel bolt

Nut M12

Bag clamp

Stand board groupware

Hex bolt M5×8

Stand pipe

Bolt M5×30

Handle

Bolt M5×35

Front cover

Inside ring

Bearing 6201-2Z

Rotor

Bolt ST4.8×70

Stator

Bearing 6001-2Z

Damping ring

Brush cap

Brush

Brush holding

Press wire board

Bolt M5×8

Cover board

Body

Oilness bearing

Ring for shaft 16

Gear

Output shaft

Half-round key 5×6.5×16

Ring for hole/shaft 35

Bearing 6003-2Z

Gear cover

Bolt M5×16

Pipe bush

Wheel support

Hex bolt M6×10

Hex wrench 5

Switch board

Support board

Extension pole(B)

Adjustment screw

Extension pole(A)

Screw M6×50

Stand washer

Description Qty

No Description Qty

Page 37

37

No

239

240

1

1

Dado insert

hex wrench 5

241

242

1

1

hex wrench 5

bolt

Description Qty

No Description Qty

Page 38

38

Imported by Mastercraft Canada Toronto, Canada M4S 2B8

1

2

3

4

5

6

2

7

8

10

9

11

12

13

14

15

13

16

17

18

13

13

19

20

21

13

19

22

23

24

135

26

27

28

29

30

31

32

33

34

34

35

32

36

37

38

38

39

40

4

41

42

43

42

41

4

44

22

45

4

46

5

47

48

50

49

18

51

52

53

54

55

56

57

59

58

60

25

61

62

63

64

25

65

18

22

66

67

18

51

68

69

70

71

72

73

71

69

68

51

74

67

66

75

75

76

77

78

78

79

80

81

12

85

82

83

84

22

86

87

4

88

89

90

91

107

90

79

92

81

93

84

22

12

85

94

95

96

97

5

4

82

230

12

22

98

57

99

100

101

102

103

104

105

106

107

108

33

109

110

111

112

113

114

115

116

117

118

119

4

120

117

114

121

122

22

123

124

12

125

126

33

128

127

129

127

125

123

122

130

131

132

133

134

135

5

136

137

138

78

139

140

141

142

143

144

145

135

146

147

148

146

149

150

151

152

153

154

155

156

78

25

157

158

138

78

160

161

159

162 163

164

165

167

166

168

169

146

170

171

172

173

174

175

176

177

178

175

179

180

33

181

182

188

188

102

203

12

22

204

205

206

207

208

33

209

210

211

212

213

214

78

215

216

108

33

217

212

213

214

218

219

220

221

222

223

224

225

226

227

232

233

234

235

236

237

238

185

183

184

185

186

187

189

190

81

189

191

192

193

194

195

196

194

198

199

108

200

201

175

202

228

229

230

11

22

231

239

240

241

242

Loading...

Loading...