Page 1

INSTRUCTION

MANUAL

DRILL PRESS

IMPORTANT:

Please read this manual carefully before using this drill

press and save it for reference.

model no. 055-5530-8

Page 2

3

TABLE OF CONTENTS

SAVE THESE INSTRUCTIONS

This manual contains important safety and operating instructions. Read all

instructions and follow them when using this product.

NOTE:

If any parts are missing or damaged, or if you have any questions, please call our

toll-free helpline at 1-800-689-9928

TABLE OF CONTENTS

Quick Start Guide

Specifications

Safety Guidelines

Know Your Drill Press

Assembly Instructions

Operating Instructions

Maintenance

Troubleshooting

Exploded View

Parts List

Warranty

4

5

6-13

14-16

17-28

29-32

33

34

35

36-37

38

Page 3

• Place the column tube (2) on the base (1),

align the column support holes with the

base holes.

• Install a bolt M8 x 25 (3), a flat wahser

M8 (4) and a spring washer M8 (5) in

each column support hole and tighten

with the wrench.

see page 20

1

• Lift the drill press head assembly (1)

carefully and place the mounting hole of

the drill press head onto the top of the

column (2). Make sure the head is seated

properly on the column.

see page 21

2

model no. 055-5530-8 | contact us 1-800-689-9928

SPECIFICATIONS

Motor

Pulley speeds

Table size

Base size

Spindle travel

Column diameter

Max. drilling capacity

Capacity

Chuck

Weight

120 V, 60 Hz, 4.1A

620, 1150, 1630, 2180, 3070 RPM (no load)

7 1/4 X 7 1/4" (18.4 x 18.4 cm)

13 3/8 X 8 1/4" (34 x 21 cm)

5 cm

ø5 cm

5/8" (1,2 cm) diameter

5" (12.7 cm) chuck to column

12 3/16" (31 cm) chuck to table

17 1/4" (43.8 cm) chuck to base

1/16–5/8" (1.5–16 mm), keyed

49 lb 8 oz (22.5 kg)

5

SPECIFICATIONS

4

QUICK START GUIDE

• Mark the desired depth of the hole on the

side of the workpiece (1).

• With the switch off, bring the drill bit (2)

down until the tip is even with the mark.

see page 30

3

1

2

1

2

3

4

5

1

2

3

Page 4

WARNING!

To avoid mistakes that could cause serious injury, do not plug in the drill press

until you have read and understood the following rules.

WARNING!

• All repairs, electrical or mechanical, should be attempted only by trained technicians.

Contact the nearest Service Centre, Authorized Service Station or other competent

repair service.

• Use only identical replacement parts. Any others may create a hazard.

• The use of any other accessories may create a hazard.

DANGER!

Potential hazard that will result in serious injury or loss of life.

WARNING!

Potential hazard that could result in serious injury or loss of life.

CAUTION!

Potential hazard that may result in moderate injury or damage to equipment.

model no. 055-5530-8 | contact us 1-800-689-9928

7

SAFETY GUIDELINES

6

SAFETY GUIDELINES

SAFETY GUIDELINES

This manual contains information that relates to PROTECTING PERSONAL SAFETY and PREVENTING

EQUIPMENT PROBLEMS. It is very important to read this manual carefully and understand it thoroughly before

using the product. The symbols listed below are used to indicate this information.

Note: The word “Note” is used to inform the reader of something the operator needs to know about the tool.

SAFETY RECOMMENDATIONS

These precautions are intended for the personal safety of the operator and others working with the operator.

Failure to follow these instructions may result in a permanent loss of vision, serious personal or even fatal

injury, property damage and/or tool damage. Please take time to read and understand the instructions.

Safety is a combination of common sense, staying alert, and knowing how your drill press works.

WORK AREA

• Keep children away. Do not let visitors contact tool or extension cord. All visitors should be kept at a

safe distance from work area.

• Keep work areas clean. Cluttered areas and benches invite accidents.

• Make workshop childproof. With padlocks, master switches, or by removing starter keys.

• Avoid dangerous environments. Don’t use power tools in damp or wet locations. Keep work area

well lit. Do not expose power tools to rain. Do not use the tool in the presence of flammable liquids or

gases.

PERSONAL SAFETY

• Know your power tool. Read and understand the owner’s manual and labels affixed to the tool. Learn

the tool's uses and limitations as well as the specific potential hazards particular to this tool.

• Don’t overreach. Keep proper footing and balance at all times.

• Stay alert. Watch what you are doing. Use common sense. Do not operate tool when you are tired. Do

not operate while taking medication or while using alcohol or other drugs.

• Wear proper apparel. Do not wear lose clothing, gloves, neckties, rings, bracelets or other jewelry

that may get caught in moving parts. Nonslip footwear is recommended. Wear protective hair covering

to contain long hair.

• Always use safety glasses. Also use face or dust mask if cutting operation is dusty, and ear plugs

during extended periods of operation. Everyday eyeglasses have only impact-resistant lenses, they are

NOT safety glasses.

• Guard against electric shock. Prevent body contact with grounded surfaces. For example: pipes,

radiators, ranges, refrigerator enclosures.

• Disconnect tools from power source, when not in use, before servicing, when changing blades, bits,

cutters, etc.

• Keep guards in place, in working order, and in proper adjustment and alignment.

• Remove adjusting keys and wrenches when not in use, before servicing and when changing blades,

bits, cutters, etc.

• Reduce the risk of unintentional starting. Make sure the switch is in the “Off” position before

plugging in the tool.

• Ground all tools. This tool is equipped with an approved three conductor cord and a three prong

grounding-type plug to fit the proper grounding-type receptacle. The green conductor in the cord is the

grounding wire. Never connect the green wire to a live terminal.

• Never stand on tool or its stand. Serious injury could occur if the tool is tipped or if the cutting tool is

accidentally contacted. Do not store materials on or near the tool such that it is necessary to stand on the

tool or its stand to reach them.

• Check damaged parts. Before further use of the tool, a guard or other part that is damaged should be

carefully checked to ensure that it will operate properly and perform its intended function. Check for

alignment of moving parts, mounting and any other conditions that may affect the tool's operation. A

guard or other part that is damaged should be properly replaced.

ADDITIONAL SAFETY GUIDELINES FOR DRILL PRESS

TOOL USE

• Don’t force tool. It will do the job better and safer at the rate for which it was designed.

• Use the right tool. Don’t force a small tool or attachment to do the job of a heavy-duty tool. Don’t use

tool for purpose not intended—for example, don’t use a circular saw for cutting tree limbs or logs.

• Secure work. Use clamps or vise to hold work. It is safer than using your hand and it frees both hands

to operate the tool.

Page 5

WARNING!

Before connecting the tool to a power source (receptacle, outlet, etc.), be sure voltage supplied

is the same as that specified on the nameplate of the tool. A power source with a voltage greater

than that specified for the tool can result in serious injury to the user, as well as damage to the

tool. If in doubt, DO NOT PLUG IN THE TOOL. Using a power source with a voltage less than the

nameplate rating is harmful to the motor.

model no. 055-5530-8 | contact us 1-800-689-9928

9

SAFETY GUIDELINES

8

SAFETY GUIDELINES

• Never leave tool running unattended. Turn power off. Don’t leave tool until it comes to a complete

stop.

TOOL CARE

• Do not alter or misuse tool. These tools are precision built. Any alteration or modification not specified

is misuse and may result in dangerous conditions.

• Avoid gaseous areas. Do not operate electric tools in a gaseous or explosive atmosphere. Motors in

these tools normally spark, and this may result in a dangerous condition.

• Maintain tools with care. Keep tools sharp and clean for best and safest performance. Follow

instructions for lubricating and changing accessories. Inspect tool cords periodically and, if damaged,

have repaired by authorized service facility. Inspect extension cords periodically and replace if damaged.

Keep handles dry, clean and free from oil and grease.

• For your own safety, do not operate your drill press until it is completely assembled and

installed according to the instructions, and until you have read and understood the following:

1. Technical specifications

2. Safety guidelines

3. Know your drill press

4. Assembly instructions

5. Operating instructions

7. Maintenance

8. Troubleshooting

9. Stability of the drill press

If there is any tendency of the drill press to tilt or move during use, bolt it to the bench top or to a piece

of 3/4" (2 cm) exterior plywood large enough to stabilize the drill press. Bolt the plywood to the underside

of the base so it extends beyond the sides of the base. DO NOT USE PRESSED WOOD PANELS. They can

break unexpectedly. If the workpiece is too large to easily support with one hand, provide an auxiliary

support.

10. Location

Use the drill press in a well-lit area and on a level surface, clean and smooth enough to reduce the risk

of trips and falls. Use it where neither the operator nor the casual observer is forced to stand in line with

a potential kickback.

11. Protection: Eyes, hands, ears and body.

TO AVOID BEING PULLED INTO THE SPINNING TOOL—

DO NOT WEAR: Loose-fitting gloves

Necktie

Loose clothing

Jewelry

DO: TIE BACK LONG HAIR

ROLL LONG SLEEVES ABOVE ELBOWS

a. If any part of your drill press is missing, malfunctioning, has been damaged or broken, such as the

motor switch or other operating control, a safety device or the power cord, cease operating the drill

press immediately until the particular part is properly repaired or replaced.

b. Never place your fingers in a position where they could contact the drill bit or other cutting tool if the

workpiece should unexpectedly shift or your hand should slip.

c. To avoid injury from parts thrown by the spring, follow the instructions exactly as given and shown in

“SPINDLE RETURN SPRING” section.

d. To prevent the workpiece from being torn from your hands, spinning on the table, shattering the tool,

or being thrown, always support your work so it won’t shift or bind to the tool.

• Always position “backup material” (used beneath the workpiece) to contact the left side of the column.

• Whenever possible, position the workpiece to contact the left side of the column. If the workpiece is

short or the table is tilted, clamp workpiece solidly to the table. Use table slots or clamping ledge

around the outside edge of the table.

• When using a drill press vise, always fasten to the table.

• Never do any work “free hand” (hand holding a workpiece rather than supporting it on the table),

except when polishing.

• Securely lock head and table support to column, and table to table support, before operating drill press.

• Never move the head or table support while the tool is running.

• Before starting the operation, jog the motor switch to make sure the drill bit or other cutting tool does

not wobble or cause vibration.

• If a workpiece overhangs the table such that it will fall or tip if not held, clamp it to the table or provide

auxiliary support.

• Use fixtures for unusual operations to adequately hold, guide and position the workpiece.

• Use the SPINDLE SPEED recommended for the specific operation and workpiece material. Check the

panel inside the pulley cover for drilling information. For accessories, refer to the instructions provided

with the accessories.

e. Never climb on the drill press table; it could break or pull the entire drill press down on you.

f. Turn the motor switch “Off” and unplug from power source when not in operation.

g. To avoid injury from thrown work or tool contact, DO NOT perform layout, assembly or setup work on

the table while the cutting tool is rotating.

Page 6

CAUTION!

In all cases, verify that the outlet in question is properly grounded. if you are not sure, have a

licensed electrician check the outlet.

model no. 055-5530-8 | contact us 1-800-689-9928

11

SAFETY GUIDELINES

10

SAFETY GUIDELINES

12. Use only accessories designed for this drill press to avoid serious injury from thrown,

broken parts or workpieces.

a. WHEN CUTTING LARGE DIAMETER HOLES: Clamp the workpiece firmly to the table. Otherwise

the cutter may grab and spin at high speed. Use only one-piece, cup-type, hole cutters. DO NOT

use fly cutters or multi-part hole cutters, as they come apart or become unbalanced in use.

b. Drum sanders must NEVER be operated on this drill press at a speed greater than the

speed rating of the drum sander.

c. Do not install or use any drill bit that exceeds 7" (17.8 cm) in length or extends 6"

(15.2 cm) below the chuck jaws. They can suddenly bend outward or break.

d. Do not use wire wheels, router bits, shaper cutters, circle (fly) cutters or rotary planers

on this drill press.

e. Use recommended speed for drill accessory and workpiece material.

f. Accessories must be rated for at least the spindle speed setting of the drill press. This drill

press has five spindle speeds. Check spindle speed setting of the drill press based on the pulley speed

chart located inside the pulley housing. Ensure accessories used have a higher speed rating than the

current spindle speed setting of the drill press. Accessories running over their rated speed can fly apart

and cause injury.

13. Direction of feed for drum sanding

• Feed workpiece into a sanding drum or other approved accessory, against the direction of rotation.

• A kickback occurs when workpiece suddenly binds on the cutting edge of the tool and the workpiece

is thrown by the cutter in the direction of the cutter’s rotation. This can cause serious injury.

14. Note and follow the safety warnings and instructions:

For your own safety, read and understand instruction manual before operating drill press:

• Wear safety glasses or safety goggles.

• Do not wear loose fitting gloves, necktie or loose clothing. Tie back long hair.

• Clamp workpiece or brace against column to prevent rotation.

• Use recommended speed for drill accessory and workpiece material.

• Use only recommended accessories.

• Before starting, be certain chuck key is removed from chuck and that motor, head and table are

locked.

• Keep pulley cover closed when not making belt adjustments.

• Unplug drill press before making bit/accessory changes, adjustments or repairs.

• Do not expose to rain or use in damp locations.

15. This drill press has five speeds: 620 RPM, 1150 RPM, 1630 RPM, 2180 RPM AND 3070

RPM. See inside of guard for specific placement of belt on pulleys.

16. Think safety

Safety is a combination of operator common sense and alertness at all times when the drill press is

being used.

USE SAFETY GOGGLES AND EAR PROTECTION:

ALWAYS WEAR EYE PROTECTION THAT CONFORMS WITH CUL REQUIREMENTS. FLYING

DEBRIS can cause permanent eye damage.

The tool is loud and the sound can cause hearing damage. Always wear ear protection to help

prevent hearing damage and loss. Failure to comply may result in moderate injury.

USE DUST MASK:

Some dust created by drilling contains chemicals that are known to cause cancer, birth defects

or other reproductive harm. Some examples of these chemicals come from lead-based paints,

crystalline silica from bricks, cement and other masonry products, arsenic and chromium from

chemically treated lumber. To reduce exposure to these chemicals, work in a well-ventilated

area with approved safety equipment, such as dust masks that are specially designed to filter out microscopic

particles.

ELECTRICAL SAFETY

GROUNDING INSTRUCTIONS:

This machine must be grounded while in use to protect the operator from electric shock.

In the event of a malfunction or breakdown, grounding provides a path of least resistance for electric current

to reduce the risk of electric shock. This tool is equipped with an electric cord having an equipment-grounding

conductor and a grounding plug. The plug must be plugged into a matching outlet that is properly installed

and grounded in accordance with all local codes and ordinances.

WARNING!

Do not allow familiarity (gained from frequent use of your drill press) to become commonplace.

Always remember that a careless fraction of a second is sufficient to inflict severe injury.

CAUTION!

In all cases, verify that the outlet in question is properly grounded. if you are not sure, have a

licensed electrician check the outlet.

Page 7

NOTE:

Recycle unwanted materials rather than disposing of them as waste. Sort the tool and its components in

specific categories and take to the local recycling centre or dispose of them in an environmentally safe way.

WARNING!

This tool must be grounded while in use in order to protect the operator from electric shock.

WARNING!

• Use the proper extension cord. Make sure to use an extension cord that is heavy enough to carry

the current required by the tool. An undersized cord will cause a drop in line voltage, resulting in

loss of power and overheating of the tool.

• Use the extension cord only for intended purpose. Do not pull the extension cord to remove it

from the power socket.

Do not modify the plug provided. If it will not fit the outlet, have the proper outlet installed by a qualified

electrician.

Improper connection of the equipment-grounding conductor

can result in a risk of electric shock. The conductor with

a green surface, with or without yellow stripes, is the

equipment-grounding conductor. If repair or replacement of

the electric cord or plug is necessary, do not connect the

equipment-grounding conductor to a live terminal.

Check with a qualified electrician or service technician if

the grounding instructions are not completely understood,

or if in doubt as to whether the tool is properly grounded.

Use only three wire extension cords that have three prong

grounding plugs and three pole receptacles that accept the tool’s plug, as shown in Fig. 1. Repair or replace

a damaged or worn cord immediately.

GROUNDING INSTRUCTIONS:

• Make sure the extension cord is in good condition. When using an extension cord, be sure to use one

that is heavy enough to carry the current that your product will draw. An undersized cord will cause a

drop in line voltage, which will result in loss of power and overheating. The table on the next page shows

the correct size to be used according to cord length and nameplate ampere rating. When in doubt, use

the next heavier gauge. The smaller the gauge number, the heavier the cord.

• Make sure your extension cord is properly wired and in good condition. Always replace a damaged

extension cord, or have it repaired by a qualified person before using it. Protect your extension cords from

sharp objects, excessive heat, and damp or wet areas.

• Use a separate electrical circuit for your tools. This circuit must consist of not less than #12 wire with a

20 A time-delayed fuse or a #14 wire with a 15 A time-delayed fuse. Before connecting the motor to the

power line, make sure the switch is in the Off position and the electric current is rated the same as the

current stamped on the motor nameplate. Running at a lower voltage will damage the motor.

Fig. 1

Three-prong plug

Grounding prong

Properly grounded outlet

model no. 055-5530-8 | contact us 1-800-689-9928

13

SAFETY GUIDELINES

12

SAFETY GUIDELINES

AMPERAGE RATING OF THE TOOL

(120 V CIRCUIT ONLY)

MORE THAN

0

6

10

12

NOT MORE THAN

6

10

12

16

25’ (7.6 m)

18

18

16

14

50’ (15.2 m)

16

16

16

12

100’ (30.5 m)

16

14

14

Not recommended

150’ (45.7 m)

14

12

12

TOTAL LENGTH OF THE EXTENSION CORD

MINIMUM GAUGE FOR THE EXTENSION CORD (AWG)

Recommended size for extension cords

Page 8

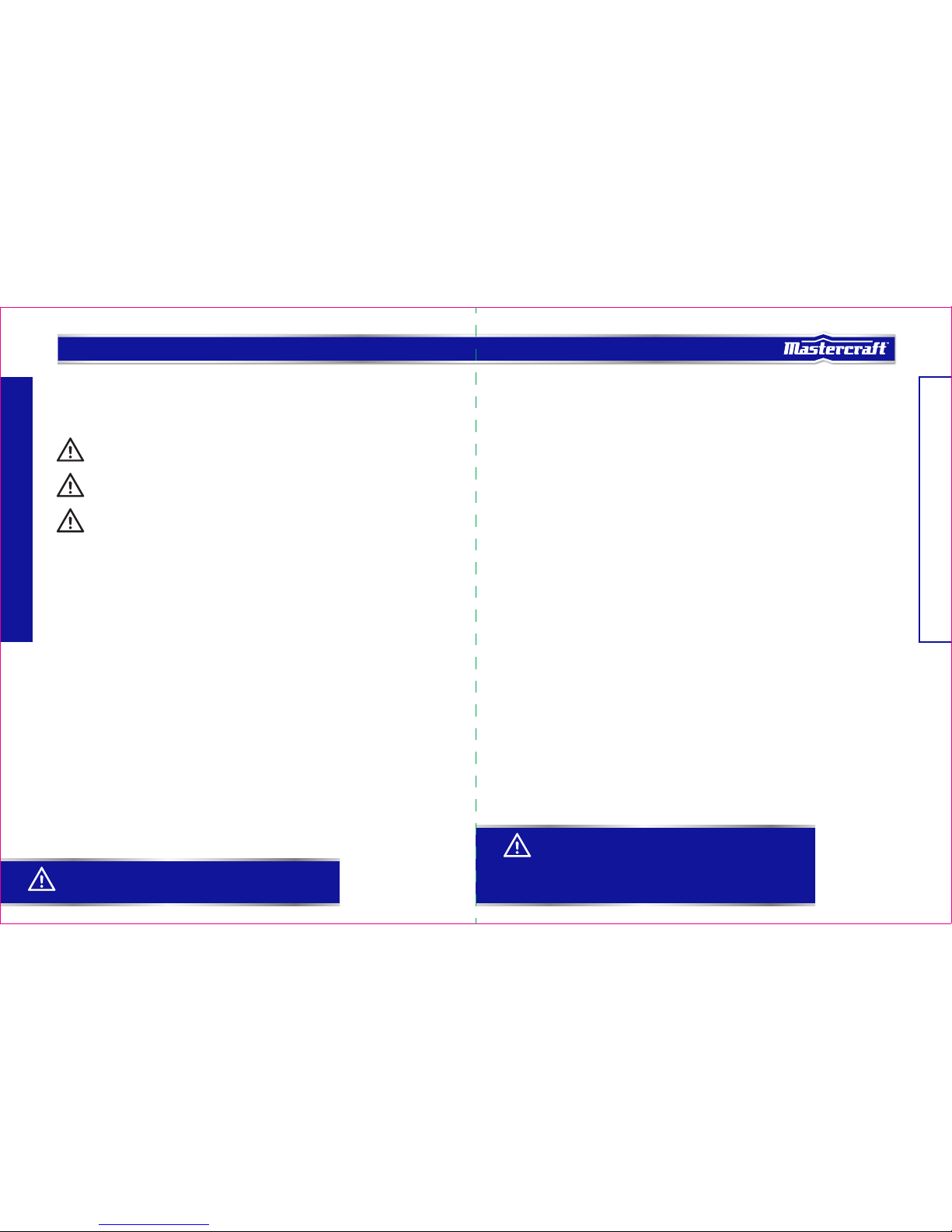

model no. 055-5530-8 | contact us 1-800-689-9928

15

KNOW YOUR DRILL PRESS

14

KNOW YOUR DRILL PRESS

1

2

3

4

5

6

7

14

13

12

11

10

On/Off switch:

The On/Off switch located on the front of the drill press allows the operator to turn On/Off the drill press easily.

To lock the switch in the Off position, remove the safety key from the switch. Place the safety key in a location

that is not accessible to children and others who are not qualified to use the tool.

Spindle speed:

Five different spindle speeds allow you to drill a wide variety of material including wood, plastic and metal.

Bevel scale:

The bevel scale indicates the degree to which the table is tilted.

Chuck:

Your drill press features a standard three-jaw type chuck with a self-ejecting chuck key, which prevents

accidentally starting the drill press with the key still engaged in the chuck.

Depth scale:

A depth scale is located between the pulley housing and feed handles to aid in drilling at desired depths.

Feed handles:

Feed handles raise and lower the chuck and bit during the drilling operation.

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Description

Pulley housing cover

LED worklight switch

Feed return spring and cover

LED worklight

Chuck

Column

Table

Chuck key

Bevel scale

Column support

Support lock handle

Rack collar

Power cord

Locking screws

Belt/pulley speed chart

NO.

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

Description

Motor pulley

Belt

Feed handle

Motor

Tension lock knob

Depth tension knob

Rack

Crank handle

Base

Quill

Pointer

On/Off switch

Depth scale

Spindle pulley

Pulley housing screw

9

8

16

15

17

29

30

18

19

20

21

22

23

24

28

26

27

25

Page 9

PACKAGE CONTENTS

No Description Qty Illustration

Head assembly

Base

Table/support assembly

Crank handle

Chuck

Feed handles

Rack

Column/support assembly

1

2

3

4

5

6

7

8

1

1

1

1

1

3

1

1

model no. 055-5530-8 | contact us 1-800-689-9928

17

ASSEMBLY INSTRUCTIONS

16

KNOW YOUR DRILL PRESS

Motor:

Your drill press is equipped with an industrial-duty induction motor for long-lasting, smooth performance.

Table:

The table of your drill press rotates 360˚ and bevels up to 45˚ for angle drilling.

LED worklight (3.2-3.4 V):

The drill press comes equipped with an LED worklight that lights the work area for more accurate cuts. The

worklight turns on with the LED worklight switch.

Page 10

WARNING!

If any parts are damaged or missing, do not operate this tool until the parts are replaced. Use of

this product with damaged or missing parts could result in serious personal injury.

• Do not attempt to modify this tool or create accessories not recommended for use with this tool.

Any such alteration or modification is misuse and could result in a hazardous condition leading

to possible serious personal injury.

• Do not connect to power supply until assembly is complete. Failure to comply could result in

accidental starting and possible serious personal injury.

• Risk of injury! Always pull out the mains plug (disconnect the product from its power supply)

before commencing work on the product.

• To avoid fire or toxic reaction, never use gasoline, naptha or similar highly volatile solvents.

No Description Qty Illustration

Rack collar

Flat washers M8

Spring washers M8

Bolts M8x25

Batteries

3 mm/4 mm Hex key

Chuck key

9

10

11

12

13

14

15

1

3

3

3

2

2

1

TOOLS NEEDED FOR ASSEMBLY

Star-head screwdriver Framing square

Block of wood Ruler

Wrench Hammer

UNPACKING

Do not use this product if any parts of the package contents are already assembled to your product when you

unpack it. Package contents are not assembled to the product by the manufacturer and require customer

installation. Use of a product that may have been improperly assembled could result in serious personal injury.

• Inspect the tool carefully to make sure no breakage or damage occurred during shipping.

• Do not discard the packing material until you have carefully inspected and satisfactorily operated the tool.

• Remove the protective oil that is applied to table, base and column. Use any ordinary household grease

and spot remover.

• Apply a coat of paste wax to the table, column and machined surfaces of base to prevent rust.

Wipe all parts thoroughly with a clean, dry cloth.

• If any parts are damaged or missing, please call 1-800-689-9928 for assistance.

model no. 055-5530-8 | contact us 1-800-689-9928

19

ASSEMBLY INSTRUCTIONS

18

ASSEMBLY INSTRUCTIONS

Page 11

NOTE:

One or two of the feed handles may be removed if an unusually-shaped workpiece interferes with handle

rotation.

WARNING!

To reduce the risk of injury, never connect plug to power source outlet until all assembly steps

are completed.

Fig. 2

model no. 055-5530-8 | contact us 1-800-689-9928

21

ASSEMBLY INSTRUCTIONS

20

ASSEMBLY INSTRUCTIONS

BASE TO COLUMN (Fig. 2)

• Set the base (1) on the floor.

• Place the column tube (2) on the base (1), align the

column support holes with the base holes.

• Install a bolt M8 x 25 (3), a flat wahser M8 (4) and a

spring washer M8 (5) in each column support hole and

tighten with the wrench.

TABLE TO COLUMN (Fig. 3–5)

• Insert the rack (1) into the geared groove of the table

support (2). Make sure the worm shaft (3) on the

inside of the table support is engaged with the teeth of

the rack. The table support should sit at the centre of

the rack.

• Slide the table support and rack assembly (1, 2, 3)

down together onto the column. Insert the bottom edge

of the rack into the lip (4) of the column support. HOLD

IN THIS POSITION until the next step is completed.

• Place the collar (5) bevel side down over the rack.

Tighten the set screw (6) with the 3 mm Allen wrench

to hold the rack in position.

Make sure there is enough clearance to allow the table to

rotate around the column. The collar must sit loosely over

the rack and not angled on the column. To avoid column or

collar damage, only tighten the set screw enough to keep

collar in place (Fig. 4).

DRILL PRESS HEAD TO COLUMN (Fig. 6)

• Lift the drill press head assembly (1) carefully and place

the mounting hole of the drill press head onto the top

of the column (2). Make sure the head is seated

properly on the column.

• Align the direction of the drill press head with the

direction of the base and the table.

• Tighten the two set screws (3) using an Allen wrench.

FEED HANDLES (Fig. 7)

• Thread the three feed handle rods (1) into the holes on

the feed hub (2).

• Hand tighten.

Fig. 6

Fig. 7

Fig. 3

Fig. 4

Fig. 5

• Insert the table support crank handle (7) into the worm

gear shaft on the side of the table support (8). Make

sure the set screw (9) is aligned on the flat of the shaft

and as close to the table support as possible. Tighten

the set screw (Fig. 5).

• Position the table in the same direction as the base,

and tighten the column lock handle (10).

1

2

3

4

5

1

2

4

3

5

6

9

8

7

10

1

2

3

1

2

Page 12

NOTE:

To avoid possible damage, be prepared to catch the chuck as it falls.

CAUTION!

If the stand or workbench has a tendency to move during operation, fasten it securely to the floor.

WARNING!

Battary may explode or cause injury if disassembled recharged or explosed to fire.

CAUTION!

Remove the LED worklight batteries when the tool is to be stored without use for a few days or

more. If left in position, the batteries might leak and damage the LED worklight assembly.

Damage due to leaking batteries is not covered under the warranty.

CAUTION!

To avoid damaging the chuck, make sure the jaws are completely recessed into the chuck.

Do not use a metal hammer directly to drive the chuck into the spindle.

model no. 055-5530-8 | contact us 1-800-689-9928

23

ASSEMBLY INSTRUCTIONS

22

ASSEMBLY INSTRUCTIONS

LED WORKLIGHT BATTERIES (Fig. 8)

• Turn off the worklight.

• Push the tab (1) located on the worklight switch cover (2)

down and toward you, then remove it.

• Insert two “AAA” batteries in the worklight battery

compartment (3).

• Replace the worklight switch cover.

MOUNT THE DRILL PRESS (Fig. 9)

Your drill press must be securely fastened through the

mounting holes (1) to a stand or workbench with heavy-duty

fasteners. This will prevent the drill press from tipping over,

sliding or walking during operation.

INSTALL THE CHUCK (Fig. 10)

• Inspect and clean the taper hole in the chuck (1) and

the spindle (2). Remove all grease, coatings, and

particles from the chuck and spindle surfaces with a

clean cloth.

• Open the chuck jaws (3) by turning the chuck barrel

clockwise by hand. Make sure the jaws are completely

recessed inside the chuck.

• Seat the chuck on the spindle by placing a block of

wood (4) under the chuck (1) and tapping the wood

with a hammer (5) or tap the chuck with a rubber

mallet.

REMOVE THE CHUCK (Fig. 11)

• Turn the feed handles (1) to lower the chuck (2) to the

lowest position.

• Place a ball joint separator (not shown) above the chuck

and tap it lightly with a hammer (3) to cause the chuck

to drop from the spindle.

Fig. 8

Fig. 10

Fig. 11

2

3

1

4

1

Fig. 9

1

3

5

2

3

1

2

2

1

Page 13

NOTE:

The belt (4) should be tight enough to prevent slippage. Correct tension is set if the belt flexes about 1/2"

(13 mm) when thumb pressure is applied at the midpoint of the belt between the pulleys (Fig. 12).

CAUTION!

To reduce the risk of injury, keep pulley cover in place and in proper working order when operating.

Fig. 12

Fig. 13

model no. 055-5530-8 | contact us 1-800-689-9928

25

ASSEMBLY INSTRUCTIONS

24

ASSEMBLY INSTRUCTIONS

OPERATING ADJUSTMENTS

INSTALL THE BELT (Fig. 12)

• Open the pulley and belt cover (1).

• Loosen the belt tension lock knobs (2) on both sides of

the drill press.

• Slide the motor (3) as close to the drill press head as

possible.

• Place a belt (4) on the motor pulley (5) and the spindle

pulley (6) in the proper position for the desired speed.

• Pull the motor away from the drill press head until the

belt is properly tensioned. Tighten the belt tension lock

knobs (2).

ALIGN THE BELT PULLEYS (Fig. 13)

• Check the alignment of the pulleys with a straight edge

(1) (such as a ruler, level, or framing square) by laying

the straight edge across the top of the pulleys (2).

• If the pulleys are NOT aligned, release belt tension by

loosening the belt tension lock knobs (3) on both sides

of the head.

• Loosen the motor mount nuts (4) with an adjustable

wrench, and lower or raise the motor until the pulleys

are aligned.

• Tighten the motor mount nuts (4) with an adjustable

wrench to maintain the position.

• Lock the motor for the proper belt tension and tighten

the tension lock knobs (3).

Fig. 14

Fig. 15

SPINDLE SPEEDS (Fig. 14)

This drill press offers five spindle speeds from 620 to 3070 RPM. The highest speed is obtained when the belt

is positioned on the largest motor pulley step and the smallest spindle pulley stop.

ASSEMBLY AND ADJUSTMENTS

ADJUST SPEEDS AND TENSION THE BELT (Fig. 15)

• Open the drill press pulley cover (1).

• Loosen the belt tension knobs (2) on both sides of the

drill press head.

• Pull the motor (3) towards the drill press head.

• Set the belt on the desired steps of the motor pulley (4)

and spindle pulley (5) according to the belt positions

on the spindle speed chart (Fig. 14).

• Pull the motor away from the drill press head to

increase the belt tension. Tighten the tension knobs

(2).

• The belt (6) should be tight enough to prevent slippage.

Correct tension is set if the belt flexes about 1/2"

(13 mm) when thumb pressure is applied at the

midpoint of the belt between the pulleys.

1

4

3

2

1

1/2"

3

2

6 4 5

1

1/2"

3

2

5 6 4

Page 14

NOTE:

Do not overtighten the two nuts. If the nuts are tightened too much, the movement of the spindle and feed

handles will be sluggish.

Fig. 16

Fig. 17

Fig. 18

ADJUSTMENTS TO RAISE OR LOWER TABLE (Fig. 16)

• Raise or lower the table by loosening the column lock

handle (1) and turning the crank handle (2) until the

table is at the desired height.

• Tighten the table lock handle (1) before drilling.

• Rotate the table around the column by loosening the

column lock handle (1) and turning the table around the

column to the desired position.

• Tighten the lock handle before drilling.

TO TILT THE TABLE (Fig. 17)

The table can be tilted from 0 - 45° to the left and right.

• Loosen the bevel lock bolt (1) with a wrench.

• Tilt the table (2) to the desired angle, using the bevel

scale (3) as a basic guide.

• Re-tighten the bevel lock bolt (1).

• To return the table to its original position, loosen the

bevel lock bolt. Realign the bevel scale (3) to the 0°

setting.

• Tighten the bevel lock bolt (1) with the wrench.

TO SQUARE THE TABLE TO THE HEAD (Fig. 18)

• Insert a 3" (7.6 cm) drill bit (1) into the chuck (2) and

tighten.

• Raise and lock the table (3) about 1" (2.5 cm) from

the end of the drill bit.

• Place a combination square (4) on the table as shown.

The drill bit should be parallel to the straight edge of the

square.

• If an adjustment is needed, loosen the bevel lock (5)

with a wrench.

• Square the table to the bit by tilting the table.

• Tighten the bevel lock bolt (5) when square.

DRILLING DEPTH (Fig. 19)

• To stop the drill at a specific depth for consistent and

repetitive drilling, loosen the depth scale lock (1)

located on the depth scale hub (2).

• Turn the hub until the pointer (3) is aligned to the

desired depth on the scale.

• Tighten the depth scale lock (1). The chuck will stop

after traveling downward to the distance selected.

SPINDLE RETURN SPRING (Fig. 20)

The spindle is equipped with an auto-return mechanism.

The main components are a spring and a notched housing.

The spring was properly adjusted at the factory and should

not be readjusted unless absolutely necessary. If it needs

to be adjusted, proceed as follows:

• Unplug the drill press.

• Place a screwdriver into the loop (1) to hold the spring

in place.

• Loosen the two housing nuts (2) approximately 1/4"

(6 mm). Do not remove the nuts from the threaded

shaft.

• While firmly holding the spring housing (3), carefully

pull it out until it clears the raised notch (4). Turn it

until the next notch (5) is engaged with the raised

notch (to increase the tension, turn it counter-clockwise;

to decrease the tension, turn it clockwise). Tighten the

two housing nuts.

model no. 055-5530-8 | contact us 1-800-689-9928

27

ASSEMBLY INSTRUCTIONS

26

ASSEMBLY INSTRUCTIONS

1

3

1

4

5

2

3

Fig. 19

Fig. 20

1

2

2

3

5

2

1

4

3

2

1

Page 15

NOTE:

For small workpieces that cannot be clamped to the table, use a drill press vise (optional accessory, not

included). The vise must be clamped or bolted to the table to avoid injury.

WARNING!

• To reduce the risk of injury, only use the chuck key provided with this drill press or a duplicate

of it. This chuck key is self-ejecting and will “pop” out of the chuck when you let go. This action

is designed to help prevent throwing of the chuck key from the chuck when power is turned

“on”. Do not use any other key as a substitute; order a new one if damaged or lost.

• To reduce the risk of injury, make sure the chuck key is removed from the chuck before starting

any drilling operation.

WARNING!

• To reduce the risk of injury, and the workpiece and the backup material from being torn from

your hand while drilling, position them to the left side of the column. If the workpiece and the

backup material are not long enough to reach the column, clamp them to the table. Failure to

do this could result in personal injury.

• To reduce the risk of injury, make sure the chuck key is removed from the chuck before starting

any drilling operation.

Fig. 21

Fig. 22

ANGULAR PLAY OF THE SPINDLE (Fig. 21)

Move the spindle to the lowest downward position and hold

in place. With your other hand, try to make it revolve around

its axis with a side motion. If there is too much play, proceed

as follows:

• Loosen the lock nut (1).

• Turn the screw clockwise to eliminate the play but

without obstructing the upward and downward motion

of the spindle (a little bit of play is normal).

• Tighten the lock nut (1).

INSTALL DRILL BITS (Fig. 22)

• Place the chuck key (1) into the side keyhole of the

chuck (2), meshing the gear teeth (3).

• Turn the chuck key counter-clockwise to open the

chuck jaws (4).

• Insert a drill bit into the chuck far enough to obtain

maximum gripping of the chuck jaws.

• Centre the drill bit in the chuck jaws before final

tightening of the chuck.

• Use the chuck key for the final tightening to make sure

the drill bit will not slip while drilling.

model no. 055-5530-8 | contact us 1-800-689-9928

29

OPERATING INSTRUCTIONS

28

ASSEMBLY INSTRUCTIONS

ON/OFF SWITCH (Fig. 23)

• To turn the drill press On, insert the safety key (1) into

the switch housing (2). As a safety feature, the switch

cannot be turned On without the key.

• Flip the switch upward to the On position.

• To turn the drill press Off, move the switch to the down

position.

• To lock the switch in the Off position, remove the

safety key from the switch. Store the key in a safe

place.

LED WORKLIGHT SWITCH (Fig. 24)

The LED worklight switch (1) is located on the left side of

the drill press housing.

• To turn the LED worklight On, press the button “I”.

• To turn the LED worklight Off, press the button “O”.

POSITION THE TABLE AND WORKPIECE (Fig. 25)

Always place a piece of backup material (1) (wood,

plywood, etc.) on the table underneath the workpiece (2).

This will prevent splintering on the underside of the

workpiece as the drill bit breaks through. To keep the

material from spinning out of control, it must contact the

left side of the column as illustrated, or be clamped to the

table.

Fig. 23

Fig. 24

Fig. 25

2

1

2

2

1

1

3

1

4

1

Page 16

WARNING!

To reduce the risk of injury, make sure the chuck key is removed from the chuck before starting

any drilling operation.

Fig. 26

DRILLING A HOLE

Use a centre punch or sharp nail to dent the workpiece where you want the hole. With the switch Off, bring

the drill bit down to the workpiece, lining it up with the hole location. Turn the switch On and pull down on

the feed handles with only enough effort to allow the drill to cut.

• Feeding too slowly might cause the drill bit to burn.

• Feeding too rapidly might stop the motor, causing the belt or drill to slip, tearing the workpiece loose, or

breaking the drill bit.

• For deeper cuts, drill into the workpiece about 1/4" (6.4 mm) and raise the drill bit out of the workpiece.

This will clear chips out of the hole. Drill again another 1/4" (6.4 mm) and raise the drill bit out of the hole

to clear debris and chips. Repeat until finished drilling the hole. Practice with scrap material to get the

feel of the machine before attempting to do any regular drilling operation.

• When drilling metal, it will be necessary to lubricate the tip of the drill with oil to prevent overheating the

drill bit.

DRILLING TO A SPECIFIC DEPTH

Drilling a blind hole (not all the way through the workpiece) to a given depth can be done in two ways.

WORKPIECE METHOD (Fig. 26)

• Mark the desired depth of the hole on the side of the

workpiece (1).

• With the switch off, bring the drill bit (2) down until the

tip is even with the mark.

• Hold the feed handle at this position.

• Lock the depth scale lock knob. The chuck and the drill

bit will now be stopped at the distance selected on the

depth scale.

model no. 055-5530-8 | contact us 1-800-689-9928

31

OPERATING INSTRUCTIONS

30

OPERATING INSTRUCTIONS

DEPTH SCALE METHOD (Fig. 27)

• With the switch (1) Off, turn the feed handle (2) until

the drill bit tip (3) slightly touches the top of the

workpiece (4).

• Hold the feed handles in that position.

• Loosen the depth lock knob (5).

• Spin the depth scale hub (6) until the desired drilling

depth is at the scale pointer.

• Lock the depth lock knob. The chuck and drill bit will

now drill into the workpiece only to the distance

selected on the depth scale.

GENERAL DRILLING GUIDELINES

DRILLING SPEEDS

Important factors when determining the best drilling speed:

• Type of material

• Size of the hole to be drilled

• Type of drill bit or cutter

• Desired quality of the cut

Remember, smaller drill bits require greater speed than larger drill bits. Softer materials require greater speed

than harder materials.

DRILLING METAL

• Use metal-piercing twist drill bits.

• It is always necessary to lubricate the tip of the drill with oil to prevent overheating the drill bit.

• All metal workpieces should be clamped down securely. Any tilting, twisting, or shifting causes a rough

drill hole and increases the potential of drill bit breakage.

• Never hold a metal workpiece with your bare hands. The cutting edge of the drill bit may seize the

workpiece and throw it, causing serious injury. The drill bit will break if the metal piece suddenly hits the

column.

• If the metal is flat, clamp a piece of wood under it to prevent turning. If it cannot be laid flat on the table,

then it should be blocked and clamped.

Fig. 27

1

2

1

6

3

4

5

2

Page 17

WARNING!

To reduce the risk of injury, turn power switch OFF and remove plug from the power source outlet

before doing maintenance on or lubricating your drill press.

CAUTION!

Certain cleaning agents and solvents damage plastic parts. Some of these are: gasoline, carbon

tetrachloride, chlorinated cleaning solvents, ammonia and household detergents that contain

ammonia. Avoiding use of these and other types of cleaning agents minimizes the probability of

damage.

To avoid shock or fire hazard, if the power cord is worn, cut or damaged in any way, have it

replaced immediately.

WARNING!

All repairs, electrical or mechanical, should be attempted only by trained technicians. Use only

identical replacement parts; any other may create a hazard.

DRILLING WOOD

• Brad point bits are preferred. Metal piercing twist bits may be used on wood.

• Do not use auger bits. They turn so rapidly that they lift the workpiece off the table and whirl it around.

• Always protect the drill bit by positioning the table so the drill bit will enter the centre hole when drilling

through the workpiece.

• To prevent splintering, feed slowly when the bit is about to cut through to the backside of the workpiece.

• To reduce splintering and protect the point of the bit, use scrap wood as a backing or a base block under

the workpiece.

FEEDING THE BIT

• Pull down on the feed handles with only enough force to allow the drill bit to cut.

• Feeding too rapidly might stall the motor, cause the belt to slip, damage the workpiece, or break the drill

bit.

• Feeding too slowly will cause the drill bit to heat up and burn the workpiece.

model no. 055-5530-8 | contact us 1-800-689-9928

33

MAINTENANCE

32

OPERATING INSTRUCTIONS

GENERAL MAINTENANCE

Frequently blow out or vacuum sawdust or metal chips that accumulate in and on the motor, pulley housing,

table and work surface.

A coat of furniture-type paste wax applied to the table, column, and machined parts of the base will help to

keep these surfaces clean.

The ball bearings in the spindle and the V-belt pulley assembly are greased and permanently sealed. Pull the

spindle down and oil the spindle sleeve moderately every three months.

1

2

Page 18

PROBLEM Possible Causes Solution

Will not start. • Power cord is not plugged in.

• Fuse or circuit breaker ripped.

• Cord damaged.

• Misaligned guides.

• Plug in.

• Replace fuse or reset tripped circuit

breaker.

• Have cord replaced by a qualified

electrician.

• Have switch replaced by a qualified

service technician.

Does not come up to

speed.

• Extension cord too light or too long.

• Low house voltage.

• Replace with adequate cord.

• Contact your electric company.

TROUBLESHOOTING

model no. 055-5530-8 | contact us 1-800-689-9928

35

EXPLODED VIEW

34

TROUBLESHOOTING

1

2

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

46

23

24

26

25

27

28

29

37

38

39

40

41

42

43

44

45

47

48

54

55

56

44

57

58

59

60

61

93

68

69

69

68

70

71

72

73

61

97

102

103

104

105

62

63

64

65

66

67

36

43

74 40

75

43

76

106

78

77

77

78

84

3

85

86

87

88

90

89

79

80

82

83

81

53

52

51

50

49

13

17

18

19

20

21

22

94

95

96

98

99

100

101

59

4

3

91

92

93

Page 19

PARTS LIST

No

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

36

37

Qty

1

1

11

7

3

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

10

1

Description

Base

Column support

Flat washer

Spring washer

Bolt

Crank handle

Gear

Pin sleeve

Working table

Spring washer

Bolt

Chuck

Bearing

Buffer washer

Axis sleeve

Axis

Lock handle

Bevel scale

Support

Rail

Screws

Column

Elastic cylindrical pin

Axis

Scale plate

Knob

Rivet

Scale label

Pointer

Screw

Body

No

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

Qty

2

2

10

4

1

18

2

1

1

1

3

1

1

1

2

2

1

1

1

1

1

5

1

3

2

1

2

2

6

6

2

Description

Gear pad

Earthing pin

Spring washer

Screw

Switch box

Flat washer

Screw

Fixed plate

Spring ring

Self-locking switch

Screw

Loop spring

Switch

Spring cap

Battery

Hex thin nut

Cover

Electrode (B)

Electrode (A)

Electrodes (B)

Box for battery

Hex nut

Screw

Screw

Hexagon nut

Lower guard

Coil protection

Pin

Flat washer

Screw

Spring ring

No

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106

Qty

2

1

1

1

1

2

1

3

3

1

1

1

1

1

1

1

1

2

1

Description

Hex nut

Motor pulley

Belt

Motor

Worm pin

Handle

Base for feed handle

Rail for feed handle

Ball for feed handle

Rack collar

Rack

Chuck key

Allen wrench

Allen wrench

Light box

LED light

Light box cover

Bolt

knob

No

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

Qty

2

1

1

1

2

2

8

1

3

3

1

4

1

1

2

4

1

2

2

Description

Axis

Axis sleeve

Spring ring

Pulley

Screw

Hinge

Hex nut

Upper guard

Flat washer

Screw

Lock

Shock washer

Power cord

Positioned pin

Connected axis

Bolt

Base board

Flat washer

Spring washer

model no. 055-5530-8 | contact us 1-800-689-9928

37

PARTS LIST

36

PARTS LIST

1

Page 20

3-Year Limited Warranty

This Mastercraft product is guaranteed for a period of 3 years from the date of original retail purchase against

defects in workmanship and materials, except for the following component:

Component A: Accessories, which are guaranteed for a period of 1-year from the date of original retail

purchase against defects in workmanship and materials.

Subject to the conditions and limitations described below, this product, if returned to us with proof of purchase

within the stated warranty period and if covered under this warranty, will be repaired or replaced (with the

same model, or one of equal value or specification), at our option. We will bear the cost of any repair or

replacement and any costs of labour relating thereto.

These warranties are subject to the following conditions and limitations:

a. a bill of sale verifying the purchase and purchase date must be provided;

b. this warranty will not apply to any product or part thereof which is worn or broken or which has become inoperative due

to abuse, misuse, accidental damage, neglect or lack of proper installation, operation or maintenance (as outlined in

the applicable owner’s manual or operating instructions) or which is being used for industrial, professional, commercial

or rental purposes;

c. this warranty will not apply to normal wear and tear or to expendable parts or accessories that may be supplied with the

product that are expected to become inoperative or unusable after a seasonable period of use;

d. this warranty will not apply to routine maintenance and consumable items such as, but not limited to, fuel, lubricants,

vacuum bags, blades, belts, sandpaper, bits, fluids, tune-ups or adjustments;

e. this warranty will not apply where damage is caused by repairs made or attempted by others (i.e. persons not

authorized by the manufacturer);

f. this warranty will not apply to any product that was sold to the original purchaser as a reconditioned or refurbished

product (unless otherwise specified in writing);

g. this warranty will not apply to any product or part thereof if any part from another manufacturer is installed therein or

any repairs or alterations have been made or attempted by unauthorized persons;

h. this warranty will not apply to normal deterioration of the exterior finish, such as, but not limited to, scratches, dents,

paint chips, or to any corrosion or discolouring by heat, abrasive and chemical cleaners; and

i. this warranty will not apply to component parts sold by and identified as the product of another company, which shall

be covered under the product manufacturer’s warranty, if any.

Additional Limitations

This warranty applies only to the original purchaser and may not be transferred. Neither the retailer nor the manufacturer

shall be liable for any other expense, loss or damage, including, without limitation, any indirect, incidental, consequential

or exemplary damages arising in connection with the sale, use or inability to use this product.

Notice to Consumer

This warranty gives you specific legal rights, and you may have other rights, which may vary from province to province.

The provisions contained in this warranty are not intended to limit, modify, take away from, disclaim or exclude any

statutory warranties set forth in any applicable provincial or federal legislation.

This product is not meant for industrial or commercial purposes. This product is for household

projects, read manual carefully

Made in China

Imported by Mastercraft Canada Toronto, Canada M4S 2B8

model no. 055-5530-8 | contact us 1-800-689-9928

38

WARRANTY

Loading...

Loading...