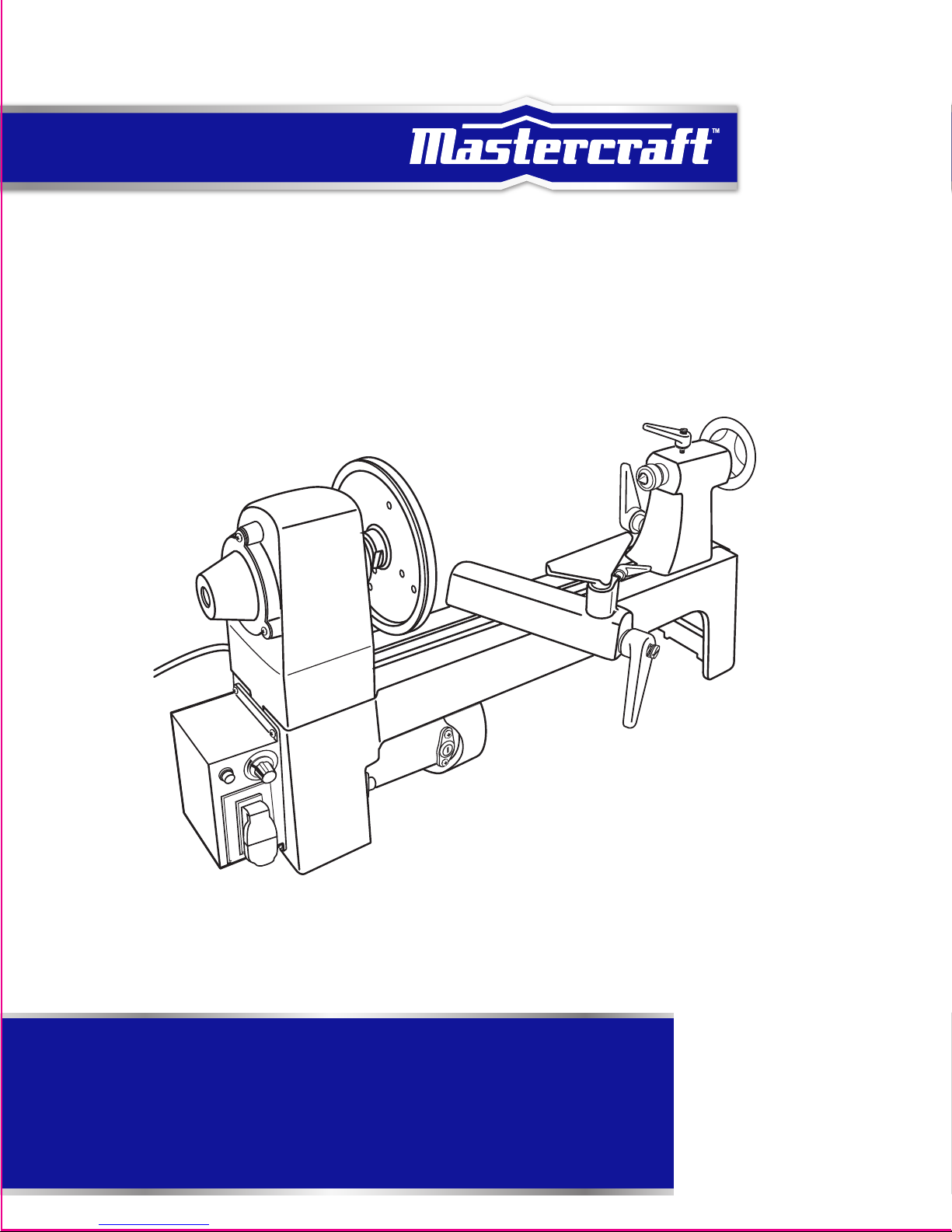

Page 1

INSTRUCTION

MANUAL

MINI WOOD LATHE

IMPORTANT:

Please read this manual carefully before running this mini

wood lathe and save it for reference.

model no. 055-4504-8

Page 2

3

TABLE OF CONTENTS

SAVE THESE INSTRUCTIONS

This manual contains important safety and operating instructions. Read all

instructions and follow them when using this product.

NOTE:

If any parts are missing or damaged, or if you have any questions, please call our

toll-free helpline at 1-800-689-9928

TABLE OF CONTENTS

Quick Start Guide

Specifications

Safety Guidelines

Know Your Mini Wood Lathe

Assembly Instructions

Operating Instructions

Maintenance

Troubleshooting

Exploded View

Parts List

Warranty

4

5

6-10

11-13

14-18

19-20

21

22

23

24-25

26

Page 3

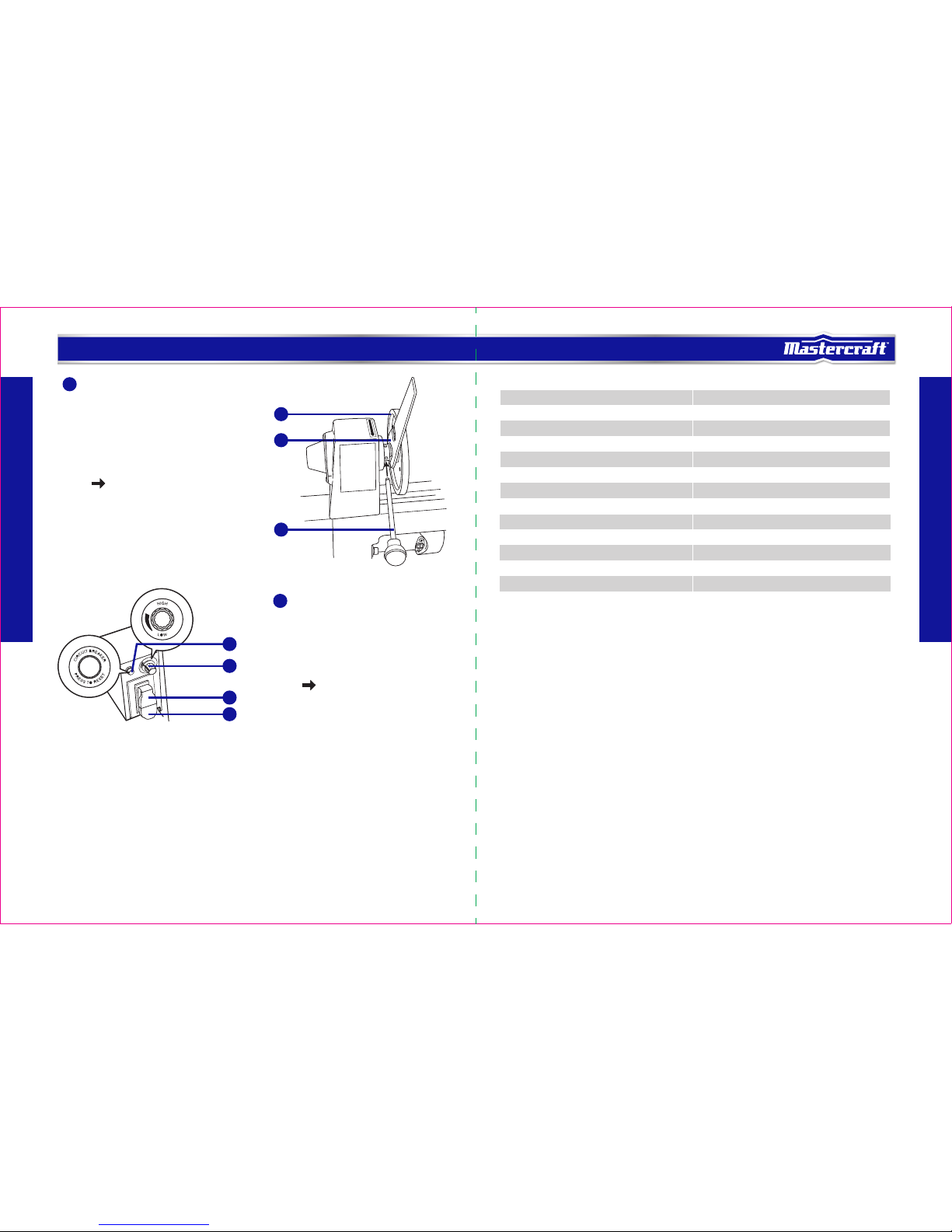

• After the lathe is started, turning the knob

clockwise will increase spindle speed (to

the maximum RPM). Turning the knob

counter-clockwise will decrease spindle

speed (to the minimum RPM).

• Adjust the knob until the desired workpiece

rotation speed is reached.

see page 19

• When installing the faceplate (1), thread it onto

the end of the headstock spindle and hand

tighten.

• Place the wrench (2) over the flats on the

faceplate.

• Insert the tip of the push-out rod (3) into one

of the slots in the side of the headstock

spindle.

see page 17

1

model no. 055-4504-8 | contact us 1-800-689-9928

SPECIFICATIONS

Motor

Speeds

Switch

Distance between centres

Swing-over bed

Drive spindle

Drive spindle through hole

Tailstock spindle through hole

Tailstock spindle travel

Headstock spur

Tailstock centre

Overall dimensions

Weight

120 V AC, 60 Hz, 3 A, 1/3 HP

500-3500 RPM

Removable key type

12" (30 cm)

8" (20 cm)

1" (2.5 cm) 8 TPI thread

3/8" (10 mm)

3/8" (10 mm)

1 1/2" (4 cm)

Spur centre, Morse #1 taper

Ball bearing cap centres, Morse #1 taper

30 5/8 x 4 13/16 x 13 1/2" (77.8 x 12.2 x 34.3 cm)

43 lb (19.6 kg)

5

SPECIFICATIONS

4

QUICK START GUIDE

2

1

2

3

1

3

2

4

Page 4

WARNING!

To avoid mistakes that could cause serious injury, do not plug in the mini

wood lathe until you have read and understood the following rules.

DANGER!

Potential hazard that will result in serious injury or loss of life.

WARNING!

Potential hazard that could result in serious injury or loss of life.

CAUTION!

Potential hazard that may result in moderate injury or damage to equipment.

model no. 055-4504-8 | contact us 1-800-689-9928

7

SAFETY GUIDELINES

6

SAFETY GUIDELINES

SAFETY GUIDELINES

This manual contains information that relates to PROTECTING PERSONAL SAFETY and PREVENTING

EQUIPMENT PROBLEMS. It is very important to read this manual carefully and understand it thoroughly before

using the product. The symbols listed below are used to indicate this information.

Note: The word “Note” is used to inform the reader of something the operator needs to know about the tool.

SAFETY RECOMMENDATIONS

These precautions are intended for the personal safety of the operator and others working with the operator.

Failure to follow these instructions may result in a permanent loss of vision, serious personal or even fatal

injury, property damage and/or tool damage. Please take time to read and understand them.

Safety is a combination of common sense, staying alert, and knowing how your mini wood lathe works.

• READ and become familiar with this entire instruction manual. Learn the tool’s applications, limitations,

and possible hazards.

• AVOID DANGEROUS CONDITIONS. DO NOT use power tools in wet or damp areas, and DO NOT expose

them to rain. Keep work areas well lit.

• DO NOT use power tools in the presence of flammable liquids or gases.

• ALWAYS keep your work area clean, uncluttered and well lit. DO NOT work on floor surfaces that are

slippery with sawdust or wax.

• KEEP BYSTANDERS AT A SAFE DISTANCE FROM the work area, especially when the tool is operating.

NEVER allow children or pets near the tool.

• DO NOT FORCE THE TOOL to do a job that it was not designed to do.

• DRESS FOR SAFETY. DO NOT wear loose clothing, gloves, neckties, or jewellery (rings, watches) when

operating the tool. Inappropriate clothing and items can get caught in moving parts and pull you in.

ALWAYS wear non-slip footwear, and tie back long hair.

• WEAR A FACE MASK OR DUST MASK. The lathe operation produces dust.

• ALWAYS remove the power cord plug from the electric outlet when making adjustments, changing parts,

cleaning, or working on the tool.

• KEEP GUARDS IN PALCE AND IN WORKING ORDER.

• AVOID ACCIDENTAL START-UPS. Make sure the power switch is in the Off position before plugging in the

power cord.

• REMOVE ADJUSTMENT TOOLS. ALWAYS MAKE SURE all adjustment tools are removed from the lathe

before turning it on.

• NEVER LEAVE A RUNNING TOOL UNATTENDED. Turn the power switch to the Off position. DO NOT leave

the tool until it has come to a complete stop.

• NEVER STAND ON THE TOOL. Serious injury could result if the tool tips or is accidentally hit. DO NOT store

anything above or near the tool.

• DO NOT OVERREACH. Keep proper footing and balance at all times. Wear oil-resistant, rubber-soled

footwear. Keep floor clear of oil, scraps, and other debris.

• MIANTAIN TOOLS PROPERLY. ALWAYS keep tools clean and in good working order. Follow instructions

for lubricating and changing accessories.

• CHECK FOR DAMAGED PARTS. Check for alignment of moving parts, jamming, breakage or any other

conditions that may affect the tool’s operation. Any part that is damaged should be properly repaired or

replaced before use.

• MAKE WORKSHOP CHILDPROOF. Use padlocks and master switches, and ALWAYS remove the starter

keys.

• DO NOT operate tool if you are under the influence of drugs, alcohol or medication that could affect your

ability to use the tool properly.

SPECIFIC SAFETY RULES FOR THE MINI WOOD LATHE

• DO not operate the lathe until it is completely assembled and installed according to the instructions.

• FOR YOUR OWN SAFETY, read the entire instruction manual before operating the lathe.

• ALWAYS WEAR eye protection.

• DO NOT wear gloves, necktie or loose clothing.

• TIGHTEN all locks before operating.

• DO NOT mount a split workpiece.

• USE the lowest speed when starting a new workpiece.

• READ the warning label attached to the lathe.

• WHEN TURNING A WORKPIECE, always rough the wood to round form at slow speed. If the lathe vibrates

when running, there is a risk that the workpiece will be thrown or the tool jerked from your hands.

• ALWAYS ROTATE the workpiece by hand before turning on the motor. If the workpiece strikes the tool

rest, it could split and be thrown out of the lathe.

• DO NOT allow the turning tools to bite into the wood. The wood could split or be thrown from the lathe.

• ALWAYS POSITION the tool rest above the centreline of the lathe when shaping a piece of stock.

• DO NOT operate the lathe if it is rotating in the wrong direction. The workpiece must always be rotating

toward you.

Page 5

WARNING!

• Use the proper extension cord. Make sure to use an extension cord that is heavy enough to carry

the current required by the tool. An undersized cord will cause a drop in line voltage, resulting in

loss of power and overheating of the tool.

• Use the extension cord only for intended purpose. Do not pull the extension cord to remove it

from the power socket.

CAUTION!

In all cases, verify that the outlet in question is properly grounded. if you are not sure, have a

licensed electrician check the outlet.

model no. 055-4504-8 | contact us 1-800-689-9928

9

SAFETY GUIDELINES

8

SAFETY GUIDELINES

• BEFORE ATTACHING a workpiece to the faceplate, always rough it out to make it as rough as possible.

This minimizes vibrations while the piece is being turned. Always fasten the workpiece securely to the

faceplate. Failure to do so could result in the workpiece being thrown from the lathe.

• POSITION your hands so that they will not slip onto the workpiece.

• REMOVE all loose knots in the stock before mounting it between the centres or on the faceplate.

• DO NOT LEAVE A RUNNING LATHE UNATTENDED. Leave the work area only after the motor has come to

a full stop.

• HANG your turning tools on the wall beyond the tailstock end of the lathe. Do not lay them on the bench

so that you must reach over the revolving workpiece to select them.

• KEEP A FIRM HOLD and remain in control of the cutting tool at all times. Take special precautions when

shaping a section of stock in which knots or voids are found.

• COMPLETE the hand-sanding of all workpieces before removing them from the lathe.

USE SAFETY GOGGLES AND EAR PROTECTION:

ALWAYS WEAR EYE PROTECTION THAT CONFORMS WITH CUL REQUIREMENTS. FLYING

DEBRIS can cause permanent eye damage.

The tool is loud and the sound can cause hearing damage. Always wear ear protection to help

prevent hearing damage and loss. Failure to comply may result in moderate injury.

USE DUST MASK:

Some dust created by sawing contains chemicals that are known to cause cancer, birth defects

or other reproductive harm. Some examples of these chemicals come from lead-based paints,

crystalline silica from bricks, cement and other masonry products, arsenic and chromium from

chemically treated lumber. To reduce exposure to these chemicals, work in a well-ventilated

area with approved safety equipment, such as dust masks that are specially designed to filter out microscopic

particles.

ELECTRICAL SAFETY

GROUNDING INSTRUCTIONS:

In the event of a malfunction or breakdown, grounding provides a path of least resistance for electric current

to reduce the risk of electric shock. This tool is equipped with an electric cord having an equipment-grounding

conductor and a grounding plug. The plug must be plugged into a matching outlet that is properly installed

and grounded in accordance with all local codes and ordinances.

Do not modify the plug provided. If it will not fit the outlet, have the proper outlet installed by a qualified

electrician.

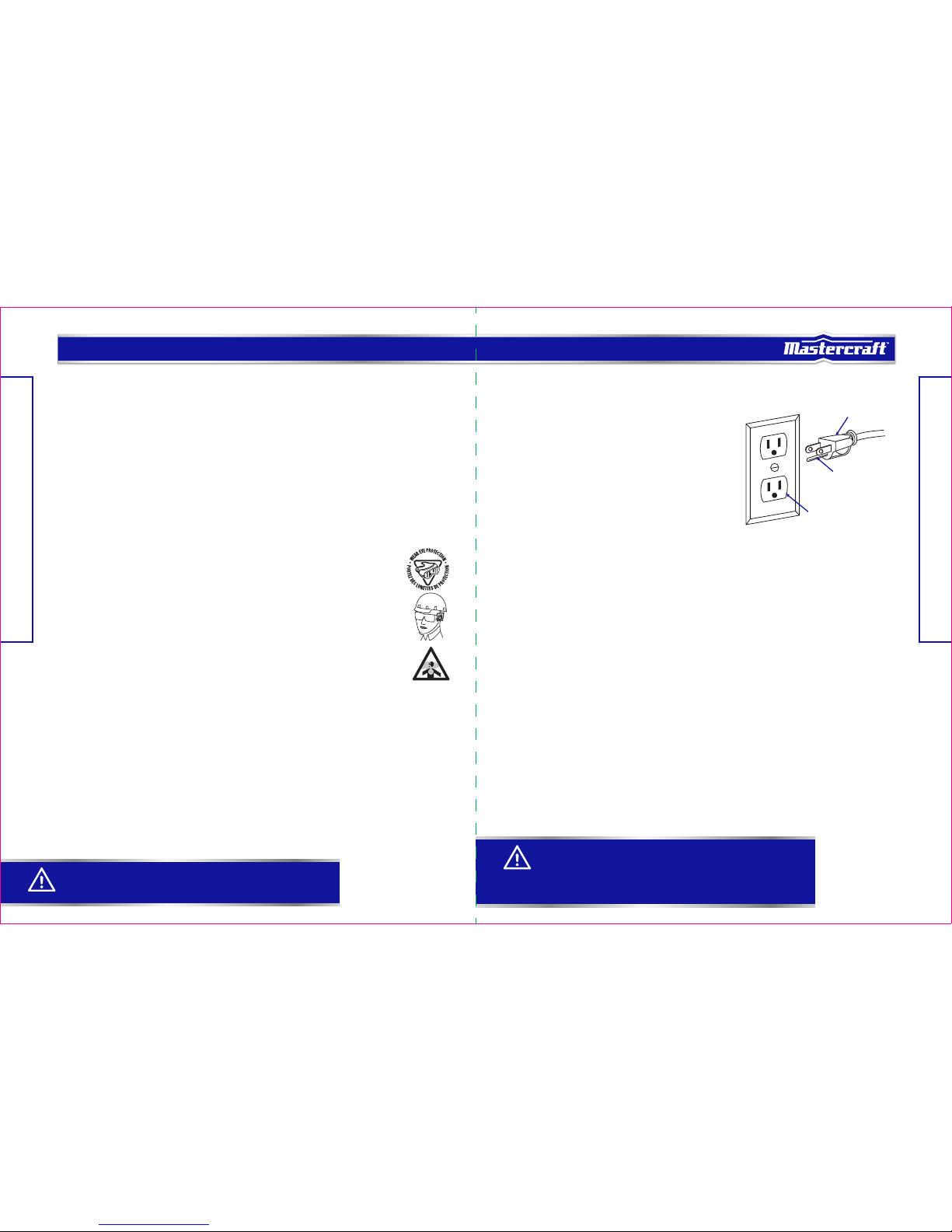

Improper connection of the equipment-grounding conductor

can result in a risk of electric shock. The conductor with

a green outer surface, with or without yellow stripes, is the

equipment-grounding conductor. If repair or replacement

of the electric cord or plug is necessary, do not connect the

equipment-grounding conductor to a live terminal.

Check with a qualified electrician or service technician if

the grounding instructions are not completely understood,

or if in doubt as to whether the tool is properly grounded.

Use only three-wire extension cords that have three-prong

grounding plugs and three-pole receptacles that accept the

tool's plug, as shown in Fig. 1. Repair or replace a damaged or worn cord immediately.

GROUNDING INSTRUCTIONS:

• Make sure the extension cord is in good condition. When using an extension cord, be sure to use one

that is heavy enough to carry the current that your product will draw. An undersized cord will cause a

drop in line voltage, which will result in loss of power and overheating. The table on the next page shows

the correct size to be used according to cord length and nameplate ampere rating. When in doubt, use

the next heavier gauge. The smaller the gauge number, the heavier the cord.

• Make sure your extension cord is properly wired and in good condition. Always replace a damaged

extension cord, or have it repaired by a qualified person before using it. Protect your extension cords from

sharp objects, excessive heat, and damp or wet areas.

• Use a separate electrical circuit for your tools. This circuit must consist of not less than #12 wire with a

20 A time-delayed fuse or a #14 wire with a 15 A time-delayed fuse. Before connecting the motor to the

power line, make sure the switch is in the OFF position and the electric current is rated the same as the

current stamped on the motor nameplate. Running at a lower voltage will damage the motor.

Fig. 1

Three-prong plug

Grounding prong

Properly grounded outlet

Page 6

AMPERAGE RATING OF THE TOOL

(120 V CIRCUIT ONLY)

MORE THAN

0

6

10

12

NOT MORE THAN

6

10

12

16

25’ (7.6 m)

18

18

16

14

50’ (15.2 m)

16

16

16

12

100’ (30.5 m)

16

14

14

Not recommended

150’ (45.7 m)

14

12

12

TOTAL LENGTH OF THE EXTENSION CORD

MINIMUM GAUGE FOR THE EXTENSION CORD (AWG)

model no. 055-4504-8 | contact us 1-800-689-9928

11

KNOW YOUR MINI WOOD LATHE

10

SAFETY GUIDELINES

Recommended size for extension cords

ON/OFF switch:

This mini wood lathe has an easy-access power switch located on the left side of the machine. To lock the

switch in the Off position, remove the switch key from the switch. Place the key in a location that is inaccessible

to children and others not qualified to use the tool.

No.

1

2

3

4

5

6

7

8

9

Description

Tool rest

Tailstock lock lever

Spindle lock lever

Hand wheel

Tailstock cup centre

Tailstock

Tool rest lock lever

Base lock lever

Tool rest base

5

6

8

7

4

16

13

14

15

12

17

1

11 10 9

2 3

No.

10

11

12

13

14

15

16

17

Description

Bed

Motor

On/Off switch

Safety key

Reset button

Speed control knob

Headstock

Faceplate

NOTE:

Recycle unwanted materials rather than disposing of them as waste. Sort the tools and its components in

specific categories and take them to the local recycling centre or dispose of them in an environmentally

safe way.

WARNING!

This tool must be grounded while in use in order to protect the operator from electric shock.

Page 7

model no. 055-4504-8 | contact us 1-800-689-9928

13

KNOW YOUR MINI WOOD LATHE

12

KNOW YOUR MINI WOOD LATHE

Between centres:

A dimension representing the maximum length of a workpiece that can be turned between centres. Also a

method of holding a workpiece by mounting it between the centres of the headstock and the tailstock

spindles.

Centre:

A precision-ground tapered cylinder with a pointed tip and a morse taper shaft. Used in the tailstock to

support the end of long workpieces. May also be used in the headstock spindle to support work between

centres at both ends.

Centreline:

An imaginary line extending from the centre of the spindle through the centre of the tailstock ram,

representing the central axis of the lathe around which the work rotates.

Parallel cutting guide:

Parallel cutting guide is fully adjustable for making cross cuts and using the mitre cutting guide.

Chuck:

A clamping device for holding work in the lathe or for holding drills in the tailstock.

Morse taper (MT):

A taper of specific dimensions used to mate matching male and female parts together tightly. The tailstock

has a MT-1 Morse taper.

Bed:

Main supporting casting running the length of the lathe.

Tool rest base:

Movable platform where the tool rest is mounted. It can be set at an angle to the workpiece (also known as

compound slide and compound rest).

Faceplate:

A metal plate with a flat face-mounted spindle to hold irregularly shaped work.

Headstock:

The main casting mounted on the left end of the bed where the spindle is mounted. Houses the spindle

gears.

Tailstock:

Assembly that slides along the bed and can be locked in place. Used to hold long workpieces in place or to

mount a drill chuck.

Hand wheel:

Moves the tailstock in and out.

Tool rest:

A device mounted on the compound that holds the cutting tool.

Tailstock lock lever:

Locks the tailstock in position. Unlock handle to position the tool rest in any location along lathe bed. Tighten

lever when properly positioned.

Page 8

model no. 055-4504-8 | contact us 1-800-689-9928

15

ASSEMBLY INSTRUCTIONS

14

ASSEMBLY INSTRUCTIONS

UNPACKING

Do not use this product if any parts of the package contents are already assembled to your product when you

unpack it. Package contents are not assembled to the product by the manufacturer and require customer

installation. Use of a product that may have been improperly assembled could result in serious personal injury.

• Inspect the tool carefully to make sure no breakage or damage occurred during shipping.

• Do not discard the packing material until you have carefully inspected and satisfactorily operated the tool.

• If any parts are damaged or missing, please call 1-800-689-9928 for assistance.

PACKAGE CONTENTS

TOOLS NEEDED FOR ASSEMBLY

No. Description Qty Illustration

Mini wood lathe assembly

Tool rest

Faceplate

Push-out rod

Headstock spur centre

Tailstock cup centre

Flat wrench

3, 4, 8 mm hex keys

1

2

3

4

5

6

7

8

1

1

1

1

1

1

1

3

No. Description Qty Illustration

M10 x40 Hexagon socket bolts

M10 Flat washers

M10 Spring washers

Mini chisel

9

10

11

12

3

3

3

3

Star-head screwdriver Wrench

Page 9

WARNING!

If any parts are damaged or missing do not operate this tool until the parts are replaced. Use of

this product with damaged or missing parts could result in serious personal injury.

• Do not attempt to modify this tool or create accessories not recommended for use with this tool.

Any such alteration or modification is misuse and could result in a hazardous condition leading

to possible serious personal injury.

• Do not connect to power supply until assembly is complete. Failure to comply could result in

accidental starting and possible serious personal injury.

• Risk of injury! Always pull out the mains plug (disconnect the product from its power supply)

before commencing work on the product.

NOTE:

To hold the lathe securely, the bolts must engage a minimum of 1" (2.5 cm) into the frame.

NOTE:

The spring-loaded handles on the lathe are designed to minimize interference with other lathe parts or the

workpiece. To operate, push the handle lever in and turn clockwise to tighten. Pulling the handle lever

outward will disengage the threaded shaft, allowing you to reposition the lever handle so it is out of the way.

NOTE:

The faceplate has an open centre, so that when drilling through a workpiece from the tailstock the drill bit

can go completely through the workpiece.

NOTE:

Since the headstock spindle is belt driven, it will turn freely if not held stationary while the faceplate is

tightened or loosened.

CAUTION!

The mini lathe is heavy and must be lifted with the help of another person.

WARNING!

The lathe must be bolted to a bench top. operating a lathe that is not bolted down may result in

serious injury.

model no. 055-4504-8 | contact us 1-800-689-9928

17

ASSEMBLY INSTRUCTIONS

16

ASSEMBLY INSTRUCTIONS

MOUNTING THE LATHE ON A BENCH TOP (Fig. 2)

• In a clear space on the bench top, measure and mark three hole centres as shown in Fig. 2.

• Drill clearance holes through the bench top. Position the lathe on the bench top.

• Install the bolts with washers (included in the hardware bag) from underneath the bench top into the

tapped holes in the bottom of the lathe frame.

SPRING-LOADED LOCK LEVERS (Fig. 3)

The spring-loaded lock levers for the tailstock spindle and

the tool rest are of four-piece construction.

The shoulder screw (1) passes through the spring (2) and

the handle lever (3). If either lock lever has come loose

from the lathe or has come apart in shipping, reassemble

it and thread into place.

INSTALLING OR REMOVING A FACEPLATE (Fig. 4)

• When installing the faceplate (1), thread it onto the end

of the headstock spindle and hand tighten.

• Place the wrench (2) over the flats on the faceplate.

• Insert the tip of the push-out rod (3) into one of the

slots in the side of the headstock spindle.

• While gripping the push-out rod firmly, turn the

wrench to either tighten or loosen the faceplate.

• Remove the push-out rod and wrench. If the faceplate

is being removed, continue turning it until it comes off

the spindle threads.

USING A FACEPLATE

Mount the workpiece onto the faceplate with brass wood screws. Make sure the screws are not so long that

they will enter the area of the workpiece where material is to be removed.

4 13/16"

(12.5 cm)

1 7/8"

(5 cm)

1 1/2" (3.8 cm)

5/8" (0.6 cm)

3 3/4" (9.5 cm)

21 3/4" (55.2 cm)

4"

(10 cm)

23" (58.4 cm)

Fig. 2

Fig. 3

Fig. 4

1

3

1

2

3

2

Page 10

NOTE:

The safety key (3) can be removed from the switch when it is in the Off position. With the key removed, the

switch is locked in that position and the lathe cannot be started. Store the key in a safe place when the lathe

is left idle (Fig. 8).

Fig. 5

Fig. 6

Fig. 7

Fig. 8

WARNING!

Do not operate the lathe until it is completely assembled and adjusted according to the instructions.

CAUTION!

Never leave the lathe unattended until it has come to a complete stop.

WARNING!

If the motor shuts off unexpectedly, unplug the lathe from the power source, make sure the On/Off

switch is in the Off position, and allow the motor to cool down before attempting to restart the

lathe. Overheating may be caused by misaligned parts or a dull chisel. Inspect the lathe for proper

set-up before using it again.

model no. 055-4504-8 | contact us 1-800-689-9928

19

OPERATING INSTRUCTIONS

18

ASSEMBLY INSTRUCTIONS

INSTALLING SPUR AND CENTRE (Figs. 5-6)

• Insert the shaft of the headstock spur centre (1) into the

hollow centre of the headstock spindle (Fig. 5).

• Insert the shaft of the tailstock cup centre (2) into the

hollow centre of the tailstock spindle (Fig. 6).

REMOVING SPUR OR CENTRE (Fig. 7)

• Insert the push-out rod (1) into the far end of the

headstock spindle or the tailstock spindle until it comes

into contact with the shaft of the spur or centre.

• Tap the end of the push-out rod (1) until the spur or

centre comes loose.

VARIABLE SPEED CONTROL BOX

The variable speed control box contains the electrical connections to the motor, and has three external

controls—speed control knob, On/Off switch, and the circuit-breaker reset button.

SPEED CONTROL KNOB (Fig. 8)

The speed control knob (1) is used to set the speed of the

lathe to suit the weight of the workpiece or the type of tool

being used.

• After the lathe is started, turning the knob clockwise

will increase spindle speed (to the maximum RPM).

Turning the knob counter-clockwise will decrease

spindle speed (to the minimum RPM).

• Adjust the knob until the desired workpiece rotation

speed is reached.

ON/OFF SWITCH (Fig. 8)

The On/Off switch (2) controls application of electrical power to the lathe’s motor. The safety key (3) must be

placed in the switch before the switch will operate.

• Move the switch to the On position to start the motor. Electric current is immediately applied to the motor.

Wait for the one- to three-second second delay in activation before the motor begins to drive the headstock

spindle. The time it takes for the motor to reach the speed set by the speed control knob depends on the

size and weight of the workpiece.

• Move the switch to the Off position to stop the motor. Electric current is immediately disconnected, but

the spindle and workpiece will continue to spin for a few seconds.

2

1

1

1

3

2

4

Page 11

CAUTION!

Make sure the tool rest is adjusted to be as close to the workpiece as possible. rotate the

workpiece by hand to check clearance before starting the lathe.

WARNING!

For your safety, turn the switch off and remove the plug from the power source before performing

maintenance or lubrication work on the lathe.

Fig. 10

Fig. 9

model no. 055-4504-8 | contact us 1-800-689-9928

21

MAINTENANCE

20

OPERATING INSTRUCTIONS

RESET BUTTON (Fig. 8)

The reset button (4) will restart the motor after the motor shuts off due to overloading or low voltage. If the

motor stops during operation:

• Turn the On/Off switch (1) to the Off position and wait about five minutes for the motor to cool.

• Press the reset button (4). Turn the switch (1) to the On position.

TAILSTOCK (Fig. 9)

• Move the tailstock (5) by loosening the lock lever (1)

and pushing the tailstock to the desired position on the

bed. Lock by tightening the lock lever (1).

• The spindle can extend up to 2 1/2" (6.35 cm) from the

tailstock housing. Move the tailstock spindle (4) by

loosening the spindle lock lever (2) and then turning the

hand wheel (3). Turning the hand wheel clockwise

extends the spindle; turning it counter-clockwise

retracts the spindle. Lock levers (1) and (2) before

operating the lathe.

• The tailstock spindle is hollow and can be accessed

from the handwheel end. Use the push-out rod to

remove the centre cup or to drill holes through the

centre of a workpiece on a faceplate.

TOOL REST (Fig. 10)

• To move the tool rest base (1), loosen the lock lever (4),

and move the base to the right or left and back or front.

Tighten the lever (4) when the tool rest base is in the

desired position.

• To adjust the angle of the tool rest (2), loosen the lock

lever (3), move the tool rest to the desired position, and

tighten the lock lever.

• To change to the other tool rest, loosen the lock lever (3)

and pull the tool rest (2) out of the tool rest base, insert

the other tool rest, adjust to desired position, and

tighten the lock lever (3).

GENERAL MAINTENANCE

• Blow out dust accumulation inside the motor, housing, and bed assembly frequently. If the tailstock has

been used as a guide for drilling through the centre of a workpiece, also blow sawdust or shavings out of

the centre of both spindles.

• A coat of automotive wax applied to the bed will help keep the surface clean and the movement of the tool

rest and tailstock smooth.

• Periodic lubrication of the spring levers and other threaded parts will make these parts easier to operate.

3

1

1

2

2

4

5

4

3

Page 12

Excessive vibration when

turning thin workpieces.

• Cutting tool is positioned below

workpiece centre line.

• Cutting too aggressively.

• Raise cutting tool to centre line of

workpiece.

• Use a lighter touch.

Excessive vibration when

turning larger workpieces

or bowls.

• Headstock and/or tailstock

improperly located at ends of

workpiece.

• Workpiece is unbalanced.

• Check for proper workpiece centres.

• Cut off stock until workpiece is

balanced.

Lathe will not turn on. • Speed control lever not in its

lowest speed setting.

• Electrical outlet not working or is

of wrong voltage.

• Blown fuse or tripped circuit

breaker.

• Make sure speed control lever is

turned to its lowest speed setting.

• Make sure lathe is plugged into a

working, 120 V, grounded,

electrical outlet.

• Replace fuse or reset circuit

breaker.

Lathe will not turn off. • Damaged or faulty power switch

and/or internal wiring.

• Unplug the lathe from its electrical

outlet immediately. Do not operate

lathe until it is repaired by a

qualified service technician.

model no. 055-4504-8 | contact us 1-800-689-9928

23

EXPLODED VIEW

22

TROUBLESHOOTING

14

54

15

16

17

18

44

45

36

37

32

33

34

31

50

51

43

42

41

40

39

38

37

28

29

26

25

24

23

22

21

20

14

54

15

16

17

18

19

13

12

11

7

9

10

9

7

5

4

3

2

1

8

27

26 25 23 3524

48

74

63662

73

64

71

69

52

53

54

55

56

57

58

59

60

72

70

67

68

61

49

48

1

2

47

3046 29

78

77

76

75

65

66

2

1

30

31

PROBLEM Possible Causes Solution

Quality of cut is poor. • Cutting tool is above workpiece

centre line.

• Lathe speed too slow.

• Cutting tool is dull.

• Cutting too aggressively.

• Lower cutting tool to centre line of

workpiece.

• Increase lathe speed.

• Sharpen or replace cutting tool.

• Use a lighter touch.

TROUBLESHOOTING

Page 13

No.

63

64

65

66

67

68

69

70

Qty

1

1

1

1

1

1

1

1

Description

Belt

Switch box

Printed circuit board

Rotation label

Flat washer 7

Nut M7

Adjustable knob

Switch fix plate

No.

71

72

73

74

75

76

77

78

Qty

1

2

1

1

1

1

1

1

Description

Overload label

Tapping screw ST3.5X12

Overload protector

Switch

Push-out rod

3mm Hex key

Wrench

4mm Hex key

model no. 055-4504-8 | contact us 1-800-689-9928

25

PARTS LIST

24

PARTS LIST

PARTS LIST

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

Qty

9

9

1

1

1

1

2

1

2

1

1

1

1

2

2

2

1

2

1

1

1

1

2

2

2

1

1

1

2

2

2

Description

Screw M4x8

Flat washer 4

Cover

Nut

Pulley

Screw M5x10

Bearing 6004-2Z

Power cable

Retainer 42

Headstock

Spindle

Faceplate

Spur centre

Hex bolt M4

Compression spring

Handle

Jointer

Screw M4x14

Tool rest

Tool rest support

Eccentricity shaft (A)

Retainer (B)

Bolt

Handle

Compression spring

Screw M4

Shaft sleeve

Threaded rod (A)

Compression spring

Side block

Nut M8

No.

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

Qty

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

2

2

2

1

1

4

4

4

1

2

3

1

3

1

1

Description

Cap centre

Bearing 608

Cap centre rod

Tailstock

Screw M6x10

Screw M6x10

Tailstock spindle

Nut M6

Wheel

Handle

Screw

Handle cap

Eccentricity shaft (B)

Threaded sleeve

Threaded rod (B)

Plate

Hex bolt M6x16

Spring washer 6

Flat washer 6

Motor

Fix plate

Flat washer 5

Spring washer 5

Screw M5x12

Pulley

Hex bolt M8x30

Spring washer 8

Hex bolt M8x40

Flat washer 8

Tool bed

Clip

Page 14

model no. 055-4504-8 | contact us 1-800-689-9928

26

WARRANTY

3-Year Limited Warranty

This Mastercraft product is guaranteed for a period of 3 years from the date of original retail purchase against

defects in workmanship and materials, except for the following component:

Component A: Accessories, which are guaranteed for a period of 1-year from the date of original retail

purchase against defects in workmanship and materials.

Subject to the conditions and limitations described below, this product, if returned to us with proof of purchase

within the stated warranty period and if covered under this warranty, will be repaired or replaced (with the

same model, or one of equal value or specification), at our option. We will bear the cost of any repair or

replacement and any costs of labour relating thereto.

These warranties are subject to the following conditions and limitations:

a. a bill of sale verifying the purchase and purchase date must be provided;

b. this warranty will not apply to any product or part thereof which is worn or broken or which has become inoperative due

to abuse, misuse, accidental damage, neglect or lack of proper installation, operation or maintenance (as outlined in

the applicable owner’s manual or operating instructions) or which is being used for industrial, professional, commercial

or rental purposes;

c. this warranty will not apply to normal wear and tear or to expendable parts or accessories that may be supplied with the

product that are expected to become inoperative or unusable after a seasonable period of use;

d. this warranty will not apply to routine maintenance and consumable items such as, but not limited to, fuel, lubricants,

vacuum bags, blades, belts, sandpaper, bits, fluids, tune-ups or adjustments;

e. this warranty will not apply where damage is caused by repairs made or attempted by others (i.e. persons not

authorized by the manufacturer);

f. this warranty will not apply to any product that was sold to the original purchaser as a reconditioned or refurbished

product (unless otherwise specified in writing);

g. this warranty will not apply to any product or part thereof if any part from another manufacturer is installed therein or

any repairs or alterations have been made or attempted by unauthorized persons;

h. this warranty will not apply to normal deterioration of the exterior finish, such as, but not limited to, scratches, dents,

paint chips, or to any corrosion or discolouring by heat, abrasive and chemical cleaners; and

i. this warranty will not apply to component parts sold by and identified as the product of another company, which shall

be covered under the product manufacturer’s warranty, if any.

Additional Limitations

This warranty applies only to the original purchaser and may not be transferred. Neither the retailer nor the manufacturer

shall be liable for any other expense, loss or damage, including, without limitation, any indirect, incidental, consequential

or exemplary damages arising in connection with the sale, use or inability to use this product.

Notice to Consumer

This warranty gives you specific legal rights, and you may have other rights, which may vary from province to province.

The provisions contained in this warranty are not intended to limit, modify, take away from, disclaim or exclude any

statutory warranties set forth in any applicable provincial or federal legislation.

This product is not meant for industrial or commercial purposes. This product is for household

projects, read manual carefully

Made in China

Imported by Mastercraft Canada Toronto, Canada M4S 2B8

Loading...

Loading...