Page 1

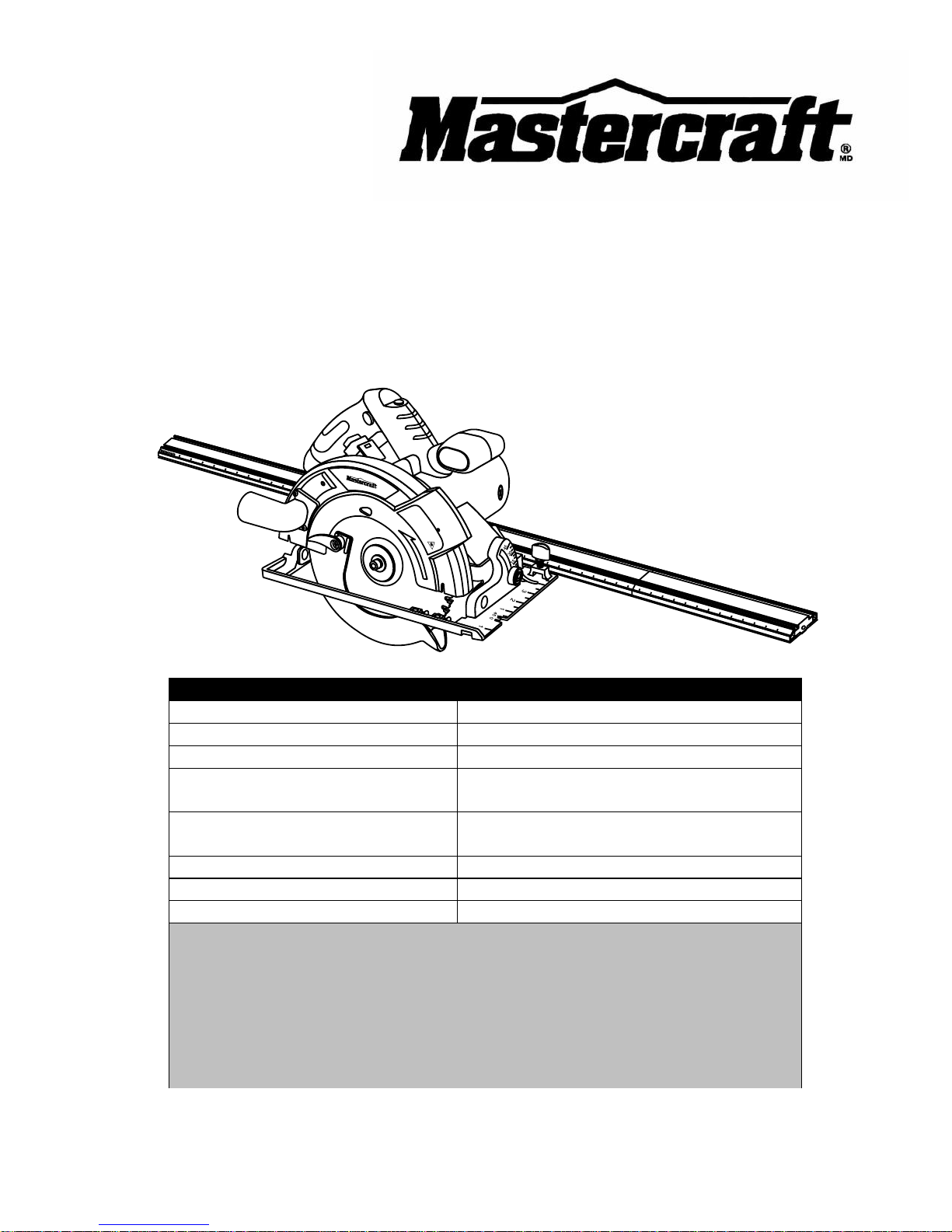

EASY SAW

054-8326-0

Owner’s Manual

PRODUCT SPECIFICATIONS

Rating:

120 V, 60 Hz AC

Amperes:

13 A

Blade speed:

4800 RPM (no load)

Blade:

7 ¼” (18.4 cm), 5/8” (15.9 mm) arbour,

40 Tungsten carbide teeth

Wood maximum cutting depth:

2 ½” (64 mm) @ 90°

1 13/16” (46 mm) @ 45°

Steel maximum thickness:

1/8" (3.2 mm)

Bevel angle:

0–50°

Weight:

13 lb 14 oz (6.3 kg)

Need Assistance?

Call us on our toll free customer support line:

1-800-689-9928

Technical questions

Replacement parts

Parts missing from package

Imported by Mastercraft Canada Toronto, Canada M4S 2B8

Page 2

2

Product specifications ………….…………………………………………………….

1

Table of contents ……………………………………………………………………...

2

General safety warnings ……………………………………………………………..

3–4

Eye, ear & lung protection ……………………………………………………………

3–4

Electrical safety ……………………………………………………………………….

4

Power tool safety ……………………………………………………………………...

5–6

General safety rules …………………………………………………………………..

5

Work area ………………………………………………………………….…………..

5

Electrical safety ……………………………………………………………………….

5

Personal safety ………………………………………………………………………..

5–6

Use and care of power tools .………………………………………………………..

6

Service …………………………………………………………………………………

6

Specific safety rules …………………………………………………………………..

7–9

Extension cord safety ………………………………………………………………...

10

Symbols ………………………………………………………………………………..

11

Know your easy saw ………………………………………………………………

12

Accessories ……………………………………………………………………………

13

Contents ……………………………………………………………………………….

13–15

Assembly and operating ……………………………………………………………..

16–33

Installing the track rider ………………………………………………………………

16

Installing the metal cutting shield ……………………………………………………

16–17

Changing the blade …………………………………………………………………...

17–18

Setting the cutting depth ……………………………………………………………..

19

Bevel cutting angle ……………………………………………………………………

19–20

Installing the rip guide ………………………………………………………………..

20

Vacuum port …………………………………………………………………………..

20–21

Lock-off button ………………………………………………………………………..

22

Trigger switch …………………………………………………………………………

22

Laser switch …………………………………………………………………………...

22

Laser adjustment ……………………………………………………………………...

23

Resettable overload switch ………………………………………………………….

23

Materials you can cut …………………………………………………………………

24

General cutting ………………………………………………………………………..

24–25

Plunge cutting …………………………………………………………………………

26

Metal cutting …………………………………………………………………………...

27

Cutting using the rip guide …………………………………………………………...

27

Assembling the guide track ………………………………………………………….

28–29

Cutting using the guide track ………………………………………………………...

30–31

Installing zero clearance inserts …………………………………………………….

31–32

Maintenance …………………………………………………………………………..

33–34

Replacing carbon motor brushes ……………………………………………………

33

General maintenance ………………………………………………………………...

34

Exploded view …………………………………………………………………………

35–36

Parts list ………………………………………………………………………………..

37–40

Warranty ……………………………………………………………………….………

41–42

TABLE OF CONTENTS

Page 3

3

EYE, EAR & LUNG PROTECTION

This instruction manual includes the following:

General Safety Rules

Specific Safety Rules and Symbols

Functional Description

Assembly

Operation

Maintenance

Accessories

!

ALWAYS WEAR EYE PROTECTION THAT CONFORMS WITH CSA

REQUIREMENTS or ANSI SAFETY STANDARD Z87.1

FLYING DEBRIS can cause permanent eye damage. Prescription

eyeglasses ARE NOT a replacement for proper eye protection.

WARNING: Non-compliant eyewear can cause serious injury if

broken during the operation of a power tool.

SAVE THESE INSTRUCTIONS FOR REFERENCE

WARNING: Use hearing protection, particularly during extended

periods of operation of the tool, or if the operation is noisy.

!

GENERAL SAFETY WARNINGS

WARNING: Before using this tool or any of its accessories, read this

manual and follow all Safety Rules and Operating Instructions. The important

precautions, safeguards and instructions appearing in this manual are not

meant to cover all possible situations. It must be understood that common

sense and caution are factors which cannot be built into the product.

!

Page 4

4

ELECTRICAL SAFETY

WARNING: To avoid electrical hazards, fire hazards or damage to the

tool, use proper circuit protection.

This tool is wired at the factory for 120 V AC operation. It must be

connected to a 120 V AC, 15 A circuit that is protected by a time-delayed

fuse or circuit breaker. To avoid shock or fire, replace power cord

immediately if it is worn, cut or damaged in any way.

GENERAL SAFETY WARNINGS

WEAR A DUST MASK THAT IS DESIGNED TO BE USED WHEN

OPERATING A POWER TOOL IN A DUSTY ENVIRONMENT.

WARNING: Dust that is created by power sanding, sawing, grinding,

drilling, and other construction activities may contain chemicals that are

known to cause cancer, birth defects, or other genetic abnormalities. These

chemicals include:

Lead from lead-based paints

Crystalline silica from bricks, cement, and other masonry products

Arsenic and chromium from chemically treated lumber

The level of risk from exposure to these chemicals varies, according to how

often this type of work is performed. In order to reduce exposure to these

chemicals, work in a well-ventilated area, and use approved safety

equipment, such as a dust mask that is specifically designed to filter out

microscopic particles.

!

SAVE THESE INSTRUCTIONS FOR REFERENCE

Page 5

5

WARNING Read all safety warnings

and instructions. Failure to follow the

warnings and instructions may result in

electric shock, fire and/or serious injury.

Save all warnings and instructions for

future reference.

Work area safety

Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

Do not operate power tools in explosive

atmospheres, such as in the presence

of flammable liquids, gases or dust.

Power tools create sparks which may

ignite the dust or fumes.

Keep children and bystanders away

while operating a power tool.

Distractions can cause you to lose control.

Electrical safety

Power tool plugs must match the outlet.

Never modify the plug in any way. Do

not use any adapter plugs with earthed

(grounded) power tools. Unmodified

plugs and matching outlets will reduce risk

of electric shock.

Avoid body contact with earthed or

grounded surfaces such as pipes,

radiators, ranges and refrigerators.

There is an increased risk of electric shock

if your body is earthed or grounded.

Do not expose power tools to rain or

wet conditions. Water entering a power

tool will increase the risk of electric shock.

Do not abuse the cord. Never use the

cord for carrying, pulling or unplugging

the power tool. Keep cord away from

heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase the

risk of electric shock.

When operating a power tool outdoors,

use an extension cord suitable for

outdoor use. Use of a cord suitable for

outdoor use reduces the risk of electric

shock.

If operating a power tool in a damp

location is unavoidable, use a residual

current device (RCD) protected supply.

Use of a ground fault circuit interrupter

(GFCI) reduces the risk of electric shock.

Personal safety

Stay alert, watch what you are doing

and use common sense when operating

a power tool. Do not use a power tool

while you are tired or under the

influence of drugs, alcohol or

medication. A moment of inattention while

operating power tools may result in serious

personal injury.

Use personal protective equipment.

Always wear eye protection. Protective

equipment such as dust mask, non-skid

safety shoes, hard hat, or hearing

protection used for appropriate conditions

will reduce personal injuries.

Prevent unintentional starting. Ensure

the switch is in the off-position before

connecting to power source and/or

battery pack, picking up or carrying the

tool. Carrying power tools with your finger

on the switch or energising power tools

that have the switch on invites accidents.

Remove any adjusting key or wrench

before turning the power tool on. A

wrench or a key left attached to a rotating

part of the power tool may result in

personal injury.

POWER TOOL SAFETY

!

Page 6

6

PERSONAL SAFETY – cont’d

Do not overreach. Keep proper footing

and balance at all times. This enables

better control of the power tool in

unexpected situations.

Dress properly. Do not wear loose

clothing or jewellery. Keep your hair,

clothing and gloves away from moving

parts. Loose clothes, jewellery or long hair

can be caught in moving parts.

If devices are provided for the

connection of dust extraction and

collection facilities, ensure these are

connected and properly used. Use of

dust collection can reduce dust-related

hazards.

Power tool use and care

Do not force the power tool. Use the

correct power tool for your application.

The correct power tool will do the job

better and safer at the rate for which it was

designed.

Do not use the power tool if the switch

does not turn it on and off. Any power

tool that cannot be controlled with the

switch is dangerous and must be repaired.

Disconnect the plug from the power

source and/or the battery pack from the

power tool before making any

adjustments, changing accessories, or

storing power tools. Such preventive

safety measures reduce the risk of starting

the power tool accidentally.

Store idle power tools out of the reach

of children and do not allow persons

unfamiliar with the power tool or these

instructions to operate the power tool.

Power tools are dangerous in the hands of

untrained users.

Maintain power tools. Check for

misalignment or binding of moving

parts, breakage of parts and any other

condition that may affect the power

tool’s operation. If damaged, have the

power tool repaired before use. Many

accidents are caused by poorly maintained

power tools.

Keep cutting tools sharp and clean.

Properly maintained cutting tools with

sharp cutting edges are less likely to bind

and are easier to control.

Use the power tool, accessories and

tool bits etc. in accordance with these

instructions, taking into account the

working conditions and the work to be

performed. Use of the power tool for

operations different from those intended

could result in a hazardous situation.

Service

Have your power tool serviced by a

qualified repair person using only

identical replacement parts. This will

ensure that the safety of the power tool is

maintained.

POWER TOOL SAFETY

Page 7

7

WARNING: Know your circular

saw. Do not plug the tool into the power

source until you have read and

understand this Instruction Manual.

Learn the tool’s applications and

limitations, as well as the specific

potential hazards related to this tool.

Following this rule will reduce the risk of

electric shock, fire, or serious injury.

Always wear eye protection.

Any power tool can throw

foreign objects into your eyes

and cause permanent eye

damage. ALWAYS wear safety goggles

(not glasses) that comply with ANSI safety

standard Z87.1. Everyday glasses have

only impact resistant lenses. They ARE

NOT safety glasses.

WARNING: Glasses or goggles

not in compliance with ANSI Z87.1

could cause serious injury when they

break.

Always keep hands out of the path of the

saw blade. Avoid awkward hand positions

where a sudden slip could cause your

hand to move into the path of the saw

blade.

DANGER: Keep hands away from

cutting area and the blade. Keep your

second hand on the tool. If both hands

are holding the saw, they cannot be cut by

the blade.

Do not reach underneath the workpiece.

The guard cannot protect you from the

blade below the workpiece.

Adjust the cutting depth according to

the thickness of the workpiece. Less

than a full tooth of the blade teeth should

be visible below the workpiece or

approximately 3/8" (10 mm).

Never hold piece being cut in your

hands or across your leg. Secure the

workpiece to a stable platform. It is

important to support the work properly to

minimize body exposure, blade binding, or

loss of control.

Hold power tool by insulated gripping

surfaces when performing an operation

where the cutting tool may contact

hidden wiring or its own cord. Contact

with a “live” wire will also make exposed

metal parts of the power tool “live” and

shock the operator.

When ripping always use a straight rip

guide. This improves the accuracy of cut

and reduces the chance of the blade

binding.

Always use blades with correct size and

shape (diamond versus round) of

arbour holes. Blades that do not match

the mounting hardware of the saw will run

eccentrically, causing loss of control.

Never use damaged or incorrect blade

washers or bolt. The blade washers and

bolt were specially designed for your saw,

for optimum performance and safety of

operation.

!

!

SAVE THESE INSTRUCTIONS FOR REFERENCE

!

SPECIFIC SAFETY RULES

Page 8

8

CAUSES AND OPERATOR

PREVENTION OF KICKBACK

Kickback is a sudden reaction to a

pinched, bound or misaligned saw blade,

causing an uncontrolled saw to lift up and

out of the workpiece toward the operator.

When the blade is pinched or bound tightly

by the kerf closing down, the blade stalls

and the motor reaction drives the unit

rapidly back toward the operator.

If the blade becomes twisted or misaligned

in the cut, the teeth at the back edge of the

blade can dig into the top surface of the

wood causing the blade to climb out of the

kerf and jump back toward the operator.

Kickback is the result of saw misuse

and/or incorrect operating procedures or

conditions and can be avoided by taking

proper precautions as given below:

Maintain a firm grip with both hands on

the saw and position your arms to

resist kickback forces. Position your

body to the left or right side of the

blade, but not in line with the blade.

Kickback could cause the saw to jump

backwards, but kickback forces can be

controlled by the operator, if proper

precautions are taken.

When the blade is binding, or when

interrupting a cut for any reason,

release the trigger and hold the saw

motionless in the material until the

blade comes to a complete stop.

Never attempt to remove the saw from

the work or pull the saw backward while

the blade is in motion or kickback may

occur. Investigate and take corrective

actions to eliminate the cause of blade

binding.

When restarting a saw in the workpiece,

centre the saw blade in the kerf and

check that saw teeth are not engaged

into the material. If the saw blades are

binding, it may walk up or kickback from

the workpiece as the saw is restarted.

Support large panels to minimize the

risk of blade pinching and kickback.

Large panels tend to sag under their own

weight. Supports must be placed under the

panel on both sides, near the line of cut

and near the edge of the panel.

Do not use dull or damaged blades.

Unsharpened or improperly set blades

produce narrow kerf causing excessive

friction, blade binding and kickback.

ADDITIONAL SPECIFIC SAFETY RULES

Use extra caution when making a

“plunge cut” into existing walls or other

blind areas. The protruding blade may cut

objects that can cause kickback.

Check the lower guard for proper

closing before each use. Do not operate

the saw if the lower guard does not

move freely and close instantly. Never

clamp or tie the lower guard into the

open position. If the saw is accidentally

dropped, the lower guard may be

damaged. Raise the lower guard with the

retracting handle and make sure it moves

freely and does not touch the blade or any

other part in all depths of cuts.

Check the operation of the lower guard

spring. If the guard and the spring are

not operating properly, they must be

serviced before use. The lower guard

may operate sluggishly due to damaged

parts, gummy deposits, or a build-up of

debris.

SPECIFIC SAFETY RULES

SAVE THESE INSTRUCTIONS FOR REFERENCE

Page 9

9

ADDITIONAL SPECIFIC SAFETY RULES –

cont’d

The lower guard should be retracted

manually only for special cuts such as

“plunge cuts” and “compound cuts”.

Raise lower guard by retracting handle

and as soon as the blade enters the

material, the lower guard must be

released. For all other sawing, the lower

guard should operate automatically.

Always observe that the lower guard is

covering the blade before placing saw

down on the bench or on the floor. An

unprotected, coasting blade will cause the

saw to walk backwards, cutting whatever is

in its path. Be aware of the time it takes for

the blade to stop after the switch is

released.

Never operate the saw while it is being

carried to another location. The blade

guard may be open and potentially cause

serious injury.

If the switch fails to turn the saw ON or

OFF properly, stop using it immediately

and have the saw switch repaired.

Always allow the saw to reach full speed

before beginning the cut.

Never use the side of the blade for cutting.

When making horizontal cuts, make sure

the weight of the tool is not forcing the side

of the blade to do the cutting. This will

reduce the risk of kickback.

Make sure there are no nails or foreign

objects in the area of the workpiece to be

cut.

Never lay workpiece on hard surfaces

like concrete, stone, etc. The protruding

blade may cause the tool to jump.

DANGER: To avoid injury from

accidental starting, always remove the

plug from the power source before

making any adjustments and before

installing or removing a saw blade.

When replacing the blade, make sure

the replacement blade is 7¼ "

(18.4 cm) in diameter and is rated for at

least 7,000 RPM. Installing an incorrect

blade will result in possible injury and poor

cutting action.

After changing a blade or making

adjustments, make sure the blade

clamp screw is securely tightened.

Loose blades and adjustment devices will

be violently thrown.

Never touch the blade during or

immediately after use. After use the

blade is too hot to be safely touched with

bare hands.

DANGER: Never use the laser in the

presence of small children. Small children

may stare directly into the laser light beam

and cause serious eye injury.

DANGER: The laser light beam that

is projected from the front of the laser level

can be dangerous to eyesight. Never allow

anyone to stare directly into the light.

Staring directly into the light beam may

result in serious eye damage.

DANGER: Always remove the plug

from the power source when changing the

blade.

SPECIFIC SAFETY RULES

! ! !

!

SAVE THESE INSTRUCTIONS FOR REFERENCE

Page 10

10

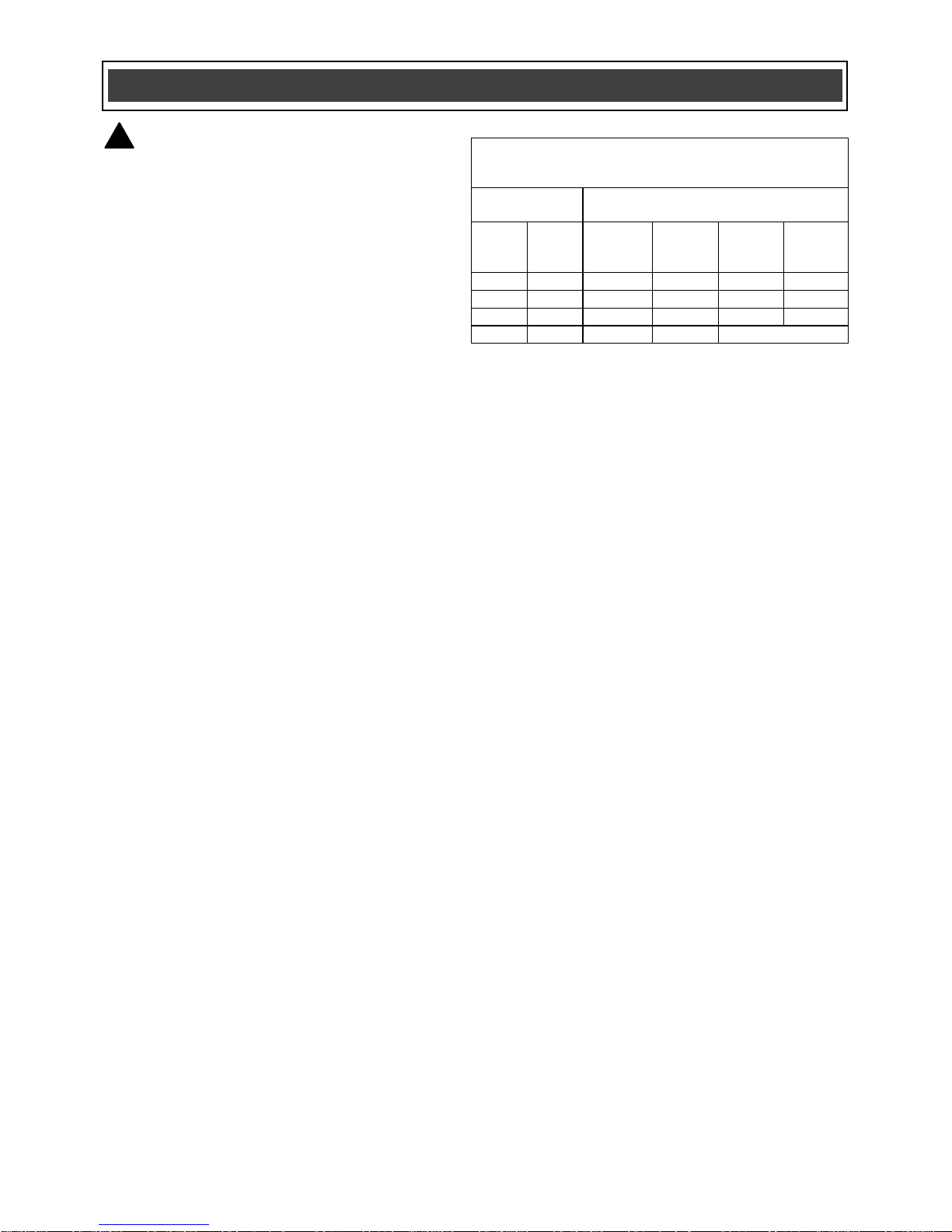

WARNING: Keep the extension

cord clear of the working area. Position

the cord so it will not get caught on the

workpiece, tools or any other obstructions

while you are working with the power tool.

Make sure any extension cord used with

this tool is in good condition. When using

an extension cord, be sure to use one of

heavy enough gauge to carry the current

the tool will draw. An undersized cord will

cause a drop in line voltage resulting in

loss of power and overheating.

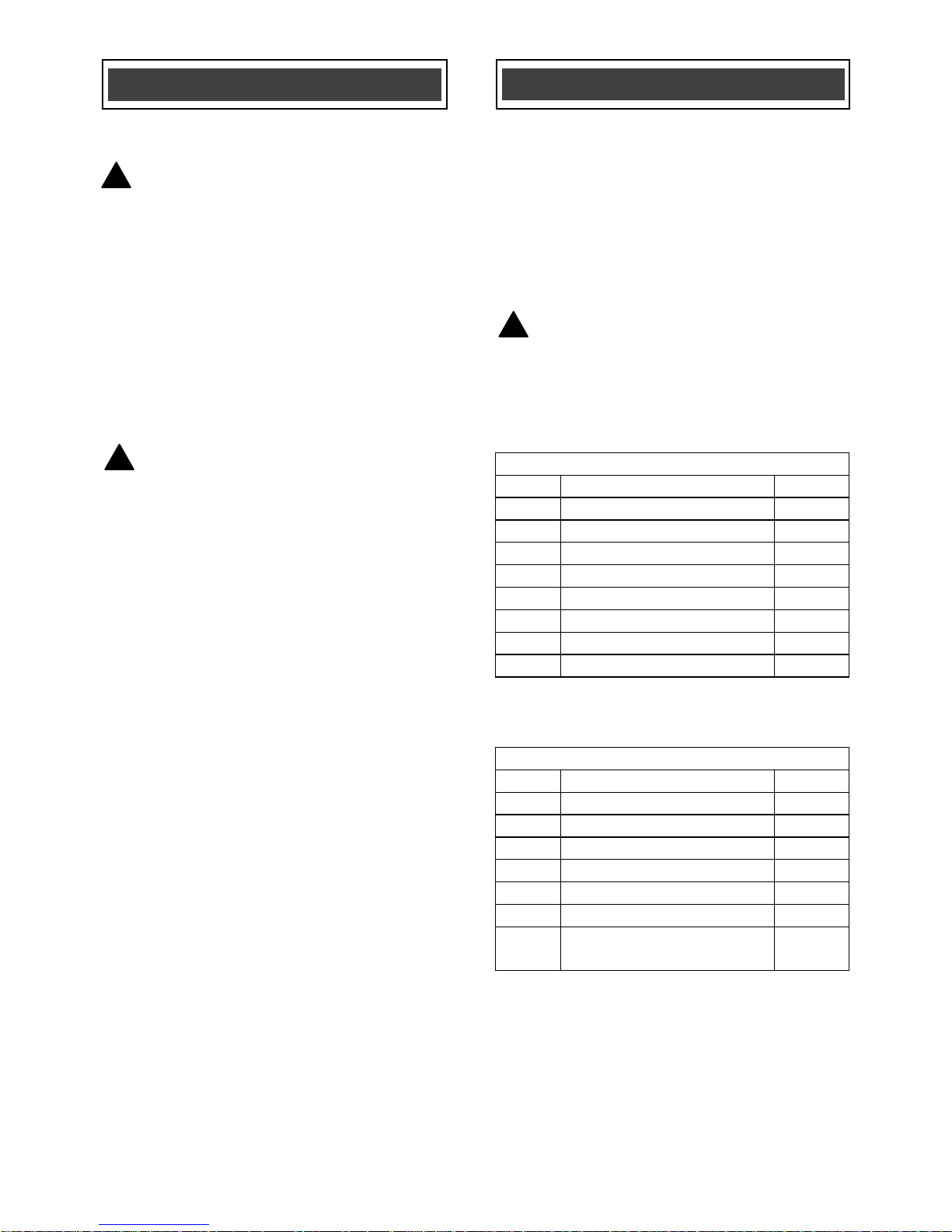

The table at right shows the correct size to

use according to cord length and

nameplate ampere rating. If in doubt, use

the next heavier gauge. The smaller the

gauge number the heavier the cord.

Be sure your extension cord is properly

wired and in good condition. Always

replace a damaged extension cord or have

it repaired by a qualified electrician before

using it. Protect your extension cord from

sharp objects, excessive heat and damp or

wet areas.

Use a separate electrical circuit for your

power tools. This circuit must not be less

than 14 gauge wire and should be

protected with either a 15 A time delayed

fuse or circuit breaker. Before connecting

the power tool to the power source, make

sure the switch is in the OFF position and

the power source is the same as indicated

on the nameplate. Running at lower

voltage will damage the motor.

!

MINIMUM GAUGE (AWG)

EXTENSION CORDS (120 V use only)

Amperage

rating Total length

More

than

Not

more

than

25'

(7.5 m)

50'

(15 m)

100'

(30 m)

150'

(45 m)

0 6 18

16

16

14 6 10

18

16

14

12

10

12

16

16

14

12

12

16

14

12

Not Applicable

EXTENSION CORD SAFETY

SAVE THESE INSTRUCTIONS FOR REFERENCE

Page 11

11

V

Volts

A

Amperes

Hz

Hertz

W

Watts

kW

Kilowatts

Microfarads

L

Litres

kg

Kilograms

H

Hours

N/cm2

Newtons per square

centimetre

Pa

Pascals

Min

Minutes

S

Seconds

Alternating current

Three-phase alternating

current

Three-phase alternating

current with neutral

Direct current

No load speed

Alternating or direct

current

Class II construction

Splash-proof

construction

Watertight construction

Protective grounding at

grounding terminal,

Class I tools

Revolutions or

reciprocations per

minute

Diameter

Off position

Arrow

Warning symbol

Warning, bright light

SYMBOLS

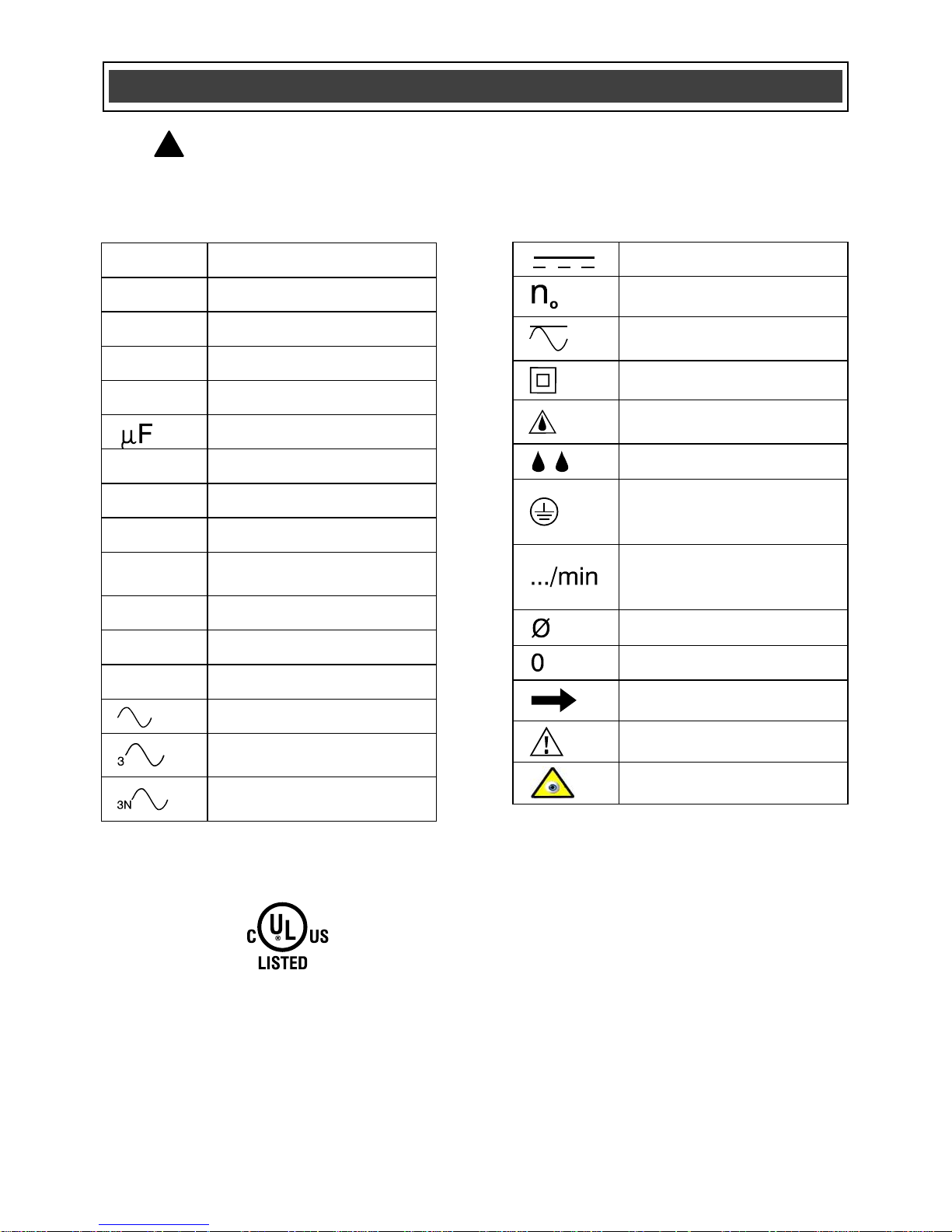

WARNING: Some of the following symbols may appear on the easy

saw. Study these symbols and learn their meaning. Proper interpretation of

these symbols will allow for more efficient and safer operation of this tool.

!

This symbol designates that this tool is

listed with both Canadian and U.S.

requirements by Underwriters

Laboratories.

Conforms to UL Std. 60745-1& 60745-2-5.

Certified to CAN/CSA Std. C22.2 No.

60745-1 & 60745-2-5.

HOMOLOGUE

61TN

E213739

Page 12

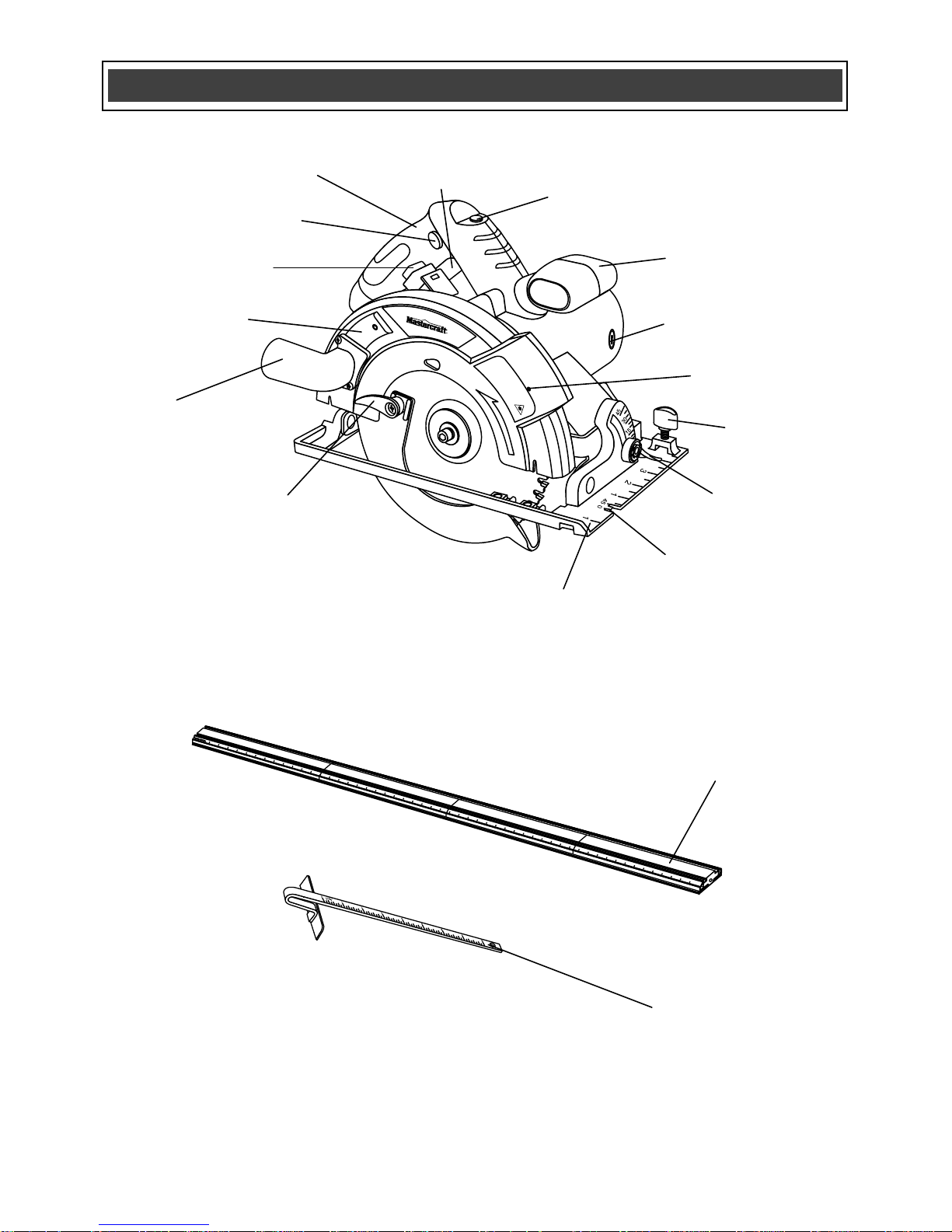

12

Rip guide

Guide track

(not exactly as illustrated)

KNOW YOUR EASY SAW

ON/OFF

Trigger switch

Laser ON/OFF

button

Lock-off button

Vacuum port

Vacuum port

baffle

Laser adjustment

screw

Brush cap

Sole plate

45° & 0°

cutting marks

Bevel cutting

adjustment lever

Rip guide

adjustment knob

Depth adjustment

stop button

Main handle

Front handle

Blade guard

lever

Page 13

13

AVAILABLE ACCESSORIES

WARNING: Use only accessories

that are recommended for this easy

saw. Follow the instructions that

accompany the accessories. The use of

improper accessories may result in

injury to the operator or damage to the

tool.

Before using any accessory, carefully read

the instructions or the owner’s manual for

the accessory.

Saw blades

WARNING: If any part is missing or

damaged, do not plug the tool into the

power source or install any accessory until

the missing or damaged part is replaced.

CONTENTS

Carefully unpack the easy saw. Compare

the contents against the “EASY SAW

COMPONENTS” and “GUIDE TRACK

COMPONENTS” charts below.

NOTE: See illustrations of the easy saw

components on Pages 14 & 15.

WARNING: To avoid fire or toxic

reaction, never use gasoline, naphtha,

acetone, lacquer thinner or similar

highly volatile solvents to clean the

tool.

CONTENTS

EASY SAW COMPONENTS

KEY

DESCRIPTION

QTY

A

Easy saw

1

B

5 mm Hex key

1

C

40 T blade

1

D

Rip guide

1

E

Track rider

1

F

Zero clearance insert

3

G

Metal cutting shield

1

Owner’s Manual

1

!

ACCESSORIES

!

!

GUIDE TRACK COMPONENTS

KEY

DESCRIPTION

QTY

H

Track section “A”

1

I

Track section “B”

1

J

Track section “C”

1

K

Track section “D”

1

L

Joining bars

6

M

Screws

12

N

End caps

(preassembled)

2

Page 14

14

CONTENTS

Page 15

15

CONTENTS

Page 16

16

INSTALLING THE TRACK RIDER

The track rider is required for use with the

guide track. It is recommended that the

track rider be installed on the easy saw

and left in place during general cutting. If

necessary, the track rider may be removed

for general cutting.

1. Lift the front and rear track rider

locking levers (1) upward to release

the locking mechanism (Fig. 1). Insert

both track rider tabs (2) into the

matching mounting slots (3) in the

sole plate (4).

NOTE: Make sure the locking pin heads

are below the track rider tabs.

2. When the track rider locking tabs are

fully inserted into the mounting slots,

press both locking levers downward to

lock the track rider into place on the

sole plate.

INSTALLING THE METAL CUTTING

SHIELD

WARNING: The metal cutting shield

must be installed on the tool when cutting

any type of metal. The cutting shield will

prevent hot cuttings and sparks from

hitting the operator.

NOTE: When cutting metal, always set the

base plate angle to 0°.

To install the metal cutting shield:

1. Remove the plug from the power

source.

2. Rotate the guard lever (1) counter

clockwise (Fig. 2).

3. Slide the lower locking tabs (2)

upward into the matching slots (3) in

the upper blade guard (Fig. 3).

ASSEMBLY AND OPERATING

Fig. 1

Fig. 2

Fig. 3

!

Page 17

17

INSTALLING THE METAL CUTTING SHIELD –

cont’d

4. Rotate the locking cam arm (4)

counter clockwise and push the

locking cam into the matching hole (5)

in the upper blade guard.

5. Rotate the locking cam arm clockwise

to lock the shield into place.

NOTE: To remove the metal cutting shield,

simply reverse the above procedure.

CHANGING THE BLADE

WARNING: Always remove the plug

from the power source before removing

the blade or adjusting the saw in any way.

WARNING: Use caution when

handling the blade. It is sharp and can

easily cut your hand.

1. Press inward on the shaft locking

button (1) (Fig. 4).

2. Insert a 5 mm hex key into the blade

screw (2) (Fig. 5). While pressing

inward on the shaft locking button,

rotate the hex key counter clockwise

until the shaft locking button engages

with the blade shaft. Continue turning

the hex key counter clockwise and

remove the blade screw, lock washer

(3), flat washer (4) and the large outer

flange washer (5).

3. Rotate the blade guard lever (6)

clockwise (Fig. 6).

4. Open the blade guard by lifting

upward on the blade guard lever.

Rotate the blade guard in a clockwise

direction to expose the blade (7).

!

ASSEMBLY AND OPERATING

Fig. 3

Fig. 5

ASSEMBLY AND OPERATING

!

Fig. 4

Fig. 6

Page 18

18

CHANGING THE BLADE – cont’d

5. While holding the blade guard lever in

the open position, lift the blade off the

shaft (8) and slide it out through the

slot in the sole plate (9).

NOTE: Do NOT remove the inner large

flange washer.

6. To place a new blade onto the motor

shaft, rotate the blade guard forward

(Fig. 6) and slide the blade through

the slot in the sole plate until it fits

over the motor shaft.

NOTES:

a) Make sure the blade teeth are pointing

forward at the bottom of the blade.

b) Make sure the hole in the blade is

placed over the matching boss on the

inner large flange washer.

7. Place the large outer flange washer

onto the motor shaft.

NOTE: Make sure the flat sections of the

large outer flange washer fit over the

matching flat sections on the motor shaft.

8. Insert the blade screw through the

lock washer, flat washer and the large

outer flange washer and thread it

clockwise into the end of the motor

shaft.

9. Lock the motor shaft using the shaft

locking button and firmly tighten the

blade screw using the hex key.

NOTE: Make sure the screw is NOT crossthreaded and that the blade does not

wobble when turned by hand.

ASSEMBLY AND OPERATING

Fig. 6

ASSEMBLY AND OPERATING

Page 19

19

SETTING THE CUTTING DEPTH

The cutting depth of the blade should be

set to suit the thickness of the material

being cut. The cutting depth should be

approximately 1/8" (3 mm) greater than the

thickness of the material being cut.

WARNING: The cutting depth

adjusting system is spring loaded. When

the cutting depth locking lever is released,

the sole plate will immediately open to its

minimum depth position. Make sure the

base is resting on a table or other flat

surface when releasing the locking lever.

1. Lift the cutting depth locking lever (1)

upward to release the spring loaded

sole plate (2) (Fig. 7).

2. Depress the cutting depth stop button

(3) and slide the depth stop (4) to the

appropriate depth setting (5).

3. Release the cutting depth stop button.

NOTE: When the cutting depth stop button

is released, move the depth stop up and

down until it clicks into the appropriate

preset position. Preset positions are in ¼”

(2.3 mm) increments. Always use the

deeper setting.

4. Once the correct depth is set, move

the sole plate upward until it stops at

the preset depth stop. Push the

cutting depth locking lever downward

to lock the sole plate into position.

BEVEL CUTTING ANGLE

The sole plate can be tilted to provide

bevel cuts from 0°–50°.

ASSEMBLY AND OPERATING

Fig. 7

!

Page 20

20

BEVEL CUTTING ANGLE– cont’d

Adjusting the sole plate angle

1. Loosen the bevel adjustment by lifting

upward on the bevel gauge

adjustment lever (1) (Fig. 8).

2. Rotate the sole plate (2) to the desired

angle as shown on the bevel gauge

(3).

3. Press downward on the bevel gauge

adjustment lever to lock the sole plate

into position.

INSTALLING THE RIP GUIDE

1. Loosen the rip guide adjusting knob

(1) (Fig. 9).

2. Slide the rip guide rod (2) into the rip

guide slot (3). Continue to slide the

guide rod across the sole plate and

into the adjusting knob slot (4) on the

opposite side of the sole plate.

3. Adjust the rip guide shoe (5) to the

correct distance from the blade and

tighten the rip guide adjusting knob.

NOTE: The rip guide may be installed from

the opposite side, but the rip guide rod

MUST engage both of the rip guide slots in

the sole plate.

VACUUM PORT

A workshop vacuum can be attached to

the vacuum port to extract much of the

dust that is created while cutting wood.

When using a workshop vacuum, pull the

vacuum port baffle tab (1) upward until the

hole in the baffle engages with the

matching pin (2) in the upper blade guard

(Fig. 10).

ASSEMBLY AND OPERATING

Fig. 10

Fig. 8

Fig. 9

Page 21

21

VACUUM PORT – cont’d

NOTE: When cutting wood without using

the workshop vacuum, the vacuum port

baffle should be closed to limit the amount

of sawdust being exhausted toward the

operator.

WARNING: The vacuum port baffle

MUST be in the closed position when

cutting metal to prevent hot cuttings from

hitting the operator.

WARNING: Never attach a

workshop vacuum to the vacuum port

when cutting metal. The cuttings will be hot

and may cause a fire in the workshop

vacuum.

ASSEMBLY AND OPERATING

For safety reasons, the operator must

read the sections of this Owner’s

Manual entitled “GENERAL SAFETY

WARNINGS”, “POWER TOOL

SAFETY”, “SPECIFIC SAFETY

RULES”, “EXTENSION CORD SAFETY”

and “SYMBOLS” before using this

easy saw.

Verify the following every time the

easy saw is used:

1. Safety glasses, safety goggles, or

face shield are being worn.

2. Hearing protection is being worn.

3. The blade is in good condition.

4. The metal cutting shield is

installed before cutting metal.

5. All adjustment devices are tight

and any accessory is properly

tightened into the accessory

holder of the tool.

Failure to observe these safety rules

will significantly increase the risk of

injury.

WARNING

!

!

!

Page 22

22

LOCK-OFF BUTTON

The lock-off button (1) is a safety device

designed to reduce the possibility of

accidentally starting the saw (Fig. 11). This

button must be depressed before the

trigger switch (2) can be depressed.

NOTE: The lock-off button can be

depressed either left or right.

TRIGGER SWITCH

1. To turn the saw ON, depress the lockoff button with your thumb.

2. While holding the lock-off button in the

depressed position, squeeze the

trigger switch to start the saw.

3. Once the saw starts, release the lockoff button. The saw will remain

running until the trigger switch is

released.

4. To turn the saw OFF, release the

trigger switch.

NOTE: The lock-off button will have to be

depressed again to restart the saw.

LASER SWITCH

This saw is equipped with a laser guidance

system for more precise cutting.

DANGER: Never allow the laser

beam to shine into a person’s eyes.

Serious eye damage could result.

To turn the laser ON, press the laser

switch (1) once (Fig. 12). To turn the laser

OFF, press the laser switch again.

ASSEMBLY AND OPERATING

Fig. 11

Fig. 12

!

Page 23

23

LASER ADJUSTMENT

The laser guide line should be centered in

the 0° cutting groove (1) (Fig. 13). If the

laser guide line is not correctly centered it

can be centered using a 5/64” (2 mm) slot

screwdriver.

Moving the laser line to the right

1. Turn the right laser adjustment screw

(2) counter clockwise ¼ turn.

2. Turn the left laser adjustment screw

clockwise ¼ turn.

3. Repeat steps #1 and #2 until the laser

guide line is moved to the correct

location.

Moving the laser line to the left

4. Turn the left laser adjustment screw

counter clockwise ¼ turn.

5. Turn the right laser adjustment screw

clockwise ¼ turn.

6. Repeat steps #4 and #5 until the laser

guide line is moved to the correct

location.

RESETTABLE OVERLOAD SWITCH

To avoid damaging the tool due to

overloading, the overload switch will

automatically turn the tool OFF when it

senses an overloaded condition.

When the switch turns the tool OFF, the

overload button (1) will pop out (Fig. 14).

When this condition happens, simply wait

approximately one minute and press the

overload switch button inward. Once reset,

the tool will operate normally.

Fig. 13

ASSEMBLY AND OPERATING

Fig. 14

Page 24

24

MATERIALS YOU CAN CUT

The easy saw is a versatile saw that allows

you to cut many different types of

materials. Some of the materials include:

● Wood products such as lumber,

hardwood, plywood, composition

board and panelling

● Drywall

● Masonite and plastic

This circular saw will also cut steel plate up

to 1/8” (3.2 mm) thick, aluminum and nonferrous metals.

NOTE: There are several different types of

blades available. Generally, blades with

carbide-tipped teeth cut better and stay

sharp longer. Tooth count and

configuration are also important. High

tooth counts cut slower and are best suited

for making smooth cuts on thinner

materials such as panelling. Use the

correct blade for your application.

GENERAL CUTTING

NOTE: Always make a test cut on a scrap

workpiece to verify that all settings are

correct.

1. Make any adjustments to the saw

before plugging it into the power

source. Adjustments include cutting

depth, bevel cutting angle and rip

guide (if installed).

2. Clearly mark the workpiece to locate

the position of the cut.

3. Hold a smaller workpiece with a vise.

Clamp a larger workpiece to a work

bench or table.

ASSEMBLY AND OPERATING

Page 25

25

GENERAL CUTTING – cont’d

DANGER: Any workpiece that is

not adequately clamped in place or

properly supported for cutting may

come loose or jamb the blade, causing

serious injury. Never hold the

workpiece in your hand.

4. Make sure there are no nails, screws,

clamps or foreign materials in the path

of the saw blade.

5. Turn the laser ON.

6. Place the front edge of the sole plate

on the workpiece.

7. With both hands firmly gripping the

saw, and with the blade NOT in

contact with the surface to be cut,

start the saw by depressing the lockoff button and then the trigger switch.

8. Once the saw has reached full speed,

gradually bring the moving blade into

contact with the workpiece at the

appropriate location.

NOTE: To align the saw blade with the

cutting mark, use the guide marks on the

front of the sole plate (Fig. 15). Use the 0°

cutting mark (1) and the laser line (2) for

right angle cuts. Use only the 45° mark (3)

for 45° bevel cuts. The 45° mark will allow

for the extra material needed for the angle

cut. Always make a test cut on a scrap

workpiece before cutting the new material.

WARNING: Do not force the

circular saw. Use only enough force to

keep the blade cutting at full speed.

Excessive pressure on the blade will

cause it to slow down and overheat,

resulting in poor cut quality and

damage to the motor.

!

ASSEMBLY AND OPERATING

Fig. 15

!

Page 26

26

PLUNGE CUTTING

WARNING: To avoid loss of

control, damage to the blade or damage

to the workpiece, always use extreme

caution when making plunge cuts. It is

not recommended to plunge cut any

material other than wood.

1. To plunge cut inside the edges of a

workpiece, clearly mark the cutting

line on the workpiece.

2. Set the depth stop (Fig. 7) and set the

bevel angle at 0° (Fig. 8). Do NOT

lock the depth stop locking lever.

3. Set the saw on the workpiece so the

sole plate is flat on the workpiece

(Fig. 16).

4. Open the blade guard by rotating the

blade guard lever (1) forward.

5. Align the saw blade with the cutting

line (2) using the 0° cutting mark on

the sole plate and the laser line.

NOTE: Make sure the saw blade is inside

the area to be cut out.

6. Start the saw and slowly lower the

blade onto the workpiece while

holding the blade guard lever forward

to allow the blade to cut into the

workpiece (Fig. 17). Allow the blade to

cut through the wood.

7. Continue lowering the blade into the

workpiece until the full cutting depth

has been achieved. Continue sawing

toward the cutting line and complete

the cut as required.

!

ASSEMBLY AND OPERATING

Fig. 16

Fig. 17

Page 27

27

METAL CUTTING

Several types of metal can be cut with your

easy saw.

NOTES:

a. Use only the 40 tooth blade supplied

with the tool to cut metal

b. Only cut aluminum, copper and steel

c. Do NOT attempt to cut metals thicker

than 1/8” (3.2 mm). Thicker metals

may overheat the blade.

WARNING: Metal cutting shield

must be installed. Never allow

bystanders or pets to be in front of the

easy saw when cutting metal. Hot

sparks can injure bystanders.

When cutting any kind of material, be

careful not cut a curve. Do not force the

blade. If the blade chatters or vibrates

excessively, reduce the travel speed of the

blade into the workpiece. Clamp all work

firmly and saw as close as possible to the

clamping point to eliminate any vibration of

the work being cut.

When cutting conduit, pipe or angle iron,

clamp the workpiece in a vice if possible

and saw close to the vice. To cut thin

sheet materials, “sandwich” the material

between hardboard or plywood and clamp

the layers to eliminate material vibration

and tearing. By doing this, the material will

be cut smoothly. Lay out your pattern or

cutting lines on top of the “sandwich”.

CUTTING USING THE RIP GUIDE

Whenever possible, install the rip guide on

the right hand side of the sole plate

(Fig. 18). This will place the majority of the

tool weight on the larger portion of the

workpiece, making it easier to control the

tool. If necessary, the rip guide may be

installed from the opposite side, but the rip

guide rod MUST engage both of the rip

guide slots in the sole plate.

ASSEMBLY AND OPERATING

!

Fig. 18

Page 28

28

ASSEMBLING THE GUIDE TRACK

The aluminum guide track is used in

conjunction with the easy saw to make

precise cuts across a workpiece up to 39”

(1 m) wide. The guide track is shipped in

four sections. To assemble the guide track,

you will need a table or work bench at

least 4’ (1.2 m) long. Assemble the guide

track as follows:

1. Lay the left track section marked “A”

(1) on its back toward the left hand

side of the work surface (Fig. 19).

2. Insert two joining bars (2) into the

matching cavities (3) in the left hand

track section “A” and fasten in place

using two screws (4) (Fig. 20).

NOTE: Do not tighten any screws until the

guide track has been fully assembled

(step #8).

3. Lay the second track section marked

“B” (5) on its back (Fig. 21). Slide the

cavities over the two joining bars that

are protruding from track section (A)

and fasten in place using two screws

(4).

4. Insert two joining bars into the

matching cavities in the right hand end

of track section “B” and fasten in place

using two screws (Fig. 22).

ASSEMBLY AND OPERATING

Fig. 19

Fig. 20

Fig. 21

Fig. 22

Page 29

29

ASSEMBLING THE GUIDE TRACK – cont’d

5. Lay the third track section marked “C”

(6) on its back (Fig. 23). Slide the

cavities over the two joining bars that

are protruding from the right hand end

of track section “B” and fasten in place

using two screws (4).

6. Insert two joining bars into the

matching cavities in the right hand end

of track section “C” and fasten in

place using two screws (Fig. 24).

7. Lay the fourth track section marked

“D” (7) on its back (Fig. 25). Slide the

cavities over the two joining bars that

are protruding from the right hand end

of track section “C” and fasten in place

using two screws (4).

8. Once all track sections are

assembled, tighten all 12 screws.

NOTE: It is important to ensure that the

fully assembled guide track forms a

straight line for cutting. Turning the guide

track assembly on its edge on a flat table

or workbench will help in aligning all four

sections as they are tightened. Once all

screws are fully tightened, recheck the

assembly with a straight edge. Loosen and

retighten the screws as required to

properly align all sections of the guide

track assembly.

ASSEMBLY AND OPERATING

Fig. 23

Fig. 24

Fig. 25

Page 30

30

CUTTING USING THE GUIDE TRACK

The guide track can be used to make

precision cuts on workpieces up to

39” (1 m) wide.

1. Install the track rider on the sole plate

(Fig. 1).

2. Mark the cut line (1) on the workpiece

(Fig. 26).

3. Mark guide track alignment marks (2)

on the workpiece at each edge 5½” to

the left of the cut line.

NOTE: The guide track alignment mark

placement will vary depending upon the

type of blade being used and the bevel

angle. Always make a test cut on a scrap

workpiece to verify the set-back distance.

4. Place the guide track (3) on the

workpiece to the left of the guide track

alignment marks (2) (Fig 27).

5. Place the right edge of the guide

track on the guide track alignment

marks.

ASSEMBLY AND OPERATING

Fig. 26

Fig. 27

Page 31

31

CUTTING USING THE GUIDE TRACK – cont’d

6. Place one small clamp on the left

hand side of the guide track at each

end to hold it firmly onto the workpiece

with the right edge on the guide track

alignment marks.

7. Set the saw cutting depth (Fig. 7).

NOTE: Make sure you support both the

“good” and “cut-off” sections of the

workpiece to prevent binding and kickback

as the saw cut is completed.

8. Place the runner of the track rider (7)

into the matching groove in the guide

track (8) (Fig. 28).

9. Slide the saw back until only 1"

(25.4 mm) of the front of the sole plate

is resting on the workpiece.

NOTE: Make sure the blade does NOT

contact the workpiece.

10. Turn the saw ON and slide the saw

and the track rider into the workpiece

and complete the cut (Fig. 29).

INSTALLING ZERO CLEARANCE

INSERTS

This easy saw includes three zero

clearance inserts. These inserts will help to

prevent raised wood grain on the top side

of the cut. Each insert requires a slot to be

cut. The most common slots are 90°, 30°

and 45°.

ASSEMBLY AND OPERATING

Fig. 28

Fig. 29

Page 32

32

INSTALLING ZERO CLEARANCE INSERTS –

cont’d

To install a zero clearance insert:

1. Release the depth adjustment lever to

allow the sole plate to completely

clear the saw blade.

2. Place the insert tabs (1) into the four

slots (2) in the under side of the sole

plate (3) (Fig. 30).

3. While pressing the insert into the

mounting slots, slide it toward the front

of the sole plate.

NOTE: The insert will snap into place

when it is slid toward the front of the sole

plate.

4. Set the depth stop to the desired

depth of cut (Fig. 7) and the bevel

angle to the desired angle (Fig. 8).

5. Using a scrap workpiece that is

THICKER than the depth setting, turn

the saw ON and make a plunge cut to

the preset depth (Fig. 16 & 17).

NOTE: The plunge cut will allow the blade

to make a precise cut in the insert, leaving

very little clearance between the blade and

the slot in the insert.

6. Turn the saw OFF and remove the

insert. It is important to mark the cut

angle and depth on the upper side of

the insert with a felt marker for future

reference.

NOTE: To remove the insert, push a

medium sized flat blade screwdriver into

the slot at the tab (4) (Fig. 31). Twist the

screwdriver to slide the insert back until

the four tabs can be removed from the

mounting slots in the sole plate.

ASSEMBLY AND OPERATING

Fig. 30

Fig. 31

Page 33

33

REPLACING THE CARBON MOTOR

BRUSHES

The carbon motor brushes will wear down

and require replacing. The time intervals

between replacements will vary depending

upon the torques being achieved and the

hours of use. It is recommended that the

brushes be checked after each 10 hours of

use. When the length of the carbon brush

reaches 1/4" (6.35 mm), the brushes

should be replaced.

WARNING: Unplug the tool from the

power source.

1. Use a 1/4" (7 mm) slot screwdriver

and remove one brush cap (1)

(Fig. 32). Turn the brush cap counter

clockwise to remove it from the motor

housing.

2. Pull the spring & brush assembly (2)

from the brush holder (3) in the motor

housing (4).

3. Insert the new spring & brush

assembly into the motor housing.

4. Compress the spring into the brush

holder and thread the brush cap back

into the motor housing.

NOTE: Make sure the brush cap threads

are not cross-threaded. Do NOT over

tighten.

5. Repeat steps 1 to 4 and replace the

second carbon brush located on the

opposite side of the motor housing.

!

MAINTENANCE

Fig. 32

Page 34

34

GENERAL

WARNING: When servicing this

tool, use only identical replacement

parts. The use of any other part may

create a hazard or cause product

damage.

DO NOT use solvents when cleaning

plastic parts. Plastics are susceptible to

damage from various types of commercial

solvents and may be damaged by their

use. Use a clean cloth to remove dirt, dust,

oil, grease etc.

WARNING: Do not allow brake

fluids, gasoline, petroleum-based

products, penetrating oils, etc. to come

into contact with plastic parts. They

contain chemicals that can damage,

weaken or destroy plastic.

DO NOT abuse power tools. Abusive

practices can damage the tool and the

workpiece.

WARNING: DO NOT attempt to

modify tools or create accessories. Any

such alteration or modification is

misuse and could result in a hazardous

condition leading to possible serious

injury. It will also void the warranty.

It has been found that electric tools are

subjected to accelerated wear and

possible premature failure when they are

used on fibreglass boats and sports cars,

wallboard, spackling compounds or

plaster. The chips and grindings from

these materials are highly abrasive to

electric tool parts such as bearings,

brushes, commutators, etc. Consequently,

it is not recommended that this tool be

used for extended work on any fibreglass

material, wallboard, spackling compounds

or plaster. During any use on these

materials it is extremely important that the

tool is cleaned frequently by blowing the

accumulated debris out with an air jet.

WARNING: Always wear safety

goggles or safety glasses with side

shields during all cutting operations. It

is critical that you wear safety goggles

or safety glasses with side shields and

a dust mask while blowing dust out of

the circular saw with an air jet. Failure

to take these safety precautions could

result in permanent eye or lung

damage.

LUBRICATION

All of the bearings in this tool are

lubricated with a sufficient amount of highgrade lubricant for the life of the unit under

normal conditions. Therefore, no further

lubrication is required.

!

MAINTENANCE

! ! ! ! !

Page 35

35

EXPLODED VIEW

Page 36

36

EXPLODED VIEW – GUIDE TRACK

Page 37

37

WARNING: When servicing, use only Mastercraft

®

replacement parts. The use of

any other parts may create a safety hazard or cause damage to the easy saw.

Any attempt to repair or replace electrical parts on this easy saw may create a safety

hazard unless repairs are performed by a qualified technician. For more information, call

the Toll-free Helpline, at 1-800-689-9928.

Always order by PART NUMBER, not by key number.

Key #

Part #

Part Name

Quantity

1

4030010096

Tapping screw 3.9X12

5

2

3160010044

Back cover

1

3

4020010034

Screw M5x52

1

4

4020010035

Screw M5x60

2

5

4040030003

Spring washer 5 mm

3

6

4040010012

Flat washers 5 mm

3

7

4030010106

Tapping screw 4X19

10

8

3120070075

Handle

1

9

1210190002

Overload protector

1

10

1062020030

Switch

1

11

1130090006

PCB

1

12

1210140003

120V transformer

1

13

3120010051

Laser button

1

14

3011120005

Housing

1

15

4100050011

Circlip 8 mm

1

16

2030100040

Plunge pivot bracket

1

17

2020060015

Bevel scale

1

18

2030020017

Washers 6 mm

1

19

3120100036

Locking lever

2

20

4100050012

Clamp spring 10 mm

2

21

2040150020

Serrated nut M6

2

22

4090040012

Rivet Φ6x16

2

23

4040010033

Flat washer 8 mm x .8 mm

1

24

2040290045

Plunge pivot shaft

1

25

4050040005

Cup head square neck bolt M6x25

1

26

2050050029

Plunge torsional spring

1

27

4030010126

Tapping screw 4x65

2

28

3150050048

Air deflector

1

29

1020120007

Stator 1 30

3160090061

Pivot spring cover

1

31

2040160123

Pin 5 mm

1

PARTS LIST

!

Page 38

38

Key #

Part #

Part Name

Quantity

32

3140040012

629 bearing cover

1

33

3150060030

Plastic brush support

2

34

2030070010

Copper brush sleeve

2

35

1230010076

Carbon brush

2

36

3150140019

Carbon brush cover

2

37

4030010099

Tapping screw 4X14

2

38

2030050002

Cable clamp

1

39

3140010006

Cable guard

1

40

1190030031

Cable

1

41

4010010084

629 2RS bearing

1

42

1010120007

Rotor 1 43

3140070016

Spindle lock cover

1

44

2030030175

Spindle lock

1

45

2050060011

Spindle lock spring

1

46

4010010055

6001 2RS bearing

1

47

4020010006

Screw M4x12 (galvanized)

3

48

4040030001

Spring washer 4 mm

3

49

4020120005

Clamping screw M3x10

2

50

2020020020

Gear box

1

51

3160060008

Laser holder

1

52

1220030006

Laser

1

53

3140090001

Rubber bushing

1

54

4020080007

Hex head screw M6x16

1

55

4010020003

HK0810

2

56

2030020203

Flat thrust washer 8 mm

2

57

4120010002

Flat key 5x10

2

58

2040040053

Transmission shaft

1

59

2040080015

Transmission gear

1

60

2020150054

Gear box cover

1

61

2020080030

Fixed guard

1

62

4020120009

Screw M4x12

1

63

2050050030

Moveable guard torsional spring

1

64

2020080031

Moveable guard

1

65

4100020009

Circlip for shaft 36 mm

1

66

2040210003

Inner flange

1

67

6070050003

Blade 1 68

2040210004

Outer flange

1

69

4040030013

Lock washer 6 mm

1

70

4020080006

Hex head screw M6x20

1

71

3120100037

Metal cutting guard locking lever

1

72

2030130030

Metal cutting guard

1

73

3150130100

Metal cutting guard lock

1

PARTS LIST

Page 39

39

Key #

Part #

Part Name

Quantity

74

4020010003

Screw M4x12 (black)

1

75

2030020163

Flat washer 4x11 (black)

1

76

2050060141

Moveable guard tortional spring

1

77

3120100038

Tortional spring stop

1

78

4020010103

Screw M3x8 (black)

2

79

3180040097

Vacuum dust port

1

80

3140070017

Vacuum dust port baffle cover

1

81

3180040098

Vacuum dust port baffle

1

82

4020010019

Screw M5x14 (galvanized)

2

83

4020020005

Countersunk screw M5x12

5

84

4010010081

6201 2RS bearing

1

85

2040080016

Big gear

1

86

2040040054

Output shaft

1

87

4100020011

Circlip for shaft 15 mm

1

88

4010020014

HK101410

1

89

4020010001

Screw M4x8 (galvanized)

1

90

2030160100

Lead clamp

1

91

3160090067

Air baffle

1

92

4050040006

Cup head square neck bolt M6x40

1

93

3150160131

Depth gauge housing (right)

1

94

2030030176

Depth gauge

1

95

3120020098

Depth adjusting button

1

96

2050040039

Depth button spring

1

97

3120120098

Depth slider

1

98

2040160124

Depth button pin

1

99

3150160132

Depth gauge housing (left)

1

100

3150130101

Track rider

1

101

2040160025

Cross pin

2

102

2040160125

Track rider locking pin

2

103

2050060142

Track rider locking lever spring

2

104

3120100039

Track rider locking lever

2

105

2050060143

Edge guide locking knob spring

1

106

2050060010

Edge guide locking knob

1

107

2020120033

Sole plate

1

108

3150130102

Zero clearance insert

3

109

6220040011

Rip guide

1

110

2030100041

Depth adjusting support

1

111

6140020001

Hex key 5 mm

1

PARTS LIST

Page 40

40

Key #

Part #

Part Name

Quantity

1

2020210006

Track section "A"

1

2

2020210007

Track section "B"

1

3

2020210008

Track section "C"

1

4

2020210009

Track section "D"

1

5

2040160132

Joining Rod

6

6

4020020001

Screw

12

7

3160090066

Track end cap

2

PARTS LIST – GUIDE TRACK

Page 41

41

3-Year Limited Warranty

This Mastercraft product is guaranteed for a period of 3 years from the date of

original retail purchase against defects in workmanship and materials, except for the

following components:

a) Component A: Batteries, chargers and carrying cases, which are

guaranteed for a period of 2 years from the date of original retail purchase

against defects in workmanship and materials;

b) Component B: Accessories which are guaranteed for a period of 1 year

from the date of original retail purchase against defects in workmanship

and materials.

Subject to the conditions and limitations described below, this product, if returned to

us with proof of purchase within the stated warranty period and is covered under

this warranty, will be repaired or replaced (with the same model, or one of equal

value or specification),at our option. We will bear the cost of any repair or

replacement and any costs of labour relating thereto.

These warranties are subject to the following conditions and limitations:

a) A bill of sale verifying the purchase and the purchase date must be

provided;

b) This warranty will not apply to any product or part thereof that is worn,

broken or that has become inoperative due to abuse, misuse, accidental

damage, neglect or lack of proper installation, operation or maintenance

(as outlined in the applicable owner’s manual or operating instructions) or

that is being used for industrial, professional, commercial or rental

purposes;

c) This warranty will not apply to normal wear and tear or to expendable parts

or accessories that may be supplied with the product that are expected to

become inoperative or usable after a reasonable period of use;

d) This warranty will not apply to routine maintenance and consumable items

such as, including but not limited to, fuel, lubricants, vacuum bags, blades,

belts, sandpaper, bits, fluids, tune-ups or adjustments;

e) This warranty will not apply where damage is caused by repairs made or

attempted by others (i.e.: persons not authorized by the manufacturer);

f) This warranty will not apply to any product that was sold to the original

purchaser as a reconditioned or refurbished product (unless specified

otherwise in writing);

Page 1 of 2

Page 42

42

3-Year Limited Warranty – cont’d

These warranties are subject to the following conditions and limitations:

g) This warranty will not apply to any product or part thereof if any part

from another manufacturer is installed therein or any repairs or

alterations have been made or attempted by unauthorized persons;

h) This warranty will not apply to normal deterioration of the exterior

finish, such as, including but not limited to, scratches, dents, paint

chips, or to any corrosion or discoloring by heat, abrasive and

chemical cleaners; and

i) This warranty will not apply to component parts sold by and identified

as the product or company, which shall be covered under the product

manufacturer’s warranty, if any.

Additional Limitations

This warranty applies only to the original purchaser, and cannot be transferred.

Neither the retailer not the manufacturer shall be liable for any other expense, loss

or damage, including, without limitation, but not limited to any indirect, incidental,

consequential or exemplary damages arising in connection with the sale, use or

inability to use this product.

Notice to Consumer

This warranty gives you specific legal rights, and you may have other rights, which

may vary from province to province. The provisions contained in this warranty are

not intended to limit, modify, take away from, disclaim or exclude any statutory

warranties set forth in any applicable provincial or federal legislation.

Mastercraft is a superior line of products selected for their workmanship and

materials. These products are designed to meet rigorous quality and performance

standards, and are approved by our Quality Assurance laboratory.

TOLL-FREE HELPLINE: 1-800-689-9928

Page 2 of 2

Rev 1.8 10/11/2010

Loading...

Loading...