Page 1

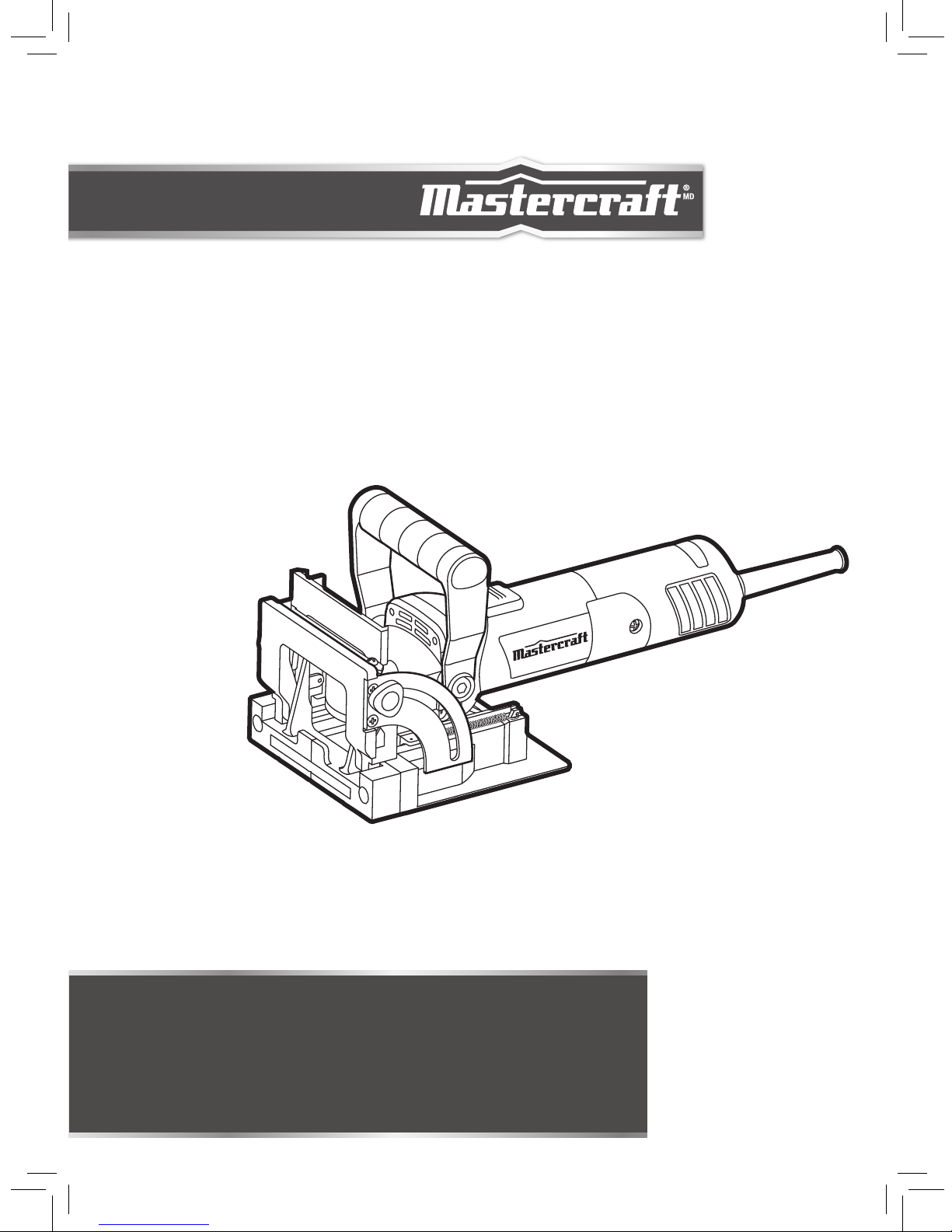

model no. 054-8106-4

BISCUIT JOINER

IMPORTANT:

Read and understand this instruction manual thoroughly

before using the product.

INSTRUCTION

MANUAL

Page 2

headline bars

3

TABLE OF CONTENTS

Technical Specifications 4

Safety Guidelines 5

Key Parts Diagram 9

Assembly Instructions 11

Operating Instructions 13

Maintenance 15

Troubleshooting 17

Parts List 18

Warranty 21

NOTE:

If any parts are missing or damaged, or if you have any questions,

please call our toll-free helpline at 1-800-689-9928.

SAVE THESE INSTRUCTIONS

• This manual contains important safety and operating

instructions. Read all instructions and follow them with use

of this product.

TABLE OF CONTENTS

Page 3

headline bars

model no. 054-8106-4 | contact us 1-800-689-9928

5

4

TECHNICAL SPECIFICATIONS

TECHNICAL SPECIFICATION

Rated power input 5A

Rated voltage 120 V~, 60 Hz

No-load speed 11,000 RPM

Max cutting depth 45/64" (18 mm)

Adjustable height 3/16 to 1 3/8" (5 to 35 mm)

Cutting angle 0˚ – 90˚

Biscuit sizes #0, #10, #20

Tool weight 6 lb 6 oz (2.9 kg)

Noise level 81.3 dB(A)

Vibration a

hi

= 7.4 m/s2, K=1.5

SAFETY GUIDELINES

WARNING!

Safety symbols in this instruction manual are used to flag possible dangers. The safety

symbols and their explanations require your full understanding. The safety warnings do not,

by themselves, eliminate any danger, nor are they substitutes for proper accident prevention

measures.

WARNING!

This safety alert symbol indicates caution, warning, or danger. Failure to obey a safety

warning can result in serious injury to yourself or others. To reduce the risk of injury, fire, or

electric shock, always follow the safety precautions.

KNOW YOUR TOOL

To operate this tool, carefully read this instruction manual and all labels affixed to the biscuit joiner

before using. Keep this manual available for future reference.

IMPORTANT

This tool should only be serviced by a qualified service technician. For more information,

call the toll-free helpline at 1-800-689-9928.

READ ALL INSTRUCTIONS THOROUGHLY

SAVE THESE INSTRUCTIONS

GENERAL POWER TOOL SAFETY WARNINGS

WARNING!

Read all safety warnings and instructions. Failure to follow the warnings and instructions

may result in electric shock, fire and/or serious injury.

SAVE ALL WARNINGS AND INSTRUCTIONS FOR FUTURE REFERENCE.

The term “power tool” in the warnings refers to your mains-operated (corded) power tool or

battery-operated (cordless) power tool.

WORK AREA SAFETY

• Keep the work area clean and well lit. Cluttered or dark areas invite accidents.

• Do not operate power tools in explosive atmospheres, such as in the presence of

flammable liquids, gases or dust. Power tools create sparks, which may ignite the dust or

fumes.

• Keep children and bystanders away while operating a power tool. Distractions can cause

you to lose control.

SAFETY GUIDELINES

Page 4

headline bars

model no. 054-8106-4 | contact us 1-800-689-9928

7

6

ELECTRICAL SAFETY

• Power tool plugs must match the outlet. Never modify the plug in any way. Do not use

any adapter plugs with earthed (grounded) power tools. Unmodified plugs and matching

outlets will reduce risk of electric shock.

• Avoid body contact with earthed or grounded surfaces, such as pipes, radiators,

ranges and refrigerators. There is an increased risk of electric shock if your body is earthed or

grounded.

• Do not expose power tools to rain or wet conditions. Water entering a power tool will

increase the risk of electric shock.

• Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the

power tool. Keep cord away from heat, oil, sharp edges or moving parts. Damaged or

entangled cords increase the risk of electric shock.

• When operating a power tool outdoors, use an extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use reduces the risk of electric shock.

• If operating a power tool in a damp location is unavoidable, use a ground-fault circuit

interrupter (GFCI) protected supply. Use of a GFCI reduces the risk of electric shock.

PERSONAL SAFETY

• Stay alert, watch what you are doing and use common sense when operating a power

tool. Do not use a power tool while you are tired or under the influence of drugs,

alcohol or medication. A moment of inattention while operating power tools may result in

serious personal injury.

• Use personal protective equipment. Always wear eye protection. Protective equipment

such as dust mask, non-skid safety shoes, hard hat, or hearing protection used for appropriate

conditions will reduce personal injuries.

• Prevent unintentional starting. Ensure that the switch is in the off-position before

connecting to power source and/or battery pack, picking up or carrying the tool.

Carrying power tools with your finger on the switch or energising power tools that have the

switch on invites accidents.

• Remove any adjusting key or wrench before turning the power tool on. A wrench or a

key left attached to a rotating part of the power tool may result in personal injury.

• Do not overreach. Keep proper footing and balance at all times. This enables better

control of the power tool in unexpected situations.

• Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing and

gloves away from moving parts. Loose clothes, jewellery or long hair can be caught in moving

parts.

• If devices are provided for the connection of dust extraction and collection facilities,

ensure that these are connected and properly used. Use of these devices can reduce dust-

related hazards.

POWER TOOL USE AND CARE

• Do not force the power tool. Use the correct power tool for your application. The correct

power tool will do the job better and more safely at the rate for which it was designed.

• Do not use the power tool if the switch does not turn it on and off. Any power tool that

cannot be controlled with the switch is dangerous and must be repaired.

• Disconnect the plug from the power source and/or the battery pack from the power

tool before making any adjustments, changing accessories, or storing power tools.

Such preventive safety measures reduce the risk of starting the power tool accidentally.

• Store idle power tools out of the reach of children and do not allow persons unfamiliar

with the power tool or these instructions to operate the power tool. Power tools are

dangerous in the hands of untrained users.

• Maintain power tools. Check for misalignment or binding of moving parts, breakage of

parts and any other condition that may affect the power tool’s operation. If damaged,

have the power tool repaired before use. Many accidents are caused by poorly maintained

power tools.

• Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to control.

• Use the power tool, accessories, tool bits, etc. in accordance with these instructions,

taking into account the working conditions and the work to be performed. Use of the

power tool for operations different from those intended could result in a hazardous situation.

SERVICE

• Have your power tool serviced by a qualified repair person using only identical

replacement parts. This will ensure that the safety of the power tool is maintained.

SAFETY GUIDELINES FOR BISCUIT JOINER

• Blades must be rated for at least the speed marked on the tool. Blades running over the

rated speed can fly apart and cause injury.

• Always use the guard. The guard protects the operator from broken blade fragments and

unintentional contact with the blade.

• Hold the power tool by its insulated gripping surfaces, because the blade may contact

its own cord. Cutting a “live” wire may make exposed metal parts of the power tool “live” and

could give the operator an electric shock.

• Always use correctly sized blades with the fitting mounting bore. Blades that do not fit to

the mounting components of the biscuit joiner rotate irregularly and lead to loss of control.

• Do not use blunt or damaged blade. Blunt or damaged blades cause increased friction, can

become jammed and lead to imbalance.

• Before putting into operation, check that the guard is retracting freely.

• Always wear hearing protection when operating the biscuit joiner.

SAFETY GUIDELINES

SAFETY GUIDELINES

Page 5

headline bars

9

headline bars

model no. 054-8106-4 | contact us 1-800-689-9928

8

PACKAGE CONTENTS:

Biscuit joiner, hex key, blade wrench, 4" (10 cm) blade, dust bag and instruction manual.

KEY PARTS DIAGRAM

3

5

14

4

1

10

2

9

6

1213

7

11

8

• The label on your tool may include the following symbols. The symbols and their

definitions are as follows:

V ..................... Volts

A ..................... Amperes

Hz ................... Hertz

W .................... Watts

min ................. Minutes

................. Alternating current

............. Direct current

n

0

................... No-load speed

............... Class II Construction

…/min ........... Revolutions or reciprocation per minute

............... Grounding terminal

BPM ............... Beats per minute

.............. WARNING – To reduce the risk of injury, user must read instruction manual.

.............. WARNING – To reduce the risk of injury always wear eye protection.

.............. WARNING – To reduce the risk of injury always wear ear protection.

WARNING!

• Remove the biscuit joiner from the package and examine it carefully. Do not discard the

carton or any packaging material until all parts have been examined.

SAFETY GUIDELINES

KEY PARTS DIAGRAM

Page 6

headline bars

11

headline bars

model no. 054-8106-4 | contact us 1-800-689-9928

10

No. Description No. Description

1 Live-tool indicator light 8 Auxiliary handle locking bolt

2 Auxiliary handle 9 Spindle-lock button

3 Angle-guide plate 10 Height-adjustment locking knob

4 Angle-adjustment locking knob 11 Height indicator

5 Centre mark 12 Cutting-depth stopper

6 Angle scale 13 Dust-exhaust port

7 Blade cover 14 On/off switch

ASSEMBLY INSTRUCTIONS

THE LIVE-TOOL INDICATOR LIGHT

The biscuit joiner is equipped with a live-tool indicator light. When the tool is plugged into an electrical

supply, the live-tool indicator light will illuminate to remind you that the tool is plugged in. When the tool

is unplugged, the indicator light will turn off.

ADJUSTING THE DEPTH OF CUT

(fig 1)

Four different cutting depths can be preset.

Refer to the table below for the correspondence

between the sizes marked on the cutting depth

stopper and the biscuit size.

Fine adjustments to the cutting depth can be made

by turning the adjusting screw after loosening the hex

nut. This may become necessary after the blade has

been re-sharpened a few times.

Set the cutting-depth stopper to match the size below:

Size on cutting-depth stopper 0 10 20 M

Biscuit size 0 10 20 /

Depth of groove 8 mm 10 mm 12.3 mm 18 mm

ASSEMBLY INSTRUCTIONS

WARNING!

• Never connect the biscuit joiner to a power source when you are assembling parts,

making adjustments, installing or removing blade, cleaning, or when it is not in use.

Disconnecting the biscuit joiner will prevent accidental starting, which could cause

serious personal injury.

WARNING!

• Do not allow familiarity with the biscuit joiner to cause a lack of alertness. A fraction of a second of

carelessness is enough to cause severe injury.

KEY PARTS DIAGRAM

fig 1

Cutting depth

adjusting screw

Hex nut

Cutting depth

stopper

Page 7

headline bars

13

headline bars

model no. 054-8106-4 | contact us 1-800-689-9928

12

ADJUSTING THE HEIGHT OF CUT

(fig 2)

The angle guide height can be moved up and down to

adjust the position of the blade in relation to the top

of the workpiece.

1. Loosen the height-adjustment locking knob.

2. Move the angle guide up and down until the

indicator points to the desired height on the

height scale.

3. Securely tighten the height-adjustment locking

knob.The height scale indicates the distance from the top of the workpiece to the centre of the

blade.

ADJUSTING THE CUTTING ANGLE

(fig 3)

Most biscuit joining applications require the blade

to cut into the workpiece at a 90° angle. In special

cases, such as mitre joints, it is necessary to insert

the biscuit at a different angle. Adjust the cutting

angles as follows:

1. Loosen the angle-adjustment locking knob, and

tilt the angle guide plate until the indicator points

to the desired angle on the angle scale.

2. Securely tighten the angle-adjustment locking knob.

DUST COLLECTION

(fig 4)

Attach the dust bag to the dust-exhaust port. When

the dust bag is about half full, turn off the tool and

unplug it. Remove the dust bag from the tool. Unzip

the dust bag and empty it.

Alternatively you can attach a suitable vacuum

cleaner to the dust bag adapter.

OPERATION INSTRUCTIONS

TURNING THE BISCUIT JOINER ON/OFF

To turn on the biscuit joiner, slide the switch toward the “l” (ON) position. For continuous operation,

press the front of the switch to lock it.

To turn it off, press the rear of the switch; the switch will return to the “O” (OFF) position automatically.

HOW TO MAKE JOINTS

To make joints, proceed as follows:

1. Fit the two workpieces together as they will appear in the finished joint position (refer to fig a-e).

2. Use a pencil to mark the centre of the intended biscuit grooves on the workpiece.

3. For Corner Joint and T Joint: Clamp the vertical workpiece to the workbench (fig a1).

For Mitre Joint: Clamp one workpiece to the workbench with the mitred edge facing up (fig c1).

For Frame Joint and Edge-To-Edge Joint: Clamp one workpiece to the workbench (fig d1).

4. Set the depth of cut according to the size of the biscuit to be used. Refer to the table in the

“Adjusting the depth of cut” section.

5. Adjust the angle guide height so that the blade is centred in the board thickness.

6. Align the centre mark on the base with the pencil line on the workpiece.

7. Turn on the tool and gently push it forward in order to extend the blade into the workpiece.

8. Gently pull the tool back to its original position after the cutting depth adjusting screw reaches the

cutting-depth stopper.

9. For Corner Joint and T Joint: Clamp the horizontal workpiece to the workbench (fig a2 and fig b2).

For Mitre Joint: Clamp the other workpiece to the workbench with the mitred edge facing up (fig c2).

For Frame Joint and Edge-To-Edge Joint: Clamp the other workpiece to the workbench

(fig d2 and fig e2).

10. Repeat the steps 6 – 8 to to make the cuts in the second workpiece.

ASSEMBLY INSTRUCTIONS

OPERATING INSTRUCTIONS

NOTICE:

• The centres of the grooves should be at least 50 mm (2") from the outer edge of the workpieces.

• Allow 100 mm – 150 mm (4" – 6") between grooves in applications that require multiple biscuits.

WARNING!

• The dust that is produced while cutting can be detrimental to health, flammable, or explosive. Suitable

safety measures are required. Examples: Some types of dust are known to cause cancer. Always wear

a dust mask.

WARNING!

• Before plugging in the tool, always check to see that the on/off switch is in the “OFF”

position and actuates properly.

• Always clamp the workpiece to the workbench before each operation.

fig 2

Height scale

Indicator

Heightadjustment

locking knob

fig 3

Angle

guide

plate

Angle scale

Indicator

Angle-adjustment

locking knob

fig 4

Adapter

Page 8

headline bars

15

headline bars

model no. 054-8106-4 | contact us 1-800-689-9928

14

Joint

Type

Joint Illustration

Cutting the First

Workpiece

Cutting the Second

Workpiece

Corner

Joint

fig a

fig a1

fig a2

T Joint

fig b

fig b1

fig b2

Mitre

Joint

fig c

fig c1

fig c2

Frame

Joint

fig d

fig d1

fig d2

EdgeTo-Edge

Joint

fig e

fig e1

fig e2

MAINTENANCE

BEFORE EACH USE

1. Inspect the biscuit joiner, the on/off switch, the cord and the accessories for damage.

2. Check for damaged, missing, or worn parts.

3. Check for loose screws, misalignment or binding of moving parts, or any other condition that may

affect the operation.

4. If abnormal vibration or noise occurs, turn the tool off immediately and have the problem corrected

before further use.

5. Unplug the tool from power source before cleaning or performing any maintenance.

CLEANING

Unplug the tool from power source before cleaning or performing any maintenance. Regularly clean the

dust and debris from the tool with compressed air or a brush. Using compressed air may be the most

effective cleaning method. Always wear safety goggles when cleaning tools using compressed air.

LUBRICATION

All of the bearings in this tool are lubricated with a sufficient amount of high-grade lubricant for the life

of the unit under normal conditions. Therefore, no further lubrication is required.

OPERATING INSTRUCTIONS

MAINTENANCE

WARNING!

• Do not let brake fluids, gasoline and petroleum-based products, penetrating oil, etc.

come into contact with plastic parts. These substances contain chemicals that can

damage, weaken, or destroy plastic.

• When servicing, use only identical replacement parts. The use of any other parts may

create a hazard or cause damage to the product.

• Use only accessories that are recommended for this biscuit joiner by the manufacturer.

Accessories that may be suitable for one tool may become hazardous when used with

another tool.

• To ensure safety and reliability, all repairs should be performed by a qualified service

technician.

• If the replacement of the supply cord is necessary, this has to be done by the

manufacturer or his agent in order to avoid a safety hazard.

Page 9

headline bars

17

headline bars

model no. 054-8106-4 | contact us 1-800-689-9928

16

REPLACING THE BLADE

(fig 5)

1. Unplug the biscuit joiner from the power supply.

2. Loosen the 4 screws with a screwdriver to open

the blade cover.

3. Press the spindle-lock button and loosen the outer

flange using the blade wrench.

4. Place a new cutting blade on the spindle, taking

care that direction of rotation indicated on the

blade corresponds with the arrow indicator on the

tool.

5. Press the spindle-lock button and tighten the

outer flange with the blade wrench.

6. Reinstall the blade cover.

REPLACING THE CARBON BRUSHES

(fig 6)

Both carbon brushes should be replaced at the same

time. Use only identical carbon brushes.

Use a screwdriver to loosen the screw and remove

the cover. Release the spring, take out the worn

carbon brushes and insert the new ones. Reset the

spring to fix the carbon brush and secure the cover.

Make sure the groove on the carbon brush points

towards outside of the tool.

TROUBLESHOOTING

Problem Possible Causes Solution

The biscuit joiner does not start Not connected to power source Plug the biscuit joiner into a

power source

The blade binds or smokes from

friction

Blade is dull Replace with a new sharp blade

Blade is on backwards Install the blade correctly

If the problem remains unsolved after performing the checks described above, call the toll-free helpline

at 1-800-689-9928.

MAINTENANCE

TROUBLESHOOTING

NOTE: Always check the depth of cutting after replacing the blade. Readjust it if necessary.

WARNING!

• Make sure that the rotation direction on the blade corresponds with the indicator on the tool.

CAUTION!

• The flat surface of the outer flange must point outwards.

fig 5

Outer flange

Inner flange

Cutting blade

Blade cover

fig 6

Cover

Carbon brush

Page 10

headline bars

19

headline bars

model no. 054-8106-4 | contact us 1-800-689-9928

18

EXPLODED VIEW

No. Part No. Description No. Part No. Description

1 5481064001 Bearing set 31 5481064031 Roller

2 5481064002 Bearing 32 5481064032 Stator

3 5481064003 Armature 33 5481064033 Screw

4 5481064004 Check ring 34 5481064034 Fan guide

5 5481064005 Screw 35 5481064035 Screw

6 5481064006 Bearing 36 5481064036 Nut

7 5481064007 Stop pin 37 5481064037 Depth base block

8 5481064008 Spring 38 5481064038 Screw

9 5481064009 Gear box 39 5481064039 Pinion

10 5481064010 Screw 40 5481064040 Spring washer

11 5481064011 Check ring 41 5481064041 Nut

12 5481064012 Bearing 42 5481064042 Screw

13 5481064013 Spring washer 43 5481064043 Front handle

14 5481064014 Gear 44 5481064044 Label

15 5481064015 Front cap 45 5481064045 Switch drawbar

16 5481064016 Spring washer 46 5481064046 Switch button

17 5481064017 Screw 47 5481064047 Switch

18 5481064018 Wood ruff-key 48 5481064049 Spring

19 5481064019 Spindle 49 5481064050 Plug

20 5481064020 Screw 50 5481064051 Cord armor

21 5481064021 Cover 51 5481064052 Flange

22 5481064022 Back cap 52 5481064053 Grinding wheel

23 5481064023 Light 53 5481064054 Flange unt

24 5481064024 Cord clamp 54 5481064055 Screw

25 5481064025 Housing 55 5481064056 Spring

26 5481064026 Screw 56 5481064057 Steel ball

27 5481064027 Right brush cover 57 5481064058 Setting wheel

28 5481064028 Brush 58 5481064059 Screw

29 5481064029 Brush holder 59 5481064060 Spring

30 5481064030 Left brush cover 60 5481064061 Slide plate

If the problem remains unsolved after performing the checks described above, call the toll-free helpline

at 1-800-689-9928.

PARTS LIST

PARTS LIST

Page 11

headline bars

21

headline bars

model no. 054-8106-4 | contact us 1-800-689-9928

20

PARTS LIST

WARRANTY

No. Part No. Description No. Part No. Description

61 5481064062 Base plate 72 5481064073 Dowel

62 5481064063 Screw 73 5481064074 Angle ruler

63 5481064064 Screw 74 5481064075 Cap

64 5481064065 Depth mark 75 5481064076 Screw

65 5481064066 Support stand board 76 5481064077 Entrance for dust

66 5481064067 Knob 77 5481064078 Dust bag

67 5481064068 Angle fence 78 5481064079 Oblique pipe

68 5481064069 Depth pointer 79 5481064080 Wrench

69 5481064070 Screw 80 5481064081 Screw

70 5481064071 Angle pointer 81 5481064082 Cover

71 5481064072 Pivot bracket

If the problem remains unsolved after performing the checks described above, call the toll-free helpline

at 1-800-689-9928.

This Mastercraft product is guaranteed for a period of 3 years from the date of original retail

purchase against defects in workmanship and materials, except for the following components:

a) Component A: Batteries, chargers and carrying case, which are guaranteed for a period of 2 years

from the date of original retail purchase against defects in workmanship and materials;

b) Component B: Accessories, which are guaranteed for a period of 1 year from the date of original

retail purchase against defects in workmanship and materials.

Subject to the conditions and limitations described below, this product, if returned to us with proof

of purchase within the stated warranty period and if covered under this warranty, will be repaired or

replaced (with the same model, or one of equal value or specification), at our option. We will bear the

cost of any repair or replacement and any costs of labour relating thereto.

These warranties are subject to the following conditions and limitations:

a) a bill of sale verifying the purchase and purchase date must be provided;

b) this warranty will not apply to any product or part thereof which is worn or broken or which has

become inoperative due to abuse, misuse, accidental damage, neglect or lack of proper installation,

operation or maintenance (as outlined in the applicable owner’s manual or operating instructions) or

which is being used for industrial, professional, commercial or rental purposes;

c) this warranty will not apply to normal wear and tear or to expendable parts or accessories that may be

supplied with the product that are expected to become inoperative or unusable after a reasonable period

of use;

d) this warranty will not apply to routine maintenance and consumable items such as, but not limited

to, fuel, lubricants, vacuum bags, blades, belts, sandpaper, bits, fluids, tune-ups or adjustments;

e) this warranty will not apply where damage is caused by repairs made or attempted by others (i.e.

persons not authorized by the manufacturer);

f) this warranty will not apply to any product that was sold to the original purchaser as a reconditioned

or refurbished product (unless otherwise specified in writing);

g) this warranty will not apply to any product or part thereof if any part from another manufacturer

is installed therein or any repairs or alterations have been made or attempted by unauthorized

persons;

Page 12

headline bars

model no. 054-8106-4 | contact us 1-800-689-9928

22

WARRANTY

h) this warranty will not apply to normal deterioration of the exterior finish, such as, but not limited to,

scratches, dents, paint chips, or to any corrosion or discolouring by heat, abrasive and chemical

cleaners; and

i) this warranty will not apply to component parts sold by and identified as the product of another

company, which shall be covered under the product manufacturer’s warranty, if any.

Additional Limitations

This warranty applies only to the original purchaser and may not be transferred. Neither the retailer nor

the manufacturer shall be liable for any other expense, loss or damage, including, without limitation,

any indirect, incidental, consequential or exemplary damages arising in connection with the sale, use or

inability to use this product.

Notice to Consumer

This warranty gives you specific legal rights, and you may have other rights, which may vary from

province to province. The provisions contained in this warranty are not intended to limit, modify, take

away from, disclaim or exclude any statutory warranties set forth in any applicable provincial or federal

legislation.

Made in China

Imported by

Mastercraft Canada Toronto, Canada M4S 2B8

Loading...

Loading...