Page 1

INSTRUCTION MANUAL

FIXED-BASE ROUTER

054-6908-8

Page 2

FIXED-BASE ROUTER - 054-6908-8

2

FIXED-BASE ROUTER - 054-6908-8

TABLE OF CONTENTS

TECHNICAL SPECIFICATIONS 3

SAFETY GUIDELINES 4–10

DESCRIPTION 11

OPERATING INSTRUCTIONS 12–29

MAINTENANCE 30–32

TROUBLESHOOTING 33

PARTS LIST 34–36

WARRANTY 37–38

If any parts are

missing or damaged,

or if you have any

questions, please call

our toll-free helpline

at 1-800-689-9928.

Read and understand this instruction manual

thoroughly before using the product. It contains

important information for your safety as well as

operating and maintenance advice.

Keep this instruction manual for future use. Should

this product be passed on to a third party, then this

instruction manual must be included.

Page 3

FIXED-BASE ROUTER - 054-6908-8FIXED-BASE ROUTER - 054-6908-8

3 4

WARNING!

Safety symbols in this Instruction Manual are used to flag possible dangers. The safety

symbols and their explanations require your full understanding. The safety warnings do

not, by themselves, eliminate any danger, nor are they substitutes for proper accident

prevention measures.

WARNING!

This Safety Alert Symbol indicates caution, warning, or danger. Failure to obey a safety

warning can result in serious injury to yourself or others. To reduce the risk of injury, fire, or

electric shock, always follow the safety precautions.

Know your tool

To operate this tool, carefully read this Instruction Manual and all labels affixed to the Router before

using. Keep this Instruction Manual available for future reference.

Important

This tool should only be serviced by a qualified service technician. For more information, call the tollfree helpline at 1-800-689-9928.

Read all instructions thoroughly

Save these instructions

General power tool safety warnings

WARNING!

Read all safety warnings and instructions. Failure to follow the warnings and instructions

may result in electric shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

The term “power tool” in the warnings refers to your mains-operated (corded) power tool or

battery-operated (cordless) power tool.

SAFETY GUIDELINES

MOTOR 120 V ~ 60 Hz, 9.5A

HORSEPOWER 1 3/4 HP

NO-LOAD SPEED 25,000 RPM

COLLET CAPACITY 1/4" & 1/2"

BASE DIMENSION 6"

(15.2 cm)

SUB-BASE OPENING DIAMETER 2"

(5 cm)

WEIGHT 9 lb 14 oz

(4.5 kg)

TECHNICAL SPECIFICATIONS

Page 4

FIXED-BASE ROUTER - 054-6908-8FIXED-BASE ROUTER - 054-6908-8

5 6

• Remove any adjusting key or wrench before turning the power tool on. A wrench or a key

left attached to a rotating part of the power tool may result in personal injury.

• Do not overreach. Keep proper footing and balance at all times. This enables better control of the

power tool in unexpected situations.

• Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing and gloves away

from moving parts. Loose clothes, jewellery or long hair can be caught in moving parts.

• If devices are provided for the connection of dust extraction and collection facilities,

ensure that these are connected and properly used. Use of these devices can reduce dust-

related hazards.

Power tool use and care

• Do not force the power tool. Use the correct power tool for your application. The correct power

tool will do the job better and more safely at the rate for which it was designed.

• Do not use the power tool if the switch does not turn it on and off. Any power tool that

cannot be controlled with the switch is dangerous and must be repaired.

• Disconnect the plug from the power source and/or the battery pack from the power tool

before making any adjustments, changing accessories, or storing power tools. Such

preventive safety measures reduce the risk of starting the power tool accidentally.

• Store idle power tools out of the reach of children and do not allow persons unfamiliar

with the power tool or these instructions to operate the power tool. Power tools are

dangerous in the hands of untrained users.

• Maintain power tools. Check for misalignment or binding of moving parts, breakage of parts and

any other condition that may affect the power tool’s operation. If damaged, have the power tool

repaired before use. Many accidents are caused by poorly maintained power tools.

• Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting edges

are less likely to bind and are easier to control.

• Use the power tool, accessories, tool bits, etc. in accordance with these instructions,

taking into account the working conditions and the work to be performed. Use of the power

tool for operations different from those intended could result in a hazardous situation.

Service

• Have your power tool serviced by a qualified repair person using only identical

replacement parts. This will ensure that the safety of the power tool is maintained.

SAFETY GUIDELINES

Work area safety

• Keep the work area clean and well lit. Cluttered or dark areas invite accidents.

• Do not operate power tools in explosive atmospheres, such as in the presence of

flammable liquids, gases or dust. Power tools create sparks, which may ignite the dust or fumes.

• Keep children and bystanders away while operating a power tool. Distractions can cause

you to lose control.

Electrical safety

• Power tool plugs must match the outlet. Never modify the plug in any way. Do not use any

adapter plugs with earthed (grounded) power tools. Unmodified plugs and matching outlets will

reduce risk of electric shock.

• Avoid body contact with earthed or grounded surfaces, such as pipes, radiators, ranges

and refrigerators. There is an increased risk of electric shock if your body is earthed or grounded.

• Do not expose power tools to rain or wet conditions. Water entering a power tool will increase

the risk of electric shock.

• Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the power tool. Keep

the cord away from heat, oil, sharp edges or moving parts. Damaged or entangled cords increase the

risk of electric shock.

• When operating a power tool outdoors, use an extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use reduces the risk of electric shock.

• If operating a power tool in a damp location is unavoidable, use a ground-fault circuit

interrupter (GFCI) protected supply. Use of a GFCI reduces the risk of electric shock.

Personal safety

• Stay alert, watch what you are doing and use common sense when operating a power

tool. Do not use the tool while tired or under the influence of drugs, alcohol, or medication. A

moment of inattention while operating power tools may result in serious personal injury.

• Use personal protective equipment. Always wear eye protection. Protective equipment, such as

dust mask, non-skid safety shoes, hard hat, or hearing protection, used for appropriate conditions,

will reduce personal injuries.

• Prevent unintentional starting. Ensure that the switch is in the off-position before connecting to

a power source and/or battery pack, picking up or carrying the tool. Carrying power tools with your

finger on the switch or plugging in power tools that have the switch on invites accidents.

SAFETY GUIDELINES

Page 5

FIXED-BASE ROUTER - 054-6908-8FIXED-BASE ROUTER - 054-6908-8

7 8

• Routing operations must always be performed against the direction of rotation of the

cutter bit (cutter rotation).

• The router must be running at full speed before it is lowered to the workpiece.

• Always hold the handles firmly with both hands, and always ensure that your footing is

secure when operating the router.

• Be prepared for the reaction torque of the router, particularly if the cutter bit becomes

jammed in the workpiece.

• Become familiar with the working area, and be alert for possible hazards that cannot be

heard due to the noise of the router.

CAUTION!

Allow sufficient run-down time for the cutter bit after turning the router off. Wait for it to

come to a complete stop before removing it from the workpiece.

• Never slow the router down with your hands.

• Do not touch the cutter bit immediately after operation. It may be extremely hot, and

could burn.

• Never stop the router by applying lateral pressure to the cutter bit.

• Do not force the router. It will do a better job if it is allowed to work at its intended speed.

• Avoid cutting nails and screws. Inspect timber before cutting, and remove all nails and screws.

• In the event of an electrical or mechanical malfunction, switch the router off immediately

and disconnect the power cord from the outlet.

• Never use router bits with a diameter exceeding the maximum diameter specified in the technical

data section.

• Always use cutter bits that are designed for this router. Never use cutter bits which are larger in

diameter than the opening in the router base. Cutter bits that have cutter diameters larger than the

opening could cause possible loss of control or create other hazardous condition that could cause

serious personal injury.

SAFETY GUIDELINES

Specific safety rules for electric routers

• Hold a power tool by the insulated gripping surfaces when performing an operation where

the tool or accessory may contact hidden wiring or its own cord. Contact with a “live” wire

may make exposed metal parts of the tool live and could give the operator an electric shock.

• Use clamps or another practical way to secure and support the workpiece to a stable

platform. Holding the work by your hand or against the body leaves it unstable and may lead to loss

of control.

• The label on your tool may include the following symbols. The symbols and their

definitionsare as follows:

V ..................... Volts

A ..................... Amperes

Hz ................... Hertz

W .................... Watts

min ................. Minutes

............... Alternating current

............. Direct current

n

0

................... No load speed

............... Class II Construction

…/min ........... Revolutions per minute

............... Grounding terminal

BPM ............... Beats per minute

.............. WARNING – To reduce the risk of injury, user must read instruction manual.

• Always wear a dust mask and ear protection when using this power tool. Use only cutter

bits that are designed for this router.

• Use sharp cutter bits that are not chipped or cracked. Blunt cutter bits will cause stalling.

• Secure small pieces of wood firmly before working. Never hold a workpiece by hand.

• Keep hands away from the cutting area. Secure the workpiece with appropriate clamping equipment.

• Before starting the router, check that the cutter bit is firmly positioned and secured in the collet.

• Do not exceed the maximum indicated rotation speed of the cutter bit.

SAFETY GUIDELINES

Page 6

FIXED-BASE ROUTER - 054-6908-8FIXED-BASE ROUTER - 054-6908-8

9 10

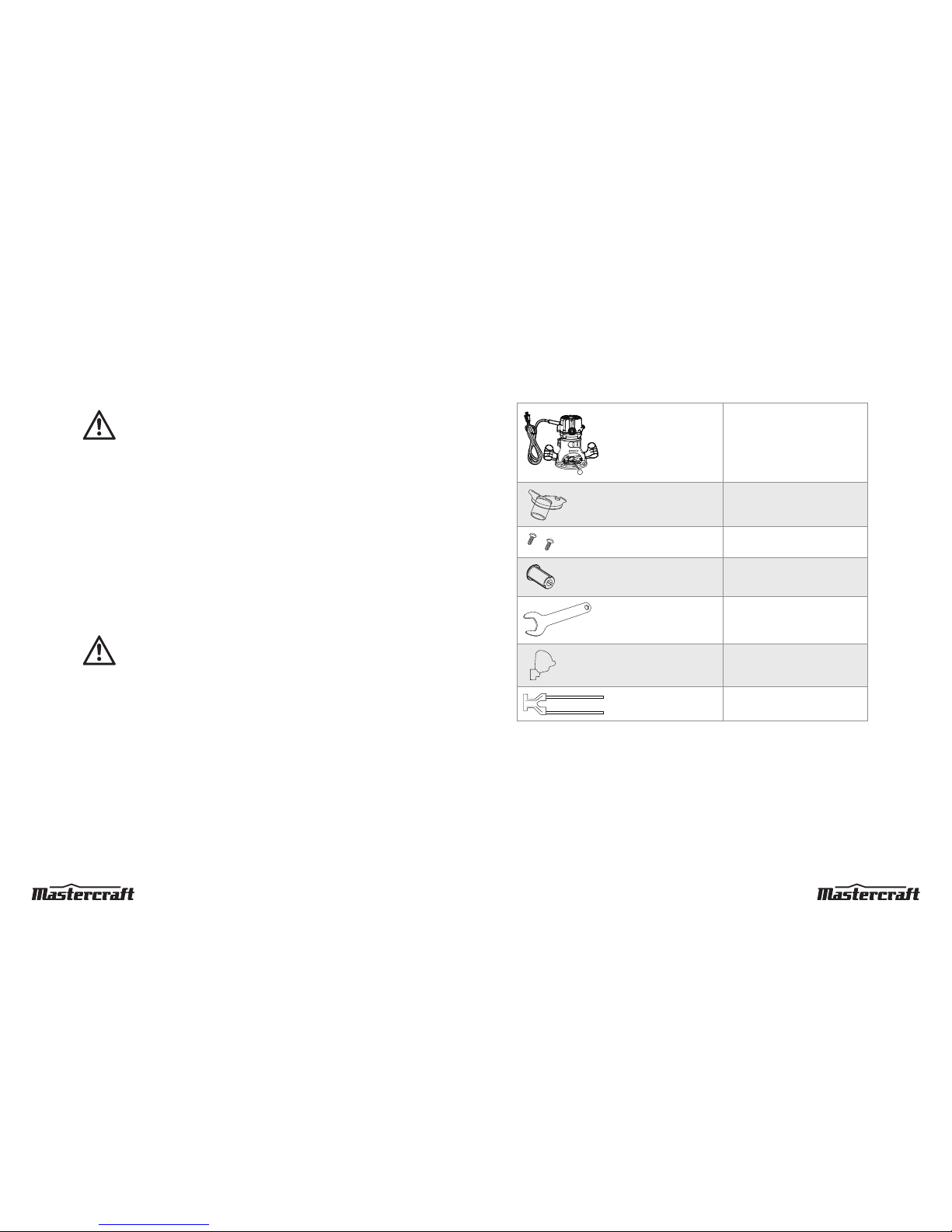

Contents:

A

Fixed Base and Motor with 1/2" Collet

A

Vacuum adaptor

A

2 Screws for attaching adaptor

A

1/4" Collet sleeve

A

Collet Wrench

A

Chip guard

A

Edge guide

Unpacking

WARNING!

NEVER have the router connected to the power source when assembling parts, making

adjustments, installing or removing collets or cutter bits, during cleaning, or when it is

not in use. Disconnecting the router will prevent accidental start-ups, which could cause

serious personal injury.

When unpacking the box, don’t discard any packing materials until all of the contents are accounted for:

1. Carefully lift the Router Motor and Fixed Base with the 1/2" collet alread y installed out of the

carton, and place it on a stable, flat surface.

2. Open the parts bag to locate the following:

• Vacuum adaptor and 2 Screws used to attach the adaptor to the base

• Chip Guard

• 1/4" Collet Sleeve

• Edge Guide

• Wrench

3. Carefully inspect the items to ensure that no breakage or damage has occurred during shipping. If

any of the items in the parts list is missing, call the Toll-free Helpline – 1-800-689-9928.

WARNING!

If any parts are broken or missing, do not attempt to plug in the power cord or operate the

router until the broken or missing parts are replaced. Failure to heed this warning could

result in serious injury.

SAFETY GUIDELINES

SAFETY GUIDELINES

Page 7

FIXED-BASE ROUTER - 054-6908-8FIXED-BASE ROUTER - 054-6908-8

11 12

Assembly

Selecting a cutter bit

This router comes with 1/4" and 1/2" collets that, accept 1/4" and 1/2" diameter shanked cutter bits

respectively.

WARNING!

Do not use router cutter bits that have a cutter bit diameter larger than 1-1/4", because

they will not fit through the sub-base opening, could cause damage to the sub-base and

the motor, and could cause serious personal injury to the operator.

Installing and removing the cutter bit

WARNING!

ALWAYS turn the motor off and unplug the router from the power source before making any

adjustments or installing accessories. Failure to turn the motor off and unplug the router

could result in accidental starting, which can cause serious personal injury.

Installing the cutter bit

1. Turn the motor off, and unplug the tool from the power source.

2. Remove the motor housing from the fixed base (see Removing the motor from the base on page 14).

3. Set the motor upside down on its top cap, with the collet pointing up.

4. Press the spindle-lock button to engage and

lock the spindle shaft and collet (fig 1).

5. Place the wrench in the collet/nut, turn the

collet/nut counter-clockwise, and loosen the

collet slightly so that it can accept the cutter

bit shank.

6. Insert the cutter bit shank into the collet

assembly as far as it will go, and then back

the shank out until the cutter faces are

approximately 1/8" to 1/4" away from the face

of the collet.

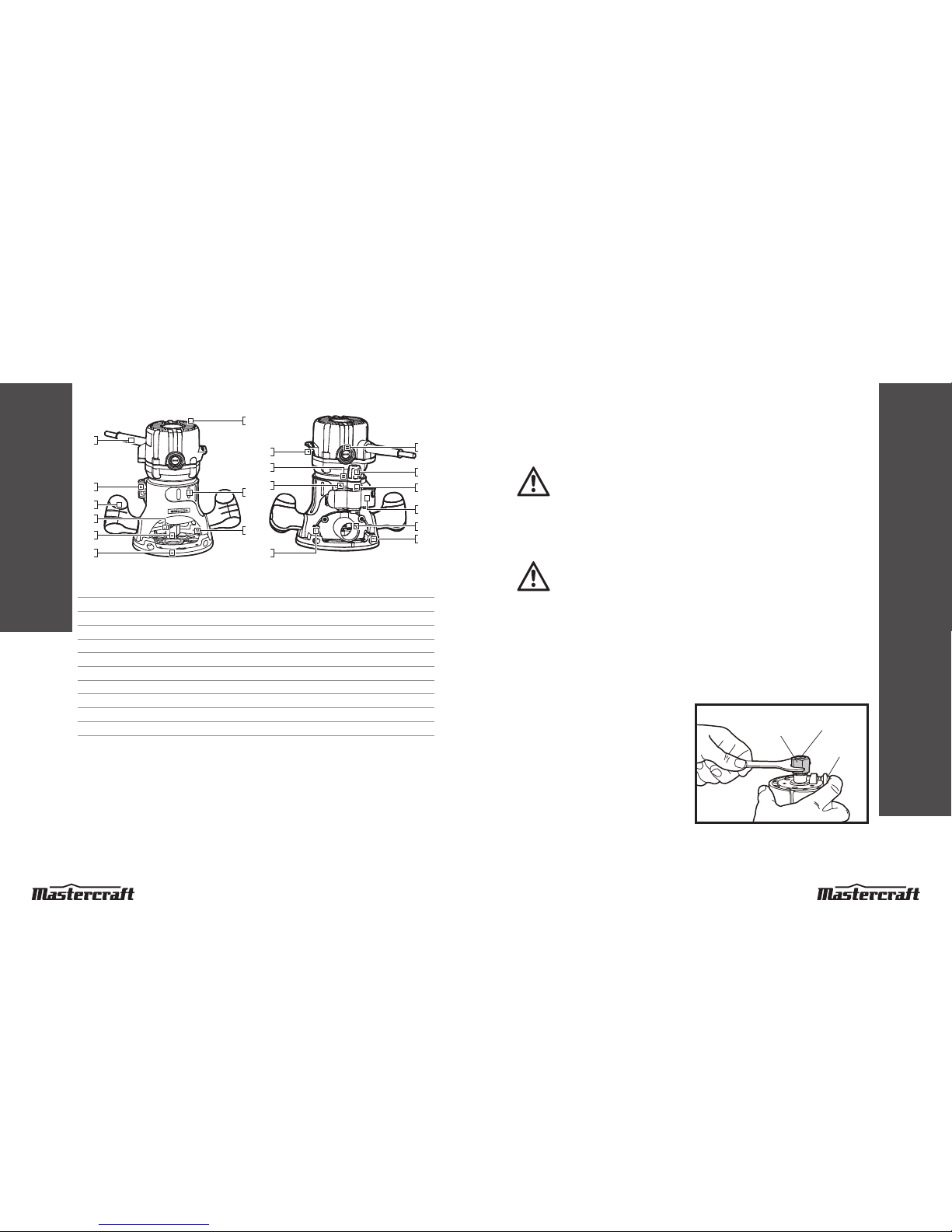

Know the fixed-base router

1

11

13

14

5

3

7

8

2

4

9

10

19

18

16

15

17

12

6

No. Description No. Description

1 Cord guard 11 On/Off toggle switch

2 Motor-housing top cap 12 Motor-housing key strip

3 Handles 13 Base keystrip slot

4 Fixed base 14 Edge-guide mounting slot

5 Quick-clamp motor changing system 15 Dust-extraction hood

6 Spindle lock 16 Edge-guide mounting slot

7 Self-releasing collet system 17 Quick-clamp motor changing system

8 Sub-base 18 Depth-indicator ring

9 Clear plastic chip guard 19 Micro-fine adjustment dial

10 Replaceable brush cap

Before attempting to use this router, become familiar with all of its operating features and safety

requirements.

DESCRIPTION

OPERATING INSTRUCTIONS

fig 1

Nut

Collet

Spindle

Lock

Page 8

FIXED-BASE ROUTER - 054-6908-8FIXED-BASE ROUTER - 054-6908-8

13 14

Collet care

• From time to time, inspect the collet to make sure it is clean and is gripping the cutter bit properly.

• With the router cutter bit removed, turn the collet counter-clockwise (with the spindle lock engaged)

until it is free of the motor’s spindle shaft.

• Blow the collet out with compressed air, and clean the tapered inside of the collet to remove

woodchips, dust residue, grease, and rust before re-installing it.

• Apply a small amount of machine oil to the spindle shaft if it looks dry.

• Replace worn or damaged collets immediately.

NOTICE: The collet is self-releasing. It is NOT necessary to strike the collet to free the router cutter bit.

If the cutter bit seems to be stuck after use, loosen the collet further until it releases.

Cutter bit care

• Get faster, more accurate cutting results by keeping cutter bits clean and sharp. Remove all

accumulated pitch and gum from cutter bits after each use.

• When sharpening cutter bits, sharpen only the inside of the cutting edge. Never grind the outside

diameter. When sharpening the end of a cutter bit, be sure to grind the clearance angle the same as

it was originally ground.

OPERATING INSTRUCTIONS

7. With the cutter bit inserted and the spindlelock button pressed in to engage the shaft,

place the wrench on the collet/nut, and turn

it clockwise until the collet is firmly tightened

around the cutter bit (fig 2, fig 3).

WARNING!

Tighten the collet securely to prevent

the cutter bit from slipping. If the

collet is not tightened securely, the

cutter bit may detach during use,

causing serious personal injury.

NOTICE: To ensure proper gripping of the cutterbit shank and minimize run-out, the shank of the

cutter bit must be inserted at least 5/8" (16 mm)

into the collet.

NOTICE: To prevent damage to tool, do not tighten

the collet without a cutter bit installed.

Removing the cutter bit (fig 1

and fig 2)

1. Turn the motor off, and unplug the tool from the power source.

2. Remove the motor from the fixed base.

3. Set the motor upside down on its top cap, with the collet pointing up.

4. Press the spindle-lock button in order to engage and lock the spindle shaft and collet.

5. Place the wrench on the collet and turn it counter-clockwise in order to loosen the collet slightly

and remove cutter bit shank.

OPERATING INSTRUCTIONS

fig 3

Cutters

Collet/Nut

Cutter

Bit Shank

Spindle Lock

fig 2

Page 9

FIXED-BASE ROUTER - 054-6908-8FIXED-BASE ROUTER - 054-6908-8

15 16

WARNING!

ALWAYS turn the motor off and unplug the router from the power source before making any

adjustments or installing accessories. Failure to turn the motor off and unplug the router could

result in accidental starting, which can cause serious personal injury.

1. Turn the motor off, and unplug the tool from the power source.

2. Place the fixed base on a flat surface.

3. With the back of the fixed base facing the operator, loosen the motor clamp (A) (fig 4).

4. Press the Rough-adjustment Knob (B) to disengage the gears (C) while aligning the motor housing’s

key strip (D) with the key strip slot (E) in the fixed base (fig 4).

5. When the motor’s key strip is aligned and engaged with the base’s key strip slot, slide the motor

down into the fixed base.

6. The motor will now slide up or down when the Rough-adjustment knob is pressed in, permitting

rough adjustments.

7. After all adjustments are made, tighten the motor clamp securely.

OPERATING INSTRUCTIONS

Removing the motor from

the base

1. Turn the motor off, and unplug the tool from

the power the source.

2. Place the router (fixed base/motor housing) on

a flat surface.

3. With the back of the router facing the operator,

loosen the motor clamp (A) (fig 4).

4. Push the Rough-adjustment knob (B) to

release the motor housing key strip from the

gear in the base while lifting the motor free of

the base (fig 4).

5. Set the motor upside down on its top cap, with

the collet pointing up, and remove the cutter

bit.

6. Store the motor and base in the case when the

router is not being used.

WARNING!

ALWAYS remove cutter bits from the collet when the router is not being used. Leaving bits

installed could result in an accident causing serious personal injury.

WARNING!

ALWAYS turn the motor off and unplug the router from the power source before making any

adjustments or installing accessories. Failure to turn the motor off and unplug the router could

result in accidental starting, which can cause serious personal injury.

Installing the router motor in the base

WARNING!

NEVER use the router motor without installing it into an approved fixed or plunge base.

Failure to do so could result in serious personal injury and damage to the motor.

NOTICE: Before installing the motor housing in the fixed base, install the collet and router cutter bit in

the motor housing. See “INSTALLING AND REMOVING THE CUTTER BIT”.

OPERATING INSTRUCTIONS

fig 4

D

E

B

C

A

Page 10

FIXED-BASE ROUTER - 054-6908-8FIXED-BASE ROUTER - 054-6908-8

17 18

ADJUSTING THE DEPTH

1. Turn the motor off, and unplug the tool from the power source.

2. Place the router on a flat, level surface, with the back of the fixed base facing the operator.

3. Loosen the Motor Clamp (A).

4. With the cutter bit already installed, press the Rough-adjustment Knob (B), and lower the motor into

the base until the cutter bit is very close to the flat surface on which the base is sitting.

5. Turn the Micro-fine Adjustment Dial (C) until the cutter bit “just” touches the flat surface on which

the base is sitting.

6. Tighten the motor clamp.

7. While continuing to press the Rough-adjustment Knob, turn the Micro-fine Adjustment Dial until the

zero “0” mark on the Depth-indicator Ring is lined up with the “I” mark on the base.

8. Release the Rough-adjustment Knob, making sure that the “0” remains aligned with the mark.

9. Place the router on two level scrap

workpieces, positioned so that the cutter bit

can be lowered below the sub-base (fig 5a).

10. Turn the Micro-fine Adjustment Dial

clockwise to lower the bit to the desired

cutting depth. Turn the dial counter-clockwise

in order to raise the cutter bit.

11. Once the cutting depth is set, tighten the

motor clamp securely.

NOTICE: Making a single deep cut is never

advisable. Smaller diameter cutter bits are easily

broken by too much lateral thrust and torque.

Larger cutter bits will cause a rough cut, and

will be difficult to guide and control. For these

reasons, do not exceed 1/8" cutting depth in a single pass.

OPERATING INSTRUCTIONS

OPERATING INSTRUCTIONS

Adjustments

Adjusting the cutting depth (fig 5)

WARNING!

Ensure that the router is never turned on

or connected to the power source when

assembling parts, making adjustments,

or installing or removing collets and

cutter bits, during cleaning, or when it

is not in use. Disconnecting the router

will prevent accidental start-ups, which

could cause serious personal injury.

NOTICE: All depth adjustments on the fixed base

must be made with the motor clamp loosened.

NOTICE: For all fixed-base routers, the cutter bit

depth equals the amount of the cutter that is exposed below the surface of the sub-base.

The fixed base is designed with a micro-fine adjustment worm-gear system. When the bit is lowered to the

approximate desired position (rough setting), the system can then be micro-adjusted to the precise depth.

ROUGH ADJUSTMENT:

Depressing the Rough-adjustment Knob (B) allows the operator to quickly lower or raise the cutter bit

to an approximate depth setting.

MICRO-FINE ADJUSTMENTS:

NOTICE: Be sure the worm-gear system is engaged before making fine adjustments. Test it by turning

the Micro-fine Adjustment Dial (C) clockwise and counter-clockwise to see if the bit lo wers and rises. If

it does not, press the Rough-adjustment Knob, and turn the Micro-fine Adjustment Dial until the gears

engage, and then reset zero “0” on Depth-indicator Ring (D).

The Depth-indicator Ring (D) is located on the Micro-fine Adjustment Dial, and is marked in 1/64"

increments. Turning the Micro-fine Adjustment Dial clockwise 180° (1/2 turn), lowers the cutter bit

1/16". One full turn clockwise (360°) – zero “0” to zero “0” – lowers the bit 1/8".

The system allows a maximum of 7 full 360° clockwise revolutions in order to lower the cutter bit 7/8"

(22.3 mm).

The Depth-indicator Ring may be reset to zero “0” without moving the Micro-fine Adjustment Dial. This

allows the user to begin adjustments from any desired reference point.

fig 5a

C

B

A

fig 5

C

D

B

A

Page 11

FIXED-BASE ROUTER - 054-6908-8FIXED-BASE ROUTER - 054-6908-8

19 20

LED worklights (fig 7)

The router motor has 3 built-in worklights located

around the collet; these provide high visibility

of the workpiece when cutting. These lights are

always “ON” when the toggle switch is in the “on”

position.

“Live tool indicator” light (fig 8)

The router also has a green “LIVE TOOL

INDICATOR” light located on the motor housing

top cap where the power cord enters the motor

housing. This green light is always on when router

motor is plugged into a power source.

Heavy-duty edge guide

This Fixed-base Router comes with a Heavy-duty

Edge Guide. This edge guide can be used as an aid

in routing applications such as decorative edging,

straight-edge planing and trimming, grooving,

dadoing, and slotting.

To assemble the edge guide onto fixed or plunge bases, simply insert the edge-guide rods into the edgeguide mounting slots, adjust to the desired position, and lock down using the edge-guide locking knobs.

Placing the router onto the workpiece and starting the cut

WARNING!

The direction of cutter bit rotation is clockwise. Note that, when installed upside-down in a

router table, the direction of cutter bit rotation will be counter-clockwise.

WARNING!

Before operating the router, follow all safety instructions in this Manual. Failure to do so

could result in serious personal injury.

NOTICE: Making test cuts is essential with most routing applications. A test cut yields information

about the set-up, the speed of the router, the cutting depth and how the cutter bit reacts to the workpiece. Much

of routing is a trial-and-error process of making various adjustments, followed by test cuts, while learning all of

the router’s operational abilities. To avoid ruining good material, make the test cuts on scrap material.

The techniques for starting a cut are different for edge routing and internal routing.

DEEP CUTS

The proper cutting depth (for each pass) is always determined by the material, the size and type of

cutter bit, and the power of the motor.

Always make several progressively deeper cuts, starting at one depth and then making several passes,

increasing the cutting depth each time until the desired depth is reached.

Making a cut that is too deep will put stress on the motor and the cutter bit, and it may burn the

workpiece and dull the cutter bit. It could also “grab” too much of the workpiece and result in loss of

control of the router, causing a serious accident.

To be certain that the depth settings are as desired, always make test cuts in scrap material similar to

the workpiece before beginning the final cut.

Remember, knowing the right depth for each cut comes with routing experience.

“On/off” toggle switch (fig 6)

The router motor is turned “ON” and “OFF” using

the toggle switch located on the top cap of the

motor housing.

The left side of the toggle switch hood (when

facing the operator) is marked “I” for “ON”, and

the right side (when facing the operator) is marked

“O” for “OFF”.

To turn the motor “ON”, push the toggle switch to

the left side, marked “I” for “ON”.

To turn the motor “OFF”, push the toggle switch to the right side, marked “O” for “OFF”.

Always hold the router and cutter bit away from the workpiece when turning the toggle switch “on”.

Only allow the router and cutter bit to come into contact with the workpiece after the router has

reached full speed. Only remove the router and cutter bit from the workpiece after turning the router

motor “off” and allowing the cutter bit to come to a complete stop. Operating in this manner will

increase the life of the toggle switch and motor, and will increase the quality of the work.

Soft start feature

The soft start feature minimizes torque twist, which is customary in larger router motors, by limiting the

speed at which the motor starts. This increases the life of the motor.

OPERATING INSTRUCTIONS

OPERATING INSTRUCTIONS

fig 8

fig 7

fig 6

Page 12

FIXED-BASE ROUTER - 054-6908-8FIXED-BASE ROUTER - 054-6908-8

21 22

Internal routing (fig 10, 10a, 10b

and 11)

1. With the cutting depth set, tilt the router and place

it on the workpiece, with only the leading edge of

the sub-base contacting workpiece (fig 11).

2. Turn the motor “on”, and allow the motor to

attain full speed, being careful not to allow the

cutter bit to contact the workpiece.

3. To begin the cut, gradually feed the cutter bit

into the workpiece until the sub-base is level

with the workpiece (fig 10a, 10b).

4. When the cut is completed, turn the motor

“off”, and allow the cutter bit to come to a

complete stop before removing it from the

workpiece.

5. Unplug the router from the power source,

place the router upside down on the worktable,

and inspect the finished cut.

WARNING!

Always clamp the workpiece securely

and keep a firm grip on the router

base with both hands at all times.

Failure to do so could result in loss

of control, causing possible serious

personal injury. When using a router

table, large cutter bits should be used

for edging only.

WARNING!

Removing the cutter bit from the

workpiece while it is still rotating could

damage the workpiece and result

in loss of control, causing serious

personal injury.

Edge routing or internal routing

For ease of operation, and to maintain proper control, the router has two handles, located on either side

of the router base. When operating the router, always hold it firmly with both hands.

Turn the router “On”, let the motor build to its full speed, and then gradually feed the cutter bit into the

workpiece.

Always be alert and pay attention to the operation. Never operate the router while fatigued.

Edge routing (fig 9)

1. With the cutting depth set, place the router on

the edge of workpiece, making sure that the

cutter does not contact the workpiece.

2. Have an edge guide (board or metal

straightedge) clamped in place in help guide

the router’s base when making an edge cut.

3. Turn the router “On”, and let the motor attain

full speed.

4. To begin the cut, gradually feed the cutter bit

into the edge of the workpiece.

5. When the cut is complete, turn the motor “Off”,

and allow the cutter bit to come to a complete

stop before removing it from the workpiece.

6. Unplug the router from the power source,

place the router upside down on the worktable, and inspect the finished cut.

WARNING!

Always clamp the workpiece securely and keep a firm grip on the router base with both

hands at all times. Failure to do so could result in loss of control, causing possible serious

personal injury.

WARNING!

Removing the cutter bit from the workpiece while it is still rotating could damage the

workpiece and result in loss of control, causing serious personal injury.

NOTICE: Making test cuts in scrap material that is similar to the workpiece is essential. Learning how the

router’s speed, cutting depth, and cutter bit will react in the workpiece will help produce quality cuts.

OPERATING INSTRUCTIONS

OPERATING INSTRUCTIONS

fig 10

fig 10a

fig 10b

Feed Direction

fig 11

Feed Direction

Edge Guide

Internal sloting on workpiece

with base

fig 9

Edge Guide

Edging with Fixed Base

Page 13

FIXED-BASE ROUTER - 054-6908-8FIXED-BASE ROUTER - 054-6908-8

23 24

Edging with a pilot bit (figs 13

and 13a)

Arbor-type bits with pilots are excellent for shaping

the edge of any workpiece that is either straight or

curved, if the curvature is at least as great as the

radius of the bit to be used.

The pilot prevents the bit from making an

excessively deep cut, and holding the pilot firmly in

contact with the edge of the workpiece throughout

the operation prevents the cut from becoming too

shallow.

Whenever the thickness of the workpiece and with

the desired cutting depth (as adjusted by router

depth setting) are such that only the top part of the

edge is to be shaped (leaving an uncut portion at

the bottom that is at least 1/16" thick), the pilot

can ride against the uncut portion, which serves to

guide it (fig 13).

If the workpiece is too thin, or if the bit is set too

low, such that there will be no uncut edge against

which to ride the pilot, an extra board must be placed under the workpiece to act as a guide (fig 13a). This

“guide” board must have exactly the same contour – straight or curved – as the edge of the workpiece.

If it is positioned so that its edge is flush with the edge of the workpiece, the bit will make a full cut (as

far in as the radius of the bit). If the guide is positioned as shown in fig 13a (out from the edge of the

workpiece), the bit will make less than a full cut, which will alter the shape of the finished edge.

NOTICE: The size (diameter) of the pilot that is used determines the maximum width of the cut that can

be made with the pilot against the edge of the workpiece. A small pilot exposes the entire bit, while

a large pilot reduces this amount by 1/16". Any pilot cutter bit can be used without a pilot for edge

shaping with guides.

WARNING!

Always clamp the workpiece securely and keep a firm grip on the router base with both

hands at all times. Failure to do so could result in loss of control, causing possible serious

personal injury.

Freehand routing with the fixed

base (fig 12)

WARNING!

Do not use large cutter bits for

freehand routing. The use of large

cutter bits when freehand routing

could cause loss of control or create other

hazardous conditions that could result in personal

injury. When using a router table, large bits should

be used for edging only.

When used freehand, the router becomes a flexible and versatile tool. This flexibility makes it possible

to easily rout signs, relief sculptures, etc.

WHEN FREEHAND ROUTING:

1. Draw or lay out the pattern on the workpiece.

2. Choose the appropriate bit.

3. Rout the pattern in two or more passes. Do not exceed 1/8" cutting depth in a single pass. This will

help provide better control, and will serve as a guide on subsequent passes.

NOTICE: A core box or V-groove bit is often used for routing letters and engraving objects. Straight

bits and ball mills are often used to make relief carvings. Veining bits are used to carve small, intricate

details.

NOTICE: Making a single deep cut is never advisable. Smaller diameter bits are easily broken by

too much lateral thrust and torque. Larger bits will cause a rough cut, and will be difficult to guide and

control. For these reasons, DO NOT EXCEED 1/8" CUTTING DEPTH in a single pass.

WARNING!

Always clamp the workpiece securely and keep a firm grip on the router base with both

hands at all times. Failure to do so could result in loss of control, causing possible serious

personal injury.

OPERATING INSTRUCTIONS

OPERATING INSTRUCTIONS

fig 13

Spindle

Lock

Motor Housing

Spindle

Collet/Nut

Fixed Base

Cutter-bit

TOP EDGE SHAPING

Pilot

Workpiece

Top Edge of

Workpiece

fig 13a

Workpiece

Guide

Board

Whole Edge of

Workpiece

WHOLE EDGE SHAPING

fig 12

Page 14

FIXED-BASE ROUTER - 054-6908-8FIXED-BASE ROUTER - 054-6908-8

25 26

Feeding the router (fig 14)

fig 14

ROUTER FEED

ROUTER FEED

ROUTER

END

GRAINS

FIRST

ROUTER FEED

ROUTER FEED

DIRECTION

DIRECTION

DIRECTION

BIT

ROTATION

DIRECTION

The secret to professional routing is to set-up for the cut carefully, selecting the proper cutting depth,

knowing how the cutter bit reacts in the workpiece, and selecting the appropriate rate and direction of

feed for the router.

Direction of feed for external cuts (fig 14)

The router motor and cutter bit rotate clockwise. This means that the feed of the cutter bit must

be from left to right. Feeding the bit from left to right will cause the bit to pull the router toward (up

against) the workpiece.

If the router is fed in the opposite direction (right to left), the rotating force of the cutter bit will tend

to push the bit away from the workpiece, making it hard to control. This is called “Climb-cutting,” or

cutting in the direction opposite the proper feed direction.

“Climb-cutting” increases the chance for loss of control, resulting in possible personal injury. When

“climb-cutting” is required (e.g., backing around a corner), exercise extreme caution to maintain

control of the router.

OPERATING INSTRUCTIONS

Because of the high speed of the cutter bit during a proper feeding operation (left to right), there is very

little kickback under normal conditions. However, if the cutter bit strikes a knot, an area of hard grain

in the wooden workpiece, or a foreign object, the normal cutting action may be affected, which may

cause “kickback”.

This kickback may cause damage to the workpiece, and could result in loss of control of the router,

causing possible personal injury. Kickback is always counter-clockwise, or in the opposite direction of

the clockwise rotation of the cutter bit.

To guard against and help prevent kickback, plan the set-up and direction of feed so that the

router is constantly thrust into the workpiece, keeping the sharp edges of the cutter bit continuously

biting straight into new (uncut) wood (workpiece). Also, always inspect the workpiece for knots, hard

grain, and foreign objects that could cause a kickback problem.

Direction of feed for internal

cuts (figs 15 and 15a)

When making an internal cut, such as a groove,

dado or slot, always position the guide (edge

guide, straight edge, board guide) on the righthand side of the router as the cut is made (fig 15).

When the guide is positioned on the right-hand

side of the router, the router travel should be

from left to right, and “counter-clockwise” around

curves (fig 15). This counter-clockwise action

around the curve could cause “climb-cutting”.

Always be alert and exercise extreme caution

in order to maintain control of the router when

making this type of cut around curves.

When the guide is positioned as shown in fig 15a,

the router travel should be from left to right, and

clockwise around curves.

If there is a choice, the set-up in fig 15 is easier

to use, but there is the possibility of “climb-

cutting” around curves. In either case, fig 15 or

fig 15a, the lateral thrust of the router cutting is always against the guide, as is proper.

WARNING!

Always clamp the workpiece securely and keep a firm grip on the router base with both

hands at all times. Failure to do so could result in loss of control, causing possible serious

personal injury.

OPERATING INSTRUCTIONS

fig 15

GUIDE OUTSIDE

BIT ROTATION

BIT ROTATION

ROTATION FEED DIRECTION

GUIDE

THRUST

fig 15a

GUIDE INSIDE

BIT ROTATION

BIT ROTATION

ROTATION FEED DIRECTION

GUIDE THRUST

Page 15

FIXED-BASE ROUTER - 054-6908-8FIXED-BASE ROUTER - 054-6908-8

27 28

RATE OF FEED (figs 16 and 16a)

The proper rate of feed depends on several

factors: the hardness and moisture content of

the workpiece, the cutting depth, and the cutting

diameter of the bit. Use a faster rate of feed when

cutting shallow grooves in soft woods, such as

pine. Use a slower rate of feed when making deep

cuts in hardwoods, such as oak.

Feeding too quickly (fig 16)

Clean and smooth finished cuts can only be

achieved when the cutter bit is rotating at a

relatively high speed, taking very small bites, and

producing tiny, clean-cut chips.

Forcing the feed of the cutter bit forward too

quickly slows the RPM of the cutter bit, and the

bit takes larger bites as it rotates. Larger bites

mean larger chips and a rougher finish. This

forcing action can also cause the router motor to

overheat.

Under extreme force-feeding conditions, the rotation can become so slow and the bites so large that

chips are only partially cut off, causing splintering and gouging of the workpiece.

The router will make clean, smooth cuts if it is allowed to run freely, without the overload of forced

feeding. Forced feeding can be detected by the sound of the motor. The usual high-pitched whine will

sound lower and stronger as it loses speed. Holding the router against the workpiece will also cause

strain and increase the difficulty.

Feeding too slowly (fig 16a)

When the cutter bit is fed too slowly, the rotating cutter bit does not cut into new wood fast enough to

take a bite. Instead, it scrapes away sawdust-like particles. This scraping produces heat, which can

glaze, burn, and mar the cut in the workpiece and in extreme cases, overheat the cutter bit.

When the cutter bit is scraping instead of cutting, the router is more difficult to control.

With almost no load on the motor, the cutter bit has tendency to bounce off the sides of the cut in the

workpiece, producing a cut that has a rippled finish instead of clean, straight sides.

Chip guard (fig 17)

WARNING!

ALWAYS wear eye protection. The chip

guard is not intended as a safety guard.

WARNING!

ALWAYS turn the motor off and unplug

the router from the power source

before making any adjustments or

installing accessories. Failure to turn the motor off and unplug the router could result in

accidental starting, which can cause serious personal injury.

To remove the chip guard from the fixed base, press inward on its tabs until the chip guard releases

from the base, and then remove it. To attach the chip guard, place it back in position, and flex the sides

while pushing it in until it snaps back into place (fig 17).

WARNING!

The chip guard helps keep dust and chips away from the operator. It will not stop objects

larger than woodchips that are from the bit.

CAUTION!

ALWAYS have the chip guard in place on the base when operating the router.

WARNING!

ALWAYS turn the motor off, and unplug the router from the power source before making

any adjustments or installing accessories. Failure to turn the motor off and unplug the

router could result in accidental start-ups, which can cause serious personal injury.

OPERATING INSTRUCTIONS

Tabs

fig 17

fig 16

Bit Shank

Cut

Cutter

TOO FAST

fig 16a

Bit Shank

Cut

Cutter

TOO SLOW

OPERATING INSTRUCTIONS

Page 16

FIXED-BASE ROUTER - 054-6908-8FIXED-BASE ROUTER - 054-6908-8

29 30

Dust collection with a vacuum

adaptor (fig 18)

WARNING!

ALWAYS turn the motor off and unplug

the router from the power source before

making any adjustments or installing

accessories. Failure to turn the motor

off and unplug the router could result

in accidental starting, which can cause

serious personal injury.

A vacuum adaptor is included with this router. The adaptor is sized to accept a 1-1/4" (3.2 cm) vacuum

hose adaptor (not included).

To attach the adaptor onto the fixed base, position and secure it to the back of the base using the two

screws (included), as shown in fig 18.

General

Only the parts shown on the parts list are intended for repair or replacement by the customer. All other

parts represent an important part of the double-insulation system.

Toll-free Helpline – 1-800-689-9928.

WARNING!

To ensure safety and reliability, all repairs should be performed by a qualified service

technician.

WARNING!

For personal safety, always turn the switch off and unplug the router motor from the power

source before performing any maintenance or cleaning.

WARNING!

If the supply cord is damaged, it must be replaced by a specially prepared cord available

through the service organization.

It has been found that electric tools are subject to accelerated wear and possible premature failure

when they are used to work on fibreglass, wallboard, spackling compounds or plaster. The chips and

grindings from these materials are highly abrasive to electrical tool parts, such as bearings, brushes,

commutators, etc. Therefore, it is not recommended that this tool be used for extended work on any

fibreglass material, wallboard, spackling compound or plaster. During any use on these materials, it is

extremely important that the tool is cleaned frequently by blowing with an air jet.

WARNING!

Always wear safety goggles or safety glasses with side shields during power tool

operations, or when blowing dust. If the operation is dusty, also wear a dust mask.

2 screws included

fig 18

MAINTENANCE

OPERATING INSTRUCTIONS

Page 17

FIXED-BASE ROUTER - 054-6908-8FIXED-BASE ROUTER - 054-6908-8

31 32

Router maintenance

WARNING!

DO NOT allow brake fluid, gasoline, petroleum-based products, penetrating oils, etc. to

come into contact with plastic parts at any time. These substances can damage, weaken, or

destroy plastic, which may result in serious personal injury.

1. When the work has been completed, clean the tool to allow smooth functioning of the tool over time.

2. Use a clean, damp cloth to wipe the tool.

3. Check the state of all electrical cables.

4. Keep the motor air openings free of oil, grease, and sawdust or woodchips, and store the tool in a

dry place.

5. Be certain that all moving parts are well lubricated, particularly after lengthy exposure to damp and/

or dirty conditions.

Replacing carbon brushes (fig 19)

1. Unplug the router motor before inspecting or

replacing brushes.

2. Replace both carbon brushes when either has

less than 1/4" of carbon remaining, or if the

spring or wire is damaged or burned.

3. Using a slotted screwdriver, remove the black

plastic cap on each side of the router motor

(fig 19), and carefully remove the springloaded brush assemblies. Keep brushes clean

and sliding freely in their guide channels.

NOTICE: To reinstall the same brushes, make sure the brushes go back in the same way they

came out. This will avoid a break-in period.

4. Insert new brush assemblies into the guide channels, with the carbon part going in first, and be

sure to fit the two metal “ears” into their slots in the channel (fig 19).

5. Remember to replace both end caps after inspecting or servicing the brushes. Tighten the caps

snugly, but do not over-tighten. The router should be allowed to “RUN IN” (run at no load without a

cutter bit) for 5 minutes before use to seat the new brushes properly.

WARNING!

For personal safety, always turn the switch off and unplug the router motor from the power

source before performing any maintenance or cleaning.

Cleaning

Sawdust accumulation may cause uneven movement, binding of the gear assembly and possible

damage to the router. Clean the dust and debris from the gear rack and plunger with compressed dry

air or brush. Wear a mask and proper eye protection when you clean the tool. Always ensure that the

gear rack mechanism has been cleaned and the plunger mechanism operates as intended before each

use.

WARNING!

ALWAYS turn the motor off and unplug the router from the power source before making any

adjustments or installing accessories. Failure to turn the motor off and unplug the router

could result in accidental starting, which can cause serious personal injury

WARNING!

Certain cleaning agents and solvents damage plastic parts. Some of these are: gasoline,

carbon tetrachloride, chlorinated cleaning solvents, ammonia and household detergents

that contain ammonia.

Lubrication

All of the bearings in this tool are lubricated with a sufficient amount of high-grade lubricant for the life

of the tool under normal operating conditions. Therefore, no further lubrication is required.

MAINTENANCE

MAINTENANCE

Cap

Ears

Brushes

fig 19

Page 18

FIXED-BASE ROUTER - 054-6908-8FIXED-BASE ROUTER - 054-6908-8

33 34

PROBLEM POSSIBLE CAUSES SOLUTIONS

The router does not work. The router switch is in “OFF” position. Move the switch to the “ON” position.

TROUBLESHOOTING

Exploded view

PARTS LIST

Page 19

FIXED-BASE ROUTER - 054-6908-8FIXED-BASE ROUTER - 054-6908-8

35 36

No. Part No. Description No. Part No. Description

1 5610220000 Screw 31 5700056000 Ball Bearing

2 3123916000 Rear Cover 32 3420356000 Motor Housing

3 3121518000 Transparent Cap 33 3520227000 Gear Rack

4 5610017000 Screw 34 5620062000 Screw

5 4900046000 PCB Assembly 35 3550592000 Spindle Lock

6 4540017000 Power Supply Indicator 36 5660005000 E-Ring

7 5620017000 Hexagon Socket Screw 37 3660174000 Stop Spring

8 5610106000 Tapping Screw 38 5630179000 Nut

9 3122798000 Cord Anchor 39 5630187000 Collet Nut

10 5610059000 Thread Forming Screw 40 3550721000 Collet

11 3120537000 Brush Cover 41 3121637000 Chip Shield

12 2800005000 Brush Holder Assembly 42 5620024000 Hexagon Socket Screw

13 4960019000 Carbon Brush Assembly 43 3320631000 Right Handle

14 3122851000 Seal Ring 44 5670040000 Located Pin

15 4870073000 Switch 45 3420396000 Mounting

16 3121494000 Middle Housing 46 3400189000 Locking Bolt

17 3121050000 Cord Guard 47 3320632000 Left Handle

18 4810002000 Power Cord & Plug 48 3121648000 Button

19 3123926000 Bearing Holder 49 3550579000 Gear Shaft

20 3121049000 Rubber Spring 50 3520141000 Gear

21 3700249000 Washer 51 3520147000 Locking Gear

22 5700008000 Ball Bearing 52 3550615000 Worm

23 2740116000 Stator 53 5620033000 Screw

24 5610048000 Tapping Screw 54 3660167000 Spring

25 2822039000 Internal Wire Assembly 55 5630015000 Prevailing Torque Hexagon Nut

26 2822038000 Internal Wire Assembly 56 3700848000 Plate

27 2750719000 Rotor 57 5660003000 E-Ring

28 3121495000 Fan Baffle 58 3420395000 Clamping Lever

29 5620040000 Screw 59 5620332000 Screw

30 2820887000 LED Holder Assembly 60 3550596000 Locking Pin

If any parts are missing or damaged, or if you have any questions,

please call the Toll-free Helpline, at 1-800-689-9928.

No. Part No. Description No. Part No. Description

61 5620041000 Screw 70 5650015000 Spring Washer

62 3121646000 Adjusting Knob 71 5650013000 Plain Washer

63 3121647000 Indicator 72 3703591000 Parallel Guide

64 5650172000 Wave Washer 73 3550683000 Guiding Rod

65 3550613000 Shaft 74 3550560000 Collet

66 5630003000 Hexagon Nut 75 3700807000 Wrench

67 3122924000 Mounting Plate 76 3122784000 Vacuum Adaptor

68 5620049000 Screw 77 5620040000 Screw

69 5620050000 Screw

If any parts are missing or damaged, or if you have any questions,

please call the Toll-free Helpline, at 1-800-689-9928.

PARTS LIST

PARTS LIST

Page 20

FIXED-BASE ROUTER - 054-6908-8FIXED-BASE ROUTER - 054-6908-8

37 38

This Mastercraft product is guaranteed for a period of 3 years from the date of original retail

purchase against defects in workmanship and materials, except for the following components:

a) Component A: Batteries, chargers and carrying case, which are guaranteed for a period of 2 years

from the date of original retail purchase against defects in workmanship and materials;

b) Component B: Accessories, which are guaranteed for a period of 1-year from the date of original

retail purchase against defects in workmanship and materials.

Subject to the conditions and limitations described below, this product, if returned to us with proof

of purchase within the stated warranty period and if covered under this warranty, will be repaired or

replaced (with the same model, or one of equal value or specification), at our option. We will bear the

cost of any repair or replacement and any costs of labour relating thereto.

These warranties are subject to the following conditions and

limitations:

a) a bill of sale verifying the purchase and purchase date must be provided;

b) this warranty will not apply to any product or part thereof which is worn or broken or which has

become inoperative due to abuse, misuse, accidental damage, neglect or lack of proper installation,

operation or maintenance (as outlined in the applicable owner’s manual or operating instructions)

or which is being used for industrial, professional, commercial or rental purposes;

c) this warranty will not a pply to normal wear and tear or to expendable parts or accessories that

may be supplied with the product that are expected to become inoperative or unusable after a

seasonable period of use;

d) this warranty will not apply to routine maintenance and consumable items such as, but not limited

to, fuel, lubricants, vacuum bags, blades, belts, sandpaper, bits, fluids, tune-ups or adjustments;

e) this warranty will not apply where damage is caused by repairs made or a ttempted by others (i.e.

persons not authorized by the manufacturer);

f) this warranty will not apply to any product that was sold to the original purchaser as a

reconditioned or refurbished product (unless otherwise specified in writing);

g) this warranty will not apply to any product or part thereof if any part from another manufacturer

is installed therein or any repairs or alterations have been made or attempted by unauthorized

persons;

h) this warranty will not apply to normal deterioration of the exterior finish, such as, but not limited

to, scratches, dents, paint chips, or to any corrosion or discolouring by heat, abrasive and chemical

cleaners; and

i) this warranty will not apply to component parts sold by and identified as the product of another

company, which shall be covered under the product manufacturer’s warranty, if any.

Additional Limitations

This warranty applies only to the original purchaser and may not be transferred. Neither the retailer nor

the manufacturer shall be liable for any other expense, loss or damage, including, without limitation,

any indirect, incidental, consequential or exemplary damages arising in connection with the sale, use

or inability to use this product.

Notice to Consumer

This warranty gives you specific legal rights, and you may have other rights, which may vary from

province to province. The provisions contained in this warranty are not intended to limit, modify, take

away from, disclaim or exclude any statutory warranties set forth in any applicable provincial or federal

legislation.

IMPORTED BY MASTERCRAFT CANADA TORONTO, CANADA M4S 2B8

WARRANTY

WARRANTY

Page 21

Loading...

Loading...