MasterCraft 054-1250-0 Owner's Manual

Owner’s Manual

ROTARY TOOL

054-1250-0

CAUTION:

Before using this

rotary tool or any of its

accessories, read this

manual and follow all

its Safety Rules and

Operating Instructions.

General Safety Rules

Specific Safety Rules

and Symbols

Functional Description

Assembly

Operation

Maintenance

Accessories

Imported by Mastercraft Canada Toronto, Canada M4S 2B8

Rev 1.8 05/05/2012

2

SECTION

PAGE SECTION

PAGE

Warranty ….……………………….

2

Accessories ……………………

10

Product specifications …………...

2

Carton contents ……..………...

10–14

Power tool safety ………………..

3–5

Accessory description & use ...

15–16

Specific safety rules ……………..

6

Assembly & operation ..………

16–21

Extension cord safety ……………

7

Maintenance …….……………..

20

Symbols …………………………..

8

Parts & service ..……..………..

21–24

Know your rotary tool ……………

9

Motor rating …………………………

120 V, 60 Hz

Amp. …. …………………………….

1.5 A

RPM (no load) ………………………

5000–35000 RPM

Collets ……………………………….

1/16”, 3/32” & 1/8”

Weight ……………………………….

9 lb 8 oz (4.3 kg)

TABLE OF CONTENTS

WARRANTY

Limited 3-year Replacement Warranty

This Mastercraft product carries a three (3) year repair warranty against defects in

workmanship and materials. At its discretion, Mastercraft Canada agrees to have

any defective part(s) repaired or replaced free of charge, within the stated warranty

period, when returned by the original purchaser with proof of purchase. This

product is not guaranteed against wear or breakage due to misuse and/or abuse.

This product is not guaranteed if used for industrial or commercial purposes.

Mastercraft is a superior line of products selected for their workmanship and

materials. These products are designed to meet rigorous quality and performance

standards, and are approved by our Quality Assurance laboratory.

TOLL FREE HELPLINE: 1-800-689-9928

3

POWER TOOL SAFETY

WARNING: To avoid electrical hazards, fire hazards or damage to the rotary

tool, use proper circuit protection.

This rotary tool is wired at the factory for 120 V operation. It must be connected to a

120 V 15 A time delayed fuse or circuit breaker. To avoid shock or fire, replace

power cord immediately if it is worn, cut or damaged in any way.

!

WARNING: Some dust created by power sanding, sawing, grinding, drilling

and other construction activities contains chemicals known to cause cancer, birth

defects or other reproductive harm. Some examples of these chemicals are:

Lead from lead-based paints

Crystalline silica from bricks, cement and other masonry products

Arsenic and chromium from chemically-treated lumber

Your level of risk from these exposures varies, depending on how often you do

this type of work. To reduce your exposure to these chemicals, work in a wellventilated area and work with approved safety equipment such as dust masks that

are specially designed to filter out microscopic particles.

!

!

ALWAYS WEAR EYE PROTECTION

Any power tool can throw foreign objects into your eyes which could cause

permanent eye damage. ALWAYS wear safety goggles (not glasses) that

comply with ANSI safety standard Z87.1. Everyday glasses have only

impact resistant lenses. They ARE NOT safety glasses.

WARNING: Glasses or goggles not in compliance with ANSI Z87.1 could

cause serious injury when they break.

4

POWER TOOL SAFETY

GENERAL SAFETY RULES

WARNING: Read and understand

all instructions. Failure to follow all

instructions listed below may result in

electric shock, fire and/or serious personal

injury.

WORK AREA

Keep your work area clean and well lit.

Cluttered benches and dark areas invite

accidents.

Do not operate power tools in potentially

explosive environments, such as in the

presence of flammable liquids, gas or

dust. Power tools create sparks which may

ignite the dust or fumes.

Keep bystanders, children and visitors

away while operating the tool.

Distractions can cause you to lose control.

ELECTRICAL SAFETY

Double insulated tools are equipped

with a polarized plug (one blade is wider

than the other). This plug will fit in a

polarized plug only one way. If the plug

does not fit fully in the outlet, reverse

the plug. If it still does not fit, contact a

qualified electrician to install a polarized

outlet. Do not alter the plug in any way.

Double insulation eliminates the need for

the three-prong grounded power cord and

grounded power supply system.

Avoid body contact with grounded surfaces

such as pipes, radiators, ranges and

refrigerators. There is increased risk of

electric shock if your body is grounded.

Do not expose power tools to rain or wet

conditions. Water entering the power tool

will increase the risk of electric shock.

Do not abuse the cord. Never use the

cord to carry the tool or pull the plug from

an outlet. Keep cord away from heat, oil,

sharp edges or moving parts. Replace

damaged cords immediately. Damaged

cords increase the risk of electric shock.

When operating a power tool outdoors,

use an outdoor extension cord marked

“W-A” or “W”. These cords are rated for

outdoor use and reduce the risk of electric

shock.

PERSONAL SAFETY

Stay alert, watch what you are doing and

use common sense when operating a

power tool. Do not use the tool while

tired or under the influence of drugs,

alcohol or medication. A moment of

inattention while operating power tools may

result in serious personal injury.

Dress properly. Do not wear loose

clothing or jewellery.

Contain long hair. Keep your hair,

clothing and gloves away from moving

parts. Loose clothing, jewellery or long hair

can be caught in moving parts.

Avoid accidental starting. Be sure the

switch is OFF before plugging in.

Carrying tools with your finger on the switch

or plugging in tools that have the switch ON

invites accidents.

SAVE THESE INSTRUCTIONS FOR REFERENCE

!

5

POWER TOOL SAFETY

PERSONAL SAFETY – cont’d

Remove adjusting keys or wrenches

before turning the tool ON. A wrench or

key that is left attached to a rotating part of

the tool may result in personal injury.

Do not overreach. Keep proper footing

and balance at all times. Proper footing

and balance enables better control of the

tool in unexpected situations.

Use safety equipment. Always wear eye

protection. Dust mask, non-skid safety

shoes, hard hat or hearing protection must

be used for appropriate conditions.

TOOL USE AND CARE

Use clamps or another practical way to

secure and support the workpiece to a

stable platform. Holding the work by hand

or against your body is unstable and may

lead to loss of control.

Do not force the tool. Use the correct

tool for your application. The correct tool

will do the job better and safer at the rate

for which it was designed.

Do not use the tool if the power switch

does not turn it ON or OFF. Any tool that

cannot be controlled with the switch is

dangerous and must be repaired.

Disconnect the plug from the power

source before making any adjustments,

changing accessories or storing the

tool. Such preventive safety measures

reduce the risk of starting the tool

accidentally.

Store idle tools out of reach of children

and other untrained persons. Tools are

dangerous in the hands of untrained users.

Maintain tools with care. Keep cutting

tools sharp and clean. Properly

maintained cutting tools with sharp cutting

edges are less likely to bind and are easier

to control.

Check for misalignment or binding of

moving parts, breakage of parts and any

other condition that may affect the tool’s

operation. If damaged, have the tool

serviced before using. Many accidents

are caused by poorly maintained tools.

Use only accessories that are

recommended by the manufacturer for

your model. Accessories that may be

suitable for one tool may become

hazardous when used on another tool.

SERVICE

Tool service must be performed only by

qualified personnel. Service or

maintenance performed by unqualified

personnel could result in risk of injury.

When servicing a tool, use only identical

replacement parts. Follow instructions

in the Maintenance section of this

manual. Use of unauthorized parts or

failure to follow Maintenance instructions

may create a risk of electric shock or injury.

SAVE THESE INSTRUCTIONS FOR REFERENCE

6

SPECIFIC SAFETY RULES

WARNING: Know your rotary tool.

Read the Owner’s Manual carefully.

Learn the tool’s applications and

limitations, as well as the specific

potential hazards related to this tool.

Following this rule will reduce the risk of

electric shock, fire or serious injury.

Always wear eye protection. Any power

tool can throw foreign objects

into your eyes which could

cause permanent eye damage.

ALWAYS wear safety goggles

(not glasses) that comply with ANSI safety

standard Z87.1. Everyday glasses have

only impact resistant lenses. They ARE

NOT safety glasses.

WARNING: Glasses or goggles

not in compliance with ANSI Z87.1 could

cause serious injury when they break.

Hold tool by insulated gripping surfaces

when performing an operation where the

cutting tool may contact hidden wiring

or its own cord. Contact with a “live” wire

will make exposed metal parts of the tool

“live” and shock the operator.

Always make sure the work surface is

free from nails and other foreign

objects. Cutting into a nail can cause the

bit and the tool to jump and damage the bit.

Never hold the workpiece in one hand

and the tool in the other hand when in

use. Never place the hands near or

below the cutting surface. Clamping the

material and guiding the tool with both

hands is much safer.

Never lay workpiece on hard surfaces

like concrete, stone, etc. Protruding

cutting bit may cause the tool to jump.

Always wear safety goggles and dust

mask. Use only in well-ventilated area.

Using personal safety devices and working

in a safe environment reduces risk of injury.

After changing the bits and accessories

or making adjustments, make sure the

collet nut and any other adjustment

devices are securely tightened. Loose

adjustment devices will be violently thrown.

Always use the correct collet size. If the

collet size is larger than the accessory

shank size it will not grip the shank

properly, leading to possible injury to the

operator or damage to the tool.

Always check accessory bits, grinding

stones, cut-off wheels etc. for damage

before each use. Damaged accessories

can break during use and cause serious

injury.

Never use dull or damaged bits. Sharp

bits must be handled with care.

Damaged bits can snap during use. Dull

bits require more force to push the tool,

possibly causing the bit to break.

Never touch the bit during or

immediately after use. After use the bit is

too hot to be touched by bare hands.

Never operate the flexible shaft with a

bend radius of less that 6”. Shorter bend

radii will damage the flexible shaft and the

rotary tool motor.

SAVE THESE INSTRUCTIONS FOR REFERENCE

!

!

7

EXTENSION CORD SAFETY

WARNING: Keep the extension

cord clear of the working area. Position

the cord so it will not get caught on the

workpiece, tools or any other

obstructions while you are working with

the power tool.

Make sure any extension cord used with

this tool is in good condition. When

using an extension cord, be sure to use one

of heavy enough gauge to carry the current

the tool will draw. An undersized cord will

cause a drop in line voltage resulting in loss

of power and overheating.

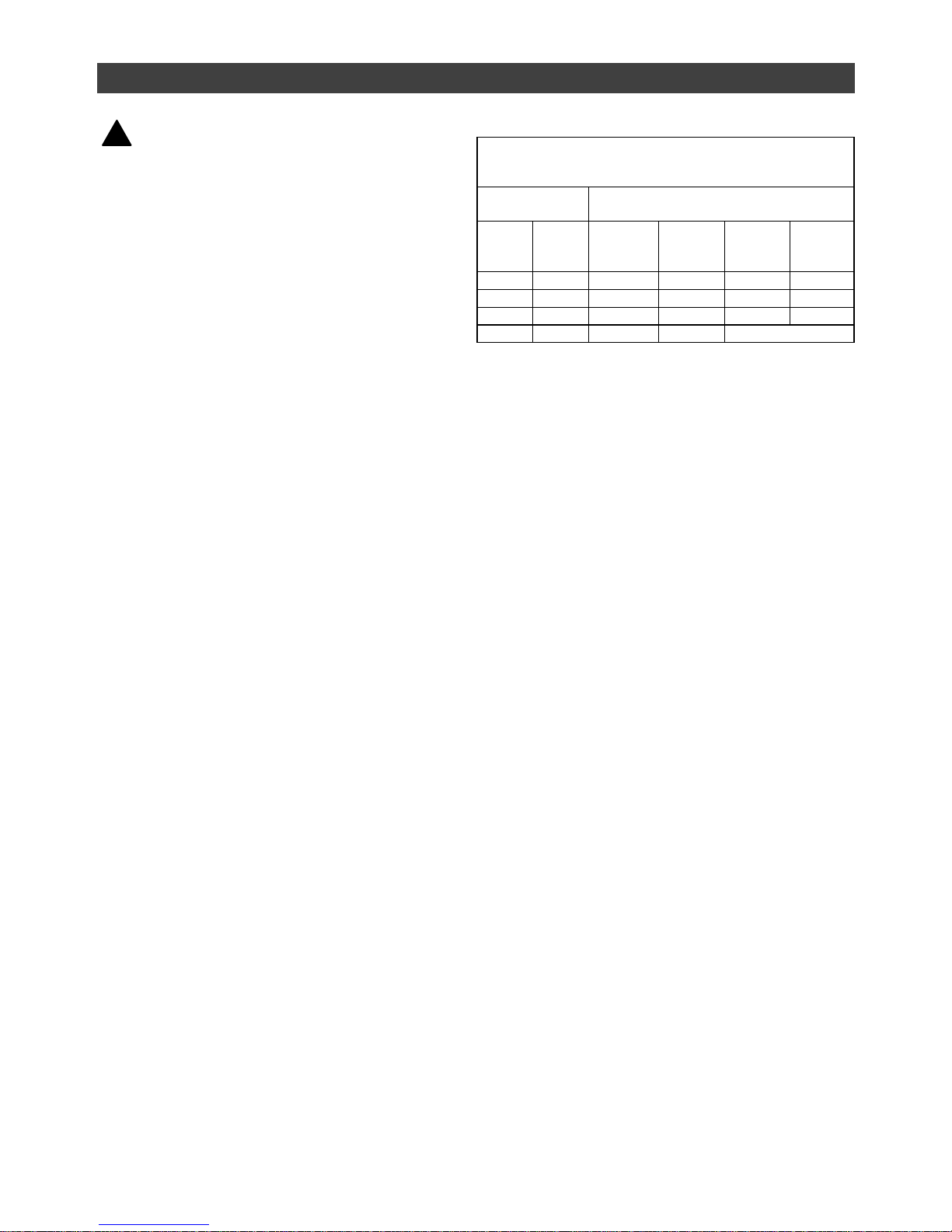

The table at right shows the correct size to

use according to cord length and

nameplate ampere rating. If in doubt, use

the next heavier gauge. The smaller the

gauge number the heavier the cord.

Be sure your extension cord is properly

wired and in good condition. Always

replace a damaged extension cord or have

it repaired by a qualified electrician before

using it. Protect your extension cord from

sharp objects, excessive heat and damp or

wet areas.

Use a separate electrical circuit for your

power tools. This circuit must not be less

than 14 gauge wire and should be

protected with either a 15 A time delayed

fuse or circuit breaker. Before connecting

the power tool to the power source, make

sure the switch is in the OFF position and

the power source is the same as indicated

on the nameplate. Running at lower voltage

will damage the motor.

!

SAVE THESE INSTRUCTIONS FOR REFERENCE

MINIMUM GAUGE (AWG)

EXTENSION CORDS (120 V use only)

Amperage

rating Total length

More

than

Not

more

than

25'

(7.5 m)

50'

(15 m)

100'

(30 m)

150'

(45 m)

0 6 18

16

16

14 6 10

18

16

14

12

10

12

16

16

14

12

12

16

14

12

Not Applicable

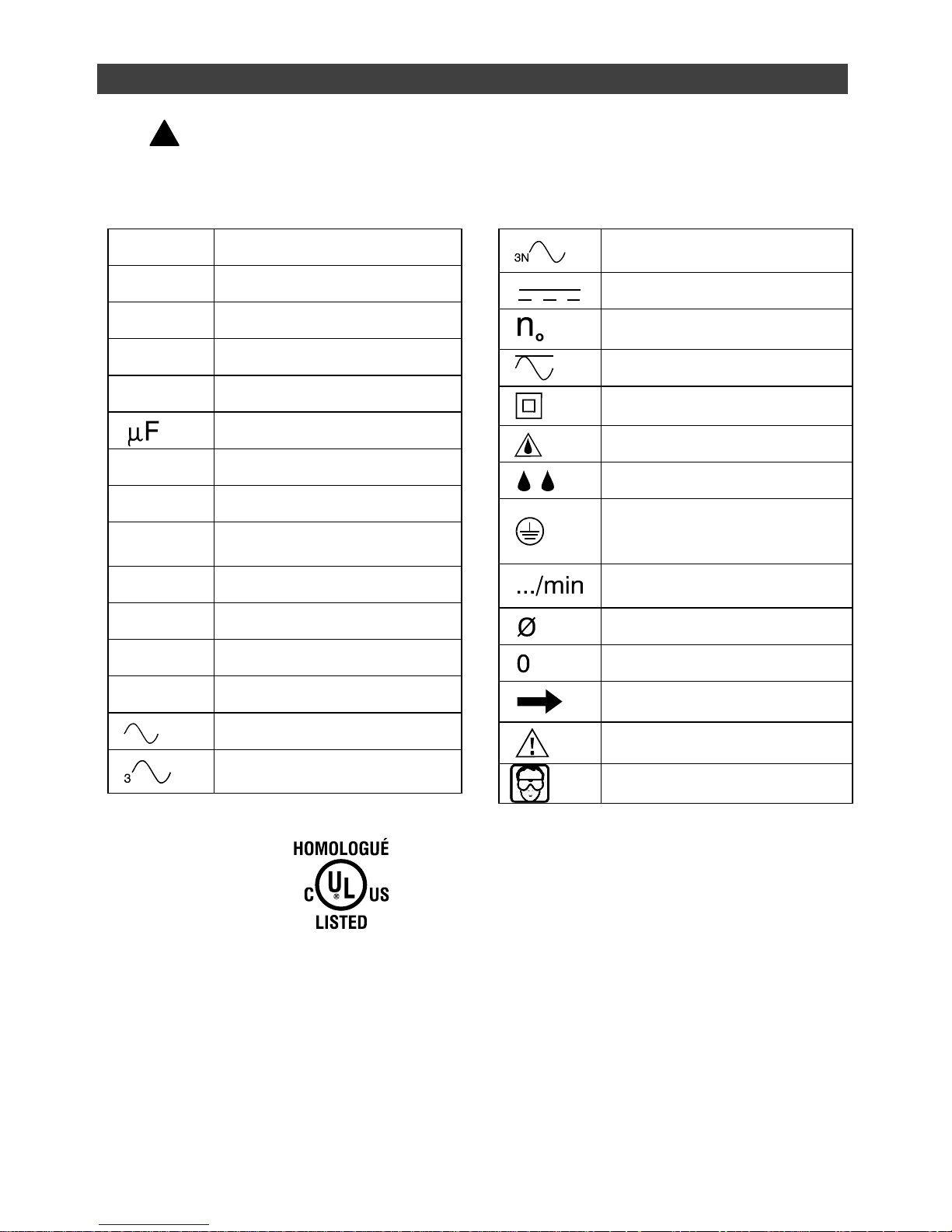

8

V

volts

A

amperes

Hz

hertz

W

watt

kW

kilowatts

microfarads

L

litres

Kg

kilograms

N/cm2

newtons per square

centimeter

Pa

pascals

H

Hours

Min

minutes

S

seconds

alternating current

three-phase alternating

current

three-phase alternating

current with neutral

direct current

no load speed

alternating or direct current

class II construction

splash proof construction

watertight construction

protective earthing at

earthing terminal, Class I

tools

revolutions or

reciprocations per minute

diameter

off position

arrow

warning symbol

wear your safety glasses

SYMBOLS

WARNING: Some of the following symbols may be used on your

tool. Please study them and learn their meaning. Proper interpretation of

these symbols will allow you to operate the tool better and safer.

!

This symbol designates that

this tool is listed with both

Canadian and U.S.

requirements by Underwriters

Laboratories.

61TN

E213739

JD3306U

Loading...

Loading...