Page 1

Owner’s Manual

Manual de Operación

CAUTION

SAVE AND READ THESE

IMPORTANT INSTRUCTIONS

Read all instructions carefully before setting up and

operating this unit. This manual was designed to provide you with important information needed to setup,

operate, maintain, and trouble-shoot your cooler.

Failure to follow these instructions may damage

and/or impair its operation and void the warranty.

U.S. Models:

MMB10, MMB12, MMB14 & MMPC12

Mexico Modelos:

MMB10, MMB12 & MMB14

PRECAUCIO´N

LEA Y CONSERVE ESTE MANUAL

Lea todas las instrucciones cuidadosamente antes

de montar y operar esta unidad. Este manual fue

diseñado para proveerle importante información

necesaria para instalar

problemas en su enfriador. La falla en seguir estas

instrucciones puede dañar y/o afectar la operación

del enfriador y anular la garantía.

, operar

, mantener y detectar

1450 E. Grant Street, Phoenix, Arizona U.S.A.

www.AdobeAir.com 602-257-0060

AP059719 2/2008

Av. Carr. Miguel Alemán #6061, Col. América, Cd. Guadalupe, Nuevo León, México, C.P. 67130

www.Impco.com.mx (81)-8144-5440

Page 2

1

INTRODUCTION

Evaporative cooling works on the principle of heat absorption

by moisture evaporation. Simply put, heat is removed from the

ir as water evaporates. You feel this principle in action when

a

you step out of a swimming pool or shower; you feel immediately cooler as water evaporates from the surface of your skin.

!

WARNINGS AND SAFETY RULES

WARNING…

To reduce the risk of electric shock, fire or injury:

• Read instructions and labels carefully.

Always unplug the electric cord to your cooler before

•

you work on the cooler.

• Your cooler will run on 120 Volt AC, 60 Hz (cycle)

current only.

Your evaporative cooler works on the same principle. Hot outside air is pulled through water-saturated pads, where the air is

ooled by evaporation and then discharged from the cooler. In

c

order for your cooler to work at maximum efficiency, it must

have hot air to draw in (from an open door or window) and an

outlet to vent out the air (window or vent). To learn more about

evaporative cooling, visit our website at www.AdobeAir.com.

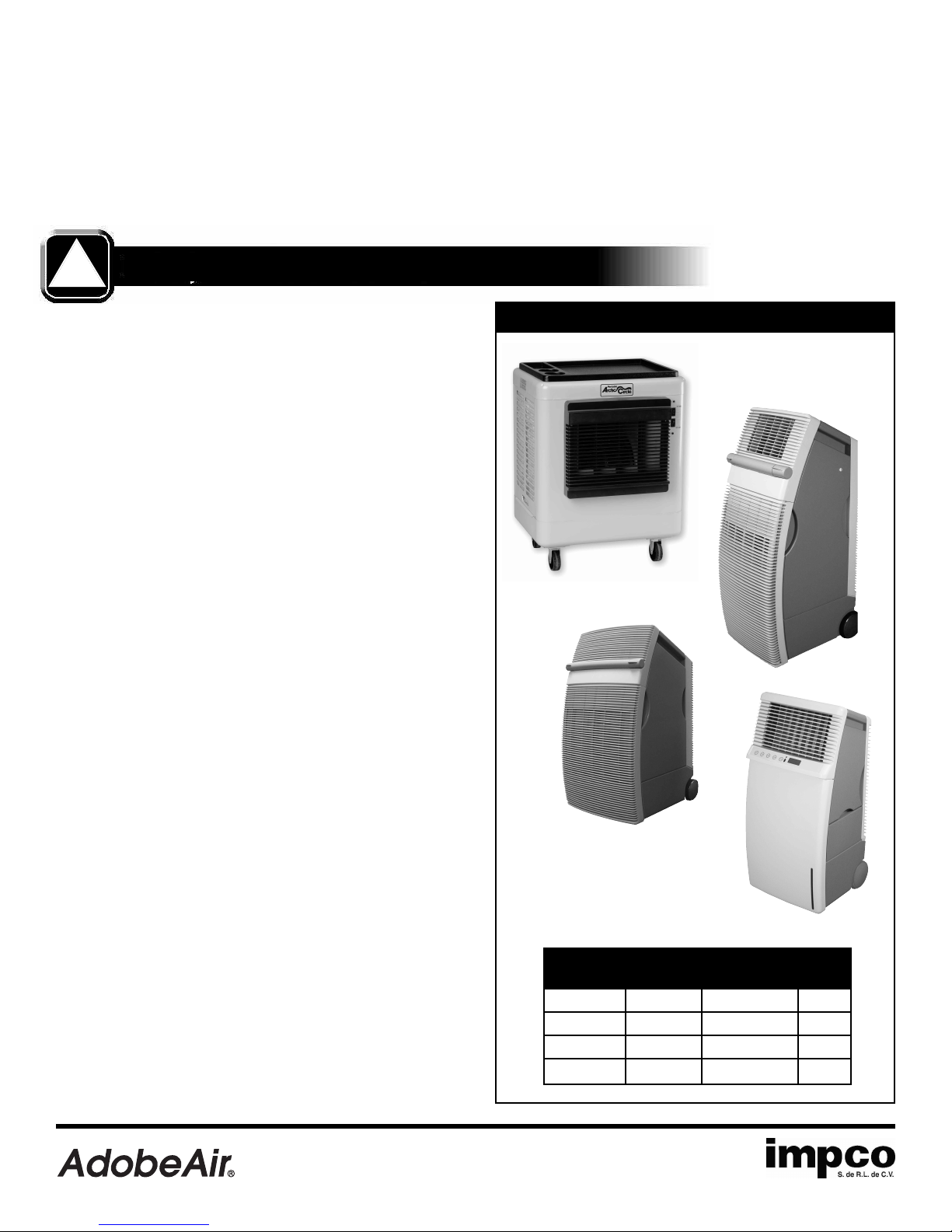

Other Mobile Products by AdobeAir

MMB8

• Plug into three-prong grounded GFCI protected

electrical receptacle only.

• Do not operate if plug or cord are damaged in any way.

• Do not step on or roll over power cord with heavy or

sharp objects.

• Do not operate unit unless all panels are securely in

place.

• Remove the plug from the electrical receptacle by

pulling on the plug and not the cord.

• Test the GFCI receptacle or breaker monthly to ensure

it is functioning properly.

• Do not operate near open containers of flammable

liquids or gases.

Never wash your cooler cabinet with a garden hose;

•

water may harm the motor and pump.

• If the unit is damaged or it malfunctions, do not continue to operate it. Refer to the warranty or troubleshooting

section at www.AdobeAir.com or call AdobeAir Customer

Service Department at (602) 257-0060.

P12

MMB8 500 ft

P700 500 ft

P10 700 ft

P12 1,000

P10

P700

Cools Water Motor

Up T

Capacity

o

2

4.5 Gallons

2

2.5 Gallons 1/12

2

6 Gallons

2

ft

12 Gallons

HP

1/8

1/8

1/3

1450 E. Grant Street, Phoenix, Arizona U.S.A.

www.AdobeAir.com 602-257-0060

AP059719 2/2008

Av. Carr. Miguel Alemán #6061, Col. América, Cd. Guadalupe, Nuevo León, México, C.P. 67130

www.Impco.com.mx (81)-8144-5440

Page 3

2

ASSEMBLY INSTRUCTIONS

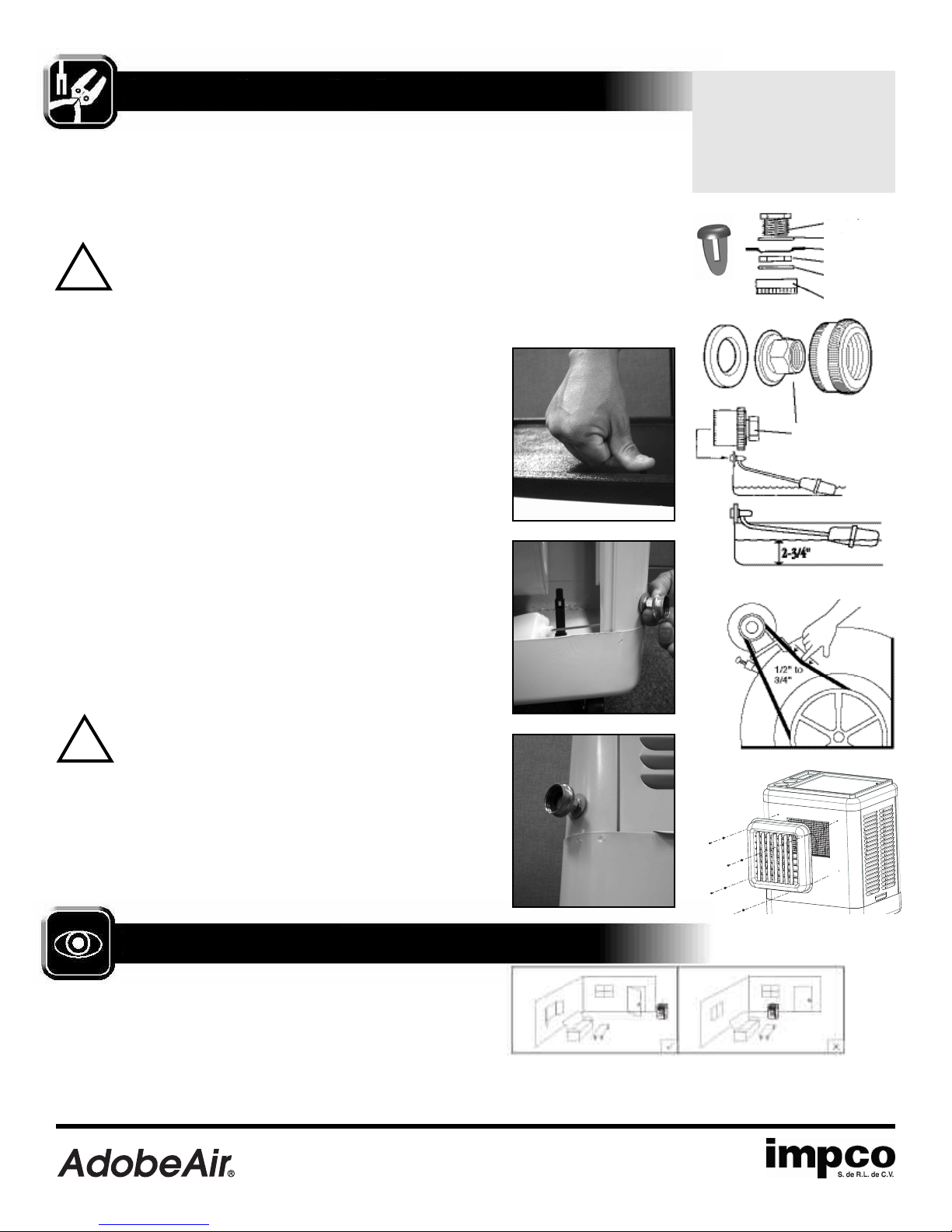

Unpacking the Mobile MasterCool®.

molded plastic tray not attached. Remove the plastic tray from the carton and

then remove the cooler from the carton.

Grille Installation.

cooler you must complete the grille installation.

Before attempting to use your new Mobile MasterCool

The unit is shipped with the

CAUTION: Handle the grille with care it may have

sharp edges or burrs.

!

Using the four Phillips screws and lock washers (included) start each screw

into each path, then tighten for assembly of the grill to the front of the cabinet.

DO NOT OVER TIGHTEN. See Figure 5

Installing the casters.

attached to the cabinet bottom. If wheels are not attached then locate the

wheels inside of the cooler and attach them to the cabinet bottom using the

bolts included.

Attaching the plastic tray.

by lifting them up and out of the cooler cabinet. Locate the parts bag in the

cooler and attach the tray top using the push rivets provided. (Picture 1)

Installing the drain bushing and plug.

to Figure 1 and install the drain bushing and cap through the hole

provided in the bottom of the cooler.

Installing the float valve and adapter.

float to the side leg of the cooler using the hole provided. The garden hose

adapter attaches to the brass inlet fitting on the float valve. Verify that the hose

washers are properly in place. (Picture 2)

Connecting to Water

with water and drained. The cooler should be located on level ground.

Connect to a water supply using a commercial grade garden hose (supplied by

customer) connected to the adapter on the float valve and turn on the water.

Verify water tight connections by visually examining both the float / hose connection and the drain plug. (Picture 2)

Some models ship with the wheels already

Remove the side pad frames from the cooler

If it is not already installed, refer

Refer to Figure 2 and attach the

.

Move the cooler to an area where it can be filled

CAUTION: Water inlet pressure should be limited to a

maximum of 105 PSI or an inline pressure regulator

!

should be installed.

Adjusting the water level.

shown by adjusting the float.

Connecting to a Power Supply

120 Volt AC 60 Hz grounded GFCI protected electrical power sup

Note:

Improper voltage will burn out the motor and pump windings and will

void the warranty.

Refer to Figure 3 and set the water height as

.

Plug the gro

d plug directly into a

unde

ply.

Check Belt Tension.

This applies only to models

with belt drive construction.

Check belt tension (Figure 4)

by pushing downward on it.

proper tension will allow

deflection 1/2˝ to 3/4˝. To

adjust belt tension, loosen

bolt in slot of motor support

bracket, adjust to proper

tension and retighten bolt.

Picture 1

Picture 2

TOOLS REQUIRED

• 3/8˝Open End Wrench

ox End Wrench

3/8

˝

B

•

• 6

˝

Adjustable Wrench

˝

• 7/16

• #2 Phillips Screwdriver

Push Rivet

Box End Wrench

D

rain Bushing

W

asher

Cooler Bottom

Lock Nut

Washer Inside

Cap

H

ose Adapter

Figure 4

Cap

Figure 2

Figure 3

igure 1

F

LOCATION

Always make sure the unit is operated on a level surface. The

best location for it is near a partially opened window or door

where hot outdoor air can be drawn into the unit. This cooler is

portable, but use caution when rolling the unit to avoid splashing and spilling of water. Cool air can best be directed through

the space by using a partly opened window or door

that is situated on the opposite side of the

1450 E. Grant Street, Phoenix, Arizona U.S.A.

www.AdobeAir.com 602-257-0060

, ideally one

AP059719 2/2008

Picture 3

Figure 5

space from the cooler. This allows the cooled air to be moved

through the space and exhausted back outdoors which is

critical to proper performance of the cooler.

Av. Carr. Miguel Alemán #6061, Col. América, Cd. Guadalupe, Nuevo León, México, C.P. 67130

www.Impco.com.mx (81)-8144-5440

Page 4

3

USE & OPERATION

1. If your model has locking casters, make sure the two

locking casters have been locked to prevent the cooler

from moving before turning on the fan.

2. Turn on the water supply to the cooler. The hose connection

to the float valve provides an automatic method of refilling

the water supply as water evaporates.

3. For best results, turn the pump on a few minutes before

turning on the blower fan. This allows the cooling pads to

pre-wet for best efficiency.

4. Whenever possible, operate the blower fan at low speed for

maximum cooling. When cooling is not required you can

operate the unit as a fan by turning on the blower fan only

and leaving the pump turned off.

CAUTION

Do not operate the unit with pads or

!

grille removed.

CAUTION

Unplug the electrical cord to the cooler

!

before attempting to work on or service

the cooler.

CLEANING & MAINTENANCE

Periodic Drying of Pads. For best results allow pads to

dry after each operation by turning off the pump 15 minutes

before turning off the fan blower motor.

Periodic Draining of Sump. The entire water sump

should be drained at least once weekly to reduce mineral buildup. The failure to regularly drain the entire water sump will

greatly increase the mineral deposits and reduces the expected

life of the cooling pads. This could result in early replacement

of the pads at the owner’s expense. Use a damp cloth and wipe

off any mineral deposits that appear outside or inside the unit

at least once per week of use.

Lubrication. The pump and blower motors do not require

lubrication. For belt driven blower wheel models only, the

blower shaft bearings need periodic lubrication. The oil cups

on the blower shaft bearings should be filled with a good grade

SAE20W or 30W oil when necessary. Under normal use, oiling

is required every three months of operation. DO NOT OVER OIL.

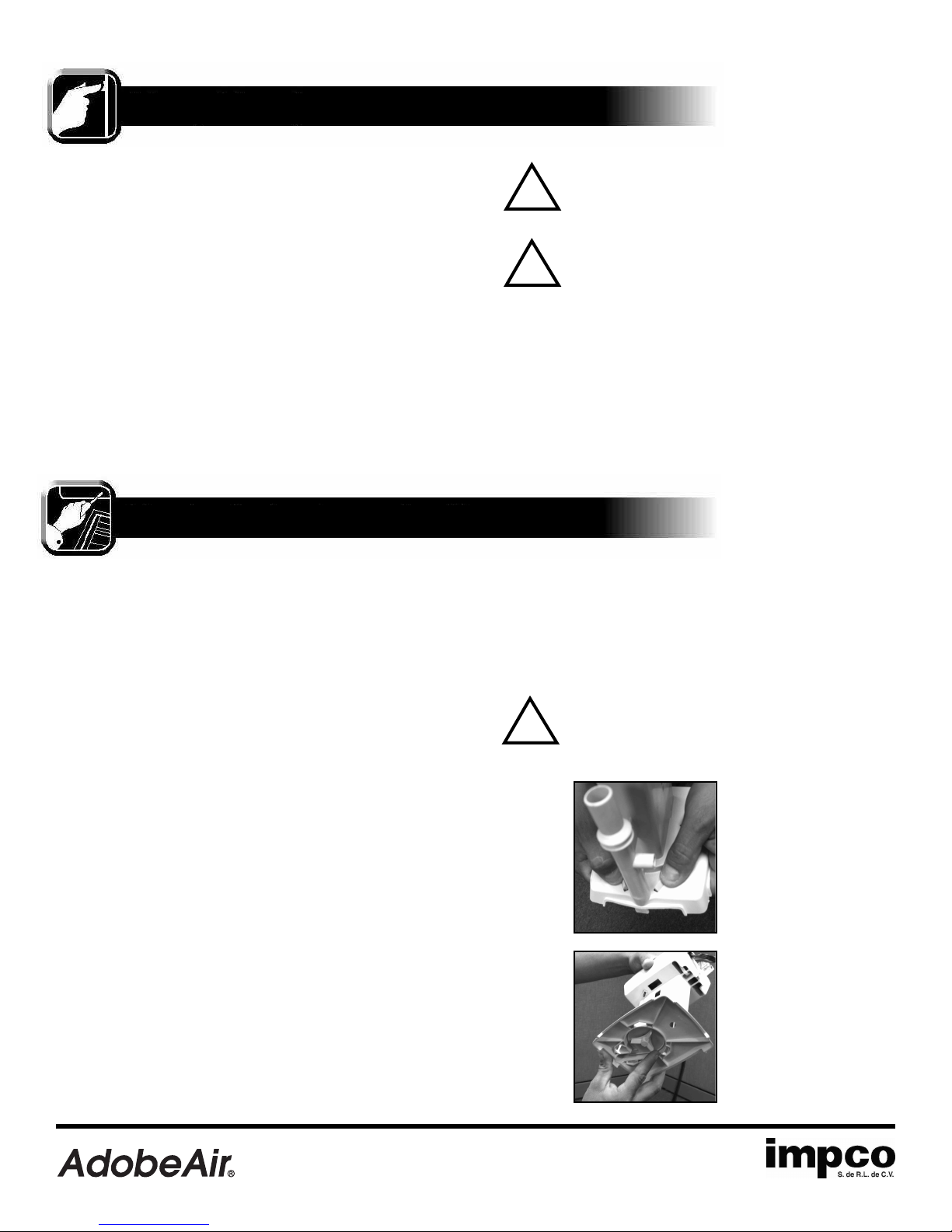

Cleaning Water Pump. (Pictures 5 and 6) Disassemble

and clean the water pump as follows.

• Use a mild detergent solution and wash all deposits from

the inside around the impeller and impeller base plate.

• Spin the impeller to dislodge any foreign material.

(Picture 6) Rinse and reinstall impeller base plate.

• Reinstall pump into the cooler.

CAUTION

Do not allow the pump to fall over and

!

become submerged in the water. Water

will damage the pump motor.

Picture 5

• Disconnect power supply to the cooler.

Access the pump by lifting the pad frames up and out of

•

the cooler. Remove pump from cooler.

• To prevent breakage, carefully release the four snap-out

tabs and lift impeller base plate from the pump body.

(Picture 5)

1450 E. Grant Street, Phoenix, Arizona U.S.A.

www.AdobeAir.com 602-257-0060

AP059719 2/2008

Picture 6

Av. Carr. Miguel Alemán #6061, Col. América, Cd. Guadalupe, Nuevo León, México, C.P. 67130

www.Impco.com.mx (81)-8144-5440

Page 5

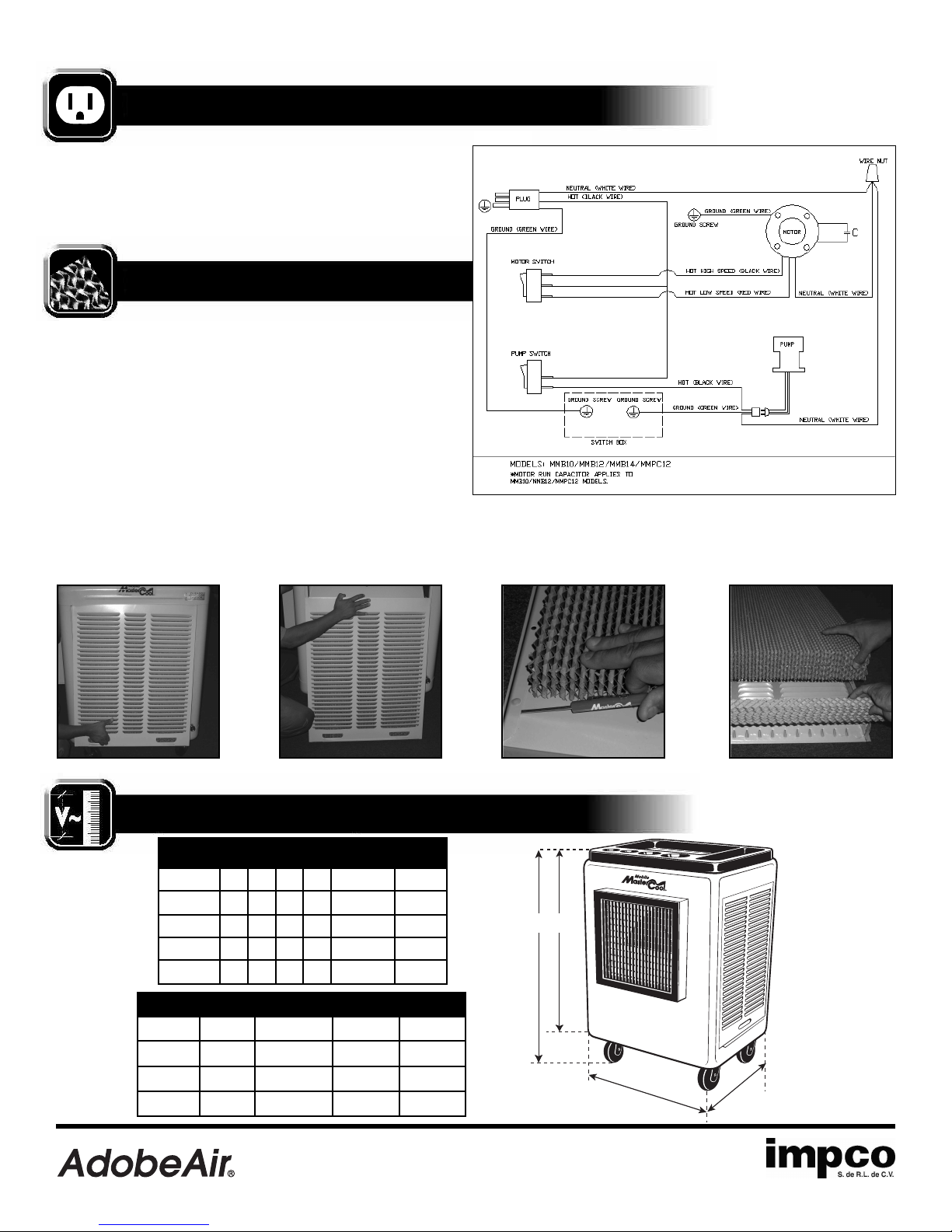

ELECTRICAL

D C

A

B

lectrical wiring on your unit is not required as the unit has

E

been wired at the factory. For your future reference, the wiring

diagram in Figure 7 shows rocker switches, two-speed motor,

capacitor and pump.

COOLING PAD REPLACEMENT

igure 7

F

4

The cooling pads should be changed at least every two years.

Check and clean them at the beginning of the season and

clean and reverse them in the middle of the season. The pads

may need to be replaced more frequently depending on local

conditions and the maintenance schedule followed.

Replacement Instructions:

To remove pad assemblies from the unit, lift up, pull out and then

down. Lay the metal side down on a flat surface and remove the

pad retainers. The MasterCool pad can now be removed. Rinse

off pad assembly, then install new MasterCool pad and retainer.

Replacement filter pads are available at your cooler dealer. See

pictures 7-10.

Picture 7

Picture 8

Picture 9

Picture 10

SPECIFICATIONS AND DIMENSIONS

Model Dimensions (in)

ABCD

MMB10 22 20 27.5 32.7 6.4 Gallons 60 lb

MMB12 26.5 25 33 38.7 7.2 Gallons 119 lb

MMB14 34 31 35.4 41 14.5Gallons 130 lb

MMPC12

Model Motor Frequency Volts Current

1450 E. Grant Street, Phoenix, Arizona U.S.A.

www.AdobeAir.com 602-257-0060

MMB10 1/8 HP 60 Hz 120 3.0 Amps

MMB12

MMB14

MMPC12 1/3 HP 60 Hz 120 5.5 Amps

26.5 26 31 35.7 7.2 Gallons 95 lb

1/3 HP 60 Hz 120 5.5 Amps

1/2 HP

60 Hz

Water Shipping

Capacity Weight

120

AP059719 2/2008

7.5 Amps

Av. Carr. Miguel Alemán #6061, Col. América, Cd. Guadalupe, Nuevo León, México, C.P. 67130

www.Impco.com.mx (81)-8144-5440

Page 6

5

TROUBLESHOOTING

The following troubleshooting guide is intended to address the most common symptoms and is by no means exhaustive. If

symptoms persist, call a qualified service provider. Only a certified electrician should complete electrical work.Turn off all power

to the cooler before attempting to troubleshoot any of the following symptoms.

SYMPTOM POSSIBLE CAUSES REMEDY

Unit fails to start or deliver air 1. No electrical power to unit 1. Check power

A. Fuse blown A. Replace fuse*

B. Circuit breaker tripped B. Reset breaker*

C. GFCI tripped C. Reset GFCI*

D. Cord(s) unplugged or damaged D. Plug in cord(s) or replace if damaged

If condition persists, call an electrician

*

2. Motor overheated (thermally protected) 2. Try to restart after cool down

3. Motor frozen

4. Motor able to free spin 4. Replace capacitor

Unit starts but air delivery is inadequate 1. Insufficient air exhaust 1. Open windows or doors

2. Insufficient water – pad not wet 2. Check water distribution system

A. Cooling pads plugged A. Clean or replace pads

B. Dry streaks on pads B. Check water level

C. Large dry spots on pads C. Make sure cooler is level

D. Pump not working D. Clean or replace pump

E. Loose water connections E. Check for leaks and correct

3. Replace motor

Water draining from cooler 1. Float arm improperly adjusted 1. Adjust float to proper level

2. Seat in float valve leaking 2. Replace float valve

3. Drain bushing not tight 3. Tighten fitting

Musty or unpleasant odor 1. Stale or stagnant water in sump 1. Drain, flush and clean sump

2. Pads mildewed or clogged 2. Replace pads

3. Pads not completely wet before 3. Turn on pump before starting fan

cooler is turned on

Knocking, shaking or rattling sounds 1. Loose parts 1. Check and tighten where needed

2. Blower wheel loose or rubbing 2. Inspect and adjust, or replace

Water droplets in the discharged air stream 1. Too much water delivered to the 1. Make sure pads are properly positioned

cooling pads in the pad frames and that the unit is level.

, reduce the flow of water to

If necessar

the pads by tightening the screw on the

hose restrictor clamp found on the pump

discharge hose.

2. Outdoor humidity level is too high 2. Use cooler as a fan only (turn pump off)

or it is raining or discontinue use of cooler until outdoor

humidity level drops.

y

NOTE

Do not use cooler cleaners, cooler treatments, or other additives in this evaporative cooler. The use

!

of any of these products will void your warranty and may impair the life of your evaporative cooler.

1450 E. Grant Street, Phoenix, Arizona U.S.A.

www.AdobeAir.com 602-257-0060

AP059719 2/2008

Av. Carr. Miguel Alemán #6061, Col. América, Cd. Guadalupe, Nuevo León, México, C.P. 67130

www.Impco.com.mx (81)-8144-5440

Page 7

WARRANTY

MODELS MMB10, MMB12, MMB14,

AND MMPC12 Mobile MasterCool

1-YEAR LIMITED WARRANTY

AdobeAir, Inc., Phoenix, Arizona, extends this limited warranty

to the original purchaser of a Mobile MasterCool Evaporative

Cooler operated under normal conditions within the continental

United States.

I. One Year Coverage applies to all components and

accessories furnished by AdobeAir. At our option, we

will exchange or repair any part which fails due to

non-conformance of material or workmanship during

the first year from the date of initial purchase.

II. What this warranty does not cover:

a. This warranty does not cover any failure or damage

resulting from unauthorized modification or service;

or from the use of products or replacement parts

other than those from AdobeAir; including, but not

limited to, motors and pumps.

b. This warranty does not cover any damage or

malfunction unless caused by a non-conformance

in material or workmanship. Damage or malfunction

which is not covered by this warranty includes, but is

not limited to, water damage to the motor, abuse,

misuse, alteration, improper installation / maintenance

/ operation, and transportation damage.

c. Mineral accumulations, dirt, and dust on the pad are

not defects and are excluded from this warranty. Refer

to the Owners’ Manual section here for maintenance

instructions to help minimize these conditions.

d. This warranty does not cover the cost of a service call

at the site of installation to diagnose cause of trouble,

the cost of labor to install the part, or mileage

allowance to or from the site. AdobeAir does not

pay freight or postage on any exchange.

This specific warranty does not cover evaporative

e.

coolers installed and operated outside the continental

United States.

6

IV. To obtain service under this warranty, contact the dealer

where you purchased your evaporative cooler. As a final

step, if you cannot locate your dealer, contact Customer

Service, AdobeAir, Inc. Include your name, address and

ZIP code, the model number and serial number of your

evaporative cooler, date of installation, and a description

of your problem.

AdobeAir

1450 E. Grant Street

Phoenix, Arizona 85034 U.S.A.

Tel: 602-257-0060

www

.AdobeAir.com

This warranty is the only warranty extended by AdobeAir to

suppliers and/or purchasers of this evaporative cooler.

AdobeAir disclaims all other warranties, express or implied,

that arise by the operation of the law, except that implied

warranties of merchantability or fitness for a particular purpose

are limited to the duration of the warranty period. AdobeAir

shall not be liable for any incidental or consequential damage

which may have resulted from any alleged breach or warranty.

Some states do not allow limitations on how long an implied

warranty lasts or the exclusion or limitation of incidental or

consequential damages, so the limitations or exclusions stated

above may not apply to you.

This warranty gives you specific legal rights and you may have

other rights, which vary from state to state.

Since AdobeAir, Inc., follows a policy of continuous product

improvement; it reserves the right to change design and

specification without prior notice or liability.

For information on the entire family of AdobeAir cooling

solutions, visit us online at www

.AdobeAir

.com.

III. Do not use cooler cleaners, cooler treatments, or other

additives in this evaporative cooler. The use of any of

these products will void your warranty and may impair

the life of your evaporative cooler.

1450 E. Grant Street, Phoenix, Arizona U.S.A.

www.AdobeAir.com 602-257-0060

AP059430 2/2008

Av. Carr. Miguel Alemán #6061, Col. América, Cd. Guadalupe, Nuevo León, México, C.P. 67130

www.Impco.com.mx (81)-8144-5440

Page 8

7

NOTES

1450 E. Grant Street, Phoenix, Arizona U.S.A.

1450 E. Grant Street, Phoenix, Arizona U.S.A.

www.AdobeAir.com 602-257-0060

www.AdobeAir.com 602-257-0060

AP059430 2/2008

Av. Carr. Miguel Alemán #6061, Col. América, Cd. Guadalupe, Nuevo León, México, C.P. 67130

Av. Carr. Miguel Alemán #6061, Col. América, Cd. Guadalupe, Nuevo León, México, C.P. 67130

www.Impco.com.mx (81)-8144-5440

www.Impco.com.mx (81)-8144-5440

Page 9

MANUAL DE OPERACIÓN

8

INTRODUCCIO´N

El enfriamiento evaporativo funciona bajo el principio de

absorción de calor por medio de evaporación de la humedad.

En otras palabras, el calor es removido del aire cuando el agua

se evapora. Usted lo puede experimentar cuando sale de una

alberca o de la regadera y siente inmediatamente frío cuando el

agua se evapora de la superficie de su piel.

Su enfriador evaporativo trabaja bajo el mismo principio.

El aire caliente exterior es jalado a través de filtros

!

Para reducir el riesgo de descarga eléctrica,

fuego o lesiones:

ADVERTENCIAS Y REGLAS DE SEGURIDAD

• Lea las instrucciones y las etiquetas cuidadosamente.

• Siempre desconecte el cable eléctrico de su enfriador

de aire antes de trabajar en él.

• Su enfriador de aire trabaja únicamente con

corriente alterna de 120 V~ 60 Hz 1 Fase

saturados de agua, donde el aire se enfría por evaporación

para después salir del enfriador de aire hacia su habitación.

ara lograr que su enfriador funcione de manera eficiente,

P

debe asegurarse que esté tomando aire del exterior, y de

siempre mantener una ventana o puerta entreabiertas para

que el aire fluya libremente.

Otros Productos de Impco

MMB8

• Conecte el aparato únicamente a una toma de corriente

eléctrica haciendo tierra con tres espigas.

• No lo opere si el tomacorriente o el cable están dañados

de alguna forma.

• No pise o aplaste el cable de corriente con objetos

pesados o afilados.

• No opere la unidad a menos que todos los paneles estén

bien asegurados en su lugar.

• Desconecte el tomacorriente de la toma de corriente

jalando el enchufe y no el cable.

• Pruebe el cable tomacorriente o el interruptor mensualmente, para asegurar su funcionamiento adecuado.

No opere el enfriador cer

•

contengan líquidos o gases inflamables.

• Nunca lave el gabinete de su enfriador de aire con el

chorro directo de una manguera de jardín; el agua puede

dañar al motor y la bomba.

• Si la unidad se daña o no funciona, consulte la sección

de resolución de problemas. Para hacer válida su

garantía, llame al 01(81) 81445400 ó al 01(800)

8317700 en Monterrey, N.L., México.

ca de recipientes abiertos que

P12

P700

Enfria Capacida Motor

Hasta (m2) de Agua (C.F.)

MMB8 46 17 litros 1/8

P700 46 10 litros 1/12

P10 65 23 litros 1/8

P12 93 45 litros 1/3

.impco.com.mx

www

P10

1450 E. Grant Street, Phoenix, Arizona U.S.A.

www.AdobeAir.com 602-257-0060

AP059430 2/2008

Av. Carr. Miguel Alemán #6061, Col. América, Cd. Guadalupe, Nuevo León, México, C.P. 67130

www.Impco.com.mx (81)-8144-5440

Page 10

9

INSTRUCCIONES DE INSTALACIÓN

Desempacando la unidad Mobile MasterCool.

La unidad está empacada con la charola de plástico moldeado sin

colocar. Retire la charola de plástico de la caja de cartón y después

saque el enfriador de aire de la caja de cartón.

Instalación de la Rejilla. Antes de operar su nuevo cooler

Mobile MasterCool, debe completar la instalación de la rejilla al

gabinete.

PRECAUCIÓN: Maneje con cuidado la rejilla,

ésta podría tener las orillas filosas o alguna

!

rebaba.

Usando las cuatro pijas hexagonales y las rondanas estriadas

(incluidas en la bolsa de accesorios), fije la rejilla al gabinete

apretando las pijas a los orificios marcados en el gabinete. No

apriete en exceso. Vela la ilustración 5.

Instalando las ruedas. Algunos modelos se empacan con las

ruedas colocadas en la base del gabinete. Si las ruedas no están

colocadas, busque las ruedas dentro del enfriador de aire y atorníllelas a la base del gabinete con los tornillos que se incluyen.

Revise la tensión de la

banda.

corresponde solamente a los

modelos que se mueven por

medio de una banda. Revise la

tensión de la banda (Figura 4)

empujándola hacia abajo. Si la

banda tiene la tensión adecuada

ésta bajará entre 1/2” y 3/4”.

Para ajustar la tensión de la

banda, afloje el tornillo en la

ranura del soporte del motor,

ajústela a la tensión adecuada,

y apriete el tornillo.

Esta instrucción

HERRAMIENTAS REQUERIDAS

ARA LA INSTALACIÓN

P

• Llave española de 3/8˝

• Llave se estrías de 3/8˝

• Perica ajustable de 6˝

• Desarmador #2

• Llave de Ojo ó Desarmador de

Caja de 7/16

Figura 1

Colocando la charola de plástico. Retire los marcos laterales

de los paneles del enfriador de aire levantándolos hacia arriba y hacia

afuera del gabinete del enfriador de aire. Encuentre la bolsa de partes

adentro del enfriador de aire y atornille la parte superior de la charola

con los tornillos y las tuercas que se incluyen.

Instalando la boquilla y el tapón de drenado.

Si aún no está conectada, remítase a la Figura 1 e instale la boquilla y

el tapón de drenado a través del orificio que se encuentra en la base

del enfriador de aire.

Instalando la válvula y el adaptador del flotador.

Remítase a la Figura 2 e inserte el flotador en la pata lateral del

enfriador de aire usando el orificio suministrado. El adaptador de

manguera de jardín se conecta a la toma de bronce ajustándose a la

válvula del flotador. Verifique que los empaques de la manguera estén

adecuadamente colocados en su lugar.

Conectando el agua. Mueva el enfriador de aire a un área donde

pueda ser llenado de agua y drenado. El enfriador de aire deberá

colocarse en un piso nivelado. Conéctelo a una fuente de agua usando

una manguera de jardín de grado comer

cliente) conectada al adaptador en la válvula del flotador

llave del agua. Verifique que las conexiones de agua sellen bien

examinando visualmente tanto a la conexión del flotador / manguera

como a la boquilla de drenado.

cial (suministrada por el

, y abra la

PRECAUCIÓN:

La presión de la toma de agua no debe de ser

!

mayor a 0,588 MPa, o menor 0,392 MPa, ó se

deberá instalar un regulador de presión en la

línea.

Figura 2

Fotografia 1

Figura 3

Fotografia 2

Figura 4

Ajustando el nivel del agua.

altura del agua como se muestra, ajustando al flotador

1450 E. Grant Street, Phoenix, Arizona U.S.A.

www.AdobeAir.com 602-257-0060

Remítase a la Figura 3 y ajuste la

.

AP059430 2/2008

Fotografia 3

Figura 5

Av. Carr. Miguel Alemán #6061, Col. América, Cd. Guadalupe, Nuevo León, México, C.P. 67130

www.Impco.com.mx (81)-8144-5440

Page 11

UBICACIÓN DEL ENFRIADOR DE AIRE

Asegúrese de que la unidad sea operada en una superficie

nivelada. Cuando use el enfriador de aire en el interior, la mejor

ubicación para el enfriador es cerca de una ventana o puerta

arcialmente abierta donde pueda jalar aire caliente del exterior

p

hacia adentro de la unidad. El enfriador Mobile MasterCool es

portátil, pero tenga cuidado cuando ruede la unidad, para evitar

que riegue o derrame agua. El aire frío se puede dirigir mejor a

través del espacio, usando una ventana o puerta parcialmente

abiertas, idealmente una que esté situada en el lado opuesto

INSTRUCCIONES DE OPERACIÓN

1. Si su modelo tiene ruedas con seguros, asegúrese de que

las dos ruedas con seguros estén bloqueadas para evitar

que el enfriador de aire se mueva antes de encender el

ventilador.

2. Abra la llave del agua del enfriador de aire. La conexión de

la manguera a la válvula del flotador proporciona un método

automático de rellenar el suministro de agua a medida que

ésta se evapora.

del espacio del enfriador de aire. Esto permite que el aire fresco circule por el espacio y sea sacado nuevamente al exterior,

lo que es una condición crítica para la adecuada operación del

nfriador de aire.

e

PRECAUCIÓN

Desconecte el cable de corriente

!

eléctrica del enfriador de aire antes de

darle servicio o empezar a trabajar en él.

PRECAUCIÓN

No opere la unidad cuando la rejilla o

!

los paneles hayan sido removidos.

10

3. Para mejores resultados, encienda la bomba unos minutos

antes de encender el ventilador. Esto permite que los

paneles de enfriamiento se mojen previamente para mayor

eficiencia.

4. Siempre que sea posible opere el ventilador a velocidad

baja para obtener el máximo enfriamiento. Cuando no se

requiere enfriamiento de aire, puede operar la unidad sólo

como ventilador, sencillamente encendiendo el ventilador y

dejando apagada la bomba.

MANTENIMIENTO REGULAR

Secado Periódico de los Paneles. Para mejores resul-

tados, permita que los paneles se sequen después de cada

operación, apagando la bomba 15 minutos antes de apagar el

motor del ventilador.

Vaciado Periódico del Depósito de Agua. El depósito

de agua deberá vaciarse completamente cuando menos una

vez por semana para reducir la acumulación de sales min

erales. Si no se vacía completa y regularmente el depósito de

agua, se acumularán demasiados depósitos de sales minerales

y se reducirá la vida esperada de los paneles de enfriamiento.

Como consecuencia de esto, deberá reemplazar más seguido

dichos paneles a expensas del propietario. Use un trapo húme

-

do y limpie cualquier depósito de minerales que aparezcan en

el exterior o interior de la unidad, por lo menos una vez por

semana cuando lo esté usando.

Lubricación. Los motores de la bomba y del ventilador

no requieren lubricación. Sólo en el caso de los modelos de

rueda de ventilador movida por banda, los baleros del eje del

ventilador necesitan lubricación periódica. Los depósitos del

aceite de los baleros del eje del ventilador deberán llenarse con

un aceite de buena calidad de especificación SAE20W ó 30W

siempre que sea necesario. En condiciones de uso normal,

se requiere llenar de aceite cada tres meses de operación.

-

NO LLENE DE MÁS EL DEPÓSITO DEL ACEITE.

1450 E. Grant Street, Phoenix, Arizona U.S.A.

www.AdobeAir.com 602-257-0060

AP059430 2/2008

Av. Carr. Miguel Alemán #6061, Col. América, Cd. Guadalupe, Nuevo León, México, C.P. 67130

www.Impco.com.mx (81)-8144-5440

Page 12

1

1

Limpieza de la Bomba de Agua. Vea las fotos 5 y 6.

esarme y limpie la bomba de agua de la siguiente manera.

D

• Desconecte el cable de corriente eléctrica del enfriador

e aire.

d

• Llegue a la bomba levantando hacia arriba y hacia afuera

os marcos de los paneles del enfriador de aire. Saque la

l

bomba del enfriador de aire.

• Para evitar que se rompa, con cuidado suelte las cuatro

lengüetas de desprendimiento rápido y levante la placa de

la base del impulsor del cuerpo de la bomba.

• Usando una solución de detergente suave, lave todos los

depósitos del interior alrededor del impulsor y de la placa

de la base del impulsor.

• Gire el impulsor para expulsar cualquier material extraño.

Enjuague y reinstale la placa de la base del impulsor.

• Reinstale la bomba en el enfriador de aire.

PRECAUCIÓN

No permita que la bomba se caiga y se

!

sumerja en el agua. El agua daña el motor

de la bomba.

Fotografia 5

Fotografia 6

Eléctrico

No se requiere cableado eléctrico en su unidad, ya que la

unidad ya viene cableada de la fábrica. Para referencia futura,

el diagrama eléctrico de la Figura 7, muestra los interruptores,

el motor de dos velocidades, el capacitor y la bomba.

Nota: El capacitor solo

aplica para modelos MMB10

y MMB12

Nota: Si el cordón de

alimentación es dañado, éste

debe ser reemplazado por el

fabricante o su agente de

vicio o por personal

ser

calificado para evitar el

riesgo.

1450 E. Grant Street, Phoenix, Arizona U.S.A.

www.AdobeAir.com 602-257-0060

AP059430 2/2008

Figura 7

Av. Carr. Miguel Alemán #6061, Col. América, Cd. Guadalupe, Nuevo León, México, C.P. 67130

www.Impco.com.mx (81)-8144-5440

Page 13

REEMPLAZO DE LOS FILTROS

D C

A

B

Los paneles de enfriamiento deben reemplazarse por lo menos

una vez cada dos años. Revíselos y límpielos al principio de la

emporada y voltéelos a media temporada. Puede ser necesario

t

reemplazar los paneles con mayor frecuencia, dependiendo de

las condiciones locales y del programa de mantenimiento que

se siga.

Reemplazo de los Filtros:

Remueva las paredes, jalando hacia arriba, hacia afuera y

entonces hacia abajo. Coloque el lado metal de la pared hacia

bajo sobre una superficie plana y retire los soportes del filtro

a

y el filtro usado. Limpie las cavidades de la pared e instale un

nuevo filtro.

Pregunte por nuestros Distribuidores de Partes Originales.

12

Fotografia 7

Fotografia 8

ESPECIFICACIONES Y DIMENSIONES

Modelo Motor Frecuenc Tensión Corriente

MMB10 1/8 C.F. 60 Hz 120 V~ 3,0 A

MMB12 1/3 C.F. 60 Hz 120 V~ 5,5 A

MMB14 1/2 C.F. 60 Hz 120 V~ 7,5 A

MMPC12

Modelo Dimensiones (cm)

MMB10 56 51 70 84 24.2 L 27.3 Kg

1/3 C.F. 60 Hz 120 V~ 5,5 A

Cap.

de Agua

ABCD

Peso

Fotografia 9

Fotografia 10

MMB12 67.3 63.5 84 98.5 27.4 L 54 Kg

MMB14

86.3

79

104 54.5 L 59 Kg

90

MMPC12 67 66 79 91 27.4 L 43 Kg

1450 E. Grant Street, Phoenix, Arizona U.S.A.

www.AdobeAir.com 602-257-0060

AP059430 2/2008

Av. Carr. Miguel Alemán #6061, Col. América, Cd. Guadalupe, Nuevo León, México, C.P. 67130

www.Impco.com.mx (81)-8144-5440

Page 14

13

SOLUCIÓN DE PROBLEMAS

a siguiente guía de Solución de Problemas se elaboró con la intención de abarcar los síntomas más comunes, y no se pretende

L

que sea exhaustiva. Si el síntoma persiste, llame a un técnico calificado de servicio. Solamente un electricista certifcado puede

realizar el trabajo eléctrico. Apague todos los interruptores del enfriador de aire antes de intentar solucionar los problemas de

cualquiera de los siguientes síntomas.

SÍNTOMA CAUSAS POSIBLES REMEDIO

La unidad no arranca o no echa aire 1. No le llega corriente eléctrica a la unidad 1. Revise la corriente eléctrica

A. Fusible fundido A. Reemplace el fusible*

B. Interruptor de corriente botado B. Reprograme/reconecte el interruptor de

corriente*

C. Interruptor botado C. Reprograme/reconecte el interruptor de

corriente.

D. Cable/s desconectado/s o dañado/s D. Conecte el/los cable/s o reemplácelo/s si

está/n dañado/s

*Si la condición persiste, llame a un electricista

2. El motor se sobrecalentó 2. Trate de encenderlo después de que se enfríe

(protegido termalmente)

3. El motor se congeló 3. Reemplace el motor

4. El motor puede girar libremente 4. Reemplace el capacitor

La unidad arranca pero la salida de aire no es 2. Agua insuficiente – filtro seco 2. Revise el sistema de distribución

la adecuadaa A. Filtros tapados de enfriamiento filtros A. Limpie o remplace los filtros

B. Rayas secas en los filtros B. Revise el nivel del agua

C. Grandes manchas secas en los filtros C. Asegúrese de que el enfriador esté nivelado

D. No trabaja la bomba D. Limpie o remplace la bomba

E. Conexiones flojas de agua E. Revise para detectar fugas y corríjalas

Agua drenándose del enfriador 1. Brazo del flotador mal ajustado 1. Ajuste el brazo del flotador al nivel adecuado

2. Fugas en el asiento de la válvula del flotador 2. Reemplace la válvula del flotador

3. Boquilla/tapón de drenado flojos 3. Apriete el accesorio y/o el tapón

Olor desagradable o a humedad 1. Agua estancada o vieja en el depósito de agua 1. Vacíe, descargue y limpie el depósito de agua

2. Filtros mohosos o tapados 2. Remplace los filtros

3. Filtros parcialmente secos antes

de encender el enfriador de aire

Golpeteos, sacudidas, traqueteo 1. Partes sueltas 1. Revise y apriete donde se necesite

2. La turbina está suelta o rozando 2. Inspeccione y ajuste, o reemplace

Gotitas de agua en la corrientede

de descarga de aire

1. Demasiada agua suministrada al filtro

2. Nivel de humedad exterior muy alto o está

lloviendo si está lloviendo deje de usar el enfriador de aire

3. Encienda la bomba antes de encender el ventilad

1. Asegúrese de que los filtros estén colocados

correctamente en sus marcos, y que la unidad

esté nivelada. Si fuese necesario, reduzca el flujo

de agua a los paneles apretando el tornillo de la

abrazadera de la manguera de descarga de la

bomba

2. Sólo use el enfriador de aire (apague la bomba),

hasta que baje el nivel de humedad en el exterior

No use limpiadores para enfriadores de aire, tratamientos para enfriadores de aire, ni otros aditivos en este

enfriador evaporativo. El uso de cualquiera de estos productos invalidará su garantía y puede afectar la vida

de su enfriador de aire por evaporación.

1450 E. Grant Street, Phoenix, Arizona U.S.A.

www.AdobeAir.com 602-257-0060

AP059430 2/2008

ATENCION

Av. Carr. Miguel Alemán #6061, Col. América, Cd. Guadalupe, Nuevo León, México, C.P. 67130

www.Impco.com.mx (81)-8144-5440

Page 15

PÓLIZA DE GARANTÍA

14

IMPCO, S. DE R.L. DE C.V. Garantiza al comprador y usuario

riginal del enfriador identificado en la presente y en los térmi-

o

nos que aquí se mencionan exclusivamente lo siguiente:

Conceptos Cubiertos por la Garantía

Defectos de fabricación que impiden total o parcialmente el

funcionamiento del enfriador, que se presenten dentro del

término de vigencia de esta garantía. En este caso, la

reparación será sin costo alguno para el comprador. Si se

requiere el reemplazo de alguno de los componentes o del

enfriador así mismo correrá por cuenta del otorgante.

Términos

Esta garantía tiene una vigencia de: 12 MESES a partir de la

fecha de compra, excepto filtros.

ESTA GARANTÍA SE INVALIDA EN LOS SIGUIENTES CASOS:

1. Cuando el producto haya sido utilizado en condiciones

distintas a las normales.

2. Si el producto no ha sido operado conforme a las

recomendaciones en este instructivo.

3. Si se ha tratado de reparar parcial o totalmente el producto

por personal no autorizado por la empresa.

Procedimiento para Hacer Efectiva la Garantía

Esta garantía queda sin efecto cuando el cliente no cuenta con la

documentación que acredite a la unidad dentro del período de

garantía, o cuando personas o establecimientos no autorizados

intervengan en la reparación o reemplazo de algunos de sus

componentes.

Modelo: ____________________________________________

__________________________________________________

__________________________________________________

Fecha de compra: ____________________________________

__________________________________________________

__________________________________________________

Lugar de compra: ____________________________________

__________________________________________________

__________________________________________________

Para solicitar asistencia técnica de la unidad,

servicios de garantía o refacciones originales llame:

En Monterrey: 01(81)-8144-5440

Sin cargo para usted, Servicio Nacional a Clientes:

01-800-831-7700

Impco, S. de R.L. de C.V.

Carretera Miguel Alemán #6061 Col. América,

Guadalupe Nuevo León, Mexico

Tel: (01) 81- 81445400

www.impco.com.mx

e-mail: ventas@impco.com.mx

El modelo y el número de serie del aparato se localiza en una

etiqueta colocada en la parte posterior del gabinete. Durante la

vigencia de esta póliza, nos comprometemos a efectuar, sin

cargo, la reparación de su aparato en un plazo no mayor de

30 días.

1450 E. Grant Street, Phoenix, Arizona U.S.A.

www.AdobeAir.com 602-257-0060

AP059430 2/2008

OMOM-MKT/MMC-062007

Av. Carr. Miguel Alemán #6061, Col. América, Cd. Guadalupe, Nuevo León, México, C.P. 67130

www.Impco.com.mx (81)-8144-5440

Page 16

1450 E. Grant Street, Phoenix, Arizona U.S.A.

www.AdobeAir.com 602-257-0060

AP059430 2/2008

Av. Carr. Miguel Alemán #6061, Col. América, Cd. Guadalupe, Nuevo León, México, C.P. 67130

www.Impco.com.mx (81)-8144-5440

Loading...

Loading...