Page 1

INSTALLATION AND OPERATING MANUAL

MANUAL DE INSTALACIÓN Y FUNCIONAMIENTO

with

MCP SERIES

MCP44, MCP44E & MCP59

con Funciones de Control Mejoradas

SLIM-LINE

EVAPORATIVE

WINDOW COOLER

LÍNEA DELGADA ENFRIADOR DE VENTANA

Read and Keep this document for future reference.

Access this manual online at www.championcooler.com

Leer y Guardar este documento para consultarlo en el futuro.

Puede acceder a este manual en línea en www.championcooler.com

Enhanced Control Features

Serial number / Número de serie:

72968 -201

Page 2

MasterCool® MCP Series Evaporative Window Cooler

Installation and Operating Manual

Congratulations on your purchase of the MasterCool® MCP Series plastic evaporative cooler. This unit is manufactured with

the intent of offering you years of reliable, ef¿ cient cooling.

NOTE: READ THESE INSTRUCTIONS BEFORE INSTALLING THE COOLER. Follow the installation instructions in

this manual carefully. Varying from them may create safety concerns and will void the warranty.

Safety Instructions

1. Use only with 110V 60 Hz single phase grounded outlet.

2. Ensure cooler is turned OFF and UNPLUGGED before installing, servicing or cleaning the unit.

3 . Do not operate unit with damaged cord or plug, or with any other damaged or missing parts.

4 . Do not run cord under carpeting. Do not cover cord with throw rugs, runners, or similar coverings.

Do not route cord under furniture or appliances. Arrange cord away from traf¿ c area and where it will

not be tripped over.

5. Do not operate cooler with the rear media guard removed.

6. Do not use an extension cord to operate cooler.

7. Do not use an adapter to convert the three pin connector for use in an ungrounded 2 prong outlet.

8. Do not use with a solid state speed control device. Violation of this could cause ¿ re or electrical shock.

9. Do not alter or modify this cooler.

10. Repairs or replacement of electrical components should only be carried out by quali¿ ed electricians.

11. Do not allow children to install, service, or operate the cooler.

12. This fan cannot be used as an exhaust fan in a kitchen, and must be a minimum of 3 feet from open À ame.

Table of Contents

Safety Instructions ........................................................................................................................................................2

Note About Evaporative Coolers .................................................................................................................................... 3

Features of the MasterCool

Installation Procedures .................................................................................................................................................. 4

Cooler Assembly ................................................................................................................................................... 4

Installation in Window ............................................................................................................................................4

Installation in Wall .................................................................................................................................................. 5

Water Connections ......................................................................................................................................................... 6

Water Pump ............................................................................................................................................................. 6

Water Line Connections .......................................................................................................................................... 6

OverÀ ow Drain ........................................................................................................................................................ 7

Water Level ............................................................................................................................................................. 7

Electrical System ............................................................................................................................................................ 7

Operating Instructions .................................................................................................................................................... 8

Optional Installations / Accessories ................................................................................................................................ 8

Optional Purge Pump .............................................................................................................................................. 8

Programming Purge Pump .............................................................................................................................. 9

Optional MasterLink

Optional Plug-in Thermostat Usage ........................................................................................................................9

Servicing Instructions .....................................................................................................................................................10

Annual Maintenance ...............................................................................................................................................10

Winterization ..........................................................................................................................................................12

Troubleshooting ..............................................................................................................................................................12

Cooler Diagram and Parts List ......................................................................................................................................13

Warranty ........................................................................................................................................................................14

Español Manual… ..........................................................................................................................................................15

®

MCP Series Window Cooler ........................................................................................... 3

TM

Thermostat / Remote ...........................................................................................................9

2

Page 3

NOTE: Evaporative coolers

WILL NOT

work in a Closed Room

EXHAUST

NOTE ABOUT EVAPORATIVE COOLERS

For this cooler to effectively cool

a whole house there must be open

windows or doors in each room

where cooling is desired.

EXHAUST

Door or window should

be open 4 to 6 inches

NOTE: Evaporative coolers

Water bleed or purge:

Evaporative Coolers require a continuous supply of water

to keep the media saturated for maximum cooling. Water

pumped into the cooler must be removed from the unit to

ensure mineral and bacteria build-up do not occur. This can

occur with a gravity-fed steady bleed off stream or a timed

purge system via a pump. A purge pump kit (MCP44-PPK)

is available at www.championcooler.com or at 800.643.8341

to order. See pages 8 and 9 for more details on purge pump

operation.

WILL NOT

work in a Closed Room

Ventilation:

Unlike traditional air conditioners, evaporative coolers require

an open ventilation system, not a closed system. Both a fresh

air source and an exhaust opening are required to provide

correct air À ow. Typically, a partially opened window or door in

each room where cooling is desired will create correct airÀ ow

for optimum effectiveness of an evaporative cooler. Alternately,

attic ventilation ducts such as UP-DUX

p

rovide sufficient air movement without requiring open window

NOTE: For best results, open windows/doors should

not be on the windward side on the house.

CAUTION: Water expelled from the cooler must be

routed away from any areas that could do damage to

foundations or other vulnerable areas.

NOTE: Drawings in this manual are for illustrative

purposes only and may reÀ ect slight differences

depending on design level and con¿ guration.

®

can be installed to

s.

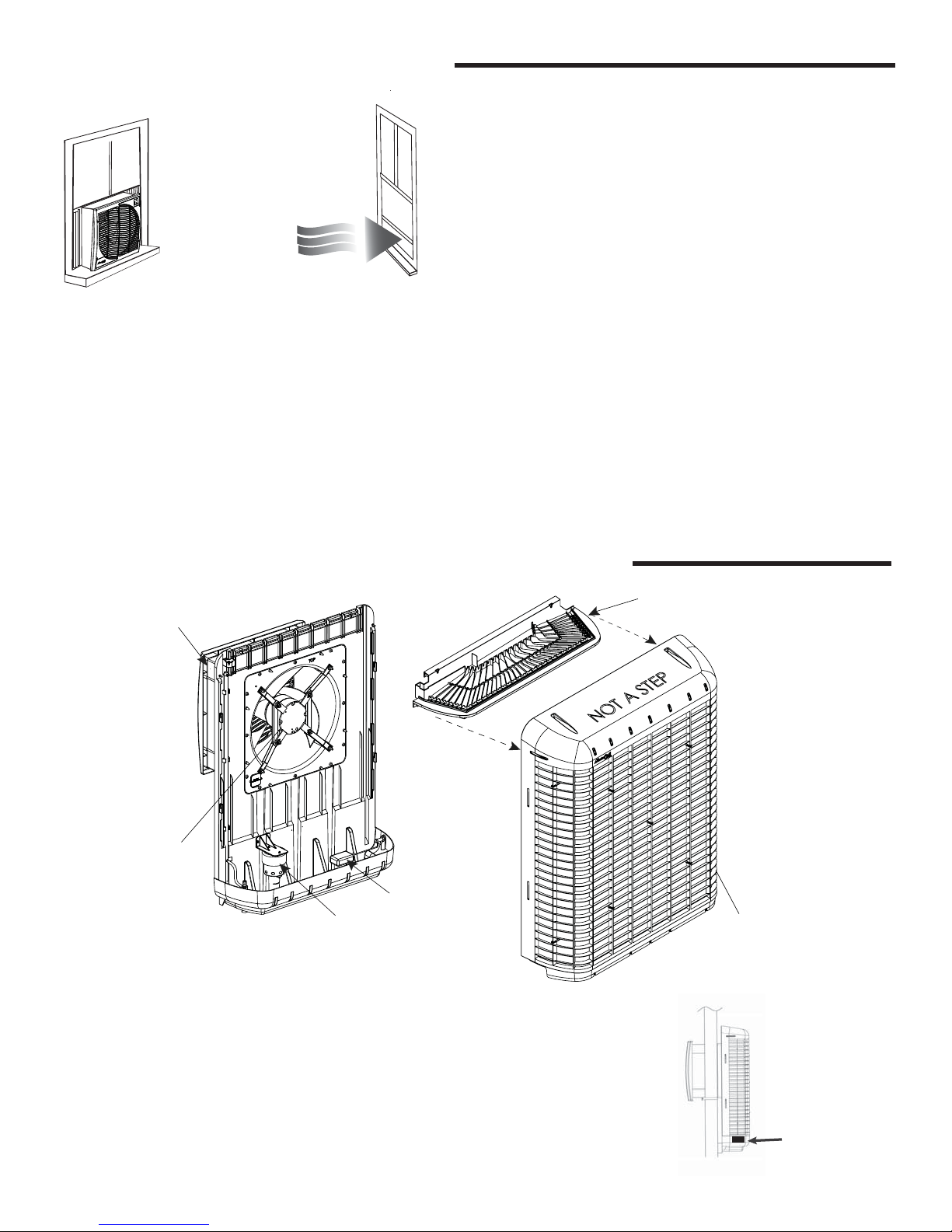

FEATURES OF THE MASTERCOOL® MCP SERIES WINDOW

FAN HOUSING

WITH REMOVABLE

FASCIA

FAN MOTOR

FLOAT

WATER PUMP

COOLER

WATER DISTRIBUTION TRAY

EXTERIOR PORTION

MEDIA GUARD

This cooler’s housing and frame are made of heavy-duty

Ultra-Violet resistant plastic to provide a light weight, easily installable cooler. The unit is constructed in two basic sections

to facilitate quick installation into traditional sash windows or

slider windows.

The high-ef¿ ciency rigid media offers superior cooling over

other types of evaporative coolers.

NOTE: Before installing

unit, take a moment to

record the serial number

and write it on the manual

cover in the space provided.

3

SERIAL NUMBER

ON RIGHT HAND

SIDE OF UNIT.

Page 4

INSTALLATION PROCEDURES

WARNING: Do not connect electrical power to the unit

until the installation is completed.

The MasterCool MCP Series cooler can be installed in a

sash-style or a slider- style window.

Alternatively, this unit is approved for in-wall installations.

In all installations, the following clearances are required:

Width: 22”; Height: 22” ; 4” clearance above the exterior

cabinet is needed for maintenance.

Parts Included:

• Cooler Unit

• Mounting brackets (4)

• Accordion spacers (2) Hardware kit

Tools & Materials Required:

• Drill (power or cordless)

• Assorted drill bits (for drilling pilot holes for mounting

hardware)

• Adjustable Wrench

• Phillips Head Screwdriver

• Silicone or all-weather caulk for sealing in¿ ll panel to

window frame

• Length of ¼” copper or plastic tubing

• Sill-cock valve

• Bubble level

• Spacer material (as required)

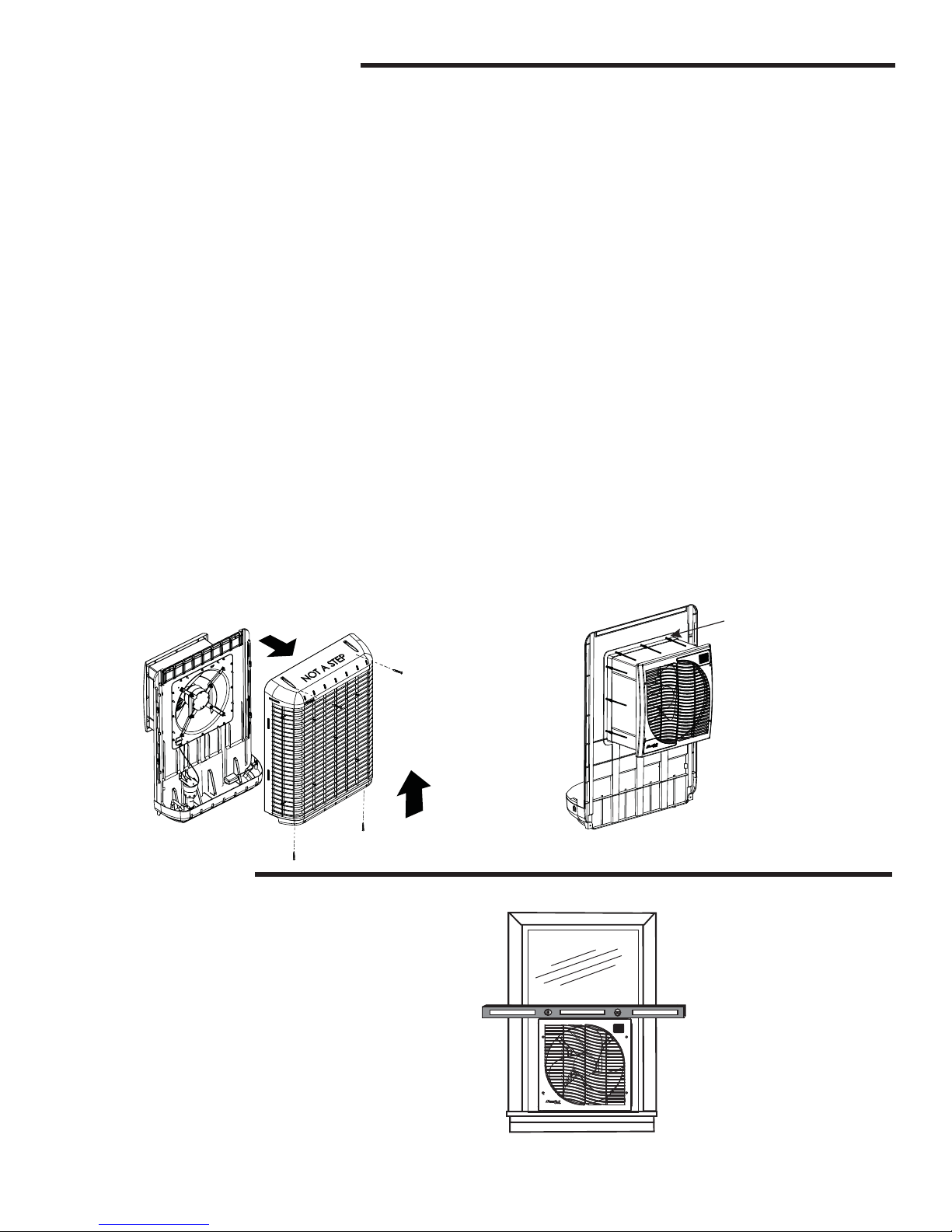

OPEN UNIT UP SECURE FAN HOUSING

Cooler Assembly

1. Remove unit from box. Verify that all parts are included.

2. Remove all packing materials.

CALL 1-800-643-8341 IF YOU FIND PARTS

MISSING OR HAVE ANY QUESTIONS

3. With the unit in an upright position, remove 4 screws

holding the back media guard, and separate the front and

back sections. Pull the fan assembly forward (about 6”)

until it is fully engaged with the mating part and secure in

place using the 12 supplied screws.

4. Verify that assembly is secure to prevent vibration between the two sections.

NOTE: Ensure the location selected for installing the

unit is strong enough to support the unit and will accept the mounting hardware. The operating weight of

the cooler is 93 pounds.

NOTE:

installation.

A minimum of two people is required for

3. PULL BACK GUARD

AWAY FROM UNIT

1. REMOVE 4 SCREWS FROM

BACK MEDIA GUARD

2. PUSH UP ON BACK GUARD

Installation in Window

1. Remove screen (as needed) and make sure window is

opened to its maximum height. From the exterior of the

window, slide the fan assembly section into the window.

Have the person on the interior adjust the exact placement of the unit for aesthetics and correct lengths of the

two accordion spacers (included).

Note: After identifying the position for installation,

place a bubble level on top of the unit and make adjustments to ensure the unit will be level when installation is complete. It is recommended to verify unit is

level at various points during installation.

EXTEND HOUSING AND

ATTACH IT TO

COOLER BODY FRONT

WITH 12 SCREWS

3. From the interior, locate

the two tracks on the

bottom of the fan assembly. Drill pilot holes as

necessary and install the

two window sill brackets

as shown in illustration on

following page.

2. Closing the window may help hold the unit in place during

the following steps – Push the unit into the window until

the bottom is À ush with the outside wall or spacer (not

supplied) as shown in the illustration.

4

Page 5

Installation in Window (continued)

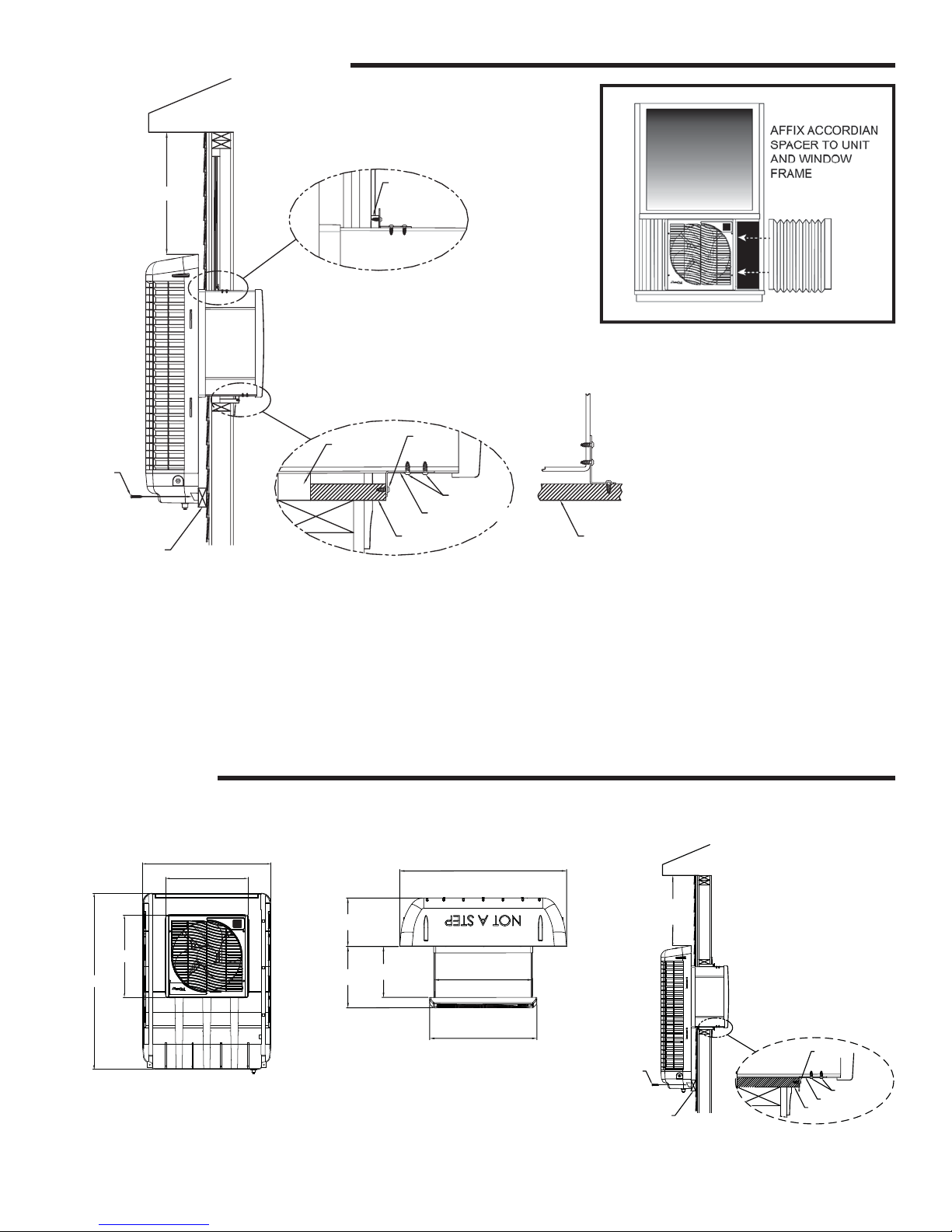

4" MINIMUM

SCREWS

SPACER TO ENSURE

FLUSH/SQUARE

INSTALLATION

(NOT SUPPLIED)

2 PLACES - MINIMUM 14" APART

WINDOW

WINDOW

SCREW

WINDOW SILL BRACKET

WINDOW SILL

4. Secure the top of the fan housing to the window frame

with two additional brackets and screws.

5. From the outside, secure the unit to the exterior wall (or

spacer) with two screws at the base of the back cover

(as shown in illustration.) Complete the installation of

the exterior portion with two screws at the top of the back

media guard.

SCREWS

WINDOW SILL

OPTIONAL MOUNTING

6.

With the unit now installed in the window, attach one ac

accordion spacer to each side of the fan assembly using

the adhesive backed edges. Short screws(not included)

can be used for a more secure installation. (Make sure

screws do not interfere with fan blade.)

7. Once accordion spacers are installed, seal any gaps

around the units with silicone or all weather caulk (not

supplied).

Installation in Wall

This cooler is approved for in-wall installation. Contact a licensed contractor to have the cooler installed in an outside wall.

5

"

33

/

8

215/

8

"

215/

8

"

1

"

/

8

46

FRONT VIEW

12

9 3/

33 5/

8

"

4

"

5

3

/

8

"

10

/

16

"

19 13/

16

"

21 5/

8

"

TOP VIEW

SPACER TO ENSURE

FLUSH/SQUARE

(NOT SUPPLIED)

4" MINIMUM

SCREWS

INSTALLATION

SCREW

SCREWS

SILL BRACKET

SILL PLATE

5

Page 6

T

WATER CONNECTIONS

Steady water supply is required for operation of the cooler. If taking

water from an external faucet, there are two options for attaching

water to the cooler.

Option 1:

Using a standard water hose to supply water:

1. Remove the nut and ferrule that secures the À oat ¿ tting in the

unit at the attach point.

2. Take the brass ¿ tting enclosed in the parts bag and attach

one end to the À oat valve and the other end to the water hose.

Option 2:

Install a sill-cock onto faucet to facilitate a dedicated water line to

the cooler.

SCREWS

DIRECTLY

ONTO END OF

WATER HOSE

SCREWS DIRECTLY

ONTO FLOAT VALVE

1. Install a standard sill-cock (locally available) with water

valve onto the faucet and connect the water supply to the

cooler.

2. Install plastic or copper line to sill-cock and connect it to the

À oat valve.

FLOAT VALVE

WATER LINE

ATTACH POIN

Water Pump

A self-contained water pump continuously circulates water through the

water distribution system and over the media.

The pump and water lines are shipped disconnected.

MAIN

WATER

LINE

JUNCTION

PUMP

(STRAINER NETTING

NOT SHOWN

OVERFLOW

DRAIN

FITTING

REMOVE NIPPLE FROM

TUBE BEFORE FEEDING

IT INTO DRAIN OVERFLOW.

REINSTALL NIPPLE INTO

OVERFLOW LINE

(AFTER

INSERTING

LINE THROUGH

OVERFLOW

FITTING)

PUMP

INLET

FOR CLARITY)

SHUT OFF VALVE

PLASTIC OR

COPPER LINE

TO COOLER

STD. HOSE CONNECTION

SILL-COCK

Water Line Connections

1. Locate the black water line snapped into plastic

keepers inside the unit.

2. Attach the bottom end of the main water line to the

pump inlet.

3. Remove the nipple inserted into the end of the

overÀ ow line. Push overÀ ow hose into one of the

slots in the sides of the overÀ ow drain ¿ tting.

4. Reinsert the nipple into the overÀ ow line.

5. Attach the top of the hose to the water distribution

tray.

6. Ensure there are no kinks in the water lines after

completion.

NIPPLE

6

Page 7

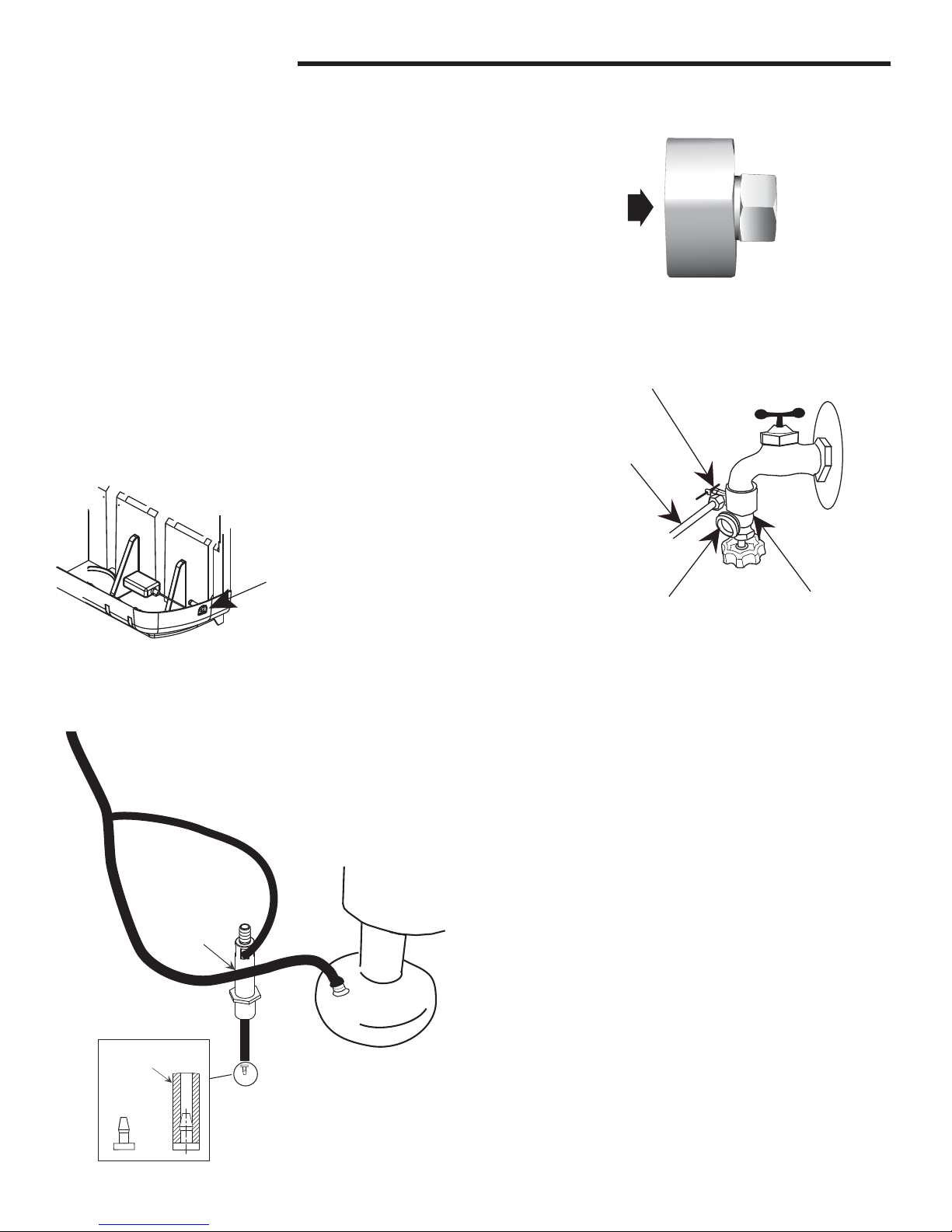

WATER CONNECTIONS (CONT’D)

OverÀ ow Drain

1. Slide the rubber washer over the overÀ ow ¿ tting and push

through the hole in the bottom of the cooler from the top

side.

2. Secure the drain from beneath the pan with the Lock Nut.

3. Make sure the rubber washer does not twist while tightening, which could cause it to leak. DO NOT OVER TIGHTEN.

LOCATION

OF DRAIN

4. If leakage occurs after reservoir is full, re-tighten the overÀ ow ¿ tting until leaking stops. A small amount of silicone

caulk may be used if necessary.

tach a drain hose to the bottom of the ¿ tting if neces-

5. At

sary.

Water Level

Two inches of water should be maintained in the bottom of

the cooler to ensure suf¿ cient water for correct operation of

the cooler.

2˝

WATER LEVEL

The À oat is factory-installed to maintain a 2 inch level of

water, but may require adjustment if shipping or installation

has caused the setting to shift.

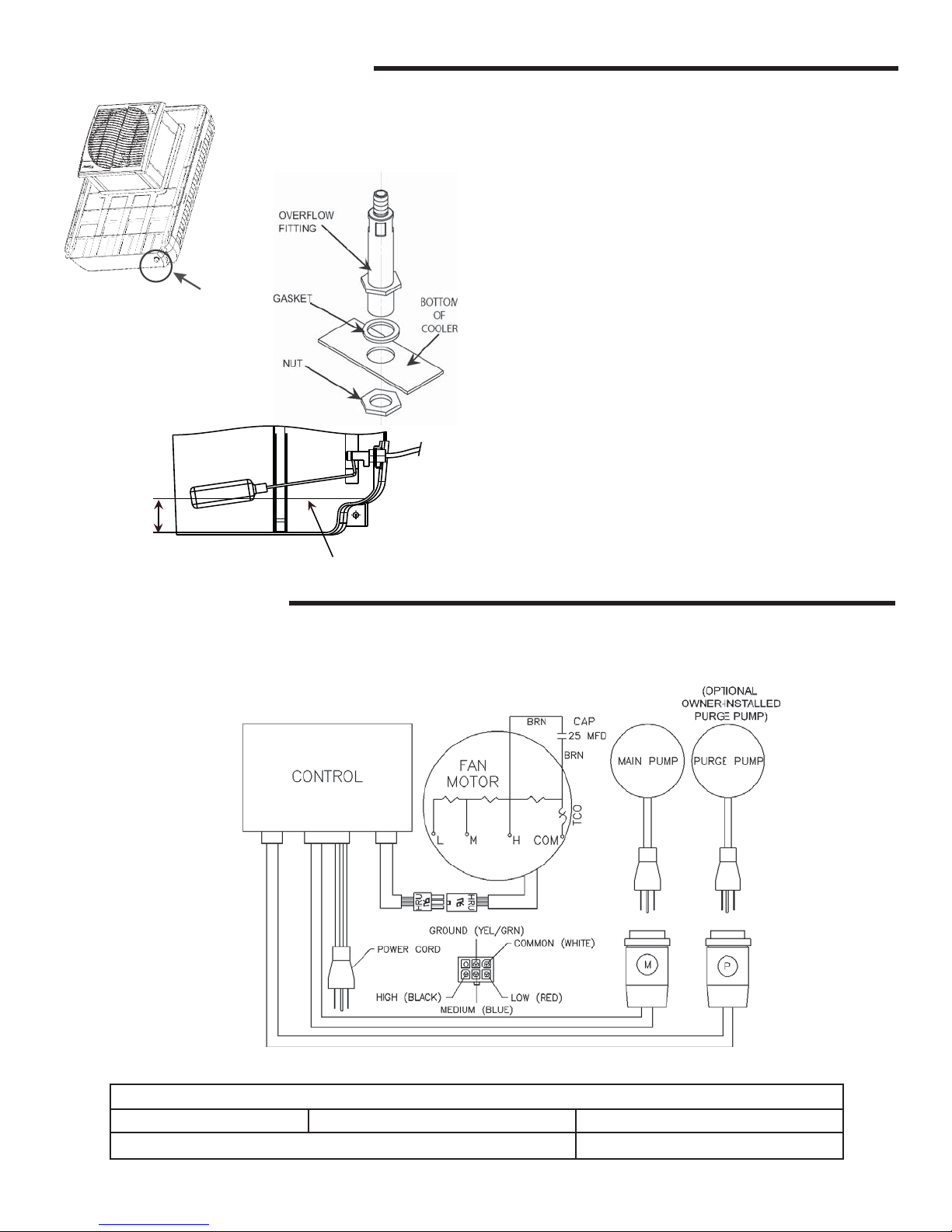

ELECTRICAL SYSTEM

The electrical system does not require general maintenance. The following wiring diagram is supplied for reference only.

ELECTRICAL SPECIFICATIONS OF MCP SERIES COOLERS

MCP Series Fan Motor 120 V, 2.8 amps Main Pump 120 V; 0.9 amps

If optional Purge Pump is installed Additional 0.9 amps

7

Page 8

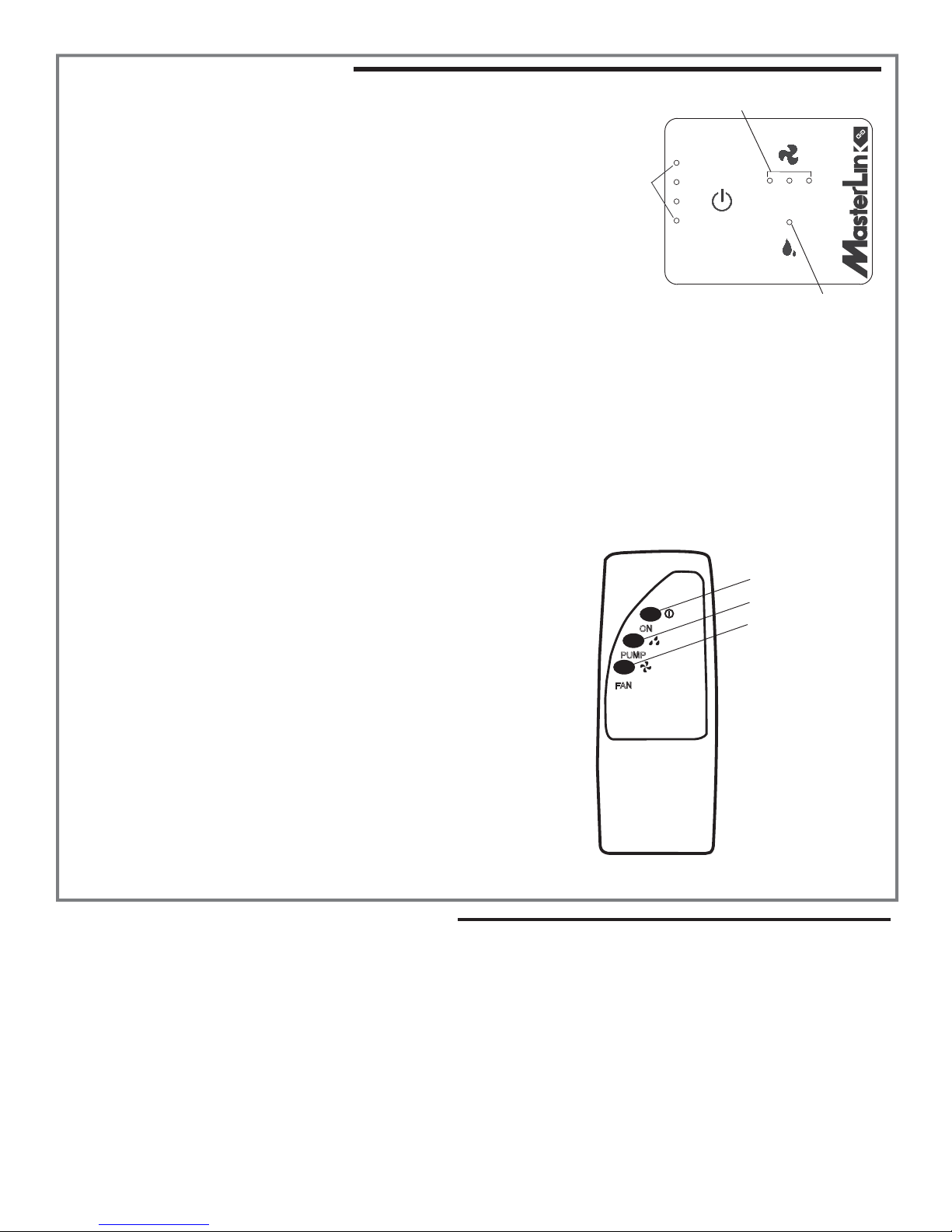

OPERATING INSTRUCTIONS

The MCP Series of Coolers has an electronic touch control panel in the

upper right hand corner.

Before turning unit on, ensure unit is plugged in, water supply to pump is

on, and there is correct ventilation, as shown on page 3 of this manual.

Note:

The MCP series coolers is controlled by the 3 buttons on

the front panel of the cooler or with the remote control

.

Purge Pump

Programming

Indicator lights

Fan Speed Indicator Lights

FAN

HI

M

ED LO

POWER

On/Off

This button initiates power to the unit. When ¿ rst plugged, pressing ON/

OFF and will start the unit in the default setting (pump ON and Fan on

HIGH). After its initial use, the last operating settings (for fan and pump)

will be reinstated when the unit is turned on again.

Pressing this button when the unit is already running will turn both fan and pump off.

After A Power Failure: Once power is restored, the unit will restart in the same settings as before power was lost.

PUMP

Pump Power Indicator

Pump

This button toggles the pump on and off. When the LED is lit, the pump is running.

The pump must be on while operating the fan for the unit to operate as an evaporative cooler, though the unit can be

used in fan mode without the pump, if desired.

Note: For best results turn on the pump for a few minutes to wet the pads

before operating the fan.

Fan

Pressing the fan button cycles the unit from HIGH, to MEDIUM to LOW

speeds and then OFF.

Please Note: There is a two second delay from the pressing of the button

for the fan to engage or change speeds. This applies to the front control

panel and the remote control.

ON

PUMP

FAN

Unit Power ON/OFF

Pump ON/OFF

Fan Speed (1-3)

Remote Control

The remote control supplied with this cooler allows you to turn the unit

on or off, control fan speed and initiate the pump. The buttons operate

i

n the same manner as those on the front control panel.

The remote control’s range is approximately 20 feet within sight

of the cooler. It uses two AA alkaline batteries (included). A wall

mountable holder is also supplied with the remote.

OPTIONAL INSTALLATIONS/ ACCESSORIES

Optional Purge Pump

In addition to the standard water pump to recirculate water

from the reservoir, a purge pump can be installed to evacuate

the contents of the reservoir on a scheduled basis.

reduce bacterial growth and mineral buildup on the media, extending its life.

It also maintains fresher air in the home.

The use of the purge pump saves water and is actually more

economical, than continual bleed. The purge pump kit (P/N

MCP44-PPK) for this unit may be purchased locally or online

at www.championcooler, or by phone at 1.800.643.8341.

This helps

Purge Pump Discharge: The water ejected at the time of

purging will be expelled at a high rate of speed, and must

be routed away from the foundation of the home or other

areas where rushing water could do damage.

1. Attach a standard water hose to the overÀ ow drain to

direct the water away from the house.

NOTE: This water is not potable, but can be used for watering vegetable or À ower gardens.

8

Page 9

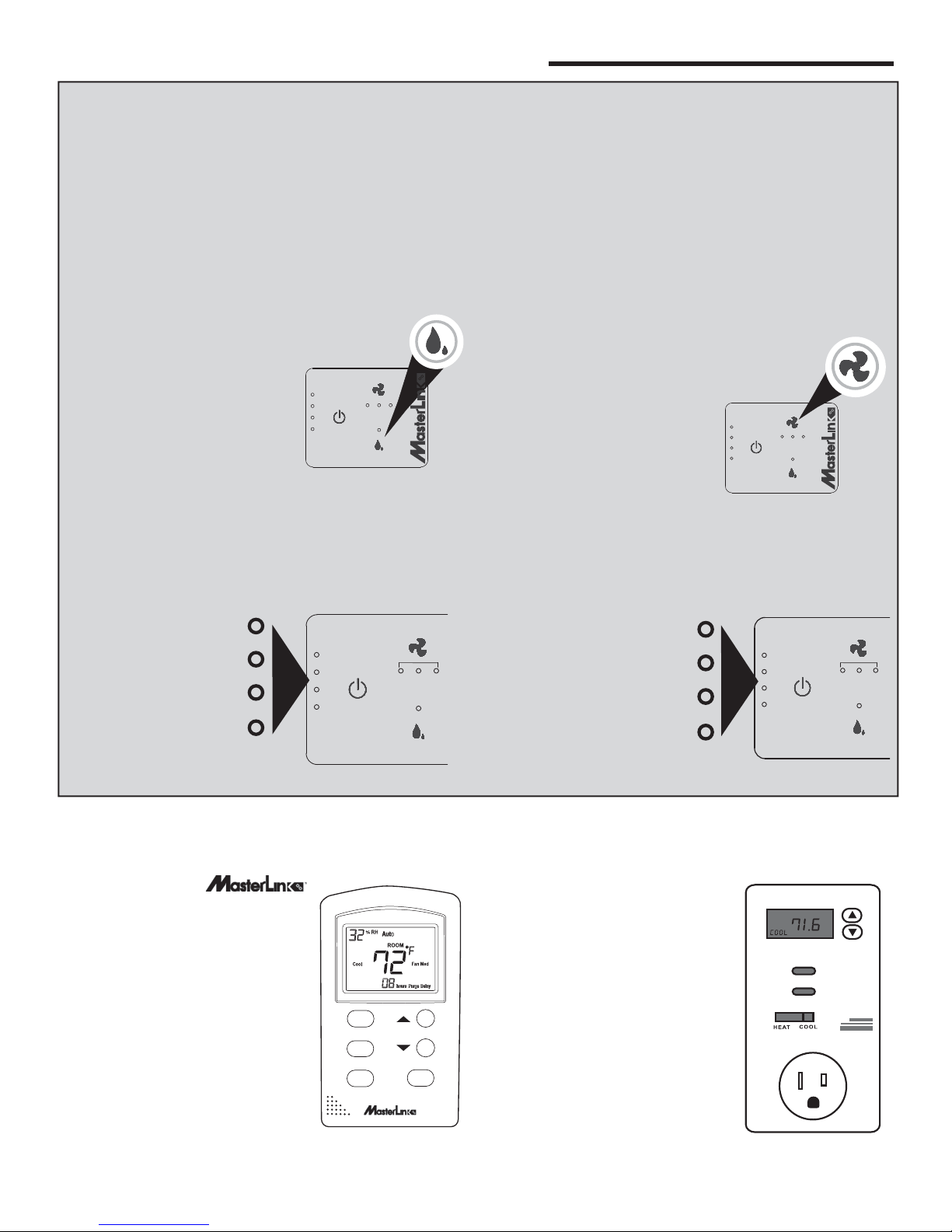

P

OPTIONAL INSTALLATIONS / ACCESSORIES (CON’T)

PROGRAMMING PURGE PUMP

NOTE: When in Purge Set Up Mode, you will not affect the fan speed or main water pump operation.

Once a purge pump has been installed and plugged

into the cooler, the purging cycle can be programmed

from the control panel:

The default setting for the purge pump is 1 minute of

purge every 24 hours. This setting can be changed to

increase interval and duration of purges as needed.

order to enter the programming

In

mode of the control panel hold

down the PUMP touch point for

¿ ve (5) seconds.

At this point the Purge Interval

PRESS AND

HOLD 5

SECONDS

PUM

FAN

can be set. Four lights on the

HI

M

left side illuminate.

purge every 24 hours.

one

This indicates

POWER

ED LO

PUMP

To change the number of hours between purges,

press PUMP again until the desired schedule is selected. The options for purge interval are 24,12, 8 and 6

hours. The lights decrease by one each time the Pump

button is pressed. Note the legend of intervals listed

below.

NOTE: Depending on the amount of minerals in

the local water, it may be advantageous to increase the purges to extend the life of the media

and the unit.

After the number of hours in the Purge Interval has

been set, you may select the duration of the purge.

Options are from 1 to 4 minutes that the water will be

expelled.

Press the FAN touch point

to enter the Purge Duration

setting feature.

PRESS TO

SET PURGE

DURATION

FAN

The four lights on the left side

POWER

FAN

HI

M

ED LO

PUMP

,

will begin blinking indicating 4

minutes of purging. Press the

PUMP touch point to change

the setting from 4 to 3 minutes,

then 2 or 1 minute duration.

To save and exit the Duration portion of the programming

press and hold the FAN touch point for 5 seconds.

NOTE: If no touch-point is pressed within 10 seconds, the program will automatically exit the set up

mode and retain previous settings.

4 LIGHTS = EVERY 24 HOURS

3 LIGHTS = EVERY 12 HOURS

2 LIGHTS = EVERY 8 HOURS

1 LIGHT = EVERY 6 HOURS

Optional MasterLink

TM

Thermostat

(Available in 2017)

MasterCool® MCP Series coolers

manufactured with the

logo on the control panel will be

compatible with the MasterLink

Thermostat, sold separately. The

thermostat will have a smart phone

app that allows wireless control over

the cooler. This thermostat controls

standard and advanced features,

such as purge pump control and

timer function.

Refer to the MasterLink

TM

owner’s manual for instructions on

how to control and program the MCP

Series coolers using this item.

TM

Thermostat

POWER

Fan

Pump

Mode

HI

FAN

M

ED LO

PUMP

Timer

4 LIGHTS BLINKING = 4 MINUTES

3 LIGHTS BLINKING = 3 MINUTES

2 LIGHTS BLINKING = 2 MINUTES

1 LIGHT BLINKING = 1 MINUTE

Optional Plug-In Thermostat Usage

The MCP Series also can be controlled by a plug-in programmable

thermostat, such as the LUX brand

WIN 100. These thermostats

are locally available, and enable

precise timing and temperature

control

that plugs into a 110 volt outlet. To

use such a device with the MCP

series cooler, follow the instructions

for the speci¿ c thermostat and plug

the cooler into the outlet on the

thermostat.

NOTE: Illustration is for reference

only, models and features vary by

model and manufacturer.

via an electronic thermostat

POWER

HI

FAN

M

ED LO

PUMP

9

Page 10

SERVICING INSTRUCTIONS

Maintenance on evaporative coolers is minimal,

but very important to the proper operation and

effectiveness of your cooler. Periodic inspection

of the cooler’s interior will reduce the potential for

substandard cooling due to insuf¿ cient or uneven

water distribution.

NOTE: For general maintenance purposes, the unit

may be rapidly drained of water by removing the

overÀ ow ¿ tting from the bottom of the unit. This is not

adequate draining for winterization (see procedures

under Winterization section.)

1. Remove the back media guard (as shown below).

2. Inspect pads in place. Remove media pads from back

guard by unscrewing the media peg clips. Be careful not

to chip or damage the media while removing. Visually

inspect both sides of media pads. Look for blockage,

mineral build-up or mildew growth, breakage or other

anomalies.

3. Wash pads with a garden hose. Do not use a pressure

washer.

4. Check water distributor for blockage or excessive buildup

of dust.

Annual Maintenance

(May be Needed More Often in Areas with Hard Water)

Cleaning

WARNING: Disconnect from electrical power and turn

unit off during all maintenance. Turn water supply off

before removing back for cleaning or maintenance.

CAUTION: In order to maintain UV resistance, do not

use abrasive cleaners on the exterior of the cooler

body.

d

. PULL BACK GUARD

c

. DISCONNECT WATER

SUPPLY HOSE

NOTE: Whenever

the back is removed

from the cooler,

always verify the

water supply tube is

reconnected to the

water distribution

tray before operating

the cooler.

AWAY FROM UNIT

OPTIONAL

OWNER-INSTALLED

PURGE PUMP

5. Set media in a safe place until all maintenance is complet

e.

6. Wash out reservoir thoroughly using a soft bristle brush.

Use plenty of water to remove algae growth. Clean areas

around pump, strainer and À oat to ensure no algae

growth remains.

CAUTION: Do not use harsh chemicals (like chlorine

bleach) to clean the interior portions of the cooler.

7. Rinse thoroughly after using any cleaning solutions on

the interior or exterior of the unit.

a

. REMOVE 4 SCREWS FROM

BACK MEDIA GUARD

b

. PUSH UP ON BACK GUARD

LOCATE MEDIA PEGS AND REMOVE.

USING PLIERS,

PULL PLUGS

OUT FROM THE

EXTERIOR.

10

OR PULL CLIPS

OFF PEGS FROM

THE INTERIOR.

Page 11

Annual Maintenance (Con’t)

Water System Pump:

1. The water pump is a self-contained unit that should require no maintenance other than ensuring that no debris

or corrosion interferes with free movement of the parts.

2. Ensure hose connection to pump is in good condition.

Water Float:

3. The À oat level is factory set for optimum performance,

however moderate adjustments can be made by bending

the À oat arm for a different water level.

4. The maximum recommen

ded water level is approximately

two inches (the height of the overÀ ow ori¿ ce.)

Water Distributor

5. Inspect the water distribution section to ensure all ori¿ ces

are clear.

6. Verify the hose connections are in good order and no

kinks or tears are present.

Water Drain OverÀ ow

7. Unscrew the drain overÀ ow pipe and check the condition

of the gasket at the bottom of the ¿ xture. When reinstall-

ing, ensure the standpipe ¿ xture is secure and there is no

leakage after the reservoir is ¿ lled.

WATER

FLOAT

WATER

SYSTEM

PUMP

WATER

DISTRIBUTOR

NOTE: If during usage of the cooler you start noticing low saturation of pads and insuf¿ cient cooling, or

leakage from the cooler, check the gasket at the base

of the standpipe. This is the most likely cause of leakage on this unit.

Optional Water Purge Pump (if installed)

8. If a purge pump has been installed on the MCP Series,

check that the purge pump and strainer are corrosion-free with freely moving parts.

OPTIONAL

PURGE PUMP

(OWNER INSTALLED)

Media Pad Replacement

9. When the media pads have become encased with mineral buildup, broken or damaged, replace them with Genuine Munters GreenGuard Celdek

model MCP44-PAD. You may purchase them on-line at

www.championcooler.com or by calling 1.800. 643.8341.

®

replacement pads,

11

Page 12

Winterization

The MCP Series cooler is durable enough to be left installed

during the winter, though a few precautions must be taken to

ensure no water freezes in the unit or lines.

If the temperatures in your area drop well below freezing it

may be wise to remove the water supply line from the

outside faucet.

Draining

1. Turn the water supply to the cooler off.

2. Turn off and unplug cooler. Remove 4 screws securing

the back media guard and access interior of unit.

3. Soak up any remaining water and ensure all water is

drained from both the water pump and purge pump

(if installed).

4. Disconnect and drain the water hoses and water

distributor.

When Optional owner-installed purge pump is installed:

1. Turn off the water supply to the cooler.

2. Turn off and unplug cooler.

3. Remove four screws securing the back media guard and

access the interior of the unit.

4. Soak up any remaining water and ensure all water is

drained from both the water pump and the purge pump.

5. Disconnect and drain the water hoses and water distributor

6. Replace the media guard.

Covering

1. An optional weatherproof exterior ¿ tted cover, model

MCP44-EC is available for purchase on line at www.

championcooler.com, at retail outlets or by calling

1.800.643.8341.

a. Use the elastic corners and straps to secure the

cover onto the back of the unit.

2. An optional interior grille cover, model MCP44-IC

(Included with MCP44E) to keep air from entering the

home through the window is available at www.championcooler.com, a retail outlet or by calling 1.800.643.8341.

a. Use the snap on clips molded into the cover to

secure the cover to the grille.

.

TROUBLE SHOOTING CHART

PROBLEM PROBABLE CAUSE SOLUTION

Unit will not start a. No Power

b. Tripped Circuit Breaker

c. Blown home fuse

d. Electrical fault

Insuf¿ cient Cooling a. Inadequate water distribution (pads not

saturated)

b. Pads dirty or covered with mineral

deposits

Water in air stream a. Water system has leaks or loose

connections

b. Water is not being absorbed by media

pads, and entering straight into airÀ ow

High indoor humidity a. Insuf¿ cient air À ow

b. Unsatisfactory exhaust

Odor in home a. Occurs initially when pads are ¿ rst

saturated

b. Bacterial growth in reservoir

c. Air intake is picking up ambient odor

from surroundings

Rapid mineral buildup on

media pads

a. Hard water a. Install purge pump to reduce build-up.

12

a. Verify unit plugged in; and outlet is functional

b. Reset Circuit Breaker

c. Replace home fuse

d. Call Champion Help line: 1.800.643.8341

a. Check water distribution tray and hose for

blockages.

- Verify pump operating correctly

- Check water supply for correct À ow

b. Wash dirt & deposits off pads or replace pads

a. Check all water connections, tubing, distribu-

tion tray for loose ¿ ttings, leakage or tears.

b. Check condition of pads. Clean or replace as

necessary.

a. Increase fan speed

b. Open doors or windows more

a. Normal. Will dissipate shortly.

b. Clean unit regularly

c. Remove source of odor or move cooler to

another window

b. Increase maintenance cycle and wash off

scale more often. Check ori¿ ces are clear of

mineral buildup.

Page 13

COOLER DIAGRAM AND PARTS LIST

19

(2 ea.)

17

20

16

12

18

(4 ea.)

15

13

14

2

4

5

1

6

3

7

OPTIONAL ACCESSORIES

22

PURGE PUMP KIT

24

23

11

8

Kit includes full set

of media, pegs

and keepers

PAD REPLACEMENT KIT

10

(OPTIONAL

OWNER INSTALLED

PURGE PUMP)

MCP44 (1 pump)

9

ON

PUMP

FAN

CHAMPION / ESSICK AIR

EXTERIOR COVER

21

INTERIOR COVER

(INCLUDED ON MCP44E)

25

AVAILABLE IN 2017

26

REMOTE

THERMOSTAT

ITEM DESCRIPTION PART NUMBER

1 Cooler Back/Media Guard 72243

2 Set of 4 screws for attaching back guard 72303

Back Media Pad; 2” X 24” X 35.5” Munters GreenGuard certi¿ ed CelDek

3

72244

4 Side Media Pad; 2” X 5.88” X 35.5” CelDek (2 ea.) 72245

5 Water distributor tray 72249

6 Tray cap 72250

7 Media Peg Clip; window cooler; PP (9 ea.) 72246

8 Media Peg; window cooler; PP (9 ea.) 72247

9 Pump assy. – Main water system 72402

10 MCP Series Water Distribution Hose assy. 72256

11 Float valve 72290

12 Cooler body front 72242

13 Receptacle cover 72407

14 Fan motor 72428

15 Fan Blade 72253

16 Fan Housing 72251

17 Grille 72257

18 Grille screw caps 72260

19 Control module

72

20 Vinyl accordion window panel (2 ea.) 72284

21 Remote control (IR- included with unit)

72302

OPTIONAL ACCESSORIES - Available for Purchase · Call 1.800.643.8341

22 Purge Pump Kit MCP44-PPK

23 Pad Replacement Kit

24 Exterior Cover

25 Interior Grille Cover

26 Remote Thermostat - AVAILABLE IN 2017

MCP44-PAD

MCP-EC

MCP-IC

ML-THERM

13

Page 14

MASTERCOOL MCP SERIES COOLER

ONE YEAR LIMITED WARRANTY

SALES RECEIPT REQUIRED AS PROOF OF PURCHASE FOR ALL WARRANTY CLAIMS.

This warranty is extended only to the original purchaser of this evaporaƟ ve cooler when the unit is installed and used under

normal condiƟ ons against defects in workmanship and materials as follows:

• One (1) year from date of sale on the unit, and

• Five (5) years on the evaporaƟ ve media, which is considered a disposable component and should be replaced

periodically, and

• Two (2) years on motor.

The manufacturer will replace the defecƟ ve part/product, at its discreƟ on, with return freight paid by the manufacturer. It is

agreed that such replacement is the exclusive remedy available from the manufacturer and that TO THE MAXIMUM EXTENT

PERMITTED BY LAW, THE MANUFACTURER IS NOT RESPONSIBLE FOR DAMAGES OF ANY KIND, INCLUDING INCIDENTAL AND

CONSEQUENTIAL DAMAGE OR LOSS OF PROFITS OR REVENUES.

Some states do not allow limitaƟ ons on how long an implied warranty lasts, so the above limitaƟ ons may not apply to you.

Exclusions from this warranty

We are not responsible for any incidental or consequenƟ al damage from any malfuncƟ on, accident, misuse, alteraƟ ons,

unauthorized repairs, abuse, including failure to perform reasonable maintenance, normal wear and tear, nor where the

connected voltage is more than 5% above the nameplate voltage.

AlteraƟ ons include the subsƟ tuƟ on of name brand components including, but not limited to media pads.

We are not responsible for any damage from the use of water soŌ eners or treatments, chemicals or descaling materials.

We are not responsible for the cost of service calls to diagnose the cause of trouble, or labor charge to repair and/or replace

parts.

No employee, agent, dealer or other person is authorized to give any warranƟ es or condiƟ ons on behalf of the manufacturer.

The customer shall be responsible for all labor costs incurred.

Some states do not allow the exclusion or limitaƟ on of incidental or consequenƟ al damages, so the above limitaƟ ons or

exclusions may not apply to you.

How to obtain service under this warranty

Within the limitaƟ ons of this warranty, purchaser with inoperaƟ ve units should contact the dealer where you purchased the

cooler. If for any reason you are not saƟ sĮ ed with the response from the dealer, contact Customer Service at 800-643-8341

for instrucƟ ons on how to obtain service within warranty as listed above.

This warranty gives the customer speciĮ c legal rights, and you may also have other rights which vary from province to

province, or state to state.

Register your product at www.championcooler.com.

MasterCool® by Champion Cooler

5800 Murray St.

Little Rock, AR 72209

800.643.8341

www.championcooler.com

14

Page 15

Enfriador Evaporativo de Ventana del MasterCool® MCP Serie

Instrucciones de uso e instalación

Felicitaciones por haber comprado el enfriador evaporativo plástico MasterCool® MCP Serie.

Esta unidad se fabricó con el propósito de brindarle un enfriamiento con¿ able y e¿ ciente durante años.

NOTA: LEA ESTAS INSTRUCCIONES ANTES DE INSTALAR EL ENFRIADOR. Siga atentamente las instrucciones de instalación de este manual. En caso contrario, podrían ocasionarse problemas relacionados con la seguridad y invalidar la garantía.

Instrucciones de seguridad

1. Use la unidad únicamente con un tomacorriente monofásico con conexión a tierra de 110 V y 60 Hz.

2. Asegúrese de que el enfriador esté APAGADO y DESENCHUFADO antes de realizar la instalación, el mantenimiento

o la limpieza de la unidad.

3. No opere la unidad con un cable o enchufe dañado ni con otras piezas dañadas o faltantes.

4. No haga funcionar el cable debajo de la alfombra. No cubra el cable con alfombras, alfombrillas o revestimientos similares. No cable de ruta debajo de los muebles o electrodomésticos. Coloque el cable lejos del área de trá¿ co y donde

no se pueda tropezar.

5. No opere el enfriador con la protección posterior del medio extraída.

6. No utilice un cable prolongador para operar el enfriador.

7. No use un adaptador para convertir el conector de tres clavijas para utilizar en un tomacorriente sin conexión a tierra

de 2 espigas.

8. NO lo use con un dispositivo de control de velocidad de estado sólido. Si lo hace, podría ocasionar un incendio o

descarga eléctrica.

9. No altere ni modi¿ que este enfriador.

10. Los componentes eléctricos deben ser reparados o reemplazados únicamente por electricistas cali¿ cados.

11. No permita que niños operen o realicen la instalación o el mantenimiento del enfriador.

12. Este ventilador no se puede utilizar como un extractor de aire en la cocina, y debe tener un mínimo de 3 pies de la

llama abierta.

Índice

Instrucciones de seguridad .................................................................................................................................................... 15

Nota acerca de los enfriadores evaporativo: ..........................................................................................................................16

Funciones del enfriador de ventana MasterCool

Procedimientos de instalación ................................................................................................................................................17

Montaje del enfriador .............................................................................................................................................................17

Instalación en ventana ...........................................................................................................................................................18

Instalación empotrada ............................................................................................................................................................18

Conexión de agua ..................................................................................................................................................................19

Bomba de agua ...................................................................................................................................................................19

Conexion de las tuberías de agua ....................................................................................................................................19

Desborde de Drenaje .........................................................................................................................................................20

Nivel de agua ......................................................................................................................................................................20

Sistema eléctrico ....................................................................................................................................................................20

Instrucciones de uso ...............................................................................................................................................................21

Accesorios/ instalaciones opcionales .....................................................................................................................................21

Opcional Bomba de purga ......................................................................................................................................................21

Programación de la bomba de purga .....................................................................................................................................22

Termostato opcional/remoto MasterLink .................................................................................................................................22

Uso del opcional de termostato plug-in ..................................................................................................................................22

Servicio usuario Instrucciones ................................................................................................................................................23

Mantenimiento anual .............................................................................................................................................................24

Acondicionamiento para el invierno ........................................................................................................................................25

Tabla de solución de problemas .............................................................................................................................................26

Diagrama del enfriador y lista de piezas ................................................................................................................................27

Garantia ............................................................................................................................................................................... 28

®

..................................................................................................................16

15

Page 16

NOTA ACERCA DE LOS ENFRIADORES EVAPORATIVO

Ó

Para enfridaor trabajar mejor, tiene que

haber una vnetana o puerta abierta

en cada habitacion donde

el enfriamiento

es deseado.

ESCAPE

Ventana o puerta

abierta 4-6 pulgades

NOTA: Elos enfriadores evaporativo NO funcionan

en habiaciones cerradas

Purga de agua:

Los enfriadores evaporativo requieren un suministro de agua

continuo para mantener saturado el medio y lograr un máximo

enfriamiento. Debe retirarse de la unidad el agua bombeada

dentro del enfriador para evitar la acumulación de minerales

y bacterias. Esto puede suceder por acción gravitatoria de

un À ujo de descarga constante o por un sistema de purga

programado a través de una bomba. . La bomba de purga

(MCP44-PPK) está disponible en www.championcooler.com

o llamando al 1.800.643.8341.Consulte las páginas 21 y 22

para obtener más detalles acerca del funcionamiento de la

bomba de purga.

Ventilación:

A diferencia de los acondicionadores de aire, los enfriadores

evaporativo necesitan un sistema de ventilación abierto y no

cerrado.

Se requieren tanto una fuente de aire fresco como una apertura de escape para generar una correcta circulación de aire.

En general, una ventana o puerta parcialmente abierta en

cada habitación donde se desea enfriamiento creará el À ujo

de aire adecuado para una efectividad óptima de un enfriador

por evaporación. De manera alternativa, los conductos de

ventilación del ático como UP-DUX® se pueden instalar para

proporcionar un movimiento de aire su¿ ciente sin necesidad

de ventanas abiertas.

NOTA: Para mejores resultados, las ventanas/puertas

abiertas no deben estar en la parte de la casa enfrentada al viento.

ADVERTENCIA: El agua expulsada del enfriador debe

dirigirse lejos de cualquier área que pudiera afectar

los cimientos u otras zonas vulnerables.

NOTA: Los dibujos de este manual son para ¿ nes

ilustrativos y pueden reÀ ejar pequeñas diferencias en

función de las diferencias de diseño y con¿ guración.

FUNCIONES DEL ENFRIADOR DE VENTANA MASTERCOOL® MCP SERIE

CARCASA DEL VENTILADOR

C/ FRENTE DESMONTABLE

MOTOR DEL

VENTILADOR

FLOTADOR

OPCIONAL

BOMBA DE AGUA

BOMBA DE PURGA

La carcasa y la estructura de este enfriador están realizados

en un plástico reforzado y resistente a los rayos UV, lo que da

como resultado un enfriador liviano y de fácil instalación. La

unidad está construida en dos secciones básicas para posibilitar una rápida instalación dentro de ventanas a guillotina o

corredizas.

El medio rígido de altísima e¿ ciencia brinda un enfriamiento

superior, comparado con otros enfriadores a evaporación.

BANDEJA DE DISTRIBUCI

DE AGUA

NOTA: Antes de insta-

lar la unidad, tómese

un momento para

anotar el número de

serie y escribirlo en la

cubierta del manual en

el espacio provisto.

16

N

SECCIÓN EXTERIOR/

PROTECCIÓN DEL MEDIO

EL NÚMERO DE SERIE

SE ENCUENTRA EN EL

LADO DERECHO DEL

ENFRIADOR

Page 17

PROCEDIMIENTOS DE INSTALACIÓN

ADVERTENCIA: No conecte la unidad hasta haber

completado la instalación.

El enfriador de ventana MasterCool MCP44 se puede instalar en una ventana a guillotina o corrediza.

Como alternativa, esta unidad se aprobó para instalaciones

empotradas. Todas las instalaciones requieren el siguiente

espacio libre:

Ancho: 22”; Altura: 22” ; Es necesario un espacio libre de

4” por encima de la caja exterior para mantenimiento.

NOTA: Asegúrese de que la ubicación elegida para la instalación sea lo su¿ cientemente resistente como para soportar

el peso de la unidad y las piezas de montaje. El peso operativo del enfriador es de 93 libras.

NOTA: Se requieren al menos dos personas para instalar

este enfriador de ventana.

• Piezas incluidas:

• Unidad de enfriamiento

• Soportes de montaje de antepecho de ventana (4)

• Juego de piezas de separadores de acordeón (2)

• Herramientas y materiales requeridos:

• Taladro (con cable o inalámbrico)

• Brocas surtidas (para realizar agujeros guía para las

piezas de montaje)

• Llave ajustable

• Destornillador Phillips

• Silicona o masilla para todo tipo de clima para sellar el

panel de relleno a la estructura de la ventana

• Tubería de cobre o plástico de ¼” de longitud

• Válvula de grifo de manguera

• Nivel de burbuja

Montaje del enfriador

1. Retire la unidad de la caja. Veri¿ que que incluya todas

las piezas.

2. Retire todo el material de embalaje.

EN CASO DE PREGUNTAS O SI ENCUENTRA QUE

HAY PARTES FALTANTES, LAME AL 1-800-643-8341

3. Con la unidad en posición vertical, retire los 4 tornillos

de la sección de espalda. Retire el módulo del ventilador

hacia adelante (aproximadamente 6”) hasta que esté

totalmente encajado en la contrapieza y asegúrelo en su

posición utilizando los 12 tornillos incluidos.

4. Compruebe que el módulo esté ¿ jo para evitar vibra-

ciones entre las dos secciones.

NOTA: Asegure que el soporte del área donde será

instalada la unidad es lo su¿ cientemente fuerte y las

piezas de montaje encajen perfectamente bien. El peso

operativo del enfriador por evaporación es de 93 libras.

Nota: se require un mínimo de dos personas para la

instalación

.

ABRA LA UNIDAD

3. SEPARE LA SECCIÓN DE LA UNIDAD

1. RETIRE LOS 4 TORNILLOS

DE LA SECCIÓN DE ESPALDA

2. EMPUJAR HACIA ARRIBA EN

LA SECCIÓN DE ESPALDA

Instalación en Ventana

1. Extraiga la pantalla (si es necesario) y asegúrese de

que la ventana esté abierta en toda su altura. Desde el

exterior de la ventana, deslice la parte del módulo del

ventilador en la ventana. Asegúrese de que la persona

que esté en el interior ajuste la colocación exacta de la

unidad para mantener el aspecto y las longitudes correctas de los dos separadores de acordeón (incluidos).

Nota: Después de identi¿ car la posición de la instalación,

coloque un nivel de burbuja en la parte superior de la unidad y realice los ajustes necesarios para asegurarse de

que la unidad esté nivelada cuando se haya completado

la instalación. Se recomienda veri¿ car que la unidad esté

nivelada en distintos puntos durante la instalación.

SUJETE LA CARCASA DEL VENTILADOR

EXTIENDA LA CARCASA Y

SUJÉTELA AL FRENTE DEL

CUERPO DEL ENFRIADOR

CON 12 TORNILLOS.

2. Cierre la ventana para

ayudar a sostener la unidad

en posición durante los

siguientes pasos: Empuje la

unidad dentro de la ventana

hasta que el fondo quede al

ras de la pared exterior o el

separador (no incluido), tal

como se ilustra.

17

Page 18

SEPARADOR

PARA GARANTIZAR

ENRASADO / INSTALACION

A ESCUADRA

Instalación en Ventana (continuado)

SEPARADOR

PARA GARANTIZAR

ENRASADO / INSTALACION

A ESCUADRA (NO INCLUIDO)

4” MINIMUM

2 LUGARES MÍNIMO 14' APARTE

VENTANA

ALFÉIZAR DE LA VENTANA

DE MONTAJE OPCIONAL

TORNILLO

RNILLOS

ANTEPECHO DE VENTANA

TORNILLOS

SOPORTE DE MONTAJE DE

ANTEPECHO DE VENTANA

SEPARADOR

PARA GARANTIZAR

ENRASADO / INSTALACION

A ESCUADRA

3. Desde el interior, ubique los dos rieles en el fondo del

módulo del ventilador. Realice dos agujeros guía según

sea necesario e instale los dos soportes del antepecho de

la ventana, tal como se indica en la ilustración.

4. Asegure la parte superior de la carcasa del ventilador a

la estructura de la ventana con dos soportes y tornillos

adicionales.

5. Desde afuera, asegure la unidad a la pared exterior (o

separador) con dos tornillos en la base de la tapa posterior (como indica la ilustración). Complete la instalación de

protección posterior del medio.

6. Una vez instalada la unidad a la ventana, acople un separador de acordeón a cada lado del módulo del ventilador

con los bordes de fondo adhesivo. Pueden utilizarse

tornillos cortos (no incluido) para obtener una instalación

más segura. (Cerciórese de que los tornillos no inter¿ eran

con las aspas del ventilador).

7. Una vez instalados los separadores de acordeón, selle

cualquier hueco que haya quedado alrededor de la unidad

con silicona o masilla para todo tipo de clima.

la parte exterior con dos tornillos en la parte superior de la

Instalación Empotrada

Este enfriador se aprobó para instalaciones empotradas. Póngase en contacto con un contratista autorizado para que instale

el enfriador en una pared externa.

5

"

/

8

33

215/

8

"

9 3/

4

"

215/

8

"

1

"

/

8

46

VISTA FRONTAL

12

3

/

8

"

10

"

5

/

16

33 5/

19 13/

16

"

21 5/

8

"

VISTA SUPERIOR

8

"

4" MINIMUM

TORNILLO

TORNILLOS

SEPARADOR

PARA GARANTIZAR

ENRASADO / INSTALACION

A ESCUADRA (NO INCLUIDO)

18

TORNILLOS

SOPORTE DE MONTAJE

DE ANTEPECHO

ANTEPECHO

Page 19

A

CONEXIÓN DE AGUA

A

Se requiere un suministro de agua constante para el funcionamiento del enfriador. Si se necesita agua de un grifo

externo, existen dos opciones para conectar el agua al

enfriador.

Opción 1:

Utilizar una manguera de agua estándar para suministrar el agua:

1. Quite la tuerca y el casquillo que asegura el accesorio del

À otante en la unidad en el punto de conexión.

2. Tome el accesorio de bronce incluido en la bolsa de piezas y

conecte un extremo a la válvula de À otador y el otro extremo a

la manguera de agua.

Opción 2:

Instale un grifo de manguera en el grifo para facilitar una línea de

agua dedicada al enfriador.

1. Instale un grifo de manguera estándar (disponible a nivel

local) con válvula de agua en el grifo y conecte el suministro

de agua al enfriador.

2. Instale una línea plástica o de cobre hasta el grifo de manguera y conéctela a la válvula de À otador.

PUNTO DE

CONEXIÓN

DE LA TUBERÍA

DE AGUA DE LA

VÁLVULA DE

FLOTADOR).

SE ATORNILLA

DIRECTAMENTE

AL EXTREMO DE

LA MANGUERA

DE AGUA

VÁLVULA DE APAGADO

TUBERÍA AL

ENFRIADOR DE

PLASTICO

O COBRE

SE ATORNILLA

DIRECTAMENTE

EN LA VÁLVULA

DE FLOTADOR

Bomba de agua

Una bomba independiente hace circular el agua de forma continua a través del sistema de distribución de agua y del medio.

La bomba y las tuberías de agua se envían in conectar.

TUBERÍA DE

AGUA

PRINCIPAL

UNIÓN

CONEXIÓN DE

DRENAJE DE

DESBORDE

VUELVA A INSTALAR LA

BOQUILLA EN LA TUBERÍA

DE DESBORDE

(DESPUÉS DE

INSTALAR LA

TUBERÍA A

TRAVÉS DE LA

GRIFERÍA DE

REBOSE)

BOQUILLA

TOMA DE

ENTRADA

DE LA

BOMBA

BOMBA

(NO SE MUESTRA L

MALLA DEL FILTRO

PARA MAYOR

CLARIDAD)

CONEXIÓN DE

MANGUERA ESTÁNDAR

GRIFO DE

MANGUER

Conexion de las tuberías de agua

1. Ubique la tubería de agua negra insertada en los sujetadores de plástico dentro de la unidad.

2. Conecte el extremo inferior de la tubería de agua principal en la toma de entrada de la bomba.

3. Retire la boquilla insertada en el extremo de la tubería

de desborde. Inserte la manguera de desborde en

una de las ranuras en el interior de la conexión de

drenaje de desborde.

4. Vuelva a insertar la boquilla en la tubería de

desborde.

5. Conecte la parte superior de la manguera a la bandeja

de distribución de agua.

6. Asegúrese de que no haya pliegues en las tubería

de agua una vez terminada la instalación.

19

Page 20

(

CONEXIÓN DE AGUA (CONTINUADO)

Desborde de Drenaje de agua

1. Deslice la arandela de goma sobre desbordamiento de

drenaje y empuje a través del ori¿ cio desde la parte supe-

rior del enfriador, hacia la parte inferior.

TUBO DE

REBOSAMIENTO

bandeja con la contra tuerca.

3. Asegure que la arandela no se tuerza mientras se la está

apretando, pues esto puede causar ¿ ltración. NO LA

2. Asegure el desbordamiento de drenaje por debajo de la

UBICACIÓN

DEL DRENAJE

EMPAQUETADURA

DE GOMA

FONDO

DEL TANQUE

APRIETE DEMASIADO.

4. Si ocurre una ¿ ltración después de llenar el tanque ,

vuelva a apretar el tubo de rebosamiento hasta detener

la ¿ ltración. Puede usarse una pequeña cantidad de cala-

fate con silicona de ser necesario.

CONTRATUERCA

5. Conecte drenar manguera hasta el fondo del montaje

como sea necesario.

Nivel de agua

Deben mantenerse dos pulgadas de agua en el fondo del

enfriador para garantizar el agua su¿ ciente para un correcto

funcionamiento del enfriador.

2˝

El À otador viene instalado de fábrica como para mantener 2”

de

nivel de agua, pero puede requerir un ajuste si el transporte

o la instalación causaron algún cambio en la con¿ guración.

NIVEL DE AGUA

SISTEMA ELÉCTRICO

El sistema eléctrico no requiere mantenimiento general. El siguiente diagrama de cableado es sólo a modo de referencia.

PROPIETARIO

MAR

INSTALADA)

BOMBA

DE PURGA

VENTILADOR

TIERRA (AMA/VER)

CABLE DE

ALIMENTACIÓN

ALTA (NEGRO)

MOTOR DE

MEDIA (AZUL)

MAR

COMÚN (BLANCO)

(ROJO)

BAJA

BOMBA

PRINCIPAL

ESPECIFICACIONES ELÉCTRICAS DE LOS ENFRIADORES MCP SERIES

Motor de ventilador: 120V; 2.8 amperios La bomba principal: 120V; 0.9 amperios

Si la bomba de purga ( opcional) se instala Adicional 0.9 amperios

20

Page 21

INSTRUCCIONES DE USO

g

El enfriador posee un panel de control electrónico táctil en la esquina superior derecha.

Antes de encender la unidad, asegúrese de que está conectada,

que el suministro de agua a la bomba está encendido y que se

cuenta con una correcta ventilación, tal como se indica en la pági-

Luces indicadoras de

la programación de

la bomba de purga

na 16 de este manual.

Nota: Estas unidades se pueden controlar por medio de 3

botones ubicados en el panel frontal del enfriador o con control

remoto.

On/Off (Encendido/Apagado)

Este botón encien

ON/OFF (Encendido/Apagado) para encender la unidad en la con¿ guración predeterminada (la bomba encendida y el ventilador

en HI (Alta)). Luego del uso inicial, se restituirá la última con¿ guración utilizada (para ventilador y bomba) cuando se encienda

nuevamente la unidad.

Al presionar este botón mientras la unidad todavía está funcionando, se apagarán el ventilador y la bomba.

de la unidad. Cuando se la conecta por primera vez, (o después de un corte de energía), presione el botón

Después de un fallo de alimentación:

Cuando se restablezca la alimentación, la unidad se reiniciará con la misma con¿ guración que antes de que se interrumpiera la

alimentación.

Pump (Bomba)

Este botón alterna la bomba entre encendida y apagada. Cuando el LED está encendido, indica que la bomba está funcionando.

La bomba debe estar encendida mientras funciona el ventilador para que la unidad funcione como un Enfriador Evaporativo de

Ventana aunque, si lo desea, también la puede utilizar en modo ventilador sin la bomba.

Nota: Para mejores resultados, encienda la bomba durante unos minutos

para humedecer las almohadillas antes de

hacer funcionar el ventilador.

Fan (Ventilador)

Al presionar el botón del ventilador, la unidad varía la velocidad de HI (Alta) a

MED (Media), a LO (Baja) y a OFF (Apagado).

Nota: Se produce una demora de dos segundos desde que se presiona el

botón hasta que el ventilador engrana o cambia de velocidad. Esto sucede

tanto con el panel de control frontal como con el control remoto.

Control remoto

El control remoto incluido con este enfriador le permite encender o apagar la

unidad, controlar la velocidad del ventilador

e iniciar la bomba. Los botones funcionan de la misma manera que los del panel

de control frontal.

Luces indicadoras de la Velocidad de ventilador

FAN

HI

M

ED LO

POWER

PUMP

PUMP

FAN

ON

Indicadore de Bomba de a

ALIMENTACIÓN DE UNIDAD

ENCENDIDA/APAGADA

BOMBA ENCENDIDA/

APAGADA

VELOCIDAD DEL

VENTILADOR (1-3)

ua

El alcance del control remoto es de aproximadamente 20 pies en relación al

enfriador. Utiliza dos baterías alcalinas AA

(incluidas). También se incluye un soporte para pared con el enfriador.

ACCESORIOS / INSTALACIONES OPCIONALES

Opcional Bomba de purga

Además de la bomba de agua estándar para recircular el

agua desde el depósito, una bomba de purga se pueden

instalar para evacuar el contenido del depósito cada 6 horas.

Esto ayuda a retardar el crecimiento bacteriano y la acumulación mineral en el medio y así prolongar su vida útil.

También conserva el aire más fresco dentro del hogar. En

realidad, el uso de una bomba de purga resulta más económico que una tubería de purga continua. El kit de bomba de

purga (n

adquirirse en línea en www.championcooler.com o llamando

al 1.800.643.8341.

o.

de pieza: MCP44-PPK) para esta unidad puede

Descarga de la bomba de purga

NOTA: El agua arrojada en el momento de la purga

saldrá expulsada a gran velocidad y se la debe alejar

de los cimientos de la casa u otras áreas donde pudiera

ocasionar daños.

1. Anexe una manguera de agua estándar al drenaje de

desborde para dirigir el agua afuera de la casa.

NOTA: Esta agua no es potable pero puede utilizarse para

regar huertos o jardines.

21

Page 22

INSTALACIONES / ACCESORIOS OPCIONALES CONTINUADO

PROGRAMACIÓN DE LA BOMBA DE PURGA

NOTA: Cuando se encuentra en el Modo de con¿ guración de purga, no afectará la velocidad del ventilador ni

el funcionamiento de la bomba de agua.

Una vez que se haya instalado una bomba de purga y se

haya conectado al enfriador, el ciclo de purga se puede

programar desde el panel de control:

La con¿ guración predeterminada para la bomba de purga

es de 1 minuto de purga cada

24 horas. Esta con¿ guración se

puede cambiar para aumentar el

intervalo y duración de las purgas

según sea necesario.

MANTENGA

PULSADO

DURANTE

5 SEGUNDOS

BOMBA

FAN

Para ingresar en el modo de

programación del panel de control,

mantenga pulsado el punto táctil

PUMP (BOMBA) durante cinco (5)

segundos.

POWER

M

ED LO

HI

PUMP

En este punto se puede con¿ gurar el Intervalo de purga. Se

encienden cuatro luces en el lado izquierdo. Esto indica una

purga cada 24 horas.

Para cambiar el número de horas entre las purgas, pulse

PUMP (BOMBA) una vez más hasta seleccionar el pro-

a deseado. Las opciones de los intervalos de purga

gram

son 24,12, 8 y 6 horas. La intensidad de las luces disminuye

por cada vez que se pulsa el botón Pump (Bomba). Observe

la leyenda de los intervalos enumerados a continuación

.

NOTA: Según la cantidad de minerales que contenga el

agua a nivel local, aumentar la frecuencia de las purgas puede ser una ventaja para extender la vida de los

medios y de la unidad.

Luego de haber ajustado El

número de horas en el Intervalo de purga, puede seleccionar

la duración de la purga. Las

opciones son de 1 a 4 minutos

para que el agua sea expul-

VENTILADOR

PULSE PARA

AJUSTAR LA

VELOCIDAD DEL

VENTILADOR

FAN

sada.

HI

M

Pulse el punto táctil FAN

(VENTILADOR) para ingresar

POWER

ED LO

a la función del ajuste de la

Duración de purga.

as cuatro luces en el lado izqui-

L

PUMP

erdo comenzarán a parpadear indicando 4 minutos de purga.

Pulse el punto táctil PUMP (BOMBA) para cambiar el ajuste de

4 a 3 minutos, luego 2 o 1 minuto de duración.

Para guardar y salir de la sección Duración de la programación,

mantenga pulsado el punto táctil FAN (VENTILADOR) durante

5 segundos.

NOTA: Si no se pulsa ningún punto táctil dentro de los 10

segundos, el programa saldrá automáticamente del modo

de con¿ guración y conservará los ajustes previos.

4 LUCES = CADA 24 HORAS

3 LUCES = CADA 12 HORAS

2 LUCES = CADA 8 HORAS

1

LUZ

= CADA 6 HORAS

Termostato opcional MasterLink

POWER

(ENCENDIDO/

APAGADO)

TM

(VENTILADOR)

HI

(ALTA, MEDIO, BAJO)

PUMP

(BOMBA)

(Disponible en 2017)

Los enfriadores de la serie MCP MasterCool® que están

fabricados con el logotipo de MasterLink

con el Termostato MasterLinkTM, que

se vende por separado. El termostato

tendrá una aplicación para teléfono inteligente que permite esl control inalámbrico.

Este termostato permite el control de las

funciones del enfriador estándar y las características adicionales, como la función

del temporizador.

Consulte el manual del usuario del Ter-

mostato MasterLink

TM

para obtener las

instrucciones acerca de cómo controlar

y programar los enfriadores de la serie

MCP utilizando este producto.

TM

serán compatibles

Fan

Pump

Mode

FAN

M

ED LO

Timer

4 LUCES PARPADEAN = 4 MINUTOS

3 LUCES PARPADEAN = 3 MINUTOS

2 LUCES PARPADEAN = 2 MINUTOS

1 LUZ PARPADEA = 1 MINUTO

POWER

(ENCENDIDO/

APAGADO)

(VENTILADOR)

HI

(ALTA, MEDIO, BAJO)

Uso del opcional de termostato plug-in

El MCP Serie puede controlarse mediante un termostato programable opcional. Estos ter

a nivel local y permiten un control preciso del tiempo y la

temperatura a través de un termostato

electrónico que se conecta a un tomacorriente de 110 V. Para utilizar dicho

dispositivo con el MCP44, siga las

instrucciones para ese termostato en

particular y conecte el enfriador al tomacorriente en el termostato.

NOTA: La

ilustración es sólo para referencia.

Modelos y características varían según el

modelo y el fabricante.

22

mostatos pueden adquirirse

FAN

M

ED LO

PUMP

(BOMBA)

Page 23

SERVICIO USUARIO INSTRUCCIONES

El mantenimiento en enfriadores evaporativo es mínimo,

pero sí muy importante para un funcionamiento y e¿ cacia

adecuados. La inspección periódica del interior del enfriador

reducirá la posibilidad de un enfriamiento de¿ ciente debido a

una distribución de agua insu¿ ciente o irregular.

NOTA: Para tareas de mantenimiento general, la unidad puede drenarse rápidamente al retirar la grifería

de rebose del fondo. Éste no es el drenaje apropiado

para el acondicionamiento para el invierno (ver procedimientos en la sección Acondicionamiento para el

invierno).

Mantenimiento Anual (puede ser necesaria una mayor

frecuencia en áreas con aguas duras)

Limpieza

ADVERTENCIA: Desconecte la alimentación eléctrica y

apague la unidad durante todas las tareas de mantenimiento. Cierre el suministro de agua antes de retirar

el fondo por limpieza o mantenimiento.

PRECAUCIÓN: Para mantener la resistencia UV, no utilice limpiadores abrasivos en el exterior del cuerpo del enfriado

1. R

etire la protección del medio posterior (como se indica abajo

2. Inspeccione las almohadillas en su sitio. Retire las

almohadillas del medio de la protección posterior desa-

r.

).

tornillando los ganchos de sujeción. Tenga cuidado de no

dañar el medio mientras los retira. Examine visualmente

ambas caras de las almohadillas del medio. Observe si

hay alguna obstrucción, acumulación mineral o crecimiento de moho, rotura o alguna otra anomalía.

3. Lave las almohadillas con una manguera de jardín.No

utilice una lavadora a presión.

4. Controle el distribuidor de agua por si existe obstrucción

o excesiva acumulación de polvo.

5. Coloque el medio en un lugar seguro hasta que termine

con todo el mantenimiento.

6. Lave el depósito de manera exhaustiva con un cepillo de

cerdas suaves. Utilice abundante agua si es necesario,

para remover el crecimiento de algas. Limpie las áreas

alrededor de la bomba, el ¿ ltro y el À otador para asegu-

rarse de que no quedan restos de algas.

PRECAUCIÓN: No utilice químicos abrasivos (tales como

blanqueadores) para limpiar las partes interiores del

enfriador. No utilice limpiadores abrasivos en el exterior

del cuerpo del enfriador para conservar su resistencia a

los rayos UV.

7. Enjuague minuciosamente después de haber utilizado

cualquier solución de limpieza en el interior o el exterior

de la unidad.

c. DESCONECTE LA MANGUERA

DE SUMINISTRO DE AGUA

NOTA:

Cada vez que

retire la parte

posterior del

enfriador, veri¿ que

siempre que el

tubo de suministro

de agua esté

reconectado

a la bandeja

de distribución

de agua antes

de utilizar el

enfriador.

d

. SEPARE LA SECCIÓN

DE LA UNIDAD

PROPIETARIO

INSTALADA

OPCIONAL

BOMBA DEL PURGA

a

. RETIRE LOS 4 TORNILLOS

DE LA SECCIÓN DE ESPALDA

b

. EMPUJAR HACIA ARRIBA EN

LA SECCIÓN DE ESPALDA

Ubique las almohadillas del medio y retírelas.

Utilizando pinzas,

retire las clavijas

del exterior.

23

O retire

los ganchos

de sujeción

del interior.

Page 24

SERVICIO USUARIO INSTRUCCIONES (CONTINUADO)

A

Bomba del sistema de agua:

1. La bomba de agua es una unidad independiente que no

requiere más mantenimiento que evitar que los residuos o la

corrosión inter¿

2. Cerciórese de que la conexión de la manguera a la bomba

esté en buenas condiciones.

Flotador de agua:

3. El nivel del À otador está ajustado de fábrica para un

rendimiento óptimo; sin embargo, se pueden realizar

leves ajustes doblando el brazo del À otador para un

nivel de agua diferente.

4. El nivel de agua máximo recomendado es aproximada

de dos pulgadas (la altura del ori¿

Distribuidor de agua

5. Revise la sección de distribución de agua para asegurarse

de que todos los ori¿ cios están sin obstrucciones.

6. Veri¿ que que las conexiones de la manguera estén en buen

estado y no haya ningún pliegue o rotura.

Desborde de drenaje de agua

7. Desenrosque el tubo de desborde de drenaje y controle el

estado de la junta en el fondo del accesorio. Cuando lo reinstale, asegúrese de que el accesorio del tubo montante esté

bien sujeto y no haya fugas después de llenar el depósito.

eran en el libre movimiento de las piezas

mente

cio de desborde).

.

BOMBA DE

SISTEMA DE AGUA

BANDEJA DE

DISTRIBUIDOR DE AGU

TUBO DE

REBOSAMIENTO

EMPAQUETADURA

DE GOMA

FLOTADOR

DE AGUA

FONDO

DEL TANQUE

NOTA: Si mientras utiliza el enfriador comienza a notar

una baja saturación de las almohadillas y un enfriamiento

insu¿ ciente, o fugas desde el enfriador, revise la junta

tórica en la base del tubo montante. Esta es la causa más

probable de fuga en esta unidad.

Opcional Bomba de purga de agua (si instalada)

8. Si la bomba de purga (MCP44-PPK) es instalada veri¿ car

la bomba de purga y el ¿ ltro estén sin corrosión y que las

piezas se muevan libremente.

Reemplazo de almohadilla

9. Cuando pastillas se han convertido en encajonado con la

acumulación de minerales, roto o dañado, reemplazar con

almohadillas de repuesto Munters’ genuino, MCP44-PAD.

Comprarlos en línea en www.championcooler.com o llamando al 1.800.643.8341

CONTRATUERCA

OPCIONAL

BOMBA DE PURGA

(PROPIETARIO INSTALADO)

24

Page 25

Acondicionamiento para el invierno

El enfriador MCP44 es lo su¿ cientemente duradero como

para dejarlo instalado durante el invierno, aunque hay que

tomar algunas precauciones para garantizar que el agua no

se congele en la unidad o las tuberías.

Si en su área las temperaturas descienden a varios grados

bajo cero, es conveniente retirar la tubería de suministro de

agua del grifo exterior.

Drenaje:

1. Cierre el suministro de agua al enfriador.

2. Apague y desconecte el enfriador. Retire los cuatro tornillos que ¿ jan la protección posterior del medio y el acceso

al interior de la unidad.

3. Absorba todo resto de agua y asegúrese de drenar toda

el agua tanto de la bomba de agua.

4. Desconecte y drene las mangueras de agua y el distribuidor de agua.

Cuando se instala opcional bomba de purga ):

1. Cierre el suministro de agua al enfriador.

2. Apague y desconecte el enfriador.

3. Retire los 4 tornillos que ¿ jan la protección posterior del

medio y el acceso al interior de la unidad.

4. Absorb

agua tanto de la bomba de agua como de la bomba de purga.

5. Desconecte y drene las mangueras de agua y el distribuidor de agua.

6.

Vuelva a colocar la protección del medio.

a todo resto de agua y asegúrese de drenar toda el

Cubrimiento

1. Una cubierta externa opcional, modelo MCP44-CE está

disponible en puntos de venta, en línea en www.championcooler.com o llamando 1.800.643.8341.

a. Utilizar las esquinas elásticas y las correas para

asegurar de la cubierta en la parte posterior de la

unidad.

2. Una cubierta de rejilla interna opcional, modelo MCP44IC está disponible en puntos de venta, en línea en

www.championcooler.com o llamando 1.800.643.8341.

a. Cierre a presión los ganchos dentro de la cubierta

para ¿ jarla a la rejilla.

25

Page 26

Tabla de solución de problemas

PROBLEMA CAUSA PROBABLE SOLUCIÓN

No arranca la unidad a. No hay energía

b. Disyuntor activado

c. Fusible quemado (en casa)

d. Falla eléctrica

Enfriamiento de¿ ciente a. Distribución de agua inadecuada (al-

mohadillas no saturadas)

b. Almohadillas sucias o cubiertas de

sedimentos minerales

a. Compruebe que la unidad esté conectada y

que el tomacorriente esté operativo

b. Restablezca el disyuntor

c. Reemplace el fusible en casa

d. Llame a la línea telefónica de ayuda de

Champion

a. Revise la bandeja de distribución de agua y la

manguera por si existen obstrucciones.

- Compruebe que la bomba funciona

correctamente

- Revise que el suministro de agua tenga

el caudal correcto

b. Lave las almohadillas para eliminar polvo y

sedimentos o reemplácelas

Agua en la corriente

de aire

Alta humedad interior a. Insu¿ ciente À ujo de aire

Olor en el hogar a. Se produce inicialmente cuando pada

Rápida acumulación mineral en las almohadillas

del medio.