Page 1

INSTALLATION & OPERATION MANUAL

SINGLE INLET EVAPORATIVE COOLERS

Circle the model of your cooler and record the serial number.

Encierrre con un circulo el modelo de su enfriador y escribe el

número de série.

Date of Purchase:

Fecha de compra:

READ CAREFULLY ALL OF THIS MANUAL BEFORE INSTALLING THE UNIT

TABLE OF CONTENTS

Safety Instructions .........................................................1

How Evaporative Coolers Work .....................................1

Installation .....................................................................2

Operation .......................................................................5

Air Balancing Methods ...........................................5

Maintenance ..................................................................6

Specifi cation Tables .......................................................7

Troubleshooting .............................................................7

Limited Warranty ...........................................................8

Tabla de Contenido En Español ..................9

Illustrated Parts List / Ilustrado

Lista de Piezas de Repuesto

(English / Español) ......................................................17

Garantía Limitada ........................................................24

SAFETY RULES

1. Read all instructions carefully.

2. Electrical connections should be done by a qualifi ed electrician,

so that all electrical wiring will conform to your local codes.

3. Always turn OFF POWER and UNPLUG motor and pump inside

the cooler before installing or performing any maintenance.

4. Your cooler will run on either 120V or 240V A.C., single phase,

60 Hz (cycle) current.

5. Motor and pump have a grounded, molded plug and an automatic

thermal overload switch which will shut motor off when it

overheats. The motor will restart automatically when it cools

down.

WARNING: To reduce the risk of fi re or electric shock, do not use

this fan with any “solid-state fan speed control device.”

ADA51

ASA51

AUA51

Serial Number:

Número de série:

ADA5112

ASA5112

AUA5112

ADA71

ASA71

AUA71

READ AND SAVE THESE INSTRUCTIONS

ADA7112

ASA7112

AUA7112

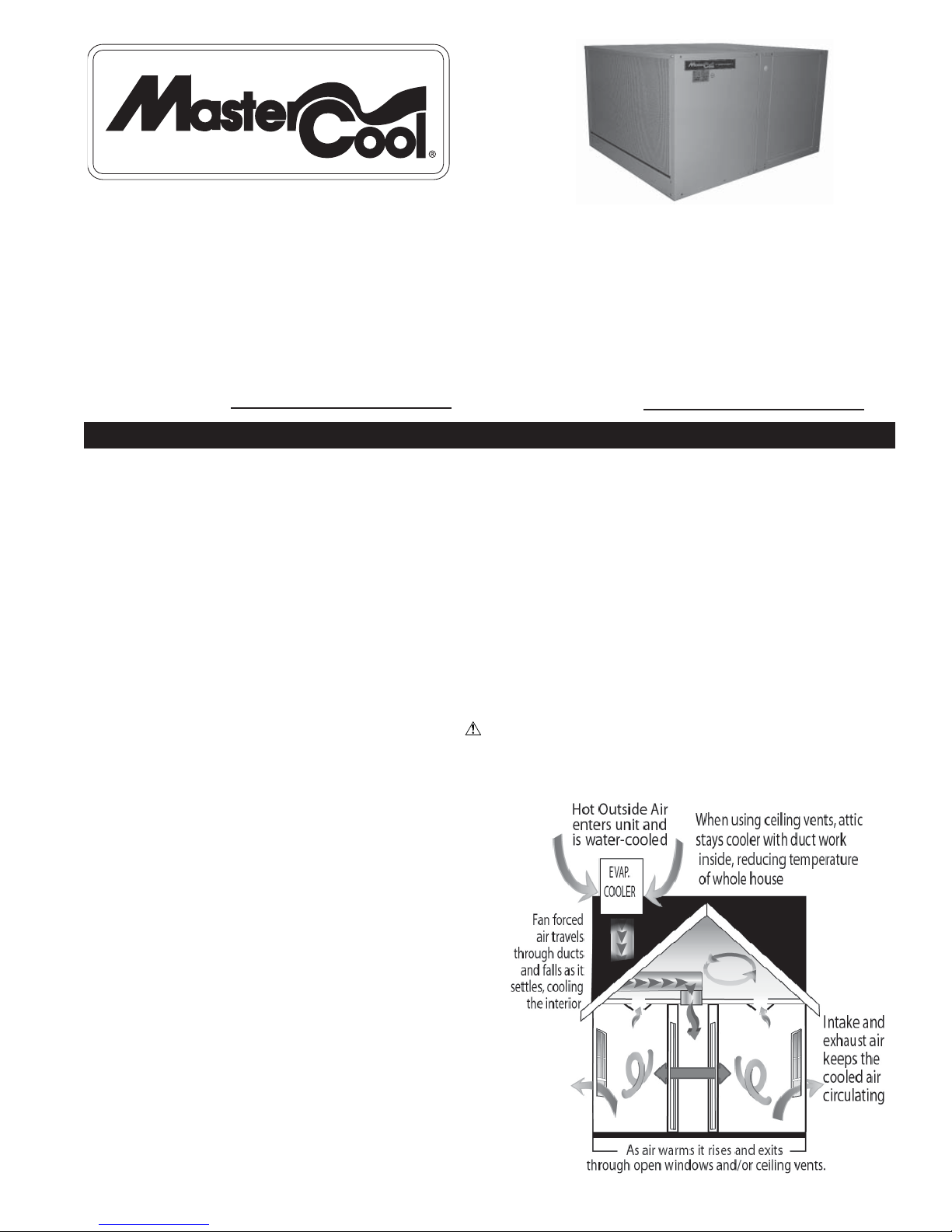

HOW EVAPORATIVE COOLERS WORK

Evaporative cooling is nature’s way of cooling. When air is

moved over a wet surface, water is evaporated and heat is

absorbed. When stepping out of swimming pool with the

wind blowing, evaporative cooling makes you feel cool, even

though the air may be warm.

This unit works on the same principle. Air is drawn across

wet fi lter pads where the air is cooled by evaporation and then

circulated throughout the building. It is this combination of

cooled air and the movement of air over the skin which makes

it feel cool.

Unlike refrigeration systems which recirculate the air, an

evaporative cooler continually brings in fresh air while

exhausting old air. You are completely replacing the air every

2 to 4 minutes by opening windows or doors, by using Up-

®

ceiling vents, or a combination of both. The air is always

Dux

fresh, not stale, laden with smoke and odors as happens with

refrigerated air conditioning.

PN 110498-2 REV. 3-15

Page 2

INSTALLATION

CAUTIONS:

Before installing the cooler, note the following items:

• Before installation, ensure your existing electrical system is rated for the additional amperage draw from unit.

• Installation inside attic areas is NOT recommended.

• If installing unit on ground, ensure surface area is level, well packed and will not erode or become unstable with water

erosion.

• If installing on brace, or existing construction, ensure structure will hold the operating weight of the cooler. (See specifi cation

table for operating weight.)

• Ensure entire unit is suffi ciently supported. If supporting the unit with legs at each corner, the middle of the unit where the two

sections join must be supported as well.

• We strongly recommend consulting a professional contractor if installation will require cutting through existing structure such

as walls or roof.

• Do not screw or drill within 5 inches of the bottom of the wet section as you could puncture the reservoir.

• Ensure all electrical work is accomplished to local standards. An electrician may be needed for correct and safe wiring.

WARNING: Disconnect all electrical service that will be used for this unit before beginning the installation

and DO NOT reconnect until installation is complete.

PARTS AND TOOLS NEEDED:

• Motor with Motor Pulley (purchased separately)

• 5/32 Allen Wrench (for pulley installation)

• 7/16 Wrench or Crescent Wrench

• Phillips Screwdriver

• Sill cock or water valve and tubing

• Multimeter (for amp reading)

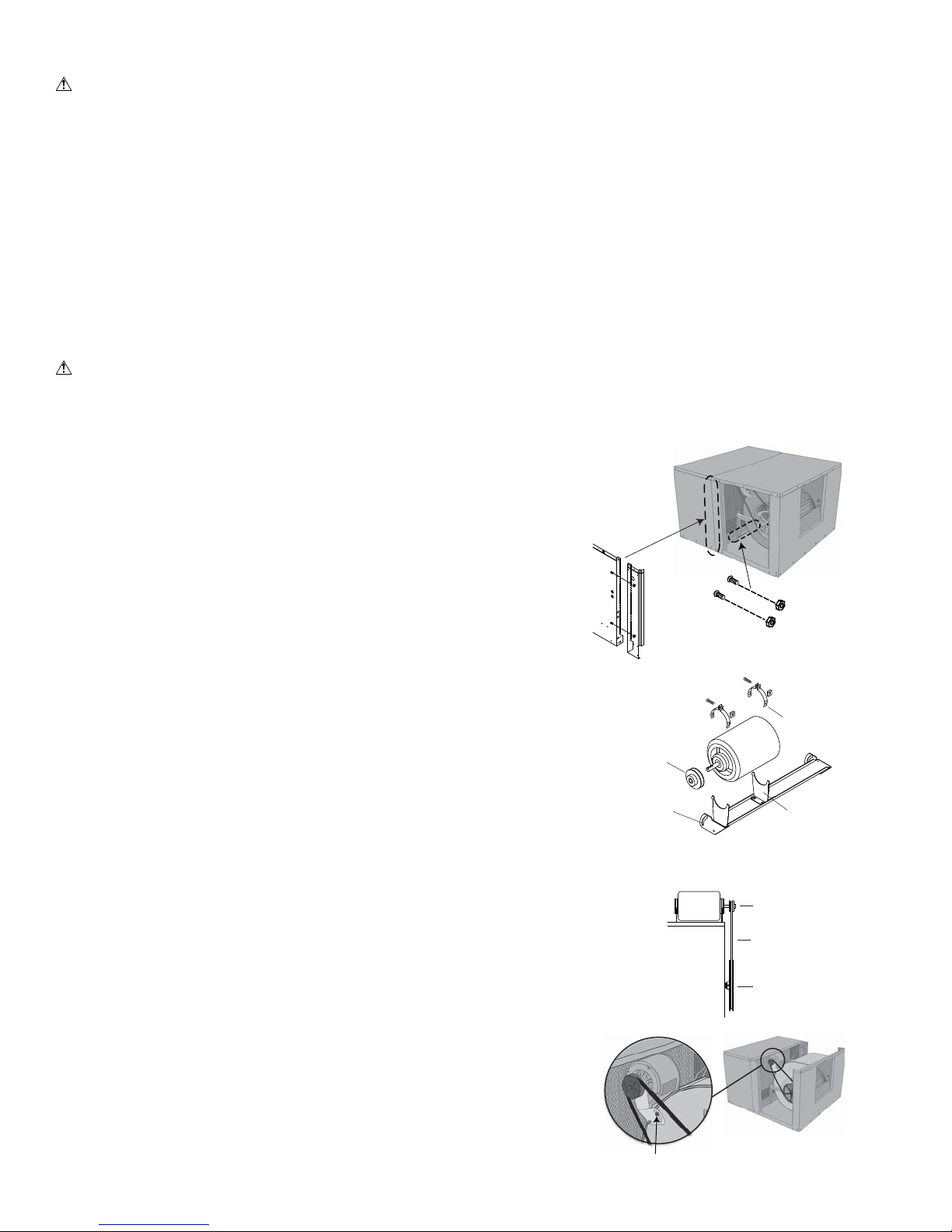

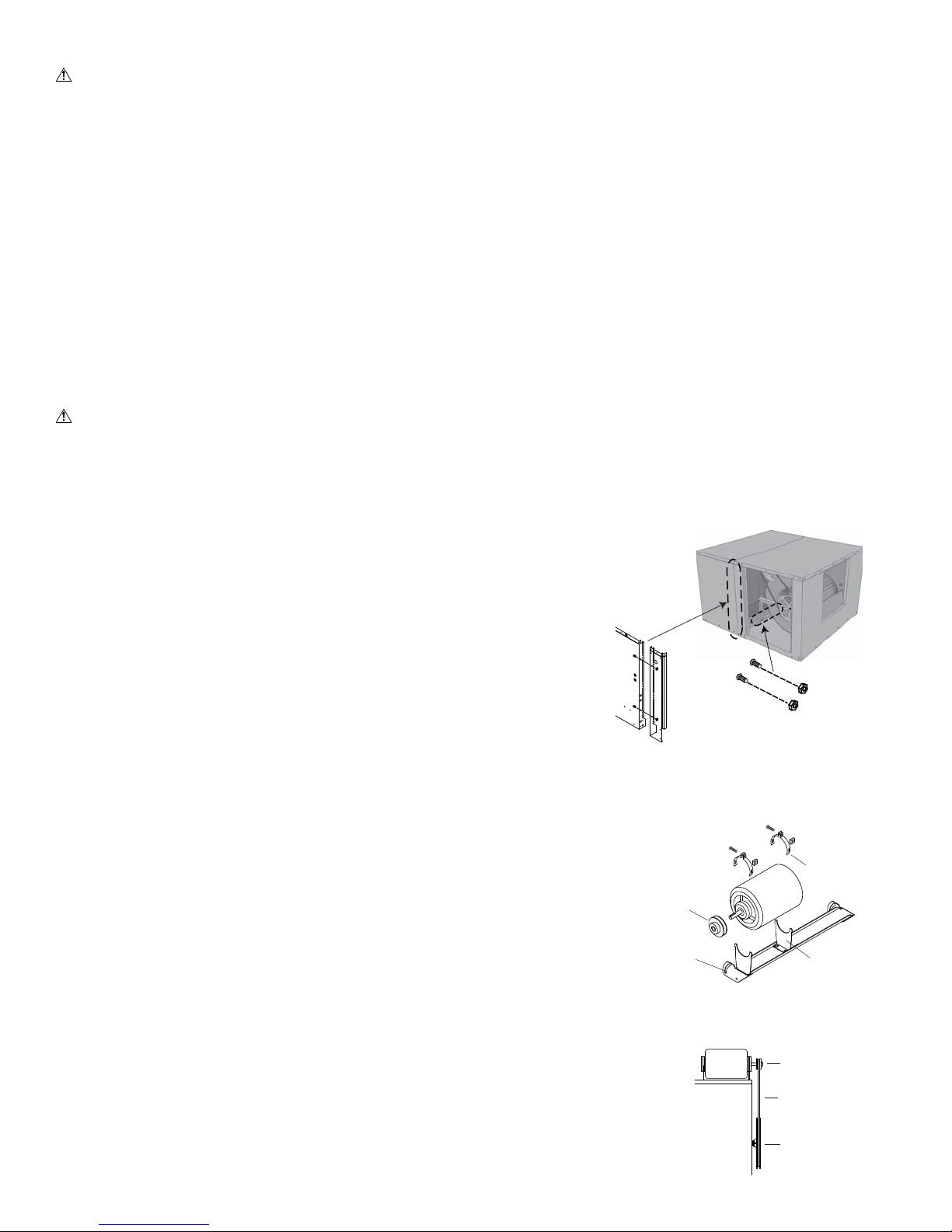

SEPARATING SECTIONS

Follow the steps below to separate the sections of the unit, if desired for ease of

installation.

1. Remove four bolts (two on each side) from the inside center post of the unit

connecting the wet section to the blower section.

2. On a few models, two bolts on the interior of the unit attaching the bottom

pans of the two sections will need to be removed as well.

MOTOR INSTALLATION

Note: Motor must be purchased separately. See Motor Specifi cation Table for

motors that can be used.

1. For typical 120V installation, install motor cord (provided) to motor

(purchased separately). Follow motor electrical diagram using the following

color code:

BLACK - HIGH; RED - LOW; WHITE- COMMON; GREEN - GROUND

2. When installing a 1 hp motor, reverse the adjustable yolk to accommodate

the larger motor. Adjust the cradle spacing as needed for size of motor.

Mount the blower motor onto the yokes of the motor mount. Fasten with

provided motor clips.

3. Leave motor cord unplugged until electrical portion of installation is

complete.

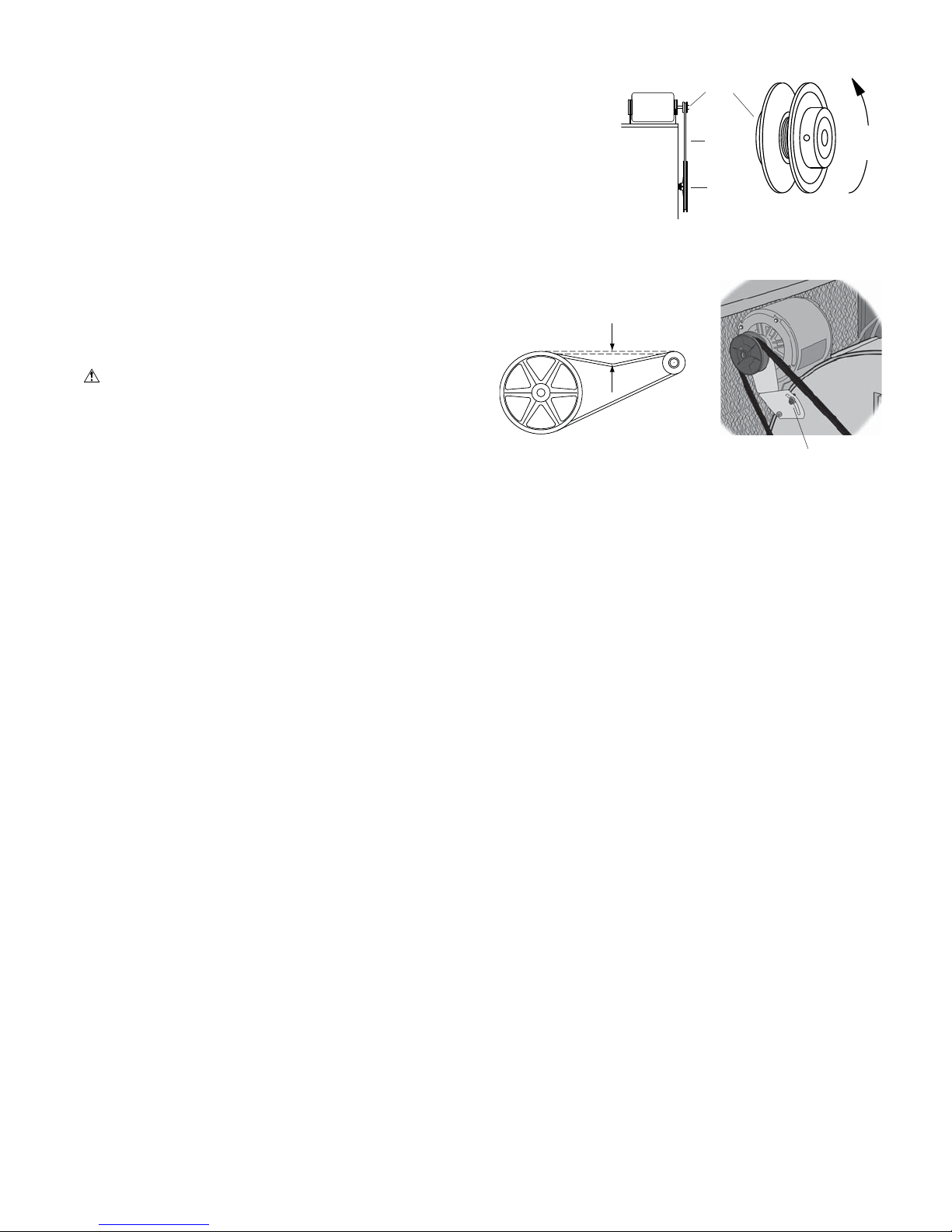

PULLEY INSTALLATION

1. Open adjustable pulley about 5 full turns to the least diameter.

2. Install the motor pulley onto the motor shaft so that it aligns with the blower

drive pulley and tighten with Allen wrench.

3. Loosen adjustment screw on motor mount.

4. Install belt onto pulleys.

5. Rotate motor mount until belt is tight, then tighten adjustment screw to

secure belt. Check belt tension per instructions on page 5.

Note: Further adjustment to belt and pulley may be required after installation is

complete.

Remove

Two Bolts

(Each Side)

Connecting

Wet And

Blower

Sections

Motor

Pulley

Adjustable

Motor Mount

Adjustment Screw

Remove Two Bolts

Connecting Bottom Pans

Motor

ALIGN PULLEYS

Motor

Motor

Pulley

Belt

Blower

Pulley

Motor

Clips

Adjustable

Yoke

2

110498-2

Page 3

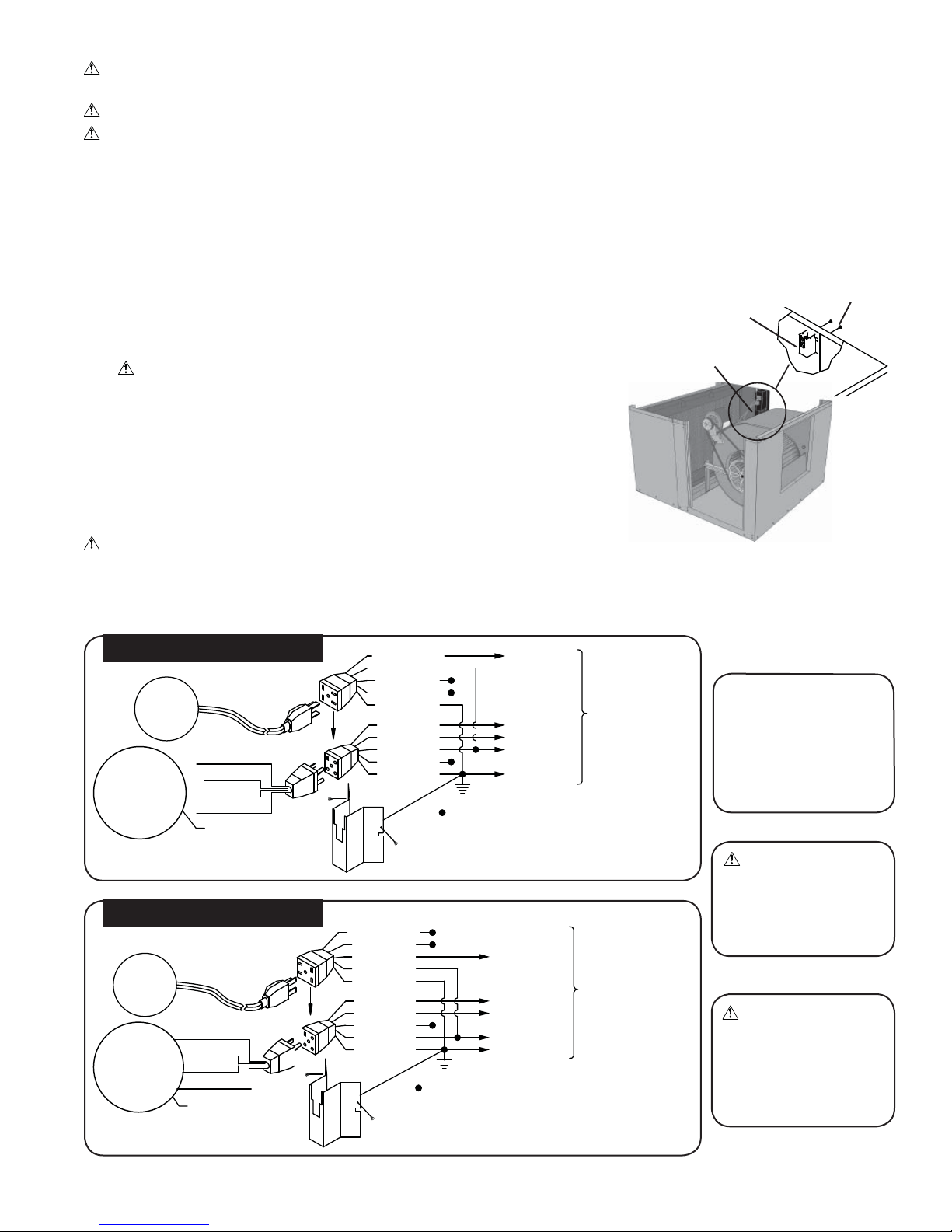

ELECTRICAL CONNECTION

Blue/Black

White

Brown

Orange

Green

Green

Orange

White

Red

Black

PUMP

HIGH

LOW

COMMON

GROUND

= WIRE NUT

HIGH

LOW

COMMON

GROUND

Black

Green

White

Red

BLOWER MOTOR

PUMP

MOTOR

TO SWITCH

COMMON

PUMP

MOTOR

BLOWER MOTOR

Red

Orange

Green

Black

GROUND

COMMON

LOW

HIGH

= WIRE NUT

GROUND

LOW

HIGH

PUMP

Black

Red

White

Orange

Green

Green

Orange

Brown

White

Blue/Black

TO SWITCH

WARNING: Electrical connections should be accomplished by a qualifi ed electrician to ensure all electrical

wiring conforms to local standards.

WARNING: Follow all safety precautions when working with electrical power.

WARNING: Before proceeding with installation, ensure electrical power is disconnected until installation is

complete.

Note: This unit can be controlled with a manual 6 position switch found at a local hardware store, or with a thermostat such as

Champion’s Masterstat

®

Wall Control Thermostat model #110423-2. For thermostat installation refer to its operating manual.

Follow the steps below for manual switch installation:

1. Determine location on internal wall for 6 position switch.

2. Supply 120V or 240V power to switch, depending on motor and pump

voltages.

3. Remove screws securing junction box to cooler cabinet.

4. Bring four conductors plus a ground from switch to cooler junction box

(such as two 2-wire Romex

CAUTION: Make sure to use correctly sized wire and follow all

®

wire)

Junction Box

Motor And Pump

Receptacles

Remove Screws to Access

Wiring Connections

local electrical codes.

5. Connect the four conductor wires to the leads of the motor and pump

receptacles located in the junction box. Follow the connection diagrams

below for 120V or 240V installations.

6. Reinstall junction box to cooler cabinet.

7. Plug motor and pump plugs into receptacles.

8. Follow switch electrical instructions for connecting the four conductors and

power leads to switch.

Warning: Pump cord must be secured in retaining clip to

prevent contact with water.

120 VOLT

240 VOLT

110498-2

3

NOTE: If single speed

motor is used, do not

use the RED electrical

leads from the motor or

receptacle. Tape off both

RED leads.

CAUTION: Receptacles in junction box are

only for Motor and pump.

Do not plug anything

else into receptacle.

WARNING: Ensure

cooler cabinet is properly grounded to a suitable

ground connection for

maximum safety and

protection of equipment.

Page 4

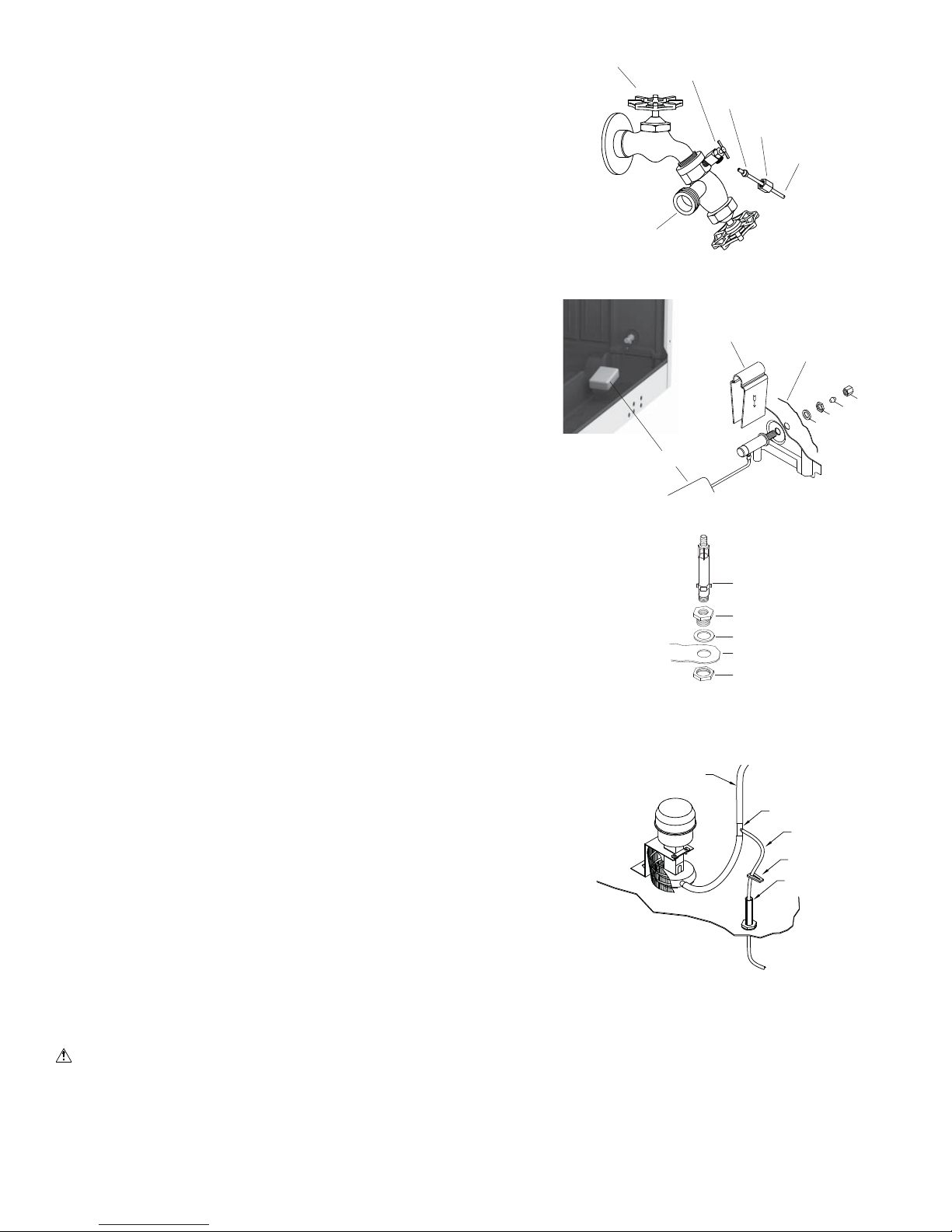

WATER CONNECTION

Note: Do not connect the water supply to any soft water applications.

Faucet

Water Shut

Off Valve

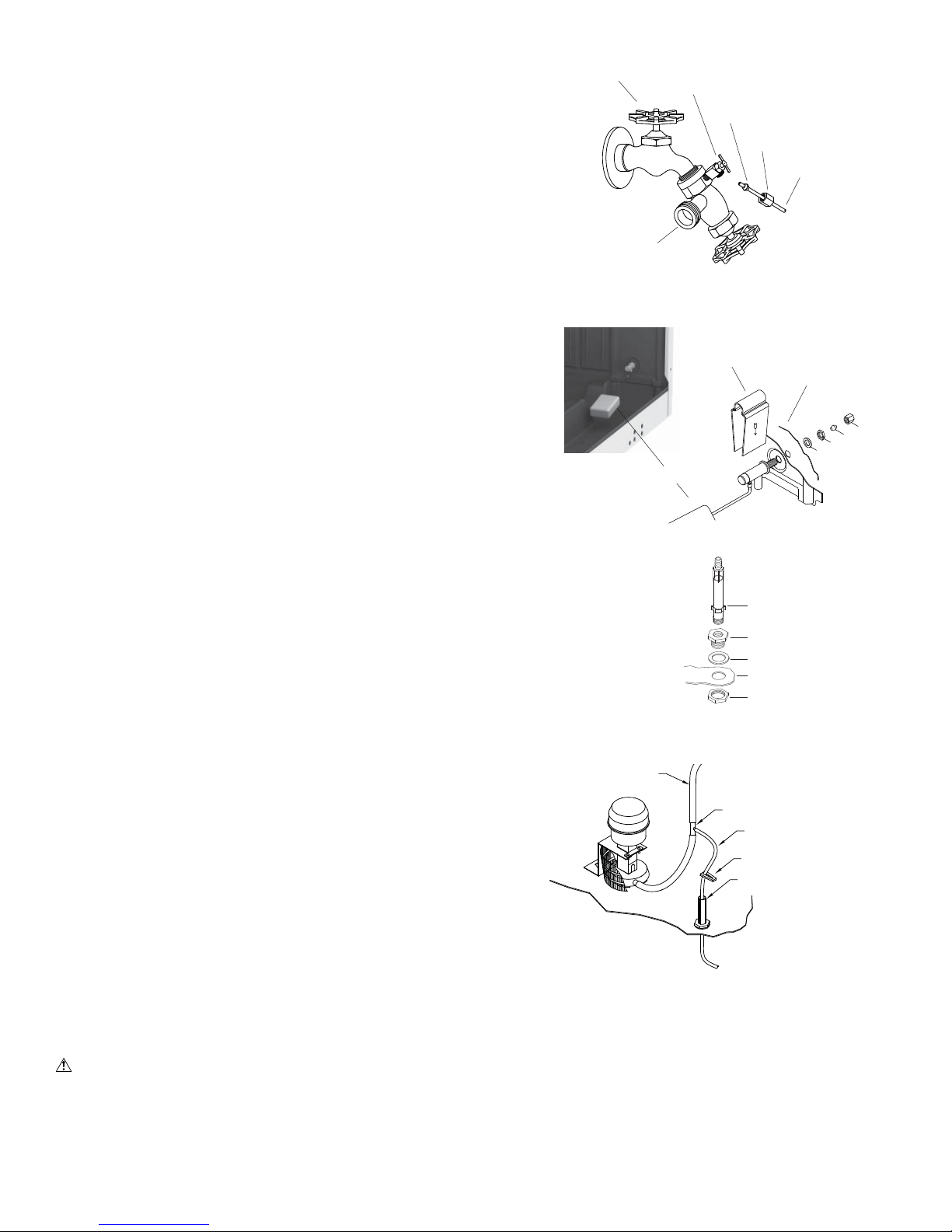

SILLCOCK INSTALLATION

A steady water supply is required for the operation of this cooler. If water

source comes from an external water faucet, a sillcock and shutoff valve

will need to be purchased and installed.

1. Install sillcock and water valve on faucet.

2. Run ¼” plastic or copper tubing from the faucet to the unit.

3. Install one end of tubing to water valve by placing nut and ferrule on

Sillcock With Std.

Hose Connection

tubing and tightening the nut until water tight.

FLOAT VALVE INSTALLATION (Refer to illustration)

1. Remove items 1, 2, 3, and 4 from fl oat.

2. Insert fl oat body through hole in media shield and back post panel as

shown.

3. Install washer (1) and nut (2). Tighten to keep fl oat from turning. Place

nut (4) and ferrule (3) on water supply line. Connect to fl oat fi tting and

tighten until water tight.

4. Slide fl oat shield over fl oat body until it snaps into place.

Note: After installation is complete and water is turned on, the fl oat level will

need to be adjusted.

5. Bend rod to adjust fl oat. Water level should be about 1 inch below the

top opening of the overfl ow pipe.

OVERFLOW INSTALLATION

1. Remove nut and place nipple through the hole in the pan with the rubber washer

between the pan and the head of the drain nipple.

2. Screw nut onto nipple and draw up tight against bottom pan.

3. Screw overfl ow pipe into nipple. This overfl ow pipe may be removed to drain pan

when necessary.

Note: A garden hose may be screwed onto the drain nipple to drain water away from the

unit.

SCALE BUILDUP PREVENTION

As water evaporates, minerals that were in the water will remain. Over time this

accumulation of minerals will cause scaling on the pads and in the reservoir. We

recommend the installation of either a bleed-off kit (included in unit) or a purge pump

(purchased separately) to help prevent scale build up and increase the life of the

unit. A purge pump will drain the pan every few hours of pump operation, to keep

fresh water in the unit. A bleed-off kit will continually bleed off a small portion of

water while the pump is running allowing fresh water to continually replace the old

stagnate water. Follow the instructions below for installing the bleed-off kit.

1. Cut the pump hose and insert the barbed ends of the bleeder tee into each cut

end.

2. Insert one end of the bleeder tubing onto the bleeder tee and run the other end

out of the cooler through the overfl ow pipe.

Note: A restrictor clamp is provided which, if desired, may be installed onto the

bleeder tubing to restrict the amount of water being bleed off. The amount of water

to bleed off depends on the quality of the water in your area. Start with 1-2 gal/hr

and increase if needed.

Float

Pump Hose

Ferrule

Nut

Float

Shield

Overfl ow Pipe

Nipple

Rubber Washer

Reservoir

Nut

BLEED-OFF KIT

Bleeder Tee

Copper Or

Plastic Line

To Cooler

Back Post

Panel

2

1

Bleed Tube

Restrictor

Overfl ow Pipe

4

3

AMPERAGE DRAW AND BELT TENSION

CAUTION: No attempt should be made to completely install this unit without the aid of an electrician or

someone familiar with testing amperage draw. Failure to comply with these instructions may void your

warranty.

This unit is equipped with an adjustable motor drive pulley for adjusting the blower wheel speed to the proper loading for different

duct systems. It is important that the motor drive pulley is adjusted to correct size to ensure maximum air delivery without damage

to the motor. Be sure to follow these instructions carefully.

4

110498-2

Page 5

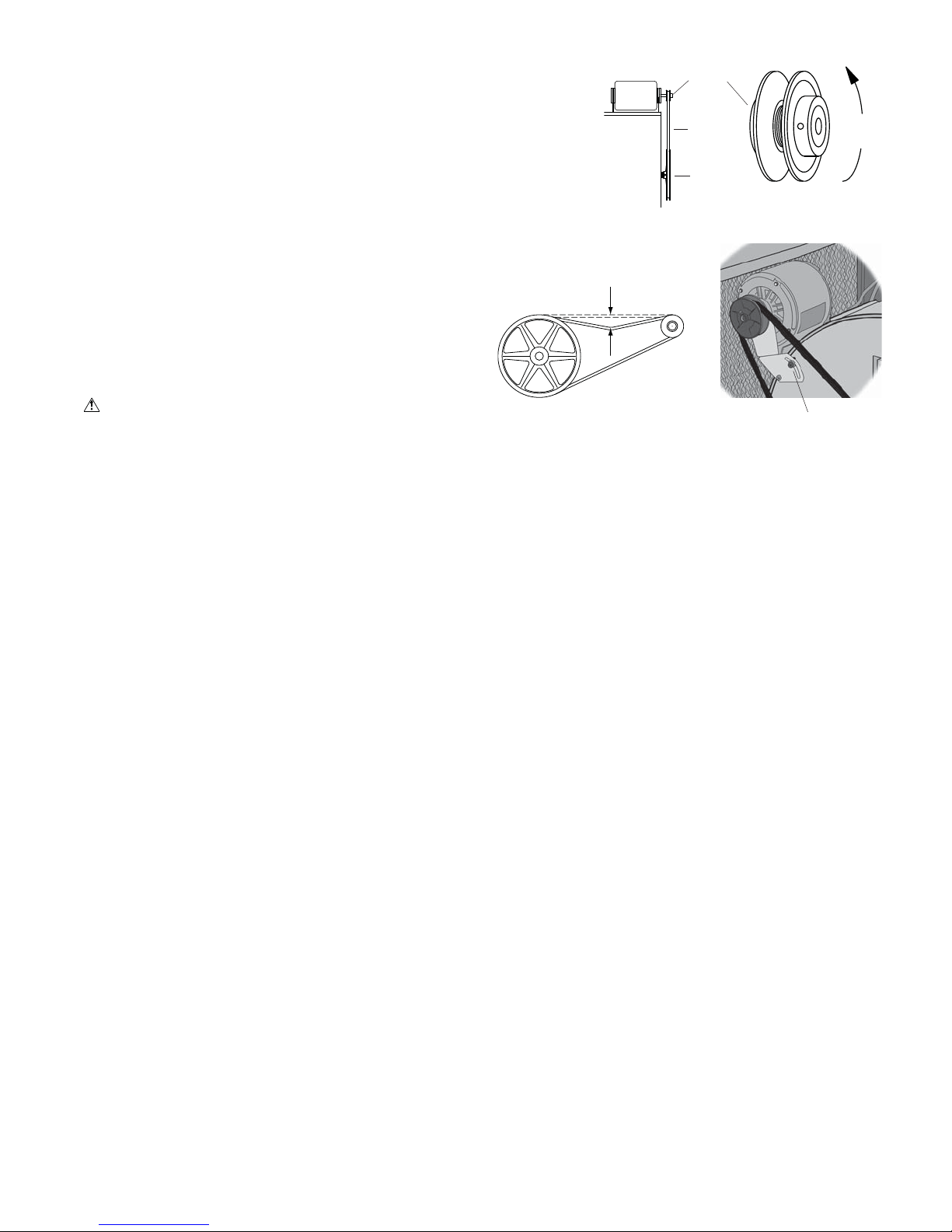

AMPERAGE DRAW AND BELT TENSION (CONT)

1. Ensure electrical connection of unit is complete and in accordance with

all safety standards and local requirements.

2. Reinstall inspection panels. Apply power, turn water and pump on and

allow cooler to run for a few minutes to wet pads.

3. Check amperage and verify it conforms to amperage listed on the

specifi cation label on motor.

• If amperage draw is less than motor rating, turn off electrical power

and remove inspection panels. Unplug motor inside cooler, this will

protect you from someone turning on unit while you are working

inside. This should be done for your safety. Adjust pulley to a larger

diameter and readjust belt tension. Plug motor in,

install inspection panels, and retest amperage draw.

Repeat this process until correct amperage draw is

attained.

Note: Increasing motor pulley diameter increases

amperage draw. Decreasing motor pulley diameter

decreases amperage draw.

CAUTION: DO NOT operate cooler with larger

amperage draw than specifi ed on motor plate. Motor

damage will occur.

4. Check belt tension after adjusting pulley. A 3 lb. force

should defl ect the belt 3/4 inches. Readjust belt if

needed by loosening adjustment screw, rotate motor

until you have the correct belt tension, then re-tighten

screw.

Motor

BELT TENSION

3 Lb. Pressure

3/4 Inches

Motor

Pulley

Belt

Blower

Pulley

Decrease

Amperage

Adjustment

Screw

OPERATION

NOTES: These coolers may be used without water for ventilation purposes. When outside air is cool (for example, at night)

or when humidity is high the water pump can be turned off.

To eliminate the delivery of hot air when starting the cooler, start the pump only for the fi rst few minutes, then turn on the

blower motor.

For an evaporative cooler to be effective, there needs to be adequate exhaust. If there is not adequate exhaust, pressure and

humidity will build up in the building. You exhaust by opening doors or windows to allow the old stale air in the building to escape.

Attic exhaust dampers may also be installed to exhaust the air into the attic. The combination of attic exhaust dampers and a

thermostat can provide a completely automatic operation.

An often misunderstood concept of evaporative cooling is the amount of air that should be exhausted. How much should you open

your windows? The following two methods will help you determine the amount to open your windows.

WINDOW AREA/CFM METHOD

For proper air fl ow, allow an opening of at least 2 square feet (288 square inches) for each 1000 CFM rating of your unit.

Example: At 3320 CFM, model ADA 51 (1/2 hp) requires 6.6 square feet (950 square inches) of opening (3320/1000 * 2 =

6.6).

Multiply the number of windows by window width in inches and divide this into the number of square inches required for your size

unit. This will give you the height to open windows. In this example, four 36 inch wide windows should be opened 6.6 inches each.

TISSUE SUCTION METHOD

1. Take a piece of tissue paper and cut it lengthwise into 3 equal strips.

2. Turn your cooler on high cool.

3. Open one window at least six inches wide in each room that you want to cool.

4. Take the piece of tissue paper and put it up against the screen of the open window furthest from the cooler discharge

opening. Let go of it. It will do one of three things.

IF: It falls down. THEN: CLOSE all of the windows one inch and try step 4 again.

IF: It plasters itself to the screen. THEN: OPEN all of the windows one inch and try step 4 again.

IF: It stays on the screen lightly. THEN: PERFECT. You are done. Enjoy your cooler.

Notes:

• When switching to low cool, you must re-balance your home. Repeat step 4.

• Once you balance your home you can cool some areas more than others by opening those windows

more and closing the others by the same amount. Repeat step 4 to make sure your home is still air balanced.

110498-2

5

Page 6

MAINTENANCE

Regular maintenance on your cooler will increase performance and extend the life of your cooler.

WARNING: Before accomplishing any maintenance ensure power is turned off and the motor and pump are

unplugged.

START OF SEASON MAINTENANCE

Accomplish these basic steps before the temperatures require cooling in case you have to acquire replacement parts.

CLEAN MEDIA

1. With power OFF, remove inspection panels, top panels and inlet grille to access

interior of unit. Place panels in a fl at, secure place to protect them from being

bent or damaged.

2. Disconnect water tube and lift off water distribution tray, accessing the media.

Remove fi lter pad on top.

3. Remove and inspect media pads. Using a garden hose sprayer, wash the media

pad ensuring openings are clear of obstruction and dirt. Some light scrubbing

may be required to remove mineral deposits. Do not use harsh detergents or

pressure washers in cleaning. Make every effort to keep the media intact.

4. The original media has a standard life of 5 years, but in areas with very high

mineral content the media may have to be replaced sooner.

5. When reinstalling existing or installing new replacement pads, ensure pads are installed in the correct confi guration:

• Place the media into the unit with the steeper fl ute angle sloping down towards the air inlet side. This provides the most effective

water fl ow to the pads, allowing higher cooling effi ciencies.

• We recommend using original equipment, MasterCool® media replacement pads for highest cooling capabilites.

NOTE: If competitor pads with equal angles are installed, disregard directional placement of media.

OIL BEARINGS

1. The blower bearings should be oiled each year with non-detergent 20/30 weight oil.

2. Locate and open the oil cup on each of the blower bearings and add a few drops of oil.

3. Add oil to motor bearings if motor has oil lines. Note: Many motors are sealed and do not

require addition of oil.

CAUTION: Do not over oil the motor, as this can cause the motor to burn out due to

excessive oil on windings.

Air Enters

Air Exits

15°

Blower Bearing

Oil Cup

45°

CLEAN PUMP

1. Pump should be cleaned at least once a year or more often if debris accumulates.

2. Unplug motor and pump from junction box, and disconnect water tube, if not already accomplished.

3. Using a screw driver, pry plastic retaining fastners straight up out of the pump-mounting bracket.

4. Slide the pump off the mounting bracket.

5. Extract pump from straining basket or netting and remove base of pump.

6. Clean pump, turn impeller to ensure free movement.

7. Remove pump spout and check for blockage.

8. Reinstall pump base and verify it is secure.

9. Before reinstalling pump, check water hose, bleeder line and water distributor tube to

ensure there is no blockage in any lines.

10. Reinstall the pump by sliding pump onto mounting bracket and reinserting the plastic

retainers to ensure pump stays in upright postion.

11. Reinstall water tube to the pump outlet spout.

CHECK BELT

1. Before unit is turned on, check that belt condition is good. If belt must be replaced, install

same sized belt.

2. Verify belt tension is correct: 3/4” defl ection with 3 lbs of force.

Remove

Base

Impeller

END OF SEASON SHUTDOWN

The cooler should be prepared before any extended period of non use, and especially before winter shutdown.

1. Drain all water from unit, supply line and pump to ensure no damage occurs from freezing. Keep water line disconnected from both

unit and supply line.

2. Unplug motor and pump from junction box.

3. Clean unit.

4. Cover unit to protect fi nish for long periods of non use.

6

110498-2

Page 7

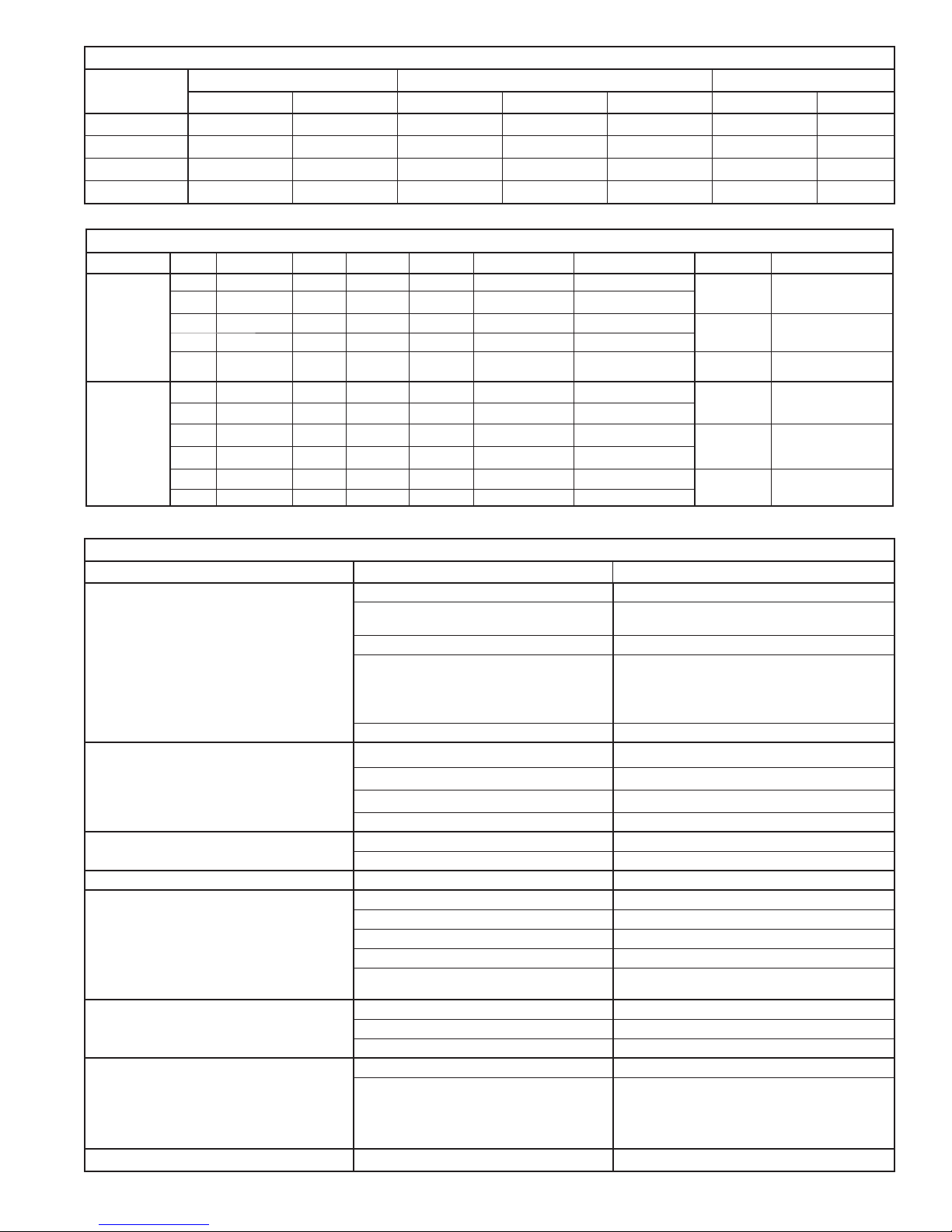

GENERAL SPECIFICATIONS

MODELS

WEIGHT (lbs) CABINET DIMENSIONS (in.) DUCT OPENING (in.)

DRY OPERATING HEIGHT WEIGHT DEPTH WIDTH HEIGHT

51 Series 177 227 28 42 45 17-3/4 17-3/4

5112 Series 190 257 28 42 49 17-3/4 17-3/4

71 Series 213 263 34-5/8 42 48 19-3/8 19-3/4

7112 Series 233 300 34-5/8 42 52 19-3/4 19-3/4

*Includes motor weight

MOTOR SPECIFICATIONS

MODELS H.P

51 & 5112

Series

71 & 7112

Series

* Amperage shown is from National Electrical Code for high speed.

MOTOR PN

1/3 110445 2 115 7.2 17 110279-002

1/2 110447 2 115 9.8 18 110279-004

1/2 110475 2 230 4.9 15 110279-004

3/4 110449 2 115 13.8 22 110279-004

3/4 110480 2 230 16.9 21 110279-004

1/2 110447 2 115 9.8 18 110279-002

1/2 110475 2 230 4.9 15

3/4 110449 2 115 13.8 22 110279-004

3/4 110480 2 230 6.9 21 110279-004

1 110471 2 115 16 29 110279-003

1 110458 2 230 8 29 110279-003

SPEED VOLTS *AMPS

WEIGHT (LBS)

MOTOR PULLEY P/N

110279-002

MODEL DRIVE BELT P/N

ADA51 &

ADA5112

ASA51 &

ASA5112

AUA51 &

AUA5112

ADA71 &

ADA7112

ASA71 &

ASA7112

AUA71 &

AUA7112

110208 (4L-520)

110229 (4L-530) -3/4 HP

110212 (4L-570)

110222 (4L-510)

110230 (4L-640)

110213 (4L-670)

110213 (4L-670)

TROUBLESHOOTING GUIDE

PROBLEM POSSIBLE CAUSE REMEDY

1. No electrical power to unit 1. Check Power

• Blown Fuse or Tripped Circuit Breaker

• Electrical cord damage

• Replace fuse or reset breaker

• Replace Cord

2. Belt too loose or too tight 2. Adjust belt tension

Failure to start or no air delivery

3. Motor overheated 3. Determine cause of overheating

• Belt too tight

• Blower bearings dry

• Motor pulley diameter too large

• Adjust pulley tension

• Oil blower bearings

• Adjust pulley to correct diameter

4. Motor locked 4. Replace motor

1. Insuffi cient air exhaust 1. Open doors or widows to increase air fl ow

Inadequate air delivery with cooler running

2. Belt too loose 2. Adjust belt tension or replace if needed

3. Pads plugged/dirty 3. Clean pads

4. Motor underloaded 4. Adjust pulley

Water draining onto roof

1. Float arm not adjusted properly 1. Adjust fl oat

2. Overfl ow assembly leaking 2. Tighten nut and overfl ow pipe

Musty or unpleasant odor 1. Stale or stagnate water in cooler 1. Drain pan and clean pads

1. Low voltage 1. Check voltage

2. Excessive belt tension 2. Adjust belt tension

Motor cycles on and off

Blower shaft and tight or locked

3.

3. Unplug unit and oil or replace bearings

4. Bearings dry 4. Oil bearings

5.

Motor pulley diameter too large ,

causing motor overload

5. Adjust pulley so full load ampere

rating of motor is not exceeded.

1. Bearings dry 1. Oil bearings

Noisy

2. Wheel rubbing blower housing 2. Unplug unit, inspect and realign

3. Loose parts 3. Tighten loose parts

1. Inadequate exhaust in house

1. Open windows or doors to increase air fl ow

2. Pads not wet 2. Check water distribution system

Inadequate cooling

• Pads clogged

• Distribution tube holes clogged

• Pump not working properly

• Clean pads

• Clean tube holes

• Unplug and replace or clean pump

Excessive humidity in house 1. Insuffi cent air exhaust 1. Open doors or windows

110498-2

7

Page 8

MASTERCOOL SINGLE INLET

LIMITED WARRANTY POLICY

SALES RECEIPT REQUIRED AS PROOF OF PURCHASE FOR ALL WARRANTY CLAIMS.

This warranty is extended only to the original purchaser of this evaporative cooler when the unit is installed and used under

normal conditions against defects in workmanship and materials as follows:

• One (1) year from date of sale on the cabinet components

• Five (5) years on the evaporative media, which is considered a disposable component

and should be replaced periodically.

• Two (2) years on the motor, if furnished by Champion Cooler

The manufacturer will replace the defective part/product, at its discretion. It is agreed that such replacement is the

exclusive remedy available from the manufacturer and that TO THE MAXIMUM EXTENT PERMITTED BY LAW,

THE MANUFACTURER IS NOT RESPONSIBLE FOR DAMAGES OF ANY KIND, INCLUDING INCIDENTAL AND

CONSEQUENTIAL DAMAGE OR LOSS OF PROFITS OR REVENUES.

Some states do not allow limitations on how long an implied warranty lasts, so the above limitations may not apply to you.

Exclusions from this warranty

We are not responsible for any incidental or consequential damage from any malfunction, accident, misuse, alterations,

unauthorized repairs, abuse, including failure to perform reasonable maintenance, normal wear and tear.

Alterations include the substitution of name brand components including, but not limited to media pads.

We are not responsible for any damage from the use of water softeners or treatments, chemicals or descaling materials.

We are not responsible for the cost of service calls to diagnose the cause of trouble, or labor charge to repair and/or replace

parts.

No employee, agent, dealer or other person is authorized to give any warranties or conditions on behalf of the manufacturer.

The customer shall be responsible for all labor costs incurred.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitations or

exclusions may not apply to you.

How to obtain service under this warranty

Within the limitations of this warranty, purchaser with inoperative units should contact the dealer where you purchased the

cooler. If for any reason you are not satisfi ed with the response from the dealer, contact Customer Service at 800-643-8341

for instructions on how to obtain service within warranty as listed above.

This warranty gives the customer specifi c legal rights, and you may also have other rights which vary from province to

province, or state to state.

Register your product at www.championcooler.com.

8

110498-2

Page 9

MANUAL DE INSTALACIÓN Y OPERACIÓN

ENFRIADOR EVAPORATIVO DE ADMISSIÓN SIMPLE

Encierrre con un circulo el modelo de su enfriador

y escribe el número de série abajo.

Número De SérieFecha de Compra

LEA CON CUIDADO TODO ESTE MANUAL ANTES DE INSTALAR LA UNIDAD.

TABLA DE CONTENIDO

Reglas De Seguridad ....................................................9

Cómo Funciona Los Enfriadores Evaporativos .............9

Instalación ...................................................................10

Operación ....................................................................13

Método de Equilibrar el Aire .................................13

Mantenimiento ...........................................................14

Tablas De Especifi caciones .........................................15

Lista De Piezas De Repuesto......................................17

Localización de Averías

Garantía Limitada ........................................................24

ADA51

ASA51

AUA51

ADA5112

ASA5112

AUA5112

ADA71

ASA71

AUA71

ADA7112

ASA7112

AUA7112

LEA Y CONSERVE ESTAS INSTRUCCIONES

NORMAS DE SEGURIDAD

1. Lea todas las instrucciones con detenimiento.

2. Las conexiones eléctricas deben ser realizadas por un

electricista califi cado, de manera que todo el cableado eléctrico

cumpla con sus normas locales.

3. Siempre CORTE LA CORRIENTE y DESCONECTE el motor y

la bomba dentro del enfriador antes de realizar la instalación o

mantenimiento.

4. Su enfriador funciona con corriente alterna de 120V o 240V,

monofásica, 60 Hz. (ciclos).

5. El motor y la bomba tienen un enchufe moldeado con descarga

a tierra y un interruptor térmico automático que apagará el

motor en caso de sobrecalentamiento. Los motores reiniciarán

de forma automática al enfriarse.

ADVERTENCIA: Para reducir el riesgo de incendio o descarga

eléctrica, no utilice este ventilador con ningún “dispositivo de estado

sólido de control de velocidad de ventilador.”

CÓMO FUNCIONAN LOS

ENFRIADORES EVAPORATIVOS

El enfriamiento por evaporación es la forma natural de enfriar.

Cuando el aire se mueve sobre una superfi cie húmeda, el

agua se evapora y se absorbe el calor. Al salir de una piscina

mientras sopla el viento, el enfriamiento por evaporación hace

que se sienta fresco, aún cuando el aire sea cálido.

Esta unidad funciona con el mismo principio. Se hace circular

aire a través de almohadillas fi ltrantes húmedas donde el

aire se enfría por evaporación y luego se propaga por todo el

edifi cio. Es la combinación de aire enfriado y movimiento de

aire sobre su piel lo que le hace sentir fresco.

A diferencia de otros sistemas de enfriamiento que

redistribuyen el aire, el enfriador por evaporación ingresa aire

fresco de forma continua mientras expulsa el aire viciado.

Usted renueva el aire por completo cada 2 a 4 minutos al abrir

ventanas o puertas, al utilizar la ventilación de techo Up-Dux®,

o una combinación de ambas. El aire siempre está fresco, no

rancio, cargado de humo y olores como suele ocurrir con el

aire acondicionado por refrigeración.

110498-2

9

Page 10

INSTALACIÓN

PRECAUCIONES:

Tome las siguientes precauciones antes de instalar su enfriador:

• Antes de la instalación, asegúrese de que su sistema eléctrico esté preparado para el consumo adicional de voltaje de la

unidad

• NO se recomienda su instalación en el ático.

• De instalar la unidad sobre el suelo, asegúrese de que la zona esté nivelada, bien apisonada y que no sufrirá erosión o se

tornará inestable al ser expuesta a líquidos.

• De instalar sobre un soporte, o una construcción existente, asegúrese de que dicha estructura soportará el peso operativo

del enfriador. (Vea la tabla de especifi caciones para conocer el peso operativo.)

• Asegúrese de que toda la unidad tenga soporte sufi ciente. Si apoyará la unidad sobre pies en cada esquina,

debe agregar un apoyo en el medio de la unidad, donde las dos secciones se unen.

• Le recomendamos que consulte a un contratista profesional si la instalación requiere cortar estructuras existentes tales como paredes o techos.

• No atornille o perfore a 5 pulgadas del fondo de la sección húmeda, ya que podría atravesar el depósito.

• Asegúrese de que el trabajo eléctrico cumpla con las normas locales. Puede requerir un electricista para un

cableado correcto y seguro.

ADVERTENCIA: DESCONECTE TODOS LOS SERVICIOS ELÉCTRICOS QUE SE UTILIZARÁN PARA ESTA UNIDAD

ANTES DE COMENZAR LA INSTALACIÓN Y NO LOS RE-CONECTE HASTA QUE FINALICE LA INSTALACIÓN.

PIEZAS Y HERRAMIENTAS NECESARIAS:

• Motor con polea para motor (se adquiere por separado)

• Llave Allen 5/32 (para instalación de polea)

• Llave 7/16 o Llave ajustable

• Destornillador Phillips

• Llave de paso o válvula de agua y tubos

• Multímetro (para lectura de amperios)

SEPARACIÓN DE SECCIONES

Siga los pasos a continuación para separar las secciones de la unidad, si lo prefi ere

para facilitar la instalación:

1. Quite las cuatro tuercas (dos a cada lado) del poste central interno de la unidad,

conectando la sección húmeda con la sección de la sopladora.

2. En algunos modelos, también será necesario quitar dos tuercas del interior de la

unidad, que unen los paneles del fondo de ambas secciones.

INSTALACIÓN DEL MOTOR

Nota: El motor se adquiere por separado. Vea la Tabla de Especifi caciones de Motor

para conocer los motores que pueden utilizarse.

1. Para una instalación típica de 120V, conecte el cable del motor (incluido) al

motor (adquirido por separado). Siga el diagrama eléctrico del motor utilizando el

siguiente código de colores:

NEGRO - ALTO; ROJO - BAJO; BLANCO - COMÚN; VERDE - TIERRA

2. Para instalar un motor de 1 CV, mueva la horquilla ajustable para hacer lugar al

motor más grande. Ajuste el tamaño del soporte según sea necesario para el

tamaño del motor. Monte el motor de la sopladora a las horquillas de la montura

del motor. Asegure el mismo con los seguros incluidos para el motor.

3. Deje el enchufe del motor desconectado hasta que la parte eléctrica de la

instalación esté completa.

INSTALACIÓN DE POLEA

1. Abra la polea ajustable unas cinco vueltas completas hasta su diámetro menor.

2. Instale la polea del motor en el eje del motor de manera que esté alineada con la

polea de transmisión de la sopladora y ajuste con la llave Allen.

3. Desajuste el tornillo del montura del motor.

4. Instale la correa en las poleas.

Quite

Los Dos

Tuercas

(A Cada

Lado) Que

Conectan

Las

Secciones

Juntas

Polea Del

Motor

Montura

Del Motor

Ajustable

Quite Dos Tuercas

Que Unen Los

Paneles Del Fondo

Seguros

Motor

Horquilla

Ajustable

ALINEAR LAS POLEAS

Motor

Polea Del

Motor

Correa

Polea Del

Soplador

10

110498-2

Page 11

5. Gire la montura del motor hasta que la correa esté ajustada, y aplique el tornillo

Azul/Negro

Blanco

Marrón

Naranja

Verde

Verde

Naranja

Blanco

Rojo

Negro

BOMBA

ALTO

BAJO

COMÚN

TIERRA

= Empalme De Plástico

ALTO

BAJO

COMÚN

TIERRA

Negro

Verde

Blanco

Rojo

Motor Del

Ventilador

BOMBA

A

Interruptor

COMÚN

A

Interruptor

BOMBA

Motor Del

Ventilador

Rojo

Naranja

Verde

Negro

TIERRA

COMÚN

BAJO

ALTO

= Empalme De Plástico

TIERRA

BAJO

ALTO

BOMBA

Negro

Rojo

Blanco

Naranja

Verde

Verde

Naranja

Marrón

Blanco

Azul/Negro

de ajuste para asegurar la correa. Verifi que la tensión de la correa según las

instrucciones de la página 13.

Nota: Puede ser necesario hacer nuevos ajustes a la correa y las poleas luego de

fi nalizada la instalación.

CONEXIÓN ELÉCTRICA

ADVERTENCIA: Las conexiones eléctricas deben ser realizadas por un

electricista califi cado para garantizar que el cableado cumpla con sus normas

locales.

ADVERTENCIA: Tome todas las precauciones de seguridad al trabajar con energía eléctrica.

ADVERTENCIA: Antes de proseguir con la instalación, asegúrese de que la energía eléctrica esté desconectada hasta

que fi nalice la instalación.

Nota: Se puede controlar esta unidad con un interruptor manual de 6 posiciones que se encuentra en una ferretería local, o con

un termostato tal como el Termostato de Pared de Champion, Masterstat® modelo n° 110423-2. Para la instalación del termostato

consulte el manual operativo del mismo. Siga los pasos a continuación para la instalación del interruptor manual:

1. Determine la ubicación para el interruptor de 6 posiciones en la pared interna.

2. Alimente el interruptor con energía de 120V o 240V, según los voltajes del motor y la bomba.

3. Quite los tornillos que fi jan la caja de conexiones a la cabina de enfriamiento.

4. Traiga cuatro conductores más una toma de tierra desde el interruptor

hasta la caja de conexiones del enfriador (similar al cable Romex® de dos

alambres).

PRECAUCIÓN: Asegúrese de utilizar cables de tamaño adecuado y

respete las normas locales de electricidad.

5. Conecte los cuatro cables conductores con las terminales del motor y los

receptáculos de la bomba ubicados en la caja de conexiones. Siga los

diagramas de conexión a continuación para las instalaciones de 120V y

240V .

6. Instale nuevamente la caja de conexiones en la cabina de enfriamiento.

7. Conecte el motor y los enchufes de la bomba en los receptáculos.

8. Siga las instrucciones del interruptor eléctrico para conectar los cuatro

conductores y el cable de energía al interruptor.

Advertencia: El cable de la bomba debe estar sujeto con la horquilla de

retención para evitar contacto con el agua.

T ornillo Ajustable

Quite los Tornillos Para

Acceder a las Conexiones

de Cableado

Caja de Conexiones

Receptáculos del

Motor y Bomba

120 VOLTIOS

240 VOLTIOS

110498-2

NOTA: De utilizar un

motor de velocidad única,

no utilice los cables

eléctricos ROJOS del motor

o receptáculo. Cubra con

cinta ambas terminales

ROJAS.

PRECAUCIÓN: Los

receptáculos de la caja de

conexiones son únicamente

para el motor y la bomba.

No conecte nada más al

receptáculo.

ADVERTENCIA:

Asegúrese de que el gabinete

del enfriador tenga una

conexión adecuada a tierra

para una mayor seguridad y

protección del equipo.

11

Page 12

CONEXIÓN DE AGUA

Nota: No conecte la alimentación de agua a equipos de agua blanda.

INSTALACIÓN DE VÁLVULA DE AGUA ACOPLADA

Se requiere un suministro de agua constante para el funcionamiento del

enfriador. Si la fuente de agua viene de un grifo externo, se deberá comprar

e instalar una llave y una válvula de paso.

1. Instale la llave de paso y la válvula de agua en el grifo.

2. Conecte la unidad al grifo con tubos de plástico o cobre de ¼ de

pulgada.

3. Instale un extremo de la tubería en la válvula de agua, colocando la

tuerca y el férula sobre el tubo y ajustando la tuerca hasta que sea a

prueba de agua.

INSTALACIÓN DE VÁLVULA DE FLOTADOR (Véase la ilustración)

1. Quite los elementos 1, 2, 3 y 4 del fl otador.

2. Inserte el cuerpo del fl otador por el orifi cio en el escudo medio y el panel

del poste trasero según muestra la fi gura.

3. Aplique la arandela (1) y la tuerca (2). Ajuste para evitar que gire el

fl otador. Coloque la tuerca (4) y el férula (3) en la línea de suministro de

agua. Conecte al conexión roscada del fl otador y ajuste hasta quedar a

prueba de agua.

4. Deslice el protector contra salpicaduras del fl otador sobre el cuerpo del

fl otador hasta que encaje en su lugar.

Nota: Una vez que termina la instalación y se enciende el agua, será necesario

ajustar el nivel del fl otador.

5. Doble la vara para ajustar el fl otador. El nivel de agua debería estar a una

pulgada por debajo de la abertura del caño de desagüe.

Con Conexión de

Manguera estándar

Grifo

Llave de Paso

Válvula De

Apagado

Protector Contra

Salpicaduras

Flotador

Férula

Tuerca

Poste Trasero

Tubo de

Plástico o

Cobre

Panel Del

1

4

3

2

INSTALACIÓN DE MONTAJE DE DESAGÜE

1. Quite la tuerca y coloque la boquilla por el orifi cio del panel con la junta de goma entre el

panel y la cabeza de la boquilla.

2. Atornille la tuerca a la boquilla y ajuste al panel inferior.

3. Atornille el caño de desagüe a la boquilla. Dicho caño de desagüe puede quitarse para

drenar la fuente cuando sea necesario.

Nota: Puede atornillarse una manguera de jardín a la boquilla para drenar el agua de la unidad.

Caño De Desagüe

Boquilla

Junta De Goma

Panel Inferior

Tuerca

PREVENCIÓN DE ACUMULACIÓN DE ÓXIDO

A medida que se evapora el agua, los minerales del agua permanecen. Con

el tiempo, esta acumulación de minerales puede resultar en óxido en los

Manguera De

fi ltros y el depósito. Recomendamos la instalación de un paquete de purga

(incluido con la unidad) o una bomba de purga (adquirida por separado)

para prevenir la acumulación de óxido y aumentar la vida útil de la unidad.

Una bomba de purga drenará la fuente de forma regular para mantener

agua fresca en la unidad. Un paquete de purga hace una purga continua de

una pequeña fracción de agua mientras la bomba funciona, lo que permite

que agua fresca reemplace el agua estancada de forma continua. Siga las

instrucciones a continuación para instalar el paquete de purga.

1. Corte la manguera de la bomba e inserte los extremos dentados del T

de purga en cada punta cortada.

2. Inserte un extremo de la línea de purga a la T de purga y lleve el otro

extremo fuera del enfriador a través del caño de desagüe.

Nota: Se incluye una pinza de restricción que puede instalarse en la línea de purga para restringir la cantidad de agua que se purga. La

cantidad de agua a purgar depende de la calidad del agua en su zona. Comience con 1-2 gal/hr. y aumente de ser necesario.

PAQUETE DE PURGA

La Bomba

T De Purga

Línea De Purga

Pinza De Restricción

Caño De Desagüe

AMPERIO Y TENSIÓN DE LA CORREA

PRECAUCIÓN: No intente instalar la unidad por completo sin la ayuda de un electricista o alguien familiarizado con las

pruebas de consumo de corriente. El incumplimiento de las presentes instrucciones puede anular su garantía.

Esta unidad está equipada con una polea ajustable de transmisión del motor para ajustar la velocidad de la rueda de la sopladora

según la carga requerida para los distintos sistemas de conductos. Es importante que la polea de transmisión del motor

sea ajustada al tamaño correcto para asegurar un máximo suministro de aire sin dañar el motor. Asegúrese de seguir estas

instrucciones.

12

110498-2

Page 13

1. Asegúrese de que la conexión eléctrica de la unidad esté completa y de

conformidad con las normas de seguridad y los requisitos locales.

2. Instale nuevamente los paneles de inspección. Active la energía, encienda

el agua y la bomba y permita que el enfriador funcione unos minutos para

Motor

Polea Del

Motor

humedecer los fi ltros.

3. Verifi que el amperio y confi rme que esté de acuerdo con el amperio

Correa

detallado en la etiqueta de especifi caciones del motor.

• Si el consumo de corriente es menor que el indicado por el motor, corte

la corriente eléctrica y quite los paneles de inspección. Desenchufe el

Polea Del

Soplador

motor dentro del enfriador, eso lo protegerá si alguien enciende la unidad

mientras usted trabaja dentro de la misma. Esto debe

realizarse por su propia seguridad. Ajuste la polea a un

diámetro mayor y reajuste la tensión de la correa. Enchufe

el motor, instale los paneles de inspección y pruebe el

consumo de corriente nuevamente. Repita el proceso

TENSIÓN DE LA

CORREA

3 Libras

3/4 Pulgadas

hasta lograr el consumo correcto de corriente.

Nota: El incremento del diámetro de la polea del motor

aumenta el consumo de corriente. La reducción del

diámetro de la polea del motor disminuye el consumo de

corriente.

PRECAUCIÓN: NO opere el enfriador con un amperio

superior al indicado en la placa del motor. Esto dañará el

T ornillo Ajustable

motor.

4. Verifi que la tensión de la correa luego de ajustar la polea. Una fuerza de 3 libras debería desviar la correa unas 3/4

pulgadas. Reajuste la correa de ser necesario afl ojando el tornillo de ajuste, gire el motor hasta que tenga la tensión correcta

de la correa y vuelva a apretar el tornillo.

Disminuir

Amperio

OPERACIÓN

NOTAS: Estos enfriadores pueden utilizarse sin agua a los fi nes de ventilación. Cuando el aire exterior está fresco (por

ejemplo, por la noche) o cuando la humedad es alta, puede apagarse la bomba de agua.

Para detener el suministro de aire caliente al prender el enfriador, encienda solo la bomba durante los primeros minutos,

luego encienda el motor de la sopladora.

Para que el enfriador evaporativo sea efectivo, debe haber una ventilación adecuada. Si no hay un escape, la presión y humedad

se acumularán dentro del edifi cio. Usted facilita el escape al abrir puertas o ventanas para permitir que el aire viciado del

edifi cio salga al exterior. Puede instalar también rejillas regulables de ventilación en el ático para descargar el aire en el ático.

La combinación de rejillas regulables de ventilación en el ático y un termostato puede brindarle una operación completamente

automática.

Un concepto frecuentemente errado sobre el enfriamiento por evaporación es la cantidad de aire que debe liberarse. ¿Cuánto

debe abrir sus ventanas? Los dos métodos siguientes le ayudarán a determinar cuánto debe abrir sus ventanas.

MÉTODO DE CFM/SUPERFICIE DE VENTANAS

Para un fl ujo adecuado de aire, se necesita una abertura de al menos dos pies cuadrados (288 pulgadas cuadradas) por cada

1000 CFM de su unidad.

Ejemplo: Con 3320 CFM, el modelo ADA 51 (1/2 CV) requiere 6,6 pies cuadrados (950 pulgadas cuadradas) de abertura

(3320/1000 * 2 = 6,6).

Multiplique el número de ventanas por el ancho de las ventanas en pulgadas y divida ese número por el número de pulgadas

cuadradas necesarias según la unidad de tamaño. Esto le indicará a qué altura debe levantar las ventanas. En este ejemplo,

cuatro ventanas de 36 pulgadas de ancho deberían levantarse 6,6 pulgadas cada una.

MÉTODO DE SUCCIÓN DE PAÑUELO DE PAPEL

1. Tome un trozo de pañuelo de papel y córtelo a lo largo en 3 tiras iguales.

2. Encienda su enfriador en “High Cool” (enfriar alto).

3. Abra una ventana por lo menos seis pulgadas de ancho en cada habitación que desea enfriar.

4. Tome el trozo de papel y colóquelo contra la superfi cie de la ventana abierta que está más lejos de la abertura de desagüe del

enfriador. Suelte el papel. Pueden ocurrir tres cosas.

SI: Cae al suelo. ENTONCES:

SI: Se pega a la superfi cie. ENTONCES: ABRA todas las ventanas una pulgada y pruebe nuevamente el paso 4.

SI:

Permanece ligeramente sobre la superfi cie.

ENTONCES: PERFECTO. Ya está todo listo. Disfrute su enfriador.

Notas:

• Cuando cambie a “Low Cool” (enfriar bajo), debe volver a equilibrar su hogar. Repita el paso 4.

• Una vez que equilibra su hogar puede enfriar algunas áreas más que otras abriendo más esas ventanas y cerrando las otras

en la misma proporción. Repita el paso 4 para asegurarse de que el aire de su hogar permanezca equilibrado.

CIERRE todas las ventanas por lo menos una pulgada y pruebe nuevamente el paso 4.

110498-2

13

Page 14

MANTENIMIENTO

Un mantenimiento periódico de su enfriador mejorará su rendimiento y ampliará su vida útil.

ADVERTENCIA: Antes de realizar cualquier mantenimiento, asegúrese de que la energía esté cortada y que el motor y

la bomba estén desenchufados.

INICIO DE MANTENIMIENTO ESTACIONAL

Realice los siguientes pasos básicos antes de que las temperaturas hagan necesario el enfriamiento por si necesita adquirir

piezas de repuesto.

LIMPIEZA DE MEDIO DE FILTRADO

1. Con la energía CORTADA, quite los paneles de inspección, los paneles superiores y la parrilla de entrada para tener acceso

al interior de la unidad. Coloque los paneles sobre una superfi cie plana y segura, para protegerlos contra daño o dobleces.

2. Desconecte el tubo de agua y levante la fuente de distribución de agua, para acceder al medio de fi ltrado. Quite la

almohadilla fi ltrante superior.

3. Quite e inspeccione las almohadillas del medio de fi ltrado. Con un pulverizador de jardín, limpie la almohadilla del medio de

fi ltrado asegurándose de que las aperturas estén libres de obstrucciones y suciedad. Puede ser necesario frotar ligeramente

para quitar los depósitos minerales. No utilice detergentes fuertes o limpiadores a presión para limpiar. Intente que el medio

de fi ltrado quede intacto.

4. El medio de fi ltrado original tiene una vida estándar de 5 años, pero

en áreas de contenido mineral muy elevado puede ser necesario

cambiar el medio de fi ltrado con anterioridad.

5. Al reinstalar almohadillas existentes o al instalar almohadillas de

repuesto nuevos, asegúrese de instalar las mismos de la manera

correcta:

• Coloque el medio de fi ltrado en la unidad con el ángulo de onda más

escarpado, inclinándose al lado de la entrada de aire. Esto facilita

un fl ujo más efectivo de agua hacia las almohadillas, lo que permite

mayor efi ciencia de enfriamiento.

• Recomendamos el uso de equipo original, las almohadillas de

repuesto de medio de fi ltrado MasterCool® para una mayor capacidad

de enfriamiento.

NOTA: De instalar almohadillas de la competencia con ángulos iguales,

desestime la colocación indicada del medio de fi ltrado.

ACEITADO DE COJINETES

1. Los cojinetes de la sopladora deben aceitarse cada año con aceite no

detergente de grado 20/30.

2. Ubique y abra el puerto de aceite en cada uno de los cojinetes de la

sopladora y agregue unas gotas de aceite.

3. Añada aceite a los cojinetes del motor si el motor tiene entradas de

aceite. Nota: Muchos motores están sellados y no requieren la adición

de aceite.

PRECAUCIÓN: No coloque aceite de más en el motor, ya que

puede ocasionar que el motor se funda por exceso de aceite en los

engranajes.

Entrada

Del Aire

Puerto de Aceite

45°

Salida Del Aire

15°

LIMPIEZA DE BOMBA

1. Se debe limpiar la bomba al menos una vez al año o más en caso de

acumulación de residuos.

2. Desenchufe el motor y la bomba de la caja de conexiones, y desconecte

el tubo de agua, si aún permanece conectado.

3. Con un destornillador abra las abrazaderas plásticas de retención hacia

arriba, fuera de los encajes de la montura de la bomba.

4. Deslice la bomba hacia afuera de la montura.

5. Quite la bomba de la red o canasta de fi ltro y quite la base de la bomba.

6. Limpie la bomba, gire el rotor para asegurar que tenga movimiento libre.

7. Quite el pico de la bomba y verifi que que no tenga obstrucciones.

8. Reinstale la base de la bomba y confi rme que esté fi rme.

9. Antes de reinstalar la bomba, revise la manguera de agua, la línea de

purga y el tubo de distribución de agua para asegurarse de que no haya

ninguna obstrucción en las líneas.

14

Quite La

Base

Hélice

110498-2

Page 15

10. Reinstale la bomba deslizando la misma a la guía de montura y reinsertando las abrazaderas plásticas para asegurarse de

que la bomba permanezca en posición vertical.

11. Vuelva a conectar el tubo de agua al pico de salida de la bomba.

REVISIÓN DE CORREA

1. Antes de encender la unidad, verifi que que la correa esté en buenas condiciones. En caso de que deba reemplazarla,

instale una correa del mismo tamaño.

2. Verifi que que la tensión sea correcta: Desvío de 3/4” con 3 libras de fuerza.

APAGADO POR FINAL DE TEMPORADA

Es necesario preparar el enfriador antes de todo período prolongado fuera de uso, y en especial antes de ser apagado por el invierno.

1. Quite toda el agua de la unidad, la línea de suministro y la bomba para asegurarse que no haya daños por congelamiento.

Mantenga la línea de agua desconectada de la unidad y del suministro de agua.

2. Desconecte el motor y la bomba de la caja de conexiones.

3. Limpie la unidad.

4. Cubra la unidad para proteger el acabado durante períodos largos sin uso.

ESPECIFICACIONES GENERALES

MODELOS

PESO (libras) DIMENSIONES DE GABINETE (PULGADAS) ABERTURA DE DUCTO

*SECO *LLENO ALTURA ANCHURA

PROFUNDIDAD

ANCHURA ALTURA

51 Serie 177 272 28 42 45 17-3/4 17-3/4

5112 Serie 190 257 28 42 49 17-3/4 17-3/4

71 Serie 213 263 34-5/8 42 48 19-3/8 19-3/4

7112 Serie 233 300 34-5/8 42 52 19-3/4 19-3/4

* Incluye el peso del motor.

ESPECIFICACIONES DEL MOTOR

MODELOS C.V. MOTOR NOVELOCIDAD VOLTIOS *AMPERAJE

1/3 110445 2 115 7.2 17 110279-002

1/2 110447 2 115 9.8 18 110279-004

51 & 5112

Serie

71 & 7112

Serie

* Amperaje listado es del código eléctrico nacional para la velocidad alta.

1/2 110475 2 230 4.9 15 110279-004

3/4 110449 2 115 13.8 22 110279-004

3/4 110480 2 230 16.9 21 110279-004

1/2 110447 2 115 9.8 18 110279-002

1/2 110475 2 230 4.9 15 110279-002

3/4 110449 2 115 13.8 22 110279-004

3/4 110480 2 230 6.9 21 110279-004

1 110471 2 115 16 29 110279-003

1 110458 2 230 8 29 110279-003

PESO

(LIBRAS)

POLEA DEL

MOTOR N

O.

MODELO CORREA N

ADA51 &

ADA5112

ASA51 &

ASA5112

AUA51 &

AUA5112

ADA71 &

ADA7112

ASA71 &

ASA7112

AUA71 &

AUA7112

110208 (4L-520)

110229 (4L-530) -3/4 C.V.

110212 (4L-570)

110222 (4L-510)

110230 (4L-640)

110213 (4L-670)

110213 (4L-670)

O

110498-2

15

Page 16

PROBLEMA CAUSA POSIBLE REMEDIO

No arranca o no sale aire

Sale poco aire cuando la unidad está

funcionando

LA LOCALIZACION DE AVERIAS

1. No llega corriente 1. Revise la corriente

• Fusible fundido

• Cable eléctrico dañado

o

Cortacircuito desactivado

• Cambie el fusible o restablecer el cortacircuito

• Reemplace el cable

2. Correa muy fl oja o apretada 2. Ajuste la tensión de la correa

3. Motor recalentado 3. Determine la causa

• Correa muy apretada

• Cojinetes de la rueda están secos

• Diámetro de la polea del motor demasiado

• Ajuste la tensión de la correa

• Lubrique los cojinetes

• Ajústela al diámetro correcto

grande

4. Motor parado 4. Cambie el motor

1. Insufi ciente abertura para que salga

el aire

Abra ventanas o puertas para aumentar

1.

fl ujo de aire

2. Poca tensión en la correa 2. Ajuste la tensión o cambie la correa

3. Filtros obstruidos 3. Limpie los fi ltros

4. Motor no se carga 4. Ajuste la polea

Agua está drenando en el tejado

1. El fl otador no se ajusta correctamente 1. Ajuste el fl otador

2. Montaje de desagüe está goteando 2. Apriete la tuerca y el tubo de desagüe

Olor a encerrado, olor desagradable 1. Agua estancado en la unidad 1. Desagüe y limpie el medio evaporativo

1. Voltaje defi ciente 1. Compruebe el voltaje

2. Demasiada tensión en la correa 2. Ajuste la tensión de la correa

Motor se apaga y se enciende

3. Eje del ventilador atorado

3. Lubrique o cambie los cojinetes (Desconecte la

unidad)

4. Cojinetes secos 4. Lubrique los cojinetes

5. Diámetro demasiado grande de la polea del

motor dando por resultado sobrecarga del motor

5. Ajústela para no exceder el grado a carga plena del

amperio del motor

1. Cojinetes secos 1. Lubrique los cojinetes

Hace Ruido

2. Rueda roza contra caja de la rueda 2. Inspeccione y alinee (Desconecte la unidad)

3. Partes sueltas 3. Apriételas

1. Insufi ciente abertura para que salga aire

1. Abra más las ventanas o puertas

2. El medio evaporativo no está mojado 2. Revise la distribución de agua

Enfriamiento inadecuado

• Filtros obstruidos

• Agujeros del tubo obstruidos

• Bomba no funciona

• Limpie los fi ltros

• Límpielos

• Cámbiela o límpiela (Desconecte la unidad)

Demasiada humedad en la casa 1. Insufi ciente salida de aire 1. Abra puertas o ventanas

16

110498-2

Page 17

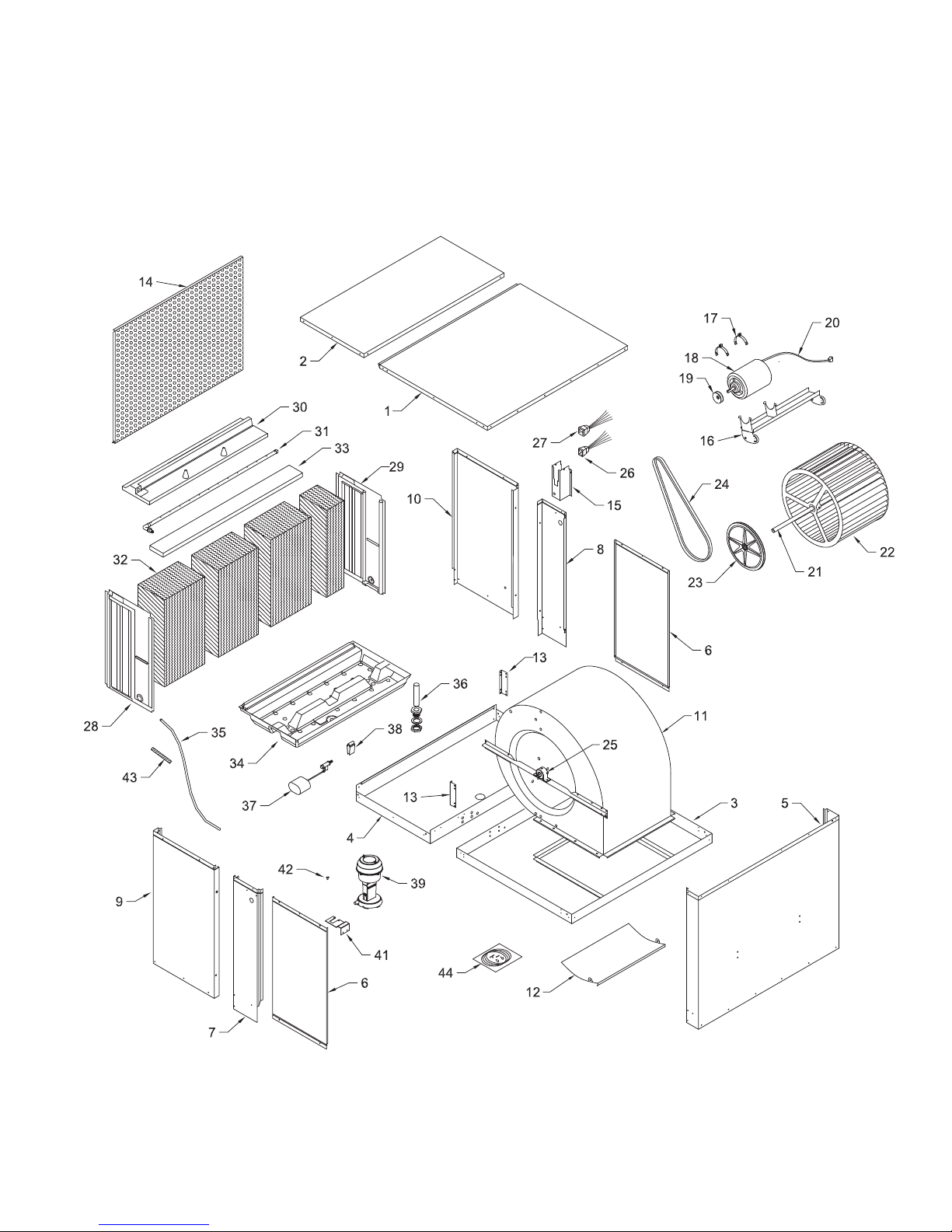

ILLUSTRATED PARTS REPLACEMENT LIST /

LISTA ILLUSTRADA DE PIEZAS DE REPUESTO

SINGLE INLET EVAPORATIVE COOLER/

ENFRIADOR DE ENTRADA SIMPLE

Type Models / Modelos Pages/Paginas

Down Discharge / Descarga Descendente ...................ADA51, ADA5112, ADA71, ADA7112 ..................................18-19

Side Discharge / Descarga Lateral..........................ASA51, ASA5112, ASA71, ASA7112 ..................................20-21

Up Discharge / Descarga Superior ..........................AUA51, AUA5112, AUA71, AUA7112 ..................................22-23

When

ordering parts, please be sure to furnish the following information on all orders. Failure to do so may delay your order. /

Al pedir piezas, incluya toda la información siquiente con su pedido. El no proporcionar toda esta información resultará en una

demora.

1. Cooler model number / El modelo de su enfriador

2. Cooler serial number / Número de serie de la unidad

3. Motor HP / C.V. del motor

4. Description and part number / Descripción y número de pieza

5. Date of purchase / Fecha de compra

110498-2

17

Page 18

PARTS LIST: DOWN DISCHARGE CONFIGURATION /

LISTA DE PIEZAS: CONFIGURACIÓN DE DESCARGA DESCENDENTE

No.

N° Description / Descripción ADA51 ADA5112 ADA71 ADA7112

1. Top, Cabinet / Tapa De La Caja .....................................................................................222130-070 222130-070 222140-053 222140-053

2. Top Access Panel / Panel Superior De Acceso ............................................................... 222130-074 222130-075 222130-074 222130-075

3. Bottom, Blower Section / Base De La Sección De La Rueda ......................................... 322130-068 322130-068 322140-051 322140-051

4. Bottom, Wet Module / Base De La Sección De Agua ..................................................... 222130-072 222130-073 222130-072 222130-073

5. Front Panel / Panel Del Frente ........................................................................................ 222130-076 222130-076 222140-055 222140-055

6. Inspection Panel (2 req.) / Panel De Inspección (2 req.) ................................................224130-002 224130-002 224140-002 224140-002

7. Center Post, Right / Poste Central, Derecho ..................................................................222130-062 222130-062 222140-045 222140-045

8. Center Post, Left / Poste Central, Izquierdo .................................................................... 222130-063 222130-063 222140-046 222140-046

9. Back Post, Right / Poste Trasero, Derecho .....................................................................222130-064 222130-066 222140-047 222140-049

10. Back Post, Left / Poste Trasero, Izquierdo ...................................................................... 222130-065 222130-067 222140-048 222140-050

11. Blower Housing / Caja De La Rueda .............................................................................. 324130-202 324130-202 324140-202 324140-202

12. Cut-Off Plate / Placa Externa .......................................................................................... 224003-015 224003-015 224004-003 224004-003

13. Blower Housing Supports (2 req.) / Soporte Para La Caja De La Rueda (2 req.) ........... 218001-034 218001-034 218001-037 218001-037

14. Grill / Parrilla .................................................................................................................... 222130-078 222130-078 222140-057 222140-057

15. Electrical Junction Box / Caja De Empalme ....................................................................322009-001 322009-001 322009-001 322009-001

16. Motor Mount / Montura Del Motor ................................................................................... 314003-011 314003-011 314003-012 314003-012

17. Motor Mount Clip Set / Conjunto De Seguros Para Montar Motor .................................. 314005-001 314005-001 314005-001 314005-001

18. Motor / Motor ...................................................................................................................* * * *

19. Pulley, Motor / Polea Del Motor .......................................................................................* * * *

20. Electrical Cord, Motor (115V) / Cable Eléctrico Del Motor (115V) ................................... 110372 110372 110372 110372

20. Electrical Cord, Motor (230V) / Cable Eléctrico Del Motor (230V) .................................. §110372-2 §110372-2 §110372-2 §110372-2

21. Shaft, Blower Wheel / Eje De La Rueda ......................................................................... 110183 110183 110183 110183

22. Blower Wheel / Rueda ....................................................................................................16BW 16BW 20BW 20BW

23. Pulley, Blower Wheel / Polea De La Rueda ....................................................................110275 110275 110276 110276

24. Drive Belt / Correa ........................................................................................................... * * * *

25. Bearings, Blower Wheel Shaft / Cojinetes Del Eje De La Rueda .................................... 110351 110351 110351 110351

26. Receptacle, Motor / Toma De Corriente Del Motor .........................................................110393 110393 110393 110393

27. Receptacle, Pump / Toma De Corriente De La Bomba ................................................... 110361 110361 110361 110361

28. Media Shield Right / Protector Para El Medio Evaporativo, Direcho ..............................281043-002 281045-002 281044-002 281046-002

29. Media Shield Left / Protector Para El Medio Evaporativo, Izquierdo ..............................281043-001 281045-001 281044-001 281046-001

30. Water Distributor Housing / Caja Del Distribuidor De Agua ............................................281038-001 281033-001 281038-001 281033-001

31. Water Distributor Tube / Tubo Del Distribuidor De Agua ................................................. 3D-23 3D-23 3D-23 3D-23

32. Evaporative Media Set / Conjunto De Medio Evaporativo .............................................. 310117-001 310118-001 310117-002 310118-002

33. Distributor Filter Pad / Filtro Del Distribuidor ................................................................... 110120 110120 110120 110120

34. Water Reservoir / Bandeja Acumuladora De Agua .........................................................281041-001 281042-001 281041-001 281042-001

35. Tube, Water Delivery / Tubo De Agua ............................................................................. 310716 310716 310716 310716

36. Over Flow Assembly / Montaje De Desagüe ...................................................................110610 110610 110610 110610

37. Float Valve / Flotador ......................................................................................................FL-C FL-C FL-C FL-C

38. Float Shield / Salpicadero Del Flotador ........................................................................... 281006 281006 281006 281006

39. Pump / Bomba ................................................................................................................110429 110429 110429 110429

41. Pump Mount / Montura De La Bomba ............................................................................. 218002-012 218002-012 218002-012 218002-012

42. Pump Retainer / Sujetador De La Bomba .......................................................................110714 110714 110714 110714

43. Anti-Flattening Coil / Espiral Protectora .......................................................................... 110847 110847 110847 110847

44. Bleed-Off Kit / Equipo De Purga......................................................................................310586 310586 310586 310586

* See the motor specifi cation table. Motor sold separately. / Vea la tabla de especifi caciones del motor. Motores se vende por separado.

§ 230V motor cord is optional and not supplied with cooler. / Cable eléctrico del motor de 230V es opcional y no se envía con el enfridor

NOTE: Standard hardware items may be purchased from your local hardware store.

NOTA: Artículos de uso corriente pueden comprarse en la ferretería de su localidad.

18

.

110498-2

Page 19

EXPLODED ILLUSTRATION: DOWN DISCHARGE CONFIGURATION /

ILUSTRACIÓN DE PIEZAS: CONFIGURACIÓN DE DESCARGA DESCENDENTE

110498-2

19

Page 20

PARTS LIST: SIDE DISCHARGE CONFIGURATION /

LISTA DE PIEZAS: CONFIGURACIÓN DE DESCARGA LATERAL

No.

N° Description / Descripción ASA51 ASA5112 ASA71 ASA7112

1. Top, Cabinet / Tapa De La Caja .....................................................................................222130-070 222130-070 222140-053 222140-053

2. Top Access Panel / Panel Superior De Acceso ............................................................... 222130-074 222130-075 222130-074 222130-075

3. Bottom, Blower Section / Base De La Sección De La Rueda .........................................322130-069 322130-069 322140-052 322140-052

4. Bottom, Wet Module / Base De La Sección De Agua .....................................................222130-072 222130-073 222130-072 222130-073

5. Front Panel / Panel Del Frente ........................................................................................ 322130-077 322130-077 322140-056 322140-056

6. Inspection Panel (2 req.) / Panel De Inspección (2 req.) ................................................ 224130-002 224130-002 224140-002 224140-002

7. Center Post, Right / Poste Central, Derecho .................................................................. 222130-062 222130-062 222140-045 222140-045

8. Center Post, Left / Poste Central, Izquierdo .................................................................... 222130-063 222130-063 222140-046 222140-046

9. Back Post, Right / Poste Trasero, Derecho ..................................................................... 222130-064 222130-066 222140-047 222140-049

10. Back Post, Left / Poste Trasero, Izquierdo ...................................................................... 222130-065 222130-067 222140-048 222140-050

11. Blower Housing / Caja De La Rueda .............................................................................. 324130-203 324130-203 324140-203 324140-203

12. Cut-Off Plate / Placa Externa .......................................................................................... 224003-015 224003-015 224004-003 224004-003

13a. Blower Housing Support, Right / Soporte Para La Caja De La Rueda, Derecho ............ 218001-035 218001-035 218001-038 218001-038

13b. Blower Housing Support, Left / Soporte Para La Caja De La Rueda, Izquierdo ............. 218001-036 218001-036 218001-038 218001-038

14. Grill / Parrilla .................................................................................................................... 222130-078 222130-078 222140-057 222140-057

15. Electrical Junction Box / Caja De Empalme ....................................................................322009-001 322009-001 322009-001 322009-001

16. Motor Mount / Montura Del Motor ................................................................................... 314003-011 314003-011 314003-012 314003-012

17. Motor Mount Clip Set / Conjunto De Seguros Para Montar Motor .................................. 314005-001 314005-001 314005-001 314005-001

18. Motor / Motor ...................................................................................................................* * * *

19. Pulley, Motor / Polea Del Motor .......................................................................................* * * *

20. Electrical Cord, Motor (115V) / Cable Eléctrico Del Motor (115V) ................................... 110372 110372 110372 110372

20. Electrical Cord, Motor (230V) / Cable Eléctrico Del Motor (230V) .................................. §110372-2 §110372-2 §110372-2 §110372-2

21. Shaft, Blower Wheel / Eje De La Rueda ......................................................................... 110183 110183 110183 110183

22. Blower Wheel / Rueda ....................................................................................................16BW 16BW 20BW 20BW

23. Pulley, Blower Wheel / Polea De La Rueda ....................................................................110275 110275 110276 110276

24. Drive Belt / Correa ........................................................................................................... * * * *

25. Bearings, Blower Wheel Shaft / Cojinetes Del Eje De La Rueda .................................... 110351 110351 110351 110351

26. Receptacle, Motor / Toma De Corriente Del Motor .........................................................110393 110393 110393 110393

27. Receptacle, Pump / Toma De Corriente De La Bomba ................................................... 110361 110361 110361 110361

28. Media Shield, Right / Protector Para El Medio Evaporativo, Direcho .............................281043-002 281045-002 281044-002 281046-002

29. Media Shield, Left / Protector Para El Medio Evaporativo, Izquierdo .............................281043-001 281045-001 281044-001 281046-001

30. Water Distributor Housing / Caja Del Distribuidor De Agua ............................................281038-001 281033-001 281038-001 281033-001

31. Water Distributor Tube / Tubo Del Distribuidor De Agua ................................................. 3D-23 3D-23 3D-23 3D-23

32. Evaporative Media Set / Conjunto De Medio Evaporativo .............................................. 310117-001 310118-001 310117-002 310118-002

33. Distributor Filter Pad / Filtro Del Distribuidor ................................................................... 110120 110120 110120 110120

34. Water Reservoir / Bandeja Acumuladora De Agua .........................................................281041-001 281042-001 281041-001 281042-001

35. Tube, Water Delivery / Tubo De Agua ............................................................................. 310716 310716 310716 310716

36. Over Flow Assembly / Montaje De Desagüe ...................................................................110610 110610 110610 110610

37. Float Valve / Flotador ......................................................................................................FL-C FL-C FL-C FL-C

38. Float Shield / Salpicadero Del Flotador ........................................................................... 281006 281006 281006 281006

39. Pump / Bomba ................................................................................................................110429 110429 110429 110429

41. Pump Mount / Montura De La Bomba ............................................................................. 218002-012 218002-012 218002-012 218002-012

42. Pump Retainer / Sujetador De La Bomba .......................................................................110714 110714 110714 110714

43. Anti-Flattening Coil / Espiral Protectora .......................................................................... 110847 110847 110847 110847

44. Bleed-Off Kit / Equipo De Purga......................................................................................310586 310586 310586 310586

* See the motor specifi cation table. Motor sold separately. / Vea la tabla de especifi caciones del motor. Motores se vende por separado.

§ 230V motor cord is optional and not supplied with cooler. / Cable eléctrico del motor de 230V es opcional y no se envía con el enfridor.

NOTE: Standard hardware items may be purchased from your local hardware store.

NOTA: Artículos de uso corriente pueden comprarse en la ferretería de su localidad.

20

110498-2

Page 21

EXPLODED ILLUSTRATION: SIDE DISCHARGE CONFIGURATION /

ILUSTRACIÓN DE PIEZAS: CONFIGURACIÓN DE DESCARGA LATERAL

110498-2

21

Page 22

PARTS LIST: UP DISCHARGE CONFIGURATION /

LISTA DE PIEZAS: CONFIGURACIÓN DE DESCARGA SUPERIOR

N

o.

N° Description / Descripción AUA51 AUA5112 AUA71 AUA7112

1. Top, Cabinet / Tapa De La Caja .....................................................................................322130-071 322130-071 322140-054 322140-054

2. Top Access Panel / Panel Superior De Acceso ............................................................... 222130-074 222130-075 222130-074 222130-075

3. Bottom, Blower Section / Base De La Sección De La Rueda ......................................... 322130-069 322130-069 322140-052 322140-052

4. Bottom, Wet Module / Base De La Sección De Agua ..................................................... 222130-072 222130-073 222130-072 222130-073

5. Front Panel / Panel Del Frente ........................................................................................ 222130-079 222130-079 222140-058 222140-058

6. Inspection Panel (2 req.) / Panel De Inspección (2 req.) ................................................224130-002 224130-002 224140-002 224140-002

7. Center Post, Right / Poste Central, Derecho ..................................................................222130-062 222130-062 222140-045 222140-045

8. Center Post, Left / Poste Central, Izquierdo .................................................................... 222130-063 222130-063 222140-046 222140-046

9. Back Post, Right / Poste Trasero, Derecho .....................................................................222130-064 222130-066 222140-047 222140-049

10. Back Post, Left / Poste Trasero, Izquierdo ...................................................................... 222130-065 222130-067 222140-048 222140-050

11. Blower Housing / Caja De La Rueda .............................................................................. 324130-204 324130-204 324140-204 324140-204

12. Cut-Off Plate / Placa Externa .......................................................................................... 224003-015 224003-015 224004-003 224004-003

13. Blower Support Bracket (2 req.) / Soporte Para La Caja De La Rueda (2 req.) .............218123-001 218123-001 218001-038 218001-038

14. Grill / Parrilla .................................................................................................................... 222130-078 222130-078 222140-057 222140-057

15. Electrical Junction Box / Caja De Empalme .................................................................... 322009-001 322009-001 322009-001 322009-001

16. Motor Mount / Montura Del Motor ................................................................................... 314003-011 314003-011 314003-012 314003-012