Page 1

Product Name: VACUUM PUMP Oil (90010, 90018, 90024, 90061, 90016)

Revision Date: 10-January-2013

Page 1 of 8

GHS and under Directive 2001/58/EC and other international

!

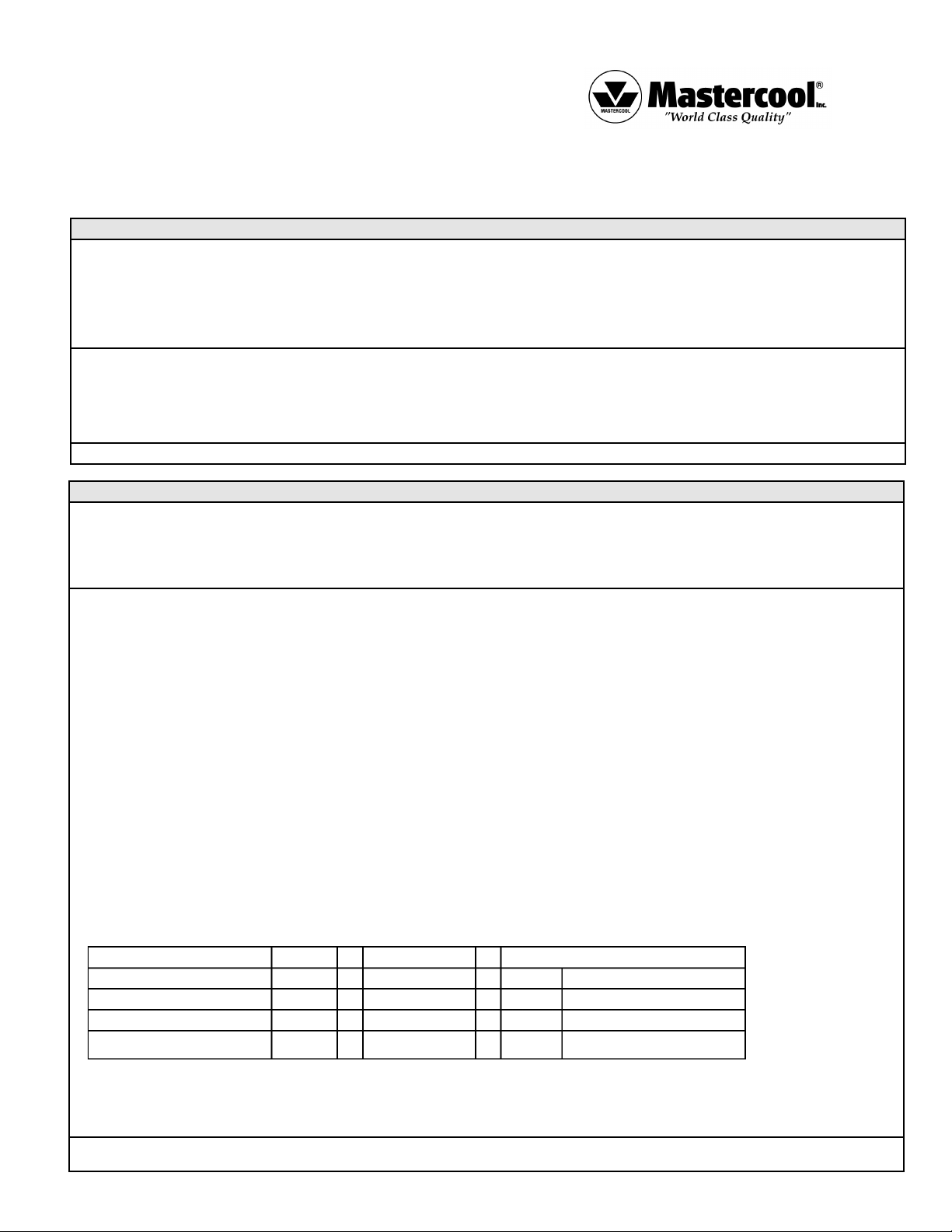

Degree of Hazard

NFPA !HMIS !HAZARD RATINGS

Health

1 !1

!

0

Insignificant

Fire

1 !1

!

1

Slight

Reactivity

0 !0

!

2

Moderate

Personal Protection

!

!B !

3

High

!

!

SAFETY DATA SHEET

!

SECTION 1: PRODUCT AND COMPANY IDENTIFICATION

PRODUCT

Product Name:

!

!

!

Product Description:

Intended Use:

!

VACUUM PUMP LUBRICANT ISO 46 - 100

BVA VAC 46, BVA VAC 68, BVA VAC 100.

!

Highly Refined Mineral Oil Base Stock (oil) with Synthetic Hydrocarbon Oil.

Lubricant, Vacuum Pump Lubricant

COMPANY IDENTIFICATION

!

Supplier

!

29222 Trident Industrial. Blvd.

!

New Hudson, MI 48165 USA

!

+1-248-348-4920

Emergency telephone numbers

USA – Chemtrec: 800-424-9300 All Others – Chemtrec: +1-703-527-3887

!

SECTION 2: HAZARDS IDENTIFICATION

This material is not considered to be hazardous according to regulatory guidelines see Section 15.

!

BVA operates a world-wide system for hazard communication. Some hazards shown in Section 2 may apply to non-EU countries

and may not result in classification and labeling in the EU. Please see Section 3 and 15 for country specific classification

information, and Section 11 for additional details.

HEALTH HAZARDS

Classification of the substance or mixture

ACUTE TOXICITY: ORAL - Category 5

INHALATION - Category 5

!

Hazard Classification: Not hazardous.

!

Label Elements Including Precautionary Statements

Symbol: None.

Signal Word: None.

Hazard Risk Statement: Not hazardous.

Precautionary Statement: Avoid contact with skin and eyes.

!

IF IN EYES: Rinse cautiously with water for several minutes. Remove contact lenses,

if present and easy to do. Continue rinsing.

!

IF ON SKIN: Wash with plenty of soap and water.

!

Other Hazard: None known.

!

U.S.A. Hazardous Material Information System and National Fire Protection Association (U.S.A.)

!

!

!

!

!

!

!

!

!

!

Note : This information is based on test data from similar products.

This product is not formulated to contain ingredients which have exposure limits established by regulatory agencies. It is not

hazardous to health as defined by the European Union Dangerous Substances/Preparations Directives. Low order of toxicity.

Excessive exposure may result in eye, skin, or respiratory irritation. High-pressure injection under skin may cause serious damage.

This material should not be used for any other purpose than the intended use in Section 1 without expert advice. Health studies

have shown that chemical exposure may cause potential human health risks which may vary from person to person.

Page 2

Product Name: VACUUM PUMP Oil (90010, 90018, 90024, 90061, 90016)

Revision Date: 10-January-2013

Page 2 of 8

GHS and under Directive 2001/58/EC and other international

!

!

!

!

!

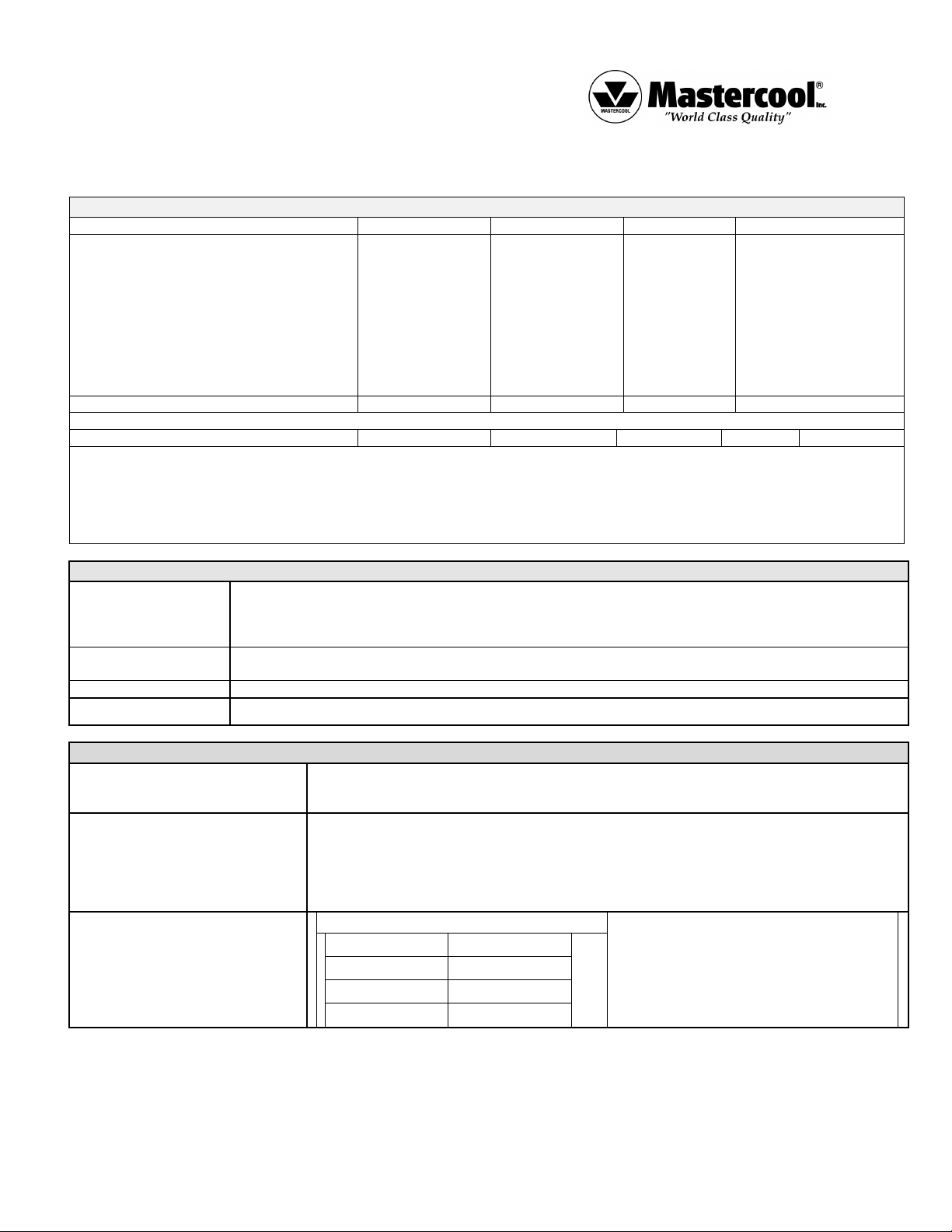

SECTION 3: COMPONENT INFORMATION

Chemical Name

CAS #

EINECs/ELINKs #

Percent (% wt)

Symbols /Risk Phrases

The base oil may be a mixture of the

Following:

!

!

1) Hydrotreated Distillate, Heavy Paraffin

2) Hydrotreated Distillate, Light Paraffin

3) 1-decene, homopolymer, hydrogenated

or other hydrogenated polyalphaolefin

Synthetic Hydrocarbon Fluids

The base oil may

be a mixture of the

Following CAS#s:

!

64742-54-7,

64742-55-8

68037-01-4

151006-62-1

!

!

!

!

!

265-157-1

265-158-7

500-183-1

417-070-7

!

!

!

!

!

All Combined

>99%

!

!

!

!

!

IK (None Required)

Proprietary additives

<1%

IK (None Required)

Reportable Hazardous Substance(s) or Complex Substance(s)

None

!!!!!

Explanation of symbols:

IK = No Classification Required,

!

INGREDIENT COMMENTS

If no EU or no CAS numbers are given for classified components the raw material supplier has applied for / will apply for

exemption, have not sent the complete information yet , or there could be no obligation to give the EU or CAS numbers.

!

SECTION 4 : FIRST AID MEASURES

Inhalation:

Remove from further exposure. For those providing assistance, avoid exposure to yourself or others. Use

adequate respiratory protection. If respiratory irritation, dizziness, nausea, or unconsciousness occurs,

seek immediate medical assistance. If breathing has stopped, assist ventilation with a mechanical device

or use mouth-to-mouth resuscitation.

Skin:

Wash with soap and water. Remove and launder contaminated clothing before reuse. If irritation develops

get medical attention.

Eye :

Flush thoroughly with water. If irritation occurs, get medical assistance.

Ingestion:

First aid is normally not required. Seek medical attention if discomfort occurs.

!

SECTION 5 : FIRE FIGHTING PROCEDURES

EXTINGUISHING MEDIA

Appropriate Extinguishing Media: Use water fog, foam, dry chemical or carbon dioxide (CO2)

to extinguish flames.

Inappropriate Extinguishing Media: Straight streams of water

FIRE FIGHTING

Fire Fighting Instructions: Evacuate area. Prevent run-off from fire control or dilution from

entering streams, sewers or drinking water supply. Fire-fighters should use standard

protective equipment and in enclosed spaces, self-contained breathing apparatus (SCBA).

Use water spray to cool fire exposed surfaces and to protect personnel.

!

Hazardous Combustion Products: Smoke, Fume, Carbon Monoxide, Aldehydes,

FLAMMABILITY PROPERTIES

!

Flash Point ASTM D92 (open cup typical)

Flammable Limits

(Approximate volume % in air):

LEL: N/D UEL: N/D

!

Autoignition Temperature: N/D

!

!

!

°C (°F)

!

VAC 46

216 (420)

VAC 68

240 (464)

VAC 100

260 (500)

Page 3

Product Name: VACUUM PUMP Oil (90010, 90018, 90024, 90061, 90016)

Revision Date: 10-January-2013

Page 3 of 8

GHS and under Directive 2001/58/EC and other international

!

!

!

!

SECTION 6 : SPILL OR LEAK HANDLING PROCEDURES

SPILL MANAGEMENT

Land Spill: Stop leak if you can do so without risk. Recover by pumping or with suitable absorbent.

!

Water Spill: Stop leak if you can do so without risk. Confine the spill immediately with booms. Warn

other shipping. Remove from the surface by skimming or with suitable absorbents. Seek the advice of

a specialist before using dispersants.

!

Water spill and land spill recommendations are based on the most likely spill scenario for this material;

however, geographic conditions, wind, temperature, (and in the case of a water spill) wave and current

direction and speed may greatly influence the appropriate action to be taken. For this reason, local

experts should be consulted. Note: Local regulations may prescribe or limit action to be taken.

ENVIRONMENTAL

PRECAUTIONS

Large Spills: Dyke far ahead of liquid spill for later recovery and disposal. Prevent entry into

waterways, sewers, basements or confined areas.

!

SECTION 7 : HANDLING AND STORAGE

HANDLING

Prevent small spills and leakage to avoid slip hazard.

Static Accumulator: This material is a static accumulator.

STORAGE

Do not store in open or unlabelled containers.

!

SECTION 8 : EXPOSURE CONTROLS / PERSONAL PROTECTION

Exposure limits/standards for materials that can be formed when handling this product: When mists / aerosols can occur, the

following are recommended: 5 mg/m³ - ACGIH TLV, 10 mg/m³ - ACGIH STEL.

!

Note: Information about recommended monitoring procedures can be obtained from the relevant agency(ies)/institute(s)

ENGINEERING CONTROLS

The level of protection and types of controls necessary will vary depending upon potential

exposure conditions. Control measures to consider:

No special requirements under ordinary conditions of use and with adequate ventilation

PERSONAL PROTECTION

Personal protective equipment selections vary based on potential exposure conditions such as

applications, handling practices, concentration and ventilation. Information on the selection of

protective equipment for use with this material, as provided below, is based upon intended,

normal usage.

Respiratory Protection: Respiratory Protection: If engineering controls do not maintain airborne contaminant

concentrations at a level which is adequate to protect worker health, an approved respirator

may be appropriate. Respirator selection, use, and maintenance must be in accordance with

regulatory requirements, if applicable. Types of respirators to be considered for this material

include:

No special requirements under ordinary conditions of use and with adequate ventilation.

For high airborne concentrations, use an approved supplied-air respirator, operated in positive

pressure mode. Supplied air respirators with an escape bottle may be appropriate when

oxygen levels are inadequate, gas/vapour warning properties are poor, or if air purifying filter

capacity/rating may be exceeded.

Hand Protection: Any specific glove information provided is based on published literature and glove

manufacturer data. Glove suitability and breakthrough time will differ depending on the specific

use conditions. Contact the glove manufacturer for specific advice on glove selection and

breakthrough times for your use conditions. Inspect and replace worn or damaged gloves. The

types of gloves to be considered for this material include:

No protection is ordinarily required under normal conditions of use.

Eye Protection: If contact is likely, safety glasses with side shields are recommended.

Skin and Body Protection: Any specific clothing information provided is based on published literature or manufacturer

data. The types of clothing to be considered for this material include:

No skin protection is ordinarily required under normal conditions of use. In accordance with

good industrial hygiene practices, precautions should be taken to avoid skin contact.

Specific Hygiene Measures Always observe good personal hygiene measures, such as washing after handling the material

and before eating, drinking, and/or smoking. Routinely wash work clothing and protective

equipment to remove contaminants. Discard contaminated clothing and footwear that cannot

be cleaned. Practice good housekeeping.

Page 4

Product Name: VACUUM PUMP Oil (90010, 90018, 90024, 90061, 90016)

Revision Date: 10-January-2013

Page 4 of 8

GHS and under Directive 2001/58/EC and other international

!

!

!

ENVIRONMENTAL CONTROLS See Sections 6, 7, 12, 13.

!

SECTION 9 : PHYSICAL & CHEMICAL PROPERTIES

Typical physical and chemical properties are given below. Consult the Supplier in Section 1 for additional data.

General Information

Physical State Liquid

HEALTH, SAFETY, AND ENVIRONMENTAL INFORMATION

Density at 20°C

0.855 - 0.863

Color Clear colorless to pale yellow

Flash Point typical °C (°F)

>205 (401) See Section 5

Odor Characteristic

Flammable Limits LEL: N/D UEL: N/D

Odor Threshold ND

Autoignition Temperature: ND

!

Boiling Point °C (°F)

>200 oC

OTHER INFORMATION

Vapor Density (Air=1) NA

Pour Point

°C (°F)

-12 (10) or below

Vapor Pressure < 0.013 kPa (0.1 mm Hg) at 20°C

Freezing Point ND

Evaporation Rate (N-Butyl ND

Acetate = 1):

Viscosity are +/- 10%

!

!

Viscosity

cSt at 40oC

!

Solubility in Water Nil

!

VAC 46

46

Oxidizing Properties See Sections 3, 15, 16.

!

!

VAC 68

68

!

VAC 100

100

!

SECTION 10 : STABILITY & REACTIVITY

STABILITY:

Material is stable under normal conditions.

CONDITIONS TO AVOID:

Excessive heat. High energy sources of ignition.

MATERIALS TO AVOID:

Strong oxidizers

HAZARDOUS DECOMPOSITION PRODUCTS:

Material does not decompose at ambient temperatures.

HAZARDOUS POLYMERIZATION:

Will not occur.

!

SECTION 11: TOXICOLOGICAL INFORMATION

ACUTE TOXICITY

Potential acute health effects

Inhalation : No known significant effects or critical hazards.

Ingestion : No known significant effects or critical hazards.

Skin contact : No known significant effects or critical hazards.

Eye contact : No known significant effects or critical hazards.

!

PRODUCT

!

Route of Exposure Conclusion / Remarks

INHALATION

Toxicity: LC50 > 5000 mg/m3 Minimally Toxic. Based on test data for structurally similar materials.

Irritation: No end point data. Negligible hazard at ambient/normal handling temperatures. Based on

assessment of the components.

INGESTION

Toxicity: LD50 > 5000 mg/kg Minimally Toxic. Based on test data for structurally similar materials.

!

Skin

Toxicity: LD50 > 5000 mg/kg Minimally Toxic. Based on test data for structurally similar materials.

Irritation: Data available. Negligible irritation to skin at ambient temperatures. Based on test data for

structurally similar materials.

Eye

!

Irritation: Data available. May cause mild, short-lasting discomfort to eyes. Based on test data for

structurally similar materials.

Page 5

Product Name: VACUUM PUMP Oil (90010, 90018, 90024, 90061, 90016)

Revision Date: 10-January-2013

Page 5 of 8

GHS and under Directive 2001/58/EC and other international

!

!

CHRONIC/OTHER EFFECTS

For the product itself:

Repeated and/or prolonged exposure may cause irritation to the skin, eyes, or respiratory tract.

!

Base oil severely refined: Not carcinogenic in animal studies. Representative material passes IP-346, Modified

Ames test, and/or other screening tests. Dermal and inhalation studies showed minimal effects; lung nonspecific infiltration of immune cells, oil deposition and minimal granuloma formation. Not sensitising in test

animals.

.

!

CARCINOGENIC EFFECTS:

!

Contains no carcinogens. Similar compounds essentially non-toxic. No component of this product at levels greater than 0.1% is

identified as a carcinogen by ACGIH or the International Agency for Research on Cancer (IARC). No component of this product

present at levels greater than 0.1% is identified as a carcinogen by the U.S. National Toxicology Program (NTP) or the U.S.

Occupational Safety and Health Act (OSHA), NTP or IARC.

!

Although there is no specific test data on all the base oil components, the mineral base oil would not be expected to exhibit carcinogenic

potential based on what is known of the toxicity of mineral base oils in general.

The DMSO extract by IP 346 of the oil is less than 3%.(Typical 0.2% with Maximum 0.5%) Consequently it is not classified

as a carcinogen.

The base oil in this product is severely hydro-treated by all hydro-processing route. By this refining history would be showed no

evidence of carcinogenic potential.

!

MUTAGENIC EFFECTS: No component of this product at levels greater than 0.1% is classified by established regulatory criteria as

a mutagen.

!

TERATOGENIC EFFECTS/DEVELOPMENTAL TOXICITY: No component of this product at levels greater than 0.1% is classified by

established regulatory criteria as teratogenic or embryotoxic.

!

REPRODUCTION TOXICITY: No component of this product at levels greater than 0.1% is classified by established regulatory

criteria as a reproductive toxin.

!

Additional information is available by request.

OVER – EXPOSURE SIGNS/SYMPTOMS

!

Skin No known significant effects or critical hazards.

Ingestion No known significant effects or critical hazards.

Inhalation No known significant effects or critical hazards.

!

SECTION 12 : ECOLOGICAL INFORMATION

!

The information given is based on data available for the material, the components of the material, and similar materials.

ECOTOXICITY

Material -- Not expected to be harmful to aquatic organisms.

MOBILITY

Base oil component -- Low solubility and floats and is expected to migrate from water to the land.

Expected to partition to sediment and wastewater solids.

PERSISTENCE AND DEGRADABILITY

Biodegradation:

Base oil component -- Expected to be inherently biodegradable

!

!

BIOACCUMULATION POTENTIAL

Base oil component -- Has the potential to bioaccumulate, however metabolism or physical properties may reduce the

bioconcentration or limit bioavailability.

!

!

ECOLOGICAL DATA

Page 6

Product Name: VACUUM PUMP Oil (90010, 90018, 90024, 90061, 90016)

Revision Date: 10-January-2013

Page 6 of 8

GHS and under Directive 2001/58/EC and other international

!

TEST

Duration

Organism Type

Test Results

Aquatic - Chronic Toxicity

21 day(s)

Water Flea

NOELR 1.05 mg/l: data for similar

materials

!

7 days

Fish

NOEC: > 5000mg/L (IUCLID Dataset)

!

7 days

Aquatic Invertebrates,

NOEC: > 5000mg/L (IUCLID Dataset)

!

Data for Highly Refined Severely Hydrotreated Base oil for similar materials

!

Care should be taken to minimize release of this product into the environment

!

!

Environmental Fate & Distribution No Data Available

Persistence & Degradation Toxicity No Data

Available

Effect on Effluent Treatment Product may be partially

removed in biological

treatment processes.

Other Typical (not a specification)

Acute Toxicity to Fish: No Data Available

Effect Concentration on Algae: No Data Available

Ready Biodegradability: No Data Available

Respiration Inhibition: No Data Available

Adsorption/Desorption: No Data Available

Abiotic Degradability-Hydrolysis : Not measurable

!

SECTION 13 : DISPOSAL CONSIDERATIONS

!

Disposal recommendations based on material as supplied. Disposal must be in accordance with current applicable laws and

regulations, and material characteristics at time of disposal.

!

DISPOSAL RECOMMENDATIONS

Product is suitable for burning in an enclosed controlled burner for fuel value or disposal by supervised incineration at very

high temperatures to prevent formation of undesirable combustion products.

!

REGULATORY DISPOSAL INFORMATION

!

European Waste Code: 13 01 10

!

NOTE: These codes are assigned based upon the most common uses for this material and may not reflect contaminants

resulting from actual use. Waste producers need to assess the actual process used when generating the waste and its

contaminants in order to assign the proper waste disposal code(s).

!

This material is considered as hazardous waste pursuant to Directive 91/689/EEC on hazardous waste, and subject to the

provisions of that Directive unless Article 1(5) of that Directive applies.

!

Empty Container Warning Empty Container Warning (where applicable): Empty containers may contain residue and can be

dangerous. Do not attempt to refill or clean containers without proper instructions. Empty drums should be completely drained and

safely stored until appropriately reconditioned or disposed. Empty containers should be taken for recycling, recovery, or disposal

through suitably qualified or licensed contractor and in accordance with governmental regulations. DO NOT PRESSURIZE, CUT,

WELD, BRAZE, SOLDER, DRILL, GRIND, OR EXPOSE SUCH CONTAINERS TO HEAT, FLAME, SPARKS, STATIC

ELECTRICITY, OR OTHER SOURCES OF IGNITION. THEY MAY EXPLODE AND CAUSE INJURY OR DEATH.

Page 7

Product Name: VACUUM PUMP Oil (90010, 90018, 90024, 90061, 90016)

Revision Date: 10-January-2013

Page 7 of 8

GHS and under Directive 2001/58/EC and other international

!

!

SECTION 14 : TRANSPORT INFORMATION

LAND (ADR/RID) : Not Regulated for Land Transport

INLAND WATERWAYS (ADNR) : Not Regulated for Inland Waterways Transport

SEA (IMDG) : Not Regulated for Sea Transport according to IMDG-Code

AIR (IATA) : Not Regulated for Air Transport

!

US DOT Classification: Not Regulated

Marine Pollutant: Not a Pollutant

Special Provisions for transport: None Identified

ICAO/IATA Classification

Proper shipping name: Not regulated

IATA Class

UN number: Not regulated.

Packing Group: Not regulated.

ADR/RID Classification

UN number: Not regulated.

Proper shipping name: Not regulated.

ADR/RID Class: Not regulated.

Packing Group: Not regulated.

IMO/IMDG Classification

Proper shipping name: Not regulated

IMDG Class: Not regulated

UN number: Not regulated.

Packing Group: Not regulated.

Marine Pollutant: Not pollutant.

USA: No special warning labels are required under OSHA 29CFR 1910.1200. OSHA hazard warnings are not applicable for this

product; therefore no OSHA Warnings would appear on the label. No EPA hazard classification code.

!

SECTION 15: Regulatory Information Product Component Ingredients

Europe

Material is not dangerous as defined by the EU Dangerous Substances/Preparations Directives.

EU LABELING: Not regulated according to EC Directives Material is not dangerous as defined by the EU Dangerous

Substances/Preparations Directives.

!

Classification and labeling have been performed according to EU Directives

67/548/EEC, 1999/45/EC and 2001/58/EC (including amendments) and the intended use.

- Consumer applications.

!

United States

EPA SARA Title III Chemical Listings

Section 302 Extremely Hazardous Substances: None.

Section 304 CERCLA Hazardous Substances: None.

OSHA HAZARD COMMUNICATION STANDARD: When used for its intended purposes, this material is not

classified as hazardous in accordance with OSHA 29 CFR 1910.1200.

!

Canada

WHMIS (Canadian Workplace Hazardous Materials Information System)

This product when tested as a whole is not a controlled substance within the meaning of the Hazardous Products Act.

!

Germany: Water Hazardous Class (WGK): 1 (low hazard to water)

!

NATIONAL LEGISLATION / REGULATIONS

Ozone depleting chemicals: No ozone depleting chemicals are present or used in manufacture.

!

REGULATORY STATUS AND APPLICABLE LAWS AND REGULATIONS

!

Complies with the following national/regional chemical inventory requirements: , DSL, ENCS, TSCA

Special:

Inventory

Status

AICS

All components are listed or exempted.

ELINCS

Restrictions Apply

IECSC

All components are listed or exempted.

KECI

All components are listed or exempted.

PICCS

All components are listed or exempted.

Page 8

Product Name: VACUUM PUMP SERIES

Revision Date: 10-January-2013

Page 8 of 8

GHS and under Directive 2001/58/EC and other international

!

!

!

!

Detail

U.S. Regulations

!

US INVENTORY (TSCA 8b): Listed on inventory.

SARA Title III Section 302 Extremely Hazardous Substances (40 CFR Part 355):: This product is not

regulated under Section 302 of SARA and 40 CFR Part 355.

SARA Title III Sections 311/312 Hazardous Categorization (40 CFR Part 370):: Defined as non-hazardous by

OSHA under 29 CFR 1910.1200(d).

SARA 313 toxic chemical notification and release reporting: No products were found.

CERCLA Sections 102a/103 Hazardous Substances (40 CFR Part 302.4):: This material is not regulated under

CERCLA Sections 103 and 107.

!

!

State

Regulations

No products were found.

California prop. 65: No products were found

!

!

SECTION 16: OTHER INFORMATION

This product safety data sheet was prepared in compliance with Commission Directive 2001/58/EC , 91/155/EEC, 67/548/EEC and

1999/45/EC as well as their relevant amendments, on the approximation of laws, regulations and administrative provisions

relative to the classification, packaging and labeling of dangerous substances and preparations.

!

N/D = Not determined, N/A = Not applicable

KEY TO THE RISK CODES CONTAINED IN SECTION 2 AND 3 OF THIS DOCUMENT (for information only):

THIS SAFETY DATA SHEET CONTAINS THE FOLLOWING REVISIONS: minor typographical 17 August 2010

Date of ISSUE/Printing 10-January-2012

The information and recommendations contained herein are, to the best of our knowledge and belief, accurate and reliable as of the

date issued. You can contact us to insure that this document is the most current available. The information and recommendat ions

are offered for the user's consideration and examination. It is the user's responsibility to satisfy itself that the product is suitable for

the intended use. If buyer repackages this product, it is the user's responsibility to insure proper health, safety and other necessary

information is included with and/or on the container. Appropriate warnings and safe-handling procedures should be provided to

handlers and users. Alteration of this document is strictly prohibited. Except to the extent required by law, re -publication or

retransmission of this document, in whole or in part, is not permitted.

!

Loading...

Loading...