Page 1

ULTIMA ID PRO ™

OPERATION MANUAL

Analyzer Part Number: 69HVAC -PRO2

Page 2

Table of Contents

TABLE OF CONTENTS V

FOR YOUR SAFETY VI

ANALYZER WARNINGS VI

GENERAL CAUTIONS VII

WELCOME VIII

1 INTRODUCTION AND OVERVIEW 1-09

1.1 GENERAL 1-09

1.2 FEATURES 1-10

1.3 Ultima ID ProTM COMPONENTS 1-11

Ultima ID ProTM Base Unit 1-11

Low Side Vapor Sample Hose 1-11

High Side Liquid Sample Hose 1-12

AC Power Adapter 1-12

Control Panel 1-13

Back Panel Connections 1-13

Hard Shell Stoarage/Carrying Case 1-14

2 ULTIMA ID PROTM OPERATION 2-15

2.1 FIRST USE 2-15

2.2 TURNING ON THE UNIT 2-15

2.3 CALIBRATION 2-16

2.4 VAPOR SAMPLING 2-17

2.5 LIQUID SAMPLING 2-18

2.6 VIEWING THE TEST RESULTS 2-18

2.7 CONTAMINATED BLEND REFRIGERANTS 2-19

2.8 PURE BLEND REFRIGERANTS 2-19

2.9 PURE BLENDS WITH INCORRECT COMPONENT RATIOS 2-20

2.10 MEASURING AIR 2-20

2.11 PRINTING THE TEST RESULTS & CHANNEL DATA 2-21

2.12 CHANNEL DATA MODELLING 2-22

3 MAINTENANCE & TROUBLESHOOTING 3-23

3.1 SETTING THE LCD CONTRAST 3-23

3.2 CHANGING THE WHITE PLASTIC SAMPLE FILTER 3-23

3.3 REPLACING THE BRASS SAMPLE HOSE RESTRICTOR 3-24

3.4 CHANGING THE PRINTER PAPER 3-25

3.5 SOFTWARE UPDATE 3-26

3.6 LOW BATTERY WARNING 3-26

3.7 AIR SENSOR LOW 3-26

3.8 ERROR MESSAGE 3-27

APPENDICES 3-28

3.9 SPARE PARTS LIST 3-28

3.10 APPENDIX B – SPECIFICATIONS 3-28

3.11 APPENDIX E – WARRANTY 3-29

CERTIFICATE OF CALIBRATION 3-30

Page V

Page 3

For Your Safety:

PLEASE READ THIS MANUAL IN ITS ENTIRETY BEFORE ATTEMPTING INSTALLATION OR OPERATION! Attempting to operate the Ultima ID Pro™ without fully

understanding its features and functions may result in unsafe conditions.

Analyzer Warnings

• REFRIGERANT BLEND WARNING: The HVAC industry is ever evolving new

refrigerants. Many of these new blends can be identied and/or proled using the

Ultima ID Pro™.

• SAMPLE FILTER WARNING: Replace the sample lter of the instrument

AS SOON AS RED SPOTS OR DISCOLORATION BEGIN TO APPEAR ON THE

OUTSIDE DIAMETER OF THE WHITE ELEMENT. Failure to properly maintain and

replace the sample lter will result in severe damage or inaccurate results.

• SAMPLE INPUT WARNING: The instrument includes sampling options. One

for High Side Liquid sampling and one for Low Side Vapor Sampling. Failure to use

the correct hose conguration on the proper sample port may result in incorrect

readings and/or damage to the instrument. DO NOT attempt to introduce liquid or

samples heavily laden with oil into the Low Side sampling hose conguration. Damage caused to the instrument due to the use of the wrong hose conguration on the

wrong port will void the warranty!

• BATTERY CHARGING WARNING: When charging the internal battery with

the supplied power supply, the power supply may become warm. If the power supply

becomes warm, unplug the immediately! When charging multiple analyzers, allow

the charger to cool between each battery.

Page VI

Page 4

General Cautions

• ALWAYS wear eye and skin protection when working with refrigerants. Escaping

refrigerant vapors will present a freezing danger.

• ALWAYS turn the compressor OFF before connecting the instrument to an air

conditioning system.

• ALWAYS inspect the sample hose before each use. Replace the hose if it appears cracked, frayed, structed or fouled with oil.

• DO NOT direct refrigerant vapors venting from hoses towards the skin.

• DO NOT disassemble the instrument. There are no serviceable components

internal to the instrument and disassembly will void the warranty.

• ALWAYS place the Analyzer on a at and sturdy surface.

• To reduce the risk of electrical shock, do not disassemble the instrument; do not

use the instrument in wet or damp areas.

• Some systems may contain hydrocarbons or ammable refrigerants. This

analyzer is designed with sealed heat sources and without sparking

components. Ensure adequate ventilation and always take proper precautions

when working with refrigerants.

• DO NOT breathe refrigerant and lubricant vapor or mist. Exposure may irritate

eyes, nose, and throat. If accidental system discharge occurs, immediately

ventilate the work area.

• DO NOT utilize any hose assembly other than those supplied with the

instrument. The use of other hose types will introduce errors into the refrigerant

analysis and instrument calibration.

• ALWAYS verify that the refrigerant which is tested from the Low Side does not

contain or will not emit heavy loads of oil or liquid.

• NEVER admit any sample into the instrument at pressures in excess of

500 psig.

• NEVER obstruct the air intake, sample exhaust or case ventilation ports of the

instrument during use.

Page VII

Page 5

1 INTRODUCTION AND OVERVIEW

1.1 General

Contamination and mislabelling of refrigerants either in storage cylinders or air conditioning systems

can lead to component corrosion, elevated head pressures and system failures when utilized by

unsuspecting technicians. The ability of the technician to determine refrigerant type and purity is severely hampered by the presence of air when attempting to utilize temperature-pressure relations.

The development of various substitute refrigerants further complicate the ability of a technician to

identify refrigerant purity based upon temperature-pressure relationships. The substitute refrigerant

blends can also introduce a ammability hazard to the technician and the ultimate end user of the

air conditioning system.

The Mastercool Ultima ID Pro™ Refrigerant Analyzer provides a fast, easy and accurate means to

determine refrigerant purity in refrigerant storage cylinders or directly in air conditioning systems.

The instrument utilizes non-dispersive infrared (NDIR) technology to determine the weight concentrations of multiple refrigerant types. Refrigerant purity is displayed on the LCD Screen and the user

must determine acceptable levels of purity based on their recovery or use standards. The instru-

ment is supplied complete with a 1⁄4” Flare Vapor Sampling Hose, a High Pressure Liquid Sample

Trap Assembly, a 100-240 VAC power transformer, built in Lithium Iron Phosphate battery, thermal

printer, and all required plumbing housed within a rugged, portable, storage case.

Testing occurs when sample gas is admitted into the instrument through the supplied sampling hose

congurations and presented to the sensing device. The instrument provides the user with direct

percent by weight concentrations.

The instrument interfaces with the user via a LCD graphic display, status indicator LED’s, and push

button communication switches. Direct percent by weight concentrations of the sampled refrigerant

are provided on the display as well as user directions and prompts. An on-board printer is provided

to print an on-the-spot analysis report.

The Mastercool Ultima ID Pro™ Refrigerant Analyzer provides the refrigerant technician with excellent knowledge of refrigerant type and purity as well as protection against refrigerant contamination

and potential ammability.

Page 1-9

Page 6

1.2 Features

The Ultima ID Pro™ Refrigerant Analyzer is the MOST advanced portable instrument ever

manufactured for determining the purity of gaseous refrigerants for the HVAC-R market.

Features Include:

• Advanced ergonomic design

• Rugged rubberized hand grips

• Large graphic display with on-screen instructions

• Fast test time

• Built in printer for instant analysis report

• Vapor or Liquid Sampling ability

• Internal, rechargeable Lithium Iron Phosphate battery for cordless operation in any

location

• Hard shell carry/storage case

• USB Port for Remote Software Updates

Page 1-10

Page 7

1.3 Ultima ID Pro™ Components

Ultima ID Pro™ Base Unit

The Ultima ID Pro™ base unit houses the Graphic Display, Infrared Bench, Electrical Connections,

built in Lithium Iron Phosphate Battery and Printer Module. These components require no main-

tenance; therefore there are no serviceable components internal to the instrument. Disassembly will void the warranty.

Low Side Vapor Sample Hose

The 6.5 foot (2 meter) Low Side Vapor Sample Hose conguration is constructed of a polyurethane tube. A Brass Sample Hose Restrictor acts to reduce pressure at the sample connection

point and reduce the introduction of harmful oil into the machine. The maximum inlet pressure is

500 psig. The hose is provided with an instrument inlet port mating connector on one end and a

1⁄4” SAE female are coupling nut on the service end.

NOTE: The analyzer will indicate “Non-Condensable” or “Unknown Refrigerant” if the analyzer

does not receive a good sample due to obstructed ow or lack of ow. If this occurs the Brass

Sample Hose Restrictor may need to be replaced.

Analyzer End

Brass Sample

Hose Restrictor

Service End

(1/4 SAE Flare Nut)

Page 1-11

Page 8

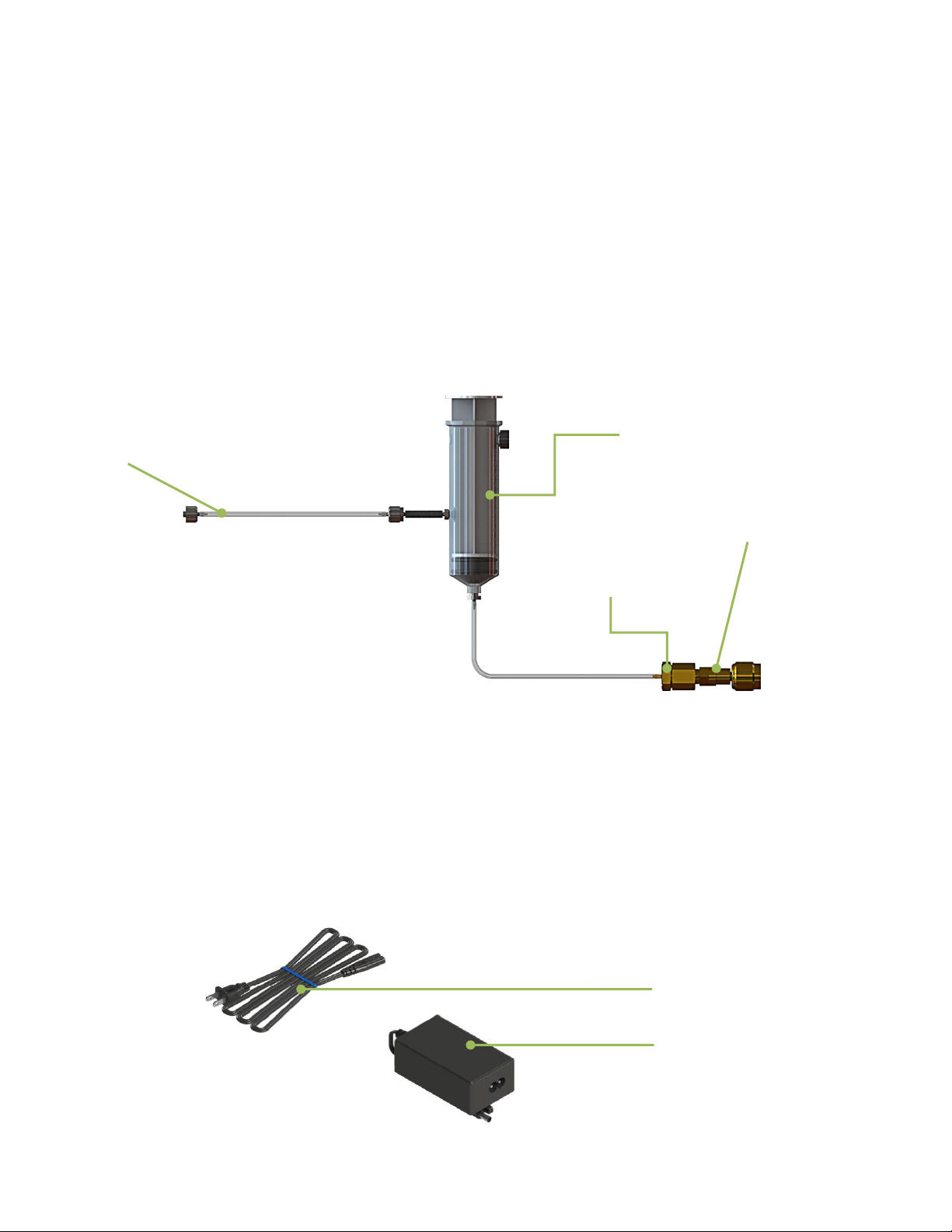

High Side Liquid Sample Hose

The 6.5 foot (2 meter) High Side Sample Hose conguration is constructed of a polyurethane tube

with an oil reservoir. A Brass Sample Hose Restrictor acts to transform Liquid refrigerant to Vapor

at the sample connection point while the High Pressure Liquid Sample Trap Assembly collects oil

and provides a means of expulsion after the test is complete. The syringe is provided with a mag-

net for attaching it to the tank, an instrument inlet port mating connector on one end and a 1⁄4”

SAE female are coupling nut on the service end. The maximum pressure is 500 psig.

NOTE: The analyzer will indicate “Non-Condensable” or “Unknown Refrigerant” if the analyzer

does not receive a good sample due to obstructed ow or lack of ow. If this occurs the Brass

Sample Hose Restrictor may need to be replaced.

High Pressure

Liquid Sample Trap

Analyzer End

Brass Sample

Hose Restrictor

Assembly

Service End

(1/4 SAE Flare Nut)

AC Power Adapter

The Ultima ID Pro™ is powered via a Lithium Iron Phosphate battery. You can also power the unit

via the 90-264 VAC, 50-60 Hz power transformer. This transformer is included with each unit and

converts a standard 100-240VAC 50/60Hz wall outlet to 12VDC, 2.0A, which powers the device.

This AC Power Adapter will also charge the battery when connected to the analyzer.

NOTE: Use of any other power source may cause damage to the unit and void the warranty

.

A/C Power Cord

A/C Power Converter

Page 1-12

Page 9

Control Panel

The Control Panel serves as the main user interface. The Control Panel features three soft key

buttons that change their function as the instrument changes modes. The current function for each

button is displayed above the Soft Key Buttons on the LCD graphic display. Red and Green LED’s

at the top of the Control Panel are used for visual status indications.

Green LED

Soft Keys Buttons

Power On/Off

Red LED

Graphic Display

Back Panel Connections

The connections located on the back panel are illustrated below.

CAUTION: The sample outlet port should never be obstructed. Keep the sample outlet port free

and clear at all times. Do not operate near open ame.

Sample Inlet

Sample Outlet

USB Port

12DC Outlet Input

(AC Adapter)

Page 1-13

Page 10

Hard Shell Storage/Carrying Case

The hard shell storage/carrying case is custom t to the Ultima ID Pro™. It provides rugged

protection for the instrument, as well as convenient storage for all components. The enclosure

is general purpose and is not watertight.

Page 1-14

Page 11

2 ULTIMA ID PRO™ OPERATION

2.1 First Use

The Ultima ID Pro™ has a built in Lithium Iron Phosphate battery. Prior to rst use charge the battery for a minimum of 2 hours with the included AC Power Supply. If a power outlet is accessible

you may also use the AC Power Supply to power the unit. The analyzer will function and charge

the battery while the AC Power Supply is connected.

2.2 Turning On the Unit

Press the left, soft key, ‘POWER’ button. The splash screen shown in (Figure 1) will appear followed immediately by the screen in (Figure 2). If you wish to adjust factory settings press ‘SET’

and refer to section 3 Maintenance & Troubleshooting. If you do not need to adjust the settings

wait for the screen in (Figure 3) to appear. Connect the sample hose to the analyzer and wait

approximately 30 seconds for the unit to warm up. Once the analyzer warms up you are ready for

Calibration.

ULTIMA ID PRO

SOFTWARE VERSION

453- XXXX-XXXX

Figure 1

CONNECT HOSE

TO ANALYZER

Figure 3

TO CHANGE

SETTINGS OR

REPLACE PAPER

ROLL PRESS

SET

Figure 2

Page 2-15

Page 12

2.3 Calibration

The supplied sample hose needs to be connected to accomplish proper Calibration.

Verify the Sampling Hose assembly is connected to the analyzer and making sure it

is disconnected from any refrigerant source before Calibration. When you rst turn the

unit on an Air Calibration will be required; additional Air Calibrations are only required periodically. A reminder to perform air calibrate will appear when needed (Figure 4). Press ‘CAL’ to

calibrate the machine. When calibrating, the unit will pull fresh air into the sample cell via an

internal pump. This fresh air purges any excess refrigerant and ensures accurate test results.

Calibration requires that the sample hose is disconnected from the refrigerant cylinder or air

conditioning system and remains connected to the instrument. (Figure 5) will display while the

Air Calibration is occurring. Calibration will take approximately 130 seconds.

AIR CALIBRATION

IS NEEDED NOW

1- DISCONNECT

HOSE FROM

SOURCE

2- PRESS CAL TO

START

OFF CAL

- CALIBRATING -

- PROGRESS -

Figure 5 Figure 4

NOTE: In the unlikely event an ‘Air Calibration Unstable’ message is displayed as shown in

(Figure 6) verify you are in a ventilate area and there is no gas owing near the air intake.

Once you have veried both parameters, press ‘RETRY’ to complete another calibration.

AIR CAL UNSTABLE

CLEAR AIR INTAKE

AND VERIFY GAS

IS NOT FLOWING.

OFF RETRY

Page 2-16

Figure 6

Page 13

When the unit has completed a successful Air Calibration, the analyzer is then ready for gas testing. The unit will display the screen shown in (Figure 7). Determine if you are Vapor Sampling or

Liquid Sampling and make sure the proper hose assembly is connected to complete your required

form of testing. Section 2.4 Vapor Sampling and 2.5 Liquid Sampling outline proper procedure

for both forms of testing.

Connect the hose to the tank or system, open the valve if connecting to a tank, and then press

‘TEST’. The Ultima ID Pro™ will display the screen shown in (Figure 8). Before the test is completed the screen in (Figure 8a) will appear to indicate the test is nearly complete.

- READY -

1 – CONNECT HOSE

2 – OPEN VALVE

3 – PRESS TEST

OFF HELP TEST

Figure 7

- TESTING -

THIS WILL ONLY

TAKE 120 SECONDS

- PROGRESS -

Figure 8

ANALYZING THE

REFRIGERANT

Figure 8a

2.4 Vapor Sampling

Vapor sampling is the most common method used for identifying refrigerants using the Ultima ID

Pro™. It is a simple process requiring the operator to take these 4 steps:

1) Connect the Low Pressure Vapor Sampling Hose to the Low Side Vapor port of the system or

cylinder.

2) Open the low side valve of the cylinder and press ‘TEST’ (Figure 7).

3) When the test is complete, close the low side valve of the cylinder and disconnect the hose

from the cylinder.

4) Disconnect the hose from the Ultima ID Pro™ for storage.

Page 2-17

Page 14

2.5 Liquid Sampling

Liquid sampling is an option that is exclusive to the Ultima ID Pro™. It permits the user to ash

liquid into vapor for introduction into the analyzer. To use the liquid sampling assembly, follow

these eight steps:

1) Inspect the High Pressure Liquid Sample Trap Assembly and ensure that the plunger is

completely depressed. Assemble the High Side Liquid Sample Hose as shown on page 1-12

of this manual.

2) Connect the appropriate end of the hose to the instrument and the opposite end of the

liquid sampling assembly to the High Side Liquid port of the system or cylinder. Afx the High

Pressure Liquid Sample Trap Assembly vertically to a tank with the magnet.

3) Open the high side valve of the cylinder. The liquid sample will exit the tank and ash to

vapor in the hose assembly. As the liquid is ashed, the plunger on the High Pressure Liquid

Sample Trap Assembly will begin to rise and the ashed refrigerant sample will travel into the

analyzer.

4) Wait for the plunger on the High Pressure Liquid Sample Trap Assembly to expand past the

outlet port.

5) Press ‘TEST’ on the Analyzer (Figure 7).

6) Upon completion of the test, close the valve on the cylinder, disconnect the hose from the

inlet of the High Pressure Liquid Sample Trap Assembly, and depress the plunger to expel any

trapped oil.

7) Inspect the hose for signs of oil and replace the Brass Sample Hose Restrictor if necessary.

8) Disconnect the hose from the Ultima ID Pro™

NOTE: Liquid sampling will likely clog the Brass Sample Hose Restrictor much faster than

Vapor Sampling. If the Restrictor becomes clogged and the analyzer continuously displays

“Non-Condensable” or “Unknown Refrigerant” readings you will need to replace the clogged

Restrictor with a new one. To avoid oil or liquid contamination from entering the analyzer, have

a designated vapor and liquid Brass Sample Hose Restrictor for each form of testing.

2.6 Viewing the Test Results

Upon completion of the test, the Ultima ID Pro™will display a screen similar to that shown in

(Figure 9). Pressing the ‘MORE’ button will display the screen shown in (Figure 10). Once

you have completed your test, press ‘DONE’ to return back to the ‘READY’ screen (Figure 7)

or refer to section 2.10 Print the Test Results & Channel Data to print.

R22

CONTAMINATED

Figure 9

0.0% AIR

PRINT MORE

- RESULTS -

R22 97.0%

R410A 3.0%

BACK PRINT DONE

Figure 10

Page 2-18

Page 15

2.7 Contaminated Refrigerants

The Ultima ID Pro™ includes the ability to detect and analyze the composition of many common

R400 Series refrigerants in addition to R134a, R22 and Hydrocarbons. In the event that the Ultima ID Pro™determines that the primary refrigerant in the system or cylinder is one of the measured refrigerants, the results will display as follows in (Figure 11). Pressing the ‘MORE’ button

will display the detail screen shown in (Figure 12). If the blend or refrigerant mixture is not recognized, the screen shown in (Figure 13) will be displayed. Refer to section 2.10 Print the Test

Results & Channel Data to print.

R410A

CONTAMINATED

PRINT MORE

Figure 11

0.0% AIR

- RESULTS -

R410A 98.7%

R22 1.3%

BACK PRINT DONE

Figure 12

PRINT DONE

UNKNOWN

REFRIGERANT

Figure 13

0.0% AIR

2.8 Pure Refrigerants

The Ultima ID Pro™ has the ability to Identify the following refrigerants: R12, R32, R408A,

R409A, R417A, R421A, R421B, R422A, R422B, R422C, R427A and Hydrocarbons (HC). All

Identied refrigerants will display with “Purity Unknown” as the analyzer cannot yield additional

information regarding the composition (Figure 14). Refer to 2.12 Channel Data Modelling for ad-

ditional information regarding Identied Refrigerants.

REFRIGERANT

0.0% AIR

R12

PURITY UNKNOWN

PRINT MORE

Figure 14

The instrument can also, Identify and Analyze the component content of pure R134a, R22, HC

(Hydrocarbons), R404A, R407C and R410A. Analysis of analyzed pure blend refrigerants will

yield additional data regarding the composition of the refrigerant sample. The Ultima ID Pro™

will display the blend refrigerant type as shown in (Figure 15). Pressing the ‘MORE’ button will

display the detail screen shown in (Figure 16). Refer to section 2.10 Print the Test Results &

Channel Data to print.

NOTE: Hydrocarbons (HC) encompass R600, R600A and R290 and this machine cannot differ-

entiate between Hydrocarbons.

Page 2-19

Page 16

0.0% AIR

100%

R410A

MORE

- RESULTS -

COMPONENTS OF

R410A 100%

R125 50.0%

R32 50.0%

BACK PRINT DONE

Figure 15 Figure 16

2.9 Pure Blends with Incorrect Component Ratios

The Ultima ID Pro™ has the ability to detect blend ratios that have been altered by contamination. As stated in section 2.8 Pure Blend Refrigerants, the blends that can be Identied and

Analyzed are R134a, R22, HC (Hydrocarbons), R404A, R407C and R410A. If one of the

multi-component refrigerant blends has incorrect component ratios, it will display as shown

below in (Figure 17). To see the component concentrations, press the ‘MORE’ button (Figure

18). Refer to section 2.10 Print the Test Results & Channel Data to print.

0.0% AIR

COMPONENTS OF

R410A

MORE

Figure 17 Figure 18

-

R410A 100.0%

R125 60.0%

R32 40.0%

BACK PRINT DONE

RESULTS -

COMPONENTS OF

2.10 Measuring Air

The Ultima ID Pro™ offers the ability to measure the presence of Air independently dur-

ing every test. The built in oxygen sensor will display the percentage of Air in all Identied or

Identied and Analyzed refrigerants if there is Air in a system or cylinder. The image below in

(Figure 19) portrays how the LCD will display Air if detected. Pressing ‘MORE’ will display the

purity of the refrigerants which were detected (Figure 19a).

NOTE: Air is measured independently from refrigerant! You can have 100% pure refrigerant

with a percentage of Air in a system or tank. The presence of Air will display on the initial results screen and on every printed test.

9.6% AIR

R22

PRINT MORE

Figure 19

R22 100.0%

BACK PRINT MORE

- RESULTS –

Figure 19a

Page 2-20

Page 17

2.11 Printing the Test Results & Channel Data

The Test Results and Channel Data can be printed after every test is completed. Pressing ‘PRINT’ on

the bottom of the screen will print the test results for all Analyzed Refrigerants. The screen in (Figure

20) will display during printing. If printing Identied or ‘Unknown Refrigerants”, pressing ‘PRINT’ will

allow you to print the Channel Data from the test. (Figure 21) will display during Channel Data printing.

Once printing is complete, carefully tear off the printout and press ‘BACK’ to return to the previous

screen. Additional printouts may be made following the same procedure. To exit the test, press the

‘DONE’ button. (Figures 22, 23, & 24) show sample printouts for various test results.

- PRINTING -

NOW PRINTING

RESULTS

BACK DONE

NOW PRINTING

COMPONENTS

BACK DONE

- PRINTING -

Figure 20 Figure 21

NOTE: Care must be taken when tearing off the printed results to leave a clean edge. Tear the paper

from RIGHT to LEFT to avoid paper jams.

Refrigerant

Analyzer

R22 = 100.0%

AIR = 0.0%

___________

(Date)

____________

(Technician)

___________

___________

Refrigerant

Analyzer

R410A = 100.0%

R125 = 50.0%

R32 = 50.0%

AIR = 0.0%

___________

(Date)

____________

(Technician)

___________

___________

Refrigerant

Analyzer

NON-CONDENSABLE

___________

(Date)

____________

(Technician)

____________

__________

Figure 22

Figure 23 Figure 24

Page 2-21

Page 18

2.12 Channel Data Modelling

Channel Data Modelling is a unique feature to the Ultima ID Pro™. It allows the user to test re-

frigerants that the analyzer may not already identify and “ngerprint” the data using the available

channels. The channel data is available for Identied and “Unknown Refrigerants.”

Once you complete a test on an Identied Refrigerant (see list in section 2.8 Pure Refrigerants)

or “Unknown Refrigerants”, the test results will display similar to (Figure 25) for Identied Refrig-

erants or (Figure 25a) for “Unknown Refrigerants.” Once displayed, the analyzer will allow the

user to print. Press the ‘PRINT’ button and the data will appear on the printout like (Figure 26).

This new feature allows the user to develop a “ngerprint” model for different refrigerants the Ultima ID Pro™ may not already analyze. If the user tests a virgin tank of refrigerant at least 3 times

and receives Channel Data that is consistent or within a close range to one another, this data

can be used as a “ngerprint” model of that particular refrigerant. This feature will allow the user

to have a guide to identify refrigerants not already established by the analyzer and increases the

capabilities of the Ultima ID Pro™.

PRINT DONE

REFRIGERANT

R32

PURITY UNKNOWN

Figure 25

0.0% AIR

PRINT DONE

UNKNOWN

REFRIGERANT

Figure 25a

0.0% AIR

Refrigerant

Analyzer

R32

Purity Unknown

Channel Data

F01: # .#

F02: # .#

F03: # .#

F04: # .#

F05: # .#

F06: # .#

F07: # .#

F08: # .#

F09: # .#

F10: # .#

F11: # .#

F12: # .#

Figure 26

NOTE: This is not a guaranteed method for identifying refrigerants. Results will vary and some

refrigerants may create inconsistent data.

Page 2-22

Page 19

3 MAINTENANCE & TROUBLESHOOTING

3.1 Setting the LCD Contrast

The Ultima ID Pro™ features an adjustable LCD contrast for use in varying light conditions.

To adjust the contrast, press the ‘SET’ button which appears after the unit is powered on. The

screen will display several options as shown in (Figure 27). Pressing the ‘SET’ button will

display the options in (Figure 28). Press ‘DOWN’ or ‘UP’ to adjust the LCD contrast. Press

‘SAVE’ to save your settings and return the (Figure 27).

TO FEED A

NEW PAPER ROLL

PRESS FEED

PRESS SET TO

ADJ LCD CONTRAST

BACK FEED SET

Figure 27

ADJUST CONTRAST

CURRENT VALUE

4 0

DEFAULT VALUE

4 0

DOWN UP SAVE

Figure 28

3.2 Changing the White Plastic Sample Filter

When inspecting the sample lter, look completely around the entire outside diameter of the

white lter element located inside of the clear plastic housing. Look for red spots or the be-

ginnings of discoloration on the white outside diameter of the element. DO NOT look into the

round ends of the white element for red spots or discoloration. The round ends of the lter

may always appear red. If red spots or discolorations are discovered on the outside diameter,

the sample lter requires replacement to prevent the inux of particulate and oil mists into the

instrument.

To change the Sample Filter, rst obtain a replacement lter, part number 6-02-6000-08-0. Remove the existing lter from the retaining clip of the instrument by pulling straight up and out.

CAREFULLY remove the exible, black rubber tubing connections from both ends of the existing lter. DO NOT allow the tubes to slip back into the internal portion of the case. Discard the

existing lter in an environmentally friendly manner.

Install the tube ends onto the barbs of the replacement lter, taking note to align the ow arrow of the lter with the ow arrow on the analyzers top panel. CAREFULLY slide the tubing

back into the internal portion of the instrument and seat the new lter into the retaining clip.

Inspect your hose assemblies for signs of oil entrapment. Replacement of the Sample Filter

usually requires replacement of the Brass Sample Hose Restrictor Assembly.

Page 3-23

Page 20

3.3 Replacing the Brass Sample Hose Restrictor

In either Vapor Sampling or Liquid Sampling mode always inspect the inside diameter of the tube

for signs of oil build up, dirt, obstructions, kinks, cuts, fraying, or any other signs of wear before

use. Oil contamination cannot be cleaned out of sample hoses due to the density of the brass oil

restrictor. If oil is visible in the hose assembly, replace the Brass Sample Hose Restrictor Assembly with P/N 6-01-6001-26-0.

NOTE: The analyzer will indicate “Non-Condensable” or “Unknown Refrigerant” if the analyzer

does not receive a good sample due to obstructed ow or lack of ow (approximately less than 30

psig or 2 Bar). If this occurs the Brass Sample Hose Restrictor may need to be replaced.

To replace the Restrictor Assembly, follow the instructions below:

1) Disconnect the sample hose from the Analyzer

2) Remove the brass restrictor (with hose attached) from the coupler and discard. Be sure to use

a backing wrench as not to damage the coupler.

3) Check for signs of oil and debris in the coupler.

4) Using “CRC Brakleen” or similar cleaner which ONLY contains, Tetrachloroethylene and carbon

dioxide, follow safety instructions on the can and spray all parts of the coupler with the cleaner to

remove the oil. DO NOT soak the parts for more than 60 seconds.

5) Allow coupler parts to dry. Check coupler parts for oil once again. Failure to clean the oil out of

the coupler will result in premature clogging of the new lter.

6) Install the Brass Sample Hose Restrictor, part number 6-01-6001-26-0, into the coupler and

lightly tighten, usually nger tight is sufcient.

Page 3-24

Page 21

3.4 Changing the Printer Paper

All Ultima ID Pro™ Refrigerant Analyzer is equipped with on-board printer that uses an inexpensive

thermal paper for printing. The paper roll should be changed when a red stripe appears on the left

side of the printout.

To change the paper roll, press the ‘SET’ button shortly after powering the analyzer on or any time

it appears. The screen will display several options as shown in (Figure 29). Press the ‘FEED’ button

to advance to the screen shown in (Figure 30).

TO FEED IN A

NEW PAPER ROLL

PRESS FEED

PRESS SET TO

ADJ LCD CONTRAST

BACK FEED SET

Figure 29 Figure 30

TO LOAD PAPER

1. PRESS FEED

2. INSERT PAPER

3. PRESS DONE

TO EXIT

FEED DONE

Open the printer door and remove the old roll by tearing the paper as it enters the printer then

pressing the ‘FEED’ button shown in (Figure 30) until the old roll exits the printer completely. Insert

the new paper roll from the underside as shown below:

Press the ‘FEED’ button shown in (Figure 30) to automatically advance the paper through the

printer. Allow at least 3 in (7cm) of paper to exit the top of the printer. Press the ‘DONE’ button to

stop the printer from advancing the paper. This will take you back to (Figure 29). Slide the paper

through the slot in the printer door and close the door.

Page 3-25

Page 22

3.5 Software Updates

From time to time, software updates may be made available to improve operating performance

or add additional features. Some updates will be provided at no charge to implement operating

efciencies while others will be optional, paid upgrades, to add new refrigerants etc. Many of the

updates can be completed by the user; however some will require the instrument to be returned to

the factory for new gas calibrations.

The Ultima ID Pro™ has a USB update port located on the Back Panel Connections. This port

should not be used for any other purpose other than to install factory updates using the Mastercool

factory USB drive. IF YOU DO NOT REGISTER THE ANALYZER WE WILL NOT BE ABLE TO

INFORM YOU OF ANY SOFTWARE UPDATES!

3.6 Low Battery Warning

A battery warning will occur when the internal Lithium Iron Phosphate battery voltage becomes low

(Figure 31). You can either continue working or connect the 12V AC Power Supply and continue

to work by pressing ‘IGNORE. The analyzer will charge the battery while it is connected to the AC

Power Supply but if you wish to use it wirelessly press ‘OFF’, plug the analyzer into the AC Power

Supply via the 12DC Outlet Input on the Back Panel and allow it to fully charge. Full charge will

take at least 2 hours.

THE BATTERY

VOLTAGE IS LOW

RECHARGE THE

BATTERY SOON OR

USE 12V POWER

SUPPLY

3.7 Air Sensor Low

OFF IGNORE

Figure 31

In the event you receive an ‘Air Sensor Low’ message like (Figure 32) there is no need to discontinue use. This message is meant to alert you that the built in oxygen sensor is depleting and will

need to be replaced in the near future. If the analyzer you are using is new and you believe you

received this message in fault, rst verify gas is not owing into the analyzer and that you are in a

well ventilated area. Once you have veried both, press ‘RECAL’ to recalibrate the analyzer. If you

have had the analyzer for a few years the oxygen sensor may be near depletion. Pressing ‘TEST’

allows you to bypass the message and nish your testing. The oxygen sensor is a consumable

part and will eventually need to be replaced. After receiving this message plan on contacting Neutronics Inc to schedule a service appointment.

Page 3-26

AIR SENSOR LOW

DISCONNECT HOSE

FROM TANK

AND PRESS RECAL

RECAL TEST

Figure 32

Page 23

3.8 Error Messages

In the unlikely event that an “Error” message is displayed on the screen, power off the unit, take

it to a location outside of the shop environment where fresh air is available and turn the unit back

on. If the “Error” message reappears, refer to the help screens on the instrument or contact our

service department for assistance.

Mastercool Inc

1 Aspen Drive

Randolph, New Jersey 07869, USA

Tel: (973) 252-9119

Fax: (973) 252-2455

Contact us:

Domestic and Canada: customerservice@mastercool.com

International: international@mastercool.com

Technical Support:

Domestic and International: techs@mastercool.com

Visit us: www.mastercool.com.com

Page 3-27

Page 24

PART NUMBER DESCRIPTION

APPENDICES

3.9 Spare Parts List

1-10-0000-08-0

1-12-2120-05-3

6-02-6001-11-0

6-02-6001-17-0

6-01-6001-26-0

6-02-6000-08-0

5-03-1000-08-0

5-06-7000-70-2

Power Cord

Power Supply

Low Pressure Vapor Sample Hose

High Pressure Liquid Sample Trap Assembly

Brass Sample Hose Restrictor Assembly (3 Pack)

White Plastic Sample Filter

Printer Paper Roll

Operating Manual

3.10 Appendix B - Specications

SAMPLE PARAM ETERS:

CONTAMINAT E SENSITIVITY:

IDENTIFIED REFRIGERANTS:

Vapor or Liquid, oil-free, 500 psig Maximum

Contaminate sensitivity filter is enabled by default. Contact

factory to disable.

R12, R32, R408A, R409A, R417A*, R421A*, R421B, R422A,

R422B, R422C, R427A, HC (Hydrocarbons)

* Due to similar formulas, R417A and R421A may be

identified as either R417A or R421A

IDENTIFIED & ANALYZED

REFRIGERANTS:

SENSOR TECHNOLOGY:

REFRIGERANT SAMPLE SIZE:

POER :

ENVIRONMENTAL CONDITIONS

OPERAT IONAL TEMPERAT RE:

R134a, R22, HC (Hydrocarbons), R404A, R407C, R410A

Non-Dispersive Infrared (NDIR)

0.3 ounces (8.5 grams) per sample

Power Supply

Input 90-24VAC, 50-0H

Output 12 VDC, 2.0 AMP

Built in Lithium Iron Phosphate Battery

LiFE 2100mAh

Do not expose unit or external components to rain or

moisture.

Humidity 0 to 95 RH non-condensing.

Protect Unit from physical abuse by keeping the unit in the

storage case when not in use.

50-120

o

F (10-49oC)

Page 3-28

Loading...

Loading...