Page 1

RECOVERY/RECYCLE/RECHARGE

Operating Instructions

69789-220

Page 2

INSTRUCTIONS MANUAL

-2-

Page 3

INSTRUCTIONS MANUAL

-3-

INDEX

INDEX .................................................................................................................................3

INTRODUCTION.................................................................................................................5

CARE OF THE MANUAL...........................................................................................................5

CONDITIONS OF WARRANTY...........................................................................................6

GENERAL INFORMATION .................................................................................................6

END-OF-LIFE......................................................................................................................7

BATTERY DISPOSAL ...............................................................................................................7

SAFETY RULES..................................................................................................................7

PRECAUTIONS FOR HANDLING AND USE OF REFRIGERANT FLUIDS .............................7

PRINCIPLES OF OPERATION...........................................................................................8

SETUP ................................................................................................................................8

THE MACHINE....................................................................................................................9

BASIC COMPONENTS .............................................................................................................9

CONTROLS AND CONTROL SYSTEM....................................................................................9

FUNCTION SELECTOR KEYBOARD.......................................................................................9

ALARMS....................................................................................................................................9

PRELIMINARY OPERATIONS..........................................................................................10

PURGING NON-CONDENSABLE GASES .............................................................................10

AUTOMATIC PROCEDURE..............................................................................................11

Edit VACUUM data:.................................................................................................................11

Edit OIL data:...........................................................................................................................12

Edit TRACER data:..................................................................................................................12

Edit FILLING data:...................................................................................................................12

ASSISTED PROCEDURE.................................................................................................15

RECOVERY AND RECYCLING..............................................................................................15

EMPTYING PIPES 16

VACUUM .................................................................................................................................16

NEW OIL REINTEGRATION...................................................................................................17

TRACER REINTEGRATION....................................................................................................17

CHARGING THE A/C SYSTEM...............................................................................................17

STATIC DIAGNOSIS (optional)...............................................................................................20

DATA.................................................................................................................................21

CONFIGURATION ............................................................................................................22

LANGUAGE.............................................................................................................................22

UNIT OF MEASURE................................................................................................................22

WEIGHT 23

PRESSURE 23

TEMPERATURE 23

Page 4

INSTRUCTIONS MANUAL

-4-

OPTIONS.................................................................................................................................23

DATE AND TIME .....................................................................................................................24

CONFIGURATION OF SETTING UP AND PRINTING............................................................24

ENTER OPERATOR N............................................................................................................ 25

SERVICES.........................................................................................................................26

REFRIGERANT MANAGEMENT.............................................................................................26

PASSWORD............................................................................................................................26

COUNTERS.............................................................................................................................27

MAINTENANCE.................................................................................................................28

FILLING THE MACHINE BOTTLE..........................................................................................28

SERVICE AND CHANGE FILTERS ALARM ...........................................................................29

QUICK GUIDE .........................................................................................................................30

CALIBRATION...................................................................................................................31

CALIBRATING THE BOTTLE SCALE .....................................................................................31

BOTTLE DATA.........................................................................................................................32

CALIBRATING THE OIL SCALE .............................................................................................33

VACUUM PUMP......................................................................................................................34

M.1) Oil top-up 34

M.2) Oil change 34

FILLING THE NEW OIL CONTAINER

(if installed)

........................................................................35

FILLING THE TRACER CONTAINER

(if installed)

.........................................................................35

REPLACING THE COLLAPSIBLE NEW OIL / TRACER CARTRIDGE

(if installed)

.......................35

INSERTING THE CARTRIDGE 35

REMOVING THE CARTRIDGE 35

EMPTYING THE USED OIL CONTAINER ..............................................................................36

REPLACING THE PRINTER PAPER ......................................................................................36

CUSTOMIZING THE DBA (DATABASE ADVANCED)......................................................37

DATA ENTRY ..........................................................................................................................37

USE..........................................................................................................................................37

DELETION...............................................................................................................................37

CONTRAST.......................................................................................................................38

INSTALLING THE USB VIRTUAL COM DRIVE................................................................38

Page 5

INSTRUCTIONS MANUAL

-5-

INTRODUCTION

This machine is a pressure unit as can be seen in the CE declaration of conformity and

Data plate. The equipment supplied conforms to the Essential Safety Requirements

according to Annexure I of Directive 97/23/CE (PED). Any work involving repairs,

modifications, and/or changing pressurised components or parts make safe use of the

equipment very risky. Any tasks done must be authorised by the Manufacturer.

This manual contains important information pertinent to operator

safety. Read this manual through before beginning operation of the

machine.

The manufacturer reserves the right to modify this manual and the machine itself with no prior

notice. We therefore recommend checking any updates. This manual must accompany the

machine in case of sale or other transfer.

Any repair, modification, or changing of components not formally agreed with and authorised

by the manufacturer poses a risk of the conformity to Directive 97/23/CE being nullified and

makes this pressure equipment a significant risk. If not authorised in writing the Manufacturer

considers the tasks indicated above to be tampering with the machine, which nullifies the initial

declaration of conformity issued, and so they do not accept any direct responsibility.

Braze welding of parts that contribute to the pressure strength of the equipment and the parts

directed attached to it was done by adequately qualified personnel, using adequate operating

methods. Approval of the operating methods and personnel was entrusted to a competent

outside party for category II pressure equipment, and any work on this equipment that involves

the need to carry out braze welding must comply with the requirements laid down in ann. 1 of

Directive 97/23/CE, or the Manufacturer must be contacted for the relevant information.

− The pressure equipment has been inspected and tested, complete with the safety

accessories identified by the manufacturer as being of a direct discharge type with

calibrated air pressure. Testing and inspection of the accessories is not necessary prior

to starting up.

− The pressure equipment must be subjected to routine inspections and checks when

operating, according to the relevant regulations and legal norms.

For the unit in question, it is hereby declared that a competent Authorised Body carried out

their part of the final check according to ann. I of point 3.2.3 of Directive 97/23/CE as well as

checking safety accessories and control devices in conformity to comma d) of art 5 of

Ministerial Decree 329 of 01/12/2004.

List of the critical components in terms of PED safety DIR 97/23/CE

Condenser, dehydrator filters, distributor, refrigerant storage bottle, airtight compressor, safety

pressure switch, pressure transducers, and safety valves.

CARE OF THE MANUAL

This manual must be kept for the entire life of the machine and protected against humidity and

excessive heat. Take care not to damage this manual in any way during consultation.

Page 6

INSTRUCTIONS MANUAL

-6-

CONDITIONS OF WARRANTY

This product is warranted against any defect in materials and/or construction for a period of 1

(one) year from the date of delivery. The warranty consists of free-of-charge replacement or

repair of defective component parts considered same by the Manufacturer.

Reference to the machine serial number must be included in any requests for spare parts. If

the serial number is not available, contact the manufacturer immediately with valid proof of

purchase (invoice or other valid fiscal document). This warranty does not cover defects arising

from normal wear, incorrect or improper installation, or phenomena not inherent to normal use

and operation of the product. The manufacturer guarantees the perfect suitability of the

materials used for packing, in terms both of composition and mechanical strength/resistance.

The guarantee does not cover breakdowns attributable to damage suffered during shipping or

warehousing or caused by the use of accessories not meeting manufacturer’s specifications, or

to tampering with or repair of the product by unauthorized personnel. It is of utmost importance

that the crates containing the machine be carefully inspected, upon delivery, in the presence of

the shipping agent. We recommend performing inspection with extreme care, since damages

to the crates due to shocks or dropping are not always immediately visible thanks to the shockabsorbing capacity of today’s composite packing materials. The apparent integrity of the

packing materials does not exclude possible damage to the goods, despite the due care taken

by the manufacturer in packing them.

NOTE: Regarding the above, the Manufacturer reminds the Customer that according to

international and national laws and regulations in force the goods are shipped at the sole risk of

the latter and, unless otherwise specified in the confirmation of order phase, the goods are

shipped uninsured. The Manufacturer therefore declines any and all responsibility in merit of

CLAIMS for damages due to shipping, loading and unloading, and unpacking. A product for

which repair under guarantee is requested must be shipped to the manufacturer under the

customer’s exclusive responsibility and at the customer’s exclusive expense and risk. In order

to avoid damage during shipping for repairs, the manufacturer’s original packing must always

be used. The manufacturer declines any and all responsibility for damage to vehicles on which

recovery/recycling and recharging are performed if said damage is the result of unskillful

handling by the operator or of failure to observe the basic safety rules set forth in the instruction

manual. This warranty replaces and excludes any other warranty or guarantee that the seller is

required to provide under law or contract and defines all the customer’s rights in regard of faults

and defects and/or scarce quality in the products as purchased.

The warranty will expire automatically at the end of the twelve-month period or whenever even

one of the following occurs: failure to perform maintenance or erroneous maintenance

procedures, use of unsuitable lubricants and/or tracer fluids, inept or improper use, repairs

performed by unauthorized personnel and/or with non-original spare parts, damage caused by

shocks, fires, or other accidental events.

GENERAL INFORMATION

Machine identification information is printed on the data plate on the rear of the machine (see

Figures 1 and 2). Overall machine dimensions:

Height: 1030 mm Width: 570 mm

Depth: 630 mm Weight: 70 kg

Operating temperature 10/40°C Storage temperature -25/49°C

Like any equipment with moving parts, the machine inevitably produces noise. The

construction system, paneling, and special provisions adopted by the Manufacturer are such

that during work the average noise level of the machine is not in excess of 70 dB (A).

Page 7

INSTRUCTIONS MANUAL

-7-

END-OF-LIFE

The symbol on the right indicates that in accordance with Directive 2002/96/EC the

machine may not be disposed of as ordinary municipal waste but must be

delivered to a specialized center for separation and disposal of WEEE (Waste

Electrical and Electronic Equipment) or be returned to the dealer in case of

purchase of a new machine. Current legislation provides severe sanctions in the

case of disposal of WEEE into the environment. If improperly used or disposed of

into the environment, electrical and electronic equipment can release substances dangerous

for the environment and for human health.

BATTERY DISPOSAL

The machine uses an electronics card containing a Nickel-metal hydride (NiMH) battery (ref.:

bt, see Fig.12). When discharged, it must be removed by expert personnel trained in machine

demolition.

SAFETY RULES

The machine is designed for use in recovering the R134a refrigerant fluid used in the airconditioning (A/C) systems of motor vehicles. The MACHINE is designed to be used by

qualified personnel only; moreover, it can be used correctly only if the operator has read this

manual and is aware of the basic safety information contained herein, including the following.

Wear protective gloves and goggles. Do not expose the machine to direct sunlight or rain. Use

only in well-ventilated work areas. Before performing any operation, check the vehicle use and

maintenance manual for the type of refrigerant fluid used by the A/C system. Do not smoke in

proximity to the machine while it is in operation.

Do not use the machine in proximity to sources of heat, open flames, or sparks. Check

whenever the engine is turned off that the ignition key is turned to the full OFF position. Always

close all the valves on the machine before connecting it to the A/C system of the vehicle.

Connect only the machine hose supplied with the RED quick-connect coupling to the highpressure branch of the A/C system. Connect only the machine hose supplied with the BLUE

quick-connect coupling to the low-pressure branch of the A/C system. Keep the connection

hoses away from moving parts and rotating elements such as cooling fans, alternators, etc.

Keep the connection hoses away from hot objects and elements such as engine exhaust

pipes, radiators, etc. Fill the A/C system only with the quantity of refrigerant recommended by

the manufacturer. Never exceed said quantity. Check the oil levels at the beginning of each

operation. Always top up with the correct quantity of oil. Before connecting the machine to the

electrical supply, check that voltage and frequency match the values shown into the CE label.

Never fill the bottle to more than 80% of maximum capacity in order to leave an

expansion chamber for absorbing any pressure increases.

Never touch the valves on the refrigerant bottle installed on-board the machine. Dispose of the

oil extracted from the A/C system and from the vacuum pump in suitable containers for used

oils. Replace the filters punctually at the prescribed replacement times. Use only filters

recommended by the manufacturer. Take care never to use the vacuum pump oil in the A/C

system, or vice-versa. Failure to observe any of the above safety precautions will invalidate all

forms of warranty on the machine.

PRECAUTIONS FOR HANDLING AND USE OF REFRIGERANT FLUIDS

Refrigerant fluids expand to the gaseous state in standard environmental conditions. In order

that they may be shipped and used they must be compressed into suitable bottles. We

therefore recommend observing all the general precautions applicable to handling of

pressurized containers. In the case of R134a in particular, we suggest the following special

precautions. Avoid inhaling highly concentrated vapors even for short periods of time, since

such vapors can cause loss of consciousness or death. R134a is not flammable, but if the

Page 8

INSTRUCTIONS MANUAL

-8-

vapor is exposed to open flames or incandescent surfaces it may undergo thermal

decomposition and form acid substances. The acrid and pungent odor of these products of

decomposition is sufficient to signal their presence. We therefore recommend avoiding use of

R134a near open flames and incandescent elements. There exists no evidence of risks

deriving from transdermal absorption of R134a Nevertheless, due to the low boiling point of the

liquid, it is advisable to wear protective garments such as to ensure that no jets of liquid or gas

can come into contact with the skin. The use of goggles to avoid contact with the eyes is

especially recommended, since the refrigerant liquid or gas can cause freezing of the ocular

fluids. Moreover, we strongly advise users to avoid dispersing the R134a refrigerant fluid

utilized in the machine since it is a substance that contributes to raising the temperature of the

planet, with a global warming potential(GWP) of 1300.

PRINCIPLES OF OPERATION

In a single series of operations, the machine permits recovering and recycling refrigerant fluids

with no risk of releasing the fluids into the environment, and also permits purging the A/C

system of humidity and deposits contained in the oil. The machine is in fact equipped with a

built-in evaporator/separator that removes oil and other impurities from the refrigerant fluid

recovered from the A/C system and collects them in a container for that purpose. The fluid is

then filtered and returned perfectly recycled to the bottle installed on the machine. The machine

also permits running certain operational and seal tests on the A/C system.

SETUP

The machine is supplied fully assembled and tested. Referring to Figure 3, mount the hose

with the BLUE quick-connect coupling on the male threaded connector indicated by the BLUE

LOW PRESSURE symbol and the RED quick-connect coupling on the male threaded

connector indicated by the RED HIGH PRESSURE symbol. Referring to Figure 4, remove the

protection under the refrigerant scale as follows::

- Loosen the nut [2].

- Completely loosen the screw [1].

- Keep the screw [1], the nut [2], and the knurled washer [4] for possible future use.

NOTE: in the event that the equipment has to be transported, the refrigerant bottle scale should

be locked in place as follows:

- Procure two size 10 wrenches.

- Tighten the nut [2] almost completely onto the screw [1].

- Insert the knurled washer [4] onto the screw [1].

- Turn the screw [1] just a few times on the threaded bush [6].

- Switch the machine on.

- Tighten the screw [1] until the display signals ZERO availability.

- Tighten the nut [2] forcefully (using the second wrench to block the screw [1]).

- Check that the screw [1] is actually locked, if necessary repeat the locking operation

from the beginning.

Page 9

INSTRUCTIONS MANUAL

-9-

THE MACHINE

BASIC COMPONENTS

Refer to Figures 5, 6, 7 and 8.

a) Control consoles b) Taps

h) Wheels l) High/Low Pressure threaded connectors

m) Used oil tank n) New oil collapsible container*

bi) Oil scale d) Bottle

e) Drying filters o) Electronic scale

r) Heating resistance ps) Serial port

i) Main switch j) Socket for electrical supply plug

k) Fuse c) Moisture indicator

f) Vacuum pump u) USB port

w) collapsible tracer cartridge* z) tracer container*

v) purge valve s) new oil container*

* if installed

CONTROLS AND CONTROL SYSTEM

Refer to Figure 9.

A1) High pressure gauge A2) Low pressure gauge

A3) Keyboard A4) Bottle pressure gauge

A5) LCD: 4 lines, 20 characters A6) Printer*

FUNCTION SELECTOR KEYBOARD

STOP: Press to interrupt the operation being performed in the case of the principal functions:

recovery - oil discharge - vacuum/oil reintegration - charging). Press START to resume

operation from the point of interruption. Pressing STOP during an alarm state, error state, or

end-of-operation silences the audible alarm.

RESET: Press to interrupt the operation being performed. The procedure may be restarted

from the beginning.

ENTER: Press to confirm the procedure or operation flashing on the LCD.

↓: Press to move downward from one procedure or operation to another within a menu.

↑: Press to move upward from one procedure or operation to another within a menu.

START: Press to launch the procedure or operation shown on the display.

ALARMS

HIGH PRESSURE ALARM: Beeper and led advise when the pressure of the fluid in the circuit

reaches 20 bar. The recovery operation is automatically interrupted.

FULL BOTTLE ALARM: Beeper and led advise when the bottle is filled to more than 80% of

maximum capacity; that is, 18 kg. The RECOVERY operation is automatically interrupted (to

cancel this alarm, charge one or more A/C systems before recovering any more refrigerant).

EMPTY BOTTLE ALARM: Beeper and led advise when the quantity of refrigerant fluid

contained in the bottle is low.

SERVICE ALARM: Beeper and led advise whenever the total recovered refrigerant amounts to

100 kg. To deactivate the alarm, replace the filters and the vacuum pump oil. A code for

canceling the alarm is supplied with the spare filters.

Page 10

INSTRUCTIONS MANUAL

-10-

INSUFFICIENT GAS ALARM: Beeper and LED advise when the charging quantity set

exceeds the difference between availability and bottle minimum.

PRELIMINARY OPERATIONS

Check that the main switch (i) is set to O. Check that all the MACHINE taps are closed.

Connect the MACHINE to the electrical supply and switch on. Check that the vacuum pump oil

level indicator shows at least one-half full. If the level is lower, add oil as explained in the

MAINTENANCE section. Check that in the new oil container (n) there are at least 100 cc of the

oil recommended by the manufacturer of the vehicle A/C system. Check that the oil level in

tank (m) is < 200 cc. Check on the MACHINE display that there are at roughly 3 kg of

refrigerant in the bottle. Should this not be the case, fill the on-board MACHINE bottle from an

external bottle of appropriate refrigerant following the procedure described in the ROUTINE

MAINTENANCE section.

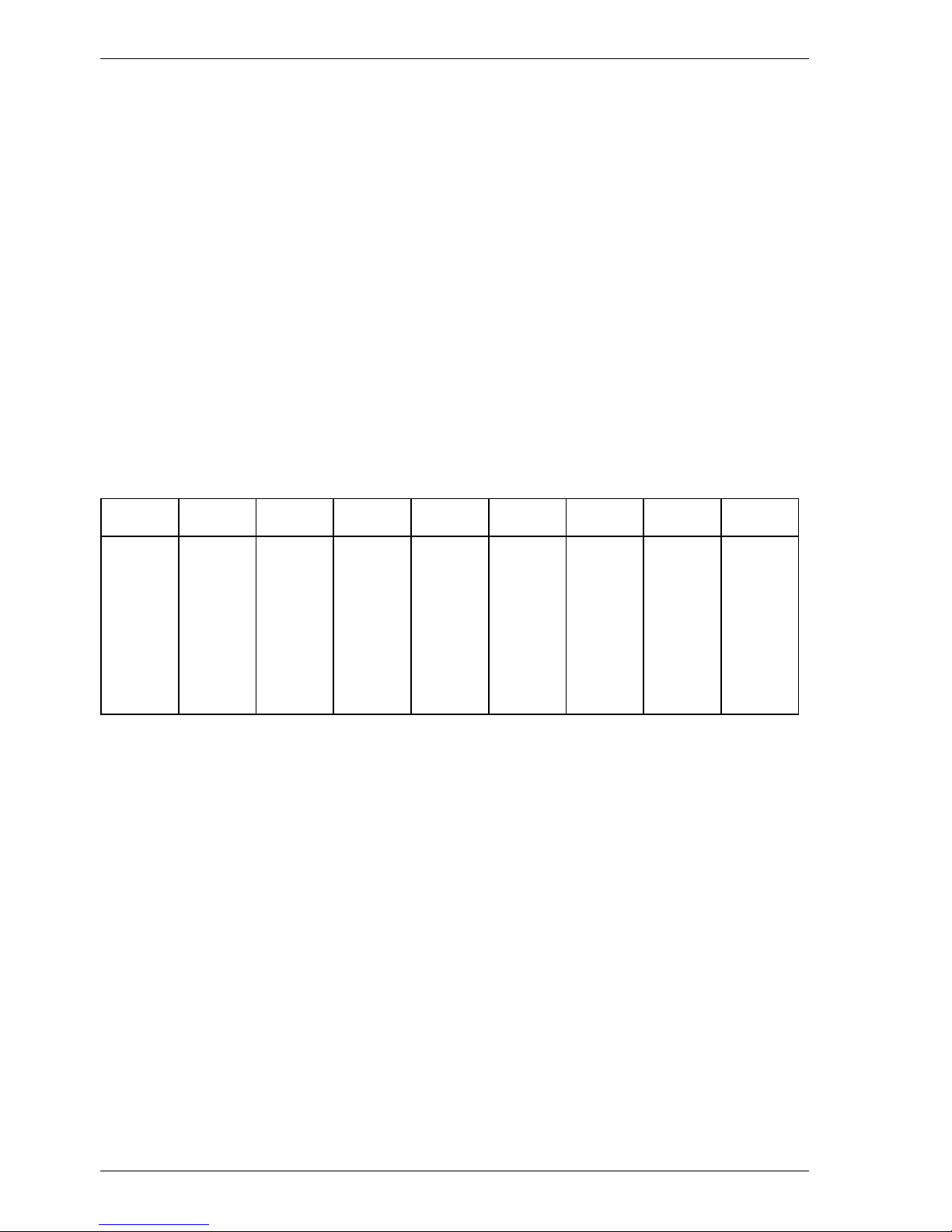

PURGING NON-CONDENSABLE GASES

Before every use, check if there is air in the bottle: select the DATA MENU and read the bottle

temperature. Compare the bottle pressure with the values given in the table; pull the ring of the

safety valve until the bottle pressure reading corresponds to the values given in the table.

Example: Bottle Temperature = 20°C. The bottle pressure must be brought to 5.2 bars.

T

(°C) P (bar) T (°C) P (bar) T (°C) P (bar) T (°C) P (bar)T (°C) P (bar)T (°C) P (bar)T (°C) P (bar)T (°C) P (bar) T (°C) P (bar)

10 3.6 15 4.4 20 5.2 25 6.1 30 7.2 35 8.3 40 9.6 45 11 50 12.6

10.5 3.7 15.5 4.4 20.5 5.3 25.5 6.2 30.5 7.3 35.5 8.4 40.5 9.7 45.5 11.2 50.5 12.8

11 3.8 16 4.5 21 5.4 26 6.3 31 7.4 36 8.6 41 9.9 46 11.3 51 12.9

11.5 3.8 16.5 4.6 21.5 5.5 26.5 6.4 31.5 7.5 36.5 8.7 41.5 10 46.5 11.5 51.5 13.1

12 3.9 17 4.7 22 5.6 27 6.5 32 7.6 37 8.8 42 10.2 47 11.6 52 13.3

12.5 4 17.5 4.8 22.5 5.6 27.5 6.6 32.5 7.7 37.5 8.9 42.5 10.3 47.5 11.8 52.5 13.4

13 4.1 18 4.9 23 5.7 28 6.7 33 7.8 38 9.1 43 10.4 48 12 53 13.6

13.5 4.1 18.5 4.9 23.5 5.8 28.5 6.8 33.5 8 38.5 9.2 43.5 10.6 48.5 12.1 53.5 13.8

14 4.2 19 5 24 5.9 29 6.9 34 8.1 39 9.3 44 10.7 49 12.3 54 14

14.5 4.3 19.5 5.1 24.5 6 29.5 7.1 34.5 8.2 39.5 9.5 44.5 10.9 49.5 12.4 54.5 14.2

QUICK GUIDE

The first time the machine is used, a quick startup guide appears: the operator is guided

through the steps described at the start of the PRELIMINARY OPERATIONS section.

- unclamp the gas bottle scale - press ENTER

- cheek the vacuum pump oil level - press ENTER

- fill the new oil container - press ENTER

- install the tracer cartridge - press ENTER

- assemble the hoses - press ENTER

- connect the quick-connect couplings - press ENTER

- press START to run the vacuum cycle for 1 minute

- fill the on-board bottle (see the instruction manual) - press ENTER

- press START to print the guide - press STOP to exit

Follow the instructions displayed. At the end of the procedure, press START to print a

summary report of the guided procedure. Press STOP to exit.

NOTE: If the guided procedure is not completed, it will be displayed again the next time the

machine is switched on.

NOTE: to display the QUICK GUIDE at any time, select from the menu of the same name

under SETUP.

Page 11

INSTRUCTIONS MANUAL

-11-

AUTOMATIC PROCEDURE

In the automatic mode, all the operations are performed automatically: recovery and recycling,

oil discharge, vacuum, new oil reintegration, and charging. The values for the quantity of gas

recovered, quantity of oil recovered, vacuum time, quantity of oil reintegrated, and quantity of

gas charged into the system are automatically printed at the end of each single operation.

Connect the hoses to the A/C system with the quick-connect couplings bearing in mind that

BLUE must be connected to the low-pressure side and RED to high pressure. If the A/C

system is equipped with a single quick-connect coupling for high or low pressure, connect only

the relative hose.

Check that the high- and low-pressure taps are closed. Start the vehicle for about 5 to 10

minutes. Switch off the vehicle engine.

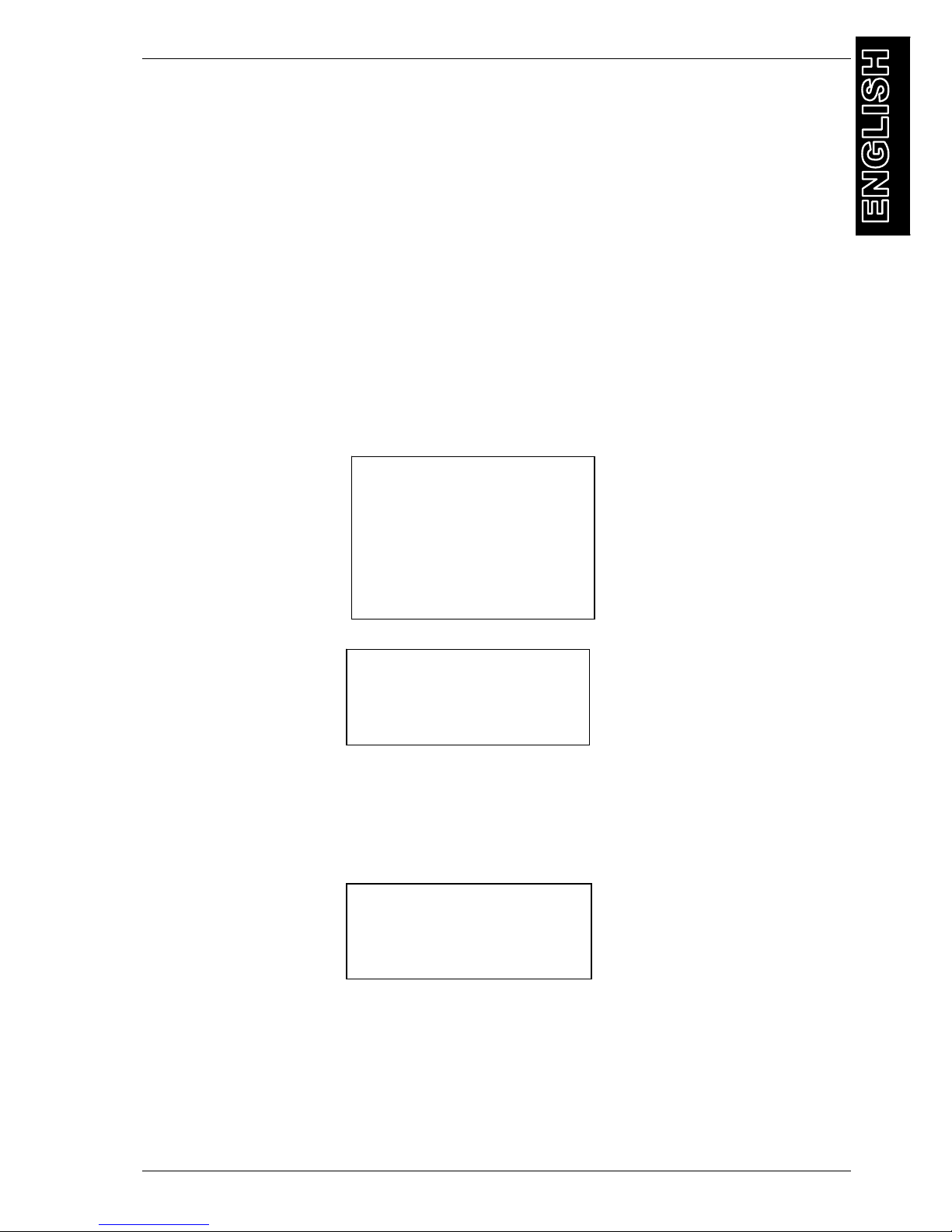

The machine is equipped with a 4-line LCD display, maximum 20 characters per line. On the

menus the selected line flashes; in this manual it is enclosed in quotation marks.

Select AUTOMATIC PROCEDURE and press the ENTER key.

The following message appears:

Press ENTER to continue – the following screen opens:

Key in the vehicle’s licence plate using the ↓↑ arrows to move around the licence plate

number. Then press "ENTER" to confirm.

NOTE: The numerical keys include an alphabet similar to that for text messages, for example:

press “2” once to display “A”, twice to display “B”, three times for "C" and four time for "2".

The following screen is displayed:

NOTES:

xy Default values extrapolated from a previous automatic procedure.

To edit the data proceed as follows:

Edit VACUUM data:

Use the arrows ↓↑ to select VACUUM and key in the new value (using keys 0 to 9).

VACUUM xy min

OIL xy ml

TRACER xy ml

REFILLING xy g

START to continue

Enter licence plate

............

Press ENTER

WARNING

USING PAG OIL OR TRACER

IN HYBRID VEHICLES CAN

DAMAGE THE COMPRESSOR

USE SPECIFIC OIL WITH A

SEPARATE DEVICE

Press ENTER

Page 12

INSTRUCTIONS MANUAL

-12-

Edit OIL data:

Use the arrows ↓↑ to select OIL, press ENTER, the following screen will be displayed:

1) Press ENTER and select AUTOMATIC OIL.

NOTE: Once the Vacuum operation has been completed the system automatically tops up

the same quantity of oil as that extracted during Recovery.

2) Select the second line using ↓, the use keys 0 to 9 to key in the volume of oil that must

automatically be refilled after the Vacuum. Finally press "ENTER" to confirm.

Edit TRACER data:

Use the arrows ↓↑ to select TRACER and press ENTER. The following screen is displayed:

1) Press ENTER to select NO and therefore skip tracer injection.

2) Select the second line using ↓, the use keys 0 to 9 to key in the volume of TRACER that

must automatically be refilled after the Vacuum. Finally press "ENTER" to confirm.

Edit FILLING data:

Use the arrows ↓↑ to select FILLING and press ENTER. The following screen is displayed:

1) Use keys 0 to 9 to enter the quantity (in grams) of refrigerant to be charged into the A/C

system and press ENTER.

NOTE: For most systems the quantity of fluid to be refilled is indicated on a plate that is in

the vehicle’s engine compartment. If this quantity is not known, look for it in the relavant

manuals.

2) If installed, you can use DATABASE BASIC (DBB): Use the arrows ↓↑ to select the second

line and press ENTER. The following screen is displayed:

Use the relevant “table” to read off the code for the vehicle. Use the numerical keypad to

key in the code. Once the setting has been completed, press ENTER to confirm. If you

wish to install DATABASE BASIC (DBB) contact the machine dealer.

3) If installed, you can use DATABASE ADVANCED (DBA): Use the arrow ↓ to select the

second line and press ENTER. The following screen is displayed:

ENTER CODE

VEHICLE MODEL

...

press ENTER to exit

AUTOMATIC PROCEDURE

FILLING <xxxg>

DATABASE

AUTOMATIC PROCEDURE

TRACER <NO>

TRACER xx ml

AUTOMATIC PROCEDURE

OIL <AUTO.>

OIL xx ml

Page 13

INSTRUCTIONS MANUAL

-13-

Use the arrow keys (↓↑) to move to the brand of vehicle you are servicing, press ENTER to

confirm, and the display will show the models for that type (for example, if you have chosen

FORD):

Use the arrow keys (↓↑) to go to the model required, and press ENTER to confirm. If you

wish to install DATABASE ADVANCED (DBA) contact the machine dealer.

Once you have checked that the data displayed is correct, you can push START to run the

AUTOMATIC PROCEDURE.

The following screen is displayed:

Open high and low pressure on the machine and press the START button. At this stage the

refrigerant recovery / recycle phase begins, marked by the message “Recovery Recycle”.

During this phase the system displays the grams of refrigerant recovered.

When recovery is complete the machine stops and discharges and automatically displays the

spent oil extracted by the A/C system during recovery. The oil discharge operation lasts 4

minutes. If during this phase some pockets of refrigerant are still inside the A/C system the

pressure increases and the machine automatically starts recovering refrigerant again.

At the end of the oil discharge phase the machine automatically moves on to the vacuum

operation for the preset time. Operator will then be prompted to check the VACUUM HOLD.

Once the vacuum phase has finished the oil top-up starts again automatically on the basis of

the volume of oil discharged or the volume entered by the operator. If installed, the tracer is

refilled automatically according to the quantity entered by the operator. At the end the system

automatically moves on to filling the quantity set.

NOTE: In rare cases the filling operation may not be completed due to the pressure balance. In

this case shut high pressure (leaving the low pressure open) and start the A/C system. Once

the filling operation has been completed the machine displays the message:

Close the high and low pressure taps.

Press START to continue:

Start the vehicle’s engine and the A/C system and wait at least 3 min:

Start the engine and A/C

System to check pressures

Press START

End filling

Close HP and LP

Press START to continue

press RESET

Open high and low

pressure, then Press START

<COUGAR>

ESCORT

ESCORT D

FIESTA

<ALFA ROMEO>

AUDI

BMW

CHRYSLER/JEEP

Page 14

INSTRUCTIONS MANUAL

-14-

At this stage the system is running normally and the high and low pressures can be checked by

reading them off the relevant pressure gauges. Press STOP to exit.

Only disconnect the high pressure rapid coupling (if necessary switch off the engine) and press

START:

Start the A/C system, open the high and low pressure taps and make the A/C system suction

the refrigerant left in the pipes. Press START to continue:

Wait until the high and low pressures balance out, after about 1 min disconnect the machine’s

low pressure rapid coupling on the vehicle’s A/C system and switch off the engine.

Press STOP to complete the procedure.

Turn the main switch (I) to the 0 position.

NB – The automatic procedure can be run even if the A/C system is empty. In this case the

machine begins the vacuum operation immediately. In the case of an A/C system with a single

high pressure rapid coupling set the filling quantity at +100 g (quantity that can remain in the

high pressure pipe because in this case it is not possible to suction up the refrigerant left in the

pipes).

NOTE: If STOP is pressed during recovery, the following screen will be displayed:

When START is pressed the procedure resumes, whereas when STOP or RESET is pressed

you go back to the MAIN MENU.

Wait for HP and LP to

Balance and close the

rapid couplings

STOP per completare

Open HP and LP taps

Start A/C system

Press START to continue

Disconnect HP coupling

Press START to empty the

pipes

CHECK PRESSURES

STOP to exit

Procedure paused.

START to continue

STOP to abort procedure

Page 15

INSTRUCTIONS MANUAL

-15-

ASSISTED PROCEDURE

In the assisted procedure mode, all the operations can be performed singly to the exception of

the recovery/recycling phase, which is automatically followed by used oil discharge. The values

for the quantity of gas recovered, quantity of oil recovered, vacuum time, quantity of oil

reintegrated, and quantity of gas charged into the system are automatically printed at the end

of each single operation.

From the MAIN MENU:

Select ASSISTED PROCEDURE and press the ENTER key.

The following screen is displayed:

NOTES:

* Only if the hardware is installed in the machine.

xy Default values extrapolated from a previous procedure.

RECOVERY AND RECYCLING

Press ENTER to confirm RECOVERY / RECYCLE. The following screen is displayed:

Press ENTER to confirm RECOVERY / RECYCLE. The following screen is displayed:

Key in the vehicle’s licence plate using the ↓↑ arrows to move around the licence plate

number. Then press "ENTER" to confirm.

NOTE: The numerical keys include an alphabet similar to that for text messages, for example:

press “2” once to display “A”, twice to display “B”, three times for "C" and four time for "2".

The following screen is displayed:

Enter licence plate

............

Premere ENTER

<RECOVERY / RECYCLE>

PIPE EMPTYING

RECOVERY / RECYCLE

VACUUM xy min

OIL xy ml

TRACER xy ml

FILLING xy g

SYSTEM FLUSHING*

STATIC DIAGNOSIS*

CHANGE OIL TYPE

AUTOMATIC PROCEDURE

<ASSISTED PROCEDURE>

DATA AND CONFIGURATION

MAINTENANCE xx.x kg

Page 16

INSTRUCTIONS MANUAL

-16-

Open the high and low pressure taps on the machine and press START to start the refrigerant

recovery/recycle phase. During this phase the display shows the quantity of refrigerant

recovered, expressed in grams.

When recovery is complete the machine stops and discharges and automatically displays the

spent oil extracted by the A/C system during recovery. The oil discharge operation lasts 4 min.

If during this phase some pockets of refrigerant are still inside the A/C system the pressure

increases and the machine automatically starts recovering refrigerant again.

NOTICE: if during recovery STOP is pressed, the following message appears:

When START is pressed the procedure resumes, whereas when STOP or RESET is pressed

you go back to the MAIN MENU.

EMPTYING PIPES

In the RECOVERY AND RECYCLE MENU select EMPTY PIPES and press ENTER to

confirm.

The following screen is displayed:

Open high and low pressure on the machine and press the START button.

VACUUM

Use the quick-connect couplings to connect the hoses to the A/C system, bearing in mind that

BLUE must be connected to the low pressure side and RED to high pressure. If the system is

equipped with a single quick-connect coupling for high or low pressure, connect only the

relative hose. Select the assisted procedure by pressing ENTER when “Assisted Procedure”

flashes on the LCD. Select the vacuum operation by pressing ENTER when the message

“Vacuum xx min.” flashes on the LCD. Set the vacuum time only if different from that previously

used. Press ENTER to confirm. Open the high- and low-pressure taps of the machine and

press START. Operator will then be prompted to check the VACUUM HOLD.

Open high and low

pressure then

Press START

RECOVERY / RECYCLE

<PIPE EMPTYING>

Procedure in standby

START to continue

STOP to exit

Procedure

Open high and low

pressure then

Press START

Page 17

INSTRUCTIONS MANUAL

-17-

NEW OIL REINTEGRATION

This operation can be carried out ONLY following a vacuum operation and before charging.

Select the assisted procedure by pressing ENTER when the “ASSISTED PROCEDURE”

message flashes on the LCD.

The following message will be displayed:

Press ENTER to continue.

Select the OIL by pressing ENTER when “OIL XX CC” flashes on the LCD. Set the volume of

new oil to be reintegrated, in cc. Press ENTER to confirm. Open the high- and low-pressure

taps (if the A/C system is equipped with a single quick-connect coupling for high or low

pressure, open only the relative tap) of the machine and press START.

TRACER REINTEGRATION

This operation can be carried out only following a vacuum procedure and before charging.

Select the assisted procedure when the “ASSISTED PROCEDURE" message flashes on the

LCD, and press ENTER. Select “TRACER” and set the volume of tracer to be reintegrated, in

cc. Press ENTER to confirm.

The following message will be displayed:

Press ENTER to continue.

Open the high- and low-pressure taps (in the case of an A/C system with only one pressure

coupling—high or low—open only the relative tap) on the machine and press START.

NOTE: To enable the TOP UP TRACER function, use the OPTIONS MENU.

CHARGING THE A/C SYSTEM

Select the ASSISTED PROCEDURE by pressing ENTER when the “Assisted Procedure”

message flashes on the LCD. Select charging by pressing ENTER when “CHARGING XXXX

G” flashes on the LCD. The following screen is displayed:

1) Use keys 0 to 9 to enter the quantity (in grams) of refrigerant to be charged into

the A/C system and press ENTER.

NOTE: For most systems the quantity of fluid to be refilled is indicated on a plate

ASSISTED PROCEDURE

CHARGING <xxxg>

DATABASE

ATTENTION

USING PAG OIL OR TRACER IN

HYBRID VEHICLES MAY DAMAGE

THE COMPRESSOR.

USE ONLY SUITABLE OIL WITH A

SEPARATE DEVICE.

ATTENTION

USING PAG OIL OR TRACER IN

HYBRID VEHICLES MAY DAMAGE

THE COMPRESSOR.

USE ONLY SUITABLE OIL WITH A

SEPARATE DEVICE.

Page 18

INSTRUCTIONS MANUAL

-18-

that is in the vehicle’s engine compartment. If this quantity is not known, look for

it in the relavant manuals.

2) If installed, you can use DATABASE BASIC (DBB): Use the arrow ↓ to select

the second line and press ENTER. The following screen is displayed:

Use the relevant “table” to read off the code for the vehicle. Use the numerical

keypad to key in the code. Once the setting has been completed, press ENTER

to confirm. If you wish to install DATABASE BASIC (DBB) contact the machine

dealer.

3) If installed, you can use DATABASE ADVANCED (DBA): Use the arrow ↓ to

select the second line and press ENTER. The following screen is displayed:

Use the arrow keys (↓↑) to move to the brand of vehicle you are servicing, press

ENTER to confirm, and the display will show the models for that type (for

example, if you have chosen FORD):

Use the arrow keys (↓↑) to go to the model required, and press ENTER to

confirm. If you wish to install DATABASE ADVANCED (DBA) contact the

machine dealer.

The following screen is displayed:

Key in the vehicle’s licence plate using the ↓↑ arrows to move around the licence plate

number. Then press "ENTER" to confirm.

NOTE: The numerical keys include an alphabet similar to that for text messages, for example:

press “2” once to display “A”, twice to display “B”, three times for "C" and four time for "2".

The following screen is displayed:

Open the machine hig-pressure tap and press START (if it is an A/C apparatus with only low or

high pressure couplings, open only the relevant tap on the machine) . NOTICE: In some cases

the refilling operation may not conclude successfully because of the pressure balance; in this

REFILLING

Gas xyz g

Press START

Enter licence plate

............

Press ENTER

<COUGAR>

ESCORT

ESCORT D

FIESTA

<ALFA ROMEO>

AUDI

BMW

CHRYSLER/JEEP

ENTER CODE

VEHICLE MODEL

... Press ENTER and exit

Page 19

INSTRUCTIONS MANUAL

-19-

case, close the high-pressure tap (leave the low pressure open), and turn the A/C apparatus

on.

Once the filling operation has been completed the machine displays the message:

Close the high and low pressure taps. Press START to continue:

Start the vehicle’s engine and the A/C system and wait at least 3 min:

At this stage the system is running normally and the high and low pressures can be checked by

reading them off the relevant pressure gauges. Press STOP to exit.

Only disconnect the high pressure rapid coupling (if necessary switch off the engine) and press

START:

Start the A/C system, open the high and low pressure taps and make the A/C system suction

the refrigerant left in the pipes. Press START to continue:

Wait until the high and low pressures balance out, after about 1 min disconnect the machine’s

low pressure rapid coupling on the vehicle’s A/C system and switch off the engine.

Press STOP to complete the procedure.

N.B. - When working with A/C systems with a single high-pressure coupling, set the charging

quantity ate about 100g in excess of the required quantity, since in this case it will be

impossible to recover the residual refrigerant from the hoses.

Wait for HP and LP to

balance and close rapid

couplings

STOP to complete

Open HP and LP pipes

Start A/C system

Press START to continue

Disconnect HP couplings

Press START to empty

pipes

CHECK PRESSURES

STOP to exit

Start the engine and the

A/C system to check

pressures

Press START

End charging

Close HP and LP

Press START to continue

Press RESET

Page 20

INSTRUCTIONS MANUAL

-20-

STATIC DIAGNOSIS (optional)

See instructions [MANUSTA001.0]

Page 21

INSTRUCTIONS MANUAL

-21-

DATA

This menu shows all the data read by the machine. Switch on the machine. From the MAIN

MENU:

Select DATA & CONFIGURATION. The following screen is displayed:

Press ENTER to open the DATA MENU:

- Gas available: quantity of refrigerant available in the storage bottle.

- Oil: quantity of oil in all the oil containers.

- Temperature: temperature of the refrigerant storage bottle.

- Pac: pressure in the external air conditioner system.

Gas avail. xxxxx g

Oil xxxx cc

Temperature xx.x °C

Pac xx bar

<DATA>

CONFIGURATION SERVICES

AUTOMATIC PROCEDURE

ASSISTED PROCEDURE

<DATA & CONFIGURATION>

MAINTENANCE xx.xkg

Page 22

INSTRUCTIONS MANUAL

-22-

CONFIGURATION

This menu is used to edit the machine’s settings. From the MAIN MENU:

Select DATA & CONFIGURATION. The following screen is displayed:

Select CONFIGURATION and press ENTER.

LANGUAGE

From the CONFIGURATION MENU:

Select LANGUAGE

NOTE : current language is indicated by the sign “<-“

Use the ARROW keys to scroll available languages, confirm your selection pressing ENTER,

the machin will reset and in a few seconds the MAIN MENU in the chosen language will

appear.

UNIT OF MEASURE

From the CONFIGURATION MENU:

Select UNIT OF MEASURE:

LANGUAGE

UNIT OF MEASURE

OPTIONS

SET DATE & TIME

SET PRINT HEAD.

ENTER OPERATOR NR.

ENGLISH

ITALIANO

FRANCAIS <ESPANOL

LANGUAGE

UNIT OF MEASURE

OPTIONS

SET DATE & TIME

SET PRINT HEAD.

ENTER OPERATOR NR.

DATA

<CONFIGURATION>

SERVICES

AUTOMATIC PROCEDURE

ASSISTED PROCEDURE

<DATA & CONFIGURATION>

MANUTENZIONE xx.xKg

Page 23

INSTRUCTIONS MANUAL

-23-

WEIGHT

Select WEIGHT:

press ENTER to swtich from g(Kg) to oz(lb) or from oz(lb) to g(kg).

Press STOP to exit.

PRESSURE

Select PRESSURE:

press ENTER to switch from bar to psi or from psi to bar.

Press STOP to exit.

TEMPERATURE

Select TEMPERATURE:

press ENTER to switch from °C to °F or from °F to °C.

Press STOP to exit.

OPTIONS

From the CONFIGURATION MENU:

WEIGHT g (Kg)

PRESSURE bar

TEMPERATURE °C

WEIGHT g (Kg)

PRESSURE bar

TEMPERATURE °C

WEIGHT g (Kg)

PRESSURE bar

TEMPERATURE °C

WEIGHT g (Kg)

<PRESSURE> bar

TEMPERATURE °C

WEIGHT g (Kg)

PRESSURE bar

TEMPERATURE °C

WEIGHT g (Kg)

PRESSURE bar

TEMPERATURE °C

WEIGHT g (Kg)

PRESSURE bar

TEMPERATURE °C

Page 24

INSTRUCTIONS MANUAL

-24-

Select OPTIONS and the following screen is displayed:

Call the technical service for the code. Once you have entered the code, press ENTER:

Select the option required and press ENTER to switch from “on” to “off” and vice versa.

Press "STOP" to go back to the PREVIOUS MENU.

DATE AND TIME

The machine keeps date and time settings even if it is not used for around one year.

From the CONFIGURATION MENU:

Select DATE AND TIME and the following screen is displayed:

Press START to change date and time

CONFIGURATION OF SETTING UP AND PRINTING

The printout can be personalised by entering 4 lines containing the workshop’s details (e.g.

Name, address, telephone n° and e-mail).

From the CONFIGURATION MENU:

Select CONF. SET & PRINT and the following screen is displayed:

LANGUAGE

UNIT OF MEASURE

OPTIONS

SET DATE & TIME

SET PRINT HEAD.

ENTER OPERATOR NR.

hh:mm:ss – gg/mm/aa

ENTER TO CONFIRM

START TO CHANGE

LANGUAGE

UNIT OF MEASURE

OPTIONS

SET DATE & TIME

SET PRINT HEAD.

ENTER OPERATOR NR.

ENABLE TRACER on

........

LANGUAGE

UNIT OF MEASURE

OPTIONS

SET DATE & TIME

SET PRINT HEAD.

ENTER OPERATOR NR.

Page 25

INSTRUCTIONS MANUAL

-25-

Key in the printing set up the ↓↑ arrows to move within the line. Then press ENTER to confirm

and go to the next lines.

NOTE: The numerical keys include an alphabet similar to that for text messages, for example:

press “2” once to display “A”, twice to display “B”, three times for "C" and four time for "2 ".

ENTER OPERATOR N

From the CONFIGURATION MENU:

Select ENTER OPERATOR N and the following screen is displayed:

It is possible to enter an alphanumeric code of 10 symbols to indicate the habilitation nr of the

operator. This number will be indicated in all printouts.

LEAK CHECK

It is possible to edit the intervals between leak checks on the A/C system.

From the CONFIGURATION MENU:

Select LEAK CHECK and the following screen is displayed:

Key in the time before the leak check and then press ENTER to exit.

NOTE: A period of less than 10 minutes cannot be set.

LEAK CHECK

Time before

Leak check: xx min

LANGUAGE

UNIT OF MEASURE

OPTIONS

SET DATE & TIME

CONF. PRINT HEAD.

ENTER OPERATOR NR.

CHECK LEAKS

NITROGEN LEAK THRESHOLD

ENTER OPERATOR N°

........

LANGUAGE

UNIT OF MEASURE

OPTIONS

SET DATE & TIME

CONF. PRINT HEAD.

ENTER OPERATOR NR.

CONF. PRINT HEAD.

1:

. . . . . . . . . . . . .

Page 26

INSTRUCTIONS MANUAL

-26-

SERVICES

This menu makes it possible to manage some auxiliary services. From the MAIN MENU:

Select DATA & CONFIGURATION. The following screen is displayed:

Select SERVICES and press ENTER.

NOTE: The SERVICES MENU is only available to authorised technicians

REFRIGERANT MANAGEMENT

The machine keeps track of the operations done on refrigerant fluid: recovery, system refilling,

inner bottle filling. For any operation, a record is made with date, time, type of operation,

quantities involved, operator nr., inner bottle refrigerant fluid availability. The machine can keep

up to 100 records. From the 90th operation on, a message appears indicating how many

operations can be done..

From the SERVICES MENU:

Select REFRIGERANT MANAGEMENT and the following screen is displayed:

Select DELETE and press ENTER to delete all the records from the memory.

Select PRINT and press ENTER to print the last 25 operations in the memory.

NOTE: If the machine is connected to a personal computer by means of a USB cable, the

GESTREF.TXT file can be downloaded that contains all the operations in the memory.

PASSWORD

From the SERVICES MENU:

Select PASSWORD and the following screen is displayed:

REFRIGERATION MANAGEMENT

PASSWORD

COUNTERS

REFRIGERATION MANAGEMENT

DELETE

PRINT

REFRIGERANT MANAGEMENT

PASSWORD

COUNTERS

DATA

CONFIGURATION

<SERVICES>

AUTOMATIC PROCEDURE

ASSISTED PROCEDURE

<DATA & CONFIGURATION>

MAINTENANCE xx.xkg

Page 27

INSTRUCTIONS MANUAL

-27-

A four-digit password can be entered to block the machine use. Once the password is entered,

it is possible to proceed from the main menu only after entering the code.

Entering 0000 as a password, the block is eliminated.

COUNTERS

This is used to check total COUNTERS of:: recovered gas, service alarm meter, total vacuum

minutes, injected gas, gas recovered into the bottle with the bottle refilling function.

From the SERVICES MENU:

Select COUNTERS and the following screen is displayed:

Use ↓ to scroll the lines.

This screen displays the total values for: gas recovered, service alarm COUNTERS, total

vacuum time (minutes), gas injected, gas recovered in the internal bottle using the “Bottle

filling” function.

Pressing START, COUNTERS can be printed out with date and time.

Rec. gas 0.0 kg

Service 0.0Kg

Vacuum 0 min

Syst. Fill. 0.0 kg

Bott. fill. 0.0 Kg

REFRIGERATION MANAGEMENT

PASSWORD

COUNTERS

. . . .

Page 28

INSTRUCTIONS MANUAL

-28-

MAINTENANCE

This menu is used for maintenance operations on the machine. From the MAIN MENU:

Select MAINTENANCE.

FILLING THE MACHINE BOTTLE

This operation must be performed whenever the available refrigerant fluid in the bottle is less

than 3 kg and must in any case be performed when the “empty bottle” alarm is displayed.

Procure a bottle of R134a gas and connect the liquid side coupling of the external bottle to the

high pressure hose (if the external bottle is not supplied with a liquid side coupling, upend it to

recover liquid refrigerant). Open the tap of the external bottle and the high-pressure tap of the

machine. If the external bottle is not supplied with a suction device, turn it upside down to

obtain a higher delivery rate.

From the MAINTENANCE MENU:

Select BOTTLE FILLING and the following screen is displayed:

Set the quantity of refrigerant to be transferred to the machine bottle (the quantity must be

between the limit values suggested by the machine) and press START to confirm:*

Press START:

Press START:

The machine will now fill the machine bottle with the preset quantity ± 500g. When the quantity

minus 500 grams is reached, the machine will stop and display:

BOTTLE FILLING

MANUAL AIR PURGING

SERVICE ALARM

CALIBRATION

AUTOMATIC PROCEDURE

ASSISTED PROCEDURE

DATA & CONFIGURATION

<MAINTENANCE> xx.x kg

FILLING BOTTLE

0 g

Open external

bottle tap, open

HP tap, and

press START.

Use the HP hose to

connect external

bottle and

press START.

Page 29

INSTRUCTIONS MANUAL

-29-

Close the bottle tap and press START. The machine will stop automatically after having

recovered the residual refrigerant from the hoses. Close the high-pressure tap. Disconnect the

external bottle. Switch the machine off.

MANUAL AIR PURGING

From the MAINTENANCE MENU:

Select MANUAL AIR PURGING and the following screen is displayed:

If the pressure xx.x bar flashes, this means that there is air in the bottle. If this happens press

START. The machine starts to purge the air making the bottle pressure drop. As soon as the

pressure returns within the parameters, the machine stops purging.

Press STOP to go back to the PREVIOUS MENU.

NOTE: Each time the bottle pressure reaches 18 bar the machine automatically discharges

non-condensable gas until the pressure drops to 16 bar.

SERVICE AND CHANGE FILTERS ALARM

Replace the filters whenever the machine gives the service alarm during the first ten seconds

of operation. Before performing any operation, check that the replacement filters are the same

type as those installed on the machine. Then proceed as described below (refer to Fig. 11):

1) Disconnect the machine from the electrical supply

2) Wear protective gloves and glasses

3) Remove the rear plastic cover from the machine.

4) Remove the used filter and install new one, respecting the direction of the arrow.

IMPORTANT: Filter replacement must be performed as quickly as possible in order

to avoid possible contamination by moisture in the ambient air.

NOTE: If possible, use an electronic leak tester to check the seal on the couplings of the

new filter.

5) Replace the rear plastic cover on the machine.

6) Reconnect the machine to the electrical supply and switch on.

7) Select MAINTENANCE, and enter SERVICE ALARM.

8) Key in the filter code to cancel the alarm. If the filter code is not available, call the

Service Center.

9) Recover about 500g of gas to charge the machine circuit.

10) Switch the machine off.

11) Disconnect the machine from the electrical supply.

AIR PURGE

Press: xx.x bar

START to purge

STOP to exit

BOTTLE FILLING

MANUAL AIR PURGING

SERVICE ALARM

CALIBRATION

FILLING BOTTLE

Close external

bottle tap

Press Start

Page 30

INSTRUCTIONS MANUAL

-30-

QUICK GUIDE

This resets the guide. Turn on the machine. Main Menu: Select MAINTENANCE. Use the

arrow to select "Quick setup" press ENTER to start the Quick Start Guide (see self-titled

paragraph in the chapter GETTING STARTED)

Page 31

INSTRUCTIONS MANUAL

-31-

CALIBRATION

Perform this operation whenever the values displayed on the LCD do not correspond to real

values. WARNING: The operations listed below must be performed with maximum attention

and care. In particular, always observe the following precautions. Always place the weights at

the centre of the scale plate. Never exert pressure on the oil scale. Always recover the gas in

the high- and low-pressure hoses before beginning calibration of the transducers.

From the MAINTENANCE MENU:

Select CALIBRATION and the following screen is displayed:

Enter code 0791 and confirm pressing ENTER. The following screen is displayed:

CALIBRATING THE BOTTLE SCALE

Disconnect the machine from the electrical supply. Procure a known reference weight from 28

to 32 kg. Remove the plastic cover on the rear of the machine to access the machine bottle.

Close the blue and red taps on the bottle. Unscrew the bottle lock nut (3 – Fig. 4). Separate the

heating coil (r – Fig. 8) from the bottle (do not touch or disconnect the wires of the resistance

coil). Remove the bottle (d – Fig. 8) from its lodging, leaving the resistance around the scale

plate. Set the bottle on a stand at least 40 cm in height.

From the CALIBRATION MENU:

Select BOTTLE SCALE and the following screen is displayed:

With BOTTLE SCALE flashing, press ENTER. The following screen will be displayed:

BOTTLE SCALE

OIL SCALE

A/C PRESSURE TR.

BOTTLE TEMPERATURE

BOTTLE SCALE

OIL SCALE

A7C PRESSURE TR.

BOTTLE TEMPERATURE

To access menu

insert code

. . . .

press ENTER

BOTTLE FILLING

SERVICE ALARM

CALIBRATION

CALIBRATION

BOTTLE DATA

PREVIOUS MENU

Page 32

INSTRUCTIONS MANUAL

-32-

Press the ENTER key.

With the bottle lifted off the scale plate, press START. The following screen will be displayed:

Place the reference weight (28 to 32 kg) at the centre of the scale plate. Use keys 0 through 9

to type in the value of the weight. Press START. Switch off the machine and disconnect it from

mains supply. Replace the bottle on the scale plate and the heating coil on the bottle (Attention:

the resistance must adhere tightly to the bottle). Replace the plastic cover. Open the blue and

red taps on the bottle. Replace the rear plastic cover.

BOTTLE DATA

N.B. This menu is reserved for use by the technician performing final testing. It contains the

maximum safety threshold value; therefore, the bottle data may not be changed for any reason.

For assistance, call the Service Center.

From the CALIBRATION MENU:

Select BOTTLE SCALE and the following screen is displayed:

Select BOTTLE DATA. The following screen will be displayed:

Use the arrow keys and the number pad to change the Max, Min, and Tare values. Then select

PREVIOUS MENU and press ENTER.

Press START to confirm saving the data or STOP to exit without saving.

BOTTLE SCALE

OIL SCALE

A/C PRESSURE TR.

BOTTLE TEMPERATURE

CALIBRATION

<BOTTLE DATA>

PREVIOUS MENU

SAVE DATA:

Press START.

To exit:

press STOP

Max xxxxx g

Min xxxxx g

Tare xxxxx g

PREVIOUS MENU

ZERO LEVEL

Raise the bottle

levels xxxxx

press START

REFERENCE VALUE

xxxxx g

levels xxxxx

press START

Page 33

INSTRUCTIONS MANUAL

-33-

CALIBRATING THE OIL SCALE

From the CALIBRATION MENU:

Select OIL SCALE and the following screen is displayed:

Empty the oil containers. Replace the empty containers in their lodgings, taking care not to

exert pressure on the scale, and press START. The following screen will be displayed:

Fill the new oil container with a known volume of new oil (from 100 a 250 cc measured on the

container measure marks). Replace the container in its lodging, taking care not to exert

pressure on the scale. Use keys 0 through 9 to type in the known oil volume, in cc, and press

START. Switch off the machine and disconnect it from the electrical supply.

CALIBRATION THE A/C PRESURE

Warning: This operation must be carried out only with the front service hoses empty. We

recommend running a brief RECOVERY phase before beginning calibration. Slowly unscrew

the blue front service hose, open the front taps, and check that both pressure gages read 0

bar. Switch the machine on. From the CALIBRATION MENU:

Select A/C RESSURE and the following screen is displayed:

Press START to ZERO.

CALIBRATING THE BOTTLE TEMPERATURE

NOTE: A digital thermometer is required for bottle temperature sensor calibration. Check that

the bottle temperature probe is disconnected from the bottle and so capable of reading the

ambient temperature.

ZERO LEVEL

Open HP and LP

Levels xxxxx

Press START

BOTTLE SCALE

OIL SCALE

A/C PRESSURE TR.

BOTTLE TEMPERATURE

BOTTLE SCALE

OIL SCALE

A/C PRESSURE TR.

BOTTLE TEMPERATURE

ZERO LEVEL

Empty oil containers

Levels xxxxx

Press START

REFERENCE VALUE

xxxx cc

Levels xxxx

Press START

Page 34

INSTRUCTIONS MANUAL

-34-

Switch on the machine. From the CALIBRATION MENU:

Select BOTTLE TEMPERATURE and the following screen is displayed:

Check that the temperature shown on the display is that also read on the external

thermometer. If necessary, press START to modify the machine value:

Type in the temperature read on the digital thermometer and press ENTER to confirm.

Replace the temperature probe on the bottle.

VACUUM PUMP

Perform the operations listed below on a routine basis in order to ensure good operation of the

vacuum pump:

M1) Oil top-up.

M2) Oil change.

When refilling or replacing the pump oil, use only the oil recommended by the manufacturer.

Contact your retailer for information concerning the correct type of oil.

M.1) Oil top-up

This operation must be performed when the level of the oil falls to less than half on the indicator

(4) (refer to Figure 10). NOTE: in order to correctly check the oil level, run the pump for at least

1 minute (running a vacuum procedure in the hose for 1 minute) so that the oil fluidifies. Check

the oil level when the pump stops. To refill the oil, perform the steps listed below in the order

given. Disconnect the MACHINE from the mains supply. Locate the oil cap (2) and screw it

completely off. The oil must be added through the hole in which the oil cap was lodged (2). Add

oil a little at a time, waiting for the level to rise before each successive addition, until the oil level

is about ½ cm above the red mark on the indicator (4). Replace the oil cap (2) and tighten

down.

M.2) Oil change

The vacuum pump oil must be replaced every 150 working hours and in any case every time

the refrigerant filters are replaced. The oil must also be replaced whenever it changes color

due to absorption of humidity. Before beginning the oil change procedure, procure a container

of at least 500 cc capacity in which to collect the used oil. The pump contains about 500 cc of

oil. Use only the oils recommended by the manufacturer (consult your retailer).

1) Disconnect the machine from the mains supply.

BOTTLE SCALE

OIL SCALE

A/C PRESSURE TR.

BOTTLE TEMPERATURE

BOTTLE TEMPERATURE

XX.X °C

START to change

STOP to exit

BOTTLE TEMPERATURE

XX.X °C

XXX.X °C

Press START

Page 35

INSTRUCTIONS MANUAL

-35-

2) Unscrew the filling cap 2 (refer to Fig. 10).

3) Unscrew the drain cap 3.

4) Allow all the oil to run out into a disposal container (with height < 10 cm).

5) Close the drain cap 3.

6) Pour in new oil through the filling hole, opened previously, until the level rises to the

midpoint on the indicator 4.

7) Replace the oil cap 2 and tighten.

FILLING THE NEW OIL CONTAINER

(if installed)

It is good practice to fill the oil container whenever the oil level falls below 100 cc in order to

guarantee that there will be sufficient oil for refilling during successive operations. Types of oil:

use only synthetic (polyester) oils or the oils recommended by the manufacturer. Always refer

to the information provided by the A/C system manufacturer. Procedure: remove the container

from its lodging. Hold the cap and unscrew the container. Fill the container with the correct

quantity of oil for compressors, of suitable type and grade. Screw the container back into the

cap while holding the latter in place. Replace the container, taking care not to exert pressure on

the scale in order not to damage it.

FILLING THE TRACER CONTAINER

(if installed)

It is good practice to refill the tracer container whenever the level drops below 50 cc, in order to

have a sufficient reserve of tracer for carrying out subsequent fillings. Procedure: Lift the tracer

container out of its lodging. Unscrew the container while holding the cap in place and fill the

container with the required quantity of tracer for compressors. Screw the container back onto

the cap and return to its lodging, taking great care not to exert pressure on the scale in order

not to damage it.

N.B.: Using tracers not recommended by the manufacturer will invalidate the warranty.

REPLACING THE COLLAPSIBLE NEW OIL / TRACER CARTRIDGE

(if installed)

The accordion-type collapsible-cartridge injection system permits simple, clean, and accurate

injection of oil / tracer into the A/C system and above all permits injecting a product free of

impurities and not subject to contamination, for example by humidity, which can cause serious

damage to the components of A/C systems.

The male-female bayonet system ensures correct coupling between the cartridge and the

equipment, reducing environmental exposition of the product to a minimum and guaranteeing

correct seal even after use.

The male coupling element is welded to the cartridge in order to prevent infiltration of air and to

maintain the product in its original state; it also makes it impossible to unscrew the coupling

and refill the cartridge, when the original product is used up, without breaking the neck of the

cartridge.

INSERTING THE CARTRIDGE

Grasp the cartridge by the tabs (fig.14).

Insert it into the female coupling on the machine and turn counterclockwise (fig.15) until the two

arrows (one on male, one on female) align (fig.16); a “click” signals that the cartridge is

correctly inserted.

Do not force rotation of the cartridge beyond the alignment point.

REMOVING THE CARTRIDGE

Grasp the two tabs on the male element and rotate clockwise (fig.17) until the cartridge

releases from the coupling; pull downward to extract from the female element (fig.18).

Page 36

INSTRUCTIONS MANUAL

-36-

ATTENTION: we recommend performing the above operati ons quickly and without hesitation,

avoiding, insofar as possible, the “center” points at which the valve on the male element

remains open and may admit air. We therefore recommend exerting as little pressure as

possible on the base of the cartridge and compressing it in order to obviate entry of air. Always

use protective gloves and goggles.

NOTE: while rotating the cartridge, compress slightly to release pressure.

NOTE: the cartridge may be removed whenever necessary; it is nevertheless preferable to

remove as infrequently as possible. The extracted cartridge retains its “collapsed” conformation

and is always ready for re-insertion.

NOTE: use only synthetic (polyester) oils or the oils recommended by the manufacturer.

Always refer to the information provided by the A/C system manufacturer

NOTE: Using tracers not recommended by the manufacturer will invalidate the warranty.

EMPTYING THE USED OIL CONTAINER

This operation must be performed whenever the oil level exceeds 200 cc. Procedure: remove

the container from its lodging very carefully and without exerting pressure on the scale.

Unscrew the container while holding the cap in place; empty the used oil into a suitable

container for used oils. Screw the container back on while holding the cap in place. Carefully

replace the container in its lodging without exerting pressure on the scale. N.B.: In order to

avoid damage to the oil scale, never exert pressure on it either from above or from below.

REPLACING THE PRINTER PAPER

Use only heat-sensitive paper of the type described below.

Paper width: 58 mm

Maximum paper roll diameter: 40mm

Page 37

INSTRUCTIONS MANUAL

-37-

CUSTOMIZING THE DBA (DATABASE ADVANCED)

Select ASSISTED PROCEDURE. Scroll down with the (↓) down arrow key until the vehicle

brands in the DBA appear:

Press the (↑) up arrow key:

Select the USER DEFINED option:

DATA ENTRY

To enter customized data, press START. The following screen will be displayed:

Type in the vehicle model on the keyboard; press ENTER to confirm.

Type in the corresponding refrigerant quantity; press ENTER to confirm.

USE

To use the customized data, scroll with the (↓↑) arrow keys to the desired vehicle model; press

ENTER to confirm.

DELETION

To delete custom data fields, scroll with the (↓↑) arrow keys to the desired vehicle model and

press “0” (ZERO). An alarm signal will sound and the following screen will be displayed.

Press START to exit the process or START to confirm deletion.

NOTE CONCERNING THE DATABASE: we have taken all due care in gathering and entering

the information contained in the database. The database data must nevertheless be

VEHICLE NAME

xxxx g

DELETE?

START: YES STOP: NO

MODEL NAME:

. . . . . . . . . . . . .

MODEL QUANTITY:

xxxx

<ABCD EDFG>

HILM NOPQ

????

????

TOYOTA

VOLKSWAGEN

VOLVO

<USER DEFINED>

<ALFA ROMEO>

AUDI

BMW

CHRYSLER/JEEP

Page 38

INSTRUCTIONS MANUAL

-38-

considered purely indicative; the manufacturer declines any and all responsibility for incorrect

data.

CONTRAST

Keys 4 and 5 may be used to adjust the screen contrast. Key 4 decreases contrast; key 5

increases contrast.

Contrast control is active only with the machine in the main menu and with “AUTOMATIC

PROCEDURE” flashing.

INSTALLING THE USB VIRTUAL COM DRIVE

System requirements for installing the drive:

1. 2008 machine

2. Iarvircomport.inf driver software

3. USB cable (male plug A / male plug B);

4. Computer with USB port and Windows XP operating system.

Copy the iarvircomport.inf file to the desktop.

Connect the machine to the computer with the USB cable. A window will appear on the

desktop, reading: “Found New Hardware, USB Device”

The operating system will start the new hardware installation procedure.

When the Wizard asks “Can Windows connect to Windows Update to check for

software?” check the button “No, not this time” and click “Next.”

From the installation window, check the button “Install from a list or specific location

(Advanced)” and click “Next”.

At this point the computer will ask for the driver location. Click “Browse” and select the

iarvircomport.inf file, previously copied to the desktop. Click “Open” to confirm.

After having clicked “Next” again, the final window will appear, informing the user that the

Windows has finished installing the software. Click “Finish” to close.

Page 39

MANUEL D’INSTRUCTIONS

-39-

INDEX

INDEX ...............................................................................................................................39

INTRODUCTION...............................................................................................................41

CONSERVATION DU MANUEL..............................................................................................41

CONDITIONS DE GARANTIE...........................................................................................42

INFORMATIONS GENERALES........................................................................................43

FIN DE VIE........................................................................................................................43

ÉLIMINATION BATTERIE ......................................................................................................43

NORMES DE SECURITE..................................................................................................43

REGLES DE COMPORTEMENT AVEC LES FLUIDES REFRIGERANTS ............................44

PRINCIPES DE FONCTIONNEMENT ..............................................................................45

MISE EN SERVICE...........................................................................................................45

LA MACHINE.....................................................................................................................46

ELEMENTS FONDAMENTAUX ..............................................................................................46

SYSTEME DE COMMANDE ET DE CONTROLE...................................................................46

CLAVIER DE SELECTION DES OPERATIONS.....................................................................46