Page 1

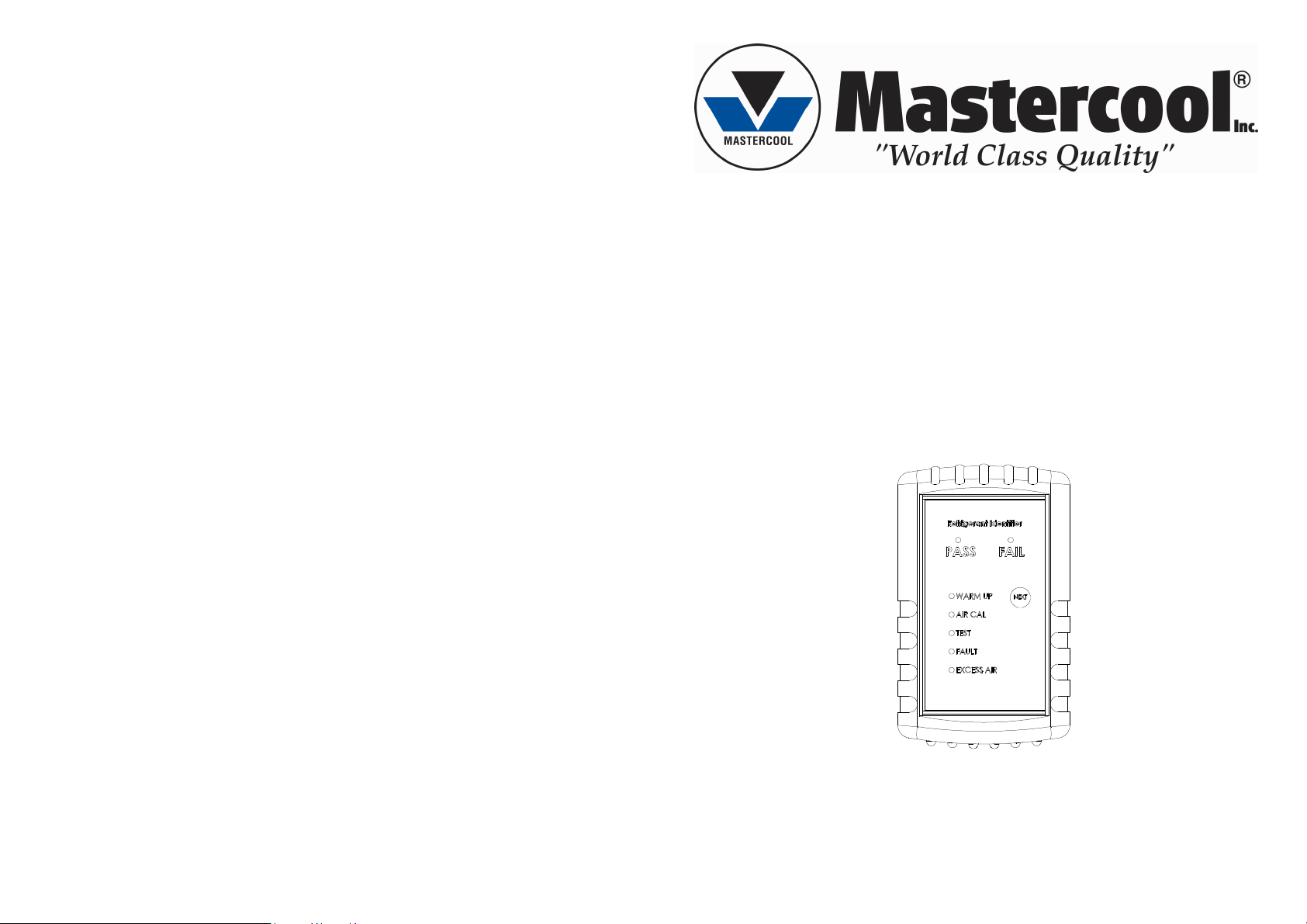

MINI ID

MINI ID

MINI IDMINI ID

R134a REFRIGERANT ANALYZER

PART NUMBER: 69134-A

OPERATION MANUAL

OPERATION MANUAL

OPERATION MANUALOPERATION MANUAL

Manual Part Number: 5-06-4900-62-1

Manual File MN-A-0201 Rev. A

Mini ID

Mastercool Inc.

Mastercool Inc.

Mastercool Inc. Mastercool Inc.

One Aspen Drive

Randolph, NJ 07869

Phone: (973) 252-9119 / Fax: (973) 252-2455

Page 2

The terms of these warranty provisions shall apply to all products sold by Mastercool

Inc., except filters which are considered “consumable items,” and as such are not

covered by the terms of these warranties. No waiver, alteration or modification of

the terms of these provisions shall be valid unless in writing and signed by an ex-

ecutive officer of Mastercool Inc..

EXCEPT AS SPECIFICALLY SET FORTH AND LIMITED IN THIS PARAGRAPH, MASTER-

EXCEPT AS SPECIFICALLY SET FORTH AND LIMITED IN THIS PARAGRAPH, MASTER-

EXCEPT AS SPECIFICALLY SET FORTH AND LIMITED IN THIS PARAGRAPH, MASTER-EXCEPT AS SPECIFICALLY SET FORTH AND LIMITED IN THIS PARAGRAPH, MASTERCOOL INC., INC. MAKES NO WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING

COOL INC., INC. MAKES NO WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING

COOL INC., INC. MAKES NO WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING COOL INC., INC. MAKES NO WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING

WARRANTIES AS TO MERCHANTABILITY, OR AS TO THE FITNESS OF THE GOODS FOR

WARRANTIES AS TO MERCHANTABILITY, OR AS TO THE FITNESS OF THE GOODS FOR

WARRANTIES AS TO MERCHANTABILITY, OR AS TO THE FITNESS OF THE GOODS FOR WARRANTIES AS TO MERCHANTABILITY, OR AS TO THE FITNESS OF THE GOODS FOR

ANY PARTICULAR USE OR PURPOSE, AND ANY WARRANTIES SET FORTH IN THIS

ANY PARTICULAR USE OR PURPOSE, AND ANY WARRANTIES SET FORTH IN THIS

ANY PARTICULAR USE OR PURPOSE, AND ANY WARRANTIES SET FORTH IN THIS ANY PARTICULAR USE OR PURPOSE, AND ANY WARRANTIES SET FORTH IN THIS

PARAGRAPH ARE IN LIEU OF SUCH IMPLIED WARRANTIES OF MERCHANTABILITY

PARAGRAPH ARE IN LIEU OF SUCH IMPLIED WARRANTIES OF MERCHANTABILITY

PARAGRAPH ARE IN LIEU OF SUCH IMPLIED WARRANTIES OF MERCHANTABILITY PARAGRAPH ARE IN LIEU OF SUCH IMPLIED WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR PARTICULAR USE OR PURPOSE.

AND FITNESS FOR PARTICULAR USE OR PURPOSE.

AND FITNESS FOR PARTICULAR USE OR PURPOSE.AND FITNESS FOR PARTICULAR USE OR PURPOSE.

Manual Part Number:

5-06-4900-62-1

Manual File:

MN-A-0201 Rev. A

Revision Date:

01/17/2011

Page 13

Page 3

MASTERCOOL INC. warrants, subject to the terms listed below, that the goods will

be free from defects in design, materials, and workmanship for a period of (1) one

year from the date that the goods are shipped to the buyer.

THE SOLE LIABILITY O

THE SOLE LIABILITY OF MASTERCOOL INC. FOR ALL PURPOSES SHALL

THE SOLE LIABILITY OTHE SOLE LIABILITY O

PAIR OR REPLACE, AT THE SOLE OPTION OF M

PAIR OR REPLACE, AT THE SOLE OPTION OF MASTERCOOL INC. , DEF

PAIR OR REPLACE, AT THE SOLE OPTION OF MPAIR OR REPLACE, AT THE SOLE OPTION OF M

ING WITHIN THE (1) ONE YEAR PERIOD. MAS

ING WITHIN THE (1) ONE YEAR PERIOD. MASTERCOOL INC.SHALL HA

ING WITHIN THE (1) ONE YEAR PERIOD. MASING WITHIN THE (1) ONE YEAR PERIOD. MAS

TION FOR REPAIR OR REPLACEMENT UNLESS MA

TION FOR REPAIR OR REPLACEMENT UNLESS MASTERCOOL INC. HAS RE

TION FOR REPAIR OR REPLACEMENT UNLESS MATION FOR REPAIR OR REPLACEMENT UNLESS MA

WRITTEN NOTICE OF THE ALLEGED DEFECT WITHIN THE (1) ONE YEAR

WRITTEN NOTICE OF THE ALLEGED DEFECT WITHIN THE (1) ONE YEAR PERIOD AND

WRITTEN NOTICE OF THE ALLEGED DEFECT WITHIN THE (1) ONE YEARWRITTEN NOTICE OF THE ALLEGED DEFECT WITHIN THE (1) ONE YEAR

THE DEFECTIVE GOODS ARE PROMPTLY RETURNED BY THE BUYER, AT THEIR EX-

THE DEFECTIVE GOODS ARE PROMPTLY RETURNED BY THE BUYER, AT THEIR EX-

THE DEFECTIVE GOODS ARE PROMPTLY RETURNED BY THE BUYER, AT THEIR EX-THE DEFECTIVE GOODS ARE PROMPTLY RETURNED BY THE BUYER, AT THEIR EXPENSE, TO MASTERCOOL

PENSE, TO MASTERCOOL INC. AT: ONE ASPEN DRIVE, RANDOLPH, NJ 07869, USA.,

PENSE, TO MASTERCOOLPENSE, TO MASTERCOOL

AND THE DEFECT OCCURS UNDER THE CIRCUMSTANCES OF PROPER USE IN AC-

AND THE DEFECT OCCURS UNDER THE CIRCUMSTANCES OF PROPER USE IN AC-

AND THE DEFECT OCCURS UNDER THE CIRCUMSTANCES OF PROPER USE IN AC-AND THE DEFECT OCCURS UNDER THE CIRCUMSTANCES OF PROPER USE IN ACCORDANCE WITH ALL INSTRUCTIONS AND MANUALS PROVIDED TO THE BUYER.

CORDANCE WITH ALL INSTRUCTIONS AND MANUALS PROVIDED TO THE BUYER.

CORDANCE WITH ALL INSTRUCTIONS AND MANUALS PROVIDED TO THE BUYER. CORDANCE WITH ALL INSTRUCTIONS AND MANUALS PROVIDED TO THE BUYER.

MASTERCOOL INC. WILL DELIVER THE REPAIRE

MASTERCOOL INC. WILL DELIVER THE REPAIRED OR NEW GOODS TO THE

MASTERCOOL INC. WILL DELIVER THE REPAIREMASTERCOOL INC. WILL DELIVER THE REPAIRE

MASTERCOOL INC. EXPE

MASTERCOOL INC. EXPENSE. IN NO EVENT WILL MASTERCOOL INC. BE LIABLE FOR

MASTERCOOL INC. EXPEMASTERCOOL INC. EXPE

ANY LOSS OR DAMAGE DIRECTLY OR INDIRECTLY ARISING FROM THE DEFECTS OR

ANY LOSS OR DAMAGE DIRECTLY OR INDIRECTLY ARISING FROM THE DEFECTS OR

ANY LOSS OR DAMAGE DIRECTLY OR INDIRECTLY ARISING FROM THE DEFECTS OR ANY LOSS OR DAMAGE DIRECTLY OR INDIRECTLY ARISING FROM THE DEFECTS OR

FROM THE USE OF THE GOODS OR FROM CONSEQUENTIAL OR INCIDENTAL DAM-

FROM THE USE OF THE GOODS OR FROM CONSEQUENTIAL OR INCIDENTAL DAM-

FROM THE USE OF THE GOODS OR FROM CONSEQUENTIAL OR INCIDENTAL DAM-FROM THE USE OF THE GOODS OR FROM CONSEQUENTIAL OR INCIDENTAL DAMAGES, WHETHER IN CONTRACT, TORT, OR OTHERWISE, FOR PERSONAL INJURY OR

AGES, WHETHER IN CONTRACT, TORT, OR OTHERWISE, FOR PERSONAL INJURY OR

AGES, WHETHER IN CONTRACT, TORT, OR OTHERWISE, FOR PERSONAL INJURY OR AGES, WHETHER IN CONTRACT, TORT, OR OTHERWISE, FOR PERSONAL INJURY OR

PROPERTY DAMAGE OR ANY FINANCIAL LOSS.

PROPERTY DAMAGE OR ANY FINANCIAL LOSS.

PROPERTY DAMAGE OR ANY FINANCIAL LOSS.PROPERTY DAMAGE OR ANY FINANCIAL LOSS.

Buyer shall be responsible for insuring that the goods are functioning properly at all

times and shall not use any goods which are not functioning properly. Buyer, therefore, agrees to indemnify Mastercool Inc. from and against all losses and claims to

or by any person or property caused in any manner by the goods or the use of the

goods, including any expenses and attorney’s fees in connection with all claims,

demands, proceedings, or other expenses.

Any description of the goods contained in any documents to which these warranty

provisions relate, including any quotations or purchase orders relating to the goods

being delivered to the buyer, are for the sole purpose of identifying the goods, and

any such description, as well as any sample or model which may have been displayed to or seen by the buyer at any time, have not been made part of the basis of

the bargain and have not created or amounted to any express warranty that the

goods would conform to any such description or any such sample or model.

MASTERCOOL INC.

MASTERCOOL INC. DOES NOT WARRANT THAT THE GOODS ARE FREE OF THE

MASTERCOOL INC. MASTERCOOL INC.

RIGHTFUL CLAIM OF ANY THIRD PERSON BY THE WAY OF INFRINGEMENT OF PAT-

RIGHTFUL CLAIM OF ANY THIRD PERSON BY THE WAY OF INFRINGEMENT OF PAT-

RIGHTFUL CLAIM OF ANY THIRD PERSON BY THE WAY OF INFRINGEMENT OF PAT-RIGHTFUL CLAIM OF ANY THIRD PERSON BY THE WAY OF INFRINGEMENT OF PATENT OR OTHER PROPRIETARY INFORMATION AND DISCLAIMS ANY WARRANTY

ENT OR OTHER PROPRIETARY INFORMATION AND DISCLAIMS ANY WARRANTY

ENT OR OTHER PROPRIETARY INFORMATION AND DISCLAIMS ANY WARRANTY ENT OR OTHER PROPRIETARY INFORMATION AND DISCLAIMS ANY WARRANTY

AGAINST SUCH INFRINGEMENT.

AGAINST SUCH INFRINGEMENT.

AGAINST SUCH INFRINGEMENT.AGAINST SUCH INFRINGEMENT.

It shall be the responsibility of the buyer to read carefully and abide by all instructions provided to the buyer in the instruction manual or elsewhere. If the buyer, or

the employees of the buyer, did not abide by such instructions, then the alleged

defect shall not be deemed to have arisen under circumstances of proper use.

F MASTERCOOL INC. FOR ALL PURPOSES SHALL BE TO R

F MASTERCOOL INC. FOR ALL PURPOSES SHALLF MASTERCOOL INC. FOR ALL PURPOSES SHALL

ASTERCOOL INC. , DEFECTS APPEAR-

ASTERCOOL INC. , DEFASTERCOOL INC. , DEF

TERCOOL INC.SHALL HAVE NO OBLIGA-

TERCOOL INC.SHALL HATERCOOL INC.SHALL HA

STERCOOL INC. HAS RECEIVED

STERCOOL INC. HAS RESTERCOOL INC. HAS RE

INC. AT: ONE ASPEN DRIVE, RANDOLPH, NJ 07869, USA.,

INC. AT: ONE ASPEN DRIVE, RANDOLPH, NJ 07869, USA., INC. AT: ONE ASPEN DRIVE, RANDOLPH, NJ 07869, USA.,

D OR NEW GOODS TO THE BUYER AT

D OR NEW GOODS TO THED OR NEW GOODS TO THE

NSE. IN NO EVENT WILL MASTERCOOL INC. BE LIABLE FOR

NSE. IN NO EVENT WILL MASTERCOOL INC. BE LIABLE FOR NSE. IN NO EVENT WILL MASTERCOOL INC. BE LIABLE FOR

DOES NOT WARRANT THAT THE GOODS ARE FREE OF THE

DOES NOT WARRANT THAT THE GOODS ARE FREE OF THE DOES NOT WARRANT THAT THE GOODS ARE FREE OF THE

BE TO RE-

BE TO RBE TO R

ECTS APPEAR-

ECTS APPEAR-ECTS APPEAR-

VE NO OBLIGA-

VE NO OBLIGA-VE NO OBLIGA-

PERIOD AND

PERIOD AND PERIOD AND

E-

E-E-

CEIVED

CEIVED CEIVED

BUYER AT

BUYER AT BUYER AT

The Mini ID utilizes a disposable oil filter that

can not be cleaned.

Be sure to have spare filters available as the

instrument cannot be operated with a contaminated filter.

P/N 6-01-6001-23-1

When properly used, this filter will protect the

instrument from oil and sealant contamination.

See Page 10 for additional information.

Manual Part Number:

5-06-4900-62-1

Manual File:

MN-A-0201 Rev. A

Revision Date:

01/17/2011

Page 12

Page 4

Table of Contents

Table of Contents

Table of ContentsTable of Contents

For Your Safety………………………………………………………………….. 3

General Cautions………………………………………………………………. 3

Welcome…………………………………………………………………………… 5

Introduction………………………………………………………………………. 6

Product Description…………………………………………………………… 7

Product Components…………………………………………………………. 8

Instructions For Use…………………………………………………………… 9

The Test Results………………………………………………………………… 9

Help/Troubleshooting………………………………………………………… 10

Specifications……………………………………………………………………. 11

Warranty…………………………………………………………………………… 12

SSSSPECIFICATIONS

PECIFICATIONS

PECIFICATIONSPECIFICATIONS

Refrigerant Detected: R134a

Pass/Fail Purity: 95%

Power: 12—15 VDC @ 1 amp

Sample Source: Oil Free Vapor Refrigerant

Minimum Input Pressure: 1.38 Bar (20 Psig)

Maximum Input Pressure: 20.70 Bar (300 Psig)

Operating Temperature : 10°— 45°C

Approvals (Pending): UL, CE, SAE J1771

Replacement Oil Filter P/N: 6-01-6001-23-1

Manual Part Number:

5-06-4900-62-1

Manual File:

MN-A-0201 Rev. A

Revision Date:

01/17/2011

Page 2

Manual Part Number:

5-06-4900-62-1

Manual File:

MN-A-0201 Rev. A

Revision Date:

01/17/2011

Page 11

Page 5

HHHHELP

ELP

/ T

/ TROUBLESHOOTING

ELPELP

Unit Fails to Power On

Unit Fails to Power On - Check the voltage and polarity of the power

Unit Fails to Power OnUnit Fails to Power On

source. Ensure that the power plug is fully inserted into the power socket on

the unit.

Excess Air / Fail

Excess Air / Fail—The Mini ID is equipped with a unique filter located be-

Excess Air / FailExcess Air / Fail

tween the coupler and hose. This is a disposable filter designed to trap oil

and sealant to prevent damage to the unit. Remove and inspect the filter for

oil etc. and replace if necessary. Remove any oil in the coupler with compressed air and a dry cloth. Replacement Filter P/N 6-01-6001-23-1

The Mini ID is equipped with internal fault codes for assistance with troubleshooting. When the “FAULT” light is illuminated, the code is determined by

counting the number of flashes.

Code 3 = Calibration Error

Code 4 = Temperature Error

Code 5 = Calibration Compensation Error

Should one of these codes appear, take the following action prior to contacting you Mastercool Service Representative.

1. Disconnect the power from the instrument and verify the power source is

between 12 and 15 VDC.

2. Place the unit in a climate controlled area between 15°C and 27°C.

3. Fully Squeeze the Calibration Bulb 10 times.

4. Allow the unit to remain in the climate controlled room for 30 minutes.

5. Reconnect the unit and re-test.

If these steps fail to restore the unit to good working order, contact:

ROUBLESHOOTING

/ T/ T

ROUBLESHOOTINGROUBLESHOOTING

Phone: (973) 252-9119 / Fax: (973) 252-2455

Randolph, NJ 07869

Mastercool Inc.

One Aspen Drive

For Your Safety:

For Your Safety:

For Your Safety:For Your Safety:

PLEASE READ THIS MANUAL IN ITS ENTIRETY BEFORE ATTEMPTING

INSTALLATION OR OPERATION! Attempting to operate the Mini ID

without fully understanding its features and functions may result in

unsafe conditions.

Always use protective eye wear and observe proper safety procedures when

working with pressurized gases.

Identifier Warnings

Identifier Warnings

Identifier WarningsIdentifier Warnings

Sample Filter Warning:

Sample Filter Warning: The Mini ID contains a unique filter designed to sig-

Sample Filter Warning: Sample Filter Warning:

nificantly reduce the probability of oil contamination. Replace the brass oil

filter of the instrument AS SOON AS OIL IS DETECTED IN THE SAMPLE HOSE.

Failure to properly maintain and replace the oil filter may result in severe

damage.

Sample Input Warning:

Sample Input Warning: The instrument requires connection of the supplied

Sample Input Warning: Sample Input Warning:

sample hose to the LOW SIDE OR VAPOUR port of refrigerant storage cylinders or vehicle air conditioning systems. DO NOT attempt to introduce liquid

or samples heavily laden with oil into the instrument. DO NOT connect the

sample hose to the HIGH SIDE or LIQUID port! Liquid or oil laden samples

may cause severe damage to the instrument that will not be covered under

warranty repairs.

General Cautions

General Cautions

General CautionsGeneral Cautions

•

Always inspect the sample hose before each use. Replace the hose if it

appears cracked, frayed, obstructed or fouled with oil.

•

Always turn the compressor or automobile engine off before connecting

the instrument to an air conditioning system.

Manual Part Number:

5-06-4900-62-1

Manual File:

MN-A-0201 Rev. A

Revision Date:

01/17/2011

Page 10

Manual Part Number:

5-06-4900-62-1

Manual File:

MN-A-0201 Rev. A

Revision Date:

Page 3

01/17/2011

Page 6

•

Always wear eye and skin protection when working with refrigerants. Escaping refrigerant vapors will present a freezing danger.

•

To reduce the risk of electrical shock, do not disassemble the instrument; do not use the instrument in wet or damp areas.

•

DO NOT direct refrigerant vapors venting from hoses towards the skin.

•

DO NOT disassemble the instrument. There are no serviceable components internal to the instrument and disassembly will void the warranty.

•

Always place the Identifier on a flat and sturdy surface.

•

DO NOT utilize any other hose other than those supplied with the instrument. The use of other hose types will introduce errors into the refriger-

ant analysis and instrument calibration.

•

Always verify that the refrigerant to be tested does not contain or will not

emit heavy loads of oil or liquid.

•

NEVER admit any sample into the instrument at pressures in excess of

300 psig.

•

DO NOT utilize the coupler supplied on the service end of the R134a

Sample Hose for any application other than with the instrument. The

coupler supplied is a modified version that does not contain a check

valve and is not suitable for any other refrigerant application.

•

NEVER obstruct the air intake, sample exhaust or case vent ports of the

instrument during use.

• WARNING – This Identifier must not be operated in flammable atmospheres.

• CAUTION – Should be operated by certified personnel.

• Avoid breathing A/C refrigerant and lubricant vapor or mist. Exposure may

irritate eyes, nose and throat. To remove HFC-134a from the A/C system,

use service equipment certified to meet the requirements of SAE J2788.

Additional health and safety information may be obtained from refrigerant

and lubricant manufacturers.

• CAUTION – Do not pressure test or leak test HFC-134a service equipment

and/or vehicle air conditioning systems with compressed air. Some mixtures of air and HFC-134a have been shown to be combustible at elevated

pressures. These mixtures, if ignited, may cause injury or property damage.

Additional health and safety information may be obtained from refrigerant

manufacturers.

IIIINSTRUCTIONS

NSTRUCTIONS

NSTRUCTIONSNSTRUCTIONS

WARNING: Be sure to turn off the vehicle and let it rest for 3 minutes.

1) Connect the power cable to the power port located on the bottom of the

instrument.

2) Connect the power clips to the 12 VDC battery source. Be sure to observe the correct polarity.

3) The lights will sequence, press “NEXT” to begin the “WARM UP”.

4) After approximately 90 seconds, the “CALIBRATING” light will flash.

5) Fully squeeze the calibration bulb 5 times and press “NEXT”.

6) The “CALIBRATING’ light will illuminate for approximately 60 seconds.

7) When the Analyzing light begin to flash, connect hose to the vehicles low

side service port and then press “NEXT”.

8) The Analyzing light will illuminate for approximately 45 seconds while the

test is in progress.

9) The “PASS”/”FAIL” light will then provide the test results (See The Test

Results)

10) Disconnect the sample hose from the vehicle, press the “NEXT” button

and squeeze the calibration bulb 5 times. Remove the power and the

instrument may now be stowed.

TTTTHE

HE

TEST

EST

HEHE

TTT

1) After the Analysis is complete, the “PASS” or “FAIL” light will flash.

a) “PASS” indicates the refrigerant tested is 95% or greater R134a and

b) “FAIL” indicates the refrigerant tested is less than 95% R134a and

c) The EXCESS AIR” light will illuminate in conjunction with the “PASS”

RESULTS

ESTEST

RRR

is suitable for recovery.

should not be recovered without special equipment.

or “FAIL” if the instrument determines that a significant amount of

air is present. (See Help/Troubleshooting) .

FOR

OR

FFF

OROR

ESULTS

ESULTSESULTS

USE

UUU

SE

SESE

Manual Part Number:

5-06-4900-62-1

Manual File:

MN-A-0201 Rev. A

Revision Date:

01/17/2011

Page 4

Manual Part Number:

5-06-4900-62-1

Manual File:

MN-A-0201 Rev. A

Revision Date:

01/17/2011

Page 9

Page 7

PPPPRODUCT

RODUCT

RODUCTRODUCT

COMPONENTS

OMPONENTS

CCC

OMPONENTSOMPONENTS

Neutronics to insert

photo of unit upon

receiving Mastercool

labels.

Base Module

WELCOME

WELCOME

WELCOMEWELCOME

Thank you for purchasing the MINI ID R134a Refrigerant Analyzer.

The Mini ID is the most economical refrigerant identifier ever designed for analysing the purity of gaseous R134a automotive refrigerant. It has many features

to offer the user, which will be described in this manual. We recommend that

all personnel who use this instrument read this manual to become more famil-

iar with its proper operation.

For further information regarding the application, operation or spare parts,

please contact the Mastercool Inc. Customer Service Department. If you have

questions or comments, we would like to hear from you.

Coupler with Filter

Mastercool Inc.

One Aspen Drive

Randolph, NJ 07869

Phone: (973) 252-9119 / Fax: (973) 252-2455

Manual Part Number:

5-06-4900-62-1

Battery Clips

MN-A-0201 Rev. A

Manual File:

Calibration Bulb

Revision Date:

01/17/2011

Page 8

Email: customerservice@mastercool.com

Visit us at http://www.mastercool.com

Copyright ©2011 Mastercool Inc.

This work is protected under International Code and is the sole property of Mastercool Inc. No part of this document may be copied or otherwise reproduced, or

stored in any electronic information retrieval system, except as specifically permitted under International copyright law, without the prior written consent of Mastercool Inc.

Manual Part Number:

5-06-4900-62-1

Manual File:

MN-A-0201 Rev. A

Revision Date:

01/17/2011

Page 5

Page 8

IIIINTRODUCTION

NTRODUCTION

NTRODUCTIONNTRODUCTION

AND

AND

ANDAND

OVERVIEW

VERVIEW

OOO

VERVIEWVERVIEW

PPPPRODUCT

RODUCT

RODUCTRODUCT

DESCRIPTION

ESCRIPTION

DDD

ESCRIPTIONESCRIPTION

Contamination of refrigerants in vehicle air conditioning systems can lead to

component corrosion, elevated head pressures and system failures when

utilized by unsuspecting technicians. The ability of the technician to determine refrigerant type and purity is severely hampered by the presence of air

when attempting to utilize temperature-pressure relations. The development of various substitute refrigerants further complicates the ability of a

technician to identify refrigerant purity based upon temperature-pressure

relationships. The substitute refrigerant blends can also introduce a flammability hazard to the technician and the ultimate end user of the vehicle air

conditioning system.

The Mini ID Refrigerant Identifier will provide an easy and accurate means to

determine if the R134a refrigerant in vehicle air conditioning systems is of

suitable purity. The instrument utilizes non-dispersive infrared (NDIR) technology to determine the weight concentrations of refrigerant types R12,

R134a, R22, as well as, hydrocarbons and air. Refrigerant purity is automatically determined for refrigerant R134a by the instrument to eliminate

human error.

The instrument is supplied complete with a R134a sample hose, a 12 VDC

power cord and all required plumbing housed within a rugged, portable in-

strument.

The Mini ID is an economical instrument designed to provide a “PASS” or

“FAIL” indication for R134a Purity. The product will also indicate if an excess amount of non-condensable gas (air) is present in the system. Excess

“air” will cause poor cooling performance and can be easily corrected by

simply recovering the refrigerant, evacuating the system and recharging the

vehicle. The Mini ID uses a simple hand pump to purge refrigerant from the

sample cell in order to calibrate the instrument. LED’s provide the user with

easy to understand status indicators. Flashing LED’s require user action

while solid LED’s indicate the instrument is performing a task.

The unique brass filter, located between the Coupler and Sample Hose, provides excellent protection from oil contamination by trapping the oil at the

coupler and preventing it from entering the instrument. If the instrument

continually gives excess air messages, this is an indication that the filter has

been compromised by oil and the filter must be changed.

Manual Part Number:

5-06-4900-62-1

Manual File:

MN-A-0201 Rev. A

Revision Date:

01/17/2011

Page 6

Manual Part Number:

5-06-4900-62-1

Manual File:

MN-A-0201 Rev. A

Revision Date:

01/17/2011

Page 7

Loading...

Loading...