Page 1

A/C SYSTEM ANALYZER MANUAL

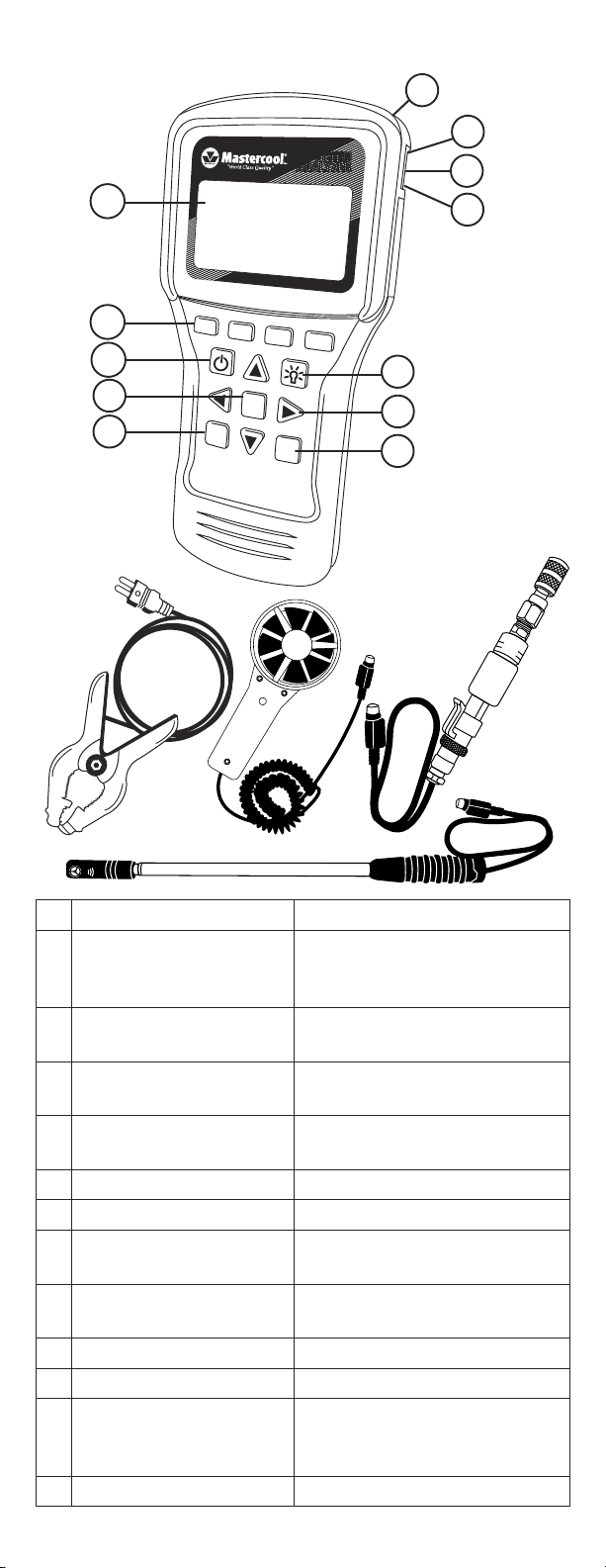

1

12

11

2

3

4

10

9

5

6

8

7

Type K

Thermocouple

Antenna Fan Meter

Round Vane

Meter

Pressure

Transducer

Assembly

with Cable

DESCRIPTION USE

1 Round Vane Meter/

Antenna Fan Meter

Socket

2 Pressure Transducer

Socket

Insert round vane meter or

antenna fan meter into socket

to use

Insert pressure transducer

cable into socket to use

3 USB Port Insert USB cable to upload

stored information

4 Type K Thermocouple

Socket

Insert thermocouple into

socket to use

5 Back Light Button Toggles back light on and off

6 Arrow Buttons Navigates screen

7 Calibration Button Use to calibrate pressure

transducer and thermocouple

8 Units Button Toggles between Imperial and

Metric units

9 Enter Button Selects highlighted value

10 Power Button Toggles power on and off

11 Function Buttons Selects operation on screen

directly above key

(F1, F2, F3, F4)

12 Screen Displays information

1ww w.m as te rc oo l. co m

Page 2

FIRST TIME USE

Set the Time

• Use POWER button to turn on A/C Analyzer.

• Use the ▼ or ▲ buttons to highlight the time.

• Press ENTER.

• Use the ◄ or ► buttons to highlight the hours, minutes,

and AM/PM or 24 hours.

• Use the ▲ or ▼ buttons to change the values.

NOTE: to change to AM or PM, add or subtract 12 hours.

• When correct, press F1 to SAVE.

NOTE: Press F4 to EXIT without saving.

Set the Date

• Use POWER button to turn on A/C Analyzer.

• Use ▼ or ▲ buttons to highlight the date.

• Press ENTER.

• Use the ◄ or ► buttons to highlight the Day, Month, Year

and Format.

• Use the ▲ or ▼ buttons to change the values.

NOTE: The format can be MM/DD/YYYY or DD/MM/YYYY.

• When correct press F1 to SAVE.

NOTE: Press F4 to EXIT without saving.

Set the Units

• Press the UNITS button at any time to toggle between

Imperial and Metric units.

QUICK START

General Functions

(in most screens:)

• Press F3 (T/S) to go to the Test Selection screen.

• Press F4 (EXIT) to go to the Main Menu screen.

Testing using Quick Start

Quick Start allows you to use the A/C System Analyzer

without entering a customer or technician.

NOTE: Testing done in Quick Start mode will only be saved

until the test is redone.

• Use power button to turn on A/C analyzer.

• Use the ▲ or ▼ buttons to highlight Quick Start.

• Press ENTER.

• Use ▼ or ▲ buttons to highlight the desired test.

• Press ENTER.

DB (DRY BULB)/WB (WET BULB)/RH

(RELATIVE HUMIDITY)/DP (DEW POINT)/ AIR

VEL (AIR VELOCITY) WITH AIR VOLUME

OPTION TESTING

• For round vane meter, twist sensor cover to the Open

position. For antenna fan meter, go to next step.

• Insert cable into socket (it may take a few seconds for

readings to appear).

• Place round vane meter or antenna fan meter

perpendicular to airflow.

AIR VOLUME TESTING

• When in DB/WB/RH/DP/Air Vel testing screen Press

ENTER.

• Use F2 (RECT/DIA) to toggle between rectangular and

round duct.

2 ww w.m as te rc oo l. co m

Page 3

• Use ► or ◄ buttons to highlight digit and ▲ or ▼ buttons

to change digit value.

• Press ENTER to toggle between Height and Width.

NOTE: Be sure to press ENTER for both Height and Width

before pressing done.

• Press F1 when DONE entering duct size.

• Place round vane meter or antenna fan meter

perpendicular to air flow to read volume.

TARGET SUPERHEAT TESTING

• Target Superheat Testing uses the round vane meter or

antenna fan meter. For round vane meter, twist sensor

cover to the Open position. For antenna fan meter, go to

next step.

• Insert cable into socket (it may take a few seconds for

readings to appear).

• Follow Target Superheat 1 screen instructions on where to

place round vane meter or antenna fan meter.

• When values have stabilized, press ENTER to save.

• Press F2 (NEXT).

• Follow Target Superheat 2 screen instructions on where to

place round vane meter or antenna fan meter.

• When values have stabilized, press ENTER to save.

• Press F2 (NEXT).

• Target Superheat will be displayed on the screen.

• If Actual Superheat has been tested, Press F1 (ANYL) for

analysis.

TEMPERATURE SPLIT TESTING

• Temperature (TEMP) Split Testing uses the round vane

meter or antenna fan meter. For round vane meter, twist

sensor cover to the Open position. For antenna fan meter,

go to next step.

• Insert cable into socket (it may take a few seconds for

readings to appear).

• Follow Temp Split 1 screen instructions on where to place

round vane meter or antenna fan meter.

• When values have stabilized, press ENTER to save.

• Press F2 (NEXT).

• Follow Temp Split 2 screen instructions on where to place

round vane meter or antenna fan meter.

• When values have stabilized, press ENTER to save.

• Press F2 (ANYL).

• Target Temperature Split and Actual Temperature Split with

analysis will be displayed on the screen.

ACTUAL SUPERHEAT TESTING

• Use ▲ or ▼ buttons to highlight Actual Superheat.

• Press ENTER.

To Input Pressure Manually

• Use ▲ or ▼ buttons and highlight Input Manually.

• Press ENTER.

• Use ▲ or ▼ buttons to highlight refrigerant.

• Press ENTER.

• Use ► and ◄, buttons to highlight unit and ▲ and ▼

buttons to adjust unit value to input low-side saturated

pressure.

• Press ENTER.

• Saturated vapor temperature will be displayed.

3ww w.m as te rc oo l. co m

Page 4

• Press F2 (NEXT).

• Insert plug for clamp-on thermocouple into type K

thermocouple socket.

• Follow screen instructions to place clamp-on thermocouple.

• When temperature has stabilized, press ENTER.

• Press F2 (NEXT).

• Actual Superheat will be displayed.

• If Target Superheat test has been done, press F1 (ANLY)

for analysis.

To use Pressure Transducer to Calculate Superheat

• Use ▲ or ▼ buttons to highlight Calculate.

• Press ENTER.

• Use ▲ or ▼ buttons to select refrigerant.

• Press ENTER.

• Insert plug from pressure transducer into pressure

transducer socket.

• Follow screen instructions to connect pressure transducer

to system.

• When saturated temperature stabilizes, press F2 (NEXT).

• Insert plug from clamp-on thermocouple into type K

thermocouple socket.

• Follow screen instructions to place clamp-on thermocouple.

• When temperature has stabilized, press ENTER.

• Press F2 (NEXT).

• Actual Superheat will be displayed.

• If Target Superheat test has been done, press F1 (ANLY)

for analysis.

ACTUAL SUBCOOL TESTING

• Use ▲ or ▼ buttons to highlight Actual Subcool.

• Press ENTER.

To Input Pressure Manually

• Use ▲ or ▼ buttons and highlight Input Manually.

• Press ENTER.

• Use ▲ or ▼ Buttons to select refrigerant.

• Press ENTER.

• Use ► and ◄, buttons to highlight unit and ▲ and ▼

buttons to adjust unit value to input high-side saturated

pressure.

• Press ENTER.

• Saturated vapor temperature will be displayed.

• Press F2 (NEXT).

• Insert plug for clamp-on thermocouple into type K

thermocouple socket.

• Follow screen instructions to place clamp-on thermocouple.

• When temperature has stabilized, press ENTER.

• Press F2 (NEXT).

• Actual Subcool will be displayed.

To use Pressure Transducer to Calculate Subcool

• Use ▲ or ▼ button to highlight Calculate.

• Press ENTER.

• Use ▲ or ▼ button to select refrigerant.

• Press ENTER.

• Insert plug from pressure transducer into pressure

transducer socket.

• Follow screen instructions to connect pressure transducer

4 ww w.m as te rc oo l. co m

Page 5

to system.

• When saturated temperature stabilizes, press ENTER.

• Press F2 (NEXT).

• Insert plug from clamp-on thermocouple into type K

thermocouple socket.

• Follow screen instructions to place clamp-on thermocouple.

• When temperature has stabilized, press ENTER.

• Press F2 (NEXT).

• Actual Subcool will be displayed.

SAVING TEST INFORMATION (NEW ENTRY)

• Use NEW ENTRY to save testing information under

Customer, Technician, and Date.

To enter a New Customer

• Use power button to turn on A/C Analyzer.

• Use ▲ or ▼ buttons to highlight NEW ENTRY.

• Press ENTER.

• New Customer will be highlighted.

• Press ENTER.

• Use ▲ or ▼ buttons to adjust letter or number.

NOTE: Using ▼ button will go directly to numbers.

• Use ► or ◄ buttons to highlight next space.

• When done press ENTER.

• Use ▲, ▼, ►, or ◄ buttons to enter Technician.

• When done press ENTER.

• Press F1 (DONE).

• NEW TEST will be highlighted.

• Press ENTER.

• Any testing will be recorded under the current date. For

instructions on how to do the testing see Quick Start.

• To see the testing summary press F2 (DATA) at the end of

each test except DB/WB/RH/DP/Air Vel.

To add a test to an Existing Customer

• Use POWER button to turn on A/C Analyzer.

• Use ▲ or ▼ buttons to highlight NEW ENTRY.

• Use ▼ or ▲ buttons to highlight existing Customer.

• Press ENTER.

• NEW TEST will be highlighted.

• Press ENTER.

• Any testing will be recorded under the current date and

time. For instructions on how to do the testing see Quick

Start.

• To see the testing summary press F2 (DATA) at the end of

each test except DB/WB/RH/DP/Air Vel.

LOOKING AT PREVIOUSLY SAVED

INFORMATION

• Use POWER button to turn on A/C Analyzer.

• Use ▲ or ▼ buttons to highlight Customer Search.

• Press ENTER.

• Use ▲ or ▼ buttons to highlight Customer.

• Press ENTER.

• Use ▲ or ▼ buttons to highlight Test Number.

• Press ENTER.

• Saved test data will be displayed.

5ww w.m as te rc oo l. co m

Page 6

NOTE: The Customer or Test can be deleted by pressing F2

(DEL) when they are highlighted.

CALIBRATION

• Use POWER button to turn on A/C Analyzer.

• From MAIN MENU press CAL button.

For Thermocouple Calibration

NOTE: Press F4 (EXIT) in Thermocouple Cal 1 Screen to

return to MAIN MENU without saving, or F2 (PT) to calibrate

the pressure transducer.

• Insert thermocouple into thermocouple socket.

• Place thermocouple at known temperature and allow

temperature to stabilize.

NOTE: Use crushed ice and just enough water to cover and

calibrate to 32˚F or 0˚C, or place thermocouple clamp on a

heavy wall copper pipe and clamp a calibrated meter next to

it.

• Use ► and ◄, buttons to highlight unit and ▲ and ▼

buttons to adjust unit value to input calibration temperature.

• Press F1 (CAL) button.

• If thermocouple has correct reading, press F4 (EXIT) to

save.

• If thermocouple reading is off, Press F1 (REDO) to redo the

calibration.

For Pressure Transducer Calibration

CAUTION: To calibrate the pressure transducer you will

need a source of high-pressure gas with a highly accurate

calibrated gauge. Do not start calibrating the pressure

transducer without it. For best results, calibrate sensor at

close to its maximum value.

NOTE: Press F4 (EXIT) in Pressure Transducer 1 and

Pressure Transducer 2 Screens to return to MAIN MENU

without saving, or F2 (TC) to calibrate the thermocouple.

• If in Thermocouple 1 screen, Press F2 (PT) button to

display Pressure Transducer 1 screen.

• Two pressures are required, one low and one high.

Atmospheric (0) is OK for the low pressure.

• With the pressure transducer at low pressure, use ► or ◄,

buttons to highlight unit and ▲ or ▼ buttons to adjust unit

value to input the low pressure.

• Press F1 (NEXT).

• With the pressure transducer at the high pressure, use ►

or ◄, buttons to highlight unit and ▲ or ▼ buttons to adjust

unit value to input the high pressure.

• Press F1 (CAL).

• If pressure transducer reading is correct, Press F4 (EXIT)

to save and return to MAIN MENU.

• If pressure transducer reading is off, press F1 (REDO) to

redo the high pressure setting.

SPECIFICATIONS:

System Analyzer

• Operating Temperature: 0 to 50˚C (32 to 122˚F), humidity <80%

• Storage Temperature: -20 to 50˚C (-4 to 122˚F), humidity <90%

• Dimensions with boot: 191mm x 93mm x 41mm

• Weight: (meter w/ batteries & round vane) 500g

• Temperature Display: ˚F and ˚C

• Pressure Display: PSI and Bar

• Backlit LCD Display

• Low battery indicator

• K-type thermocouple connection

6 ww w.m as te rc oo l. co m

Page 7

• USB connection

• 6 AA batteries

Round Vane

Temp. Range/Resolution/Accuracy:

• -20 to 60˚C (-4 to 140˚F)

• 0.1˚C (0.2˚F)

• ±0.6˚C (1.1˚F) (-20 to 50˚C (-4 to 122˚F)),

±1.2˚C (2.2˚F) at other range

Humidity Range/Resolution/Accuracy:

• 0.1% to 99.9% RH

• 0.1% RH

• ±3% RH (at 25˚C (77˚F), 10 to 90% RH), ±5% RH at other range

Windspeed Range/Resolution/Accuracy:

• 0.6 to 32 m/s

• 0.1 m/s

• ±2% of full scale

Antenna Type Meter

Temp. Range/Resolution/Accuracy:

• -20 to 60˚C (-4 to 140˚F)

• 0.1˚C (0.2˚F)

• ±0.6˚C (1.1˚F) (-20 to 50˚C (-4 to 122˚F)),

±1.2˚C (2.2˚F) at other range

Humidity Range/Resolution/Accuracy:

• 0.1% to 99.9% RH

• 0.1% RH

• ±3% RH (at 25˚C (77˚F), 10 to 90% RH), ±5% RH at other range

Windspeed Range/Resolution/Accuracy:

• 0.5 to 25 m/s

• 0.1 m/s

• ±(2% of reading +0.3 m/s)

Pressure Transducer

• Operating Pressure Range: 0-750 psi (0-52 bar)

• 1/4FL Swivel nut connection

• Accuracy: ±0.5, ±1% F.S.

• Operating Temperature: -40 to 100˚C (-40 to 212˚F)

Clamp-on Thermocouple

Temp. Range/Resolution

• -40 to 121˚C (-40 to 250˚F)

• 0.1˚C (0.2˚F)

7ww w.m as te rc oo l. co m

Page 8

USA: PH (973) 252-9119

BELGIUM: TEL. + 32 (0) 3 777 28 48

8 ww w.m as te rc oo l. co m

Loading...

Loading...